Patents

Literature

186results about How to "No instability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lepidopteran-active Bacillus thuringiensis delta-endotoxin compositions and methods of use

InactiveUS6593293B1Low steady state levelGreat and less stabilityBiocideBacteriaDelta endotoxinAureobasidium sp.

Disclosed are Bacillus thuringiensis strains comprising novel crystal proteins which exhibit insecticidal activity against lepidopteran insects. Also disclosed are novel B. thuringiensis genes and their encoded crystal proteins, as well as methods of making and using transgenic cells comprising the novel nucleic acid sequences of the invention.

Owner:MONSANTO TECH LLC

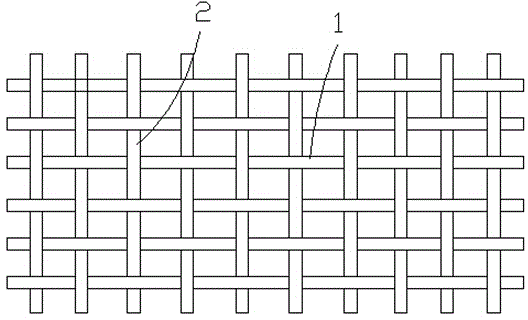

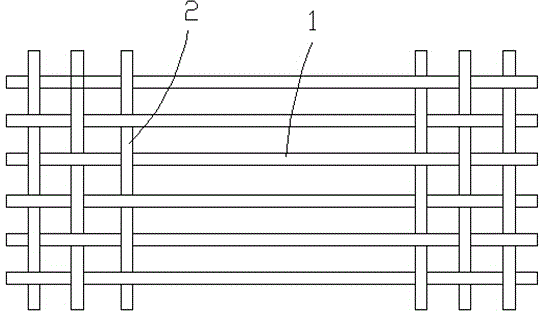

High molecular solid/solid phase changing material with net type and comb type mixed structure and its preparing method

InactiveCN1616588APhase transition temperature is suitableSolid state goodHeat-exchange elementsPhase change enthalpyPolyethylene glycol

The present invention relates to a kind of high molecular solid / solid phase changing material with mixed net and comb structure, and features that polyglycol with two active end radical and polyglycol with one active end radical are fixed onto the high molecular skeleton material to form 3D mixed net and comb structure. The material of the present invention has relatively great phase change enthalpy up to 120 J / g, proper phase change temperature capable of being altered in 0-65 deg.c, stable solid state before and after phase change without supercooling, separating and other unstable phenomenon, high mechanical strength, high solvent resistance, good machining performance, no toxicity, no leakage, no corrosion, no pollution, long service life and other advantages. The present invention may be used widely in solar energy utilization, afterheat recovering, intelligent air conditioner and other fields.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

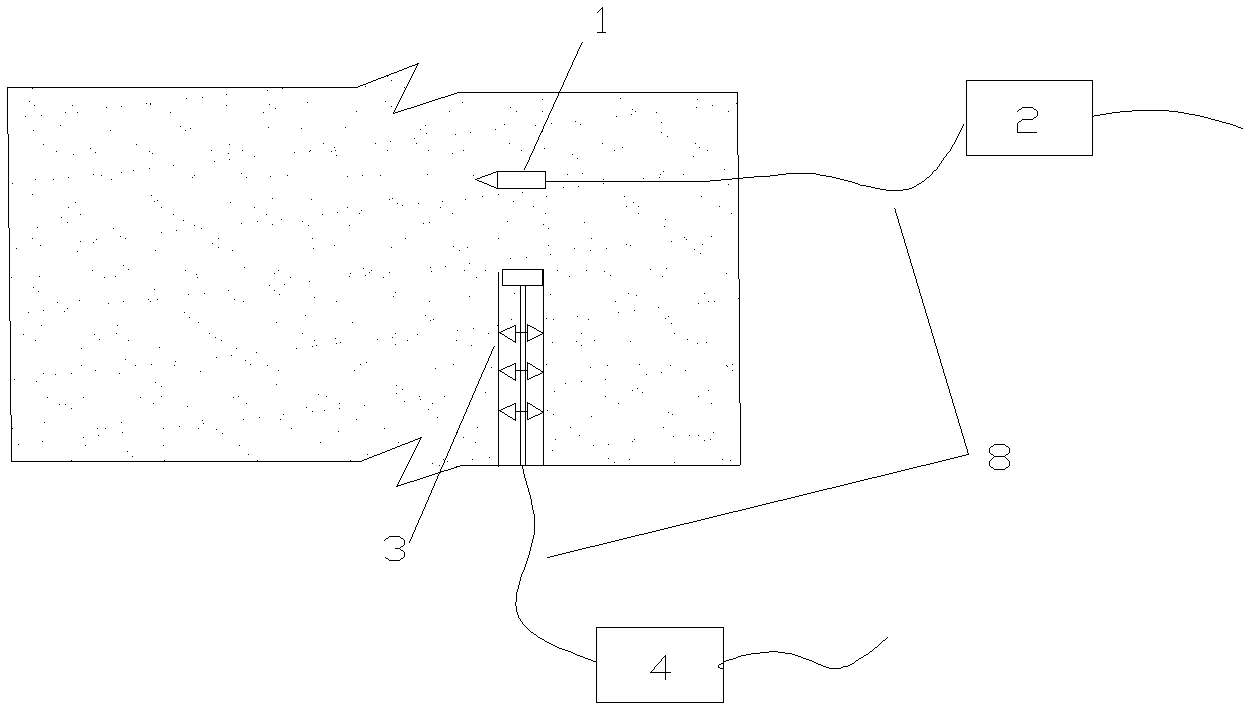

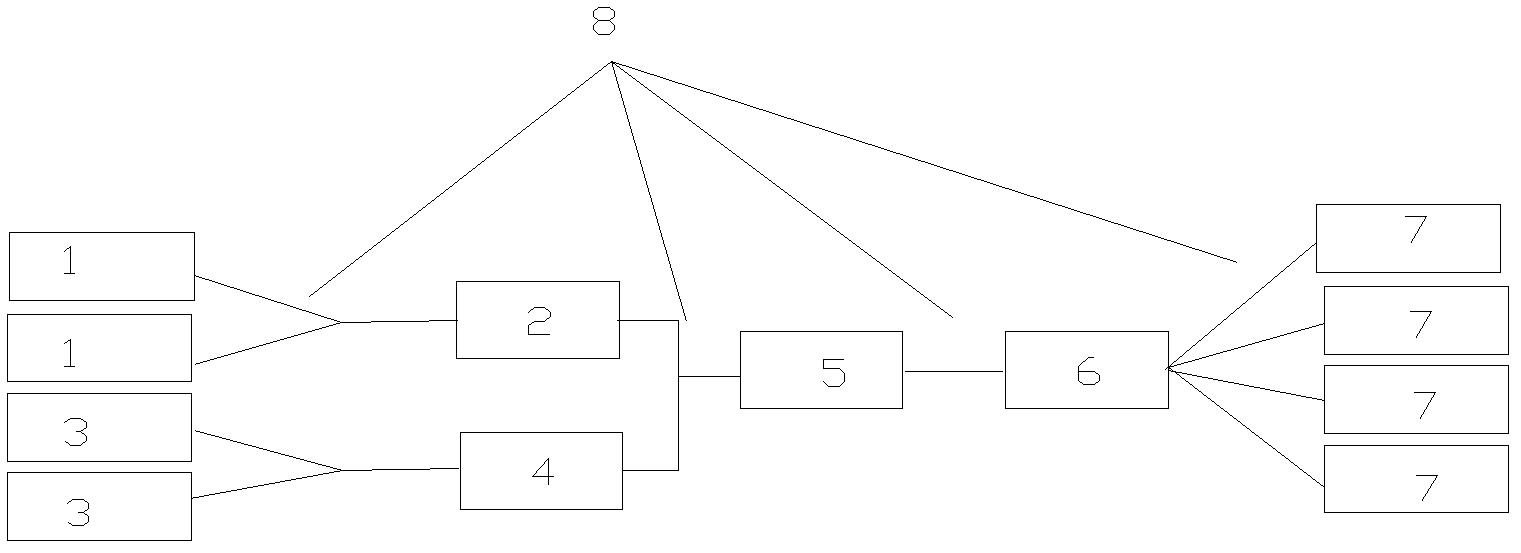

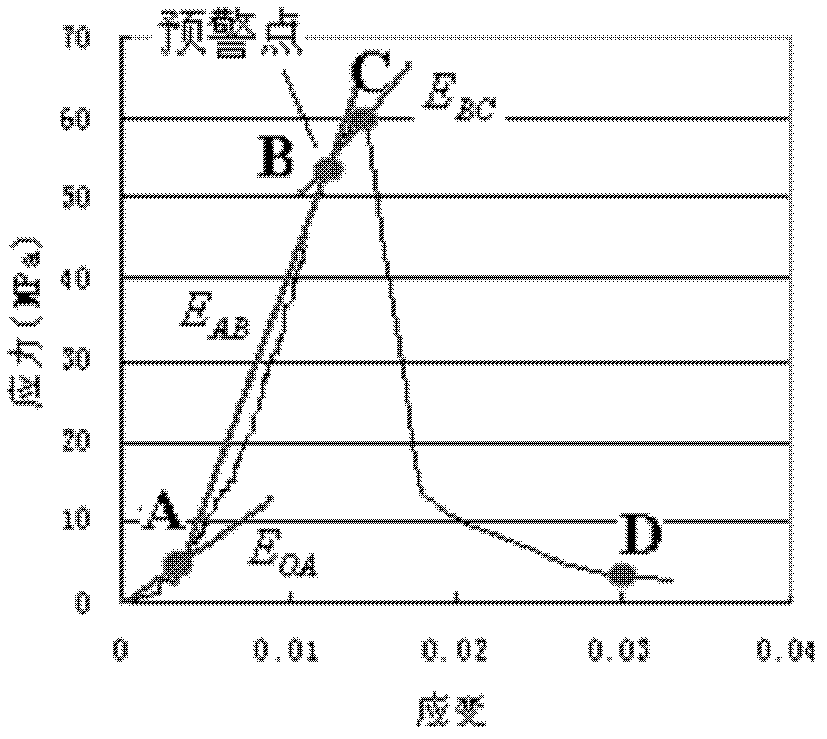

Method for identifying rock mass failure instability early warning

ActiveCN102505965AImprove the reliability of early warningThe method is simpleMining devicesForce measurementRock failureInstability

The invention belongs to the field of mine safety, relating to a method for identifying rock mass failure instability early warning by utilizing stress displacement monitoring. The method is characterized by comprising the following steps of: determining a monitoring area in an excavated rock mass and numbering, monitoring stress and deformation changes of the rock mass by utilizing a borehole stressmeter and a multipoint position extensometer and monitoring in real time, converting a tangent modulus value of the rock mass, mastering a change trend of the tangent modulus value of the rock mass, and judging whether the rock mass failure instability early warning is carried out or not. The method disclosed by the invention is simple in construction, low in cost, good in effect, has better reliability and early warning accuracy, has the capabilities of shortening the time of the rock failure instability early warning, improving the safety environment of construction and avoiding the losses of labors and devices, and is suitable for the fields of mines, tunnels, side slopes, hydropower station chambers and the like formed by excavating the rock mass.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

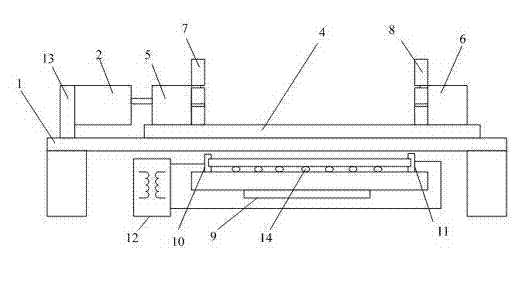

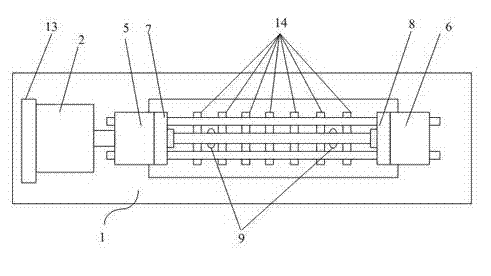

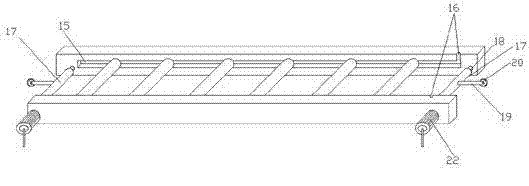

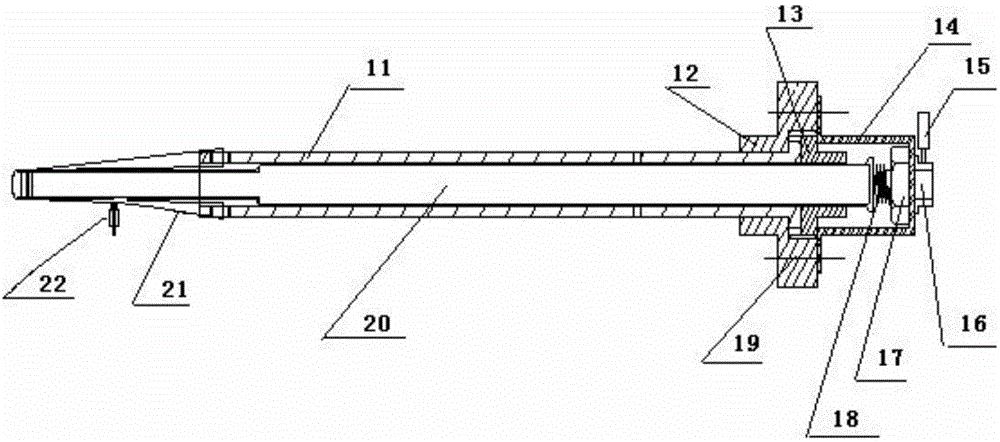

Tensile straightening device for on-line heating and straightening process of magnesium alloy extrusion

The invention discloses a stretching-straightening device for an online heating-straightening process of a magnesium alloy extrusion material, comprising a stretching-straightening device and a heating device. The stretching-straightening mechanism comprises a bracket, a stretching drive mechanism and a clamping drive mechanism. Double rails are arranged on the bracket. The rail is provided with a chuck I and a chuck II which are matched with the surfaces of the rails in a sliding manner. At least one chuck is capable of sliding forward and backward along the rail direction with the action ofthe stretching drive device. The chuck I and the chuck II are used for generating clamping forces via the clamping drive mechanism respectively. The heating device comprises a lifting mechanism and aheating mechanism. The heating mechanism comprises a positive clamping electrode, a negative clamping electrode and a transformer. The lifting mechanism is arranged under the double rails. The heating device of the stretching-straightening device is capable of guaranteeing that the extrusion material is expanded freely during heating without generating heat stress. The bending phenomenon caused by the heat stress and the instability phenomenon caused by the combined action of the heat stress and the self gravity are avoided via effective support during heating.

Owner:重庆昱华新材料科技有限公司

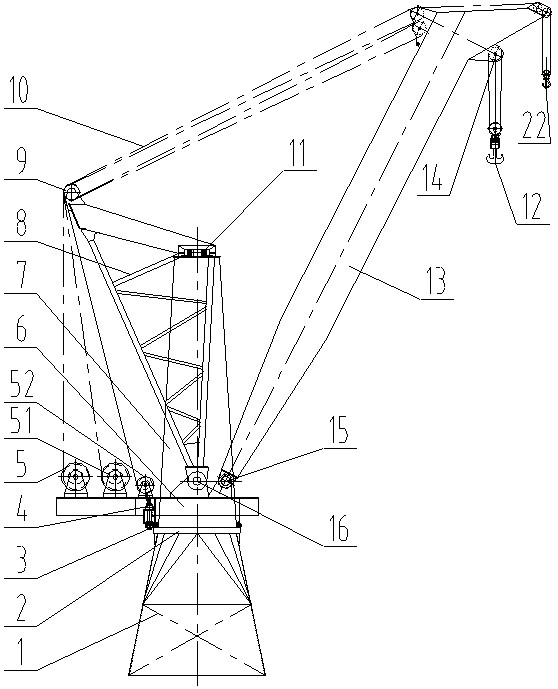

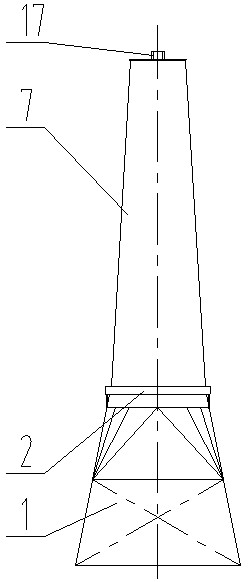

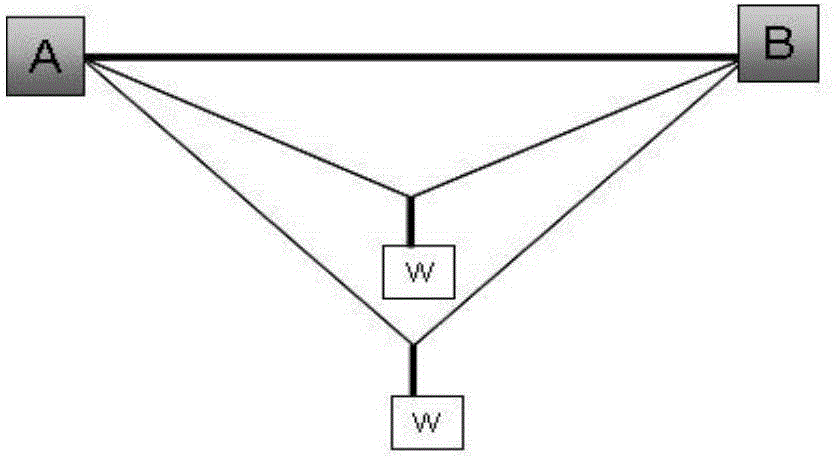

Fixed post type fully rotary crane

ActiveCN102431908ASimplify the load-bearing structureImprove the state of stressCranesEngineeringMarine navigation

The invention relates to a fixed post type fully rotary crane, which belongs to crane transportation machinery for a boat. A flange (2) is arranged on the outer surface of the middle lower section of a fixed post, a fixed post top shaft (17) is arranged in the end surface center of the top of an upper fixed post (7), a rotary supporter (3) is connected above the flange (2), the upper part of the rotary supporter (3) is fixedly connected with a rotary table (6), a hanging arm (13) and a top pulley frame (8) are respectively hinged on the rotary table (6), a top bearing (11) and a top pulley group (9) are respectively and fixedly arranged on the top pulley frame (8), the top bearing (11) is sheathed onto the fixed post top shaft (17), a rotary mechanism (4) is arranged on the rotary table (6) or a lower fixed post (1), the integral height of the crane is reduced, in addition, the full rotation is realized, the operation of the whole machine is stable, the load bearing and the bending resistance capability of the crane are greatly improved, the service life is greatly prolonged, and the fixed post type fully rotary crane is particularly suitable for being used on large-scale floatingcrane boats and ocean engineering boats with crane weight limitation and navigation height limitation.

Owner:QINGDAO HAIXI HEAVY DUTY MASCH CO LTD

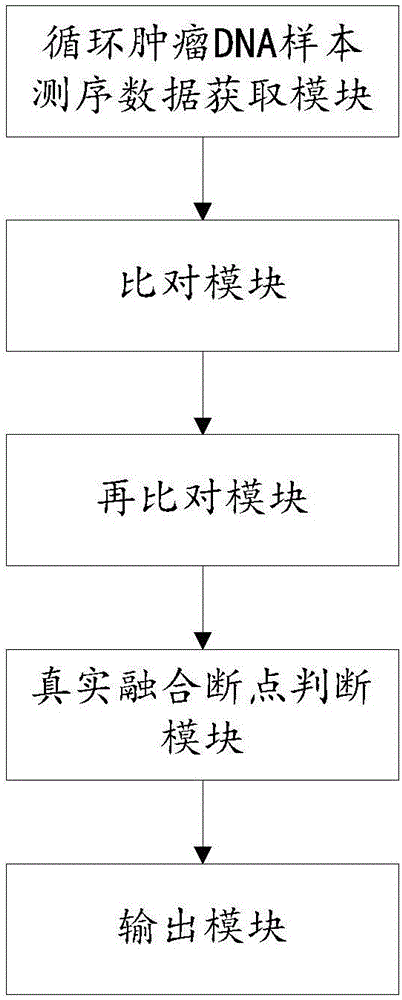

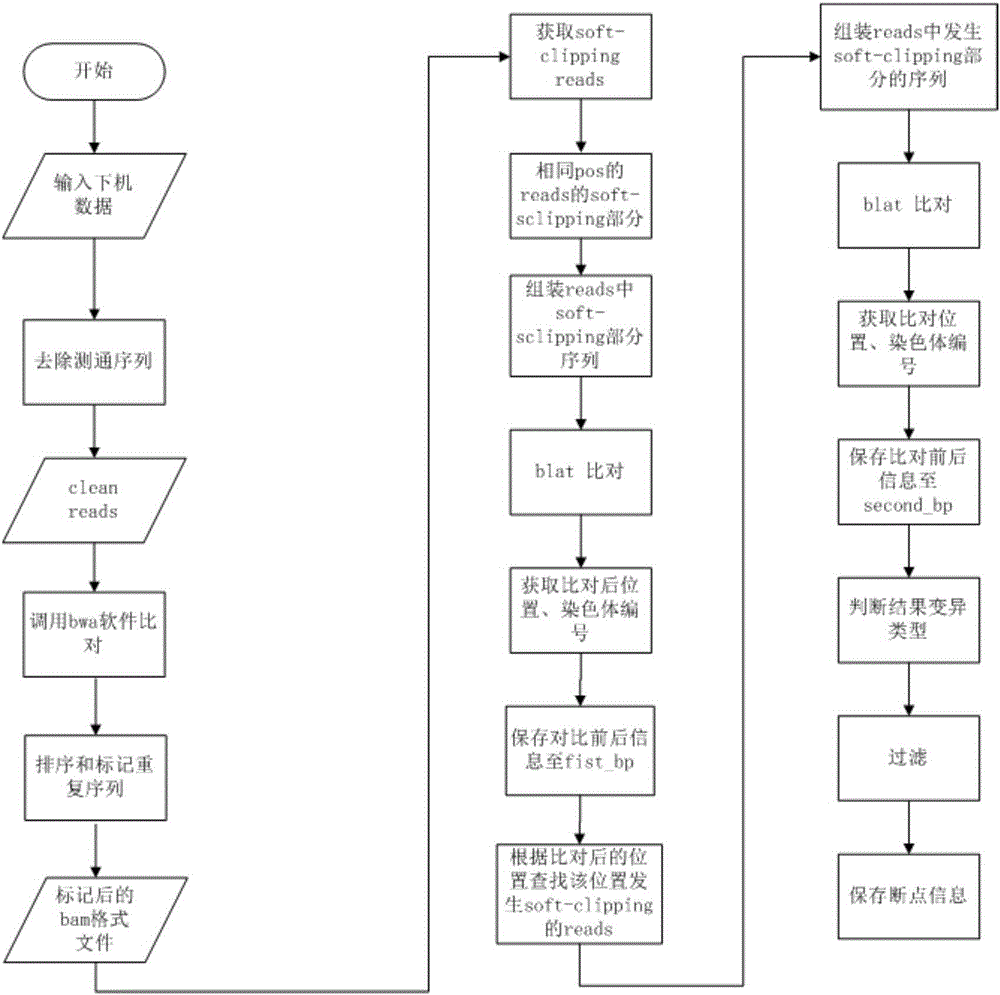

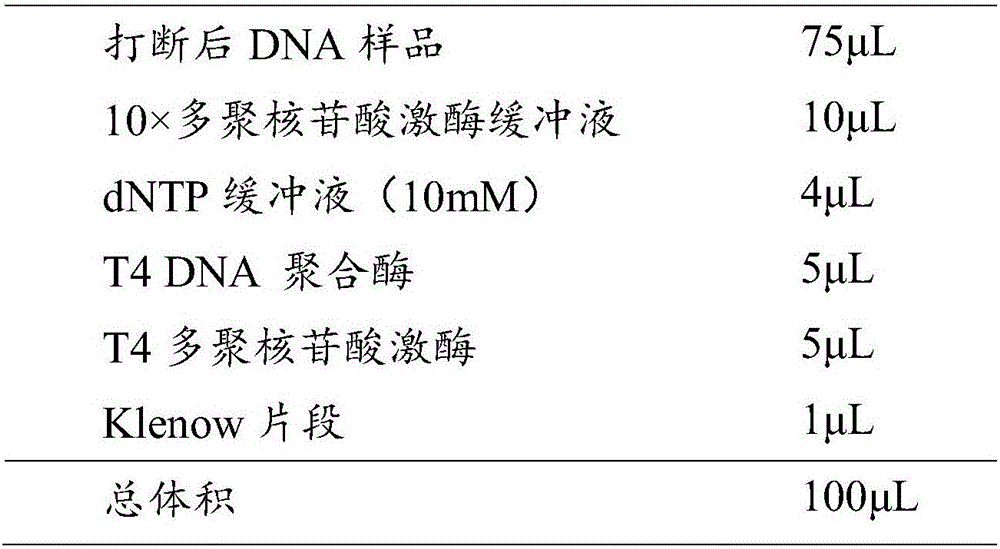

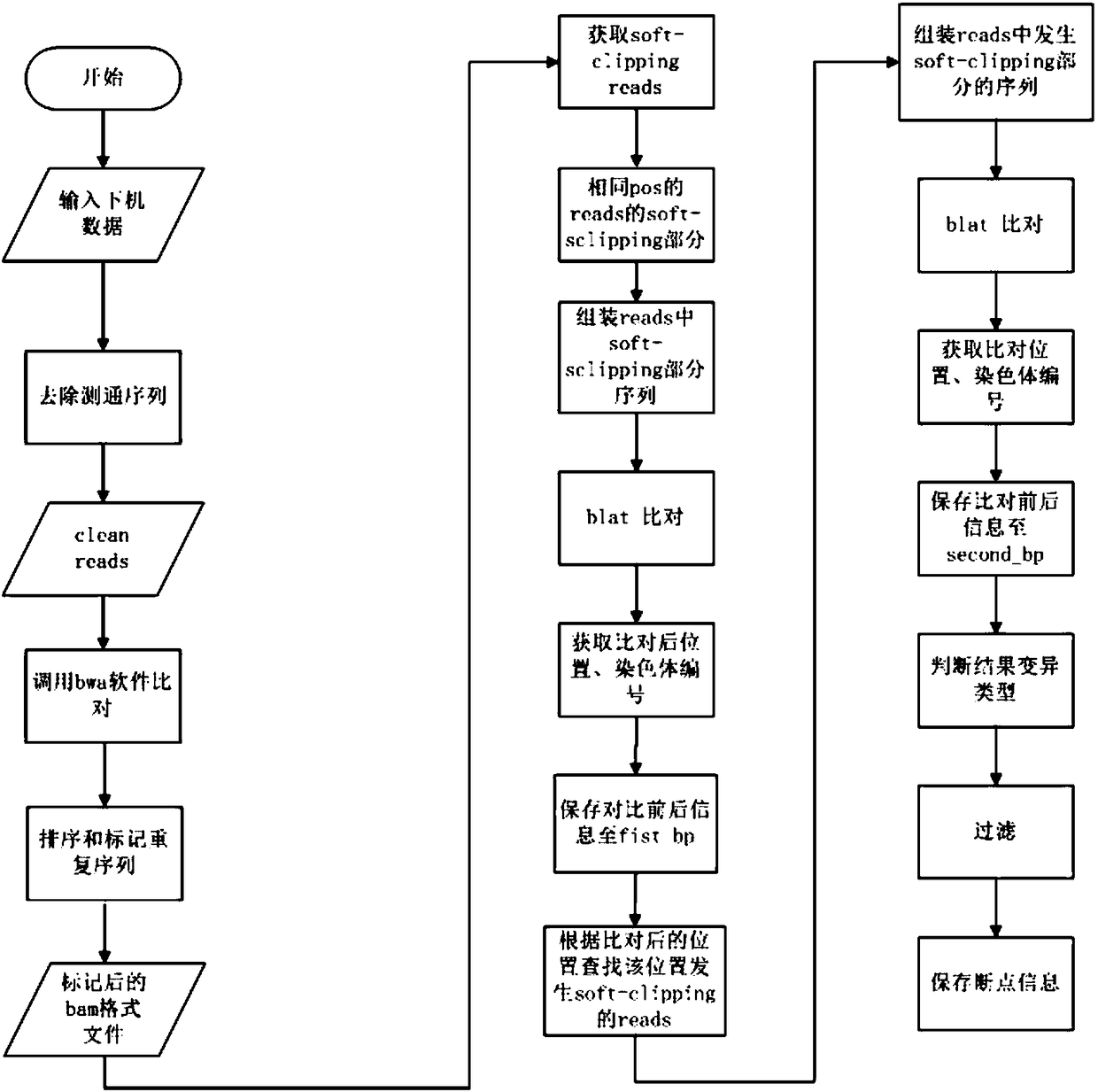

Device for detecting gene fusion of circulating tumor DNA (deoxyribonucleic acid) samples

ActiveCN106845150AReduce the number of comparisonsImprove stabilitySequence analysisHybridisationSequencing dataCirculating tumor DNA

The invention relates to a device for detecting gene fusion of circulating tumor DNA (deoxyribonucleic acid) samples. The device comprises a sequencing data acquisition module, a comparison module, a re-comparison module, a real fusion breakpoint judgment module and an output module. The device for detecting the gene fusion of the circulating tumor DNA samples has the advantages of high detection speed and stability and low resource requirement.

Owner:ZHEJIANG ANNOROAD BIO TECH CO LTD +2

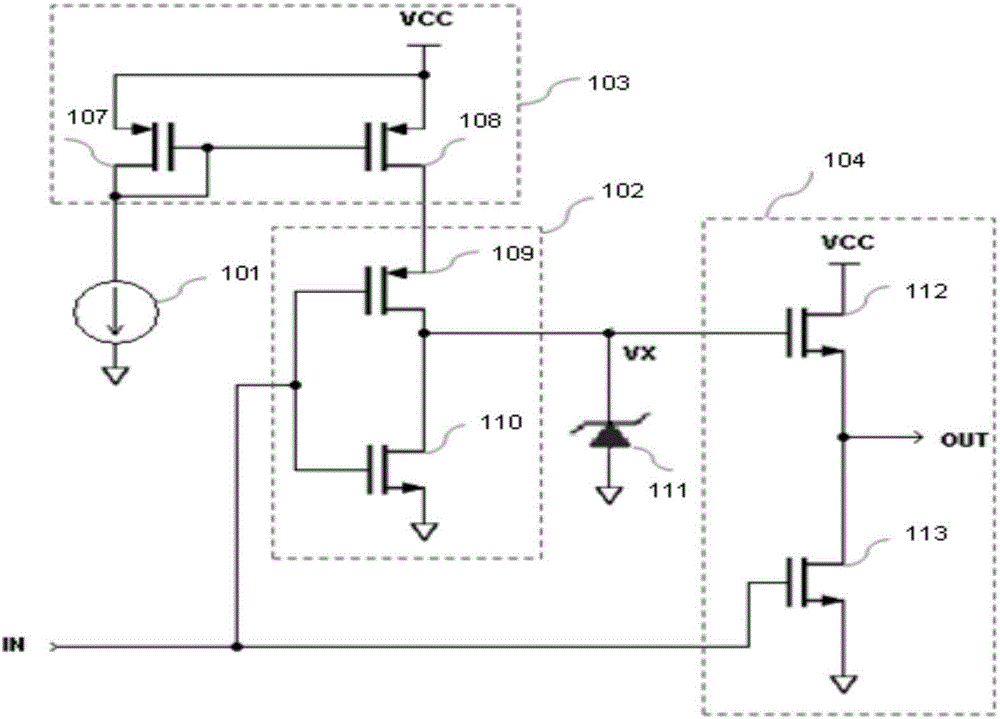

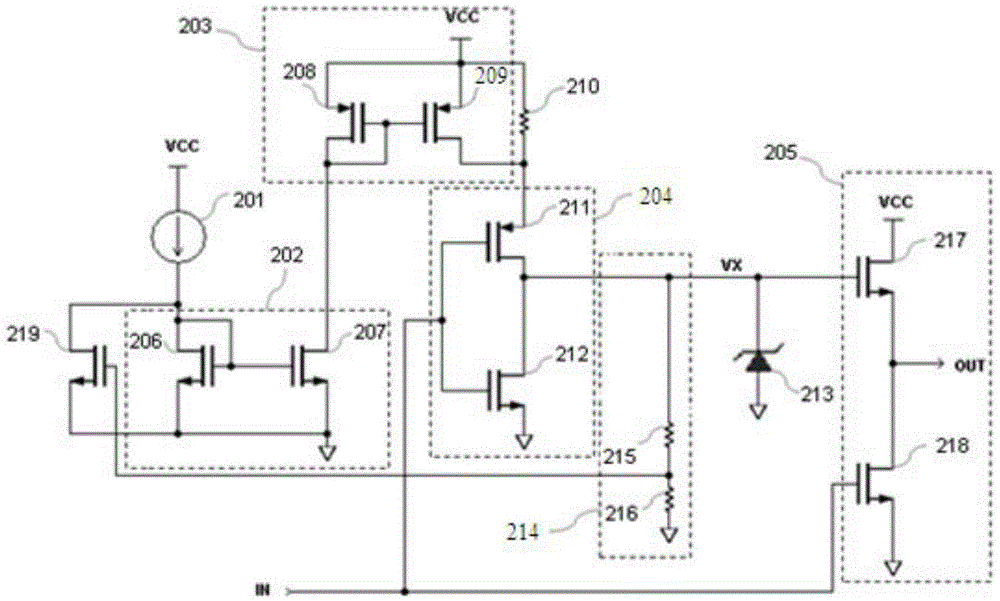

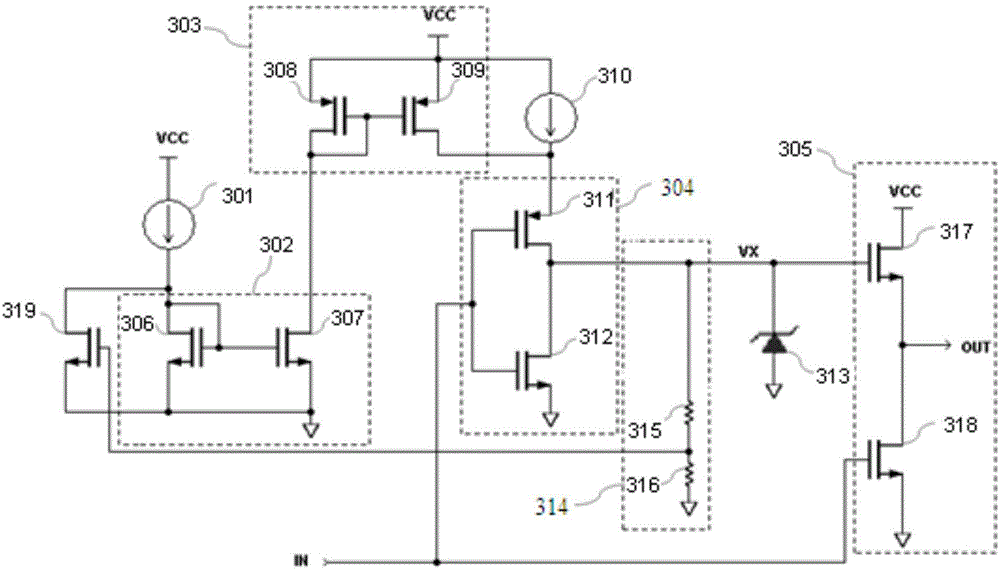

Clamp drive circuit

ActiveCN104158386AReduce power consumptionHigh speed drivePower conversion systemsElectrical resistance and conductanceEngineering

The invention relates to a clamp drive circuit which comprises a bias current source, an acceleration current mirror with a fourth MOS (metal oxide semiconductor) tube, a phase inverter with a fifth MOS tube, a totem-pole output driver with an upper drive tube, a conversion current mirror, a current mirror switch tube used for switching on and off the conversion current mirror, a stable voltage maintaining resistor or a constant current source connected between the source and the drain of the fourth MOS tube, and a clamp sampling circuit connected between the grid of the drive tube and the ground. According to the clamp drive circuit, the conversion current mirror is switched off and the acceleration current mirror is driven through the current mirror switch tube by the clamp sampling circuit so as to completely switch off high drive acceleration current; by adding the stable voltage maintaining resistor or the constant current source, the circuit consumption is reduced while high-speed drive is realized; meanwhile, due to the existence of the stable voltage maintaining resistor or the constant current source, the clamp voltage is stable in the establishment process, and the dependency degree of the whole circuit to a process is low.

Owner:SHANGHAI ORIENT CHIP TECH CO LTD

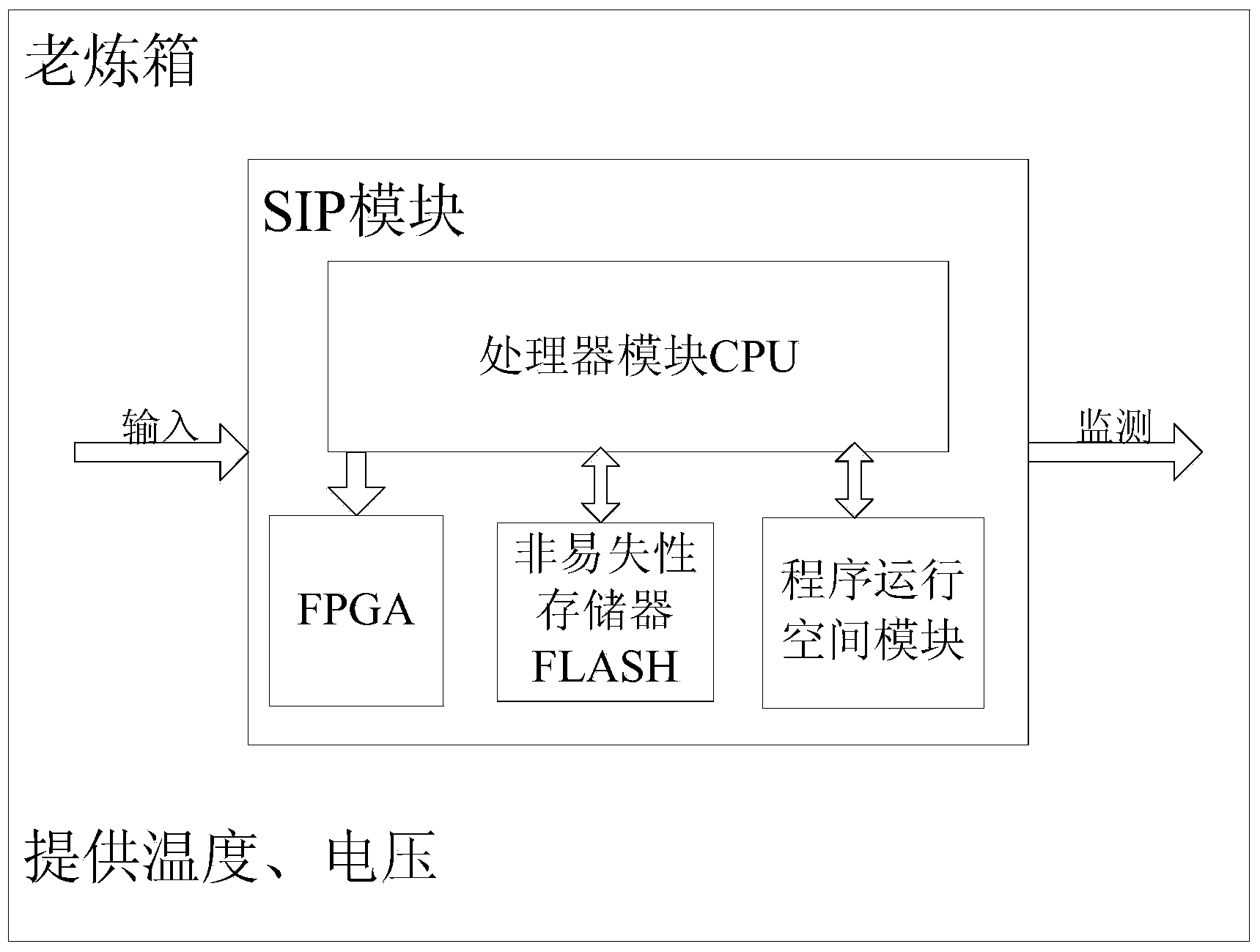

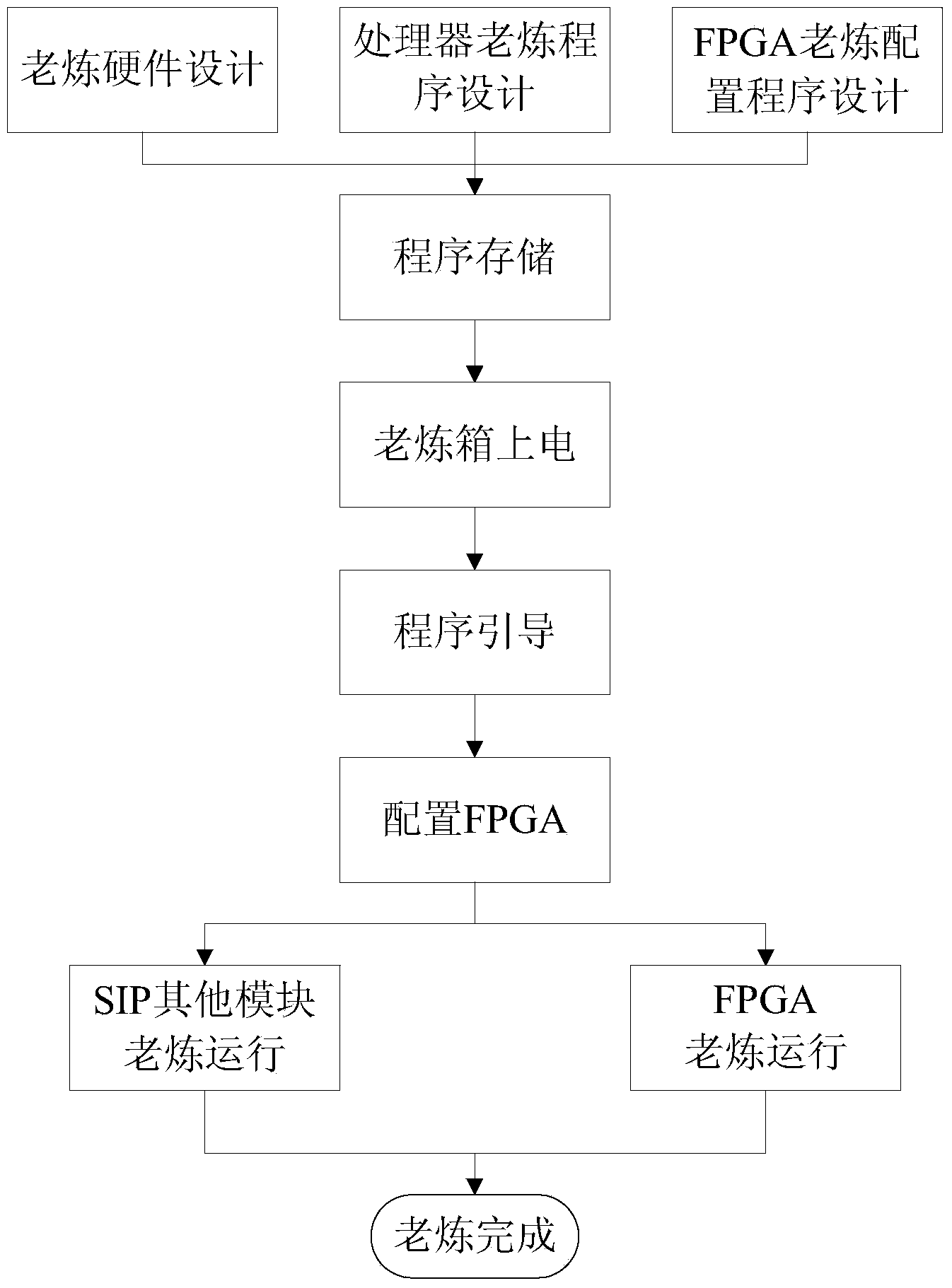

Burn-in method based on SIP module

The invention relates to a burn-in method based on an SIP module. The burn-in method is achieved in a burn-in box. The burn-in method is based on the SIP module comprising a processor module CPU, a program running space module, an FPGA module and a nonvolatile memory FLASH. According to the designed burn-in method, a burn-in program is written in the SIP module in a programmed mode, a power-on program automatically runs, the FPGA module is automatically configured, and running, access and control of all the modules are executed inside the tested SIP module in the burn-in process. The connecting circuit between the SIP module and the burn-in box is simple. According to the method, burn-in of the SIP module is achieved by fully using the functions of the SIP module, the complexity of the connecting circuit between the SIP module and the burn-in box is greatly lowered, the influences of an external circuit on the SIP module are reduced in the burn-in process, and meanwhile fault analysis can be conveniently conducted.

Owner:BEIJING MXTRONICS CORP +1

High-temperature alloy disc die forging method

ActiveCN104707929AReduce projected areaReduced tonnage requirementsWheelsHeating/cooling devicesSuperalloyTurbine

The invention belongs to the technical field of high-temperature alloy die forging, and particularly relates to a high-temperature alloy turbine disc forge piece organization and performance thermal machining method. A performing die forging plus bearizing plus die forging method includes the steps that the specification and size of the wild shape required by finish forging are determined, a finish forging die and a performing die forging die are prepared, performing die forging is conducted, bearizing is conducted till the wild shape required by the finish forging is formed, and the finish forging is conducted; an annular blank is determined according to the forge piece shape to serve as the wild shape; first-fire forging of a titanium alloy bar is forged through the performing die, and the heating number integrates traditional upsetting, punching and saddling processes; preformed forge piece core materials generated after forming die forging is conducted are removed; bearizing is conducted on a performing forge piece till the wild shape size required by finish forging is formed; one-fire finish forging is conducted till forming is finished. According to the method, the problems that the final forge piece of the high-temperature alloy turbine disc forge piece is uneven in organization and residual stress due to the blank making process of more heating numbers and smaller deformation are avoided.

Owner:SHAANXI HONGYUAN AVIATION FORGING

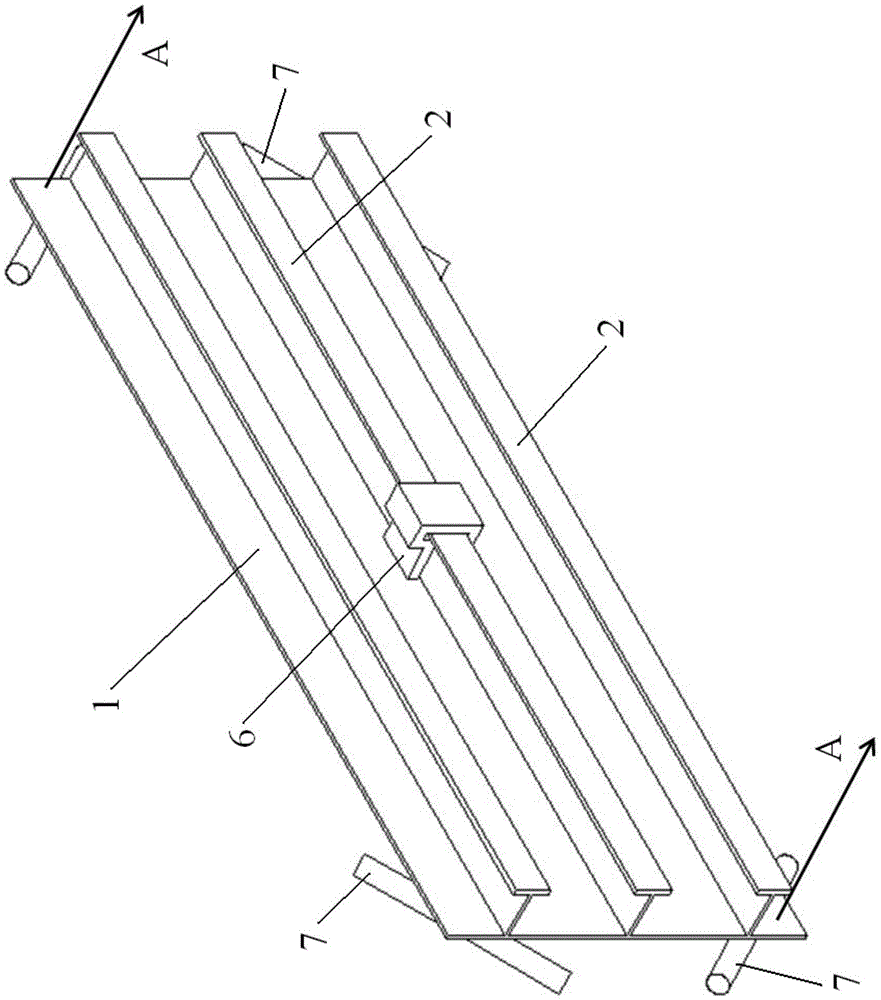

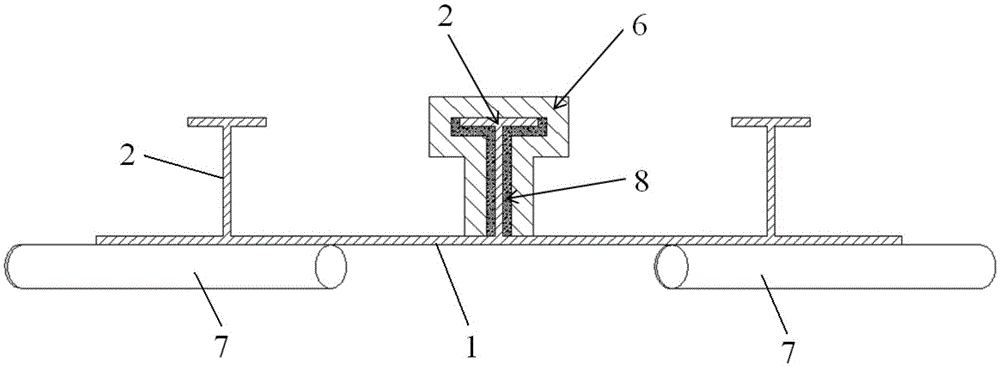

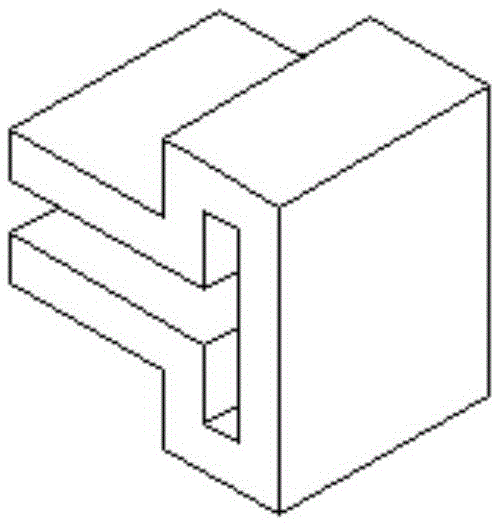

Shot peen forming method realizing torsional deformation of high-rib integral panel

ActiveCN105598851ATwist bigReduce the stress areaBlast gunsAbrasive machine appurtenancesTorsional deformationEngineering

The invention provides a shot peen forming method realizing torsional deformation of a high-rib integral panel. The method comprises steps as follows: step 1, the high-rib integral panel is clamped and fixed; step 2, force pointing to the inner side of skin (1) is applied to two ends of the high-rib integral panel, and force pointing to the outer side of the skin (1) is applied to the middle of the high-rib integral panel; step 3, a shot peening area (3) is determined on the high-rib integral panel, a first nozzle (4) performs shot peen on the outer side of the skin (1) in the shot peening area (3) along a preset shot peen track, and second nozzles (5) perform shot peen on each high rib (2). According to the shot peen forming method, the application of shot peen forming to the integral panel with high rids, thin walls and a torsional shape is broadened, so that the development of the shot peen forming technology is promoted, more space and choices are provided for design and manufacture of the integral panel of an aircraft in the future, and further increase of the integral design level of the aircraft becomes possible.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

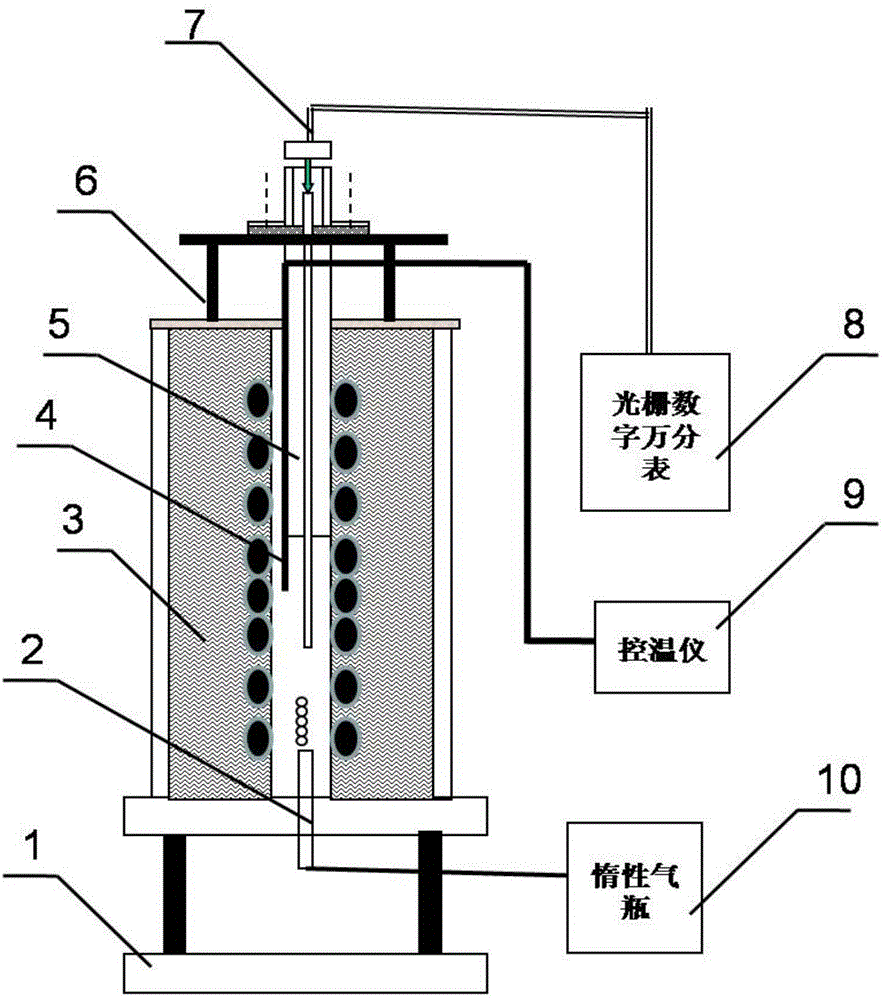

Fiber medium-temperature longitudinal coefficient-of-linear-expansion testing device

ActiveCN103983658ASimple structureStable structureMaterial thermal coefficient of expansionTemperature controlFiber

The invention discloses a fiber medium-temperature longitudinal coefficient-of-linear-expansion testing device, the temperature range of which is from a room temperature to 800 DEG C. The fiber medium-temperature longitudinal coefficient-of-linear-expansion testing device comprises a grate, a gas tube, an electric heating furnace, a thermocouple, a quartz differential sensor unit, a quartz differential sensor unit bracket, a raster digital displacement sensor probe, a raster digital universal meter, a temperature-controlled instrument, and an inert gas cylinder. The fiber medium-temperature longitudinal coefficient-of-linear-expansion testing device has a technical core of the design of the quartz differential sensor unit and a connecting method of a fiber sample to be tested. The fiber medium-temperature longitudinal coefficient-of-linear-expansion testing device is capable of effectively solving all main technical problems and difficulties of the prior art, and remarkably improving the longitudinal coefficient-of-linear-expansion testing precision of fiber materials with low coefficient-of-linear-expansion characteristic.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Acid-resistant no-bitterness soybean oligopeptide and production method and application thereof

ActiveCN101787387ADoes not produce prone to instabilityNo instabilityPlant peptidesFermentationSolubilityOligopeptide

The invention discloses acid-resistant no-bitterness soybean oligopeptide and a production method and the application thereof. The invention adopts a soy protein isoelectric point enzyme method, carries out enzymolysis simultaneously with exoproteinase and endo protease or with protease with the functions of incision enzyme and excision enzyme, so that the degree of hydrolysis of soy protein is up to 42 percent, above 85 percent of soybean oligopeptide only contains less than 8 amino acids, wherein most of the soybean oligopeptide contains 3 to 5 amino acids, the average molecular weight is below 1,000Da, and in addition, 10 to 20 percent of FAA is also contained. The acid-resistant no-bitterness soybean oligopeptide prepared by the invention has very good solubility, even at the isoelectric points of soy protein, at least 95 percent of oligopeptide is soluble; and therefore, the invention is widely applied to acid food systems, can be directly added into sports drinks, nutrition supplementary drinks and other products, and does not produce precipitation or flocculation and other unstable phenomena that protein drinks are easy to produce.

Owner:广州合诚实业有限公司

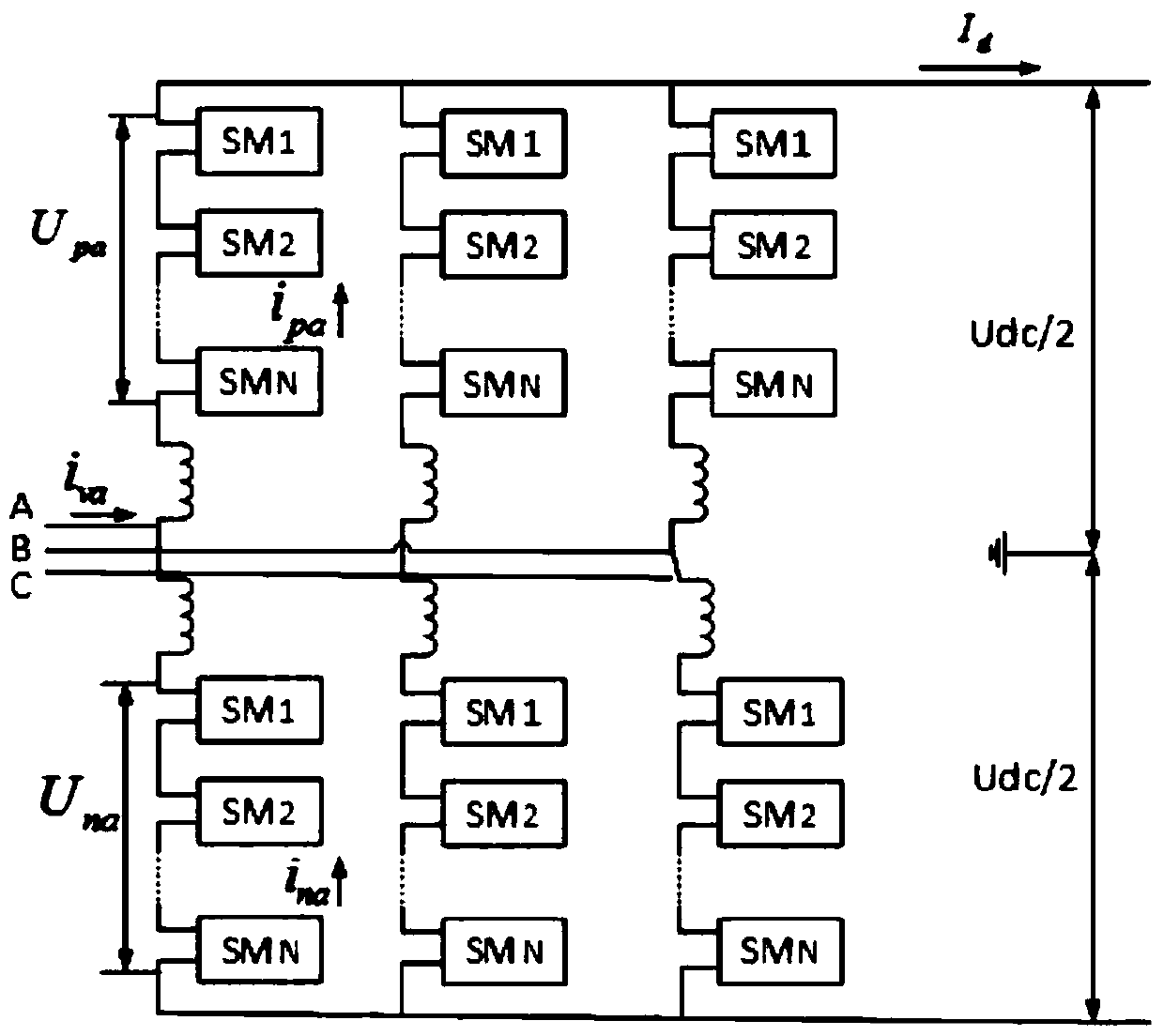

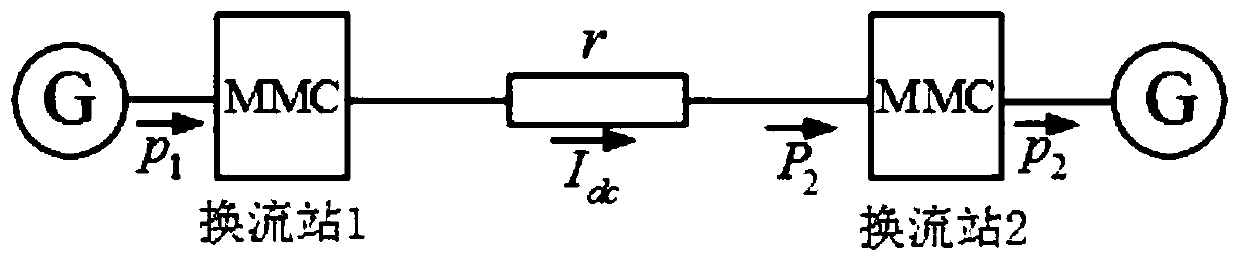

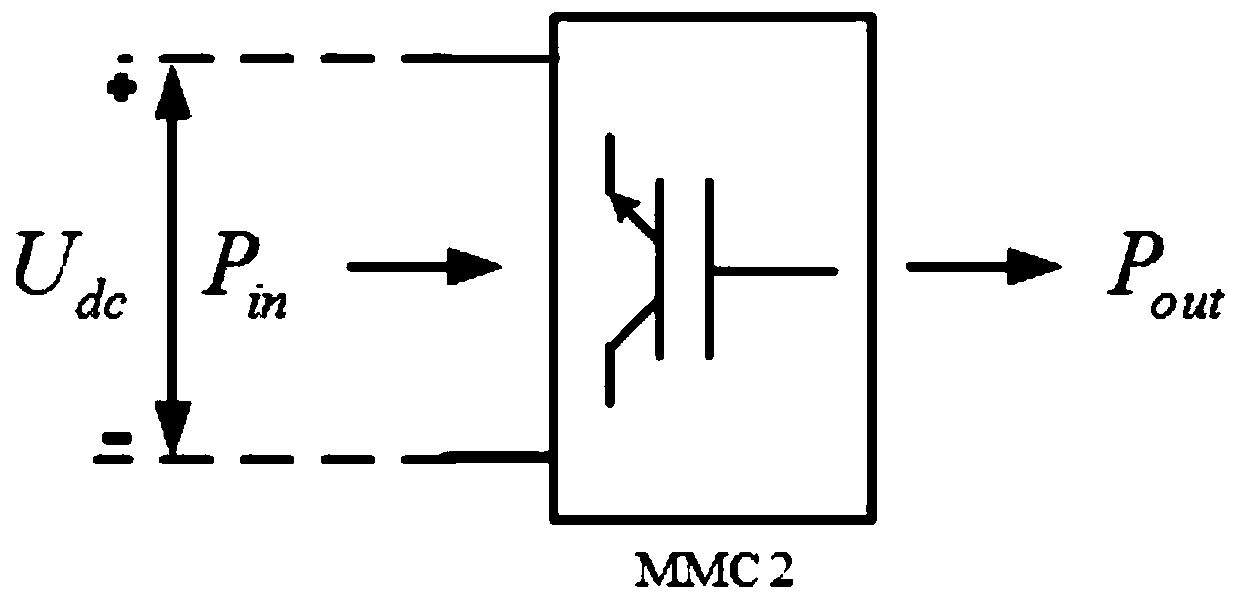

Control method for improving flexible DC power transmission AC side fault ride-through capability

ActiveCN110350571AReduce power adjustmentNo instabilityElectric power transfer ac networkSingle network parallel feeding arrangementsCapacitanceMathematical model

The invention discloses a control method for improving flexible DC power transmission AC side fault ride-through capability, The method comprises the steps: the mathematical model of the upper and lower bridge arms of a modular multi-level converter station is established through mathematical modeling by using equivalent capacitance with variable capacitance, the analytic relationship between thereal-time power value of the AC / DC side of MMC converter station and the voltage value of the DC side of the MMC converter station is obtained according to the mathematical model, the relationship between the imbalance degree between AC and DC side power of the converter station and the DC side voltage sag is deduced according to the analytic relationship, and then the real-time target value of converter station power adjustment is determined according to the relationship. The AC / DC side power imbalance degree of the converter station is obviously reduced, the power adjustment pressure of theexisting outer loop power control and the inner loop current control is reduced, the control effect of the existing control strategy is indirectly improved and the stability of the DC voltage can be greatly improved.

Owner:GUIZHOU POWER GRID CO LTD

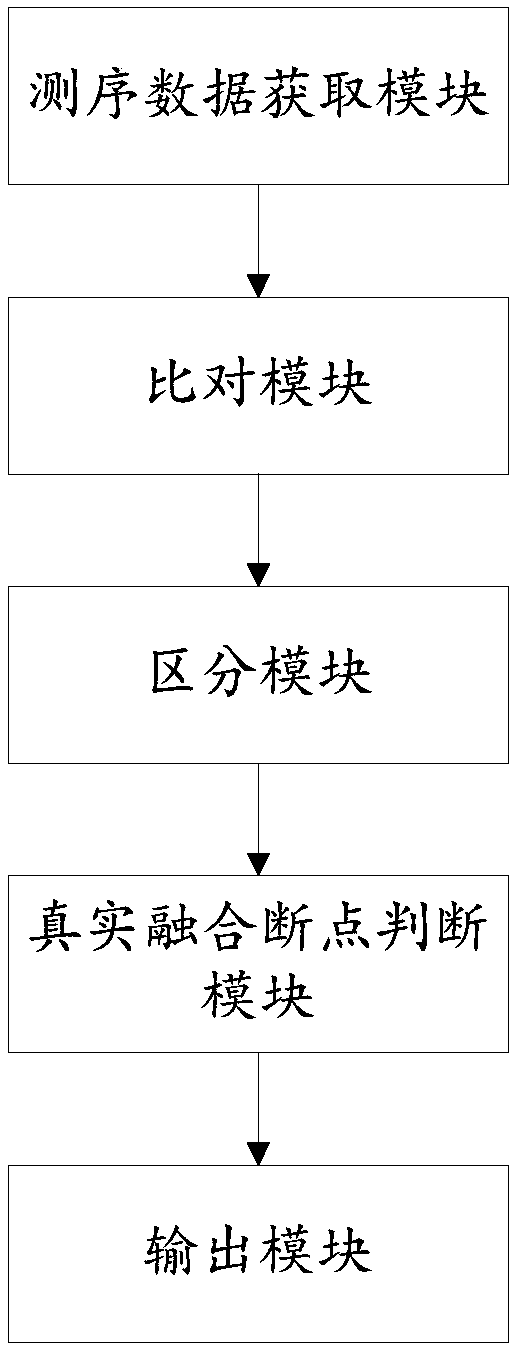

Gene fusion detection device

ActiveCN108256295AReduce the number of readsReduce the number of comparisonsHybridisationSpecial data processing applicationsData acquisitionGene

The invention relates to a gene fusion detection device. The device comprises a sequencing data acquisition module, a comparison module, a discrimination module, a true fusion breakpoint judgment module and an output module. The gene fusion detection device has the advantages of being high in detection speed, low in resource requirement and high in stability.

Owner:ANNOROAD GENE TECH BEIJING +2

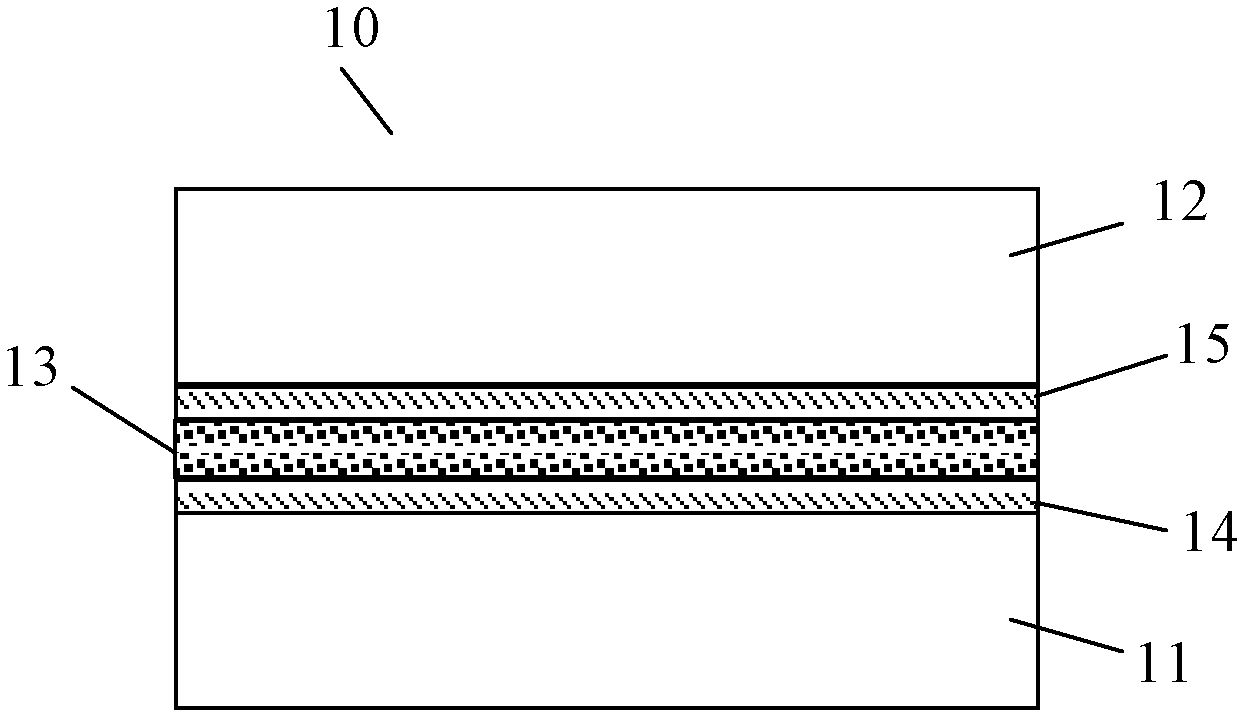

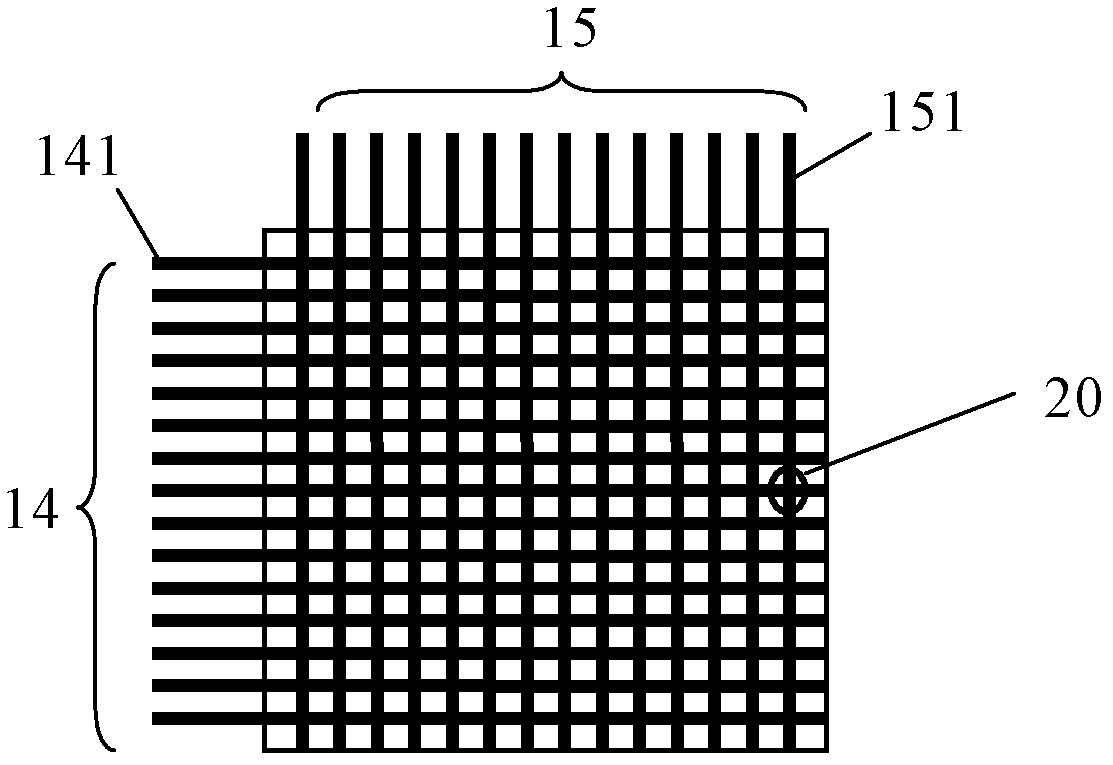

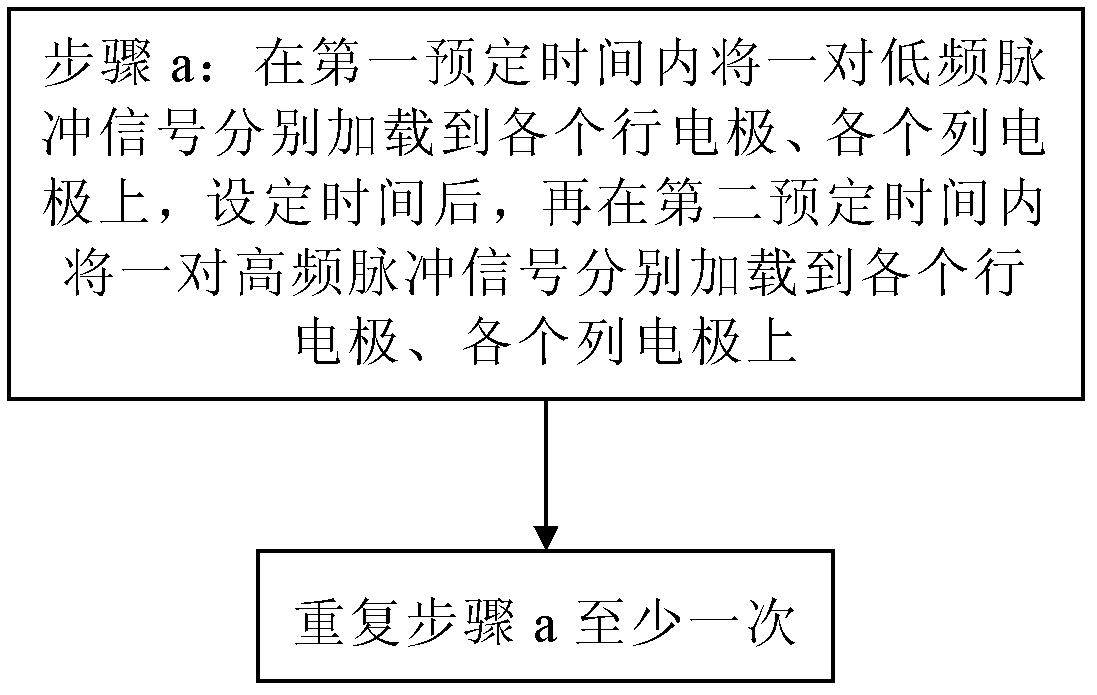

Aging method of smectic-phase liquid crystal display screen

ActiveCN102830514AImage Display ControlStable drive characteristicsStatic indicating devicesNon-linear opticsVoltage amplitudeAge method

The invention discloses an aging method of a smectic-phase liquid crystal display screen, which comprises the steps of: a. respectively loading a pair of low-frequency pulse signals to each row of electrodes and each line of electrodes within first preset time, and after set time, respectively loading a pair of high-frequency pulse signals to each row of electrodes and each line of electrodes within second preset time; and b. repeating the step a at least one time, wherein in the step a, the pair of low-frequency pulse signals have opposite phases and identical or different voltage amplitude values; and the pair of high-frequency pulse signals have opposite phases and identical or different voltage amplitude values. The voltage amplitude value and frequency of voltage signals applied to each row and each line as well as the time interval for repeatedly executing the step a can be flexibly controlled according to actual demands, so as to adjust the aging intensity and achieve optimal aging effect. By adopting the method, the drive characteristics of the smectic-phase liquid crystal material in the display screen trends to be stable, instability and diversity of the display screen are avoided, and the display quality of the display screen is guaranteed.

Owner:HALATION PHOTONICS CORP

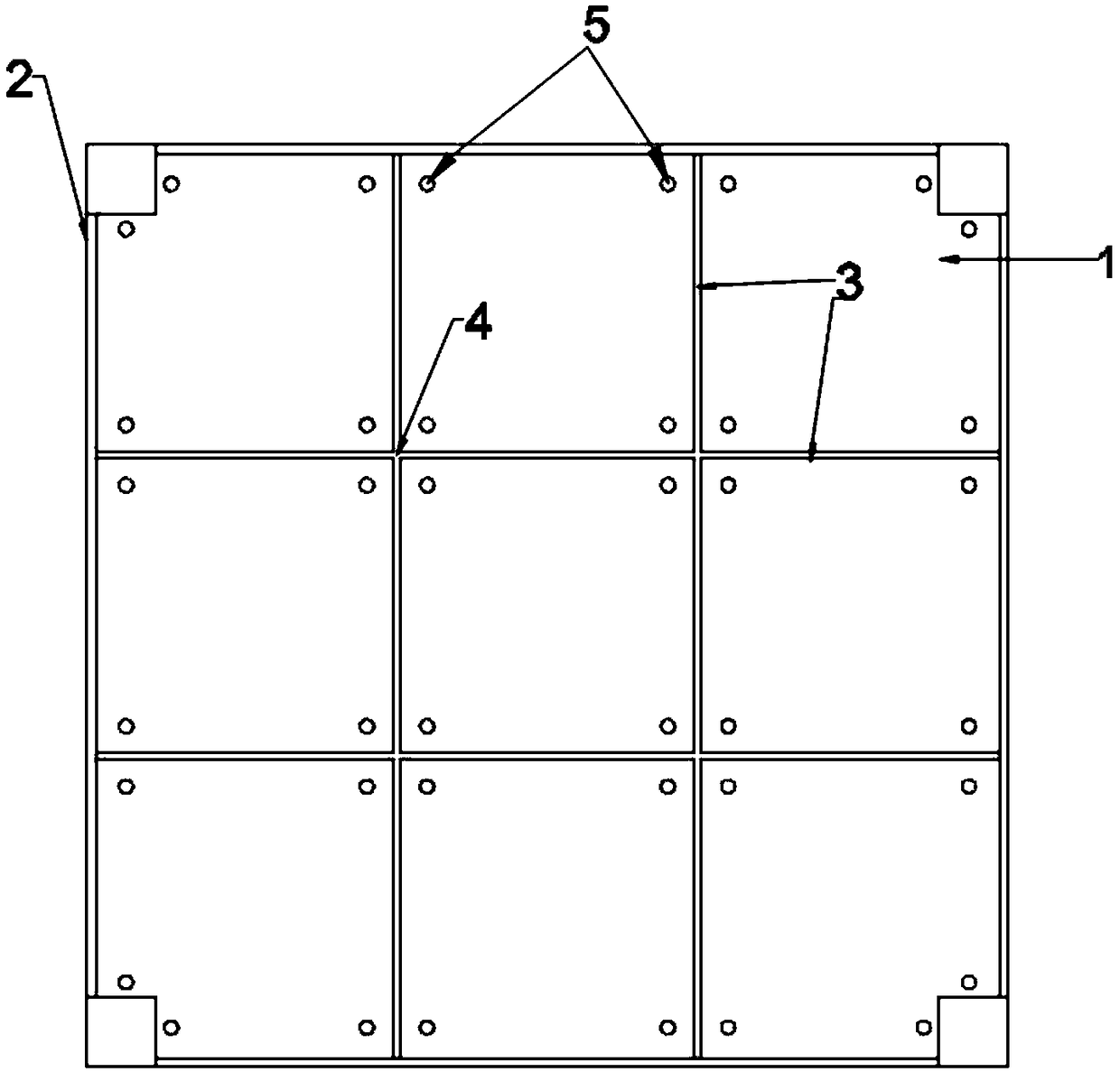

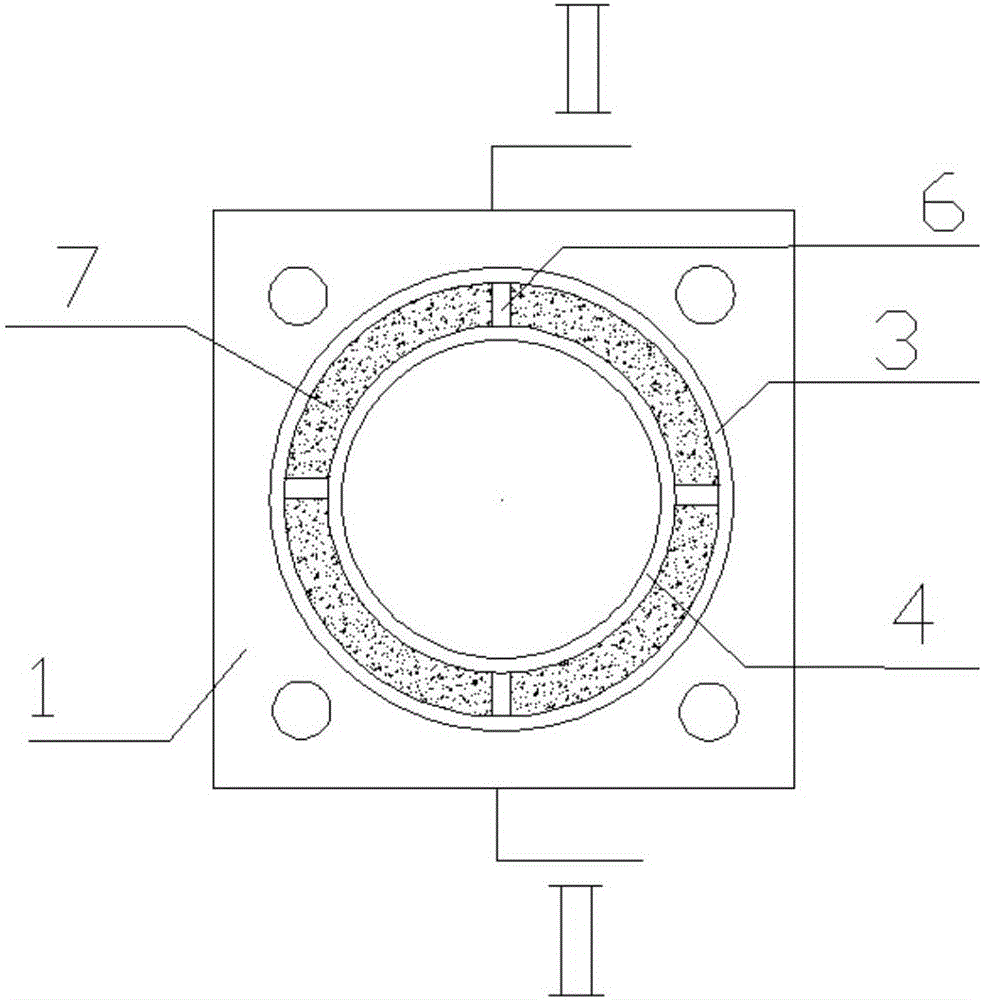

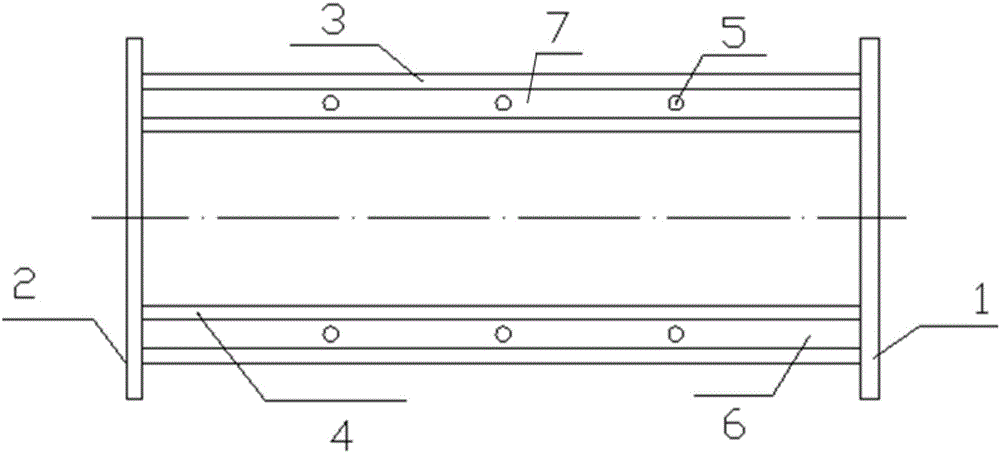

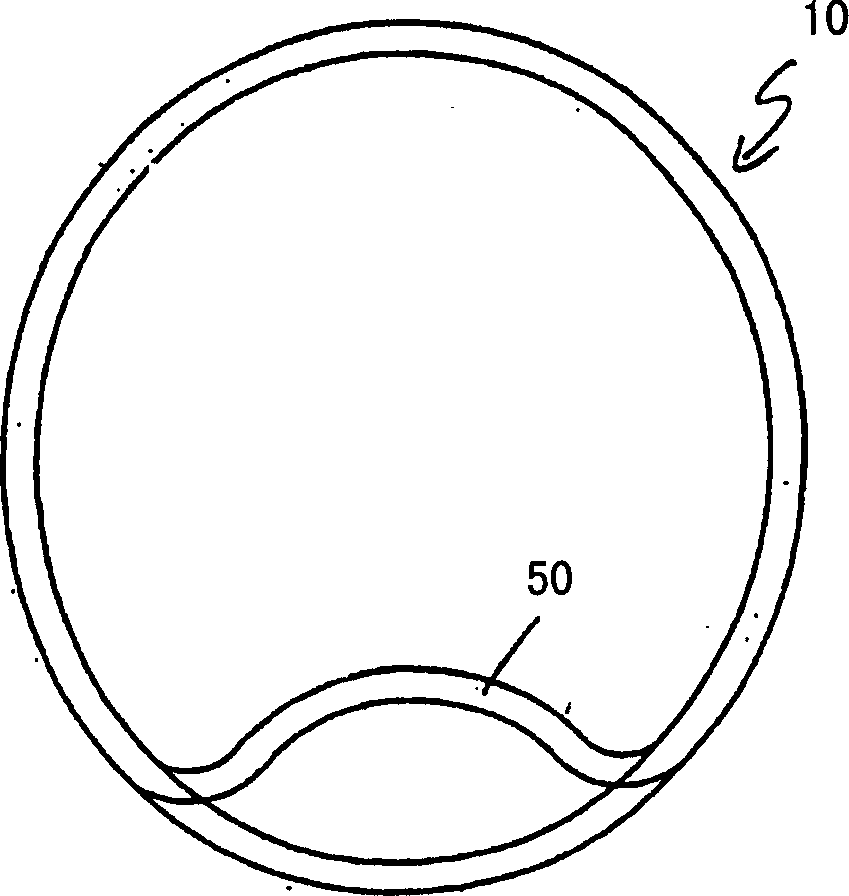

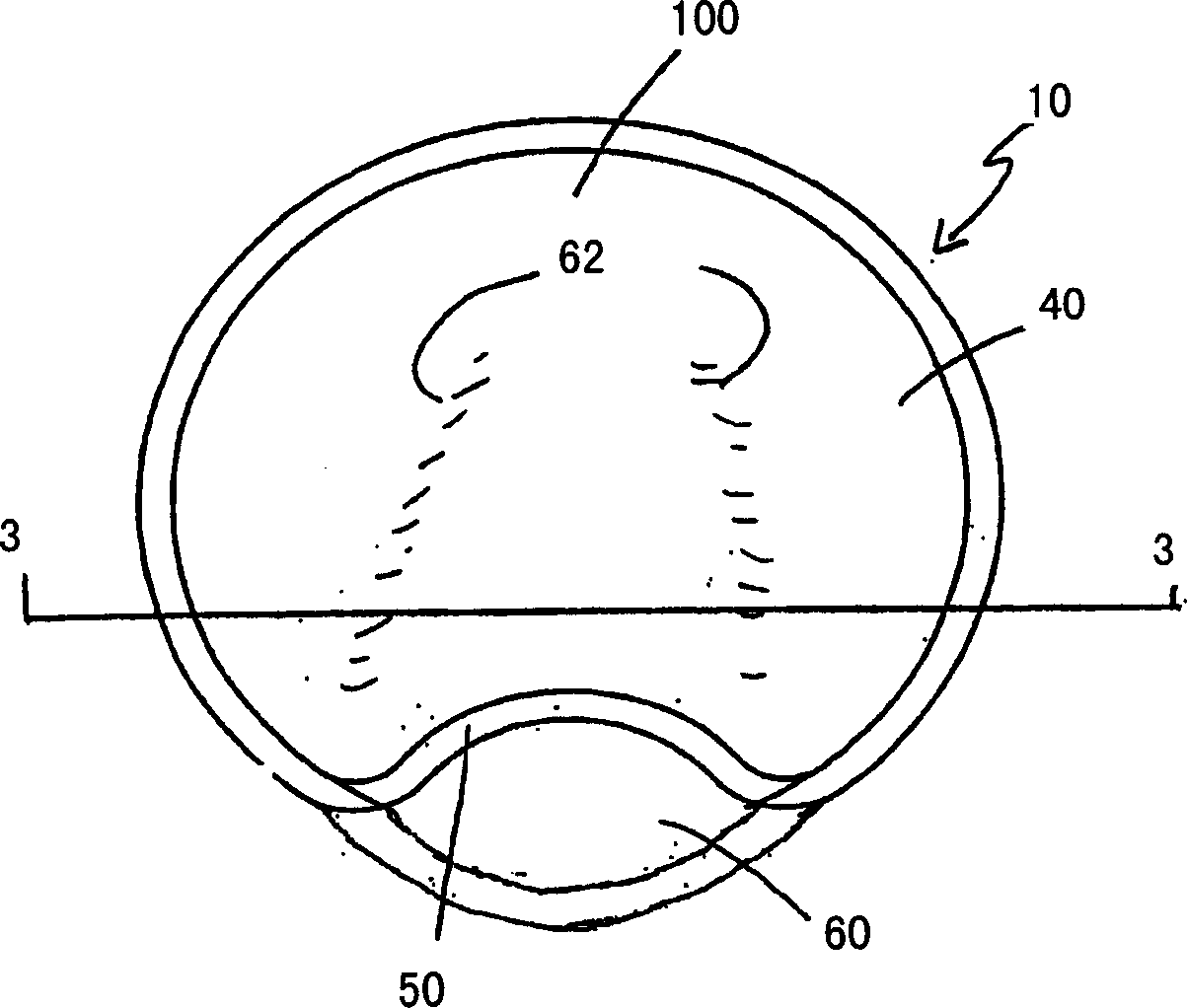

Rapid vulcanization die for building lamination shock insulation rubber bearing

InactiveCN103786282AAvoid heat transfer barriersAchieving direct heat conductionVulcanizationEngineering

The invention discloses a rapid vulcanization die for a building lamination shock insulation rubber bearing. The rapid vulcanization die comprises an inner heating die with a heat conduction strip, an outer heating die with a heat conduction strip, an excessive glue groove, heat conduction strips, an upper heating template, a lower heating template, a positioning shaft, a positioning hole and a positioning shaft mounting groove, wherein the lower heating template is mounted on a support, the outer heating die with the heat conduction strip is arranged on the upper surface of the lower heating template, the inner heating die with the heat conduction strip is arranged in the center of the outer heating die with the heat conduction strip, the height of the outer heating die with the heat conduction strip is equal to that of the inner heating die with the heat conduction strip, and the upper heating template is arranged at the tops of the outer heating die with the heat conduction strip and the inner heating die with the heat conduction strip. The rapid vulcanization die fully utilizes the structural principle of vulcanization equipment and a vulcanization target to realize rapid and uniform vulcanization and efficient mounting, is applicable to vulcanization processing of various rubber bearings, such as a standard rubber bearing, a pencil lead rubber bearing, a high damping rubber bearing and a stacked rubber bearing, and is high in vulcanization efficiency and rapid and convenient to mount and maintain.

Owner:彭勃

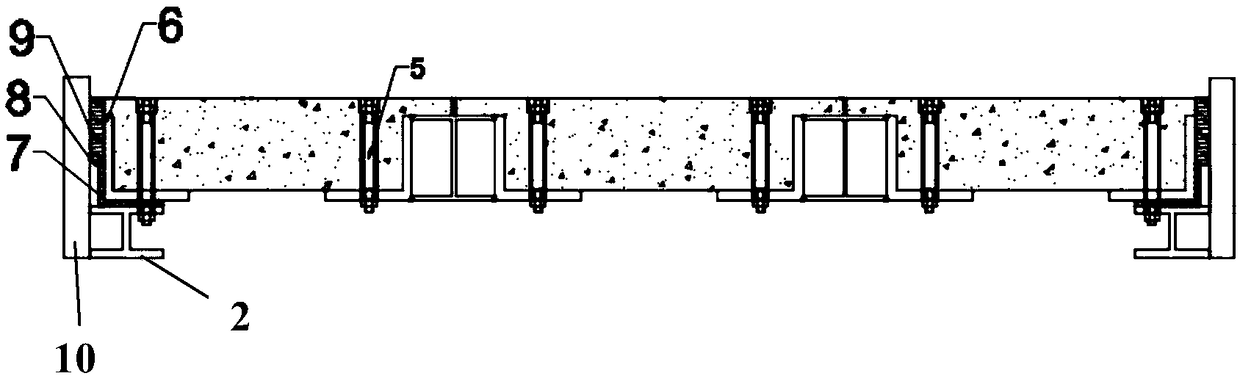

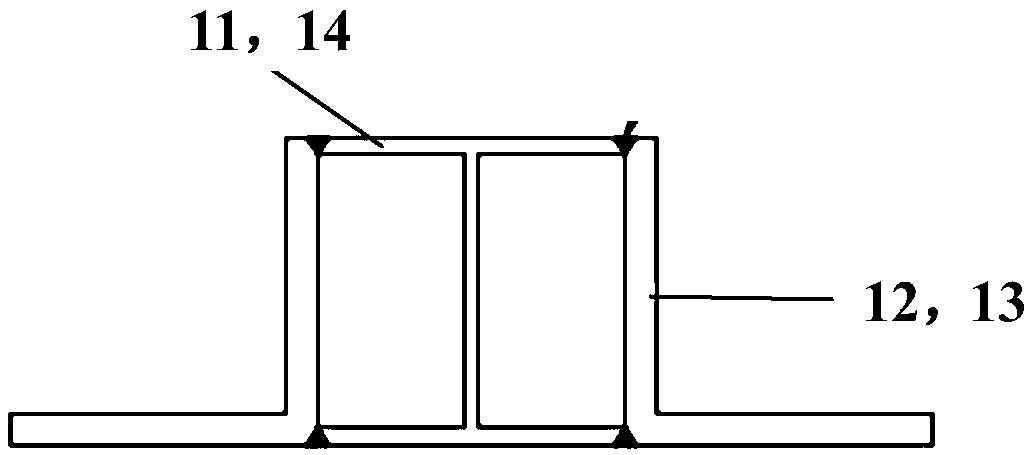

Damping standard prefabricated trave-type floor structure system convenient to construct

InactiveCN109339321AMeet the stiffness requirementsImprove structural stabilityFloorsProtective buildings/sheltersBending momentStructural stability

The invention discloses a damping standard prefabricated trave-type floor structure system convenient to construct. The damping standard prefabricated trave-type floor structure system comprises prefabricated concrete floors, a main beam, a steel structure frame, a shock insulation and energy dissipation layer, steel check blocks and a flexible material filling layer. The multiple prefabricated concrete floors are connected into a whole in the modes such as welding and bolting, and integrity and continuity of the floor structure system are ensured; the trave-type steel structure frame bears and transmits the bending moment and shearing force, thus a floor structure has the enough strength, and meanwhile the stiffness requirement of the floor structure is met; wing plates are arranged on the prefabricated concrete floors and are in lap joint with H-shaped beams, and thus structural stability is improved; when a building is under the effect of an earthquake or meets the needs of certainshocking equipment, the arranged shock insulation and energy dissipation layer achieves the effects of shock insulation and energy dissipation, and transmitting of vibration form parts of structures to the other parts of structures is blocked; and the trave-type steel structure grid frame is fixed through bolts and the steel check blocks, and it is ensured that under the effect of vibration, the situation that the floor structure generates large displacement and then loses stability is avoided.

Owner:河北水利电力学院

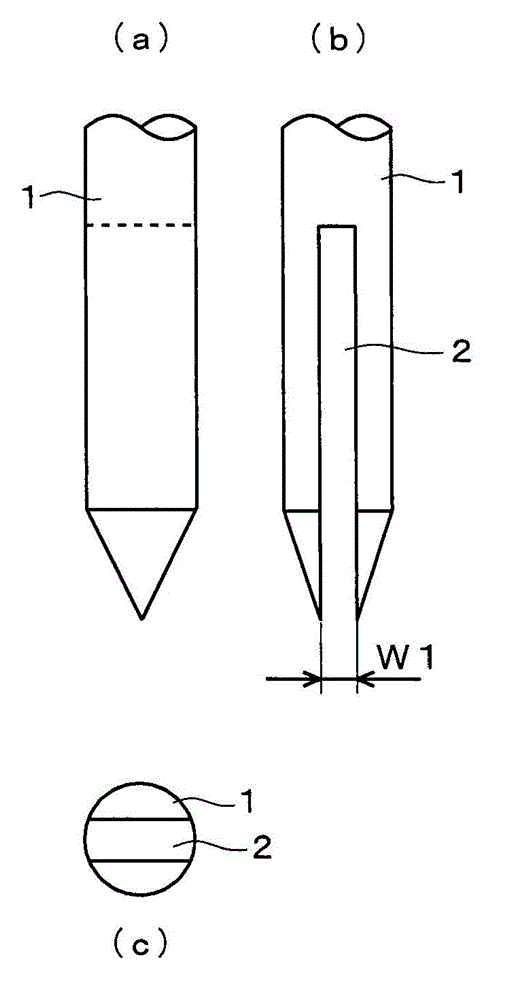

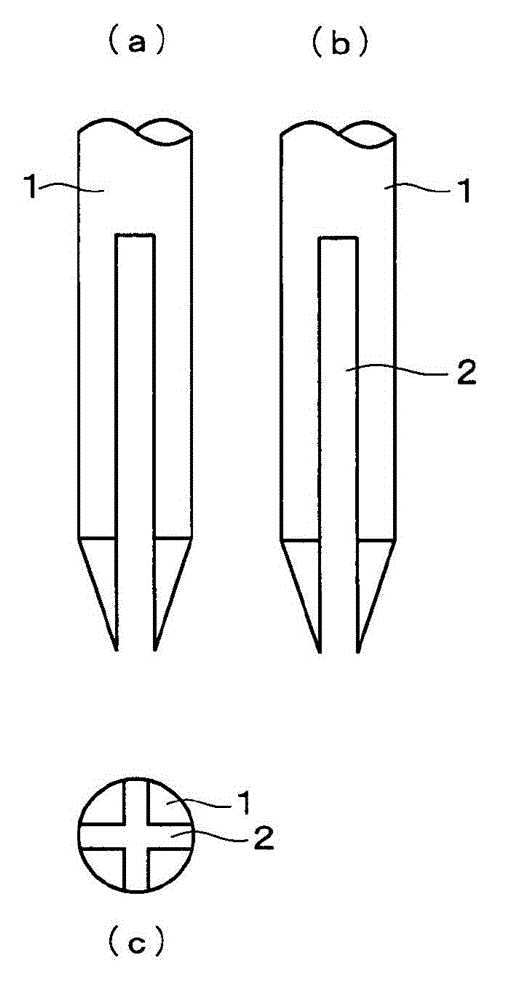

TIG arc welding electrode and TIG arc welding method

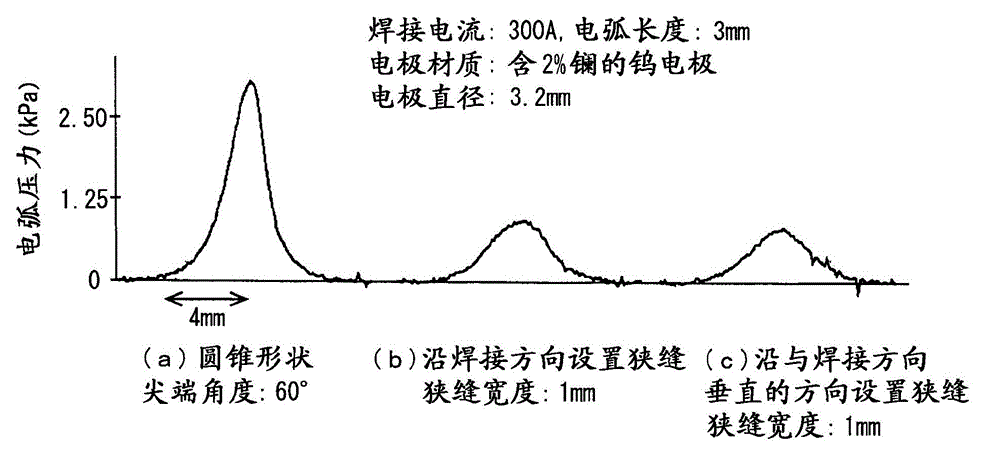

InactiveCN102753299ANo meanderingReduce current densityArc welding apparatusWelding/cutting media/materialsMeanderEngineering

The tip of a tungsten electrode (1) is polished to a cone shape or a polygonal pyramid shape, and a certain slit being along the central axis of the tip portion and having a width of 0.75 mm to 1.5 mm is provided from the tip to base end side of the electrode (1) along the axis direction, obtaining the TIG arc welding electrode (1) in which at least two or more tips are formed on mutually opposite sides of the slit, near the center of the electrode (1). The TIG welding tungsten electrode (1) can be obtained with which in a large current region, welding is possible without occurrence of an irregular bead and even in a small current region, the arc concentration can be kept and it can be avoided that the arc unevenly occurs, so beads meander and the width of a bead becomes thin, resulting in a protruding bead.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

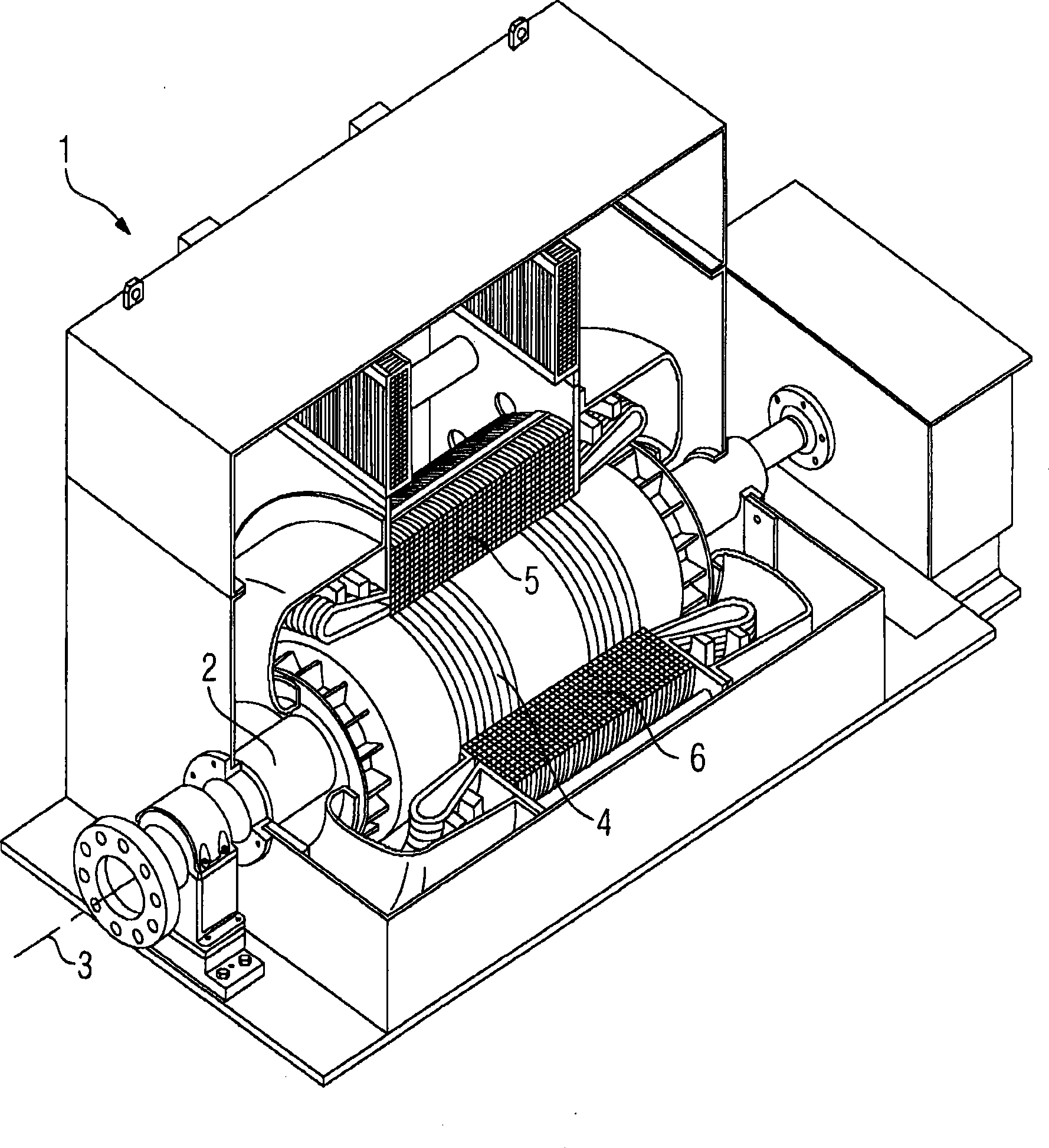

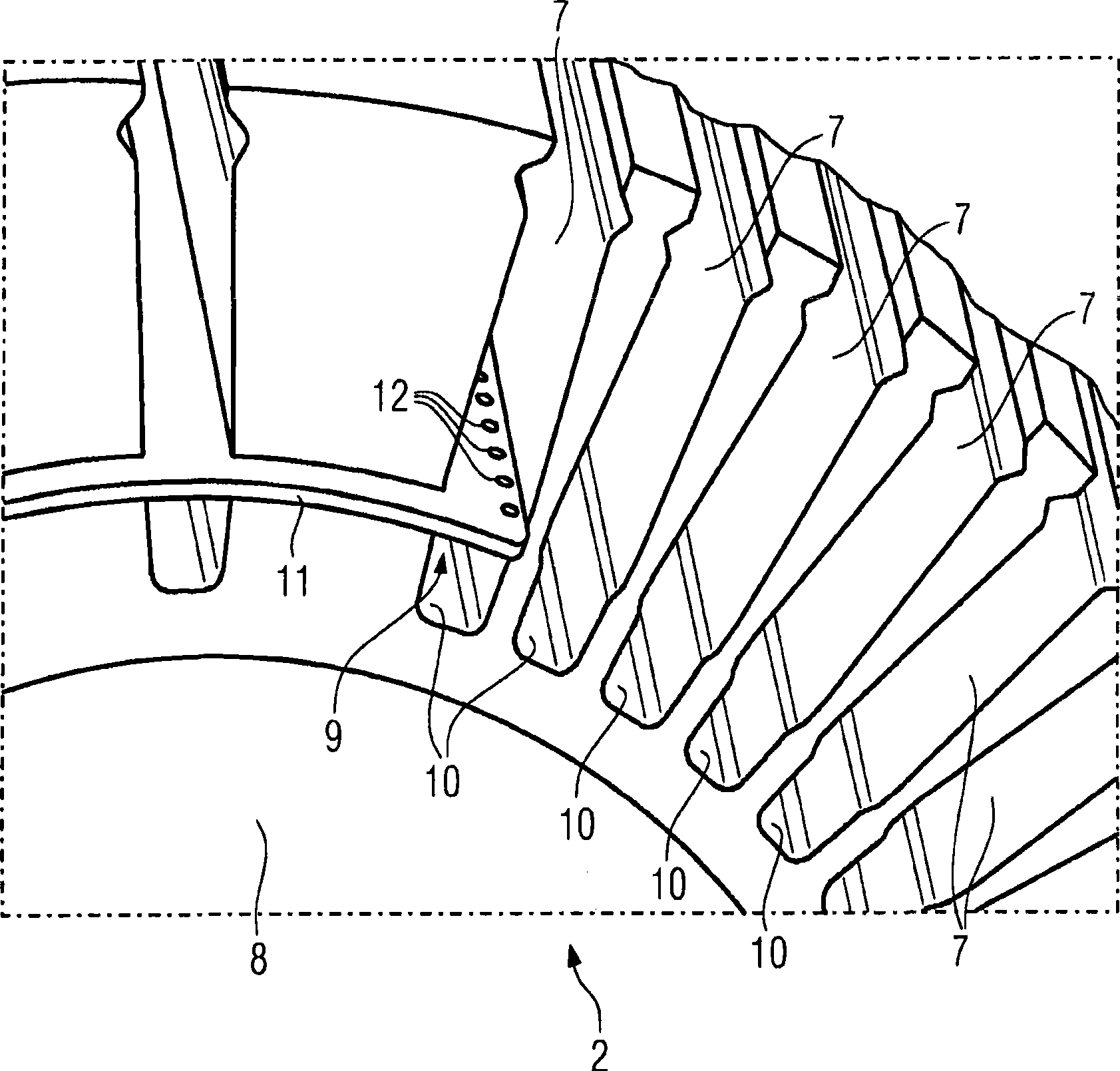

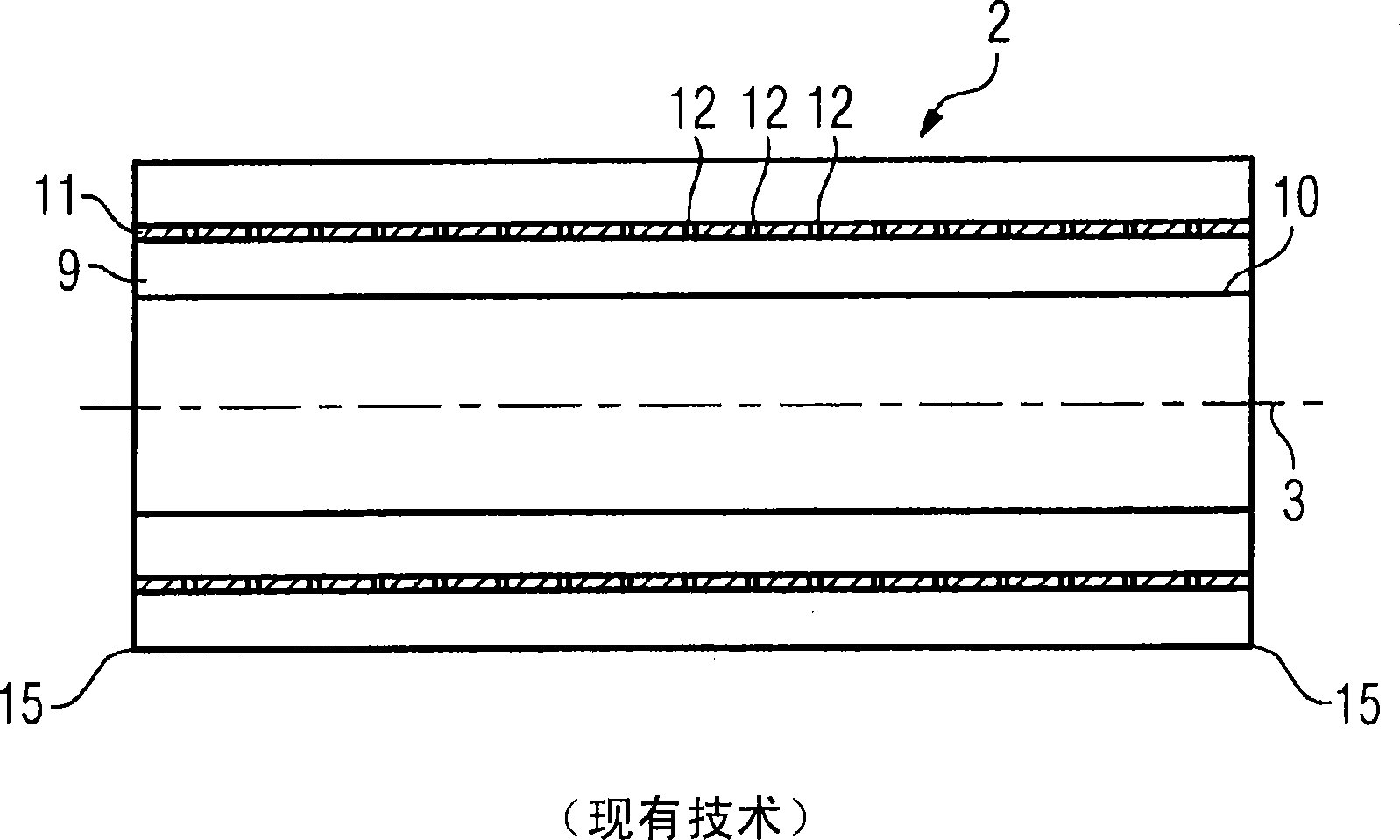

Rotor cooling for a dynamoelectrical machine

ActiveCN101512872AUniform flow velocityExtend your lifeMagnetic circuit rotating partsWindings conductor shape/form/constructionElectrical conductorCooling medium

The invention relates to a rotor (2) for a dynamoelectric machine. A bottom duct (9), through which a cooling medium flows and the conductors (4) are cooled via radial ducts (12) during operation, is disposed in the rotor (2). According to the invention, the bottom duct (9) is embodied such that the cross section thereof decreases towards the center of the rotor (2).

Owner:西门子能源全球两合公司

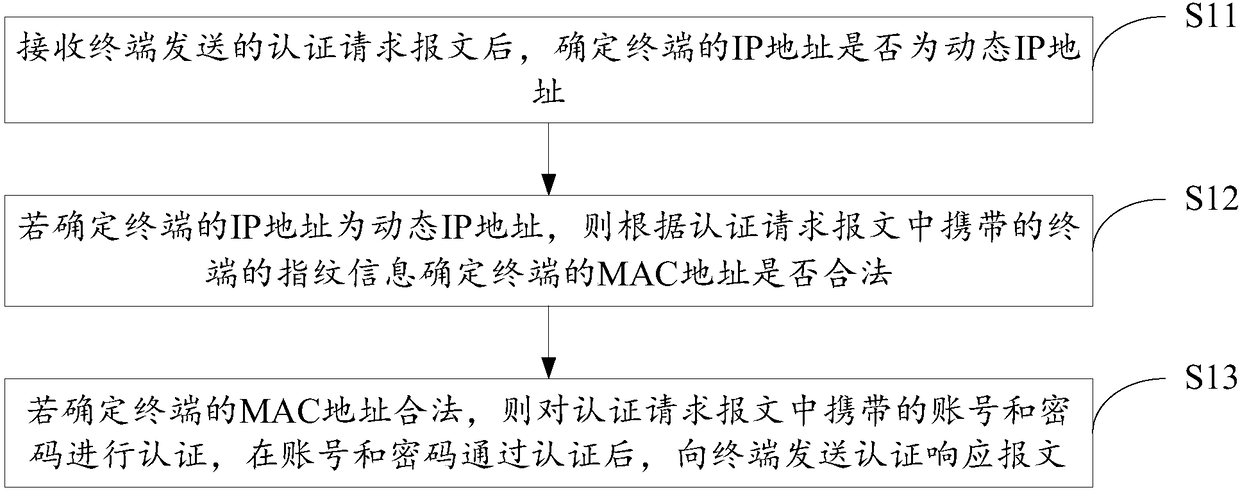

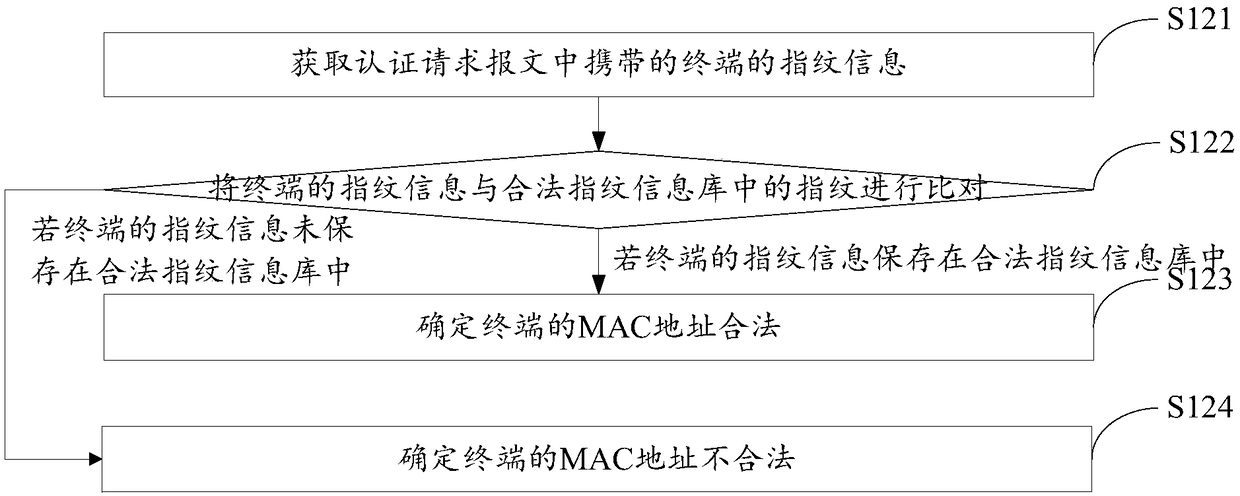

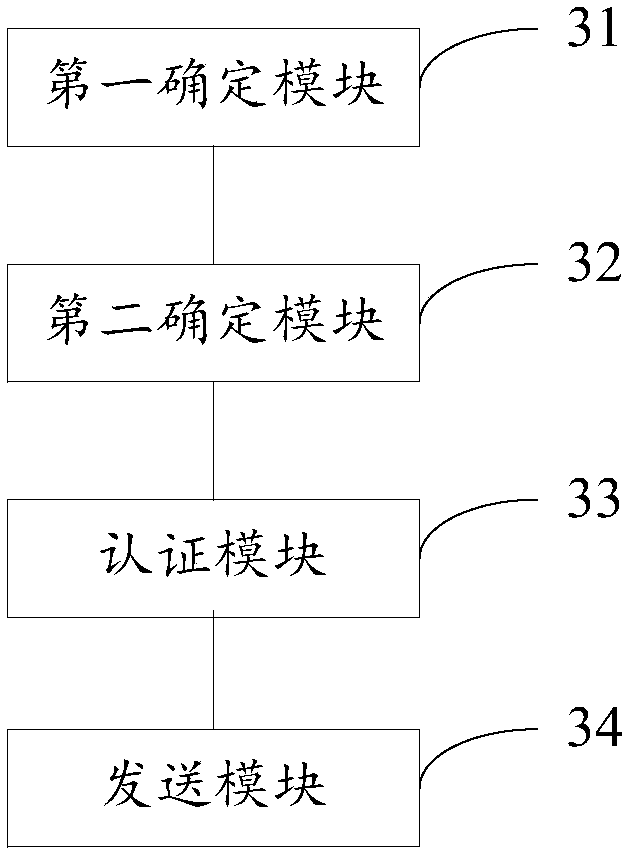

Non-aware authentication method and apparatus

The invention discloses a non-aware authentication method and apparatus. The method comprises the following steps: after an authentication request message sent by a terminal is received, determining whether an Internet Protocol IP address of the terminal is a dynamic IP address; if it is determined that the IP address of the terminal is the dynamic IP address, determining whether a media access control MAC address of the terminal is legal according to fingerprint information of the terminal carried in the authentication request message; and if it is determined that the MAC address of the terminal is legal, authenticating an account number and a password carried in the authentication request message, and sending an authentication response message to the terminal when the account number andthe password pass the authentication. By adoption of the scheme, normal network access of legal users can be ensured, no offline or network instability and other situations occur, and no billing dispute is caused.

Owner:RUIJIE NETWORKS CO LTD

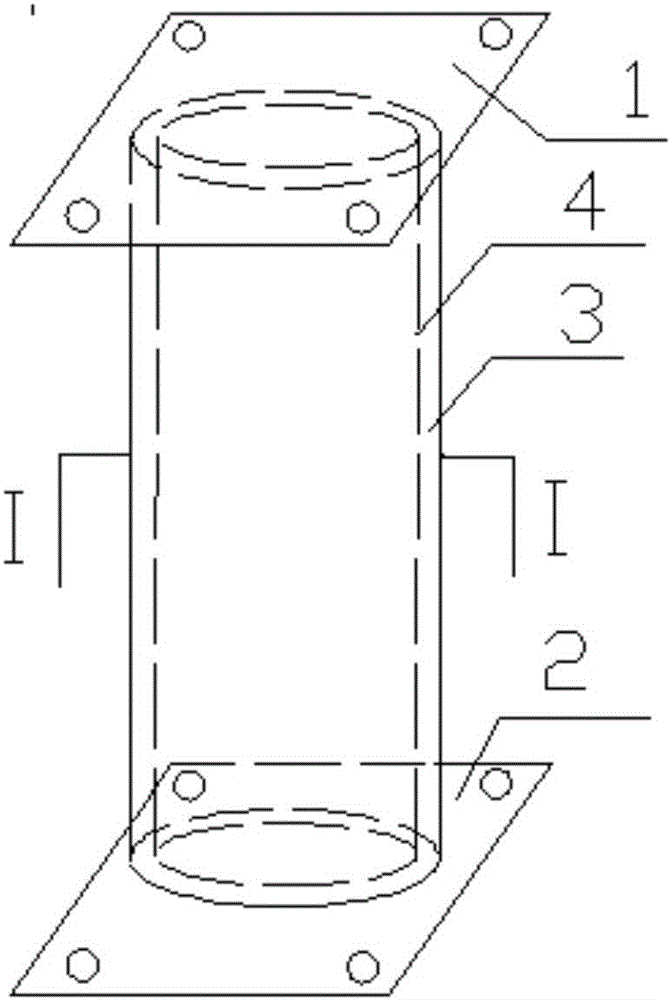

Viscous liquid damping torsion-resistant cylinder used in building structure

InactiveCN105735509AImprove energy consumptionNo residual deformationShock proofingViscous liquidResidual deformation

The invention relates to a viscous liquid damping torsion-resistant cylinder used in a building structure. The viscous liquid damping torsion-resistant cylinder comprises two cover plates, an outer cylinder body (3), an inner cylinder body (4) and damping materials (7). The inner cylinder body (4) is sleeved with the outer cylinder body (3). One end of the inner cylinder body (4) is fixedly connected with one cover plate. One end of the outer cylinder body (3) is fixedly connected with the other cover plate. A sealed cavity is defined by the two cover plates, the outer cylinder body (3) and the inner cylinder body (4), and the viscous liquid damping materials are injected into the cavity. Two or more stiffening ribs (6) are arranged between the inner cylinder body (4) and the outer cylinder body (3). At least one stiffening rib (6) is fixedly connected with the outer cylinder body (3), and at least one stiffening rib (6) is fixedly connected with the inner cylinder body (3). By the adoption of the viscous liquid damping torsion-resistant cylinder, the problems that according to an existing damper, the durability is poor, residual deformation exists, the energy dissipation capacity is insufficient, and the damping capacity is simplex are solved.

Owner:WUHAN UNIV OF TECH

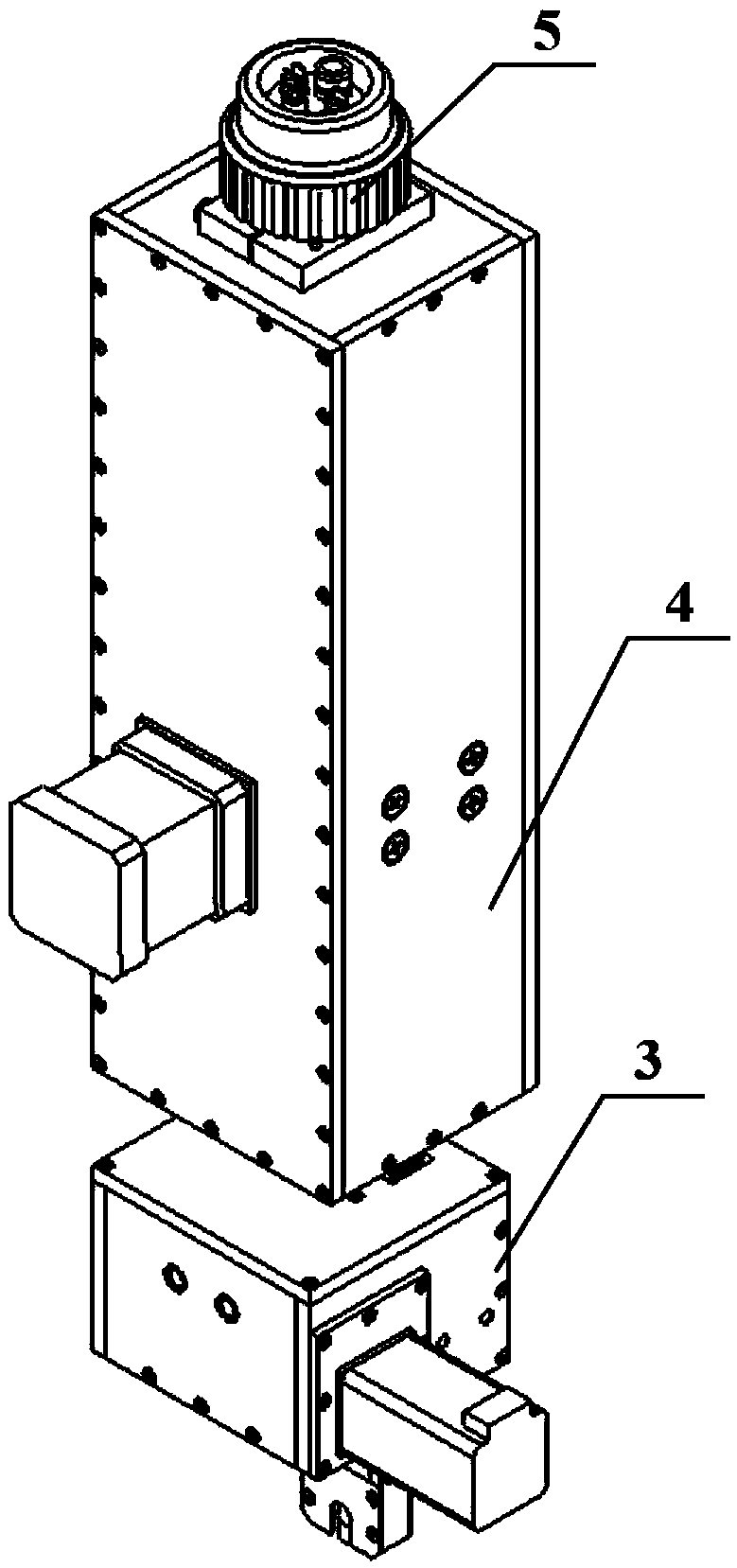

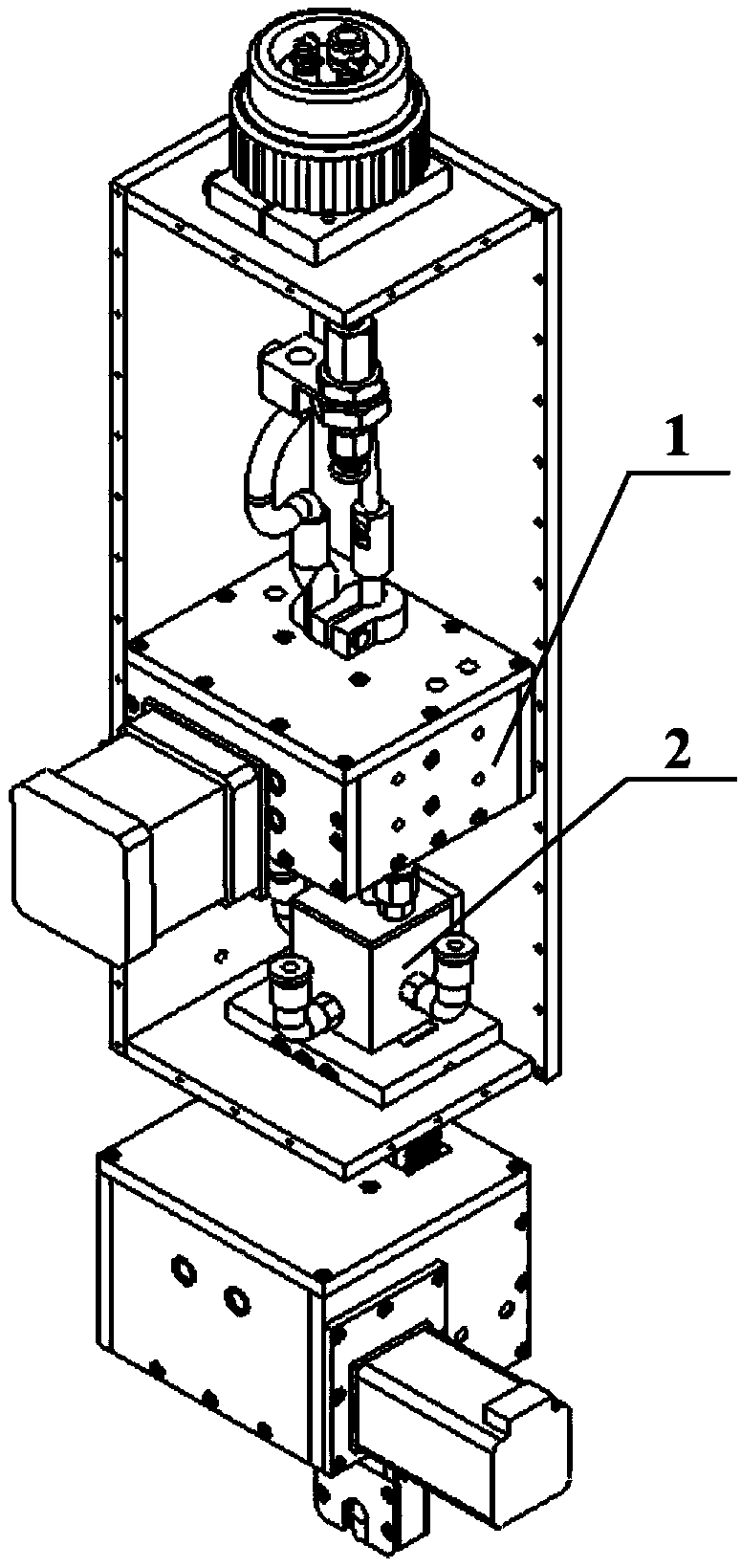

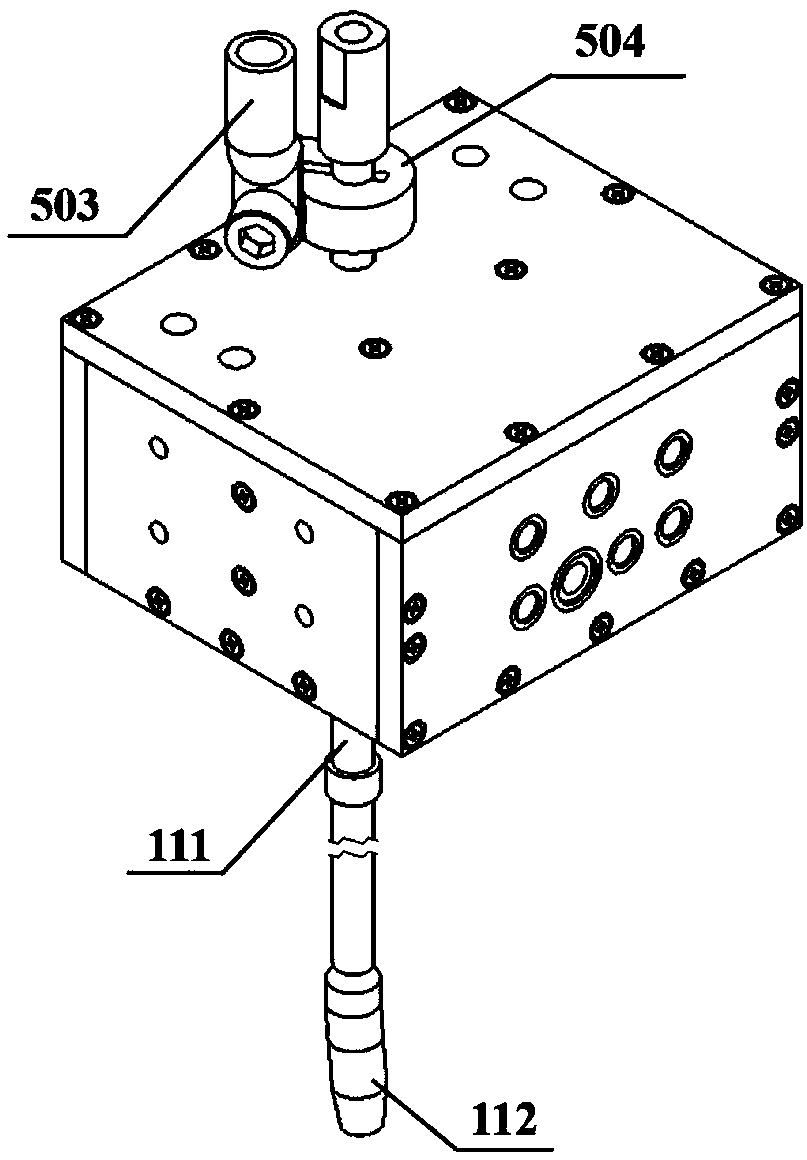

Arc oscillation narrow gap consumable electrode dual-layer gas shield automatic welding gun for robot

ActiveCN109604786AIncrease the swing frequencyAchieving arc swingElectrode supporting devicesSpeed wobbleEngineering

The invention provides an arc oscillation narrow gap consumable electrode dual-layer gas shield automatic welding gun for a robot. According to an arc oscillation module, a pair of incomplete gears rotating synchronously and oppositely is adopted for being alternately engaged with an oscillation gear to drive the arc oscillation module to oscillated back and forth, a pair of conic gears transmitsoscillation motion to a conducting rod of the welding gun, and a welding arc can oscillate in a narrow gap groove at a high speed according to preset frequency. A welding gun body module is of a flatstructure in a water cooling manner and can stretch into the bottom of the narrow gap welding groove, and inner-layer gas shield, welding wires and electric energy are provided for a high-temperatureweld pool. A lifting type outer gas shade module can be controlled by a robot to automatically adjust the height position according to the groove depth, and outer-layer gas shield is provided for theweld pool and nearby areas. The welding gun has higher arc oscillation frequency, the better gas shield effect and the smaller shape size, and therefore higher welding efficiency and a more stable welding process are achieved, and the welding gun is more suitable for intelligent welding application of the robot.

Owner:SHANGHAI JIAO TONG UNIV

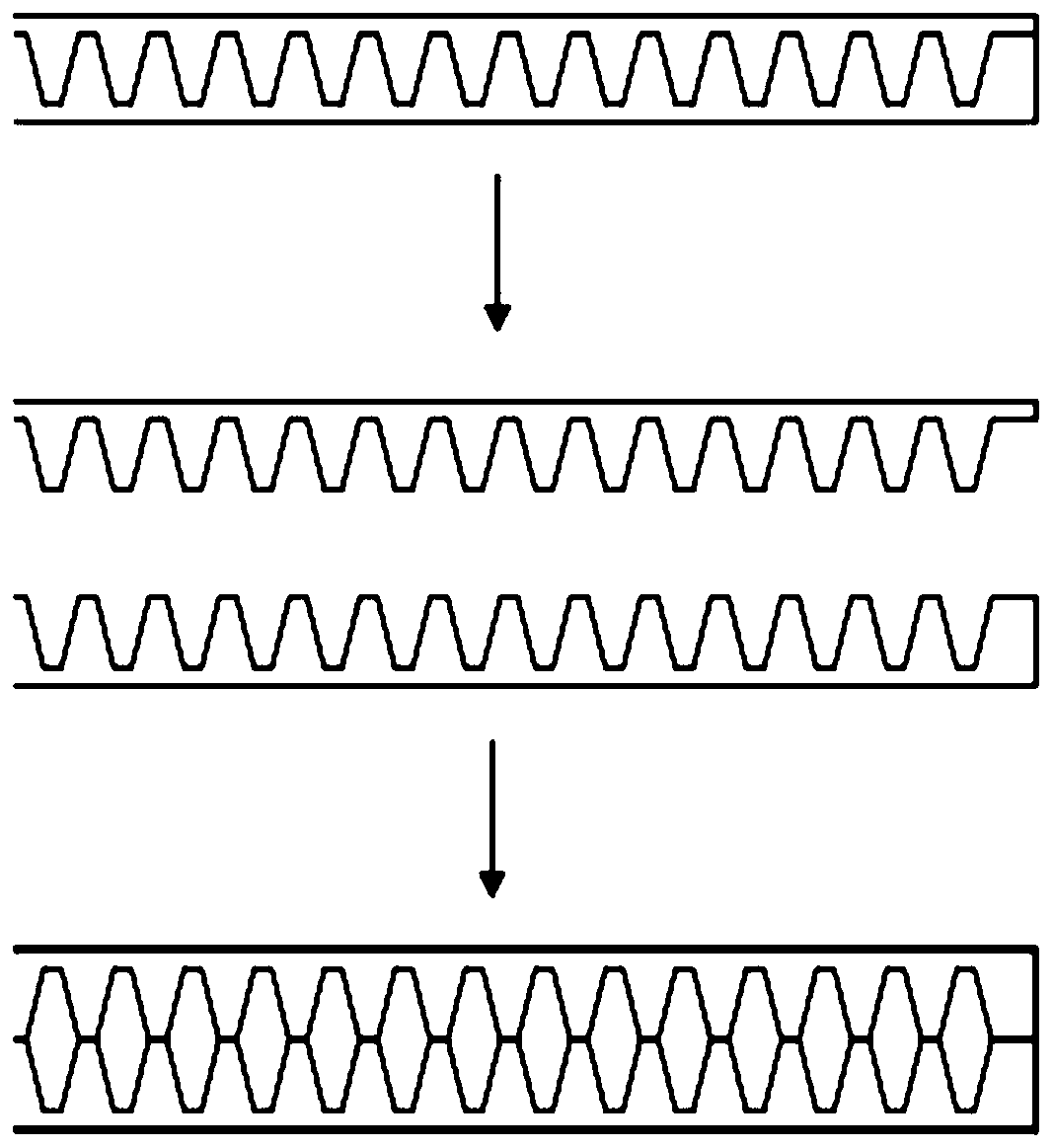

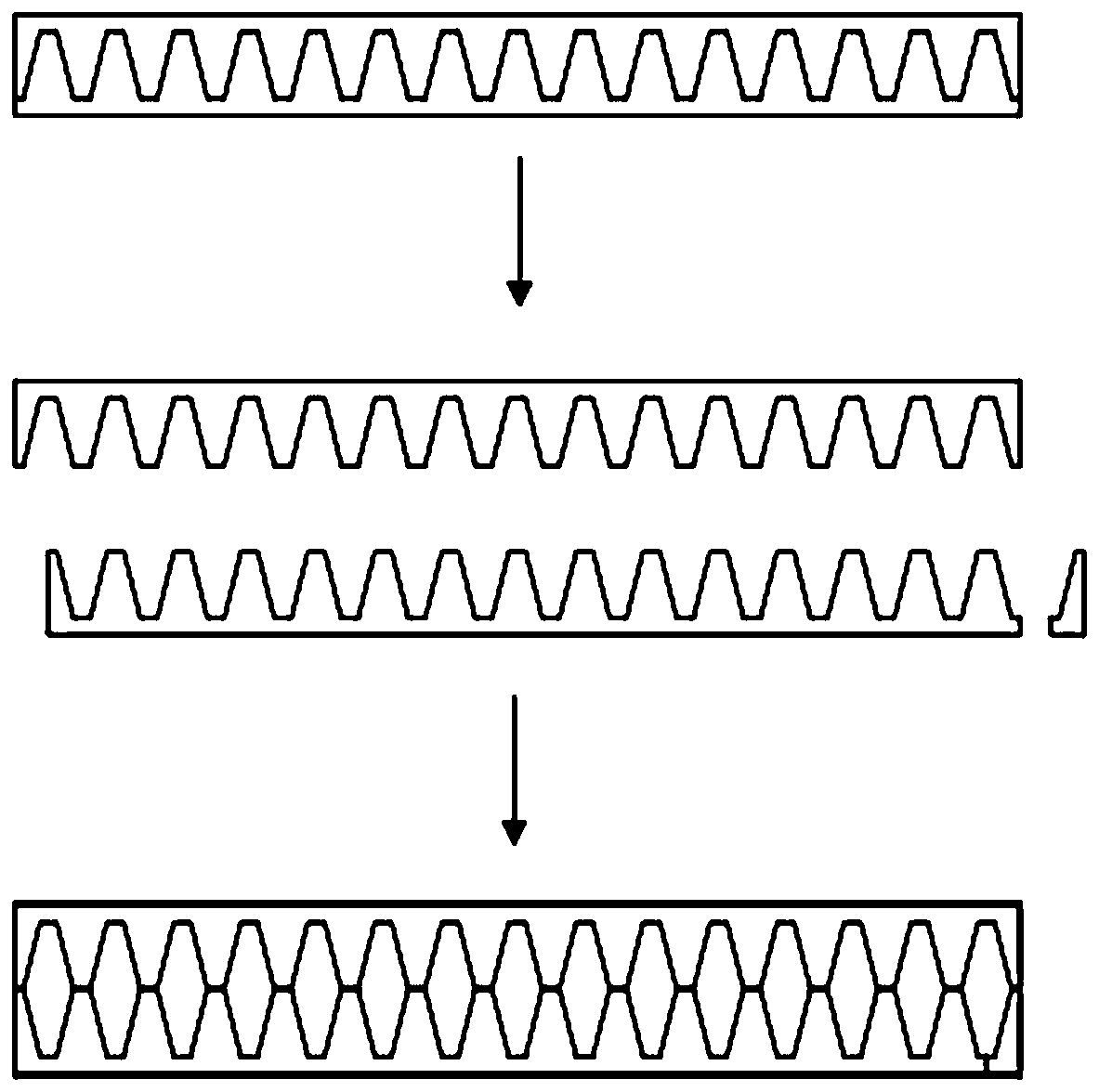

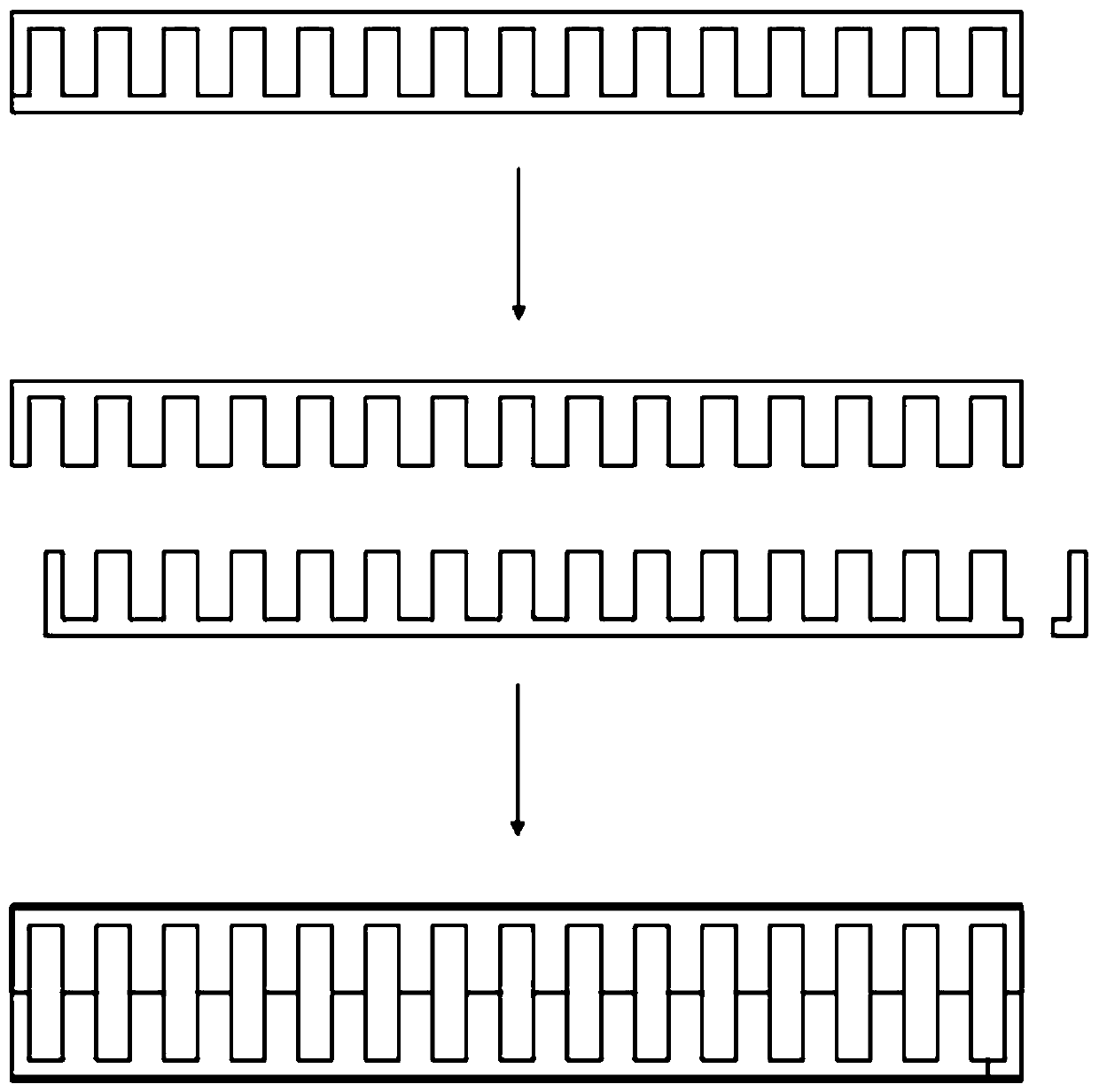

Dislocated welding type web punched prefabricated wrapped castellated beam

InactiveCN110306724ATake advantage ofIncreased beam heightGirdersJoistsShaped beamChinese characters

The invention discloses a dislocated welding type web punched prefabricated wrapped castellated beam which comprises a steel framework and a prefabricated concrete layer. The steel framework is a framework shaped like Chinese character 'ri' and is composed four main beams and one auxiliary beam. Each I-shaped beam is cut and divided into two steel beams with one side edges provided with teeth along a preset folded line on a web of the I-shaped beam, wherein the sides, provided with the teeth, of the two steel beams are welded in a dislocated manner to form one main beam or the auxiliary beam with the web provided with a hole. The prefabricated concrete layer is wrapped on the lower flanges and part of the webs of the main beams and the auxiliary beam. During construction, the prefabricatedwrapped castellated beam is conveyed to a construction field, a profiled steel sheet is arranged on the prefabricated concrete layer parallel to the main beams and the auxiliary beam in a lapped manner, the profiled steel sheet is adopted as a platform, and a pipeline is arranged by penetrating the exposed hole; cast-in-place concrete is adopted, and a cast-in-place concrete layer wrapped on theprofiled steel sheet, the pipeline, the upper flanges and the rest of the webs of the main beams and the auxiliary beam is formed. By means of the dislocated welding type web punched prefabricated wrapped castellated beam, the inertia moment and the flexural capability of a section of the castellated beam are large, and the good energy consumption capability is achieved under the earthquake load effect.

Owner:BEIJING UNIV OF TECH

Method for reinforcing soft ground by combining vacuum preloading and surcharge vibration rolling

InactiveCN102888833AImprove structural performanceImprove bearing capacitySoil preservationPressure stabilizationVacuum pressure

The invention discloses a method for reinforcing a soft ground by combining vacuum preloading and surcharge vibration rolling. The method comprises the following steps of: inserting a vertical draining plate, paving a medium-coarse sand cushion layer, digging a sealing ditch, and simultaneously, paving a horizontal draining pipe; and paving a horizontal water filtering pipe in the medium-coarse sand cushion layer, paving a vacuum film on the medium-coarse sand cushion layer, backfilling the sealing ditch, setting a measurement mark, arranging a vacuum pump, performing pressure stabilization after the vacuum pressure below the vacuum film reaches 85 kPa, performing backfilling by using pond residues, performing surcharge preloading, finishing surcharge preloading after a control requirement is met, and compacting soil on the surface layer through impaction and vibration rolling. Compared with the prior art, the method has the advantages that the soft ground is reinforced by combining vacuum preloading and surcharge vibration rolling, so that the original ground processing method through vacuum preloading or surcharge vibration rolling can be effectively improved, the cost of a ground processing project can be reduced, a construction period is shortened, and great significance is provided for improving the structural performance of the ground and the ground bearing capacity.

Owner:CHINA CONSTR FOURTH ENG DIV

Press-shooting system for novel extrusion casting machine

The invention discloses a press-shooting system for an extrusion casting machine to overcome the technical defects of press-shooting systems for existing extrusion casting machines. The press-shooting system comprises a feeding mechanism and a press-shooting mechanism. The press-shooting system can be applied to a vertical extrusion casting machine. The press-shooting system solves the problems of existing extrusion casting machines that feeding is inconvenient and unsteady, air entrapment occurs easily, the size of a casting in the thickness direction is hard to control, press-shooting stability is low, the occupied space of a press-shooting system is large, and a working table is too high.

Owner:苏州慧驰轻合金精密成型科技有限公司

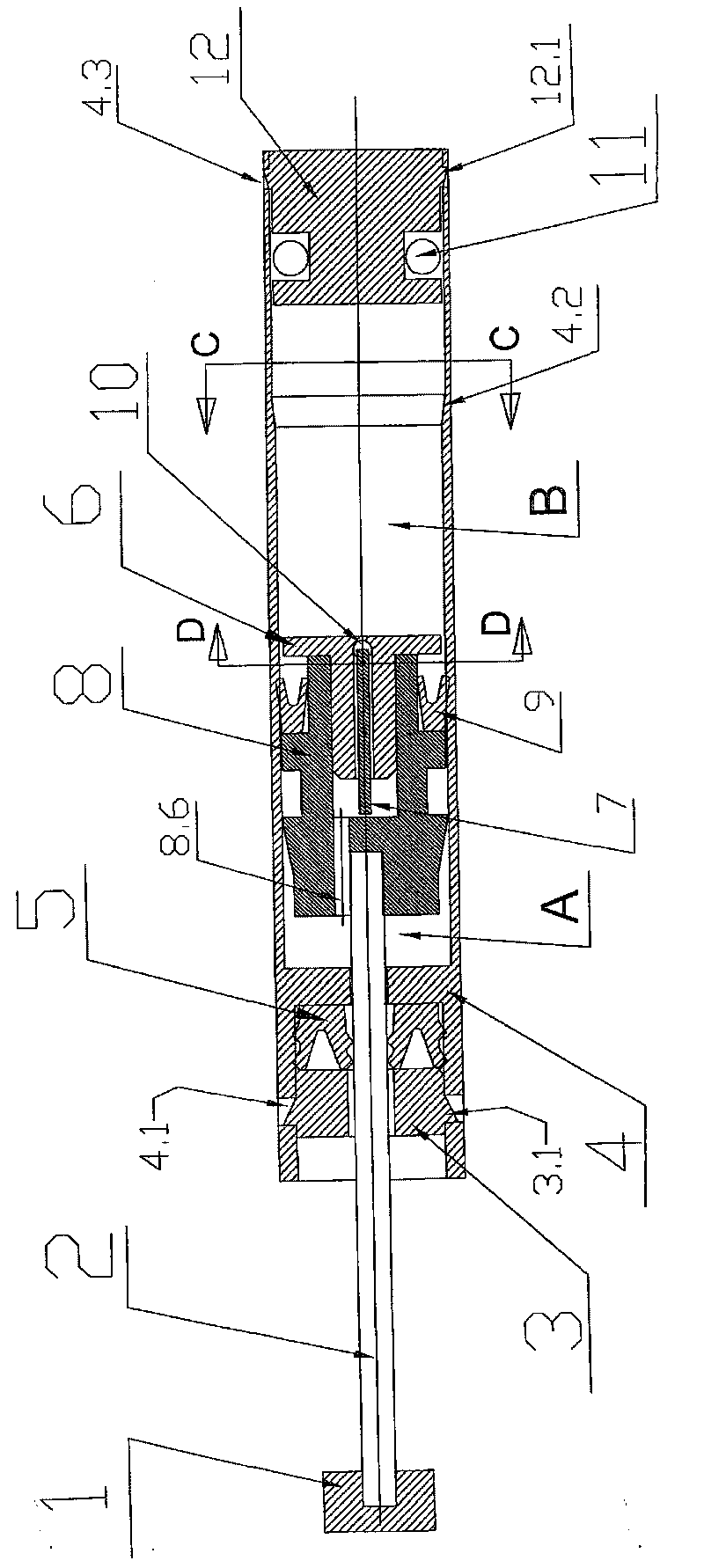

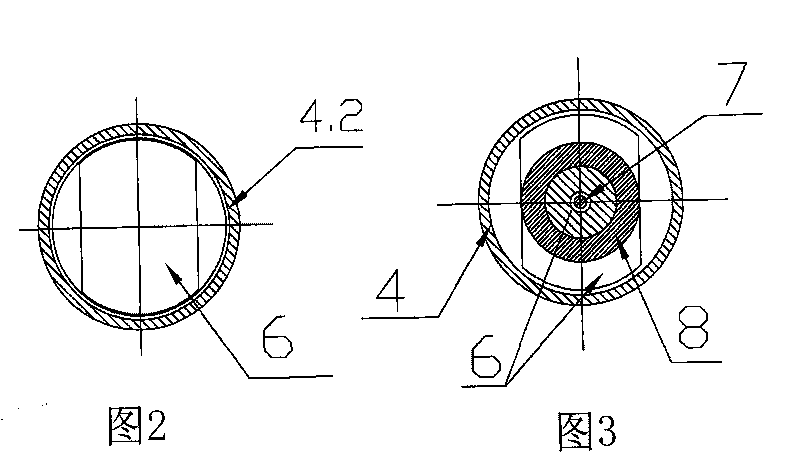

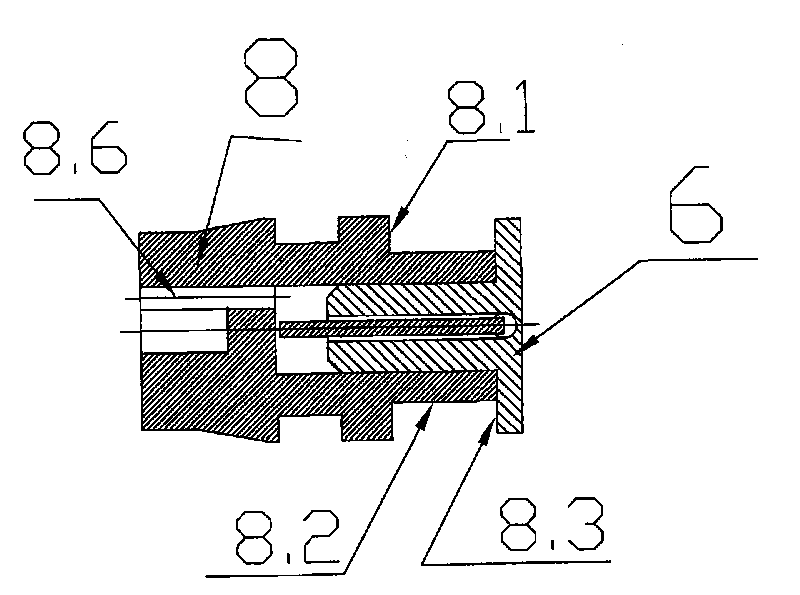

Gas damping buffer with axial piston vent hole

InactiveCN101749348AEasy assemblyFirmly connectedSpringsGas based dampersTrailing edgeCylinder block

The invention relates to a gas damping buffer with an axial piston vent hole, comprising a closed cylinder (4), a piston (8), a piston rod (2), a guide sleeve (3), a front leather cup (5), a plug (12), a clamping block I (3.1), a bayonet I (4.1), a clamping block II (12.1), a bayonet II (4.3) and a gas release ring slot (4.2), wherein the piston (8) is provided with a central piston blind hole, and the part of the piston (8) on the left of the blind hole is axially provided with an axial piston vent hole (8.6); the blind hole is internally and fixedly connected with a piston head (6), and themiddle on the outer edge of the piston (8) is provided with a front piston ring (8.1); the rear edge of the central piston head (6) is provided with a rear piston ring (8.3), a floating ring (9) is sleeved on a piston post (8.2) between the front piston ring (8.1) and the rear piston ring (8.3); the piston head (6) is provided with a central piston head hole and a vertical piston head hole (10) vertical to an axial line; the central piston head hole of the piston head (6) is internally provided with a piston damping core (7); and the outer diameter of the floating ring (9) is larger than the outer diameters of the piston (8) and the piston head (6). The gas damping buffer has simple assembly, firm connection, obvious relief function, stable damping effect and better tightness.

Owner:江苏华宏强顺科技有限公司

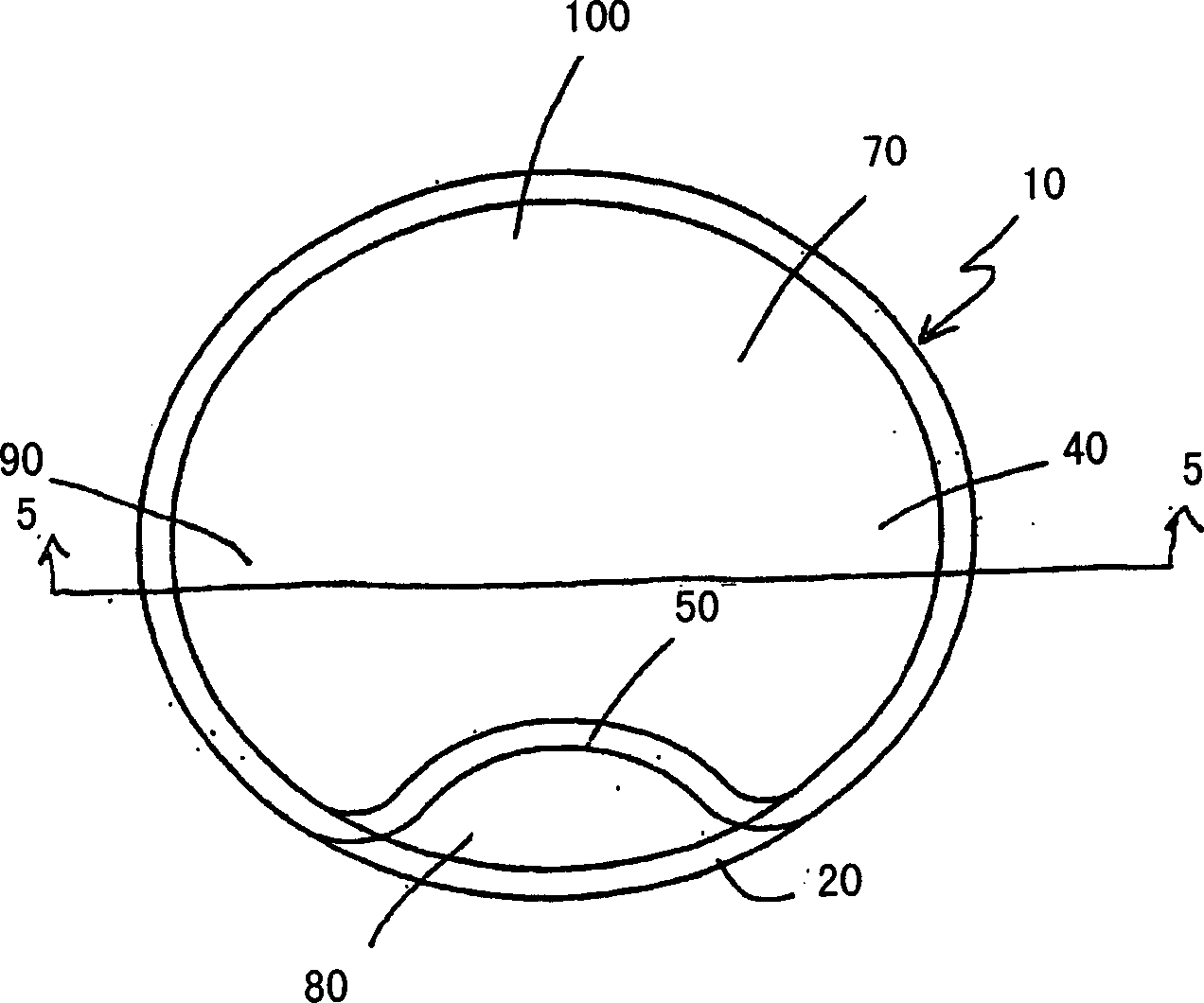

Skin treatment articles and methods

InactiveCN1861038ANot toxicNo incompatibilityCosmetic preparationsToilet preparationsSkin treatmentsBiomedical engineering

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

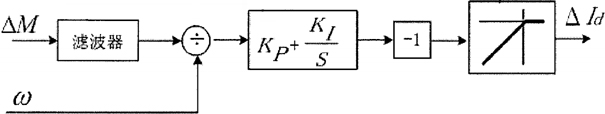

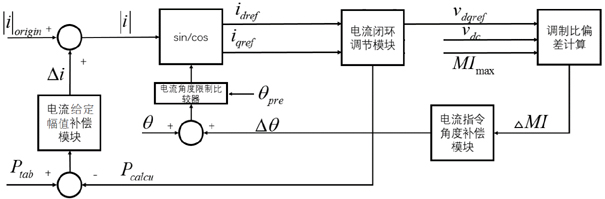

Vehicle permanent magnet synchronous motor vector field weakening control system considering torque precision

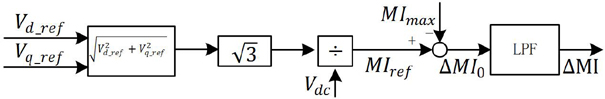

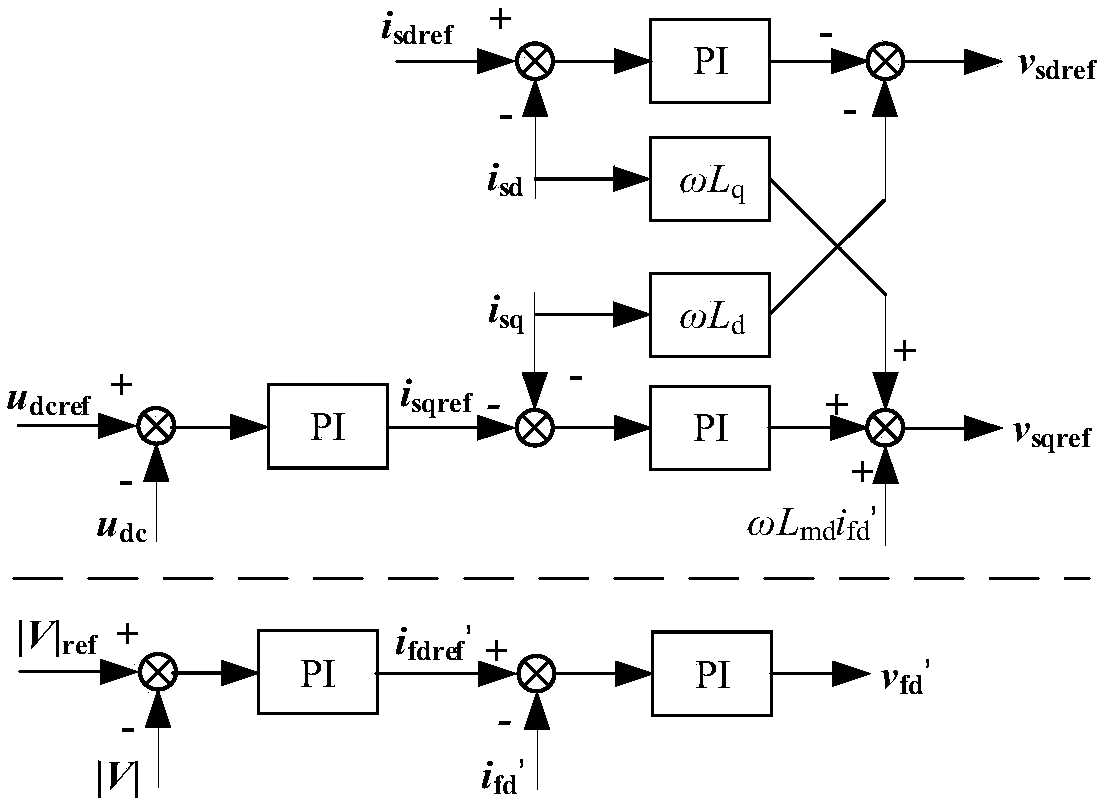

PendingCN113328666ANo instabilityAvoid large output torque deviationElectronic commutation motor controlAC motor controlAutomotive engineeringPermanent magnet synchronous motor

The invention discloses a vehicle permanent magnet synchronous motor vector field weakening control system considering torque precision. The system comprises a current closed-loop adjustment module, a modulation ratio deviation calculation module, a current instruction angle compensation module, a current angle presetting module, a current instruction angle limit comparator, a current given amplitude compensation module and a current given vector correction module. The adjustment direction is always weak magnetic direction, and instability caused by repeated adjustment is avoided; the dq current is introduced and corrected at the same time, so that the anti-voltage saturation pressure can be shared to the dq current, and the situation that the output torque deviation is too large due to too much adjustment of the single-axis current is avoided; according to the method, the torque precision is ensured while the traditional weak magnetic target which is controlled by the system and does not lose stability is ensured.

Owner:ZHEJIANG UNIV CITY COLLEGE

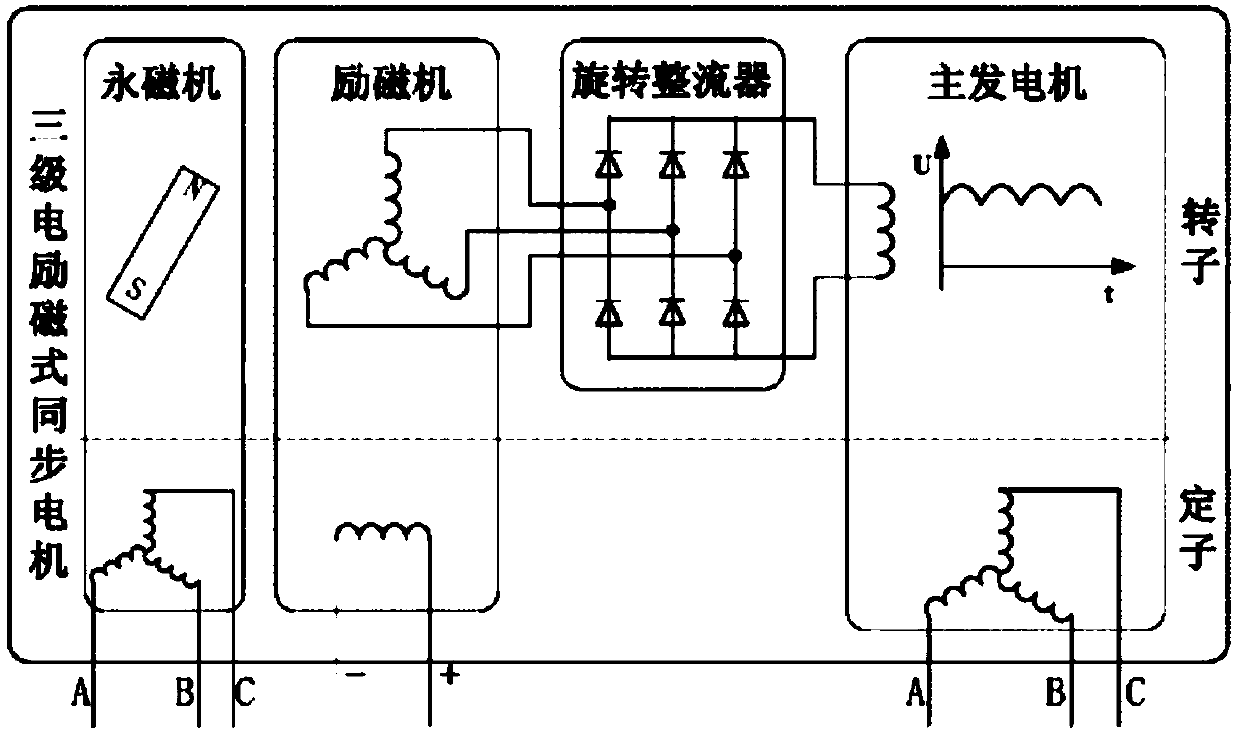

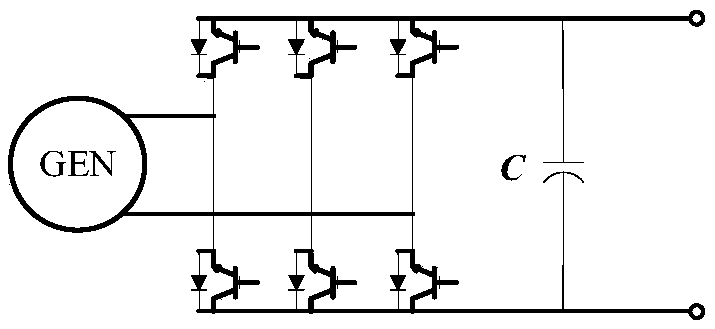

A DC power supply system stability device and method based on virtual resistance compensation

InactiveCN109039184AKeep the power supply system stableNo instabilityElectronic commutation motor controlVector control systemsSynchronous motorInstability

A DC power supply system stability compensation device and method based on virtual resistance comprise a three-stage synchronous motor, a rectifier and a rectifier control unit; The three-stage synchronous motor is connected with a rectifier, and the alternating current emitted by the three-stage synchronous motor is changed into direct current after passing through the rectifier and is loaded onboth ends of the load to supply power for the load. The rectifier control unit is connected with the rectifier, and the rectifier control unit includes a compensation signal module, and the compensation signal module generates a dummy resistance equivalent compensation AC voltage signal to be compensated to the rectifier control unit. The device and the method can maintain the stability of the power supply system when the load of the DC power supply system is suddenly increased, and the instability phenomenon does not occur.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

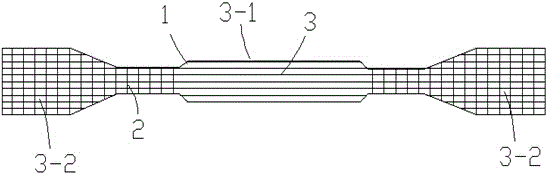

Biaxial drawing-pressing test part with matrix fiber bundle and preparation method thereof

ActiveCN104913975ASave experimental materialsLow costPreparing sample for investigationMaterial strength using tensile/compressive forcesPhysicsInstability

The invention discloses a biaxial drawing-pressing test part with a matrix fiber bundle. The biaxial drawing-pressing test part comprises a long strip-shaped sample and is characterized in that the long strip-shaped sample comprises a fiber cloth deposited matrix, the middle of the long strip-shaped sample is a test part, two ends of the long strip-shaped sample are clamping parts, the test part only contains warp-wise fibers circularly distributed along a long strip-shaped sample width direction, the clamping parts are braided structures, anti-drag rubber parts are fixed to two sides of the test part under compressive load, the length of the anti-drag rubber parts is the same to the length of the test part, and a compressive loading head is fixed to the outer side of each one of the anti-drag rubber parts. The biaxial drawing-pressing test part has the advantages of simple preparation processes, low experiment cost, good test part quality and low compressive instability.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com