Rotor cooling for a dynamoelectrical machine

A technology for rotors and cooling holes, applied to the rotating parts of the magnetic circuit, the shape/style/structure of the winding conductor, the shape/style/structure of the magnetic circuit, etc., can solve the problems of radial channel shunting difficulties, and achieve simple manufacturing, The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiment of the invention

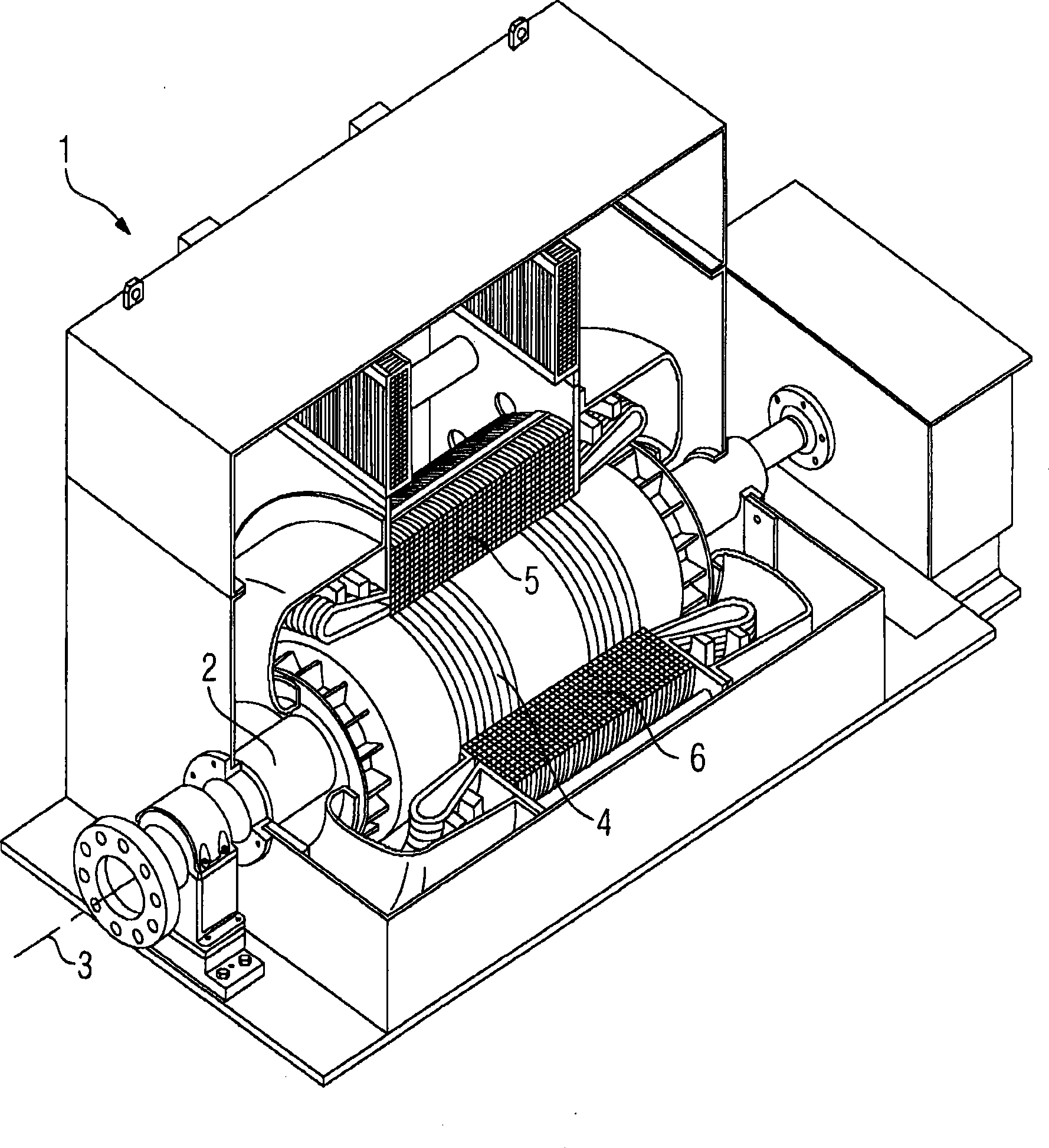

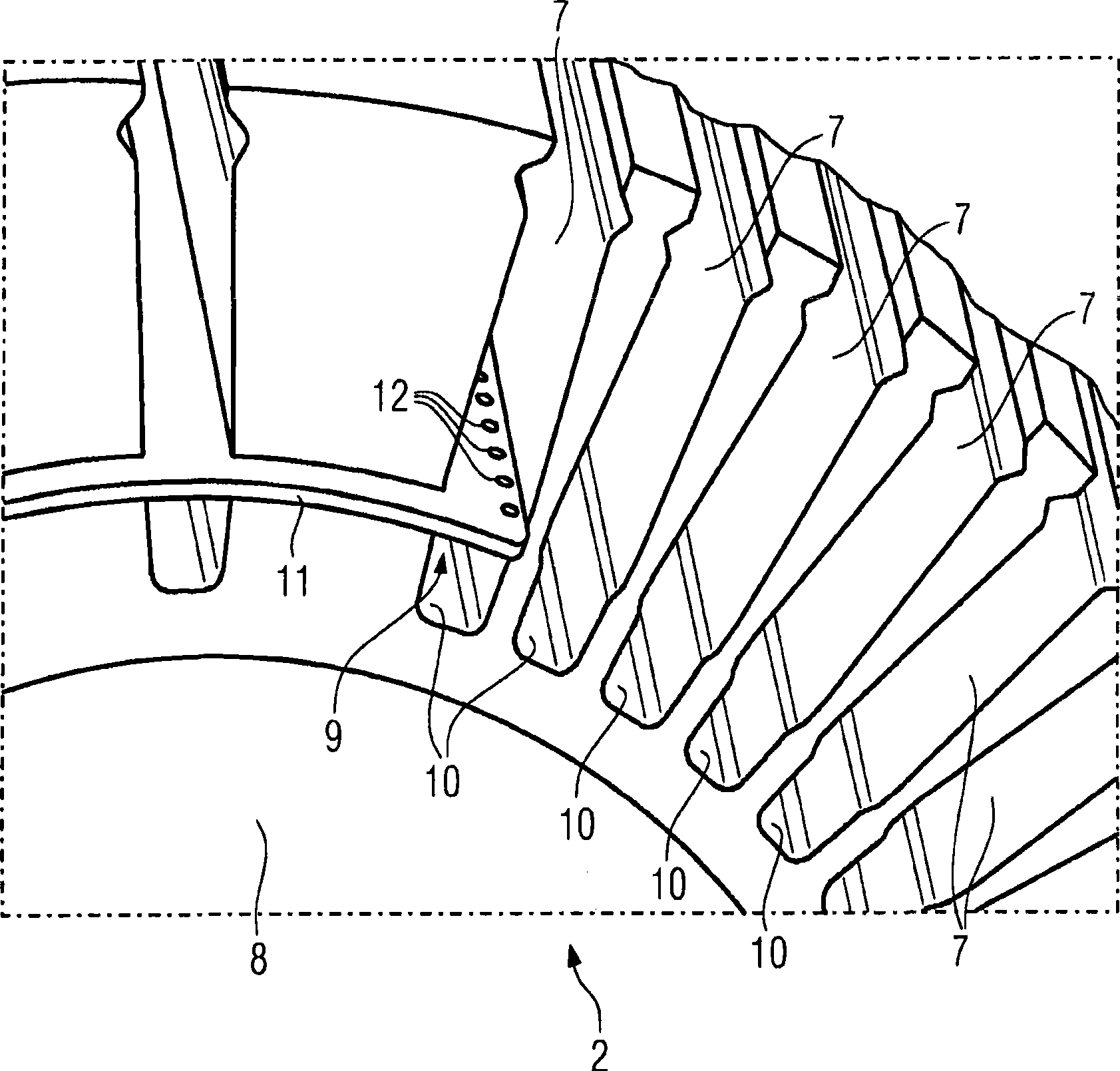

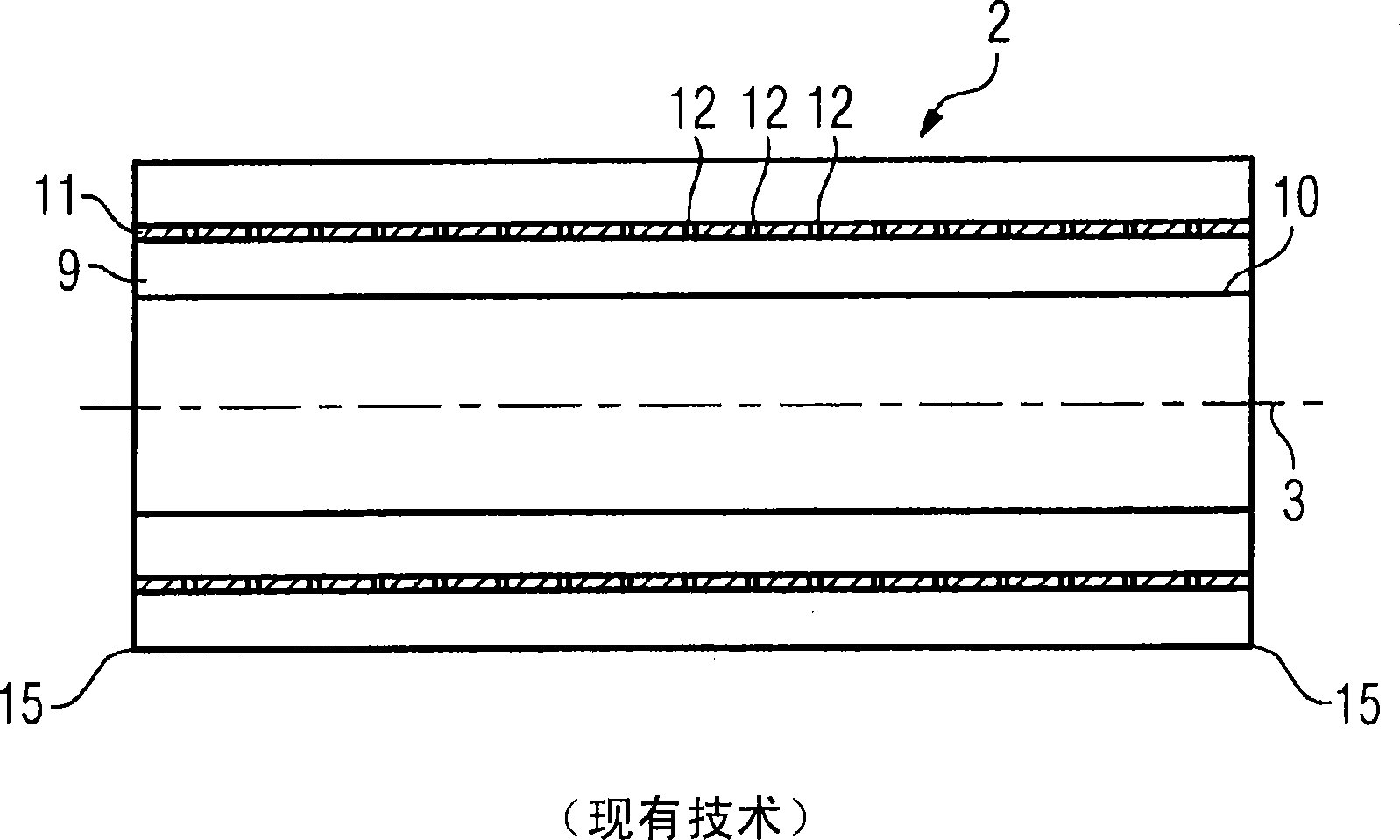

[0027] exist figure 1 A perspective view of a generator 1 can be seen in . The generator 1 is to be regarded as an embodiment of an electric machine. Another example of an electrical machine could be an electric motor. The generator 1 basically has two components. The rotor 2 is arranged rotatably about an axis of rotation 3 . The rotor 2 has a plurality of axially oriented conductors 4 . The electrical conductor 4 is supplied with an excitation current via an excitation current supply (not further shown). This produces a magnetic field surrounding the rotor 2 . The rotor 2 is set in rotation by a steam or gas turbine (not shown). The rotational frequency here is generally at 50 or 60 Hz.

[0028] Arranged around the rotor 2 is a stator 5 which has a stator winding 6 . A voltage is induced in the stator winding 6 by the rotating magnetic field of the rotor 2 and is then fed into the high-voltage network. The exciting current flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com