Gas damping buffer with axial piston vent hole

A technology of axial exhaust and gas damping, which is applied in the direction of gas shock absorbers, shock absorbers, shock absorbers, etc., can solve the problems of not ensuring the service life of the damper, high processing cost, poor sealing performance, etc., and achieve sealing performance Good, easy assembly, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

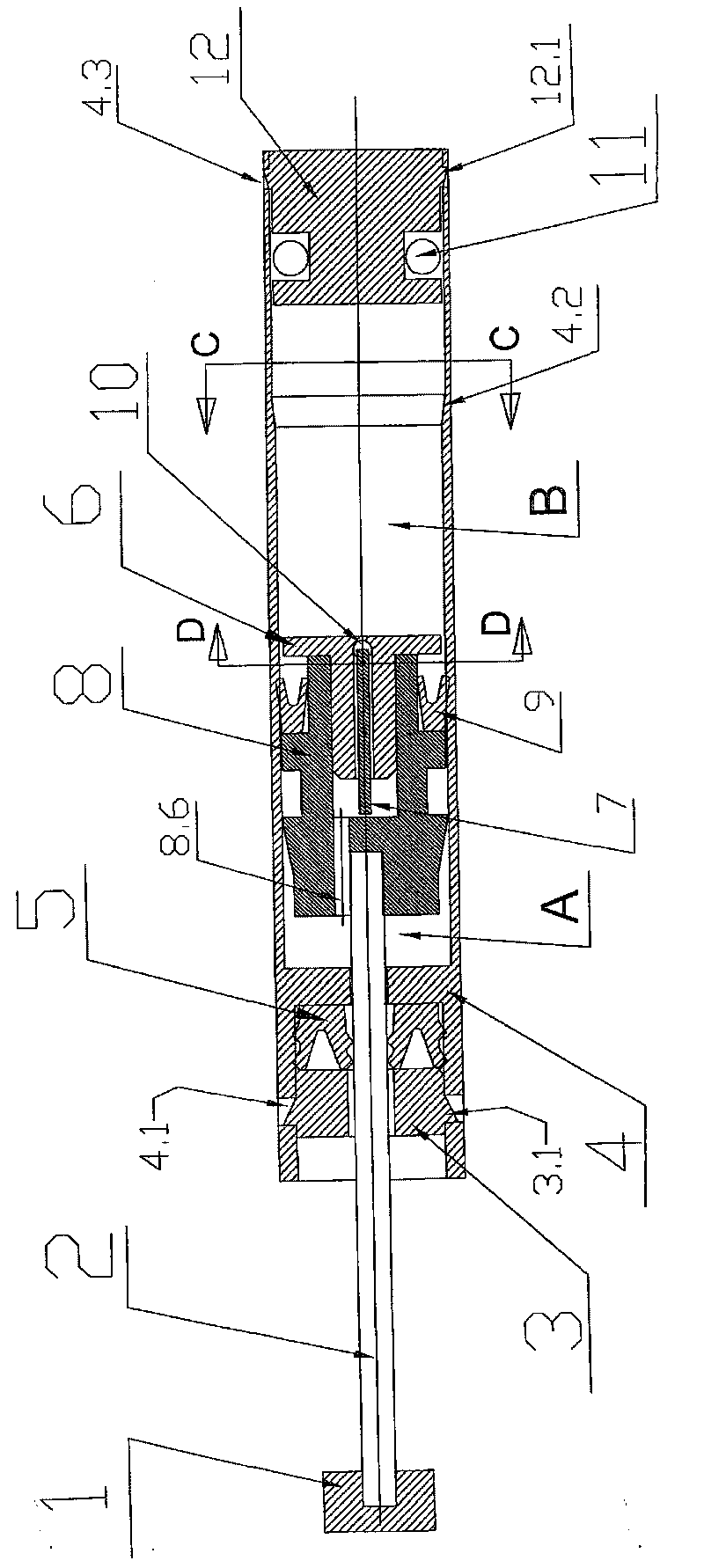

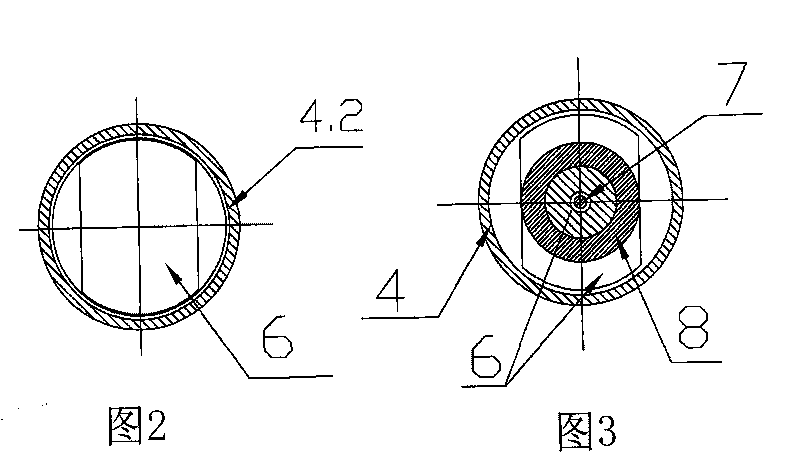

[0052] see Figure 1~4 , the present invention relates to a gas damping buffer with a piston axial exhaust hole, the damper has a closed cylinder 4, the inner chamber of the cylinder 4 is divided by a piston 8 that can slide in the cylinder 4 a first chamber A and a second chamber B filled with gas,

[0053] The damper has a piston rod 2 which is guided sealingly from one end of the cylinder 4 through the first working chamber A,

[0054] A guide sleeve 3 and a front leather cup 5 are closely arranged in sequence in the cylinder body 4 between the piston 8 and the lead-out end of the piston rod, and the guide sleeve 3 is arranged close to the lead-out end of the piston rod.

[0055] The damper also has a plug 12 solidified with the other end of the cylinder 4,

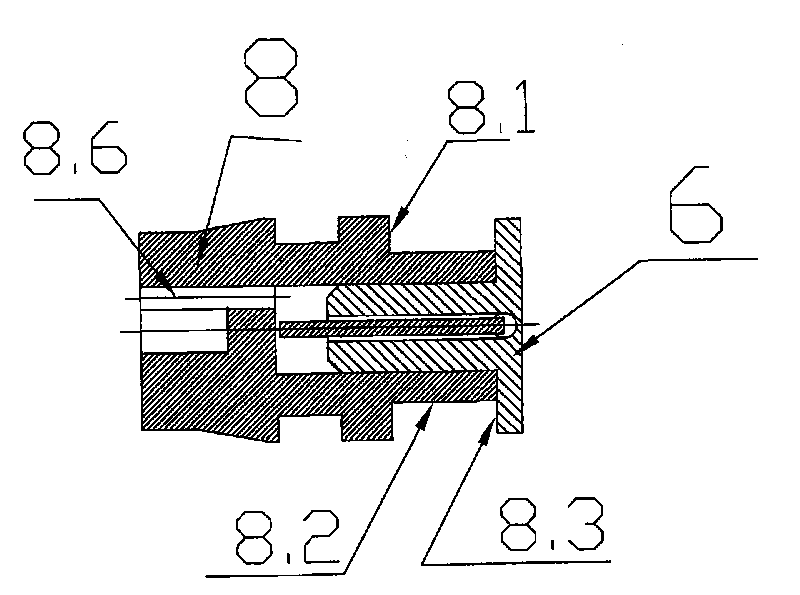

[0056] At least two blocks I3.1 protrude from the middle of the outer edge of the guide sleeve 3. Corresponding to the blocks I3.1, the cylinder body 4 is at least provided at the corresponding position on the cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com