Patents

Literature

133results about How to "Simple and ingenious structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

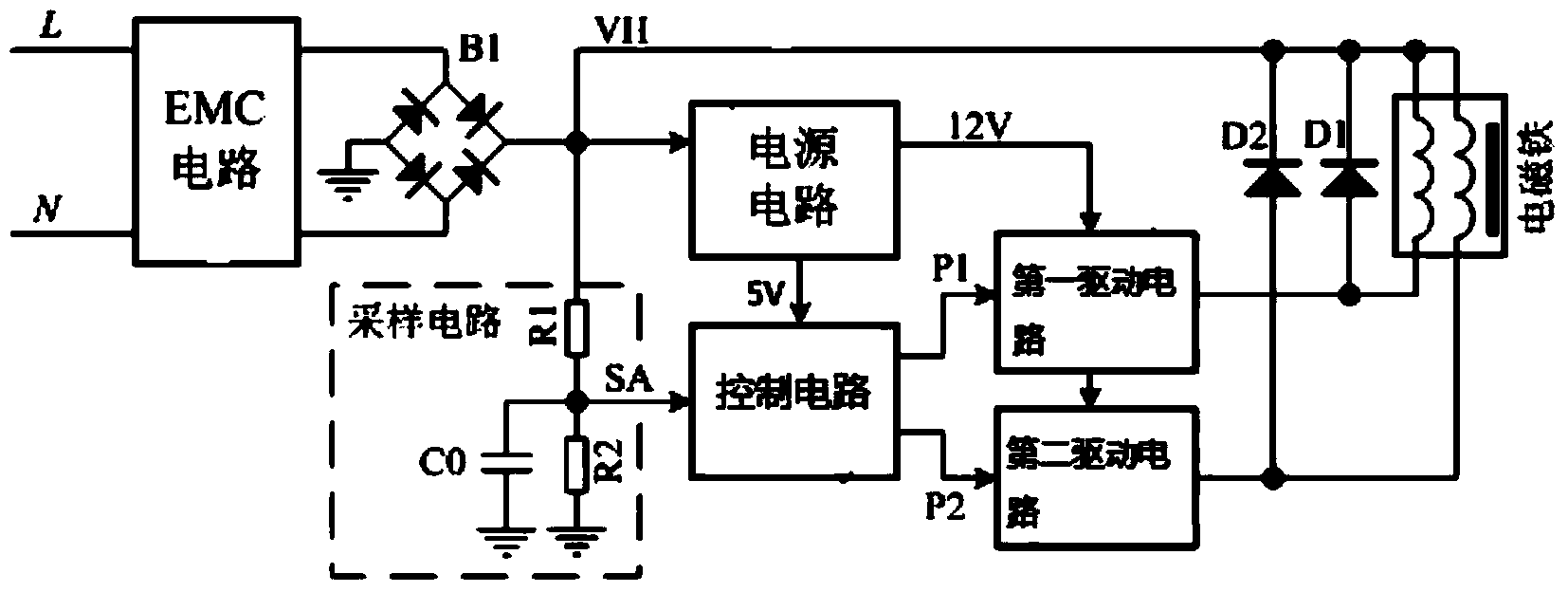

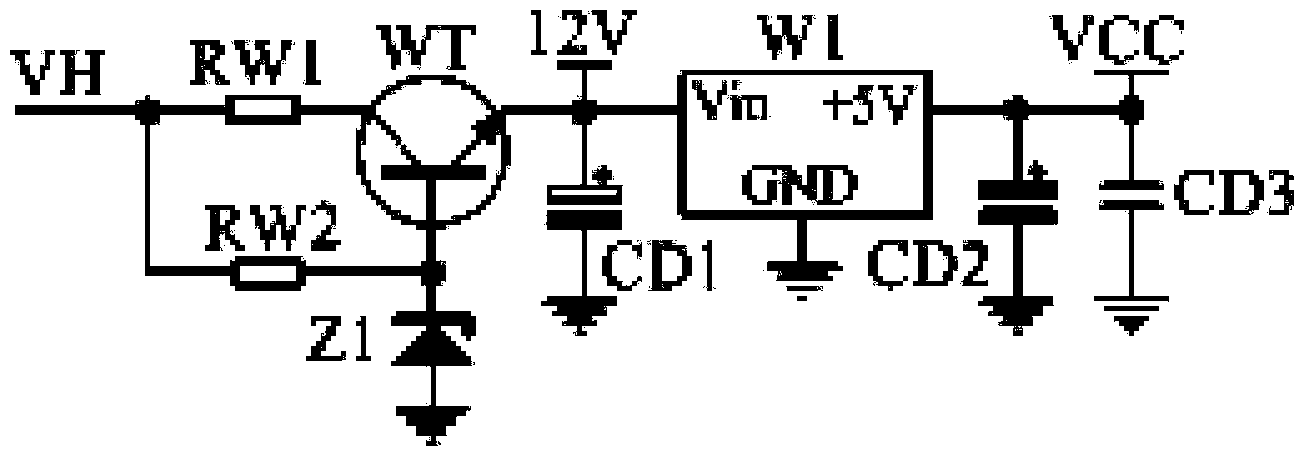

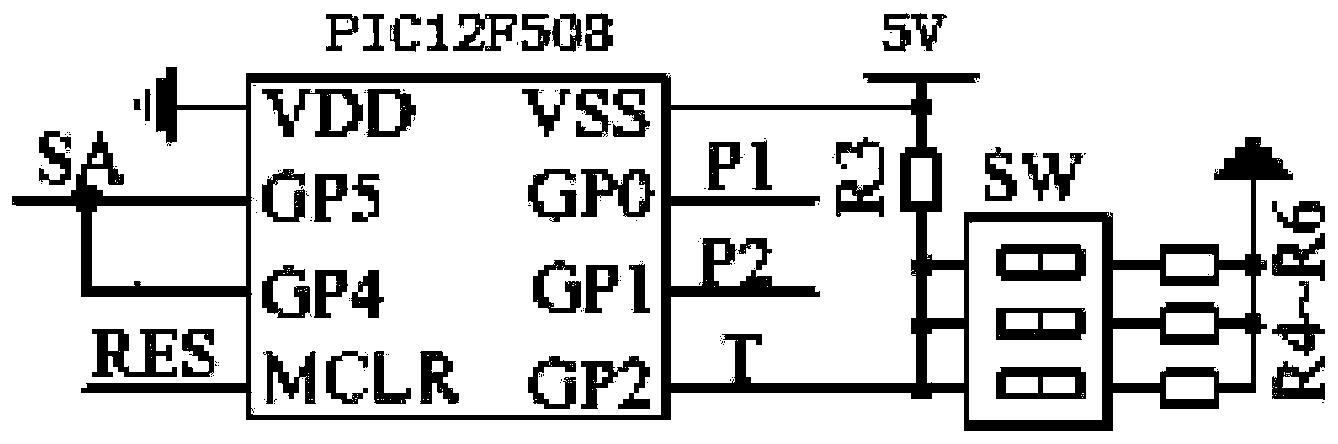

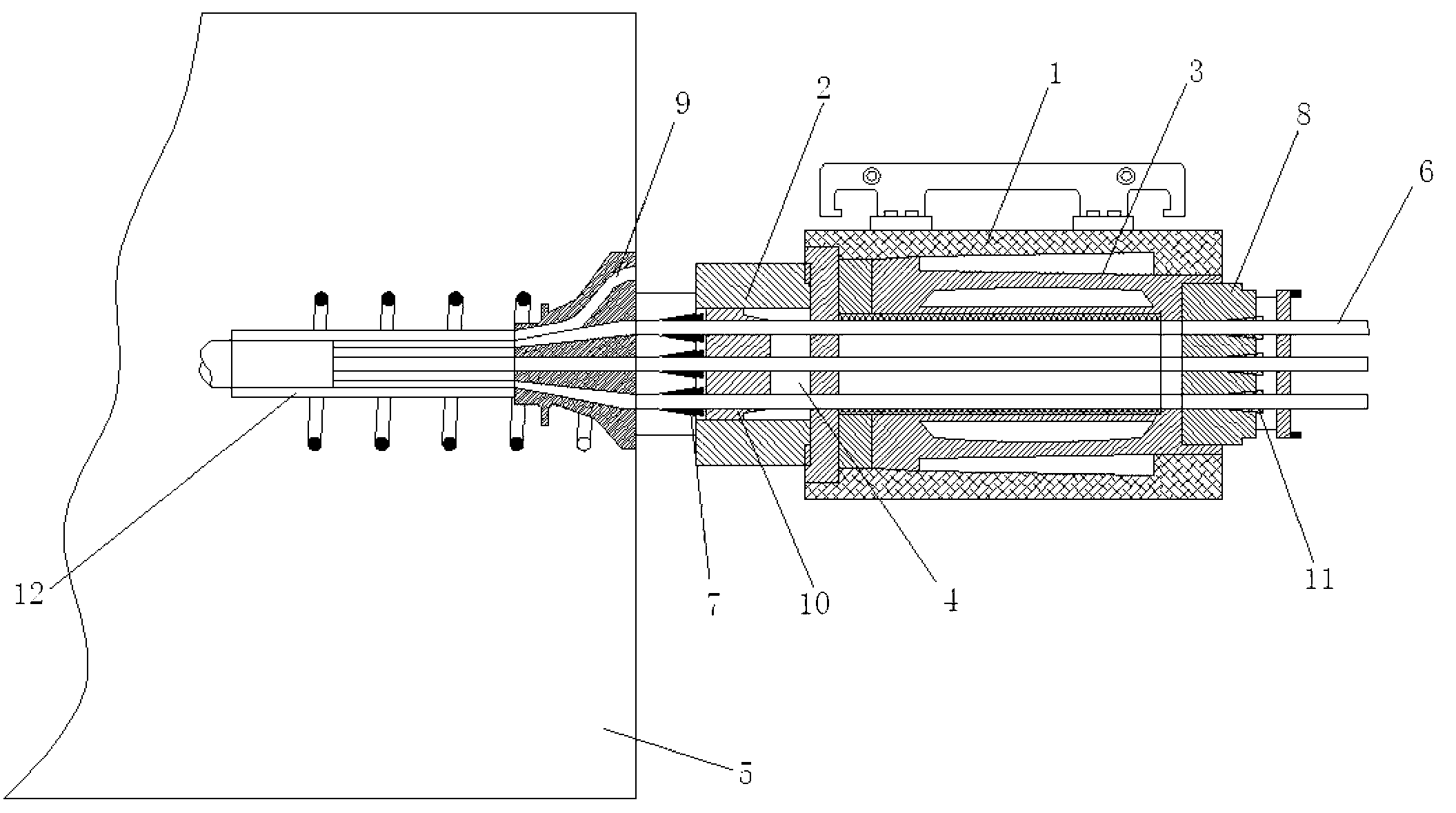

Electromagnetic under-voltage release and controlling method thereof

ActiveCN103647250ASimple and ingenious structureIncrease working currentArrangements responsive to undervoltageMicrocomputerDual coil

The invention provides an electromagnetic under-voltage release comprising a filtering rectifying circuit, a sampling circuit, a power supply circuit, a control module, a driver module and an electromagnet. A direct-current resistance of a starting winding is less than a direct-current resistance of a working winding. According to the electromagnetic under-voltage release and the controlling method thereof, a microcomputer is used for controlling the control circuit, and the controlling thinking is clear and the circuit structure is simplified and ingenious. The starting winding-working winding dual-coil electromagnet is arranged at the circuit, and the direct-current resistance of the starting winding is less than the direct-current resistance of the working winding and the working current of the starting winding is high and the starting torque is large, so that the pull-in performance of the electromagnet can be ensured. And the working current of the working winding is low and thus the basic power for pull-in maintaining of the electromagnet is provided, so that the heating value is extremely low.

Owner:JIANGSU GUOXING ELECTRIC EQUIP

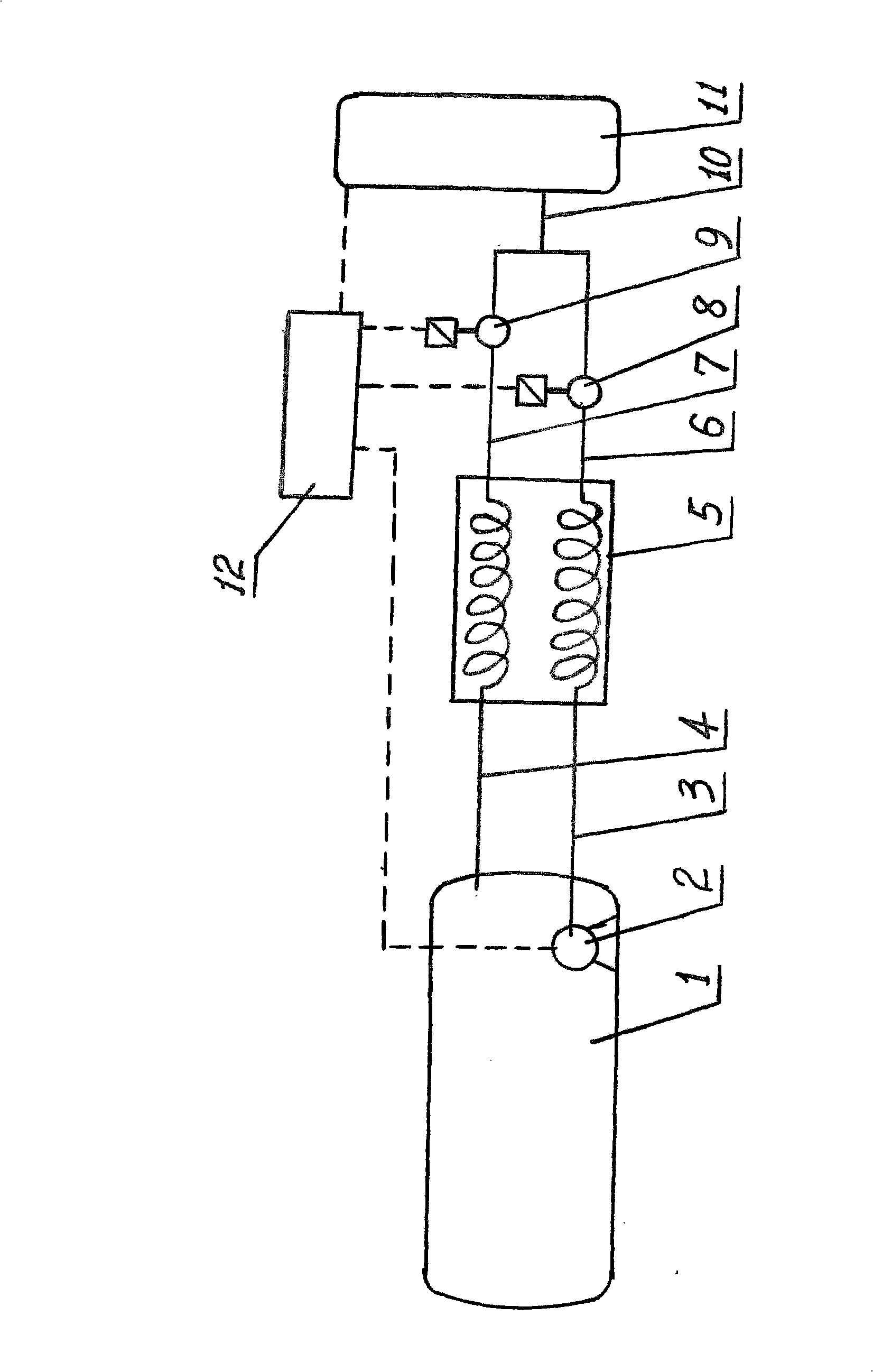

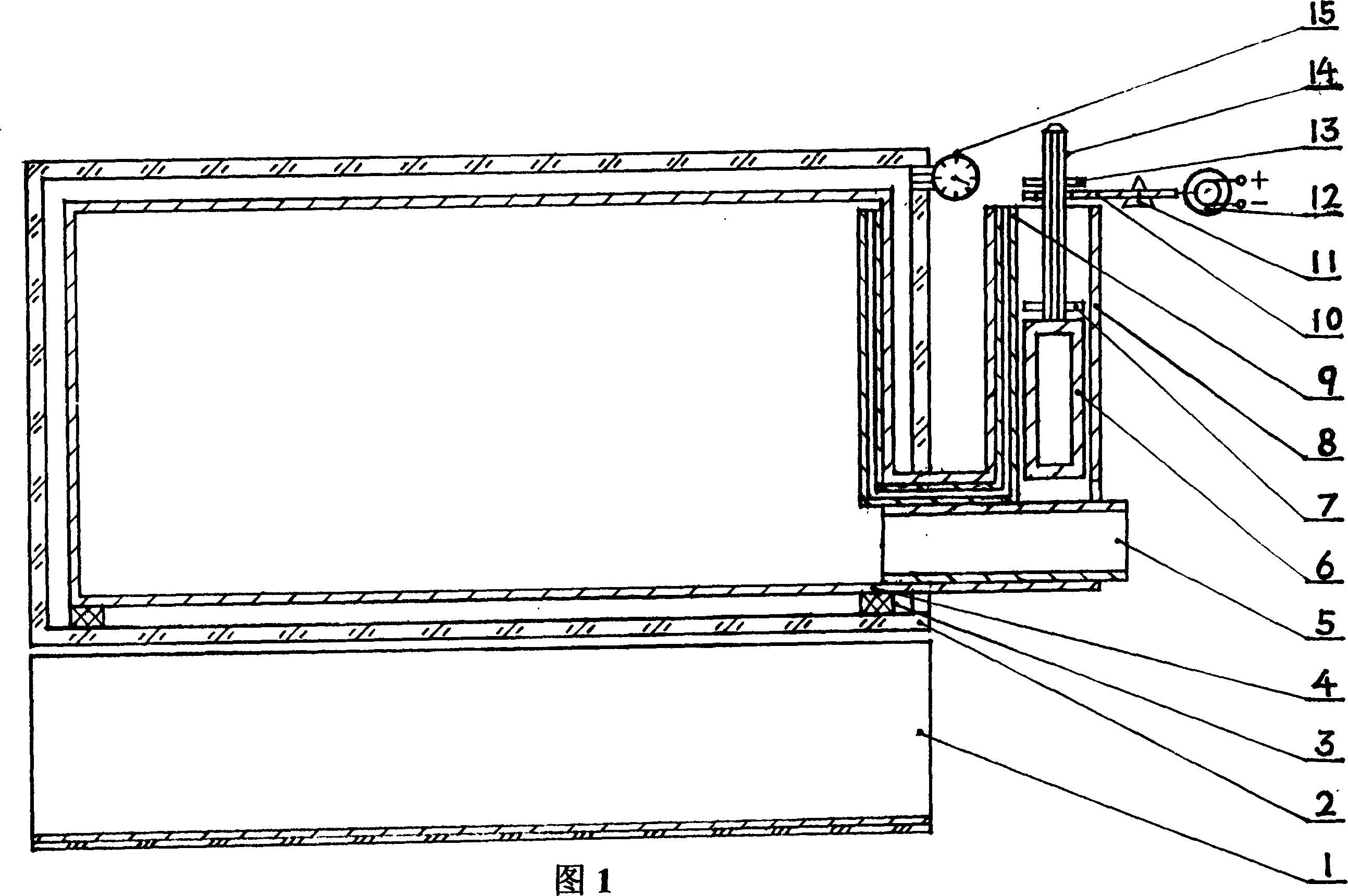

Liquefied natural gas automobile fuel gas self-pressurization gas supply system and technical control

InactiveCN101526055AScientific and reasonable technical designSimple and ingenious structureMachines/enginesLiquid fuel feedersLiquefied natural gasElectricity

The invention relates to a liquefied natural gas automobile fuel gas self-pressurization gas supply system and technical control, belonging to the mechanical field. A low temperature storage tank is internally fixed with a pump body which is electrically connected with one end of a liquid phase pipe, the low temperature storage tank is electrically connected with one end of a gas phase pipe, the other end of the liquid phase pipe is electrically connected with the lower end of one end of a carburetor, the other end of the gas phase pipe is electrically connected with the upper end of one end of the carburetor, the lower end of the other end of the carburetor is electrically connected with one end of a lower gas phase pipe, the upper end of the other end of the carburetor is electrically connected with one end of an upper gas phase pipe, the other end of the lower gas phase pipe is electrically connected with one end of a lower electromagnetic valve, the other end of the upper gas phase pipe is electrically connected with one end of an upper electromagnetic valve, the other end of the lower electromagnetic valve is electrically connected with a lower inlet end of a mixing pipe, the other end of the upper electromagnetic valve is electrically connected with an upper inlet end of the mixing pipe, the outlet end of the mixing pipe is fixed with the inlet end of an engine, the engine is electrically connected with a controller, and the controller is electrically connected with the lower and the upper electromagnetic valves. The pressure of the low temperature storage tank is 0-0.5MPa, and the pressure at the gas inlet end of the engine is 0.5-3MPa. The invention is applied for gasifying and pressurizing vehicle fuel and controlled by liquid-gas double ways of the pump body inside the storage tank.

Owner:朱婴 +1

Lamp

InactiveCN104075176ASimple and ingenious structureEasy assemblyLighting support devicesFixed installationEngineeringLight head

The invention is applicable to the technical field of lighting devices and discloses a lamp. The lamp comprises a lamp holder and at least two lamp heads. The lateral wall of each lamp head is rotatably connected to the outer peripheral wall of the lamp holder. The lamp further comprises a lifting drive part which is used for driving the lamp heads to rotate relative to the lamp holder. The lifting drive part is connected between the lamp holder and the lamp heads. The lifting drive part is longitudinally disposed and penetrates the lamp holder. The lifting drive part comprises a lifting support which can ascend and descend relative to the lamp holder. The lifting support and the lamp heads are connected through connecting rods. One end of each connecting rod is rotatably connected to the lifting support, and the other end thereof is rotatably connected to the corresponding lamp head. The lamp has the advantages that the illumination range can be flexibly adjusted according to actual situations, and application convenience is brought to users.

Owner:SHENZHEN OCEANS KING LIGHTING ENG CO LTD +1

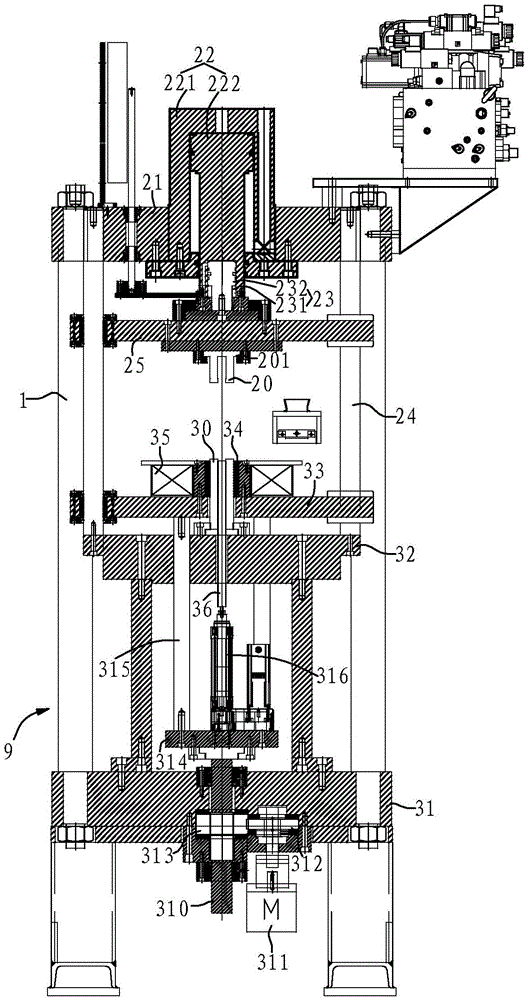

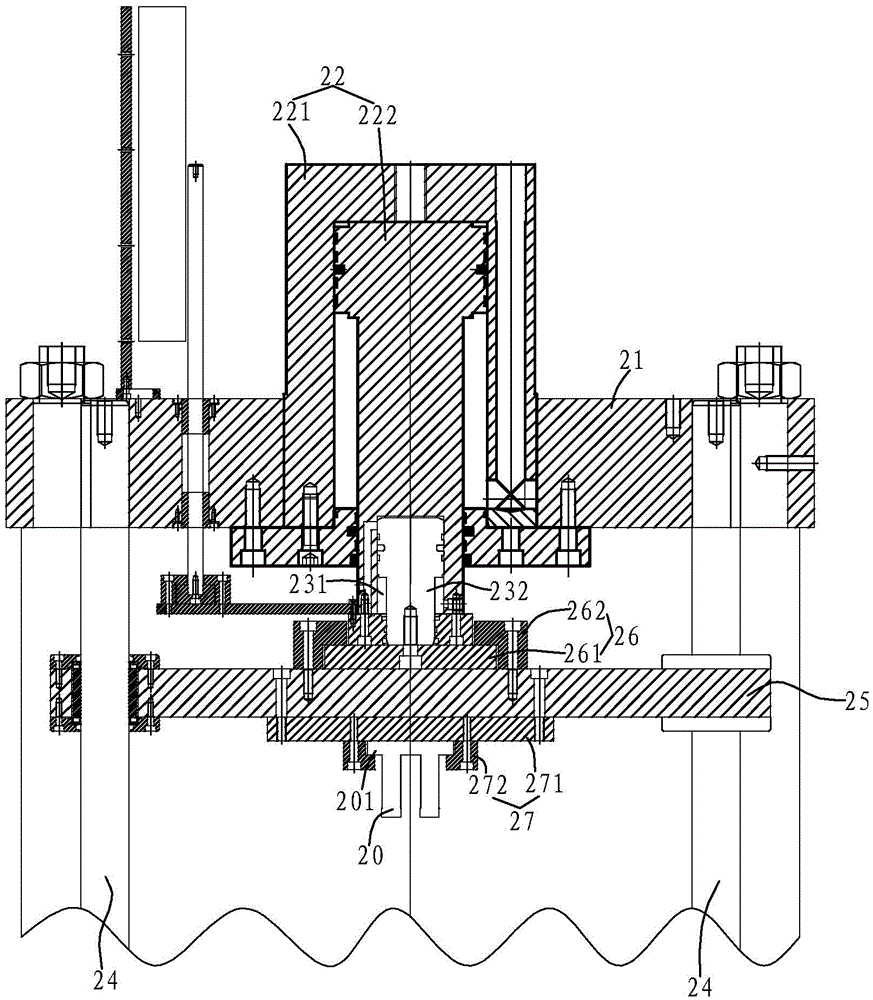

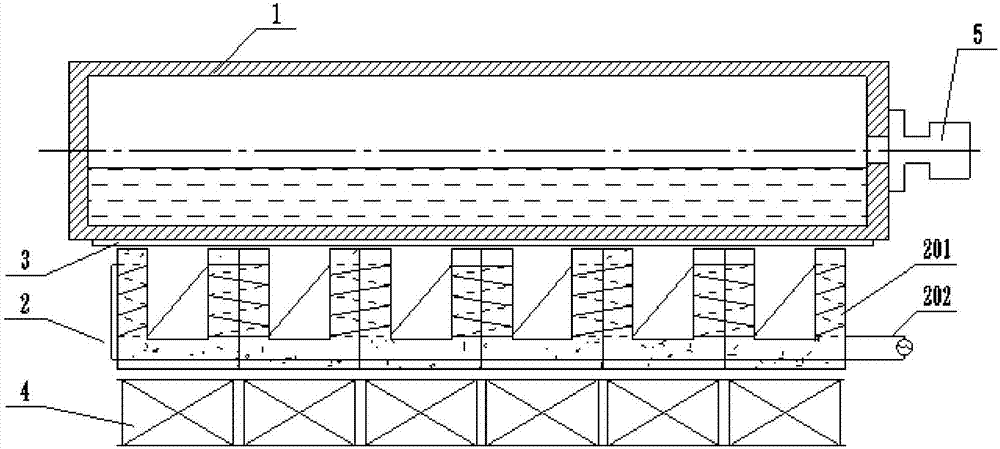

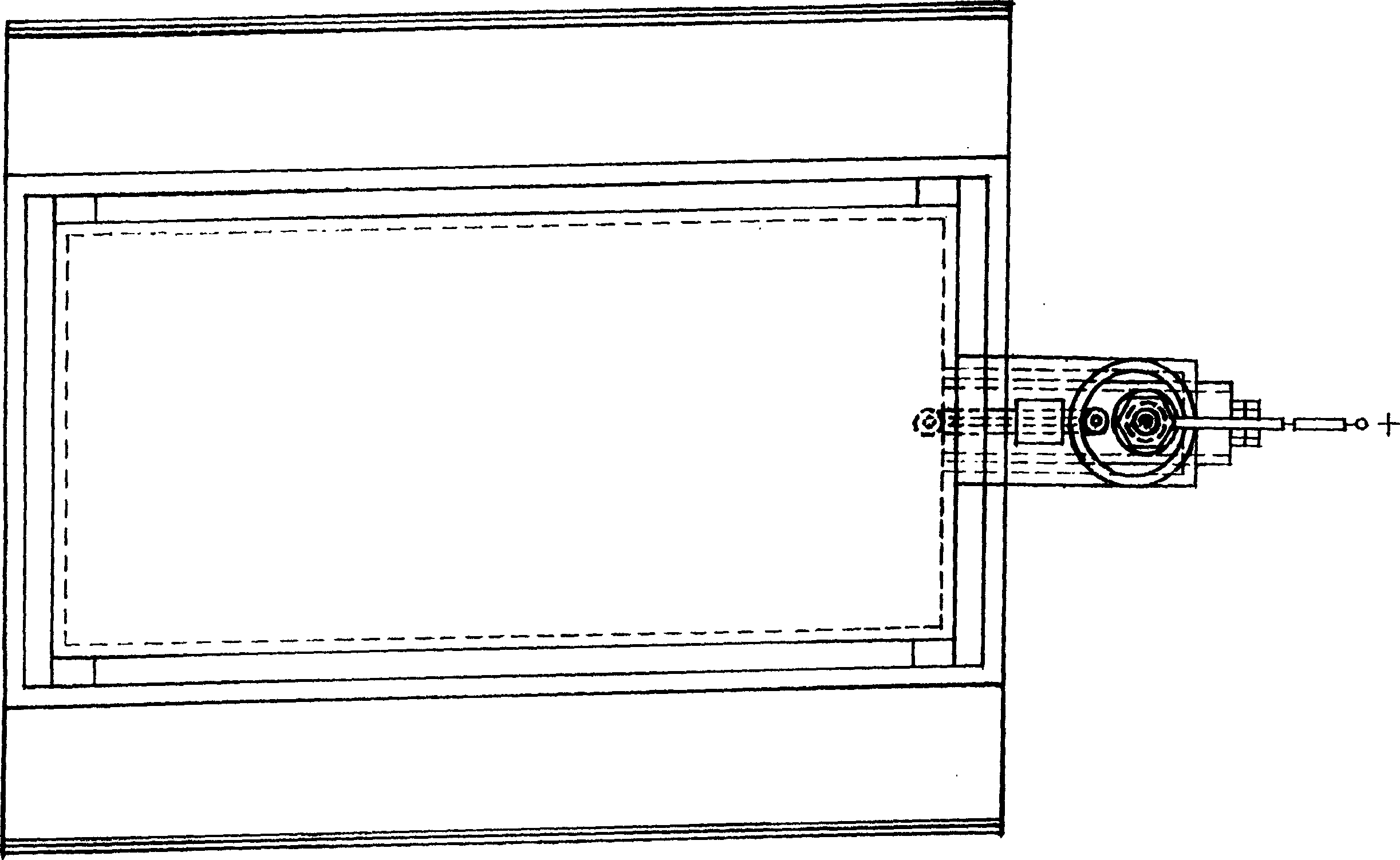

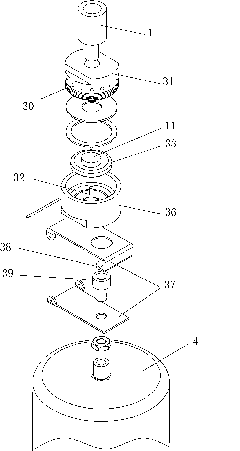

Nd-Fe-B powder molding press

ActiveCN105562685ASimple and ingenious structureReduce overall sizeMagnetic materialsEngineeringEnergy consumption

The invention relates to an Nd-Fe-B powder molding press. The Nd-Fe-B powder molding press comprises a rack, an upper punching assembly and a lower punching assembly, wherein the upper punching assembly and the lower punching assembly are arranged on the rack from top to bottom. The upper punching assembly comprises an upper pressing plate, a main hydraulic cylinder, a pressure relief piston and an upper punch, wherein the upper pressing plate is fixedly mounted on the upper portion of the rack; the main hydraulic cylinder comprises a cylinder block mounted on the upper pressing plate and a piston arranged in the cylinder block in an up-down moving mode; the lower end of the piston is provided with a containing cavity with a downward opening; the containing cavity forms a pressure relief cylinder block; the pressure relief piston is arranged in the pressure relief cylinder block in an up-down moving mode, and the pressure relief piston and the pressure relief cylinder block form a pressure relief cylinder; the upper punch is connected to the lower end of the pressure relief piston. According to the Nd-Fe-B powder molding press, the pressure relief cylinder is embedded in a piston of the main hydraulic cylinder; the structure is simple and ingenious; the overall dimensions of the Nd-Fe-B powder molding press are greatly reduced; the matching performance of the weight and the overall dimensions of the press and the dimensions of pressing blanks are improved; energy consumption is effectively reduced on the premise of guaranteeing the production efficiency.

Owner:宁波钉子博士磁性技术有限公司

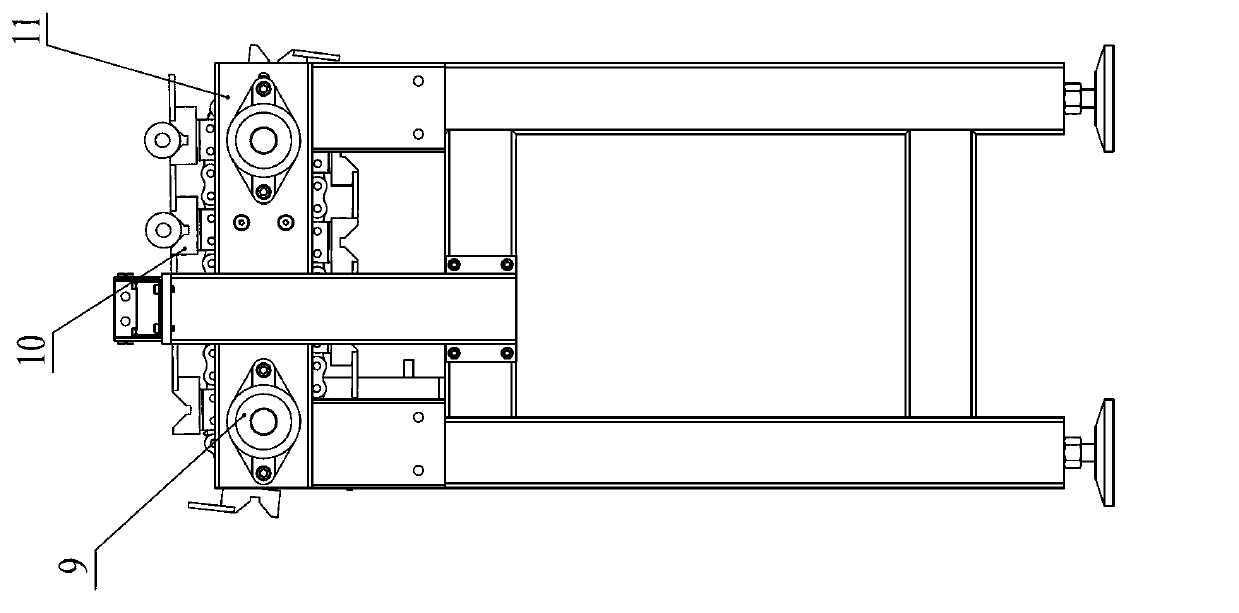

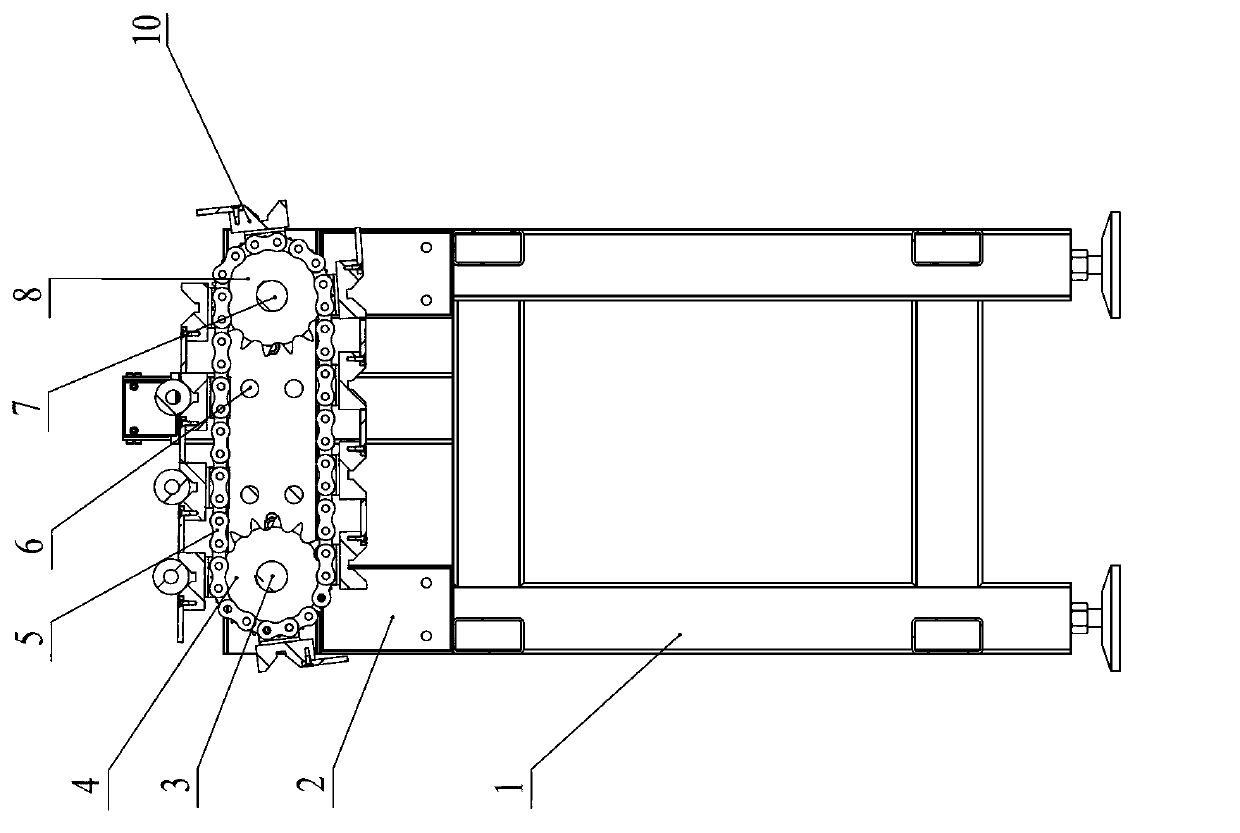

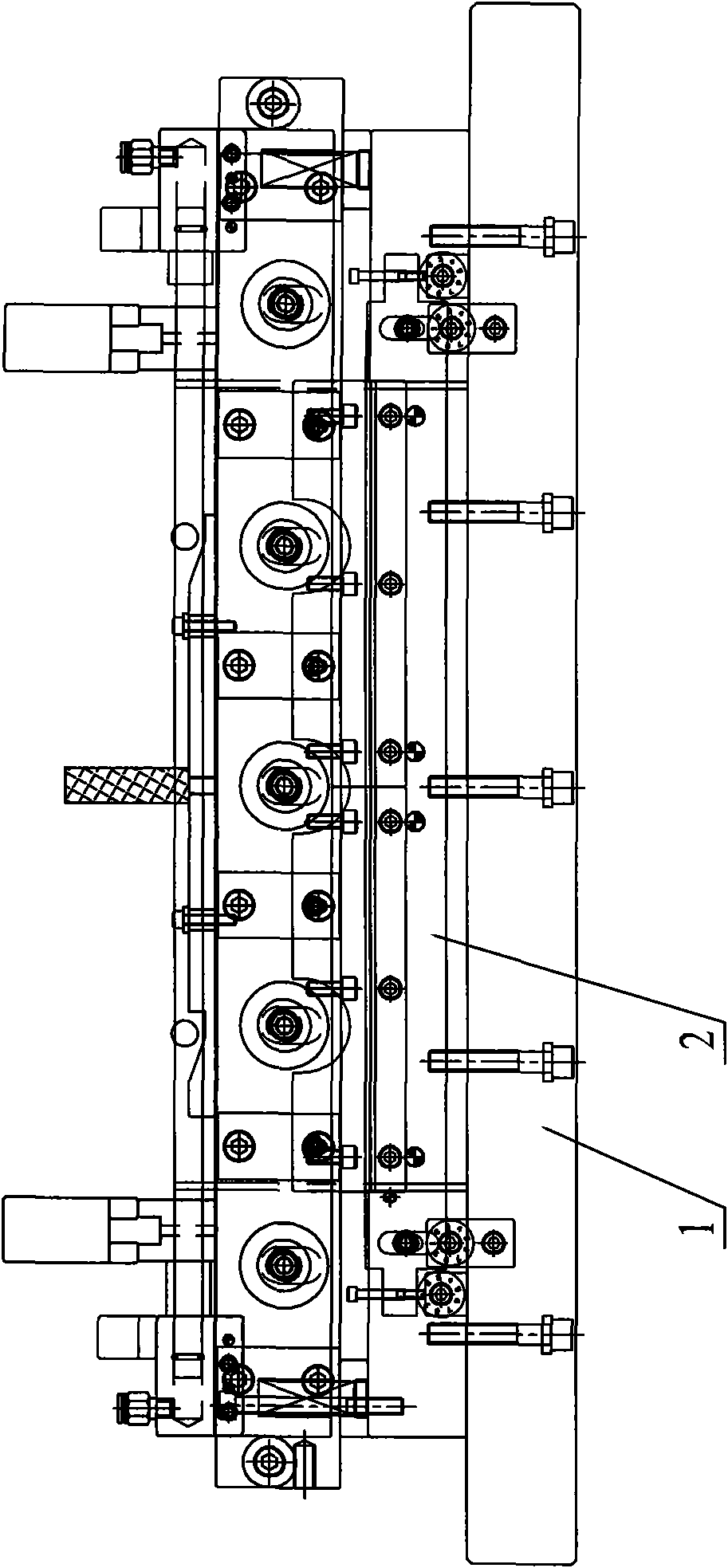

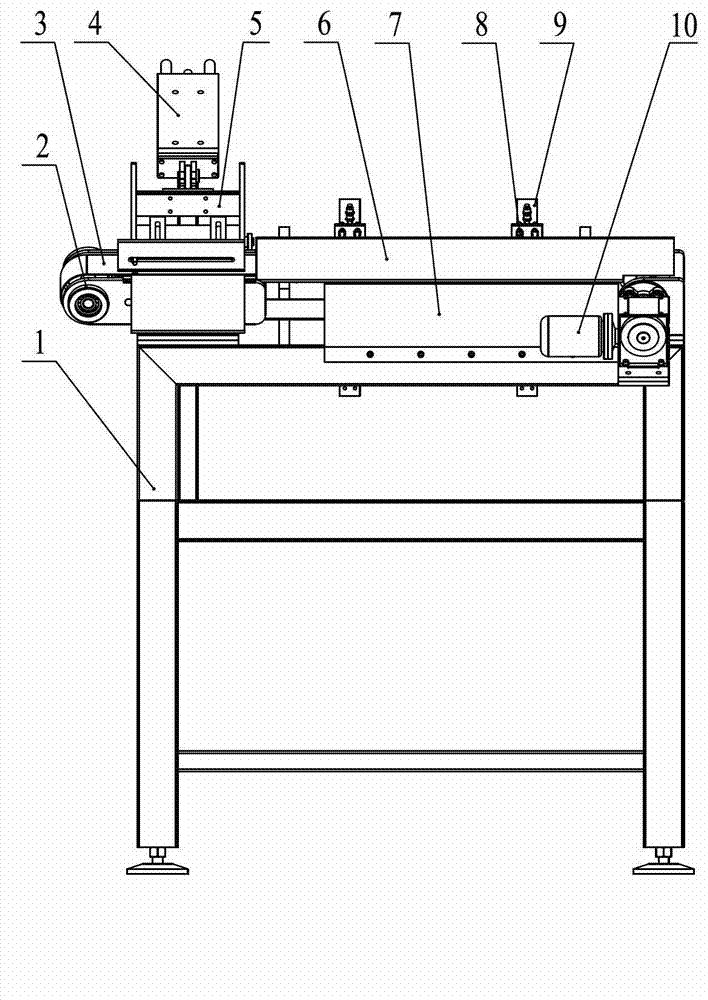

Synchronous feeding mechanism in feeding system of roller coating machine

ActiveCN102976094ASimple and ingenious structureConvenience and orderly transmission operationConveyor partsSprocketIndustrial engineering

The invention relates to a synchronous feeding mechanism in a feeding system of a roller coating machine. Two side plates are arranged on a side plate support frame, the two side plates are connected through a side plate connecting bar, the side plate support frame is arranged on the top of a support base through a lifting regulating part; a driving sprocket shaft and a driven sprocket shaft are respectively arranged on two ends of the two side plates, two ends of the driving sprocket shaft and the driven sprocket shaft are supported through mounted bearings, and the mounted bearings are fixed on the side plates; one end of the driving sprocket shaft is connected with a drive part, a driving sprocket is arranged on the driving sprocket shaft, a driven sprocket is arranged on the driven sprocket shaft, the driving sprocket is in drive transmission with the driven sprocket through a chain, and workpiece support plates are arranged on the chain and distributed at equal intervals; a material pushing cylinder is arranged near the chain, and a material pushing plate is arranged on a piston rod end of the material pushing cylinder. The hanging mechanism is capable of pushing the workpieces into a workpiece transmission rack one by one, and has the advantages of simple and ingenious structure, and convenience and orderliness for transportation operation.

Owner:WUXI HUANENG SURFACE TREATMENT

Lamp

InactiveCN104075196ASimple and ingenious structureEasy assemblyLighting applicationsLighting support devicesEngineeringLight fixture

The invention is applicable to the technical field of lighting devices and discloses a lamp. The lamp comprises a lamp holder, at least two lamp heads, connecting rods and a lifting support. The lamp heads are respectively rotatably connected to the outer peripheral wall of the lamp holder. A lifting drive part is connected between the lifting support and the lamp holder. One end of each connecting rod is rotatably connected to the corresponding lamp head, and the other end thereof is rotatably connected to the lifting support. The lamp has the advantages that the ascending and descending of the lamp holder drives the connecting rods so as to drive the lamp heads to rotate, the lamp is simple and ingenious in structure, simple to assemble, high in production efficiency, simple, easy to use, easy to manufacture, high in reliability, convenient to mount and maintain, low in cost, easy in lamp irradiation area adjustment, and application convenience is brought to users.

Owner:SHENZHEN OCEANS KING LIGHTING ENG CO LTD +1

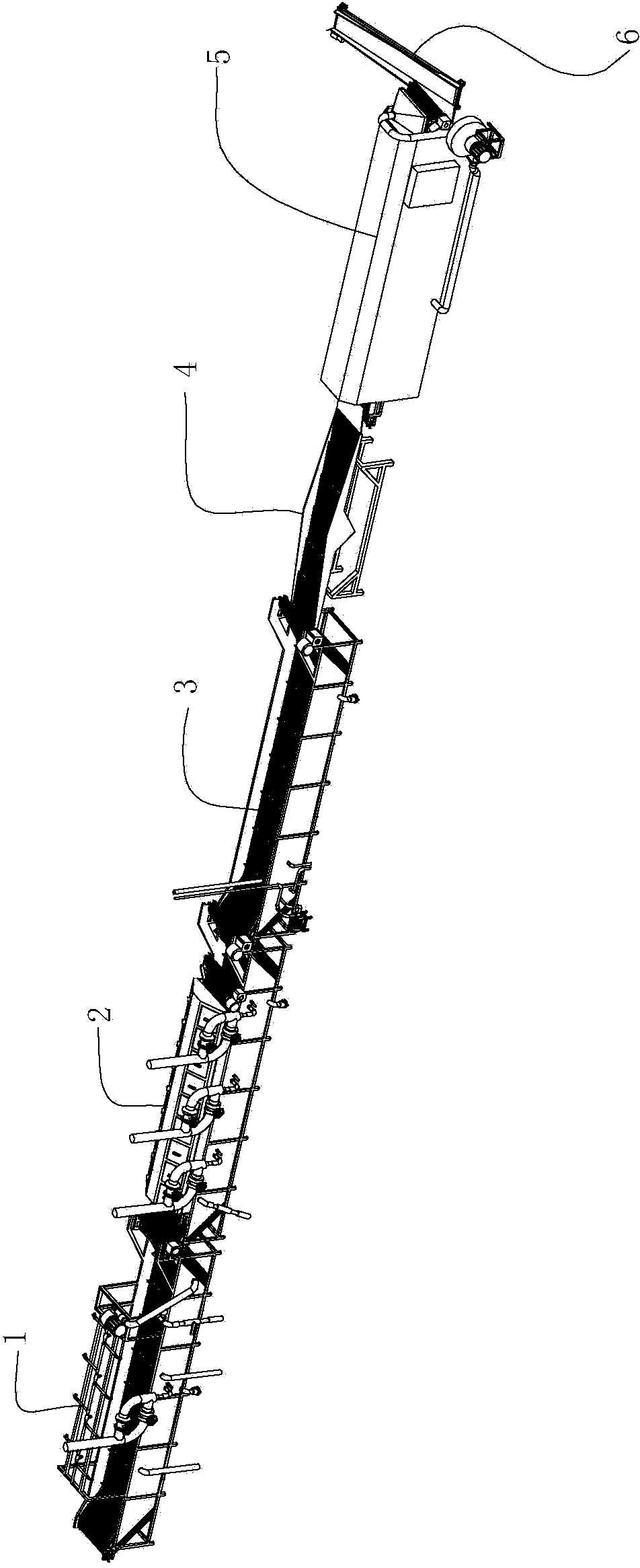

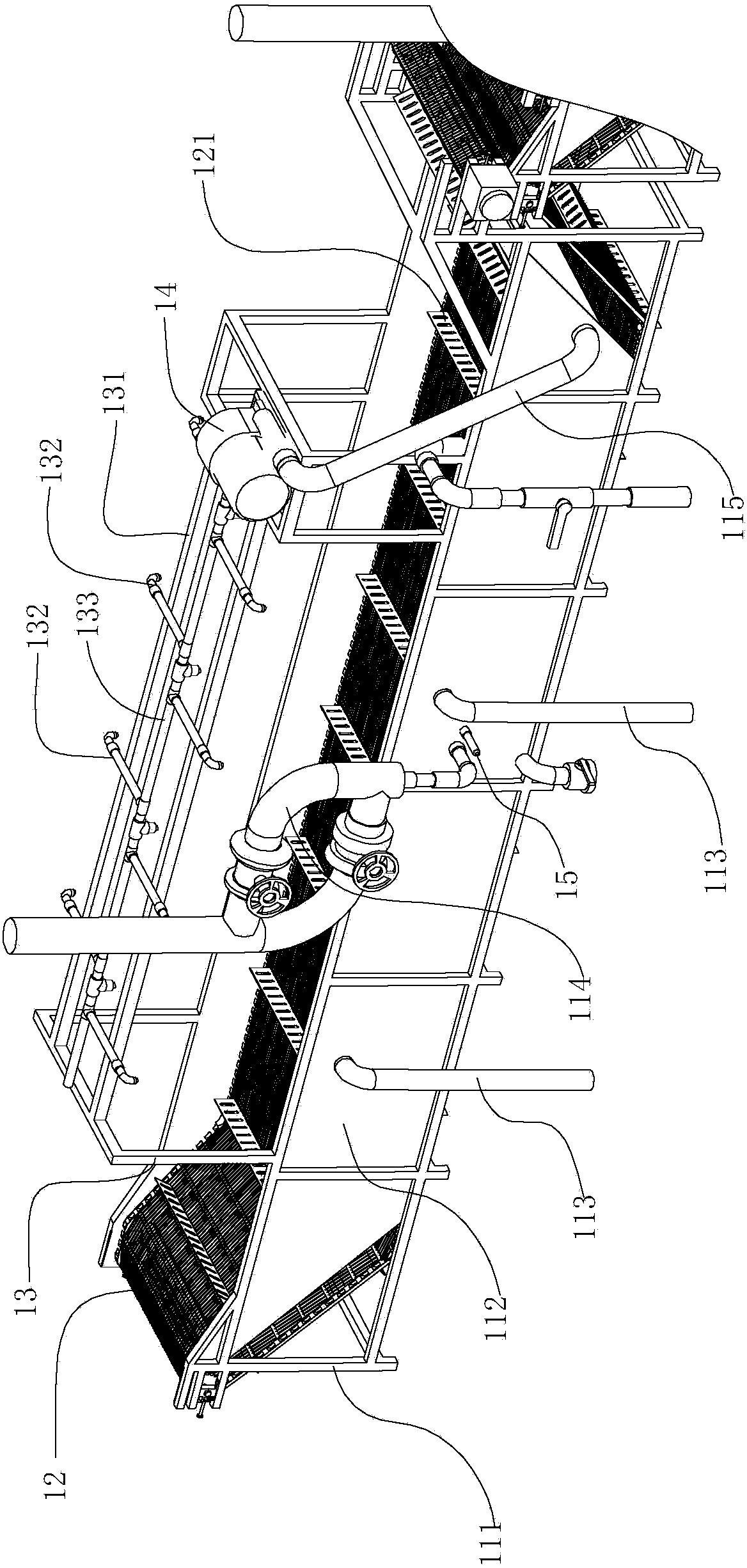

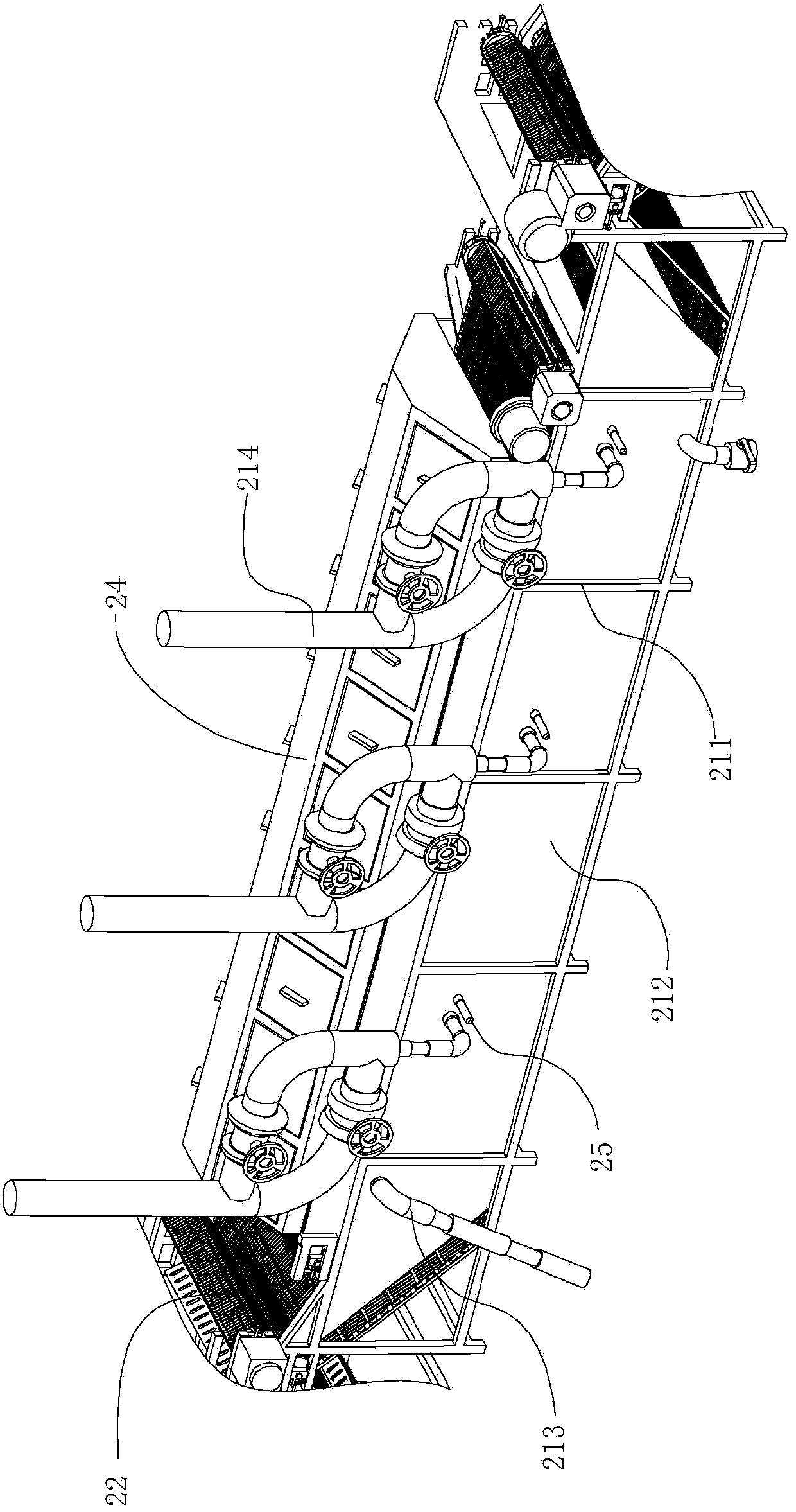

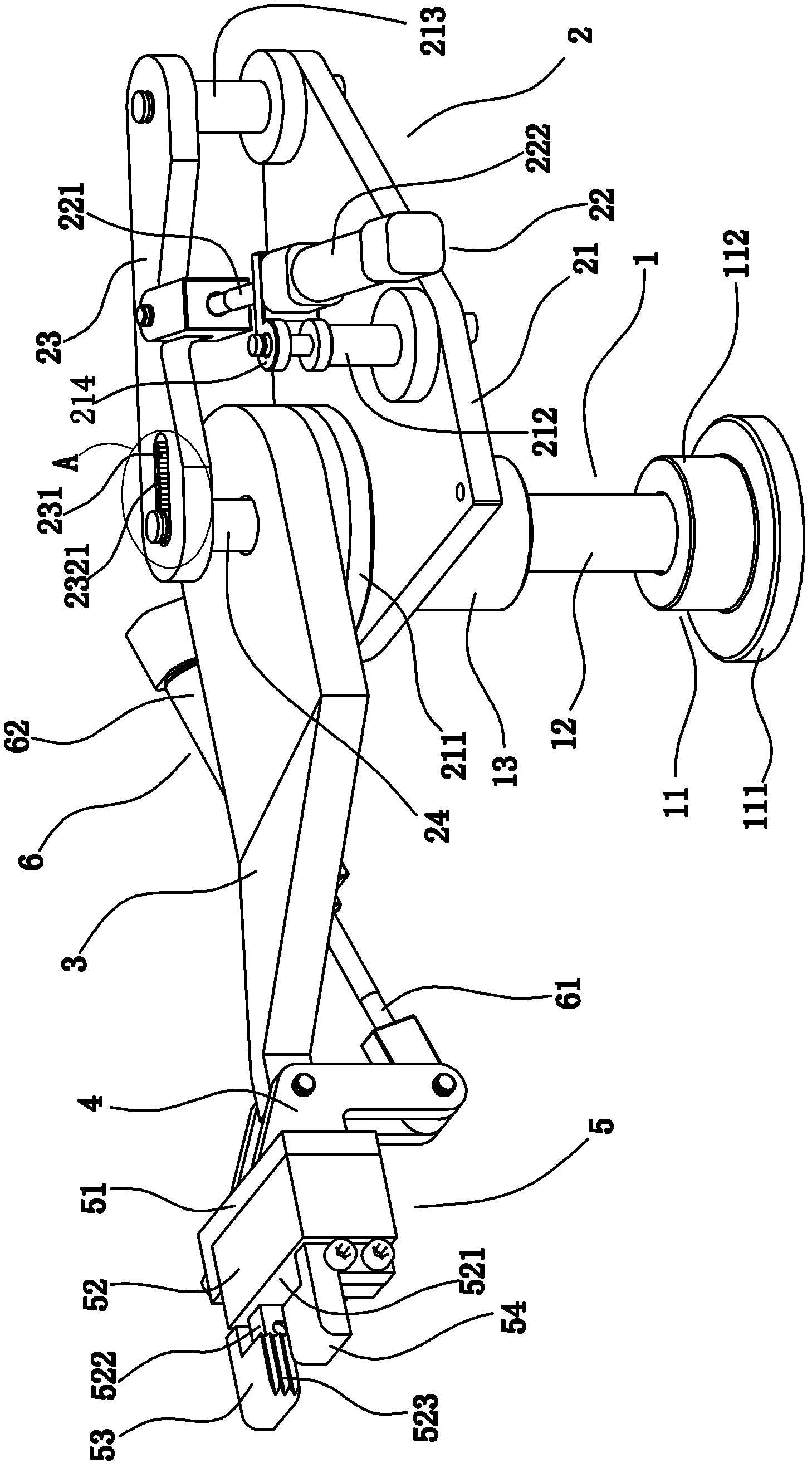

Automatic cleaning and sterilizing production line for bagged food

ActiveCN103798908ASimple and ingenious structureImprove sanitation and productivityFood preservationEngineeringSanitation

The invention relates to an automatic cleaning and sterilizing production line for bagged food. The production line comprises a cleaning device, a sterilizing device, a cooling device, a dehydration device and a drying device which are sequentially connected, wherein the cleaning device is used for cleaning the packaged and sealed bagged food; the sterilizing device is used for carrying out high-temperature sterilization with controllable temperature on the bagged food; the cooling device is used for cooling the bagged food; the dehydration device is used for carrying out vibrating dehydration on the cooled bagged food; the drying device is used for drying the bagged food; the cleaning device, the sterilizing device, the cooling device, the dehydration device and the drying device are sequentially connected by conveyor belts; the conveyor belts of the cleaning device, the sterilizing device, the cooling device, the dehydration device and the drying device are respectively provided with a plurality of through holes. The automatic cleaning and sterilizing production line for the bagged food is simple and ingenious in structure and has good cleaning and sterilizing effects; after the production line is adopted, the sanitation and the production efficiency of the bagged food can be improved; furthermore, the automatic cleaning and sterilizing production line also has the function of screening and removing bagged food with packaging defectives, thus guaranteeing the production quality of the bagged food.

Owner:YUYAO BEIDEFU VEGETABLES

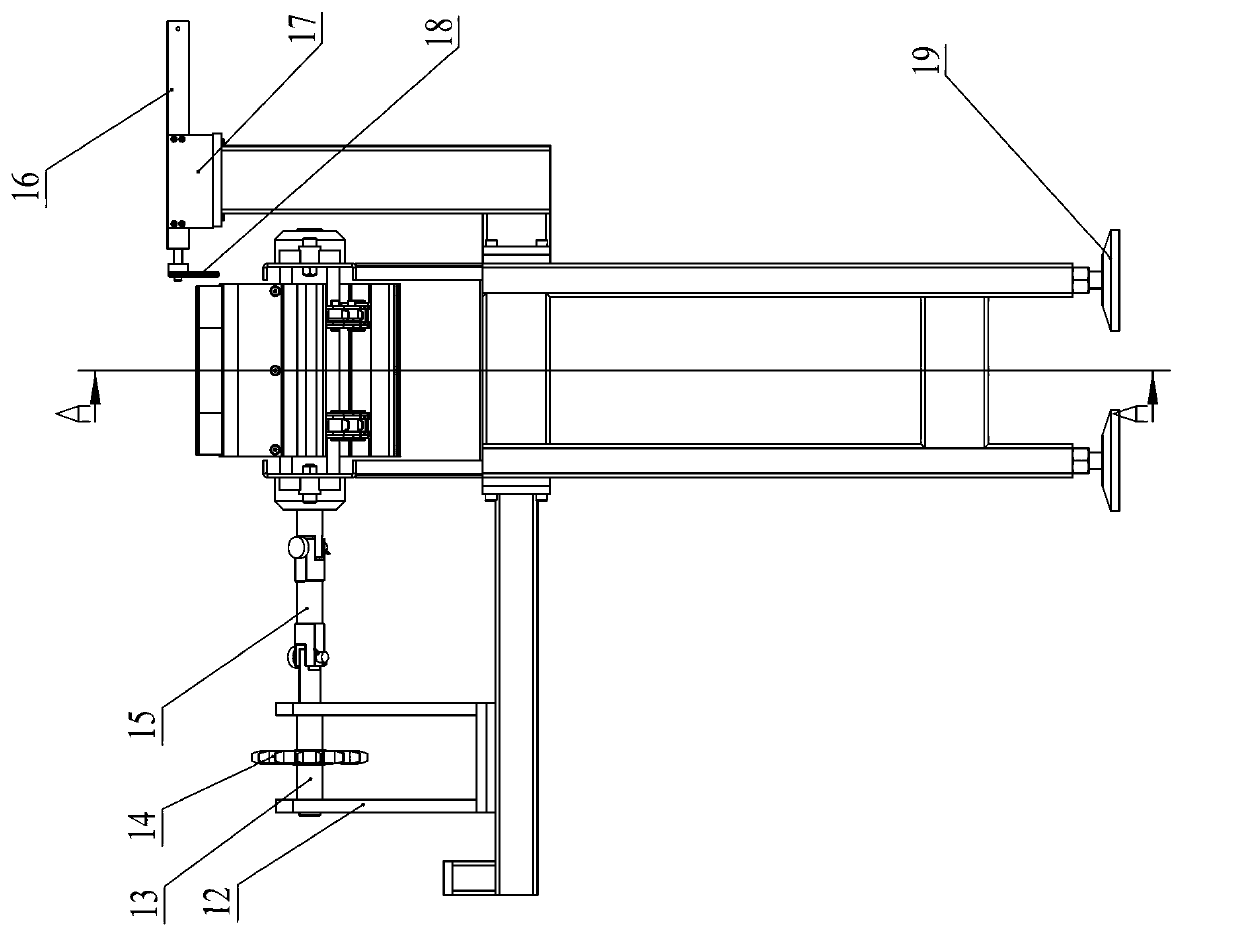

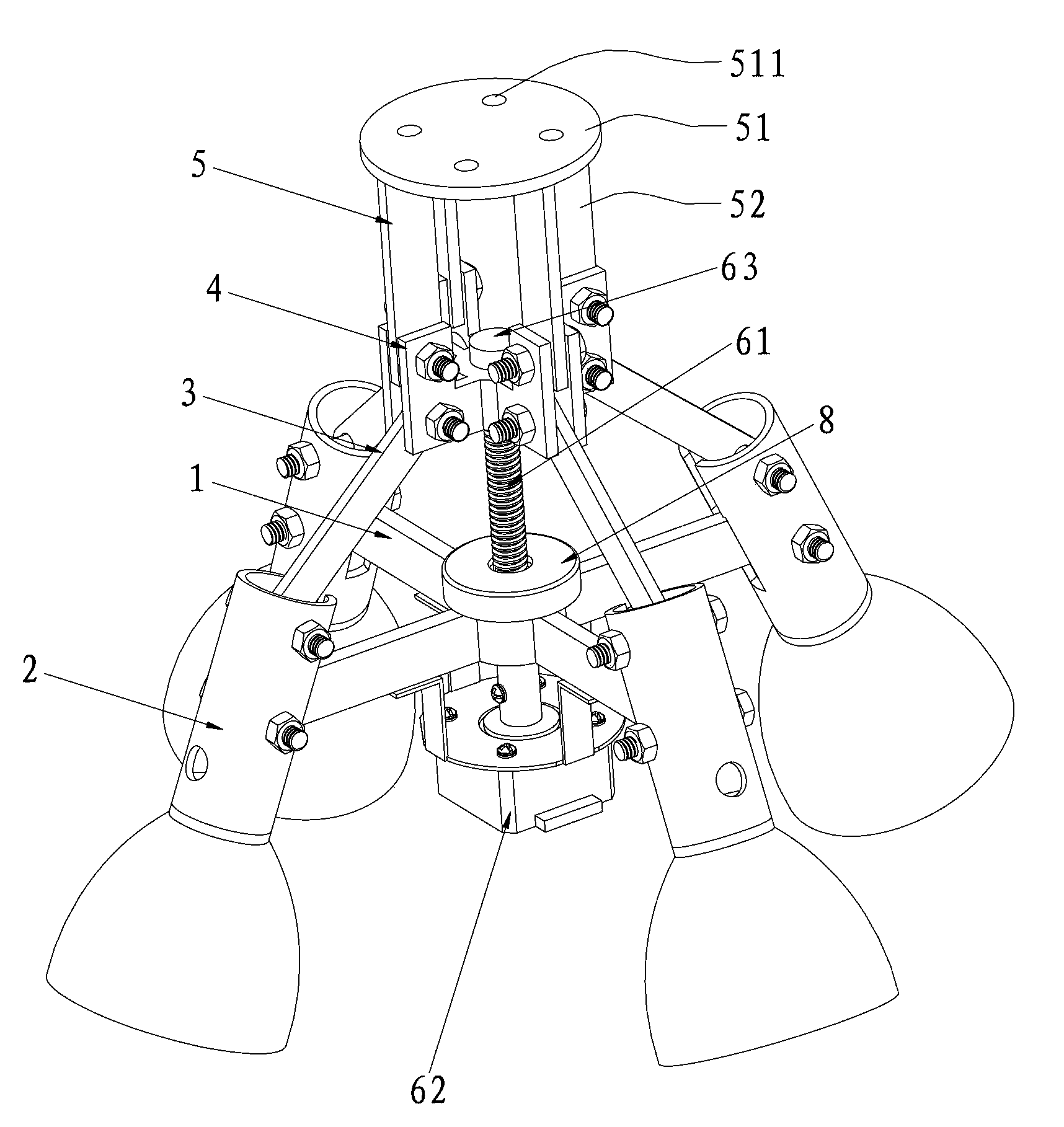

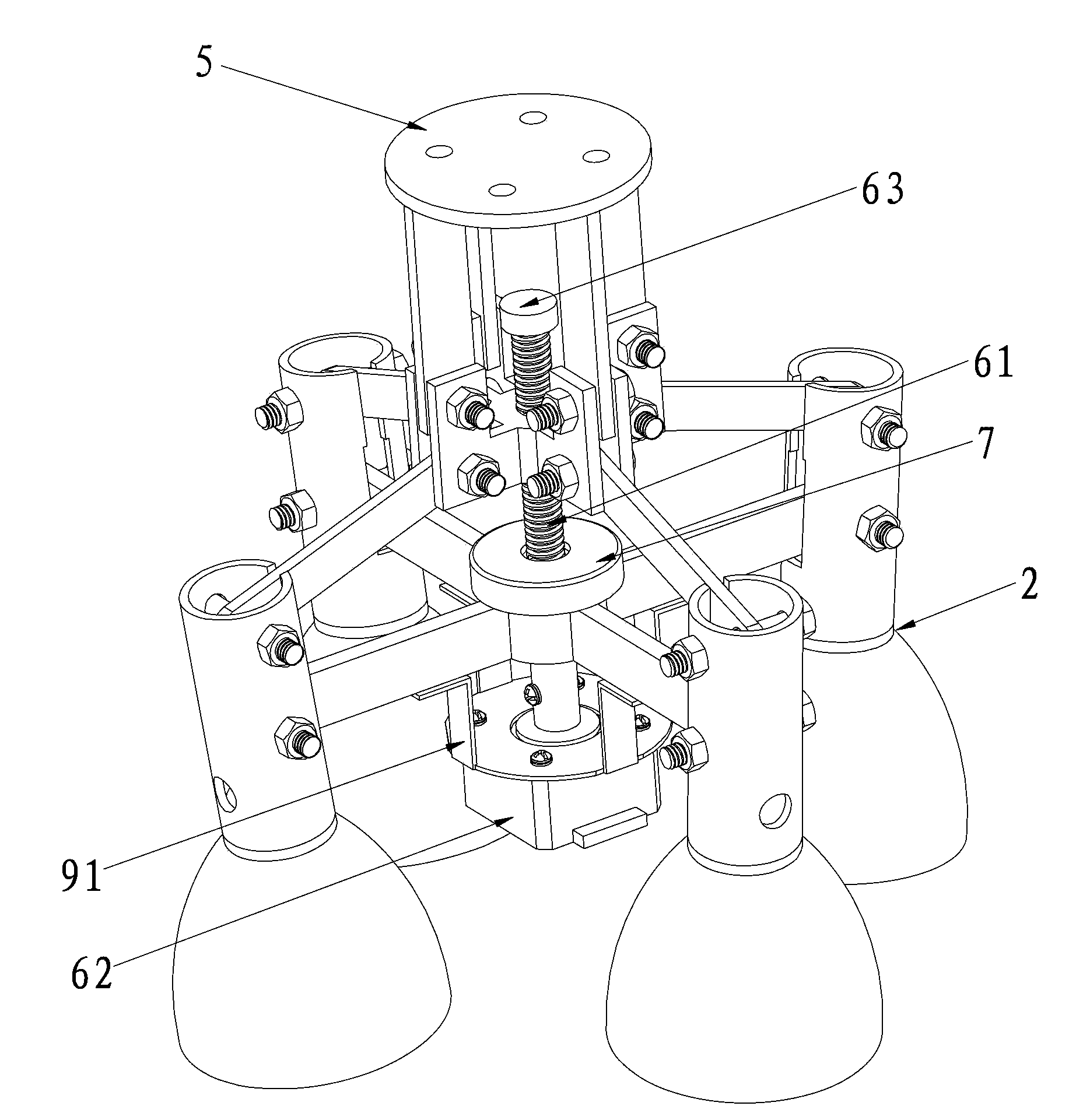

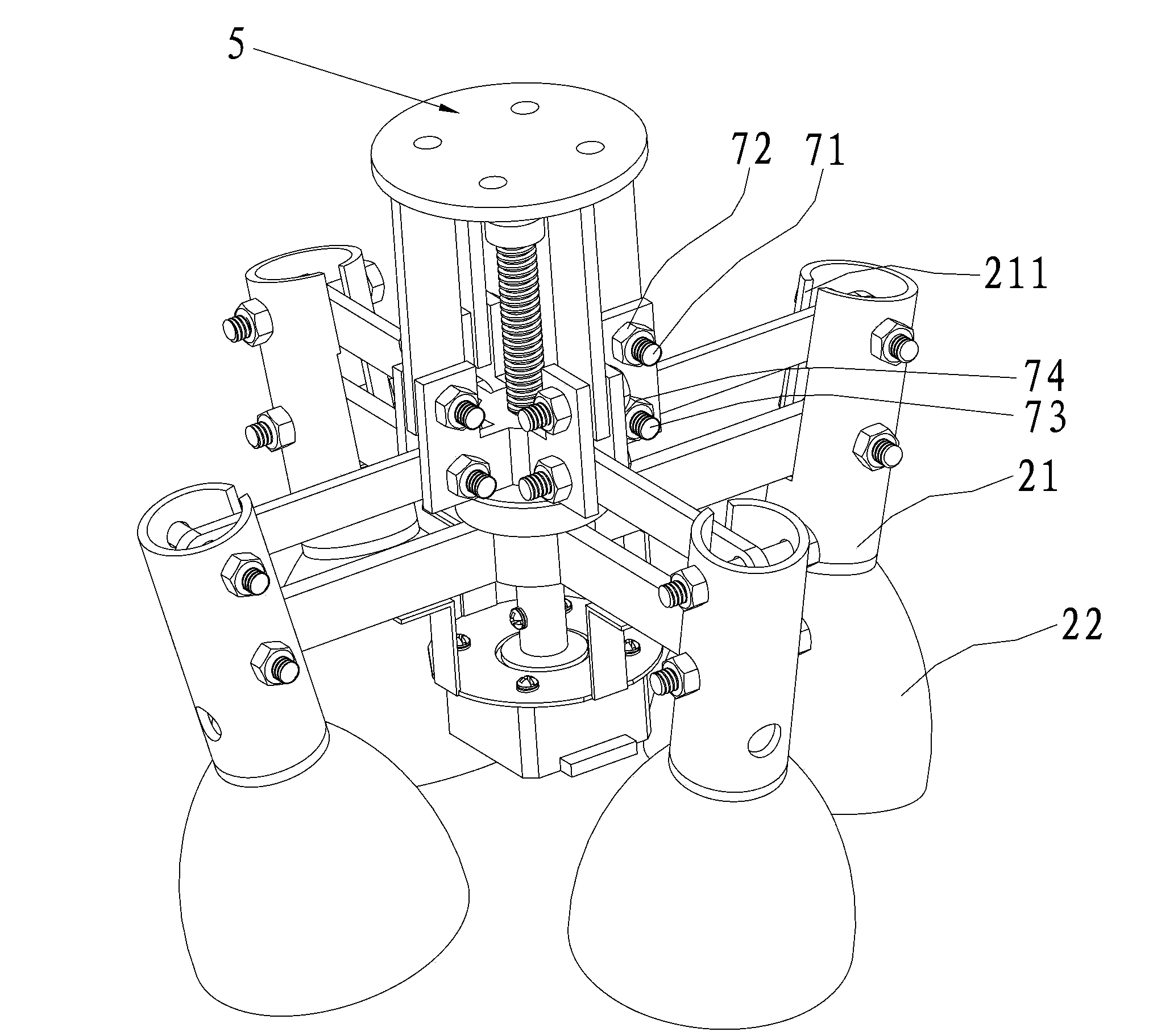

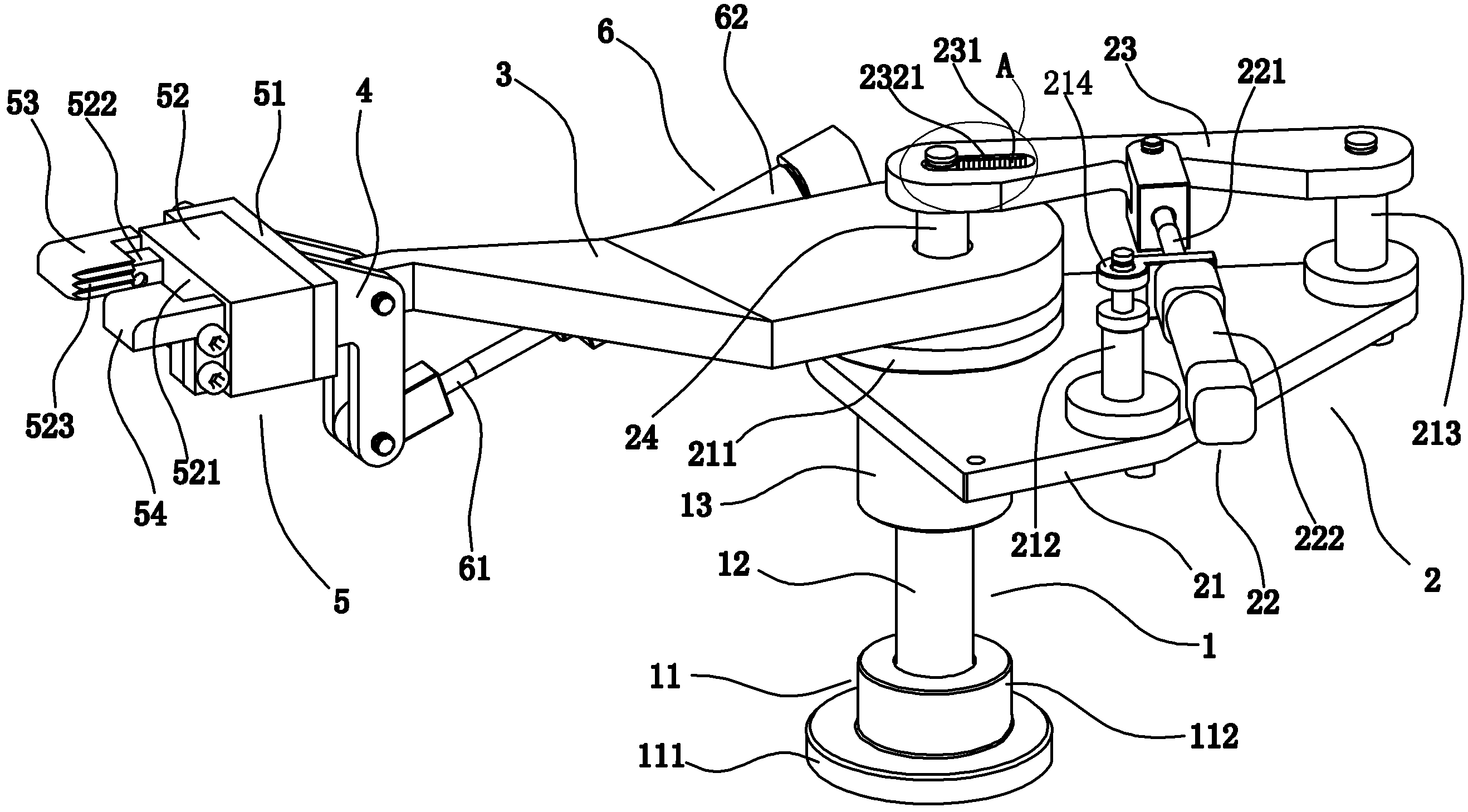

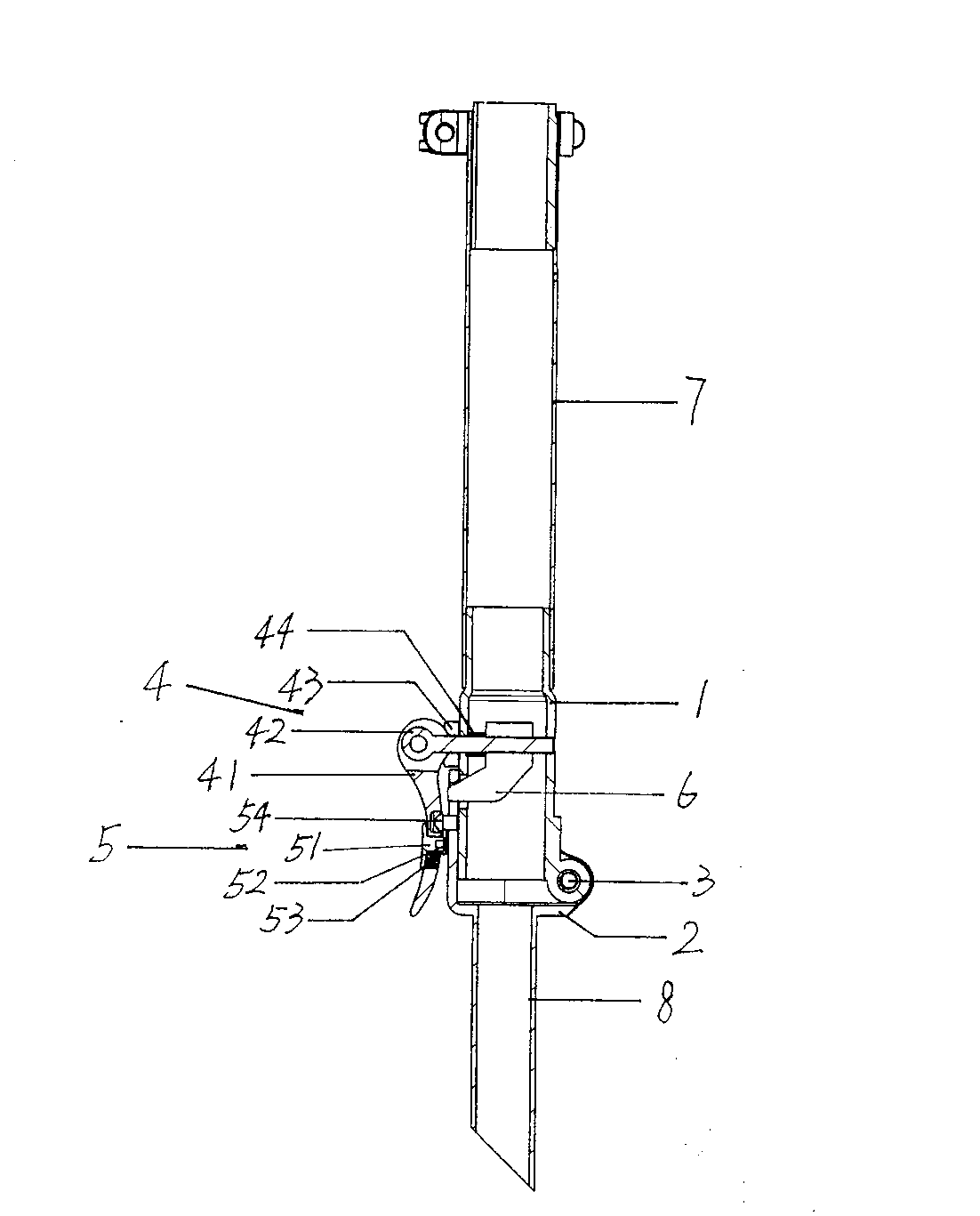

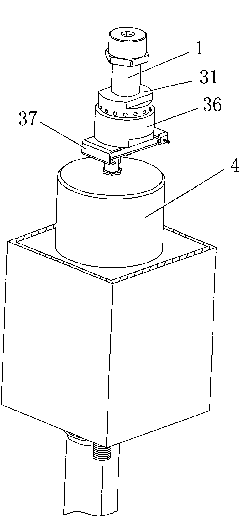

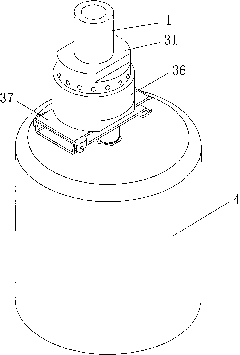

Manipulator, method for manufacturing same and application method of manipulator

ActiveCN102581846ASimple and ingenious structureReasonable designProgramme-controlled manipulatorManipulatorEngineering

The invention discloses a method for manufacturing a manipulator. The method includes the steps: (1) manufacturing a height adjusting device; (2) manufacturing a horizontal swinging component; (3) manufacturing an arm of the manipulator; and (4) fixing a bottom plate of the horizontal swinging component to the top of a rotator of the height adjusting device and completing a manufacturing process of the manipulator. The vertical height of the manipulator can be adjusted by the aid of the height adjusting device. The invention further discloses the manipulator manufactured by the aid of the method and an application method of the manipulator. The manipulator which is simple and ingenious in structure can be manufactured by the aid of the method. Besides, the manipulator is reasonable in design, small in volume, cheap in price, low in failure rate and maintenance cost, easy in maintenance and convenient to be popularization and application, and can be flexibly applied to small places and space, and the number of parts of the manipulator is small.

Owner:GUANGDONG LXD ROBOTICS CO LTD

Resilience prevention bridge girder prestress tension device

InactiveCN103174094AGuarantee the quality of the projectSimple and ingenious structureBridge erection/assemblyBridge materialsPre stressArchitectural engineering

The invention discloses a resilience prevention bridge girder prestress tension device. The resilience prevention bridge girder prestress tension device comprises a first-level oil cylinder and a second-level oil cylinder, wherein a first-level piston in the first-level oil cylinder and a second-level piston in the second-level oil cylinder move towards opposite directions, a first-level anchorage device and a second-level anchorage device are respectively connected on the first-level piston and the second-level piston, a steel strand penetrating through a bridge girder prestress hole penetrates through the first-level anchorage device and the second-level anchorage device and is fixedly connected with the first-level anchorage device and the second-level anchorage device, front end tapered clamp pieces and rear end tapered clamp pieces are respectively sleeved at the front end and the rear end of the steel strand, a bridge girder is provided with hole positions, corresponding to the front end tapered clamp pieces, of an embedded anchorage device pad, and the front end tapered clamp pieces are ejected into the hole positions of the embedded anchorage device pad along with the motion of the second-level piston. The resilience prevention bridge girder prestress tension device is delicate in structural modification, ejects the front end tapered clamp pieces into the hole positions of the embedded anchorage device pad to prevent resilience by utilizing the motion of the pistons, the project quality of the bridge girder can be guaranteed, and the operation is more convenient and safer.

Owner:HEFEI HUILIPU MOTOR

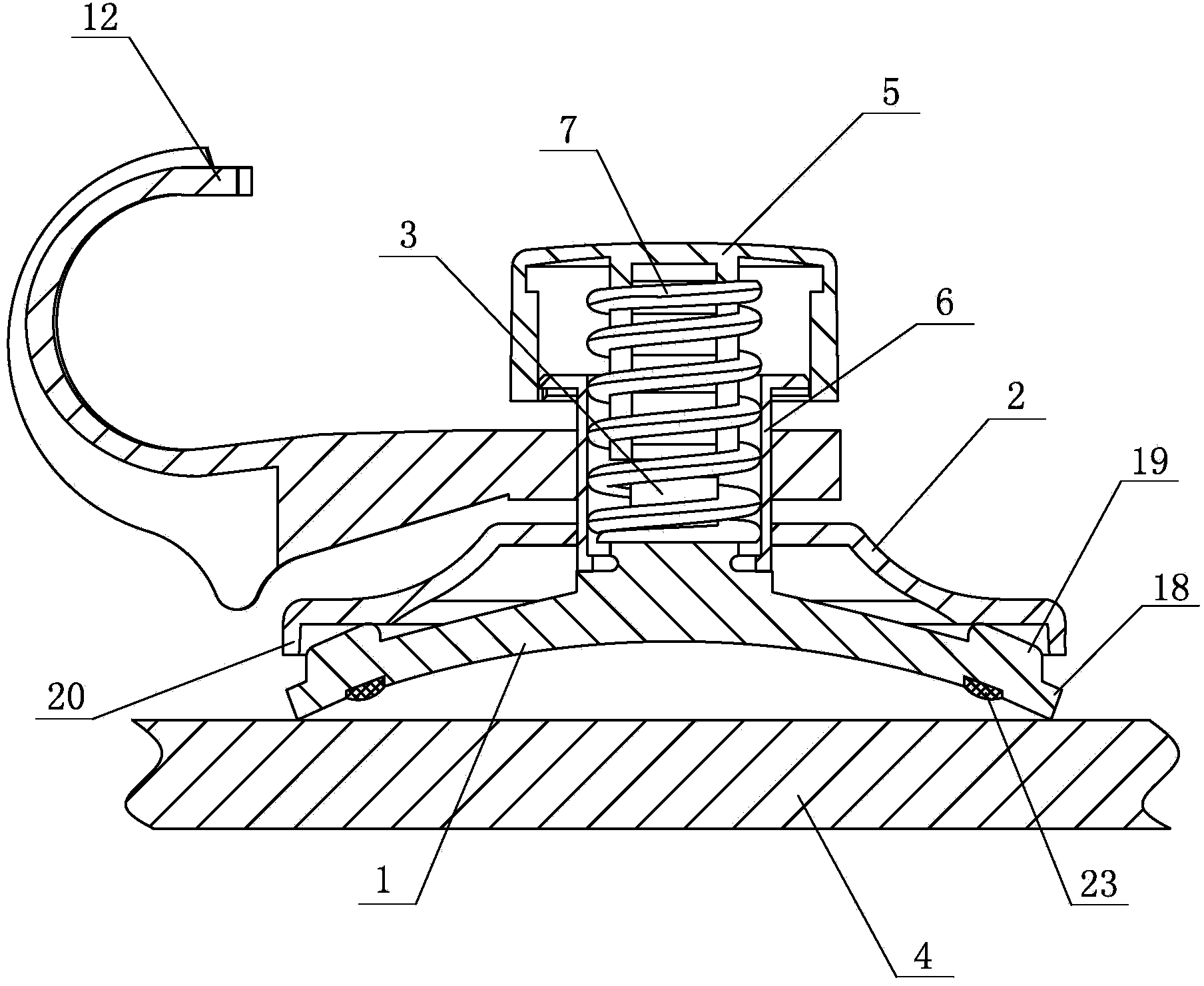

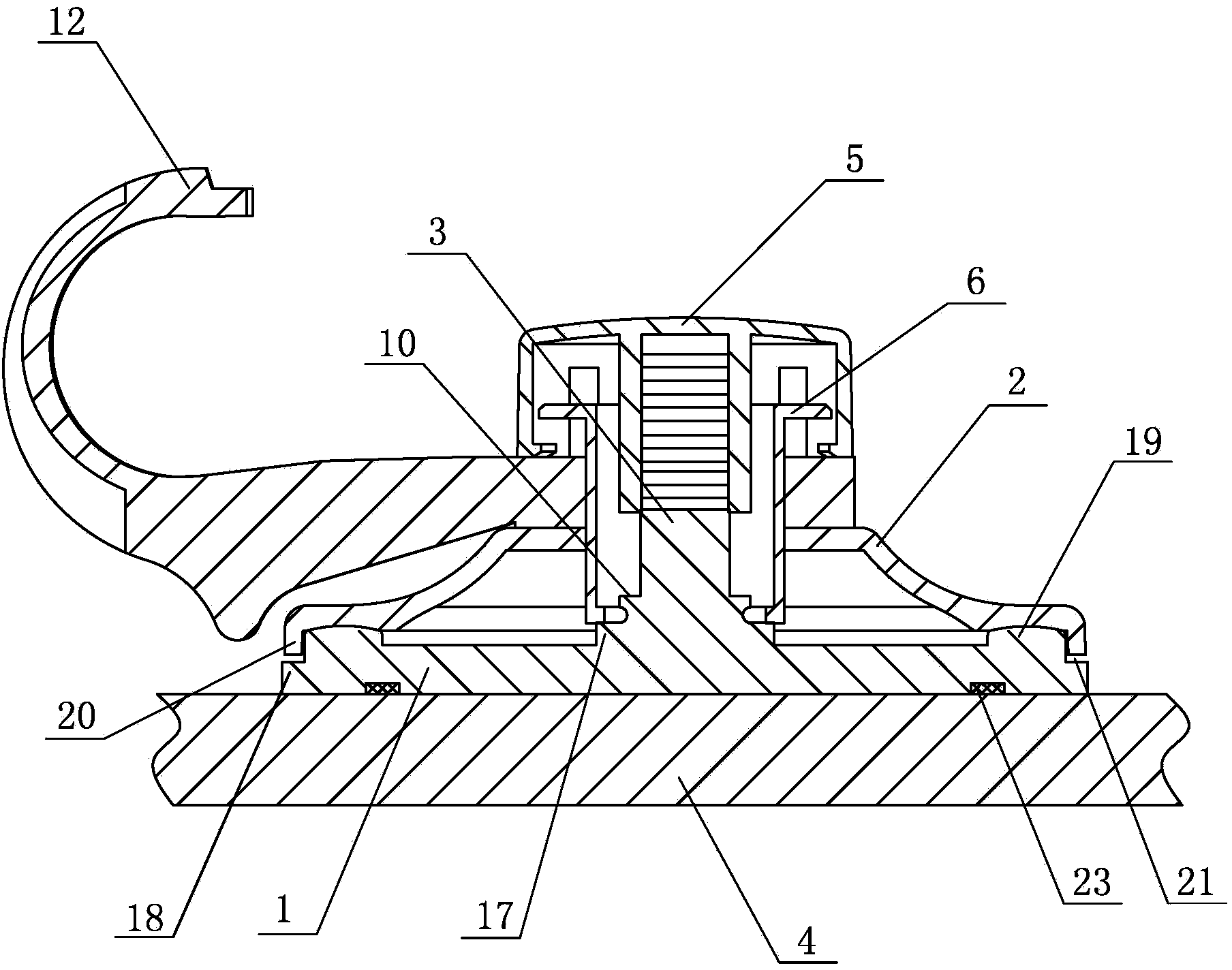

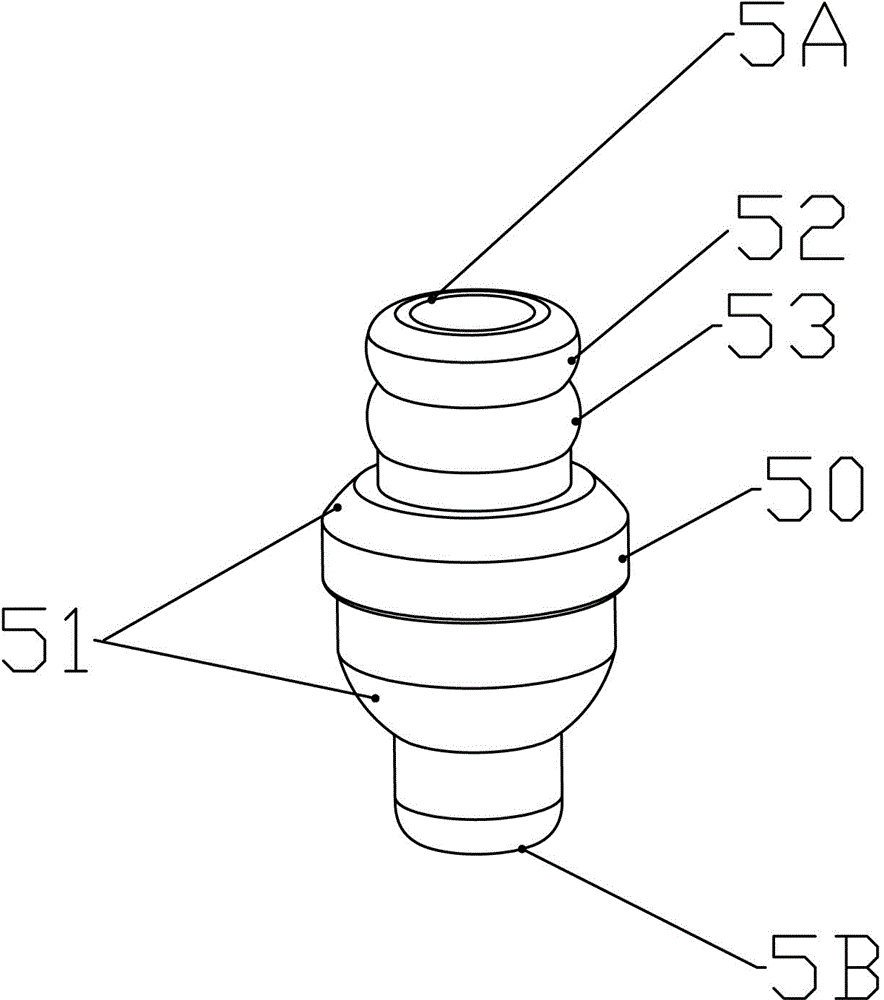

Sucker and sucking method thereof

InactiveCN103758848AAvoid installation errorsEasy to installSuction cupsEngineeringInstallation Error

The invention discloses a sucker. The sucker comprises a sucker base made of an elastic material, a sucker cover plate and an elastic pressing part. The sucker cover plate and the elastic pressing part are arranged on the back of the sucker base. The sucker is characterized in that the elastic pressing part comprises an outer cover, an inner cover and a spring, the spring is arranged between the outer cover and the inner cover, a sleeve is arranged inside the outer cover, the sleeve can penetrate the spring and the inner cover to be in threaded connection with a center connecting piece, the outer cover and the inner cover are movably connected, and the bottom of the center connecting piece is connected with the bottom of the inner cover. Mounting error of a consumer can be effectively avoided, firmness and durability of the sucker are improved, and the sucker is human friendly and reusable.

Owner:TECMAGIC TECHMOLOGIES JIANGYIN CO LTD

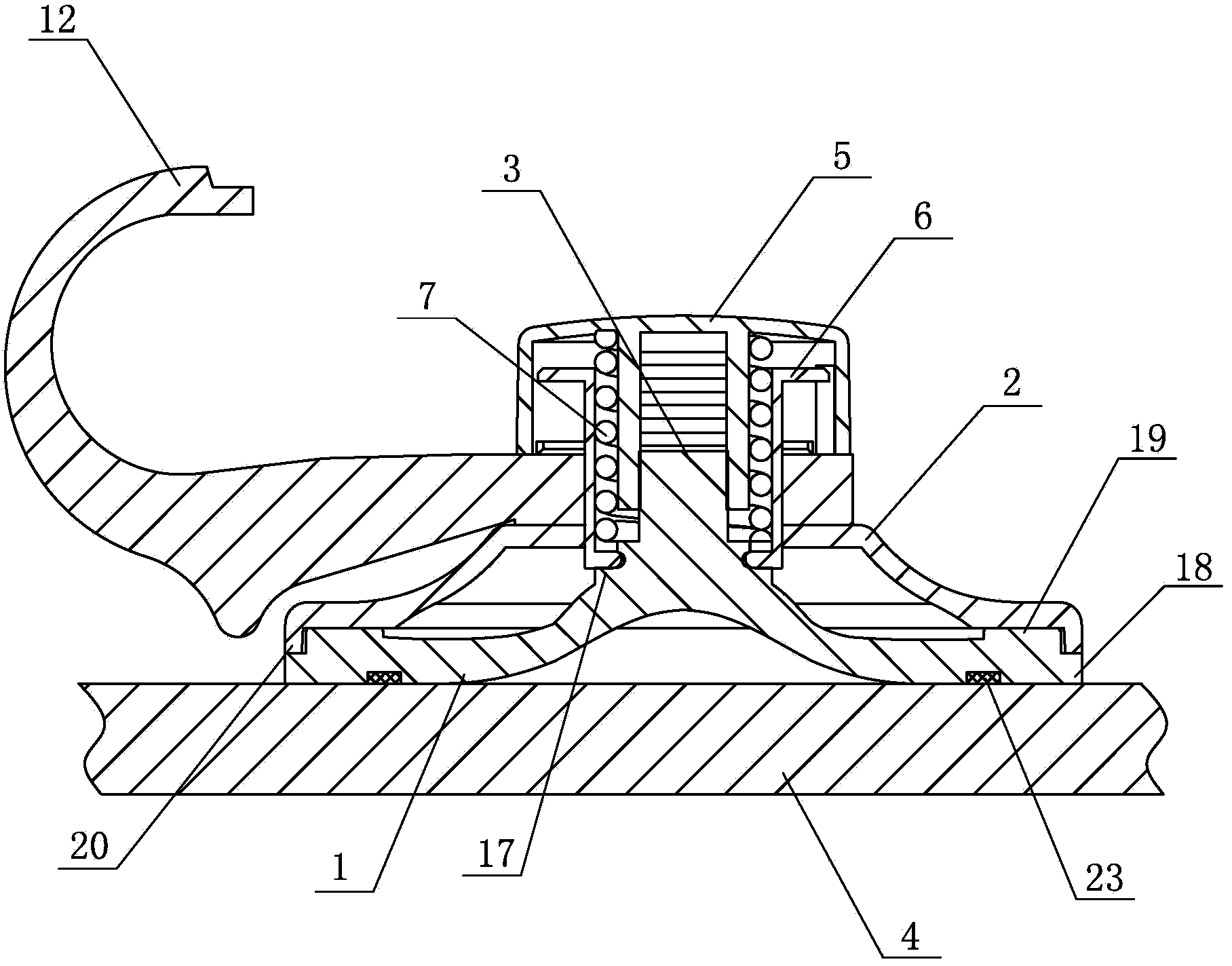

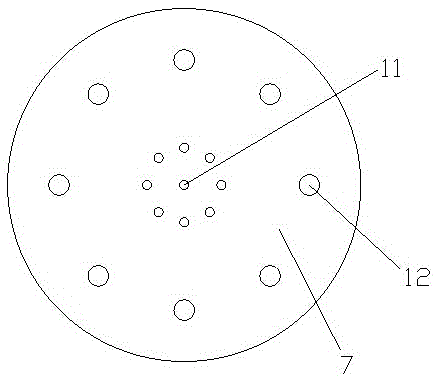

Electromagnetic heating roller used for corrugating machine, application of electromagnetic heating roller and corrugating machine electromagnetic heating method

PendingCN106903932AIncreased complexitySimplify complexityMechanical working/deformationStorage heatersMagnetic heatingEngineering

The invention discloses an electromagnetic heating roller used for a corrugating machine, an application of the electromagnetic heating roller and a corrugating machine electromagnetic heating method, and belongs to the technical field of electromagnetic heating. The electromagnetic heating roller comprises a roller body and an electromagnetic heater. The electromagnetic heater is used for heating the roller body. The roller body is provided with a cavity for encapsulating heat-conducting liquid. The electromagnetic heater can heat the heat-conducting liquid through the roller body, so that steam is produced in the cavity of the roller body. The electromagnetic heater comprises a plurality of U-shaped magnets and an electromagnetic wire. The multiple U-shaped magnets are arranged on a straight line side by side in the axis direction of the roller body. The electromagnetic wire is wound at the two ends of the U-shaped magnets in a single-loop wire winding mode to form a coil. Corrugated paper can be uniformly heated through the electromagnetic heating roller, moisture balance of the corrugated paper in the whole width direction is ensured, and the product quality is improved.

Owner:ANHUI RESUDA ELECTRONICS TECH

Water outlet mechanism having same water outlets with different water outlet functions

ActiveCN104646199ASave water outlet spaceSimple structureMovable spraying apparatusSpray nozzlesImpellerWaste management

The invention discloses a water outlet mechanism having the same water outlets with different water outlet functions. The water outlet mechanism comprises an impeller, at least two sliding units, limiting stop blocks and water outlet nozzles, wherein the limiting stop blocks are respectively matched with the sliding units; an eccentric shaft is arranged at the center position of the impeller; each of the two sliding units is provided with a hole position and a groove body which are matched with the eccentric shaft and the water outlet nozzle; the limit stopping blocks are arranged on the outer sides of the two sliding units in a matching way and the directions of the limiting stop blocks are perpendicular to the hole positions; the water outlet nozzles are connected with the two sliding units; spherical swing parts are also formed on the water outlet nozzles. The water outlet mechanism having the same water outlets with the different water outlet functions, provided by the invention, has the advantages of small size, thin thickness and delicate and ingenious structure; the switching between 360-degree rotary massage water outlet and single-swing massage water outlet can be realized, the functional water outlet space is saved, and different water outlet modes are formed by the same kind or same group of water outlets.

Owner:FUJIAN XIHE SANITARY WARE TECHNOLOGY CO LTD

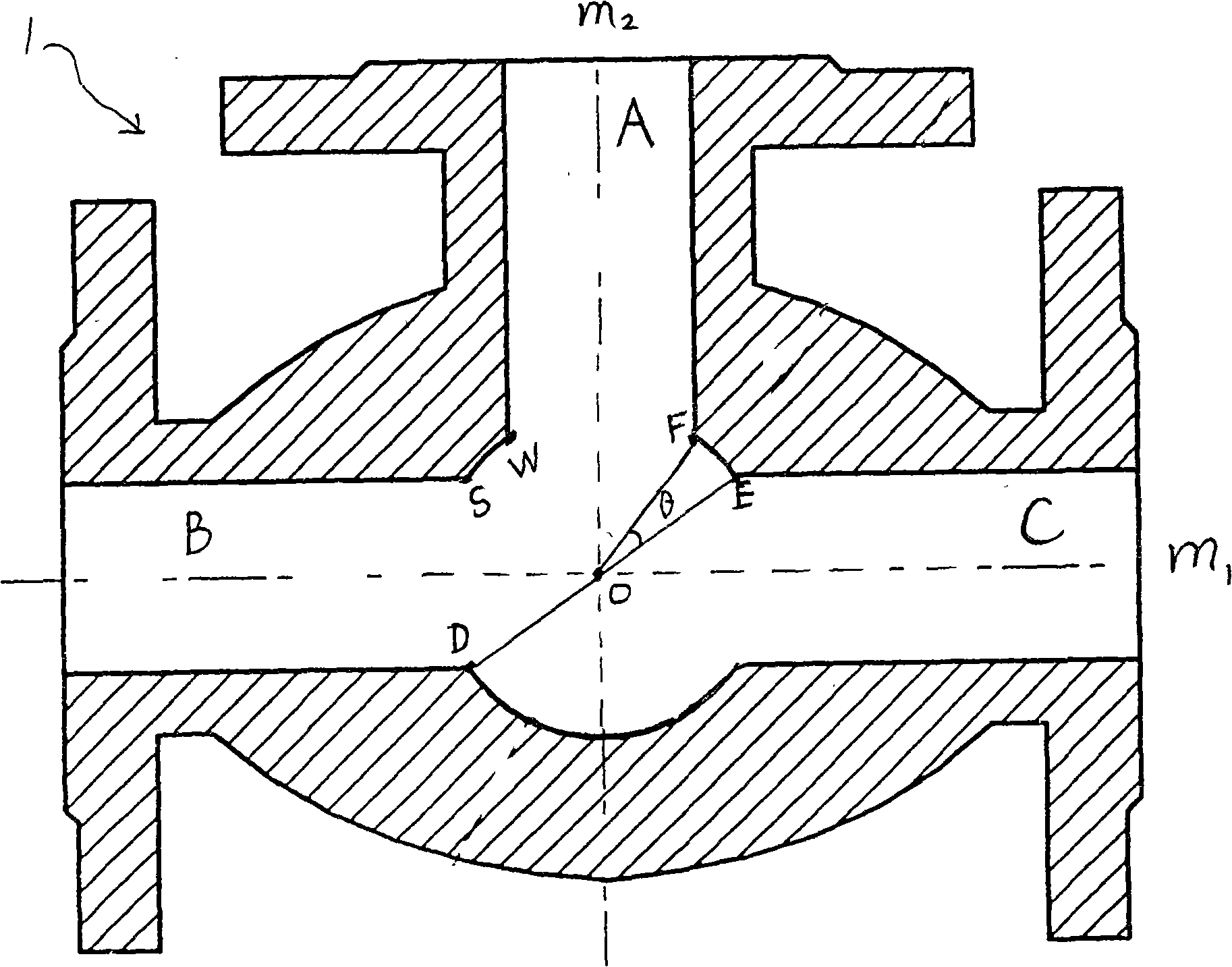

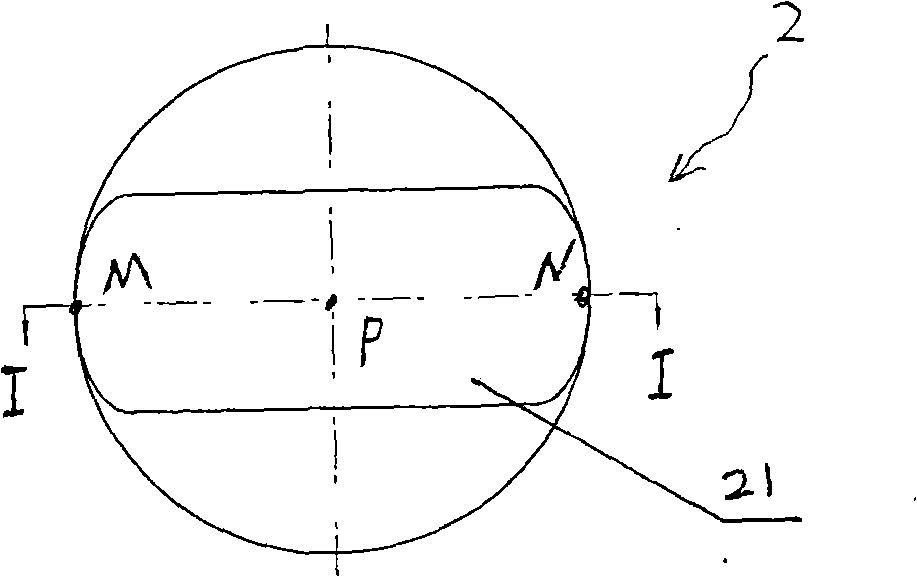

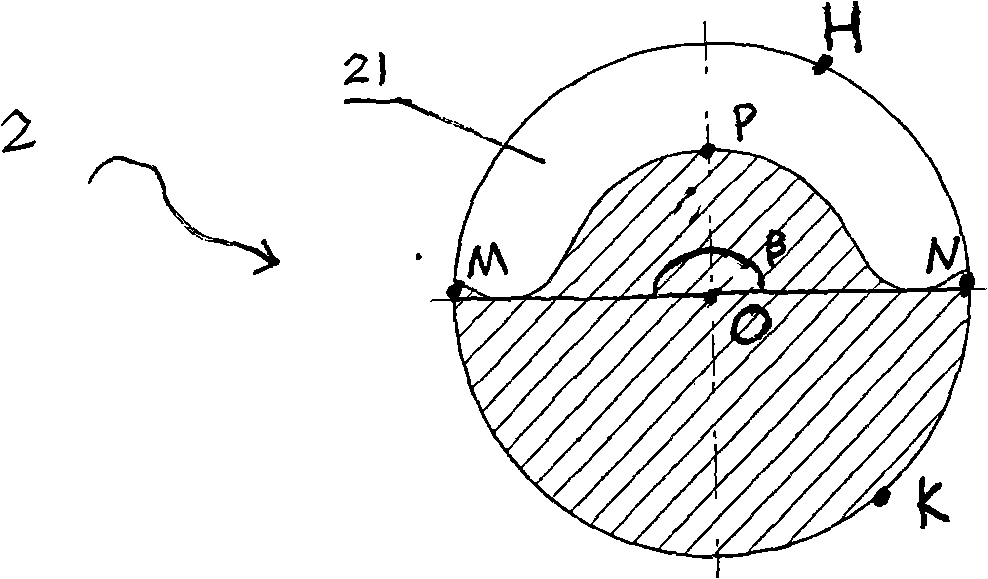

Three-way ball valve

InactiveCN101255926AFluid pressure remains stableSimple and ingenious structureEqualizing valvesMultiple way valvesBall valveLiquid pressure

A three-way ball valve comprises a valve body and a sphere spool, the valve body has a main tube (A) and two runners (B, C), the intersection point O of central axis m1 of main tube and central axis m2 of two runners is the centre of sphere of the sphere spool; the arc parts matching to sphere spool surface are arranged on the juncture of main tube and two runners; grooves are arranged on the sphere spool, the groove cavity of groove are arranged on two sides of the plane determined by intersection of the central axis m1 and the central axis m2, the radian of the groove extended on the sphere spool surface is beta, and 180 degrees-theta<beta<180 degrees +theta, wherein, theta is radian of arc part on the juncture of main tube and runners. The present invention has multiplicity work type and purpose of make-break control, can realize shut off totally, and the flux and the liquid pressure in the main tube can't changed rapidly in the process of adjusting and changing distributary proportion in the two runners.

Owner:ZHONGYEDA ELECTRIC CO LTD

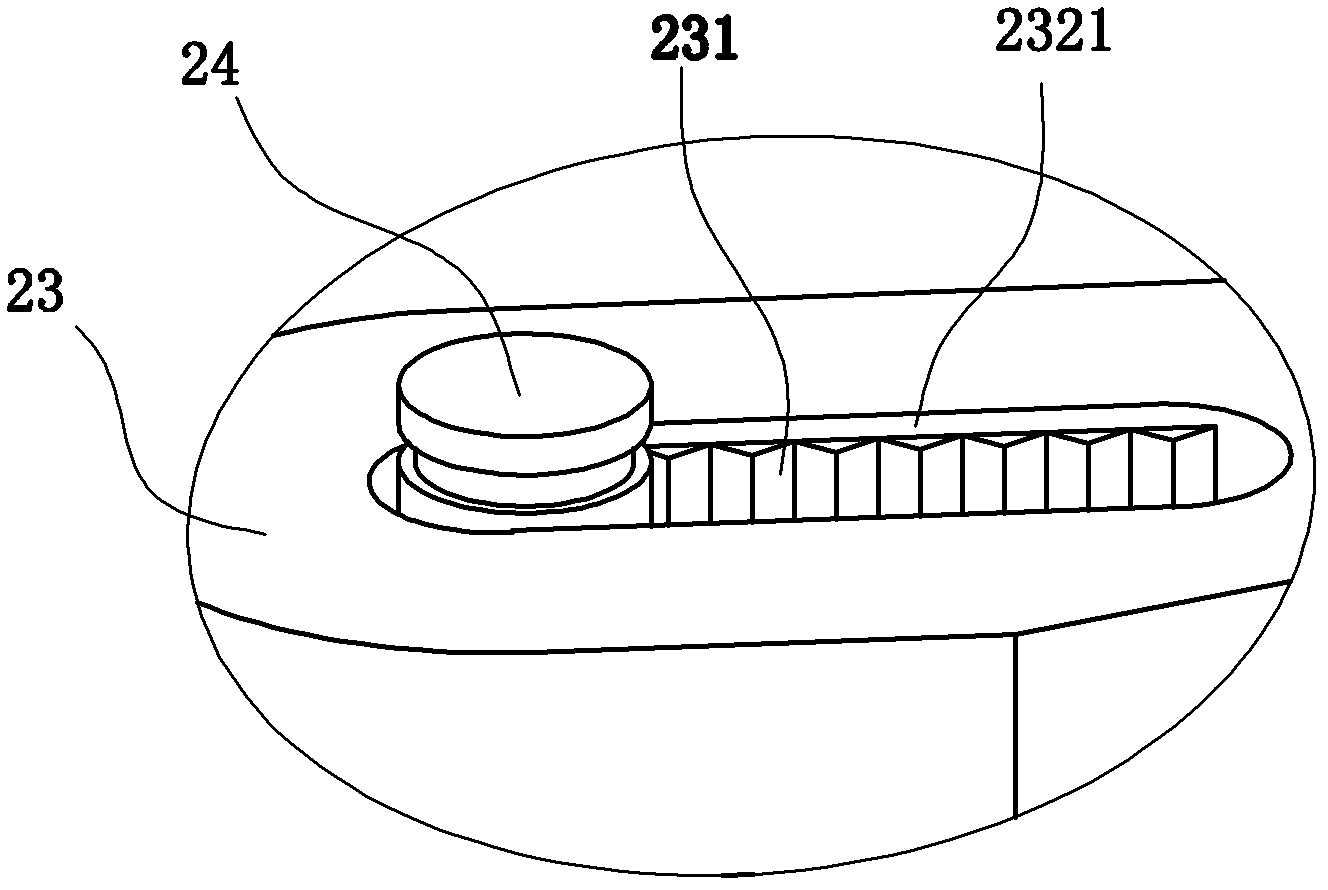

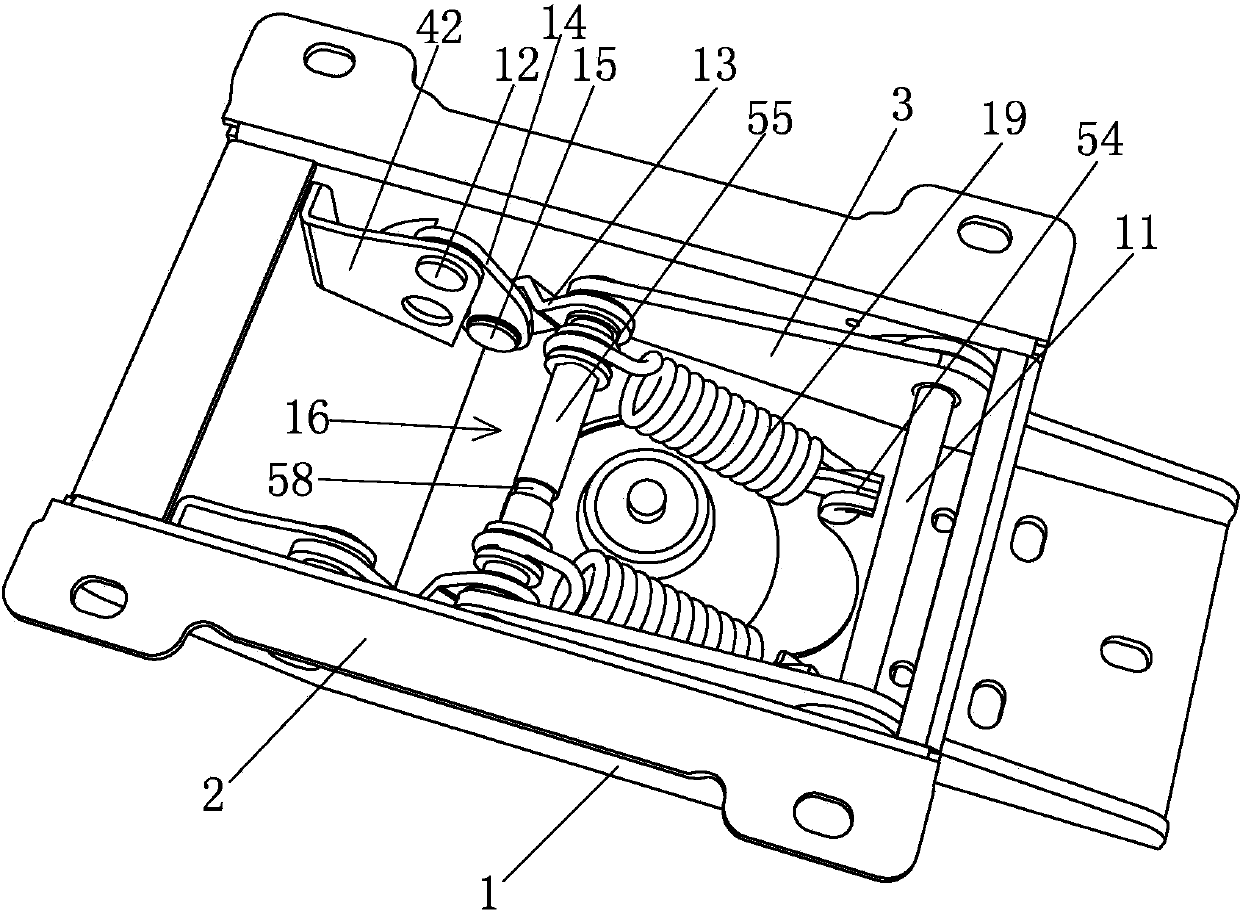

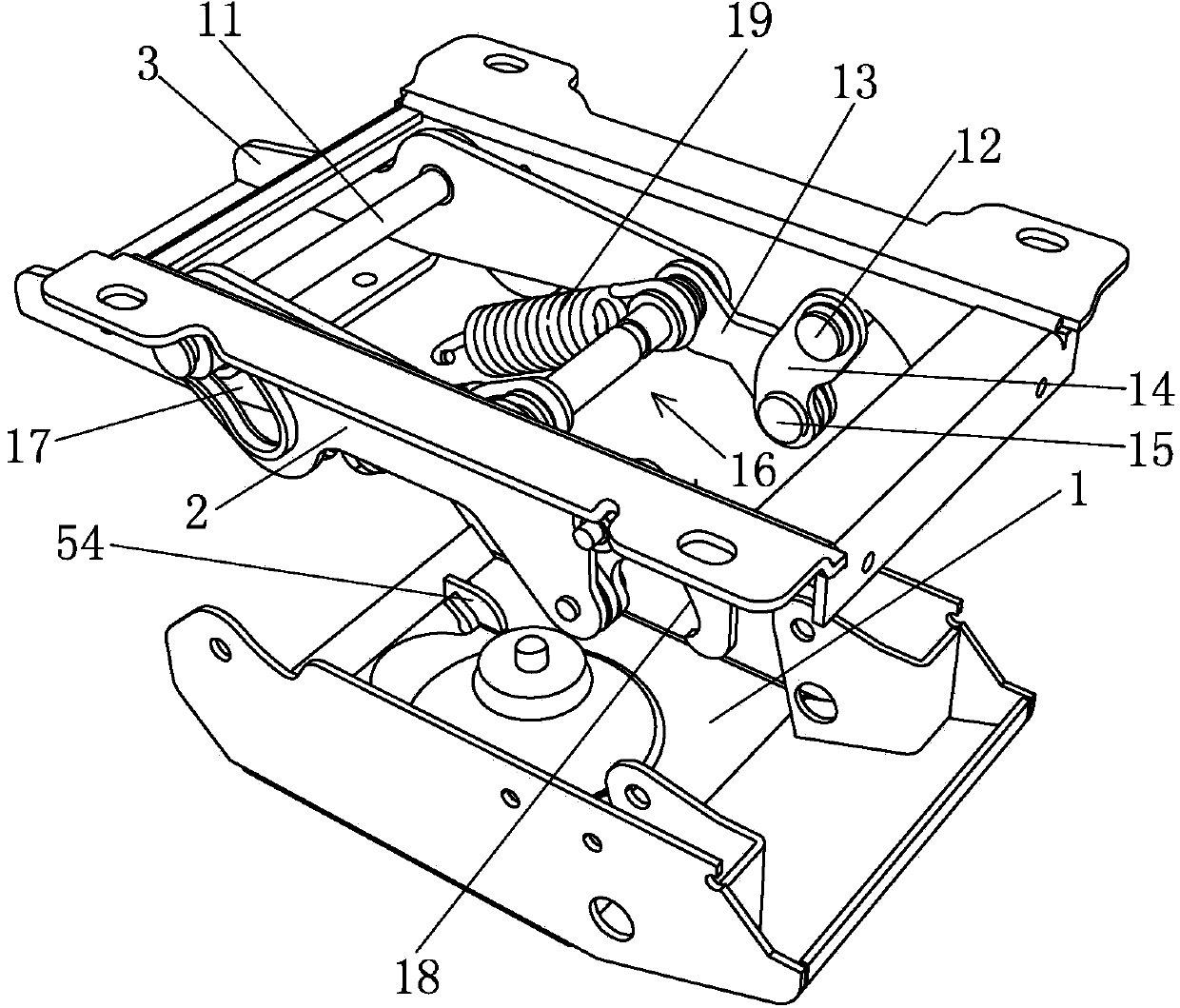

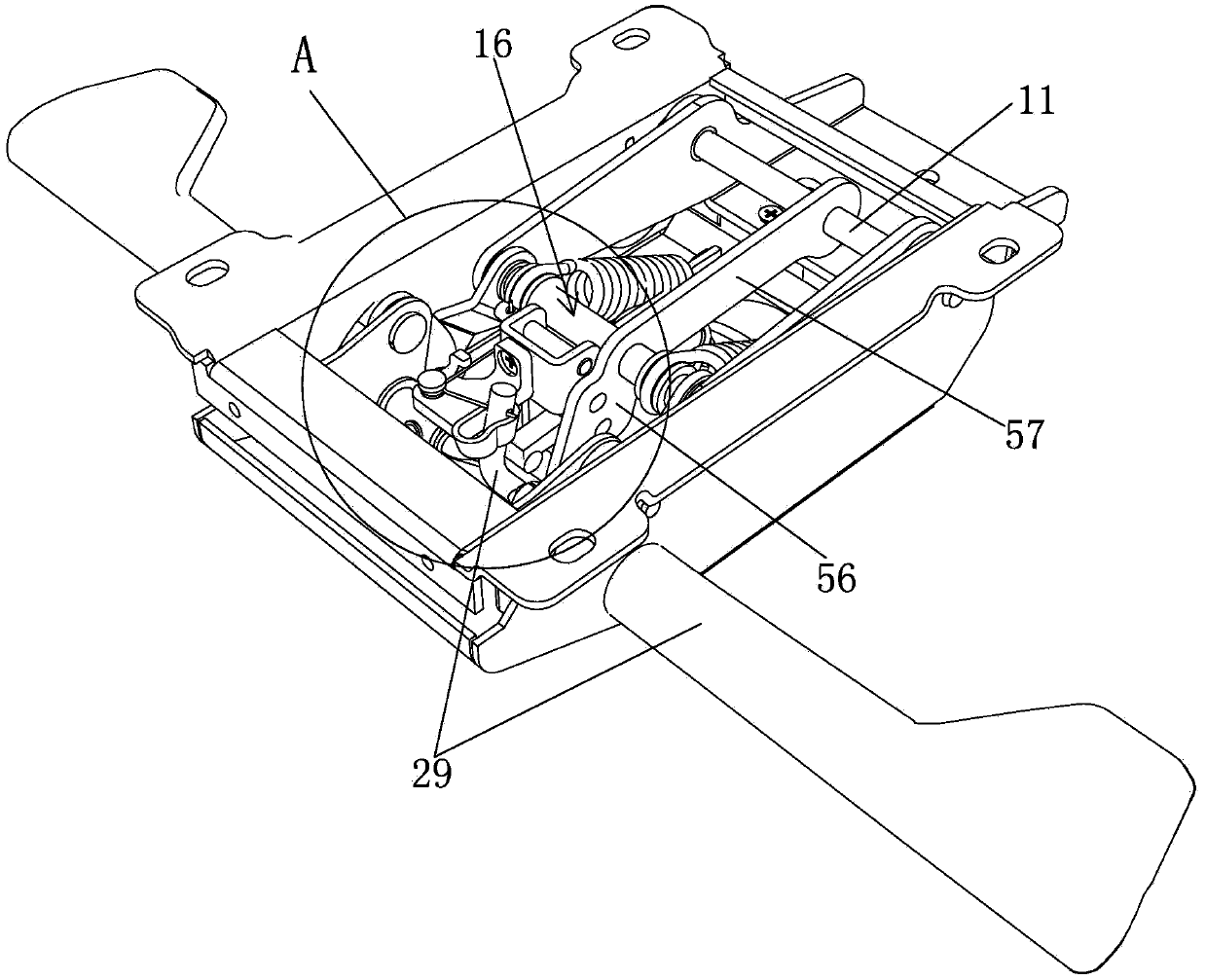

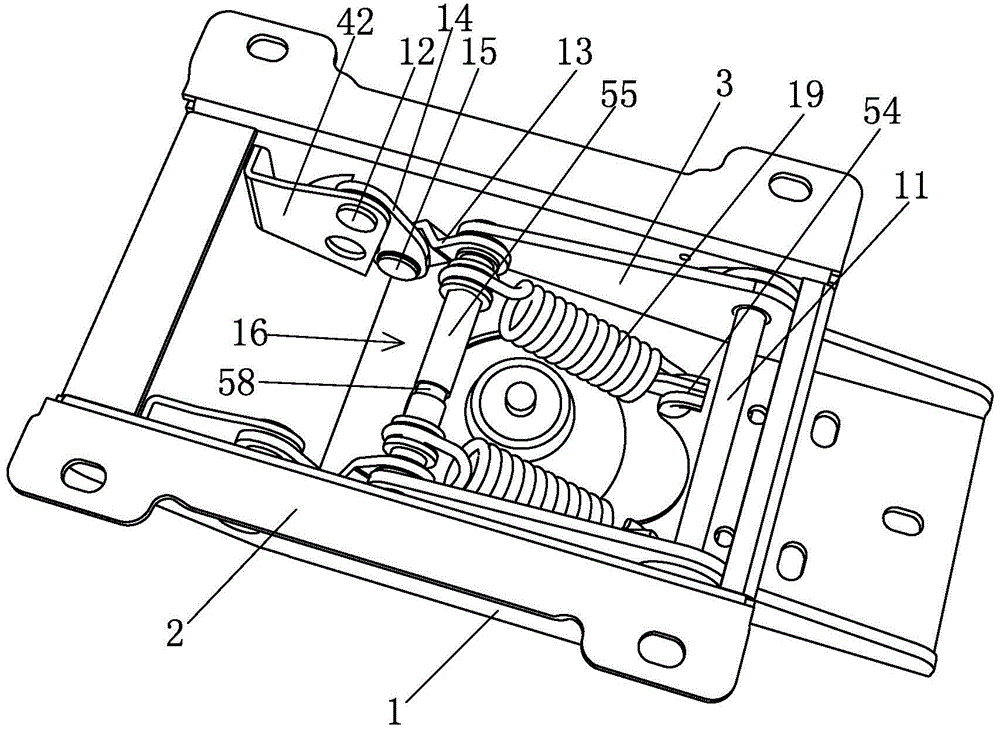

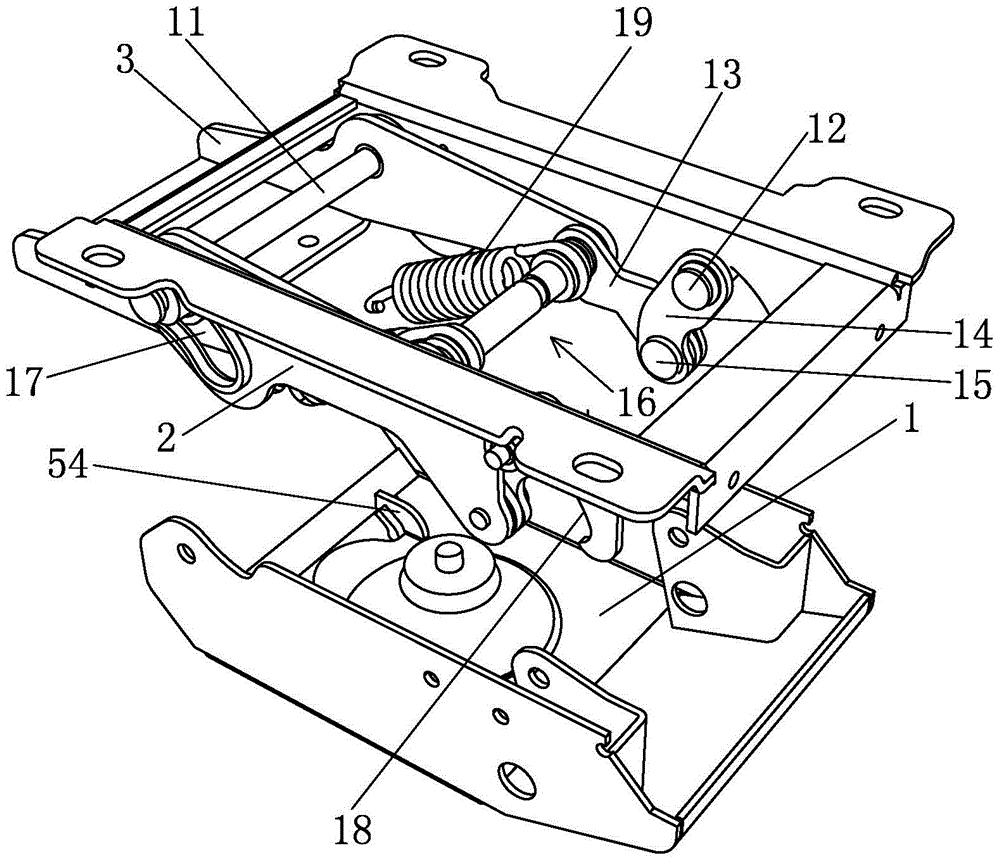

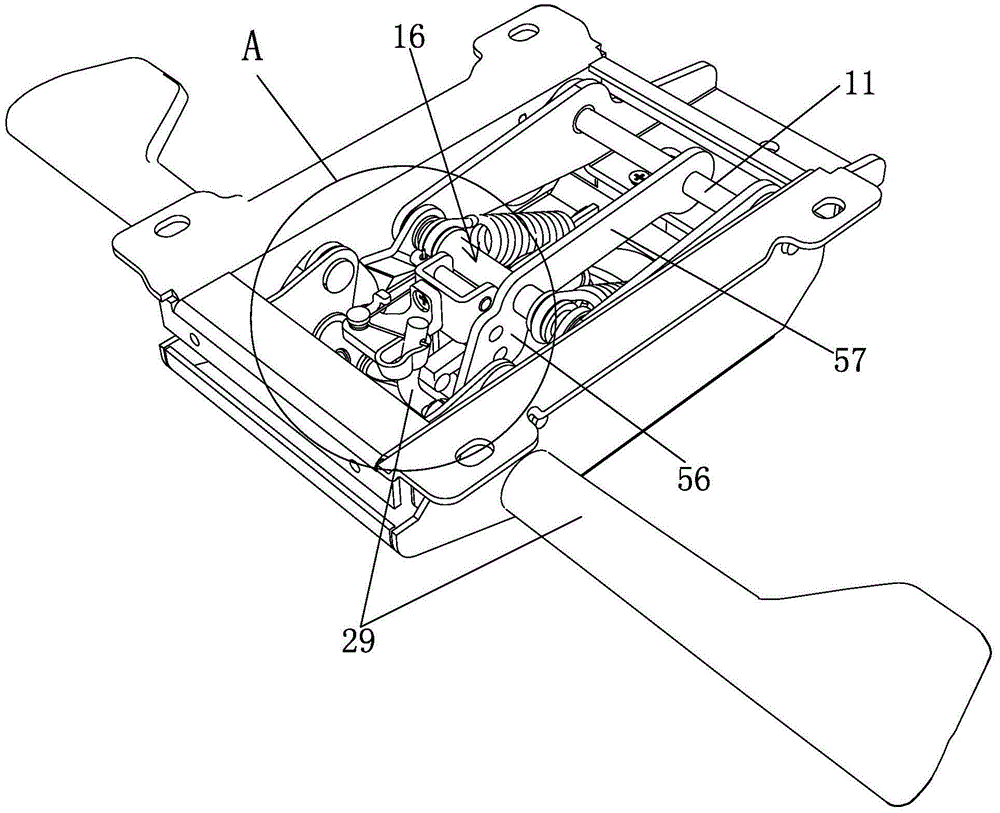

Chair back and rocker locking mechanism for chassis of swivel chair

ActiveCN104207520ASimple and ingenious structureEasy to useStoolsAdjustable chairsTorsion springEngineering

The invention discloses a chair back and rocker locking mechanism for a chassis of a swivel chair. The chair back and rocker locking mechanism comprises a locking plate, a torsion spring a, a bolt and a bolt seat, wherein a row of locking holes are formed in the locking plate, the locking plate is fixedly connected with a fourth pin shaft and performs synchronous motion along with the fourth pin shaft under the action of a rocker, the fourth pin shaft is a whole long shaft, the bolt seat is arranged beside the locking plate, the bolt seat is fixedly connected with a base of a chassis, the bolt is penetrated and inserted into the bolt seat in a sliding manner and matched with the locking holes, a first spring arm of the torsion spring a is connected with the bolt, and a second spring arm of the torsion spring a is connected to a driving device for driving the torsion spring a to rotate back and forth. The chair back and rocker locking mechanism disclosed by the invention is provided with the locking plate and the bolt, and the bolt can realize dialing according to the rotation of the torsion spring, thereby achieving the purpose that the bolt is inserted into or withdrawn from the locking holes; the locking of the rocker is realized by matching the bolt with the locking plate, thereby facilitating the control.

Owner:UE FURNITURE CO LTD

Screw oiling device

InactiveCN105583115ASimple and ingenious structureLow production costLiquid surface applicatorsCoatingsFuel tankEngineering

The invention relates to a screw oiling device. The screw oiling device comprises a main body. An oil storage box is arranged in the main body and connected with an oil inlet and an oil guide pipe. The oil inlet is connected with a sealing cover. The oil guide pipe is connected with a buffering space. An oil dissipation plate is connected with the buffering space and provided with a first oil hole and a second oil hole. An oiling layer is connected under the oil dissipation plate. The main body is connected with a bottom sealing cover. The screw oiling device has the advantages of being simple and ingenious in structure, low in manufacturing cost, practical in function and convenient to operate and increasing the resource utilization rate.

Owner:MAANSHAN RUNQI NEW MATERIAL SCI & TECH

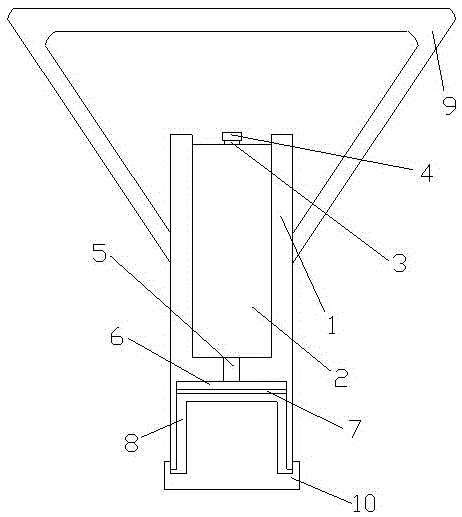

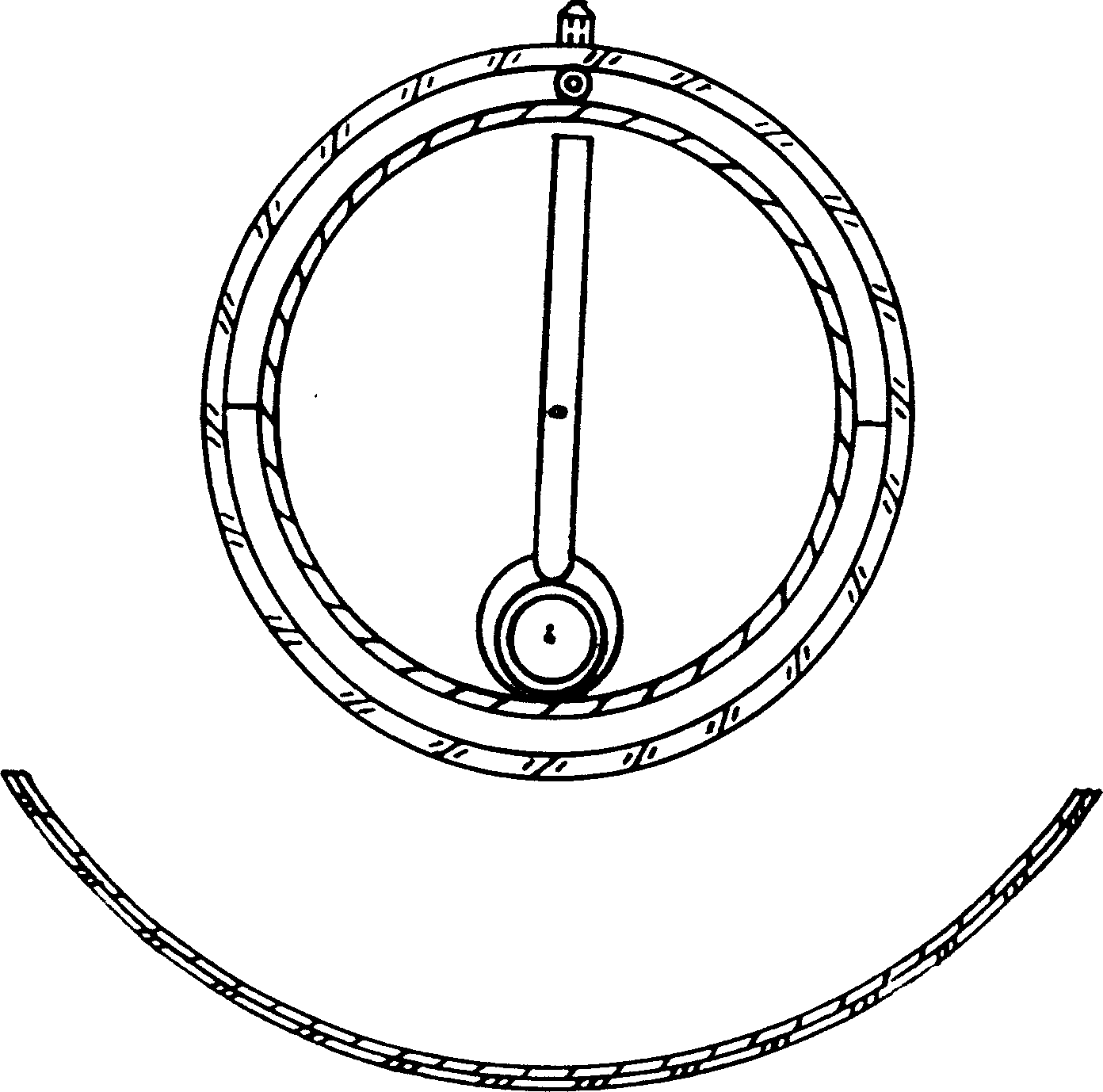

Solar energy water heater

InactiveCN1648546ASimple and ingenious structureSolar heating energySolar heat devicesEngineeringWater level

The solar energy water heater consists of vacuum barrel on support, water level controller connected to the vacuum barrel, and reflecting and focusing mirror below the vacuum barrel. The vacuum barrel consists of water storing container with blacked surface, L-shaped water pipe, U-shaped air exhausting pipe, water inlet / outlet pipe, heat insulating pads on two ends of the container and transparent sealing cover outside the container, with the sandwiched layer being vacuum pumped. The water level controller includes float inside the L-shaped water pipe, screw with nuts, lever and water inlet switch. There may be vacuum gauge installed to the transparent sealing cover. The present invention has integrated heat collector and water storing container and thus simple structure and manufacture.

Owner:梁荫健

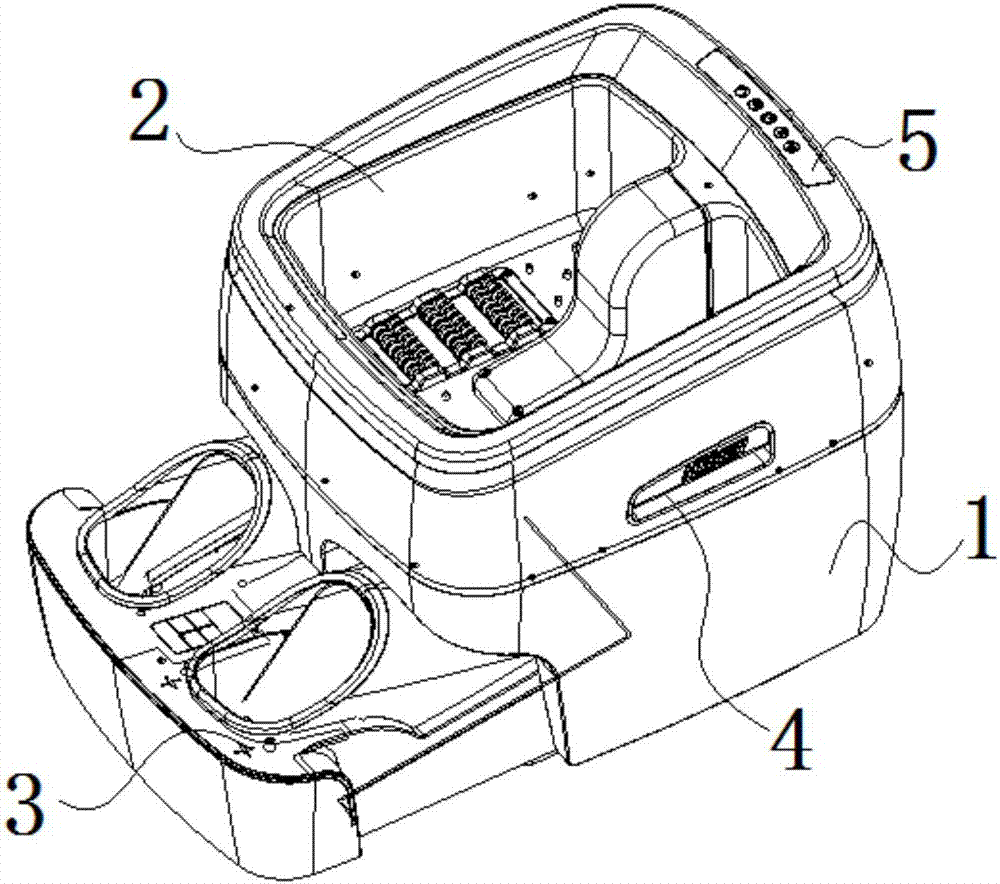

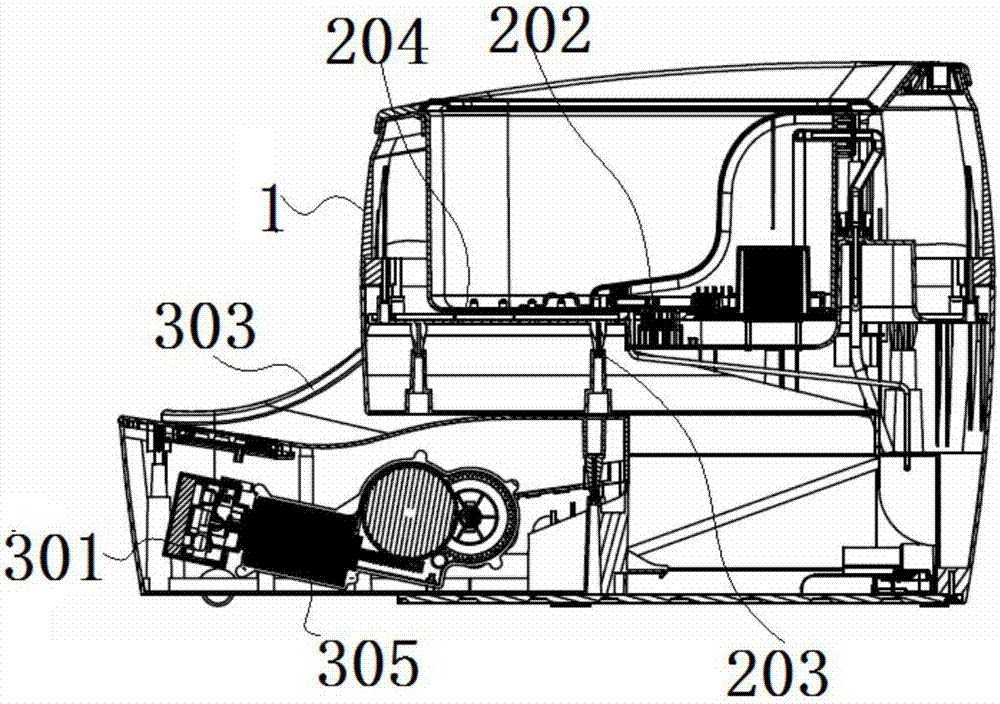

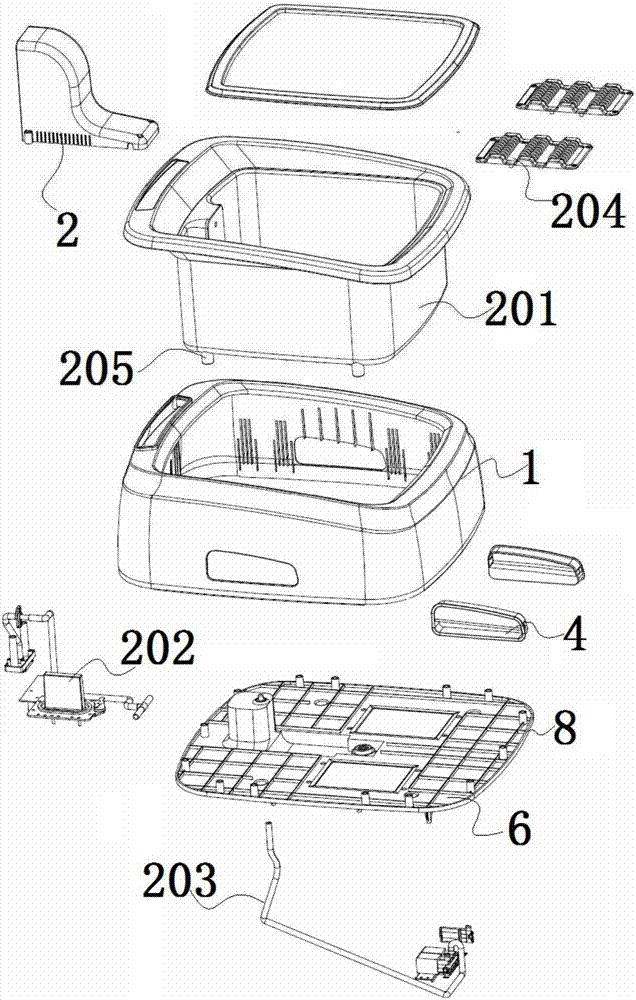

Double-layer telescopic foot-bath foot-massage multifunctional integrated machine

ActiveCN106983648AEasy to slide outSimple and ingenious structurePneumatic massageDevices for pressing relfex pointsManufacturing cost reductionWarm water

The invention discloses a double-layer telescopic foot-bath foot-massage multifunctional integrated machine. A foot-bath component is arranged on the upper portion of a housing, and a foot-massage component is located on the lower portion of the foot-bath component and can horizontally slide out from the lower portion of the housing; the foot-bath component is arranged on the upper layer, the foot-massage component is located on the lower layer, and the foot-bath component and the foot-massage component are formed into a whole; the structure is simple and ingenious, the machine is convenient to use, the functions are rich, occupied space is largely saved, at the same time, a part of modules are shared in use, and the manufacture cost is reduced; foot bath and foot massage can be separately controlled and also can be conducted at the same time. By inflating an air bag through an air pump, massage of the upper portion of foot can be achieved, and at the same time, the air pump also provides bubbles for the foot-bath component and can provide the warm water bubbles for users in the first time for foot bath.

Owner:ZHEJIANG MENGDIAO ELECTRONICS TECH CO LTD

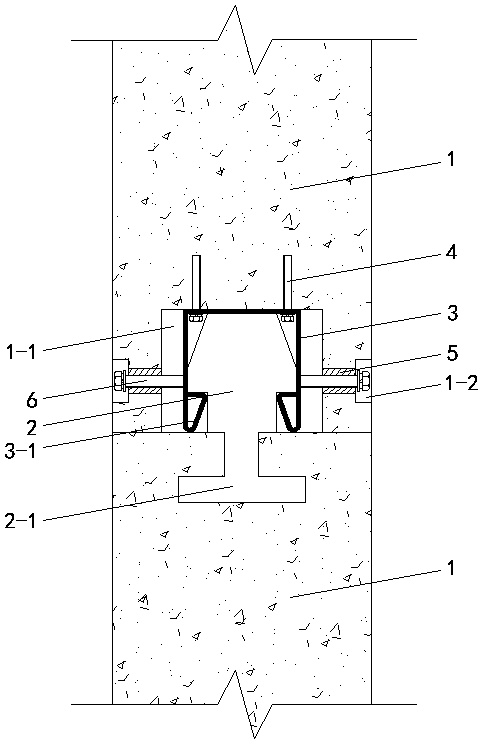

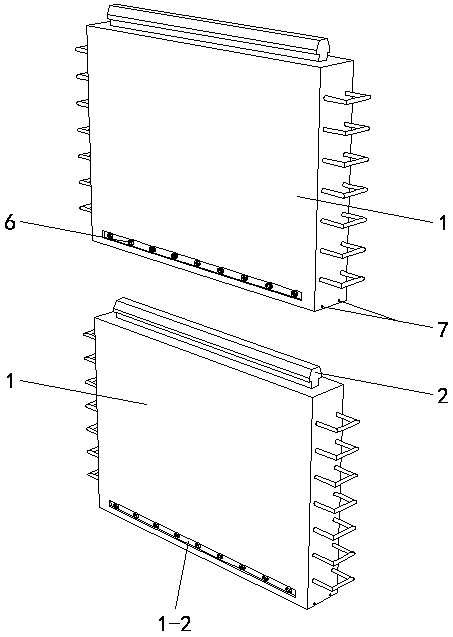

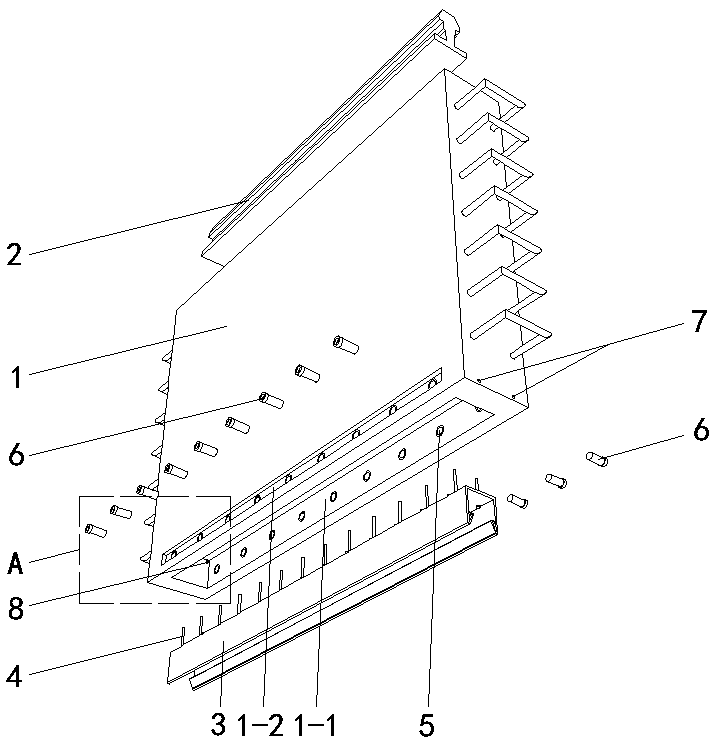

Assembly-type shear wall connecting structure and construction method thereof

An assembly-type shear wall connecting structure and a construction method thereof relate to a wall connecting structure and a construction method thereof. The upper end surface of the shear wall is embedded and fixed with an insertion connecting steel piece, the insertion connecting steel piece is provided with a snap portion, and the lower end surface of the shear wall is concavely provided witha rectangular insertion slot. The two sides of the bottom of a positioning steel channel are connected and fixed with the bottom of the rectangular insertion slot by two rows of positioning bolts. Clamping heads are arranged on the free ends of two supporting arms of the positioning steel channel in a bending manner, and the insertion connecting steel piece matches with the positioning steel channel. The snap portion and the clamping heads are in clamping cooperation to prevent disconnection of the insertion connecting steel piece and the positioning steel channel. A plurality of internally threaded sleeves are respectively embedded in the groove walls on both sides of the rectangular insertion slot in the longitudinal direction, and internal thread sleeves are screwed with fastening bolts to support and limit the two supporting arms of the positioning channel steel. One side of the slot walls of the rectangular insertion slot in the width direction is provided with two grouting holes, and the other side of the slot walls is provided with two discharging holes. The assembly is simple and effective, the alignment is accurate and fast, and certain support and positioning effects areprovided.

Owner:HEILONGJIANG COLLEGE OF CONSTR

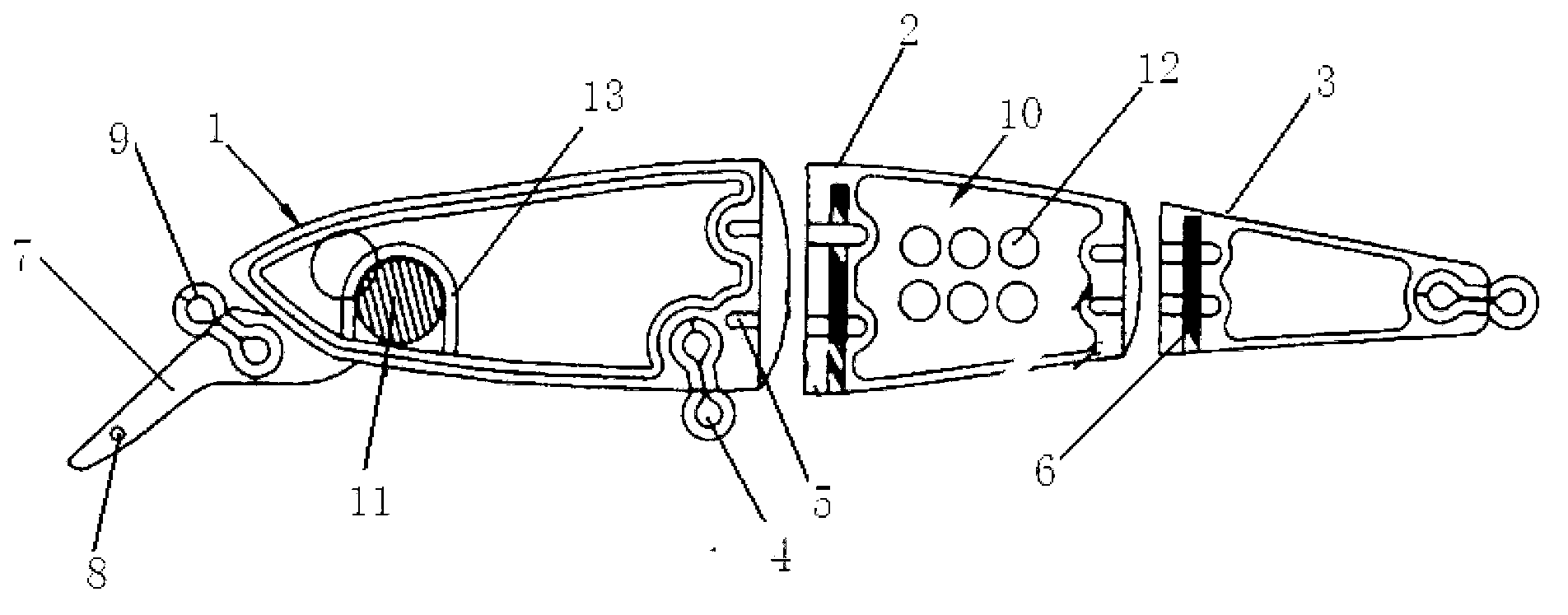

Bait

ActiveCN102907385ASimple and ingenious structureImprove fishing efficiencyBaitZoologyMechanical engineering

The invention discloses a bait which comprises multiple sections of shells made of plastics. The multiple sections of shells are connectedly fastened to form an integrated fish-shaped structure, a plurality of 8-shaped rings connected with fishhooks are mounted on the shells, two single rings are mounted at the rear end of each shell, a stainless steel plug pin is mounted at the front end of each shell, each two adjacent shells are movably sleeved on the corresponding stainless steel plug pin through the corresponding single rings and are movably connected, a baffle board which inclines forward is mounted on the head section of shell and is provided with a plurality of water passing holes, an 8-shaped ring is further mounted on the baffle board, and a hologram paper layer is adhesively attached to the surface of each of the multiple sections of shells. The bait is ingenious in structural improvement and can swing and emit light in water by means of changes of various modes on the shells to attract fish to be got hooked, so that fishing efficiency is improved.

Owner:ANHUI FOSTER FISHING GEAR

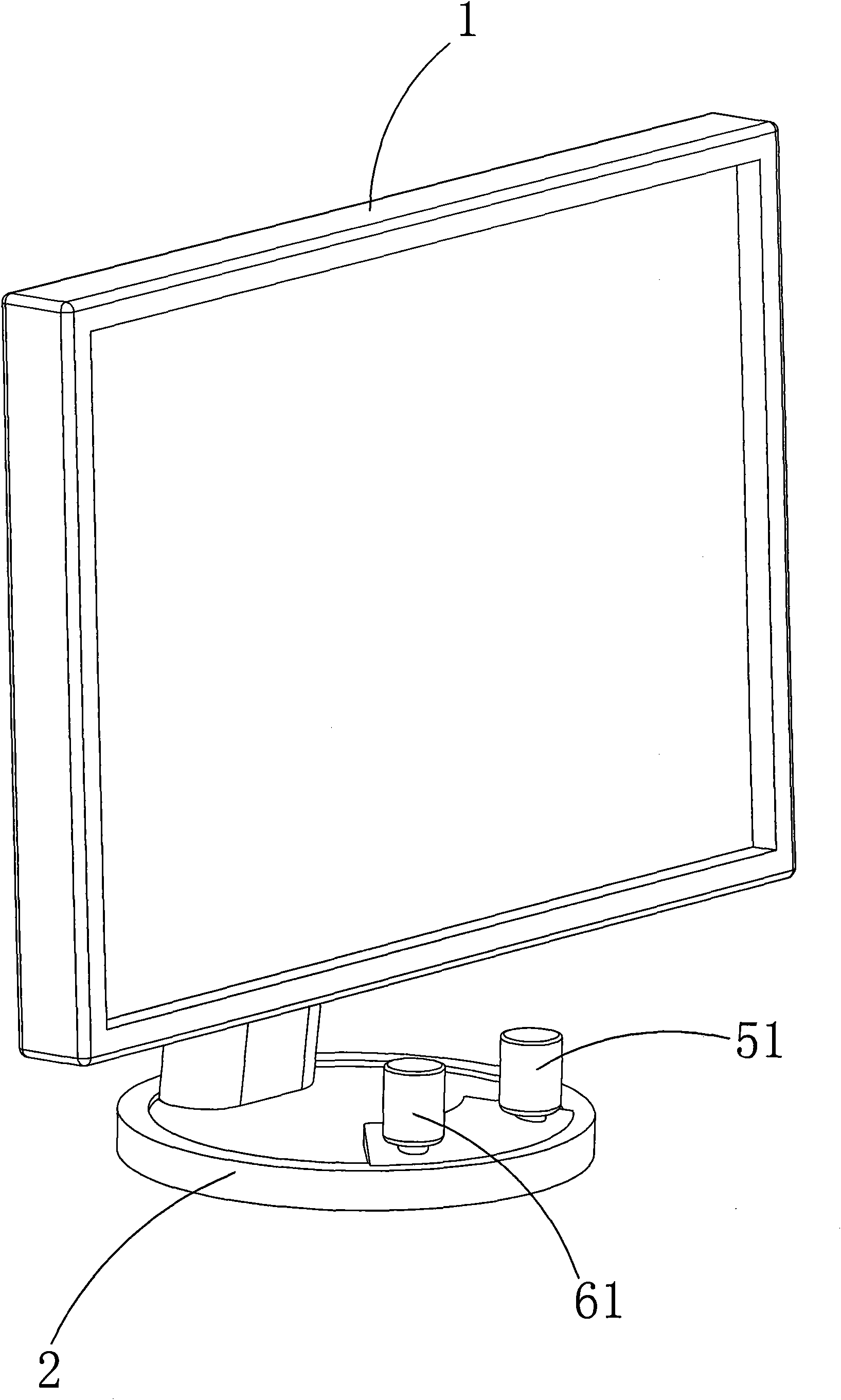

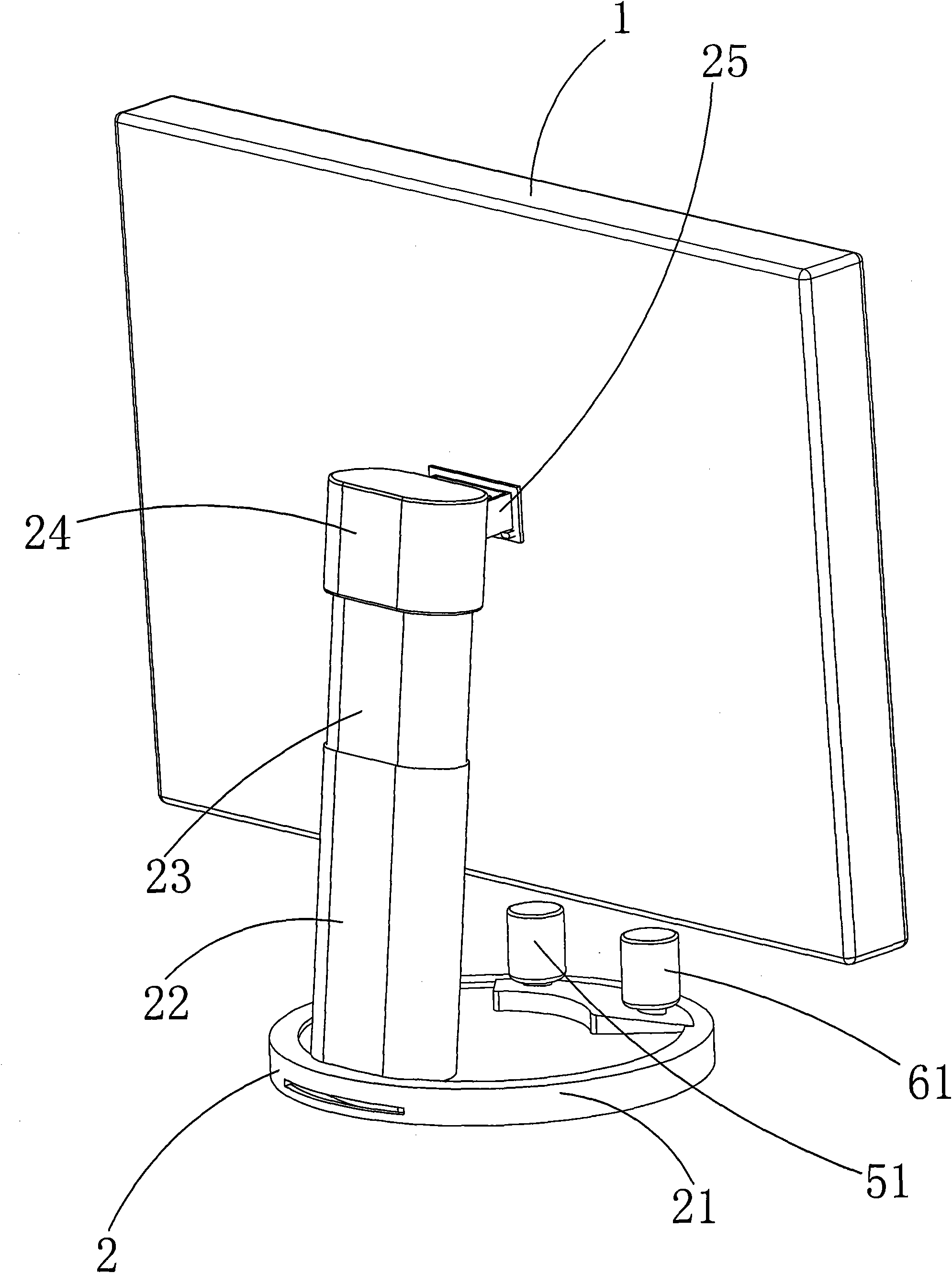

Display and support thereof

InactiveCN101872216ASimple and ingenious structureStable jobDigital data processing detailsGearingDisplay deviceTurning action

The invention relates to a display and a support thereof. The support comprises a base, an adjusting knob, an action conversion device and a steel-wire flexible shaft, wherein the adjusting knob is installed on the base; the action conversion device is connected with a display screen and is used for converting a turning action into a horizontal moving action or the turning action on a different working surface; and one end of the steel-wire flexible shaft is connected and coupled with the adjusting knob and the other end of the steel-wire flexible shaft is connected and coupled with the action conversion device. Since the steel-wire flexible shaft is used for transmitting torque and the action conversion device is used for converting the turning action into the horizontal moving action or the turning action on the different working surface, the invention has the advantages that the adjustment of the height and the pitch angle of the display screen can be controlled by using the knob arranged at the proper position, the structure is ingenious and is simplified, the working is stable, the adjustment is easy and convenient and the operation is easy.

Owner:樊学军

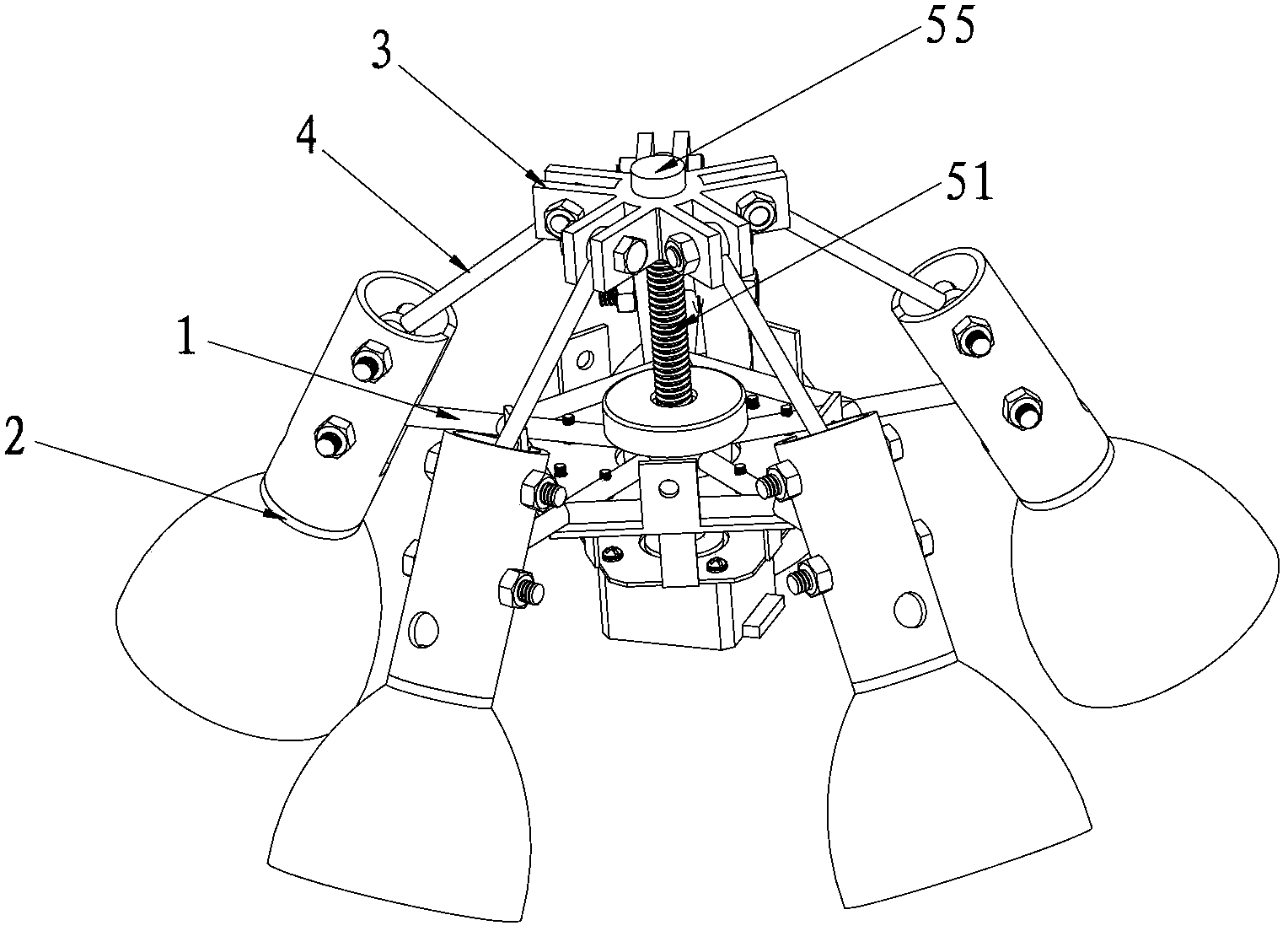

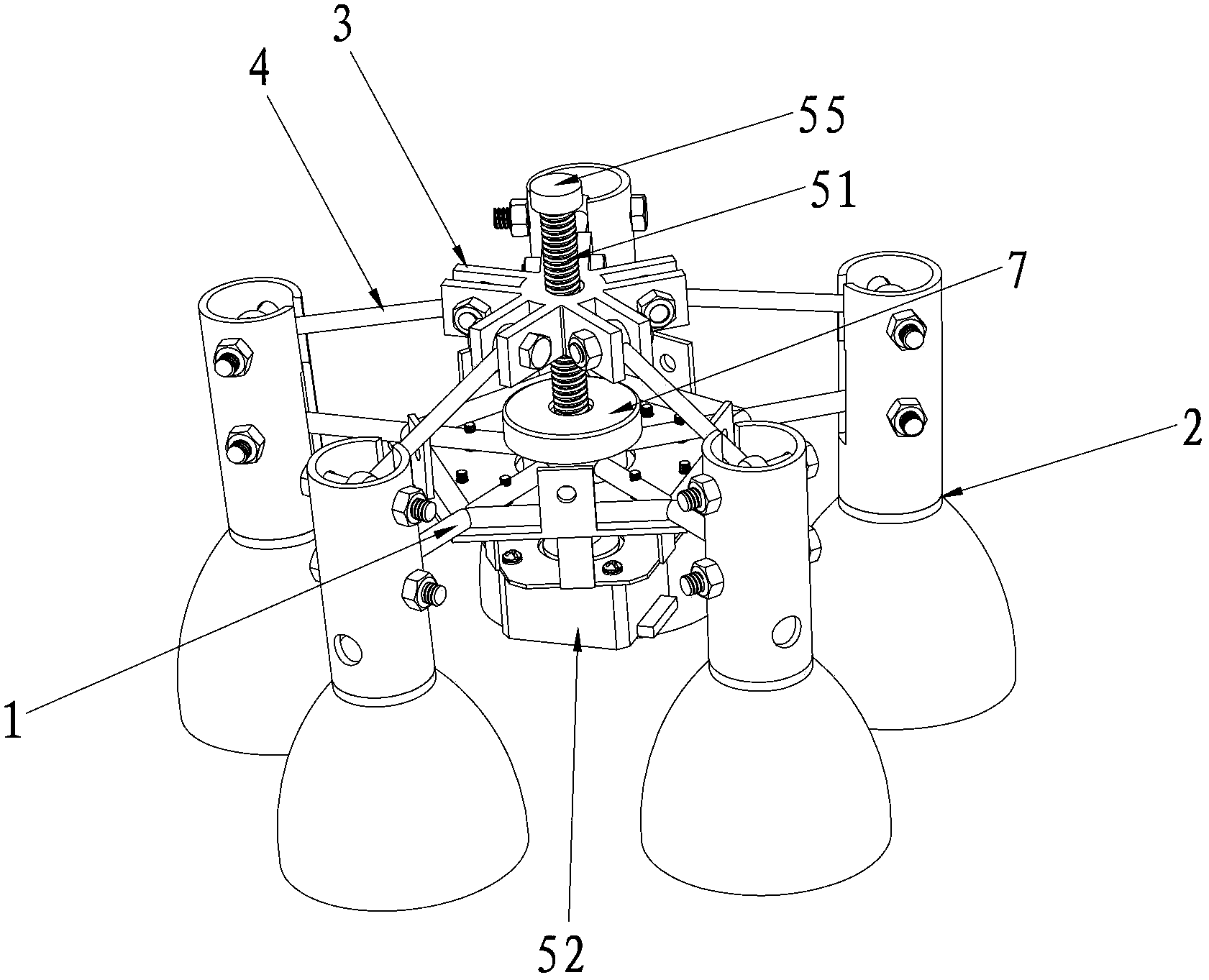

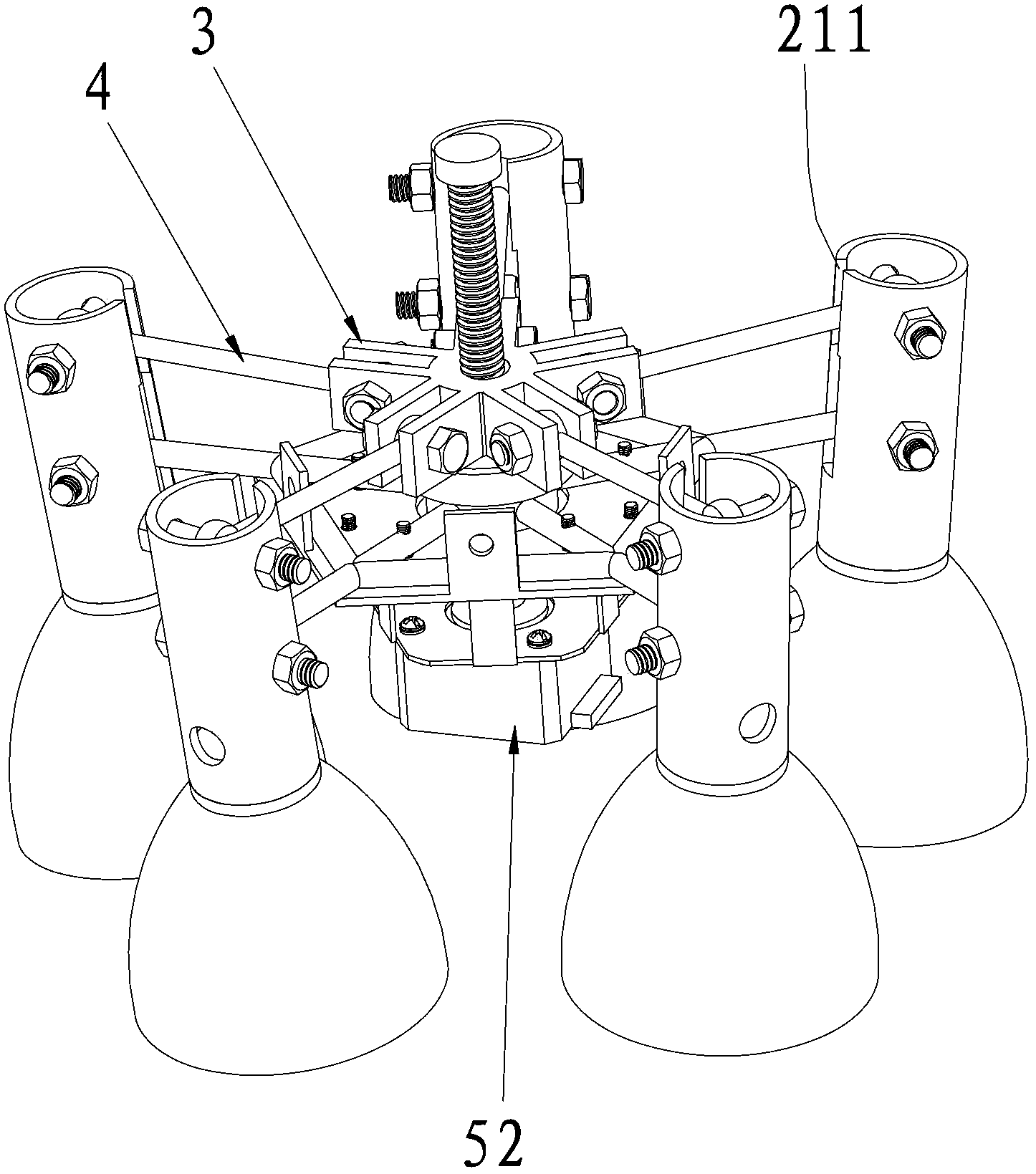

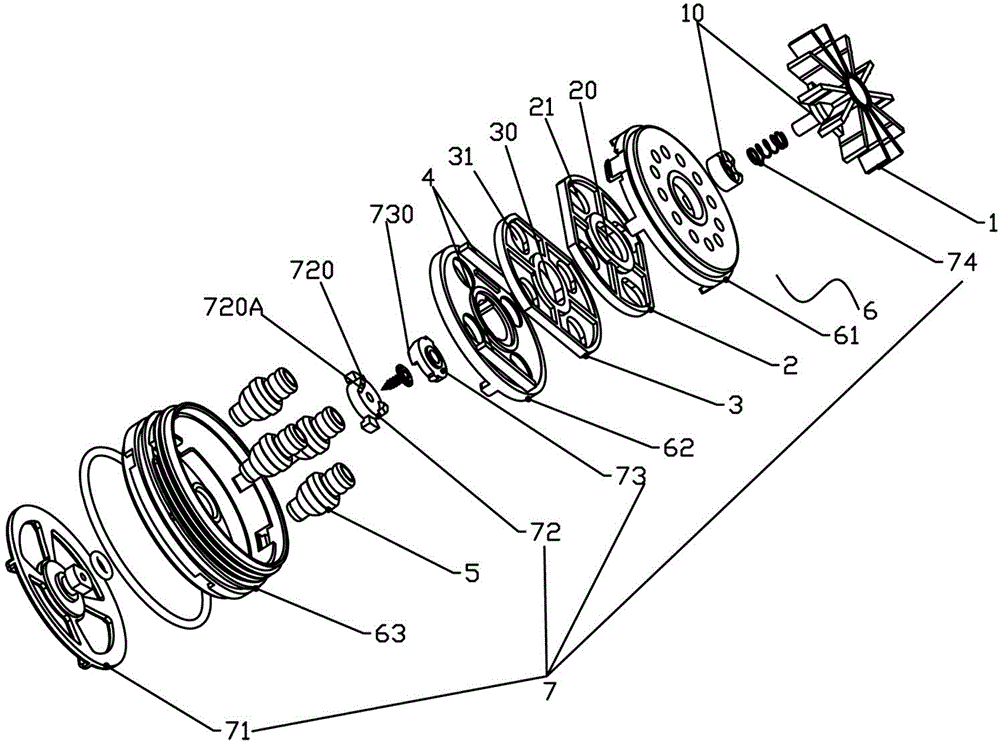

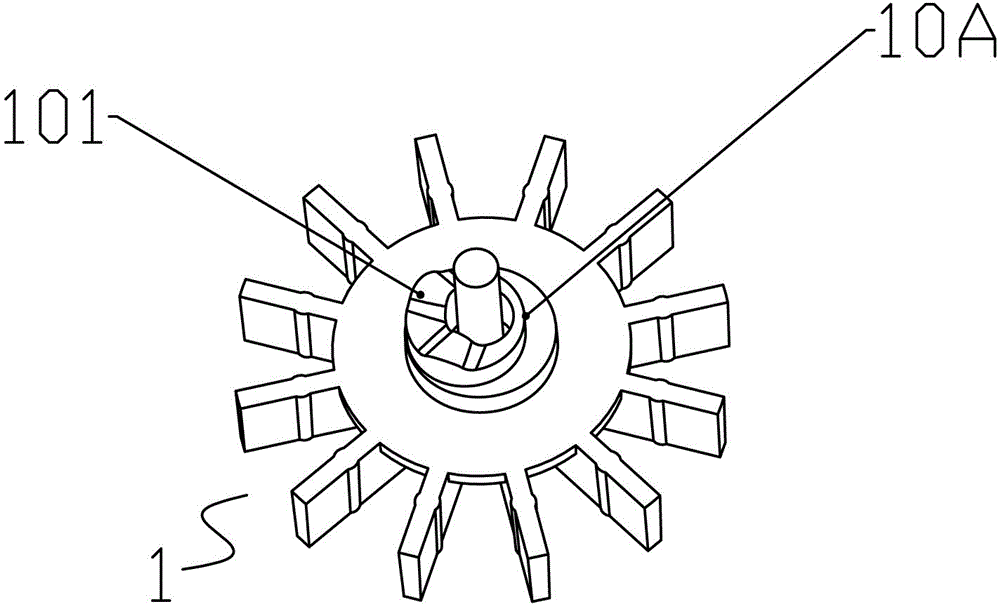

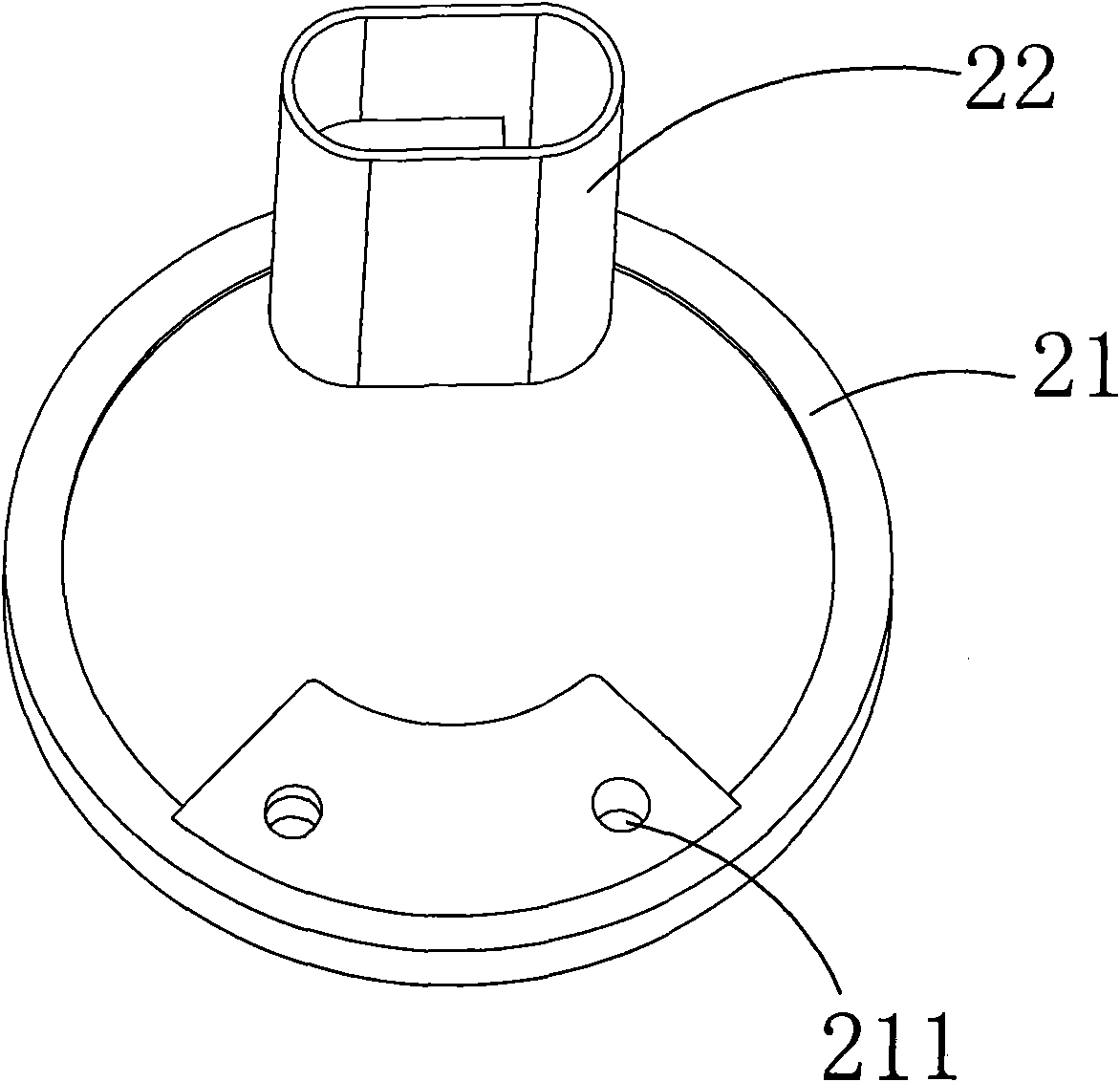

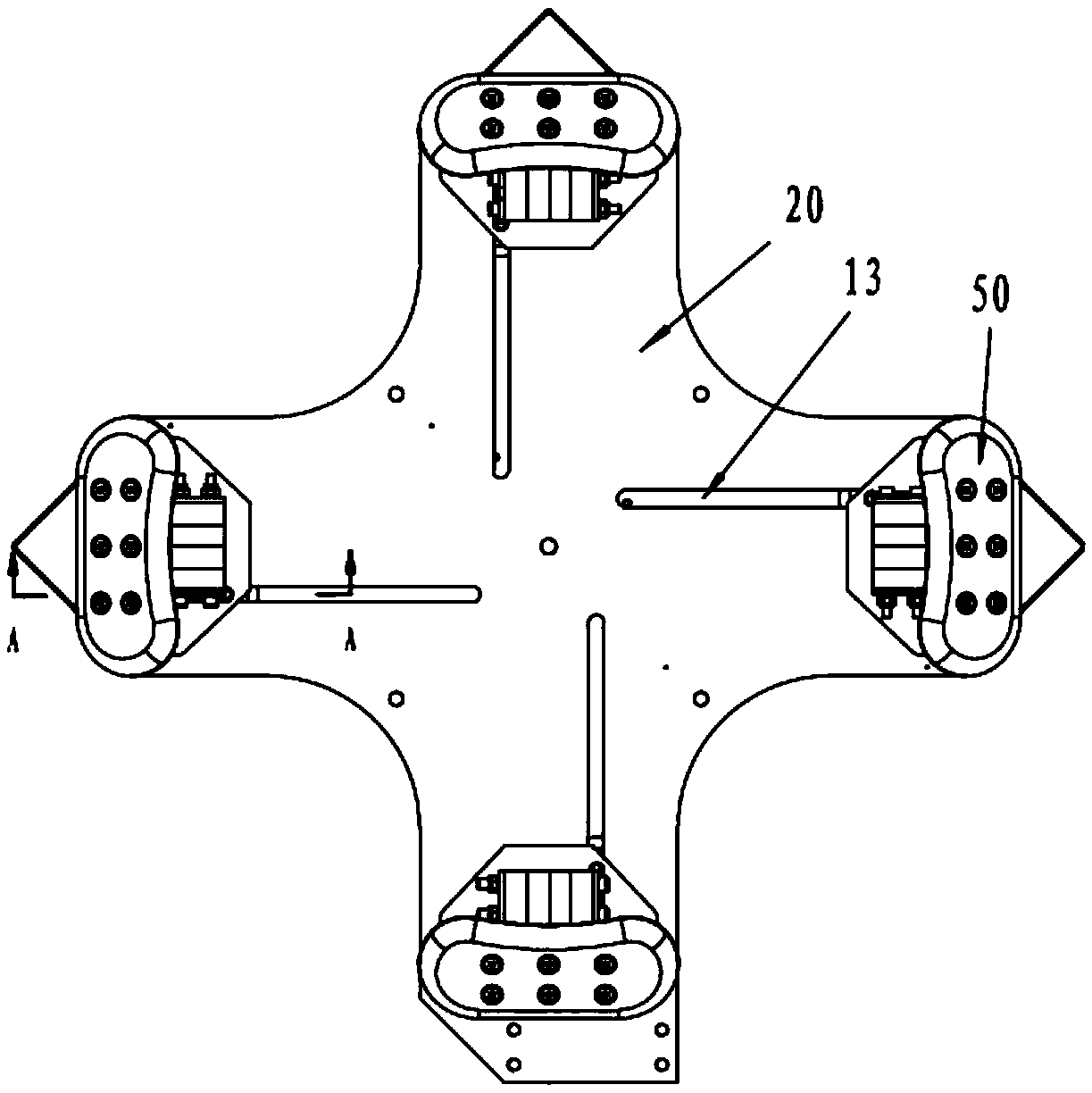

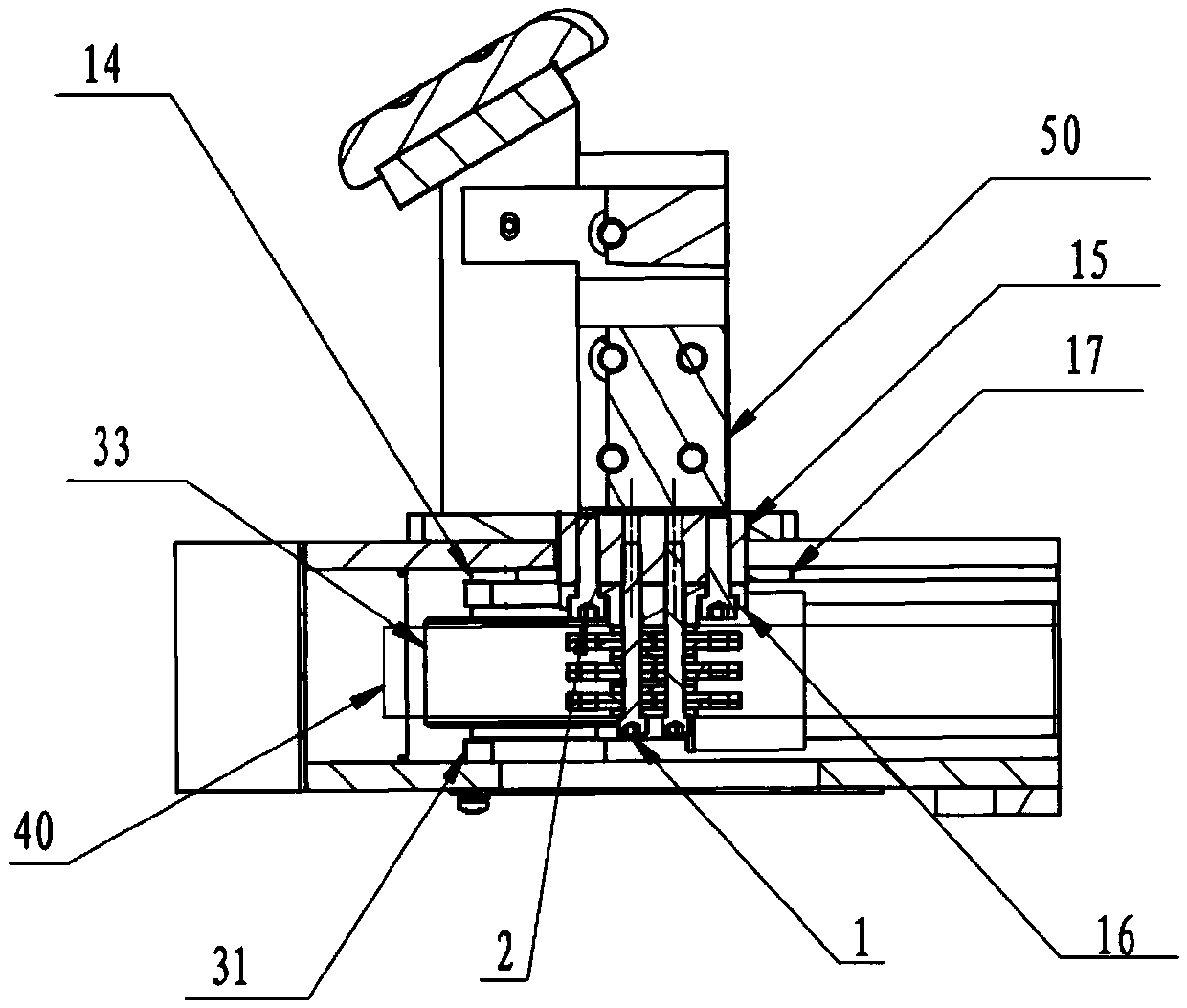

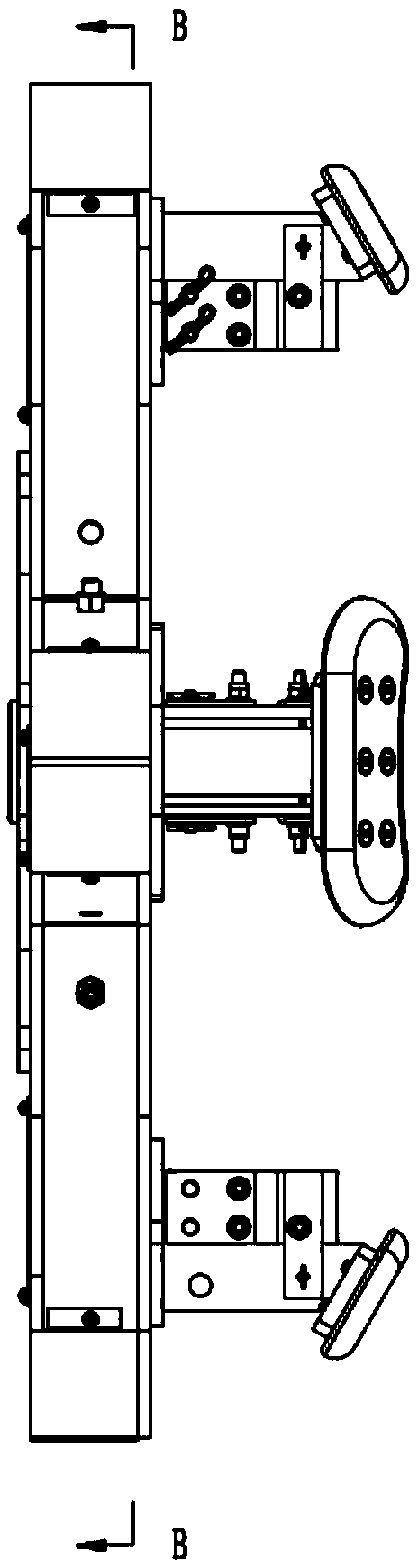

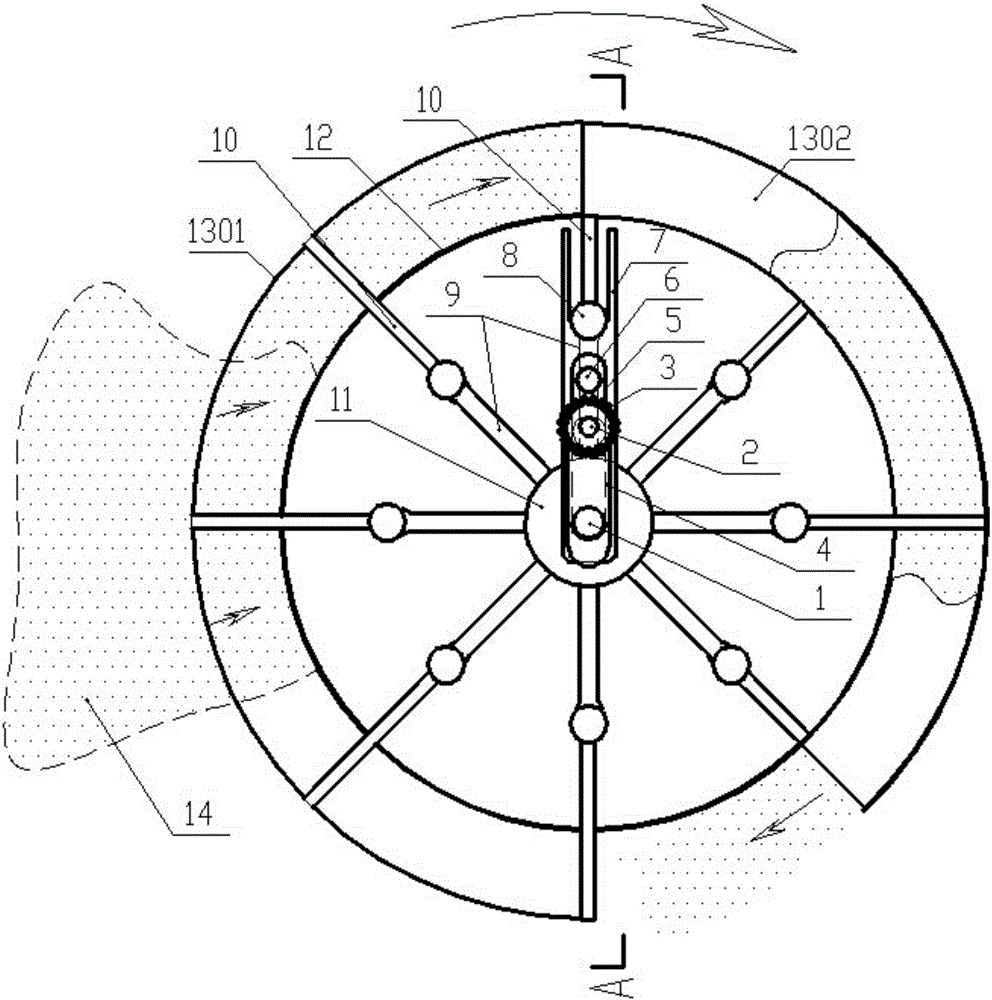

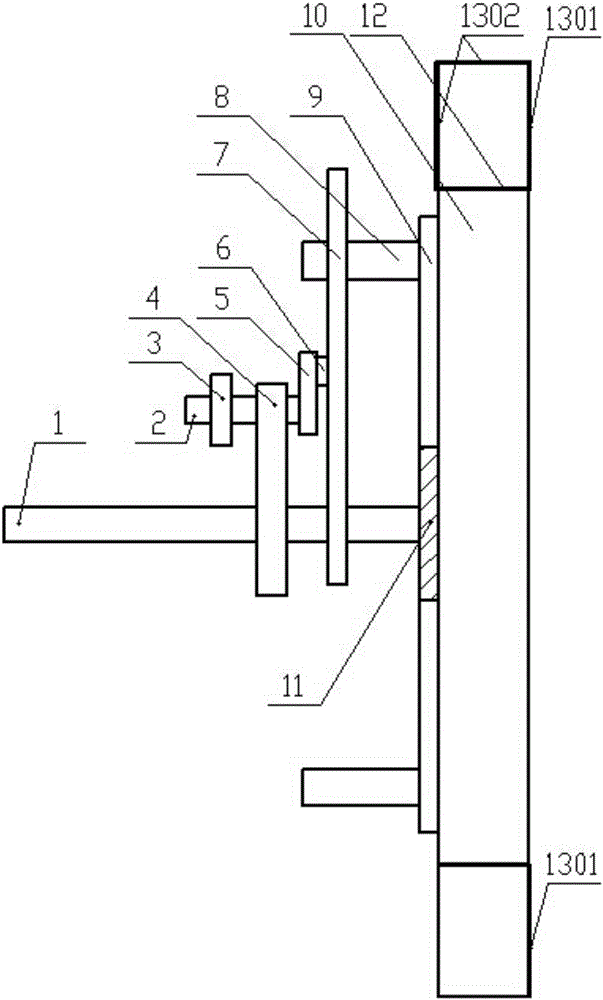

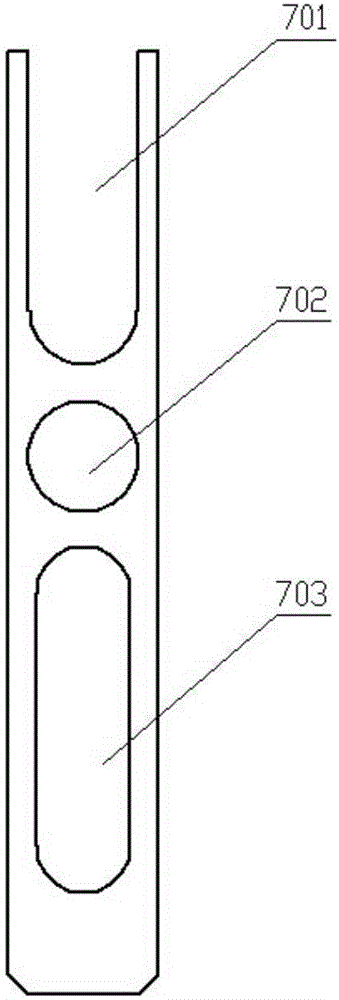

Clamping linkage mechanism and claw disc

The invention discloses a clamping linkage mechanism and a claw disc. Through cooperation of sheave groups and transmission pieces, clamping claws are fixedly arranged on the transmission pieces, one clamping claw is correspondingly arranged at one side of each sheave group, and the clamping claws are distributed in central symmetry with the center of a bottom plate as the center, and move along with the transmission pieces to move towards the center or away from the center synchronously so as to adjust the size of circumference along which the clamping claws are located. In the whole mechanism, only single power is needed to drive each single clamping claw, and the synchronous adjustment of the plurality of clamping claws is realized through the linkage mechanism in the claw disc. The structure is simple and ingenious, the cost is low, and the work efficiency is high.

Owner:VATAPLE MACHINERY KUNSHAN

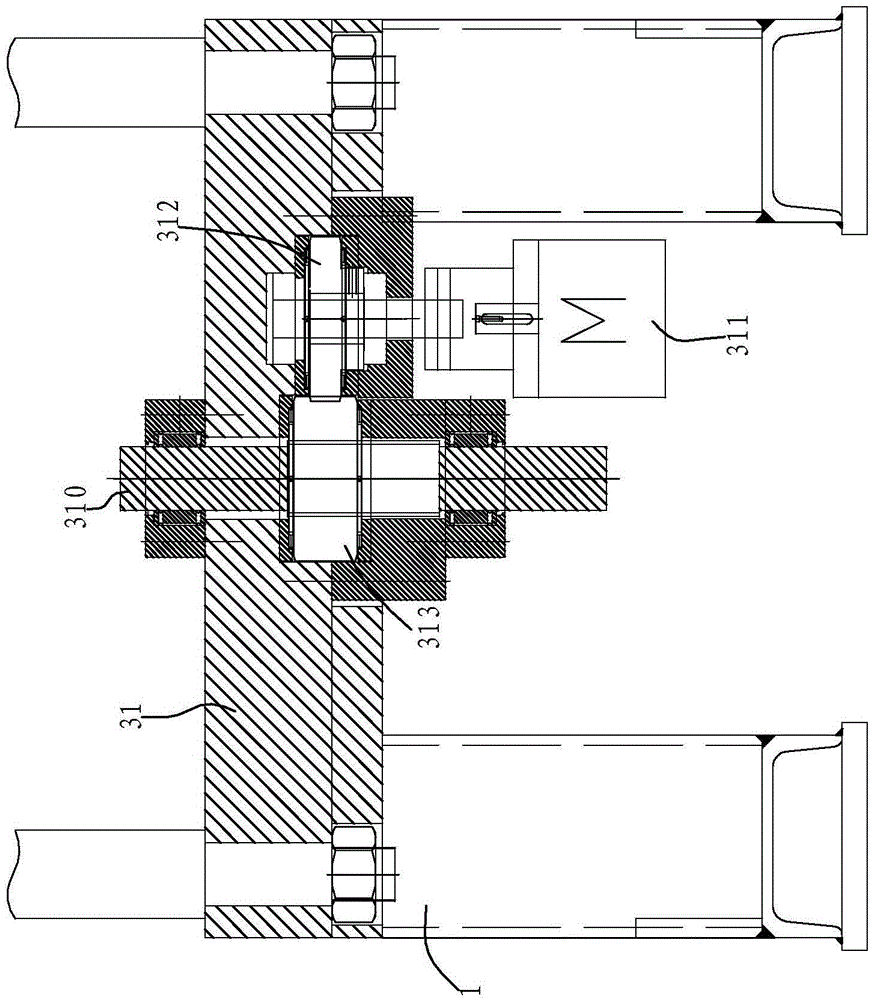

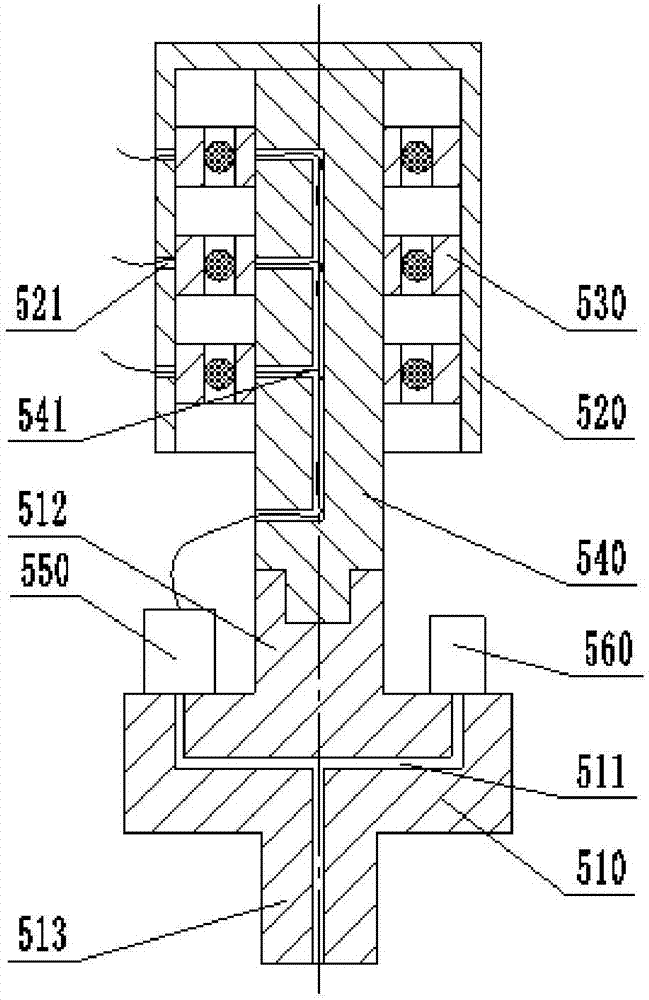

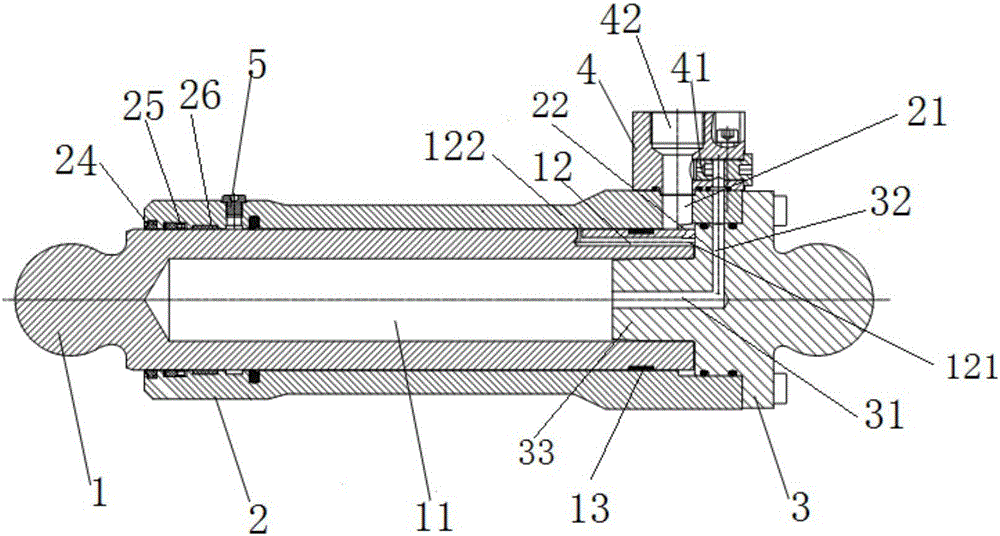

Plunger cylinder, pumping system swing valve mechanism and concrete pumping equipment

InactiveCN106224325ASimple and ingenious structureImplement bufferingFluid-pressure actuatorsPlungerConcrete pump

The invention relates to a plunger cylinder, a pumping system swing valve mechanism and concrete pumping equipment. The plunger cylinder comprises a plunger rod, a cylinder barrel and a cylinder bottom, wherein the cylinder barrel is provided with a first end and a second end; the plunger rod is movably sleeved in an inner cavity of the cylinder barrel from the first end of the cylinder barrel and is tightly attached to the side wall of the cylinder barrel; the cylinder bottom is located at the second end of the cylinder barrel; the plunger cylinder is provided with an oil opening and a first oil channel which enables the oil opening and the inner cavity to communicate; and the plunger cylinder is further provided with a throttling oil channel, and the throttling oil channel and the first oil channel are connected between the oil opening and the inner cavity in parallel. The plunger rod can block the first oil channel while retracting under stress so that hydraulic oil of the inner cavity can flow towards the oil opening after being throttled mainly by the throttling oil channel, and then buffering of the plunger rod is achieved through throttling on the hydraulic oil; and the hydraulic oil at the oil opening is supplied to the inner cavity mainly through the first oil channel in the outward extension process of the plunger rod, and accordingly normal operation of the plunger rod is achieved.

Owner:BEIQI FOTON MOTOR CO LTD

Back rocker locking mechanism for swivel chair chassis

ActiveCN104207520BAchieve lockingEasy to controlStoolsAdjustable chairsLocking mechanismTorsion spring

Owner:UE FURNITURE CO LTD

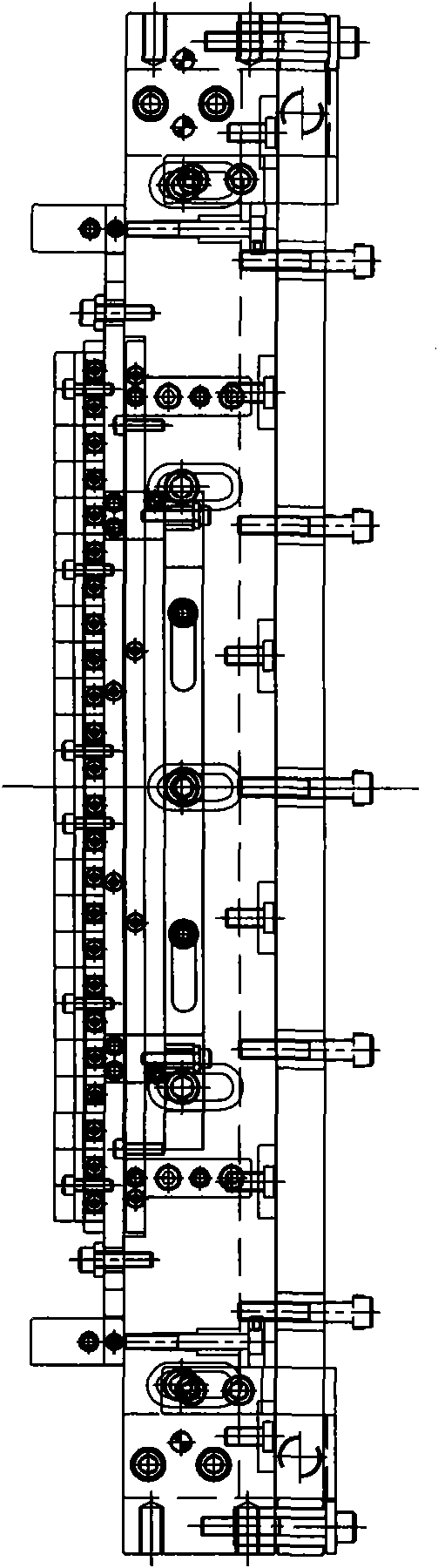

Moving adjusting mechanism for transverse cutting sub-die

The invention relates to a moving adjusting mechanism for a transverse cutting sub-die. The moving adjusting mechanism comprises moving air cylinders and compressing oil cylinders; the cylinder bodies of the moving air cylinders are fixed on a large die plate, and the piston rods of the moving air cylinders are connected on the shelf of the transverse cutting sub-die through thrust shafts; when the piston rods of the moving air cylinders are retracted, the transverse cutting sub-die is located at an odd-hole transverse cutting position or an even-hole transverse cutting position, and the travel of the piston rod of each moving air cylinder is one step; the cylinder bodies of the compressing oil cylinders are fixed on the lower part of the large die plate, the piston rods of the compressing oil cylinders upwardly pass through the large die plate and are connected with T-shaped blocks, the upper parts of the T-shaped blocks are connected with springs, and the other ends of the springs are compressed by pressing blocks; the shelf of the transverse cutting sub-die is provided with a first socket and a second socket which correspond to the T-shaped blocks, and when the transverse cutting sub-die is located at the odd-hole transverse cutting position or the even-hole transverse cutting position, the T-shaped blocks are respectively embedded into the first and the second sockets. The moving adjusting mechanism with a simple and ingenious structure can conveniently, quickly and accurately adjust the position of the transverse cutting sub-die.

Owner:WUXI MICRO RES

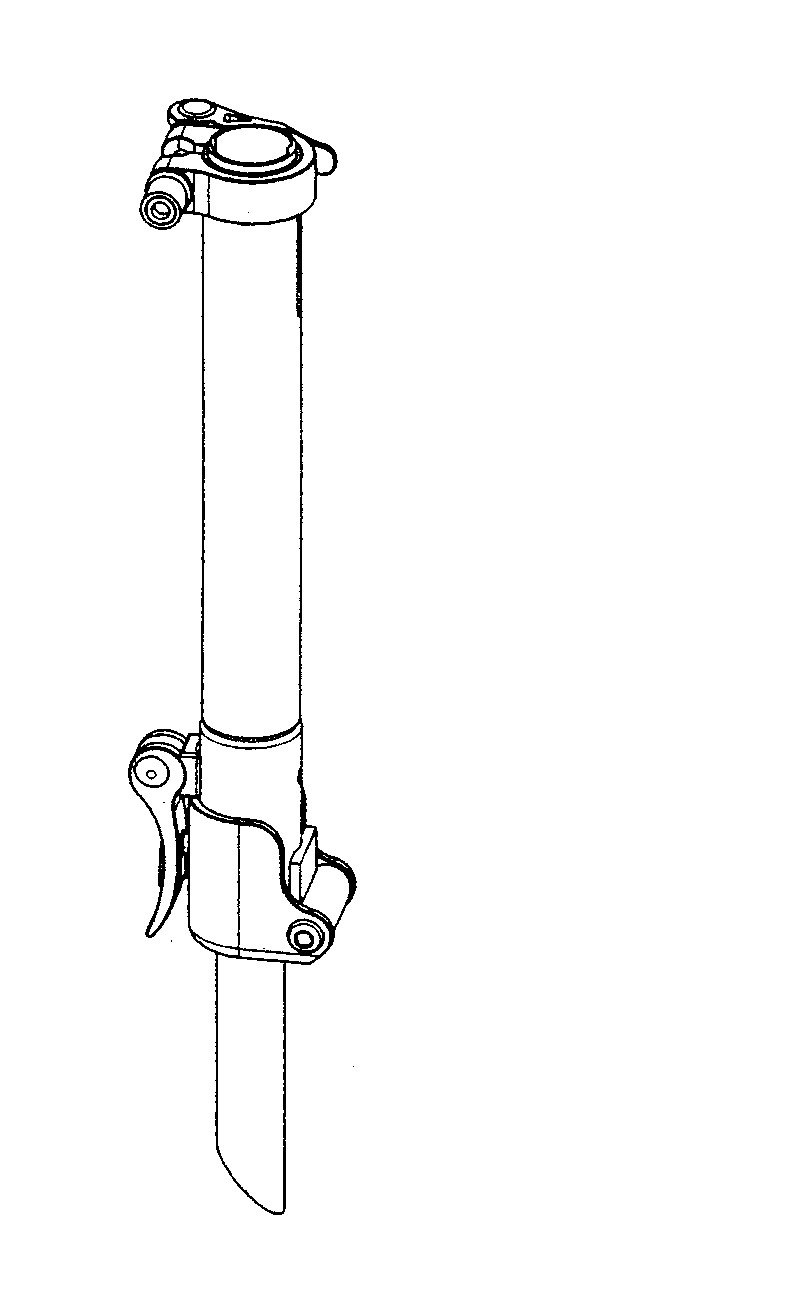

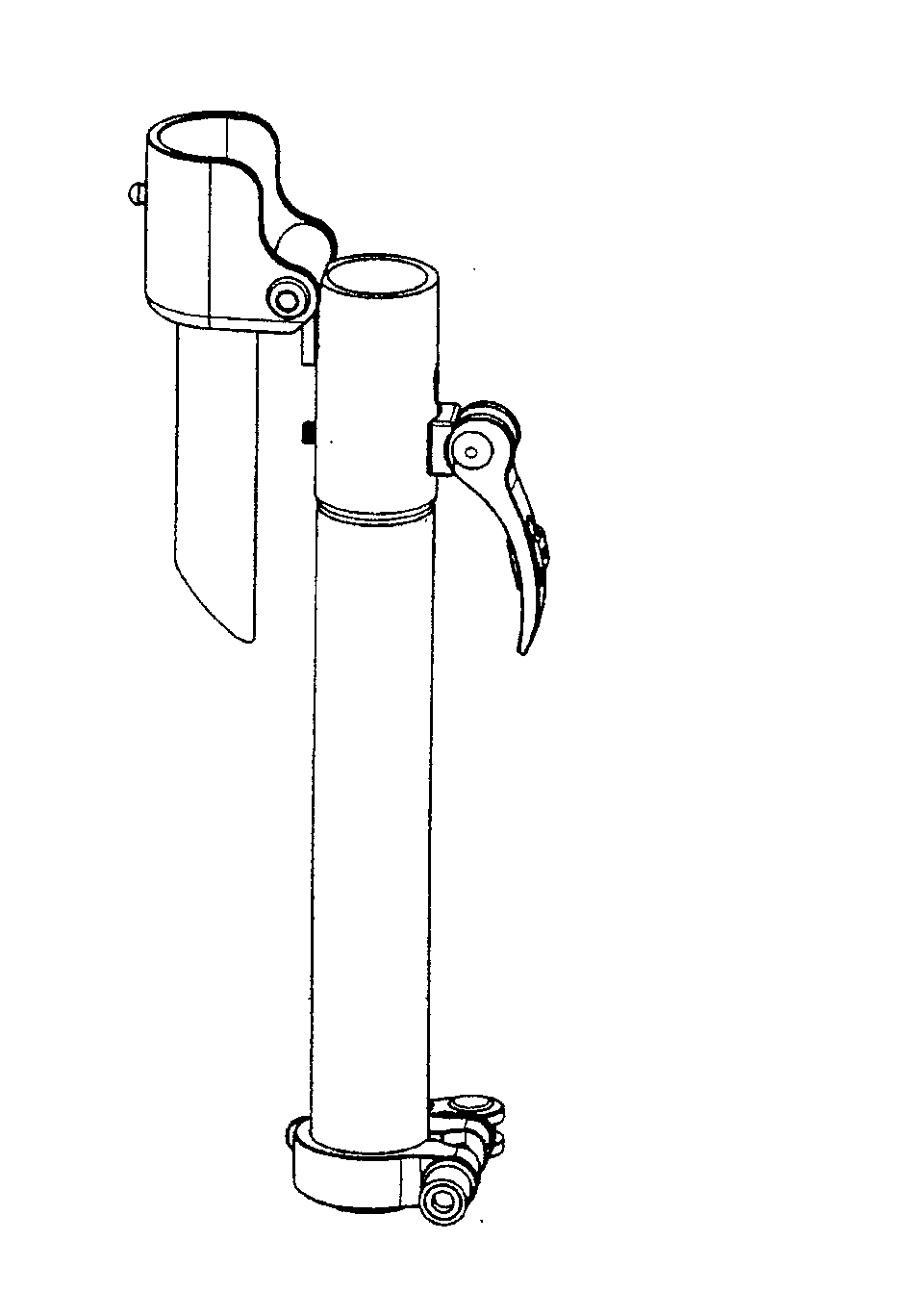

Semicircle-meshing folding handle vertical tube fast to demount and lock and having internal wedged bolt

ActiveCN103057645ASimple and ingenious structureFast and secure lockSteering deviceFastenerVertical tube

A semicircle-meshing folding handle vertical tube fast to demount and lock and having an internal wedged bolt comprises an upper part, a lower part, butt-locking bolts, a fast detacher, a security fastener, an internal wedged bolt, a handle vertical tube and an inner extending tube. The upper part is provided with a bottom circular hole and a middle butt through hole, and a guide hole is arranged below the butt through hole. The handle vertical tube is connected to the upper portion of the upper part. The lower part is a semicircular pocket provided with two lower lug holes. The lower part is provided with an upper locking hole and a lower threaded hole. The inner extending tube is welded to the bottom of the lower part. The lower part is connected with the upper part through the butt-locking bolts. A ring-head bolt of the fast detacher penetrates through a hole of a plastic spacer, the butt through hole of the upper part and a spring and is then tightened into the threaded hole of the inner wedged bolt. The inner wedged bolt is a stamping provided with an upper threaded hole and a lower oblique hook. The oblique hook of the inner wedged bolt is locked into the locking hole of the lower part. A push button and a security plate in the security fastener are slidably connected inside an elongated hole of a fast detacher handle. The ring-head bolt is tightened into the threaded hole of the lower part, and after locking, a security plate of the fast detacher handle hooks the neck of the ring-head bolt.

Owner:嘉善县临沪新城实业有限公司

Water supply device capable of controlling water level accurately

ActiveCN101825905ASimple and ingenious structurePrecise level controlLevel controlEngineeringWater tanks

A water supply device capable of controlling water level accurately comprises a water feeding pipe, a water discharge pipe and a water tank; the water tank is connected with the water feeding pipe and the water discharge pipe and is internally provided with a water level control valve subassembly; the water level control valve subassembly comprises a cavity internally provided with a sealing glue pad, a floating tube and a supporting pillar; the water pressure area at the bottom of the sealing glue pad is greater than that of the upper plane thereof; the sealing glue pad can be moved upwards and downwards by means of the pressures of upper and lower water; the supporting pillar is fixed above the floating tube; a release hole is formed at the bottom of the valve cavity at the position corresponding to the supporting pillar; a water inlet and a water outlet are formed on the valve cavity, and the water inlet is connected with the water feeding pipe. The device has simple and skilful design, accurate liquid level control effect, less stored water and highly accurate water feeding effect. The product by using the design of the device can be ultra-minimized and thinned. The raw material can be saved a lot, the cost can be reduced, and the product reliability is high. The invention can be widely applied to the product with water level to be controlled such as water boiler and water dispenser, thereby having great social and economical benefits.

Owner:周守国

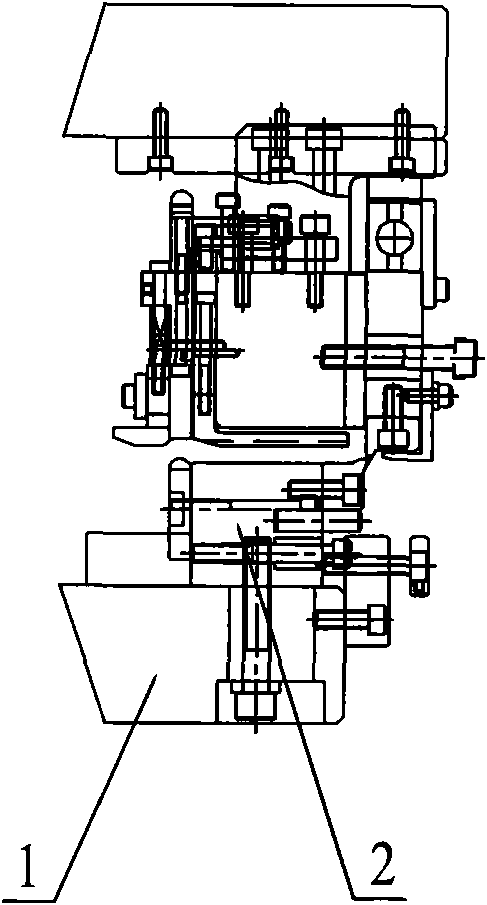

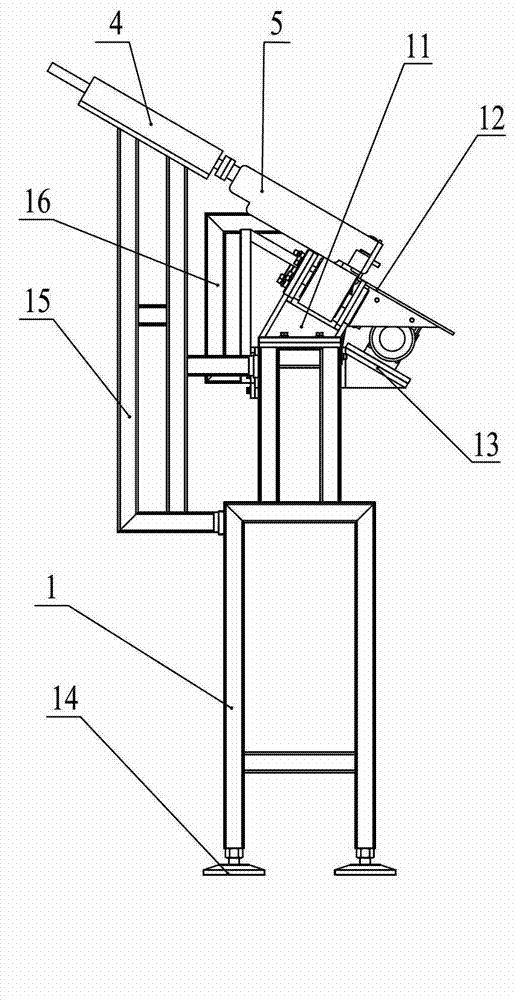

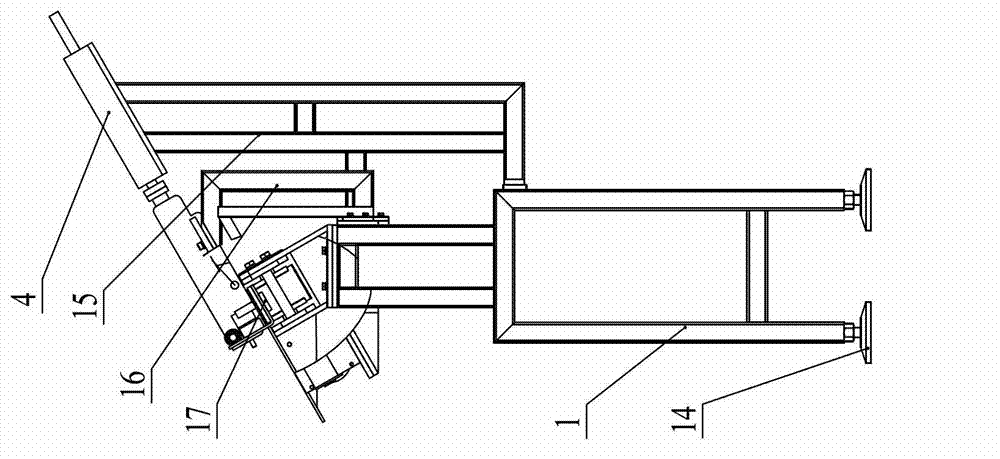

Synchronous material pushing mechanism in feeding system of roll coater

ActiveCN102962178ASimple and ingenious structureConvenience and orderly transmission operationLiquid surface applicatorsCoatingsElectric machineryMotor speed

The invention relates to a synchronous material pushing mechanism in a feeding system of a roll coater. A belt wheel base is fixedly mounted on a rack; a driving synchronous pulley is mounted at one end of the belt wheel base, and a driven synchronous pulley is mounted at the other end of the belt wheel base; the driven synchronous pulley and the driving synchronous pulley are connected and in transmission through a synchronous belt; the synchronous belt is arranged in an inclined manner; a blocking board parallel to the synchronous belt is arranged at one lower side of the synchronous belt; a motor speed reducer is mounted at one end of the rack, which is close to the driving synchronous pulley, through a motor mounting base; an output shaft of the motor speed reducer is directly connected with the driving synchronous pulley; a material pushing air cylinder is mounted at one end on the rack, which is near the driven synchronous pulley, through an air cylinder supporting rack; a piston rod end of the material pushing air cylinder is connected with a material pushing mechanical arm; and the material pushing mechanical arm is used for pushing a work piece on the synchronous belt. The synchronous material pushing mechanism provided by the invention can be used for pushing work pieces which are orderly arranged to a synchronous feeding mechanism, and has the advantages of simple and smart structure, convenience and orderliness in transmission operation and the like.

Owner:WUXI HUANENG SURFACE TREATMENT

Automatic grain metering device

InactiveCN106017593ASimple and ingenious structureLow production costStationary measuring chambersEngineeringSpoke

The invention discloses a grain automatic metering device, which comprises a casing and a rotor assembly inside the casing, the casing includes an arc floor and a curved angle steel covered on the arc bottom plate; the rotor assembly includes a fixed mandrel on which a The support plate and the center wheel that can rotate around the mandrel; the center wheel is uniformly provided with spokes in a radial shape, and the end of the spoke is provided with a cylinder on the side facing the support plate, and a scraper is connected to the side away from the support plate, and two adjacent scrapers There is an arc-shaped partition between them, and a rotating shaft parallel to the mandrel runs through the supporting plate. One end of the rotating shaft is provided with a gear, and the other end is provided with a connecting rod hinged to the sliding fork. The sliding fork is a rectangular plate structure and The plate surface is perpendicular to the rotating shaft. One end of the sliding fork is provided with a strip-shaped through chute set on the mandrel. Sporty U-shaped forks. The device can automatically and continuously weigh grain, and is easy to monitor failures.

Owner:王华银

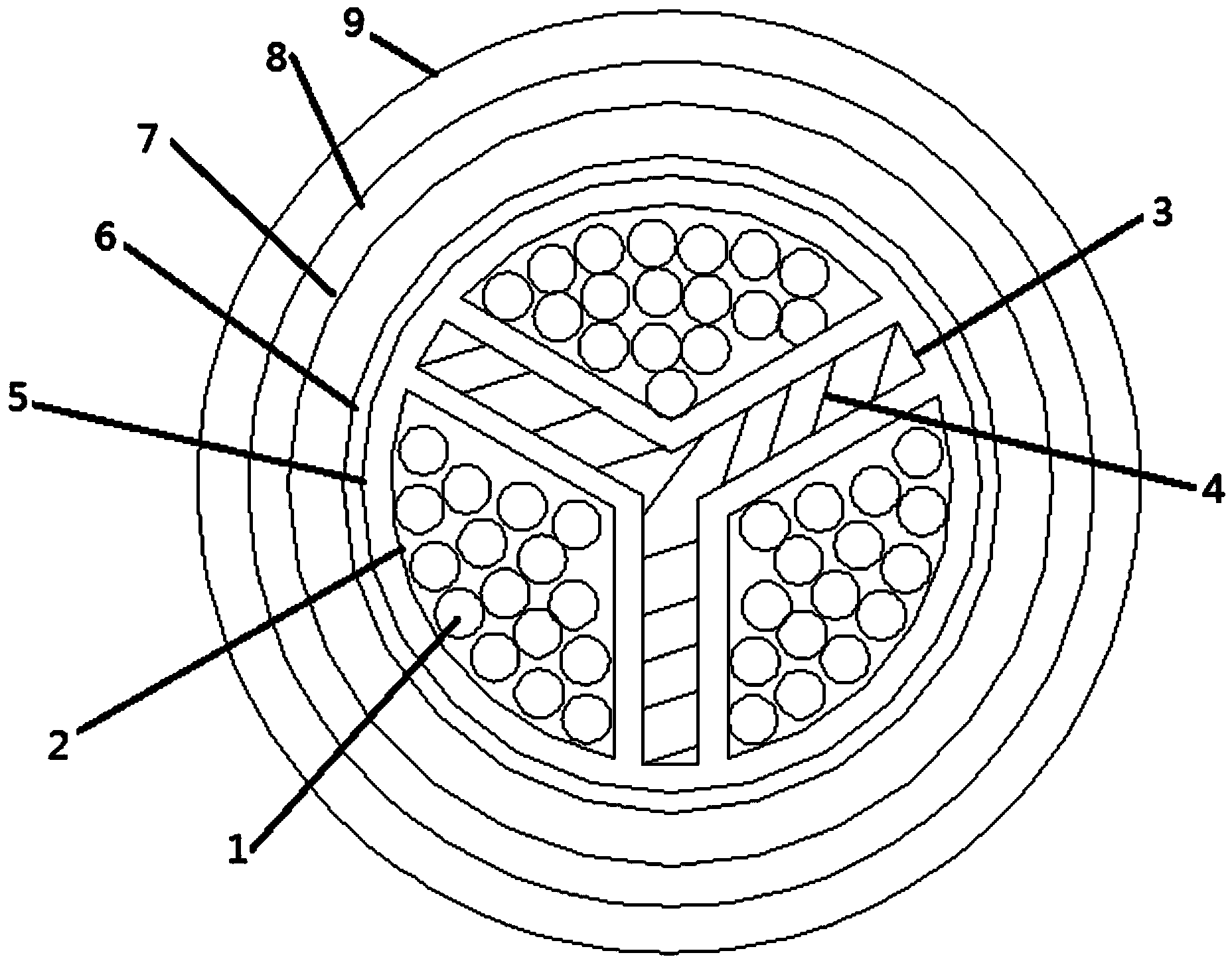

High-temperature resistant sector conductor cable

ActiveCN103928137AClosely arrangedImprove toughnessInsulated cablesInsulated conductorsFiberCopper conductor

The invention discloses a high-temperature resistant sector conductor cable which comprises multiple tinned copper conductors. The tinned copper conductors are stranded to form three sector wire cores, the three sector wire cores are distributed in an annular structure, a Y-type nylon framework is arranged among the three sector wire cores, high-temperature resistant fiber filaments are lapped and overlapped on the outer surface of the Y-type nylon framework, an insulating layer covers the three sector wire cores, and a high fire resistant fiber band isolation layer, an alkali-free glass fiber cloth wrapping tape layer, a metal shielding layer and a sheath layer wrap the insulating layer in sequence. The high-temperature resistant sector conductor cable is ingenious in structure improvement, the sector wire cores are arranged compactly, the framework with the high-temperature resistant fiber filaments is arranged, and the high-temperature resistance performance and the mechanical properties of the cable are improved integrally.

Owner:河北众邦电缆有限公司

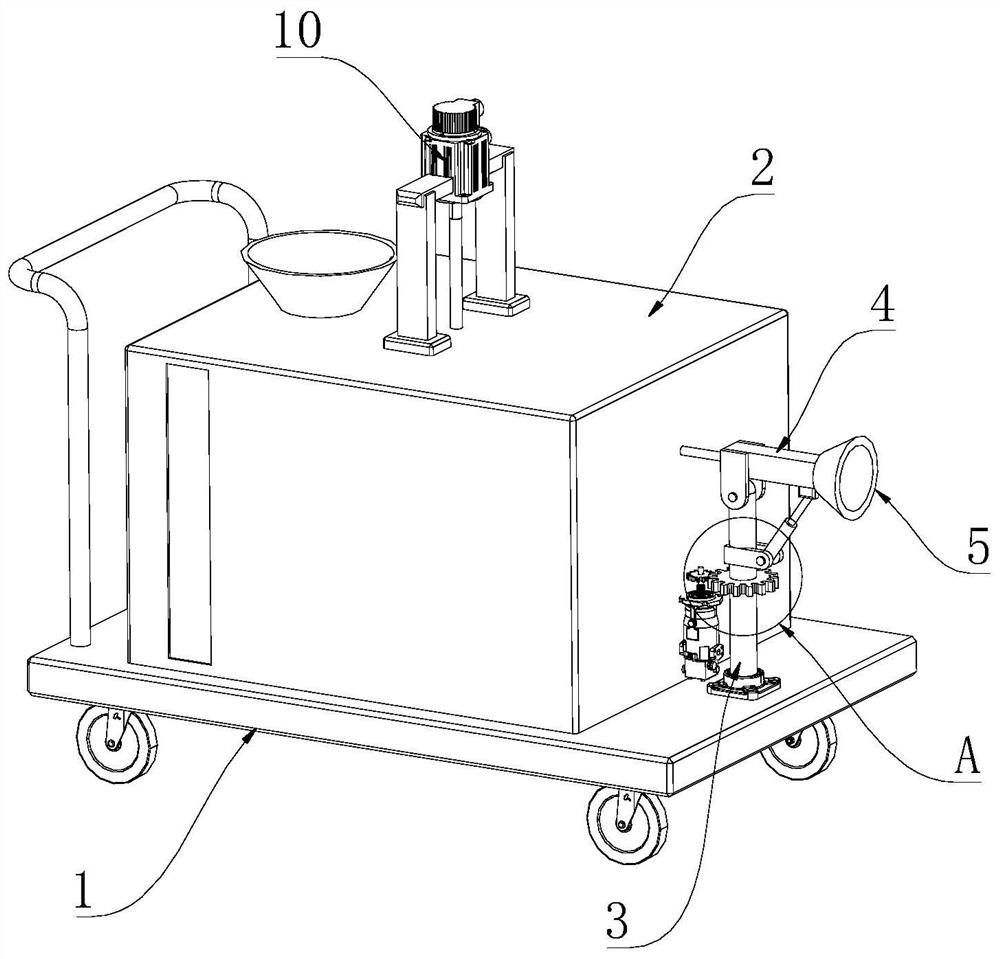

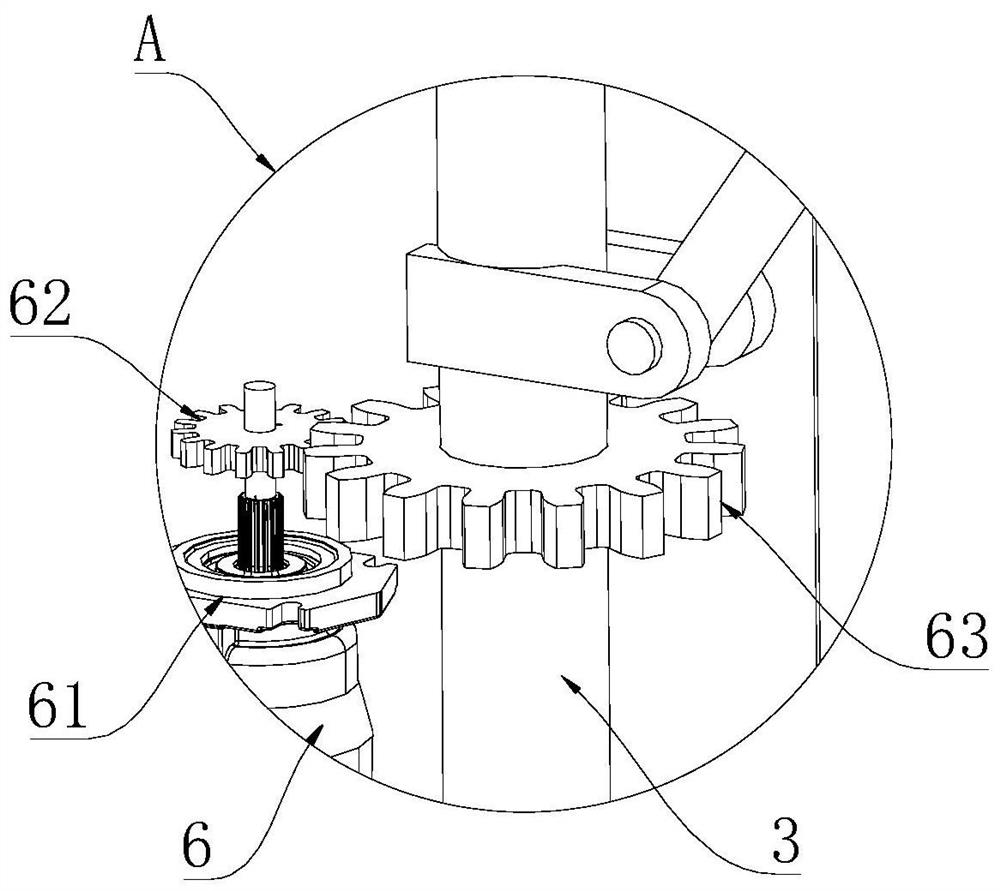

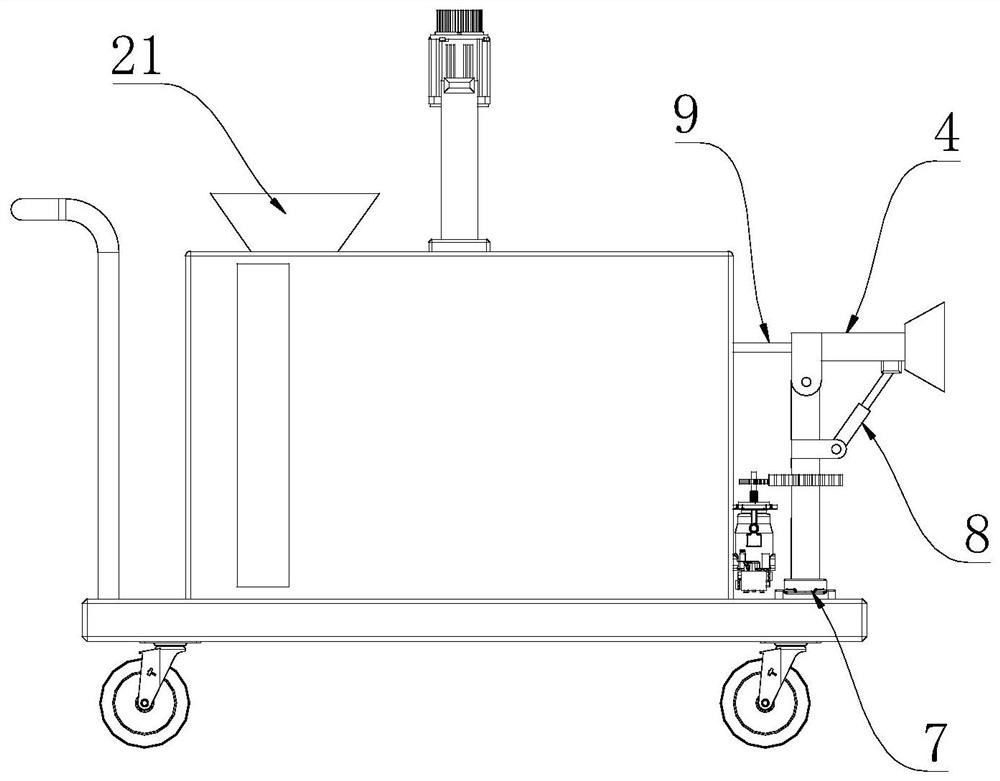

Agricultural hydraulic single-drive watering device

PendingCN112136660AExpand the scope ofImprove applicabilityWatering devicesSpraying apparatusAgricultural engineeringAgriculture

The invention discloses an agricultural hydraulic single-drive watering device which comprises a movable frame, a water tank installed on the movable frame, a spray head connected with the water tankand a flow dividing pipe horizontally arranged and connected with the water tank. The inlet end of a water spraying pipe is opposite to the inlet end of a horizontal pipe section, and the outlet end of the water spraying pipe is connected with the spray head; an axial-flow type turbine is further rotationally installed in the horizontal pipe section, and the axis of the axial-flow type turbine iscoaxial with the axis of the horizontal pipe section so that the axial-flow type turbine can be pushed to rotate when water flows into the horizontal pipe section; and a driving bevel gear is fixedlyconnected to the front end of a rotating shaft of the axial-flow type turbine, a driven bevel gear is meshed with the lower portion of the driving bevel gear, a vertically-arranged water supply pipe is coaxially and fixedly connected with a gear shaft of the driven bevel gear, and the water supply pipe is arranged outside the side wall of the horizontal pipe section and connected with a sprinklerhead. The agricultural hydraulic single-drive watering device is convenient to use, multi-dimensional in watering and high in efficiency.

Owner:重庆知遨科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com