Sucker and sucking method thereof

A suction cup and suction cup base technology, applied in suction cups, connecting components, mechanical equipment, etc., can solve the problems of easy installation by consumers, the suction cup cannot work effectively, the installation procedure is complicated, etc. Humanized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

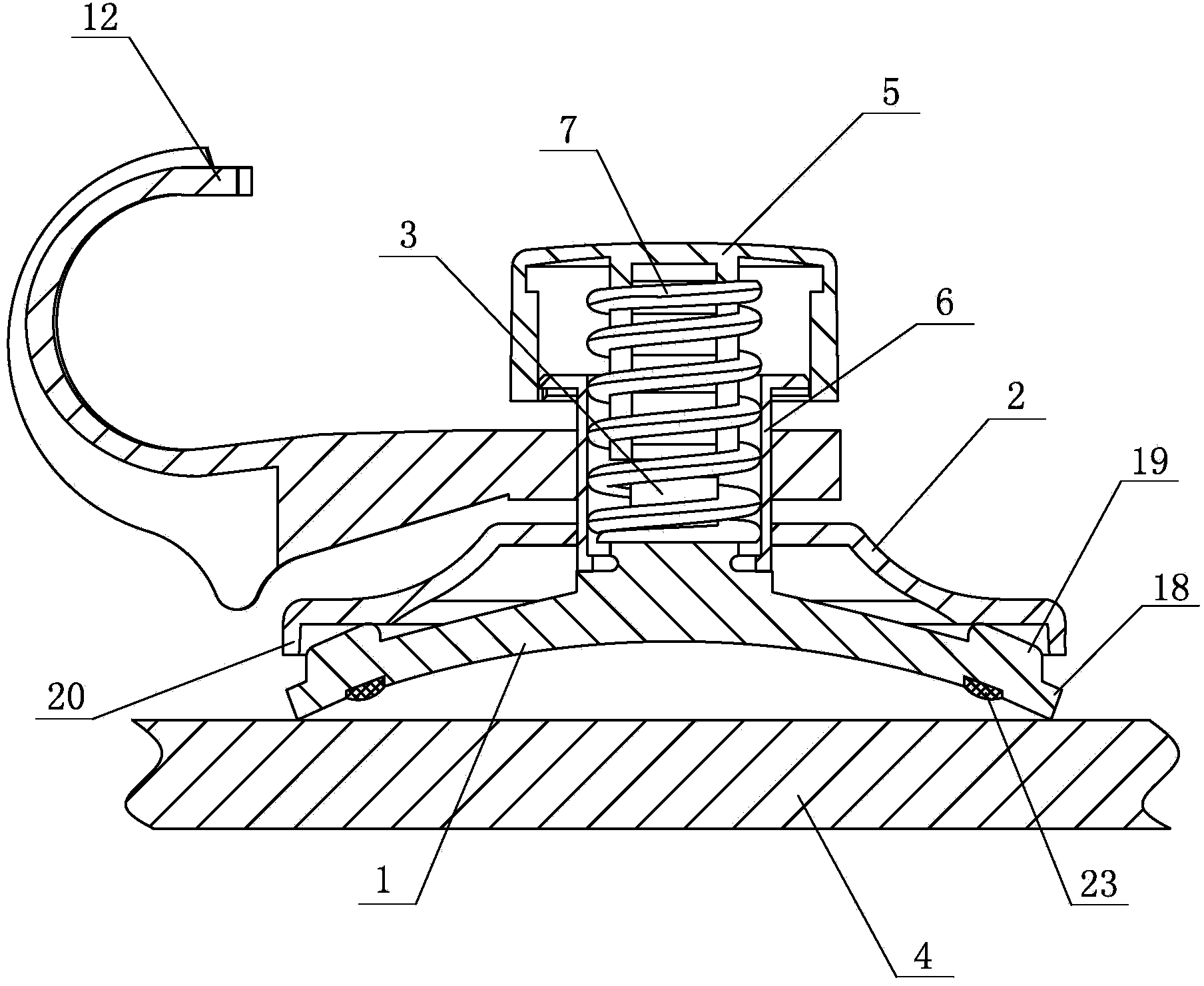

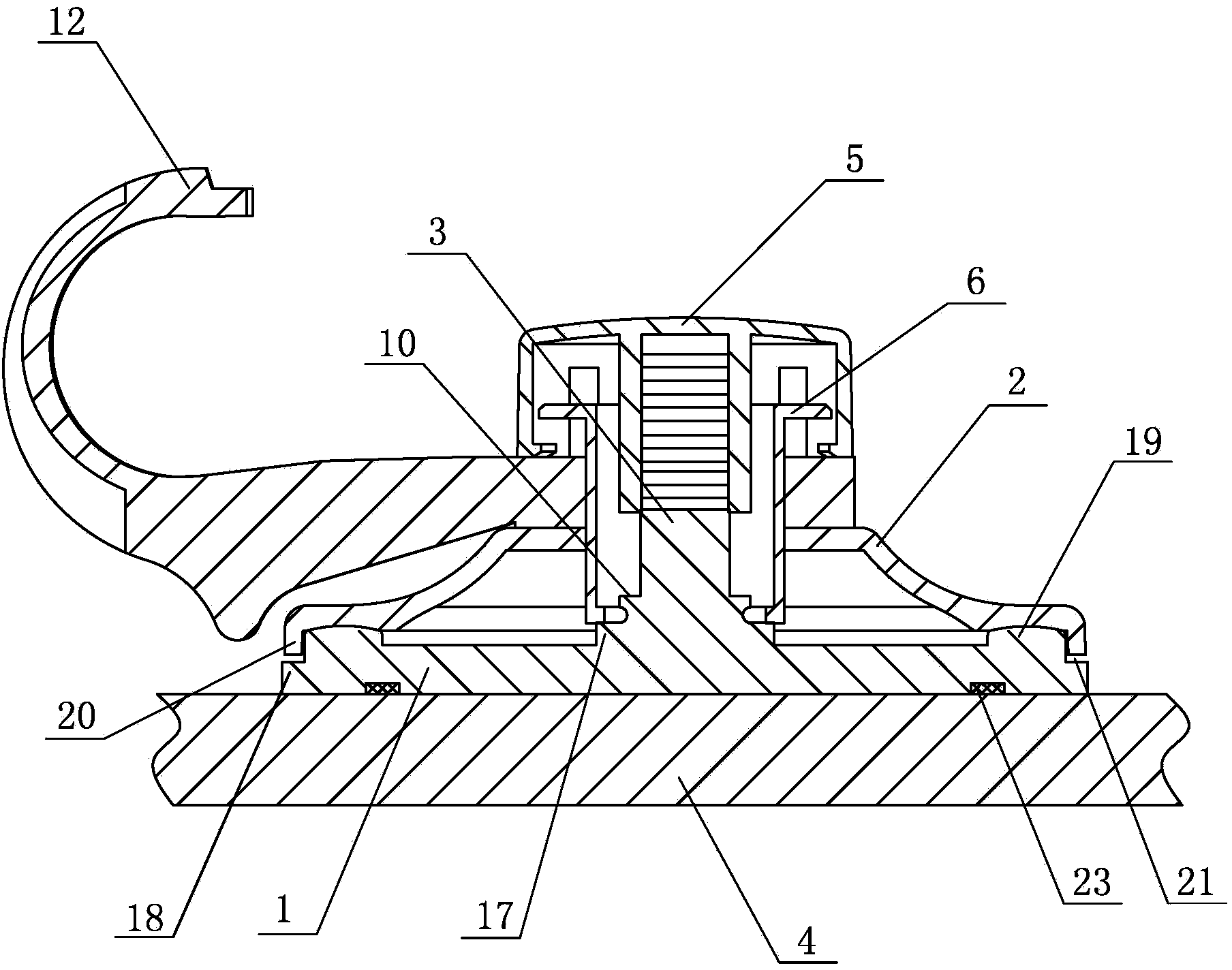

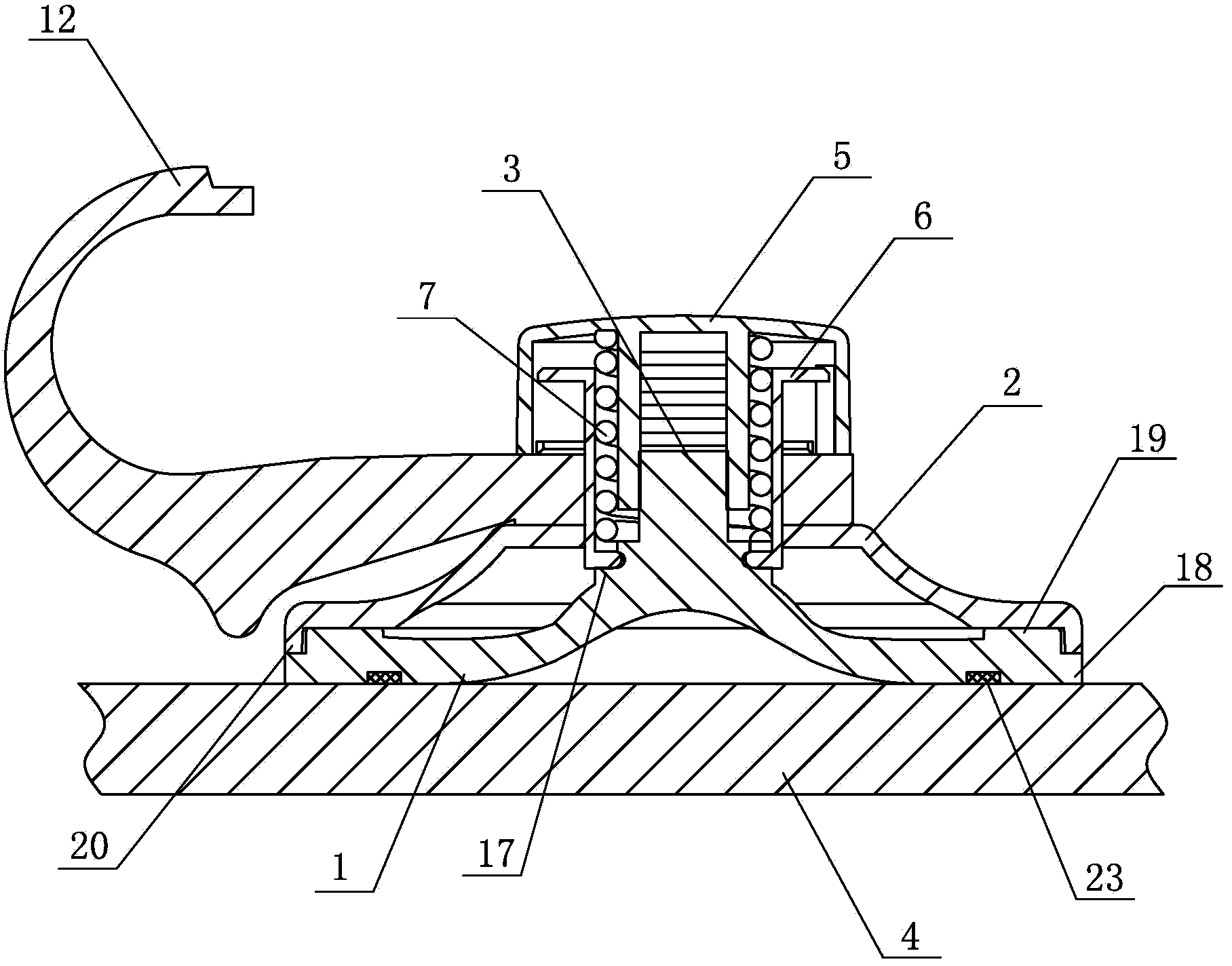

[0055] see Figure 1-10 As shown, the structure of the suction cup is as follows: a suction cup, including a suction cup base 1 made of elastic material, a suction cup cover 2 and an elastic pressing member arranged on the back of the suction cup base 1, and the suction cup cover 2 is not rigid. Deformed cover plate; the elastic pressing part is connected with the suction cup base 1 through the central connecting part 3, and the opening of the suction cup base 1 is a concave cavity facing the fixed surface 4, and the elastic pressing part is connected with the center The parts 3 are threaded, and the elastic pressing part can be rotated to lift the central connecting part 3 and then the suction cup base 1 .

[0056] Between the central connecting piece 3 and the sealing edge 18 on the edge of the suction cup base 1, an annular protrusion 19 corresponding to the pressing part of the edge of the suction cup cover plate 2 is arranged on the back of the suction cup base 1, the ann...

Embodiment 2

[0077]In this embodiment, the suction cup base is a flat surface suction cup base. Since the product is often assembled when it is sold, the suction cup base will have a certain indentation, or a certain indentation will occur due to a consumer's misuse, thus affecting Correctly installed, the structure of the present invention can avoid the occurrence of the above-mentioned unfavorable conditions. Other structures and usage methods of the suction cup are similar to those in Embodiment 1 and will not be repeated here.

Embodiment 3

[0079] In this embodiment, the suction cup cover is an elastic cover, and this elastic cover has a certain strength. Therefore, when the elastic pressing member is rotated, the elastic cover will also be deformed to a certain extent, thereby giving the suction cup base a certain degree of deformation. The edges apply extra elastic pressure to facilitate adsorption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com