Photoelectric measuring machine for precision transmission chain

A photoelectric measurement and precision transmission technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of reducing measurement accuracy, time-consuming installation of the measured object, narrow use surface, etc., to avoid installation errors, improve measurement accuracy, and increase general-purpose sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

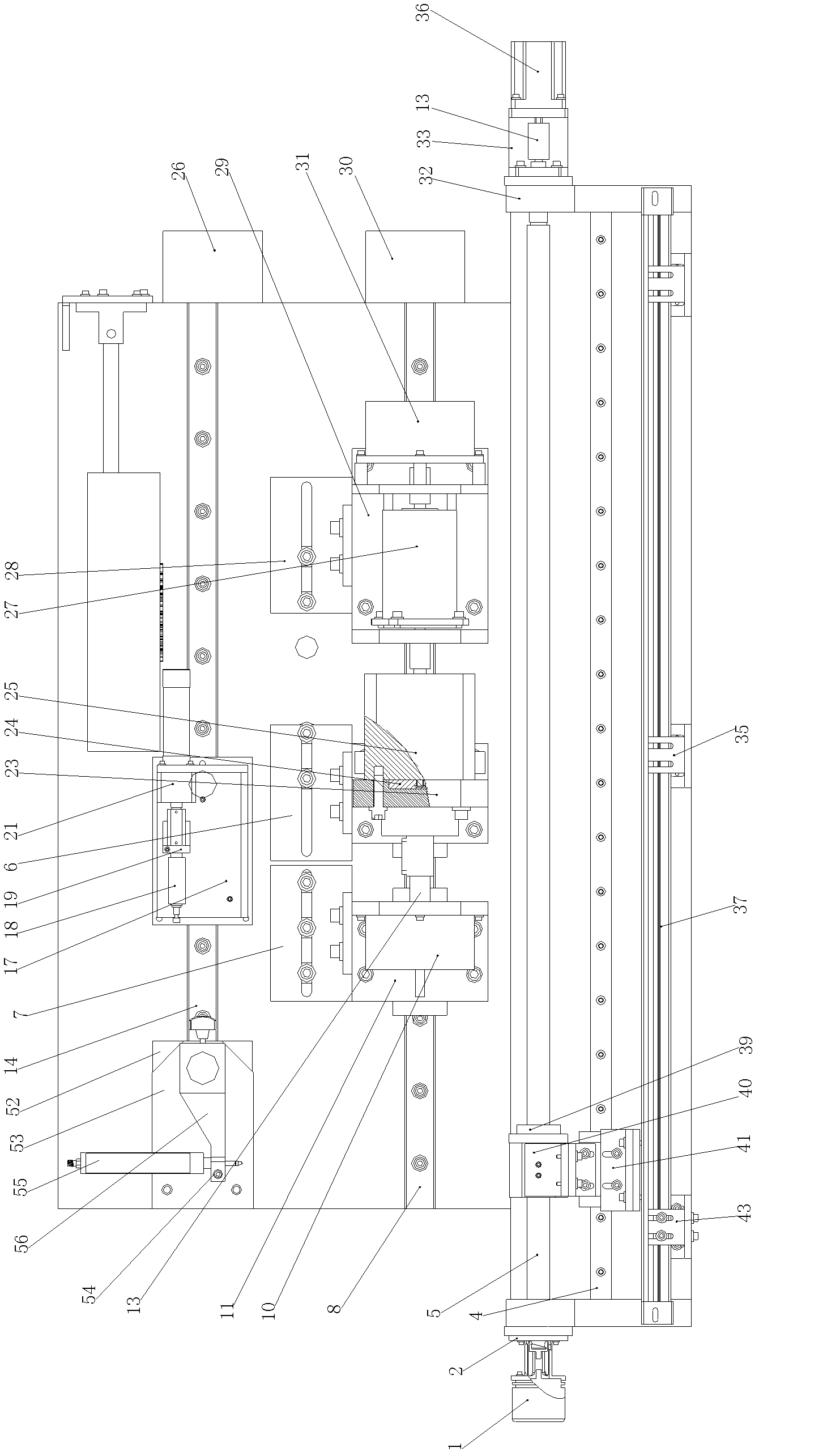

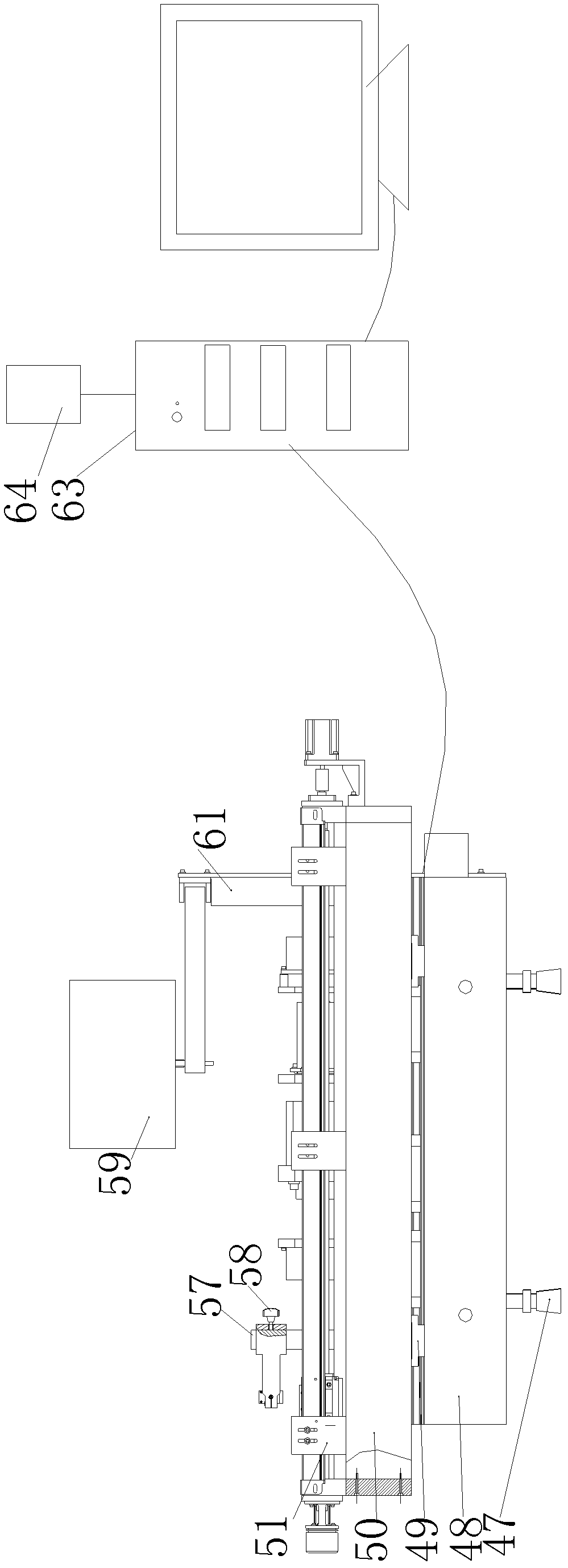

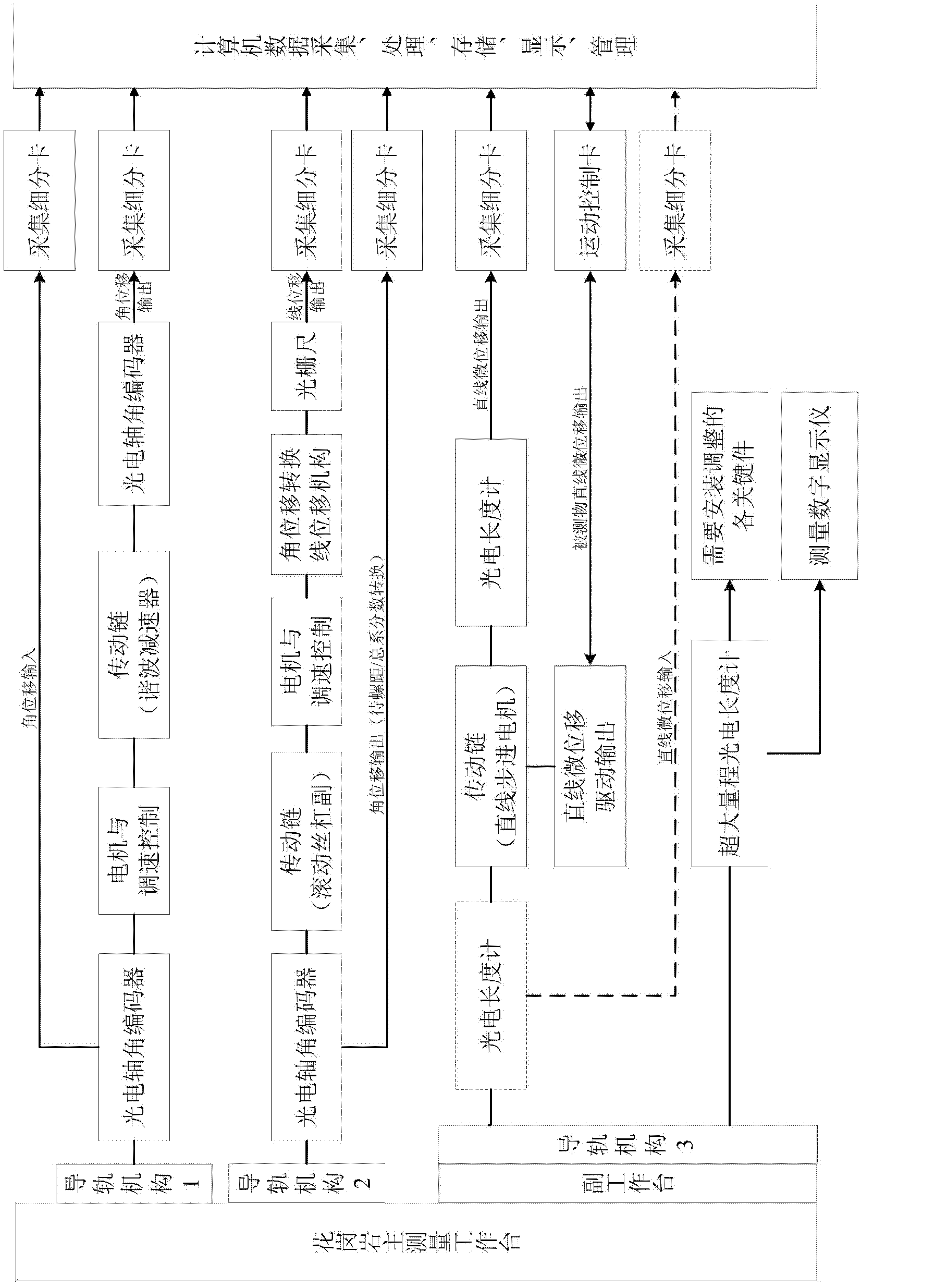

[0027] like figure 1 As shown, the precision transmission chain photoelectric measuring machine includes a measuring table, an angular displacement input and output grating measurement system, an angular displacement input and a linear displacement output grating measurement system, a linear micro-displacement input and an output grating measurement system, an installation error detection system and Measurement drive control system; three groups of precision linear guide rail mechanisms parallel to each other are installed on the base of the measurement workbench, and the angular displacement input and linear displacement output grating measurement system is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com