Patents

Literature

338results about How to "Avoid installation errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

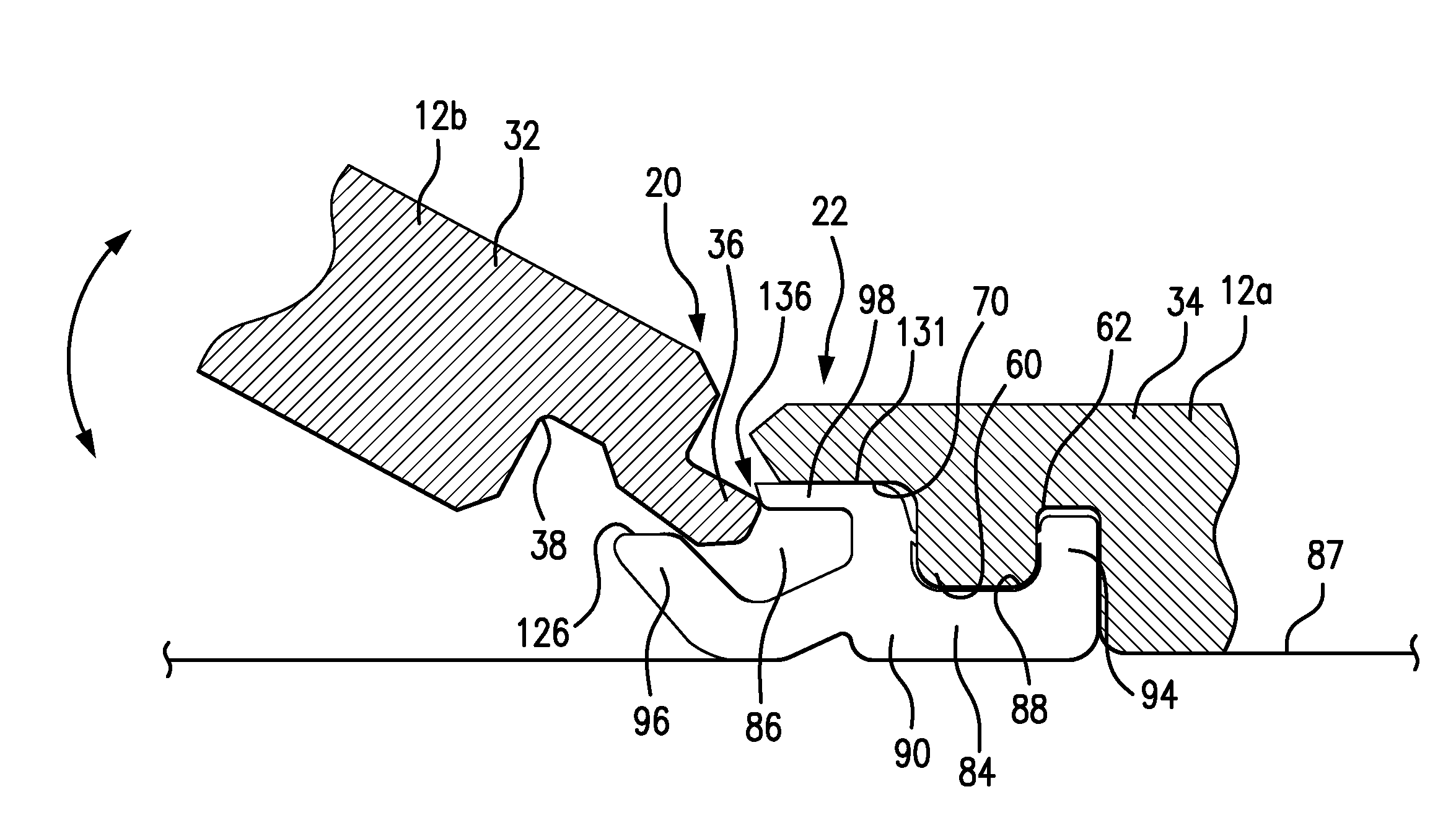

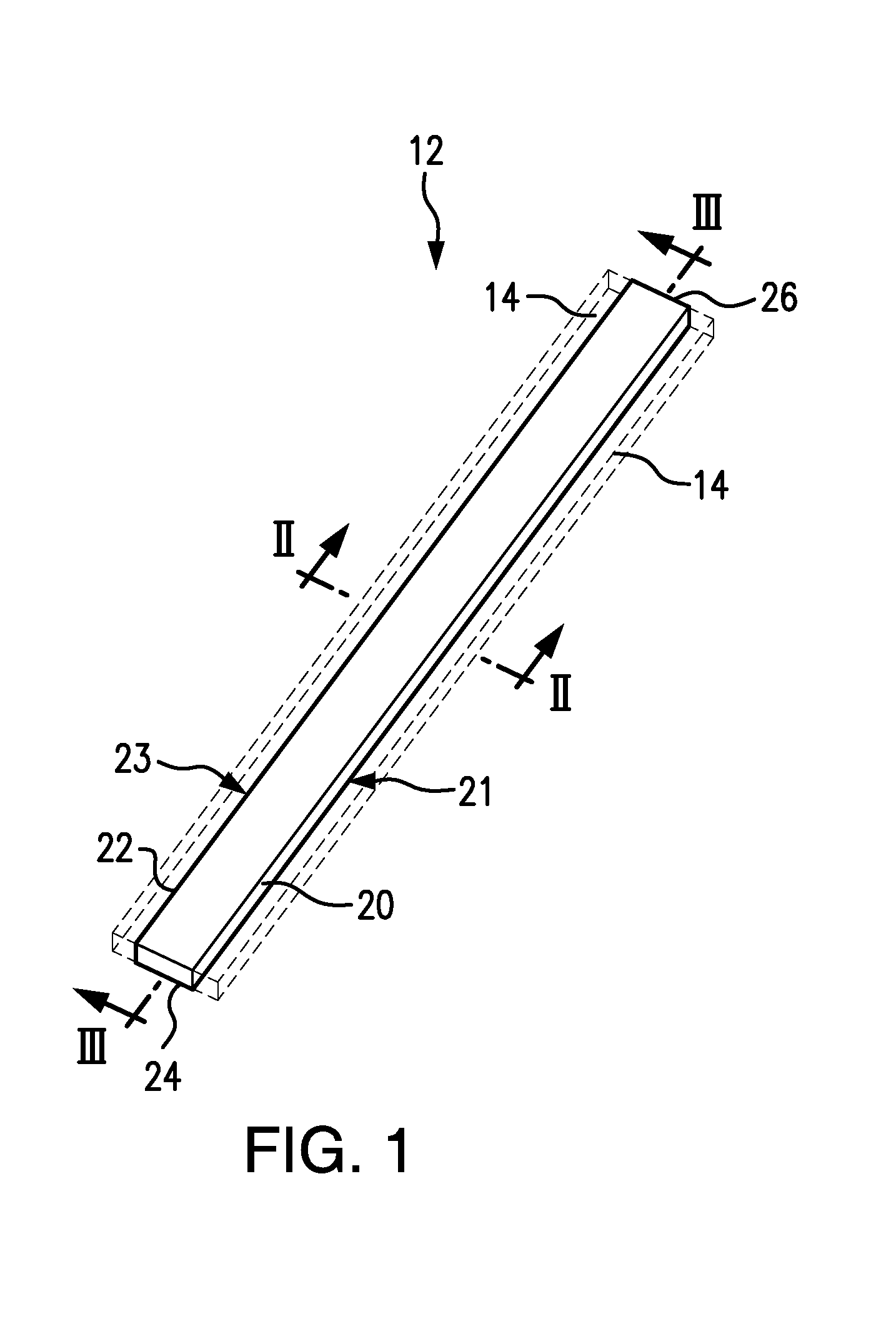

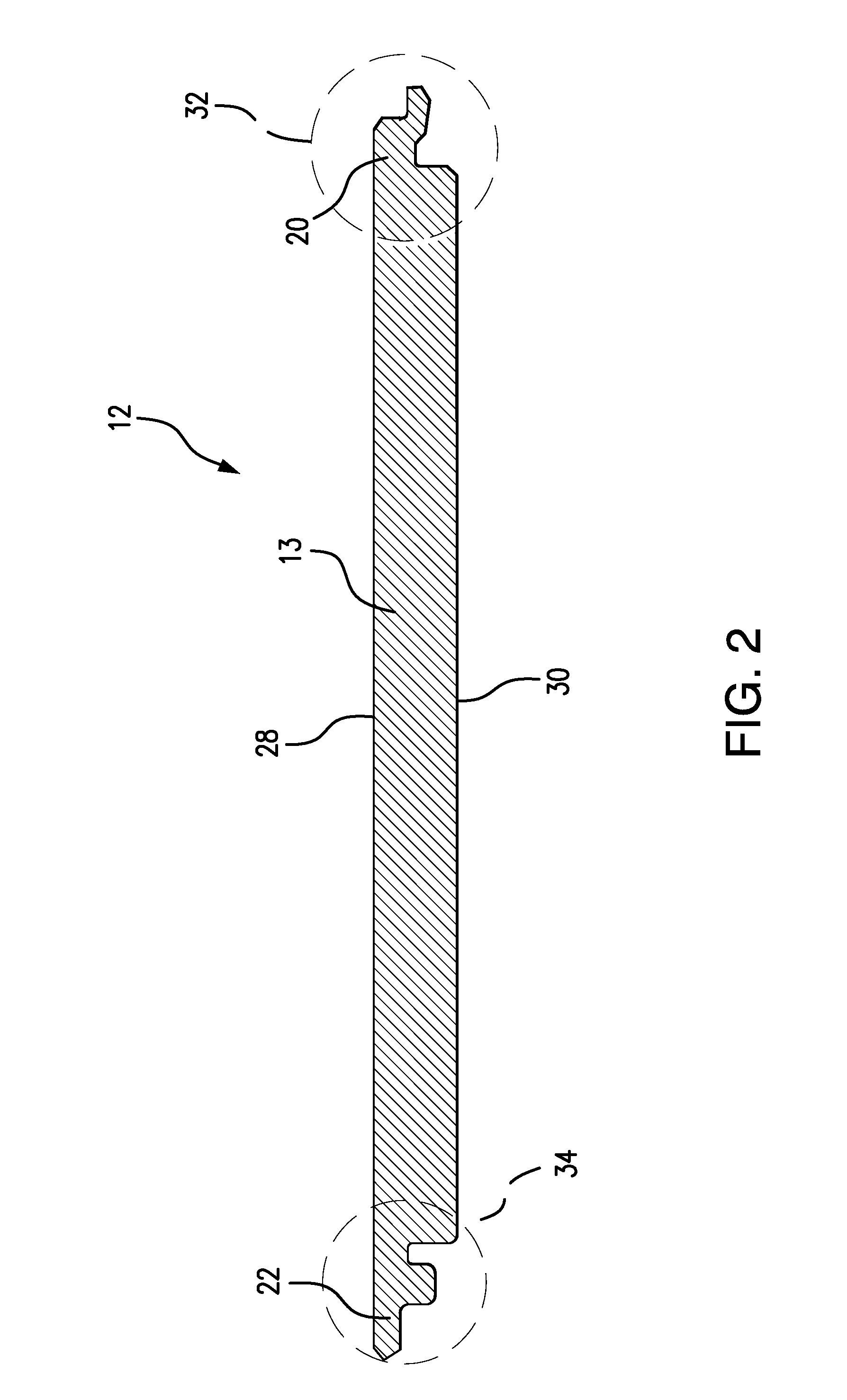

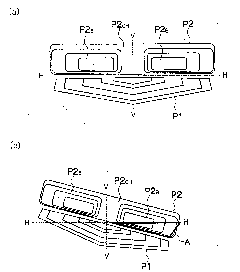

Connecting System For Surface Coverings

ActiveUS20110131916A1Provides appearance and durabilityEasy to layWallsFloorsEngineeringSurface cover

A plank, and system and method for joining surface-covering planks, which includes a disengageable connector(s) for detachably connecting multiple planks simultaneously are described. A plank can include a tongue-profiled edge and an opposite rib-profiled edge, and a disengageable connector can have a groove that can be mated with the tongue on one side edge of the plank, and also has a rib-receiving portion that alternatively can be mated with a downward extending rib on the opposite side edge of the plank. The plank can have a variety of designs on the other edges of the plank.

Owner:MANNINGTON MILLS

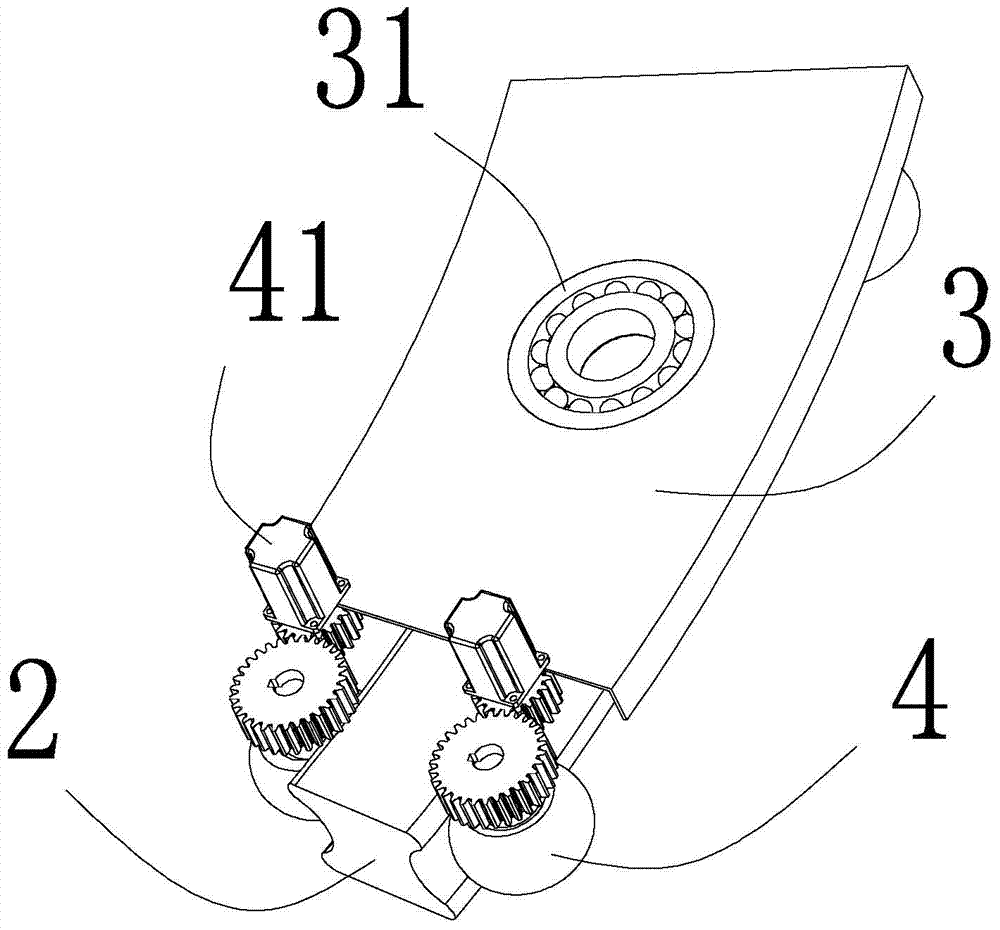

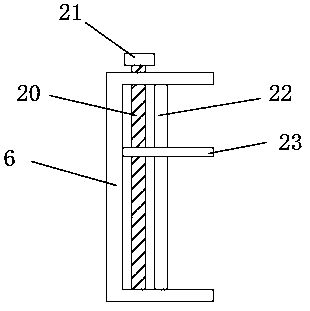

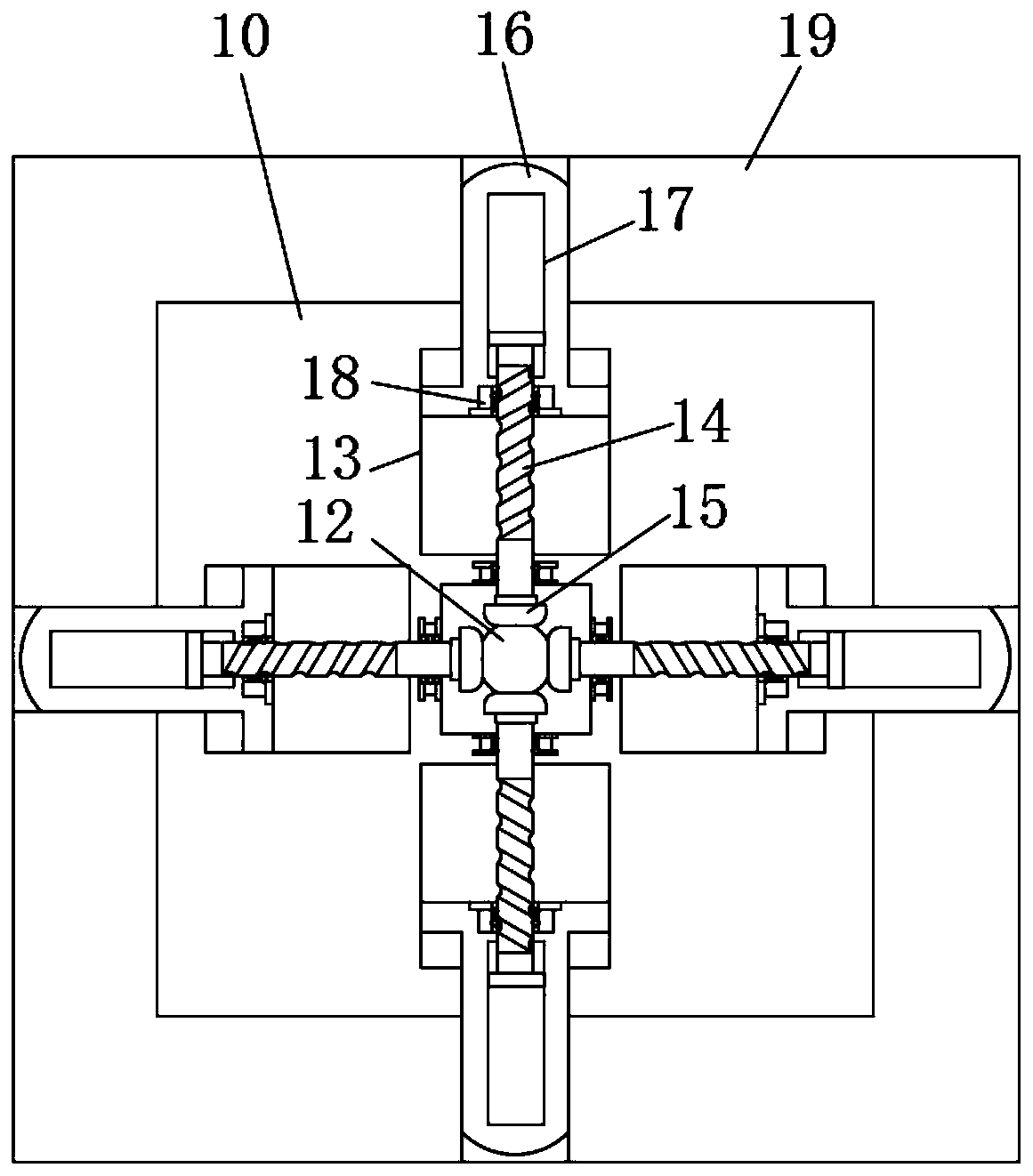

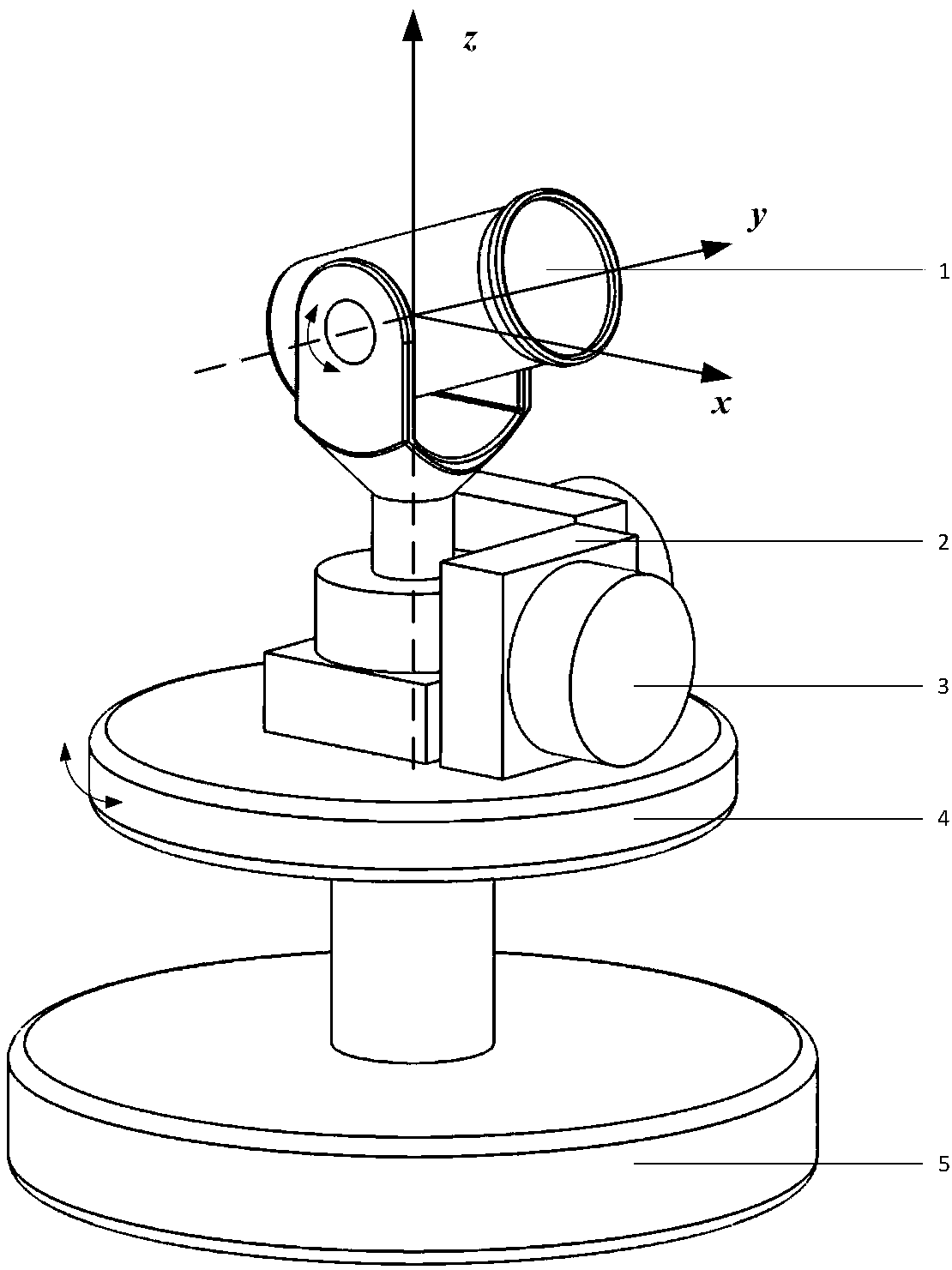

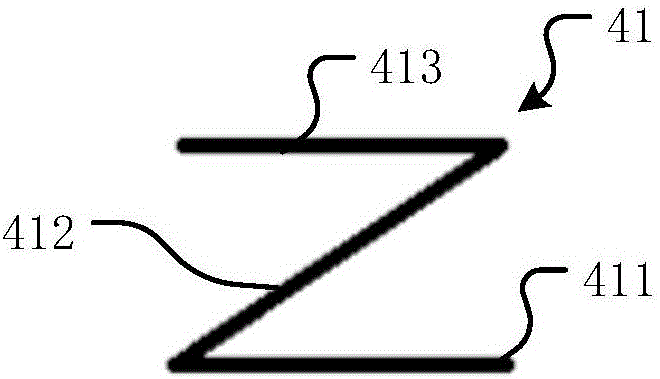

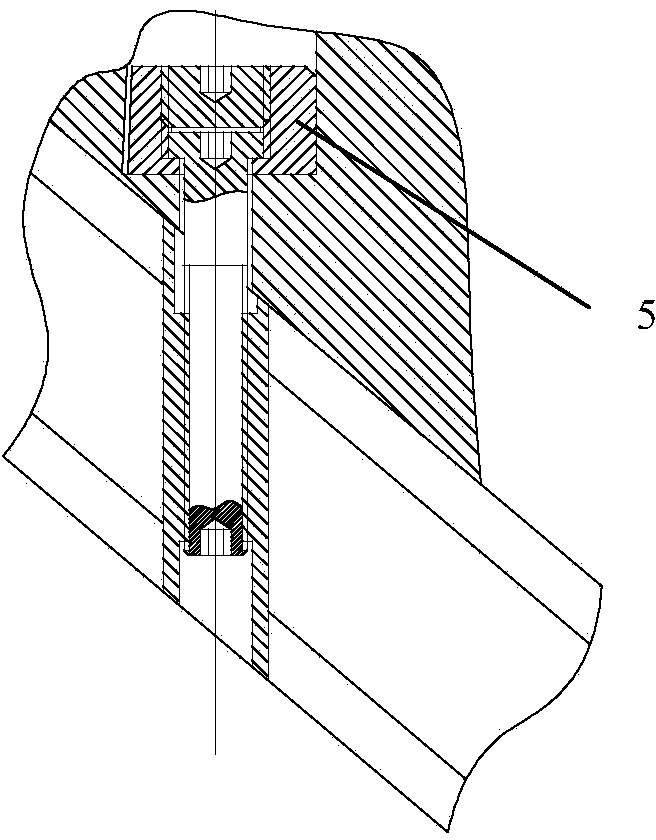

Device capable of achieving multidirectional detection

InactiveCN103900509AEasy to adjustEasy to control and calculateMeasurement devicesEngineeringMechanical engineering

Owner:HOHAI UNIV CHANGZHOU

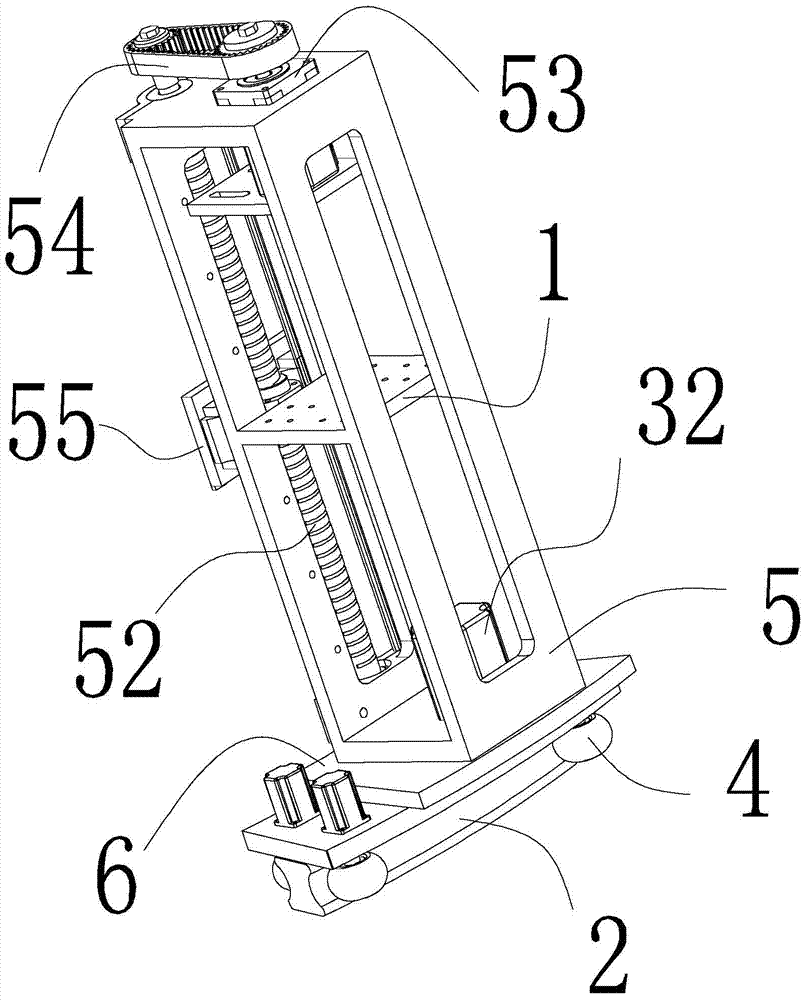

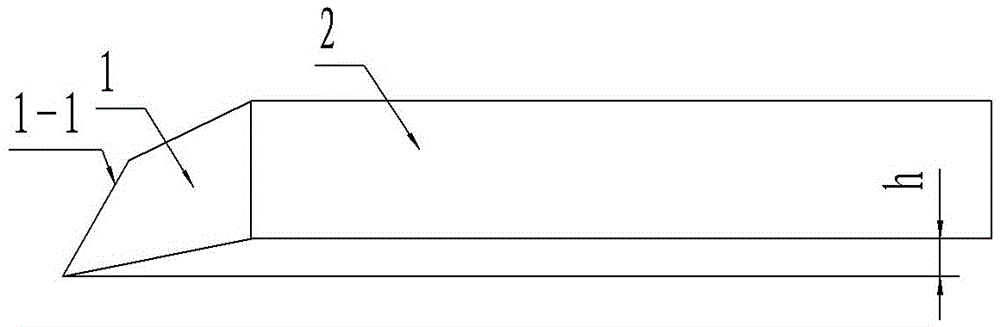

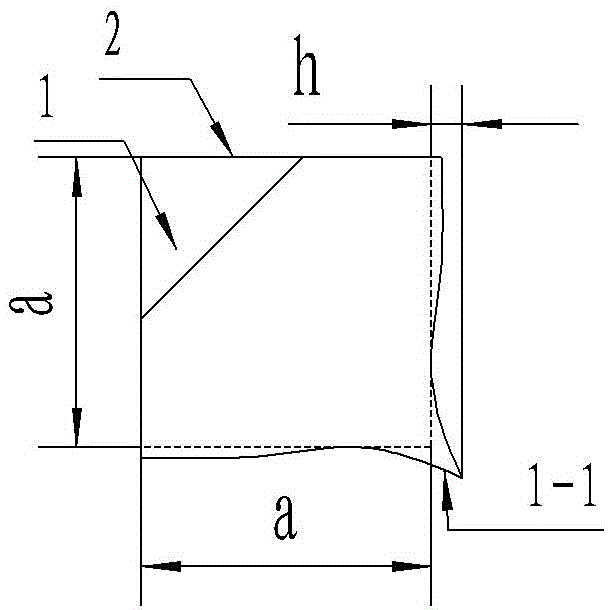

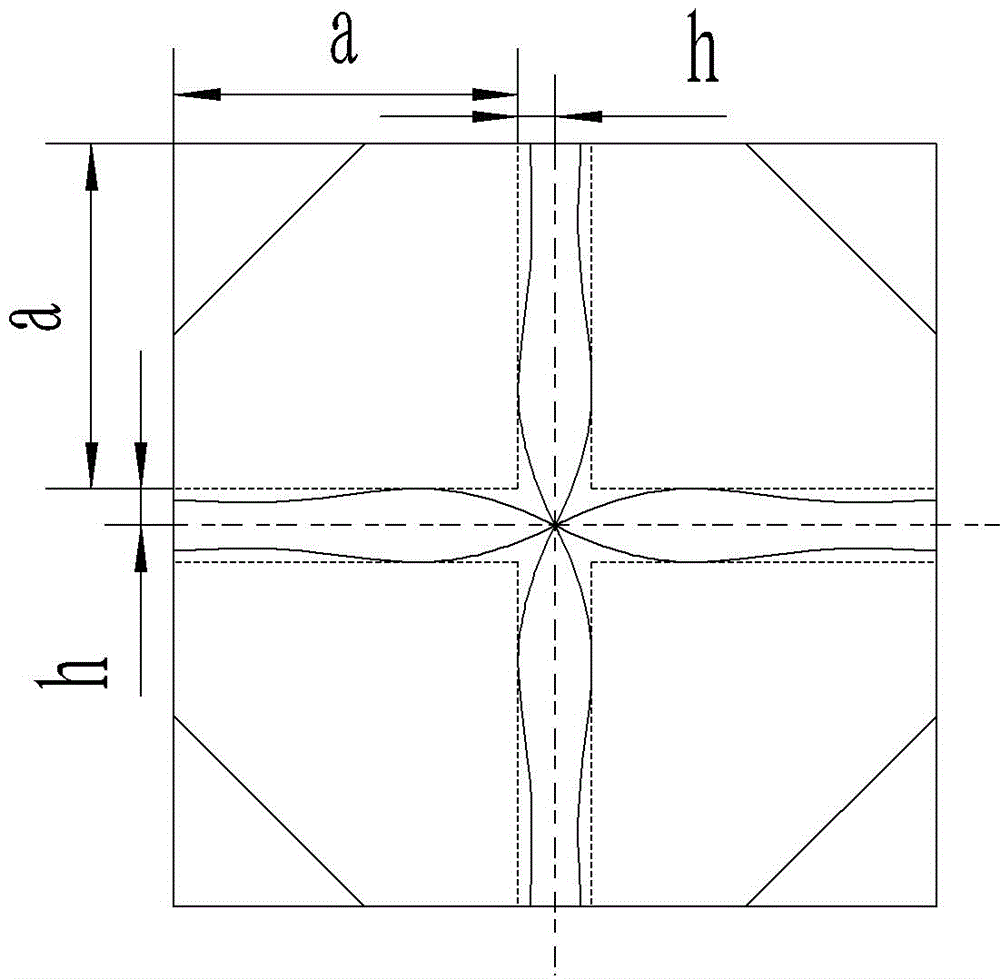

Method and device for determining grinding brittleness-ductility transformation critical cutting depth of hard and brittle material

InactiveCN103722467AImprove surface qualityHigh precisionGrinding feed controlGrinding machinesHigh surfaceRelative motion

The invention relates to the technical field of hard and brittle material ultra-precision machining. In order to achieve ductility domain grinding of the largest cutting depth, high surface quality of the hard and brittle material, and efficient and high-precision production machining, according to the technical scheme, a method and device for determining the grinding brittleness-ductility transformation critical cutting depth of the hard and brittle material comprises the following steps of (1) according to a grinding wheel used in ultra-precision grinding, determining the number, shape and distance of grains of a homemade multi-grain tool, (2) according to the grain shape, distance and front-angle parameters selected in the step (1), machining three or more grains on a grain base body, (3) controlling the multi-grain tool and a workpiece to generate relative motion, beginning to conduct scratching on the surface of the workpiece, meanwhile, controlling the multi-grain tool to conduct continuous feeding, enabling the depth of the scratch to continuously change, and observing and measuring the workpiece after scratching by utilizing a surface contourgraph and a confocal microscopy. The method is mainly applied to ultra-precision machining.

Owner:TIANJIN UNIV

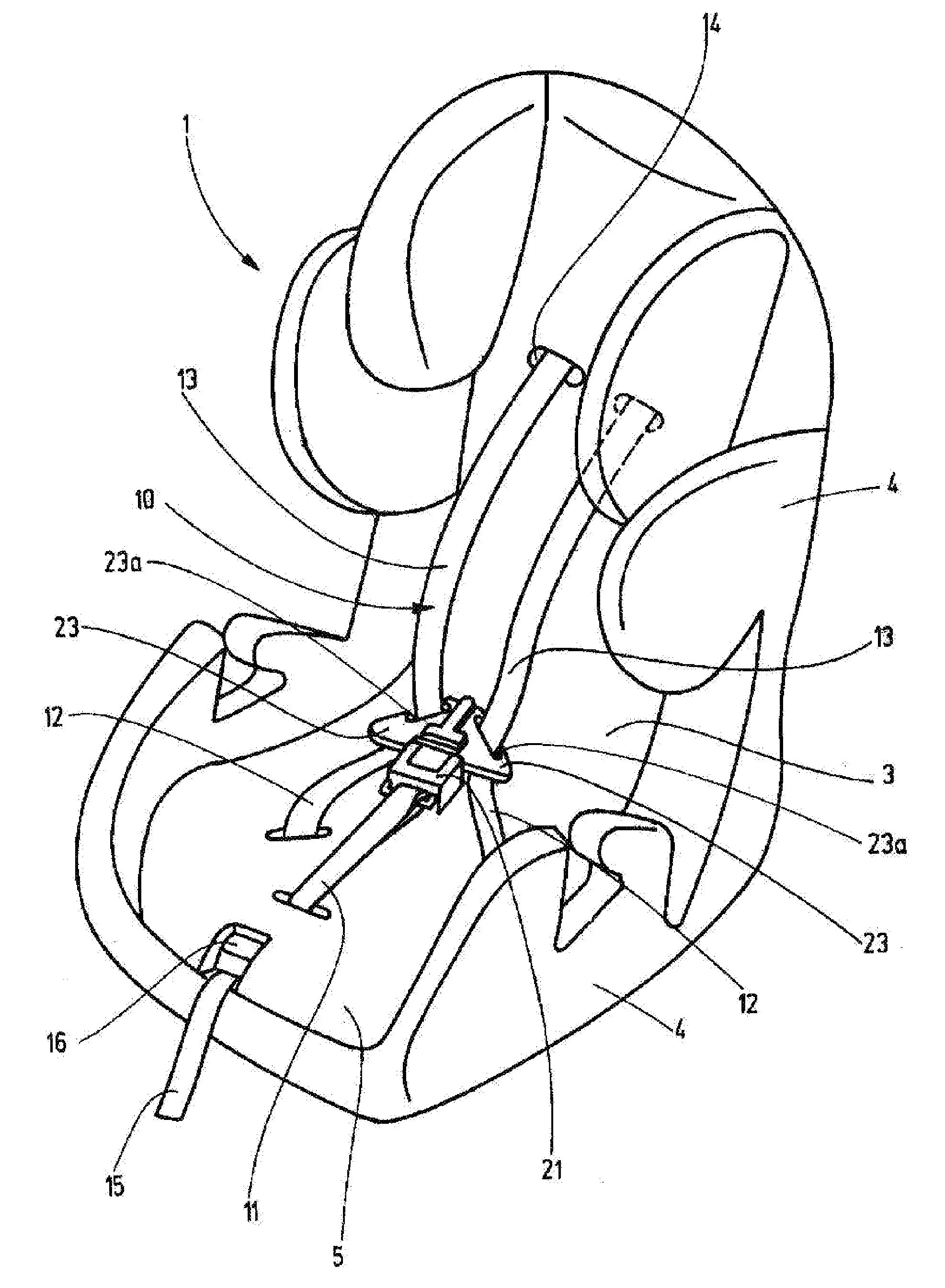

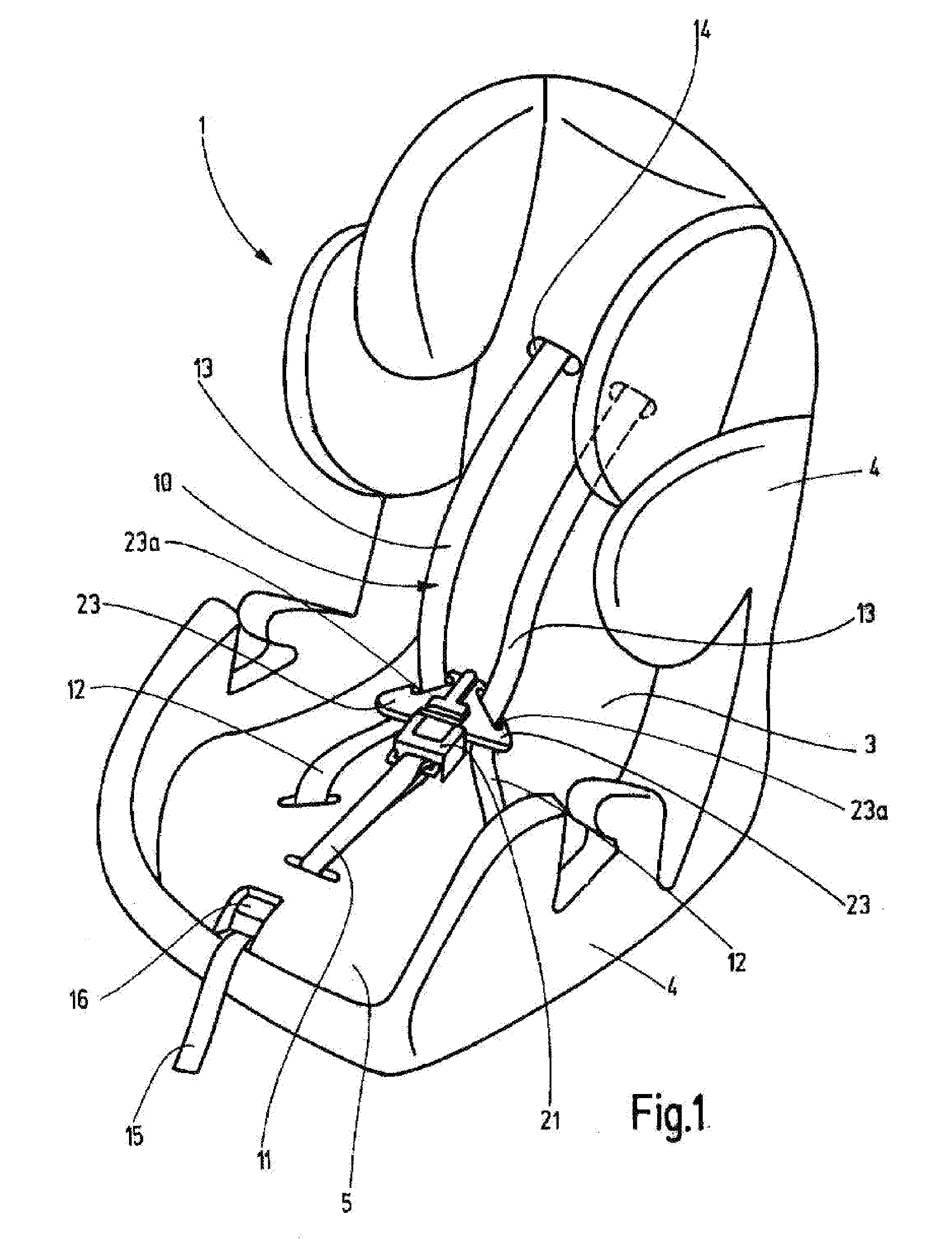

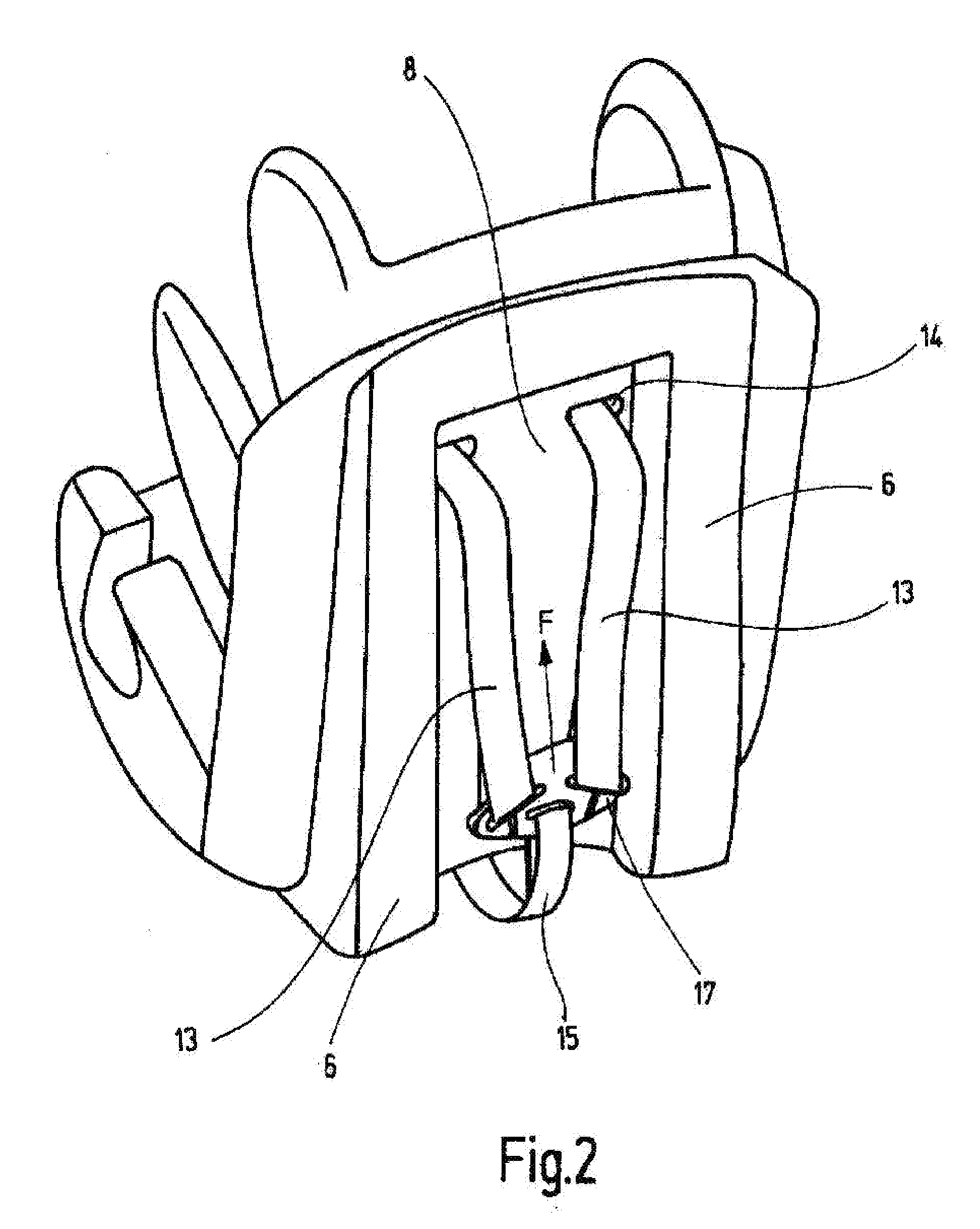

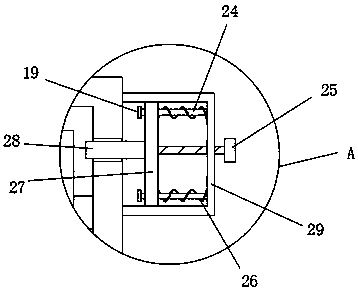

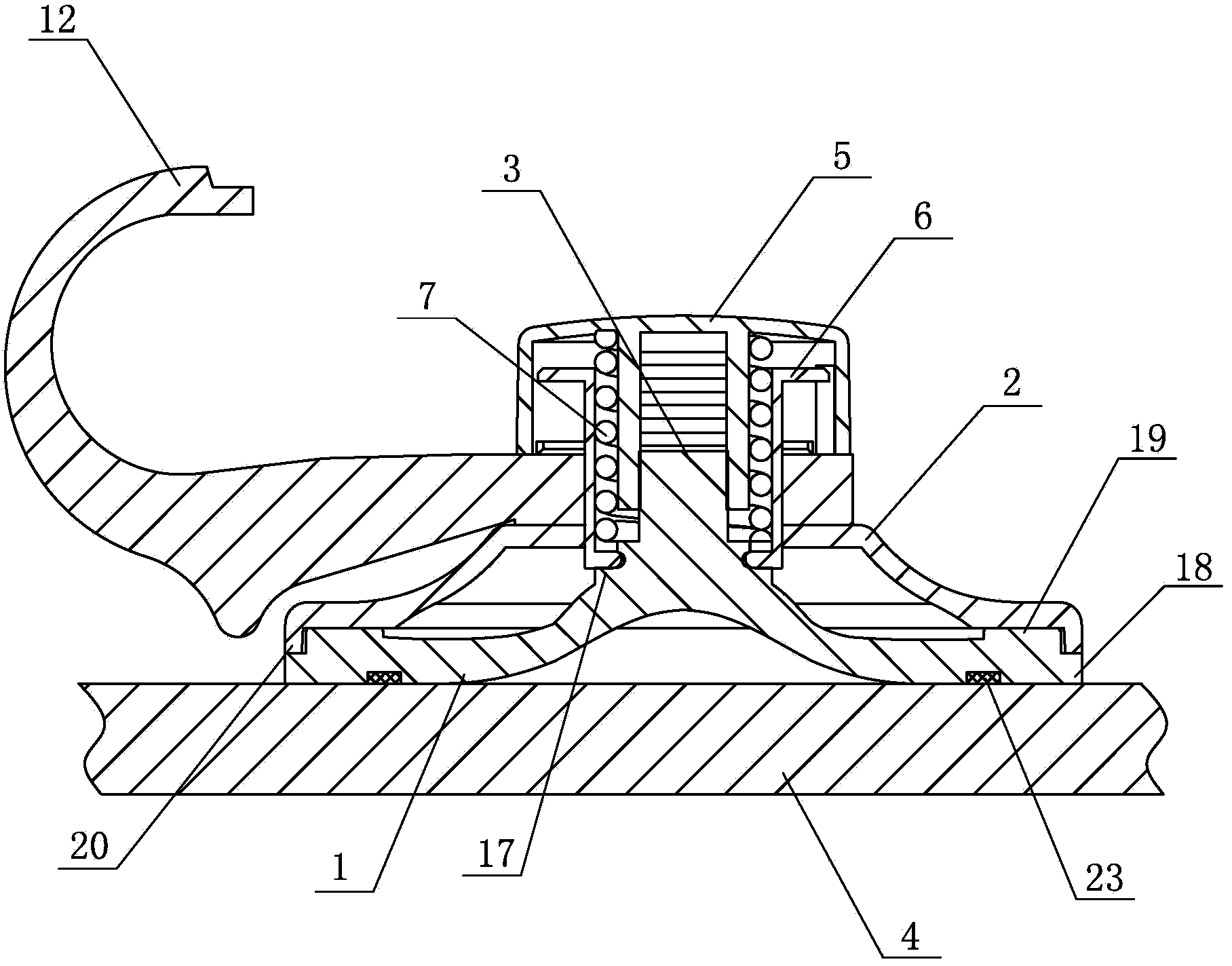

Vehicle child seat

InactiveUS20100264706A1Avoid installation errorsFunction increaseBelt retractorsSafety beltsEngineeringNormal position

A vehicle child seat is provided for directly or indirectly fastening to a vehicle seat and / or a vehicle structure. The vehicle child seat includes a backrest, a seat surface, an integrated belt system for fastening a child in the vehicle child seat and a belt tensioning device (31). The belt tensioning device (31) includes a trigger sensor, an energy storage device and a tensioning mechanism which, when exceeding a defined force acting on the vehicle child seat, in particular a crash force, abruptly tensions the belt system. All components of the belt tensioning device (31) required for the belt tensioning function being fastened to or in the vehicle child seat and being able to be removed therewith from the vehicle. A belt force limiting function is incorporated in the belt tensioning device (31). After triggering the belt tensioning device (31) when exceeding a limit force Fgrenz on the belt portion (11, 12, 13, 15) at least one belt deflector (137, 171) is displaced sufficiently far in the direction of a normal position, until the limit force Fgrenz has fallen below or the belt deflector (137, 171) has completely reached its normal position.

Owner:RECARO CHILD SAFETY

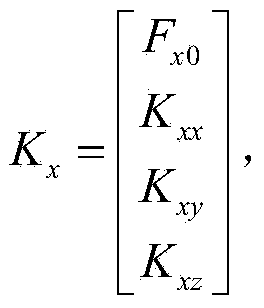

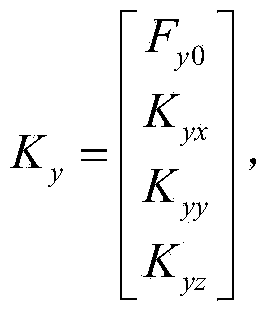

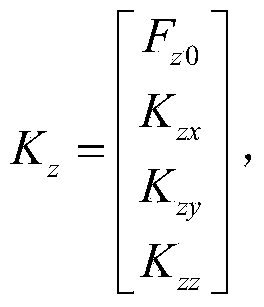

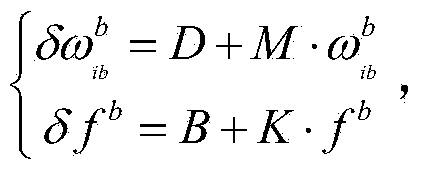

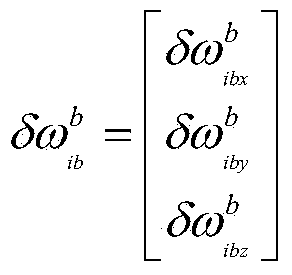

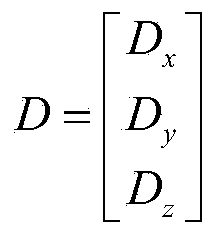

Calibration method for fiber-optic gyroscope inertial measurement device with three orthogonalized axes and one inclined axis

The invention comprises a calibration method for a fiber-optic gyroscope inertial measurement device with three orthogonalized axes and one inclined axis, particularly relates to a system calibration system for navigating, guiding and controlling a spacecraft, and belongs to the technical field of inertial measurement. The calibration method is used to accurately calibrate the zero position, the scale factor and the installing error of the fiber-optic gyroscope inertial measurement device, and the method is simple and feasible and can effectively increase the calibration accuracy. According to the method, no tool needs to be replaced, so as to guarantee the consistency of a datum plane; the method does not distinguish the scale factor and the installing error, so that the calculation error produced when calculating the small quantity of the installing error is avoided; and compared with other testing methods for the fiber-optic gyroscope inertial measurement device, the method is simple and feasible, improves the calibration efficiency and saves the manpower and material resources.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

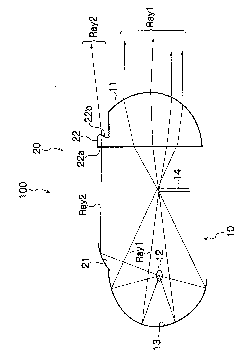

Motorcycle projector headlight

ActiveCN102192456ALow costReliable incidenceVehicle headlampsPoint-like light sourceEllipseOptoelectronics

A motorcycle projector headlight, comprises: a first reflector; a second reflector located adjacent to the outer side of an opening of the first reflector so as to make the light towards the outer side of the opening of the first reflector from the light emitted from a light source income into the second reflector; a diffusion lens arranged along the radiation direction of the reflection light from the second reflector and composed of a light incoming surface on which the reflection light from the second reflector incomes; an emitting surface for making the reflection light from the second reflector which incomes into the lens from the light incoming surface be emitted as a diffusion light diffusing along the vertical and horizontal directions, wherein the emitting surface is configured to be a concave curved surface, the horizontal cross section of the concave curved surface comprises an elliptical arc being bilateral symmetray relative to the long axis or short axis and bending towards the light incoming surface side and the vertical cross section of the concave curved surface comprises an arc and an elliptical arc bending towards one side on the horizontal surface passing through the center of the circle or ellipse and the light incoming surface side in the circle or ellipse.

Owner:STANLEY ELECTRIC CO LTD

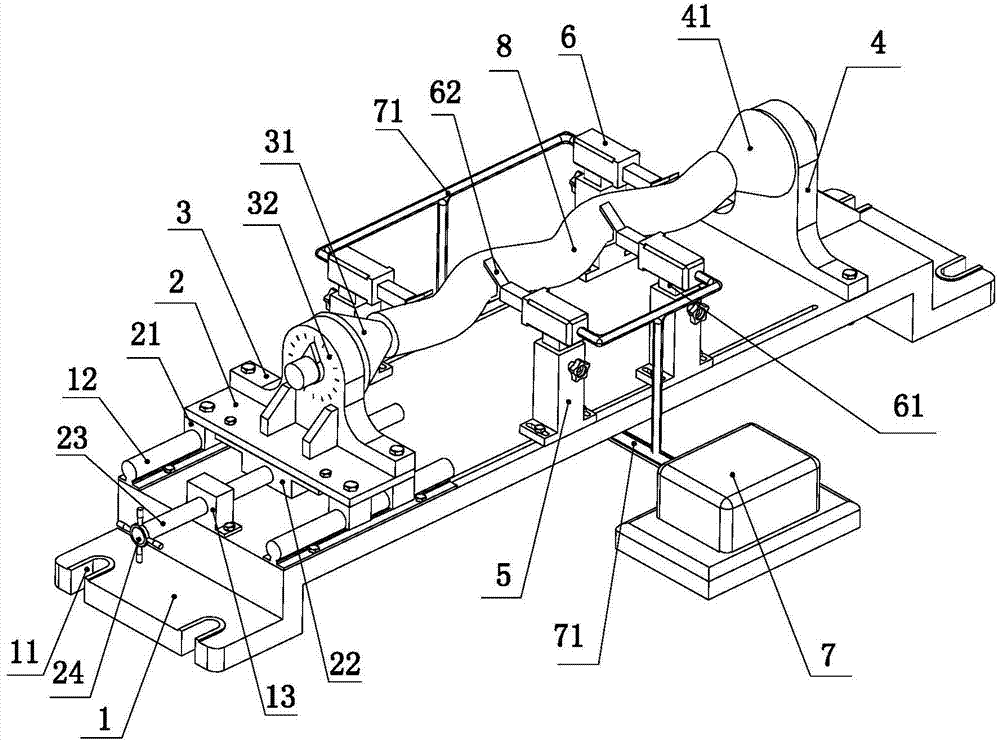

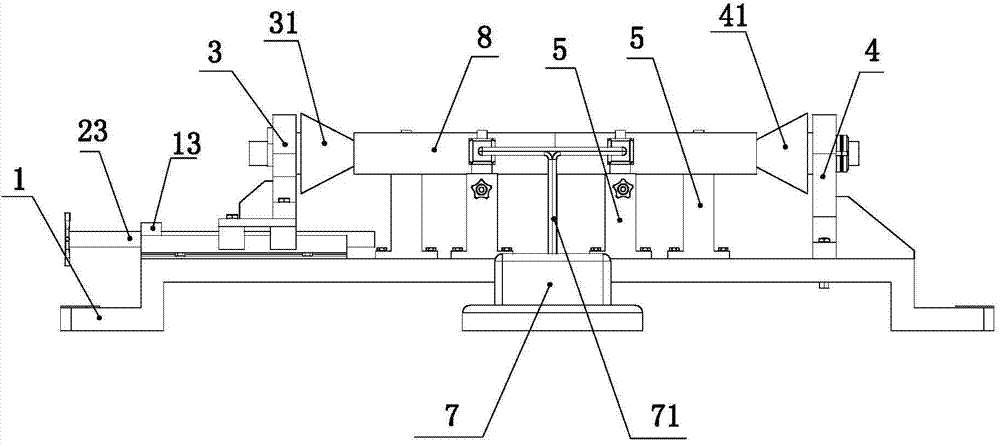

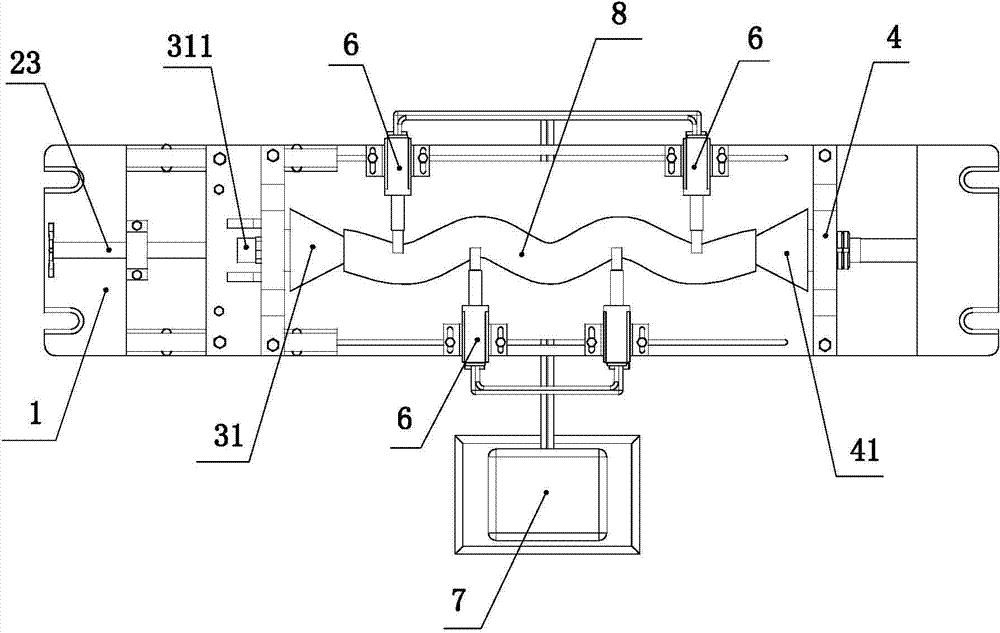

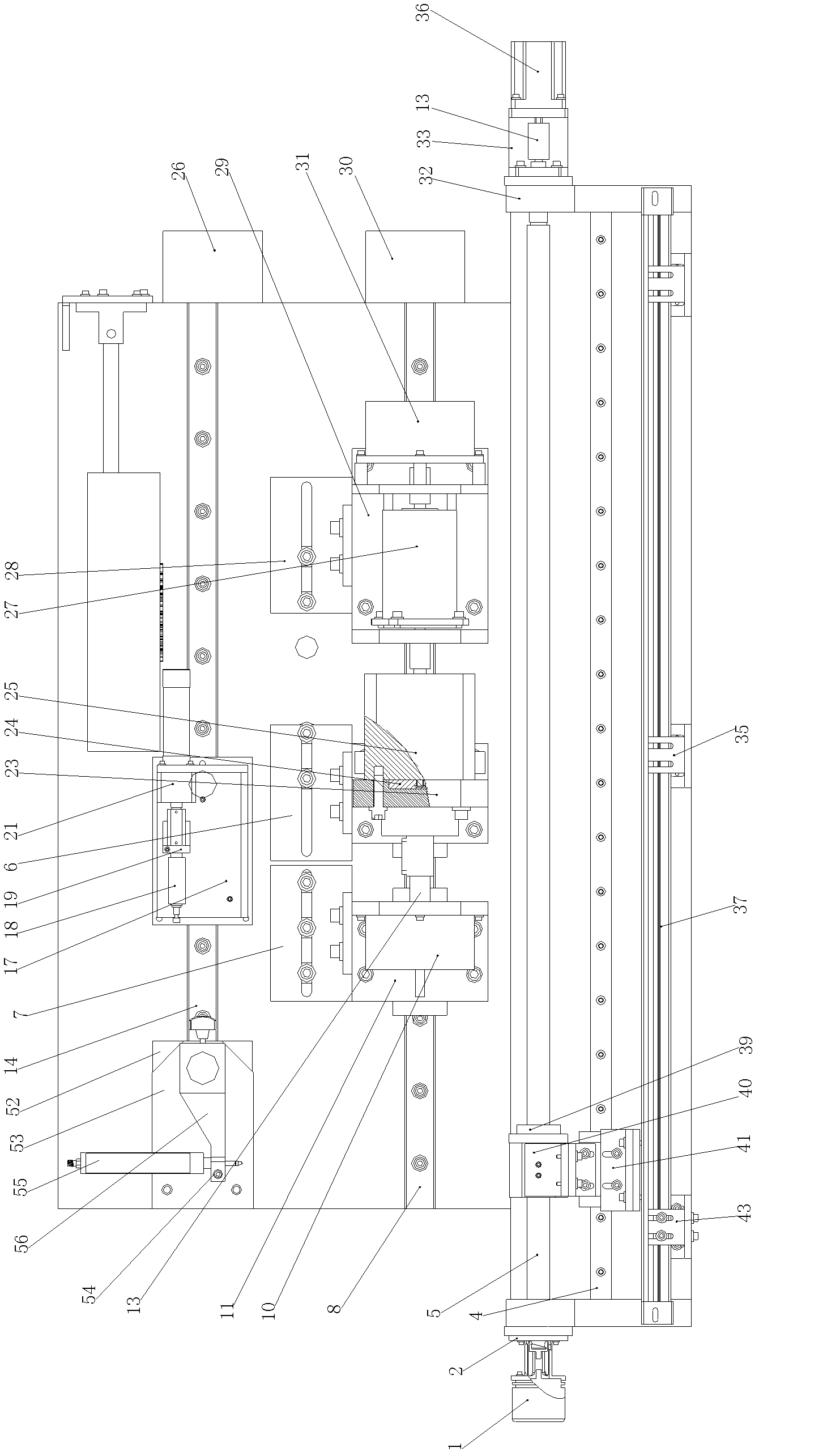

Flexible clamping device of bent pipe

ActiveCN104722619AStable clampingRealize the clamping effectMetal-working feeding devicesPositioning devicesEngineeringMachining

A flexible clamping device of a bent pipe is applied to indexing hole machining of the bent pipe and used for solving the problem that the bent pipe is not convenient to clamp or fix. A movable platform is arranged on the top of a rack in a sliding mode, a movable support is arranged on the movable platform, and a movable thrusting piece is movably installed at the upper portion of the movable support through a rotating shaft. A fixed support corresponding to the movable support is arranged at the other end of the top of the rack, a fixed thrusting piece is rotationally installed at the upper portion of the fixed support through a rotating shaft, and the pipe is clamped through the cooperation of the fixed thrusting piece and the movable thrusting piece. Oil cylinders are arranged on the front side and the rear side of the part, between the fixed support and the movable support, of the rack respectively, piston rods of the oil cylinders are provided with chucks, and the bent pipe is clamped in a horizontal plane through the cooperation of the chucks on the front side and the rear side. According to the clamping device, the bent pipe can be firmly clamped, the bent pipe can be rotated without dismounting the pipe, an indexing hole can be conveniently machined, and the machining precision is guaranteed.

Owner:山东深图智能科技有限公司

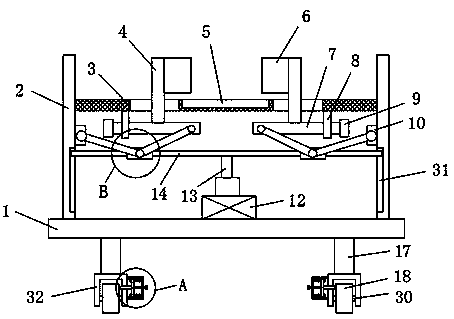

Mechanical electrical positioning device

InactiveCN108705477ARealize positioning workTo achieve the purpose of positioningWork holdersLocking mechanismElectrical devices

The invention discloses a mechanical electrical positioning device which comprises a bottom plate. Two symmetrically-arranged vertical columns are fixedly connected to the upper side wall of the bottom plate, and a supporting plate is fixedly connected between the two vertical columns. An air cylinder is arranged below the supporting plate and fixedly connected with the upper side wall of the bottom plate. The output end of the air cylinder is fixedly connected with a telescopic rod, and the upper end of the telescopic rod is fixedly connected with a moving rod which is slidably connected withtwo symmetrically-arranged sliding blocks in a sleeved mode. A first rotating rod and a second rotating rod are rotationally connected to each sliding block, and fixing blocks are fixedly connected to the side walls of the sides, close to each other, of the two vertical columns correspondingly and located above the moving rod. The mechanical electrical positioning device has the advantages that through arrangement of a clamping mechanism, the mounting positioning effect on mechanical electrical equipment can be achieved, waggle of the equipment in the mounting process is reduced, and thus themounting error is avoided; and through arrangement of idler wheels, device transferring is facilitated, and through arrangement of a locking mechanism, the whole device can be fixed.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

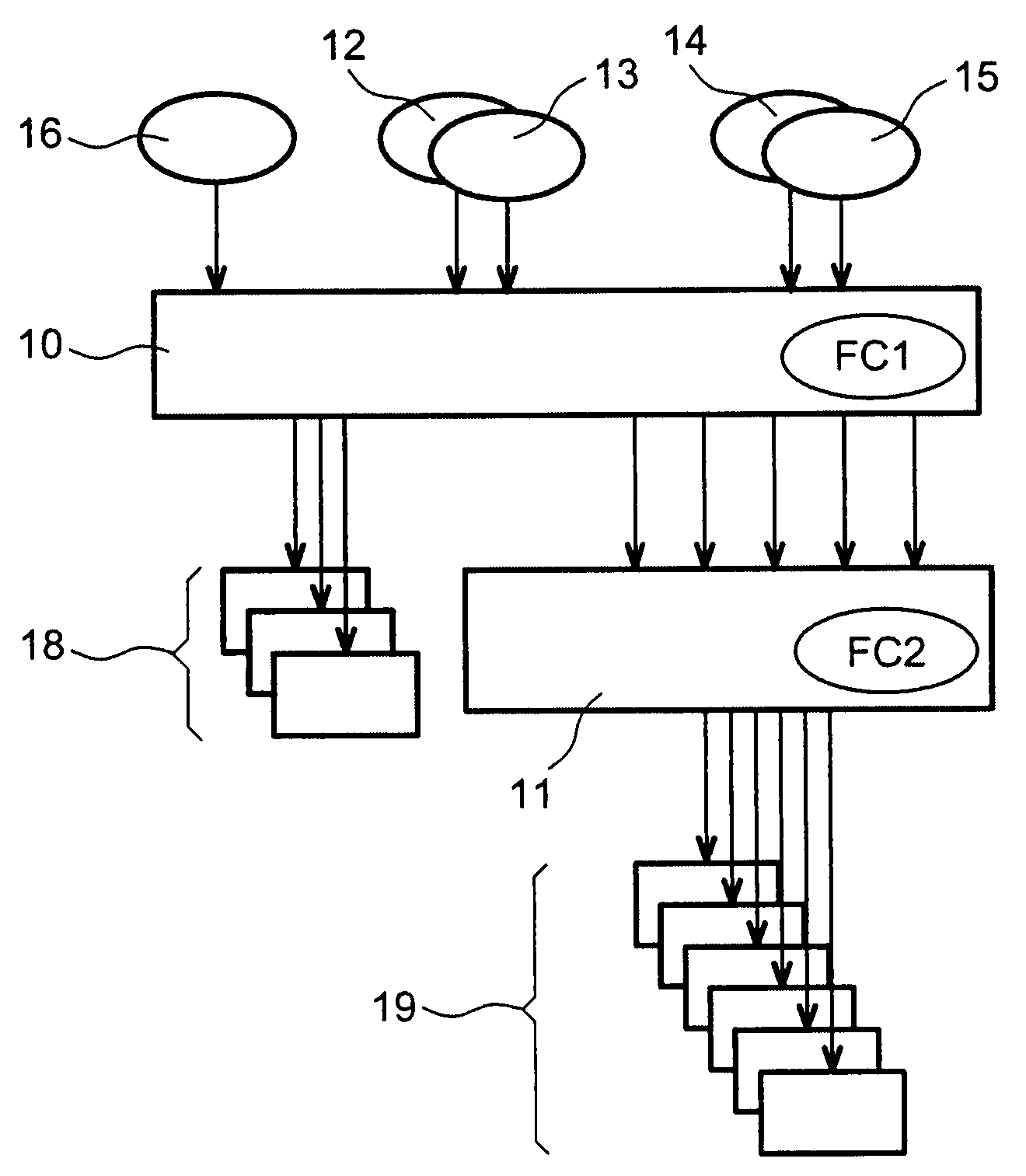

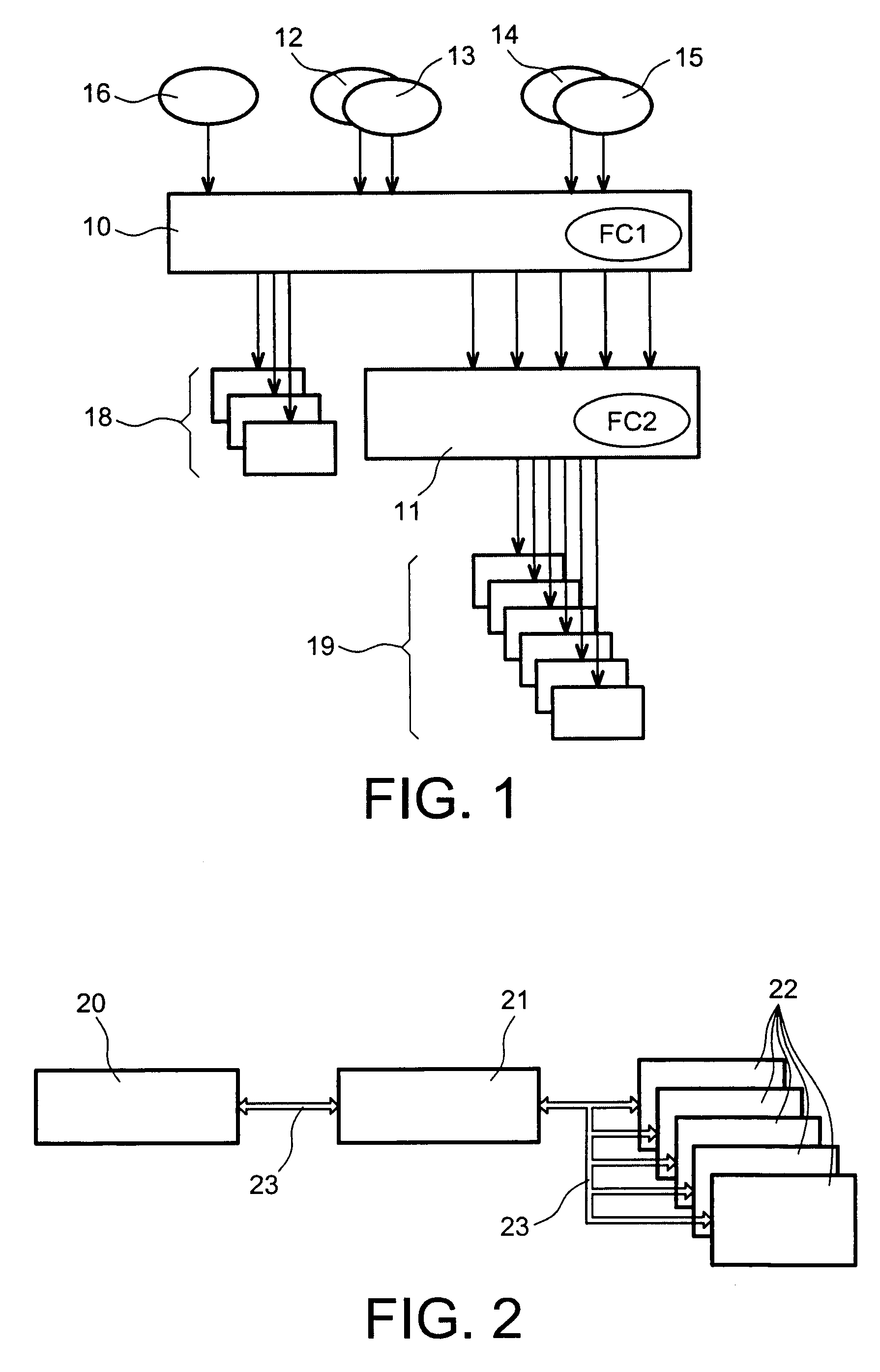

Electricity distribution system and method inside an aircraft

ActiveUS20090167076A1Short immobilizationReduce maintenance costsBoards/switchyards circuit arrangementsElectric power distributionElectric powerAirplane

A system and a method for distribution of electric power inside an aircraft. The system includes at least two systems distributing electric power from at least one power source to electric loads of the aircraft via electric and / or electronic protection / switching components, the components being configurable and commandable by dedicated electronics. Each electric distribution system includes command electronics in which a configuration file is downloaded allocating an installation status to each of the protection / switching components.

Owner:AIRBUS OPERATIONS (SAS)

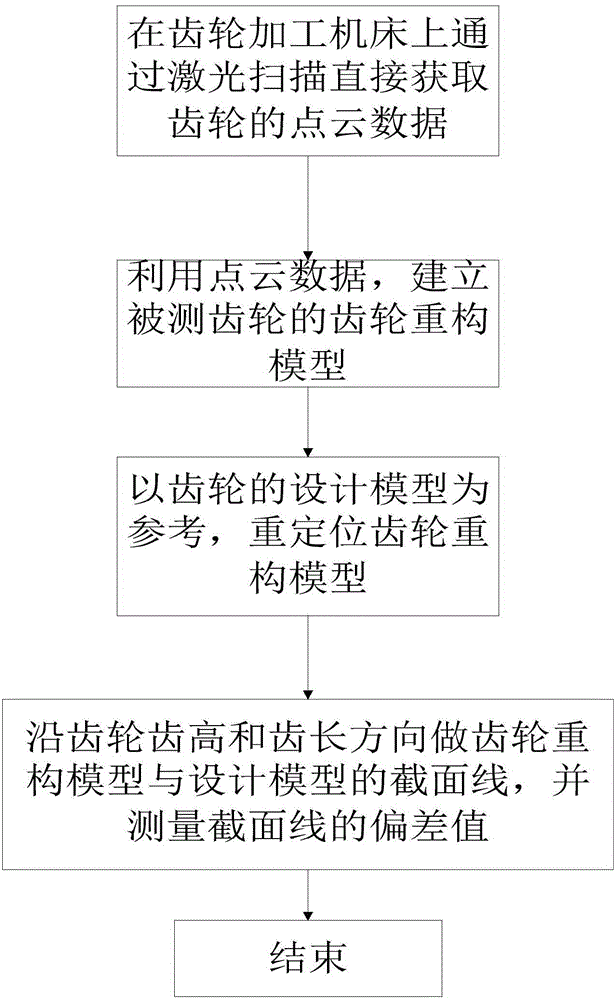

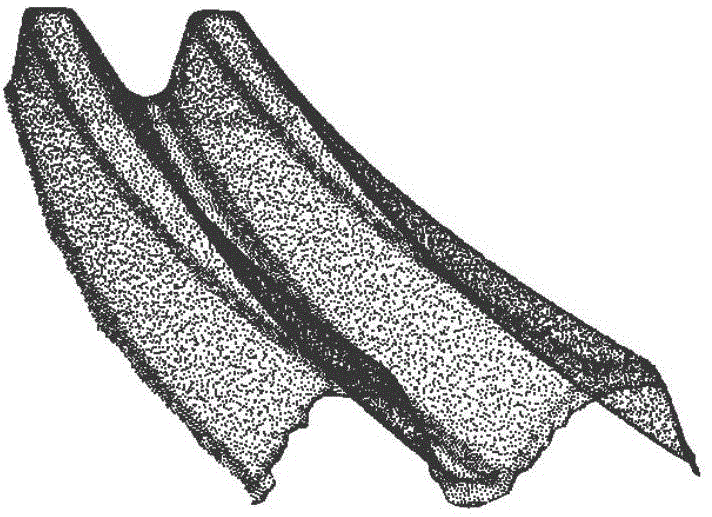

Online detecting method of spiral bevel gear machining process

InactiveCN104801784ARealize online measurementRealize online quantitative detectionMeasurement/indication equipmentsGear-cutting machinesPoint cloudLaser scanning

The invention provides an online detecting method of a spiral bevel gear machining process. The method comprises the following steps of 1, directly acquiring point cloud data of a gear on a gear machining machine tool by using a laser scanner; 2, pre-processing the point cloud data of the gear, converting the point cloud data into curve surface data with st1 format, and according to the curve surface data, building a reconstruction model of the detected gear; 3, taking the designed model of the gear as a reference target, re-positioning the reconstruction model of the gear; 4, making section lines of the reconstruction model and the designed model of the gear along the gear height direction and the gear length direction of the gear, and measuring the deviation value of the section lines. Online detection on a spiral bevel gear can be realized, and the gear is not required to be loaded or unloaded for multiple times in a detecting process, so that mounting error is avoided.

Owner:FUJIAN UNIV OF TECH

High-precision fiber-optic gyroscope inertial measurement device calibration method

InactiveCN104567932AAvoid the effects of inconsistent baselinesExcellent system levelCosmonautic vehiclesCosmonautic partsElectricityFiber

The invention discloses a high-precision fiber-optic gyroscope inertial measurement device calibration method which comprises the following steps: S1, respectively forwards turning a fiber-optic gyroscope inertial measurement device by 90 degrees, 180 degrees and 270 degrees for three times according to three axes of oi shaft (i refers to X, Y and Z), reversely rotating the device by 90 degrees, 180 degrees and 270 degrees for three times, and returning to an initial position; and S2, totally moving by 19 positions comprising the previous 18 turning positions and the initial position, fully exciting the error of the instrument under static and dynamic conditions, and performing optimal estimation by utilizing a parameter estimation method. According to the method disclosed by the invention, repeated electrification and power failure are not needed, the device is only turned according to a certain sequence, the parameters can be identified, and the influence caused by inconsistent reference in the repeated electrification and calibration process is avoided.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

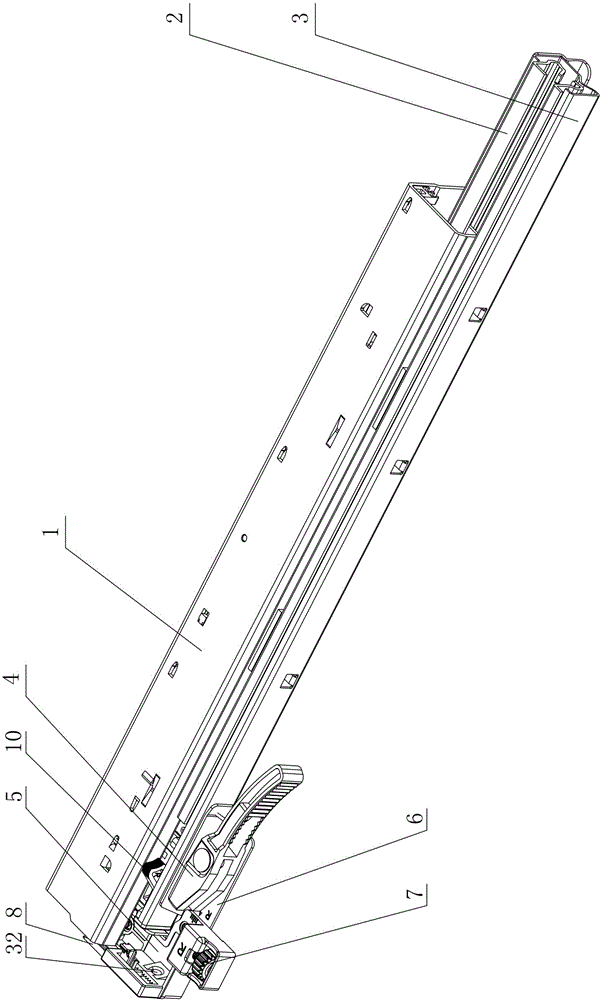

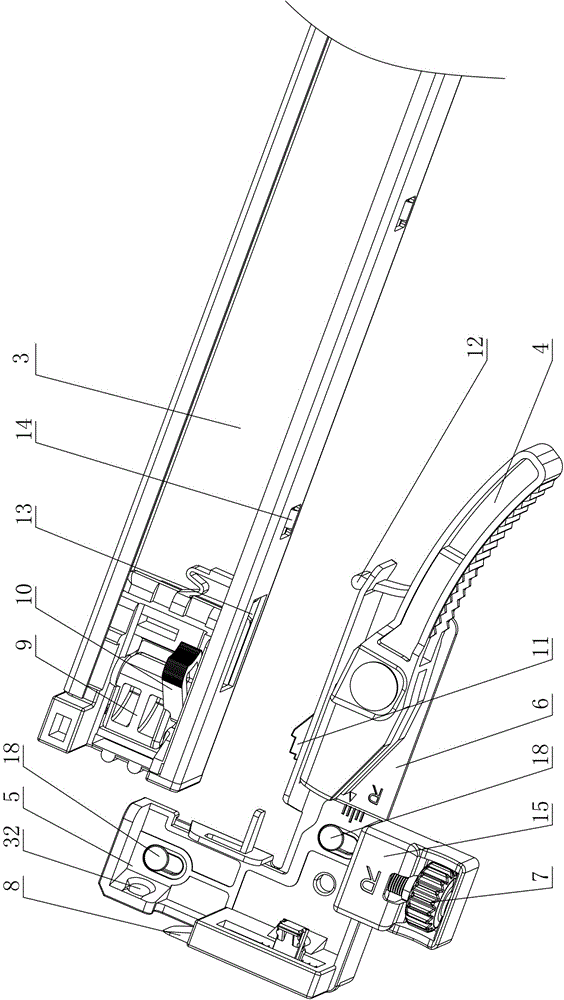

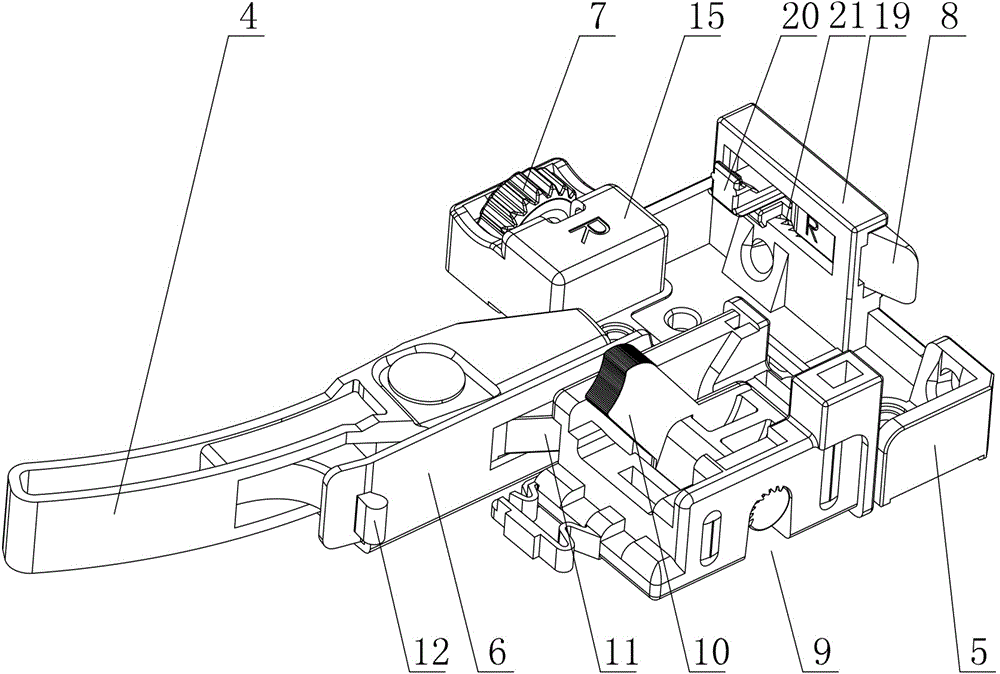

Removable multi-azimuth slide rail adjusting device

The invention discloses a removable multi-azimuth slide rail adjusting device. By means of the structural match of a handle, an adjusting base and an adjusting piece of the multi-azimuth slide rail adjusting device, slide rails, a drawer and a cabinet body can be assembled or disassembled fast, wherein the handle is buckled to a movable rail, the adjusting base is installed on the drawer, the adjusting piece is installed on the handle, stability is high, and operation is convenient and flexible. By means of the structural match of a left-right adjusting piece, a front-back adjusting piece and a height adjusting piece of the multi-azimuth slide rail adjusting device, the drawer can be installed in an adjusted mode according to the actual sizes of the components in the installing process, installation errors of the drawer are eliminated, the overall effect of the installed drawer in furniture is ensured, the stability of the slide rails can be improved, and normal use of the drawer is ensured.

Owner:GUANGDONG SACA PRECISION MFG CO LTD

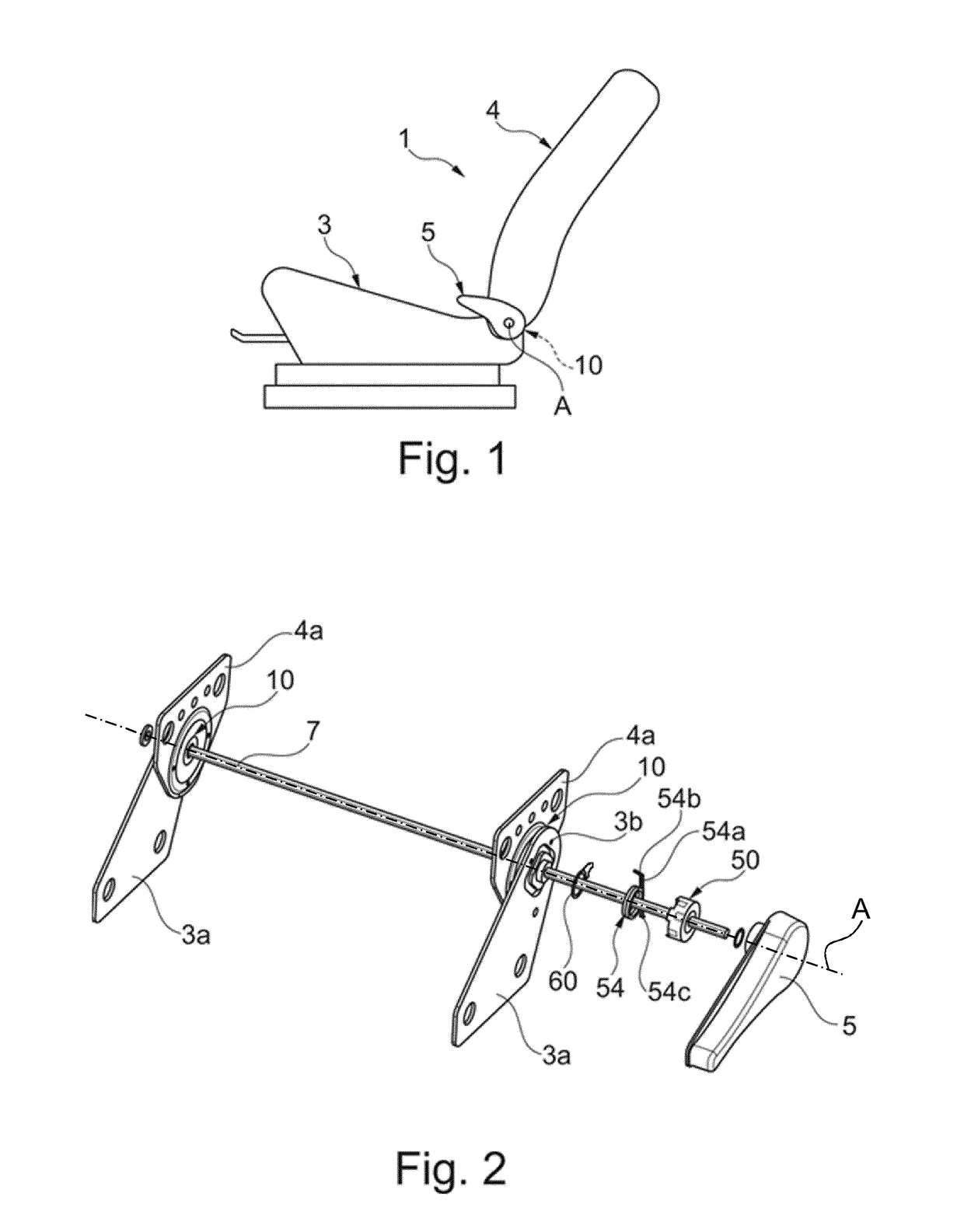

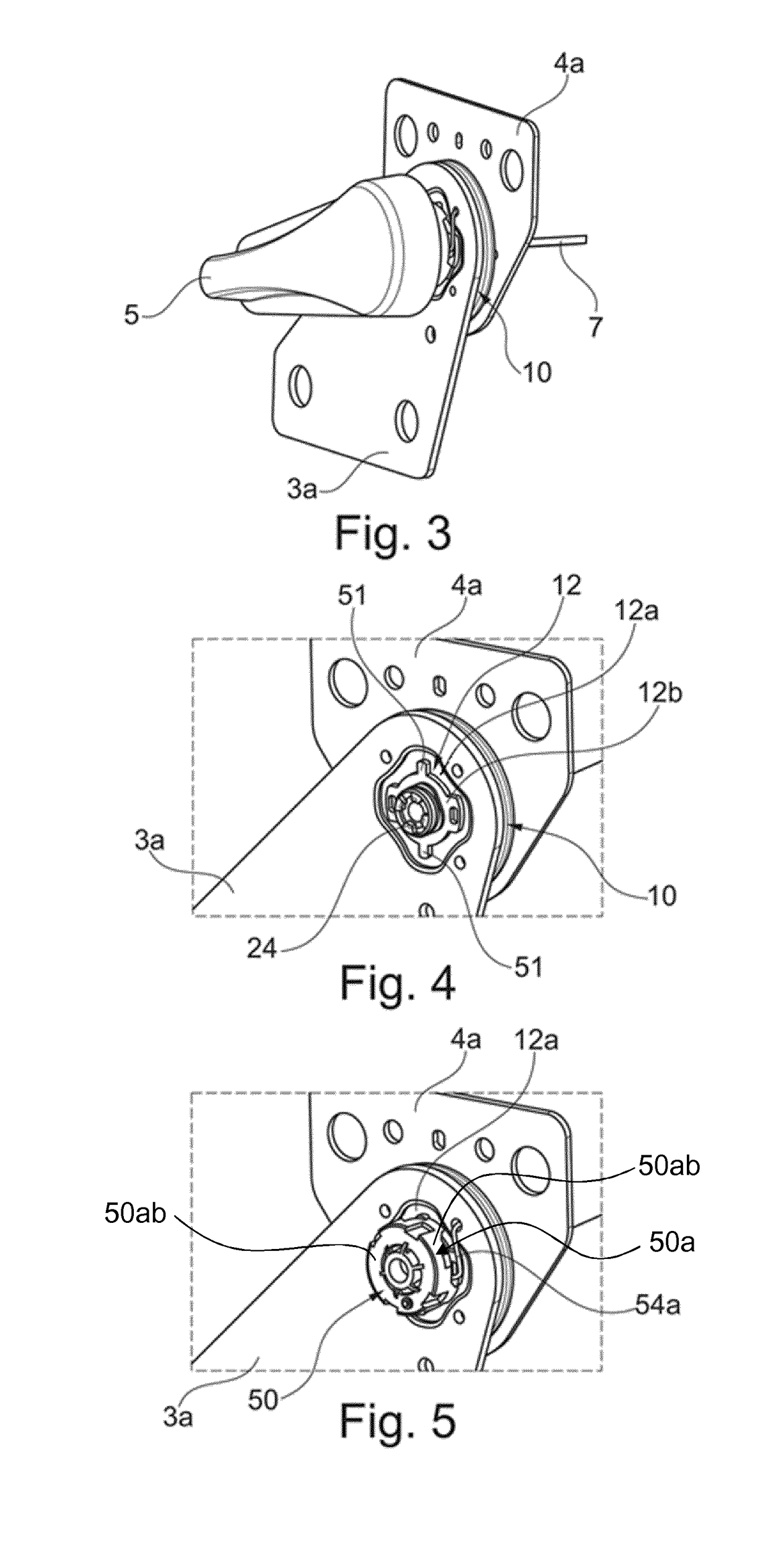

Fitting system for a vehicle seat and vehicle seat

ActiveUS9751432B2Small error probabilityAvoid installation errorsMovable seatsMechanical engineeringAngular range

Owner:KEIPER SEATING MECHANISMS CO LTD

Connecting piece used for fixing steel structure panel house frame and used in multi-angle orientation mode

InactiveCN111411700AAvoid installationAvoid installation errorsBuilding constructionsMechanical engineeringIndustrial engineering

Owner:王升

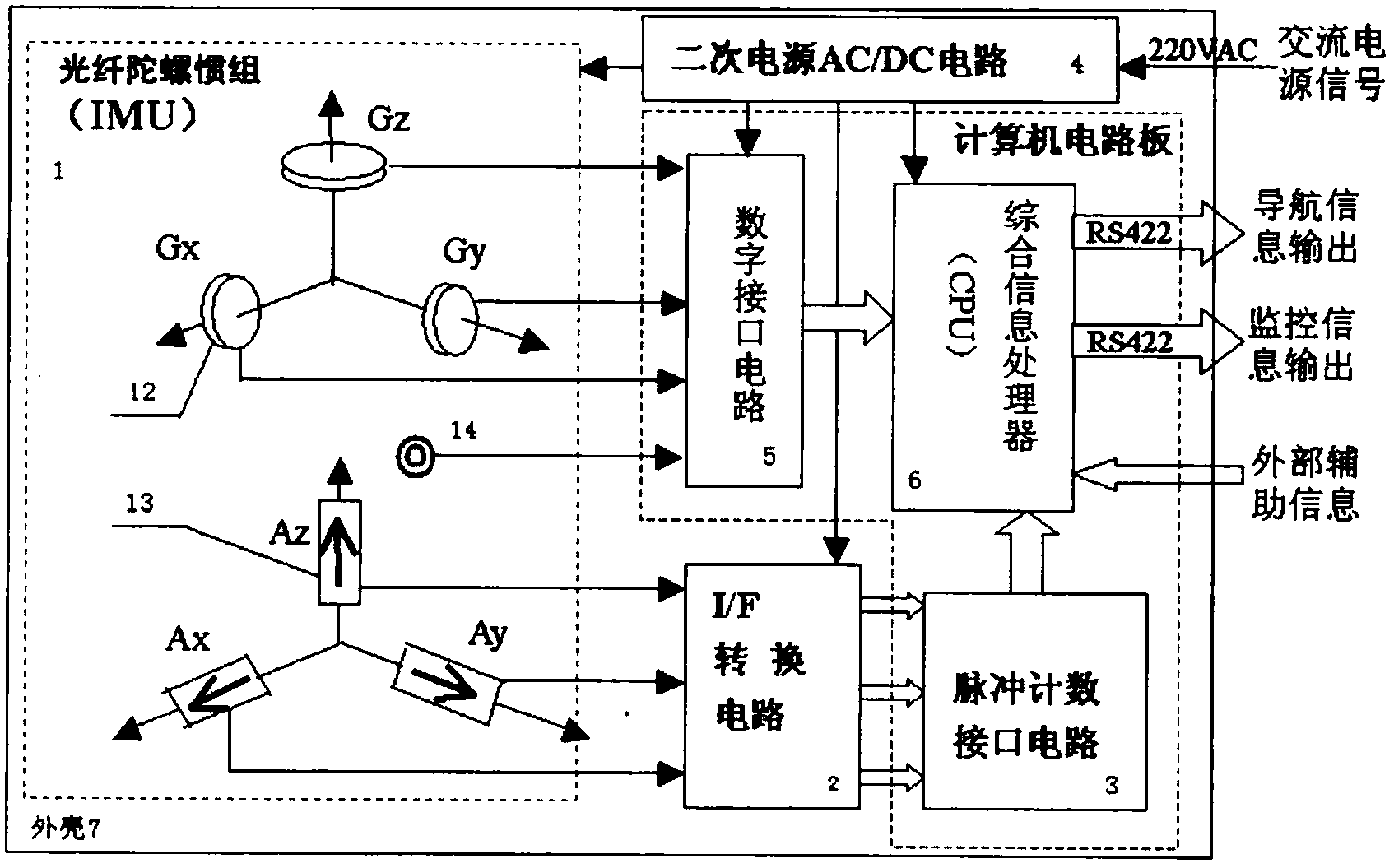

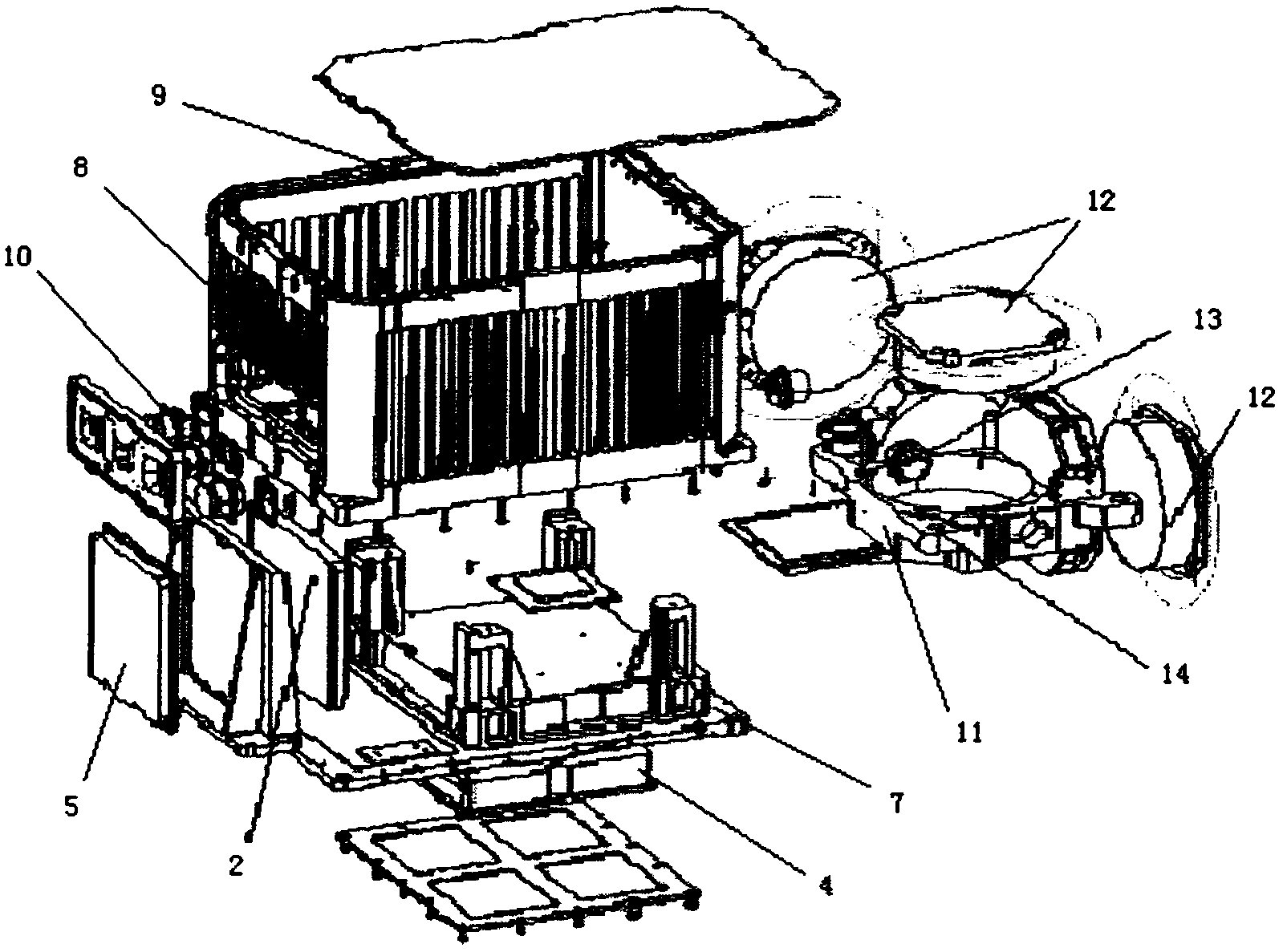

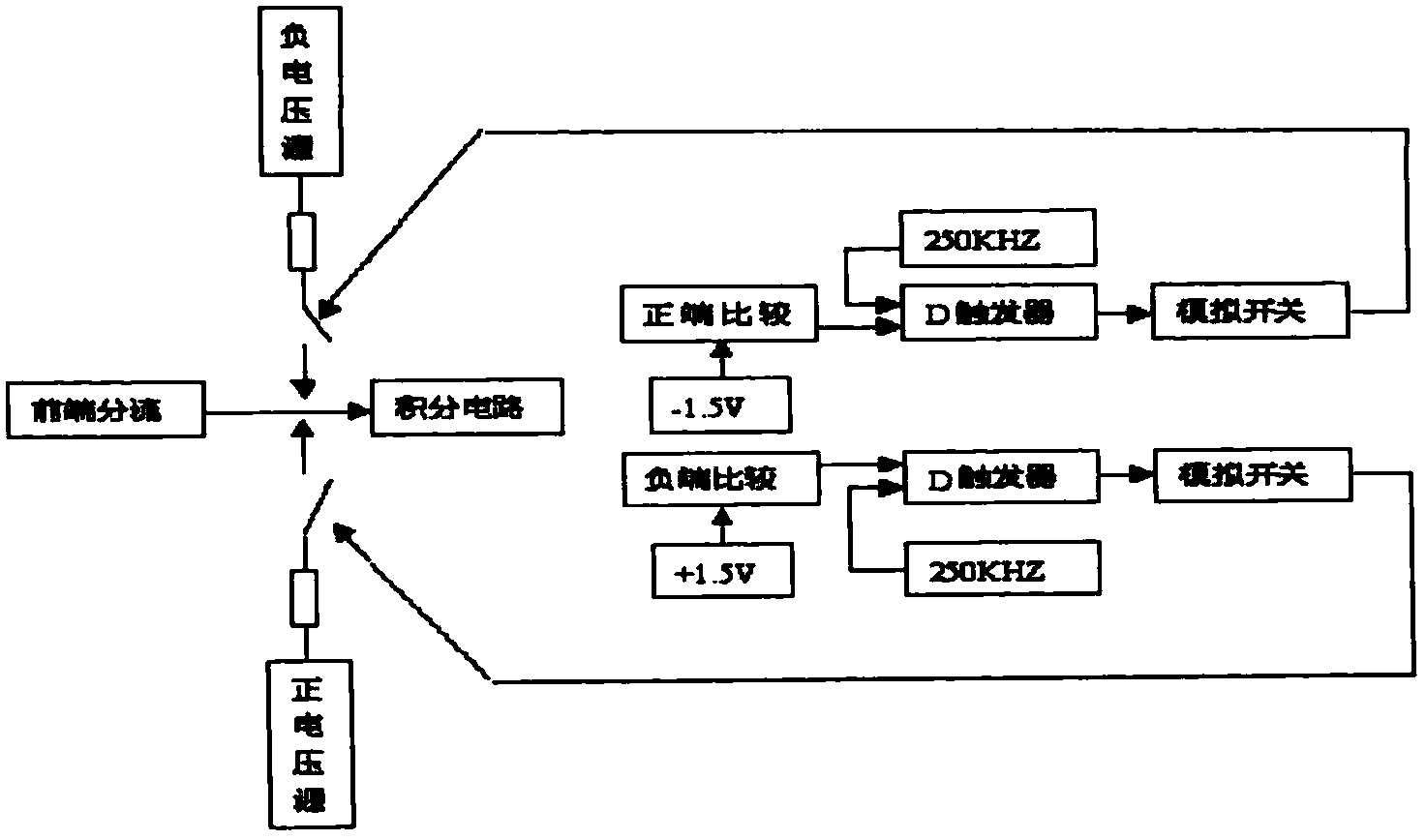

Marine integrated fiber optic gyro strapdown vertical reference system

ActiveCN105659812BImprove the accuracy of useGuarantee working reliabilityNavigation by speed/acceleration measurementsSagnac effect gyrometersInterface circuitsIntegrated circuit

The marine integrated optical fiber gyro strapdown vertical reference system adopts an integrated design, all of which are installed in one shell, including the optical fiber gyroscope inertial group, I / F conversion circuit, pulse counting interface circuit, secondary power supply AC / DC circuit, digital interface circuit 1. The integrated information processor CPU collects the original data of three fiber optic gyroscopes, three accelerometer outputs and temperature sensors via the digital interface circuit and the pulse counting interface circuit, uses the pre-established error model to perform error compensation, and then performs inertial navigation Calculation, on the basis of navigation calculation, establish the state equation of the system, and perform kalman filter according to the auxiliary velocity information input from the outside world, obtain the attitude error through filtering and complete the correction of pure inertia, so as to obtain high-precision attitude information output . The invention realizes the full digital output interface, has the advantages of compact structure, long service life, high reliability, good environmental adaptability and low power consumption, and can be applied to ship-borne weapons, vehicle-mounted weapon systems and the like.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

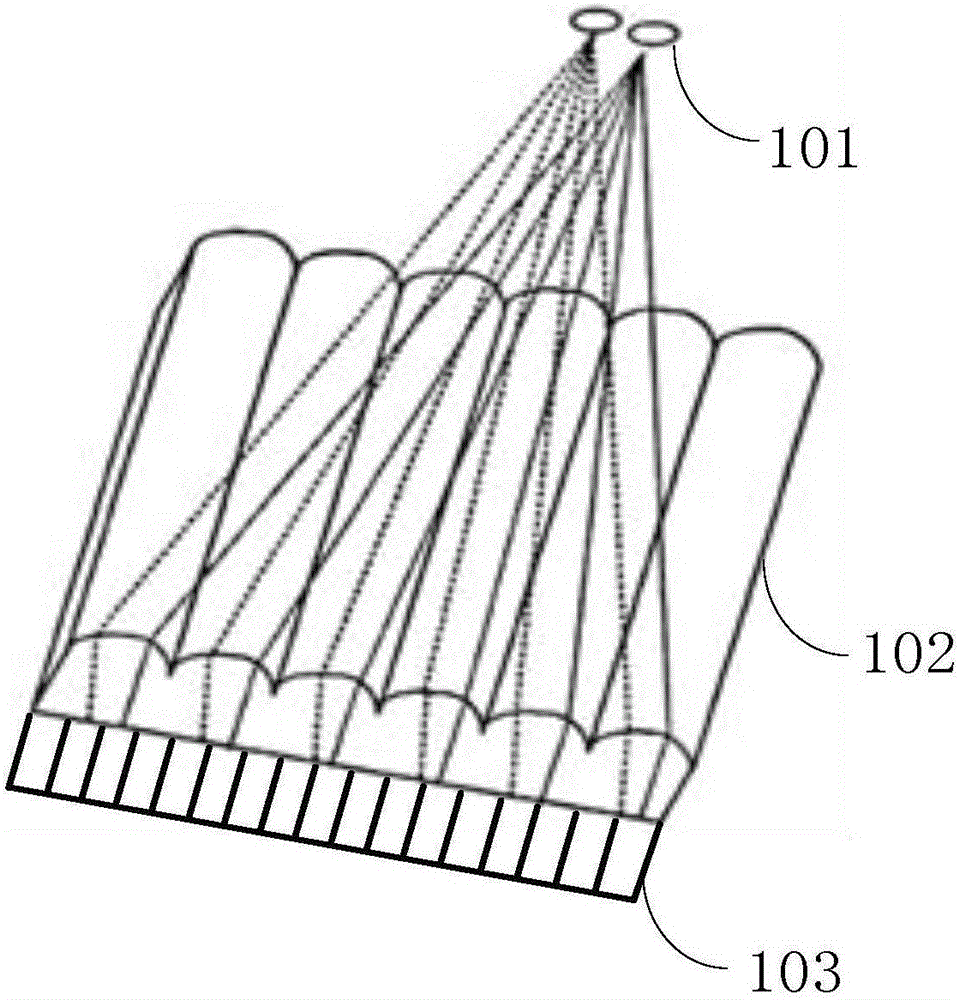

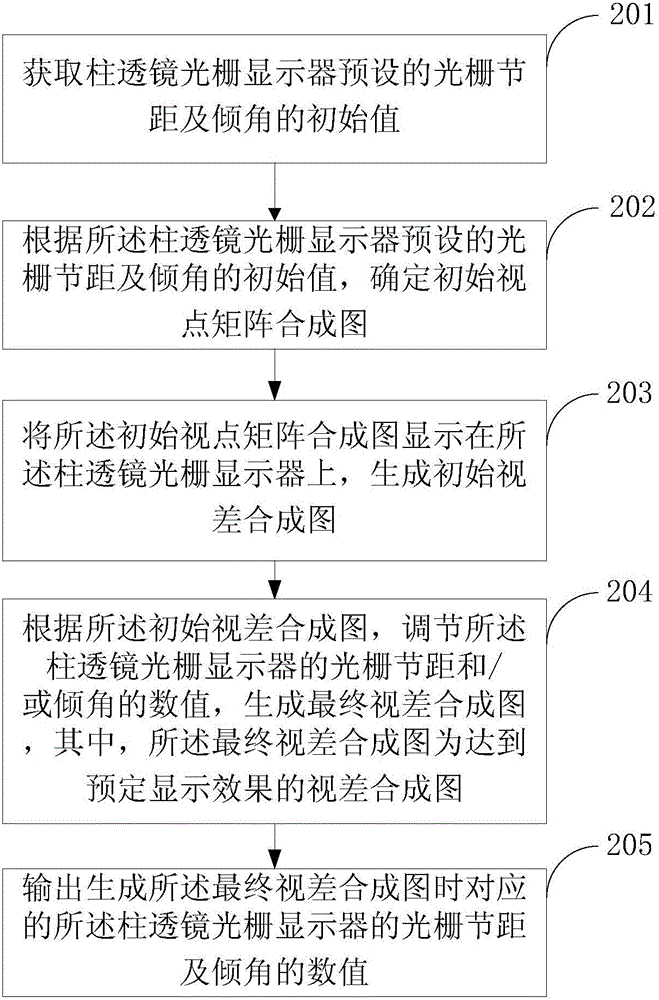

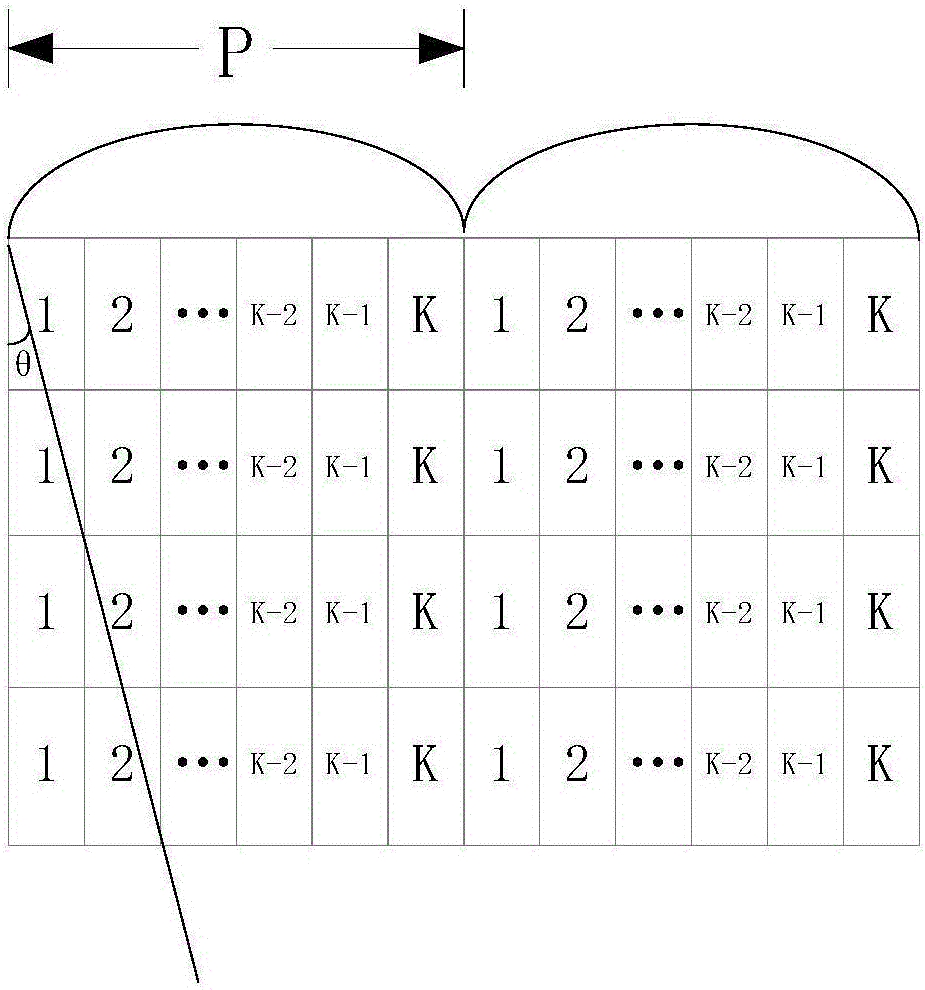

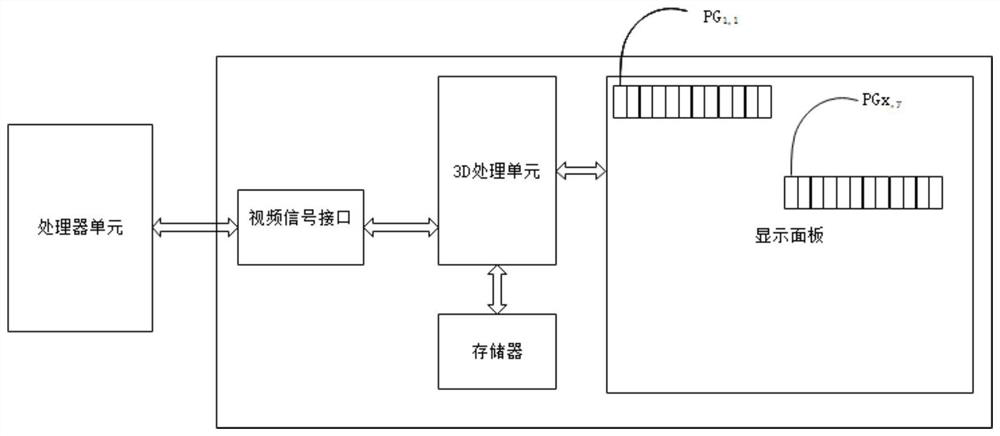

Grating parameter output method and device

ActiveCN105933697AAvoid installation errorsAccurate measurementSteroscopic systemsOptical elementsNumeric ValueDisplay device

The invention discloses a grating parameter output method and device, applied to the technical field of accurate measurement of parameters of 3D displays. The method comprises the following steps: obtaining a preset grating pitch and an inclination angle of a cylindrical lens grating display, and determining a view point matrix composite graph; displaying the view point matrix composite graph on the cylindrical lens grating display to generate a parallax composite graph; adjusting the grating pitch and the inclination angle of the cylindrical lens grating display to generate a final parallax composite graph; and outputting numerical values of the grating pitch and the inclination angle of the cylindrical lens grating display corresponding to the final parallax composite graph. According to the invention, the accurate measurement of the grating pitch and the inclination angle of the cylindrical lens grating display is achieved, and the mounting error between the cylindrical lens grating and a 2D display is effectively avoided, thereby being more labor-saving and time-saving.

Owner:BEIJING UNIV OF POSTS & TELECOMM

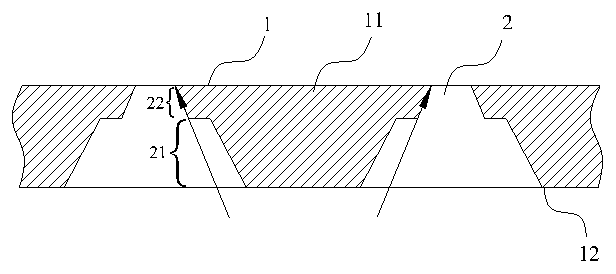

Mask plate and processing method thereof

InactiveCN103014619AImprove machining accuracyImprove processing efficiencyVacuum evaporation coatingSolid-state devicesEvaporationIndium tin oxide

The invention relates to a mask plate and a processing method thereof. The mask plate comprises an indium tin oxide (ITO) contact surface and an evaporation surface, wherein a plurality of evaporation holes are formed on the evaporation surface; the evaporation holes penetrate through the ITO contact surface from the evaporation surface, and the section of the evaporation holes is in a step shape; the evaporation holes comprise first sections and second sections which are coaxially arranged; the sizes of the evaporation holes are gradually shrunk from the first sections to the second sections. The processing of the evaporation holes is finished through a laser process only, the required secondary detachment and clamping process are saved in the process of processing the evaporation holes through multiple processes, and the mounting error brought by the operation of processing the evaporation holes through multiple processes is avoided, so that the processing precision and processing efficiency of the evaporation holes can be effectively improved, and the production cost of the mask plate is reduced; and the manufacturing cost of an organic light emitting diode (OLED) display screen is reduced, and the mask plate has wide market prospect.

Owner:南京澄超光电科技有限公司

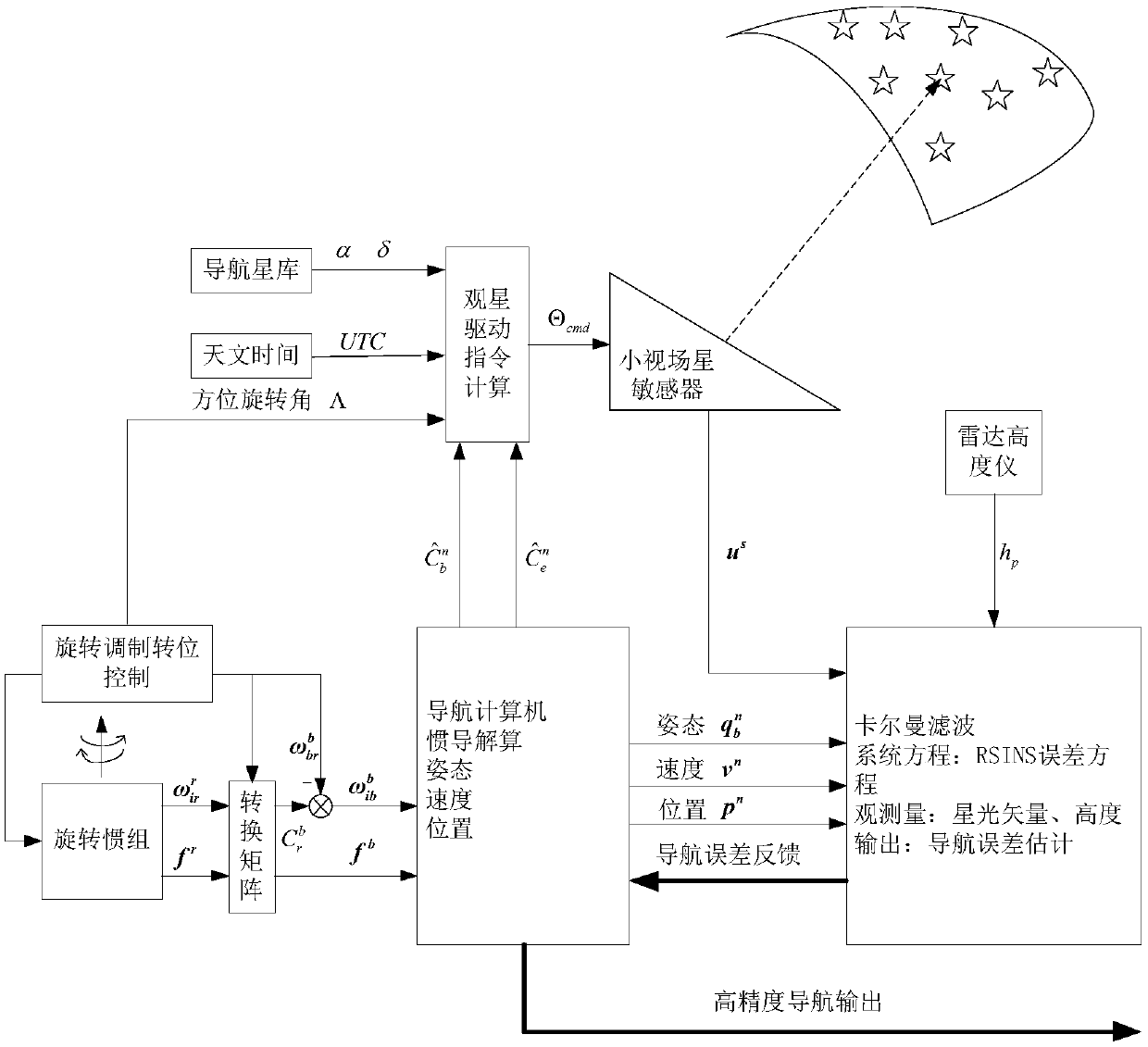

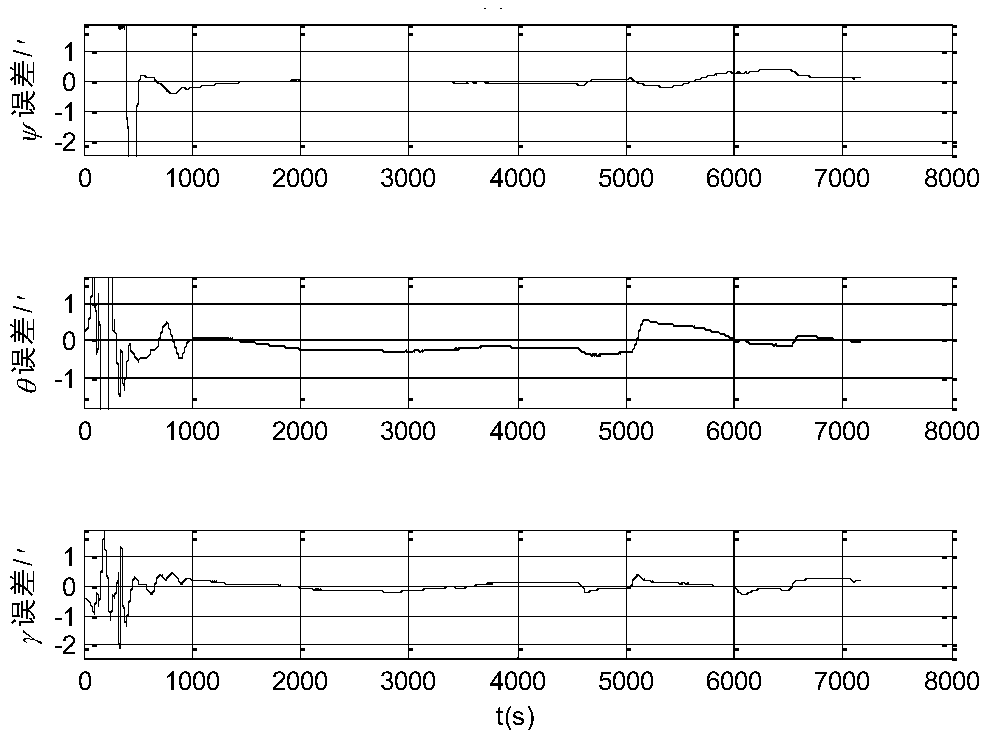

Uniaxial rotational modulation based inertial and celestial combined navigation system and calculation method

ActiveCN108731674AReduce divergenceSolve misalignmentNavigational calculation instrumentsNavigation by speed/acceleration measurementsIntegral actionCelestial navigation

The invention discloses a uniaxial rotational modulation based inertial and celestial combined navigation system and a calculation method. The system comprises a uniaxial rotational modulation strap-down inertial navigation system, a celestial navigation system and a horizontal rotating table. A rotational modulation shaft of the uniaxial rotational modulation strap-down inertial navigation systemis coincided with a shaft, perpendicular to the horizontal rotating table, of the celestial navigation system so as to realize rotational modulation along with rotation of the rotational modulation shaft. By selection of a reasonable rotating mode, inertial device biases form periodic signals under a navigation coordinate system, and caused navigation errors are eliminated through the integral action. By combination of the uniaxial rotational modulation based inertial and celestial combined navigation system and the calculation method based on the same, high-precision high-reliability navigation information output is realized, and demands of current navigation users are met.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

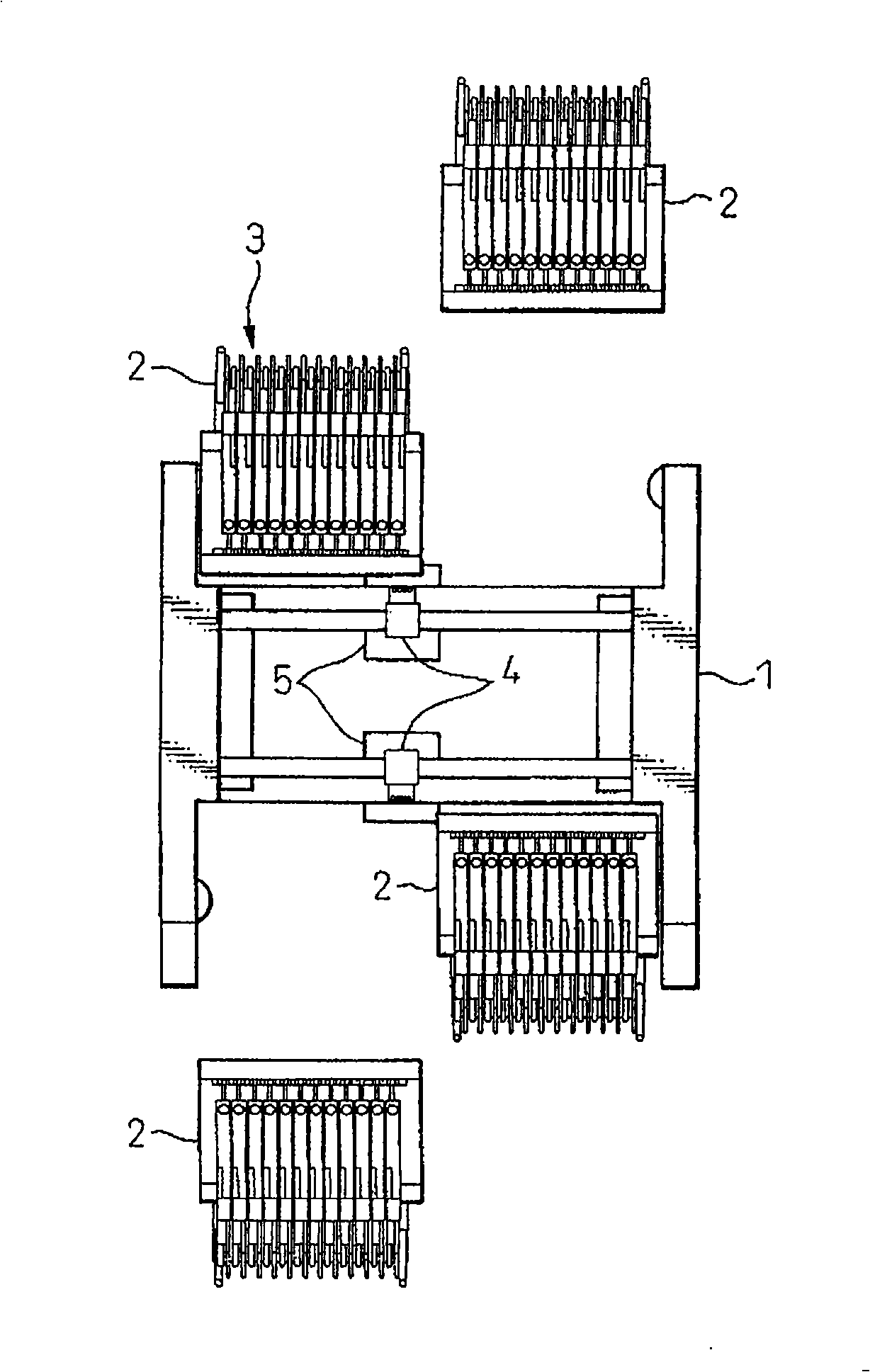

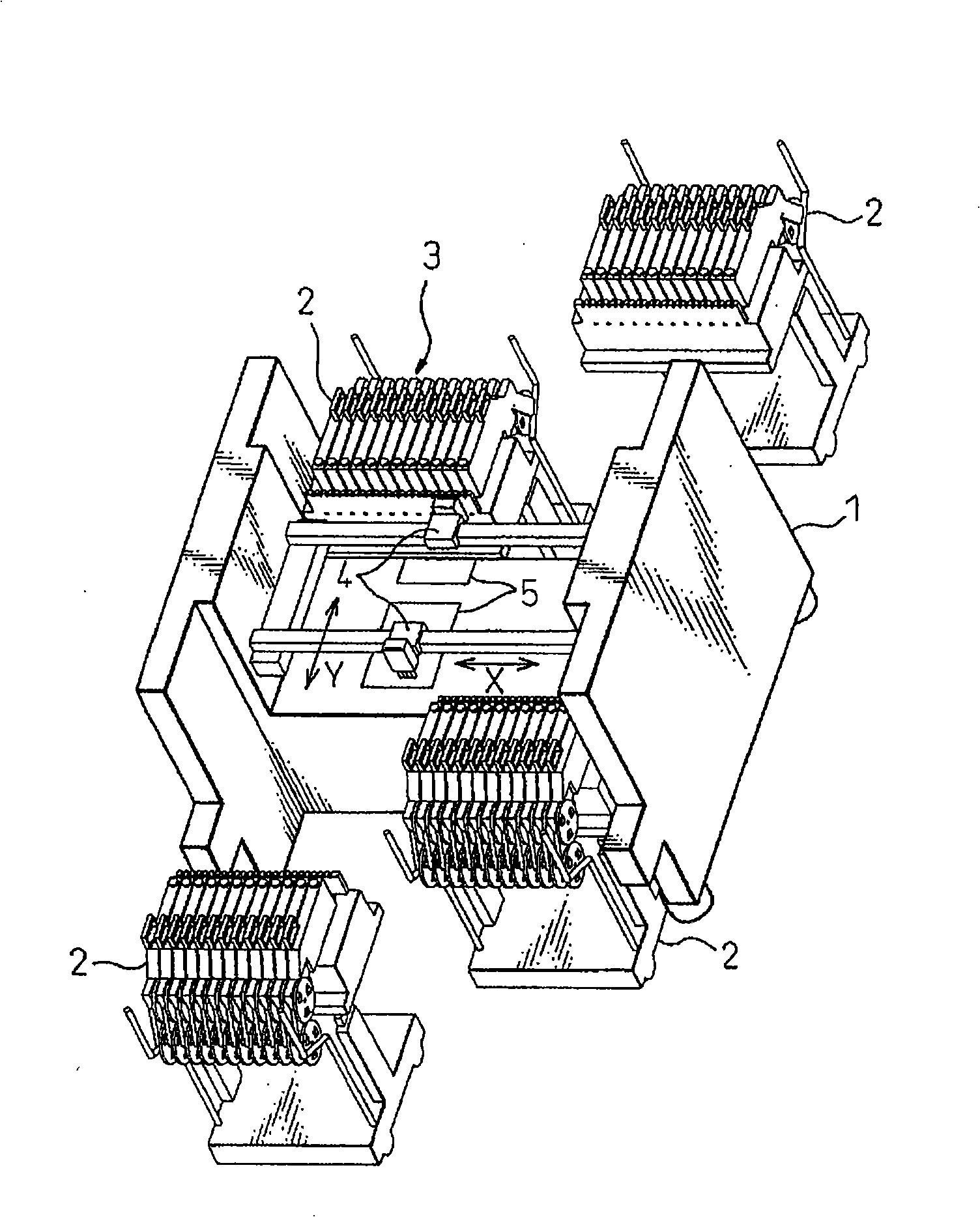

Operation support system of element assembling device, recognition method of element order and recognition method of Cassette holder order

InactiveCN101310578AAvoid installation errorsAccurate identificationElectrical componentsProduction lineSupporting system

An operation supporting system is provided for a component mounting apparatus, which is arranged on a production line for manufacturing a printed board unit incorporating a component in a printed board and mounts the component on the printed board. A cassette (50) is provided with a tag (56) wherein cassette identifying information is recorded for identifying the cassette (50) wherein at least one of reels (51, 52) with a wound tape having a component (53) is mounted; and a tag (54) wherein component identifying information is recorded for identifying the component (53) incorporated in the reels (51, 52) stored in the cassette (50).; The operation supporting system is provided with an ID reading unit (45), which is arranged at a distance from the production line, and reads the cassette identifying information and the component identifying information from the cassette; a storage unit for storing information for specifying a component to be mounted in a previously set cassette; and a component mounting checking unit, which compares the component identifying information with the specification information corresponding to the cassette identifying information, and checks whether the component (53) mounted in the cassette (50) is correct or not.

Owner:FUJITSU LTD

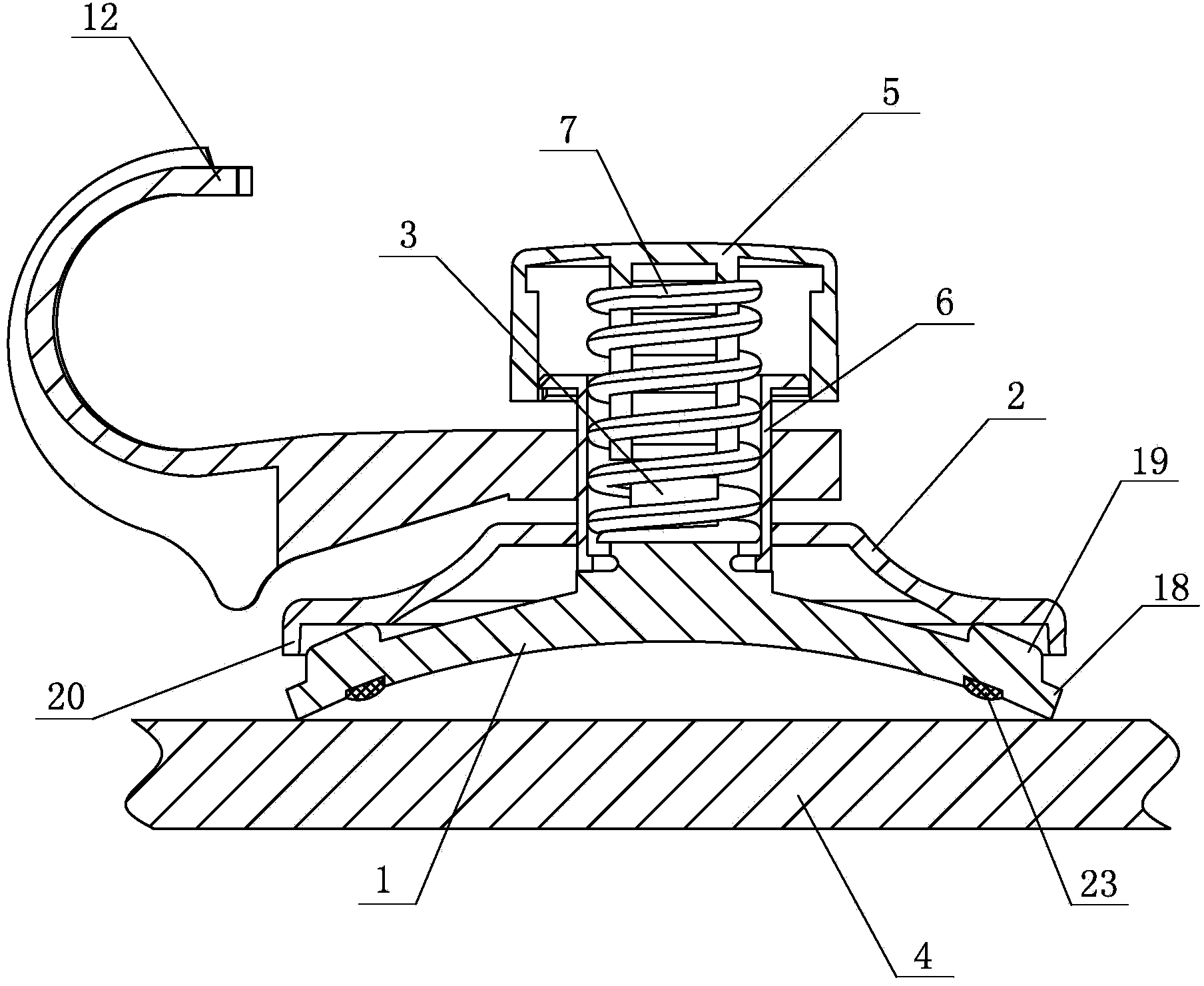

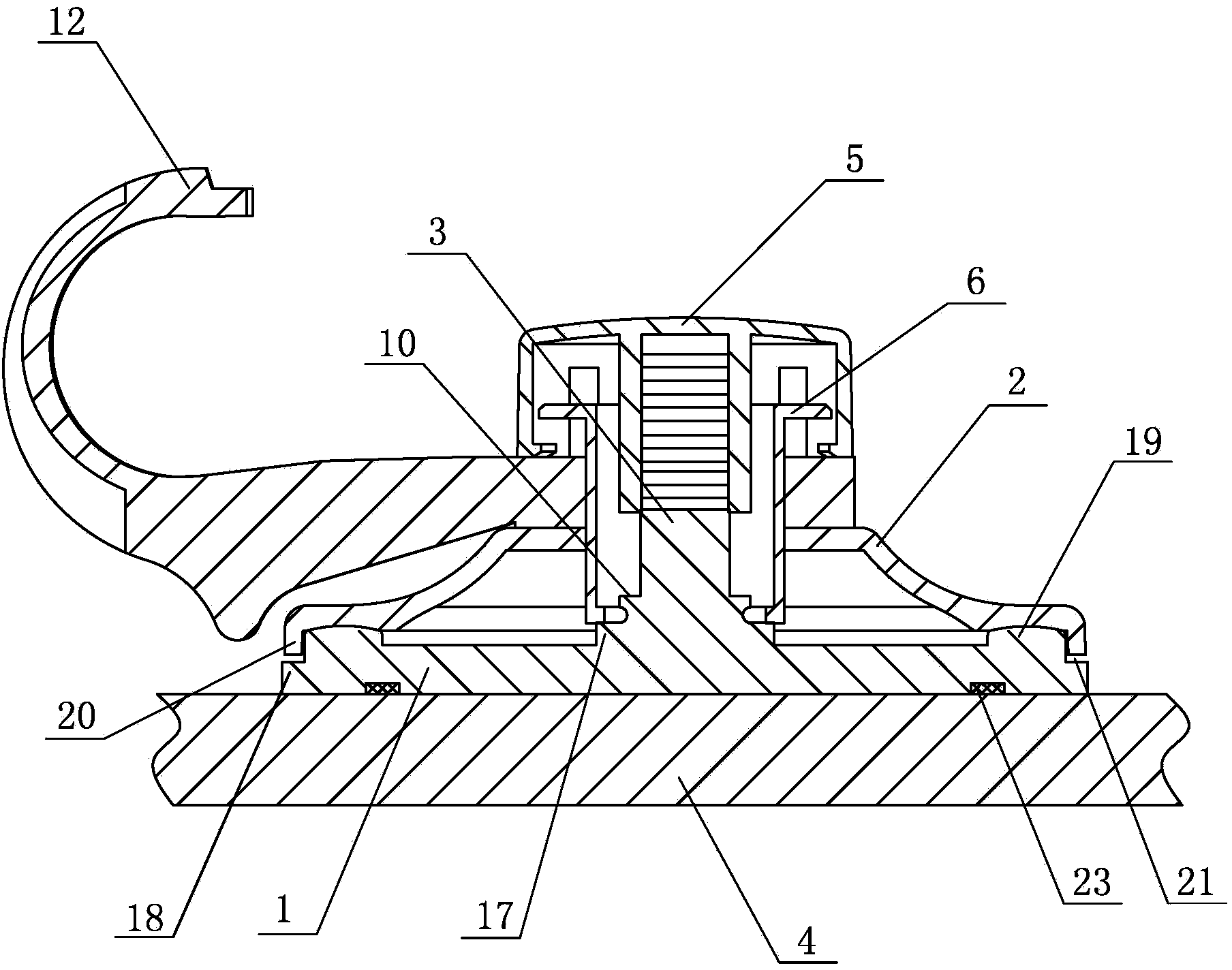

Sucker and sucking method thereof

InactiveCN103758848AAvoid installation errorsEasy to installSuction cupsEngineeringInstallation Error

The invention discloses a sucker. The sucker comprises a sucker base made of an elastic material, a sucker cover plate and an elastic pressing part. The sucker cover plate and the elastic pressing part are arranged on the back of the sucker base. The sucker is characterized in that the elastic pressing part comprises an outer cover, an inner cover and a spring, the spring is arranged between the outer cover and the inner cover, a sleeve is arranged inside the outer cover, the sleeve can penetrate the spring and the inner cover to be in threaded connection with a center connecting piece, the outer cover and the inner cover are movably connected, and the bottom of the center connecting piece is connected with the bottom of the inner cover. Mounting error of a consumer can be effectively avoided, firmness and durability of the sucker are improved, and the sucker is human friendly and reusable.

Owner:TECMAGIC TECHMOLOGIES JIANGYIN CO LTD

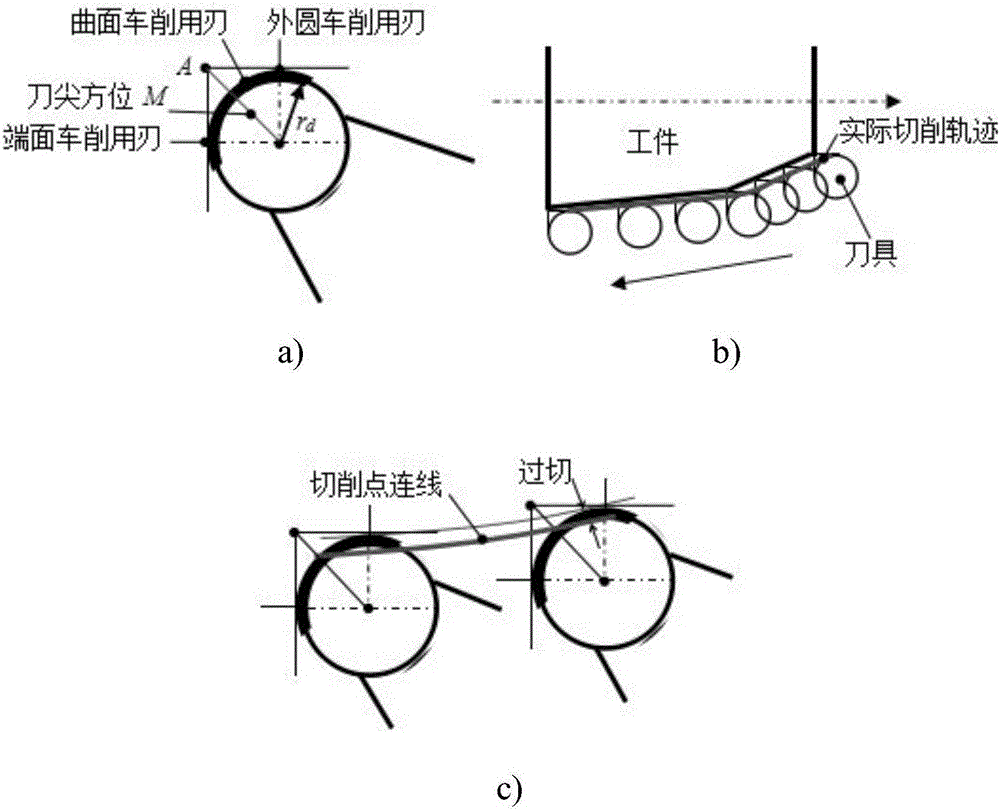

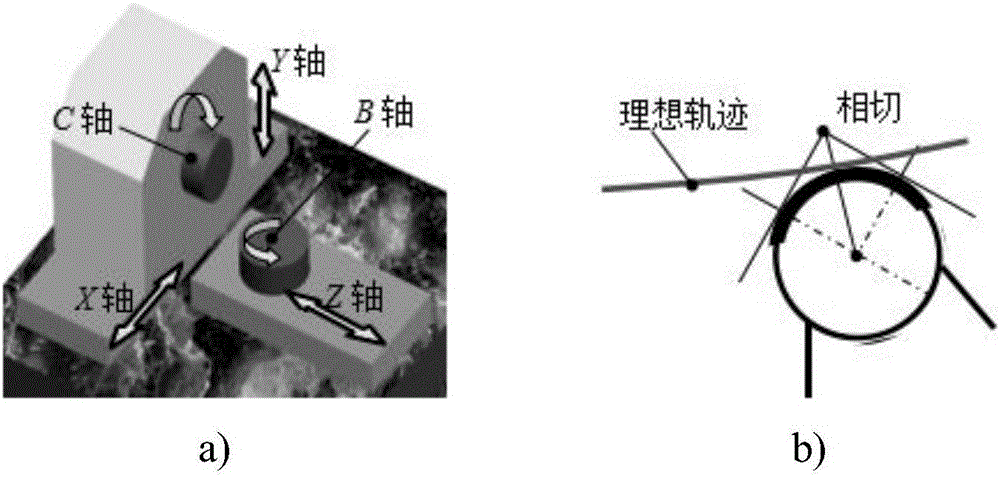

Method for precisely turning high-gradient aspheric surface through arc-edge diamond cutter

ActiveCN105867311AReduce processing costsReduce manufacturing costNumerical controlCurve lineComputer science

The invention discloses a method for precisely turning a high-gradient aspheric surface through an arc-edge diamond cutter. It is guaranteed that an arc edge of the cutter and a meridian section curve line of a workpiece are tangent at an interpolation point in the turning process by calculating the interpolation segmentation number and the interpolation point number through given machining indexes, optimizing the interpolation chord length and determining the movement trail of the cutter axis. According to the method, machining is conducted through tangency of the arc edge of the diamond cutter and the workpiece, high-precision machining of the high-gradient aspheric surface can be completed without participation of a B shaft, the problem of machining the high-precision large-gradient aspheric surface is solved on the condition that the B shaft is not additionally arranged, and single-shaft installation and control errors brought by additional arrangement of the movement B shaft and multi-shaft coordination errors are avoided; meanwhile, the manufacturing cost of a machine tool is greatly reduced, and then the machining cost of the high-gradient aspheric surface is reduced.

Owner:HARBIN INST OF TECH

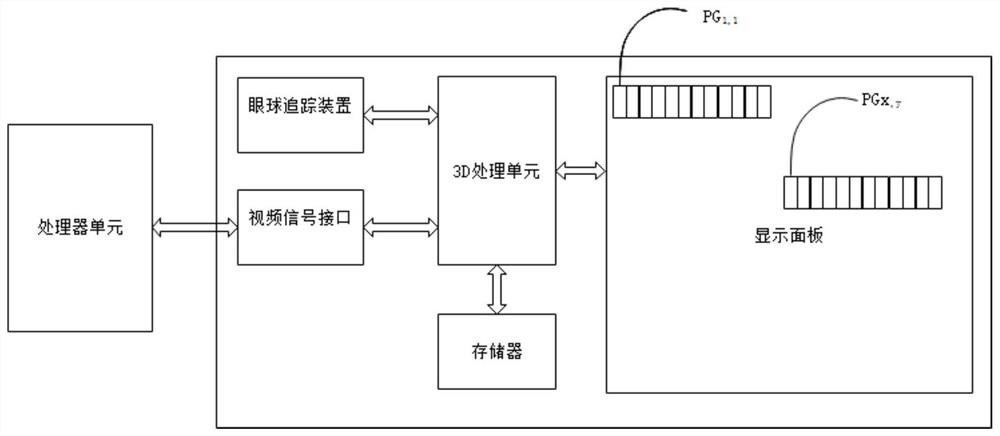

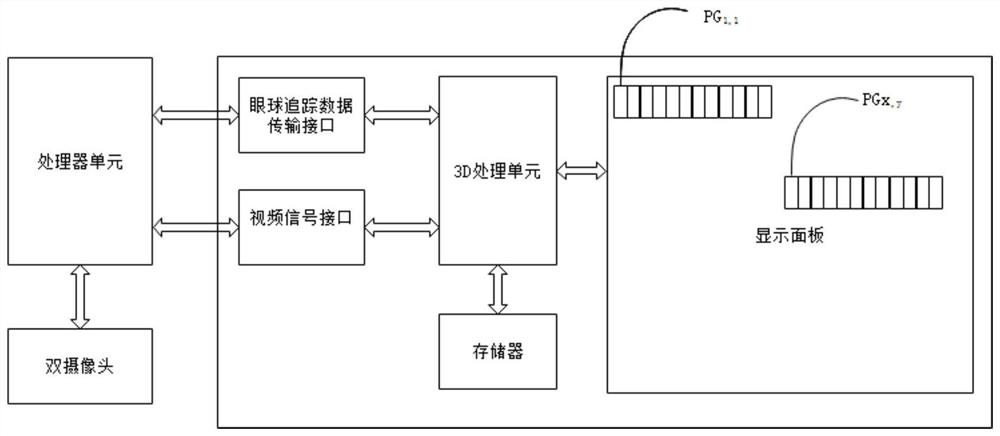

Naked-eye stereoscopic display system with lossless resolution

PendingCN111757088AImprove reliabilityHigh Reliability High DefinitionSteroscopic systemsPhysicsImage resolution

The invention relates to a multi-viewpoint naked-eye stereoscopic display device comprising a display screen with a display panel and an optical grating, a video signal interface for receiving 3D video signals and one or more 3D video processing units. The display panel comprises a plurality of rows and columns of pixels and defines a plurality of pixel groups. Each pixel group is composed of at least three pixels and corresponds to multi-viewpoint setting, and the one or more 3D video processing units are configured to generate a plurality of images corresponding to all viewpoints or a predetermined viewpoint based on the images of the 3D video signal and render the corresponding pixels in each pixel group according to the generated plurality of images. In some embodiments, the mutual arrangement positions of the plurality of pixel groups are adjusted or determined based on the optical relationship data of the pixels and the gratings and / or the corresponding relationship data of the pixels and the viewpoints of the display panel. The invention further provides a naked-eye stereoscopic display system, a display method of the naked-eye stereoscopic display device and a pixel group arrangement method of the naked-eye stereoscopic display device.

Owner:刁鸿浩

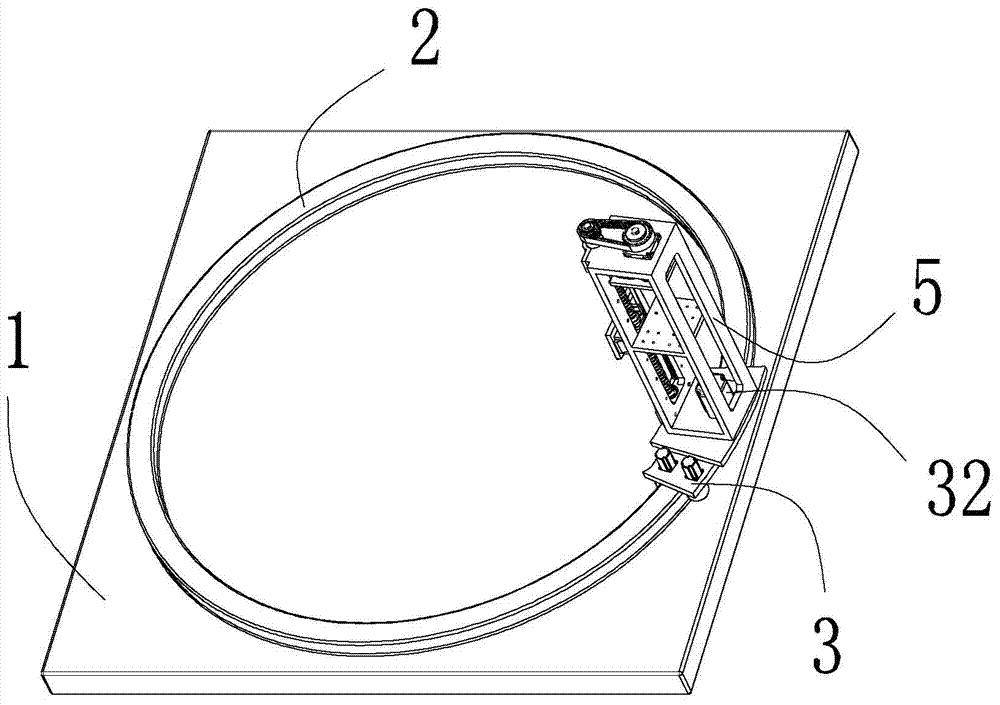

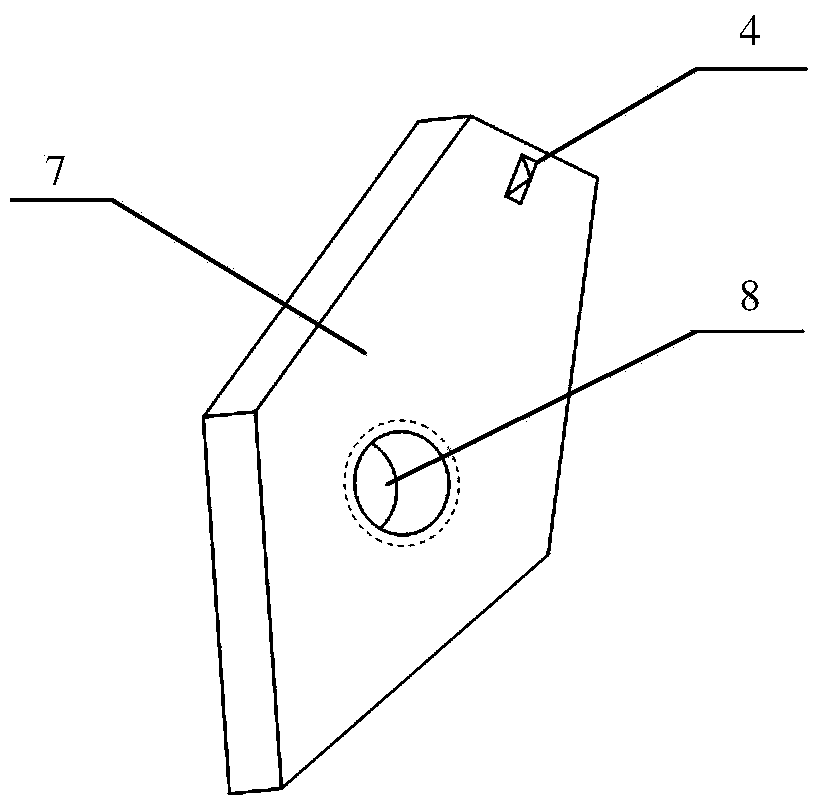

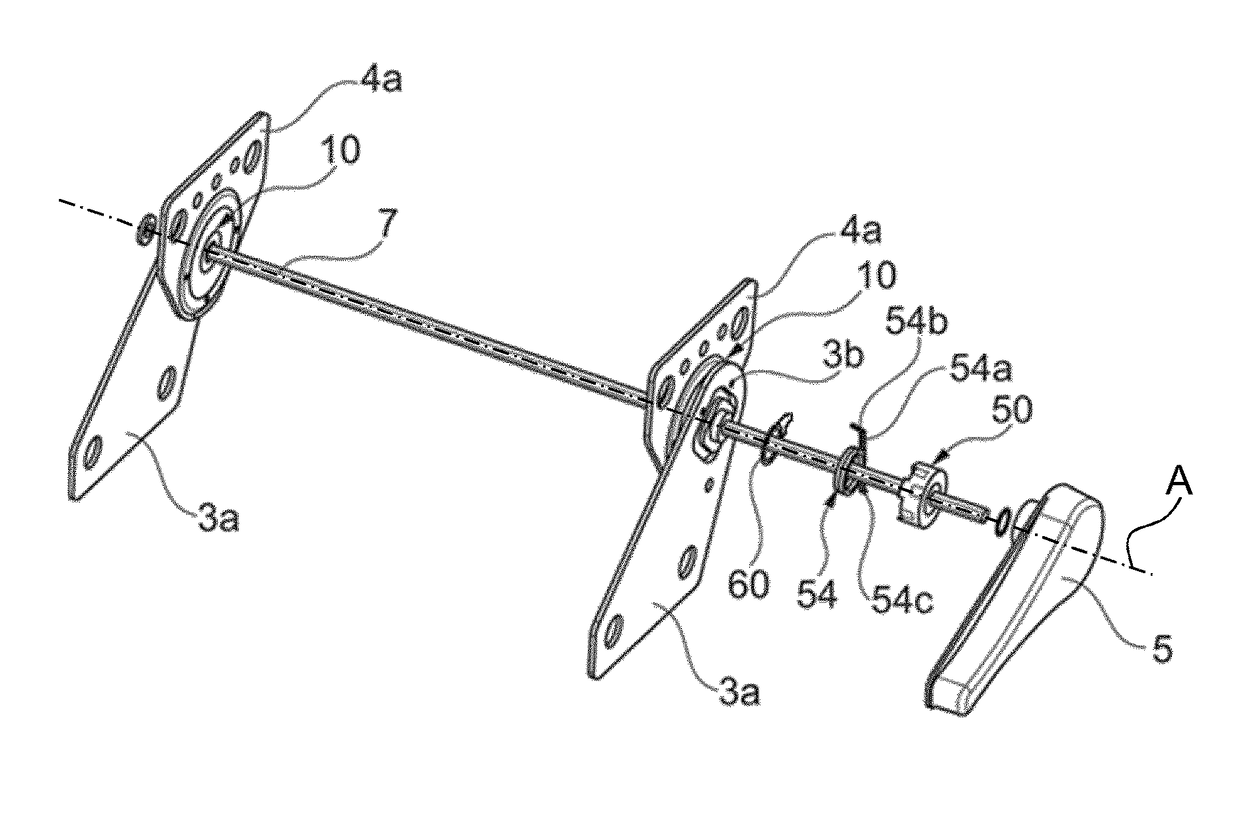

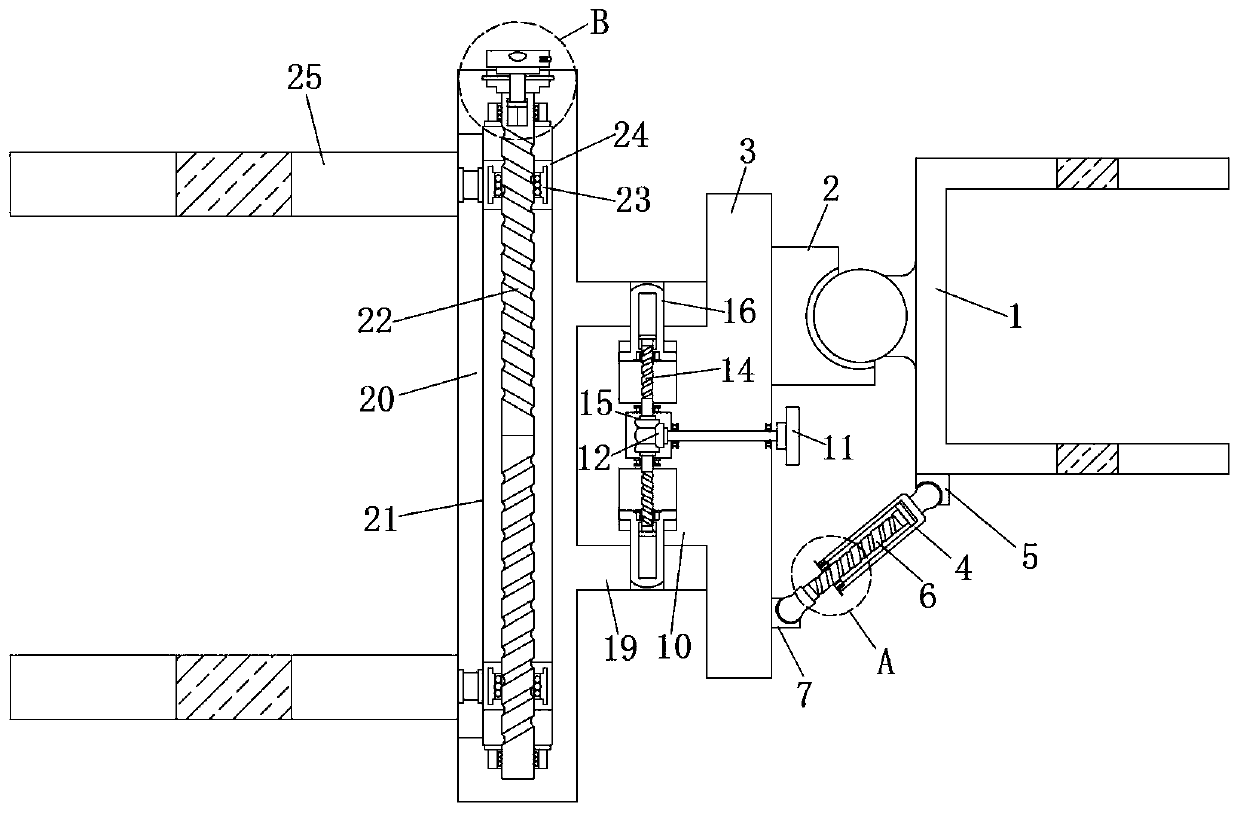

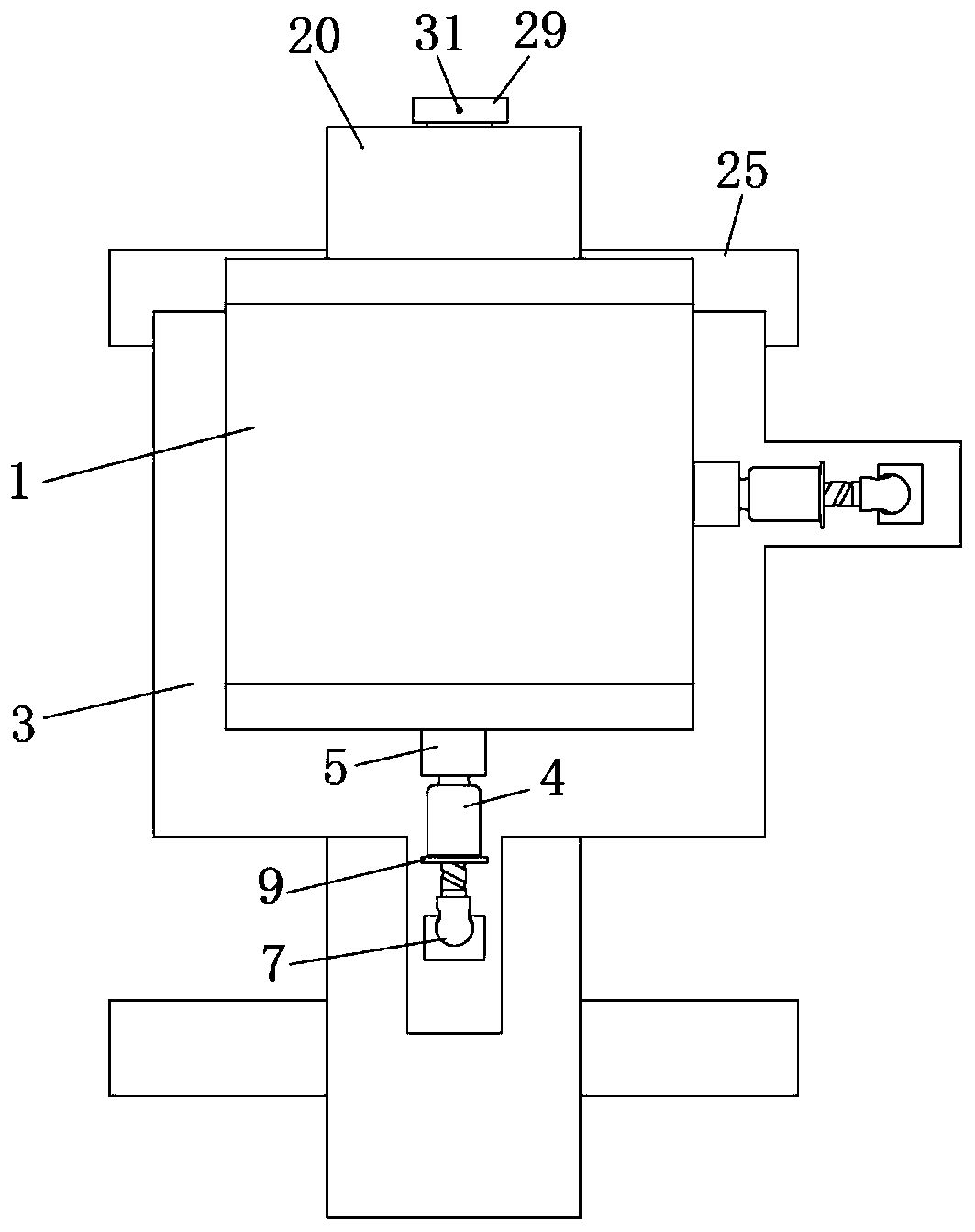

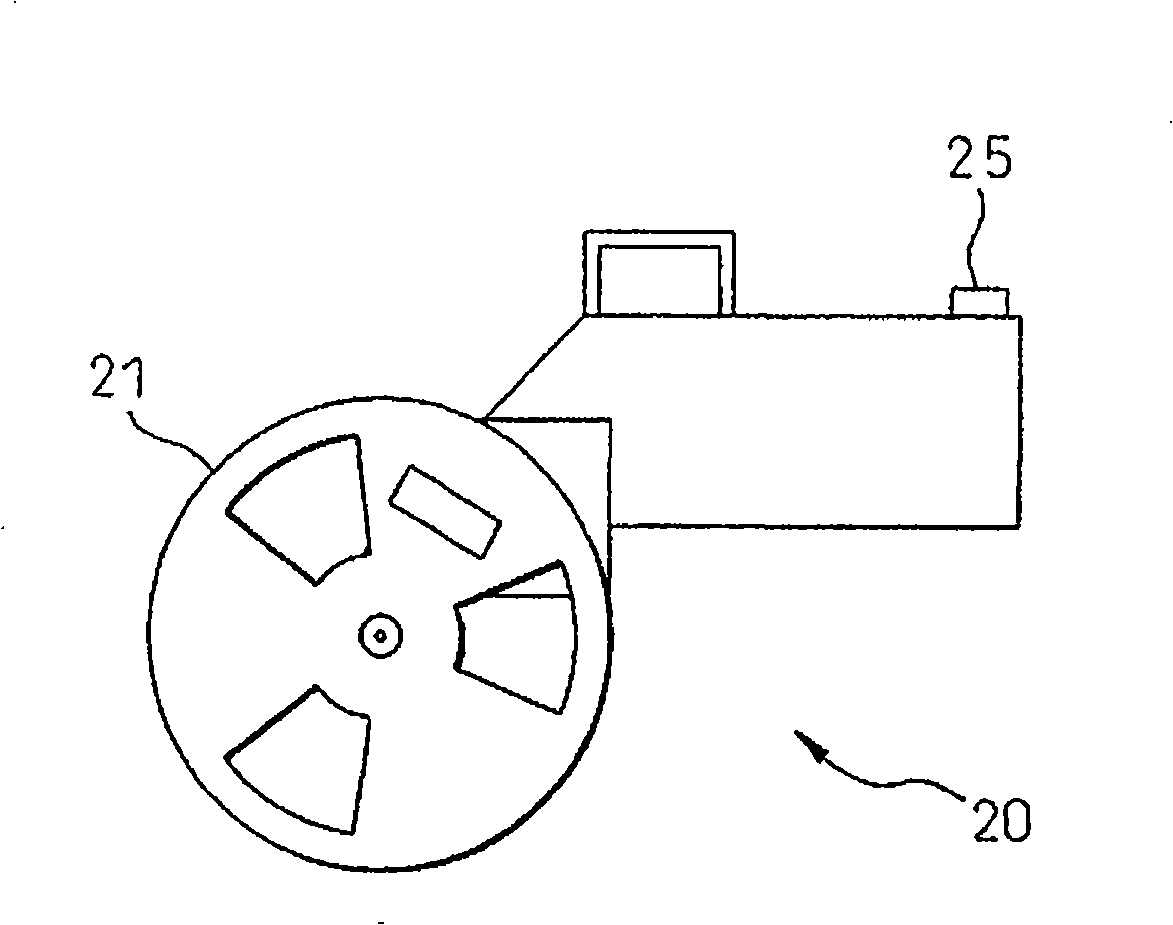

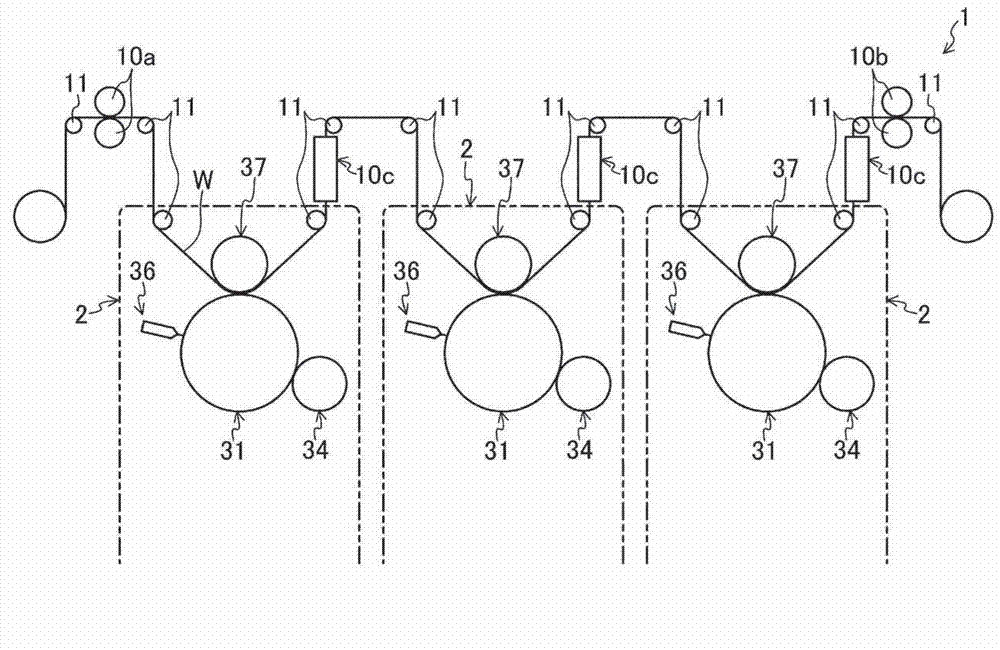

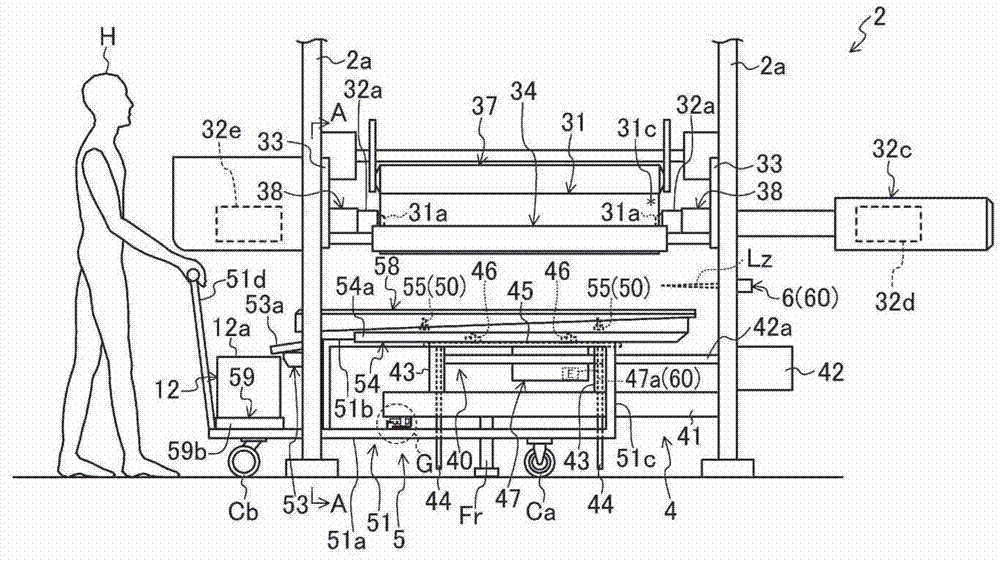

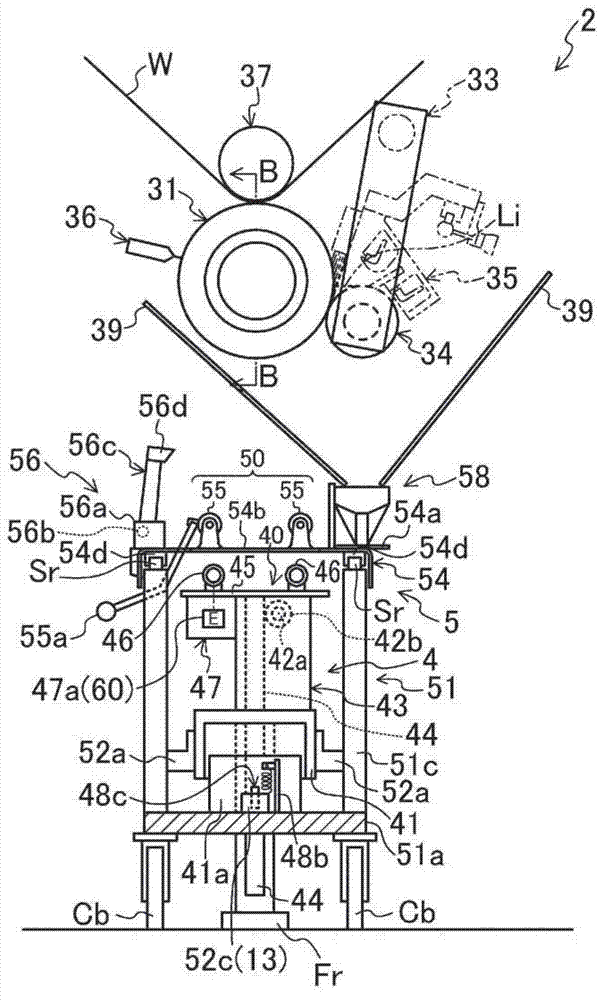

Printer and method for replacing plate cylinder thereof

ActiveCN103158346AShort stop timeImprove work efficiencyRotary intaglio printing pressPrinting press partsStop timeEngineering

The invention discloses a printer and a method for replacing a plate cylinder thereof. The plate cylinder (31) comprises a key groove (31b) and a registration mark (31c). The plate cylinder (31) is moved above or off from a printing unit (2) by a cart (5). The printing unit (2) comprises a plate cylinder hand-over mechanism (4), by which the plate cylinder (31) is handed over between two vertical frames (2a) and the cart (5), and a key groove position detection mechanism (60) for detecting the position of the key groove (31b). The cart (5) is provided with a plate cylinder rotation part (50) which enables the plate cylinder (31) to rotate around an axle center so that the registration mark (31c) can be positioned at a pre-determined position. The angle of the key groove (31b) and the registration mark (31c) around the axle center can be calculated by a control panel (7). Accordingly, the stopping time of the printer when the plate cylinder is replaced can be shortened, and the efficiency can be bettered.

Owner:FUJI KIKAI IND

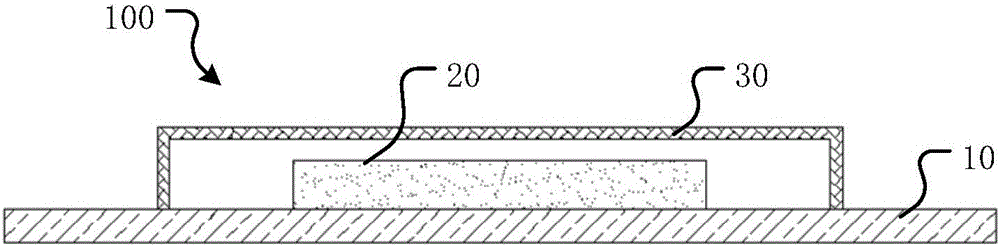

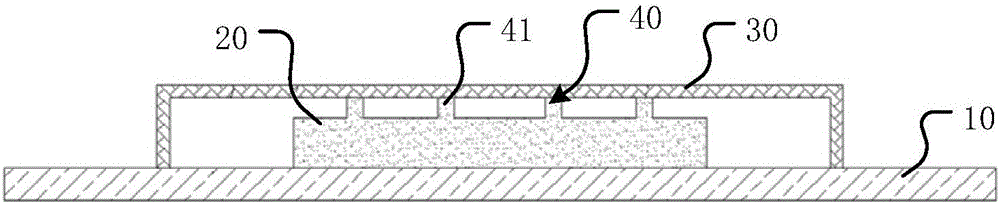

Cooling structure of package chip

ActiveCN106206493AAvoid installation errorsImprove EMC performanceSemiconductor/solid-state device detailsSolid-state devicesHeat sinkInstallation Error

The invention relates to the field of chip package, in particular to a cooling structure of a package chip. The cooling structure comprises a printed circuit board (PCB), a chip, a shielding cover and a heat sink, wherein the chip is arranged on the PCB, the shielding cover is packaged on the PCG and covers the chip, and the heat sink is arranged between an upper surface of the chip and a lower surface of the shielding cover and has an elastic activity range. In the cooling structure, an elastic metal element is used as the heat sink, an installation error between the chip and the shielding cover can be overcome, the chip heat is rapidly dissipated out, the problems that an electronic product is large in heat generation and slow in heat dissipation and the application performance is reduced, the service lifetime is shortened and the reliability is poor when the chip is in a high-temperature working condition for a long time are solved, and meanwhile, the electromagnetic compatibility (EMC) performance of the chip can also be improved.

Owner:四川苏格通讯技术有限公司 +1

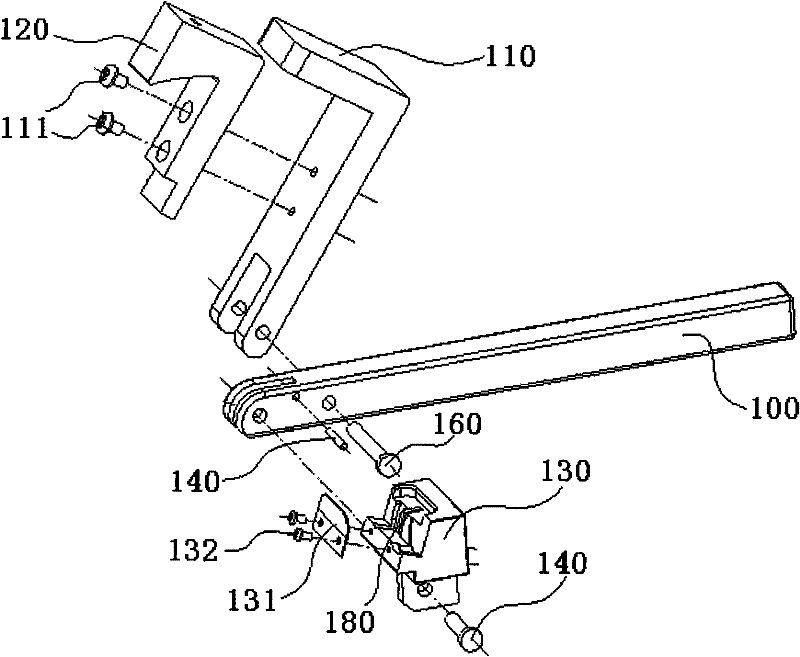

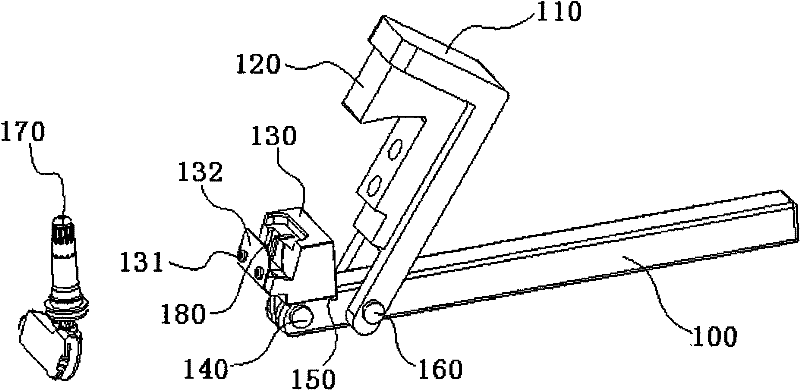

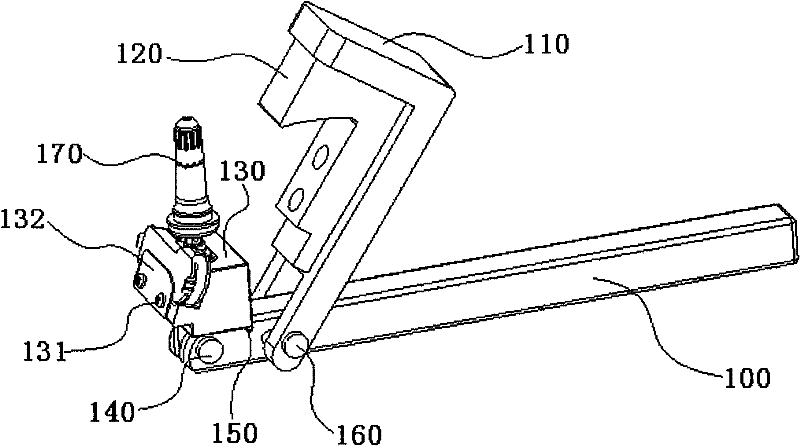

Installation tool for automobile tire pressure sensor assembly

InactiveCN102407512AFixed and accurateSo as not to damageMetal-working hand toolsEngineeringInstallation Error

The invention discloses an installation tool for an automobile tire pressure sensor assembly. The tool comprises a handle, a plastic hook, a plastic hook bracket, a sensor bracket, an elastic pressing sheet, a long pin column, a short pin column, a limit pin, a screw and the like. Through a transmission structure, a lever principle and a human engineering principle, the original complex process step for installing a rim of a tire pressure sensor becomes simple; and the tool is time-saving and labor-saving, efficiency can be improved by 5 times, the installation error can be effectively avoided, and the damage rate of the tire pressure sensor during installation is reduced.

Owner:SHANGHAI HANGSHENG IND

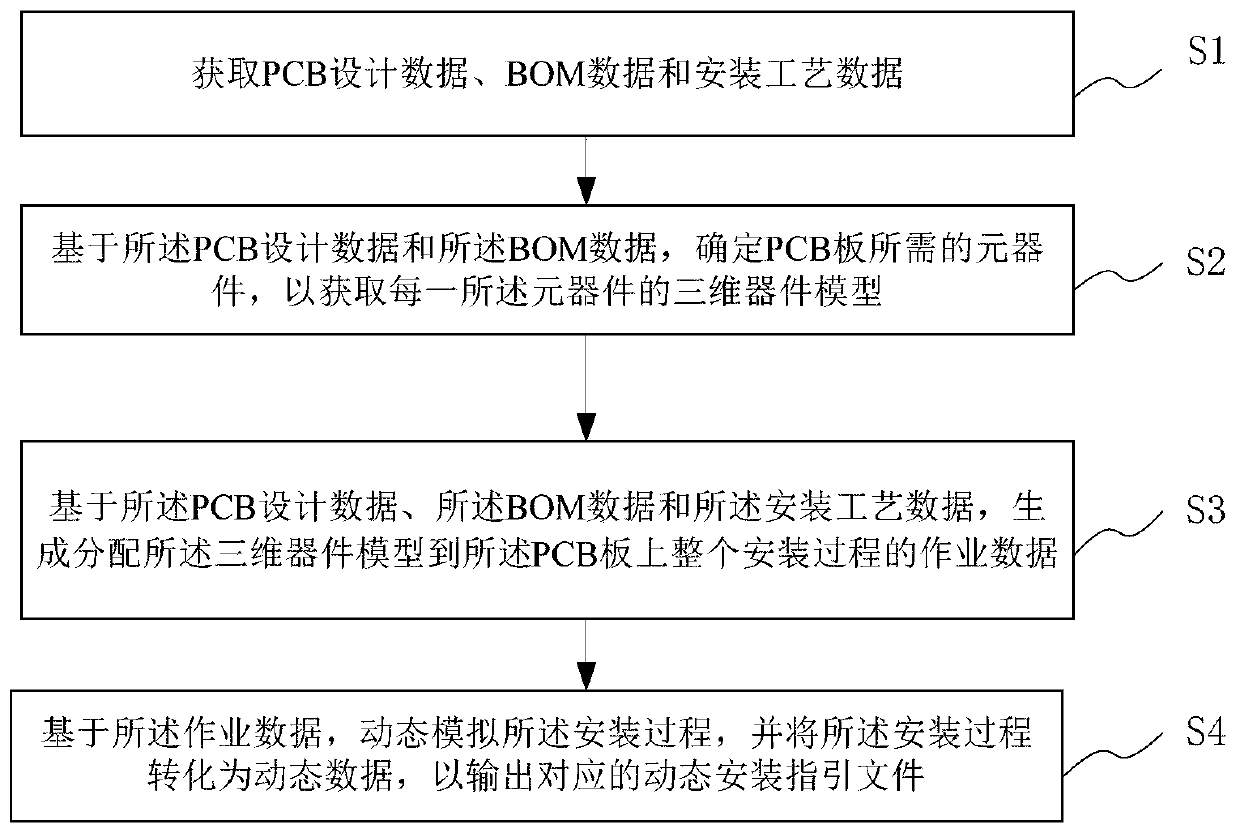

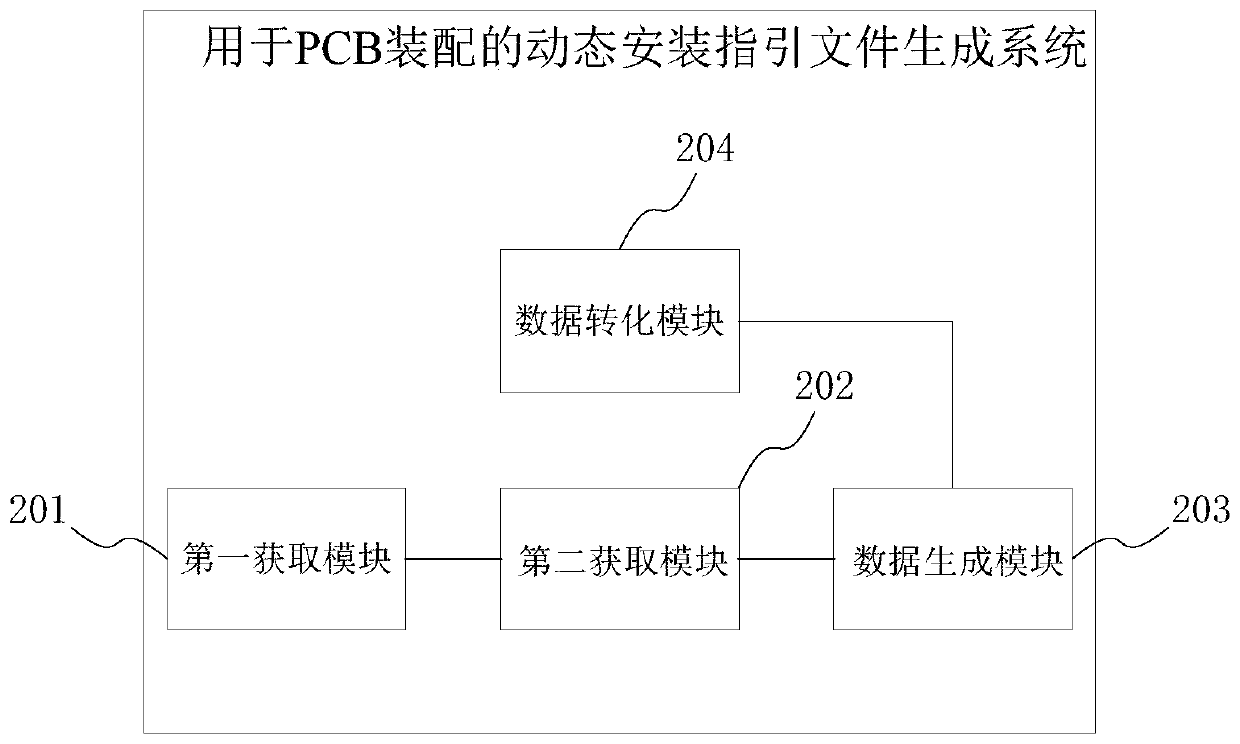

Dynamic installation guide file generation method and system for PCB assembly, medium and terminal

ActiveCN110222381AReduce lossLow costCAD circuit designSpecial data processing applicationsProcess engineeringDynamic data

The invention provides a dynamic installation guide file generation method and system for PCB assembly, a medium and a terminal. The method comprises the following steps of obtaining the PCB design data, BOM data and installation process data; determining the components required by the PCB based on the PCB design data and the BOM data so as to obtain a three-dimensional device model of each component; based on the PCB design data, the BOM data and the installation process data, generating the operation data for distributing the three-dimensional device model to the whole installation process on the PCB; and based on the operation data, dynamically simulating an installation process, and converting the installation process into the dynamic data to output a corresponding dynamic installationguide file. According to the present invention, the installation process of the PCB assembly is generated and displayed in a dynamic manner, the installation process of the PCBA can be effectively and visually embodied, the understanding deviation is effectively reduced, the understanding efficiency is improved, the installation errors during the installation process are avoided, and the reject ratio of products is reduced, so that the production efficiency is effectively improved, and the material cost is saved.

Owner:VAYO SHANGHAI TECH

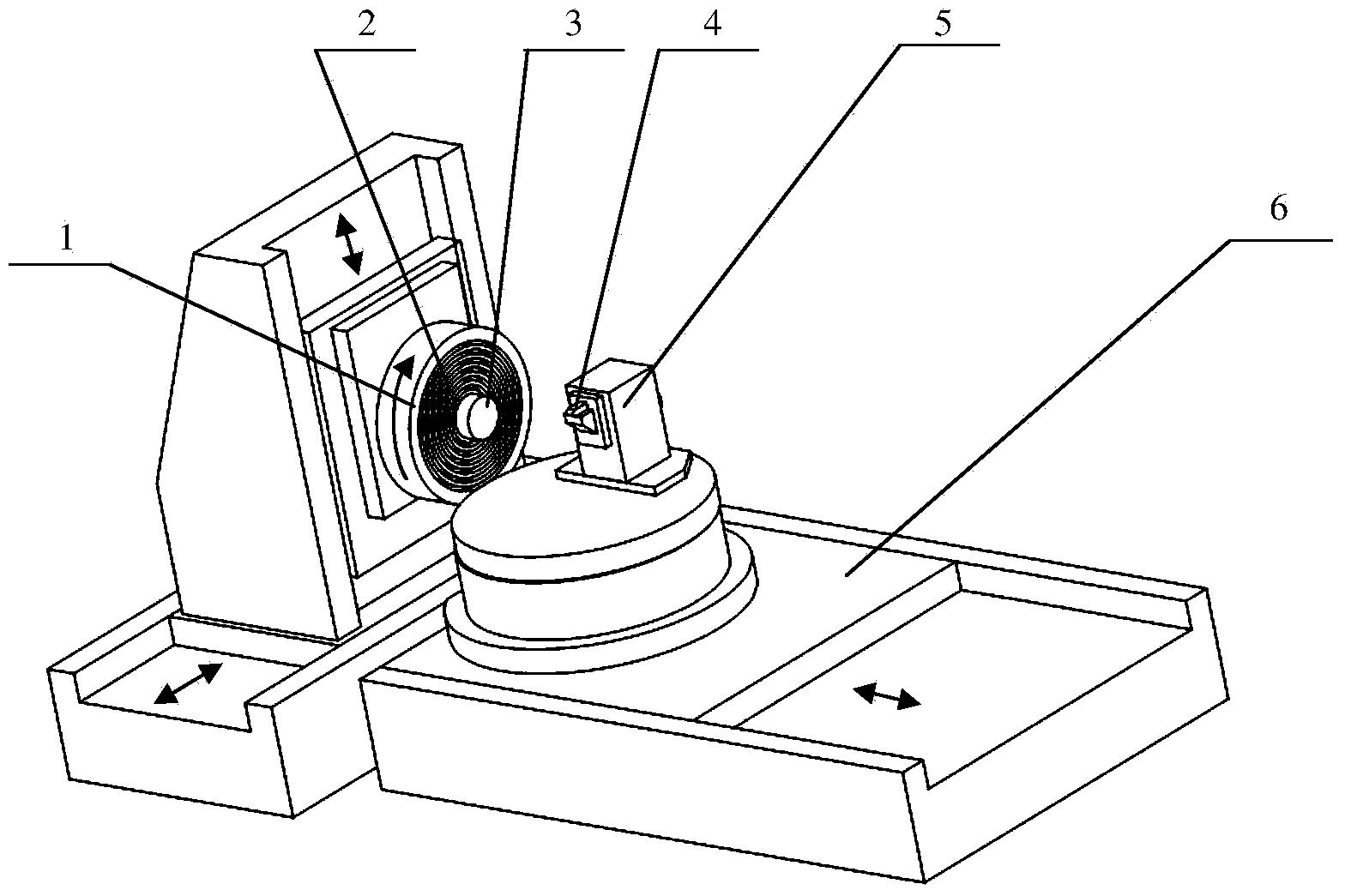

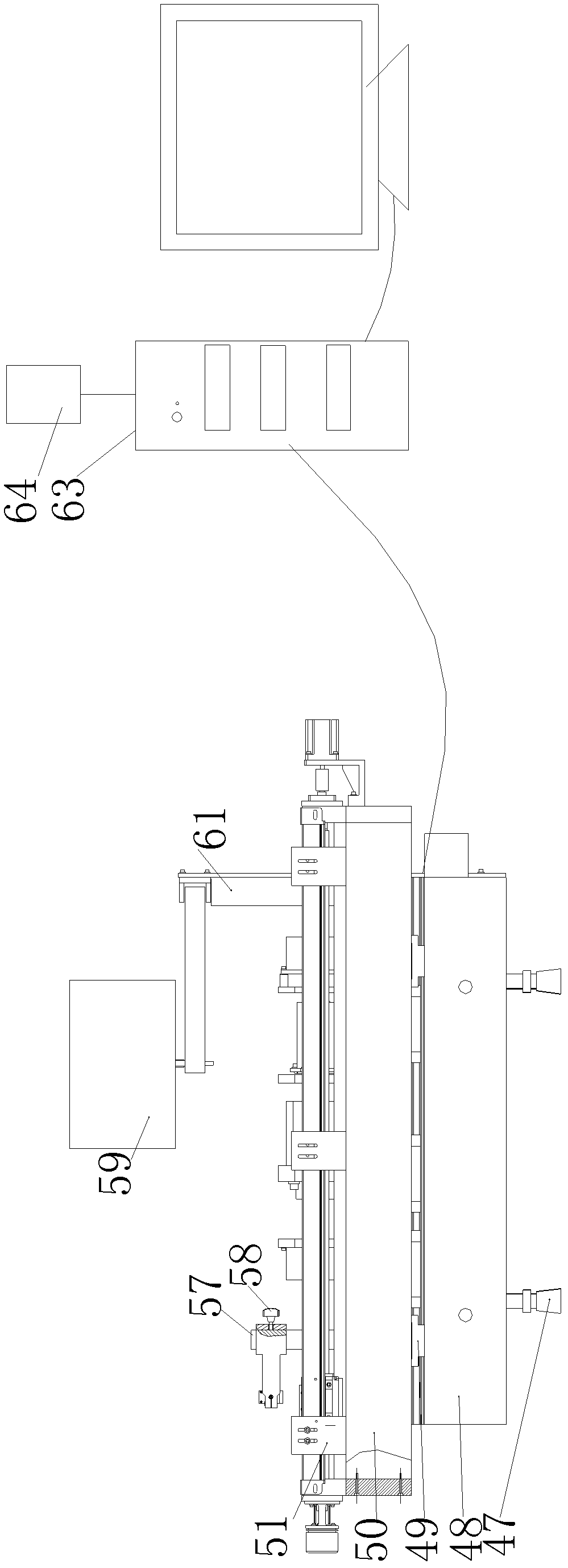

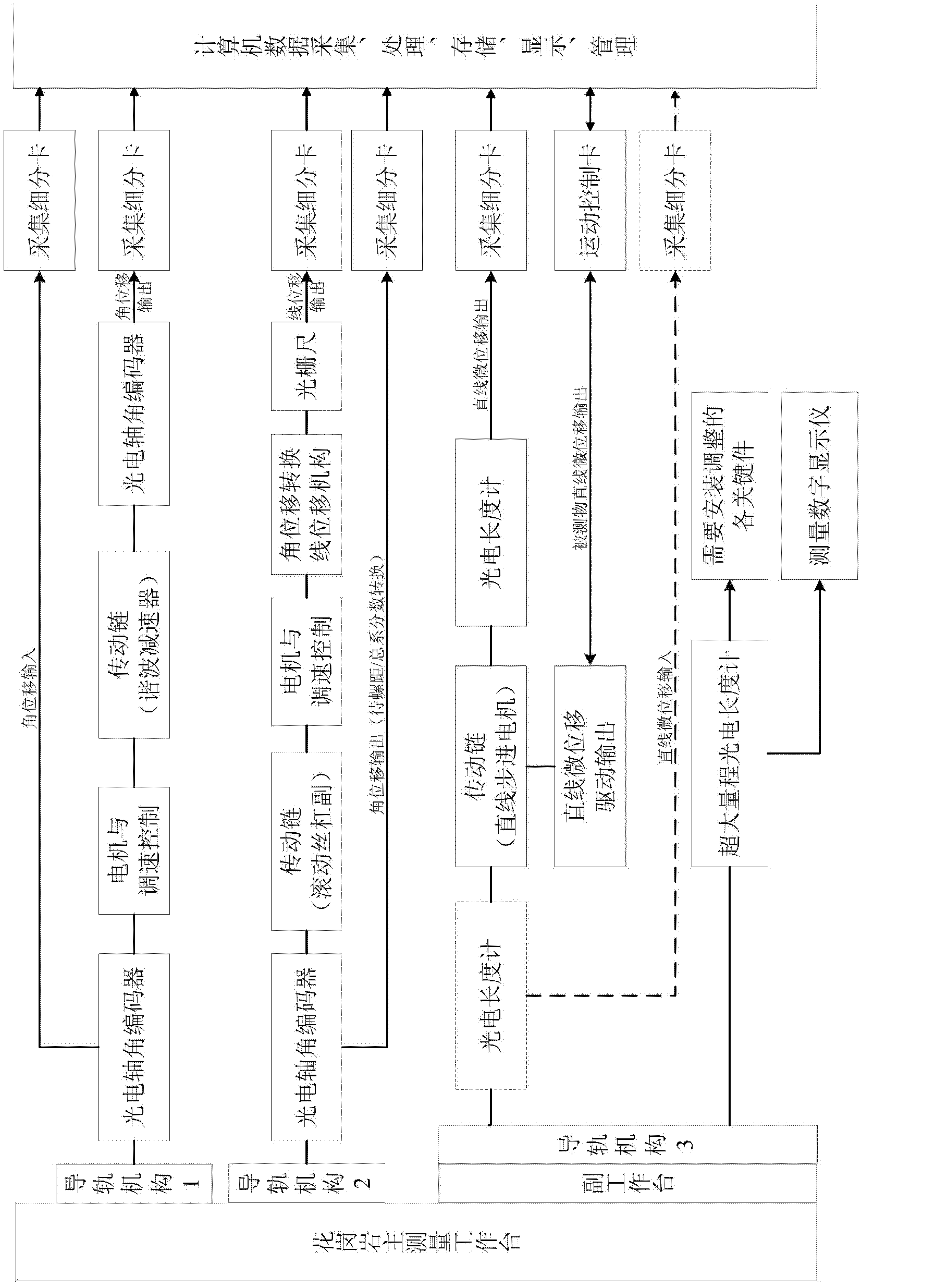

Photoelectric measuring machine for precision transmission chain

InactiveCN102353539AImprove versatilityWide range of usesMachine gearing/transmission testingElectricityGrating

The invention discloses a photoelectric measuring machine for a precision transmission chain. The photoelectric measuring machine comprises a measuring worktable, an angular displacement input-output grating measuring system, an angular displacement input-linear displacement output grating measuring system, a linear micro-displacement input-output grating measuring system, an installation error detection system and a measurement drive control system, wherein, the base surface of the measuring worktable is provided with three groups of parallel precision linear guide rail mechanisms; the angular displacement input-linear displacement output grating measuring system is arranged on the first linear guide rail mechanism; the angular displacement input-output grating measuring system is arranged on the second linear guide rail mechanism; the linear micro-displacement input-output grating measuring system and the installation error detection system are arranged on the third linear guide rail mechanism; and the measurement drive control system is electrically connected with the angular displacement input-linear displacement output grating measuring system and the angular displacement input-output grating measuring system respectively. The photoelectric measuring machine for the precision transmission chain has the advantages of wide use and high measurement accuracy.

Owner:廊坊市莱格光电仪器有限公司

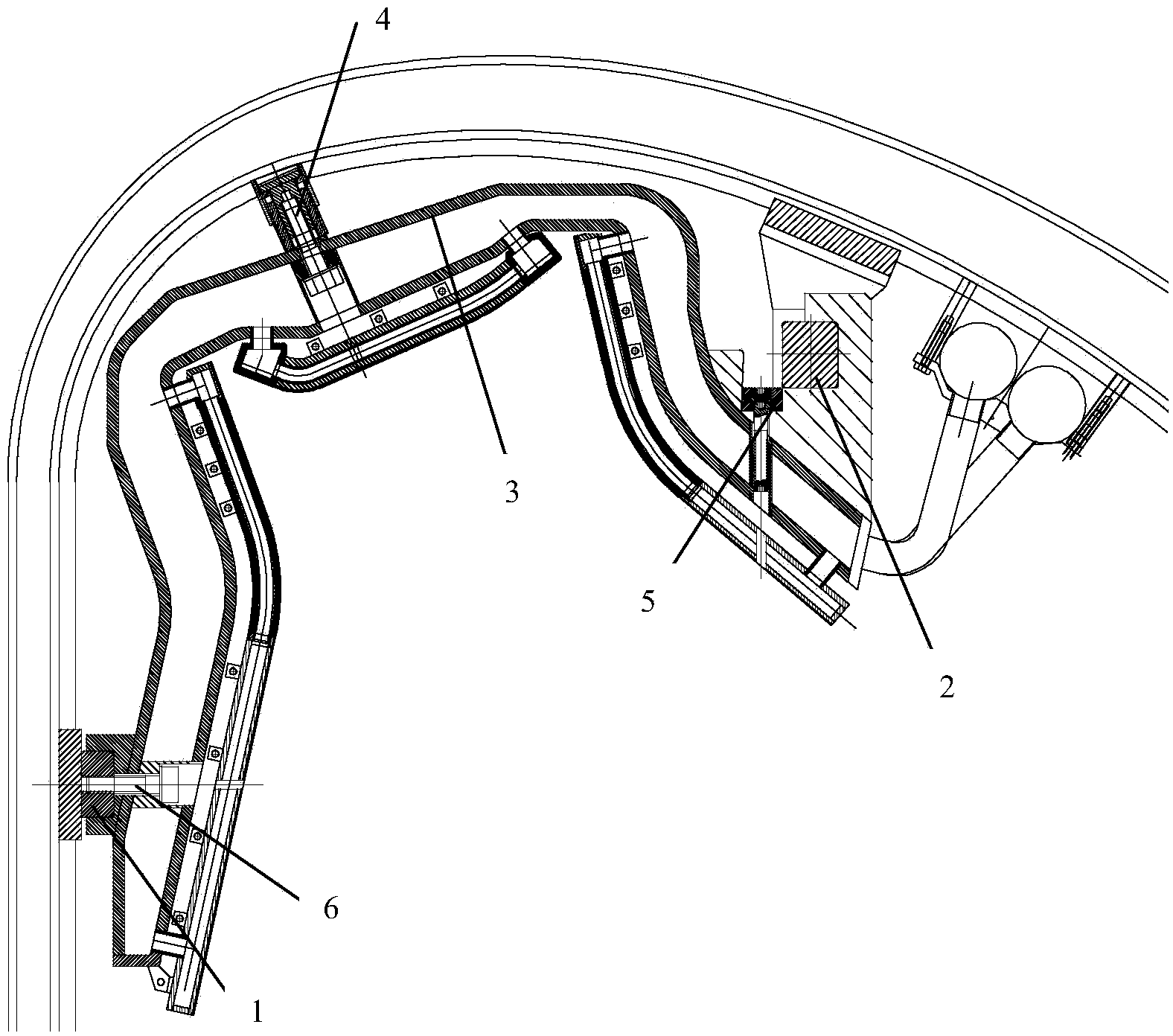

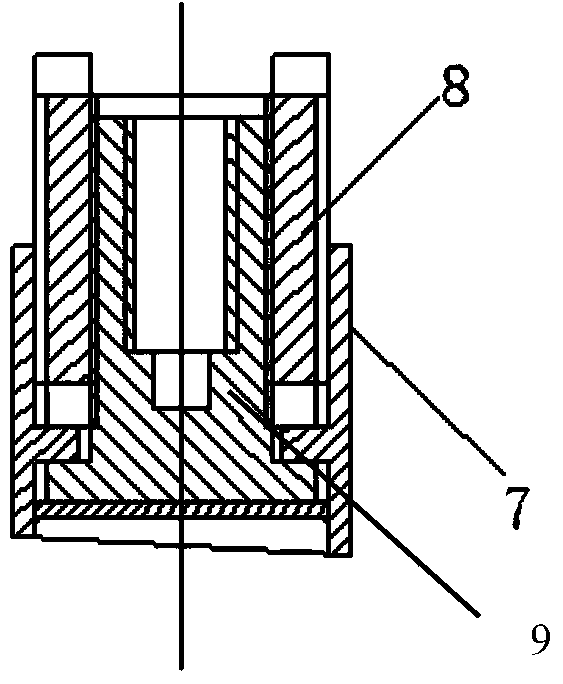

High-accuracy quick assembling and disassembling structure for tokamak divertor module

InactiveCN104021820AAvoid installation errorsSimplify the installation processNuclear energy generationThermonuclear fusion reactorDivertorMechanical engineering

The invention discloses a high-accuracy quick assembling and disassembling structure for a tokamak divertor module. The high-accuracy quick assembling and disassembling structure comprises two high-accuracy installed guide rails, the high-accuracy processed divertor module, a movable wedge block, an auxiliary support, two connecting bolts and two stopping blocks. The divertor module can be quickly installed in place through small-distance movement in two directions, and the divertor module and the guide rails are wedged by the wedge blocks to restrain the freedom degree in the axial direction and the freedom degree in the vertical direction. The stopping blocks are used for controlling the freedom degree in the annular direction, and the connecting bolts can further fasten the divertor module.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Machining method for hard-alloy turning tool

The invention discloses a machining method for a hard-alloy turning tool. The machining method comprises the step that the hard-alloy turning tool is machined. The hard-alloy turning tool comprises a tool bar part and a tool head part. The tool bar part and the tool head part are integrally formed. The cross section of the tool bar part is square. The tool head part inclines towards the cross section of the tool bar part by an included angle, and a cutting edge section of the tool head part is formed when the tool head part inclines to the sharpest position. The sharpest position of the cutting edge section protrudes from the side face of the tool bar part. The cutting edge section is recessed in the circular-arc shape before inclining to the sharpest position. The machining method comprises the following steps of A, sintering and B, linear cutting. Through the machining method, the problems of low machining precision and low efficiency of an existing hard-alloy turning tool can be solved.

Owner:平湖三川纺织染整股份有限公司

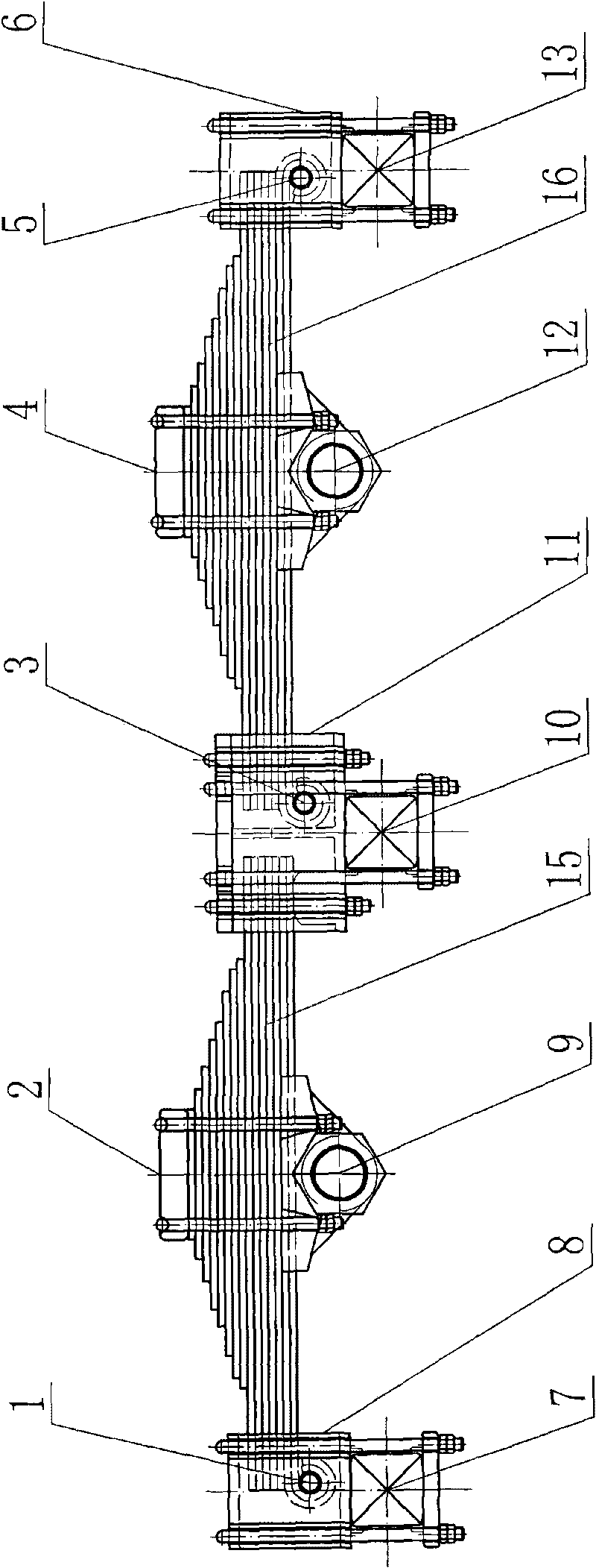

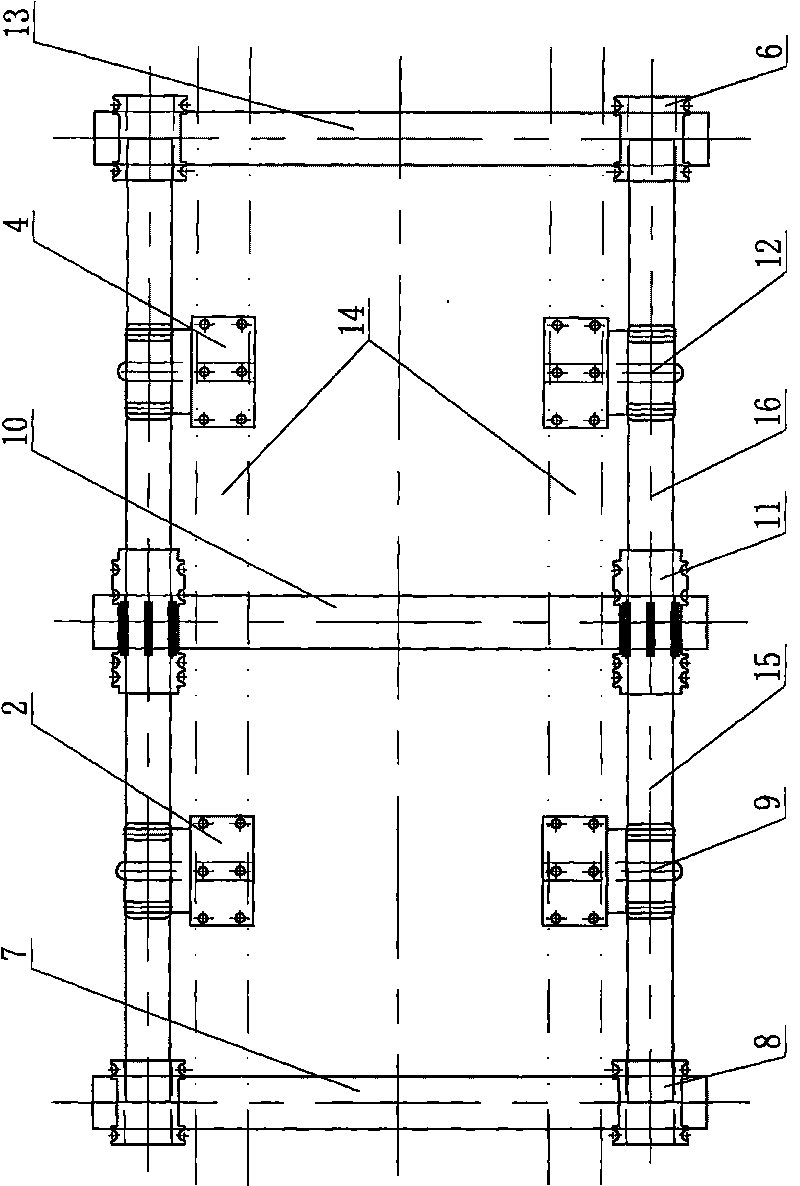

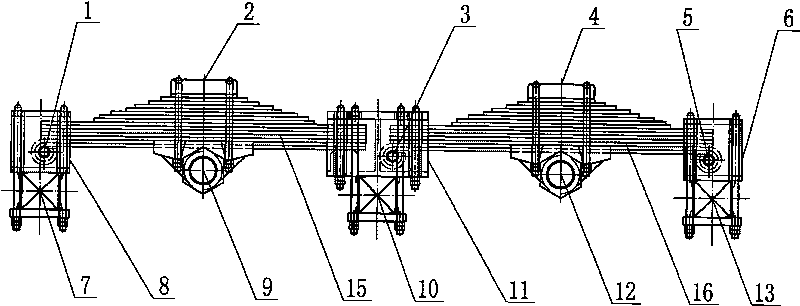

Suspension device of semitrailer

InactiveCN101700730AReduce the likelihood of breakageIncrease contact surfaceResilient suspensionsEngineering

The invention relates to a suspension device of a semitrailer, belonging to the technical field of transportation. Suspension supports (2,4) of the suspension device are arranged in the middle parts of road springs (15,16) by support seats (9,12); dumb irons (8,11,6) are fixed above axles (7, 10 and 13); the front end of the front road spring (15) is arranged on the front dumb iron (8), and the rear end is inserted into the middle dumb iron (11); and the front end of the rear road spring (16) is arranged on the middle dumb iron (11) by a hinge pin (3), and the rear end is arranged on the rear dumb iron (6) by a hinge pin (5). The suspension device can not only effectively prevent spring breaking, shaft breaking and tyre burst of the semitrailer but also can avoid the tyre-rubbing phenomenon.

Owner:李晓秋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com