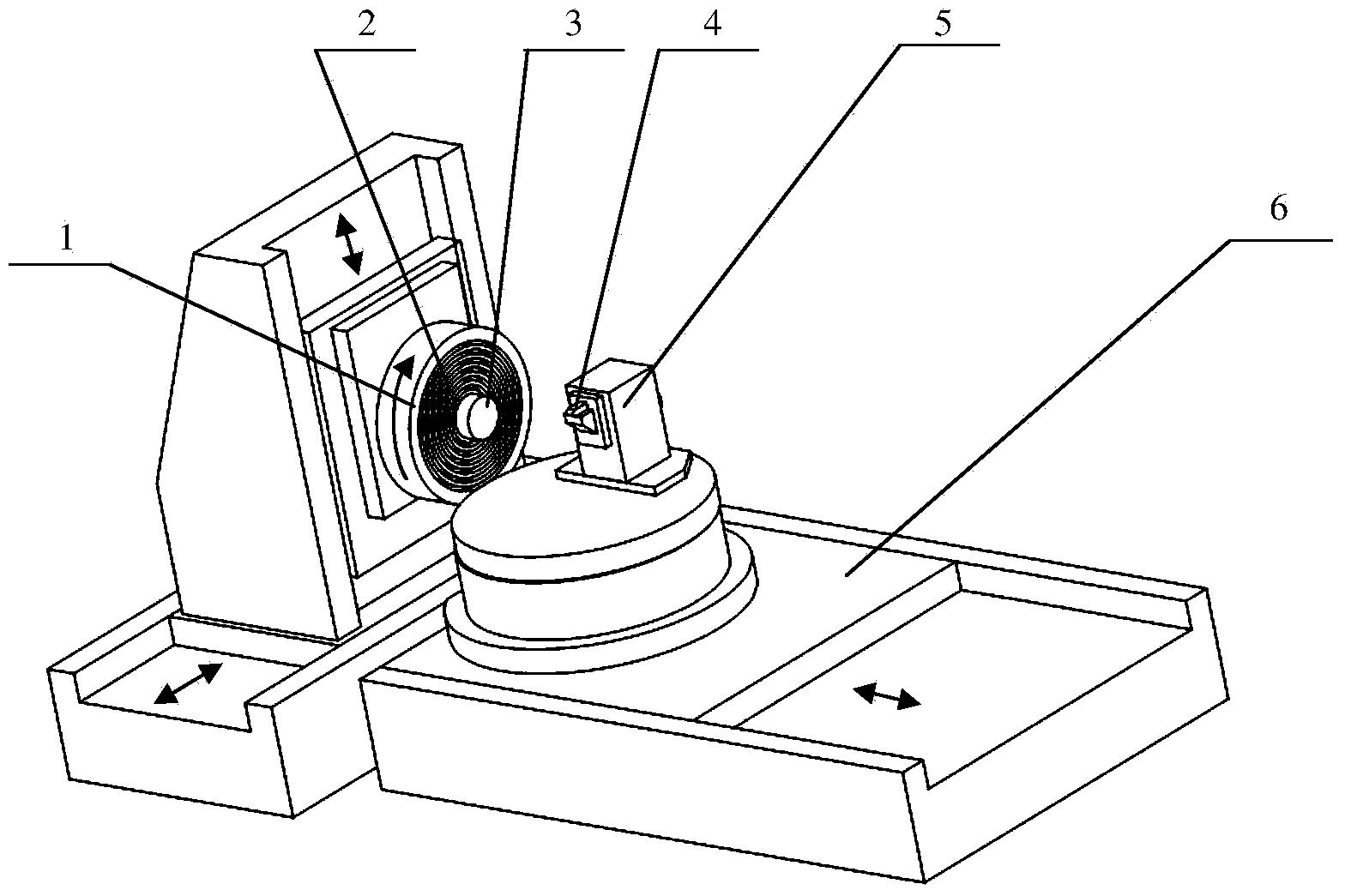

Method and device for determining grinding brittleness-ductility transformation critical cutting depth of hard and brittle material

A critical cutting depth, hard and brittle material technology, applied in the direction of grinding automatic control devices, grinding machine parts, grinding/polishing equipment, etc., can solve the problem of low processing efficiency, critical cutting depth cannot be accurately determined, and ductility cannot be achieved domain grinding etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0076] Obtained the brittle material brittle-ductile transformation critical depth of cut a of tungsten carbide cemented carbide material on a certain type of ultra-precision grinding machine by the method of the present invention c . The specific implementation process is as follows:

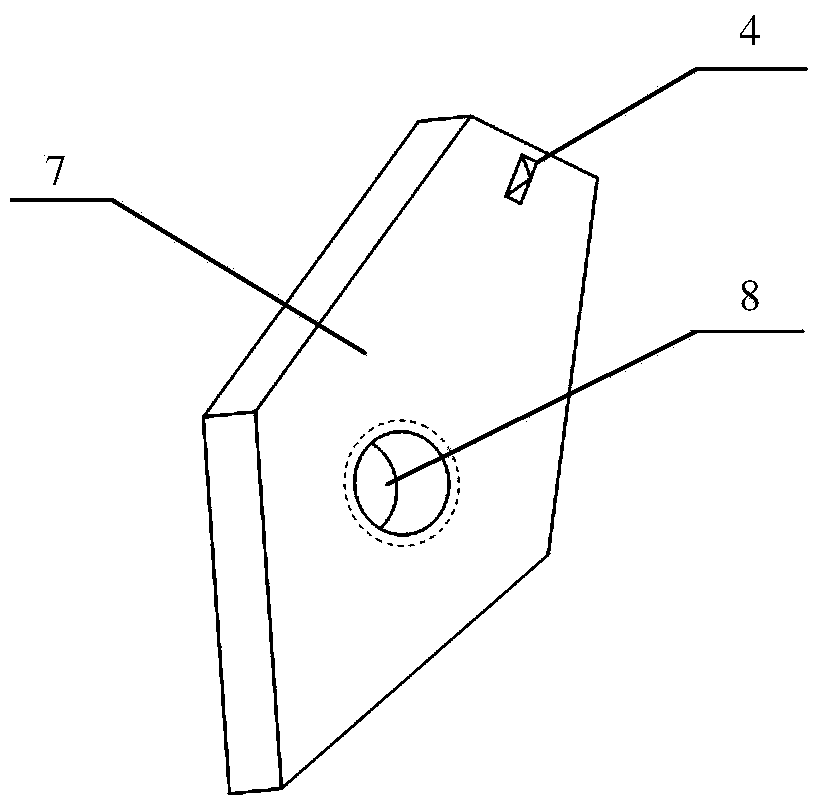

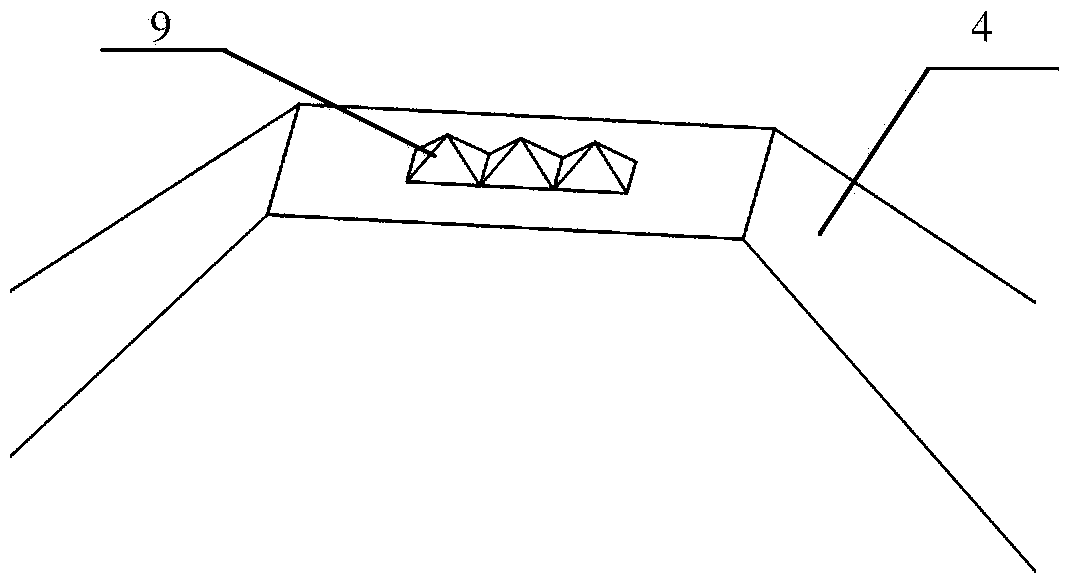

[0077] (1) According to the grinding wheel to be used for tungsten carbide grinding is a W80 resin bonded diamond grinding wheel, the concentration of the grinding wheel is 75%, and the shape of the abrasive grain is determined to be a square pyramid, and the number of abrasive grains is ≥ 3; the concentration of the grinding wheel and Substituting the particle size into formula (2) to calculate the distance between abrasive particles is 66.844 μm, since the size of the particle diameter is between d 0 =70~420μm, so according to the above-mentioned principle of determining the rake angle, the rake angle of abrasive grains is selected as -50°.

[0078] (2) Select and process the abrasive grain...

specific Embodiment 2

[0087] Obtained the brittle material brittle-ductile transformation critical depth of cut a of the brittle material of the glass-ceramic material on a certain type of ultra-precision grinding machine by the method of the present invention c . The specific implementation process is as follows:

[0088] (1) According to the grinding wheel to be used for glass-ceramic grinding is a W20 resin bonded diamond grinding wheel, the concentration of the grinding wheel is 75%, and the shape of the abrasive grain is determined to be a square pyramid, and the number of abrasive grains is ≥ 3; the concentration of the grinding wheel and the particle size Substituting formula (2) to calculate the distance between abrasive grains is 8.355 μm, since the grain size is between d 0 =20~70μm range, so according to the above-mentioned rake angle determination principle, the rake angle of abrasive grains is selected as -45°.

[0089] (2) Select and process the abrasive grain matrix, and fix it on ...

specific Embodiment 3

[0096] The brittle material brittle-ductile transformation critical depth of cut a of the quenched steel material on a certain type of ultra-precision grinding machine is obtained by the method of the present invention c . The specific implementation process is as follows:

[0097] (1) According to the grinding wheel to be used for grinding the quenched steel workpiece is a W120 resin bonded CBN grinding wheel, the concentration of the grinding wheel is 100%, and the shape of the abrasive grain is determined to be a square pyramid, and the number of abrasive grains is ≥ 3; the concentration of the grinding wheel and the particle size Substituting formula (2) to calculate the distance between abrasive grains is 86.832 μm, since the grain size is between d 0 =70~420μm, so according to the above-mentioned principle of determining the rake angle, the rake angle of abrasive grains is selected as -50°.

[0098] (2) Select and process the cubic boron nitride (CBN) abrasive grain su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com