Patents

Literature

36results about How to "Efficient production and processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

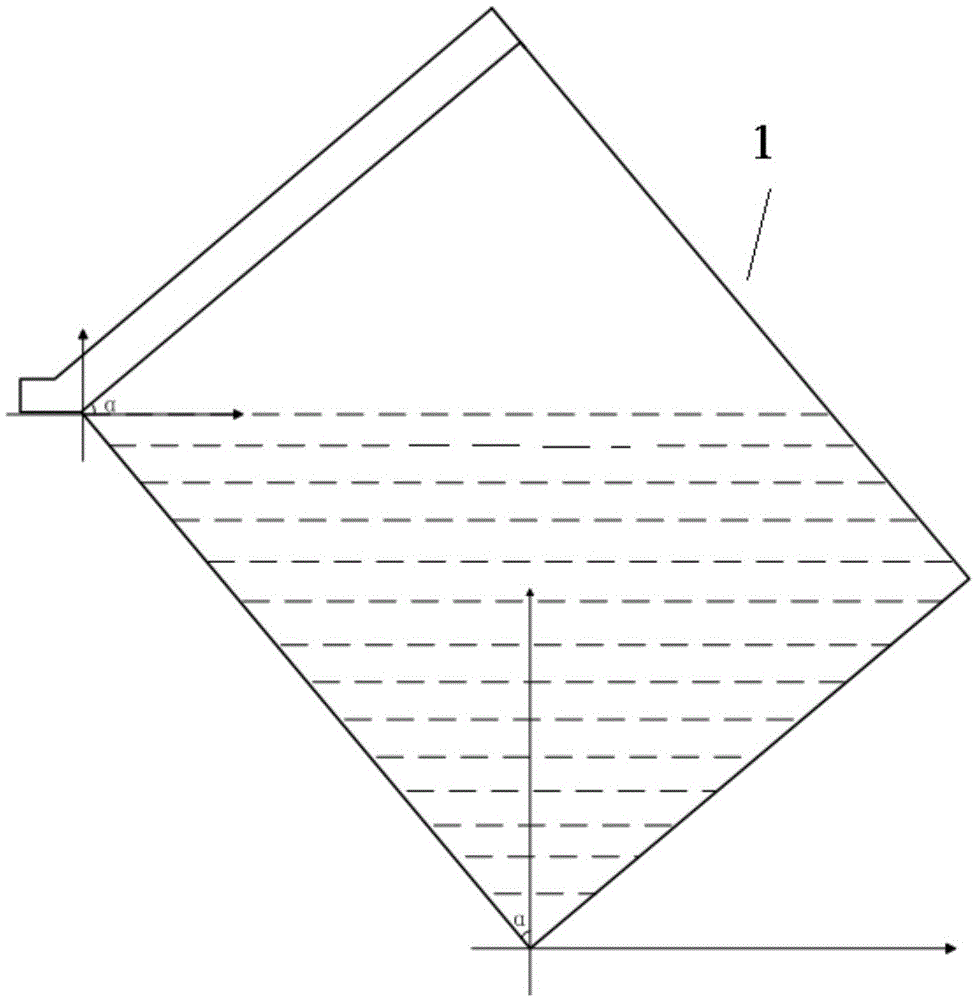

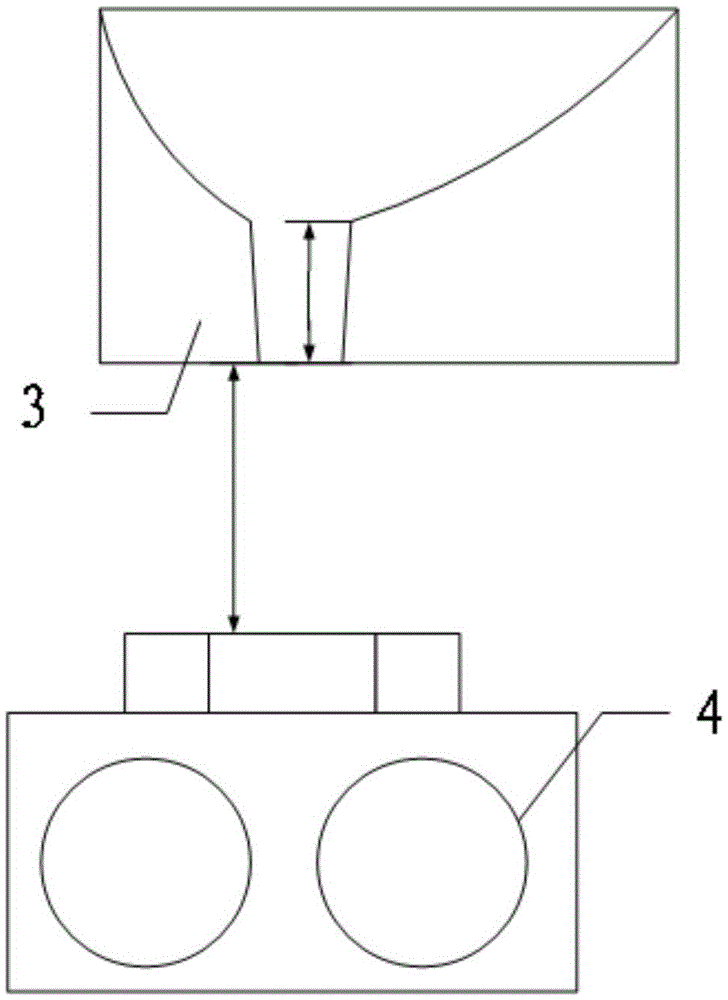

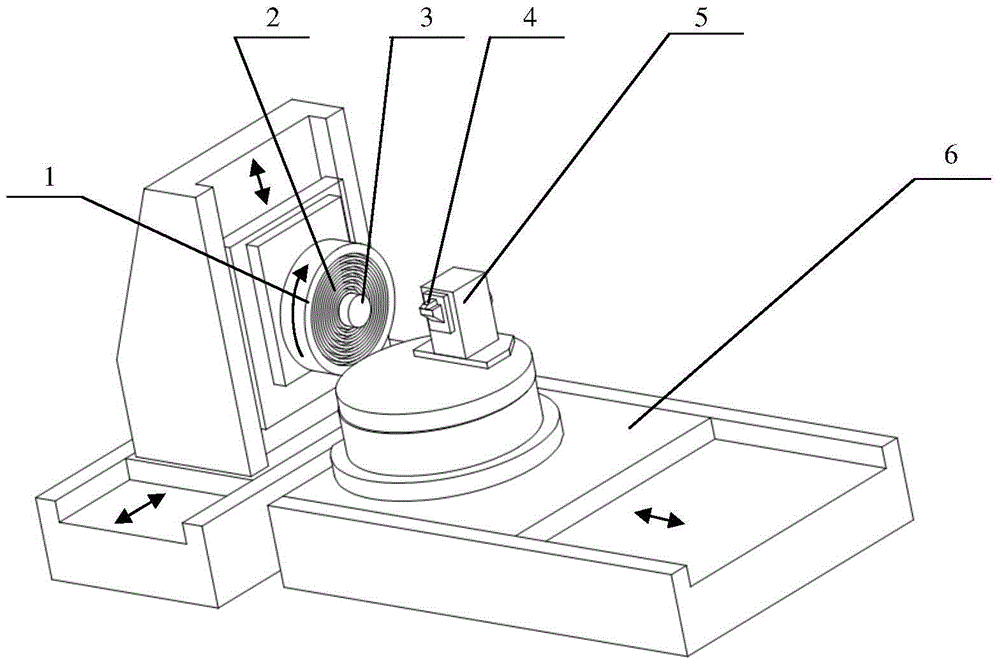

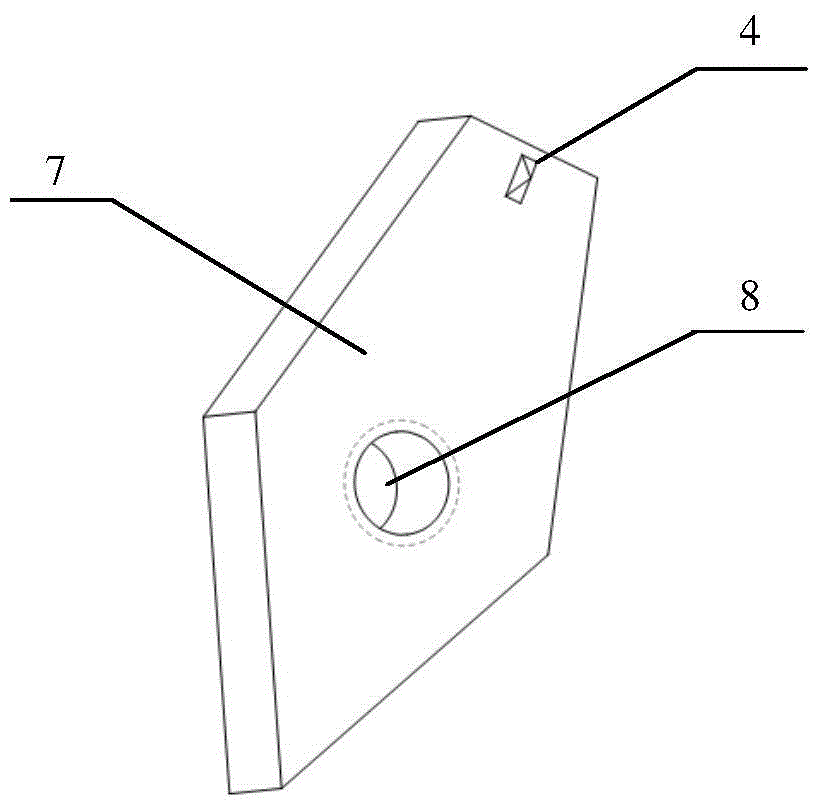

Method and device for determining grinding brittleness-ductility transformation critical cutting depth of hard and brittle material

InactiveCN103722467AImprove surface qualityHigh precisionGrinding feed controlGrinding machinesHigh surfaceRelative motion

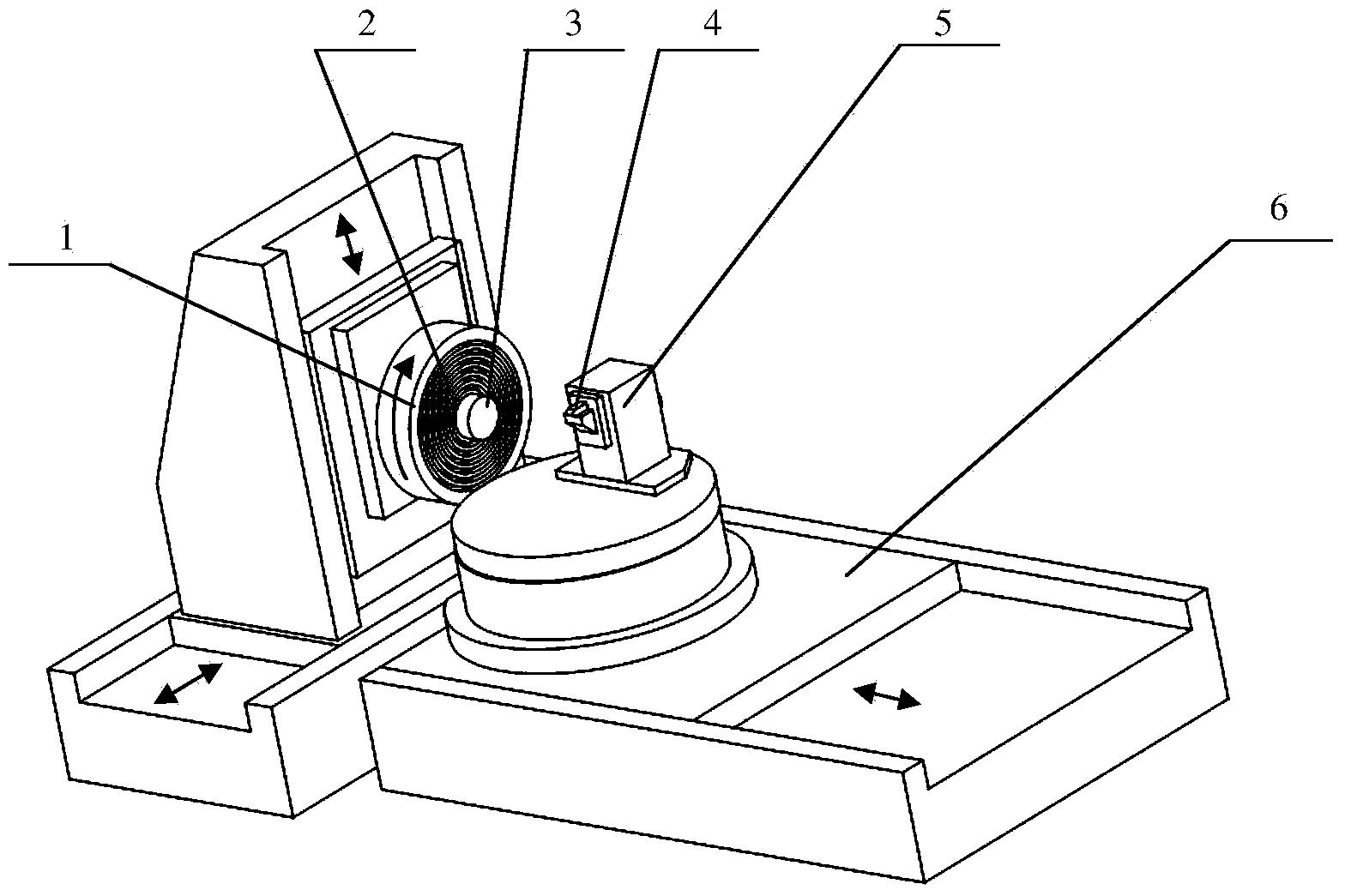

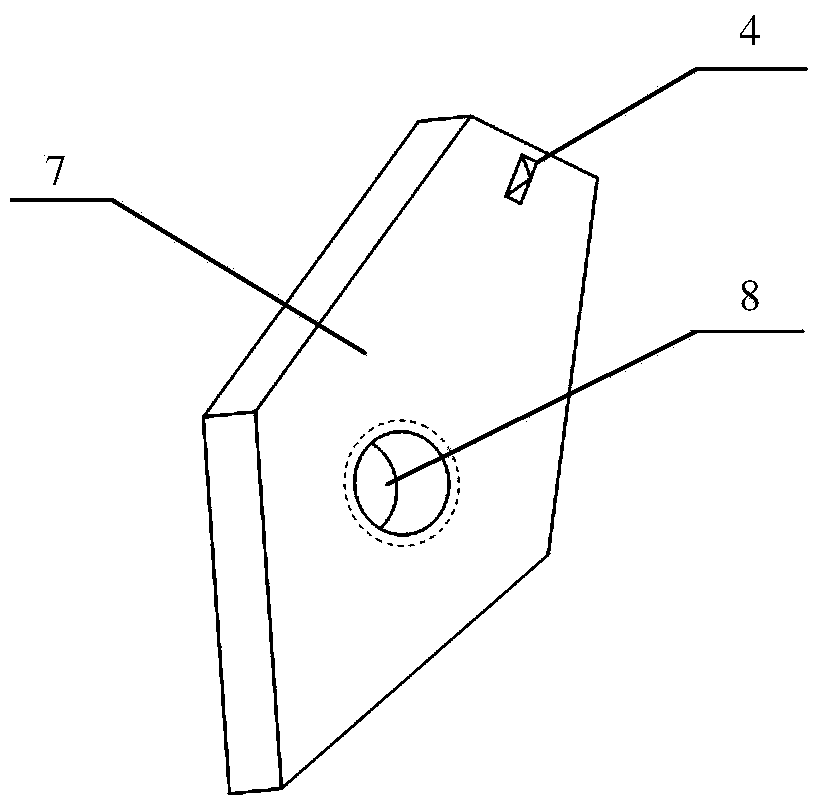

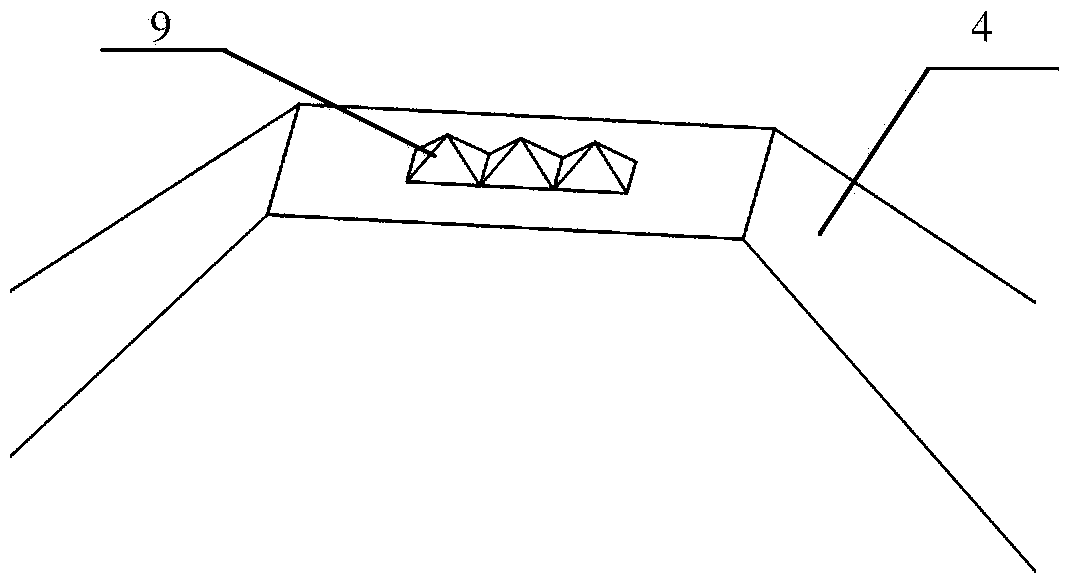

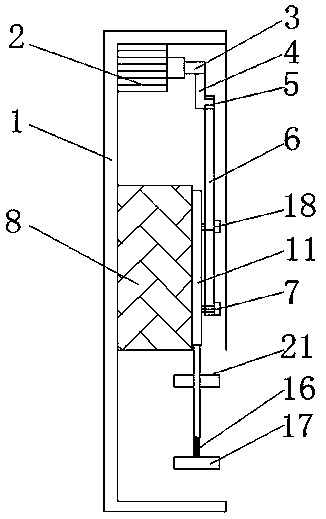

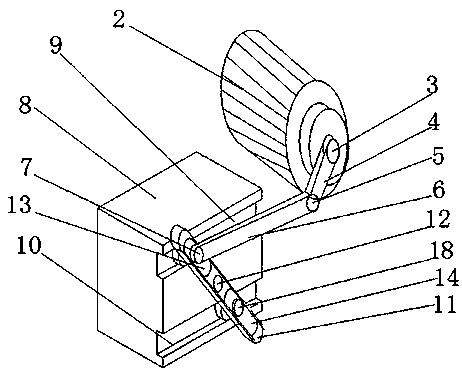

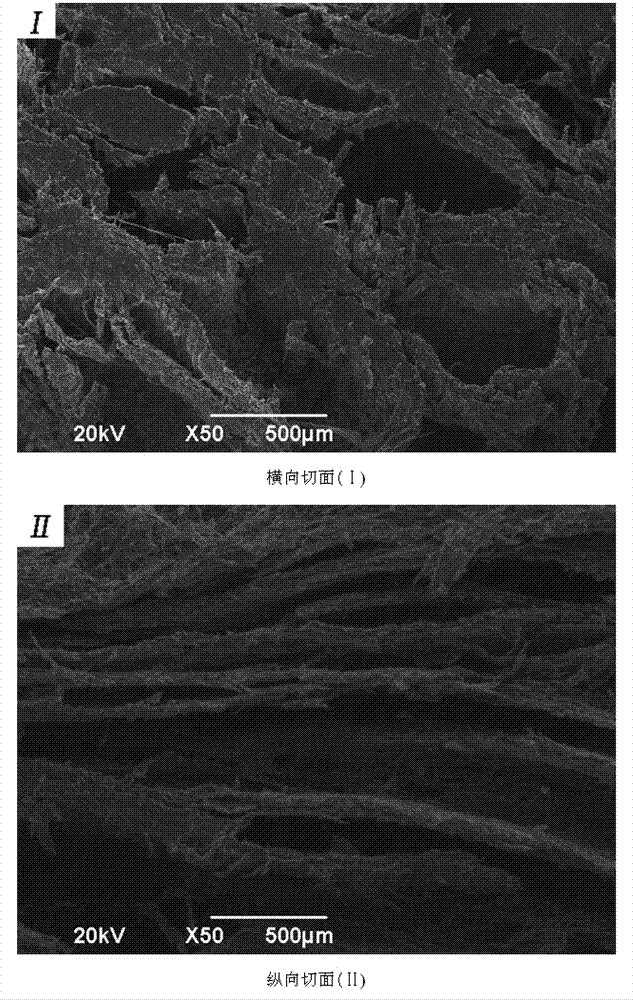

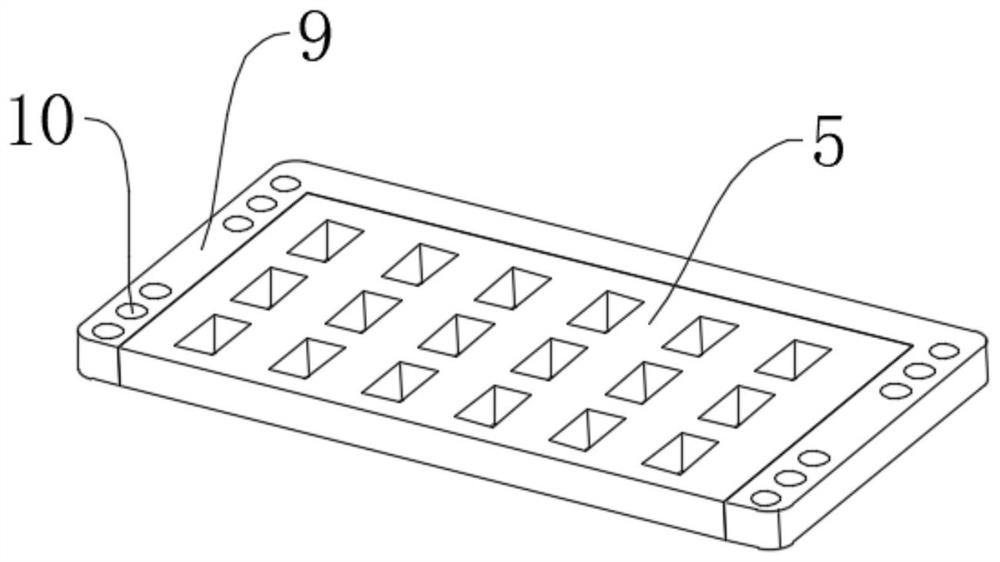

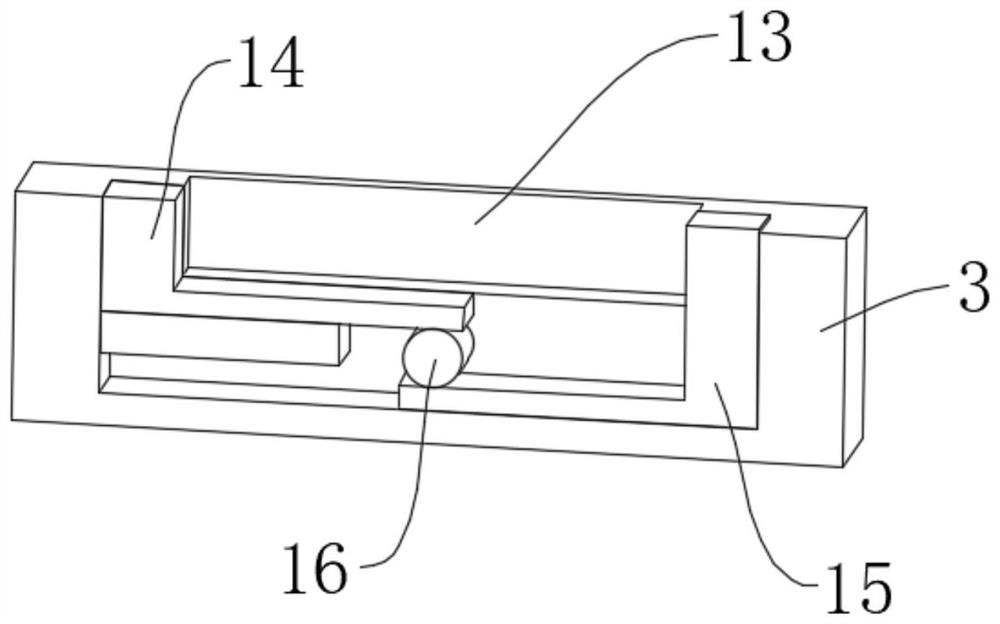

The invention relates to the technical field of hard and brittle material ultra-precision machining. In order to achieve ductility domain grinding of the largest cutting depth, high surface quality of the hard and brittle material, and efficient and high-precision production machining, according to the technical scheme, a method and device for determining the grinding brittleness-ductility transformation critical cutting depth of the hard and brittle material comprises the following steps of (1) according to a grinding wheel used in ultra-precision grinding, determining the number, shape and distance of grains of a homemade multi-grain tool, (2) according to the grain shape, distance and front-angle parameters selected in the step (1), machining three or more grains on a grain base body, (3) controlling the multi-grain tool and a workpiece to generate relative motion, beginning to conduct scratching on the surface of the workpiece, meanwhile, controlling the multi-grain tool to conduct continuous feeding, enabling the depth of the scratch to continuously change, and observing and measuring the workpiece after scratching by utilizing a surface contourgraph and a confocal microscopy. The method is mainly applied to ultra-precision machining.

Owner:TIANJIN UNIV

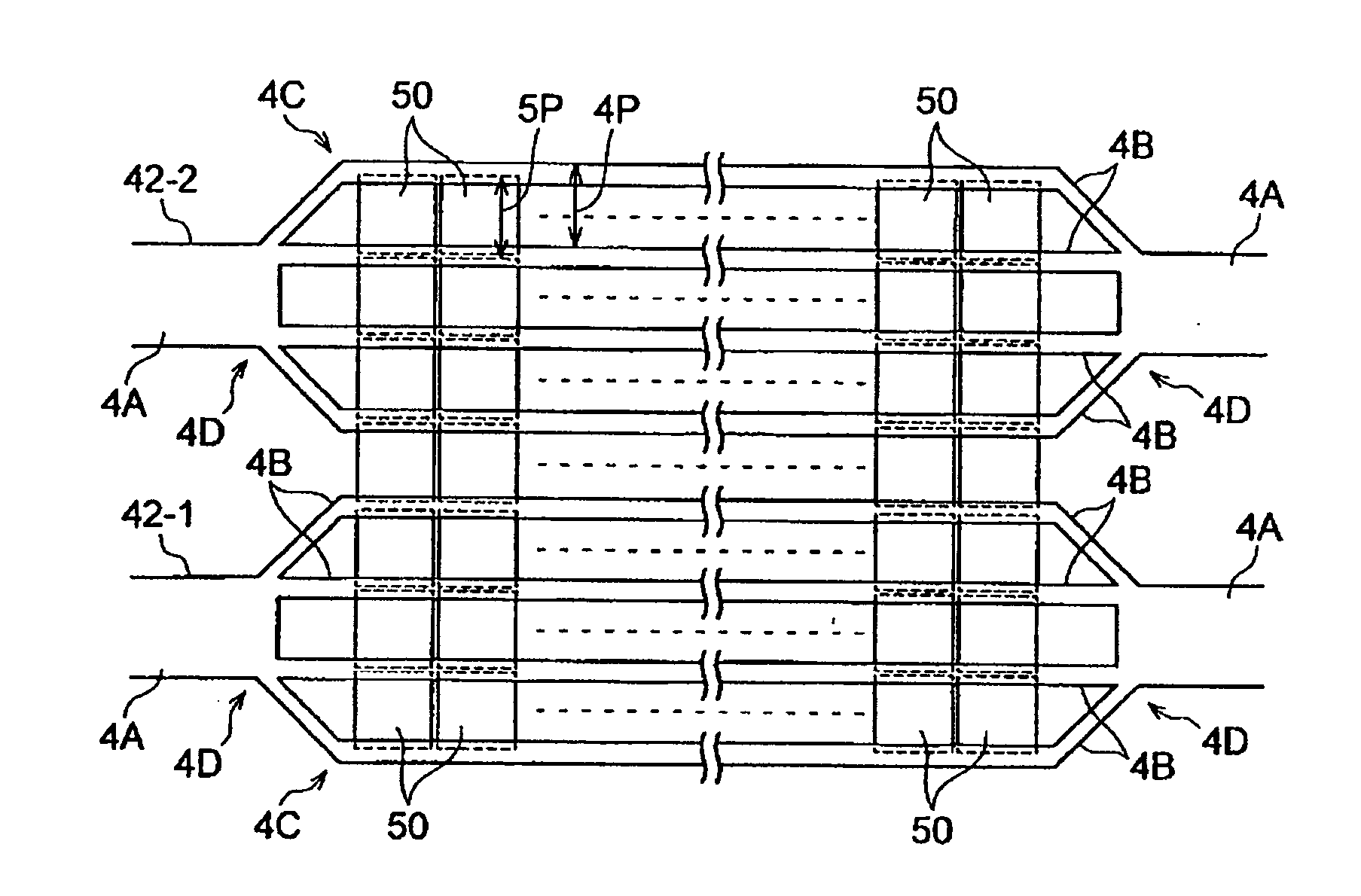

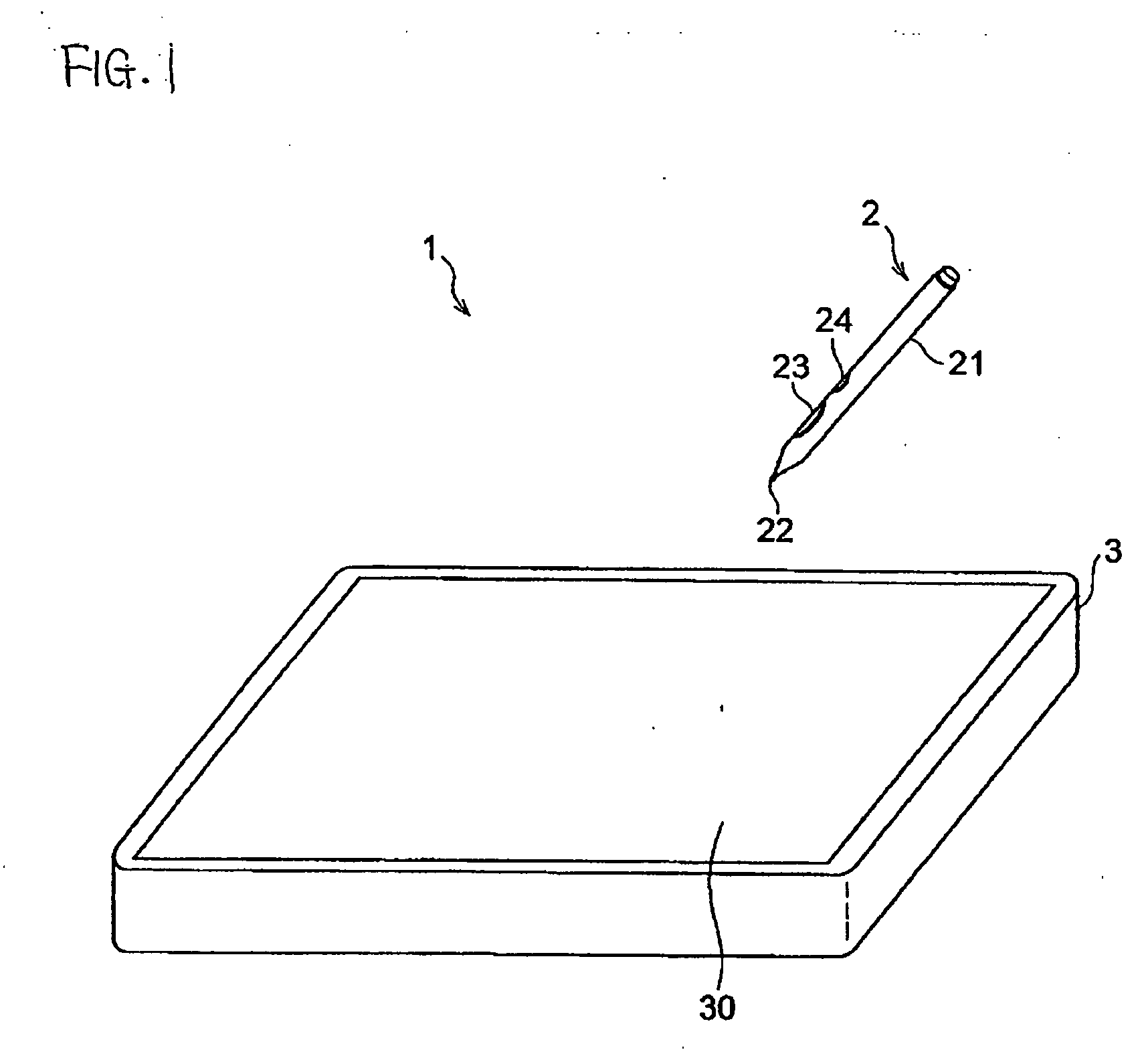

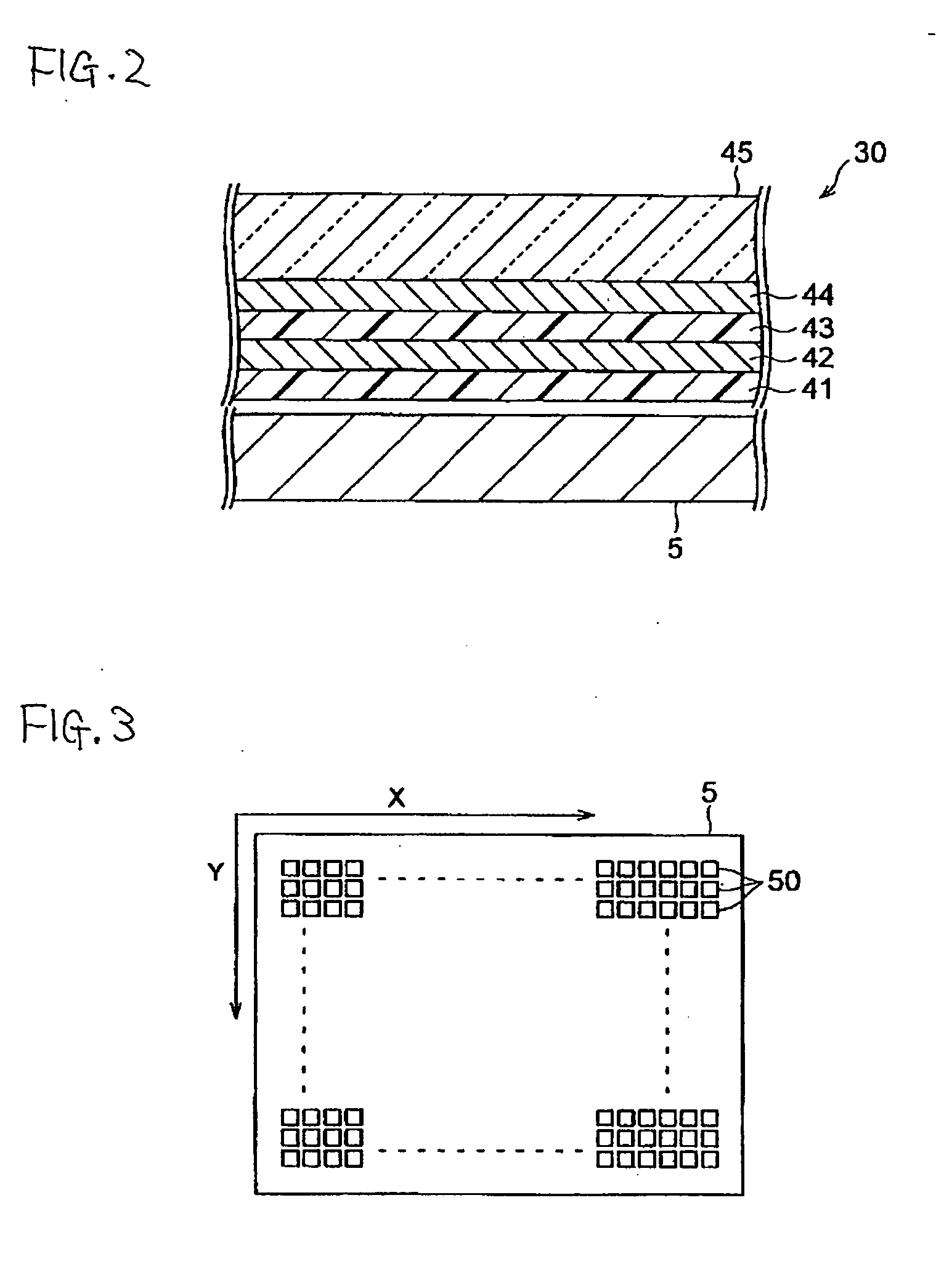

Display device, sensor panel, position-detecting device, position-inputting device, and computer system

ActiveUS20070285389A1Improve visibilityEfficient production and processingCathode-ray tube indicatorsLiquid/solution decomposition chemical coatingEngineeringElectrical conductor

A display device is provided. The display device includes a display screen having a light-transmissible display conductor extending in a predetermined plane, and at least one detection conductor extending along the predetermined plane, the at least one detection conductor having at least one base line portion formed of a conductor of a first width and a narrow line portion including a plurality of narrow-line conductors of a second width connected in parallel between the at least one base line portion.

Owner:WACOM CO LTD

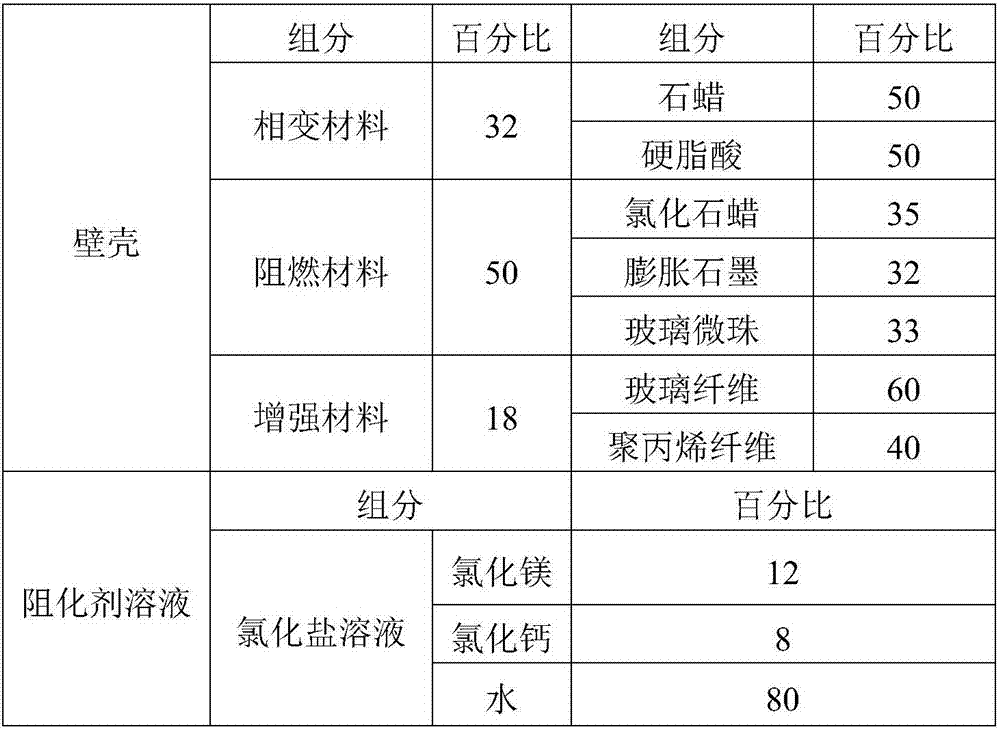

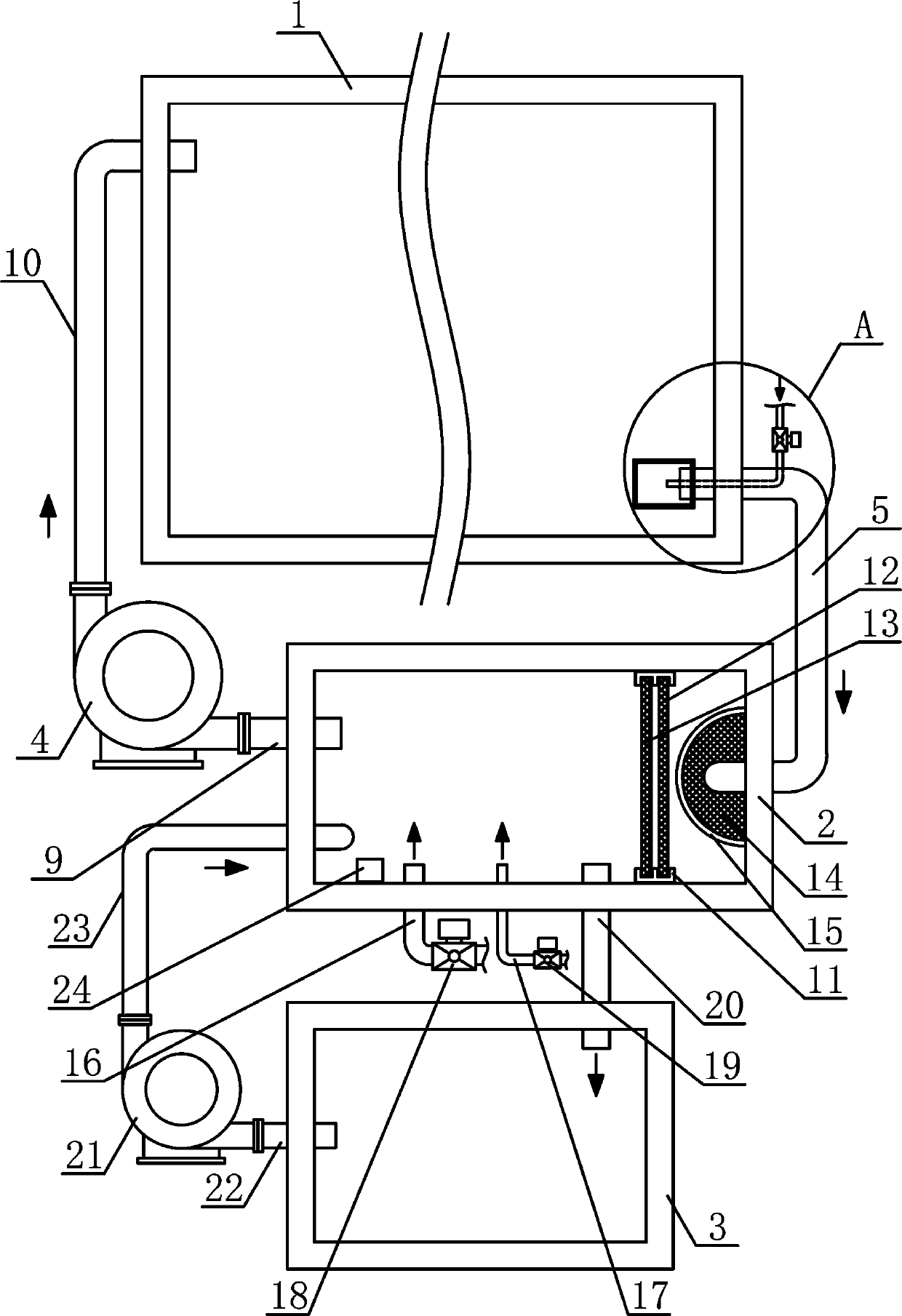

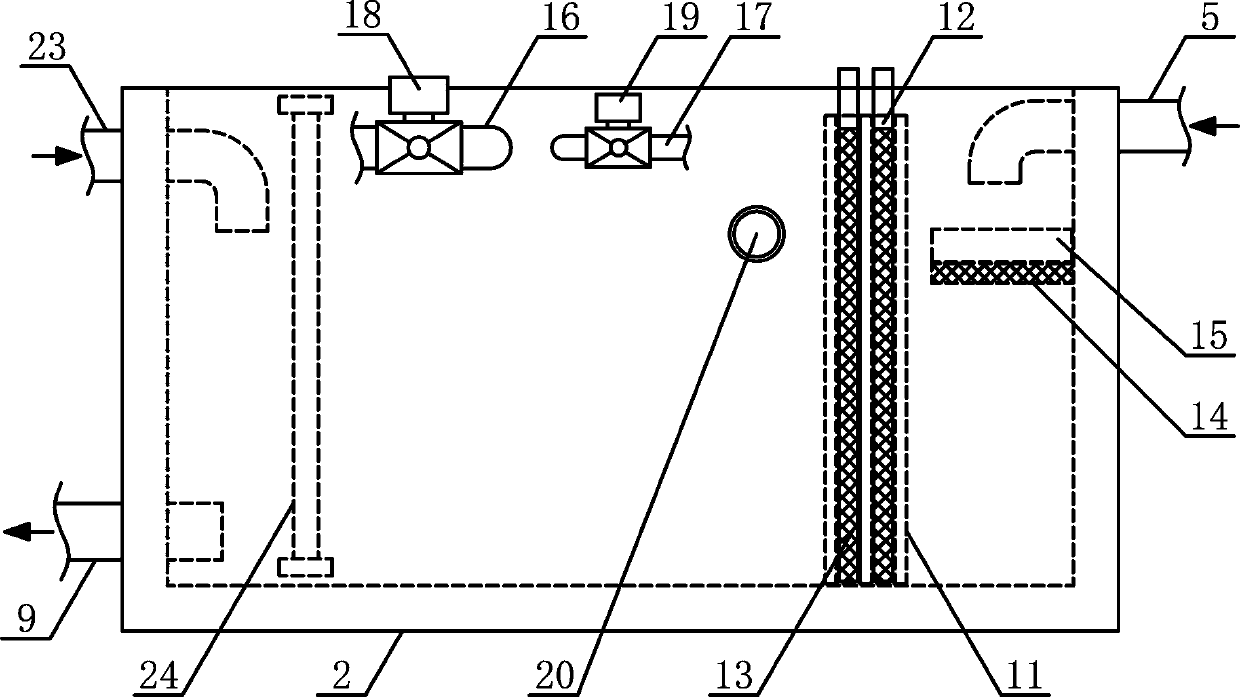

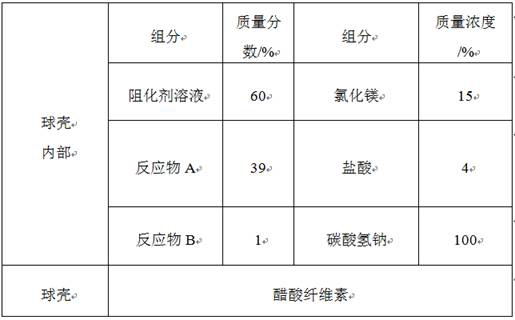

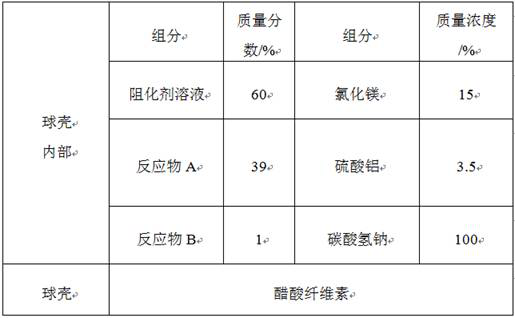

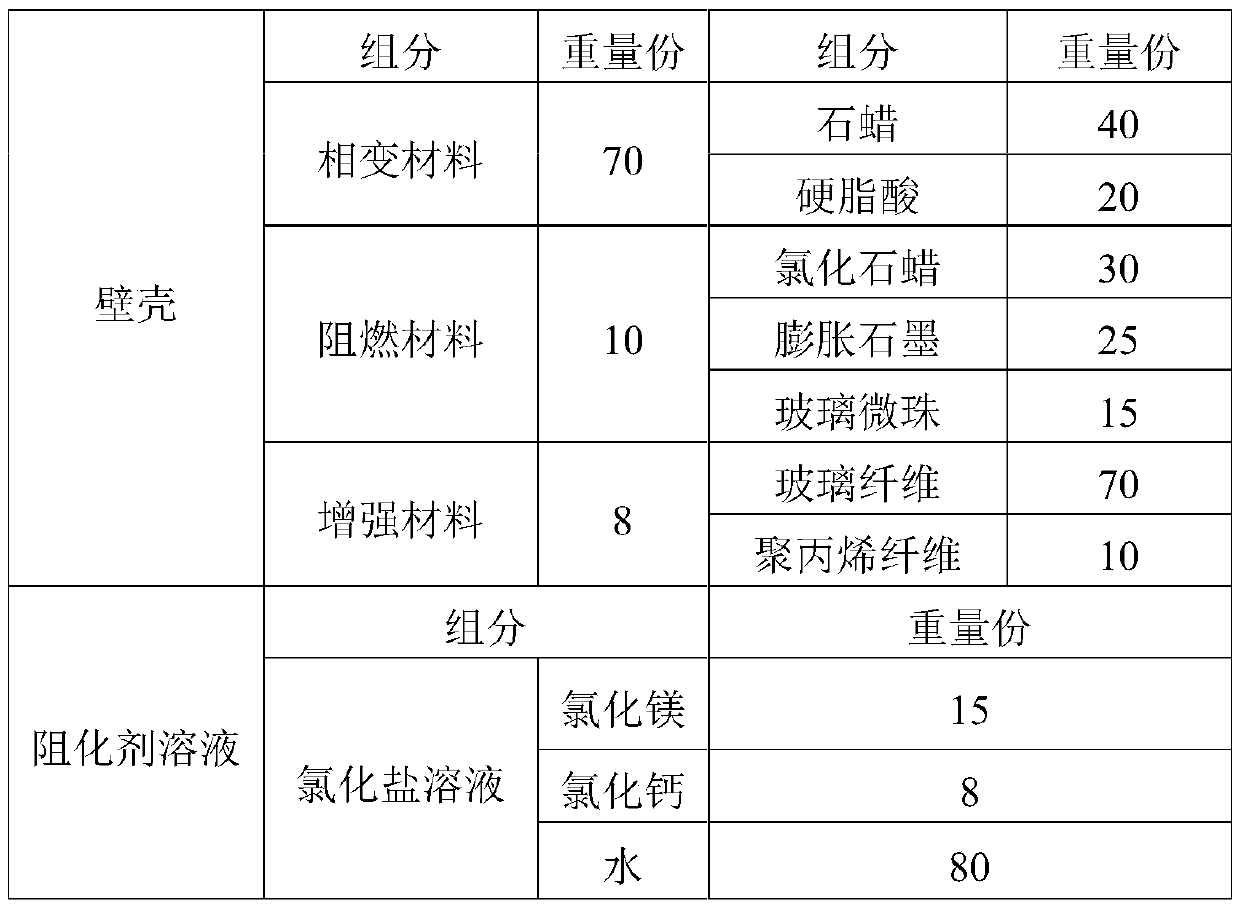

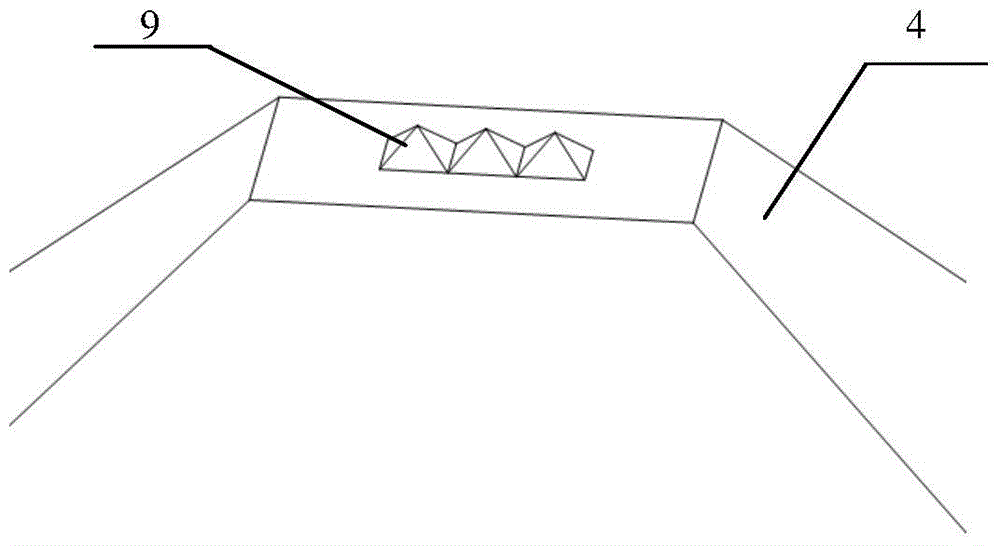

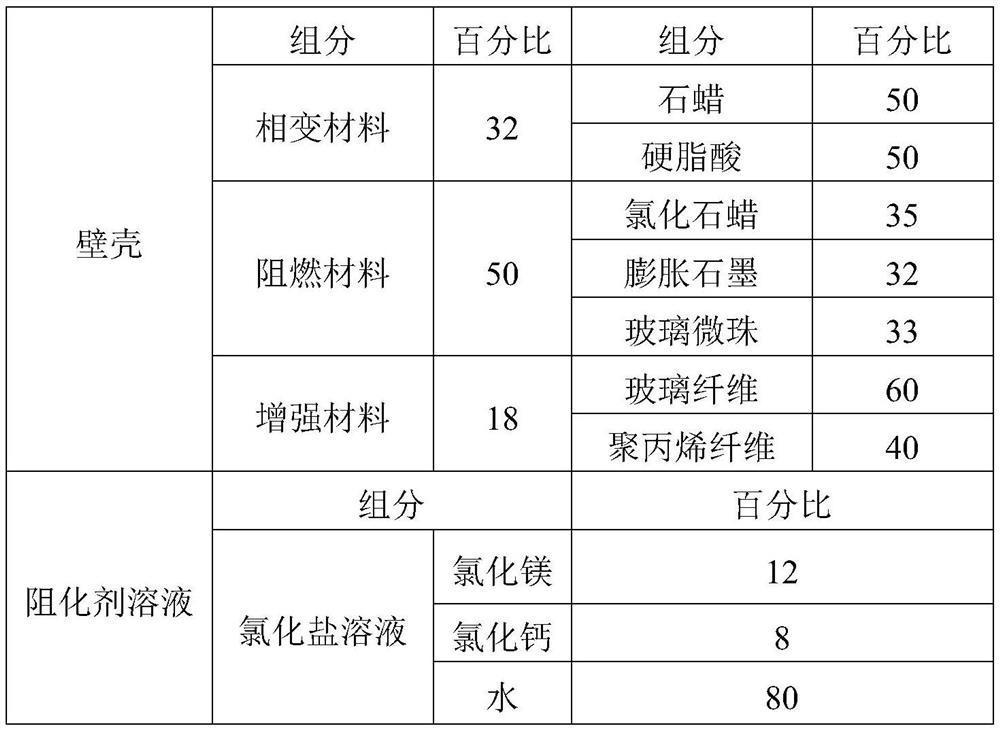

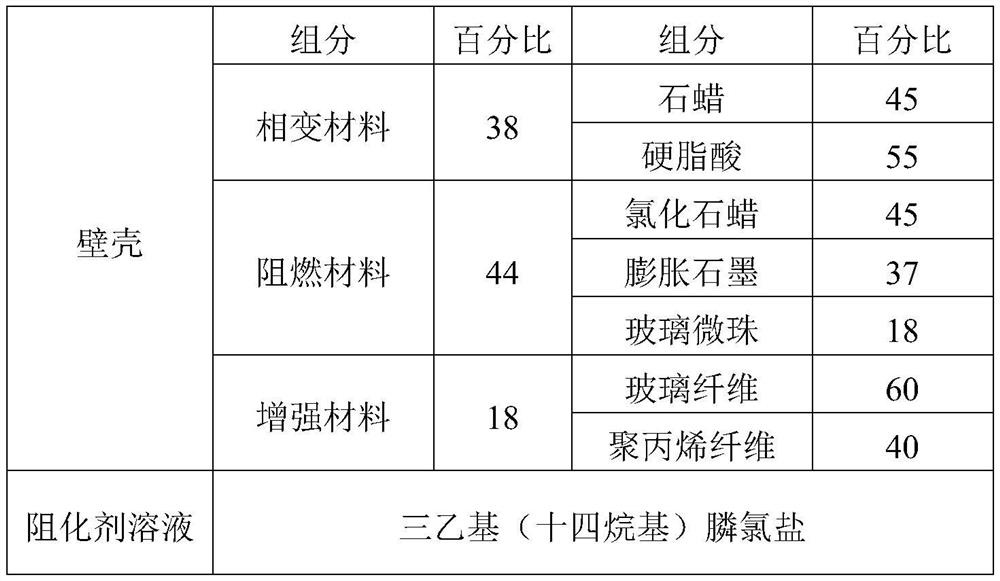

Phase change material temperature-sensitive coating as well as composite retarder and preparation method thereof

ActiveCN107955632AGood effectOvercome the disadvantages of easy failureDust removalFire preventionCoal briquetteHigh water content

The invention discloses phase change material temperature-sensitive coating as well as a composite retarder and a preparation method thereof. A temperature-sensitive phase change material is used as acoating shell, the composite retarder with high water content is directly and externally coated with a composite phase change material, and the composite material takes phase change materials such asparaffin and stearic acid as matrix, uses glass fibers, polypropylene fibers and the like as aggregates and is prepared from flame retardant materials such as magnesium hydroxide, chlorinated paraffin, expanded graphite and glass beads. The phase change material temperature-sensitive coating improves the hardness and ignition point of the phase change material, enables coal briquettes not easy tobreak when falling down, and not only overcomes the defect that the traditional fire preventing and extinguishing retarder is easy to fail, but also well maintains the properties of the retarder; furthermore, the phase change material is more sensitive to temperature rise and can be melted before the critical temperature of coal spontaneous combustion, so that the retarder in the coating can be fully released so as to inhibit the coal spontaneous combustion. The preparation system adopts a modular design, is simple in structure and easy to operate, and can be used for efficiently producing and processing the retarder for the coating.

Owner:CHINA UNIV OF MINING & TECH

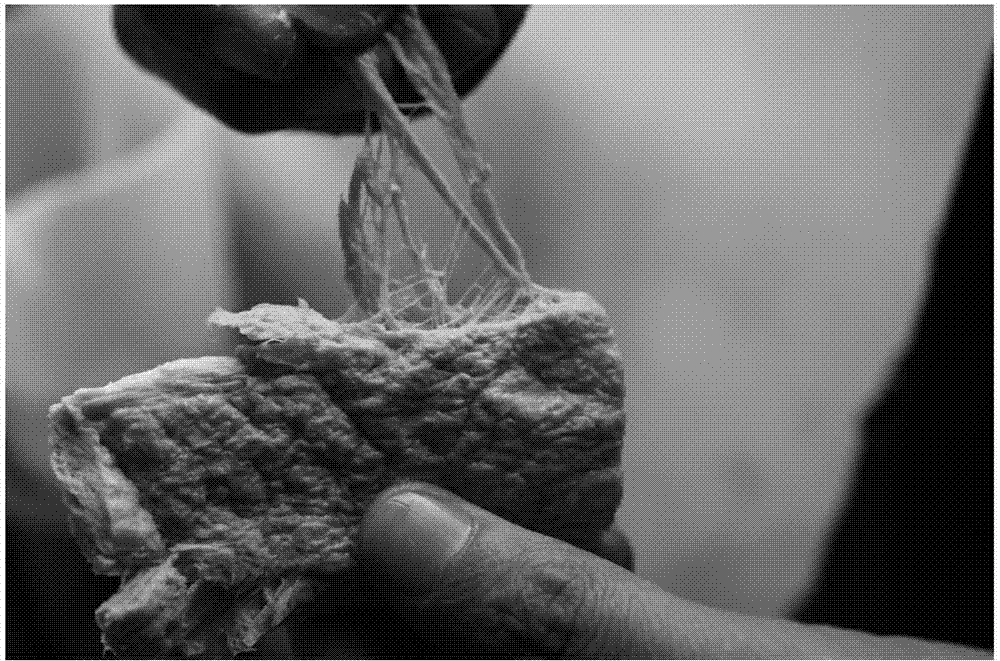

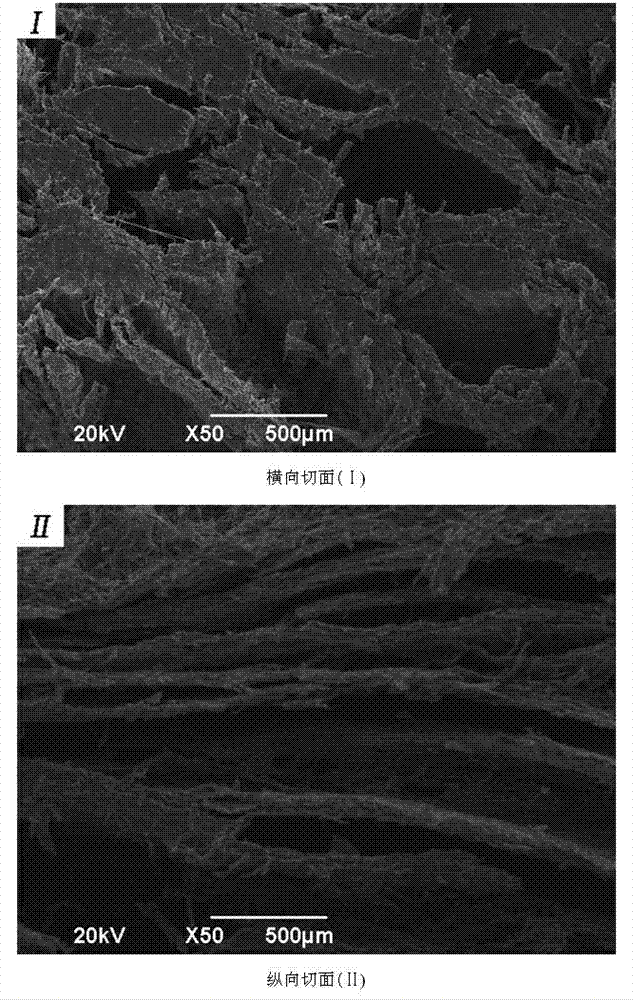

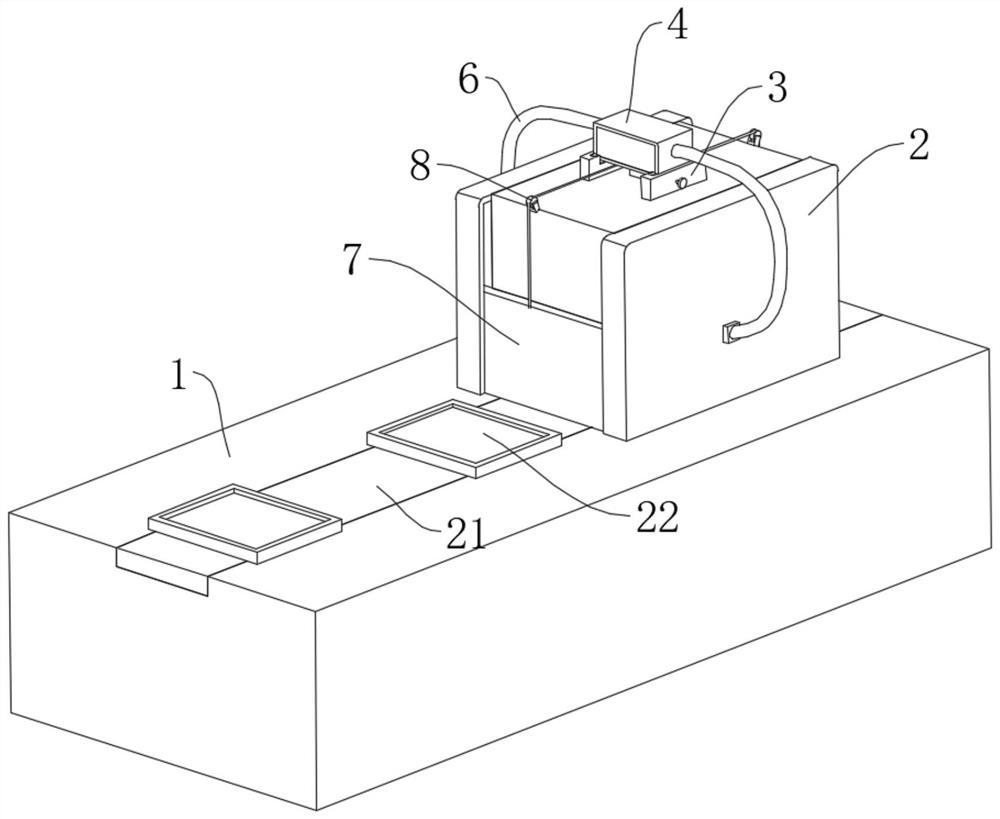

Method for preparing textured wheat protein by adopting twin-screw extrusion

ActiveCN104322858AFull of nutritionPromote digestionProteins working-up by texturisingVegetable proteins working-upBiotechnologyEngineering

The invention relates to a method for preparing textured wheat protein by adopting twin-screw extrusion. The method specifically comprises the following steps: adding powdery wheat protein and starch to a mixing stirrer to be stirred and mixed evenly; adding the mixture into a solid feeder of a high-torque twin-screw extrusion system, stirring and mixing evenly again; and adding to a high-torque twin-screw extruder to be extruded; cutting, drying and cooling extruded materials, so as to prepare the textured wheat protein product, wherein the moisture content is smaller than or equal to 13%, the puffing rate is greater than or equal to 1.20; the rehydration rate is greater than or equal to 190%; the water holding capacity is greater than or equal to 180%; the hardness of the rehydrated product is 7.00-12.50kg; the elasticity is 0.500-0.750; the chewiness is 2200-3550; the adhesion is -65.00 to -17.50g.sec; and the texturizing degree is greater than or equal to 2.0. The method is stable in processing process, simple in operation, and low in processing cost; the produced textured wheat protein product is abundant in nutrition, easy to digest, long in quality guarantee period, and good in cooking processing stability; the wheat protein resource is reasonably utilized; and the additional value of the wheat protein product is increased.

Owner:HEFEI UNIV OF TECH

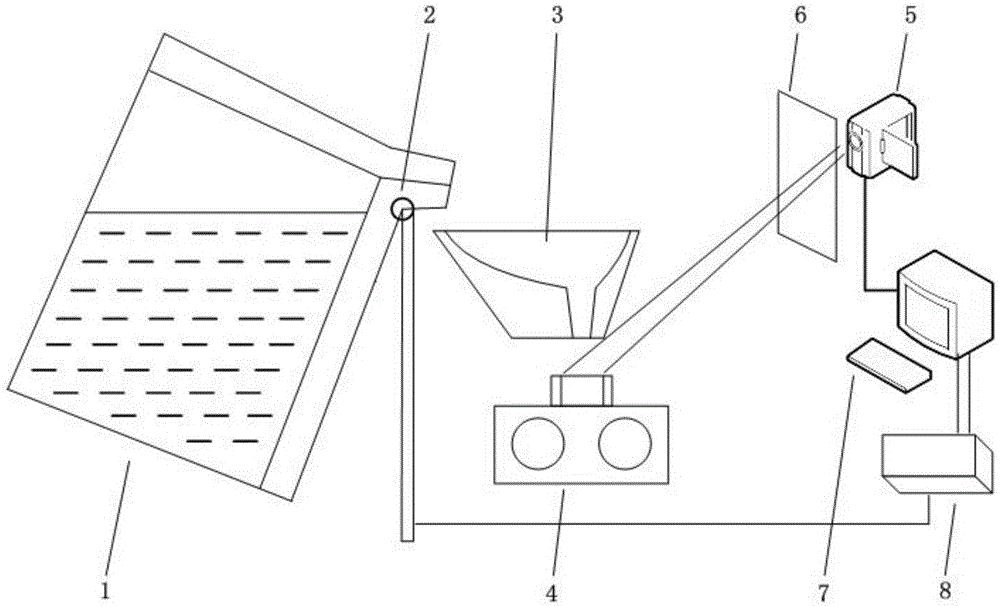

Automatic pouring method and system for heat preserving furnace pouring platform

InactiveCN105478737APouring Precise ControlPrecise control of pouring platform automatic pouringMolten metal pouring equipmentsMetallurgyMolten steel

The present invention relates to the production field of casting technique, in particular to an automatic pouring method and system for a heat preserving furnace pouring platform. By collecting an inclined effluent angle of a heat preserving furnace of the heat preserving furnace pouring platform, a pouring reference datum angle of the heat preserving furnace satisfying the pouring amount is obtained. If the inclined angle of the heat preserving furnace is equal to the pouring reference datum angle, the heat preserving furnace stops inclining. After a predetermined time, a molten steel image from a diversion trench discharge hole to a pouring mold gate is collected, and a molten steel flow velocity value is obtained according to the molten steel image. The extracted molten steel flow velocity value is compared with a corresponding predetermined velocity range. When the molten steel flow velocity value exceeds the corresponding predetermined velocity range, the inclined pouring angle of the heat preserving furnace is adjusted to control the flow velocity of the molten steel within the corresponding predetermined velocity range, so as to solve the problems of the existing technology that the inaccurate control on the pouring angle causes molten steel waste when the heat preserving furnace automatically pours, and the pouring efficiency is low.

Owner:湖南华民控股集团股份有限公司

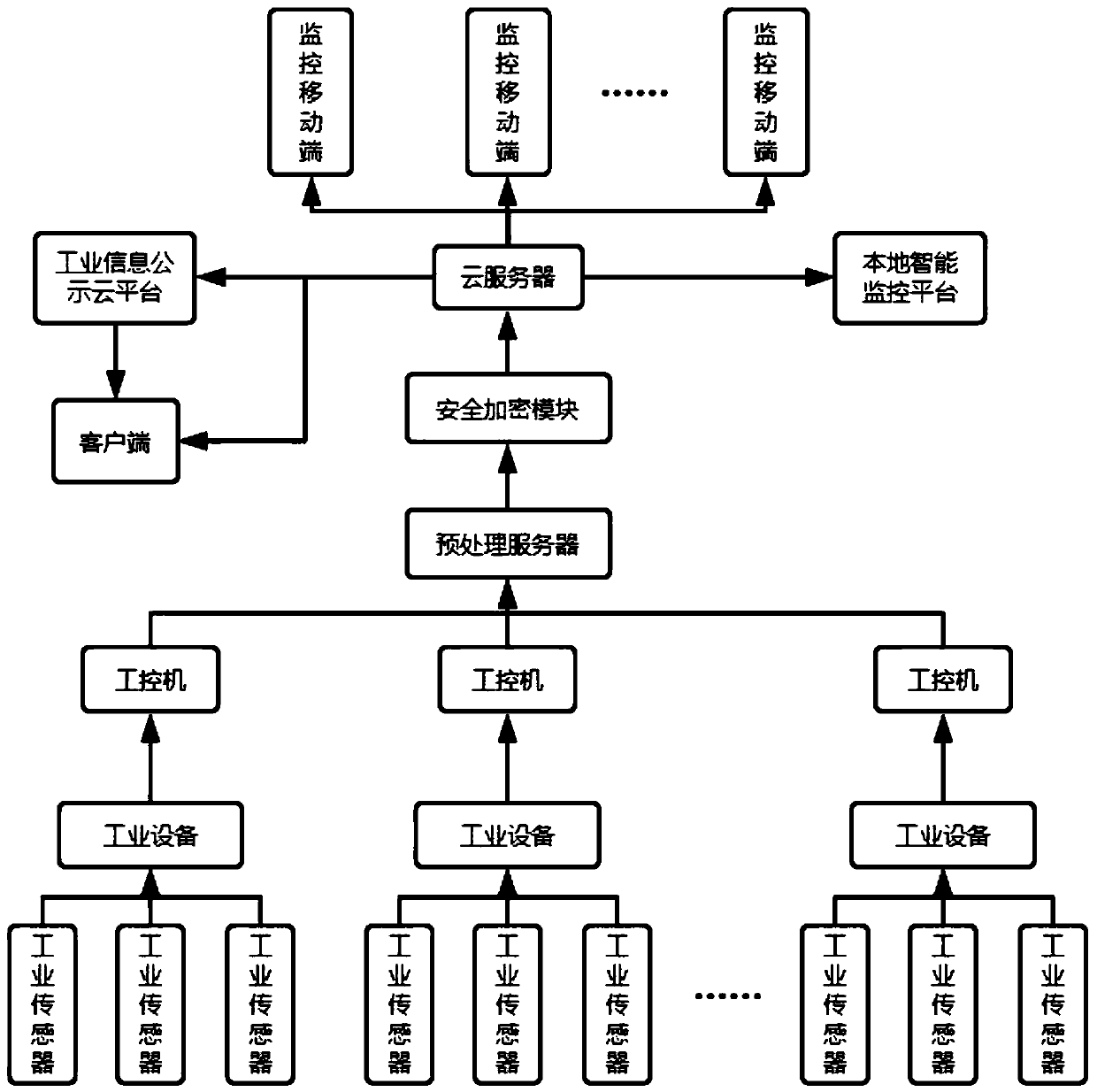

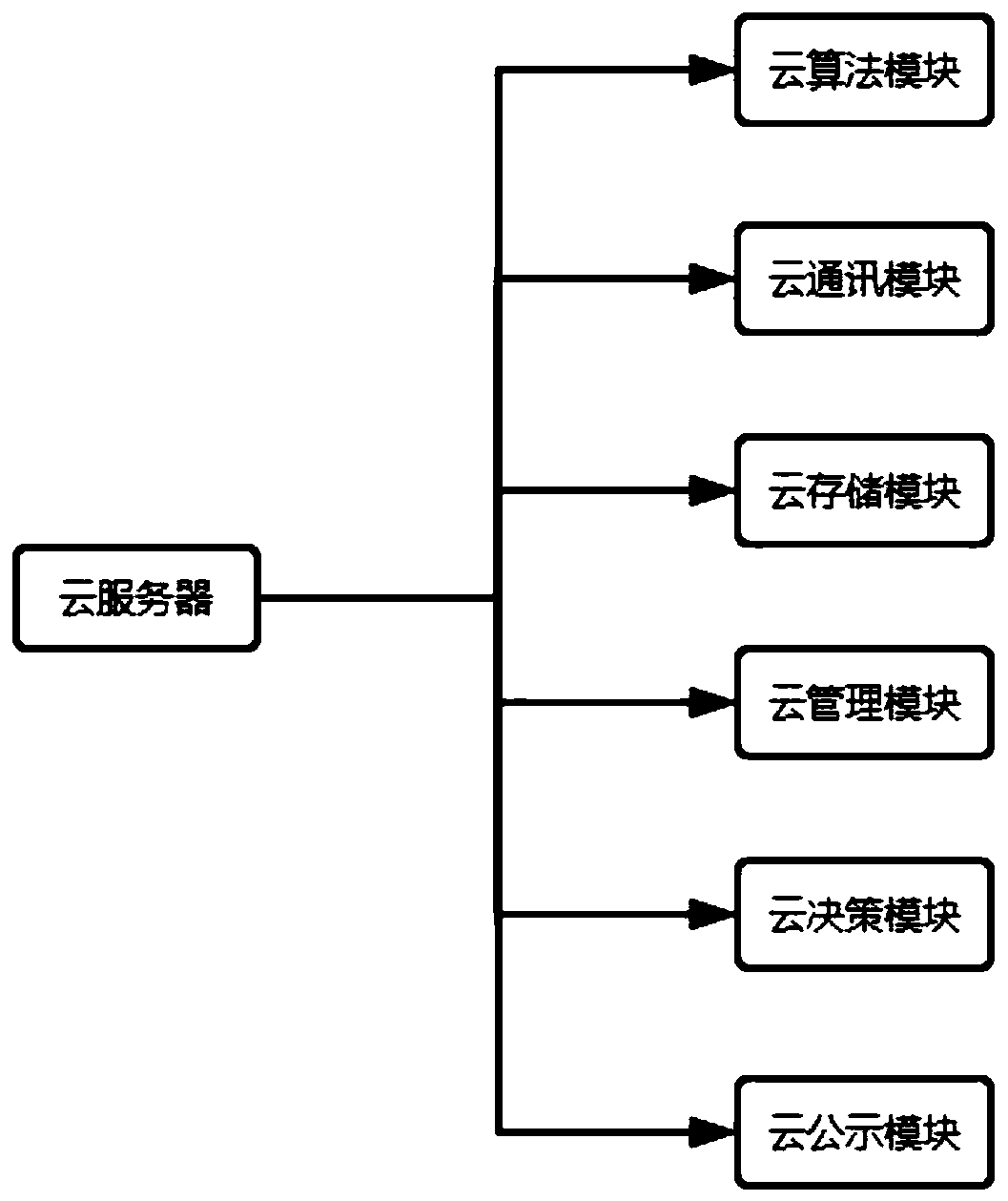

Industrial big data processing system based on artificial intelligence algorithm

InactiveCN111556032AReasonable production and processingScientific production and processingMachine learningTransmissionAlgorithmIndustrial equipment

The invention discloses an industrial big data processing system based on an artificial intelligence algorithm. The invention belongs to the technical field of industrial data processing. The supportbased on an artificial intelligence algorithm can be realized; industrial equipment information is acquired offline; useless information is removed after preprocessing; useful data information and simple integration processing are realized; a proper artificial intelligence algorithm is selected for processing according to the data type; then, the information is uploaded to a cloud server after security encryption; data processing and analysis are carried out by utilizing the strong computing power and computing speed of the cloud server; decision support is provided for industrial production;reasonable, scientific and efficient production and processing by utilizing industrial equipment are facilitated; the industrial data processing and analyzing speed and precision can be rapidly improved, a large amount of industrial data query and analysis can be achieved, an existing industrial production mode is effectively improved through rear remote centralized processing and front visual query, and industrial intellectualization and Internet of Things development are protected.

Owner:JIANGSU TIANREN IND INTERNET RES INST CO LTD

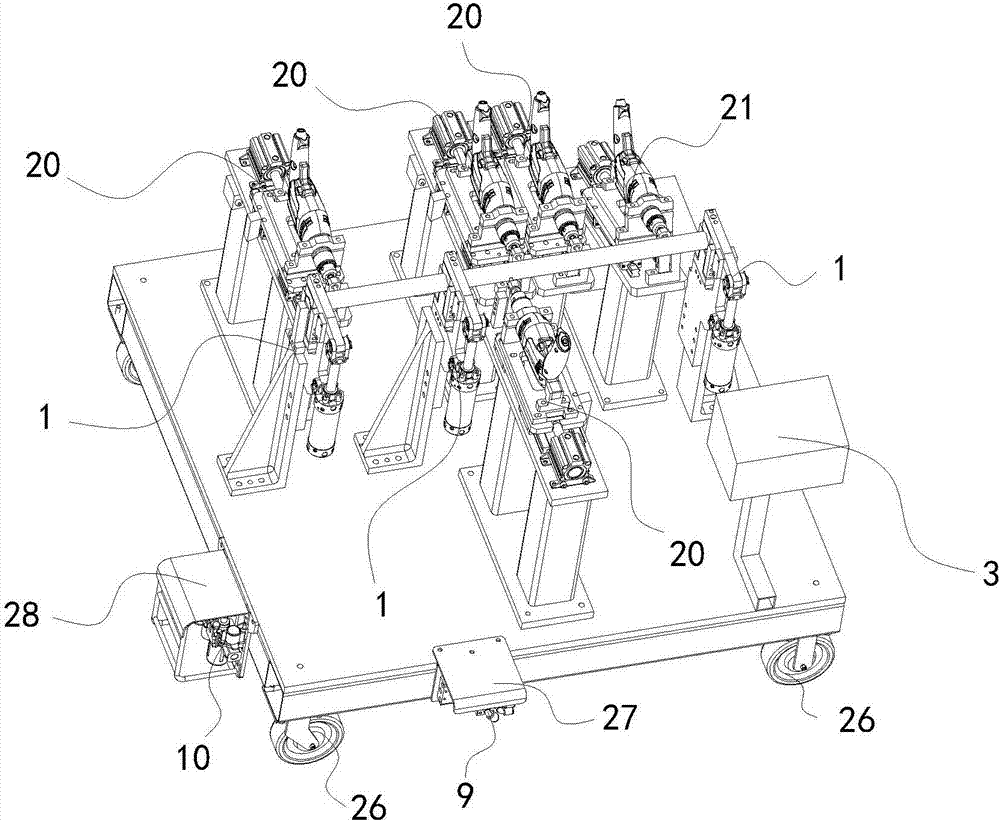

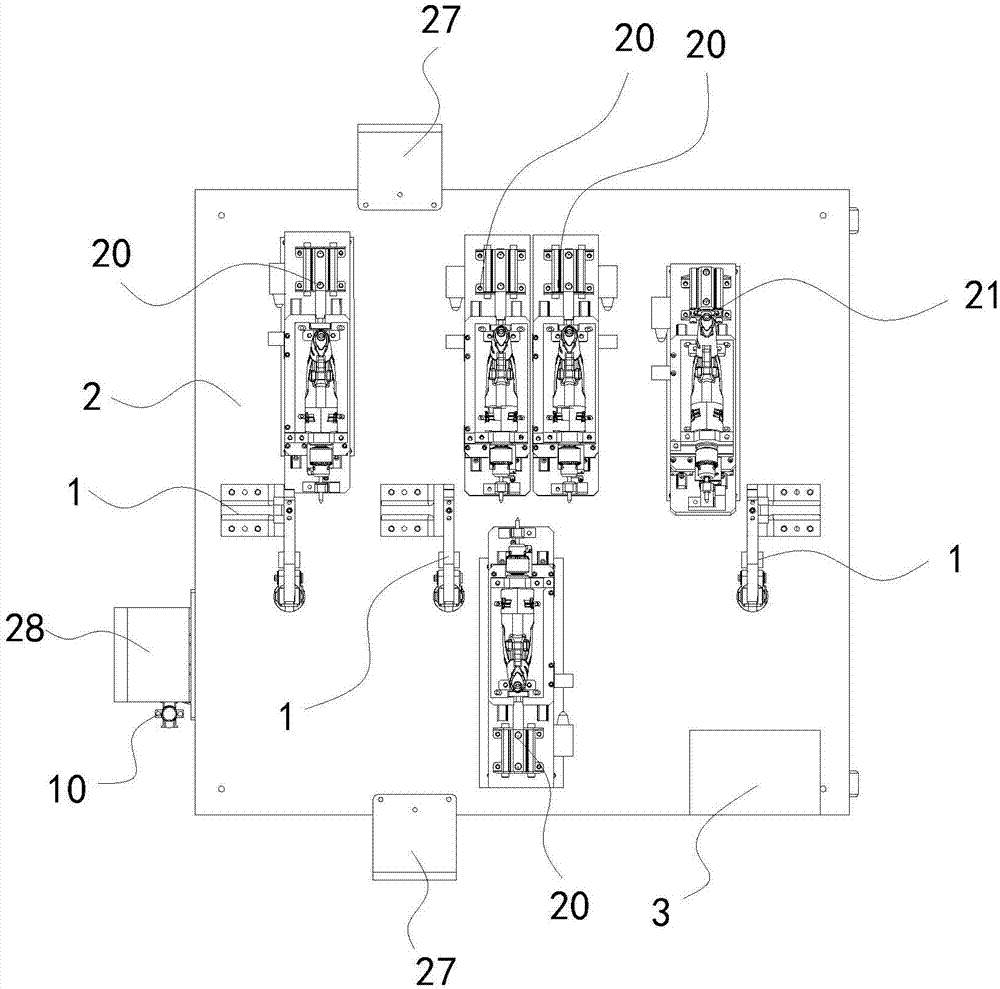

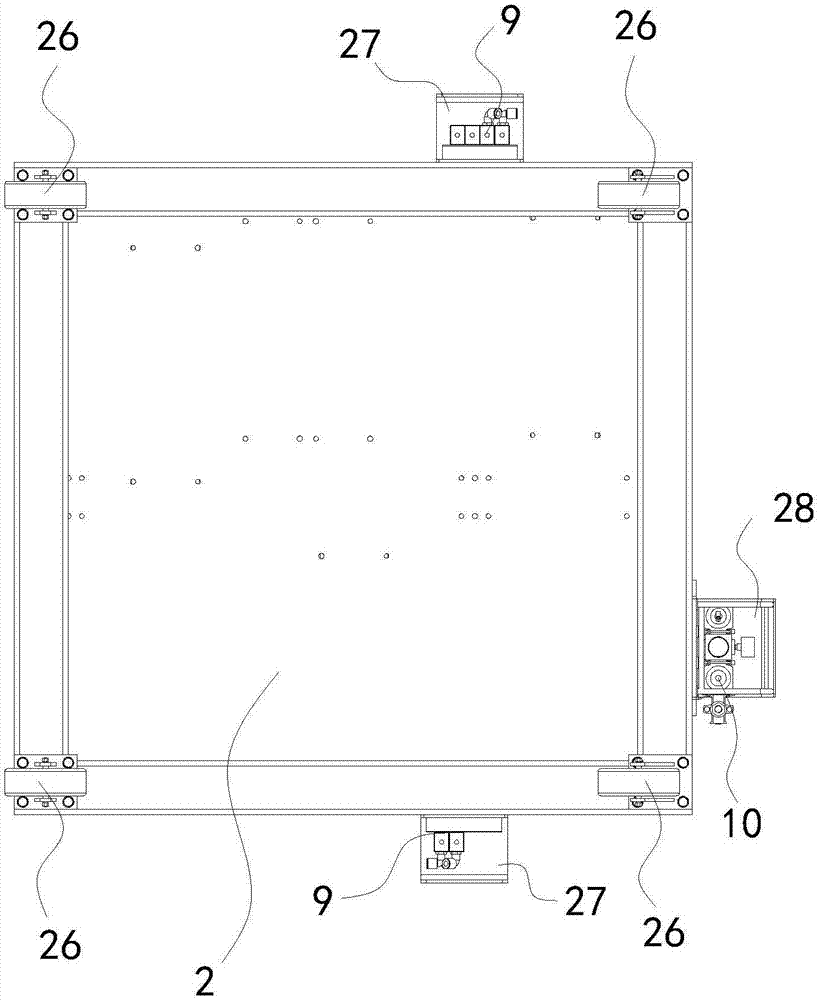

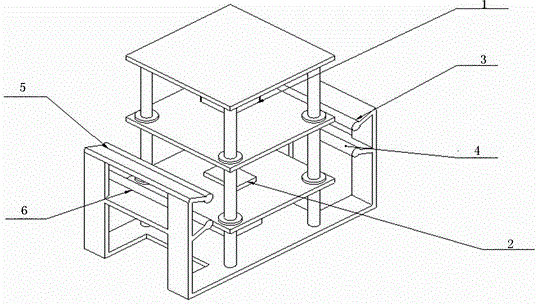

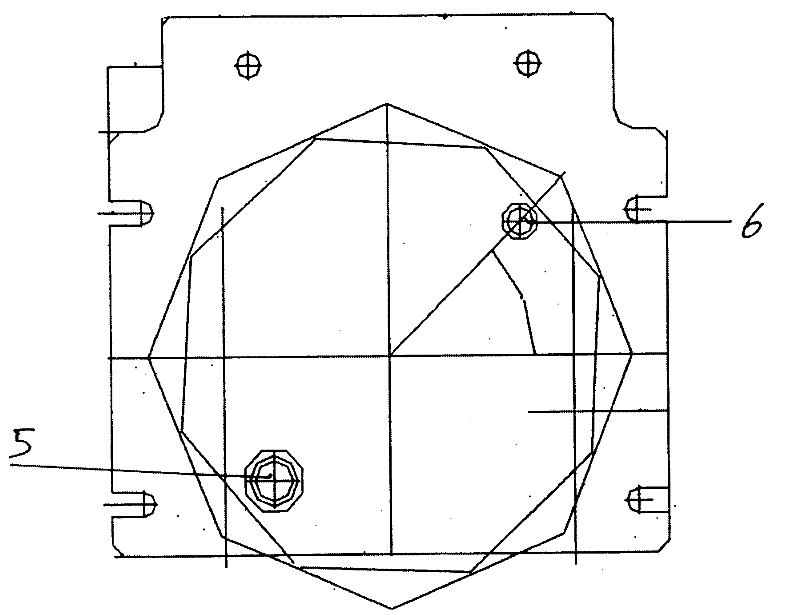

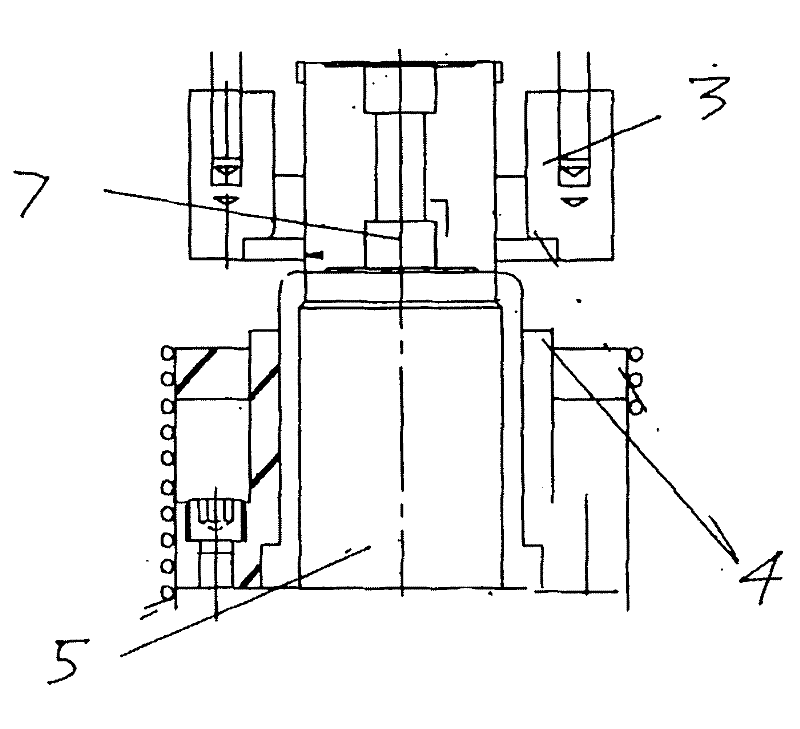

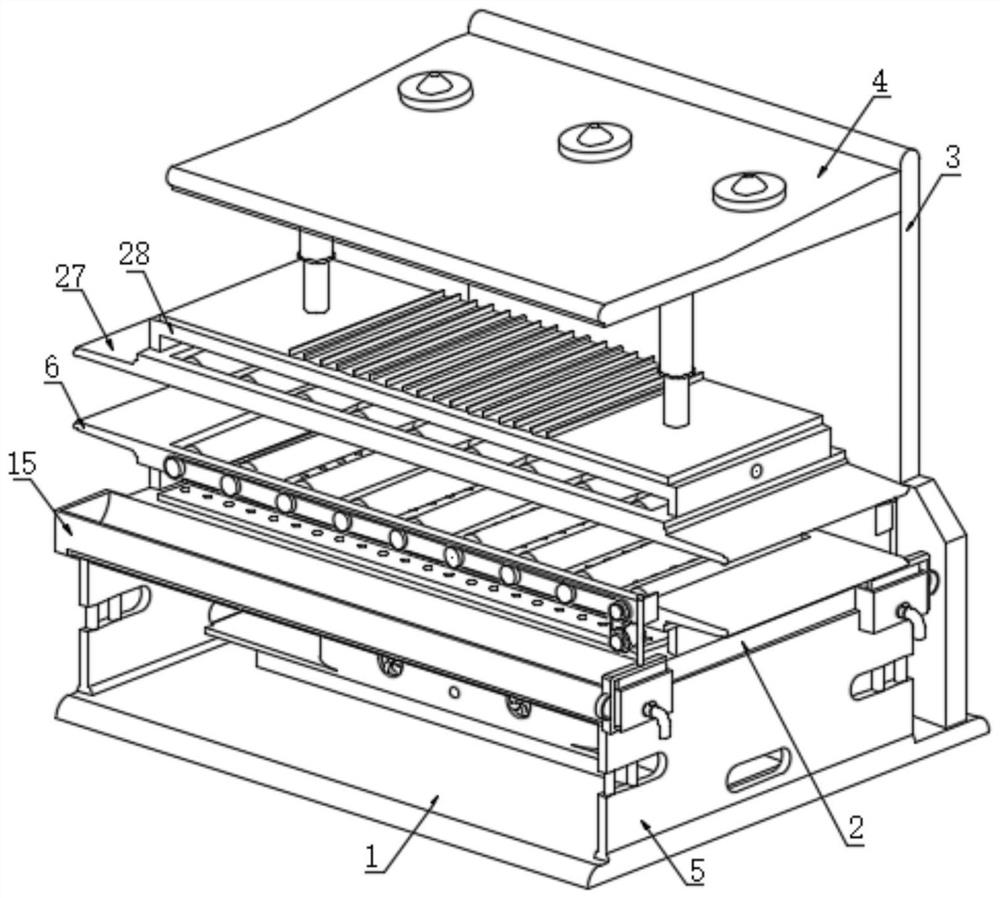

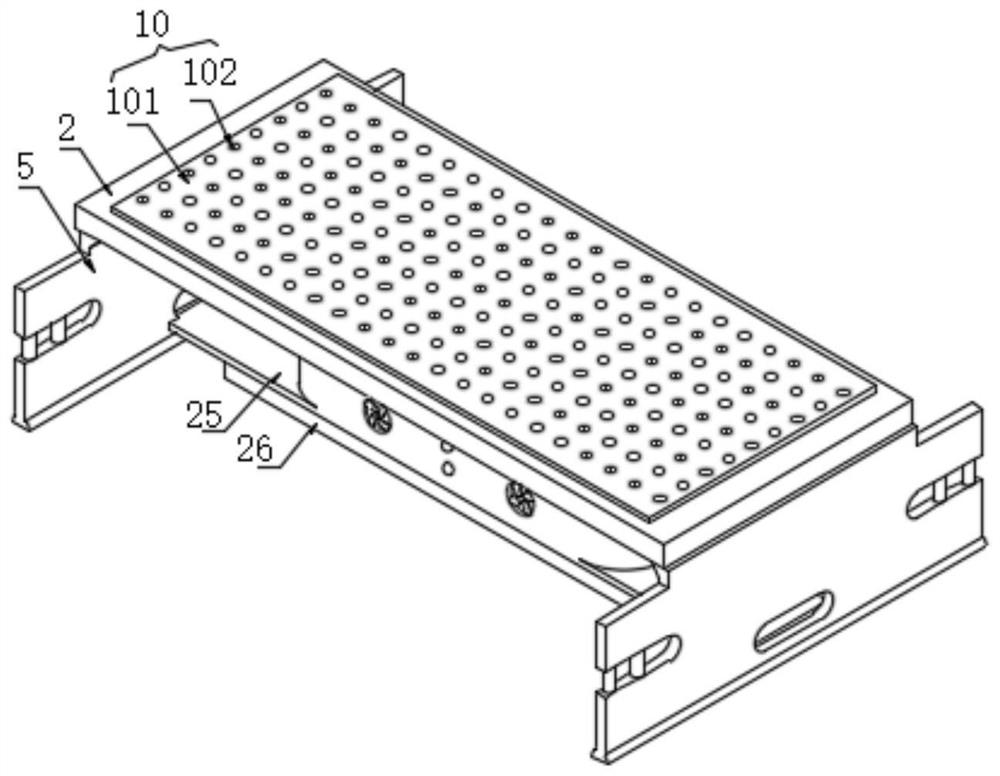

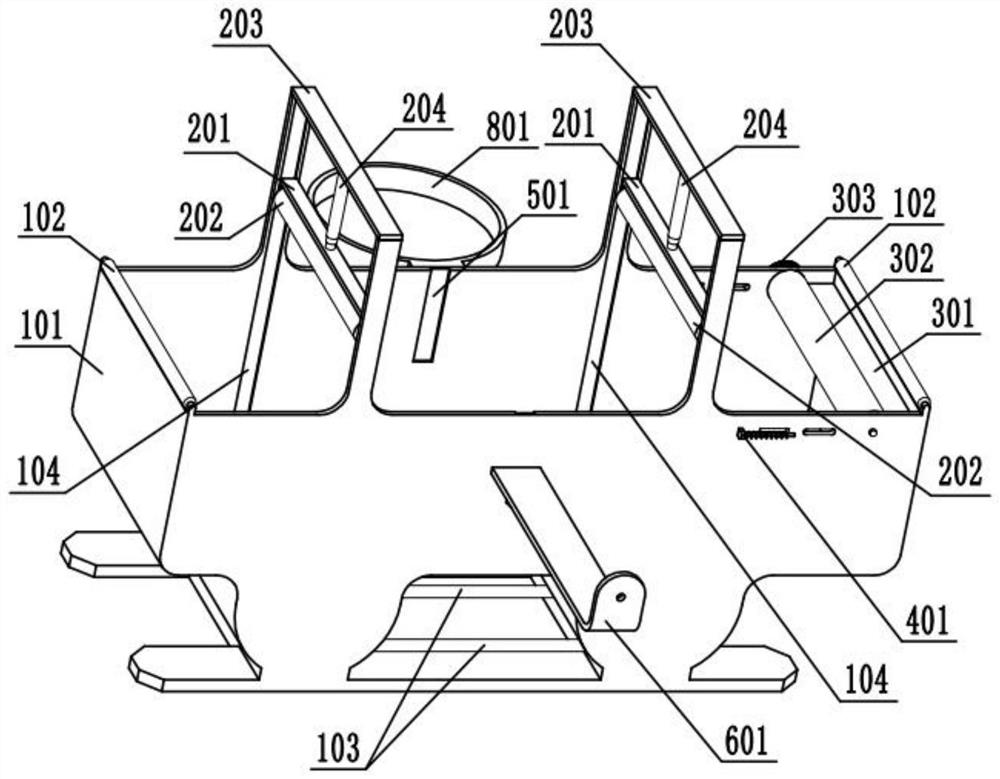

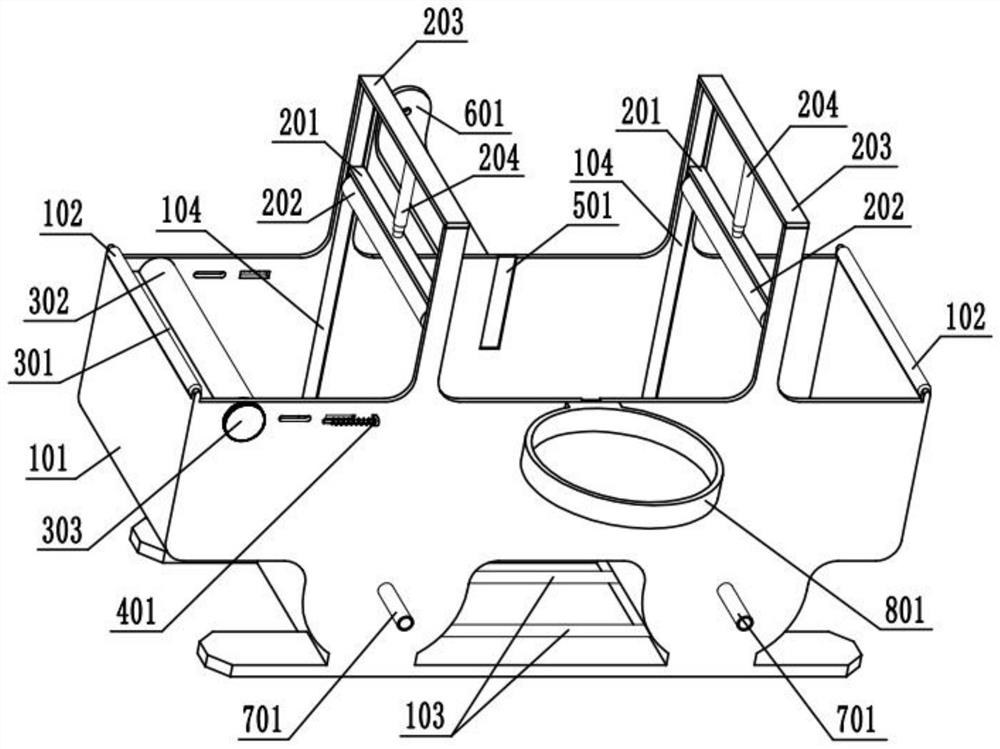

Device for drilling tubular beam

PendingCN107984438AIncrease productivitySimple structureWork benchesBoring/drilling machinesBiomedical engineeringDrill hole

The invention relates to the technical field of main tubular beam drilling tools of an automobile instrument panel, in particular to a device for drilling a tubular beam. The device comprises a plurality of drilling mechanisms, a plurality of tubular beam clamping mechanisms and a base, and each drilling mechanism comprises a support base and a drilling tool used for drilling the tubular beam andconnected to the upper end of the support base; each tubular beam clamping mechanism comprises footstand used for supporting the tubular beam, and a pressing component used for clamping the tubular beam; the pressing component is connected to the upper end of the footstand; the drilling mechanisms are arranged on the both sides or one side of the tubular beam clamping mechanisms; the support baseand the footstand are both connected to the upper surface of the base separately; and the base is provided with a switch control box used for controlling the operation of the drilling mechanisms and the tubular beam clamping mechanisms. According to the device provided by the invention, the production efficiency of main tubular beams of the automobile instrument panel is improved greatly, and thedevice has the advantages of simple structure, low cost, good processing effect and manpower saving.

Owner:重庆能正机械有限公司

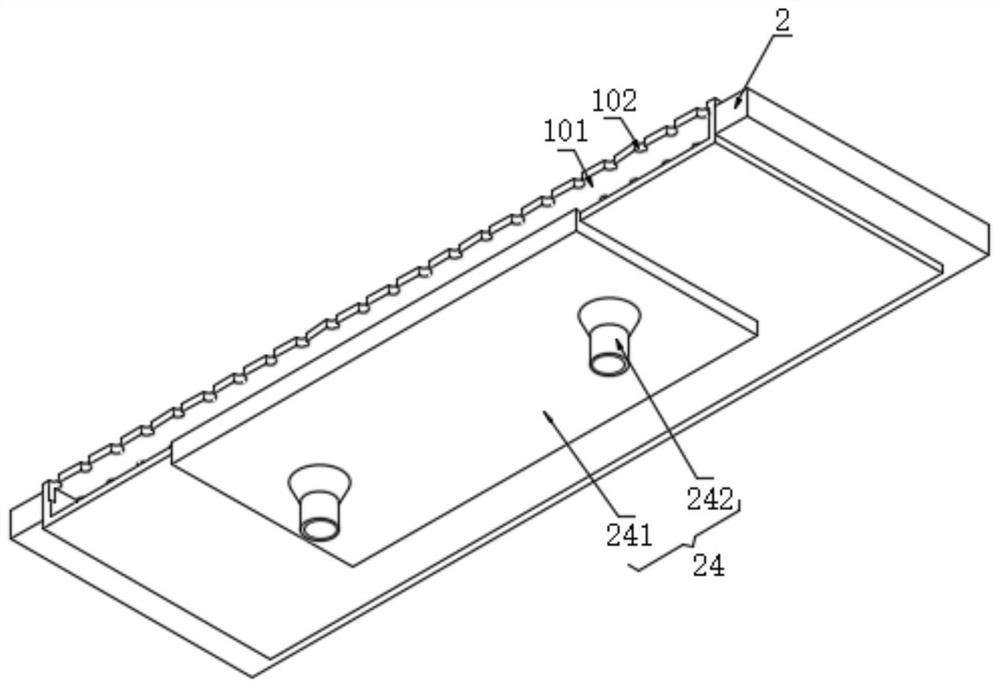

Hot press molding mechanism for electrode lugs of lithium-ion power batteries

InactiveCN105014950AHeating fastEven and stable heatingCell component detailsElectrical conductorAdhesive

The invention relates to a hot press molding mechanism for electrode lugs of lithium-ion power batteries. The hot press molding mechanism comprises a middle hot press mechanism and a metal conductor heating mechanism, wherein the middle hot press mechanism is used for compositing electrode lug adhesives and a metal conductor together through hot press. The middle hot pressing mechanism is provided with an upper hot press end socket and a lower hot press end socket which are synchronously and oppositely driven by cylinders. A left metal strap heating mechanism and a right metal strap heating mechanism are arranged on the two sides of the hot pressing mechanism respectively. Each metal strap heating mechanism is provided with an upper heating pipe and a lower heating pipe which are arranged on a support to form a 45-degree angle. The perpendicular distance between the surfaces of modulator tubes and the surface of a metal strap is 20 mm. The power of the four heating pipes is regulated to be the same. Every two heating pipes in the same set are on a perpendicular straight line and fixedly arranged on the two sides of the metal conductor to form a shape like a Chinese character 'ba'. The horizontal distance between the heating pipes and the end sockets is 15 mm. By means of the hot pressing forming mechanism, the hot sealing molding time of the power large electrode lugs can be effectively shortened, the excellent hot sealing adhesion effect is provided, the size stability and the appearance of rubber blocks molded through hot press are improved, the hot press molding mechanism is suitable for continuous production, and the production efficiency is improved.

Owner:WUXI BAISHIJIE METAL PROD TECH

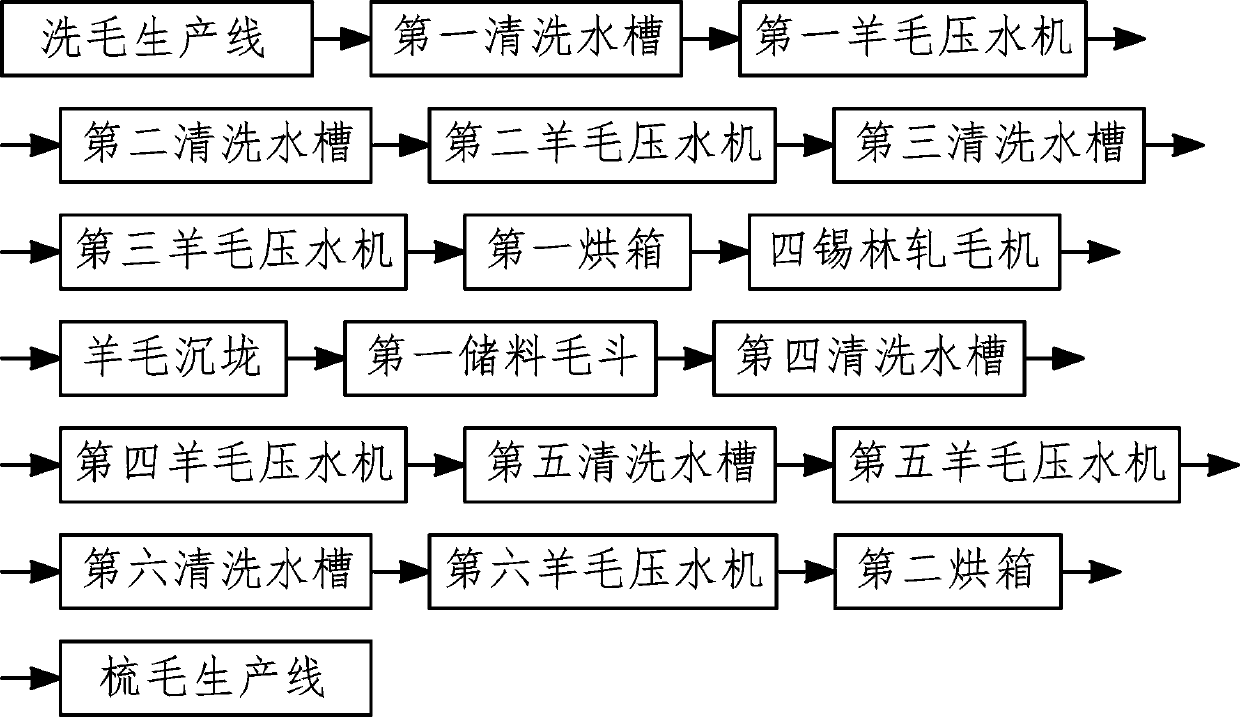

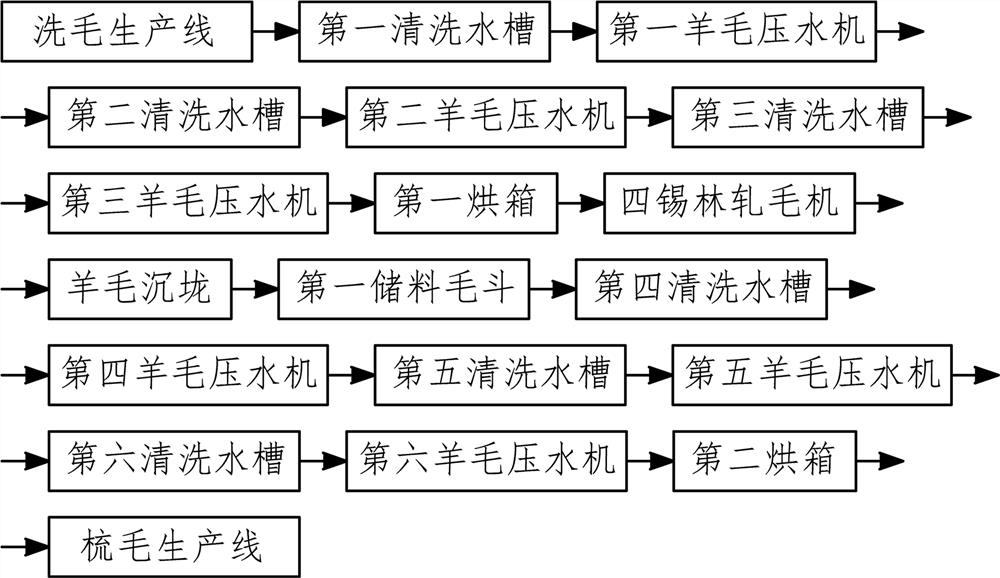

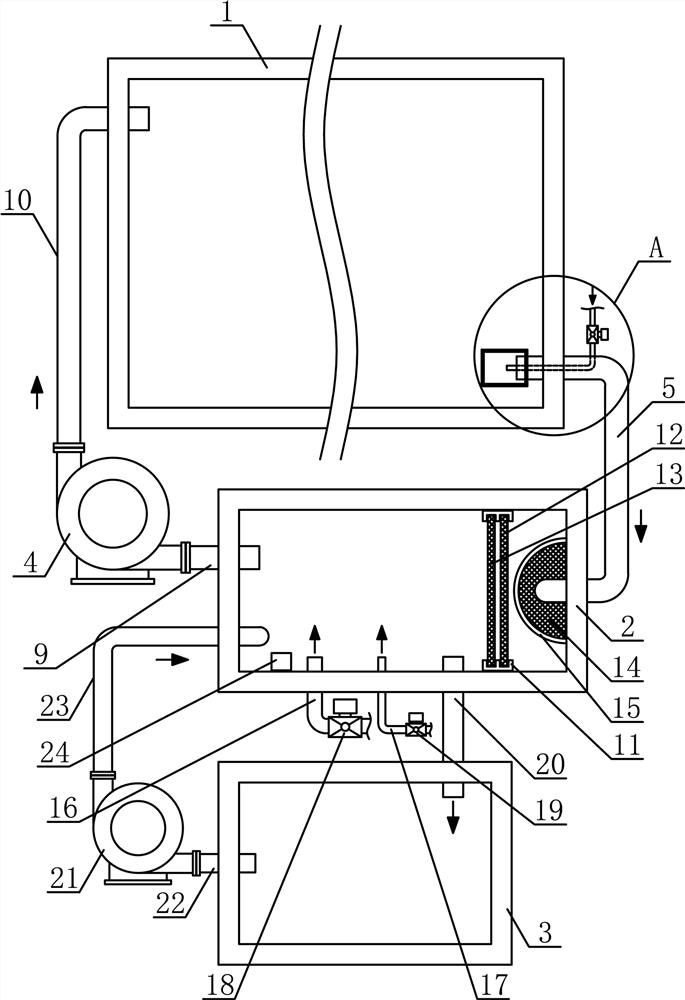

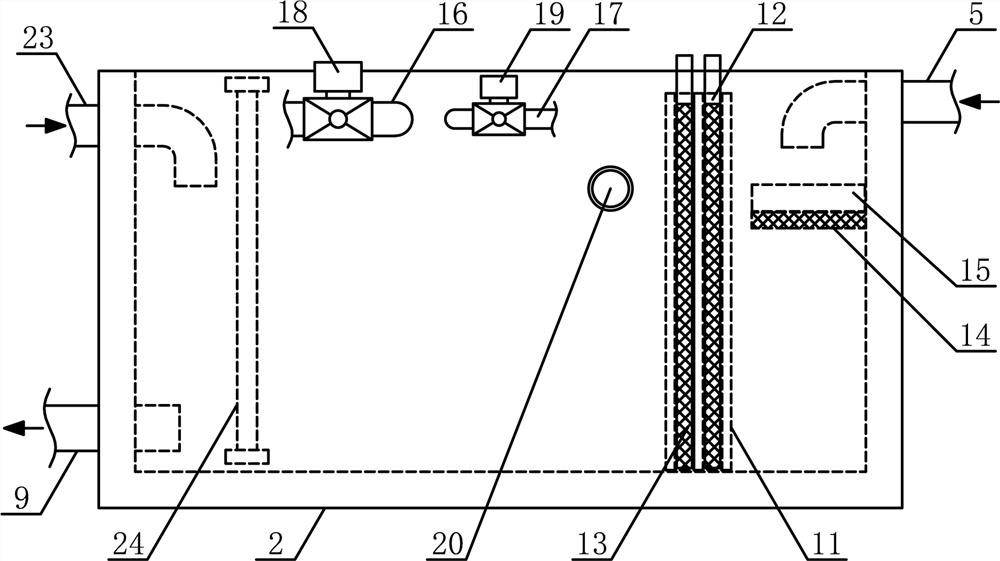

Wool light-carbonization weeding process

ActiveCN110685017AProtect fiber stateMeet production requirementsWool fibre washing/scouringFiberCarbonization

The invention discloses a wool light-carbonization weeding process and belongs to the technical field of textile processing. According to the wool light-carbonization weeding process, wool which is processed by the previous wool washing line is conveyed sequentially to a first washing sink, a second washing sink and a third washing sink to be washed, the washed wool is then conveyed to a first oven to be dried by heating, the dried wool is conveyed and rolled through a four-cylinder wool rolling mill, and is separated from weeds through a wool sinking ridge, the wool separated is conveyed to afourth washing sink, a fifth washing sink and a sixth washing sink sequentially to be washed, and then conveyed to a second oven to be dried by heating, finally, the dried wool is cooled and then conveyed to a carding production line to be carded and slivered. The wool light-carbonization weeding process is reasonable in design and can remove weeds in wool effectively while effectively protectingwool fiber, the yield of wool finished products is high, and requirements on processing are met.

Owner:张琦

A kind of temperature-sensitive explosive cell coat inhibitor and preparation method thereof

ActiveCN111287786BHigh selectivityGood water permeabilityDust removalFire preventionParaffin waxChemical agent

Owner:TAIYUAN UNIV OF TECH

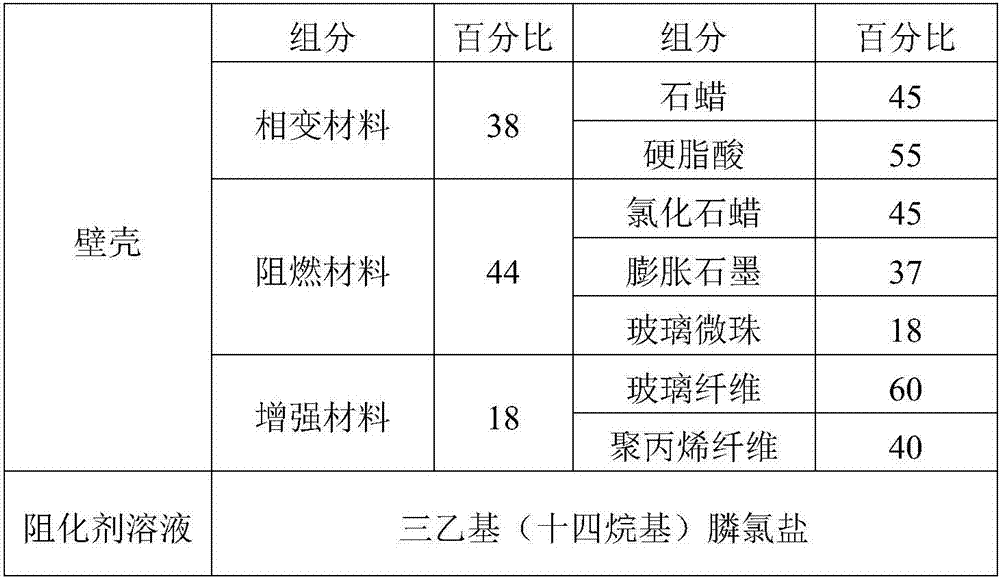

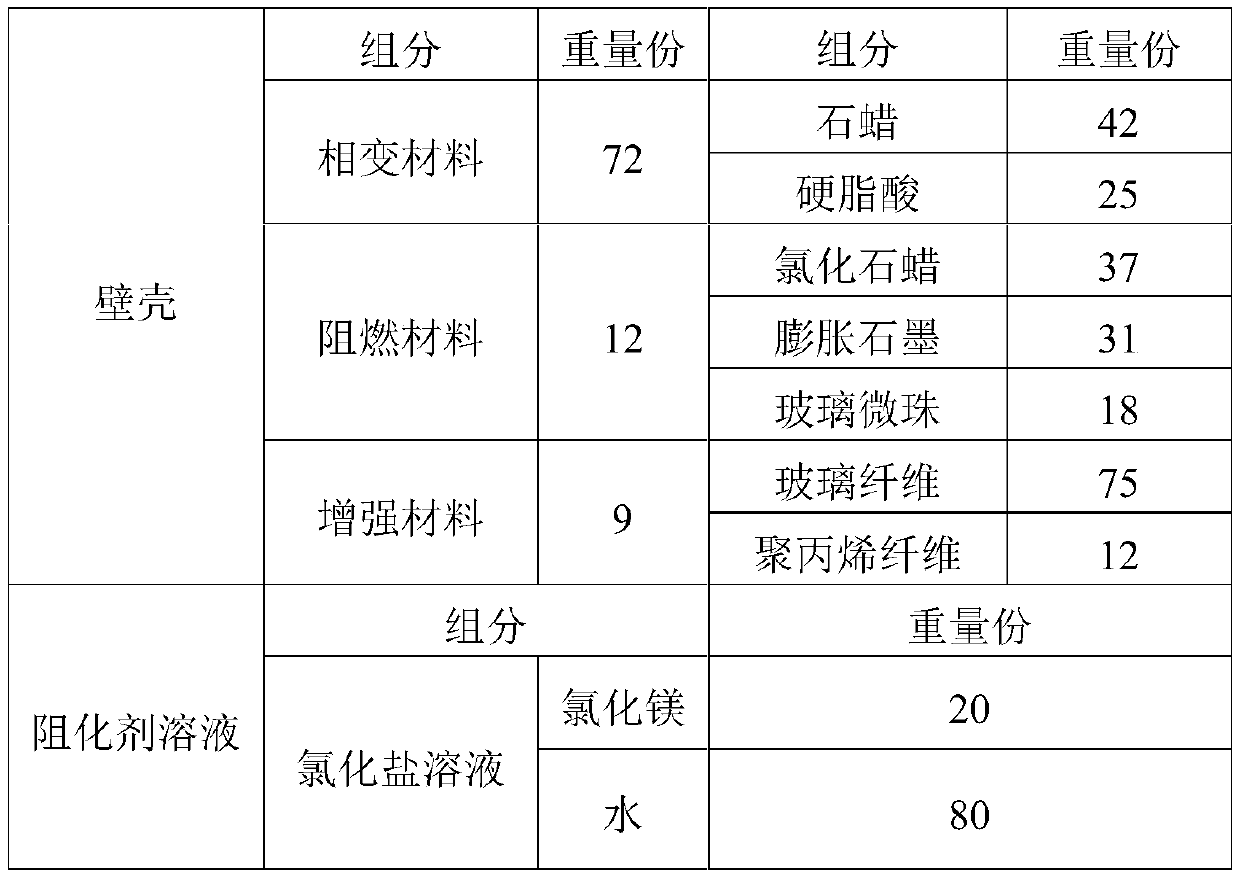

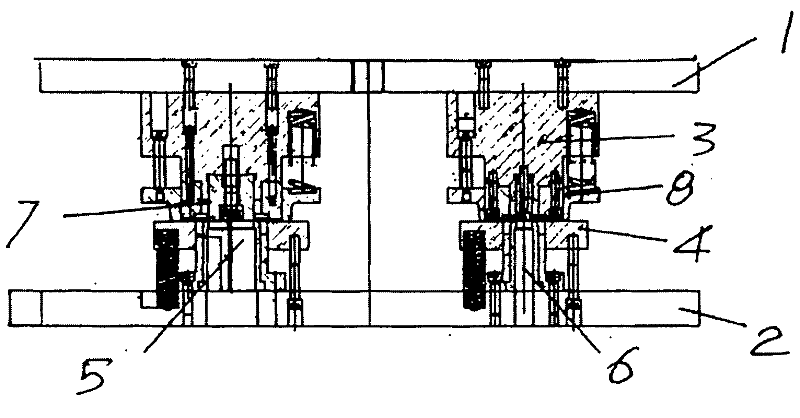

A kind of preparation method of composite microcapsule inhibitor for preventing and controlling coal spontaneous combustion

ActiveCN108167016BHigh strengthHigh ignition pointDust removalFire preventionCold airCoal spontaneous combustion

The invention relates to a composite microcapsule stopping agent for preventing coal spontaneous combustion and a preparation method of the composite microcapsule stopping agent. The stopping agent comprises a wall shell and a stopping agent solution sealed in the wall shell. The wall shell is mainly prepared from the following components of, by weight, 70-80 parts of phase-change materials, 10-20parts of flame-resistant materials and 8-12 parts of reinforcing materials. The stopping agent solution is ionic liquid or a chloride solution. The stopping agent solution is evenly composited to thecomposite phase-change materials to obtain a mixed emulsion, the mixed emulsion is sprayed into a dry porous medium in an emulsion-drop mode through a spraying device to enable mixed emulsion drops to be further atomized into mist drops with the particle diameter of 30-50 [mu]m, and after the mixed emulsion which is formed into the mist drops makes contact with cold air, the composite phase-change mixed materials are quickly solidified to wrap the stopping agent solution to form the composite microcapsule stopping agent. The stopping agent can be evenly distributed in coal seams, the coveragerange is wide, accumulation of heat is prevented, coal spontaneous combustion is resisted, and the preparation method can efficiently produce and process the composite microcapsule stopping agent.

Owner:CHINA UNIV OF MINING & TECH

A method for producing worm tea by utilizing eagle tea leaves

InactiveCN105941754BIncrease the number ofProduce moreTea substituesAnimal feeding stuffForeign matterCataphyll

Owner:DAXIAN JINHAI TRADING

Method and device for determining critical depth of cut for brittle-to-ductile transition in grinding hard and brittle materials

InactiveCN103722467BImprove surface qualityHigh precisionGrinding feed controlAutomatic grinding controlRelative motionHigh surface

The invention relates to the technical field of hard and brittle material ultra-precision machining. In order to achieve ductility domain grinding of the largest cutting depth, high surface quality of the hard and brittle material, and efficient and high-precision production machining, according to the technical scheme, a method and device for determining the grinding brittleness-ductility transformation critical cutting depth of the hard and brittle material comprises the following steps of (1) according to a grinding wheel used in ultra-precision grinding, determining the number, shape and distance of grains of a homemade multi-grain tool, (2) according to the grain shape, distance and front-angle parameters selected in the step (1), machining three or more grains on a grain base body, (3) controlling the multi-grain tool and a workpiece to generate relative motion, beginning to conduct scratching on the surface of the workpiece, meanwhile, controlling the multi-grain tool to conduct continuous feeding, enabling the depth of the scratch to continuously change, and observing and measuring the workpiece after scratching by utilizing a surface contourgraph and a confocal microscopy. The method is mainly applied to ultra-precision machining.

Owner:TIANJIN UNIV

A temperature-sensitive cell coat of phase change material, composite inhibitor and preparation method thereof

ActiveCN107955632BGood effectOvercome the disadvantages of easy failureDust removalFire preventionCoal briquetteParaffin wax

The invention discloses phase change material temperature-sensitive coating as well as a composite retarder and a preparation method thereof. A temperature-sensitive phase change material is used as acoating shell, the composite retarder with high water content is directly and externally coated with a composite phase change material, and the composite material takes phase change materials such asparaffin and stearic acid as matrix, uses glass fibers, polypropylene fibers and the like as aggregates and is prepared from flame retardant materials such as magnesium hydroxide, chlorinated paraffin, expanded graphite and glass beads. The phase change material temperature-sensitive coating improves the hardness and ignition point of the phase change material, enables coal briquettes not easy tobreak when falling down, and not only overcomes the defect that the traditional fire preventing and extinguishing retarder is easy to fail, but also well maintains the properties of the retarder; furthermore, the phase change material is more sensitive to temperature rise and can be melted before the critical temperature of coal spontaneous combustion, so that the retarder in the coating can be fully released so as to inhibit the coal spontaneous combustion. The preparation system adopts a modular design, is simple in structure and easy to operate, and can be used for efficiently producing and processing the retarder for the coating.

Owner:CHINA UNIV OF MINING & TECH

Double-station riveting mold for riveting and locking of opening of steel barrel

InactiveCN102310141AEfficient production and processingSave human effortPerforating toolsPunchingMaterials science

The invention relates to a double-station riveting mold for riveting and locking of an opening of a steel barrel, which comprises an upper mold and a lower mold. The upper surface of the lower mold is provided with two riveting bosses, i.e. a large riveting boss and a small riveting boss; and the upper mold is provided with two upper riveting punches matched with the large riveting boss and the small riveting boss on the upper surface of the lower mold. By adopting the double-station riveting mold for riveting and locking of the opening of the steel barrel, punching and extension of two holes on the upper surface of the steel barrel can be completed simultaneously. The problems of the traditional process that the production efficiency is low and two pressing machines are needed for punching can be solved effectively. High-efficiency production and process can be achieved; and the labor and equipment resources can be saved, and the production efficiency can be increased greatly.

Owner:天津大田包装容器有限公司

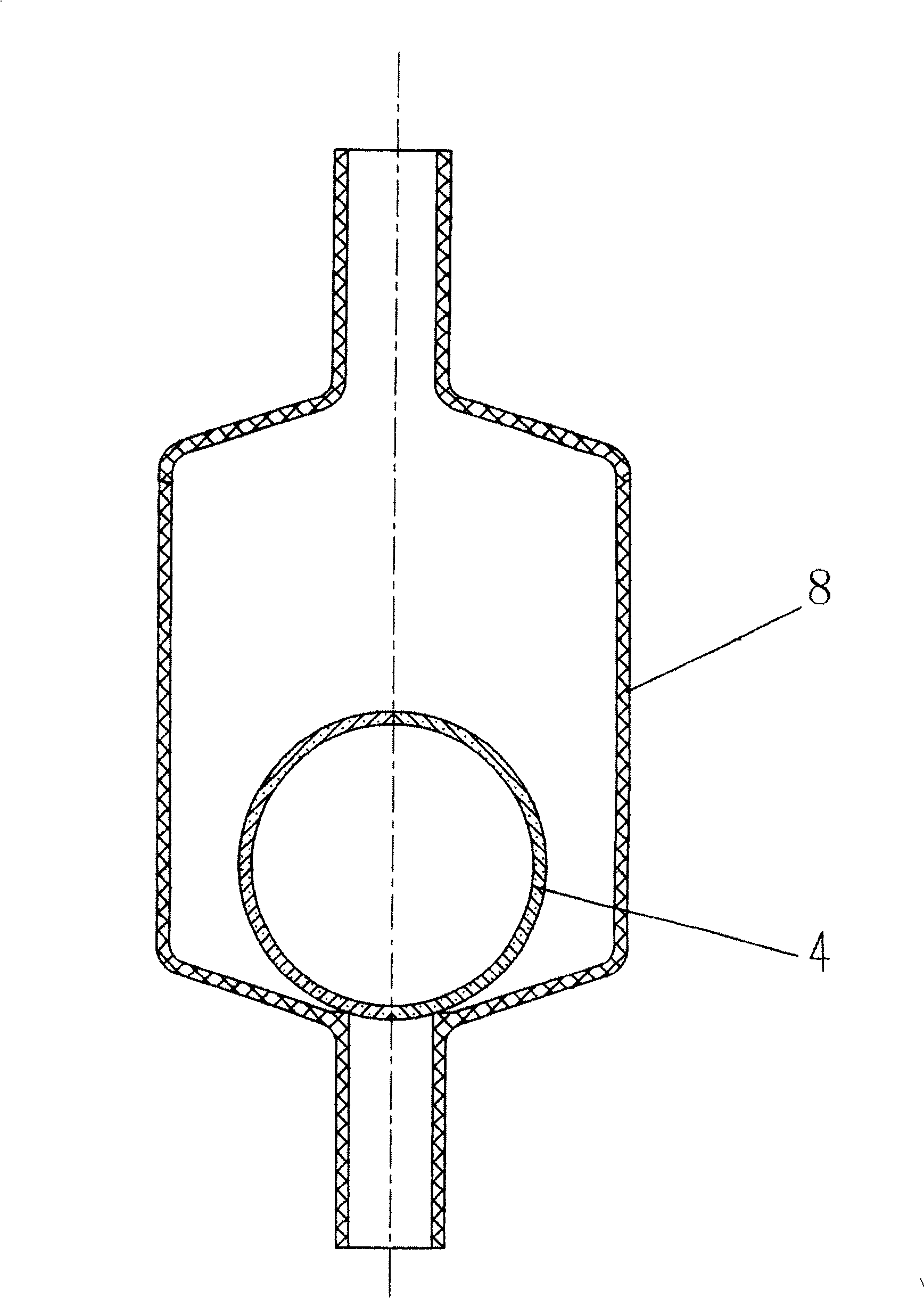

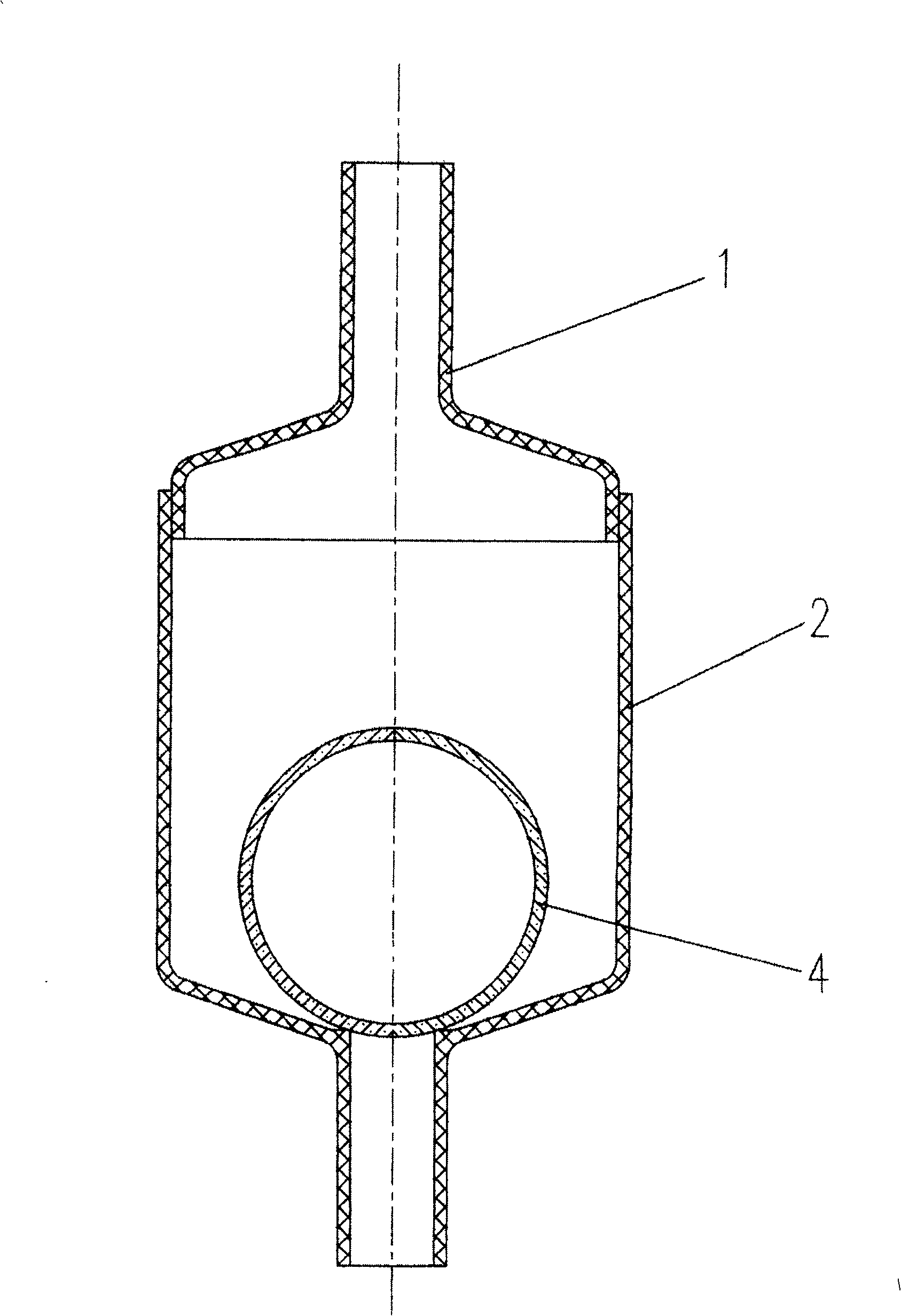

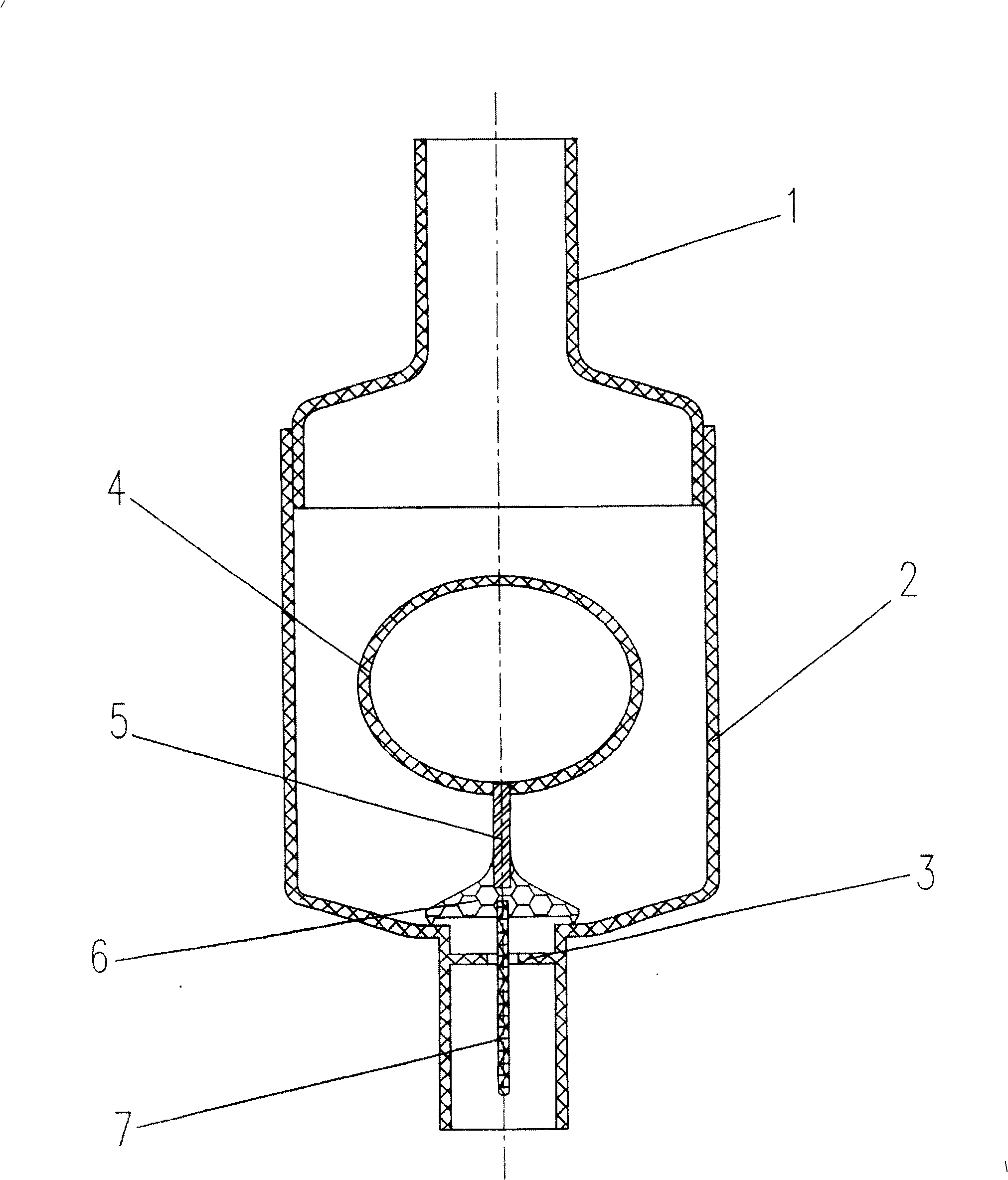

Drainage valve

InactiveCN100476271CEfficient production and processingGood sealingDomestic plumbingLift valveWater flowEngineering

Owner:李志斌

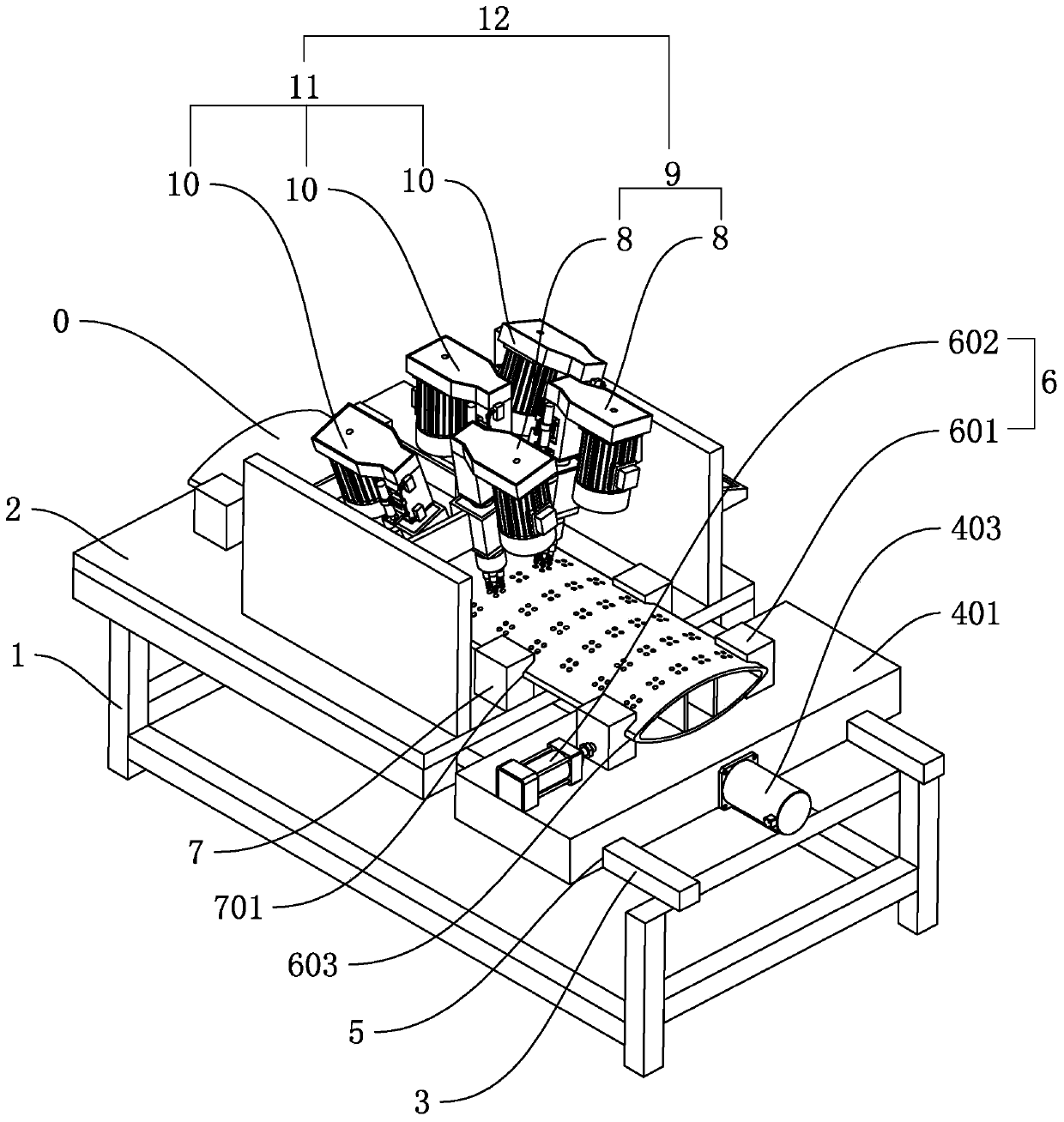

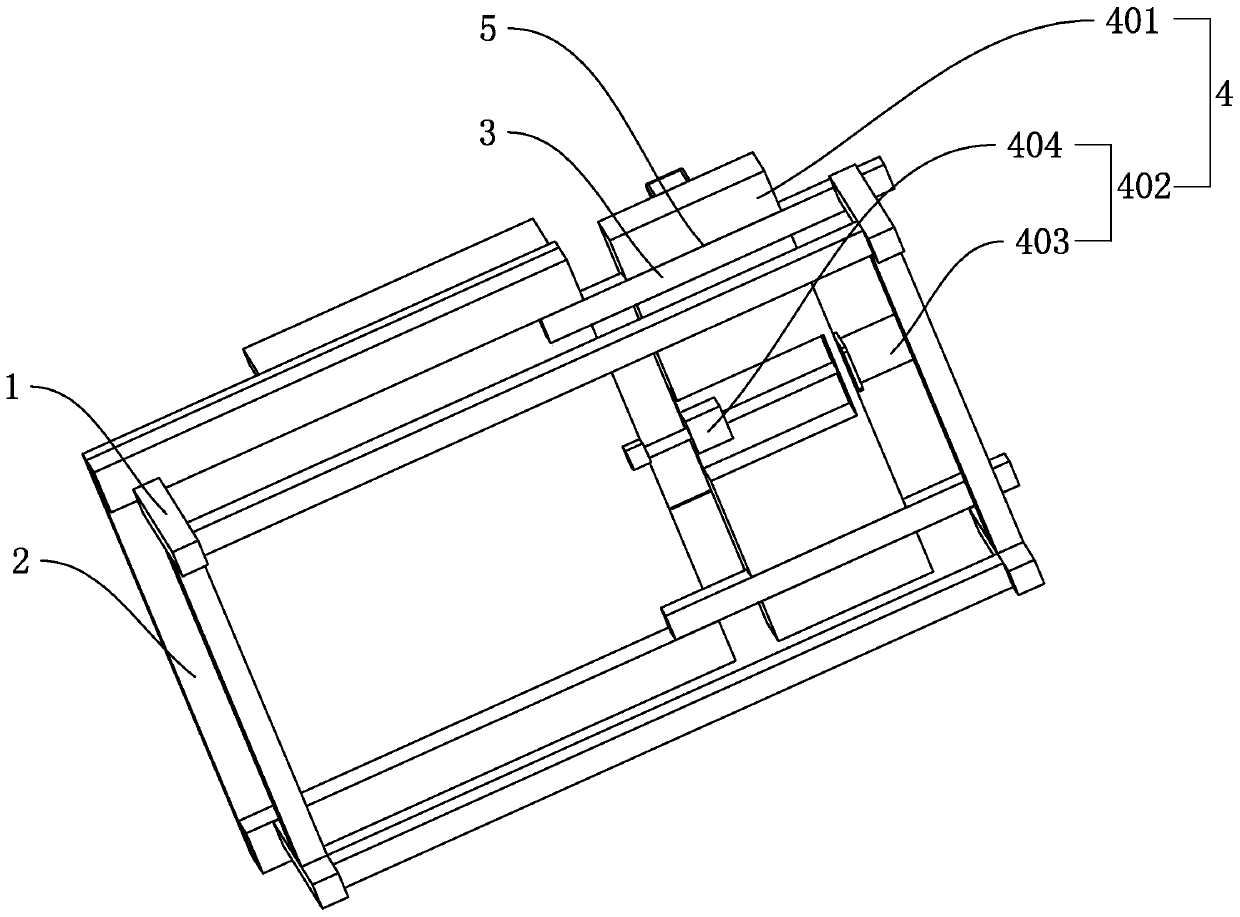

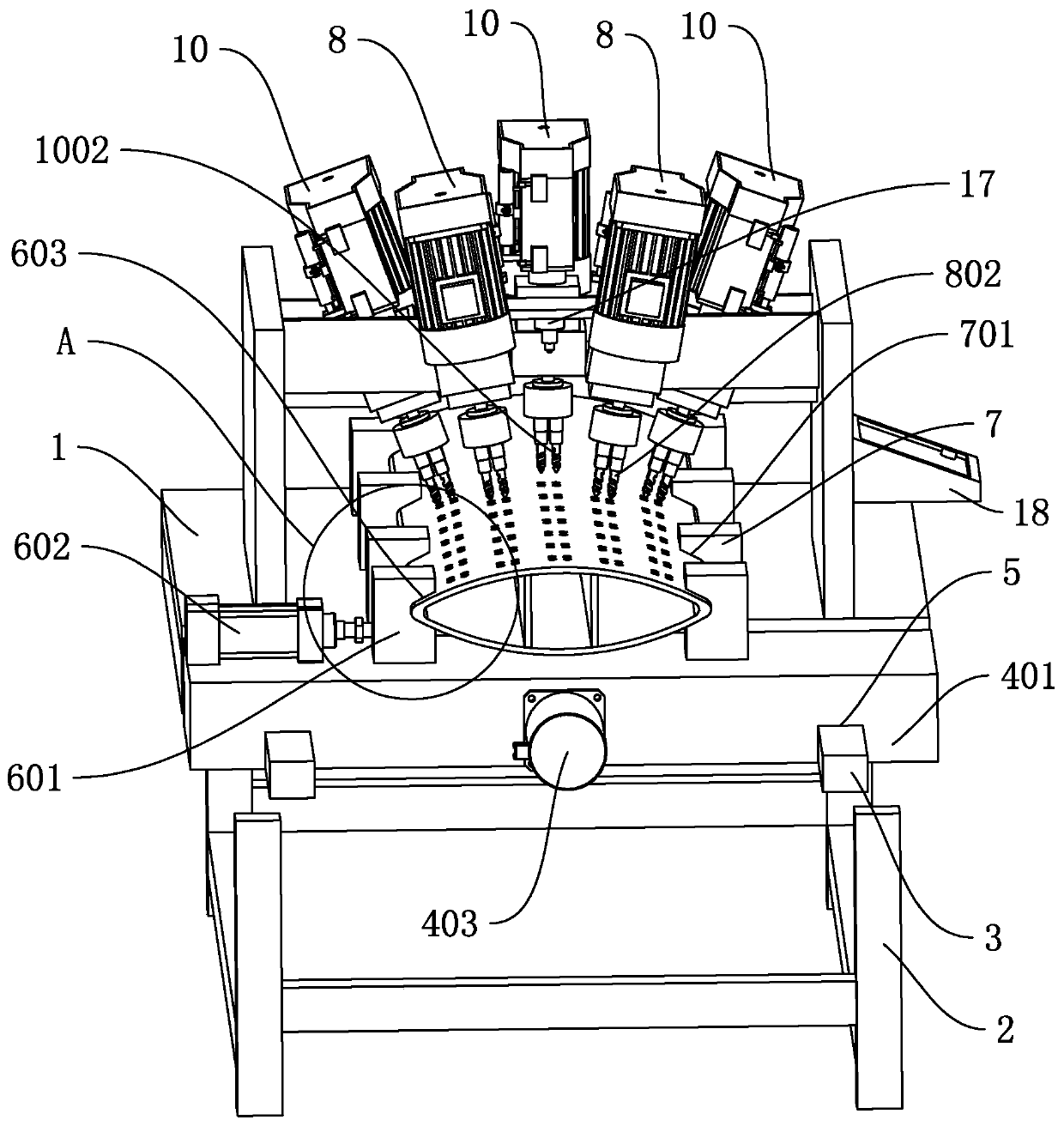

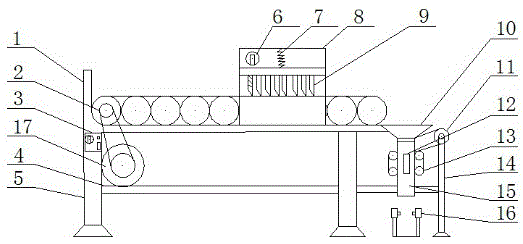

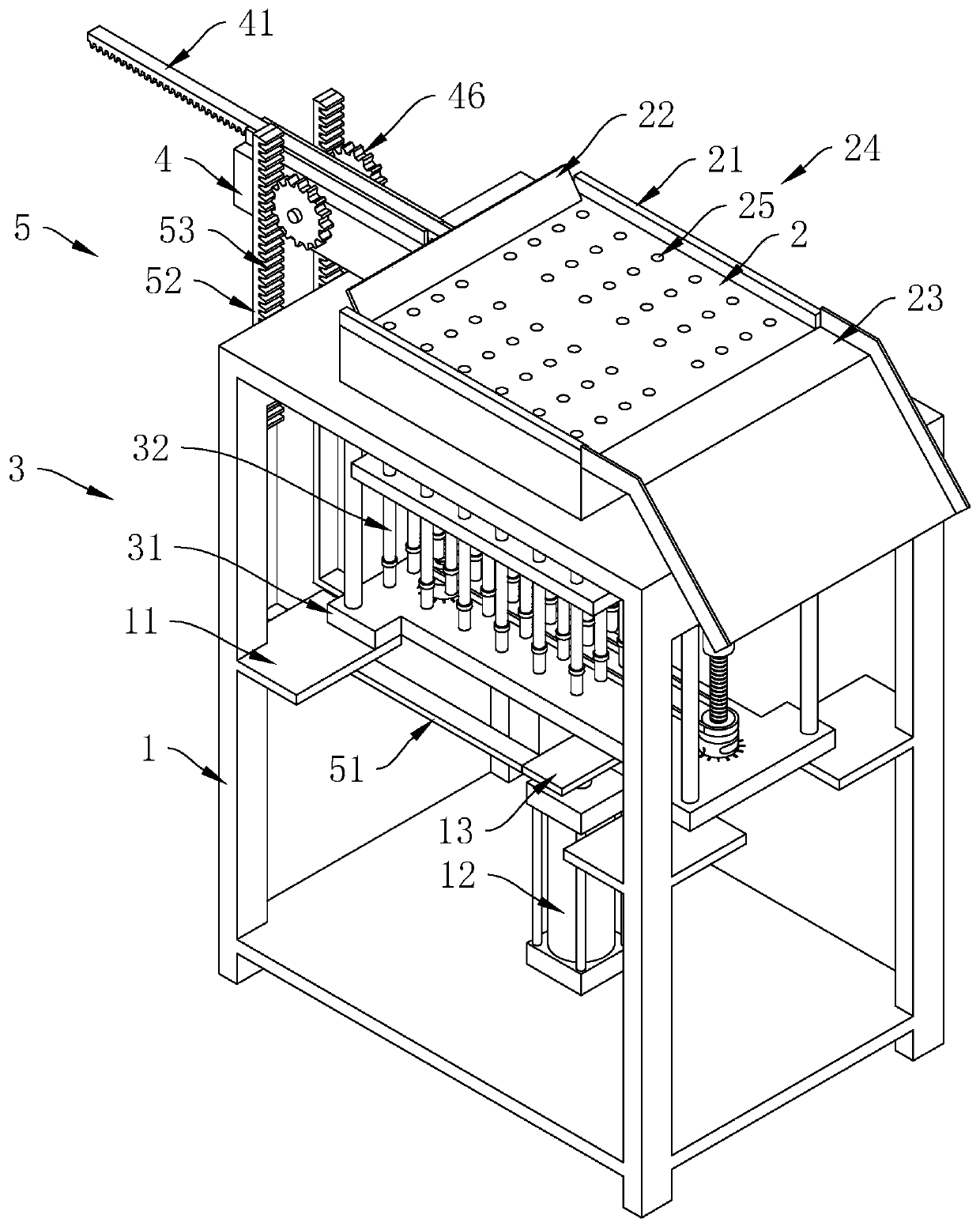

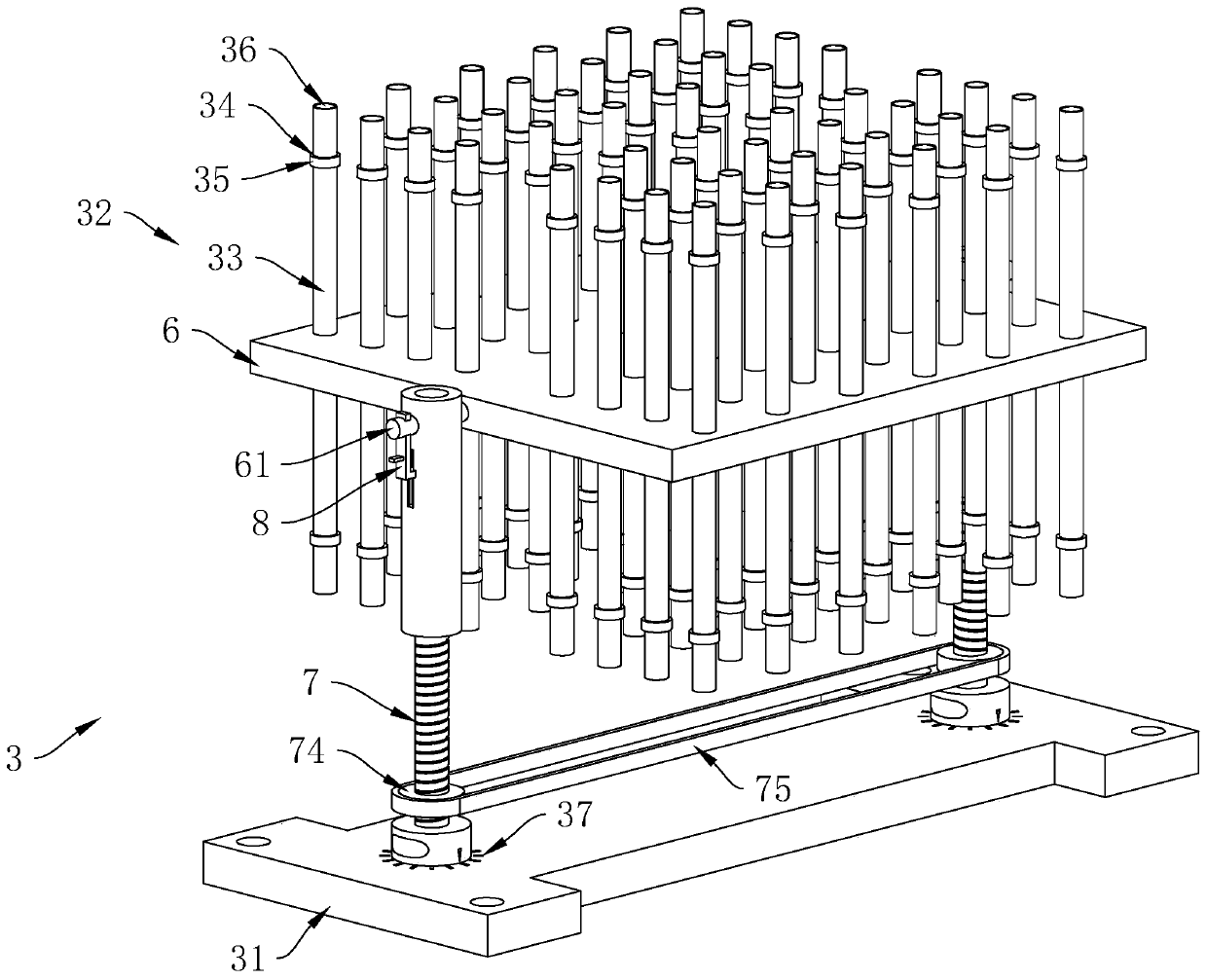

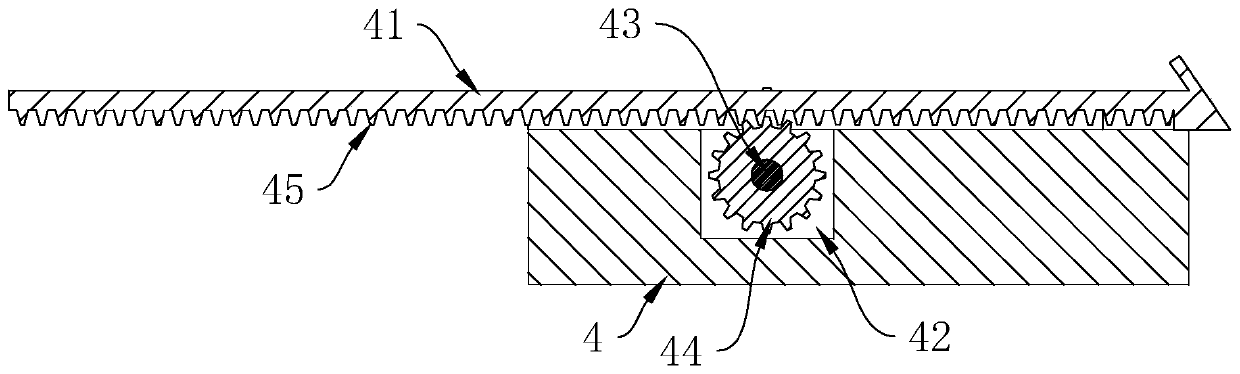

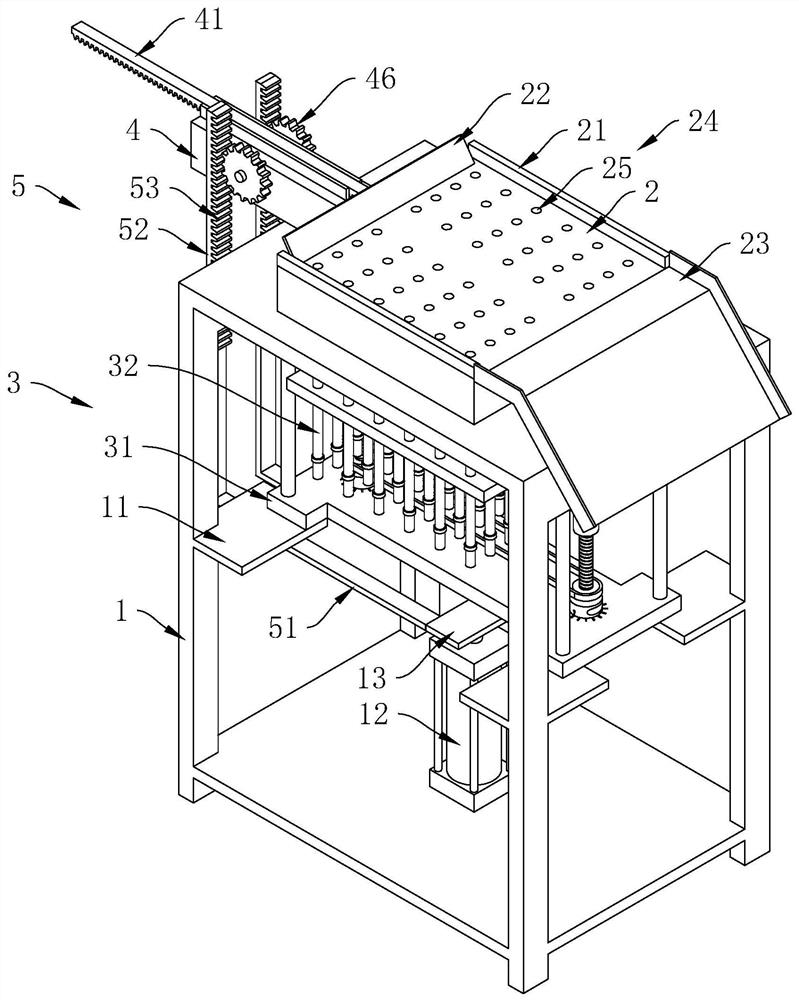

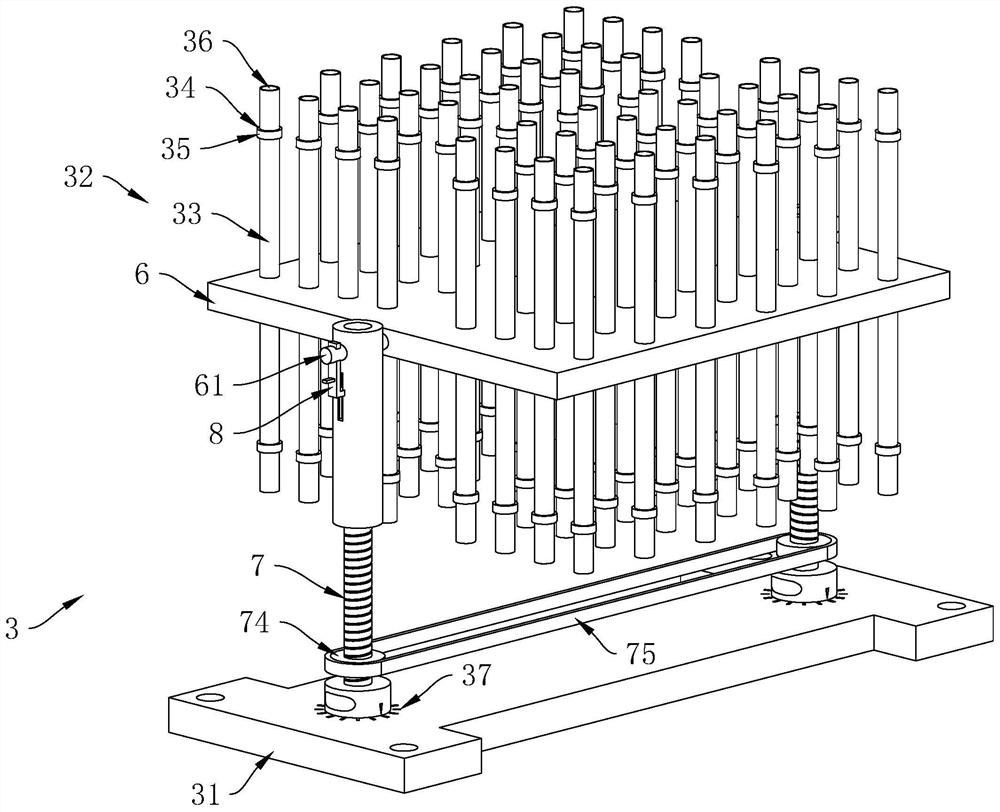

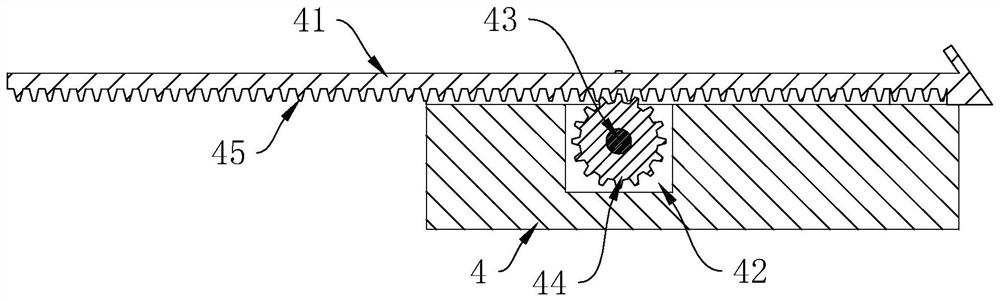

Drilling machine

ActiveCN110919048AImprove efficiencyQuality improvementWork clamping meansMeasurement/indication equipmentsDrill holeDrill bit

The invention relates to a drilling machine. The drilling machine comprises a machine frame, wherein the machine frame is provided with a worktable, a pushing mechanism for conveying shuttle-shaped sun visors on the worktable and a drilling device for drilling holes on the surfaces of the shuttle-shaped sun visors; the drilling device comprises a front-row drilling part and a rear-row drilling part which are arranged in the direction of conveying the shuttle-shaped sun visors, and a lifting driving mechanism for driving the front-row drilling part and the rear-row drilling part to carry out drilling works; the front-row drilling part comprises a pair of front-row drilling bit assemblies; the rear-row drilling part comprises three rear-row drilling bit assemblies; the front-row drilling bitassemblies and the rear-row drilling bit assemblies are staggered in the direction of conveying the shuttle-shaped sun visors; each front-row drilling bit assembly comprises at least four front-row drilling bits and a front-row drilling driving piece for driving the four front-row drilling bits to rotate; and each rear-row drilling bit assembly comprises at least four rear-row drilling bits and arear-row drilling driving piece for driving the four rear-row drilling bits to rotate. The drilling machine greatly increases the efficiency of the shuttle-shaped sun visors in the drilling process.

Owner:上海锐视门窗有限公司

Graphite polyphenyl granule novel composite insulation board production line

PendingCN114030126ANot easy to shift positionImprove quality and production efficiencyCleaning using toolsProcess engineeringManufacturing line

The invention discloses a graphite polyphenyl granule novel composite insulation board production line, and belongs to the technical field of insulation board production, the graphite polyphenyl granule novel composite insulation board production line comprises a supporting bottom plate, the upper surface of the supporting bottom plate is fixedly connected with the lower surface of a supporting plate through supporting legs, and the rear portion of the upper surface of the supporting bottom plate is fixedly connected with the lower surface of a connecting baffle; and the front face of the connecting baffle is fixedly connected with the back face of a top plate. According to the device, by arranging a transmission roller, a pressing roller, a glue scraping assembly, a discharge valve and a handle, the handle can be held to move back and forth to clean materials overflowing from the heat preservation plate within the time period when the heat preservation plate is extruded, the materials can fall into an excess material collecting box after being scraped, and the movement of a scraper push plate can accumulate the material in the excess material collecting box to both sides and discharge it from the discharge valve; the purposes of cleaning and collecting the extruded and overflowed materials are effectively achieved, the production cost is reduced, meanwhile, the working environment is not prone to being polluted, and the efficient production and machining of the heat preservation plate are facilitated.

Owner:枣阳银达银通节能建材有限公司

Multifunctional production and processing device

InactiveCN110886818AEasy to operateImprove efficiencyGearingElectric machineryStructural engineering

The invention discloses a multifunctional production and processing device, which comprises a device shell, a motor, a device mounting frame, a first connecting block and a second connecting block, wherein the motor is mounted at the top of the inner wall of the device shell; a driving bearing is mounted on the motor; the driving bearing is connected with a main transmission rod; the main transmission rod is connected with a driven bearing; the driven bearing is connected with a driven transmission rod; meanwhile, a first sliding block is mounted on the driven transmission rod; the device mounting frame is mounted at the bottom of the device shell; a first sliding groove is formed in the device mounting frame; the first sliding block is mounted in the first sliding groove; a first connecting block is mounted on a first operating rod screw opening; and a second connecting block is mounted on a second operating rod screw opening. According to the device, various different machining production operations can be carried out, two different operations can be carried out at the same time under the driving of a single motor, the operability of production and machining is improved, the efficiency of the device is improved, and the device can carry out production and machining more efficiently.

Owner:刘 杨

A method for preparing textured wheat protein by twin-screw extrusion

ActiveCN104322858BFull of nutritionPromote digestionProteins working-up by texturisingVegetable proteins working-upHigh torqueProcessing cost

The invention relates to a method for preparing textured wheat protein by twin-screw extrusion. The specific steps are: add powdered wheat protein and starch into the mixing mixer and mix well; add the mixture into the solid feeder of the high-torque twin-screw extrusion system and mix well again, and then add the high-torque twin-screw extrusion Extrusion in the machine; cut, dry, and cool the extruded product to prepare a textured wheat protein product; its moisture content is ≤13%, expansion rate is ≥1.20, rehydration rate is ≥190%, water holding rate is ≥180%, After rehydration, the product has a hardness of 7.00-12.50 kg, an elasticity of 0.500-0.750, a chewiness of 2200-3550, an adhesiveness of -65.00- -17.50 g·sec, and a texture degree of ≥2.0. The invention has stable processing process, simple operation and low processing cost; the produced textured wheat protein product is rich in nutrition, easy to digest, long in quality, good in cooking and processing stability, makes reasonable use of wheat protein resources, and increases the additional value of wheat protein products. value.

Owner:HEFEI UNIV OF TECH

Chip resistor conductor layer printing equipment and using method thereof

InactiveCN113539595AShorten heating timeReduce energy consumptionResistor chip manufactureEngineeringMechanical engineering

The invention discloses chip resistor conductor layer printing equipment and a using method thereof. The chip resistor conductor layer printing equipment comprises a working platform and a printing box arranged on the upper end face of the working platform. The chip resistor conductor layer printing equipment is characterized in that the upper end face of the printing box is fixedly connected with two mounting plates, and an equipment box body is arranged between the two mounting plates; a plurality of heating plates are arranged in a cavity of the equipment box body; ventilation pipes are arranged on the two sides of the equipment box body, and the ends, away from the equipment box body, of the ventilation pipes penetrate into the printing box; and opening and closing doors are movably arranged on the two sides of the printing box, and driving mechanisms used in cooperation with the opening and closing doors are arranged on the upper end face of the printing box. Through cooperation of the equipment box body, the heating plates and the ventilation pipes, the ventilation pipes continuously convey air heated to a certain temperature into the equipment box body, the inside of the printing box is kept at high temperature all the time, heat loss in the printing box is supplemented, and when a next workpiece is machined every time, the temperature rise time of the working bin of the printing box is shortened, and energy consumption is reduced.

Owner:安徽省富捷电子科技有限公司

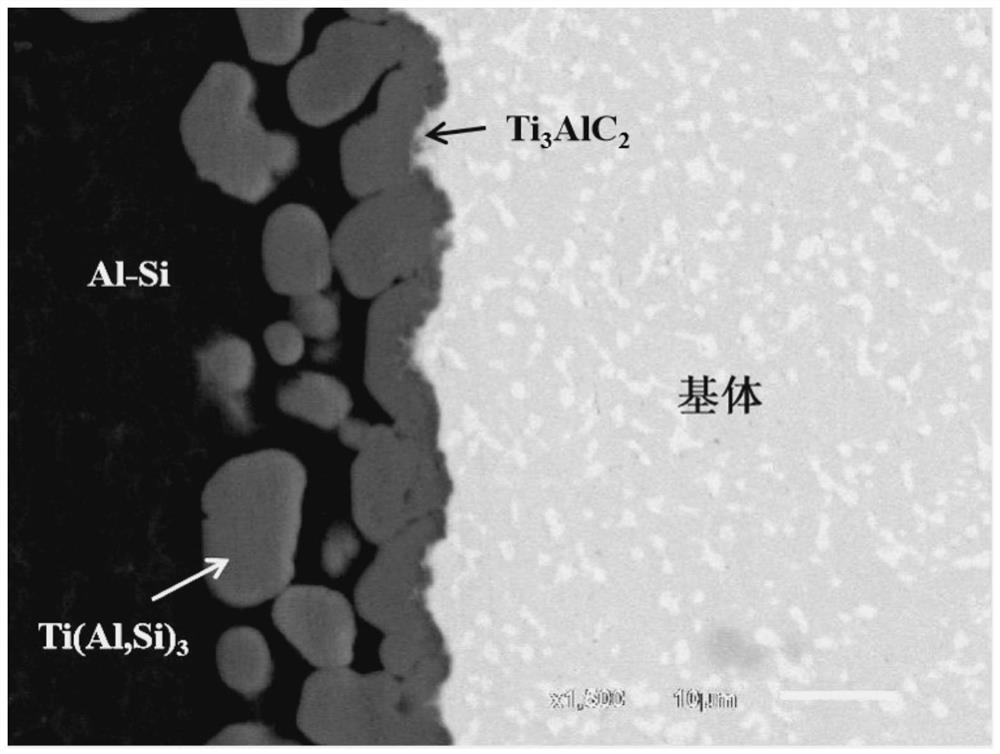

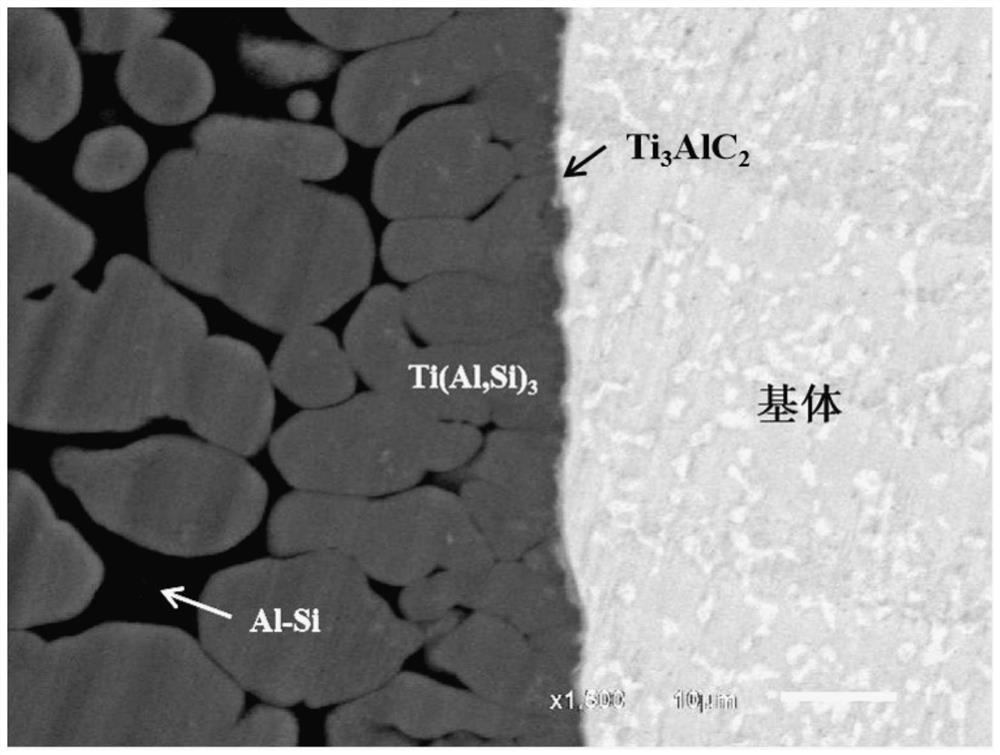

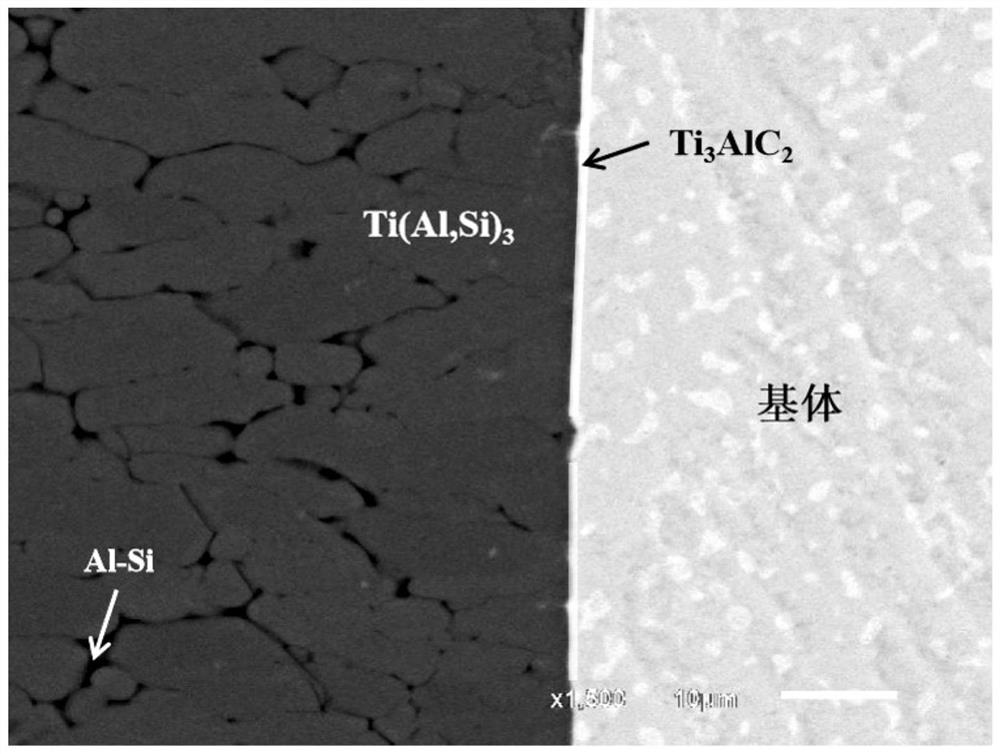

Titanium and titanium alloy surface carbon nanomaterial modified ti-al-si-c coating and preparation method thereof

ActiveCN113430479BTightly boundImprove high temperature performanceHot-dipping/immersion processesTitaniumSlurry

Owner:CHANGZHOU UNIV

A light carbon weeding process for wool

ActiveCN110685017BProtect fiber stateMeet production requirementsWool fibre washing/scouringFiberCarbonization

The invention discloses a wool light-carbonization weeding process and belongs to the technical field of textile processing. According to the wool light-carbonization weeding process, wool which is processed by the previous wool washing line is conveyed sequentially to a first washing sink, a second washing sink and a third washing sink to be washed, the washed wool is then conveyed to a first oven to be dried by heating, the dried wool is conveyed and rolled through a four-cylinder wool rolling mill, and is separated from weeds through a wool sinking ridge, the wool separated is conveyed to afourth washing sink, a fifth washing sink and a sixth washing sink sequentially to be washed, and then conveyed to a second oven to be dried by heating, finally, the dried wool is cooled and then conveyed to a carding production line to be carded and slivered. The wool light-carbonization weeding process is reasonable in design and can remove weeds in wool effectively while effectively protectingwool fiber, the yield of wool finished products is high, and requirements on processing are met.

Owner:张琦

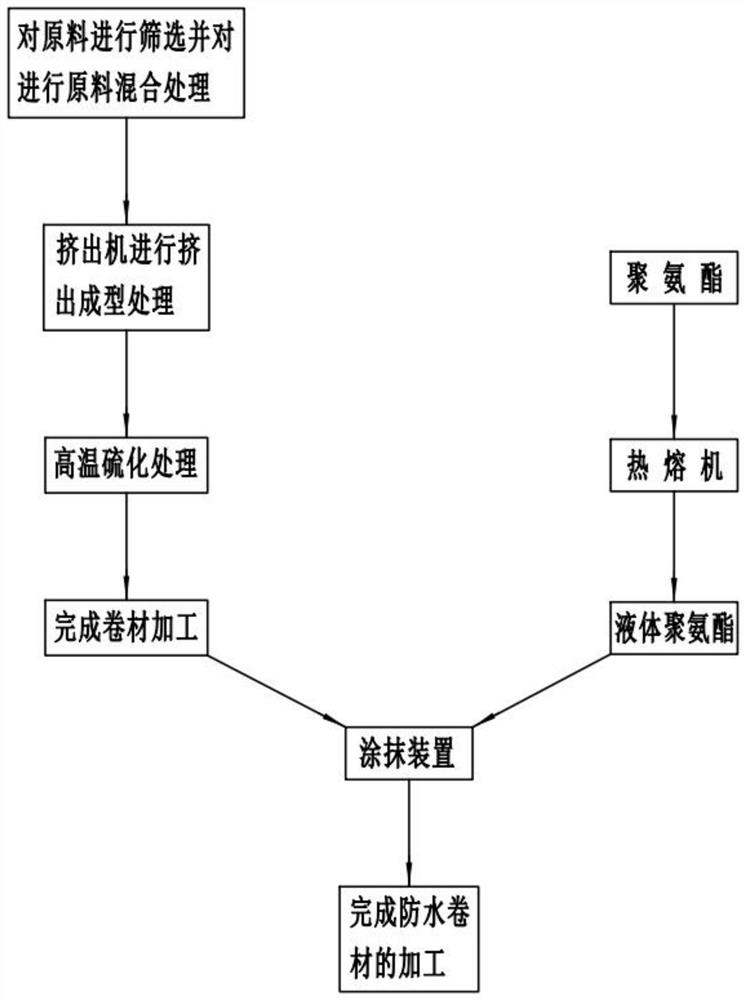

Polyurethane waterproof coiled material production and processing method

PendingCN114770893AEfficient production and processingLiquid surface applicatorsCoatingsPolymer scienceVulcanization

The invention relates to the technical field of waterproof coiled materials, in particular to a polyurethane waterproof coiled material producing and processing method which comprises the following steps: step 1, screening raw materials, and mixing qualified raw materials; 2, the raw materials obtained after slurry mixing are added into an extruder, extrusion molding treatment is conducted on the raw materials, then high-temperature vulcanization treatment is conducted on the raw materials obtained after extrusion molding, and processing of the coiled material is completed; step 3, adding polyurethane into a fuse machine, and processing solid polyurethane into liquid polyurethane; and 4, liquid polyurethane is added into the smearing device, the processed coiled material penetrates through the smearing device, and processing of the polyurethane waterproof coiled material is completed.

Owner:成臣

Squid cutting and packaging all-in-one machine

InactiveCN105644863AEasy to cutEasy to packPackaging automatic controlPackaging machinesElectric machineryEngineering

The invention discloses a squid cutting and packaging all-in-one machine. The squid cutting and packaging all-in-one machine comprises an outer shell, a packaging feeding port and a packaging roller wheel support. A control panel is arranged on the front surface of one supporting leg, and supporting rods are arranged on the right sides of supporting legs. The packaging feeding port is formed in the right side of a conveying belt, and a packaging outer shell is arranged below the packaging feeding port. The packaging roller wheel support is installed on the right side of the packaging outer shell, a packaging rolling drum is arranged on the upper portion of the packaging roller wheel support, and a cutting control switch, an electromagnetic control spring and a motor are all electrically connected with the control panel. Compared with the prior art, the squid cutting and packaging all-in-one machine has the advantages that the structure is scientific and reasonable, operation is safe and convenient, a cutting machine and a packaging machine are integrated, and thus squids are convenient to cut and package and can be produced and processed efficiently; in addition, cutting is uniform, and cutting and packaging of squids are completely automatic.

Owner:林志城

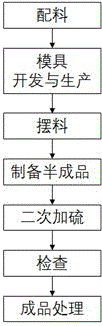

Production technology for automobile sealing ring

InactiveCN106363861AImprove the efficiency of placing materialsEasy to processDomestic articlesSulfurWork in process

The invention discloses a production technology for an automobile sealing ring. The production technology comprises the following specific steps of burdening, die developing and producing, material arranging, semi-finished product preparing, secondary sulfur adding, checking and finished product treatment. By means of the above manner, the production technology for the automobile sealing ring is provided for solving the problems that in the sealing ring producing and machining process, productivity is low, and consumed time is long. Double-layer film production is adopted for dies, the productivity is improved to 100%, the material arranging capability of 50 pcs for each die is achieved through a material arranging jig, the material arranging duration is shortened to 10 s from 65 s of manual material arranging, the material arranging efficiency is obviously improved, the equipment and labor cost is greatly reduced, and the producing and machining process is simple and efficient.

Owner:苏州井上橡塑有限公司

Wax pencil molding machine

ActiveCN111332047ARealize production and processingIncrease productivityNon-propelling pencilsCleaning using toolsMolding machineWaste material

The invention discloses a wax pencil molding machine, and relates to the field of wax pencil production. The wax pencil molding machine comprises a machine body, a molding die and an ejecting mechanism, wherein stop levers are arranged horizontally on two sides of the molding die; a scraper is arranged at one end of the molding die; a collecting hopper which communicates with an upper end face ofthe molding die is arranged at the other end of the molding die; two ends of the scraper are pressed against an inner side wall of the scraper; a sliding seat is horizontally arranged at one end of the machine body close to the scraper; a slide bar is horizontally connected to the sliding seat in a sliding way; one end close to the scraper of the slide bar is fixed to an outer side wall of the scraper; the molding die is provided with two groups of die cavities; the two groups of die cavities are distributed on two sides of the slide bar; and the ejecting mechanism is provided with a driving mechanism for driving the slide bar to slide in a reciprocating way. The wax pencil molding machine has the advantages and effects that automatic cleaning and collection of waste on the molding die arerealized through the arrangement of the highly automated scraper; the labor intensity of workers is lowered; the production efficiency of wax pencils is improved; and meanwhile the effect of clean production is achieved.

Owner:台州市美琪乐工艺品有限公司

A crayon molding machine

ActiveCN111332047BAchieve cleaning effectRealize the collectionNon-propelling pencilsCleaning using toolsMolding machineEngineering

The invention discloses a crayon forming machine, which relates to the field of crayon production. It includes a machine body, a forming mold and an ejection mechanism. Stop bars are arranged horizontally on both sides of the forming mold. One end of the forming mold is provided with a scraper, and the other end of the forming mold is provided with a scraper. One end is provided with a collecting bucket connected to the upper end surface of the mold, and the two ends of the scraper are against the inner wall of the retaining rod; the end of the body close to the scraper is horizontally provided with a sliding seat, and a sliding rod is horizontally slidingly connected to the sliding seat, and the sliding rod is close to the scraper One end is fixed to the outer wall of the scraper; the forming mold is provided with two sets of mold cavities, which are distributed on both sides of the sliding rod, and the ejection mechanism is provided with a driving mechanism for driving the sliding rod to reciprocate. The invention has the following advantages and effects: by setting up a highly automated scraper, it realizes automatic cleaning and collection of waste materials on the forming mold, reduces the labor intensity of workers, improves the production efficiency of crayons, and achieves the effect of clean production at the same time.

Owner:台州市美琪乐工艺品有限公司

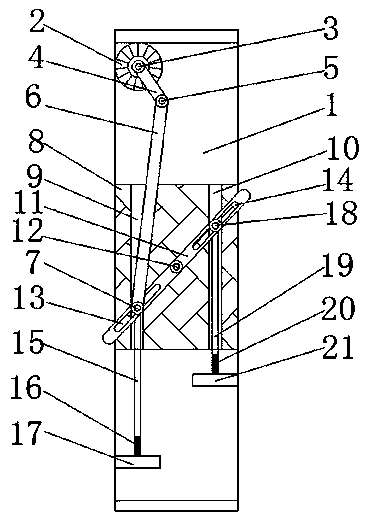

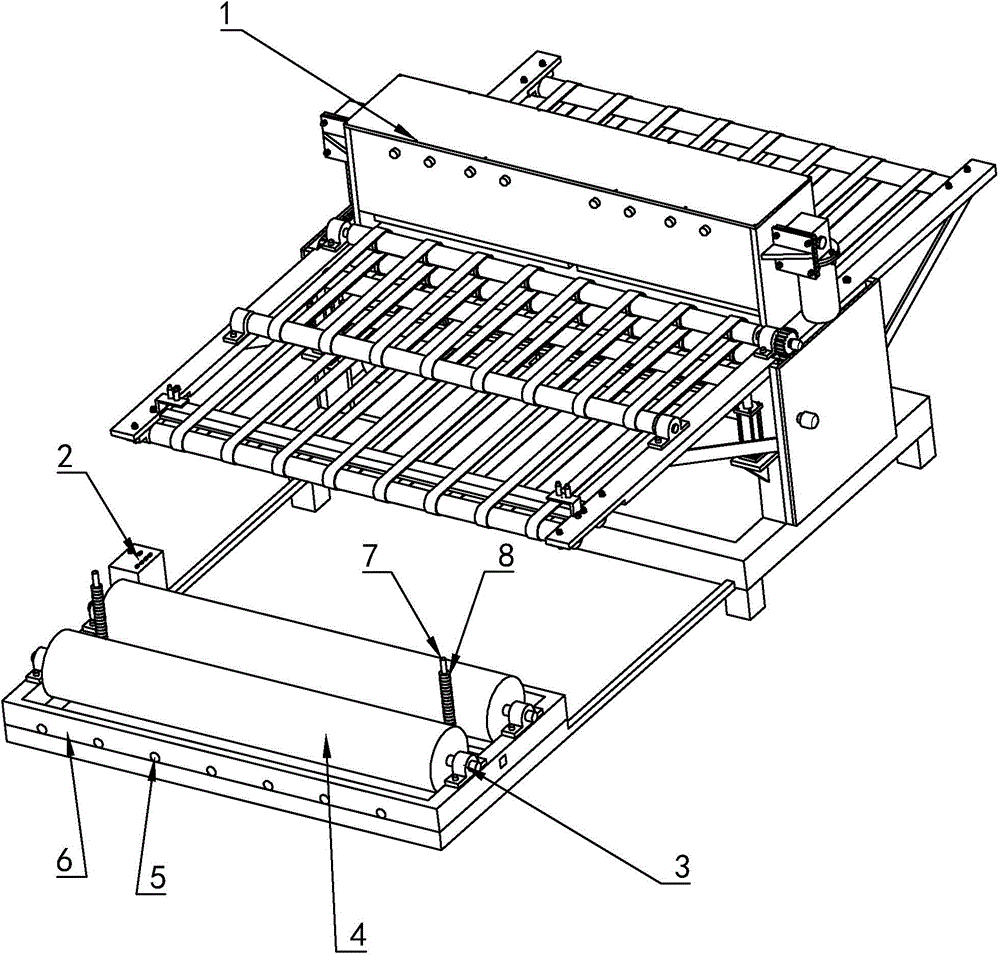

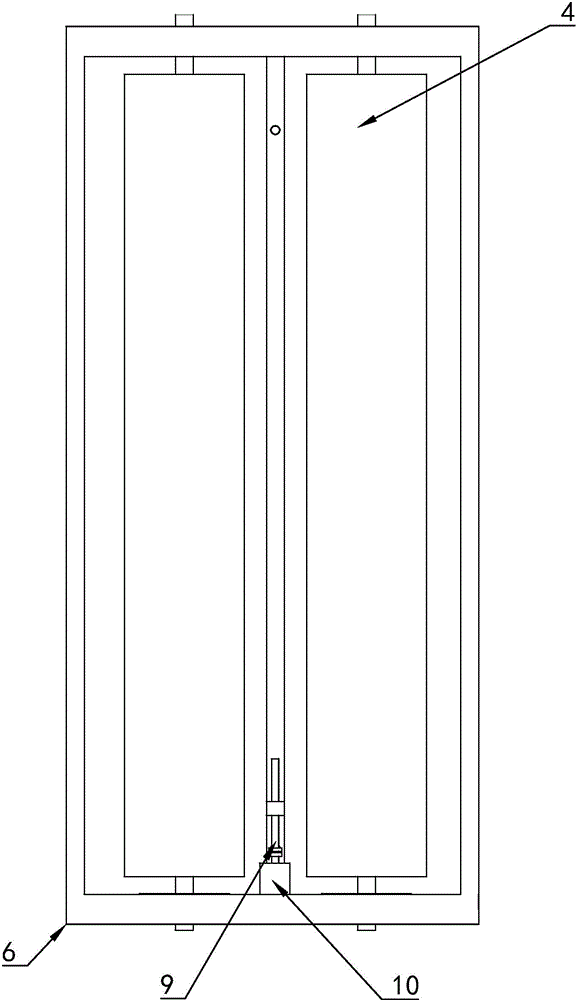

Automatic correction device for leather cutting machine

The invention relates to an automatic correction device for a leather cutting machine. The automatic correction device mainly comprises a control device, rolling shafts, a support frame and a motor, wherein the two rolling shafts are arranged on the support frame, and are connected and fixed on the upper surface of the support frame through bearings; a control device is arranged at one side of the support frame; pulleys are arranged on the lower part of the support frame; a steel structure frame is arranged at the bottoms of the pulleys; guide columns are arranged at the two ends of a gap between the rolling shafts; the guide columns are fixed on the steel structure frame; a motor is arranged on the steel structure frame; the motor is connected to the bottom of the support frame through a lead screw bearing; a sensor is arranged in a main machine body; in case of an offset during charge of leather, a signal is sent to the control device by the sensor, the control device controls the motor to work, and the motor drives the lead screw bearing to rotate, so that the support frame moves towards a corresponding direction to correct and align the leather, and the leather is subjected to processing treatment before entering the main machine body; and mechanical charge correction is realized, and working environment is improved.

Owner:刘建轻

Manufacturing method of pulp-molded stainless steel forming die

InactiveCN112238209AEasy to produceEasy to processFoundry mouldsFoundry coresSS - Stainless steelHeating furnace

A manufacturing method of a pulp-molded stainless steel forming die comprises the steps: injecting a wax liquid into a cavity formed between an upper die nut and a lower die nut, forming, by the curedwax liquid, a wax female die, and then drilling the wax female die manually, wherein a plurality of dense filtering holes can be formed in the wax female die; soaking the wax female die with the drilled holes in a high-temperature-resistant liquid material to form a protective layer on the outer surface of the wax female die, then placing the wax female die with the protective layer attached to the surface in a heating furnace to be heated, melting the wax female die inside, enabling the melted wax female die to flow out of a liquid flowing channel, and then fully casting a stainless steel liquid into the protective layer; then conducting natural cooling and curing; and finally, removing the outer protective layer, wherein the left cured stainless steel is the stainless steel forming diewith a plurality of dense filter holes. The whole manufacturing process is simple, convenient in production and processing and low in cost, the stainless steel forming die is produced and processed ina simplified manner effectively, and the production efficiency is improved.

Owner:向孙团

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com