A kind of temperature-sensitive explosive cell coat inhibitor and preparation method thereof

A technology of inhibitor and aftercoat, which is applied in mining equipment, earth square drilling, dust prevention, etc., can solve the problems of complex production process, short life of inhibitor, and reduction of process steps, so as to simplify the production process, simple processing, The effect of reducing oxygen concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

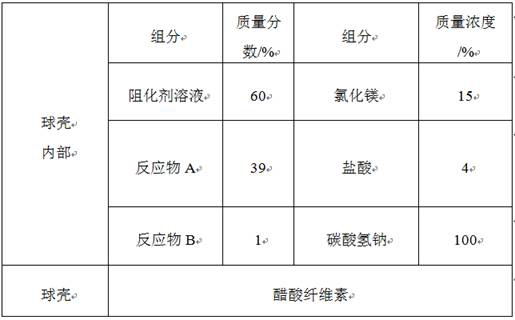

Embodiment 1

[0019] Using cellulose acetate pellets with a diameter of 4cm, when the pressure is 0.8MPa, the spherical shell of cellulose acetate can be ruptured to release the inhibitor. It can be calculated that the mass of sodium bicarbonate solid is 1-2g, and the mass fraction It is 3-5% dilute hydrochloric acid solution, and the reaction is carried out at this configuration ratio; the concentration of the inhibitor solution is not enough at this time, and 4-6g of magnesium chloride needs to be added to ensure that the concentration of the inhibitor solution is 15-20% between.

[0020] The reaction principle is as follows: .

[0021]

[0022] Step 1, making an inhibitor solution: prepare a mixed solution of dilute hydrochloric acid with a mass fraction of 4% and magnesium chloride with a mass fraction of 15%.

[0023] Step 2, making pellets wrapped in paraffin wax solid sodium bicarbonate: Weigh 1.5 g of sodium bicarbonate powder, wrap paraffin wax on the surface of sodium bicarb...

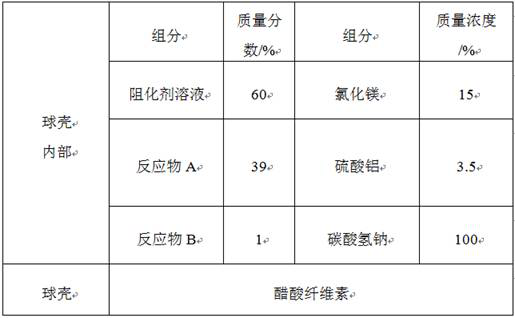

Embodiment 2

[0028] Using cellulose acetate pellets with a diameter of 4cm, under the pressure of 0.8MPa, the spherical shell of cellulose acetate can be ruptured to release the inhibitor. It can be calculated that the mass of sodium bicarbonate solid is 1-2g, aluminum sulfate Prepare a solution at 2.5-3.5g / 100ml, and react at this configuration ratio; the calculation shows that the concentration of the inhibitor solution is not enough at this time, and it is necessary to add 4-6g of magnesium chloride to ensure that the concentration of the inhibitor solution is 15-20 %between.

[0029] The reaction principle is as follows: .

[0030]

[0031] Step 1, making inhibitor solution: prepare a mixed solution of 3.5g / 100ml aluminum sulfate and 15% magnesium chloride by mass fraction.

[0032] Step 2, making pellets wrapped in paraffin wax solid sodium bicarbonate: Weigh 1.5 g of sodium bicarbonate powder, wrap paraffin wax on the surface of sodium bicarbonate, and make paraffin pellets wra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com