Wax pencil molding machine

A molding machine and crayon technology, applied in non-active pencils, printing, writing utensils, etc., can solve the problems of low automation and increased labor intensity of workers, and achieve the effects of reducing labor intensity, improving production efficiency, and ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

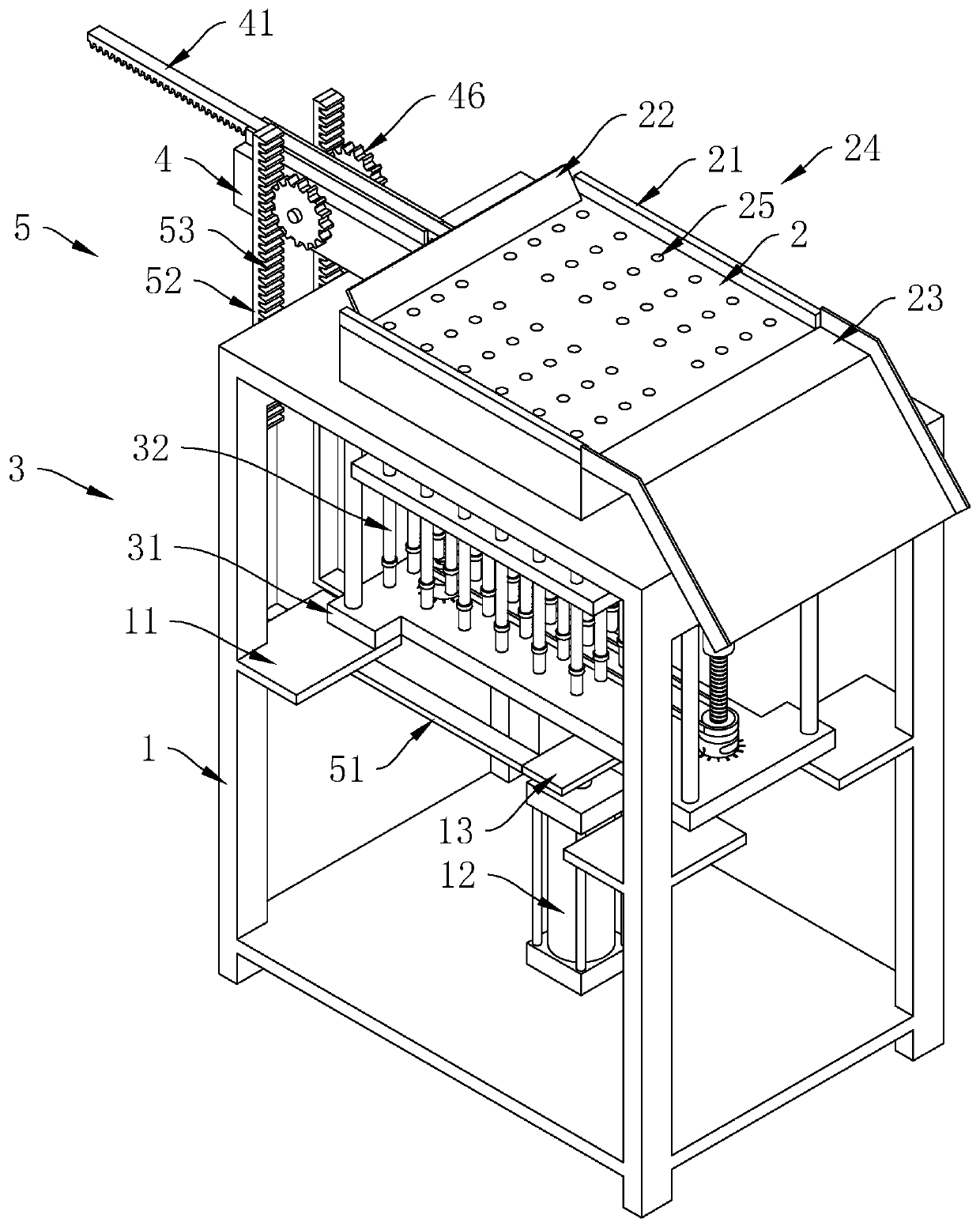

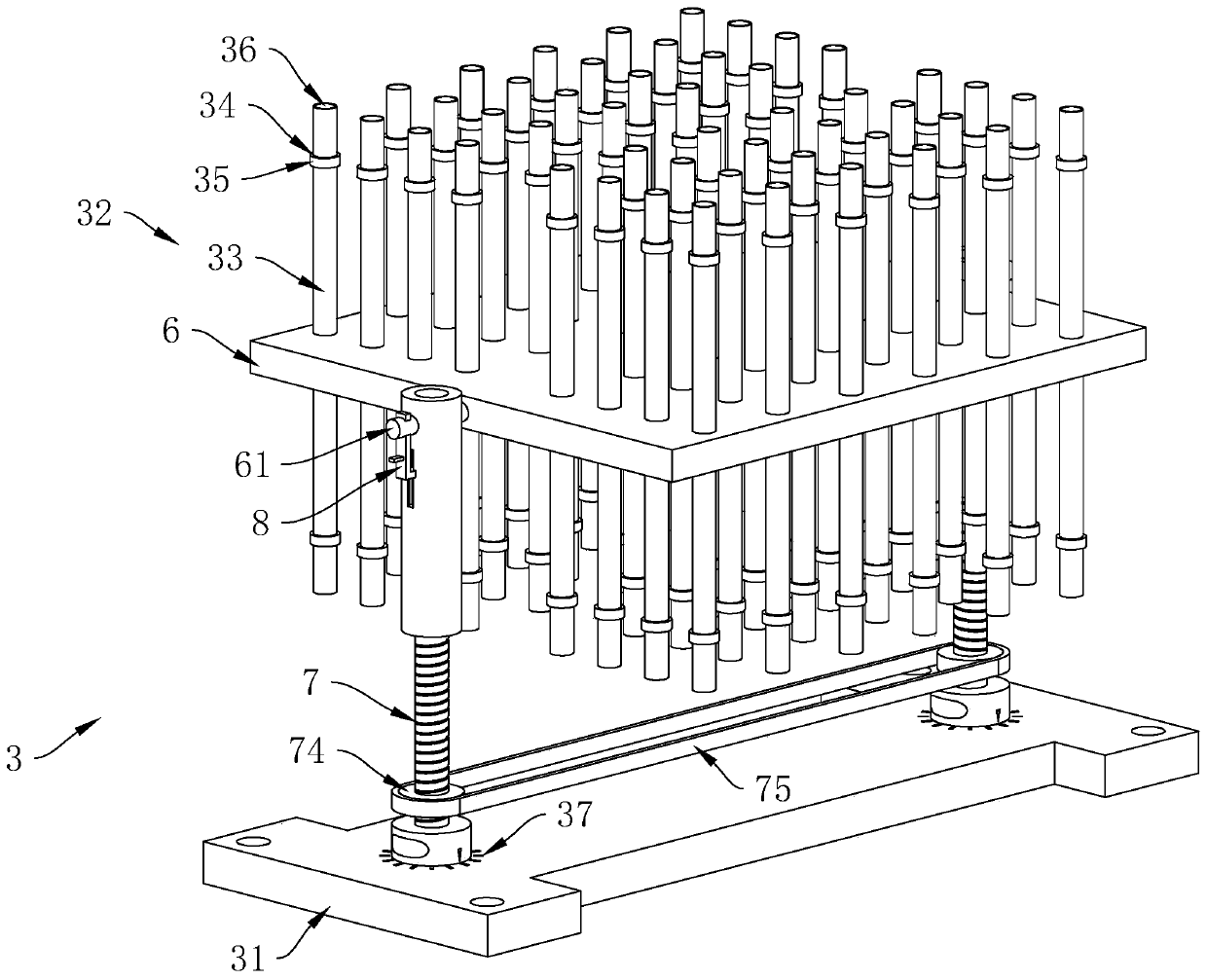

[0033] like figure 1 As shown, a crayon molding machine includes a body 1 , a molding die 2 arranged on the body 1 , and an ejection mechanism 3 located below the molding die 2 .

[0034] When producing crayons, after the paraffin wax is melted, it is fully stirred and mixed with the dyeing agent, and then the solution is injected into the molding die 2 . After the solution is cooled and solidified, the solidified waste on the surface of the forming mold 2 is cleaned, and the formed crayons are ejected by the ejector mechanism 3, and the formed crayons are collected to realize the production and processing of the crayons.

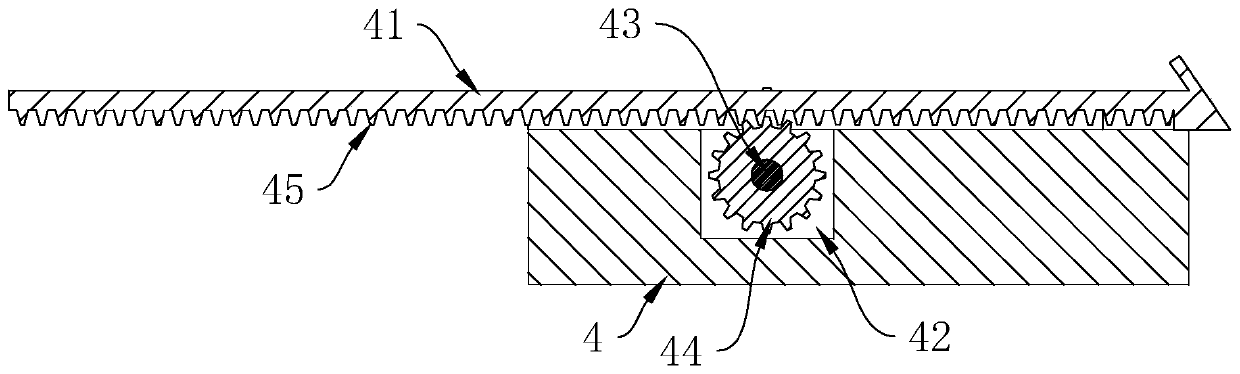

[0035] like figure 1 As shown, both sides of the forming mold 2 are horizontally provided with stop rods 21 , one end of the forming mold 2 is provided with a scraper 22 , and the other end is provided with a collecting bucket 23 connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com