Patents

Literature

43results about How to "Realize production and processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

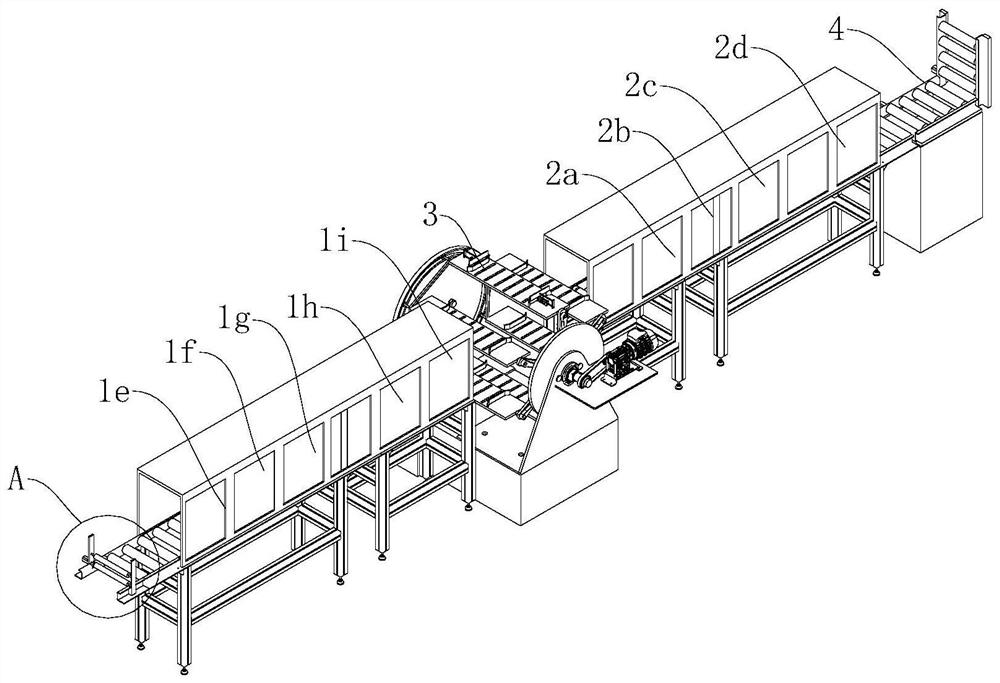

Lawn rayon production line and production method

ActiveCN104862792ASingle screw speed adjustment rangeRealize stepless speed regulationArtificial thread manufacturing machinesMelt spinning methodsProduction lineProcess time

The invention discloses a lawn rayon production line and production method. The lawn rayon production line comprises monofilament production equipment, after finishing equipment and a plying and twisting unit which are installed in sequence; two extruders of the monofilament production equipment of the lawn rayon production line are arranged in parallel and can produce monofilament with different colors and different types; the plying and twisting equipment conducts plying and twisting on the monofilament produced through the production line and monofilament which needs to be twisted, rewinding does not need to be conducted repeatedly, the process time and the workshop space are saved, requirements for plying and twisting production of two or more monofilament are met, and the production efficiency is greatly improved.

Owner:QINGDAO QINGHE ARTIFICIAL TURF

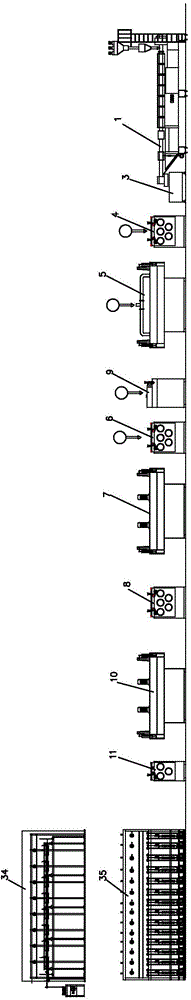

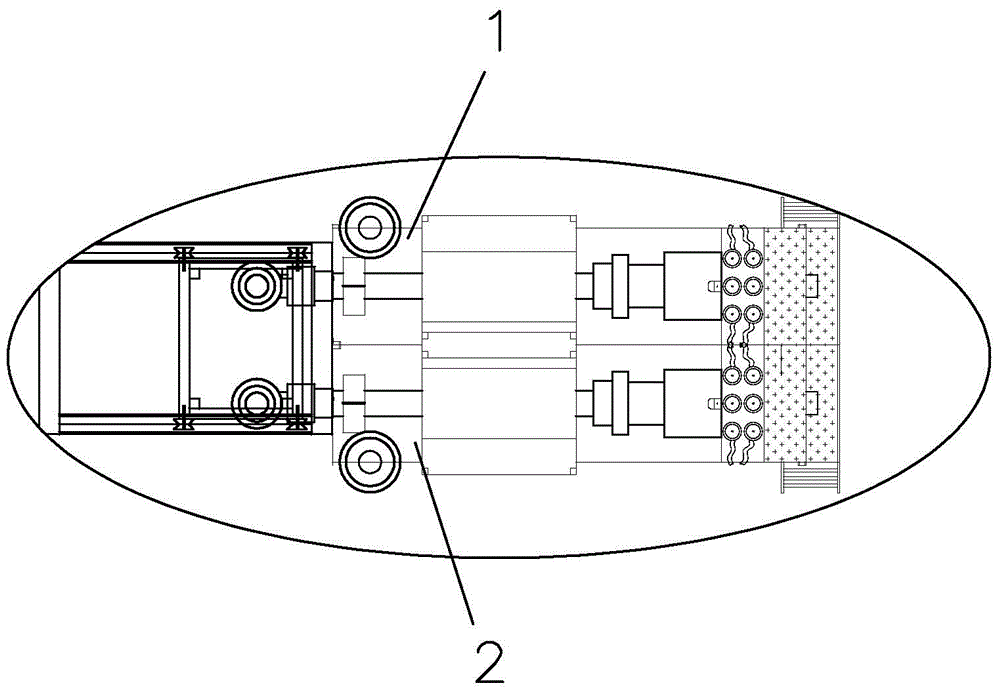

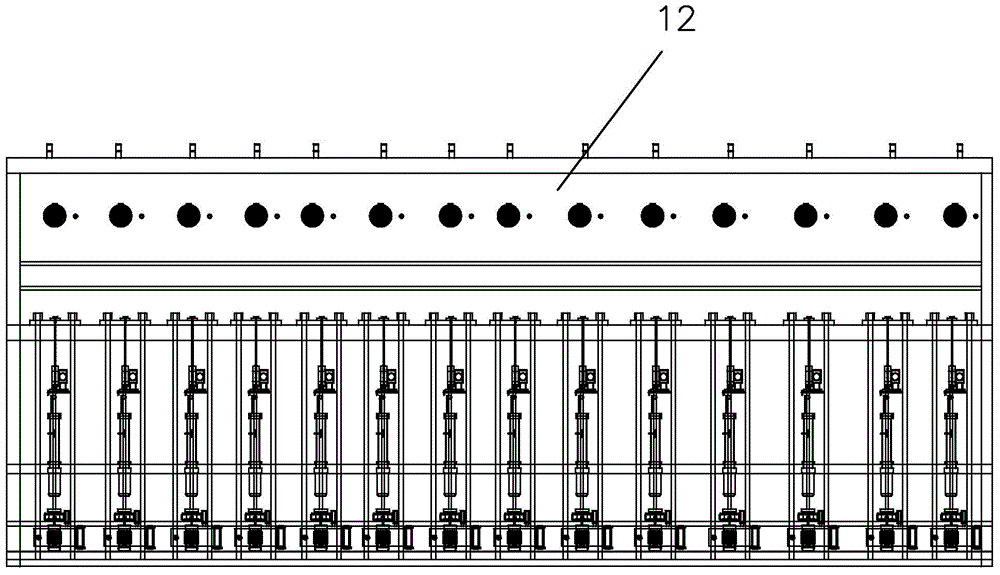

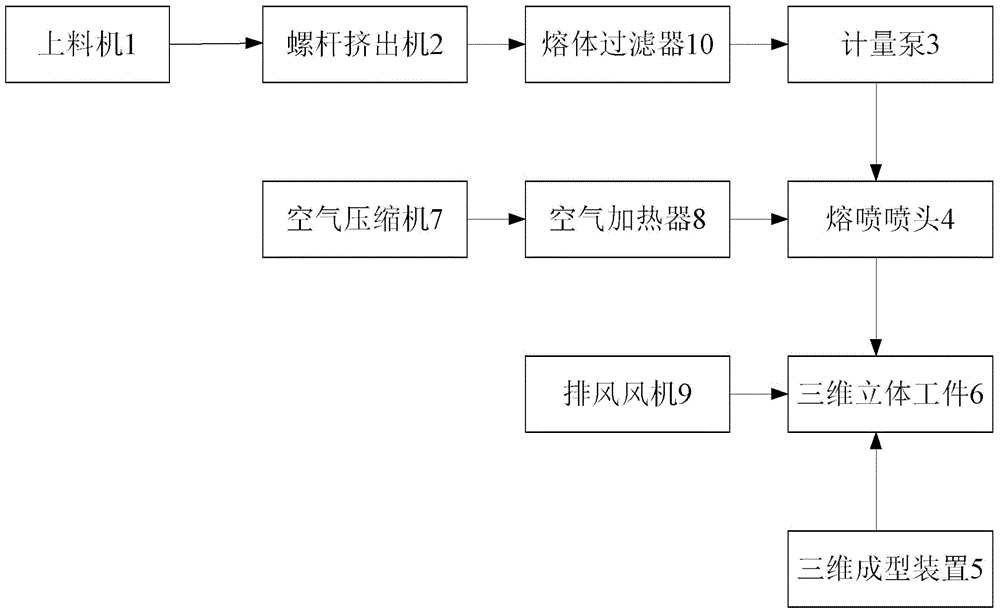

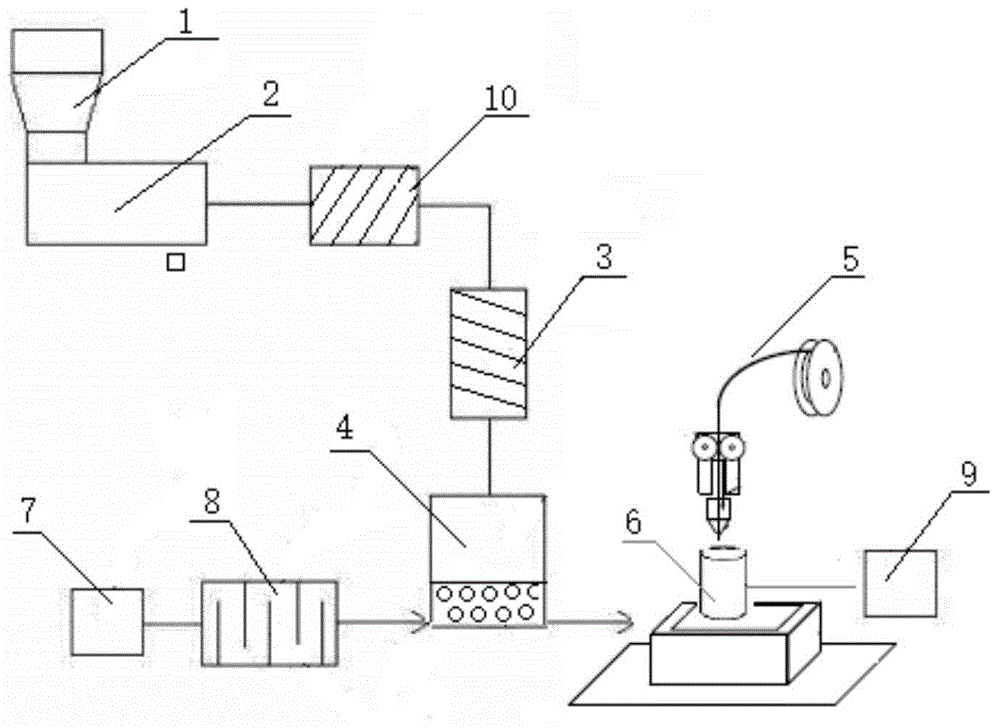

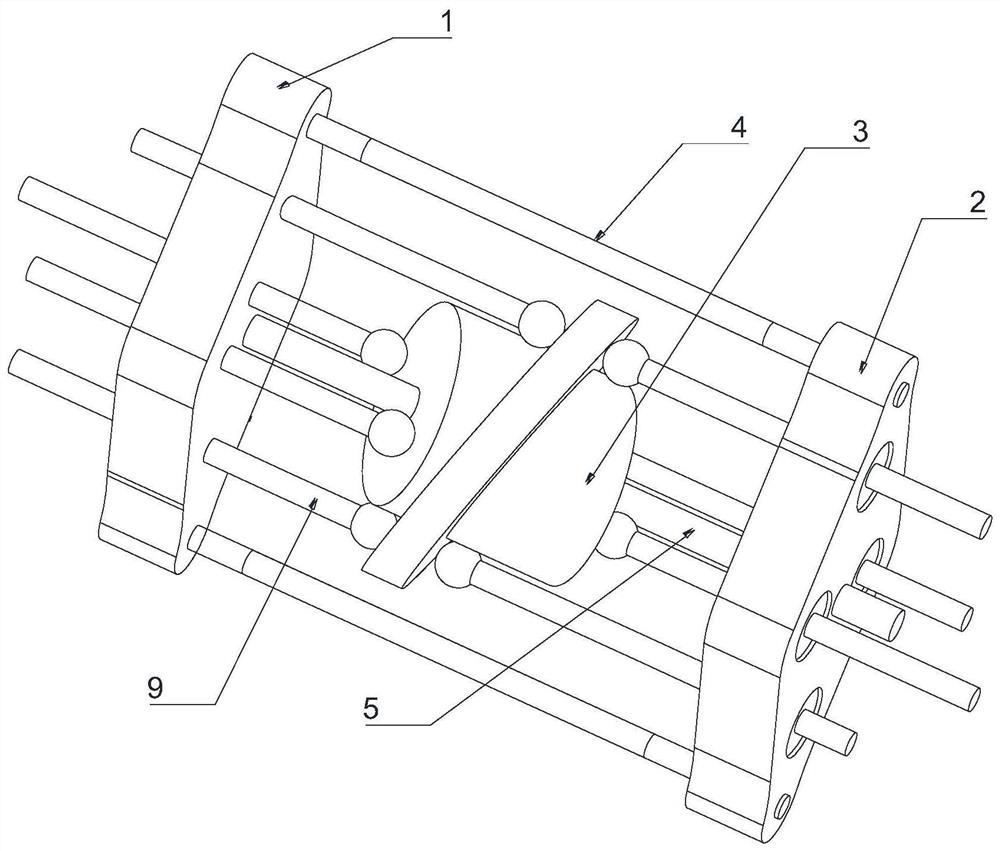

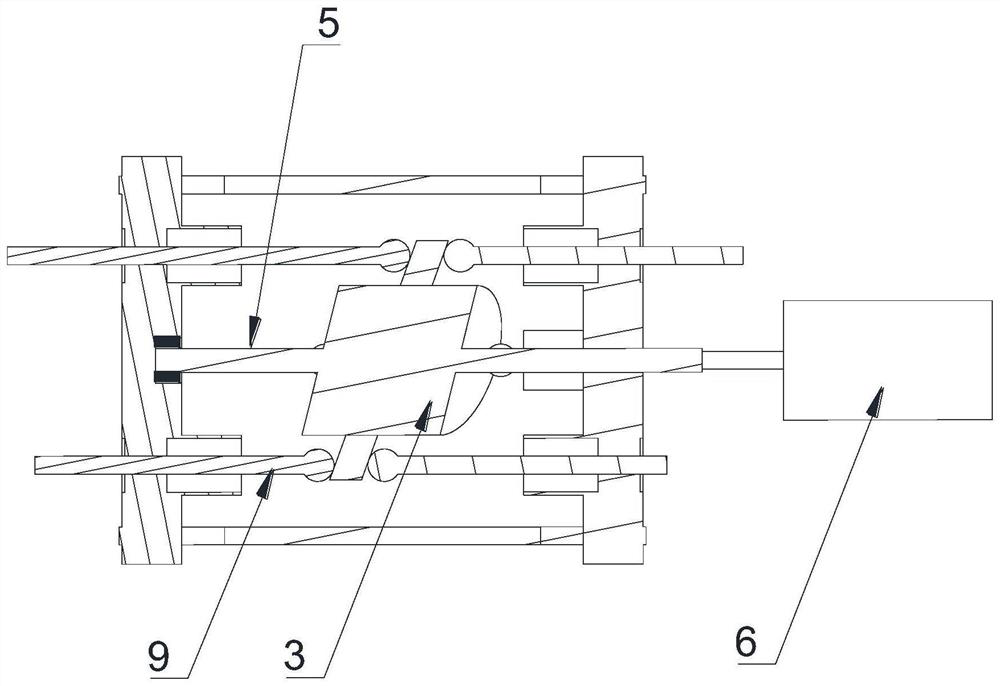

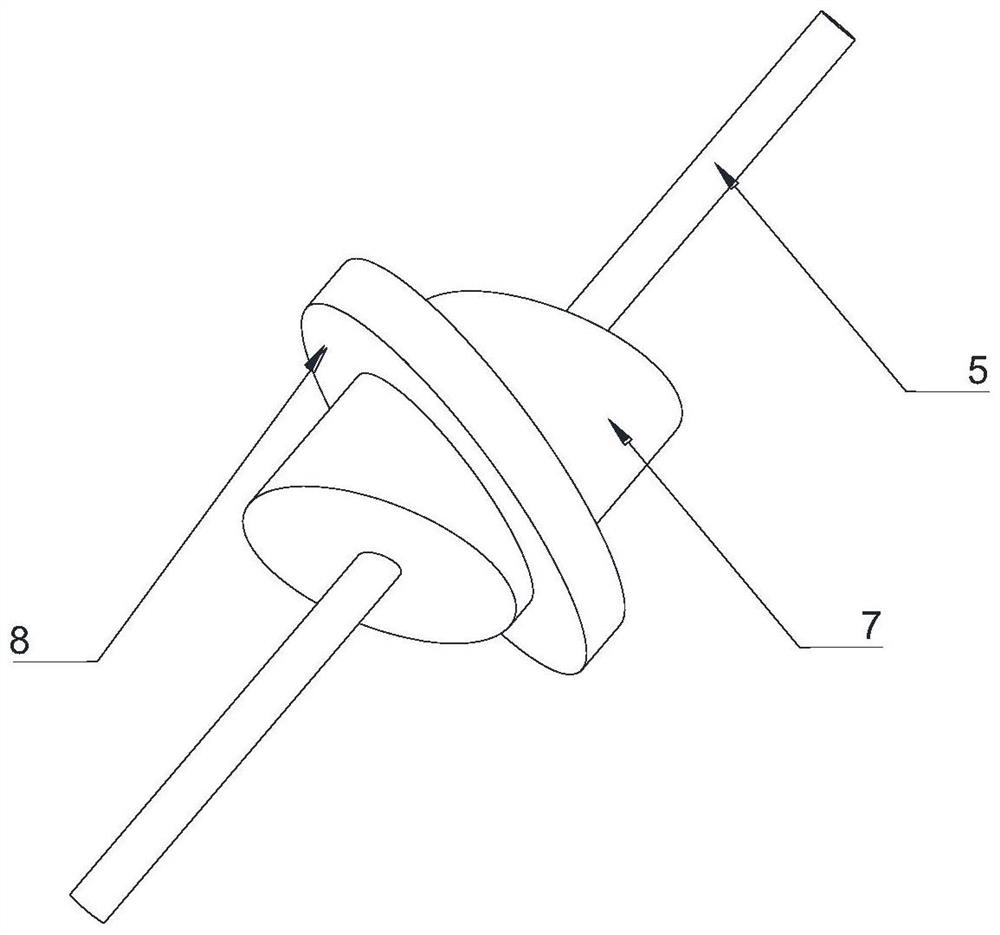

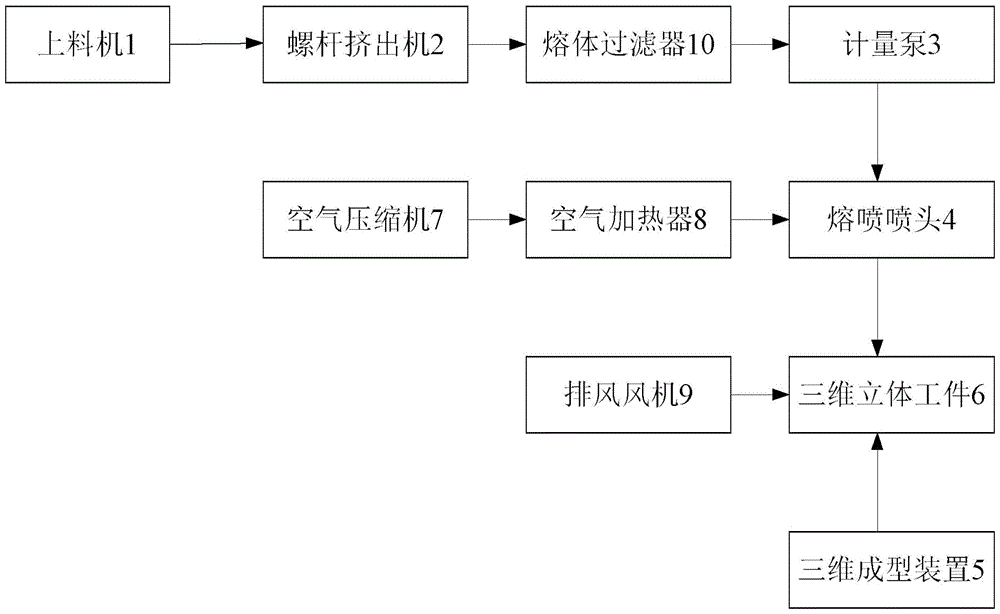

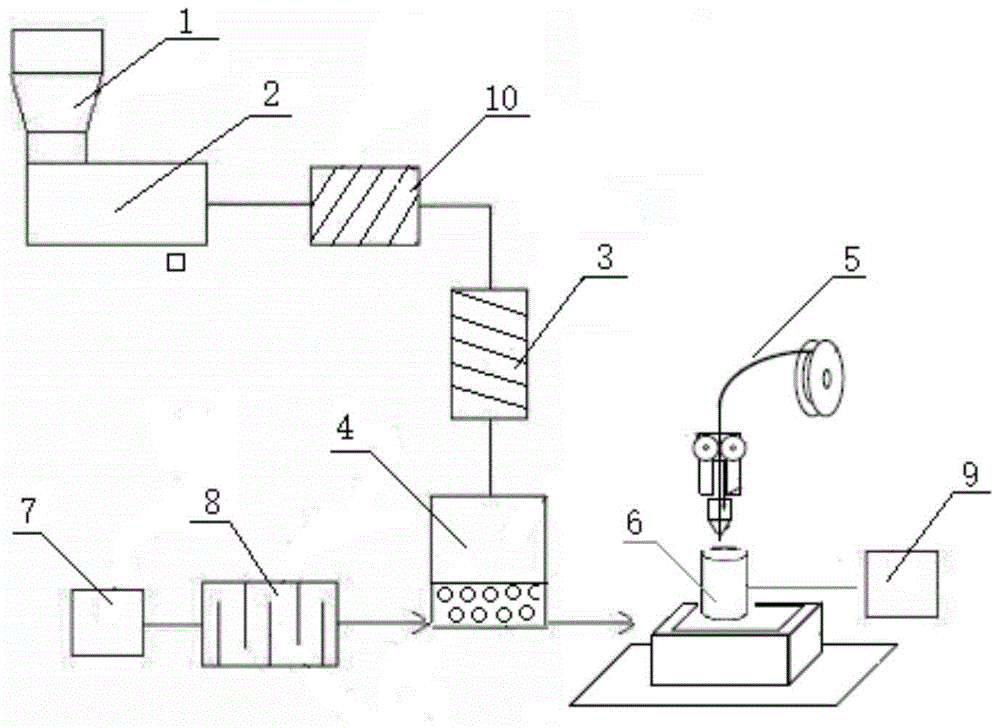

Three-dimensional flexible material molding system and method

ActiveCN104149338AEasy to printRealize production and processingAdditive manufacturing apparatusAdditive manufacturing with liquidsAir compressorMelt blowing

The invention provides a three-dimensional flexible material molding system and a three-dimensional flexible material molding method. The system comprises a feeder, a screw extruder, a metering pump, an air compressor, an air heater, a three-dimensional molding device, a melt-blowing nozzle and a solidification molding device, wherein the feeder is used for feeding molten polymers; the screw extruder is used for extruding the molten polymers; the metering pump is used for controlling the number of the molten polymers flowing into the melt-blowing nozzle; the air compressor is used for compressing air; the air heater is used for heating the compressed air; the three-dimensional molding device is used for processing and molding a three-dimensional workpiece for supporting a flexible material; the melt-blowing nozzle comprises a spinneret plate communicated with the metering pump and an air flow hole communicated with the air heater; a melt hole is formed in the spinneret plate; thin molten polymer flows are blown to the three-dimensional workpiece and are drawn into melt-blowing fibers through the air flow hole to be agglomerated on the three-dimensional workpiece; the solidification molding device is communicated with the three-dimensional workpiece and is used for solidifying the melt-blowing fibers agglomerated on the three-dimensional workpiece to generate the flexible material. According to the system and the method, the flexible material can be conveniently and quickly printed.

Owner:INVENTECSHANGHAI TECH +2

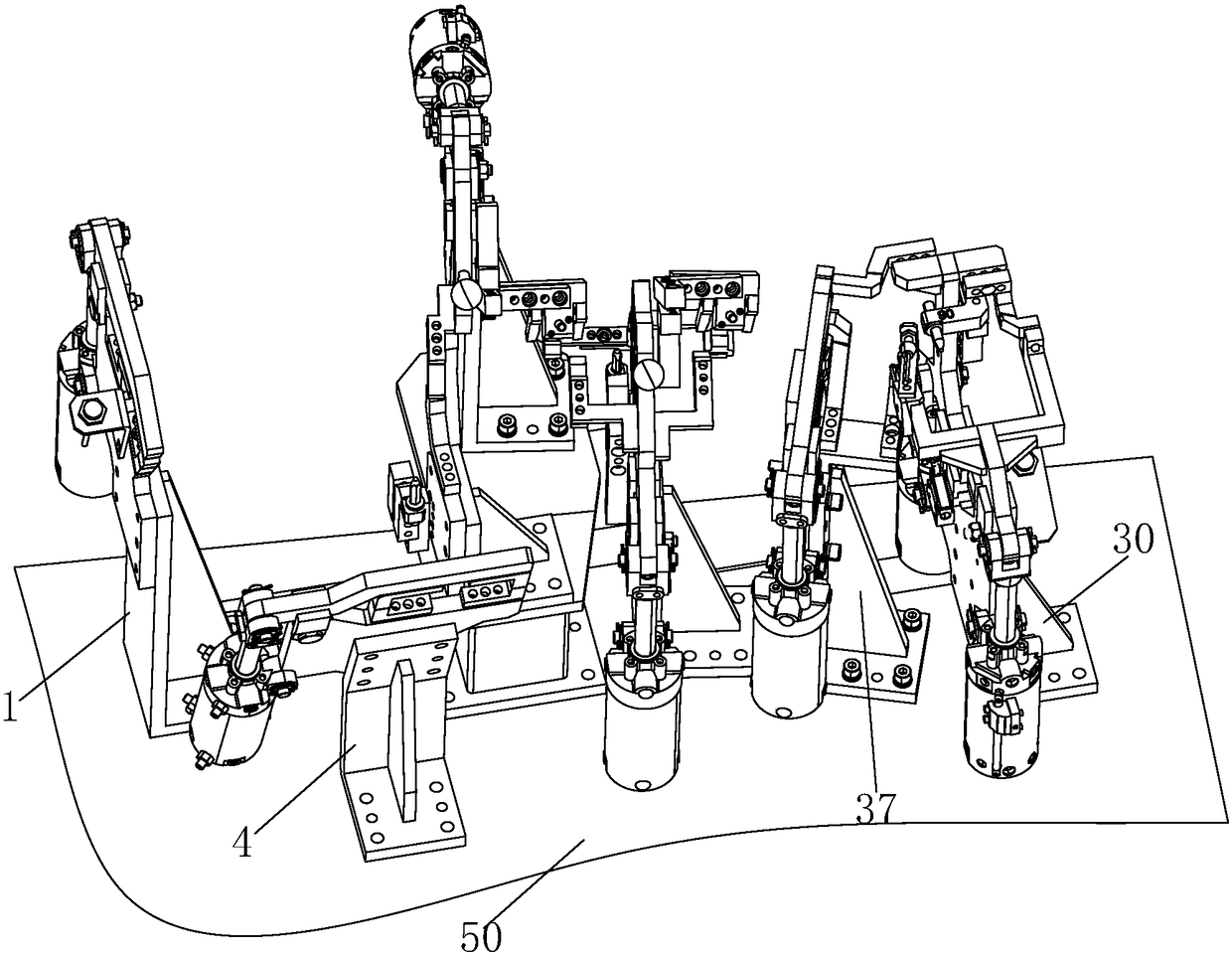

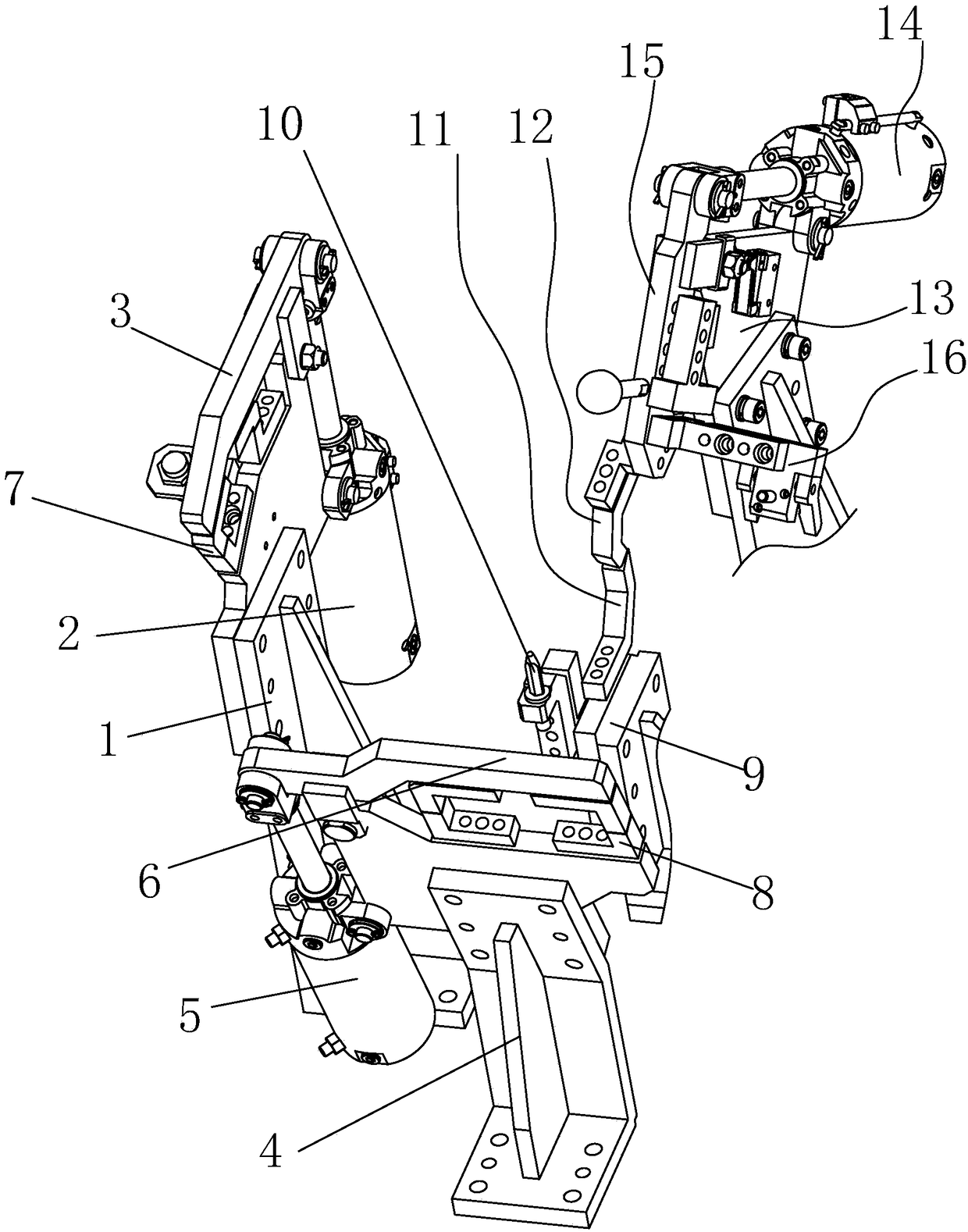

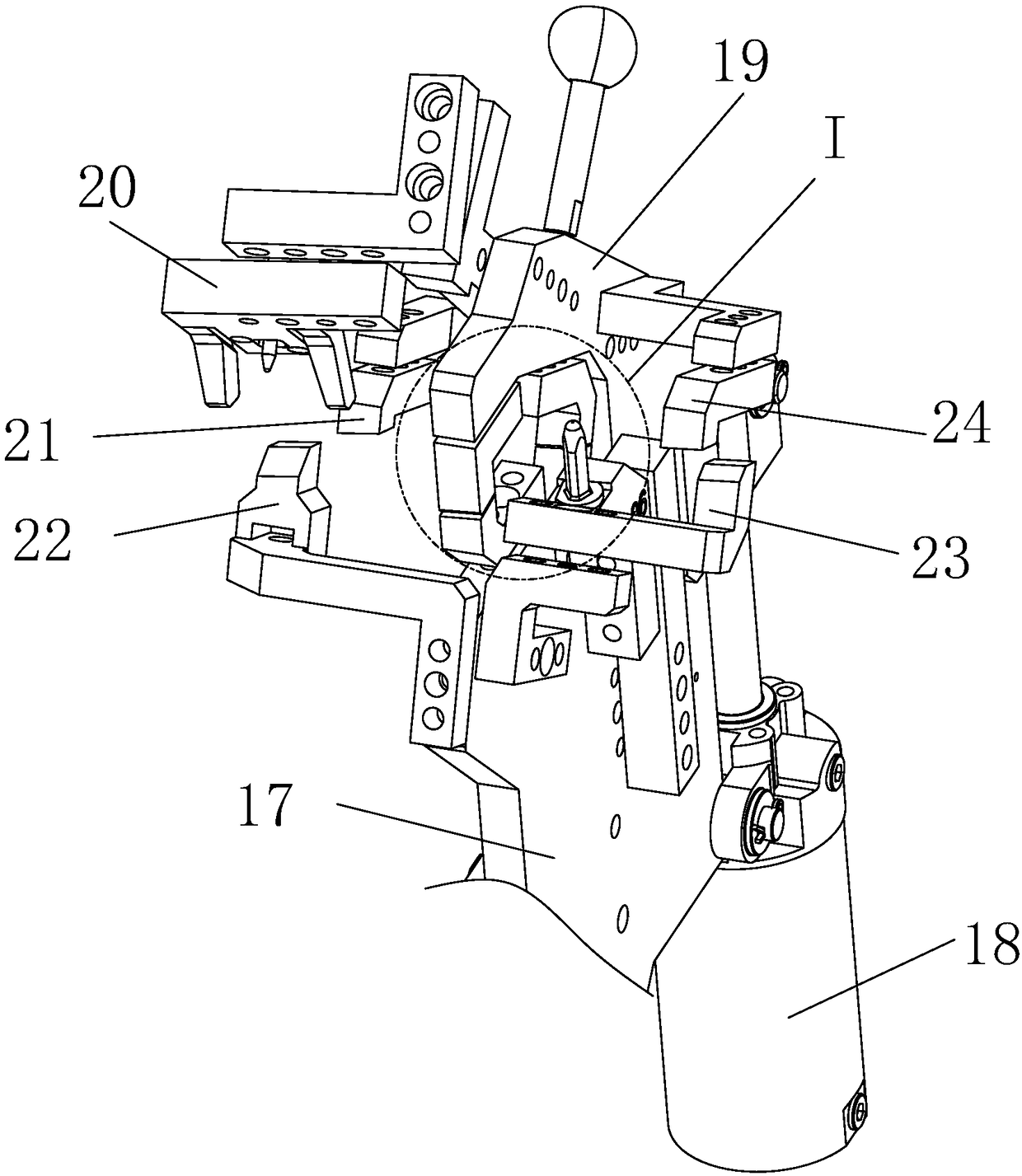

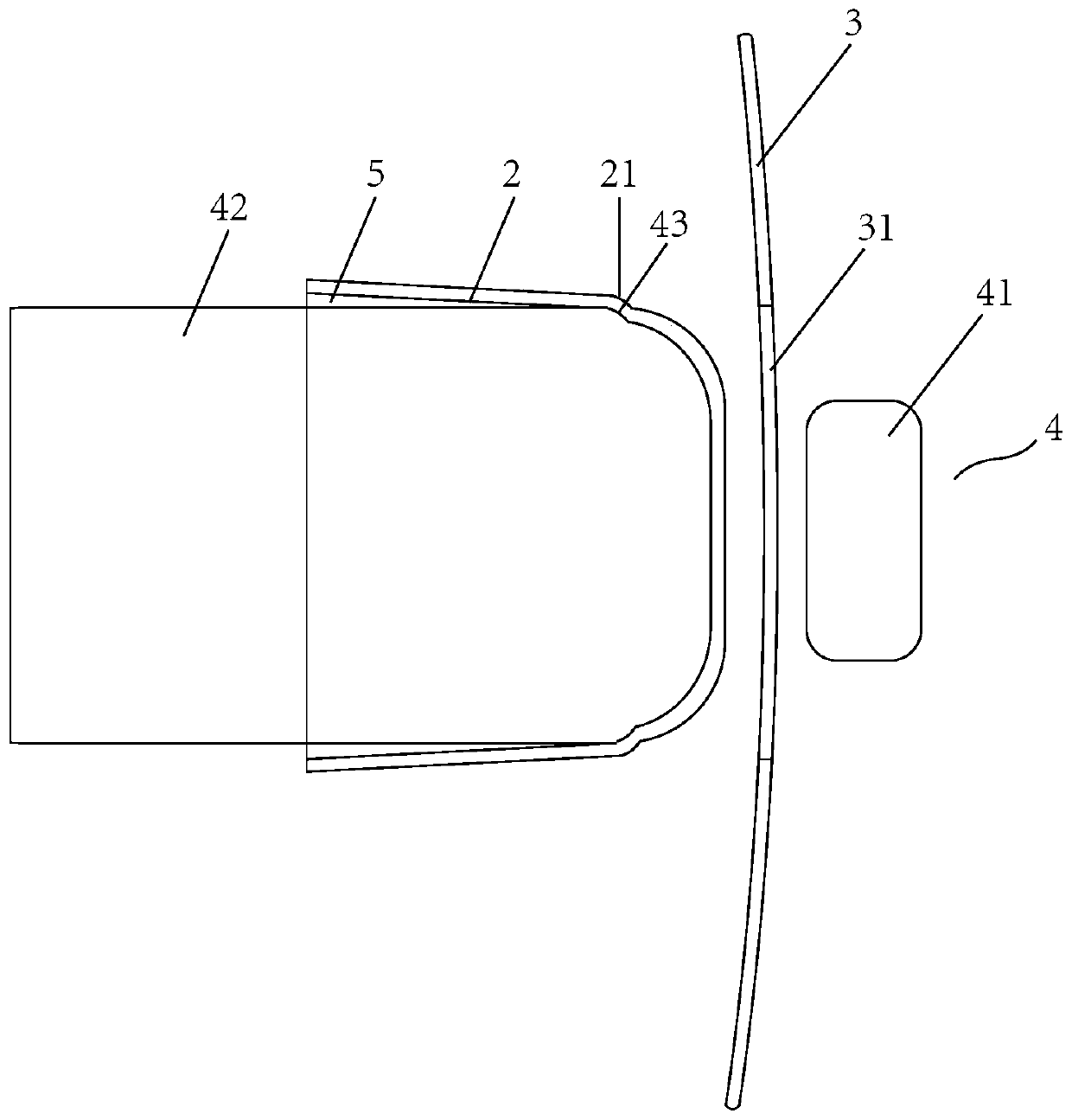

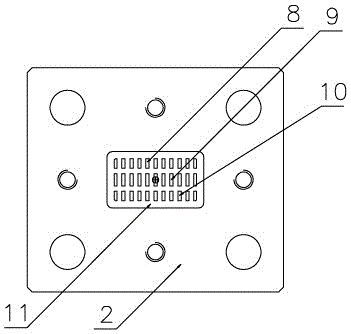

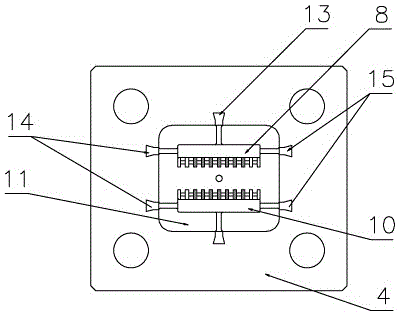

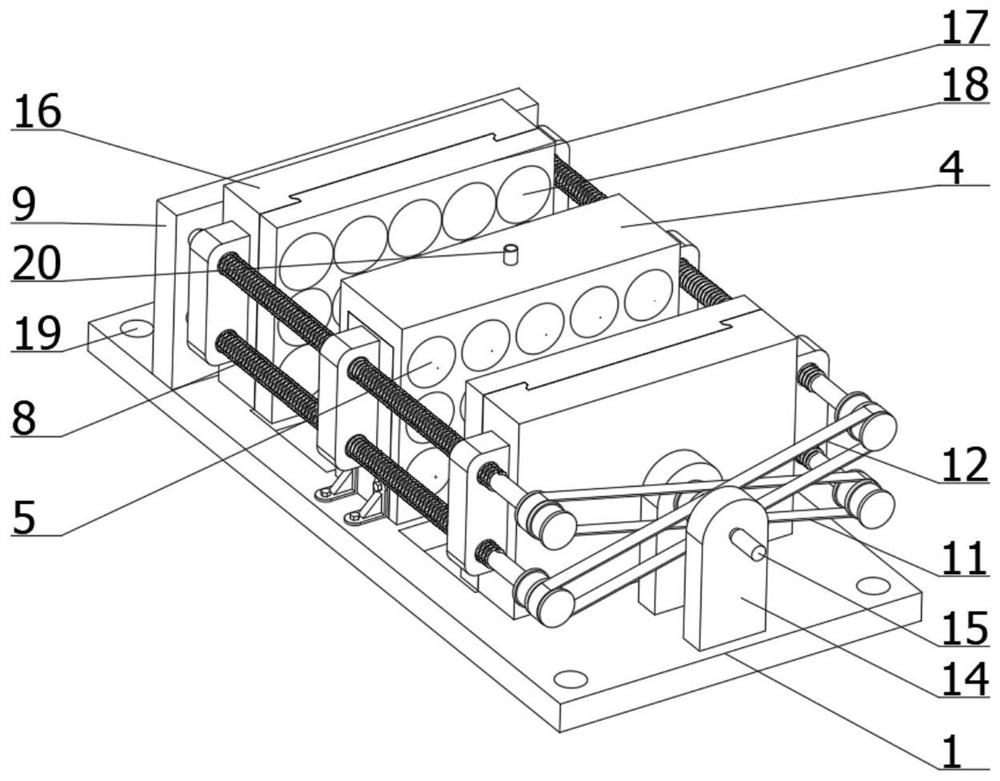

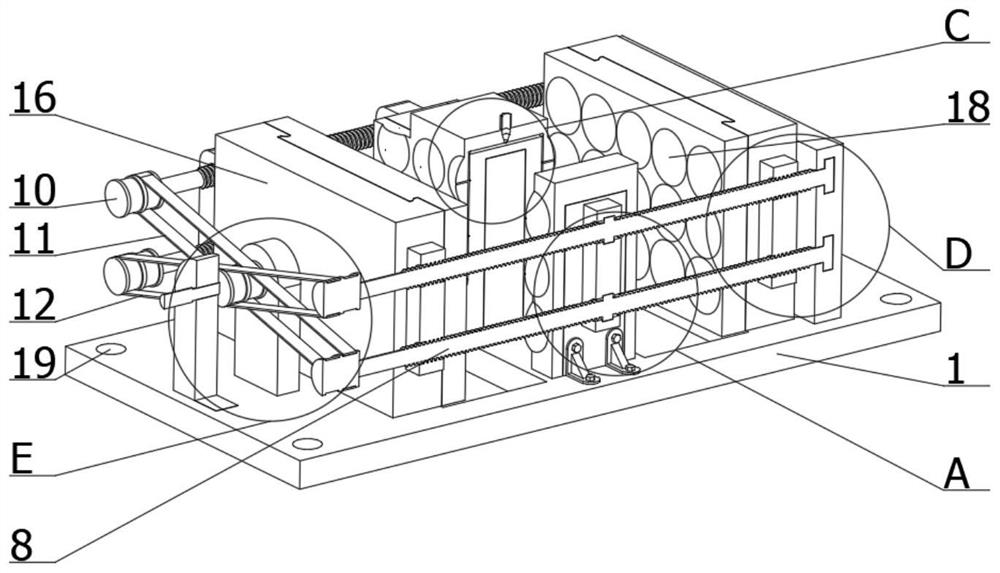

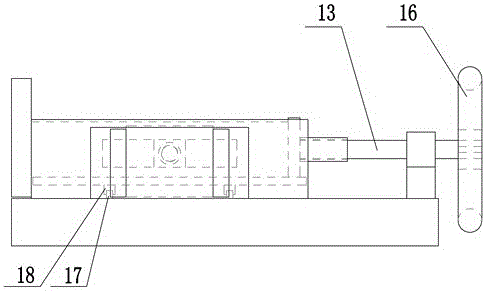

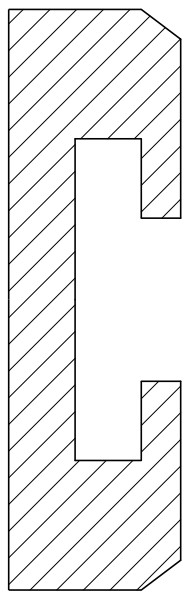

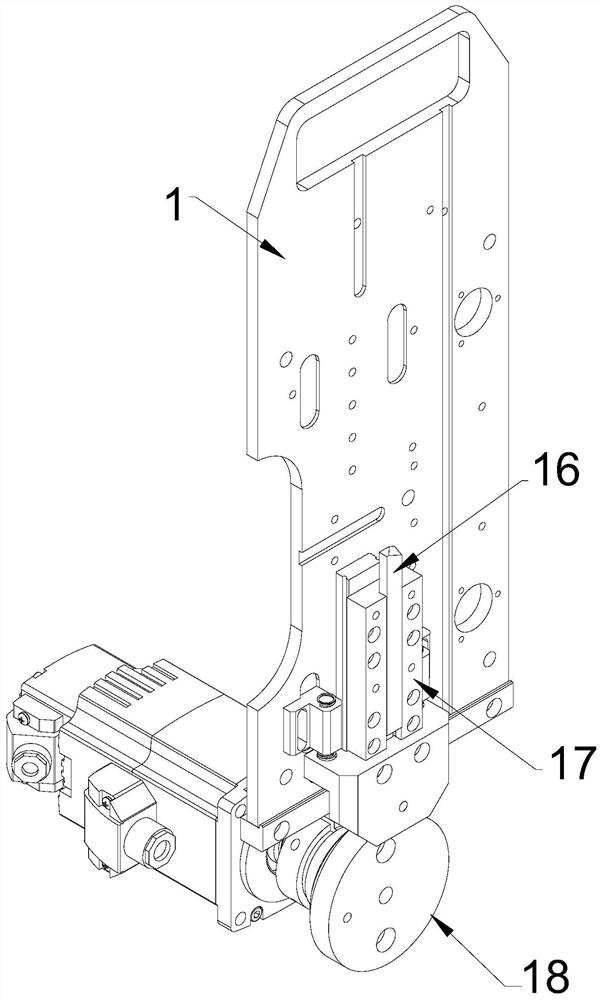

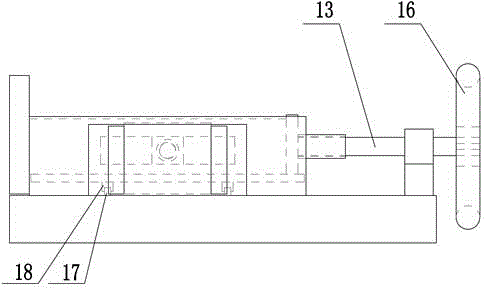

Middle combined clamping tool for welding front assemblies of inner plates of left and right side walls of automobile

InactiveCN108080870AGuaranteed accuracyEasy solderingWelding/cutting auxillary devicesAuxillary welding devicesRelative precisionMachining

The invention relates to a middle combined clamping tool for welding front assemblies of inner plates of left and right side walls of an automobile. The middle combined clamping tool for welding frontassemblies of inner plates of left and right side walls of the automobile comprises a middle supporting device, a side plate supporting device, a middle accessory positioning and pressing device anda right accessory positioning and pressing device; and the middle accessory positioning and pressing device and the right accessory positioning and pressing device are successively distributed on theright side of the middle supporting device. The middle complicated structures of the front assemblies of the inner plates of the left and right side walls of the automobile are designed specially, bythe tool, all components involved in the middle can be clamped and positioned, relative precision of the various components is ensured, the space utilization rate is high, and the production and manufacturing cost is reduced. In addition, automated welding treatment of an external welding robot is facilitated, the production efficiency and the quality of products are greatly improved, the degree of automation is high, and batched production and machining are realized favorably.

Owner:ANHUI DACHANG TECH

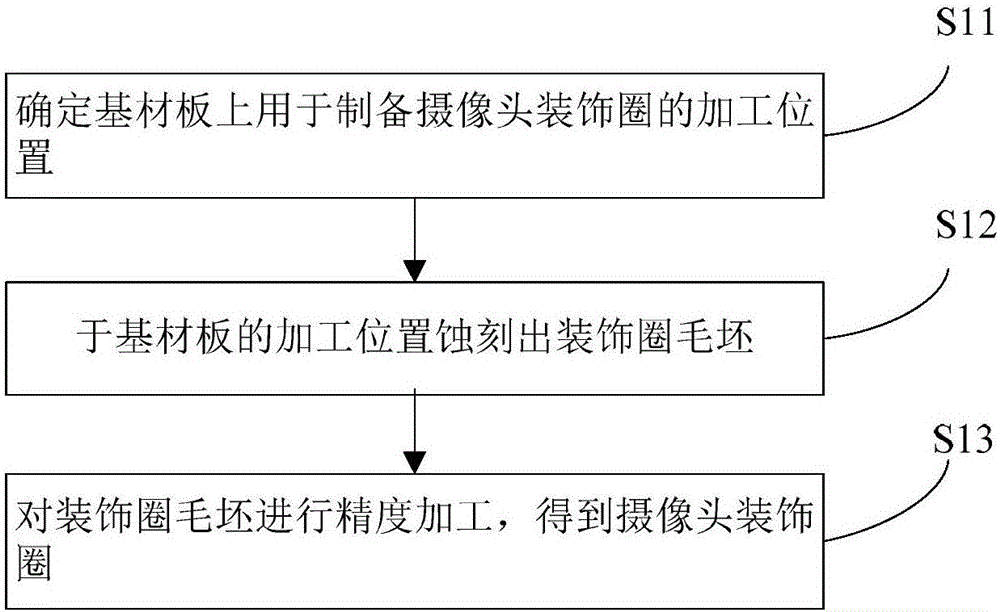

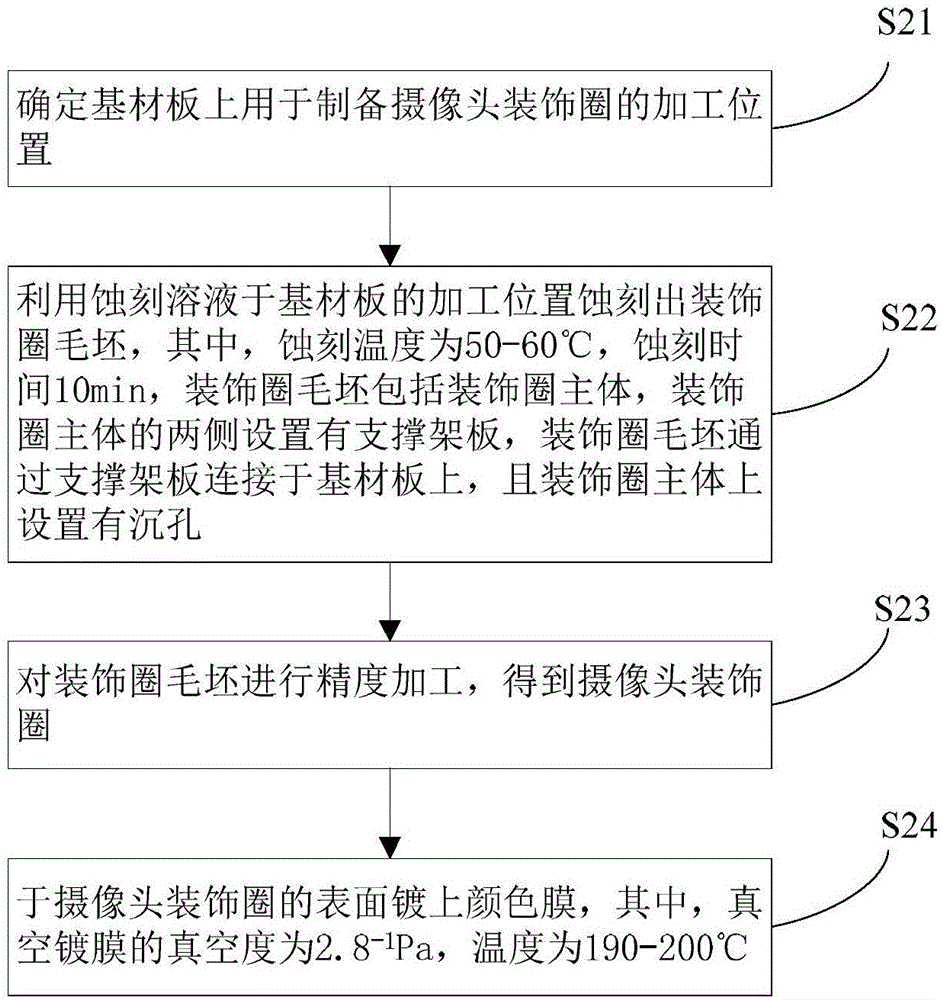

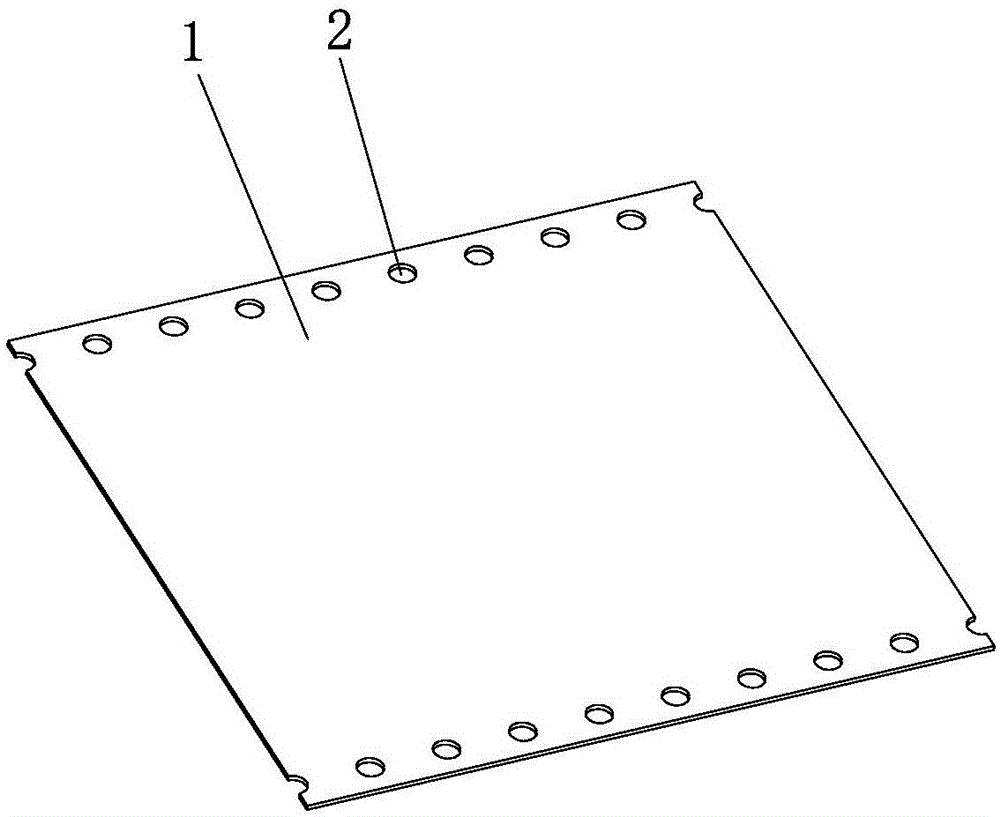

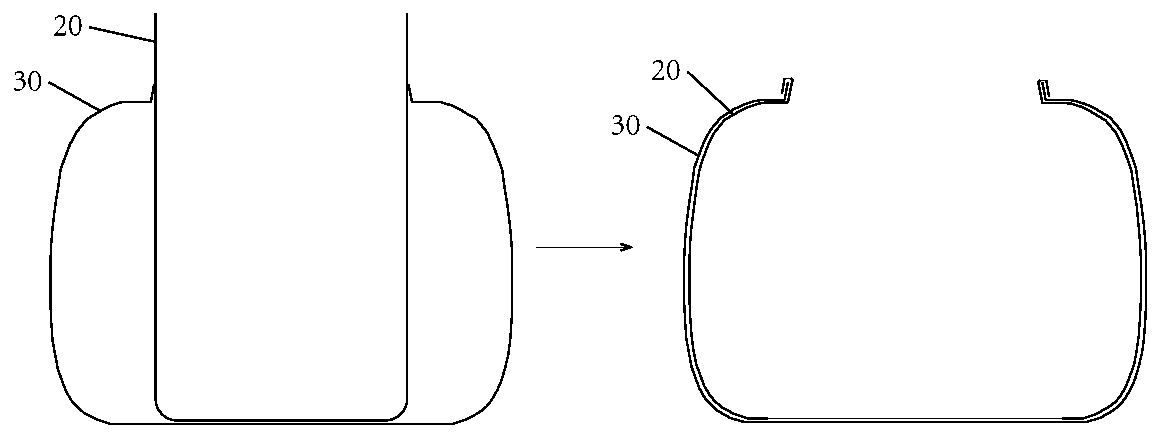

Processing method of camera decoration ring

InactiveCN106851075AMeet the precision size requirementsIncrease productivityTelevision system detailsColor television detailsComputer graphics (images)

The embodiment of the invention provides a processing method of a camera decoration ring. The method comprises the steps of providing a substrate plate; determining a processing position, for preparing the camera decoration ring, on the substrate plate; etching a decoration ring blank in the processing position of the substrate plate; and carrying out precision processing on the decoration ring blank to obtain the camera decoration ring. According to the embodiment of the invention, quantitative production processing is achieved through determining the processing position of the camera decoration ring on the substrate plate and etching the decoration ring blank in the processing position of the substrate plate; furthermore, the camera decoration ring is obtained through precision processing of the decoration ring blank to meet the precise dimension requirements of the camera decoration ring. Through the steps of the method, quantitative production of the camera decoration ring is achieved, the production efficiency of the camera decoration ring is effectively improved, the production cost is reduced and the production requirements of the camera decoration ring are met.

Owner:VIVO MOBILE COMM CO LTD

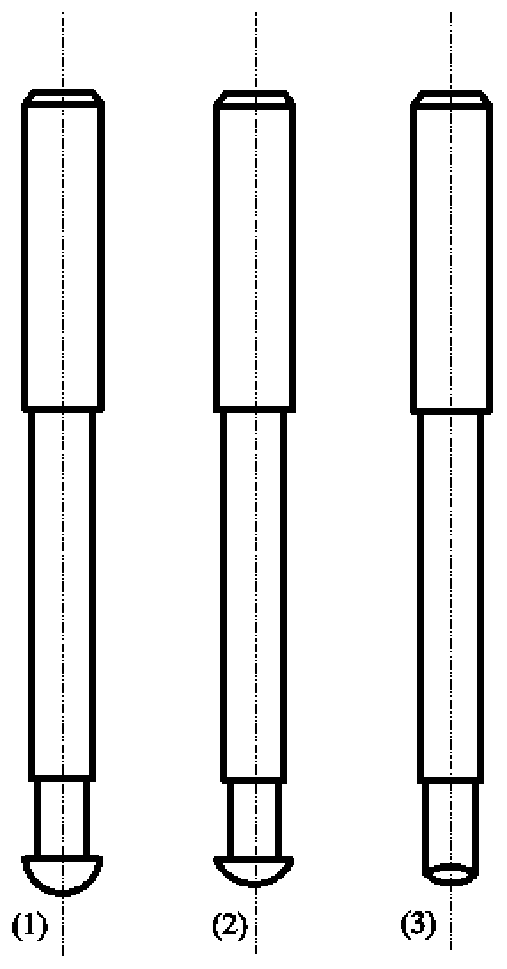

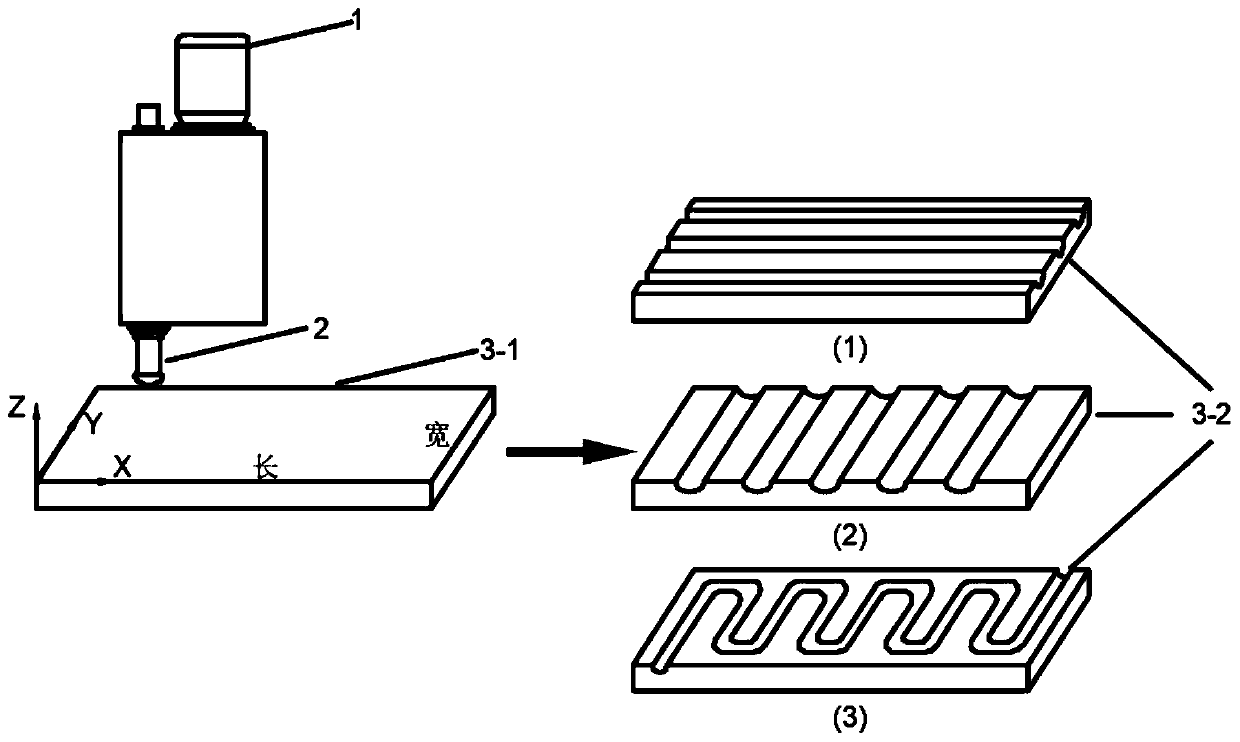

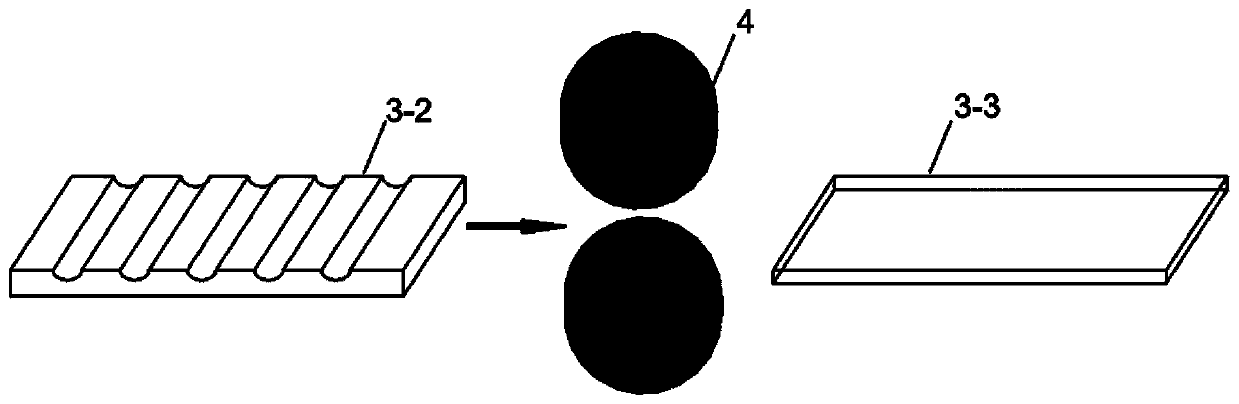

Method for preparing multi-grain-size heterogeneous aluminum alloy plate through composite rolling

ActiveCN111346939ALow equipment requirementsReduce manufacturing costFurnace typesHeat treatment furnacesAlloyMaterials science

The invention discloses a preparation method for preparing a multi-grain-size heterogeneous aluminum alloy plate through composite rolling. The method comprises the four specific procedures of surfacerolling deformation, homogenizing annealing treatment, non-uniform rolling deformation and recrystallization annealing treatment. According to material performance requirements, computer programmingis utilized, rolling tool paths of different patterns are compiled, and aluminum alloy plates of different thicknesses are obtained; the unequal-thickness aluminum alloy plate are fully annealed, so that the microstructure of the unequal-thickness aluminum alloy plate recovers to an annealed structure before deformation; non-uniform rolling deformation is carried out on the annealed unequal-thickness aluminum alloy plate to obtain an aluminum alloy rolled plate with a flat surface and uniform thickness; and the multi-grain-scale heterogeneous aluminum alloy plate is obtained through recrystallization annealing.

Owner:NANJING UNIV OF SCI & TECH

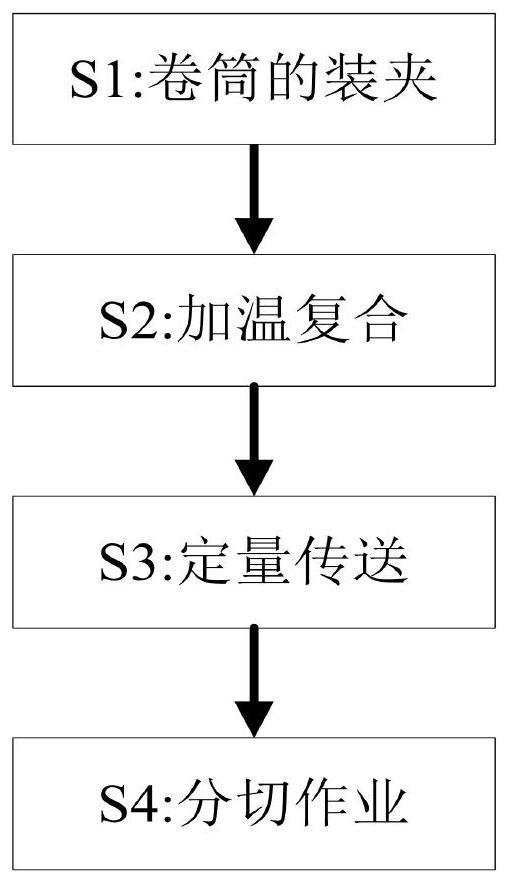

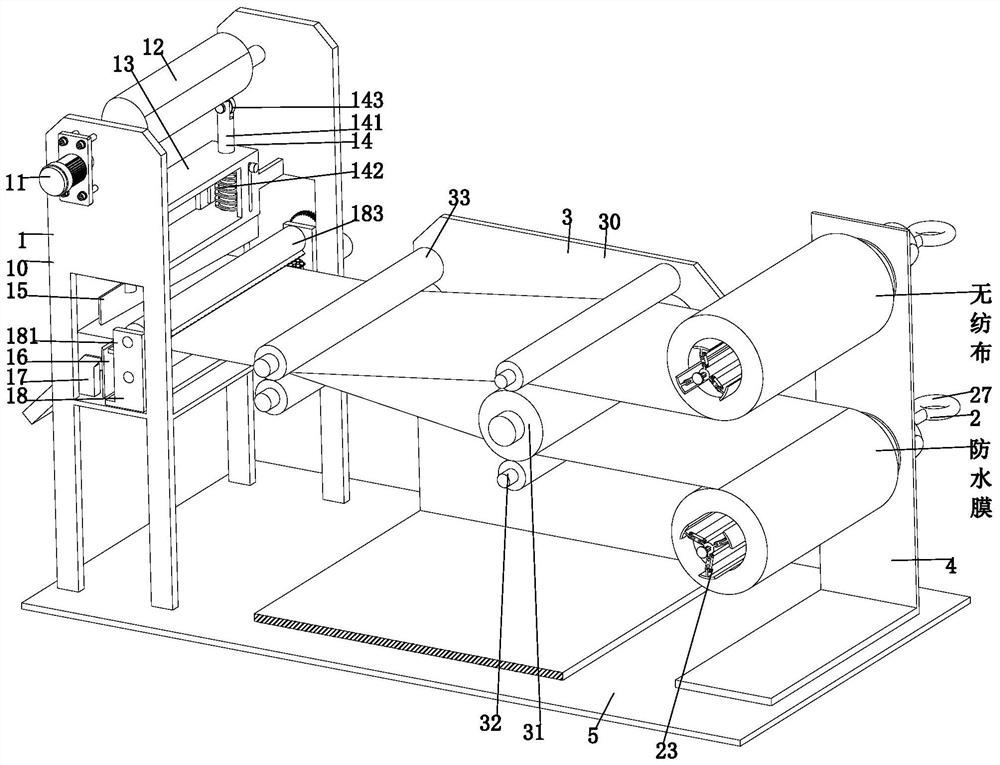

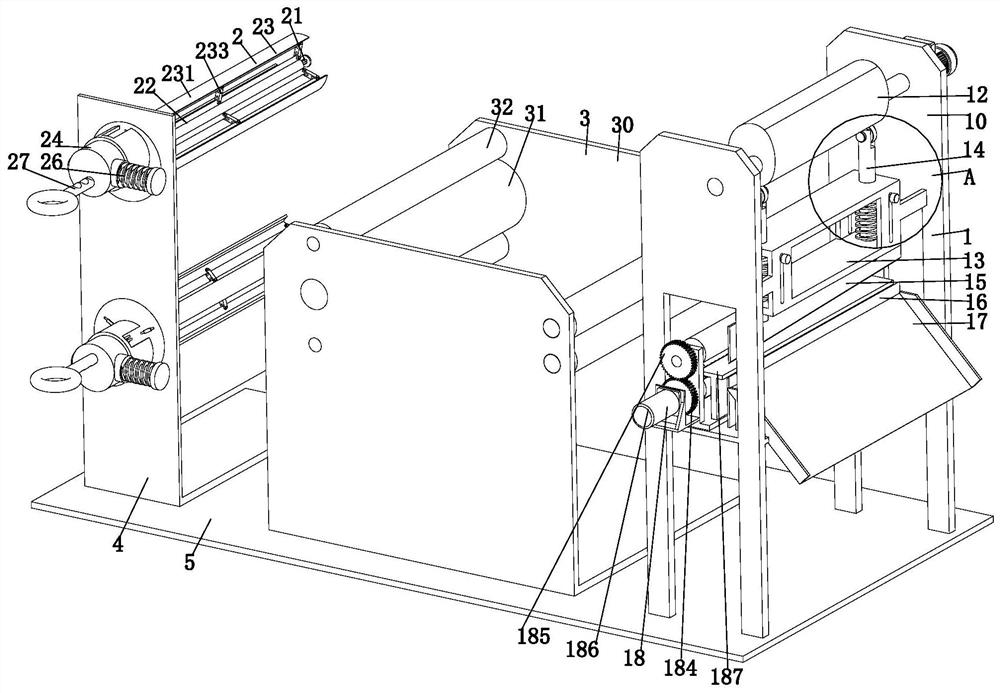

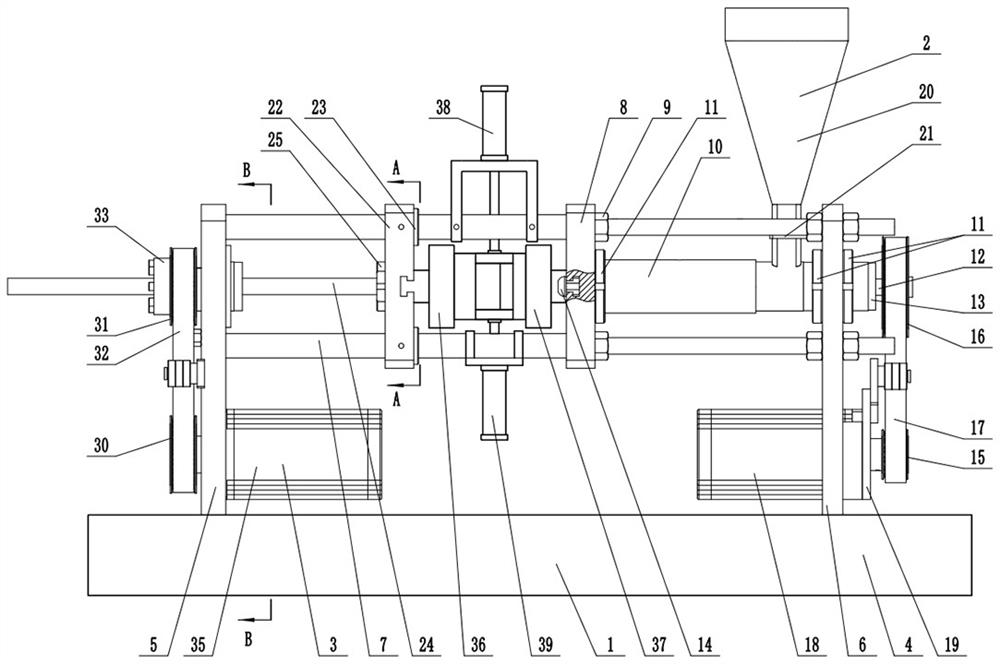

Waterproof non-woven fabric bag producing and processing method

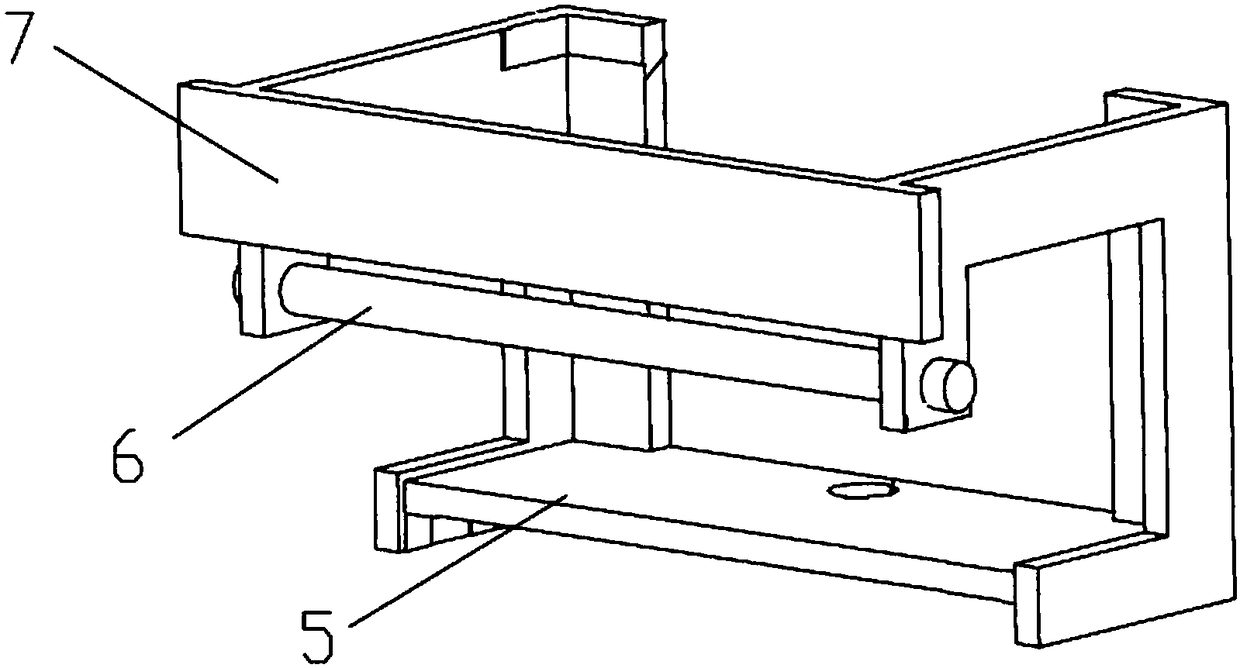

InactiveCN113059861AReduce cutting burrsReduce resistanceBag making operationsPaper-makingNonwoven fabricMechanical engineering

The invention provides a waterproof non-woven fabric bag producing and processing method. The waterproof non-woven fabric bag producing and processing method comprises a slitting mechanism, a clamping mechanism, a rolling and conveying mechanism, an L-shaped vertical plate frame and a bottom plate, wherein the rolling and conveying mechanism is mounted on the bottom plate; the slitting mechanism is arranged on the left side of the rolling and conveying mechanism, and installed on the bottom plate; the L-shaped vertical plate frame is installed on the end face of the bottom plate; the L-shaped vertical plate frame is located on the right side of the rolling and conveying mechanism; and clamping mechanisms are installed on the L-shaped vertical plate frame in a longitudinally-symmetrical mode through bearings. According to the waterproof non-woven fabric bag producing and processing method, the problems that the manufacturing requirements of waterproof non-woven fabric bags of different sizes cannot be met in existing manufacturing of waterproof non-woven bag production raw materials since non-woven fabric winding drums and waterproof film winding drums of different models and sizes cannot be clamped, the required size for slitting and manufacturing waterproof non-woven fabric bags cannot be met since the non-woven fabrics are prone to slip and rotate to cause errors during quantitative conveying of the non-woven fabrics, and the manufacturing requirements of the waterproof non-woven fabric bags cannot be met since a plurality of burrs are formed in the notches of the non-woven fabrics and the like are solved.

Owner:义乌市云翰纺织科技有限公司

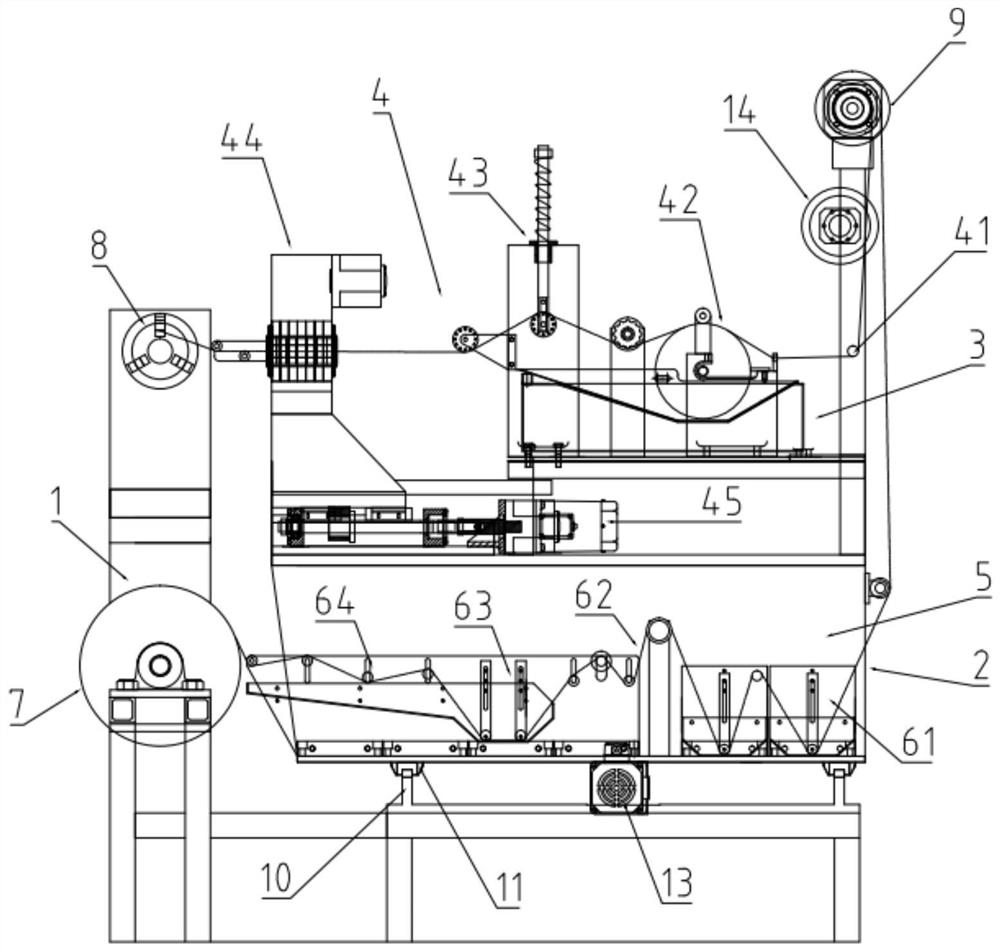

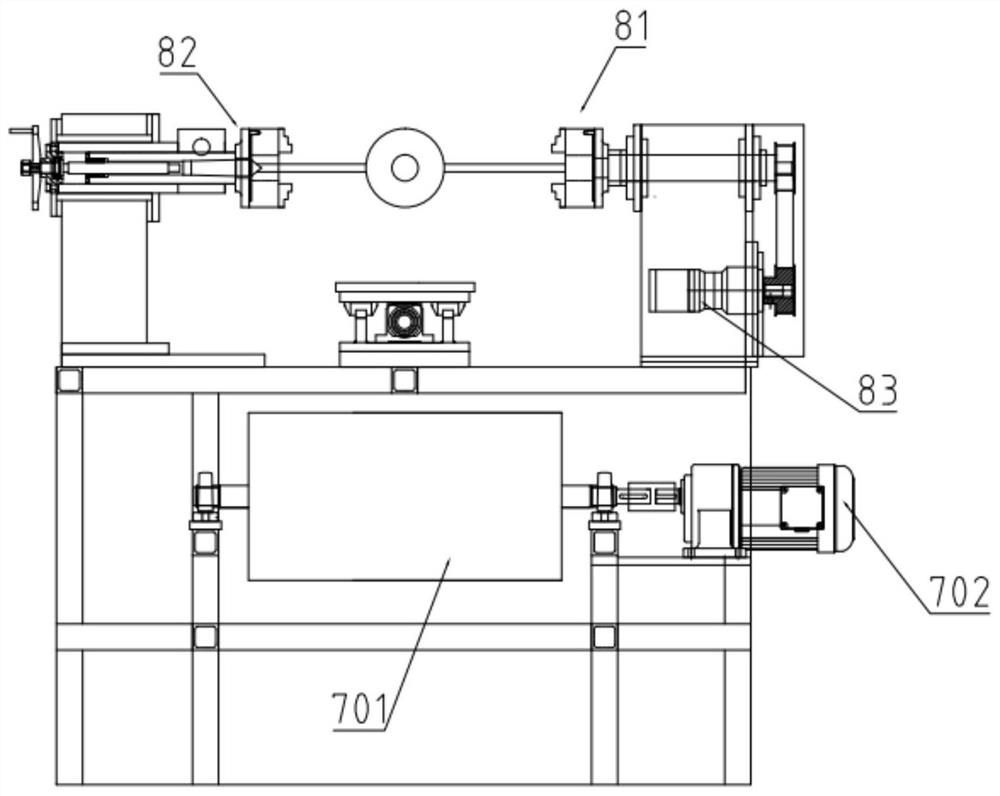

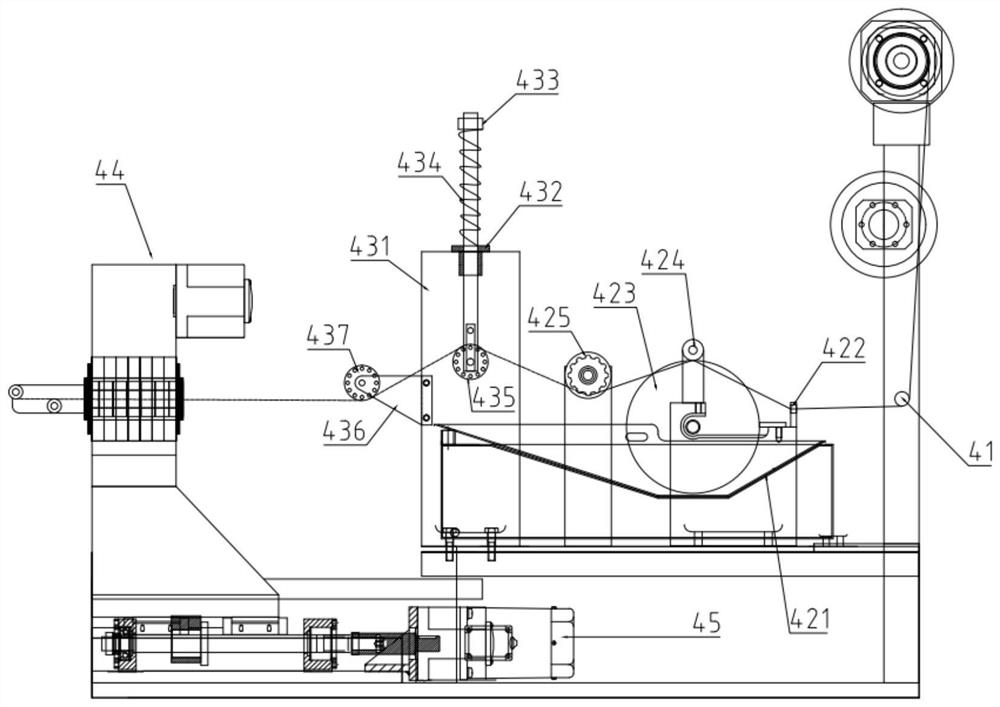

Multifunctional winding and arranging all-in-one machine

The invention relates to the technical field of carbon fiber production equipment, in particular to a multifunctional winding and arranging all-in-one machine. The multifunctional winding and arranging all-in-one machine comprises a fixed frame and a movable frame capable of moving on the fixed frame in the first direction. The movable frame is divided into an upper layer and a lower layer, the upper layer is a winding operation area provided with a winding device, and the lower layer is an arranging operation area provided with an arranging device; and the fixed frame is in an L shape, a hot roller winding device and a mold clamping device are arranged on a longitudinal frame body of the fixed frame, the position of the hot roller winding device corresponds to the position of the arranging device, and the position of the mold clamping device corresponds to the position of the winding device. The winding forming operation device and the arranging device are more reasonable in structural design, workshop space is saved, synchronous operation can be controlled in a unified mode, and independent operation can also be controlled respectively.

Owner:WEIHAI HONGCHENG ELECTROMECHANICAL EQUIP

High-strength honeycomb core production process

The invention discloses a high-strength honeycomb core production process which comprises the following steps: stamping a high-strength material plate or strip to form a high-strength profile with a multi-deformation half structure; performing staggered positioning on the corrugated surfaces on the two sides of the high-strength profile formed through stamping; welding and fixing adjacent high-strength profiles; cutting a complete high-strength profile formed on the high-strength profile to obtain a single-piece high-strength profile with the changeable shape; and stacking and welding a plurality of single-piece high-strength profiles until the high-strength honeycomb core with the required size is obtained. The high-strength honeycomb production process has the beneficial effects that the production and processing of the high-strength honeycomb core are realized through the process steps of stamping, welding, cutting and the like; and the high-strength honeycomb core with the required thickness size can be produced and manufactured, and the requirement of the actual industry for the high-strength honeycomb core is met.

Owner:苏州贝芯蜂窝科技有限公司

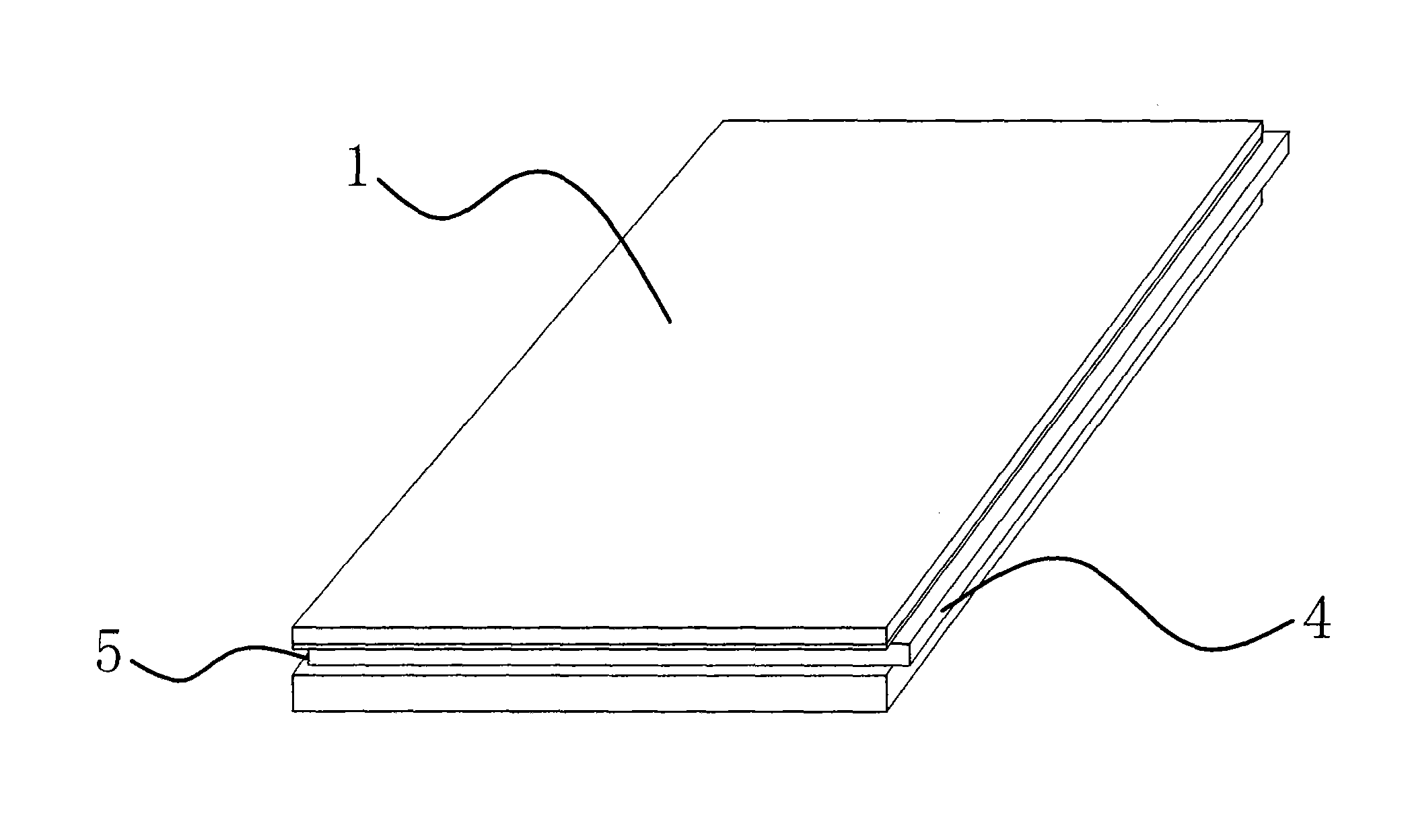

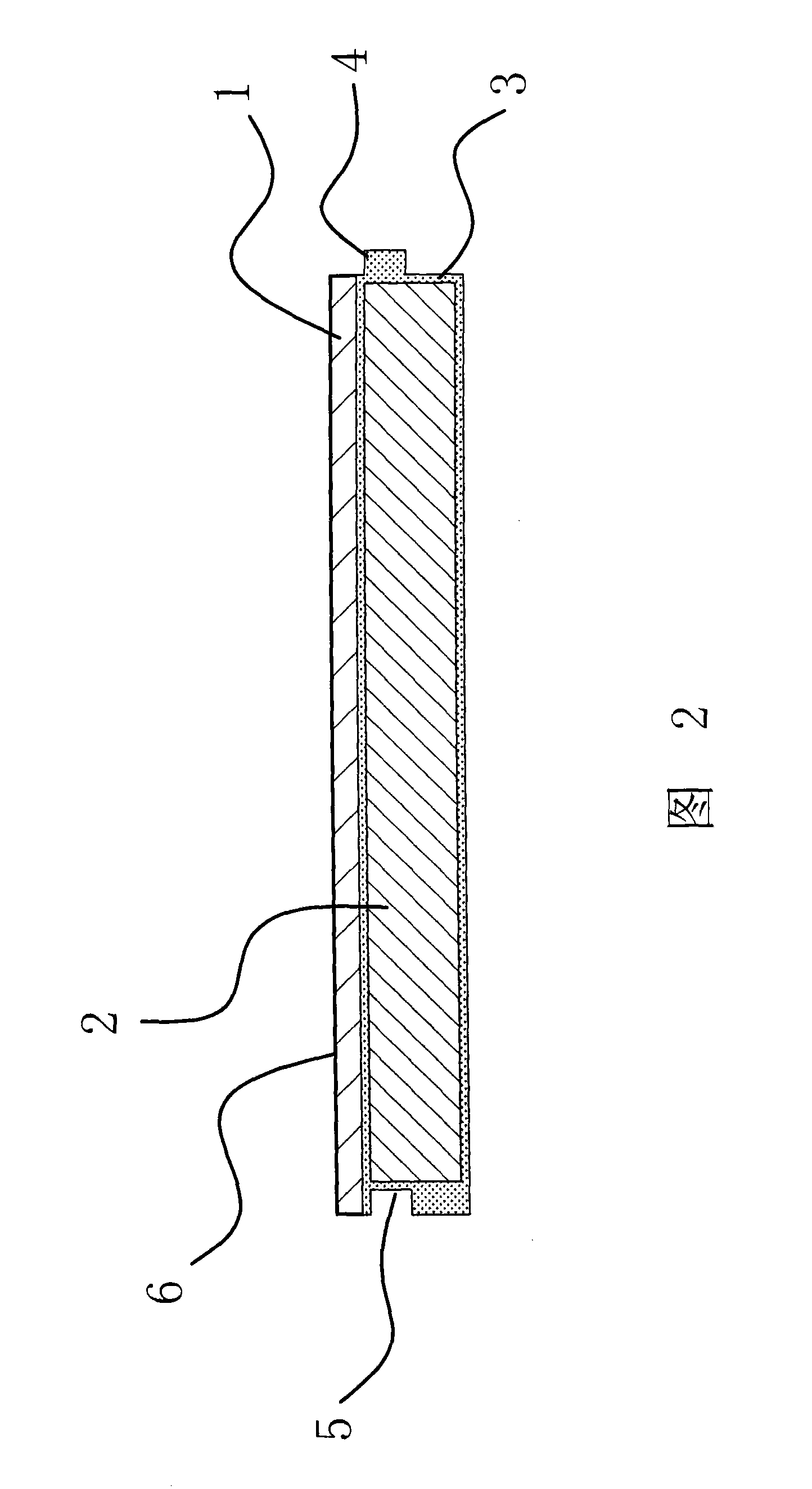

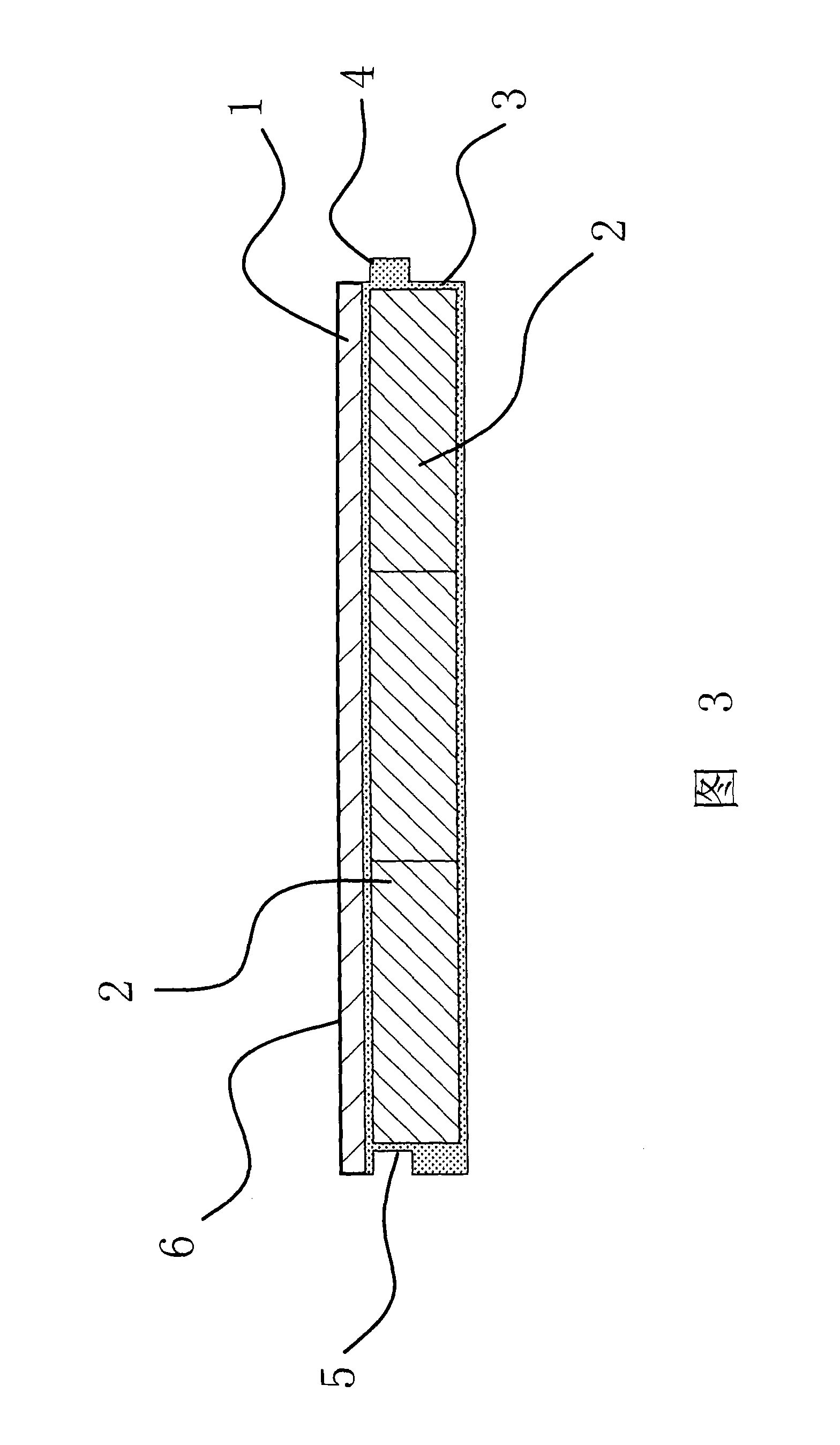

Glue sealing floor

The invention provides an adhesive-sealed floor, belonging to the technical field of finishing materials. The invention solves the problems that the current floor is liable to deformation when being affected with damp and rottenness as well as has sounds when being extruded. The adhesive-sealed floor comprises a core plate and a face plate, an outer surface of the core plate is provided with a plastic layer encasing the core plate therein, the face plate is adhered to an upper surface of the plastic layer. The adhesive-sealed floor provided by the invention has the advantages of low cost, wide use range, low possibility of deformation and rottenness, dampproof and mothproof abilities, etc.

Owner:吕海洋

Manufacturing technology of iron covering silver kettle

ActiveCN109746642ASolve the industry problem that it is impossible to produce non-cast iron iron-clad silver potsGood effectWater-boiling vesselsSilver plateManufacturing technology

The invention belongs to the technical field of processing of metal kettles, and provides a manufacturing technology of an iron covering silver kettle. The technology comprises the following steps: S1, feeding material; cutting to obtain a circular sliver plate; and cutting to obtain a circular or an annular iron plate; S2, forming the silver kettle, namely, forming the silver plate into an arc surface type silver kettle core; S3, forming and covering an iron kettle, namely, forming the iron plate into an arc surface type or barrel type iron kettle; sleeving the iron kettle cover with the ironkettle; or directly forming the iron plate on the silver kettle core; S4, shaping a kettle body, namely closing up the upper part of the kettle body; and shaping into kettle shape, wherein the innerwall of an iron kettle housing is close to the outer wall of the silver kettle core during shaping; and S5, processing to obtain a kettle product, namely, arranging a cover, a port and lugs to obtainthe iron covering silver kettle. The technology solves the technical problems that iron covering silver kettles in the prior art are all processed through cast iron and are heavy, and the outer surfaces of the cast iron cannot be carved and chiseled, and the artistry of the iron covering silver products is low.

Owner:张广韶

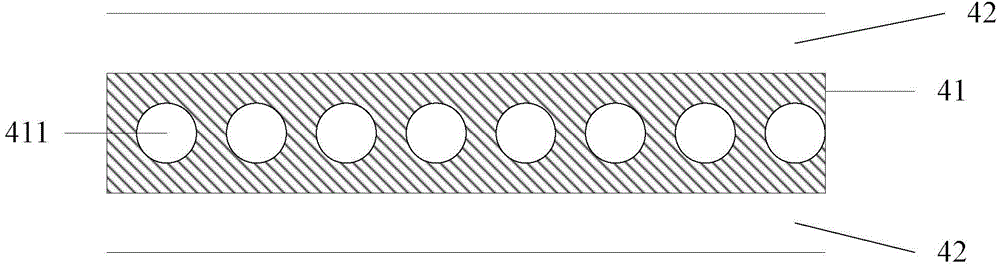

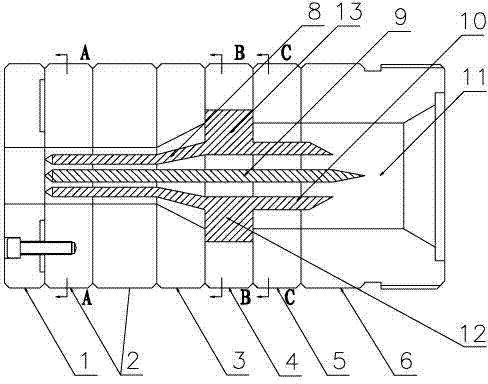

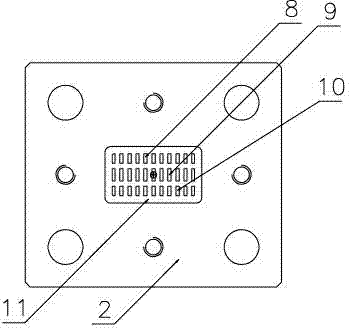

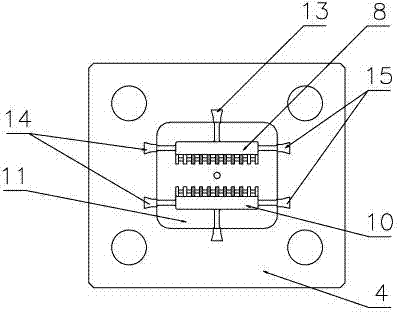

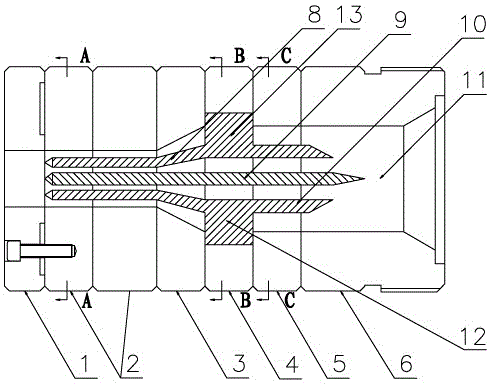

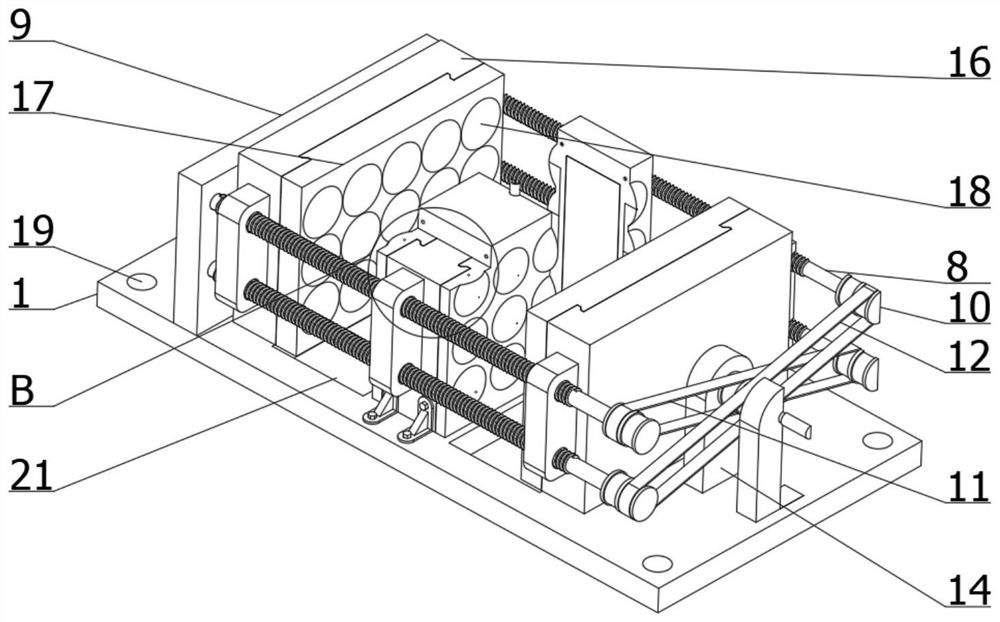

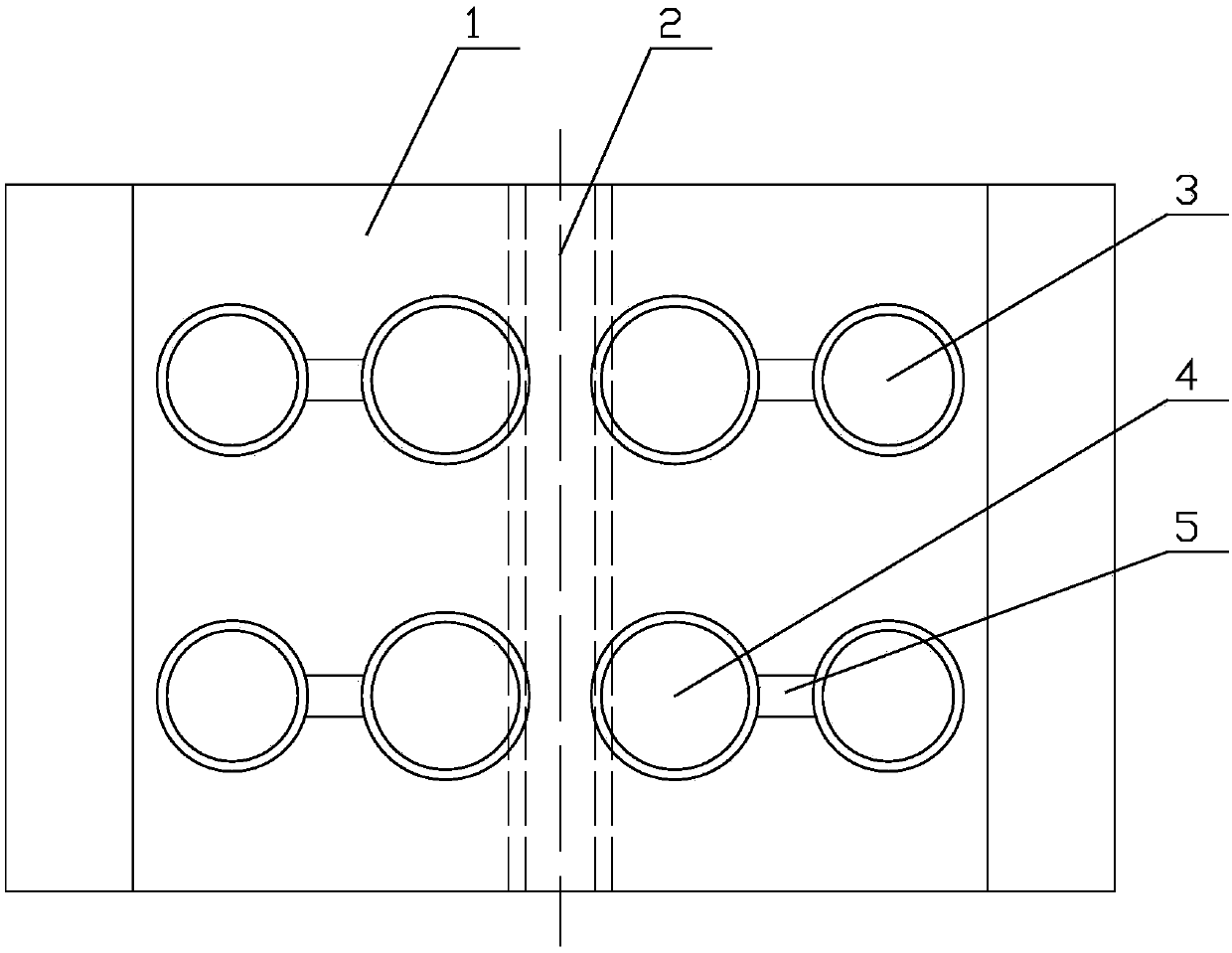

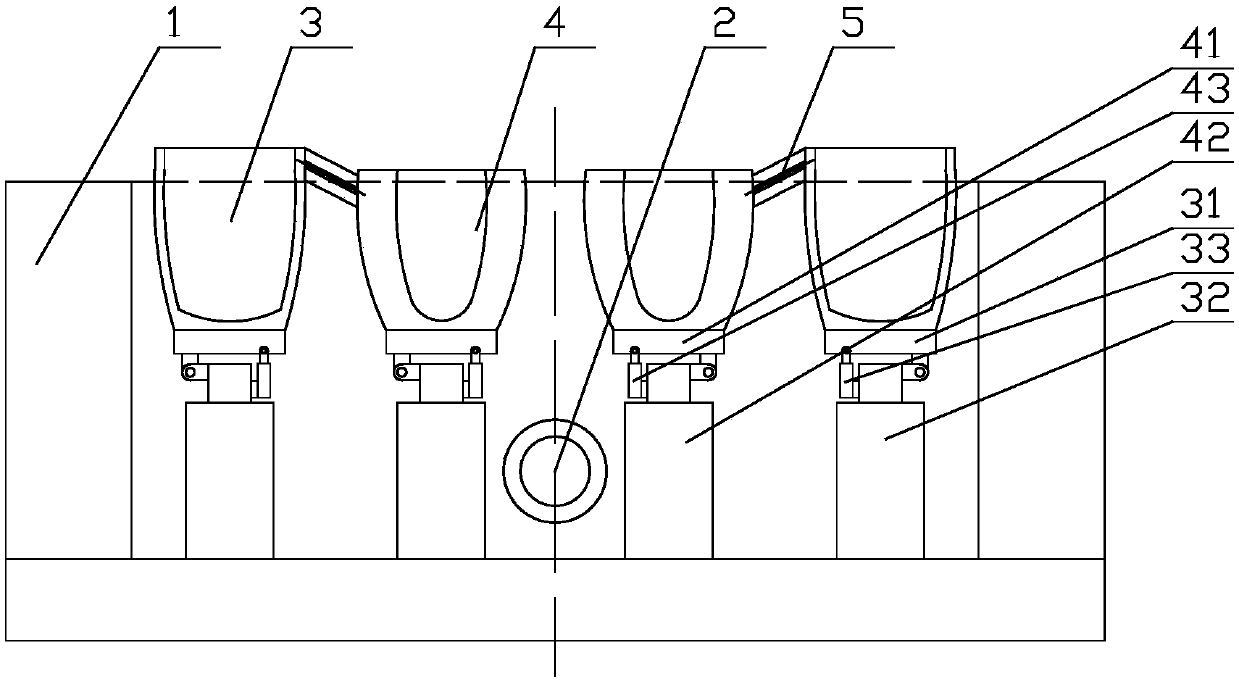

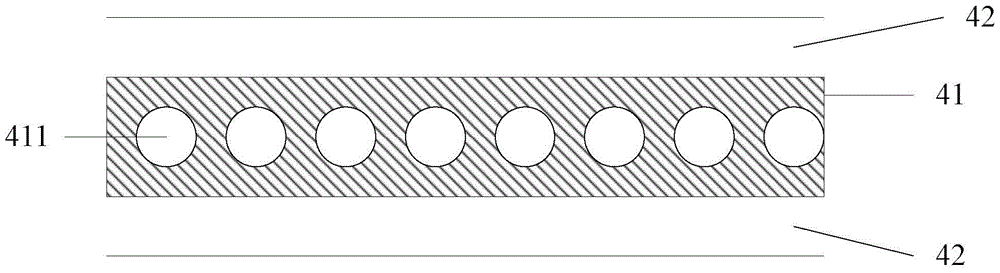

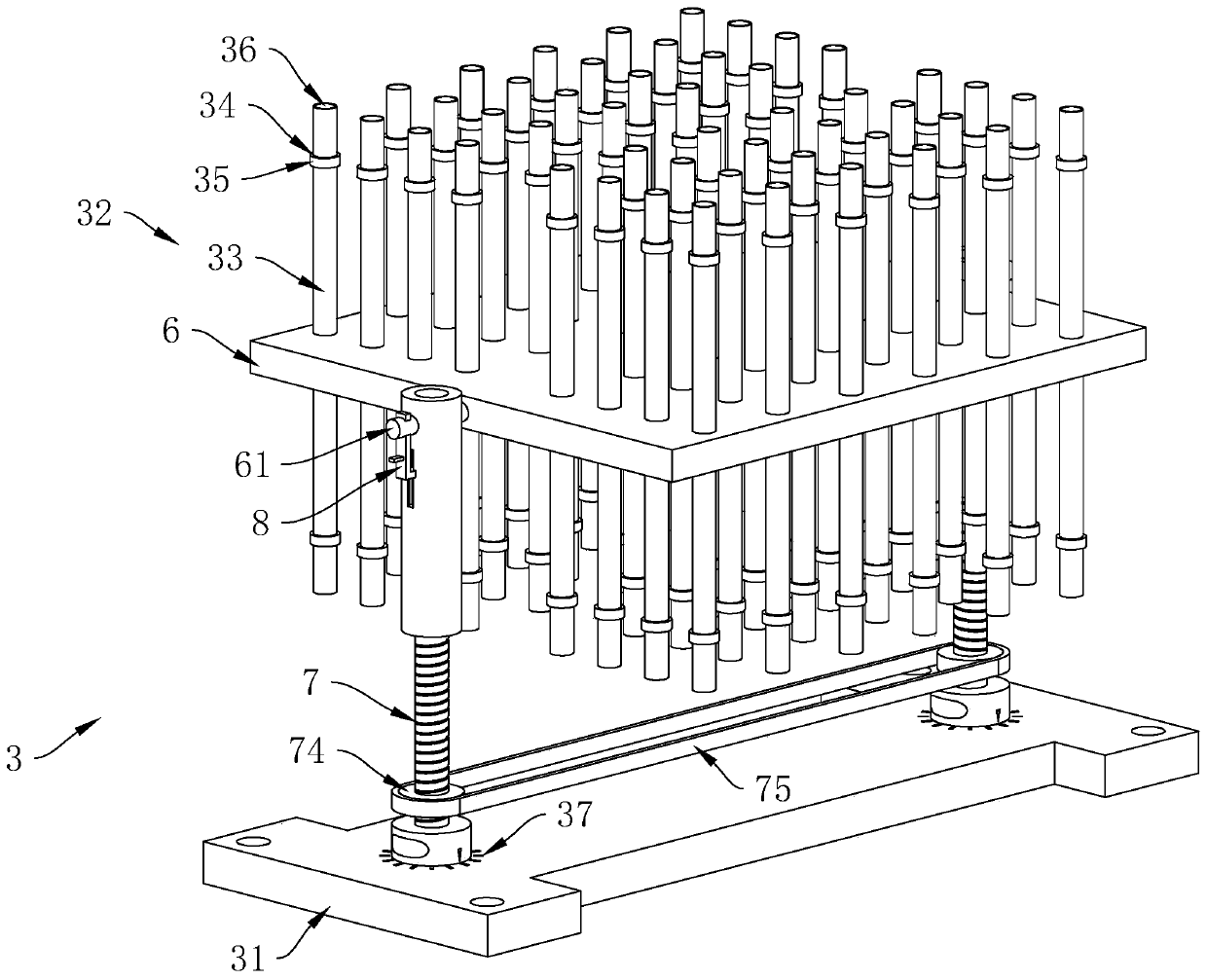

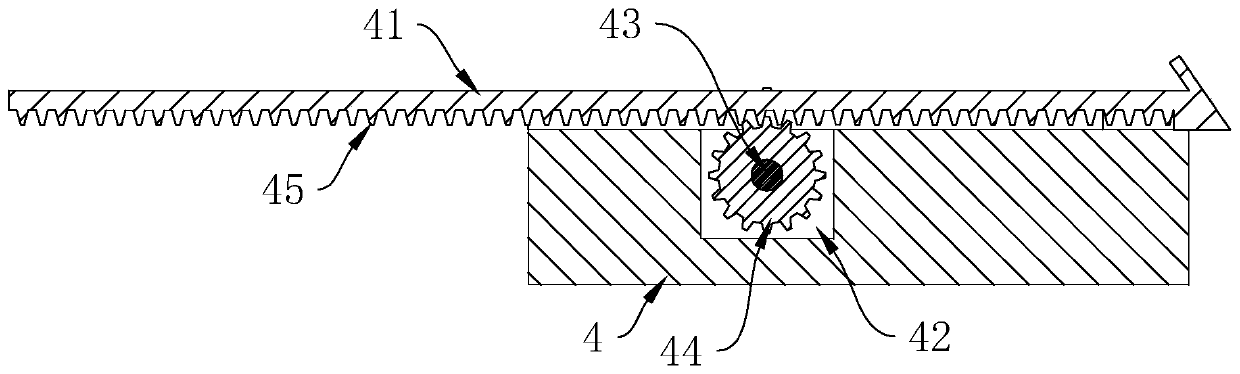

Moulding and foaming extrusion mould applicable to thick and solid PVC wood-plastic material

The invention relates to a PVC (polyvinyl chloride) wood-plastic material processing mould, and discloses a moulding and foaming extrusion mould applicable to a thick and solid PVC wood-plastic material. The moulding and foaming extrusion mould comprises a cooling plate, a mould plate, a converging plate, a mould core bracket plate I, a mould core bracket plate II and a mould body which are sequentially overlapped into a mould head, wherein a mould cavity is formed in the mould head; the mould cavity at the mould plate is a stabilizing section; the mould cavity at the converging plate is a compressing section; the mould cavity at the mould core bracket plate I, the mould core bracket plate II and the mould body is a feeding and diverting section; the moulding and foaming extrusion mould is characterized in that an upper row of core rods, a middle row of core rods and a lower row of core rods are distributed inside the mould cavity to form four circulating layers; the upper row of core rods and the lower row of core rods are connected with the mould core bracket plate I in a positioning way through left and right supporting legs and upper and lower supporting legs respectively; the middle row of core rods are connected with the mould core bracket plate II in a positioning way through the left and right supporting legs. The moulding and foaming extrusion mould can produce the solid PVC wood-plastic foamed material with the thickness greater than 20 mm; products produced by the moulding and foaming extrusion mould are uniform and dense in texture, so that bending resistance, compression resistance, tensile resistance and other performance indexes are greatly improved.

Owner:HUANGSHI JINHONG MOLD

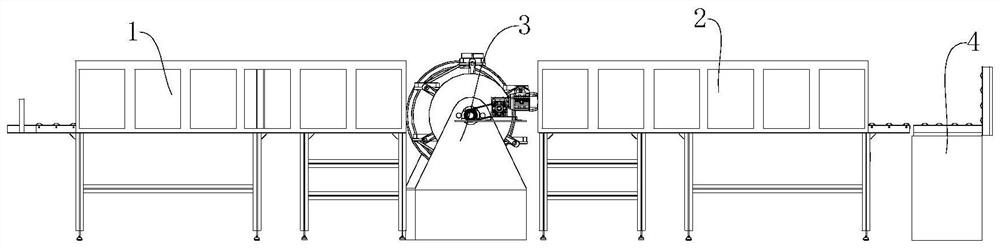

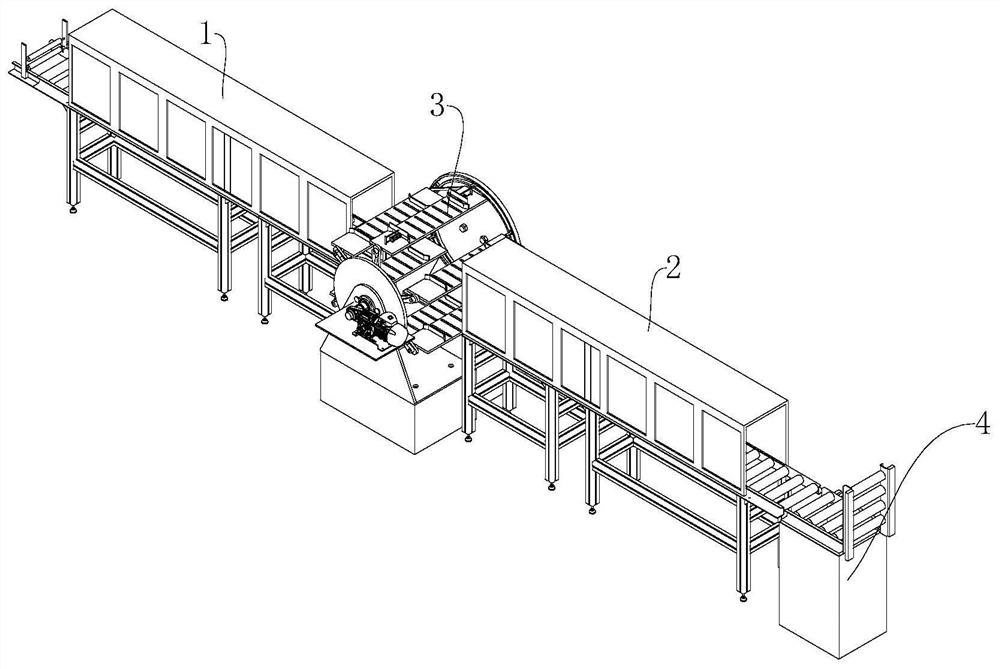

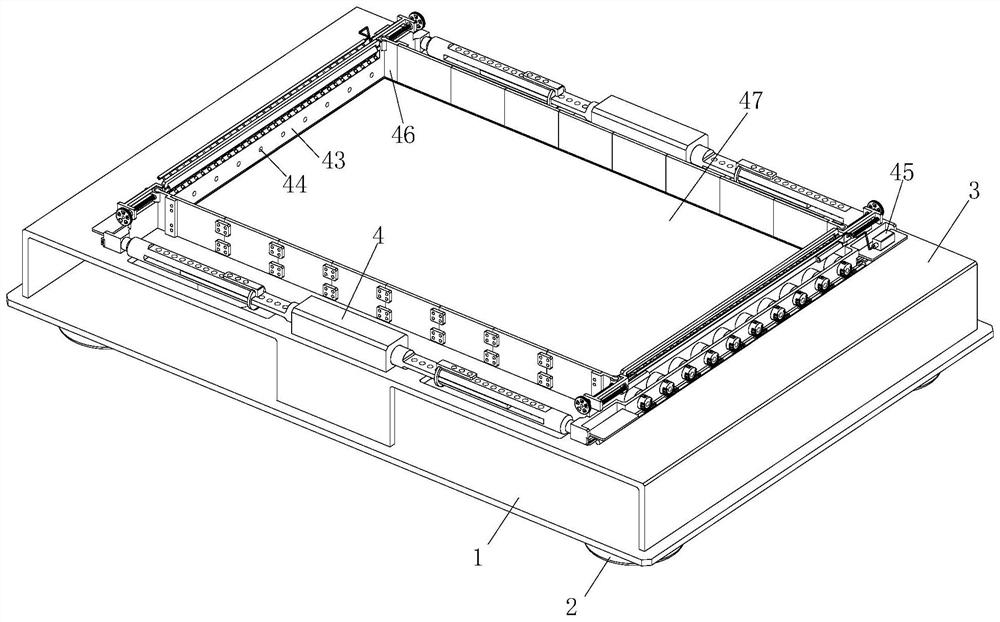

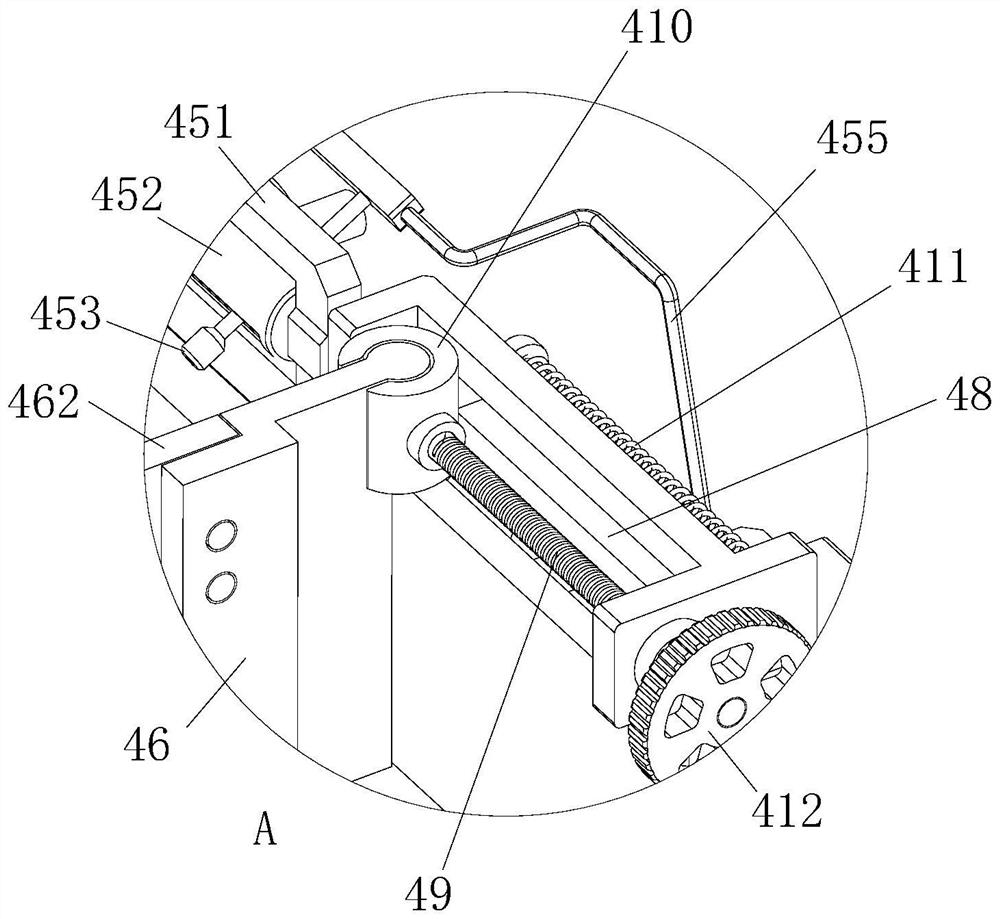

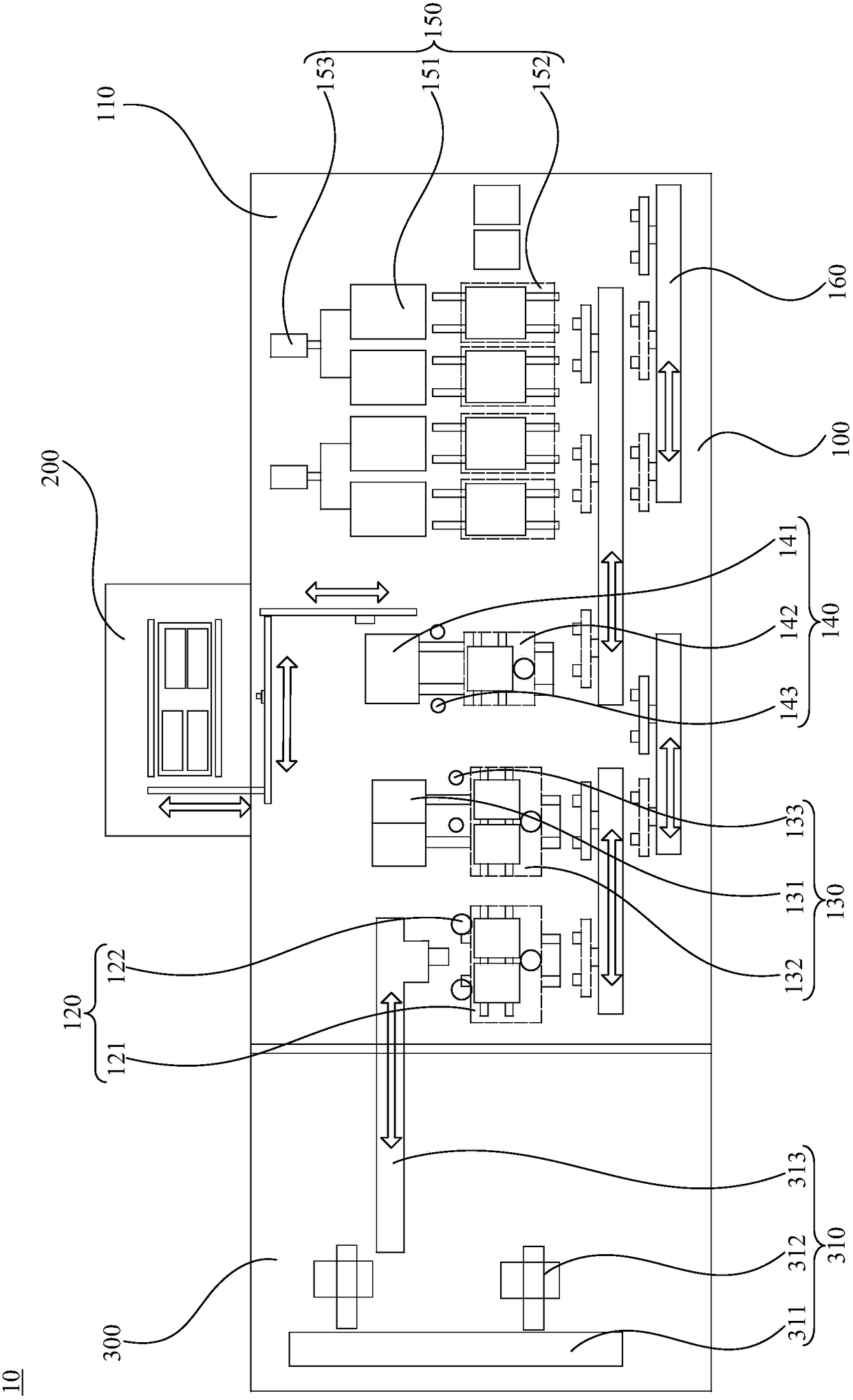

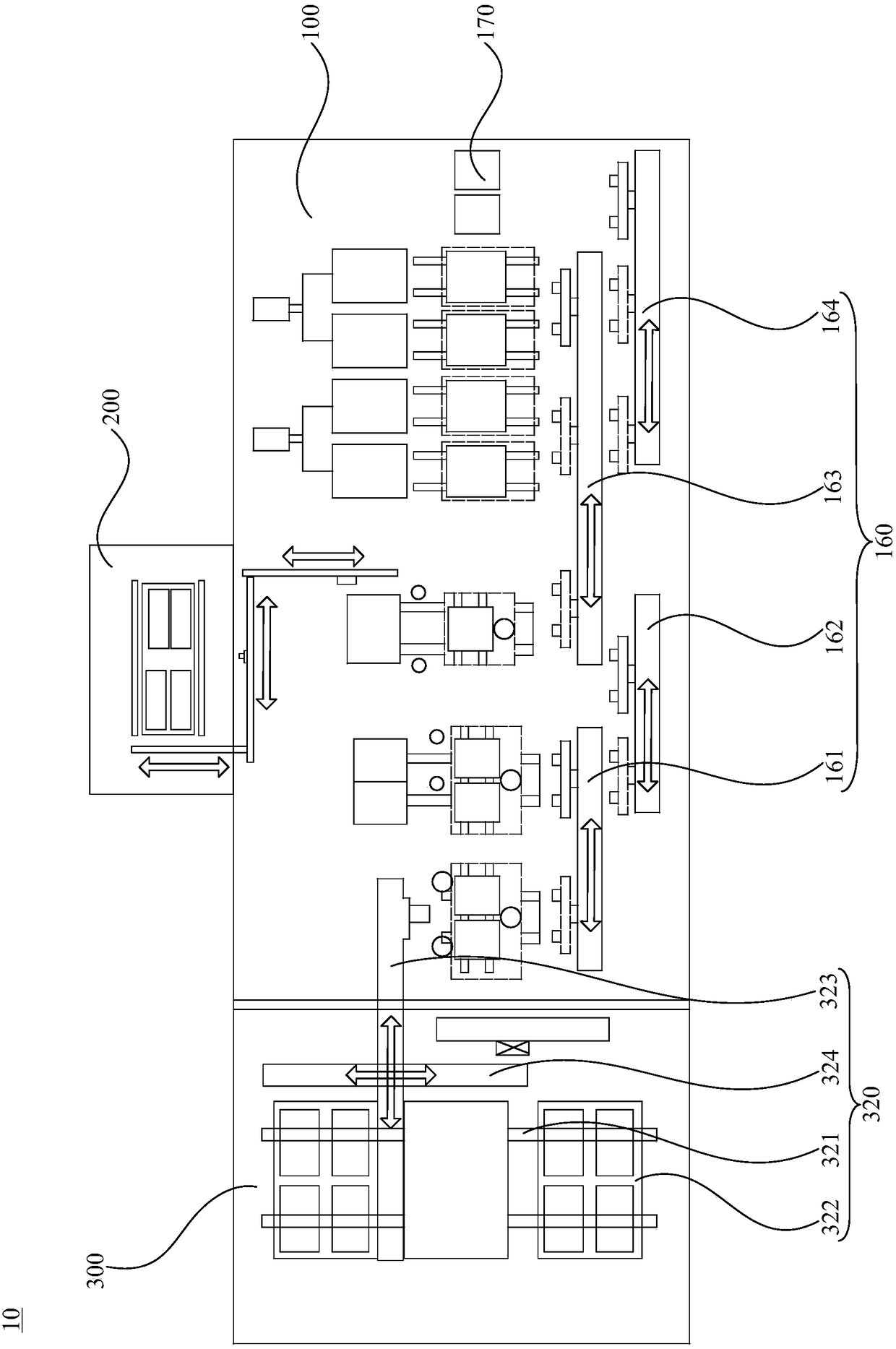

Corrugated carton production line

InactiveCN111844883AReduce labor intensityIncrease productivityEnvelopes/bags making machineryPaper-makingCorrugated fiberboardManufacturing line

The invention relates to the field of packaging supplies, in particular to a corrugated carton production line. The corrugated carton production line comprises a corrugated board production line, a corrugated carton forming production line, a connecting and conveying mechanism and a discharging assembly, wherein the corrugated board production line is used for producing and manufacturing corrugated boards; the corrugated carton forming production line is arranged on a side of the corrugated board production line and is used for forming corrugated cartons by using the corrugated boards producedand manufactured in the corrugated board production line; the connecting and conveying mechanism is arranged between the corrugated board production line and the corrugated carton forming productionline, is used for receiving the corrugated boards from the corrugated board production line, conveying the corrugated boards to the corrugated carton forming production line and is used for connectingthe corrugated board production line with the corrugated carton forming production line; and the discharging assembly is close to the output end of the corrugated carton forming production line and is used for receiving the formed corrugated cartons and switching the placement postures of the corrugated cartons. According to the corrugated carton production line, the formed corrugated boards areautomatically conveyed into the corrugated carton forming production line by utilizing the connecting and conveying mechanism, so that automatic conveying of the corrugated boards is realized.

Owner:姜玲华

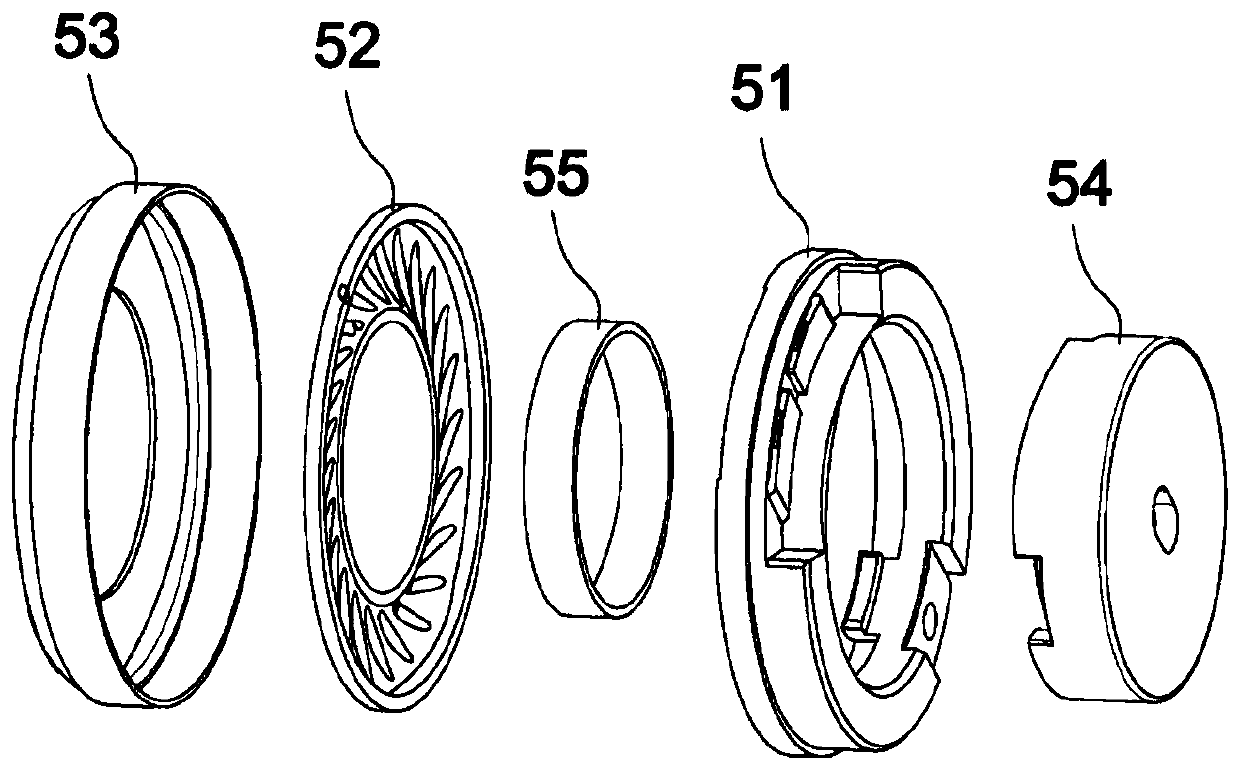

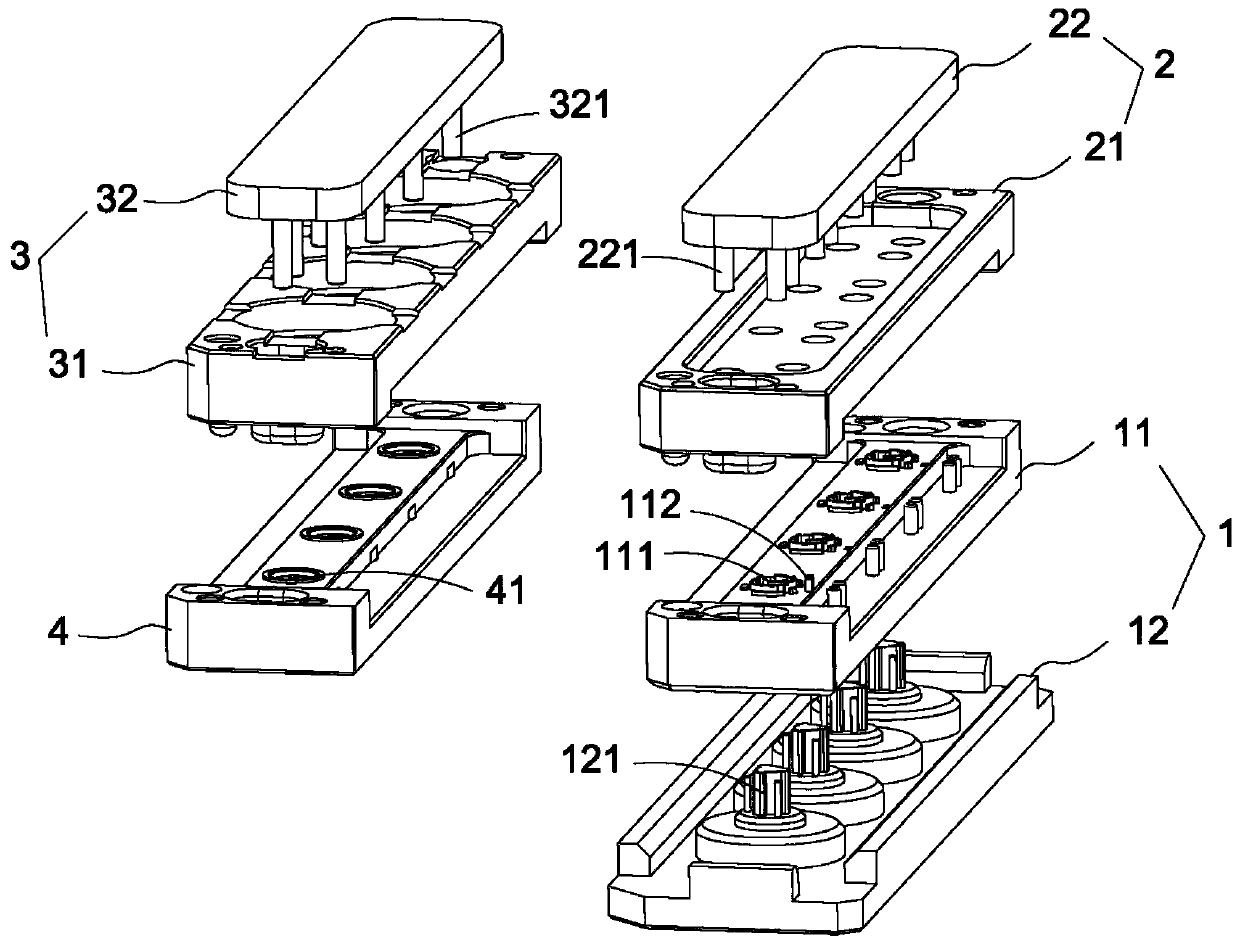

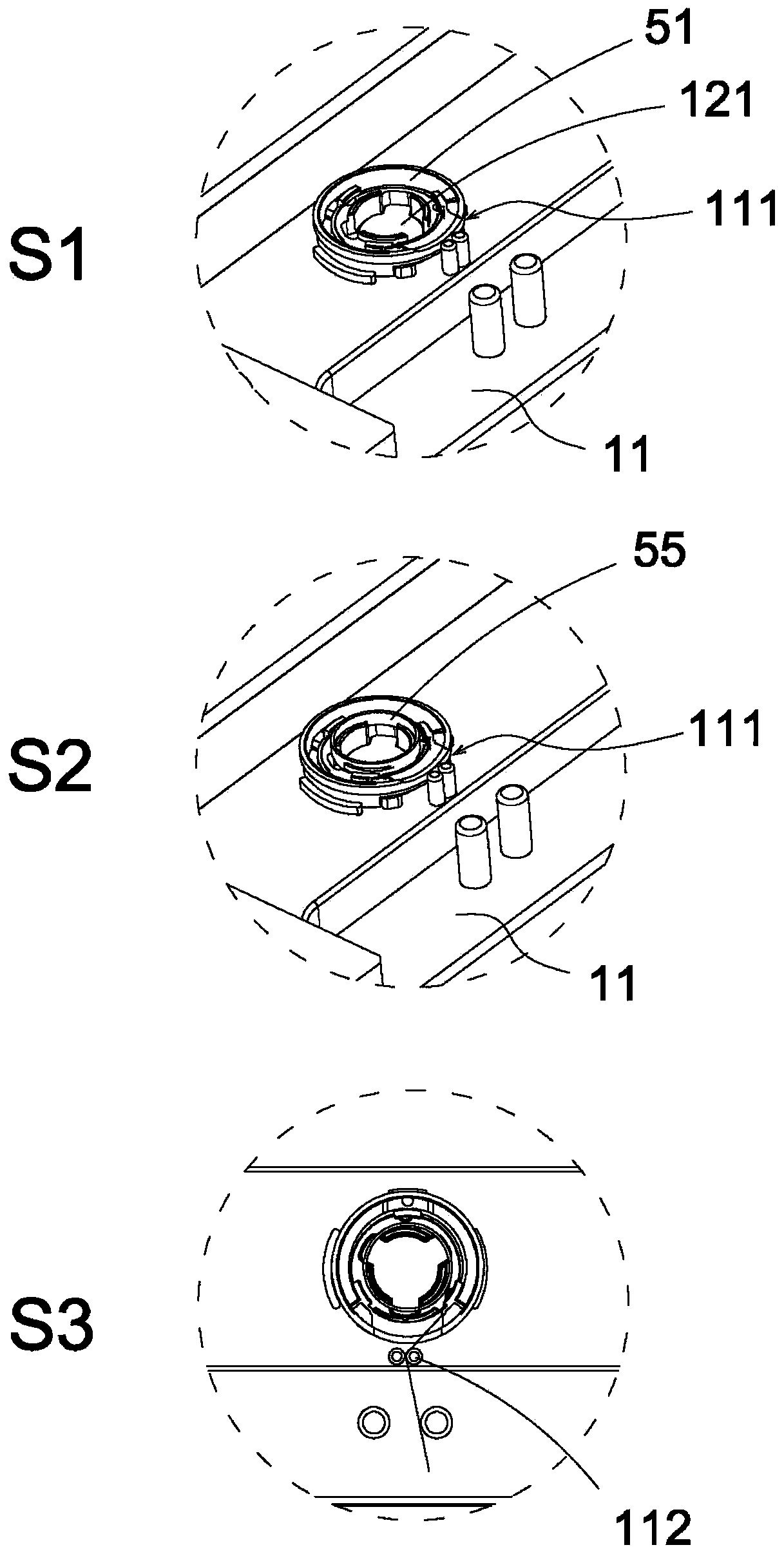

Horn processing jig and processing method thereof

PendingCN111131996ANo frequent replacementRealize production and processingElectrical transducersEngineeringVoice coil

The invention provides a horn processing jig and a processing method thereof. The jig comprises a main assembly module, a diaphragm assembly module, a front cover assembly module and a magnetic circuit carrier plate; a bracket groove and a bracket top strip are arranged in the main assembly module; a diaphragm groove and a diaphragm top strip are arranged in the diaphragm assembling module; a front cover groove and a front cover top strip are arranged in the front cover assembling module; a magnetic circuit groove is formed in the lower end of the magnetic circuit carrier plate, the support groove and the diaphragm groove can be matched to form a first press-fit cavity, the support groove and the front cover groove can be matched to form a second press-fit cavity, and the front cover groove and the magnetic circuit groove can be matched to form a third press-fit cavity. According to the invention, one main assembly module is taken as a core, the bracket and the voice coil are assembledinto the main assembly module, and then other jigs operate around the main assembly module to finish the assembly of the diaphragm, the front cover and the magnetic circuit, so that the assembly linetype production and processing is realized, the processing efficiency is high, the accommodating groove does not need to be frequently replaced, and the assembly precision is improved.

Owner:东莞市富新电子有限公司

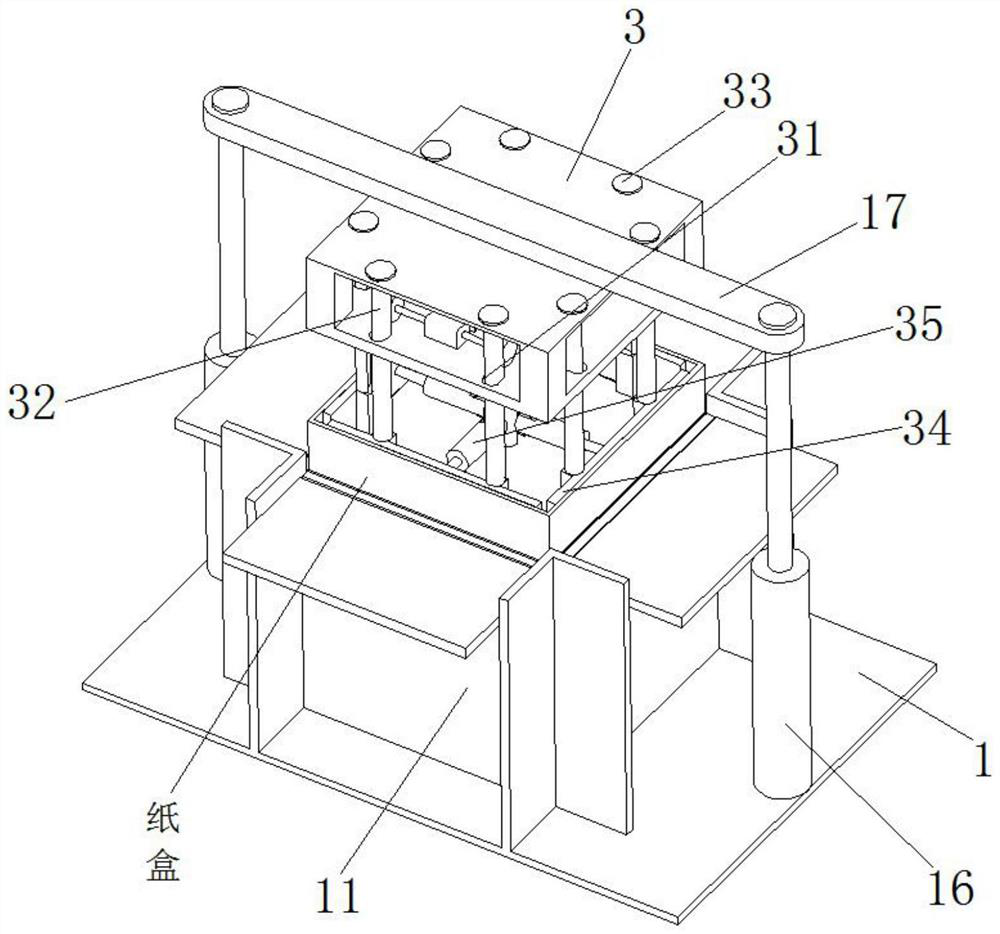

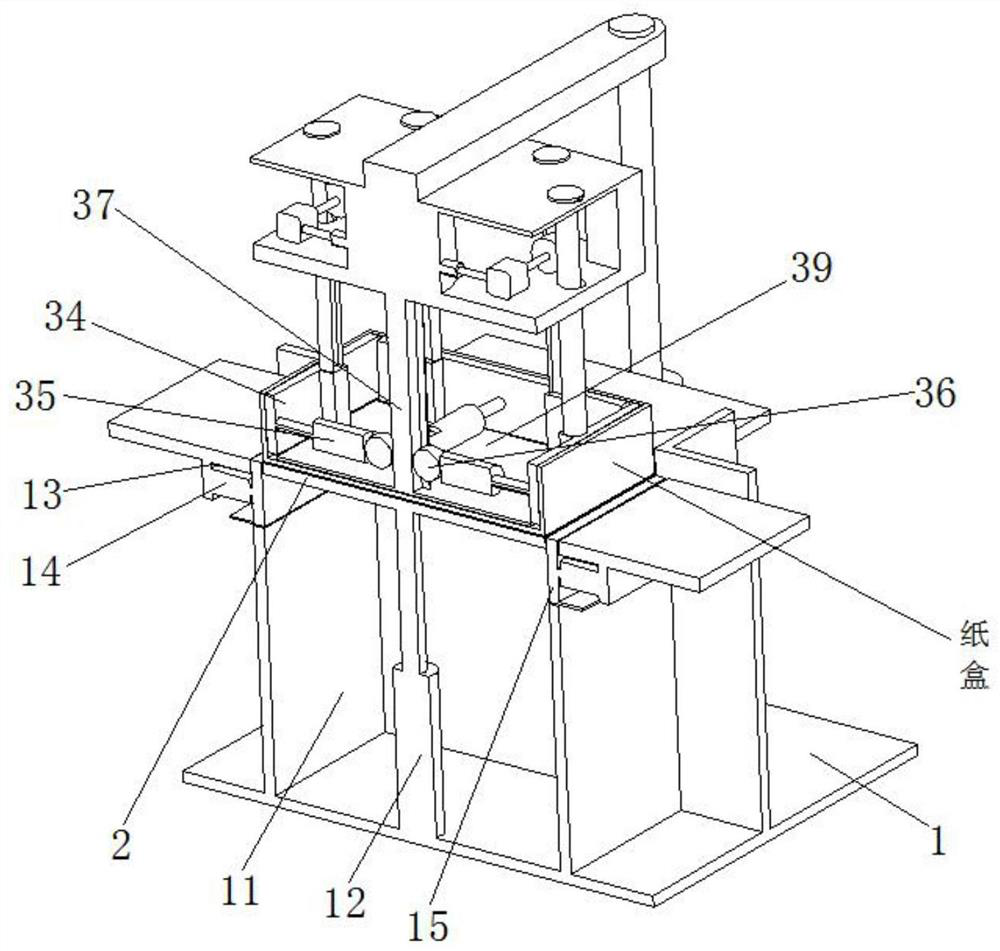

Gift packaging box manufacturing and processing method

InactiveCN112874005AFast and efficient sticky processingImprove processing efficiencyEnvelopes/bags making machineryBox making operationsStructural engineeringManufacturing engineering

The invention relates to the field of paper product packaging, in particular to a gift packaging box manufacturing and processing method. A packaging box manufacturing device is used in the method, and the packaging box manufacturing device comprises a base, a supporting plate and a lifting frame. A shaping groove of a rectangular structure is fixedly formed in the base, a first spring rod is fixedly installed in the shaping groove, and the supporting plate is of a rectangular structure. The supporting plate is fixedly installed on the first spring rod and corresponds to the shaping groove, grooves are symmetrically formed in the inner wall of the shaping groove, first air cylinders are fixedly installed in the grooves, push plates are fixedly installed at the output ends of the first air cylinders, and the sides, away from the first air cylinders, of the push plates are flush with the inner wall of the shaping groove. Second air cylinders are symmetrically and fixedly installed on the base, a connecting rod is fixedly installed between the output ends of the second air cylinders, and the lifting frame is fixedly installed on the connecting rod. According to the method, gift packaging boxes can be bonded quickly and efficiently and the method is suitable for popularization.

Owner:徐遍红

A foaming extrusion die suitable for thick pvc wood-plastic molding

The invention relates to a PVC (polyvinyl chloride) wood-plastic material processing mould, and discloses a moulding and foaming extrusion mould applicable to a thick and solid PVC wood-plastic material. The moulding and foaming extrusion mould comprises a cooling plate, a mould plate, a converging plate, a mould core bracket plate I, a mould core bracket plate II and a mould body which are sequentially overlapped into a mould head, wherein a mould cavity is formed in the mould head; the mould cavity at the mould plate is a stabilizing section; the mould cavity at the converging plate is a compressing section; the mould cavity at the mould core bracket plate I, the mould core bracket plate II and the mould body is a feeding and diverting section; the moulding and foaming extrusion mould is characterized in that an upper row of core rods, a middle row of core rods and a lower row of core rods are distributed inside the mould cavity to form four circulating layers; the upper row of core rods and the lower row of core rods are connected with the mould core bracket plate I in a positioning way through left and right supporting legs and upper and lower supporting legs respectively; the middle row of core rods are connected with the mould core bracket plate II in a positioning way through the left and right supporting legs. The moulding and foaming extrusion mould can produce the solid PVC wood-plastic foamed material with the thickness greater than 20 mm; products produced by the moulding and foaming extrusion mould are uniform and dense in texture, so that bending resistance, compression resistance, tensile resistance and other performance indexes are greatly improved.

Owner:HUANGSHI JINHONG MOLD

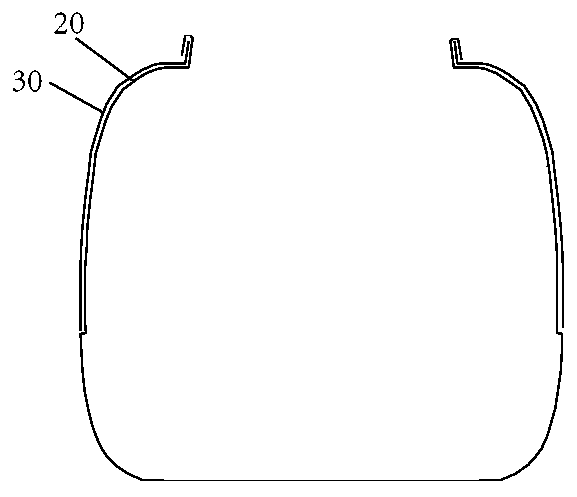

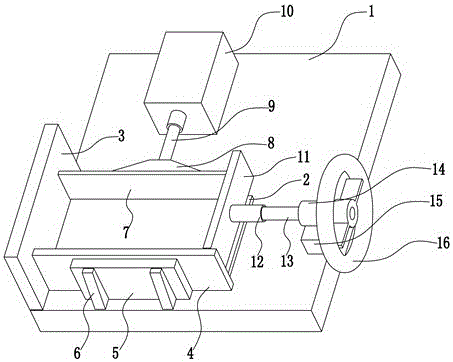

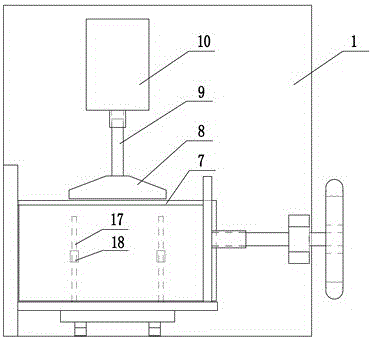

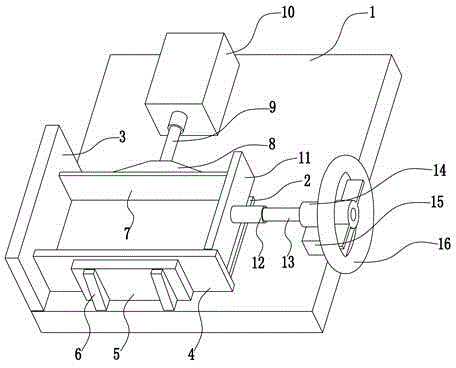

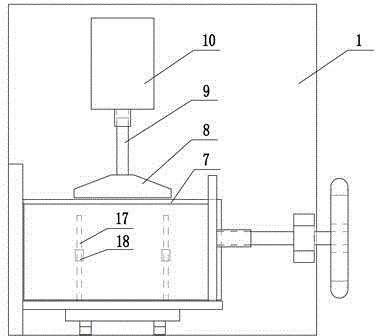

Silica gel injection molding device for breast paste production

PendingCN113580511AImprove stabilityRealize production and processingDomestic articlesEngineeringSilica gel

The invention discloses a silica gel injection molding device for breast paste production, and relates to the technical field of production and processing. The device comprises a bottom plate, a fixing block located on the upper surface of the bottom plate and a plurality of reinforcing ribs on one side of the fixing block, the plurality of reinforcing ribs are symmetrically distributed, one side of the fixing block is movably connected with a male mold, convex blocks are arranged on the two sides of the male mold, injection molding holes are formed in the inner sides of the convex blocks, a connecting block is fixedly connected to one side of the male mold, and reverse double-thread screw rods are movably connected to the interior of the connecting block. According to the device, the fixing block can be fixed and limited through the plurality of reinforcing ribs, the male mold can be limited through the fixing block, and the device can be connected with a feeding pipeline through a feeding hole, so that materials can flow on one sides of the plurality of convex blocks through the injection molding hole; the connecting block on one side of the male mold can be connected with the reverse double-thread screw rods and limit the reverse double-thread screw rods; and the reverse double-thread screw rods can be limited again through the fixing plate.

Owner:浙江维力华生物科技有限公司

Composite floor slab construction assembly

PendingCN114434611AReduce the chance of skewImprove verticalityDischarging arrangementMouldsFloor slabArchitectural engineering

The invention relates to the field of composite floor slabs, in particular to a composite floor slab construction assembly which comprises a base plate, supporting legs, a [-shaped frame, a forming mechanism and a demolding mechanism. The problems that in the traditional composite floor slab prefabricating construction operation process, prefabricating requirements of composite floor slabs of various different perimeter sizes cannot be met easily, manufacturing and machining of the composite floor slabs with complex section forms cannot be achieved easily, and in the prefabricating construction process, clamping and positioning of steel reinforcement frameworks in the composite floor slabs cannot be achieved easily are solved. The possibility that the steel reinforcement framework vibrates and deflects due to impact in the follow-up concrete pouring process is increased, the overall structural strength of the composite floor slab is reduced, concrete in all areas is difficult to dry quickly after pouring is completed, the overall solidification time of the concrete of the composite floor slab is prolonged, and the construction period of the composite floor slab is shortened. And the periphery of the composite floor slab is difficult to demould quickly after the prefabrication of the composite floor slab is completed.

Owner:ZHEJIANG YIJIAN CONSTR GROUP

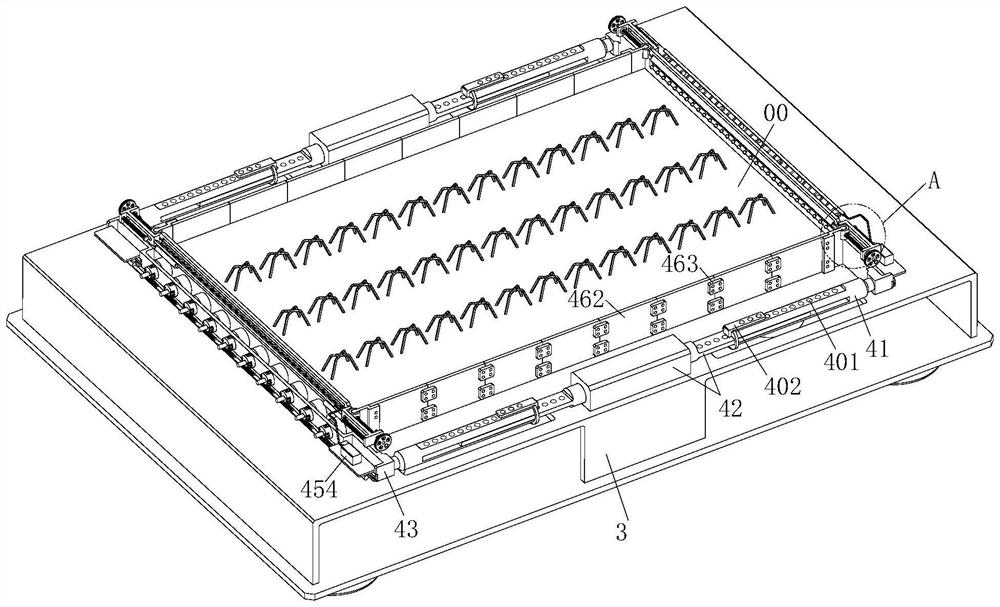

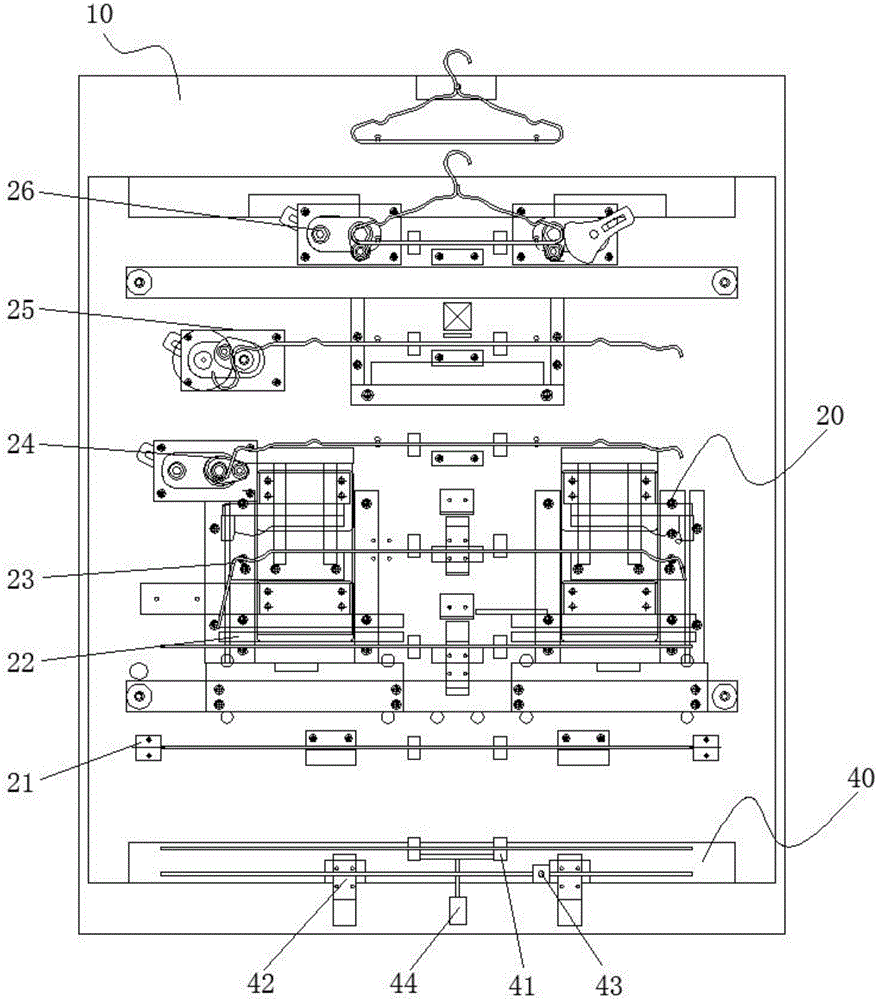

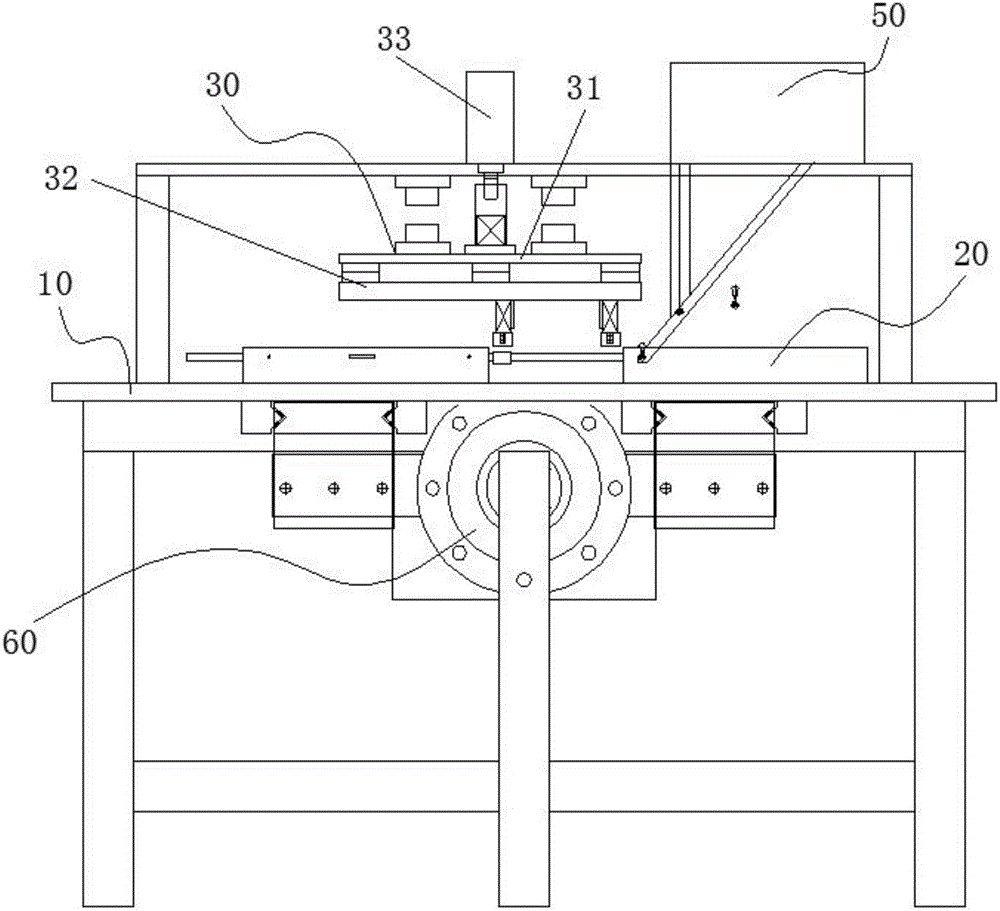

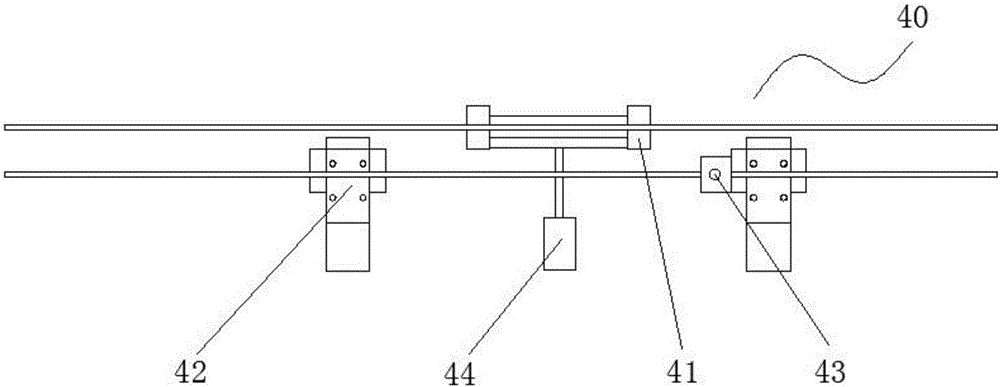

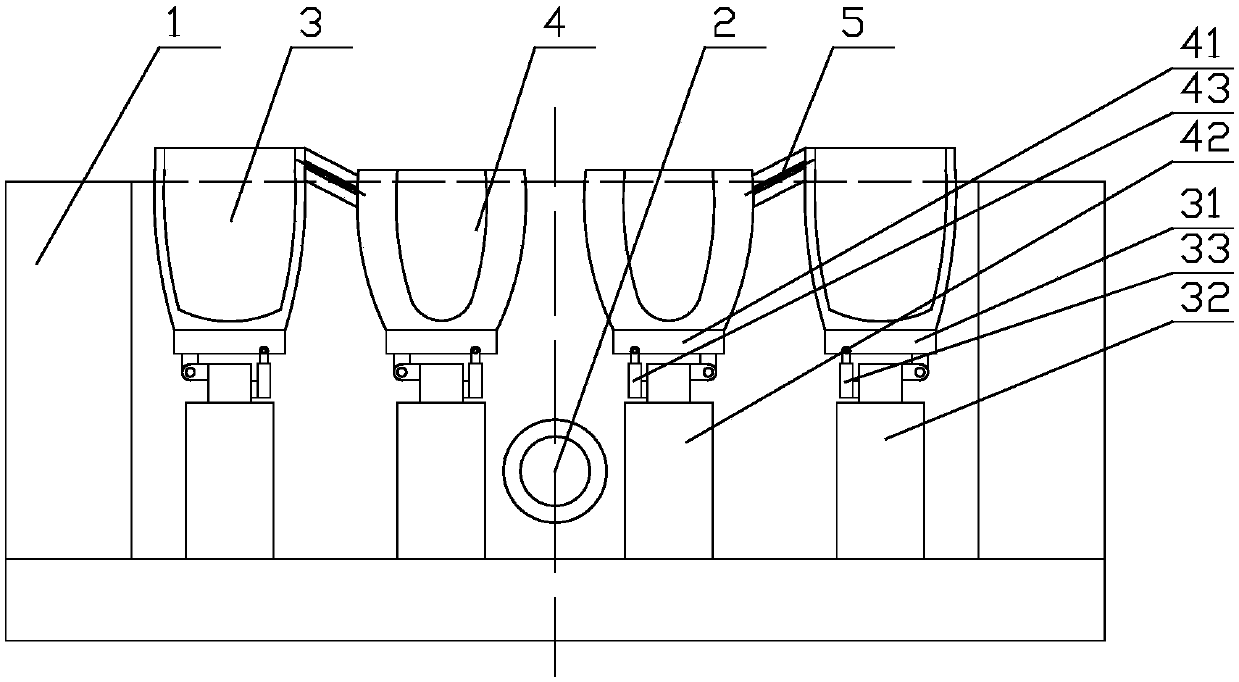

Automatic clothes hanger bending forming machine

ActiveCN106040926AIncrease the level of automationIncrease productivityWire articlesMetal working apparatusEngineeringWork in process

The invention discloses an automatic clothes hanger bending forming machine. The machine comprises a plane worktable, a feeding mechanism, a bending forming mechanism and a conveying mechanism; the feeding mechanism and the bending forming mechanism are arranged on the plane worktable in parallel; the conveying mechanism is positioned above the bending forming mechanism; the feeding mechanism is used for feeding the conveying mechanism; the conveying mechanism is used for conveying raw materials or semi-finished clothes hangers to the bending forming mechanism; the bending forming mechanism is used for bending the raw materials as the clothes hangers; the bending forming mechanism includes a pressing unit, a hanging hook forming unit and a bending unit; and the pressing unit, the hanging hook forming unit and the bending unit are arranged on the plane worktable in parallel, and are respectively used for foundation pressing, hanging hook bending and bending formation. The automatic clothes hanger bending forming machine realizes integral clothes hanger production, is high in automation level, and obviously improves the production efficiency.

Owner:台山市万力达金属制品科技有限公司

Zinc oxide melting gasification device

InactiveCN109704393AImprove processing efficiencyReduce energy consumptionZinc oxides/hydroxidesProduction lineCrucible

The invention discloses a zinc oxide melting gasification device, relates to the field of production of zinc oxide, and particularly relates to an improvement of a molten gasification device in a zincoxide production line. The molten gasification device in the zinc oxide production line is simple in structure, convenient to use, low in energy consumption, and comprises a heating tank, a heat source pipeline, a plurality of melting crucibles and a plurality of gasification crucibles; and the heat source pipeline is connected to the bottom of the heating tank, and the plurality of gasificationcrucibles are symmetrically distributed on the two sides of the heat source pipeline; and the melting crucibles are arranged on one sides, far away from the heat source pipeline, of the gasification crucibles, and the top edges of the melting crucibles are higher than the top edges of the gasification crucibles; and a flow channel is formed between the top edges of the melting crucibles and the top edges of the gasification crucibles. According to the invention, large-batch production and processing can be realized, the processing efficiency is high, and the energy consumption is low.

Owner:YANGZHOU ZHENZHONG ZINE PROD

An evaporator production device

The invention discloses an evaporator production device which comprises a working platform, a moving seat, a transverse extrusion assembly and a longitudinal extrusion assembly, wherein a guide rail is arranged on the working platform; a chute is embedded into the guide rail; the chute is embedded into the guide rail and can freely slide along the guide rail; the moving seat is fixed on the chute and longitudinally moves along with the chute; an evaporator core which is to be subjected to extrusion forming is arranged on the moving seat; the transverse extrusion assembly is arranged on the right side of the moving seat; the longitudinal extrusion assembly is arranged on the rear side of the moving seat; and the transverse extrusion assembly and the longitudinal extrusion assembly respectively move along the transverse direction and the longitudinal direction, so that the evaporator core is subjected to extrusion forming. The evaporator production device disclosed by the invention is simple in structure, convenient and rapid to use and detach, high in replaceability of parts and wide in applicability.

Owner:ZHEJIANG KHCCAC AUTOMOBILE AIR CONDITION CO LTD

Production system of high-strength precast concrete component

ActiveCN112297212APrevent tamperingImprove stabilityDischarging arrangementCeramic shaping plantsHigh strength concreteMolding machine

The invention provides a production system of a high-strength precast concrete component, and belongs to the technical field of precast concrete component processing. The production system comprises aconcrete slurry supply device and a precast component forming and discharging device, a slurry supply screw of the concrete slurry supply device is rotatably arranged on a slurry supply nozzle and aslurry supply screw supporting cover, the lower end of a hopper is communicated with a slurry supply pipe, the precast component forming and discharging device comprises a movable forming support, a movable forming mechanism, a fixed forming mechanism, an upper forming and discharging mechanism and a lower forming and discharging mechanism, the movable forming support is arranged on a rack supporting column in a left-right sliding mode through a movable forming support sliding sleeve, a lead screw is connected with a lead screw nut sleeve lead screw, and the right end of the lead screw is connected with the movable forming support through a lead screw connecting sleeve and a lead screw connecting sleeve locking nut. The production system can rapidly achieve production and machining of notch-type high-strength precast concrete components, is reasonable in structure and high in automation degree, and greatly improves the production efficiency of the notch-type high-strength precast concrete components.

Owner:桐乡市钟大建材有限公司

A poppet valve linkage driving device

ActiveCN111946886BOpen quicklyQuick closeOperating means/releasing devices for valvesSynchronous controlControl system

Owner:东营市美扬石油管件有限公司

Three-dimensional molding system and method for flexible materials

ActiveCN104149338BEasy to printRealize production and processingAdditive manufacturing apparatusAdditive manufacturing with liquidsFiberPolymer science

Owner:INVENTECSHANGHAI TECH +2

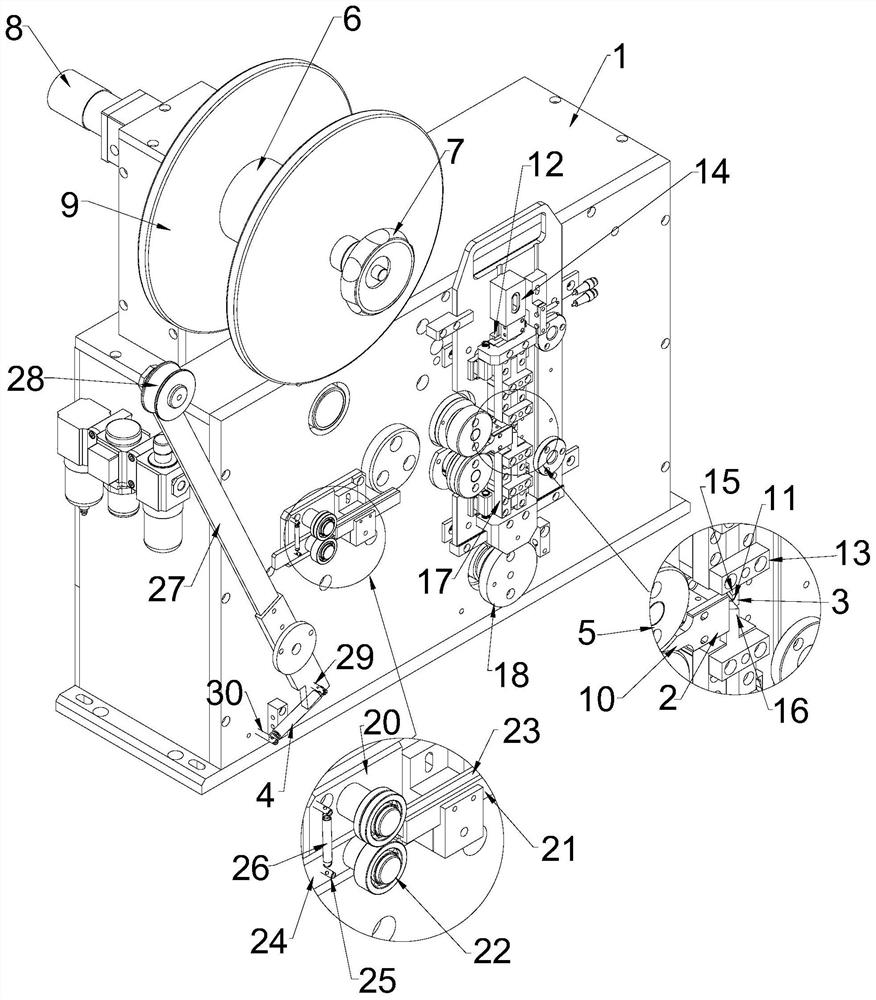

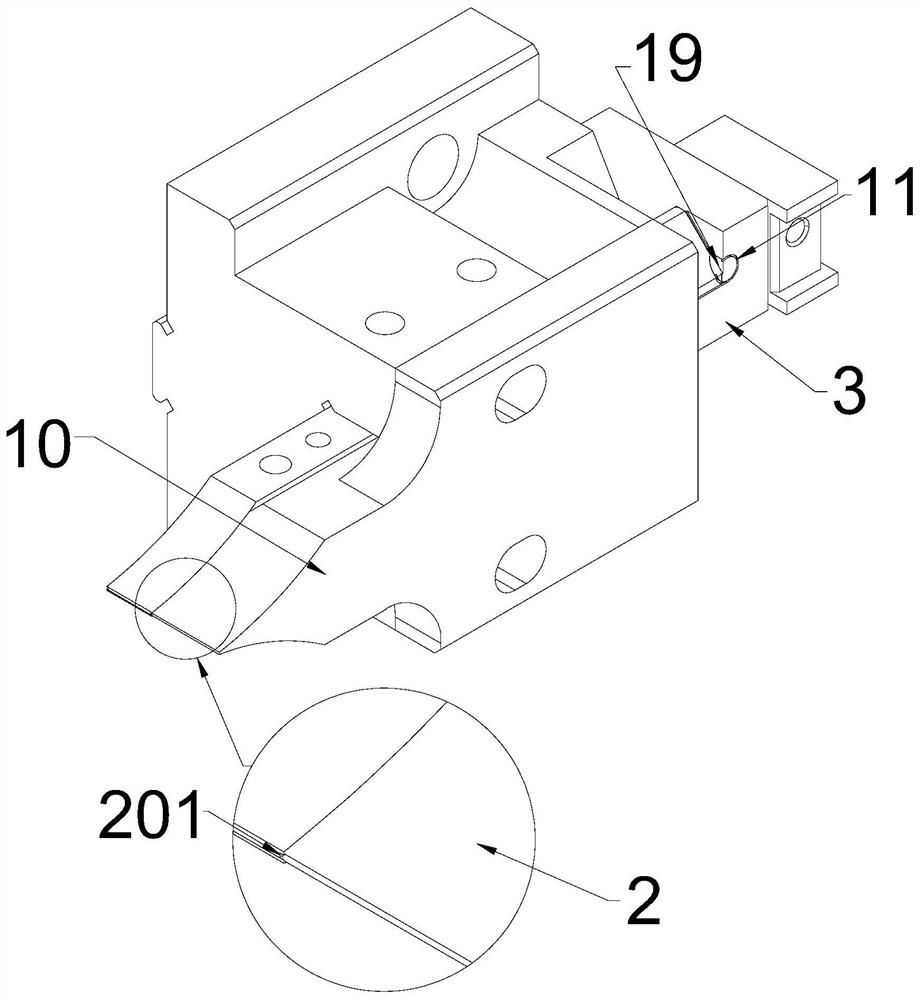

Spring machine

PendingCN112024792ARealize production and processingAvoid hard straighteningWire springsMetal working apparatusElectric machineryEngineering

The invention discloses a spring machine which comprises a machine base. A feeding mechanism, a feeding mechanism and a forming and cutting mechanism are arranged on the machine base, the feeding mechanism is located on one side of the forming and cutting mechanism, an equal-diameter mechanism is further arranged on the machine base, and the equal-diameter mechanism is located between the feedingmechanism and the forming and cutting mechanism. The feeding mechanism comprises a pair of feeding rollers driven by a feeding motor, a certain distance is reserved between the two feeding rollers toform a steel wire feeding channel, the equal-diameter mechanism comprises a forming die and a forming pressing plate, a feeding pressing nozzle is arranged at one end of the forming die, and the end of the feeding pressing nozzle is located in the steel wire feeding channel. A steel wire passing hole is formed in the forming die in the length direction, a spring forming rail is arranged on the forming pressing plate, and the two ends of the steel wire passing hole communicate with the interior of the steel wire feeding channel and the spring forming rail respectively. The structure is simple,and production and machining of high-precision micro springs can be achieved.

Owner:SUZHOU PROTEC AUTO-CONTROL TECH CO LTD

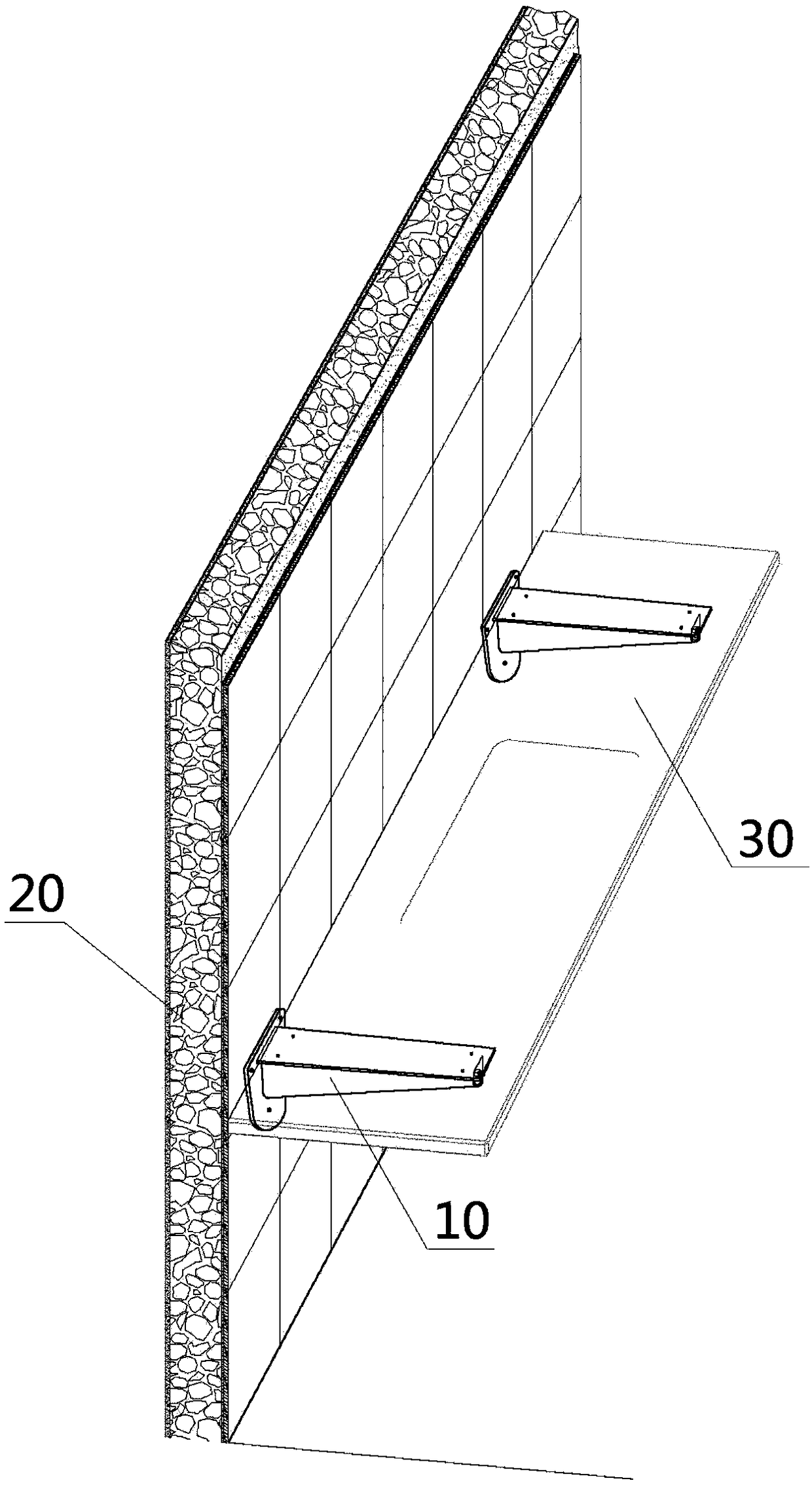

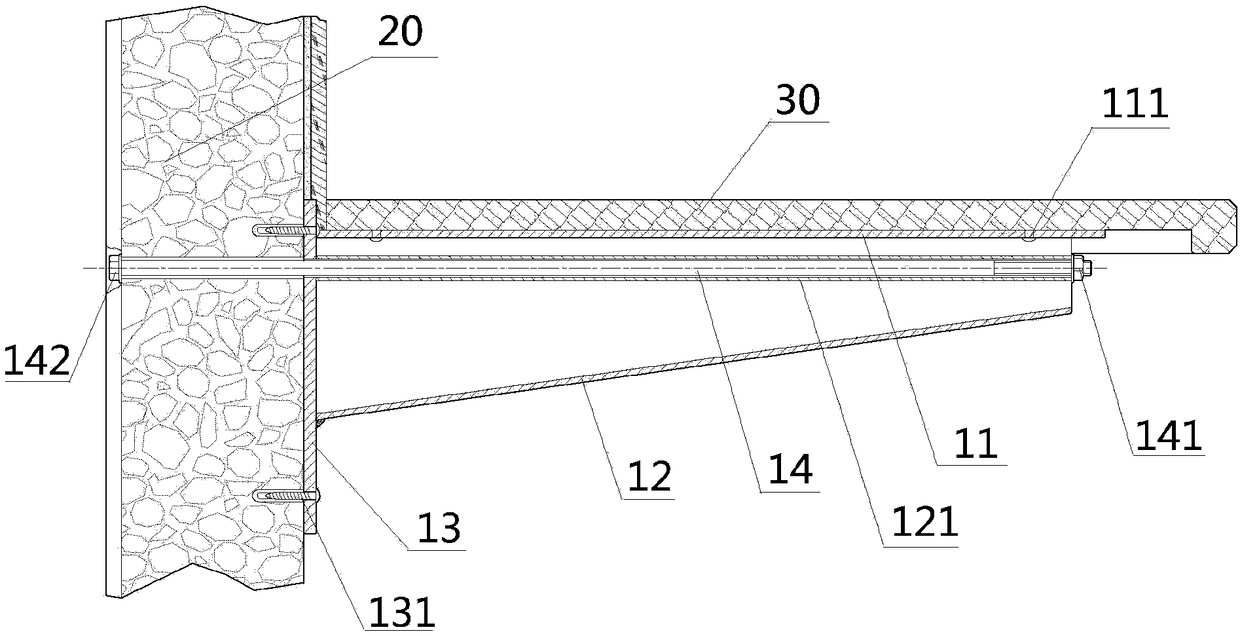

Movably-mounted wash basin bracket and mounting method thereof

InactiveCN108179790ARealize production and processingAchieve double fixationDomestic plumbingSurface mountingStructural engineering

The invention relates to the field of decoration, in particular to a movably-mounted wash basin bracket and a mounting method thereof. At least two wash basin bracket units are mounted on a wall belowa wash basin surface; each wash basin bracket unit is a triangular framework consisting of a wash basin surface fixing plate, a bracket supporting plate, a wall surface mounting plate and a wall bolt; the wash basin surface fixing plate is vertical to the wall surface mounting plate; the bracket supporting plate is connected with the wash basin surface fixing plate and the wall surface mounting plate in an inclined way; each wash basin bracket unit is mounted on the wall through the wall surface mounting plate; the wash basin surface is mounted on the wash basin surface fixing plate; the bracket supporting plate is a long slot-shaped plate with a U-shaped section; a sleeve is longitudinally arranged inside a long slot of the bracket supporting plate; the wall bolt is inserted into the sleeve; one end of the wall bolt is fixed to the end part of the bracket supporting plate; the other end of the wall bolt runs through the wall surface mounting plate and the wall and is positioned on the back surface of the wall. According to the technical scheme adopted by the invention, standard part production of the wash basin bracket unit can be achieved, the efficiency is improved, the cost isreduced, and the wash basin bracket unit achieves dual fixing and good firmness; in addition, the movably-mounted wash basin bracket is simple in structure and convenient to mount.

Owner:SHANGHAI JUTONG DECORATION GRP

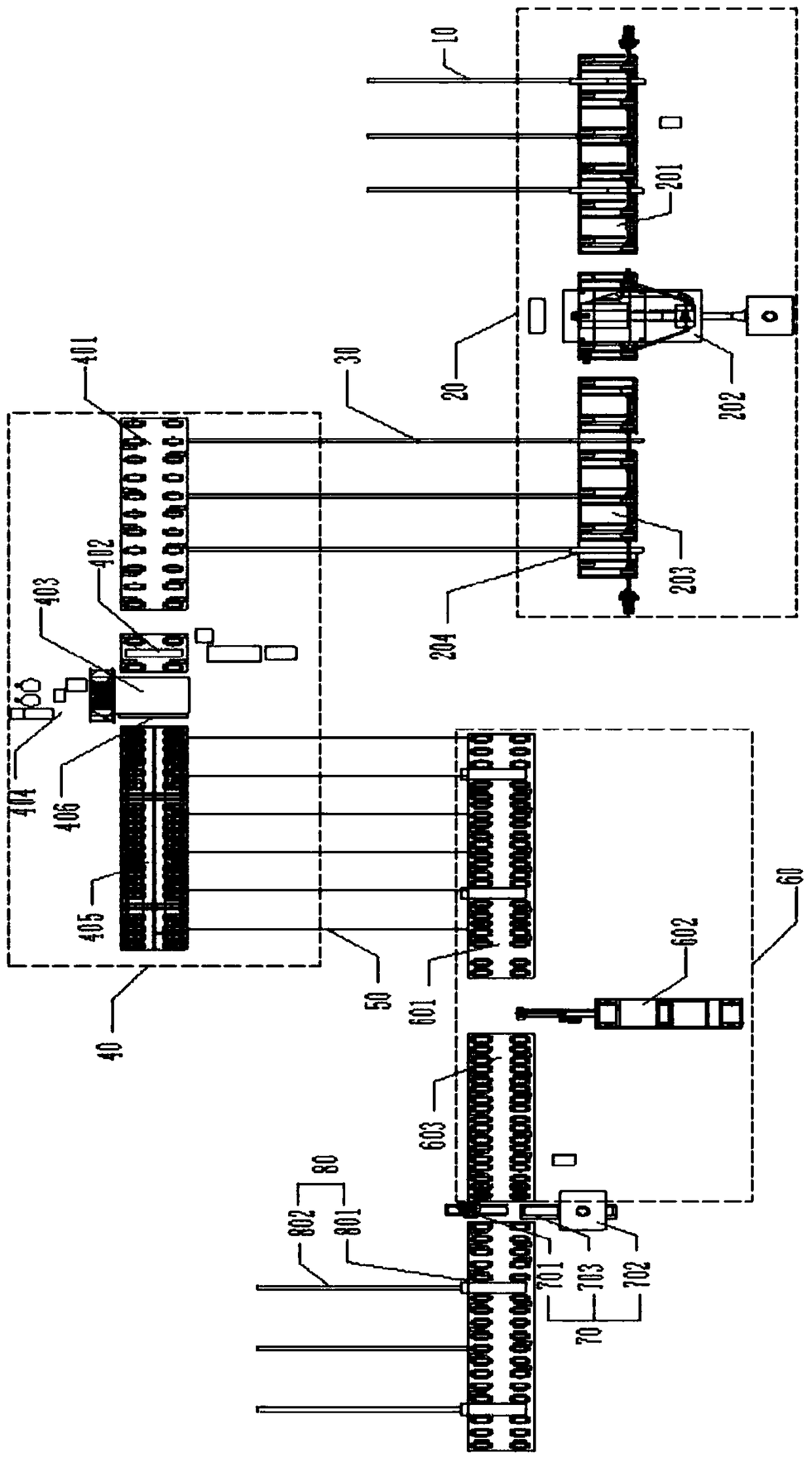

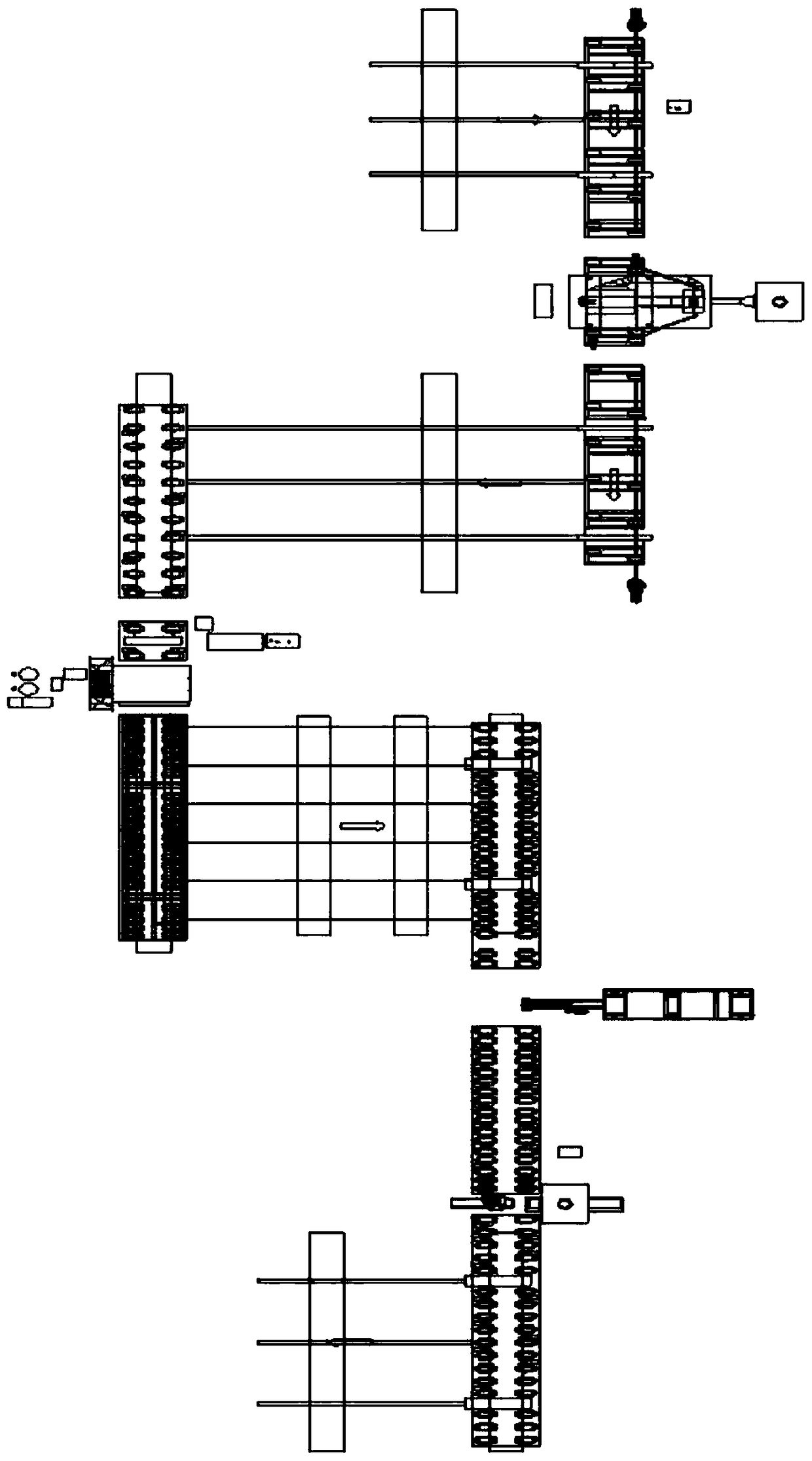

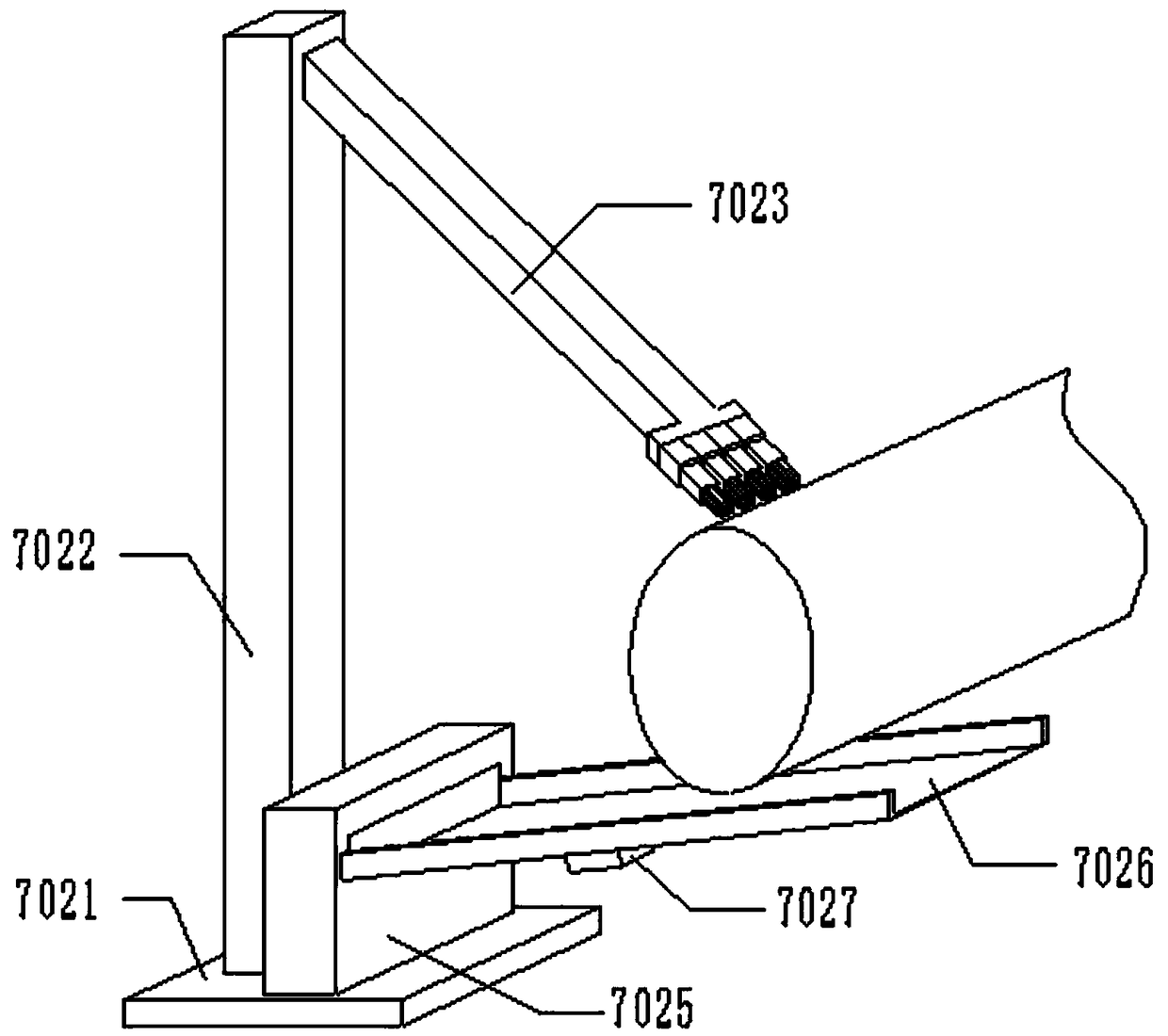

Indoor skid-mounted type polyurethane spraying polyethylene winding thermal-insulation tube production line

PendingCN108943781ACompact layoutReduce space occupationTubular articlesSteel tubeThermal insulation

The invention provides an indoor skid-mounted type polyurethane spraying polyethylene winding thermal-insulation tube production line. The indoor skid-mounted type polyurethane spraying polyethylene winding thermal-insulation tube production line comprises a tube loading platform I, a steel tube rust-removal part, a tube loading platform II, a polyurethane spraying part, a tube loading platform III, a polyurethane winding part, a cutting part and a finished product storage part, wherein the output end of the tube loading platform I is connected with the input end of the steel tube rust-removalpart; the output end of the steel tube rust-removal part is connected with the input end of the polyurethane spraying part through the tube loading platform II; the output end of the polyurethane spraying part is connected with the input end of the polyurethane winding part through the tube loading platform III; the cutting part is arranged between the polyurethane winding part and the finished product storage part; and the steel tube rust-removal part, the polyurethane spraying part and the polyurethane winding part are arranged in the form of an inverted U. The production line adopted by the invention is compact in structure, is relatively small in space usage, can meet good cutting treatment of thermal-insulation tubes of different specifications, and is relatively high in applicability.

Owner:奥菲德(天津)管道科技有限公司

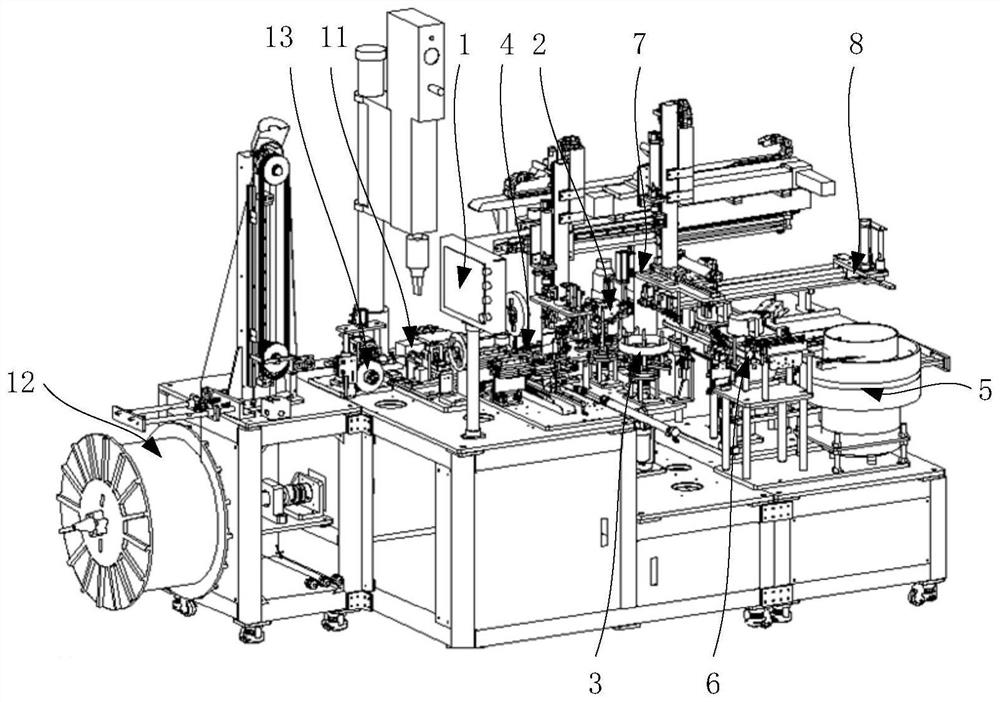

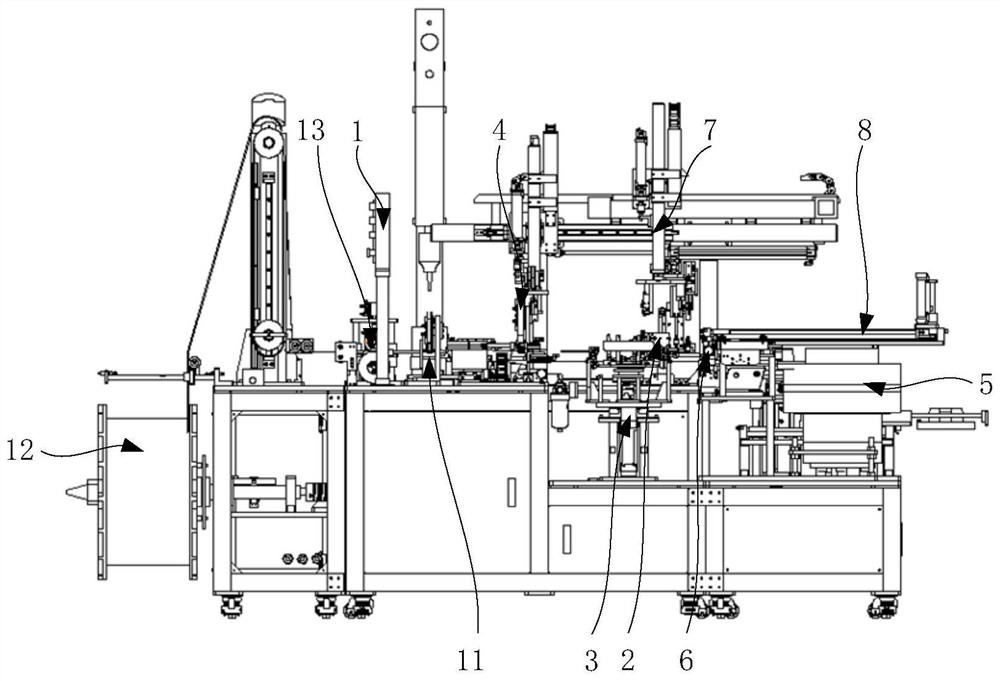

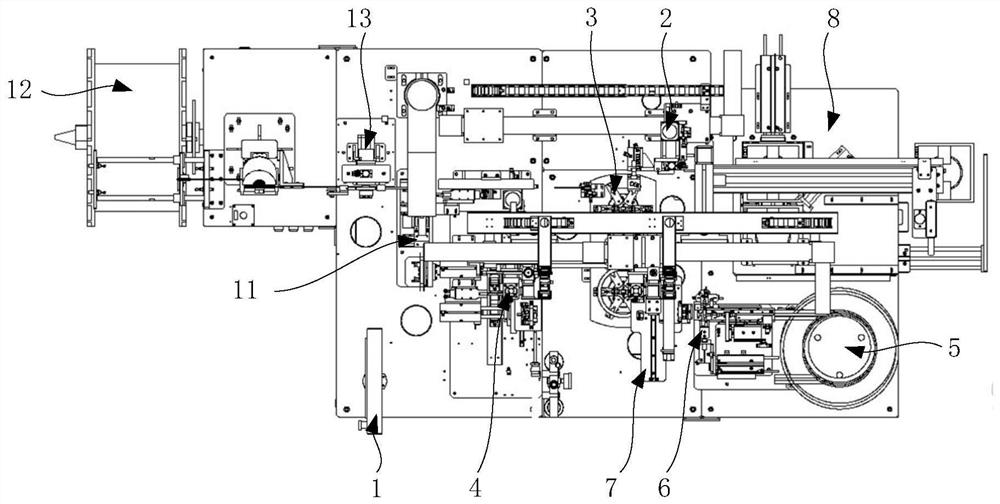

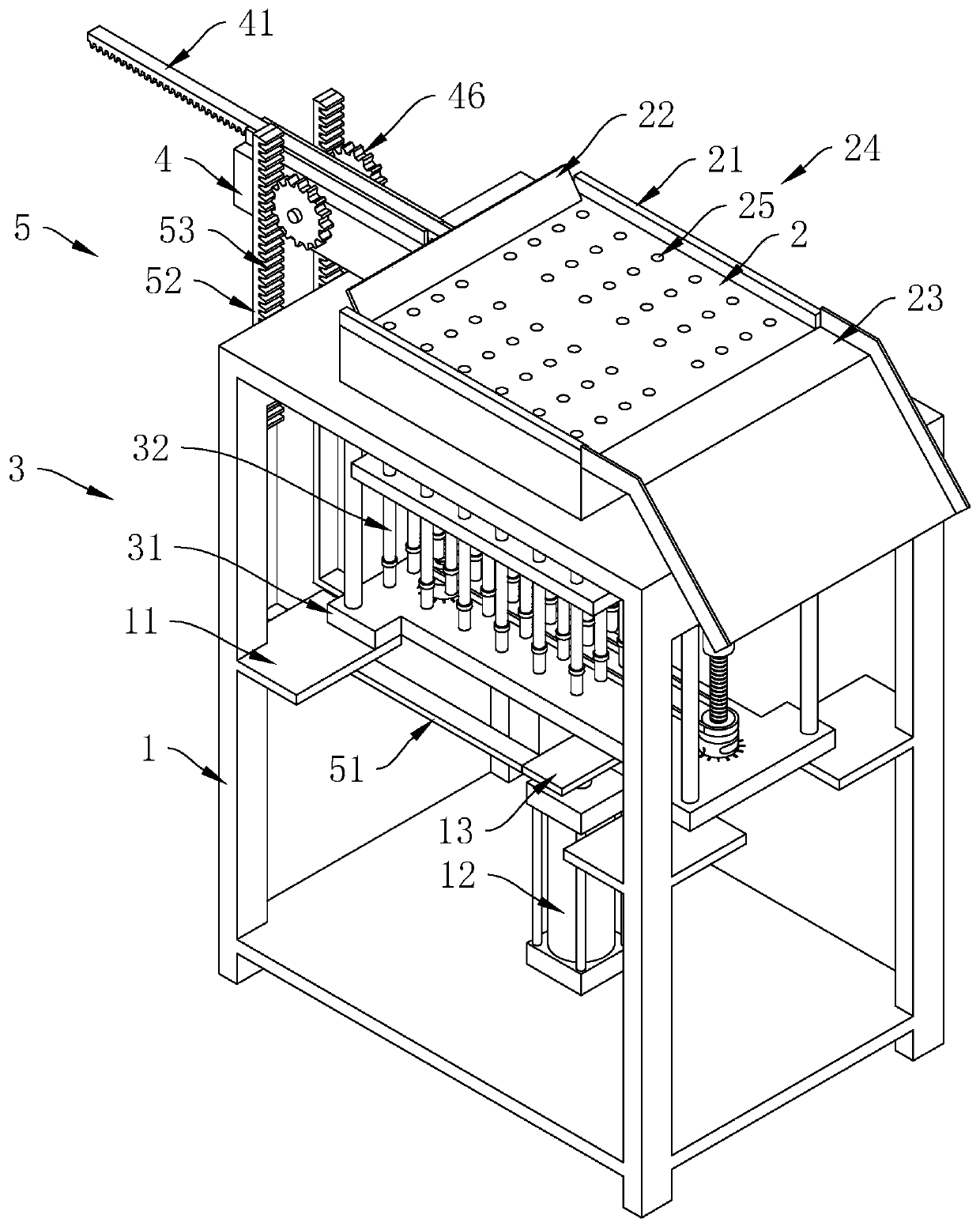

Nonel processing system

ActiveCN111187128BIncrease productivityRealize production and processingDetonatorsFuse detonationProduction lineDetonator

The invention provides a nonel processing system, which relates to the technical field of nonel detonator automatic production line. The nonel processing system provided by the invention includes nonel cutting and pulling devices arranged in sequence along the nonel processing direction, The rubber plug installation device and the mold loading and discharging device; the detonating tube cutting and pulling device is used to pull and cut the detonating tube into a nonel tube bundle; the rubber plug installation device is used to install the rubber plug to the detonating tube bundle; The mold discharge device is used to load the nonel tube bundle into the mold and discharge the material. The nonel processing system provided by the present invention can turn the nonel tubes with a length of several meters into multiple nonel tube bundles, install rubber plugs, mold and discharge the materials, and directly process them into finished products, realizing the systematic production of nonel tubes Processing, avoiding secondary processing, speeding up the production process, and improving the production efficiency of nonel tubes.

Owner:YAHUA GROUP MIANYANG INDAL

Evaporator production device

The invention discloses an evaporator production device which comprises a working platform, a moving seat, a transverse extrusion assembly and a longitudinal extrusion assembly, wherein a guide rail is arranged on the working platform; a chute is embedded into the guide rail; the chute is embedded into the guide rail and can freely slide along the guide rail; the moving seat is fixed on the chute and longitudinally moves along with the chute; an evaporator core which is to be subjected to extrusion forming is arranged on the moving seat; the transverse extrusion assembly is arranged on the right side of the moving seat; the longitudinal extrusion assembly is arranged on the rear side of the moving seat; and the transverse extrusion assembly and the longitudinal extrusion assembly respectively move along the transverse direction and the longitudinal direction, so that the evaporator core is subjected to extrusion forming. The evaporator production device disclosed by the invention is simple in structure, convenient and rapid to use and detach, high in replaceability of parts and wide in applicability.

Owner:ZHEJIANG KHCCAC AUTOMOBILE AIR CONDITION CO LTD

Bonding machine

ActiveCN105923377BImprove versatilityRealize production and processingConveyor partsEngineeringMechanical engineering

The invention relates to a bonding machine. The bonding machine comprises a bonding machine body, a first feeding mechanism used for conveying first to-be-bonded materials and second feeding mechanisms used for conveying second to-be-bonded materials. The first feeding mechanism is connected with the bonding machine body so as to convey the first to-be-bonded materials to the bonding machine body. The second feeding mechanisms are detachably connected with the bonding machine body, one of the multiple second feeding mechanisms can be selected to be connected with the bonding machine body, and therefore the different second to-be-bonded materials can be conveyed to the bonding machine body, and the bonding machine body can bond the first to-be-bonded materials and the second to-be-bonded materials. According to the bonding machine, only one second feeding mechanism needs to be selected from the multiple second feeding mechanisms to be connected with the bonding machine body, the different second to-be-bonded materials and the first to-be-bonded materials can be bonded through the bonding machine body, producing and machining of various products are achieved, and universality of the bonding machine is improved.

Owner:SHENZHEN LIANDE AUTOMATION EQUIP

Wax pencil molding machine

ActiveCN111332047ARealize production and processingIncrease productivityNon-propelling pencilsCleaning using toolsMolding machineWaste material

The invention discloses a wax pencil molding machine, and relates to the field of wax pencil production. The wax pencil molding machine comprises a machine body, a molding die and an ejecting mechanism, wherein stop levers are arranged horizontally on two sides of the molding die; a scraper is arranged at one end of the molding die; a collecting hopper which communicates with an upper end face ofthe molding die is arranged at the other end of the molding die; two ends of the scraper are pressed against an inner side wall of the scraper; a sliding seat is horizontally arranged at one end of the machine body close to the scraper; a slide bar is horizontally connected to the sliding seat in a sliding way; one end close to the scraper of the slide bar is fixed to an outer side wall of the scraper; the molding die is provided with two groups of die cavities; the two groups of die cavities are distributed on two sides of the slide bar; and the ejecting mechanism is provided with a driving mechanism for driving the slide bar to slide in a reciprocating way. The wax pencil molding machine has the advantages and effects that automatic cleaning and collection of waste on the molding die arerealized through the arrangement of the highly automated scraper; the labor intensity of workers is lowered; the production efficiency of wax pencils is improved; and meanwhile the effect of clean production is achieved.

Owner:台州市美琪乐工艺品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com