Corrugated carton production line

A corrugated box and production line technology, applied in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems of reducing labor intensity and poor connection ability of workers, and achieve the effect of reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following description is used to disclose the present invention so that those skilled in the art can implement the present invention. The preferred embodiments in the following description are only examples, and those skilled in the art can think of other obvious variations.

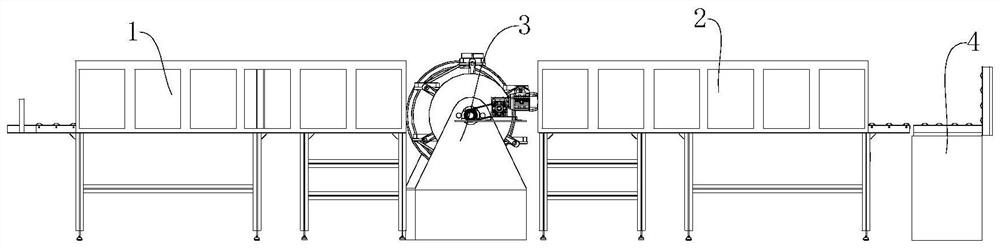

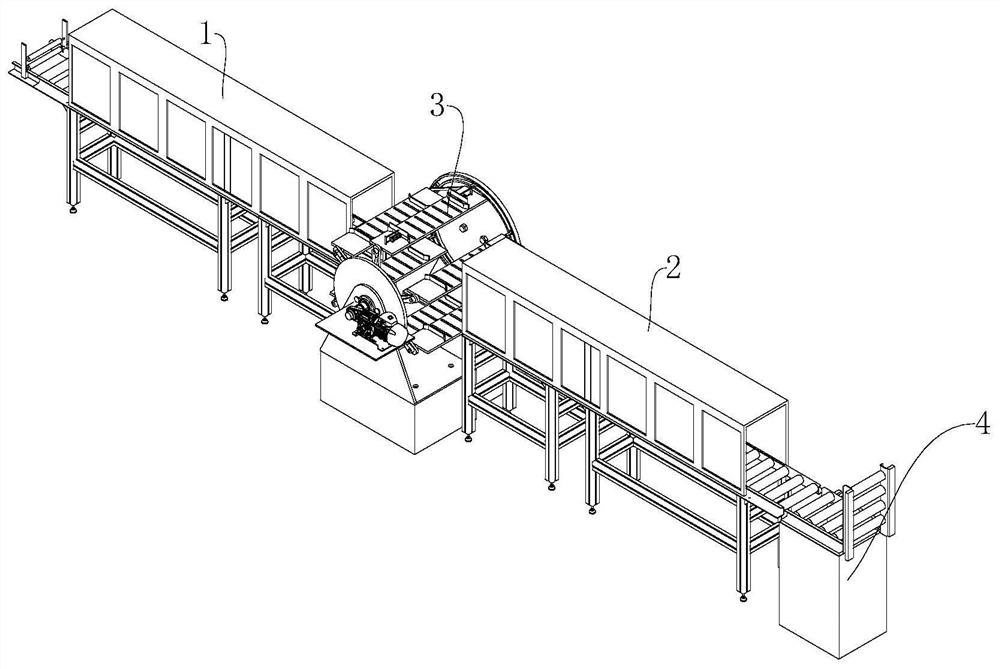

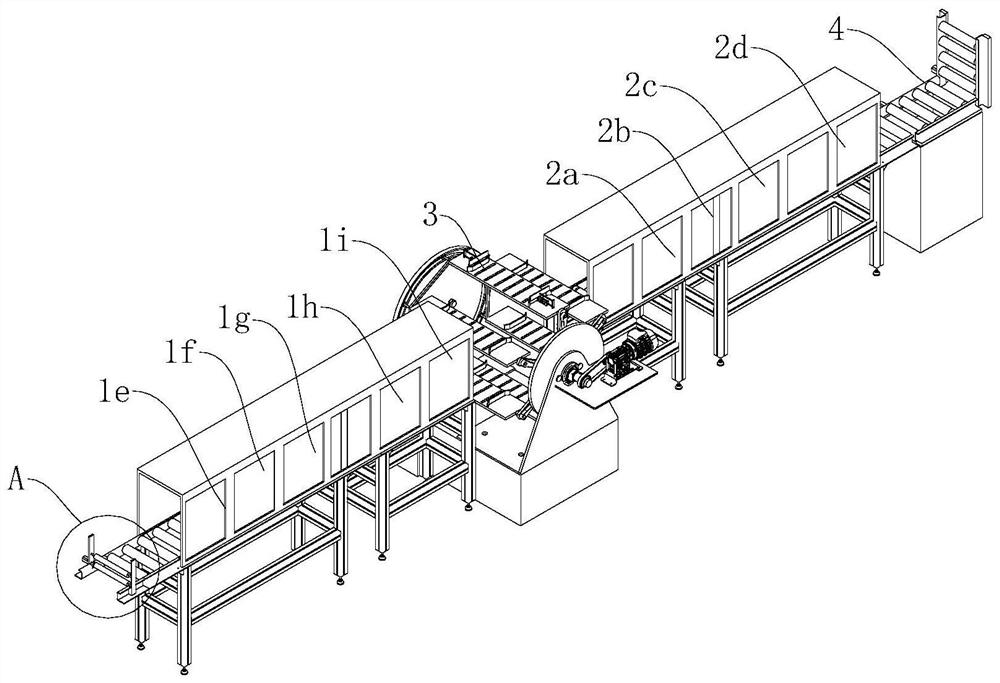

[0041] See figure 1 , figure 2 with image 3 , The corrugated box production line includes:

[0042] The corrugated cardboard production line 1 is used for the production of corrugated cardboard. Specifically, the corrugated cardboard production line 1 includes a preheating zone 1e, a corrugating zone 1f, and a pressing zone 1g, which are sequentially arranged from the input end to the output end of the corrugated cardboard production line 1 In the drying zone 1h and cutting zone 1i, the corrugated cardboard production line 1 is used to preheat, corrugate, press, dry, and cut the base paper (including longitudinal and cross-cutting) to realize the production and processing of corrugated cardboard;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com