Patents

Literature

195results about How to "Realize fully automatic processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

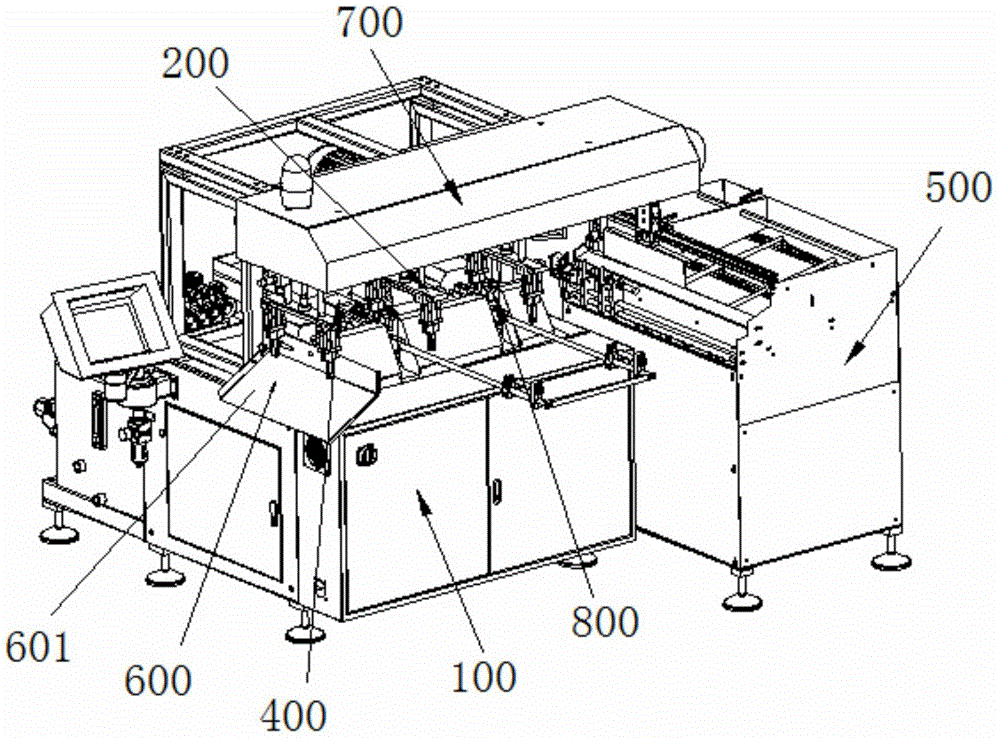

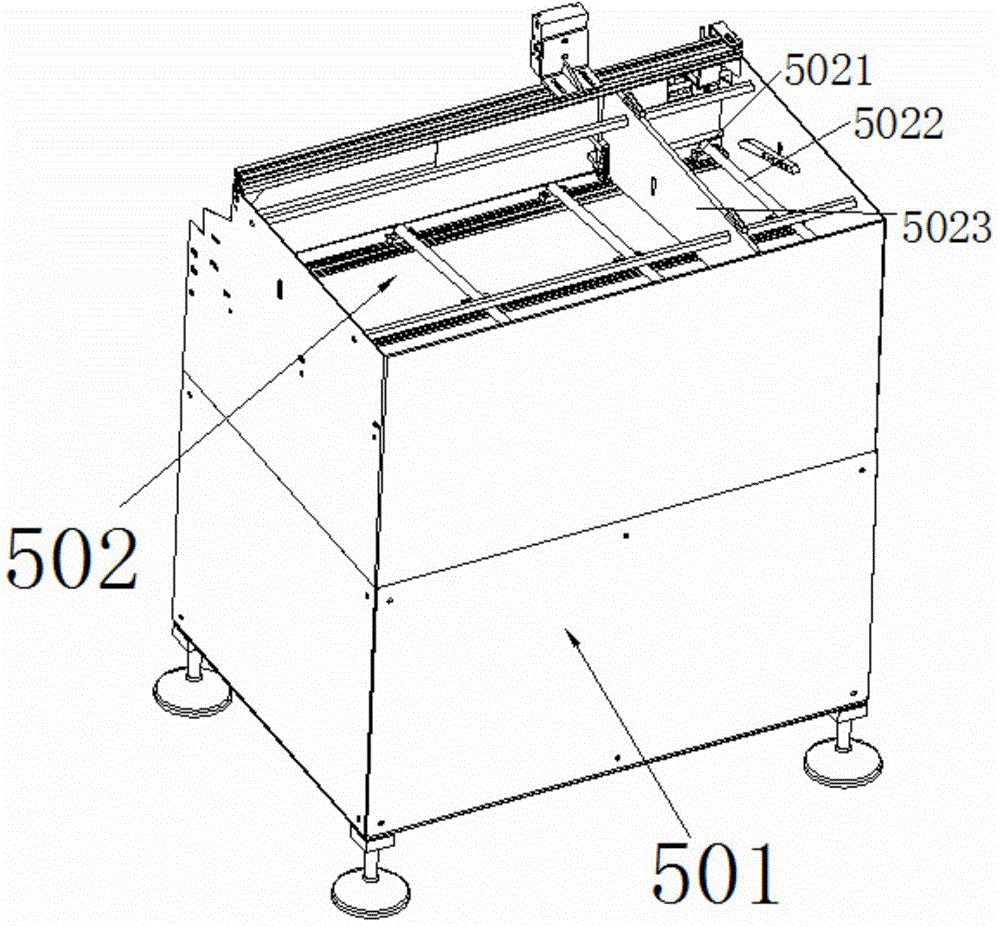

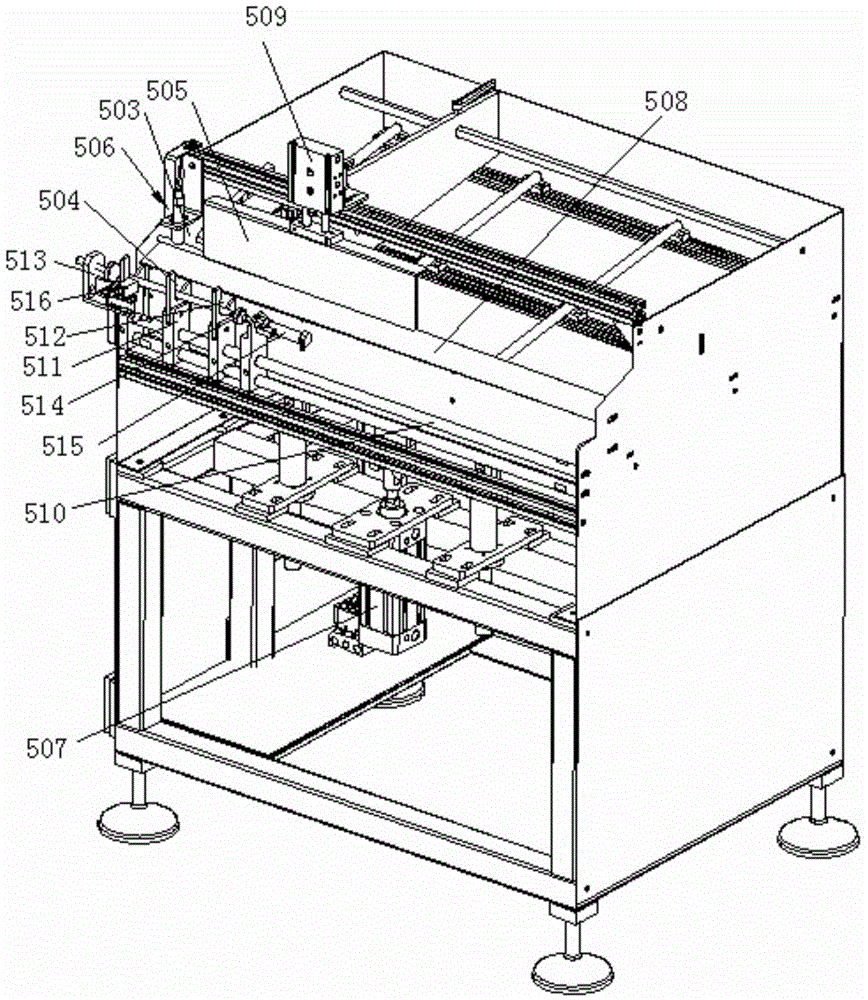

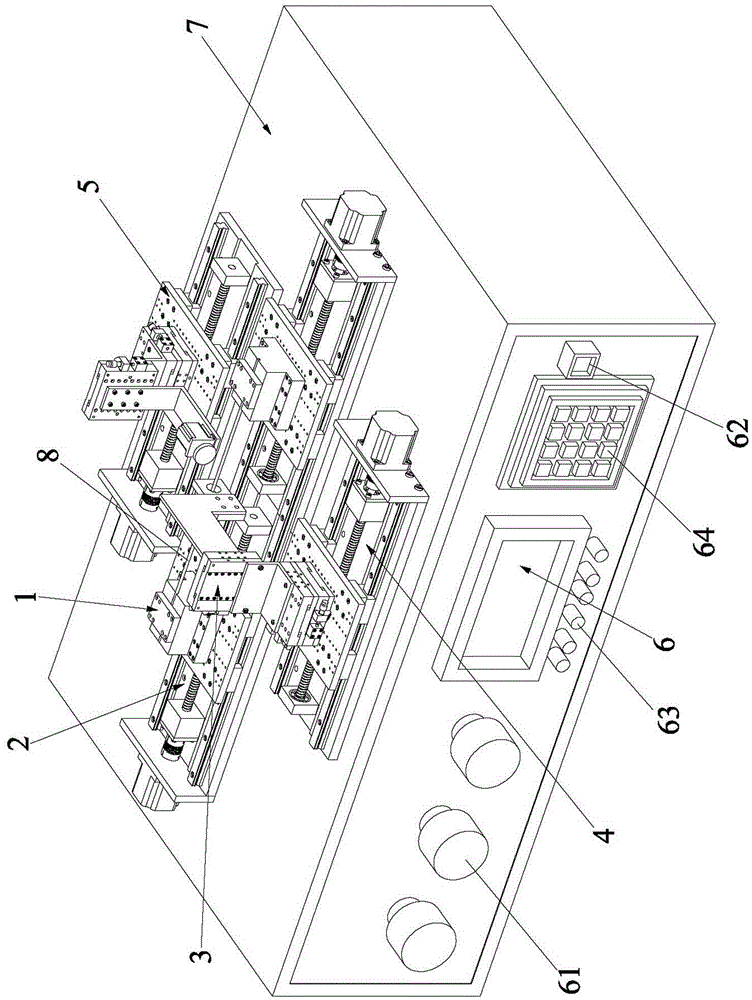

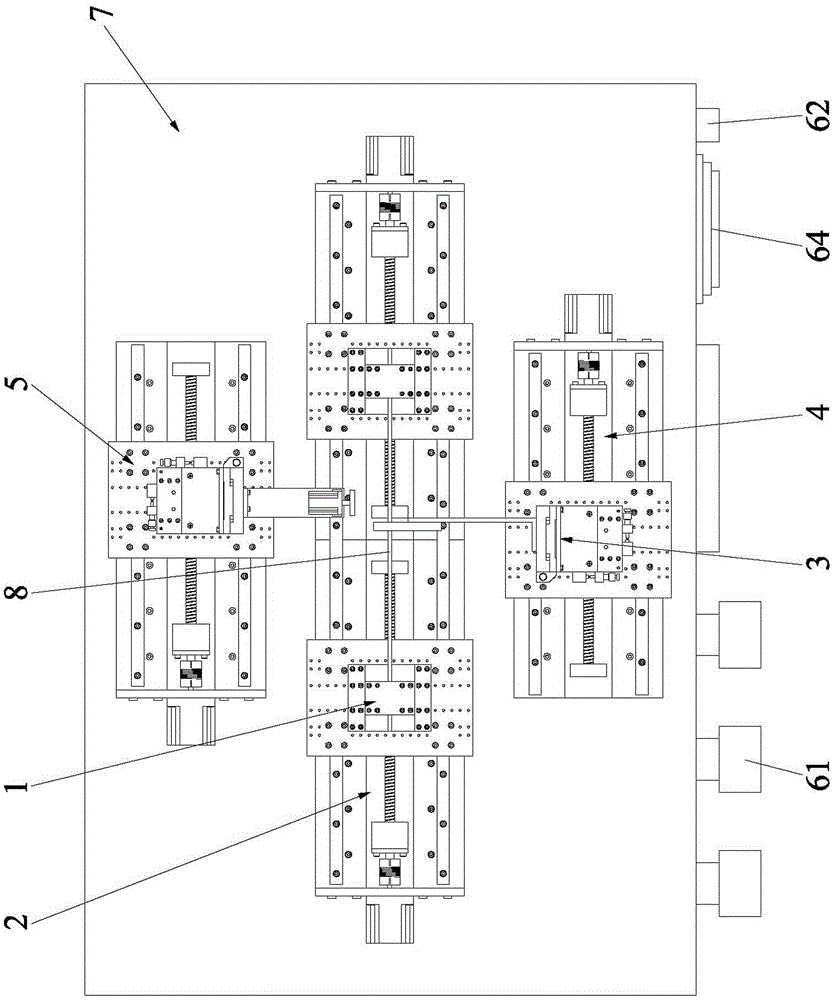

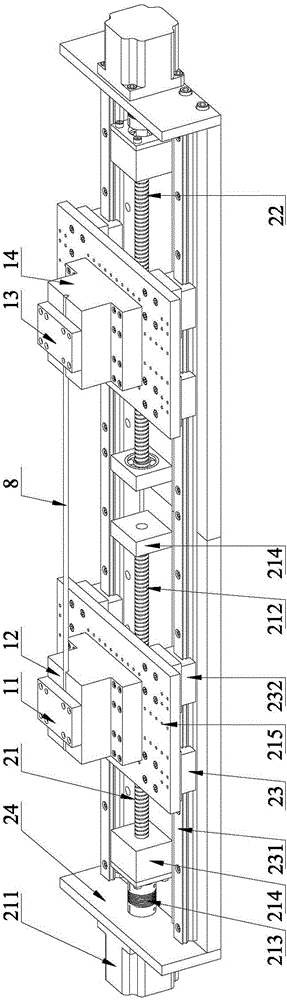

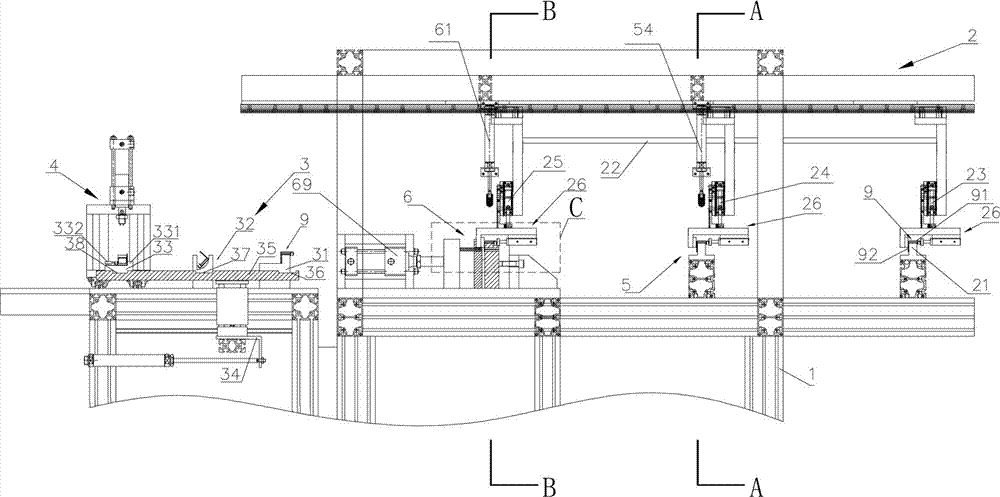

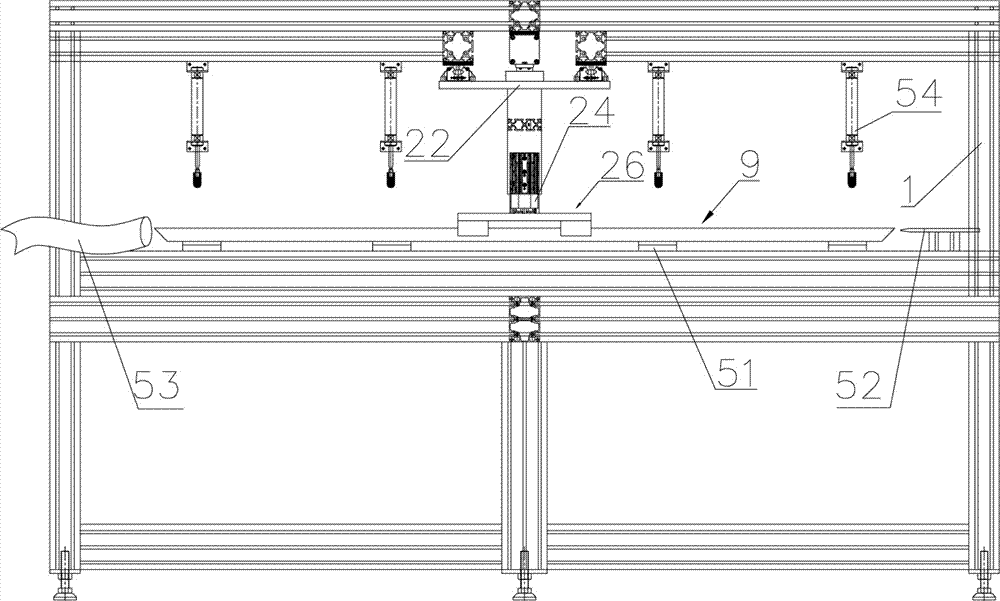

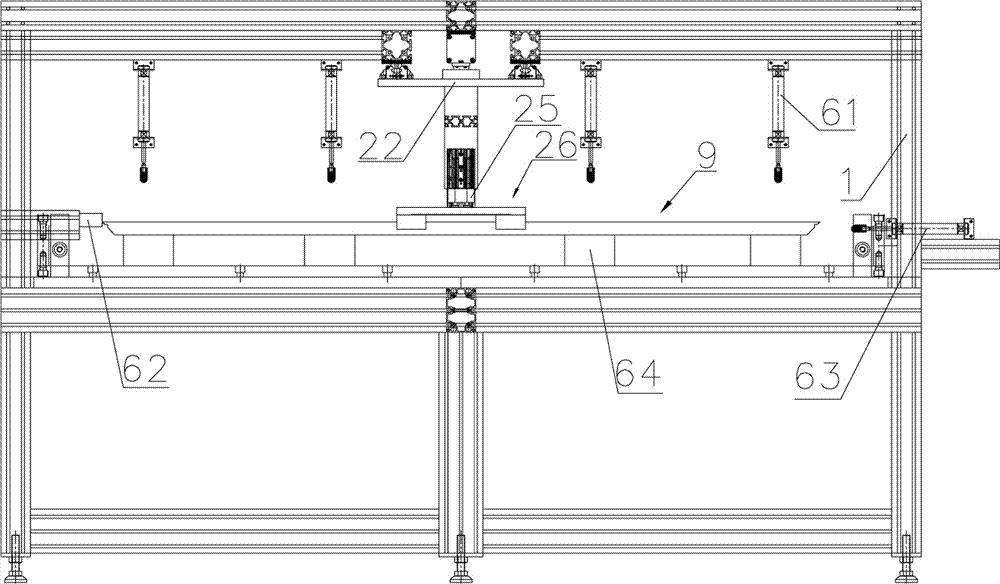

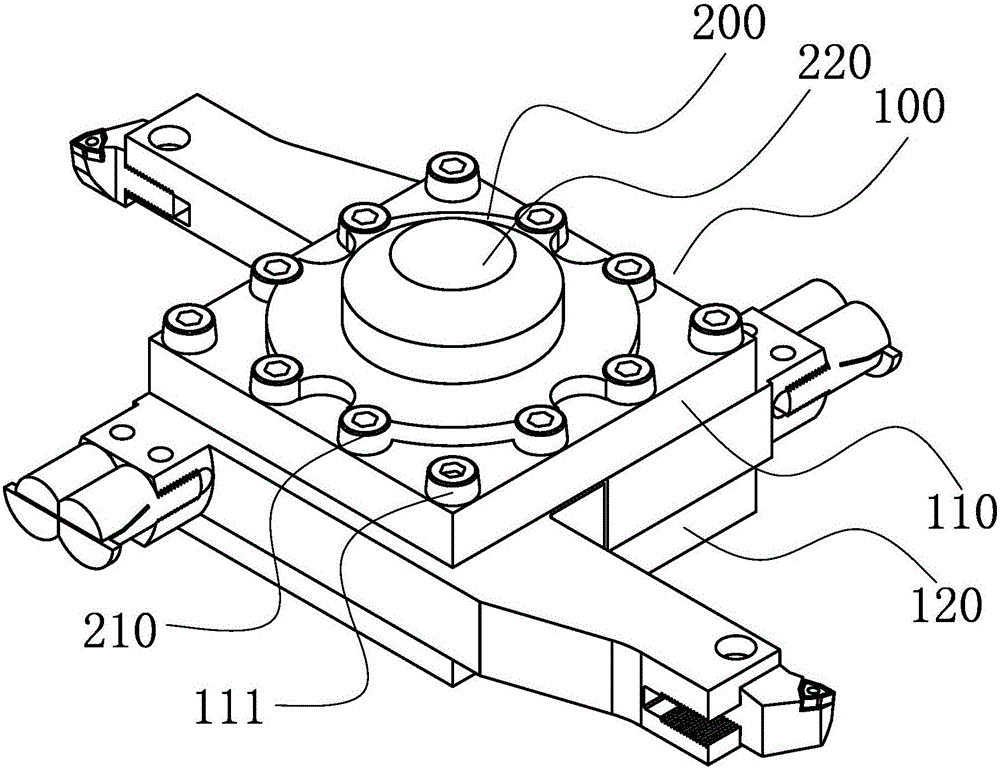

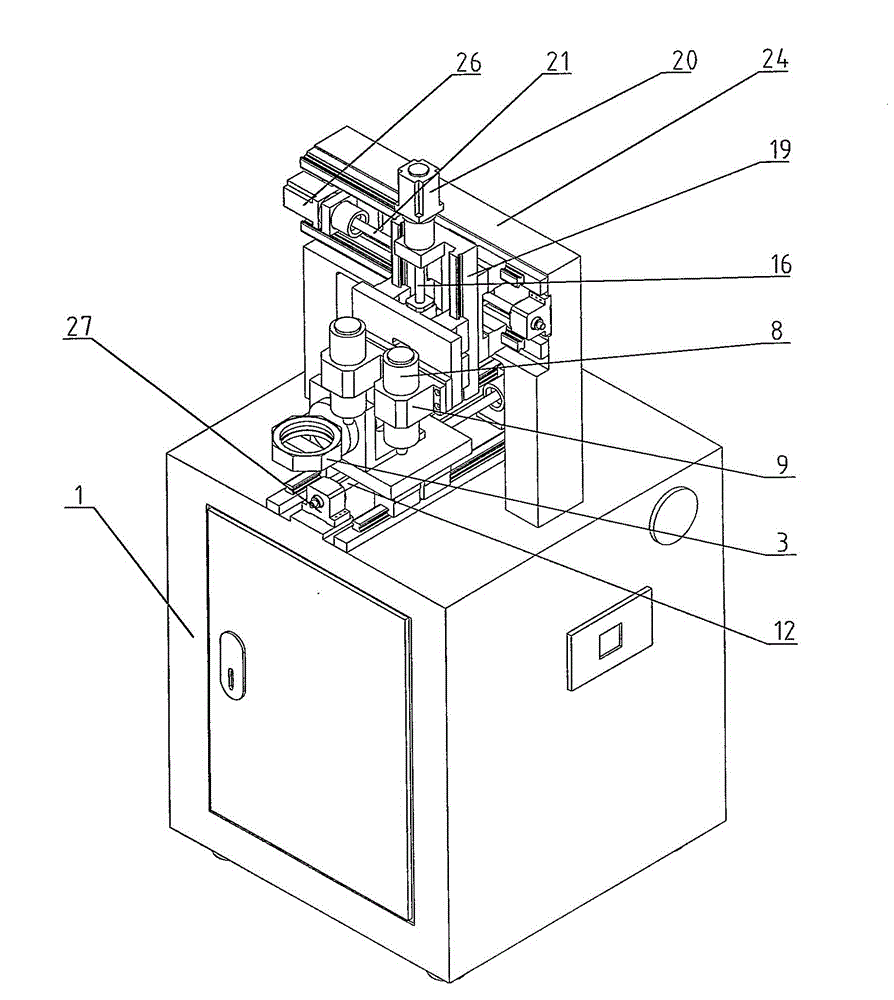

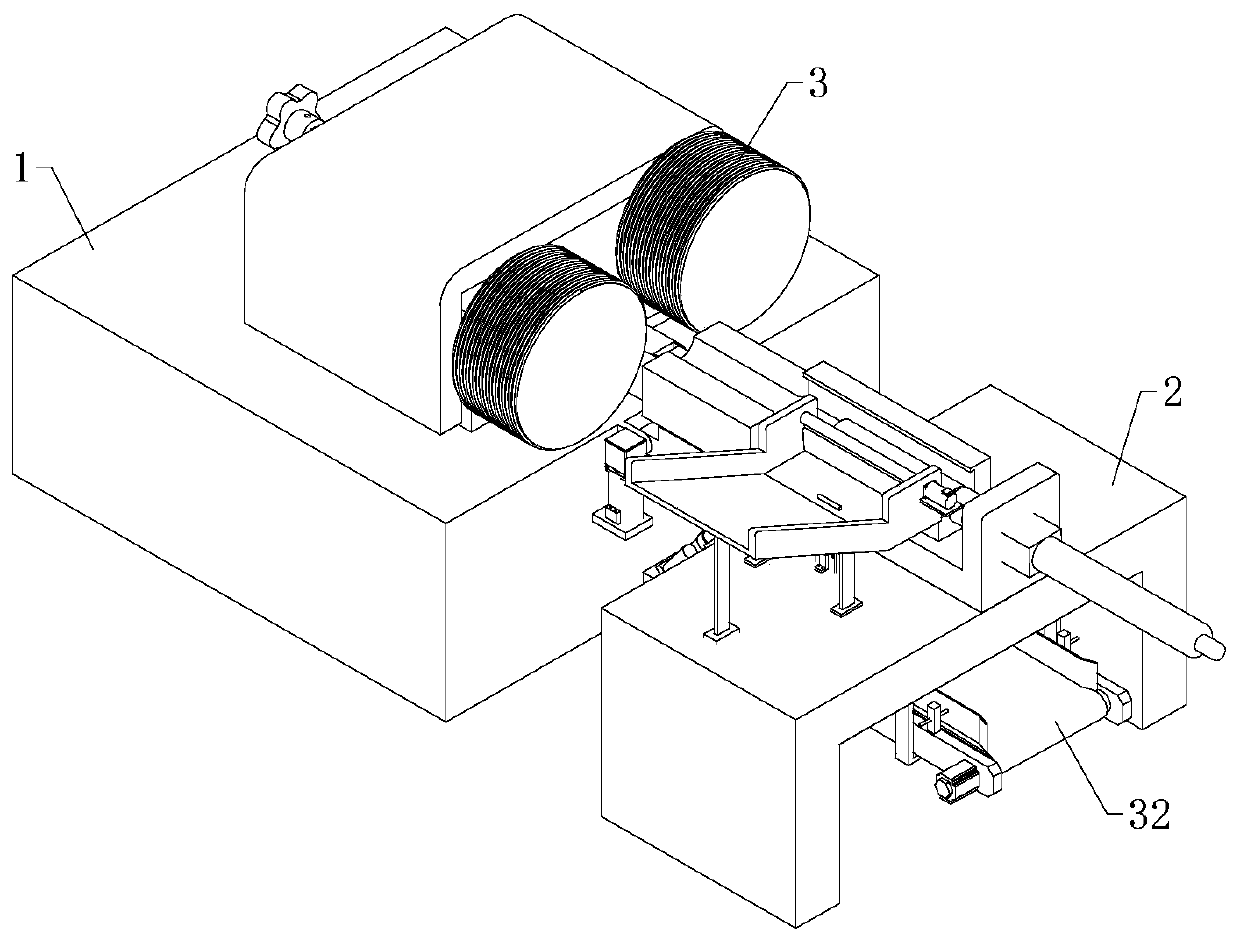

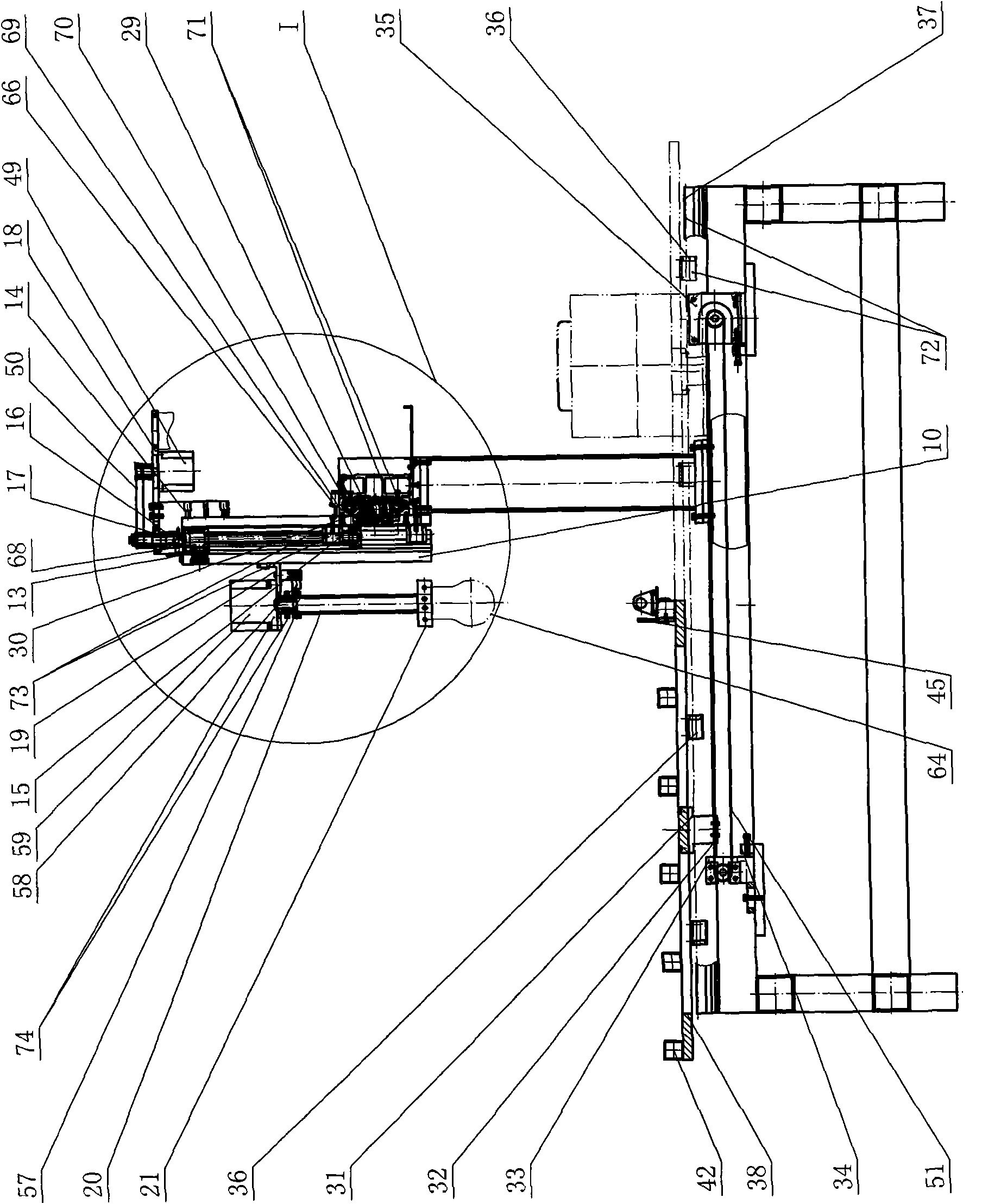

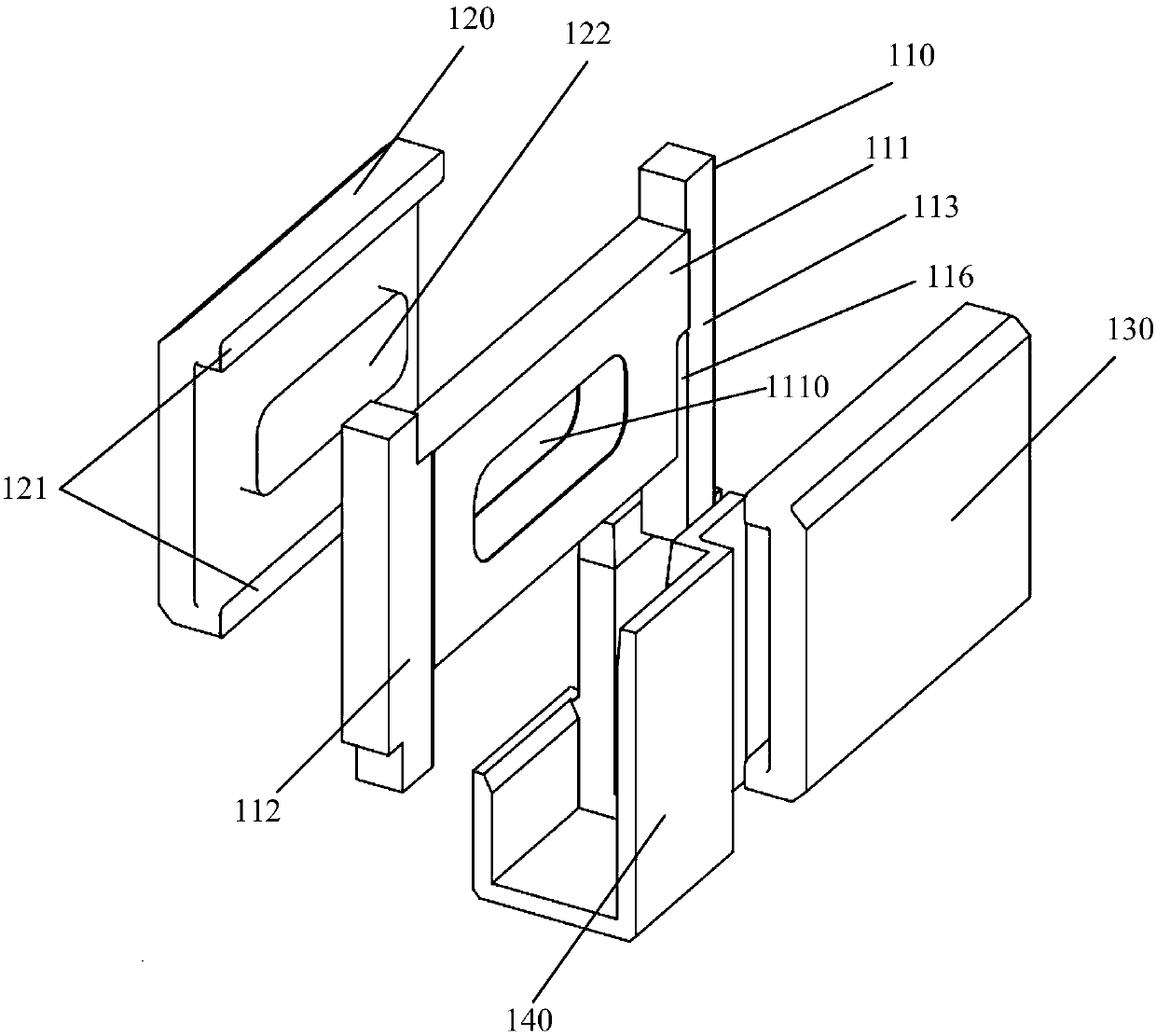

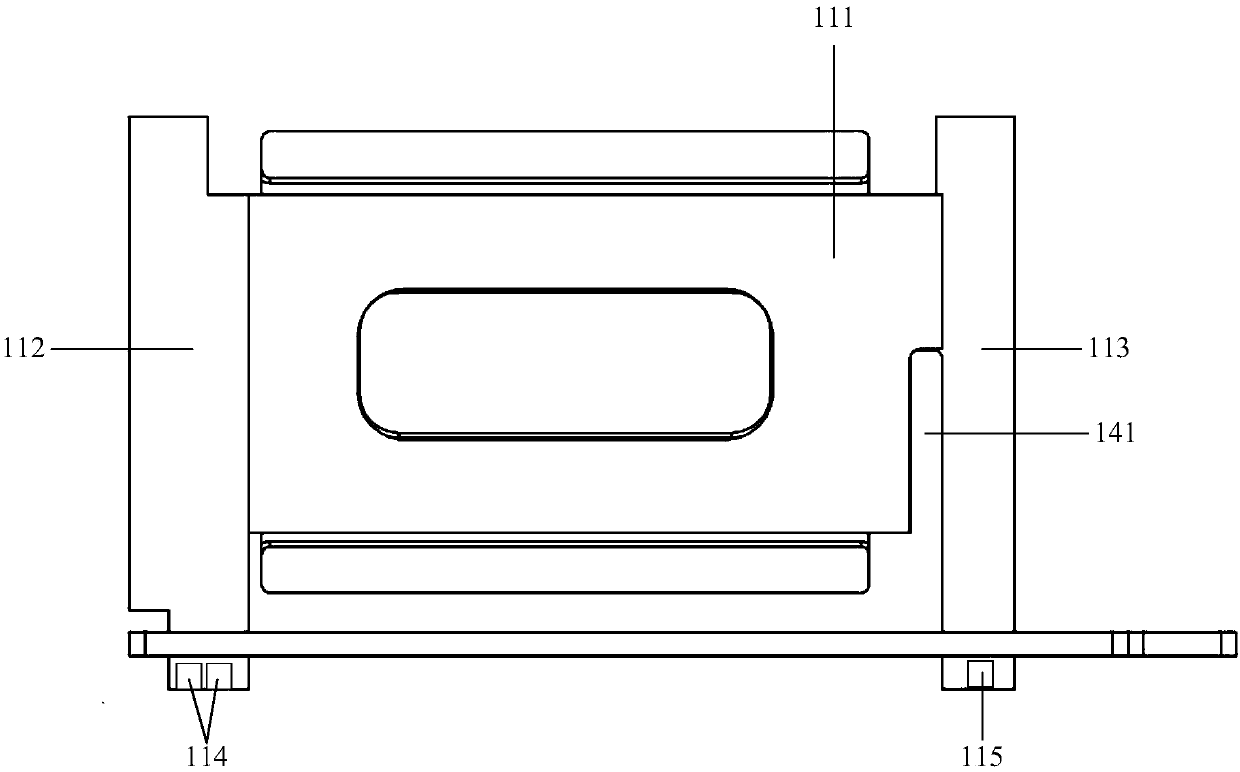

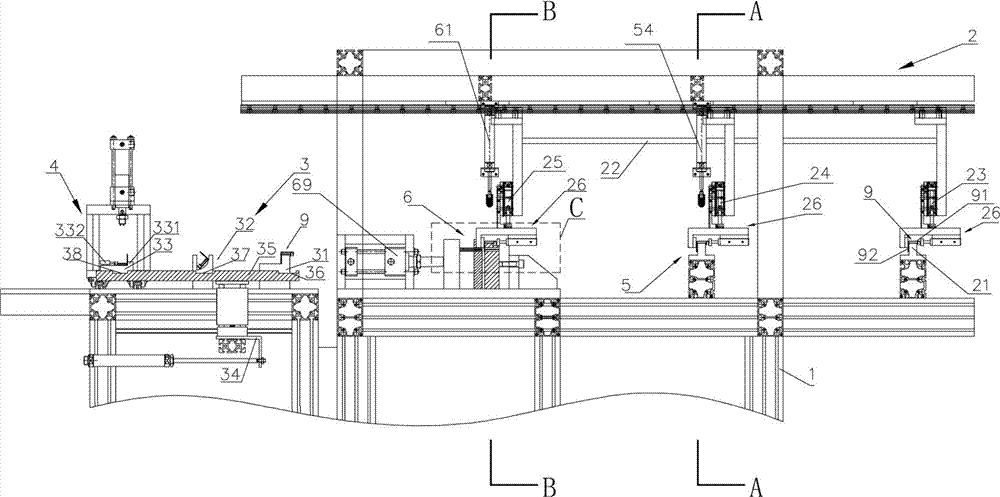

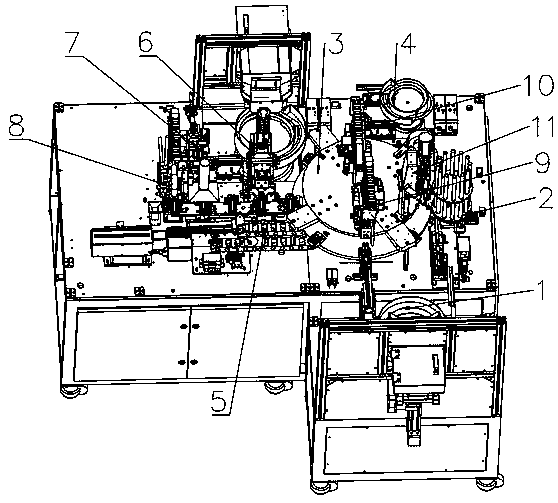

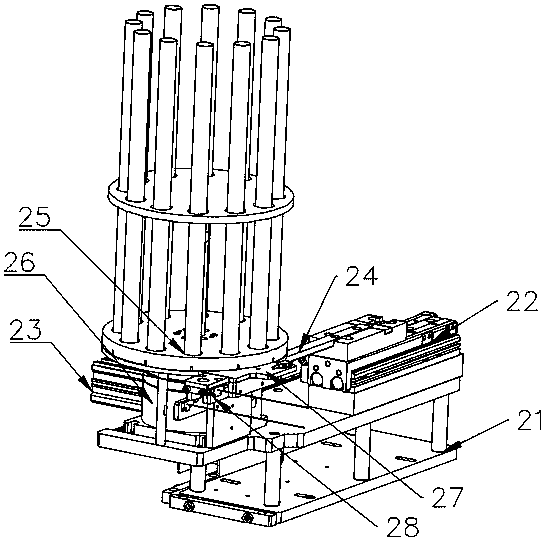

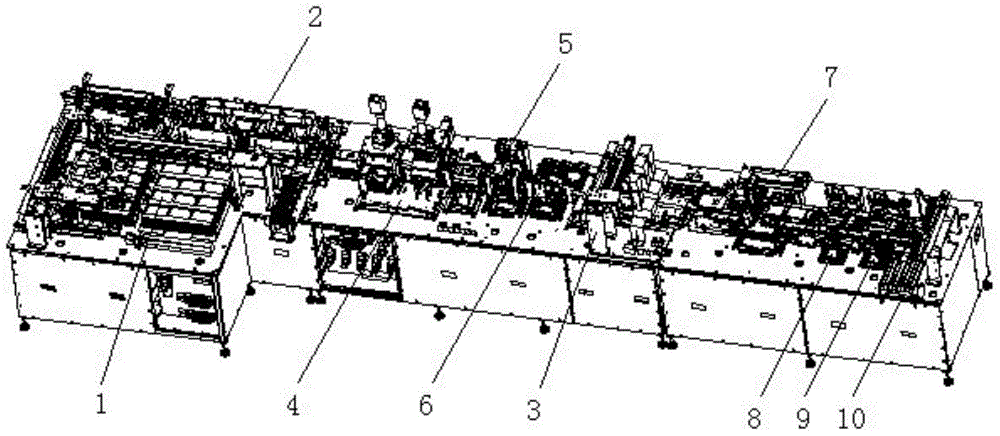

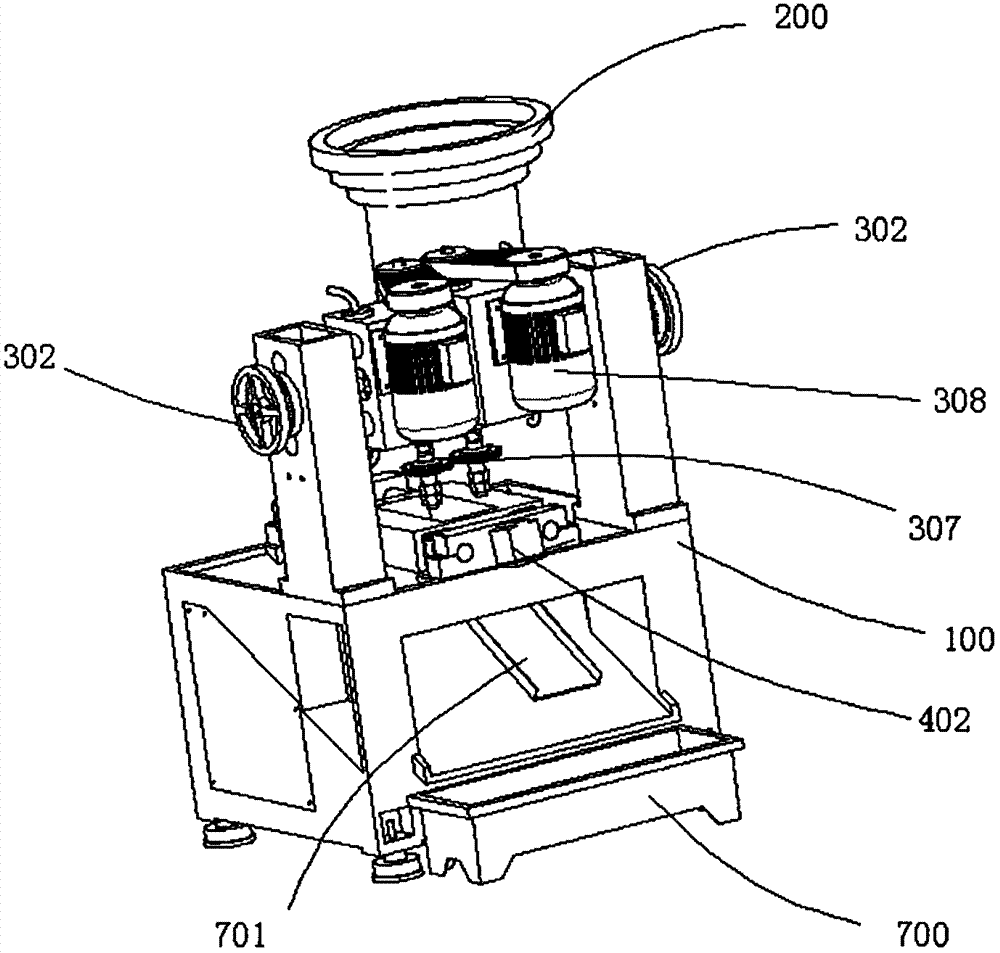

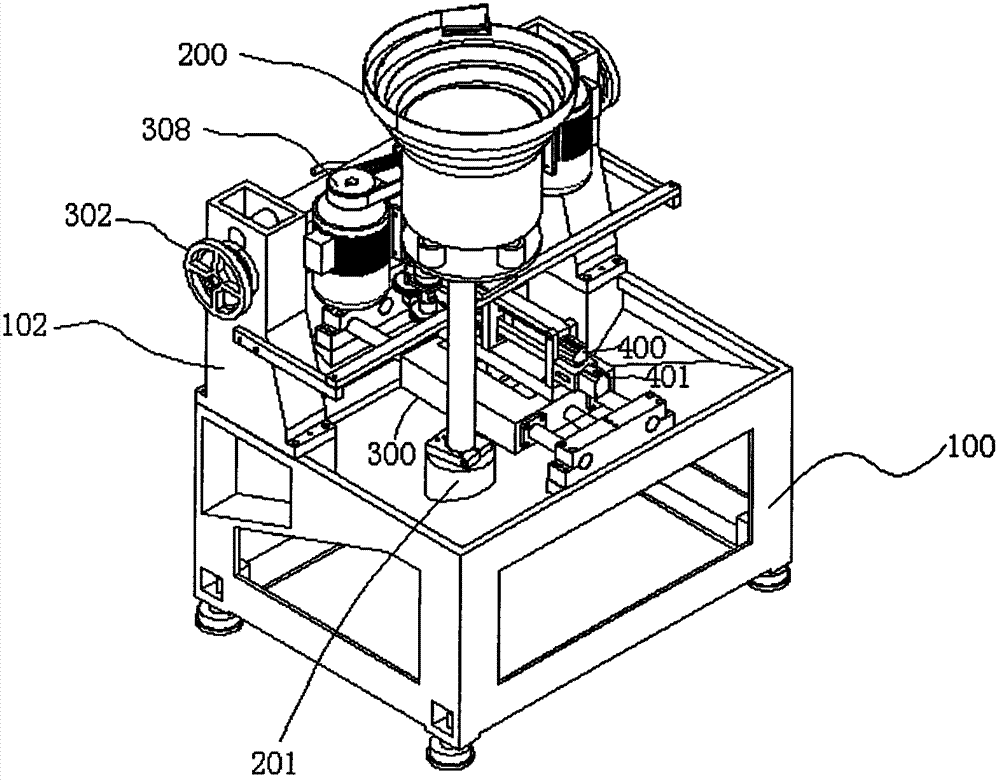

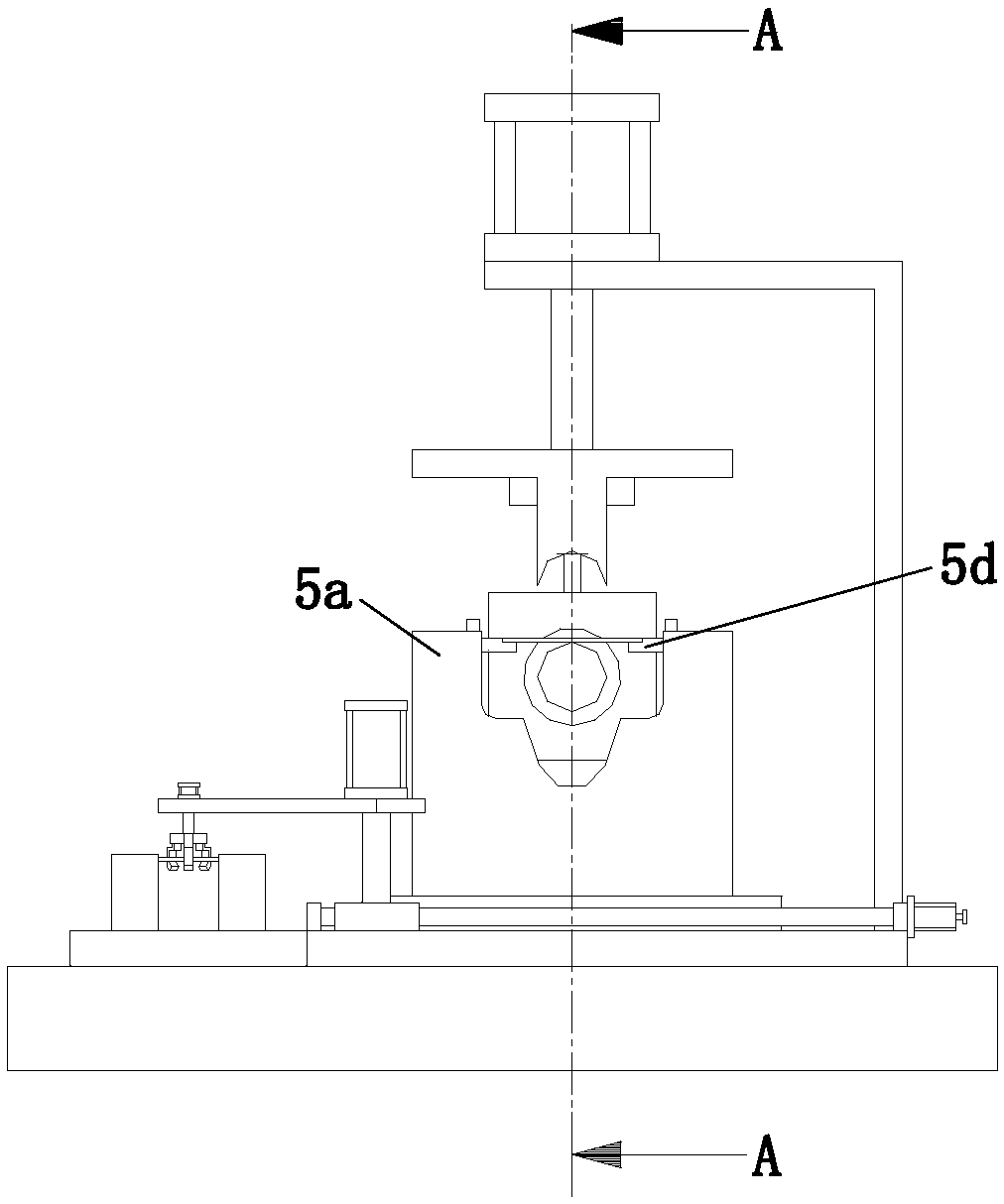

Automatic machining equipment for three-way pipe

ActiveCN104646559ARealize fully automatic processingIncrease productivityMetal-working feeding devicesStripping-off devicesEngineeringManipulator

The invention discloses automatic machining equipment for a three-way pipe. The invention discloses a machine frame, a flaring mechanism and a flattening forming mechanism which are arranged on the machine frame, a feeding device which is arranged at a feeding opening, a discharging device which is arranged at a discharging opening, and a manipulator mechanism which is arranged above the flaring mechanism and the flattening forming mechanism; the manipulator mechanism conveys a workpiece to the flaring mechanism from the feeding opening of the feeding device for the flaring mechanism to perform flaring on the workpiece, and conveys the workpiece to the flattening forming mechanism from the flaring mechanism for the flattening forming mechanism to form the workpiece; the formed workpiece is discharged by put into the discharging device through the manipulator mechanism. The invention provides the automatic machining equipment for the three-way pipe, the automatic machining of the flaring and the flattening forming of the three-way pipe is realized; the production efficiency is high; the automatic machining equipment is suitable for batch production.

Owner:浙江长兴和良智能装备有限公司

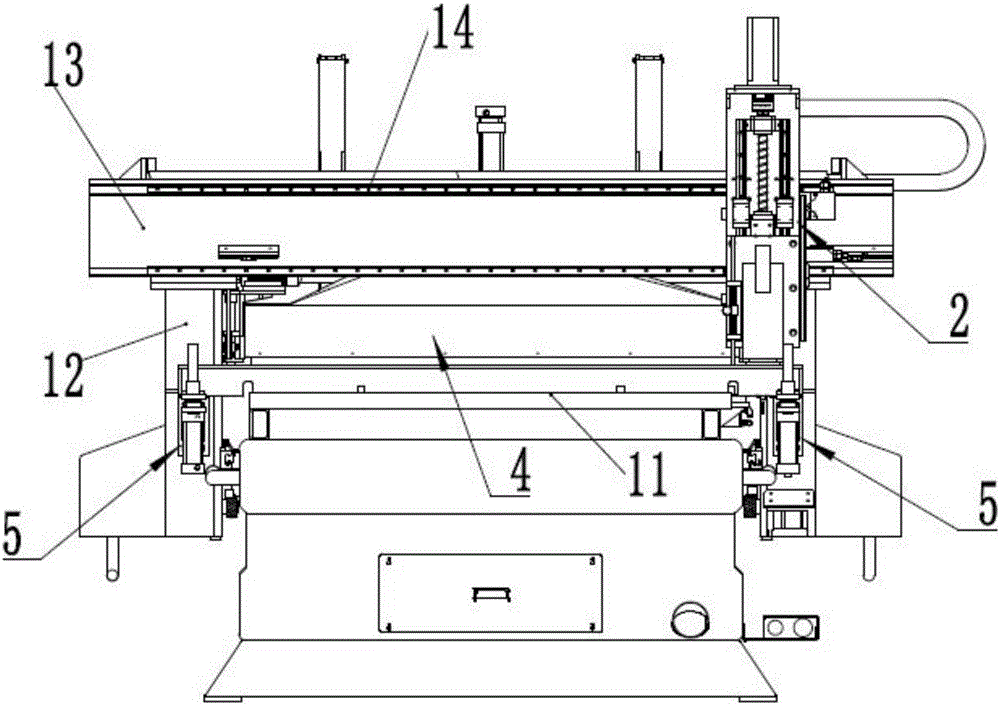

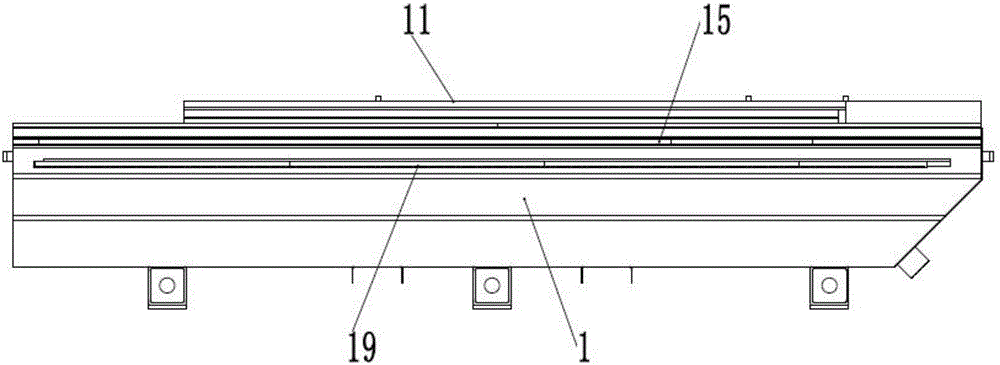

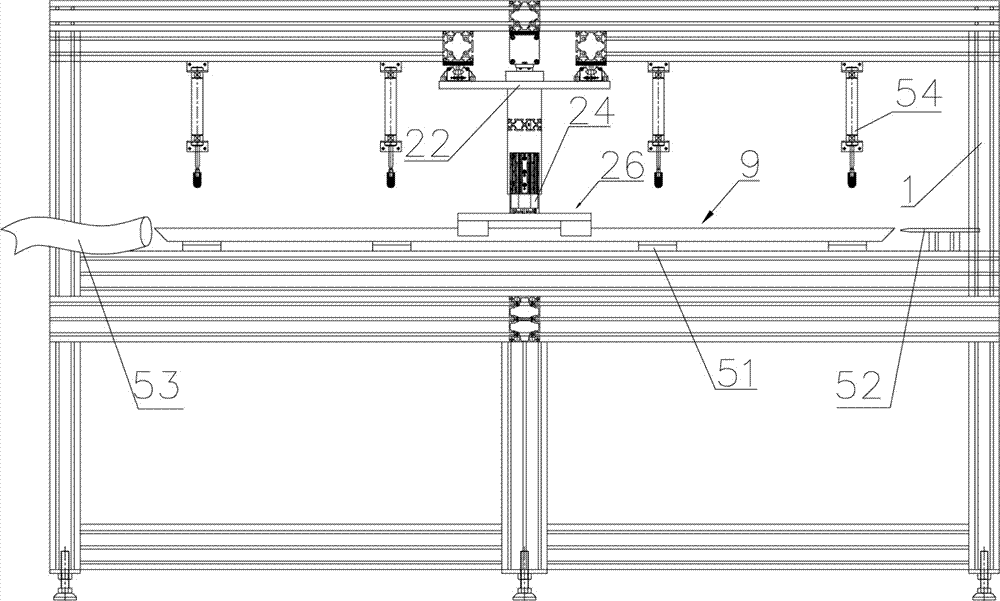

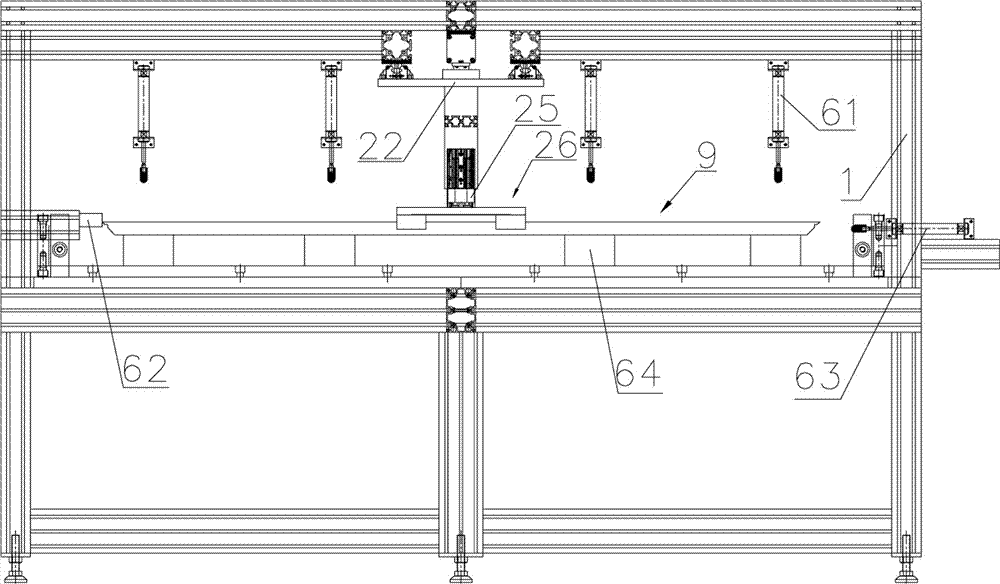

Novel numerical control cutting machine

InactiveCN105773734AImprove processing efficiencyImprove machining accuracyProfiling/shaping machinesBark-zones/chip/dust/waste removalNumerical controlEngineering

The invention discloses a novel numerical control cutting machine which comprises a rack, wherein a working table used for supporting a workpiece is arranged on the rack. The novel numerical control cutting machine further comprises a cross beam capable of moving on the rack, a processing component used for processing the workpiece on the working table, a material sucking device used for loading materials, a dust collection device used for cleaning chips on the surface of the workpiece on the working table, and a material pushing device used for pushing the processed workpiece away from the working table. According to the novel numerical control cutting machine, the processing efficiency is high, the processing accuracy is high, the automation degree is high, the operation is convenient, a straight line edge can be processed on the workpiece, an arc edge can be processed, the processing range is wide, and the processing flexibility is high.

Owner:GUANGDONG SANDAR CNC MACHINERY CO LTD

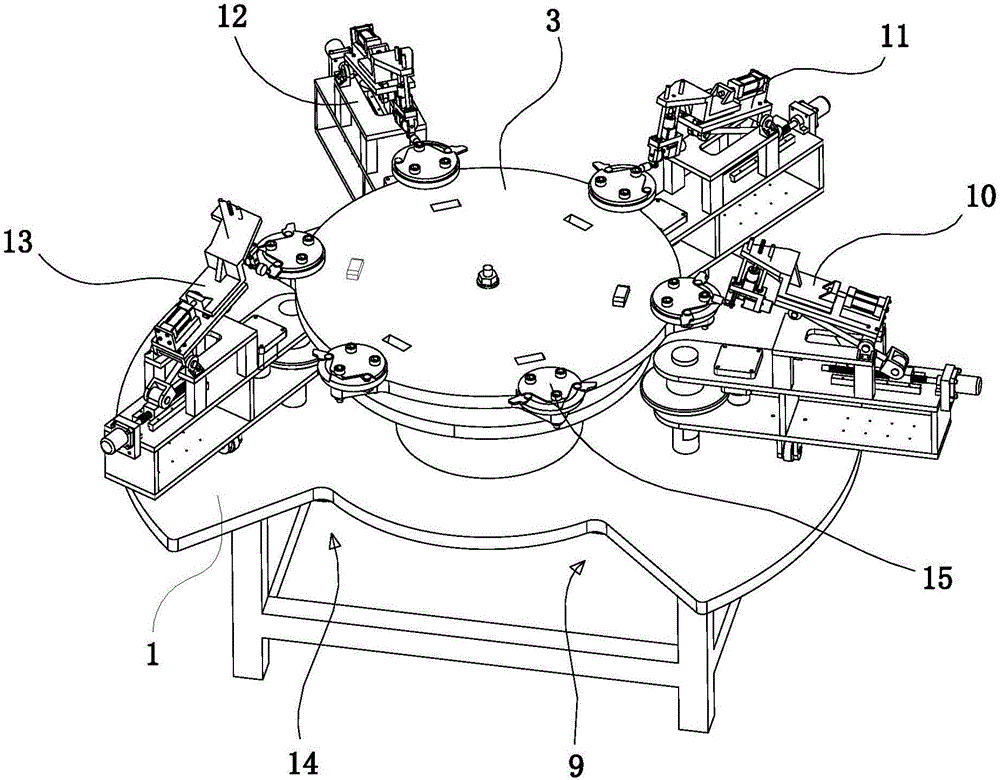

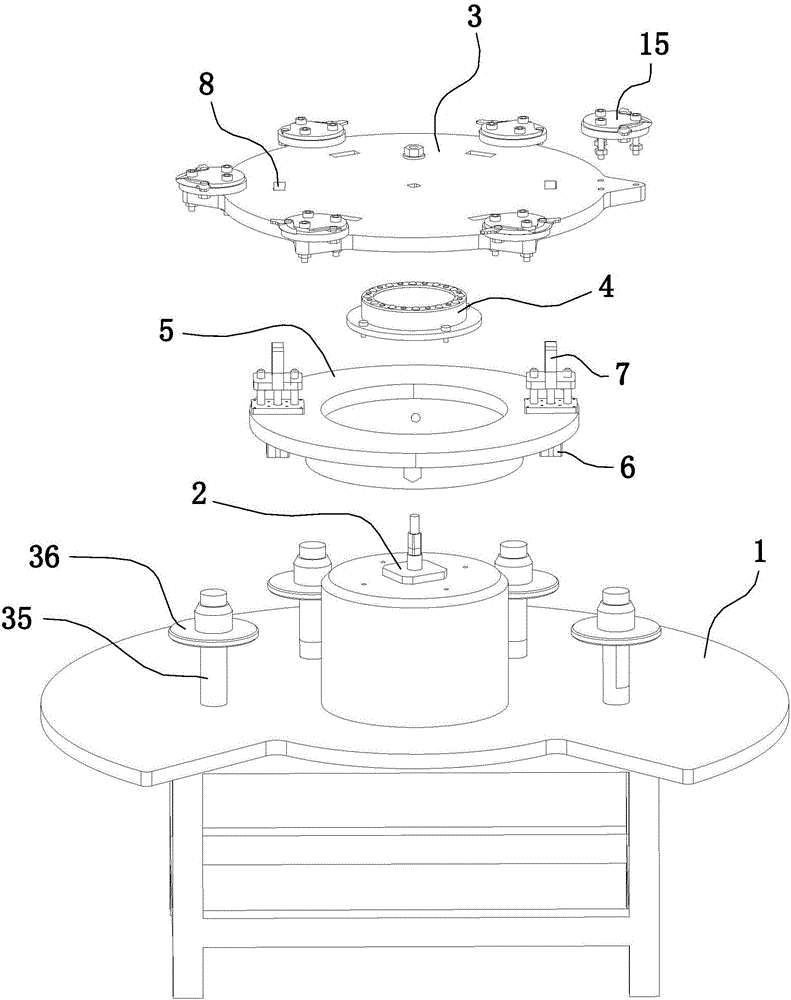

Turntable type full-automatic blade grinding machine

PendingCN105904292ARealize fully automatic processingImprove consistencyGrinding drivesOther manufacturing equipments/toolsDrive shaftDrive motor

The invention discloses a turntable type full-automatic blade grinding machine. The machine comprises a console; the console is provided with an indexing plate controlled by a stepper motor; the indexing plate is arranged on the console through a turntable, and is provided with multiple tools for clamping a trimming scissor blade at equal intervals; the console is provided with multiple grinding mechanisms for grinding the trimming scissor blade clamped on the grinding tools and support rods corresponding to the grinding mechanisms; the grinding mechanisms include frames rotationally arranged on the console; one ends of the frames are rotationally connected with the support rods; pulleys are arranged at the lower parts of the frames; rotary driving motors are arranged on the frames; and driving shafts of the rotary driving motors are provided with driving gears engaged with fluted discs. The turntable type full-automatic blade grinding machine adopts multi-station synchronous grinding, realizes full-automatic machining of edge grinding of the trimming scissor blade, and greatly improves the grinding precision and the machining efficiency.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

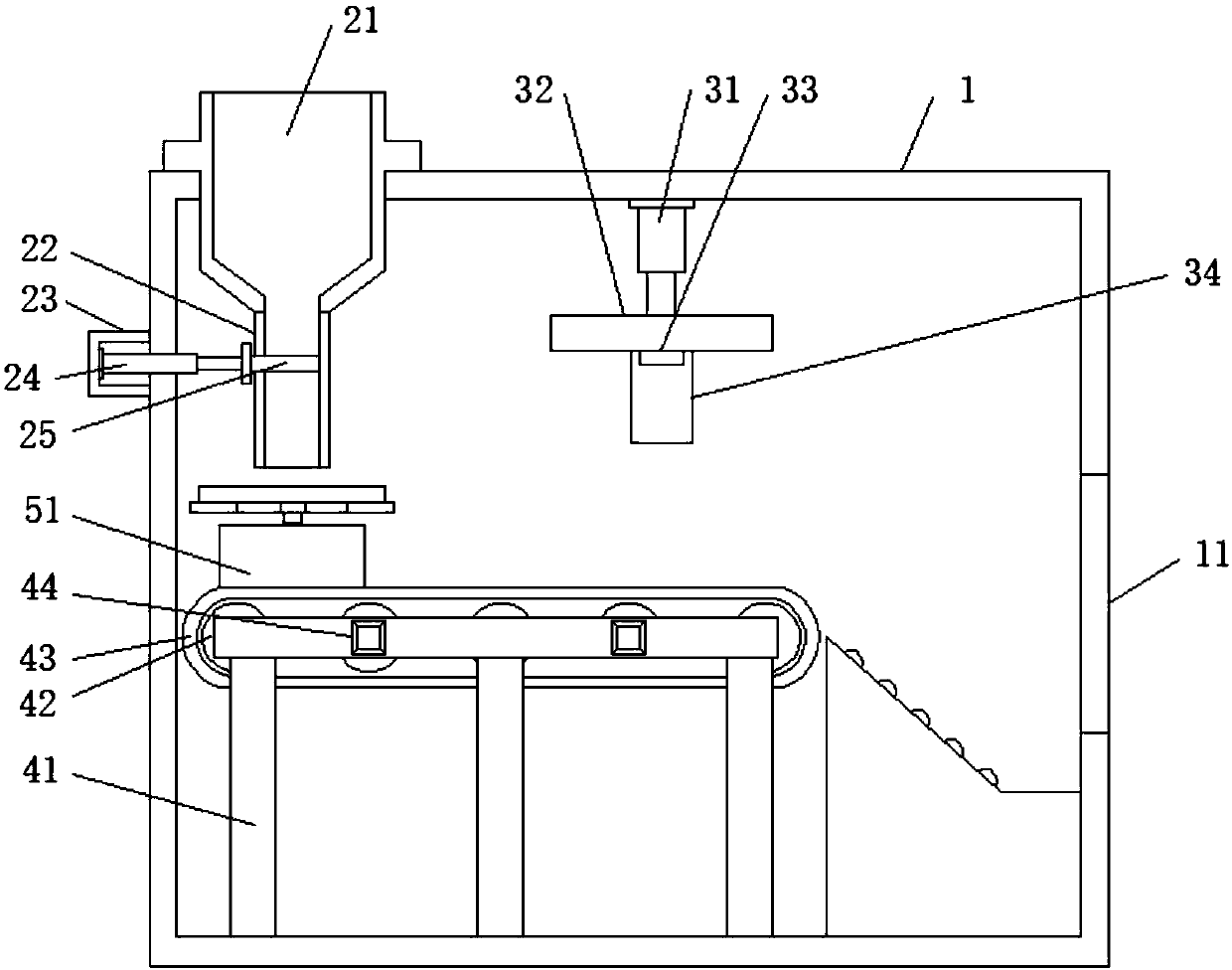

Full-automatic LED package machine

ActiveCN107910287AConvenient order placementEasy to moveSemiconductor/solid-state device manufacturingConveyor partsEngineeringAutomatic processing

The invention discloses a full-automatic LED package machine. The full-automatic LED package machine comprises a hollow-structure shell and also comprises a feeding mechanism, a package mechanism, a transmission mechanism and an adjustment mechanism, wherein the feeding mechanism is arranged at one side of the top of the shell, the package mechanism is arranged on an inner wall of the other side of the top of the shell, the adjustment mechanism moves with the transmission mechanism, the transmission mechanism comprises a support rack, a transmission shaft, a conveying belt and a third drivingdevice, the transmission shaft is rotatably connected to the top of the support rack, the conveying belt sleeves the transmission shaft, the third driving device drives the transmission shaft to rotate, the adjustment mechanism comprises a hollow fixed seat, the hollow fixed seat is fixedly arranged at the top of the transmission shaft, a positioning rod and a fourth driving device are arranged onan inner wall of the bottom of the hollow fixed seat, a first gear is arranged on an output shaft of the top of the fourth driving device, a fixed block is welded at a middle position of the positioning rod and is perpendicular to the positioning rod, and a rotation rod is rotatably connected with one side of the fixed block and is parallel to the positioning rod. The full-automatic LED package machine is reasonable in design and low in manual operation cost, full-automatic processing is achieved, the LED package efficiency and package accuracy are improved, and mass production is facilitated.

Owner:ZHONGSHAN MULINSEN ELECTRONICS CO LTD

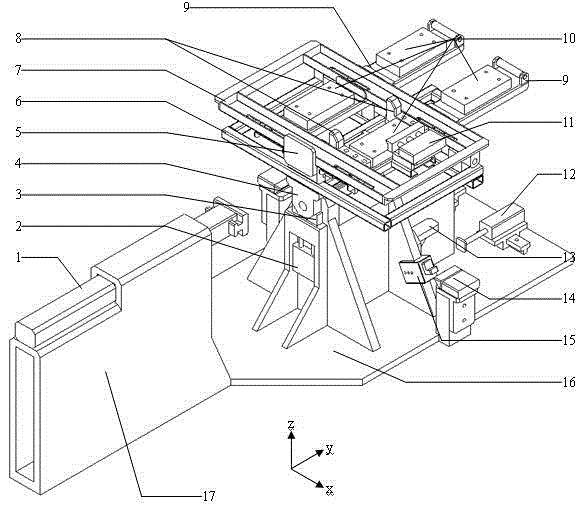

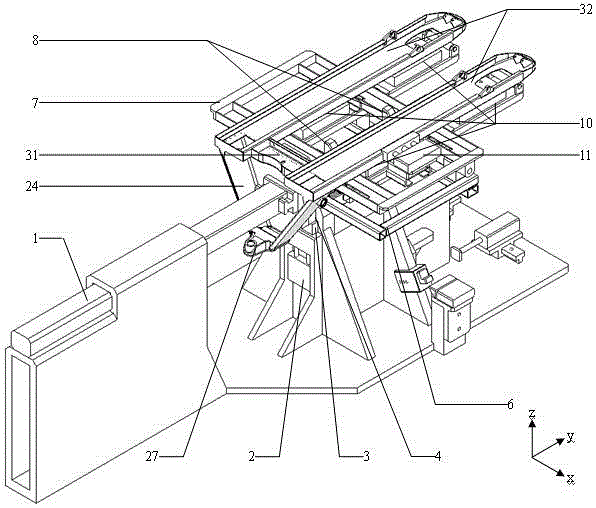

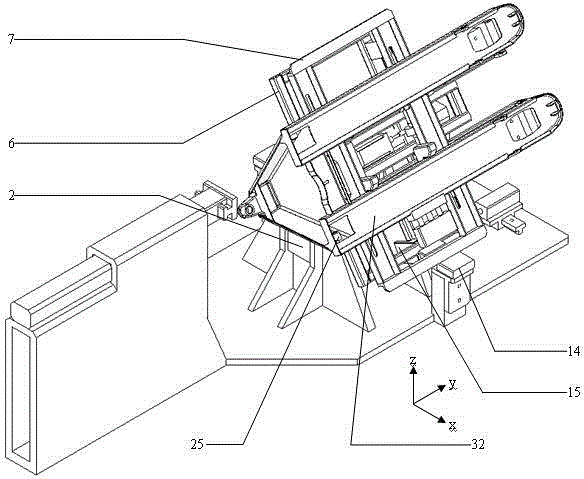

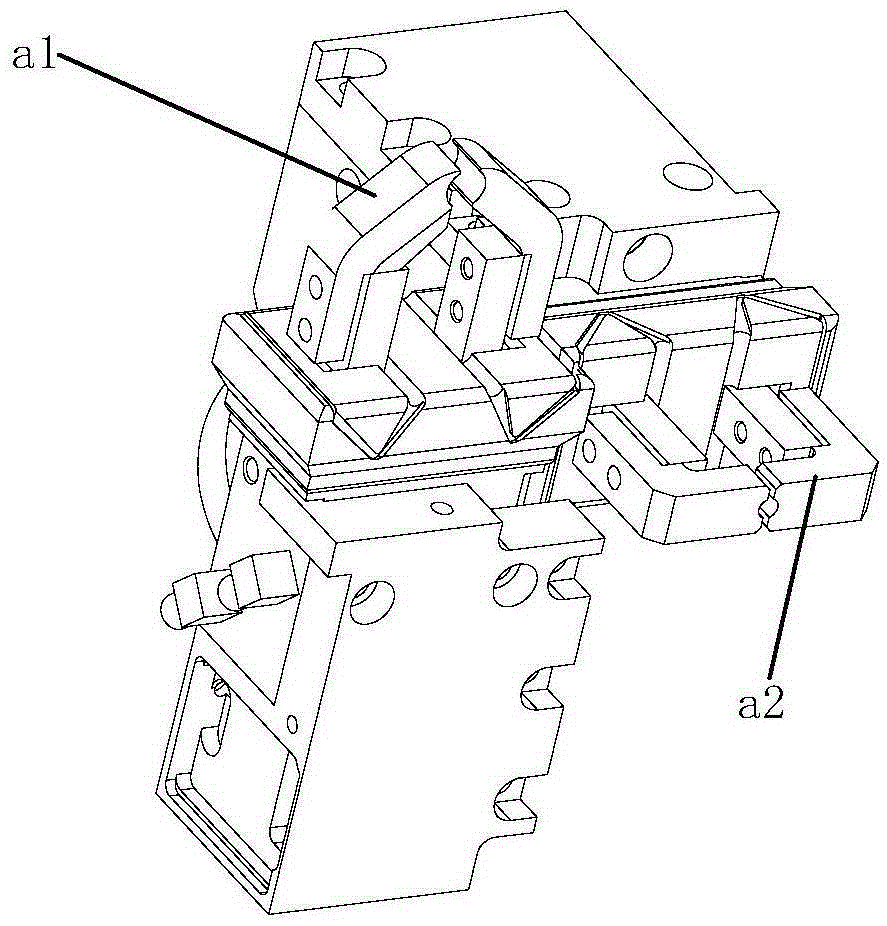

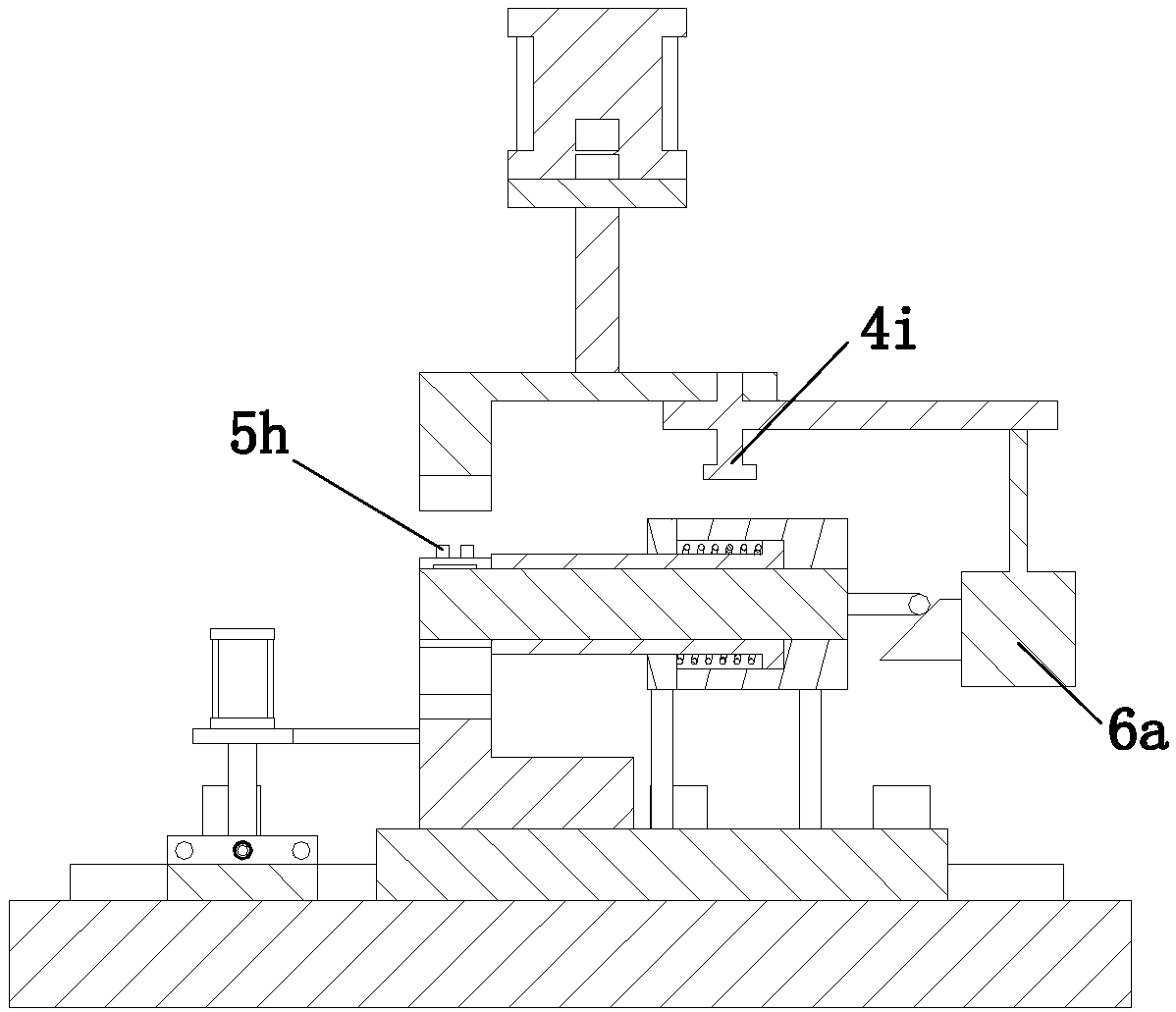

Automatic repair welding flexible positioner of manual-operation pallet truck

InactiveCN102744548AImprove quality and efficiencyIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesWorking environmentTruck

The invention discloses an automatic repair welding flexible positioner of a manual-operation pallet truck. An auxiliary foundation base is fixedly connected to one side of a foundation base, a y axis clamping cylinder is installed on the auxiliary foundation base, a lower rotation frame is rotatably connected onto the foundation base, one side of an upper rotation frame is rotatably connected with one side of the lower rotation frame away from the auxiliary foundation base, a worm wheel of a worm and gear pair is fixedly sleeved on an x axis rotation shaft, two electromagnetic chuck bases are symmetrically installed on the upper rotation frame, two electromagnetic chucks are fixedly installed on each electromagnetic chuck base, the electromagnetic chucks attract forks of the manual-operation pallet truck through electromagnetic force, two lower rotation frame limit devices are symmetrically installed on two sides of the foundation base, and two upper rotation frame limit devices are symmetrically installed on one side of the foundation base. The automatic repair welding flexible positioner of the manual-operation pallet truck is compact in structure, improves welding quality and production efficiency of the manual-operation pallet truck, reduces labor intensity of workers, improves working environment of the workers, and meets automatic repair welding processing requirements of the manual-operation pallet truck.

Owner:ZHEJIANG UNIV

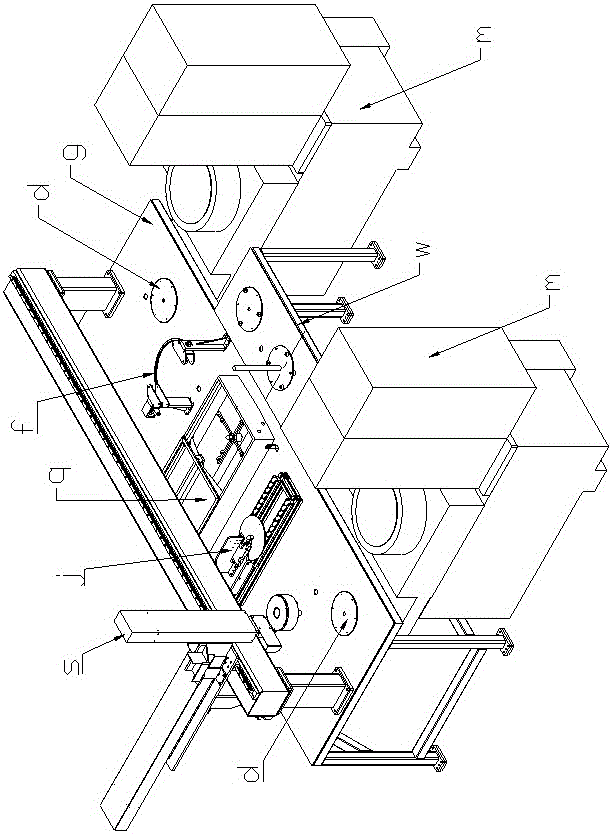

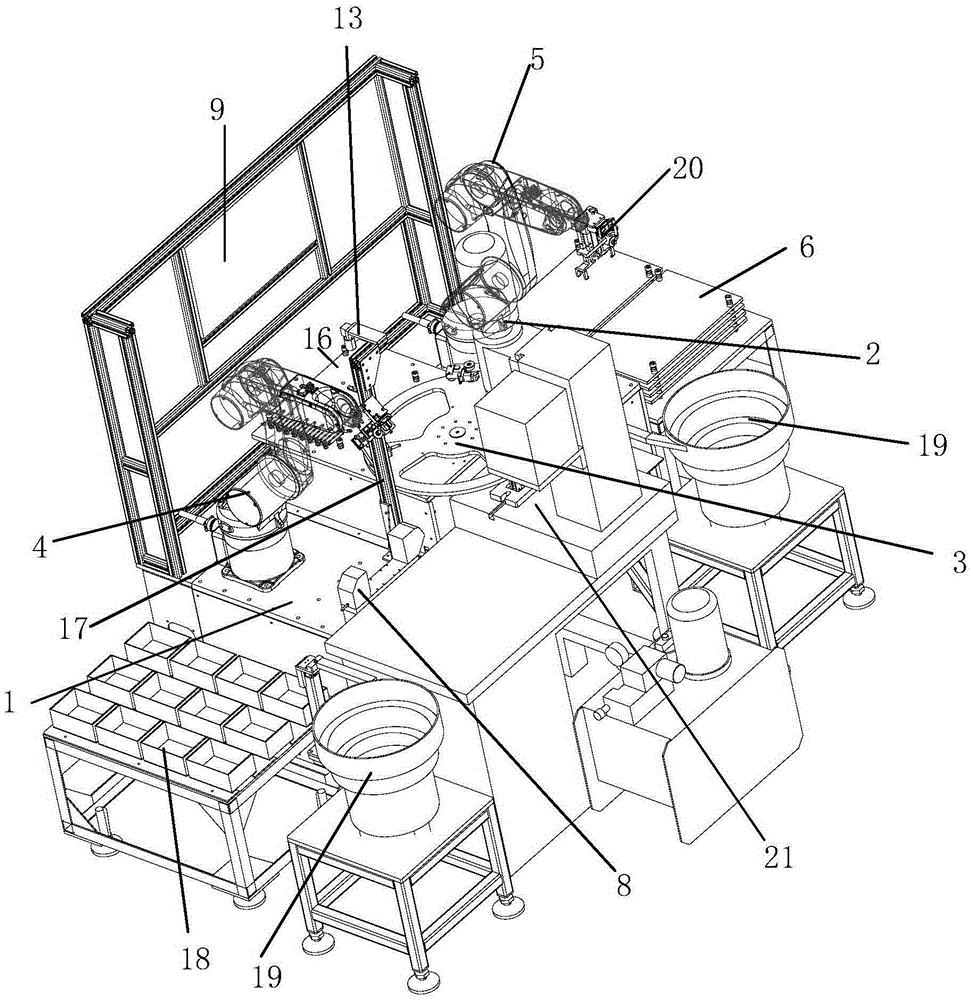

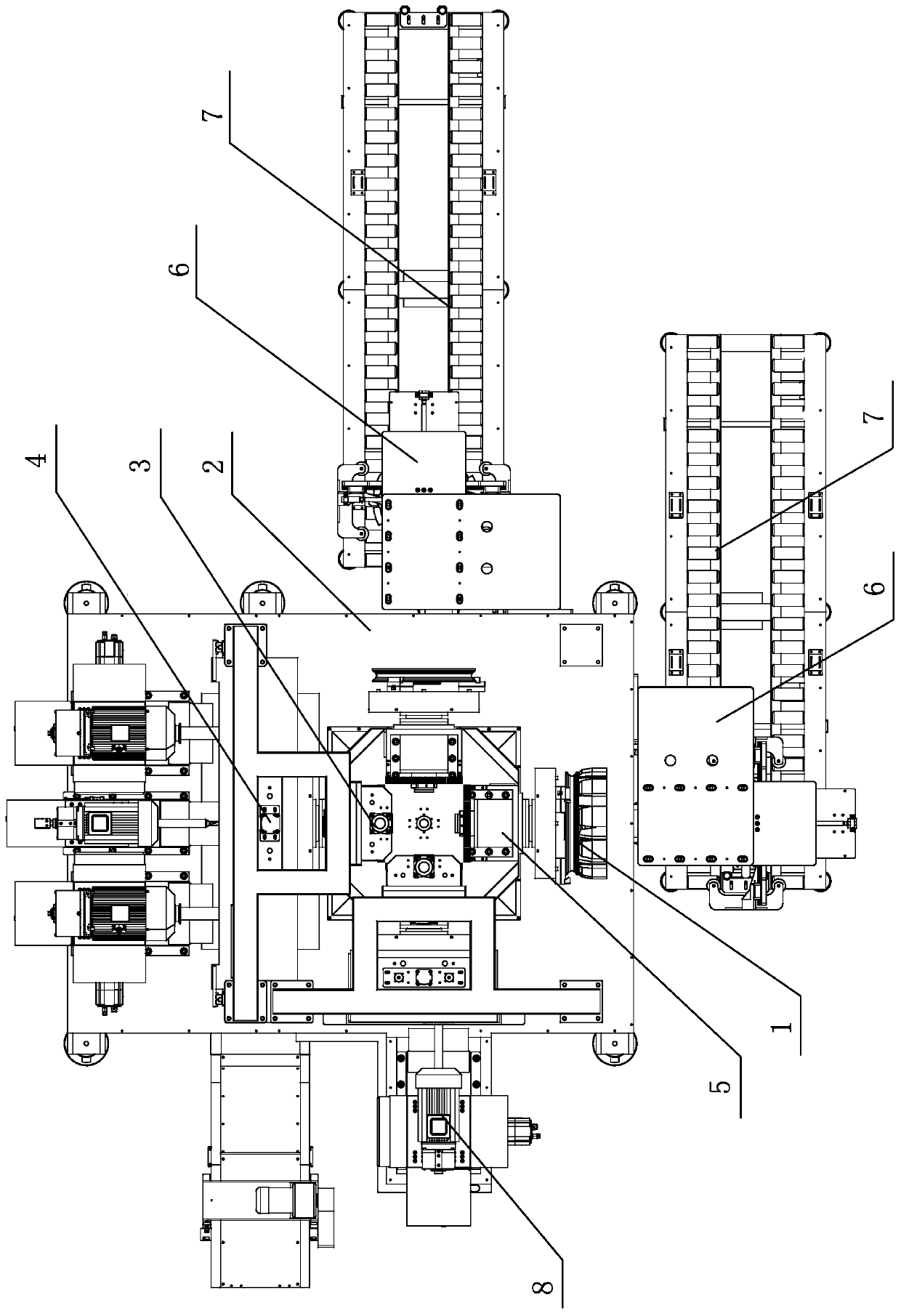

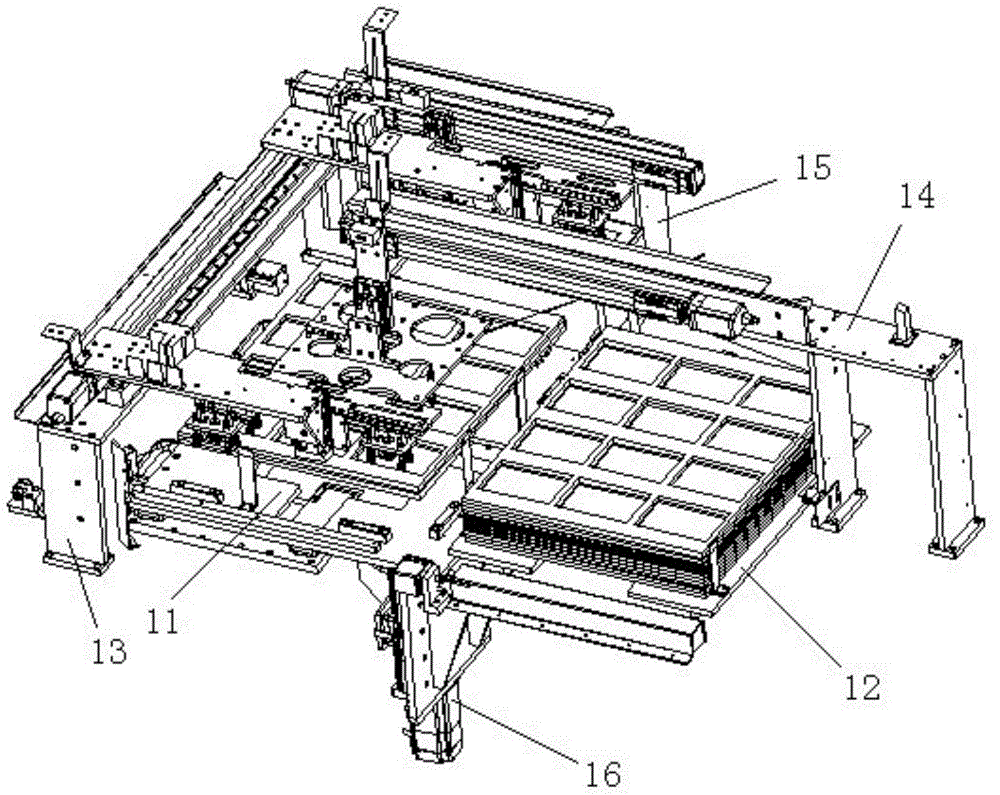

High-precision efficient automatic grinding and detecting production line and high-precision efficient automatic grinding and detecting production method

ActiveCN105728851ARealize automatic detection functionRealize fully automatic processingMetal sawing tool makingMeasurement/indication equipmentsProduction lineThree degrees of freedom

The invention discloses a high-precision efficient automatic grinding and detecting production line which comprises a manipulator mechanism (s) with three degrees of freedom, a cleaning mechanism (q), a turnover mechanism (f), a detecting mechanism (j), a working table (g), a material table (w) and two grinding machines (m). The two grinding machines (w) are respectively arranged at two ends of the working table (g); the manipulator mechanism (s) with the three degrees of freedom is used for loading and unloading materials; the working table (g) is used for mounting the manipulator mechanism (s) with the three degrees of freedom, the cleaning mechanism (q), the turnover mechanism (f), the detecting mechanism (j) and the material table (w); the material table (w) is used for arranging workpieces. The invention further provides a high-precision efficient automatic grinding and detecting production method. The high-precision efficient automatic grinding and detecting production line and the high-precision efficient automatic grinding and detecting production method have the advantages that the high-precision efficient automatic grinding and detecting production line is compact in structure, material grabbing, workpiece cleaning, workpiece turnover and workpiece detecting and mounting can be carried out on the same working table, the two grinding machines can be in simultaneous working states under various actions of manipulators, and accordingly the work efficiency can be greatly improved.

Owner:LINQING XINGHE HONGXIN MACHINE

Double-side driven glass micro-nozzle processing device and processing method

ActiveCN104909550AStructural symmetryImprove production efficiencyGrinding machinesGlass reforming apparatusSpray nozzleEngineering

The invention discloses a double-side driven glass micro-nozzle processing device and processing method. Glass tube clamping devices at two ends of a glass tube are driven to simultaneously move towards the opposite directions through the arrangement of two symmetrically arranged drive mechanisms, so that the drawing process of the glass tube is realized; two micro-nozzles with symmetrical structures are formed at two ends of a breaking point; a heater can be controlled to move to the corresponding positions at two ends of the breaking point of the glass tube to heat the nozzles, so as to finish the forging process of the two glass nozzles; and the glass nozzles are ground by a grinding device, so that the nozzles reach the required shapes. Two glass nozzles which are the same completely can be obtained in a double-end drawing manner, so that the utilization rate and the production efficiency of the material are improved; the operation is simple; and the problems of low production efficiency, low utilization rate and poor precision of the material in the past are well solved.

Owner:XIAMEN UNIV OF TECH

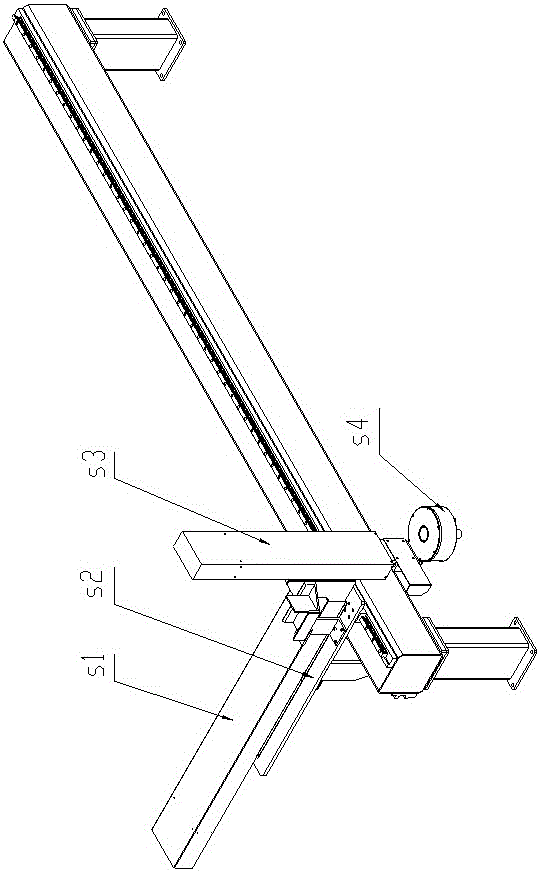

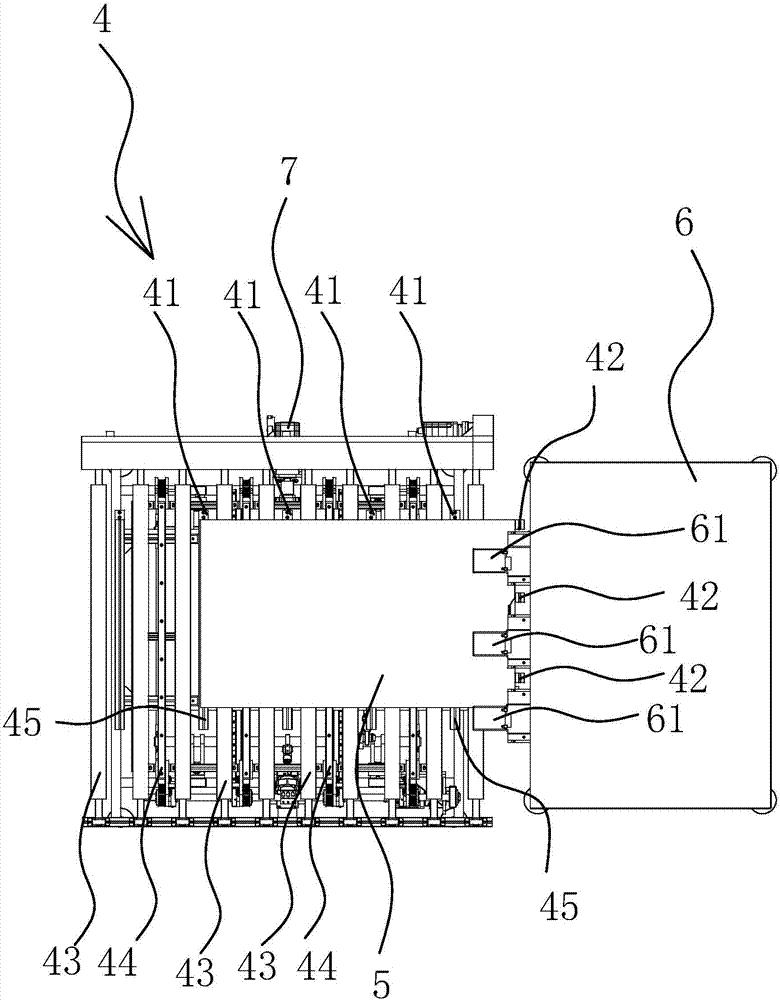

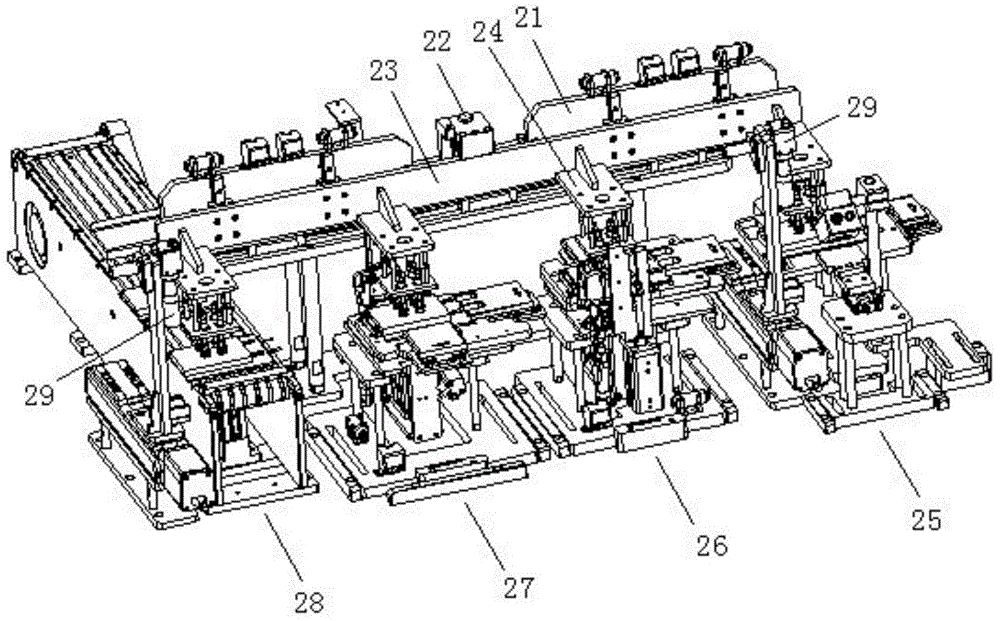

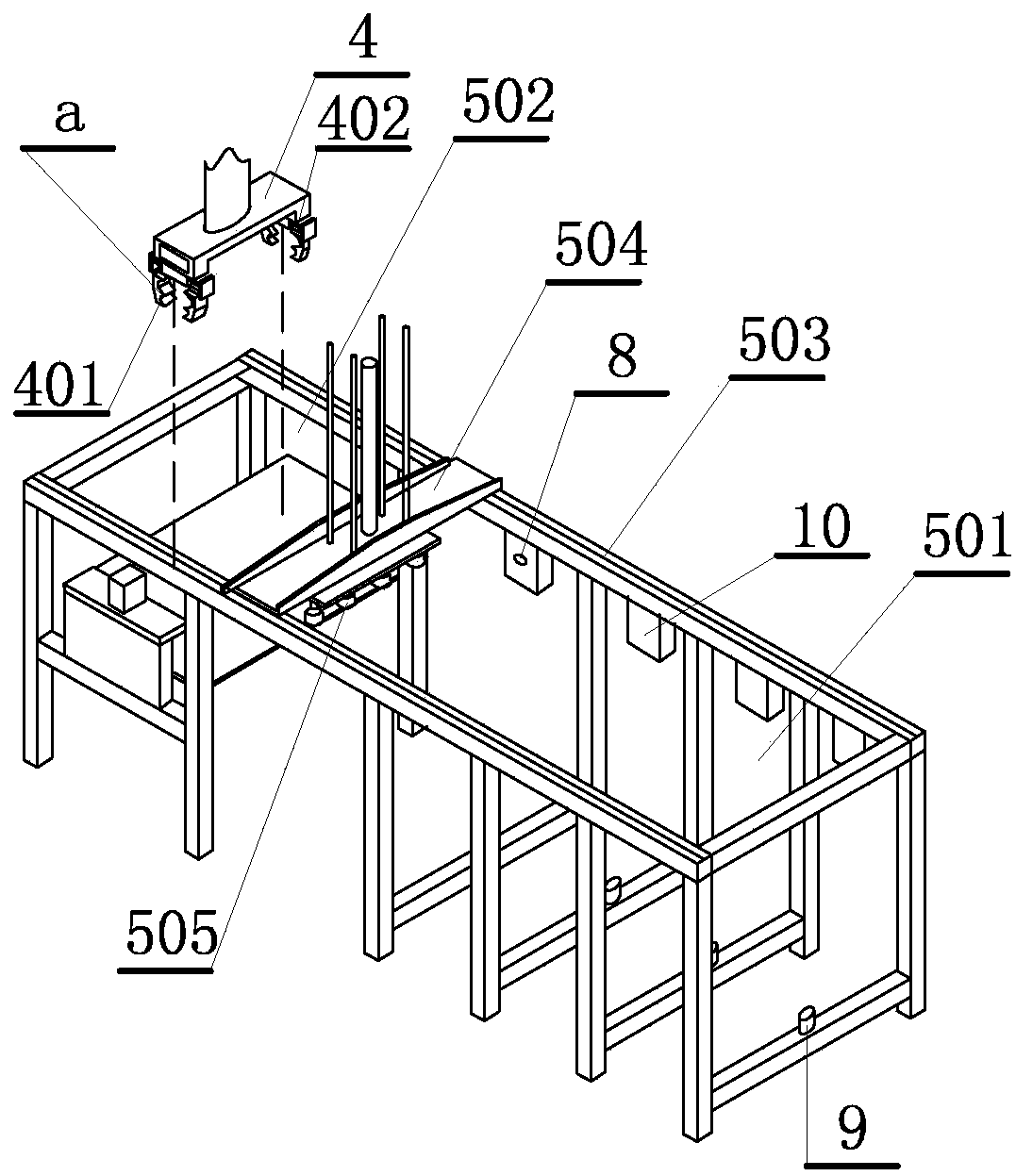

Solar module frame short side intelligent production line

ActiveCN107204738ARealize fully automatic processingReduce labor costsPhotovoltaicsPhotovoltaic energy generationProduction linePunching

The invention discloses a solar module frame short side intelligent production line. The production line comprises a rack. A sawdust blowing and punching device capable of blowing sawdust off and punching a solar module frame short side, a frame turning and transferring device capable of turning the solar module frame short side after sawdust blowing and punching and transferring the solar module frame short side backward, and a corner connector mounting and riveting device capable of mounting a corner connector on and riveting the turned solar module frame short side are arranged sequentially from front to back on the rack. Through the solar module frame short side intelligent production line, sawdust blowing, punching, corner connector mounting and riveting can be carried out on a solar module frame short side quickly, reliably and accurately. A solar module frame short side can be machined in a fully-automatic manner. The labor cost is saved. The work efficiency and machining quality are improved.

Owner:张家港易智自动化装备有限公司

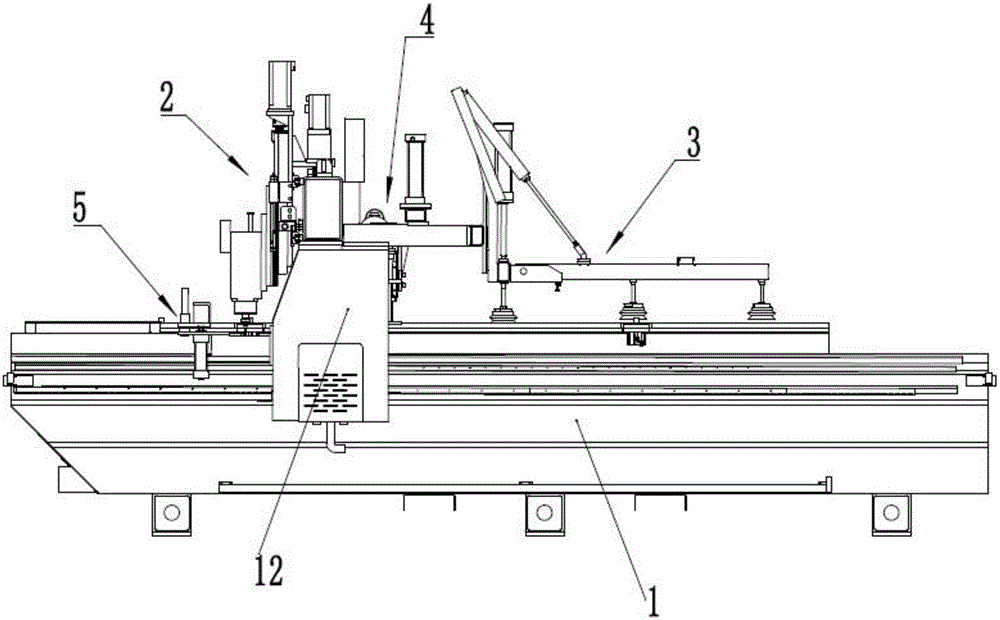

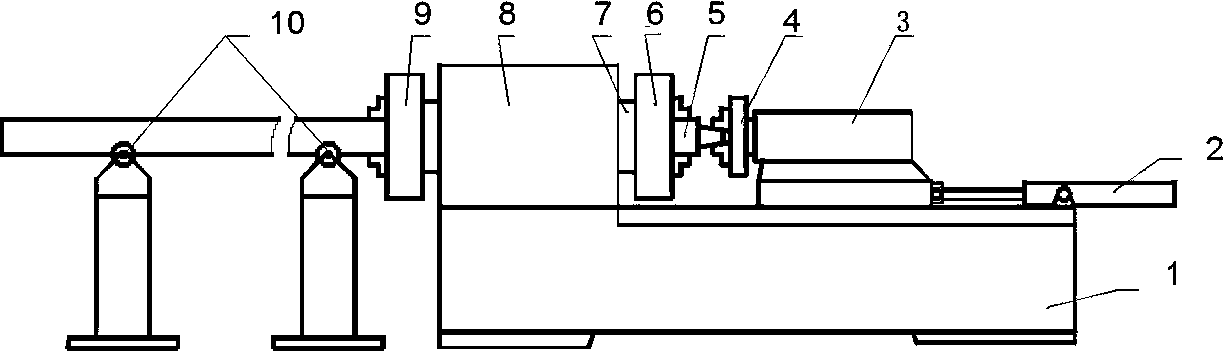

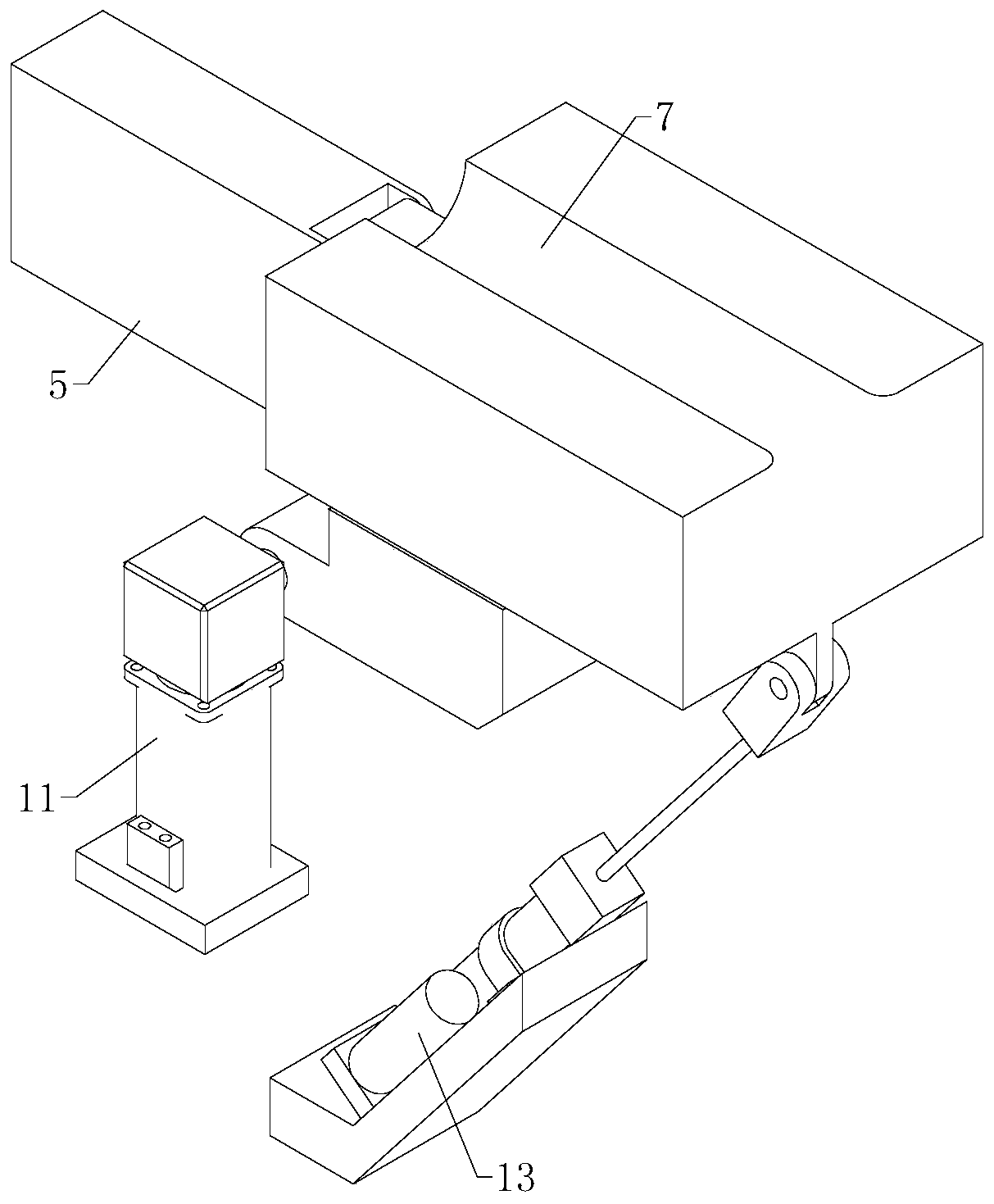

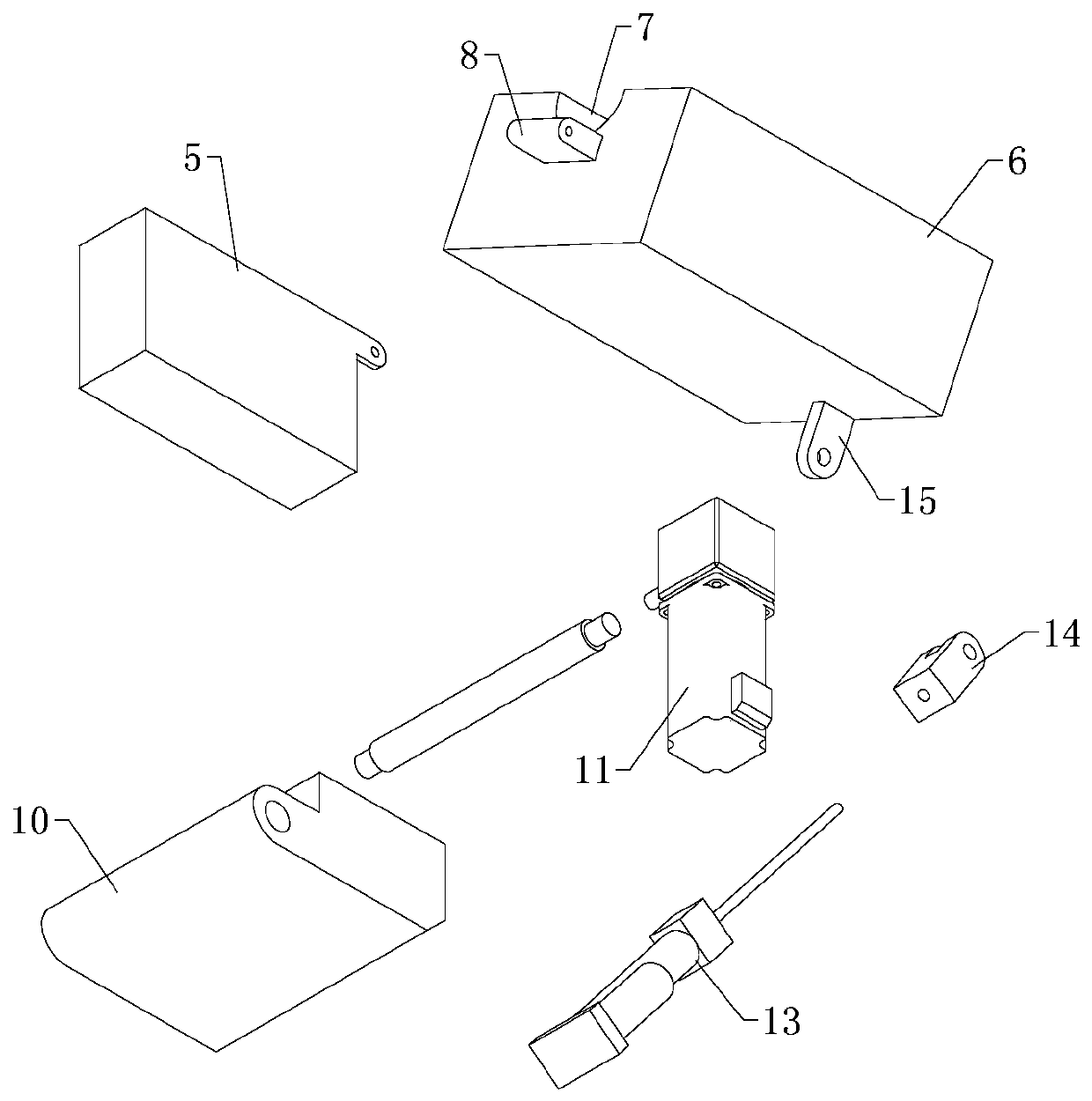

Automatic positioning and clamping device and method of drill rod and drill collar on pipe threading lathe

InactiveCN103506636ARealize automatic feeding processAchieve positioningChucksMetal working apparatusNumerical controlEngineering

The invention provides an automatic positioning and clamping device of a drill rod and a drill collar on a pipe threading lathe. The device comprises a lathe bed, a tail platform, a headstock and a bracket multi-group carrier roller. The bracket multi-group carrier roller is arranged on one side of the lathe bed, the headstock and the tail platform are arranged on the lathe bed, and the headstock (8) is arranged on one side close to the bracket multi-group carrier roller (10). According to the device and method, automatic feeding, positioning, clamping and discharging of workpieces can be achieved. The purpose of the device and method is to achieve the full-automatic machining processes, including feeding and discharging, of the numerical control pipe threading lathe.

Owner:SHENYANG POLYTECHNIC UNIV

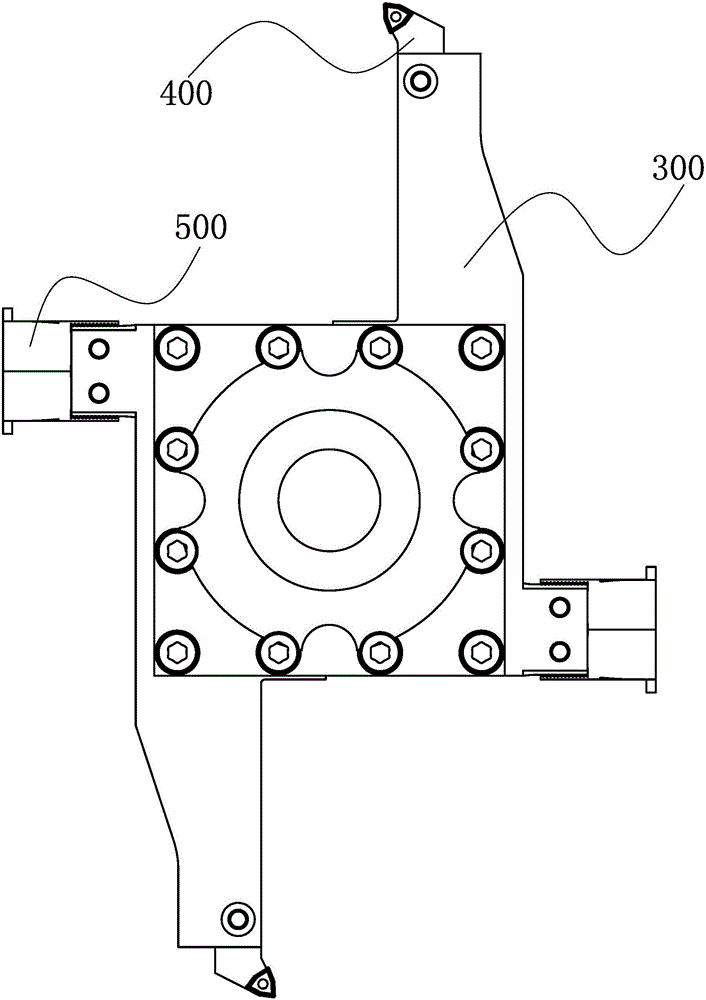

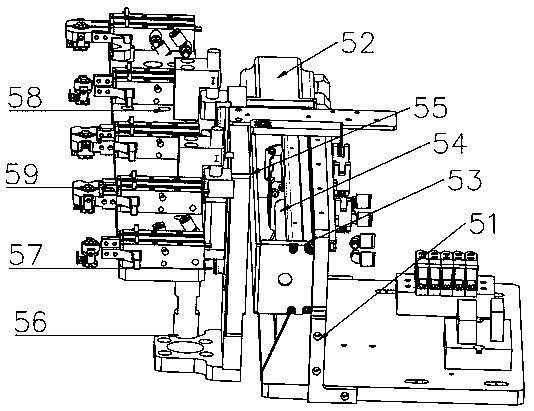

Cutter bar device of multi-functional digital controlled lathe

The invention provides a cutter bar device for a multi-functional digital controlled lathe. The cutter bar device comprises a cutter frame, a rotation shaft seat, two cutter bars, two outer-circle cutter bodies and four internal-groove cutter bodies; a first flat plate and a second flat plate are installed in the thickness direction of the cutter frame, and the first flat plate and the second flat plate are integrally molded; the rotation shaft seat is of a rotary shape, a plurality of first through holes are formed in the axial direction of the rotation shaft seat in a circular array mode, and the rotation shaft seat is fixed to the cutter frame through threaded fasteners; the two cutter bars are arranged on the two sides of the cutter frame in central symmetry, clamped between the first flat plate and the second flat plate, and fixed to the cutter frame through threaded fasteners; the two outer-circle cutter bodies are installed at one ends of the two cutter bars correspondingly; and the four internal-groove cutter bodies are installed at the other ends of the two cutter bars correspondingly. According to the cutter bar device, the cutter bars and the cutter frame are positioned through U-shaped grooves and fixed through the threaded fasteners, so that the installation of the cutter bars and the cutter frame is stable, relative sliding and relative rotation between the cutter bars and the cutter frame are prevented, and machining precision and percent of pass of workpieces are improved.

Owner:浙江金本汽车零部件有限公司

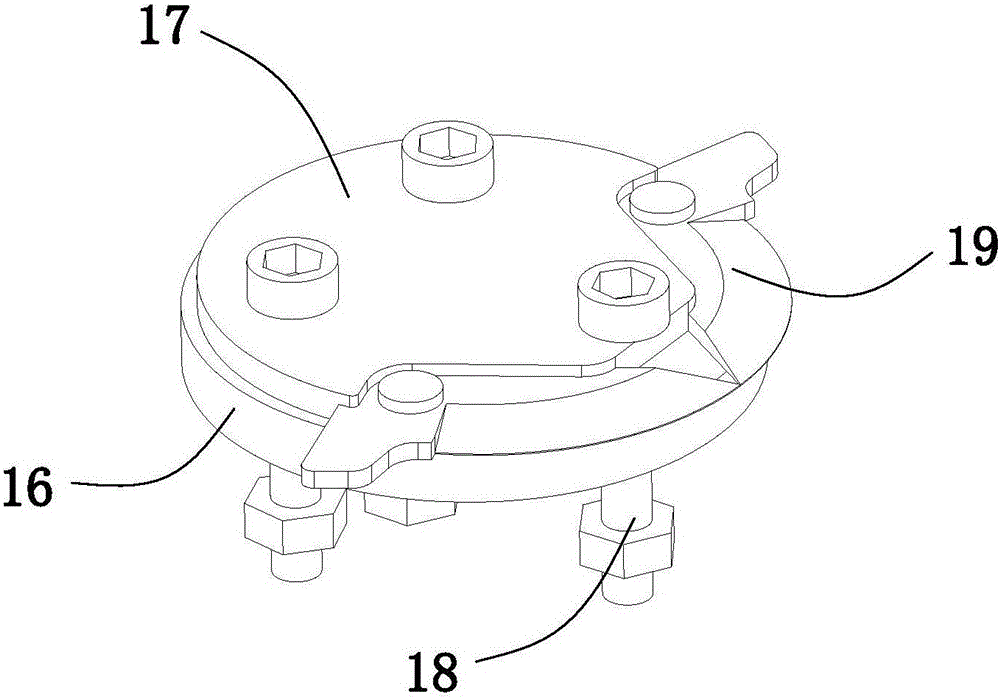

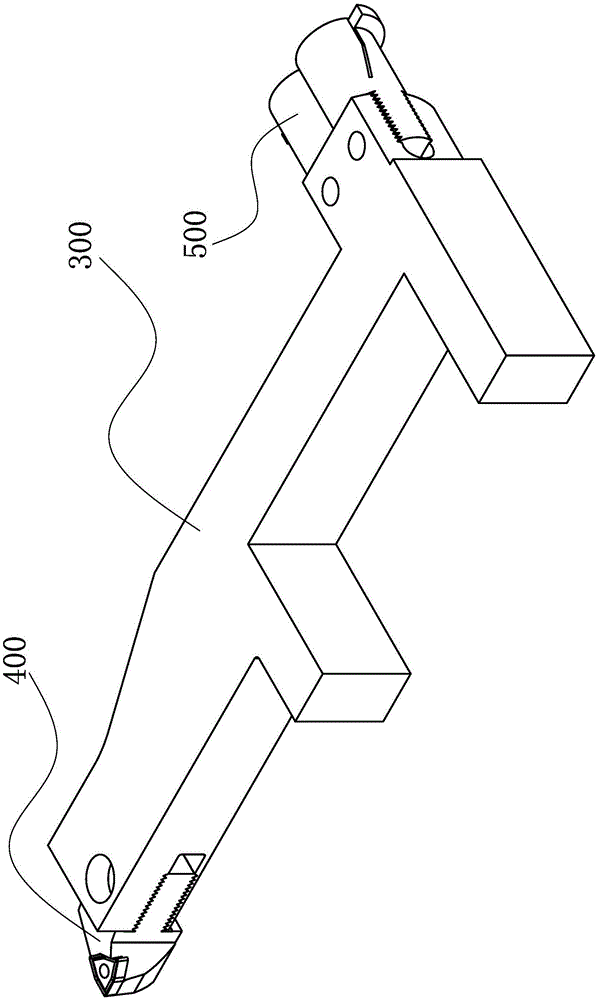

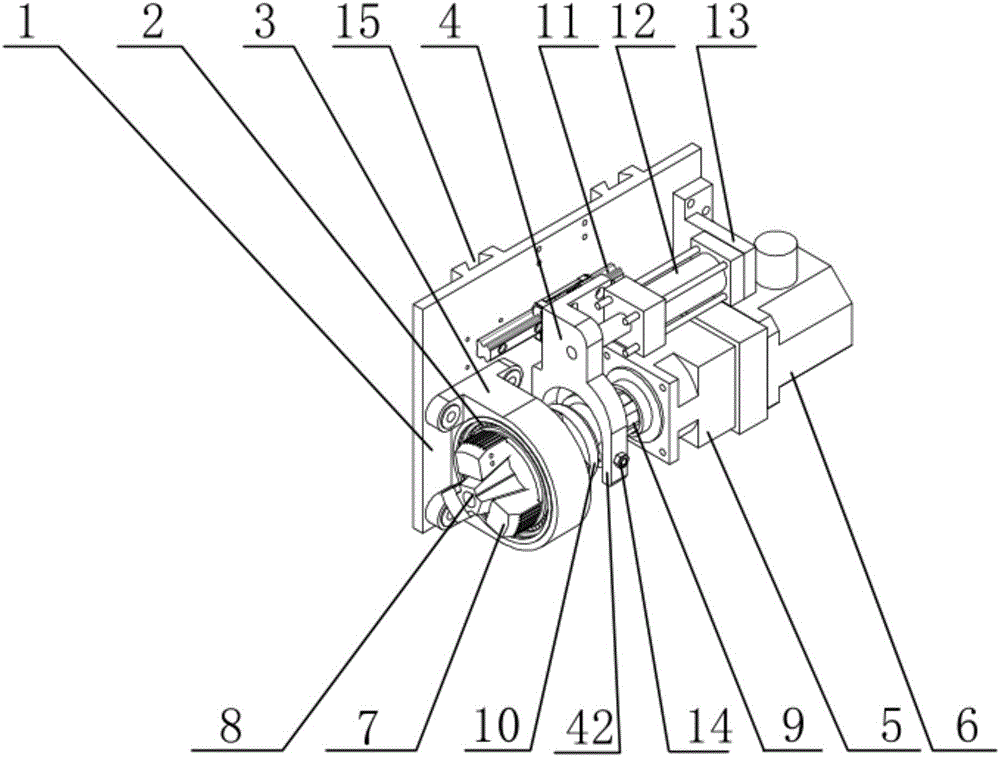

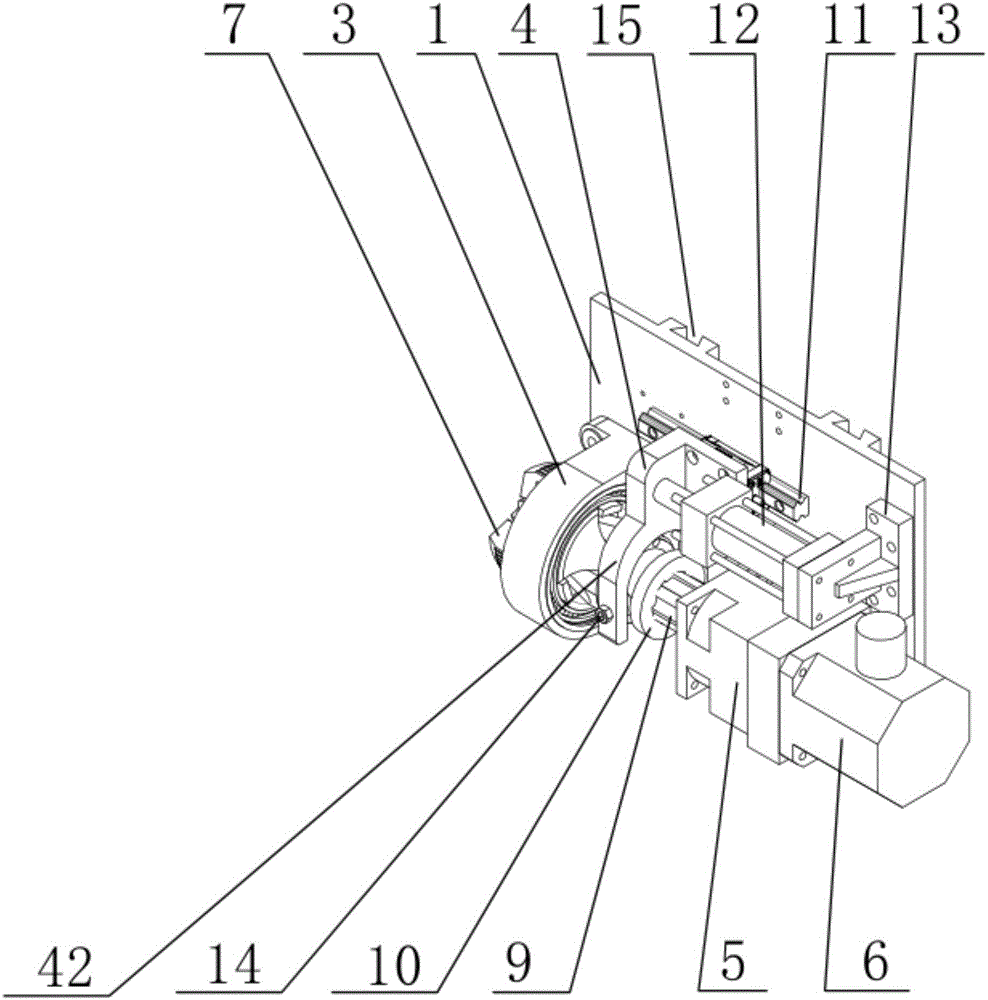

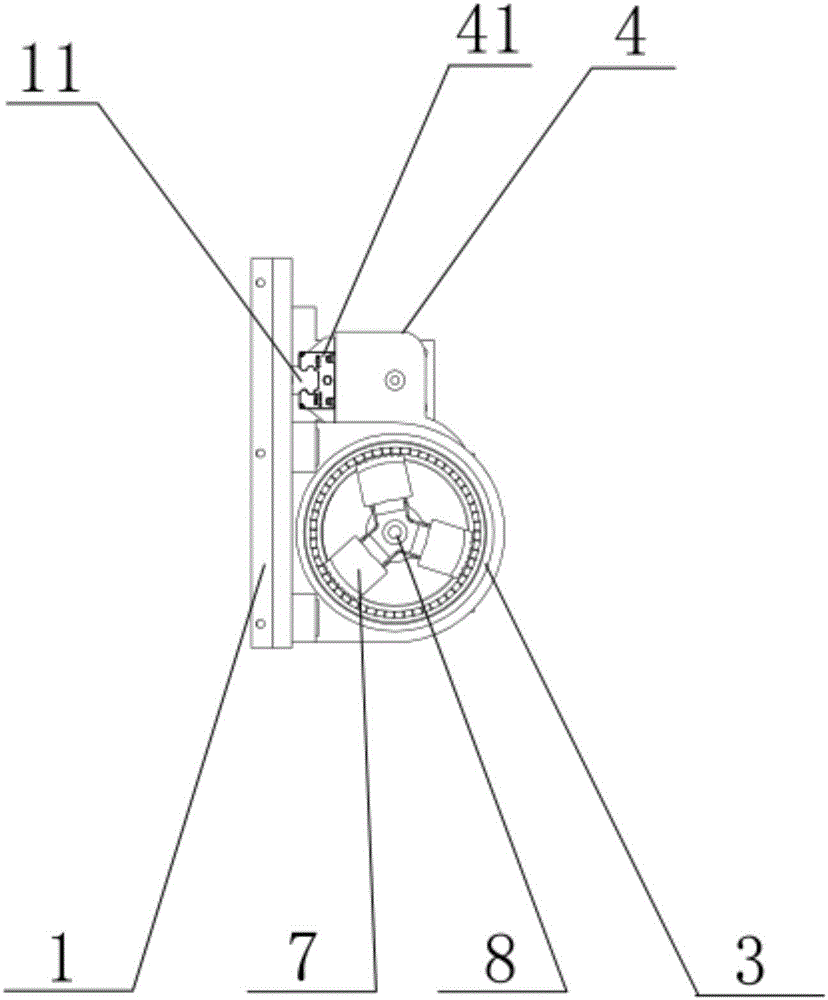

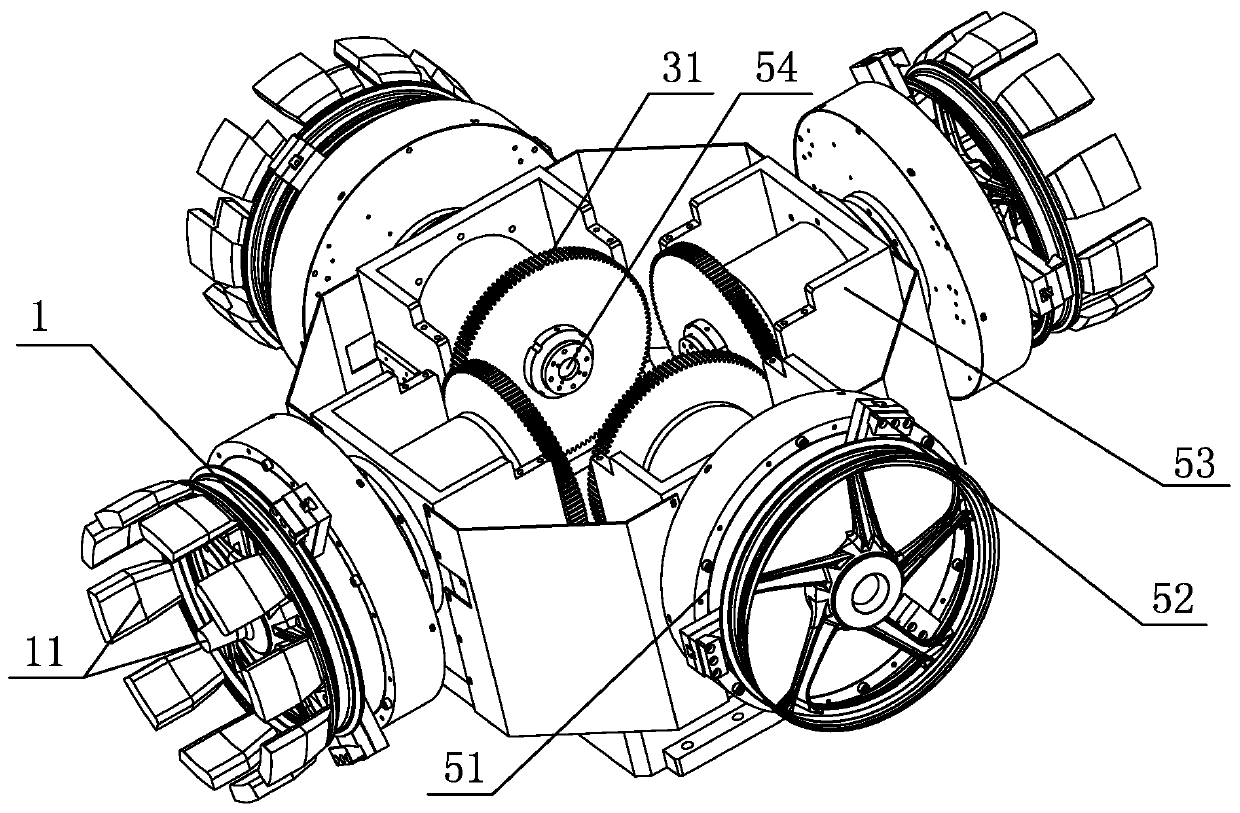

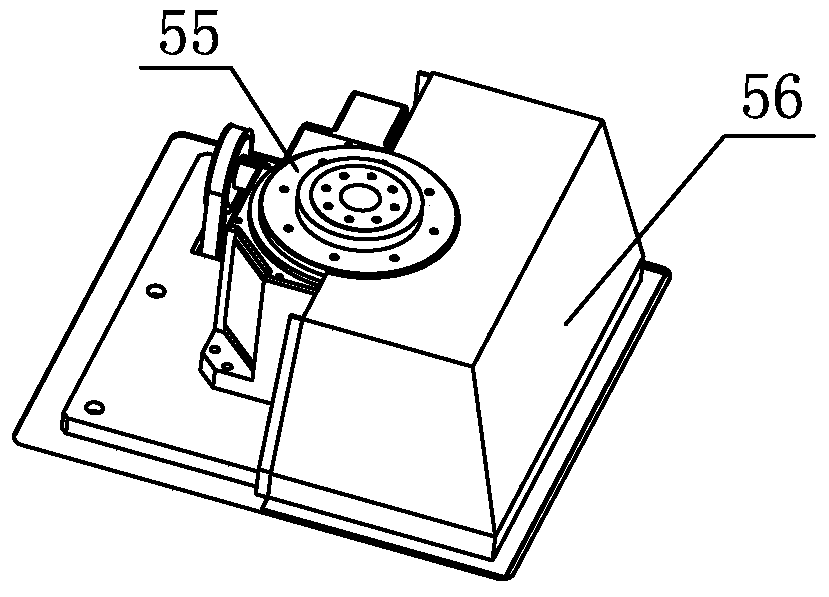

Rotating feeding device capable of achieving clamping from interior of pipe end

InactiveCN106312627AWith concentric rotation functionWith longitudinal feeding functionPrecision positioning equipmentMetal working apparatusReciprocating motionElectric machinery

The invention provides a rotating feeding device capable of achieving clamping from the interior of a pipe end. The device comprises a main shaft, a servo motor, a servo reduction machine, a shifting fork seat, a driving air cylinder, an inner strutting block and an inner strutting triple-jaw, wherein the servo motor is used for driving the main shaft to rotate, and the driving air cylinder is used for driving the shifting fork seat to perform reciprocating motion. The shifting fork seat drives a sliding block to be capable of performing inward-and-outward reciprocating motion in the axial direction of the main shaft while performing inward-and-outward reciprocating motion,. The inner strutting block and the sliding block are arranged on the main shaft from outside to inside and both can perform inward-and-outward reciprocating motion in the axial direction of the main shaft. The inner strutting triple-jaw is in limited-fit connection with a machine base. When performing outward movement in the axial direction of the main shaft, the inner strutting block can drive the inner strutting triple-jaw to perform outward expansion in the axial direction of the main shaft and the radial direction of the machine base, so that the inner strutting triple-jaw props the inner pipe wall, and the effect that the interior of the pipe end is clamped and fixed through the inner strutting triple-jaw is achieved. The rotating feeding device has the beneficial effects of being reasonable in structure, high in machining precision, good in stability, reliable in operation, convenient to adjust and the like.

Owner:ZHEJIANG KING MAZON MACHINERY

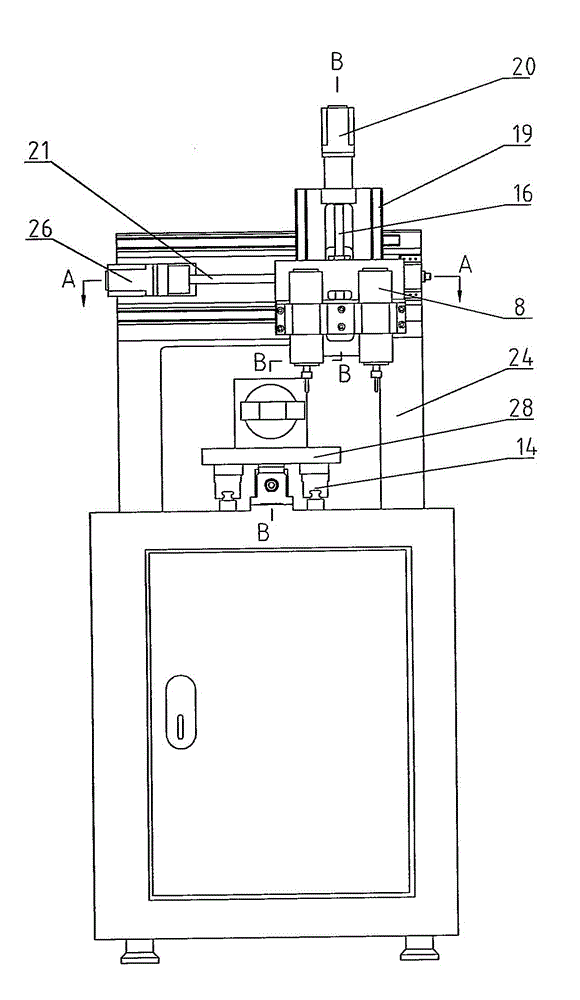

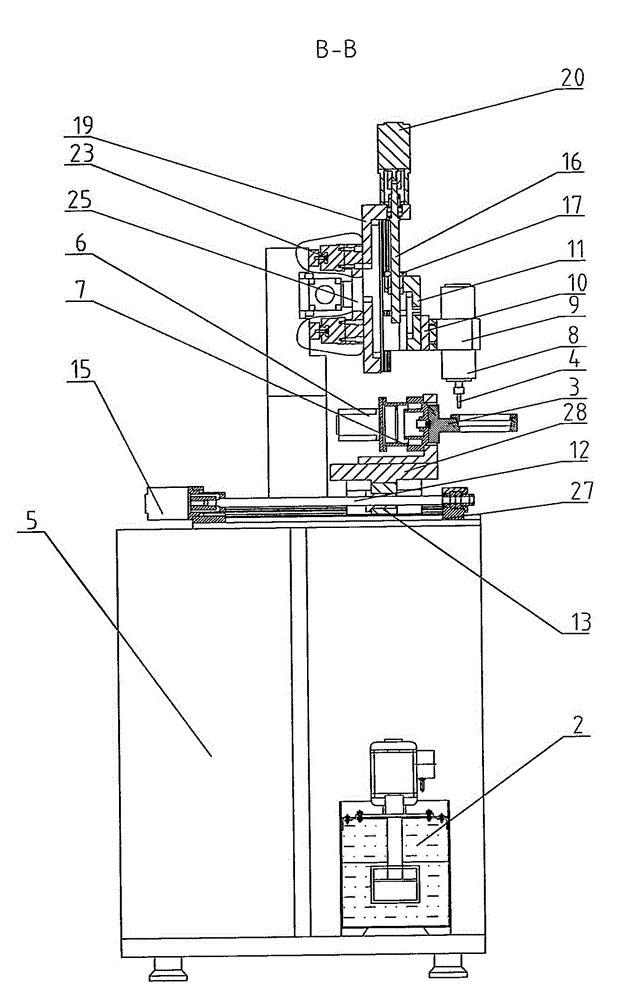

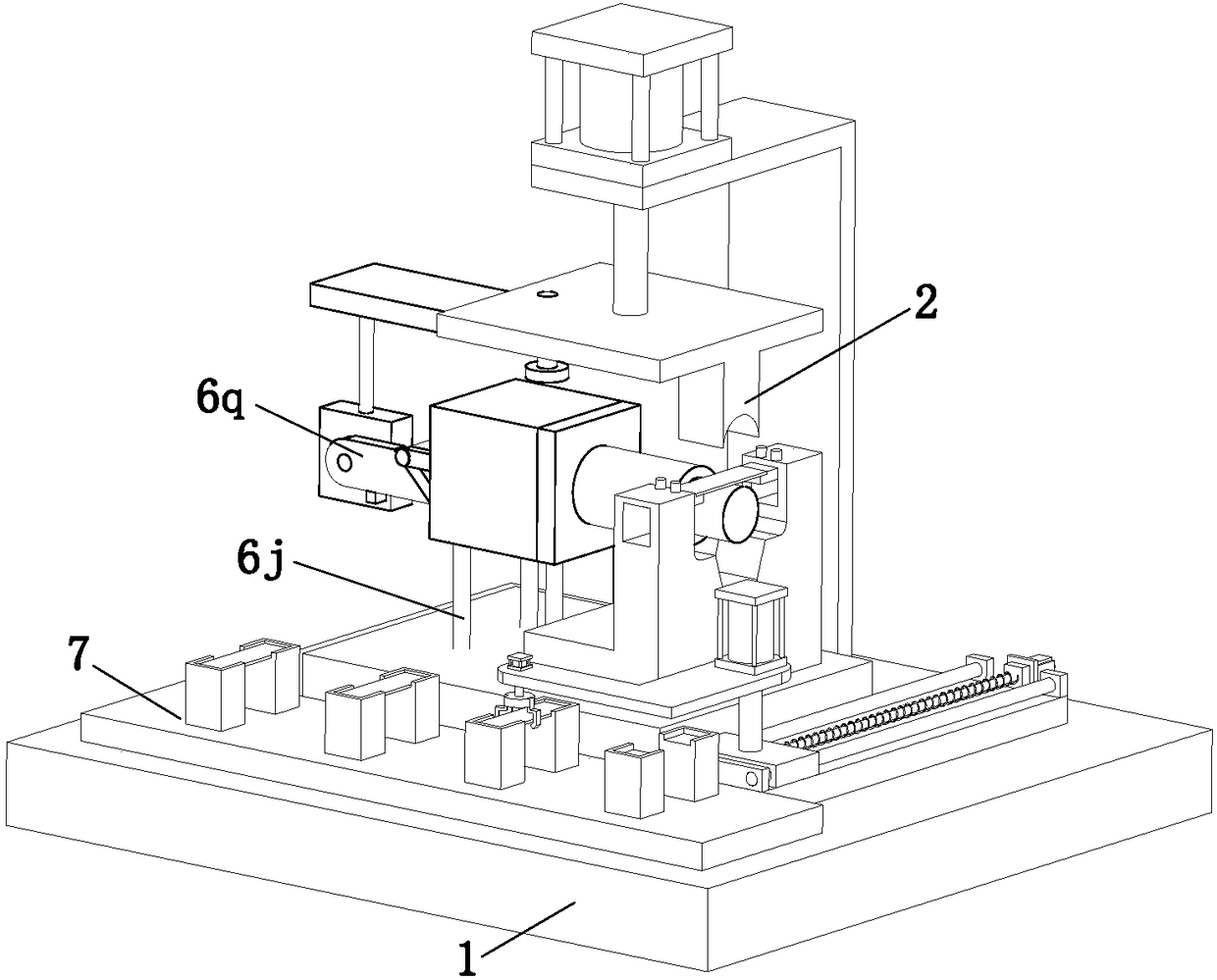

Artificial tooth machining machine

ActiveCN102871751AImprove processing efficiencyImprove machining accuracyArtificial teethMovement controlProcessing accuracy

The invention discloses an artificial tooth machining machine which comprises a base, a cutting cooling system, a too component, a double-main-shaft machining system, an A-axis workpiece rotating device, a Z-axis feed device, an X-axis feed device, a Y-axis feed device and a movement control system. The tool component is used for fixed artificial tooth blank. The double-main-shaft machining system is provided with an artificial tooth cutter. The A-axis workpiece rotating device is used for driving the tool component to rotate. The Z-axis feed device is used for driving the double-main-shaft machining system to move Z-axially. The X-axis feed device used for driving the Z-axis feed device to move X-axially. The Y-axis feed device used for driving the A-axis workpiece rotating device to move Y-axially. The movement control system is used for controlling the Z-axis feed device, the X-axis feed device, the Y-axis feed device and the A-axis workpiece rotating device to move. The double-main-shaft machining system is mounted on the Z-axis feed device. The Z-axis feed device is mounted on the X-axis feed device. The A-axis workpiece rotating device mounted on the Y-axis feed device. Four-axis linkage is achieved, machining efficiency is high, and machining precision is improved.

Owner:常州特舒隆机电设备有限公司

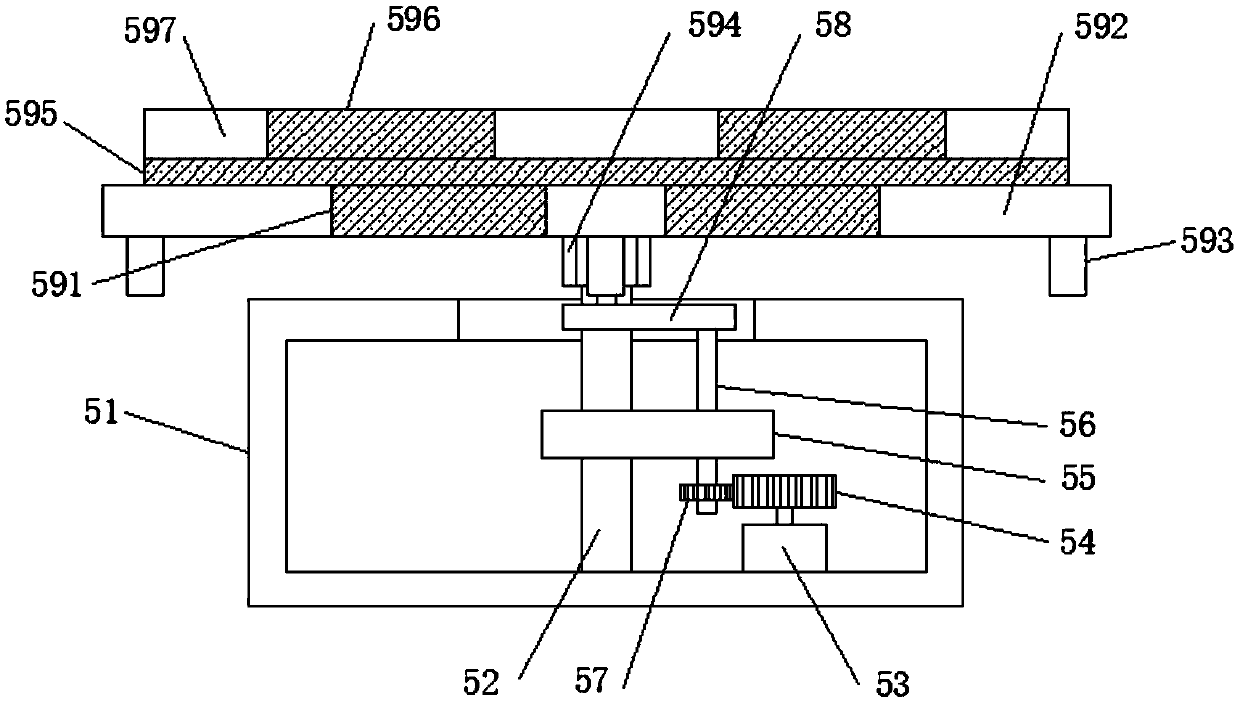

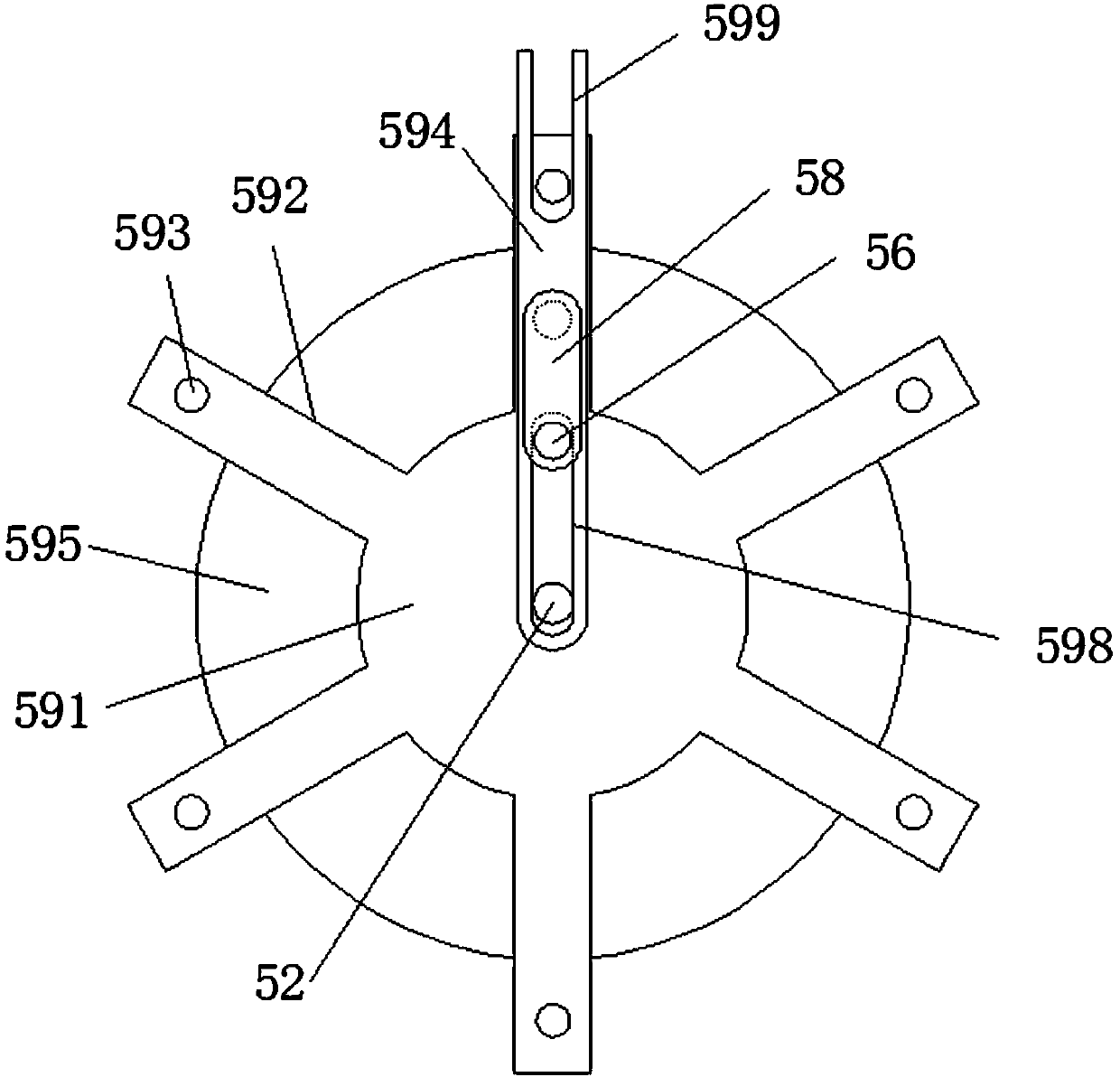

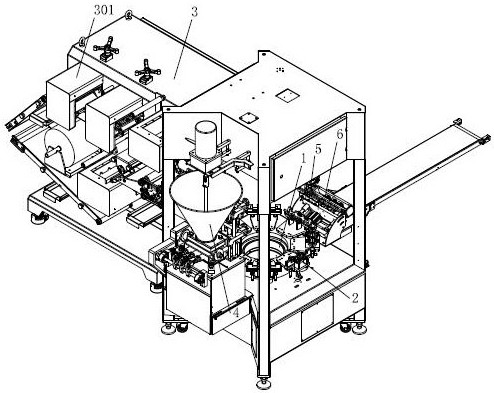

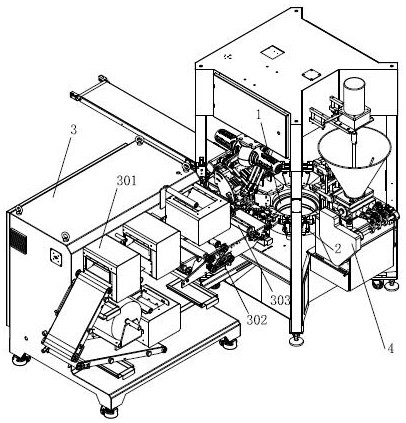

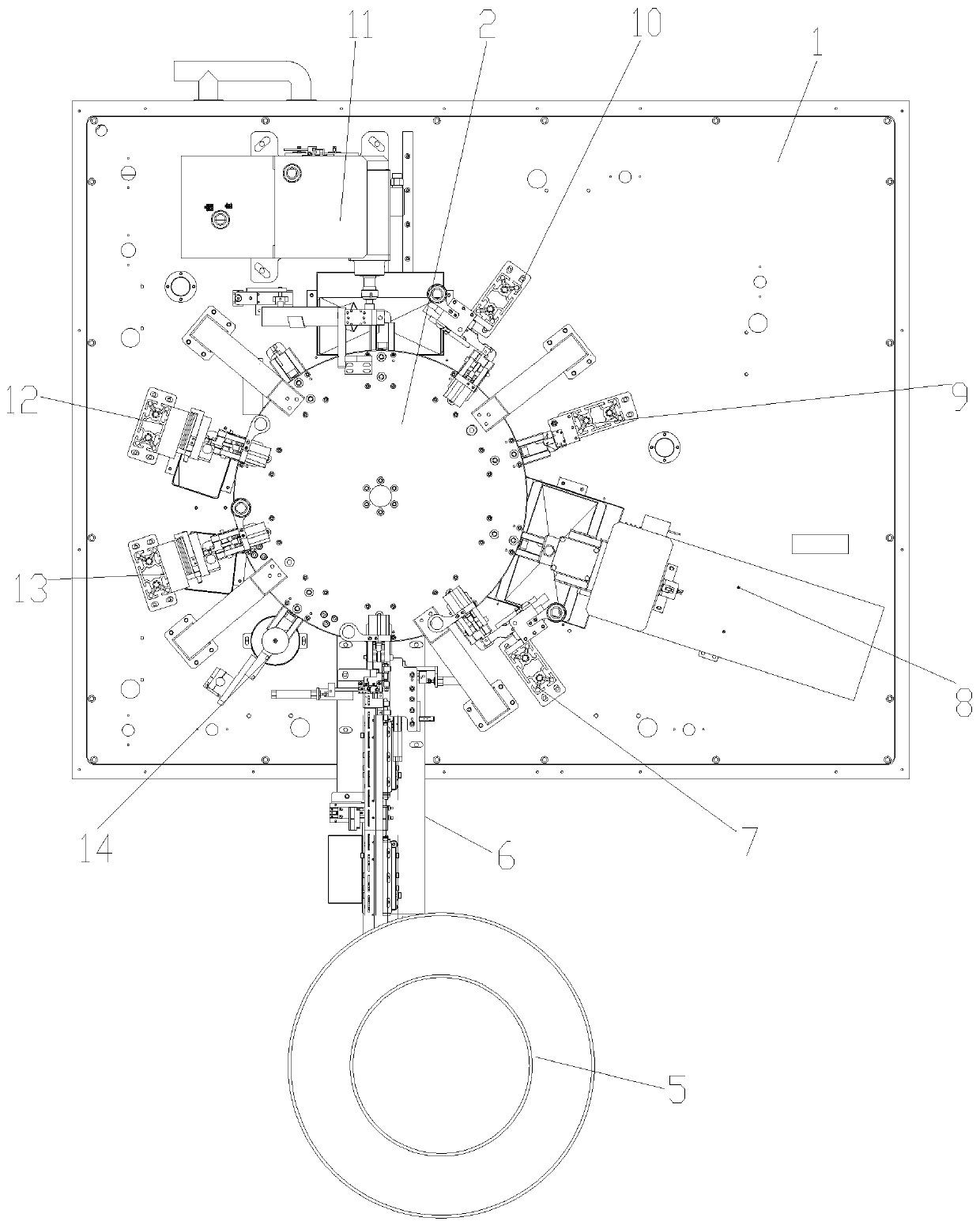

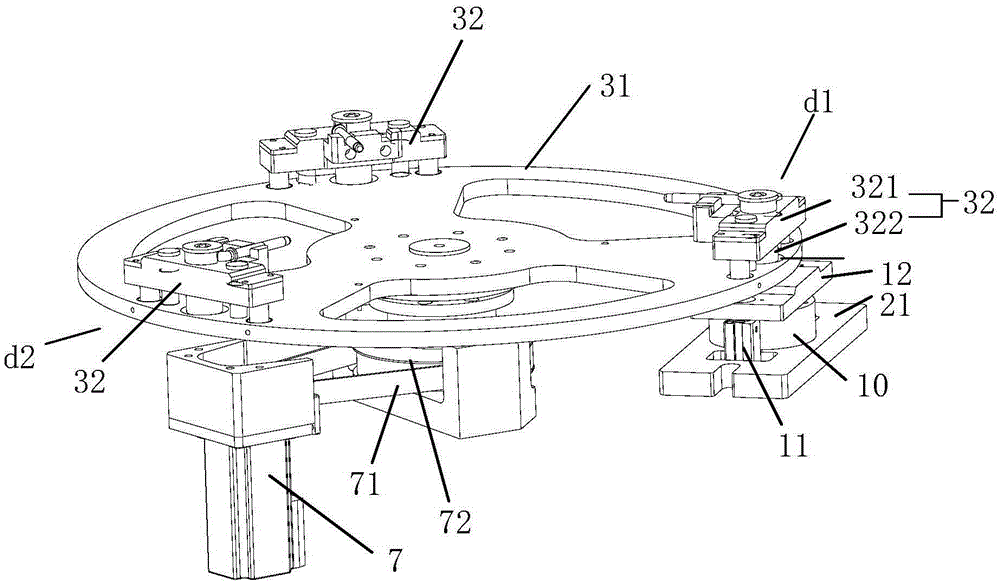

Stuffed food forming equipment and method suitable for yuanbao wontons and method thereof

InactiveCN113229302ARealize fully automatic processingAchieve a residue-free finishDough-sheeters/rolling-machines/rolling-pinsDough shaping and dividing combinationEngineeringAutomatic processing

The invention belongs to the field of food processing equipment, and particularly relates to stuffing food forming equipment and method suitable for yuanbao wontons (looks like shoe-shaped gold ingots) . The equipment can automatically process stuffed foods such as wontons, and comprises a turntable, and a wrapper making station, a stuffing injection station, a folding station and a clamping station which are sequentially distributed around the turntable, a forming station is arranged beside the clamping station, the turntable is provided with a plurality of pre-forming molds, and the pre-forming molds are driven by the turntable to rotate; and the forming station is provided with a forming device, the forming device rotates the two ends of the folded wrappers towards the middle at the same time, and the two ends of the rotated wrappers are attached together to complete final forming of the stuffed food. According to the stuffed food forming equipment suitable for the yuanbao gold ingot wontons, full-automatic processing of wonton type stuffed foods can be achieved, the overall turntable type layout is adopted, the occupied area is small, and the effect of no residual wrappers in the forming process of the stuffed food can be achieved.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

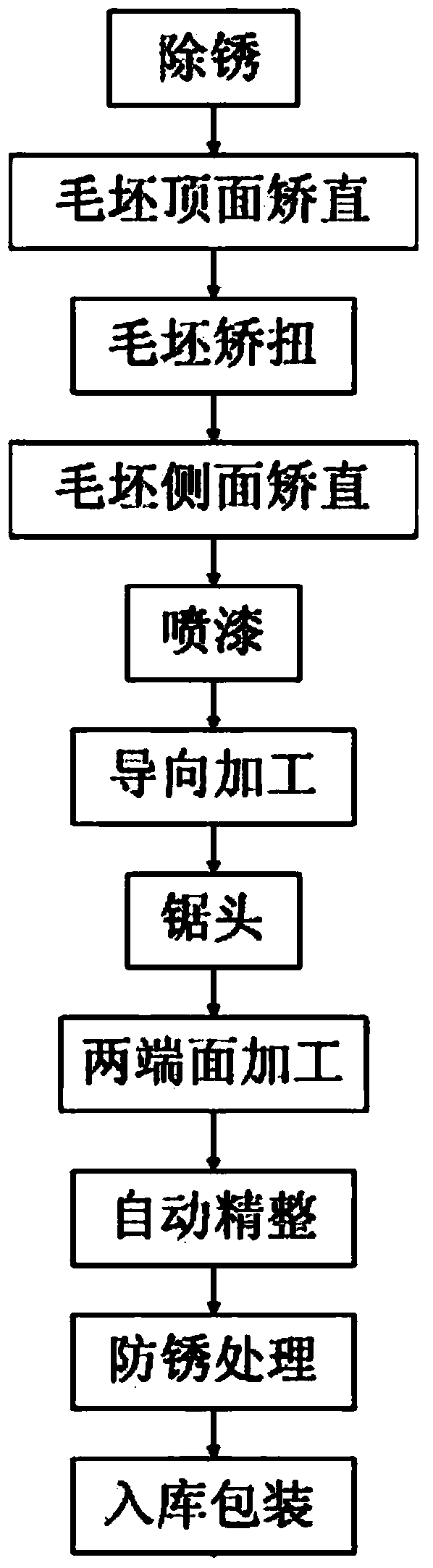

T-shaped guide rail automatic machining process

ActiveCN103817494AImprove adhesion fastnessImprove the environmentLinear bearingsEngineeringMachining process

The invention relates to a T-shaped guide rail automatic machining process. The T-shaped guide rail automatic machining process includes the following steps of removing rust, conducting straightening and twist correcting on the top face of a blank, straightening the side face of the blank, spraying paint on the non-machined face of the blank, conducting guiding and machining, sawing the head, machining the two end faces of a guide rail, conducting automatic finishing, coating antirust oil on the machined face, and conducting film pasting. The step of spraying paint on the non-machined face of the blank in the process is executed in advance, the phenomena that oil stains exist on the surface after machining and paint removing and rusting happen to the surface are eliminated, and after the step of spraying paint on the non-machined face of the blank is executed in advance, the adhesive firmness of paint is increased, and the workshop environment is improved.

Owner:长江润发(张家港)机械有限公司

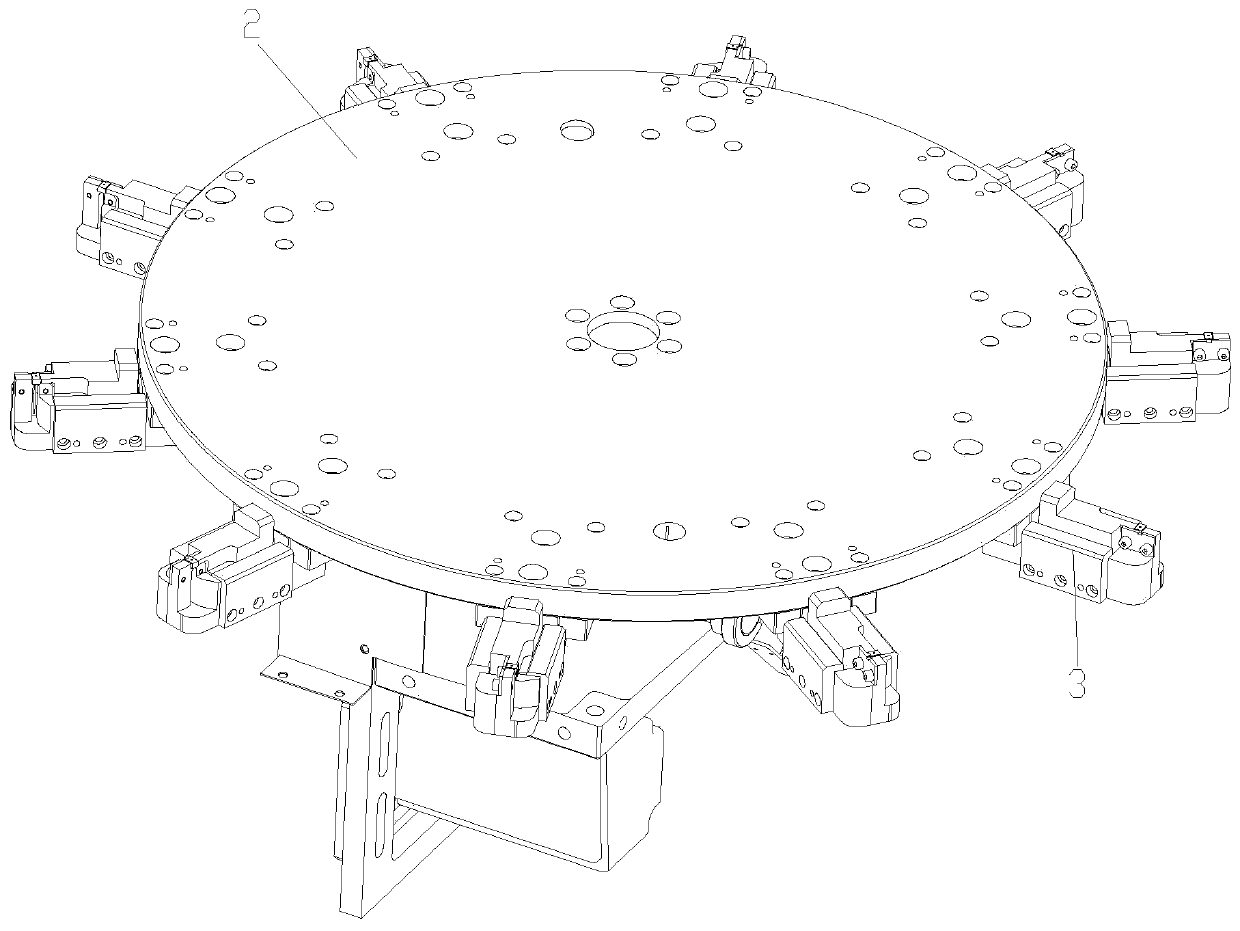

Carbon brush automatic processing machine

PendingCN110202449AImprove processing efficiencyReduce labor costsGrinding feed controlGrinding machinesEngineeringMechanical engineering

The invention provides a carbon brush automatic processing machine. The carbon brush automatic processing machine comprises a worktable, wherein a rotary disk is installed on the worktable, carriers arranged in a ring array are installed along the outside edge of the rotary disk, carbon brushes are installed in the carriers, a vibration disk is further arranged on the outer side of the worktable,the vibration disk conveys the carbon brushes into the carriers through an automatic loading mechanism, a first positioning device, a plane polishing machine, a planeness detection mechanism, a secondpositioning device, an arc surface polishing machine, an accepted product unloading mechanism, a defective product unloading mechanism and a carrier cleaning mechanism are installed on a part, on theouter side of the rotary disk, of the worktable, and surround the rotary disk, and the automatic loading mechanism, the first positioning device, the plane polishing machine, the planeness detectionmechanism, the second positioning device, the arc surface polishing machine, the accepted product unloading mechanism, the defective product unloading mechanism and the carrier cleaning mechanism arerespectively arranged in correspondence with the carriers on the outside edge of the rotary disk. The carbon brush automatic processing machine can achieve full automatic surface processing of the carbon brushes, reduces labor cost, and achieves high processing efficiency.

Owner:DONGGUAN YI CHENG AUTOMATIC EQUIP

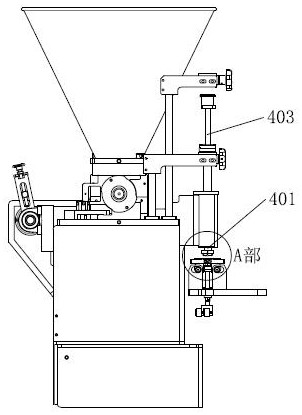

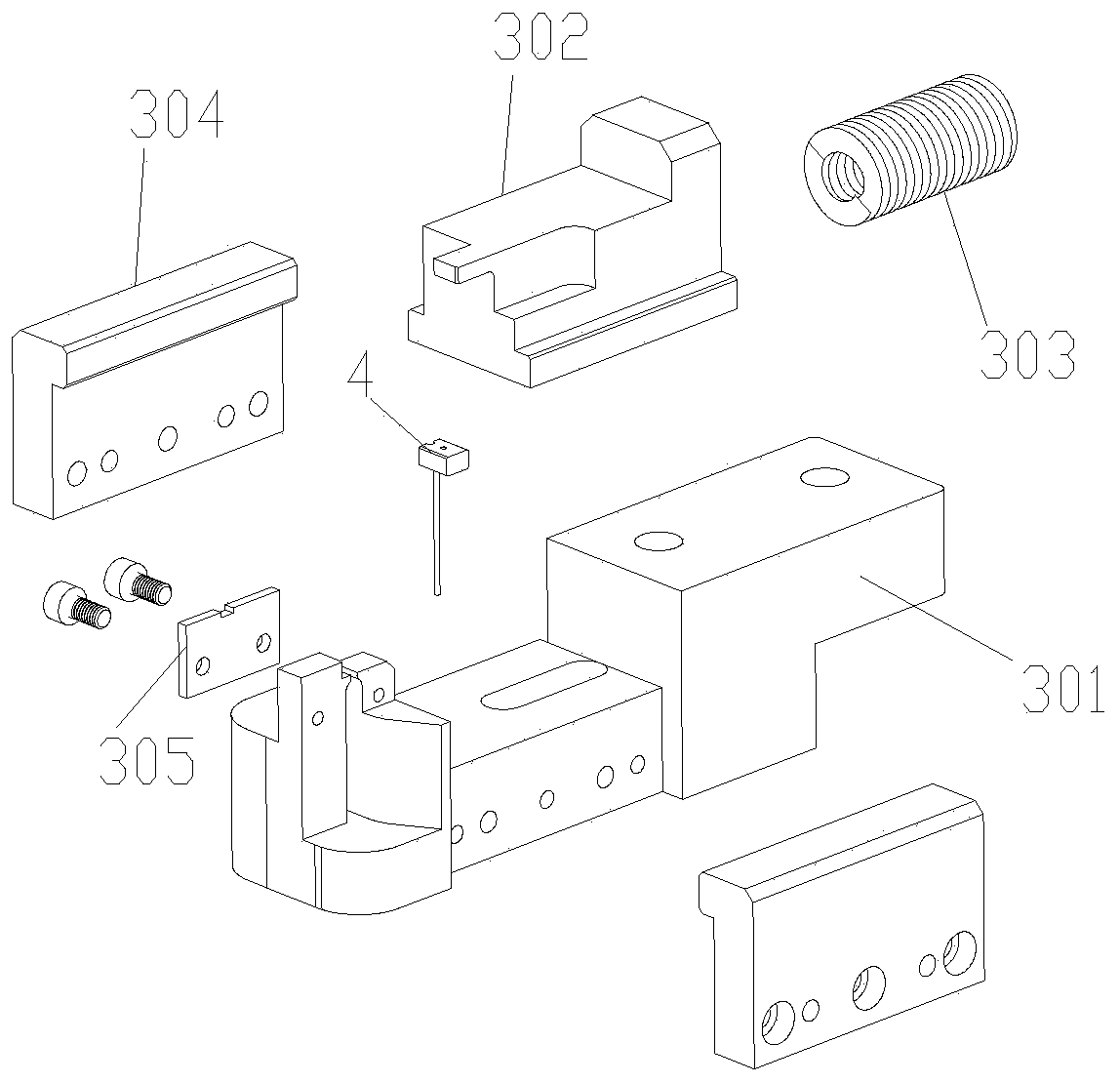

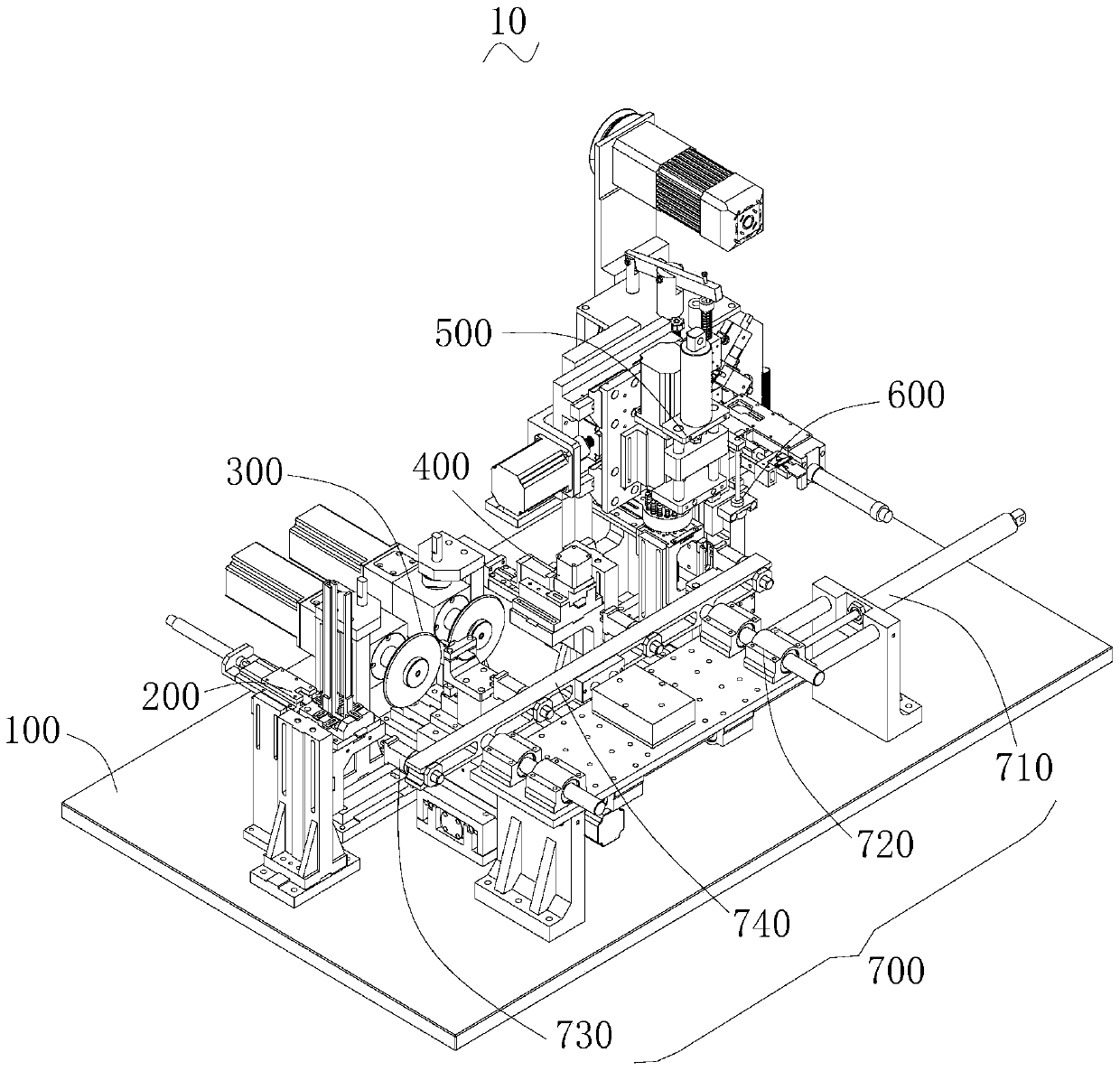

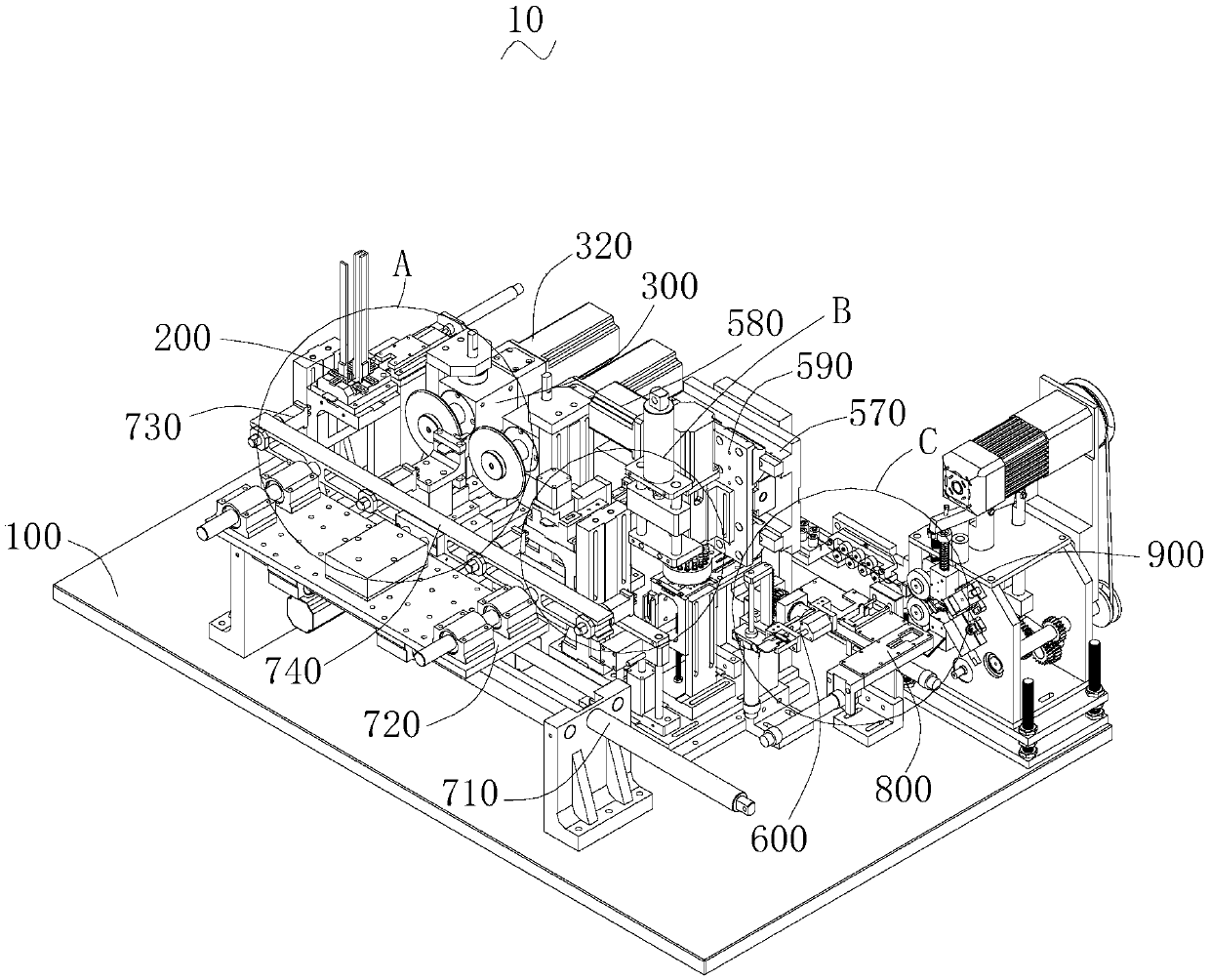

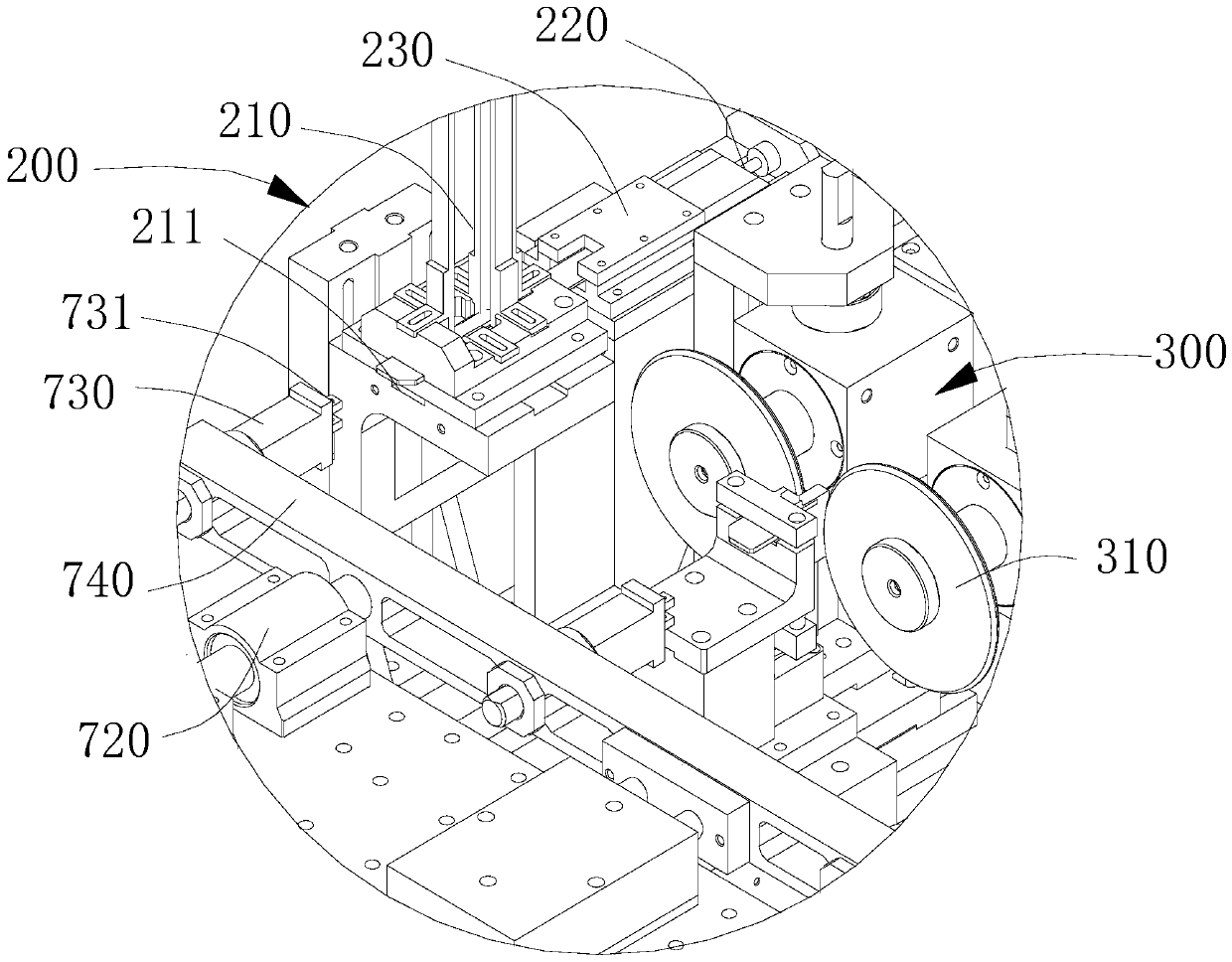

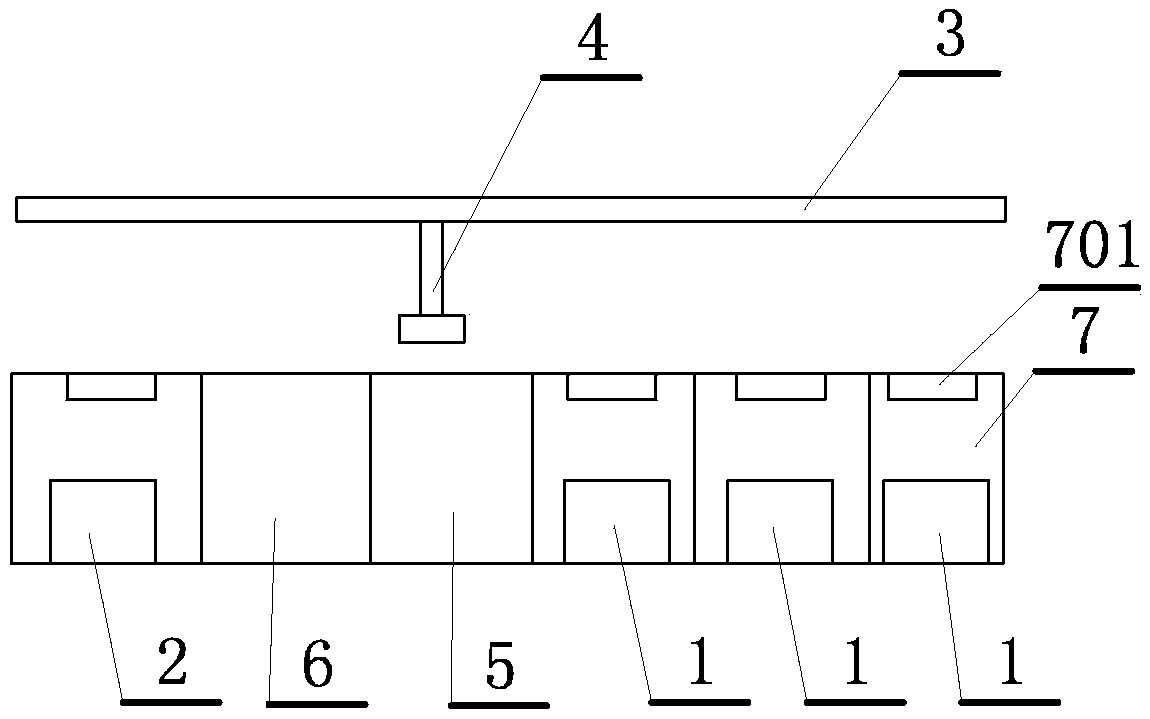

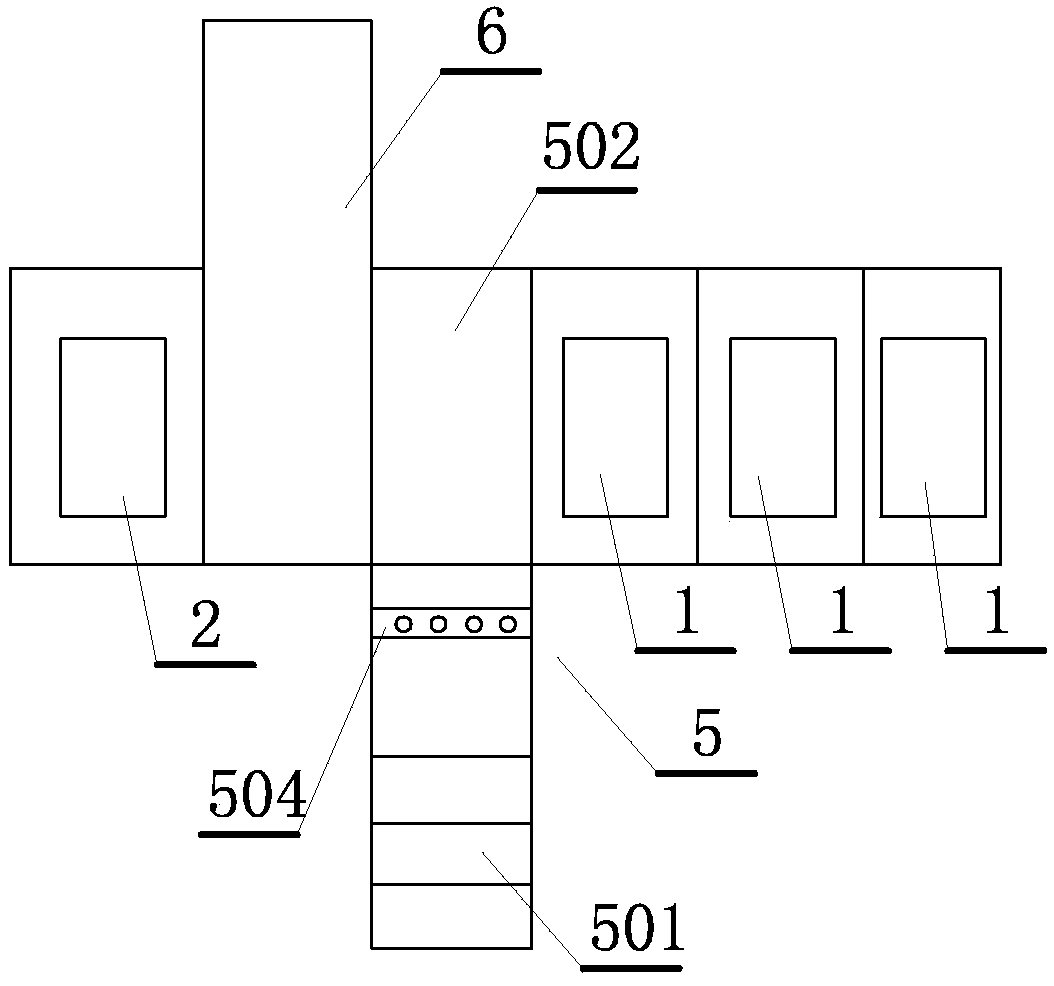

Pipe connector external thread full-automatic machining device

ActiveCN110802188ARealize fully automatic processingImprove efficiencyMetal-working feeding devicesScrew-threads articlesEngineeringScrew thread

The invention relates to the field of machining, in particular to a pipe connector external thread full-automatic machining device. The pipe connector external thread full-automatic machining device comprises a base, a thread rolling device, an abutting device, a feeding device, a pushing device, a discharging device and a conveying device; the thread rolling device is arranged at one end of the upper portion of the base; the abutting device is arranged on the upper portion of the base; the side of the base is provided with a supporting frame, and the pushing device is arranged on the upper portion of the supporting frame; the feeding device is arranged on the upper portion of the supporting frame, and the discharging device is arranged between the supporting frame and the base; the conveying device is fixedly arranged on the lower portion of the supporting frame; and the thread rolling device comprises two rollers and two moving seats, the two rollers are both provided with threads and arranged at the output ends of the two moving seats correspondingly, and the middle of the two rollers is provided with a fixing seat. According to the pipe connector external thread full-automaticmachining device, pipe connector full-automatic machining is achieved, the efficiency is high, manpower is decreased, and the production cost is reduced.

Owner:丽水市莲都区贝亿乐信息技术服务有限责任公司

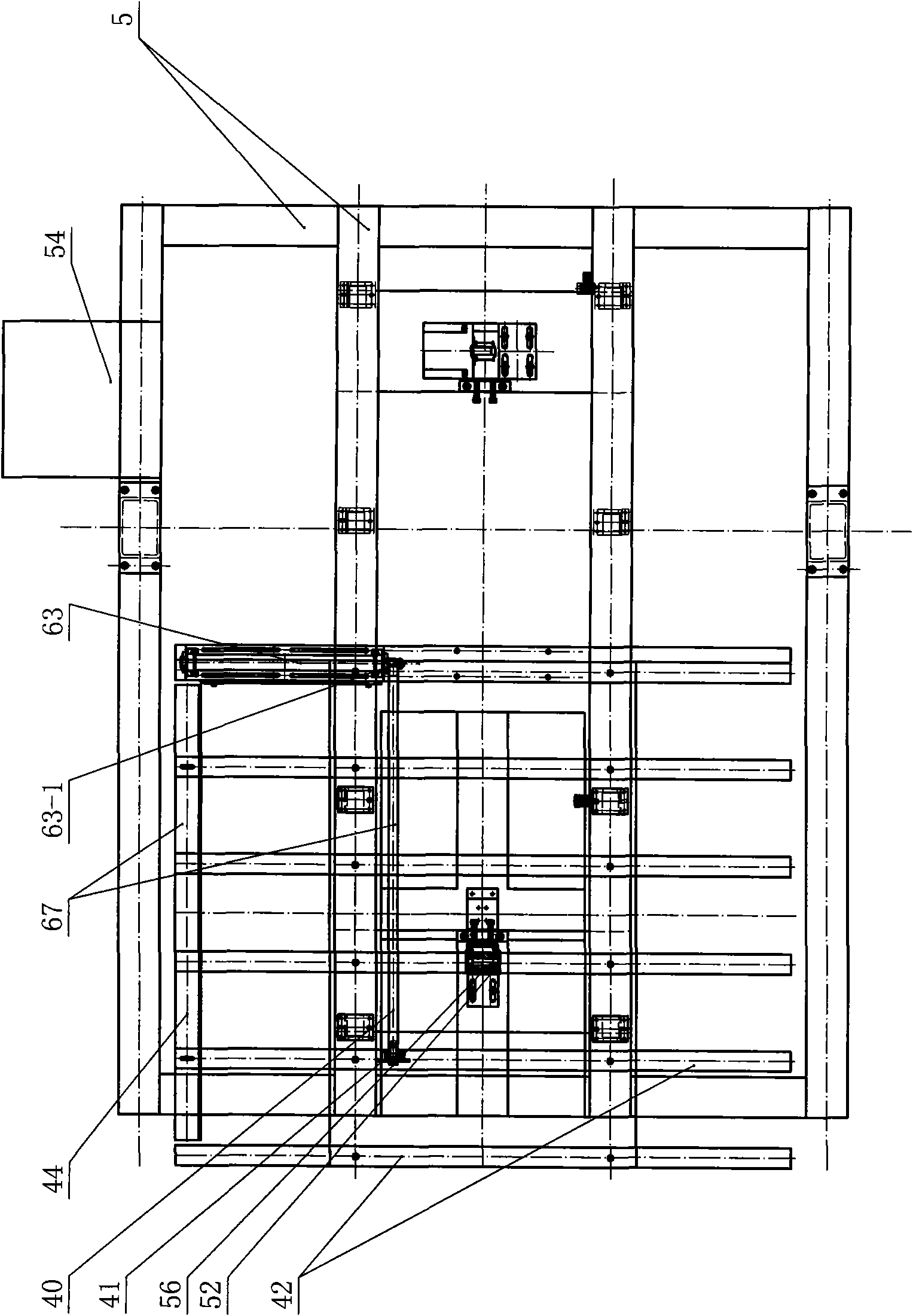

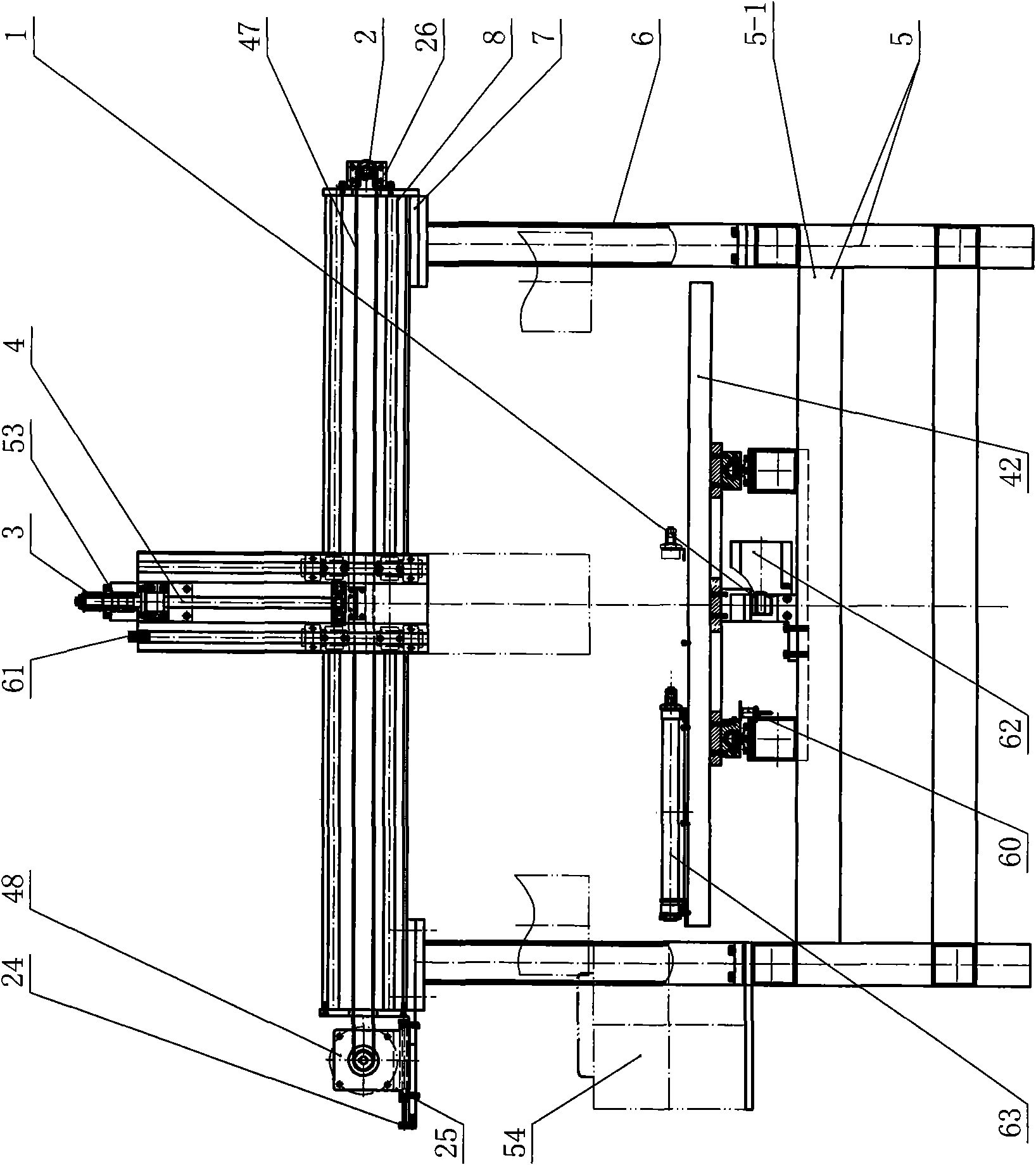

CNC (Computer Numerical Control) four-axis full-automatic foam die-free forming machine

ActiveCN102126231ARealize full circle rotationImprove processing qualityMetal working apparatusNumerical controlFree form

The invention relates to a foam forming machine, in particular to a CNC (Computer Numerical Control) four-axis full-automatic foam die-free forming machine which comprises a digital control computer, an electric heating wire transformer (54), an electric heating wire (64), a machine body (5), an operating platform (42), a stand column (6), a beam (8) and a Z-direction sliding device (73), wherein an X-direction sliding device (71) is arranged on the beam (8). The CNC four-axis full-automatic foam die-free forming machine also comprises a fixing device (67) for a workpiece to be processed on the operating platform (42). The workpiece to be processed moves linearly forth and back along the Y-axis direction, the electric heating wire (64) moves linearly left and right along the X-axis direction and moves linearly up and down along the Z-axis direction, and the electric heating wire (64) rotates. The invention has the advantages of simple structure, realization of processing various complicated shapes of foams, good processing quality, low cost and wide application range.

Owner:常州市新罗特数控机械有限公司

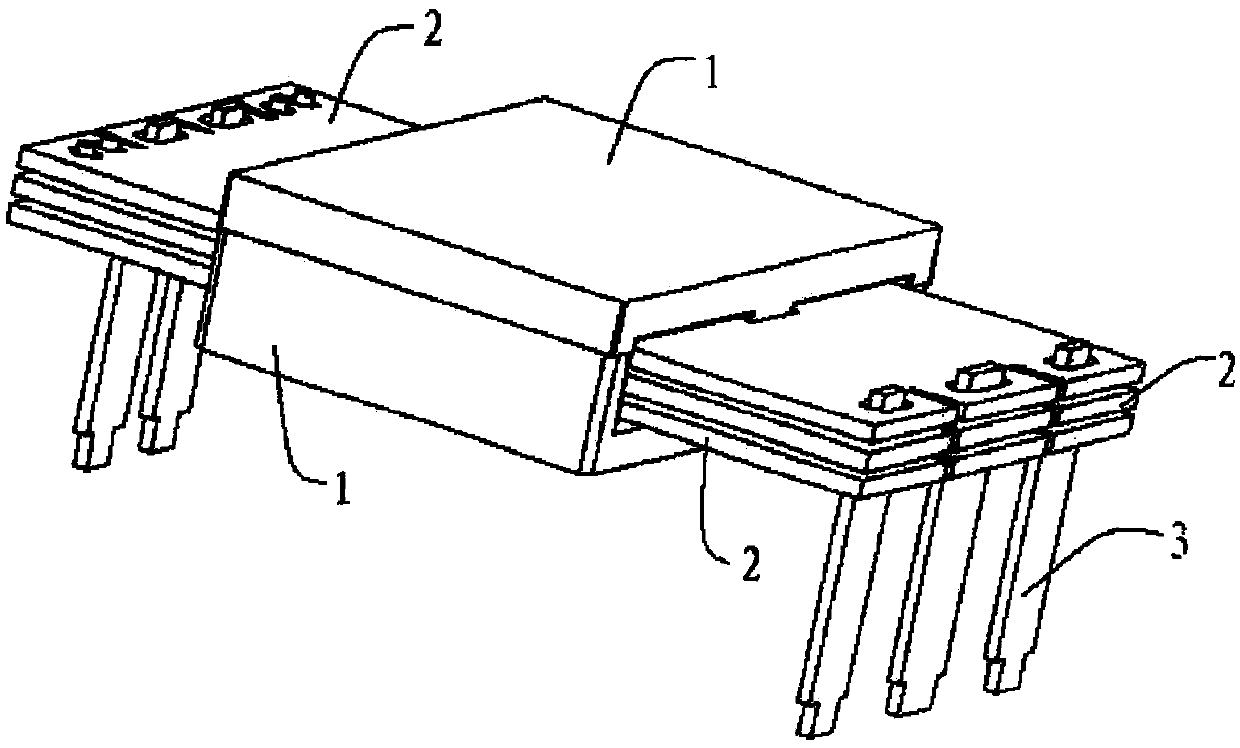

Flat panel transformer and switching power adapter

ActiveCN107808756AEasy to processImprove securityTransformers/inductances casingsTransformers/inductances coils/windings/connectionsTransformerEngineering

The present application provides a flat panel transformer and a switching power adapter. The flat panel transformer includes a PCB winding and two magnetic cores. The two magnetic cores are respectively wrapped on both sides of the winding body of the PCB winding to form a closed magnetic circuit. A first set of welding points is arranged on the side of the primary winding of the PCB winding, anda second set of welding points is arranged on the side of the side of the secondary winding. The flat panel transformer is welded directly to an external circuit board through the first set of weldingpoints and the second set of welding points. In this way, the welding of PIN pins on the PCB winding board is not needed. Therefore, the processing order of the flat panel transformer is simplified,the fully automated processing is achieved, the processing time cost is educed, and the processing efficiency is improved. Moreover, the flat panel transformer can be installed vertically on the external circuit board through the first set of welding points and the second set of welding points. Compared with a horizontal flat panel transformer, the vertical installation mode reduces the space required for occupying the external circuit board and improves the space utilization rate of the external circuit board.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

Automatic glass punching machine

ActiveCN107030402AMeet the needs of the hole positionImplement automatic transferLaser beam welding apparatusPunchingTransmission belt

The invention provides an automatic glass punching machine, and belongs to the technical field of glass machining machines. The automatic glass punching machine solves the problems that an existing automatic glass punching machine still needs to be manually operated, consequently, the work efficiency is too low, and full automation cannot be achieved. The automatic glass punching machine comprises a rack and a conveying roller bed arranged on the rack. The rack is internally further provided with a lifting platform and a positioning platform. The lifting platform is internally provided with a plurality of first carrier rollers driving workpieces to move in the X-axis direction and a plurality of first conveying belts capable of driving the workpieces to move in the Y-axis direction. The first conveying belts can convey the workpieces located on the lifting platform to the positioning platform, the positioning platform is provided with a plurality of first positioning blocks distributed in the X-axis direction, and a plurality of second positioning blocks distributed in the Y-axis direction. The positioning platform is provided with a plurality of second carrier rollers and a plurality of second transmission belts. The automatic glass punching machine can achieve automatic workpiece conveying and positioning.

Owner:ZHEJIANG JIAFU GLASS CO LTD

Key machining device

ActiveCN105500011ARealize fully automatic processingImprove processing efficiencyOther manufacturing equipments/toolsMetal working apparatusEngineeringSerial code

The invention relates to a key machining device which comprises a working table. The working tale is provided with multiple installation positions located on a straight line at equal intervals; a feeding mechanism, a grinding and milling mechanism, a burr cutting mechanism, a stamping mechanism and a reclaiming mechanism are sequentially arranged on the installation positions, the working table is further provided with a conveying mechanism which comprises a first conveying cylinder, a second conveying cylinder, at least two clamp cylinders and a reclaiming rod, the reclaiming rod is parallel to the straight line, the second conveying cylinder is driven by the first conveying cylinder to move horizontally in the direction parallel to the straight line, the reclaiming rod is driven by the second conveying cylinder to move horizontally in the direction perpendicular to the reclaiming rod, and all the clamp cylinders are fixedly arranged on the reclaiming rod. The feeding mechanism, the grinding and milling mechanism, the burr cutting mechanism and the stamping mechanism are arranged in columns, key blanks in the feeding mechanism are taken out through the conveying mechanism and put into the grinding and milling mechanism, the burr cutting mechanism and the stamping mechanism to conduct tooth milling, burr cutting and serial number printing, and full automatic machining of the keys is achieved.

Owner:惠州麒华五金制品有限公司

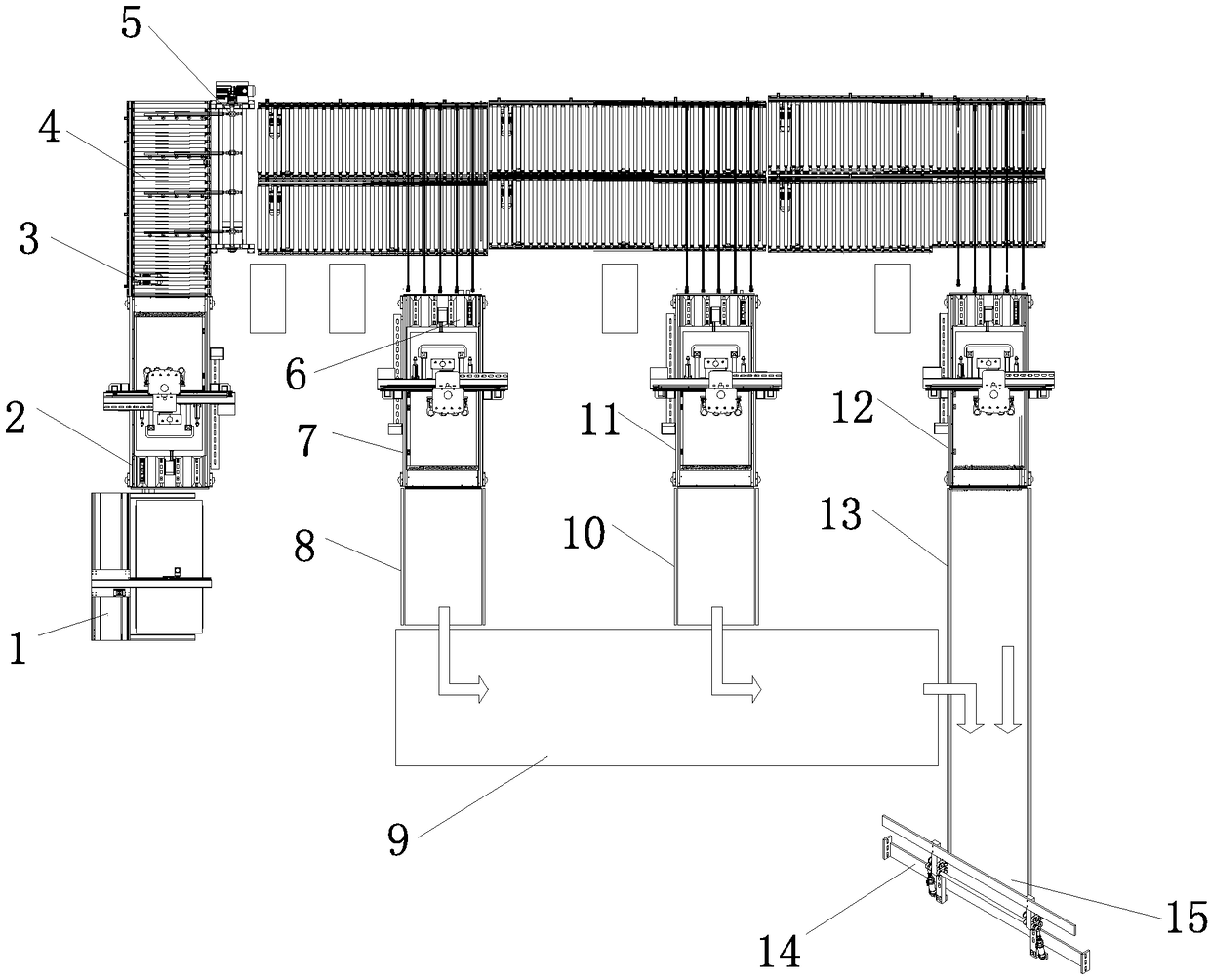

Panel furniture flexible production line

InactiveCN108466352AIncrease productivityRealize fully automatic processingWood working apparatusProduction lineEngineering

The invention relates to a panel furniture flexible production line which comprises an automatic labeling machine, an automatic tool replacing machining center, a feeding conveying line, an overturning mechanism, a first door plate machining center, a discharging conveying line, a second door plate machining center and a third door plate machining center. The automatic labeling machine and the automatic tool replacing machining center are arranged at the left end of the feeding conveying line, the first door plate machining center is connected with the discharging conveying line through a first discharging line, the second door plate machining center is connected with the discharging conveying line through a second discharging line, the third door plate machining center is connected with the discharging conveying line through a third discharging line, and a manual discharging zone is arranged at the bottom end of the discharging conveying line. According to the panel furniture flexibleproduction line, materials contained by a feeding platform are many, a large batch of door plates can be machined at a time, full-automatic processing of labeling, drilling and milling of door plateproduction is achieved, three milling centers work at the same time, the manual input is greatly reduced through the production line, the production efficiency of door plate machining is improved, andaccuracy and convenience are provided for the follow-up production process.

Owner:佛山市顺德区伟志成数控智能科技有限公司

Full-automatic assembling equipment

ActiveCN105563104ARealize fully automatic processingImprove processing efficiencyAssembly machinesEngineeringMachine tool

The invention provides full-automatic assembling equipment which comprises an installing base, a working table, machining equipment, a first robot and a second robot. The working table, the machining equipment, the first robot and the second robot are installed on the installing base. The working table comprises a rotary disc and a drive device. Three machining tools fitted with the machining equipment are installed on the rotary disc uniformly. A machining position, an operation position of the first robot and an operation position of the second robot are sequentially distributed in the rotating direction of the rotary disc. The first robot is used for taking out finished products on the machining tool located at the operation position of the first robot and placing parts on the machining tool. The second robot is used for placing the parts on the machining tool at the operation position of the second robot. The machining equipment is used for machining the parts in the machining tool at the machining position into the finished products. The full-automatic assembling equipment can automatically machine workpieces needing to be machined, so that production efficiency is improved.

Owner:NINGBO DAZHENG IND ROBOT TECH CORP

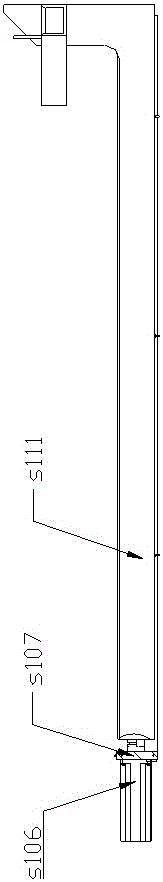

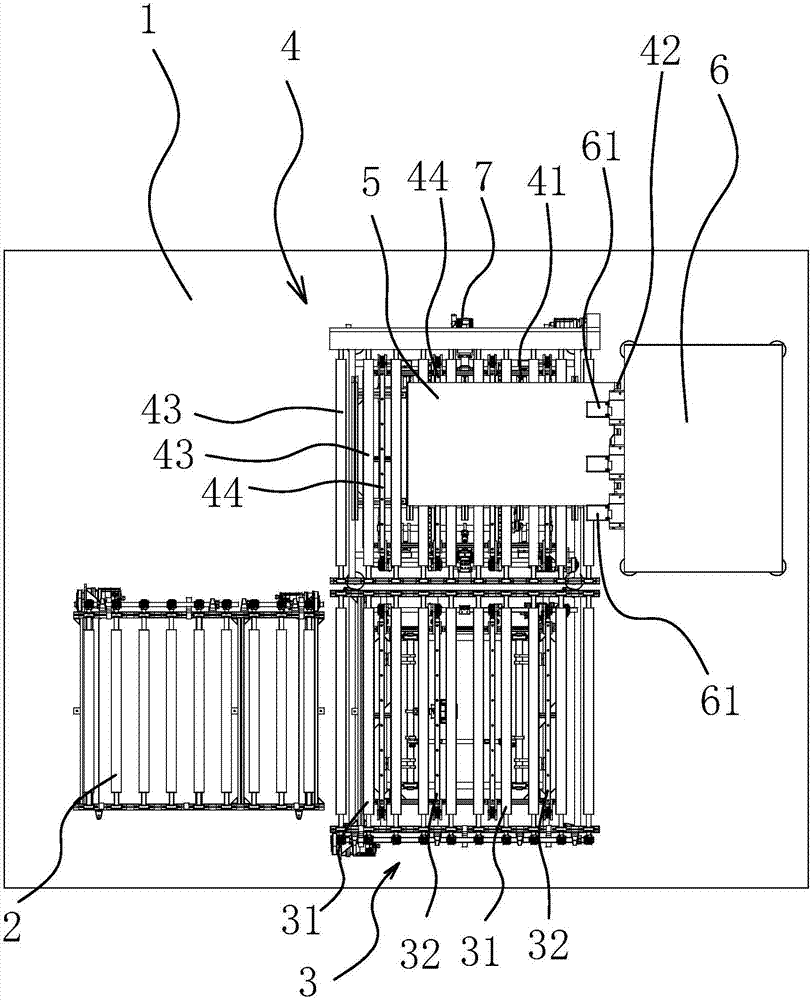

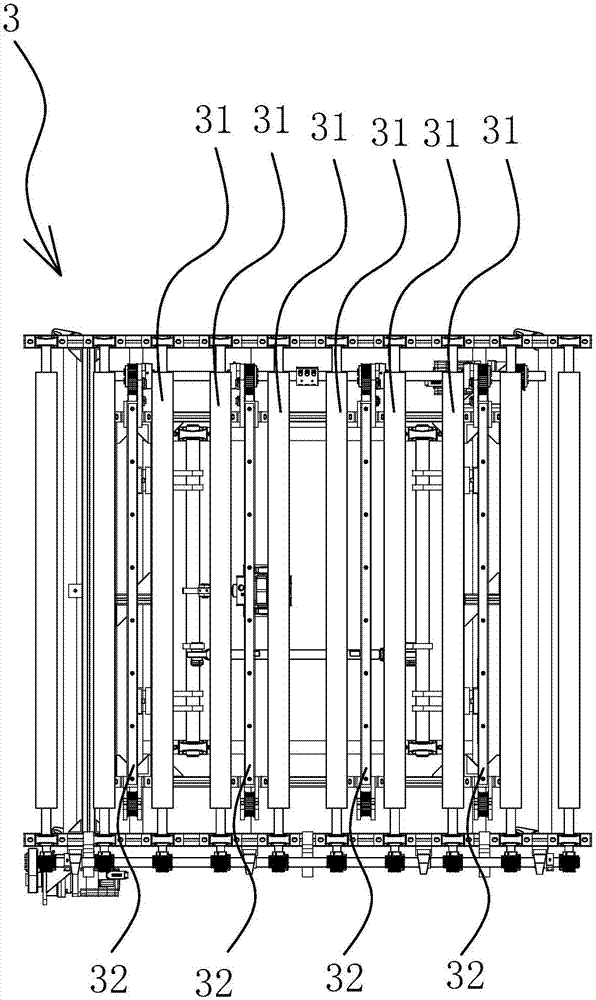

Intelligent production line for solar component frame long edge

ActiveCN107262626AAccurate riveting point processingRealize fully automatic processingMetal-working apparatusPhotovoltaicsProduction linePunching

The invention discloses an intelligent production line for a solar component frame long edge. The intelligent production line comprises a rack, a chip blowing and punching device capable of performing chip blowing and punching on the solar component frame long edge, a frame overturning and conveying device capable of overturning and backwards conveying the solar component frame long edge subjected to chip blowing and punching, and a riveting device capable of riveting the overturned solar component frame long edge, wherein the chip blowing and punching device, the frame overturning and conveying device and the riveting device are sequentially arranged on the rack from front to back. According to the intelligent production line for the solar component frame long edge, the solar component frame long edge can be quickly, reliably and accurately subjected to chip blowing, punching and riveting, full-automatic processing for the solar component frame long edge is achieved, labor cost is reduced, and working efficiency and processing quality are improved.

Owner:张家港易智自动化装备有限公司

Full-automatic cutting and drilling integrated machine for aluminum hub

PendingCN109702489AStable deliveryReduce labor intensityPrecision positioning equipmentOther manufacturing equipments/toolsEngineeringCam

A full-automatic cutting and drilling integrated machine for an aluminum hub comprises a cutting and drilling machine and automatic feeding and discharging devices; four chuck mechanisms of a workpiece clamping device of the cutting and drilling machine are installed along the circumference at an equal dividing angle and is subjected to indexing through a cam indexing device of a rotating workbench mechanism; the automatic feeding device, power head devices and the automatic discharging device are sequentially distributed around the workpiece clamping device in the clockwise direction at an interval of 90 degrees to form four stations; the second station corresponds to one power head device used for excising a center shaft hole dead head; the third station corresponds to at least two powerhead devices linearly distributed in the vertical direction of the axis of a cutter main shaft; the second station and the third station are each correspondingly provided with a workpiece rotating driving device capable of rising and falling, and power connection with a workpiece main shaft through a pair of gears engaged and disengaged in a rising and falling manner is achieved; the automatic feeding and discharging devices achieve 90-degree overturning and clamping connection of a workpiece through a manipulator device, and it is achieved that the workpiece is horizontally conveyed and lifted through a workpiece conveying device; and the problems that assembling and disassembling are inconvenient and the labor intensity is large are solved.

Owner:浙江平川智能装备股份有限公司

Full-automatic intelligent assembling and welding device

ActiveCN111347186ALabor savingRealize fully automatic processingMetal working apparatusWelding apparatusEngineeringWorkbench

The invention discloses a full-automatic intelligent assembling and welding device. The full-automatic intelligent assembling and welding device comprises a workbench, wherein a base feeding device isarranged on the front side of the workbench; a magnet feeding device, a rotating device, a top cover feeding device, a transplanting device, a welding device, a plug-in feeding device and a detectiondevice are arranged on the workbench; the magnet feeding device is arranged on the right side of the rotating device; the top cover feeding device is arranged on the rear side of the rotating device;the transplanting device is arranged on the left side of the rotating device; the welding device is arranged on the rear side of the transplanting device; the plug-in feeding device is arranged on the left side of the welding device; the detection device is arranged on the left side of the plug-in feeding device; a first grabbing device, a second grabbing device and a pressing device are arrangedon the rotating device; and the first grabbing device and the second grabbing device are transversely arranged in parallel. According to the full-automatic intelligent assembling and welding device,the labor force of workers is reduced, the reject ratio is reduced, the cost is low, the productivity is high, and the market application value is good.

Owner:深圳科易设计服务有限公司

Full-automatic battery side processing production line

ActiveCN104064624ARealize fully automatic processingIncrease productivityFinal product manufactureSmall-sized cells cases/jacketsProduction linePulp and paper industry

The invention discloses a full-automatic battery side processing production line. The full-automatic battery side processing production line comprises an automatic loading device, a feeding and waste discharging device, a conveying device, a bending device, a gumming device, a secondary bending post-processing assembly and an unloading device; the feed end of the feeding and waste discharging device corresponds to the discharge end of the automatic loading device; the feed end of the conveying device corresponds to the discharge end of the feeding and waste discharging device; the bending assembly and the gumming device are orderly arranged on the conveying device in the material feeding direction; the feed end of the secondary bending post-processing assembly corresponds to the discharge end of the conveying device; the unloading deice is arranged at the discharge end of the secondary bending post-processing assembly; corresponding manipulators are controlled by use of a machine for carrying and feeding between all the devices and assemblies, and corresponding automatic feeding links are also arranged inside partial devices, and therefore, overall full-automatic processing on the battery sides is realized; the production period is controlled by the machine so that the production efficiency and the quality of product are greatly improved.

Owner:SUZHOU LING AUTOMATION EQUIP

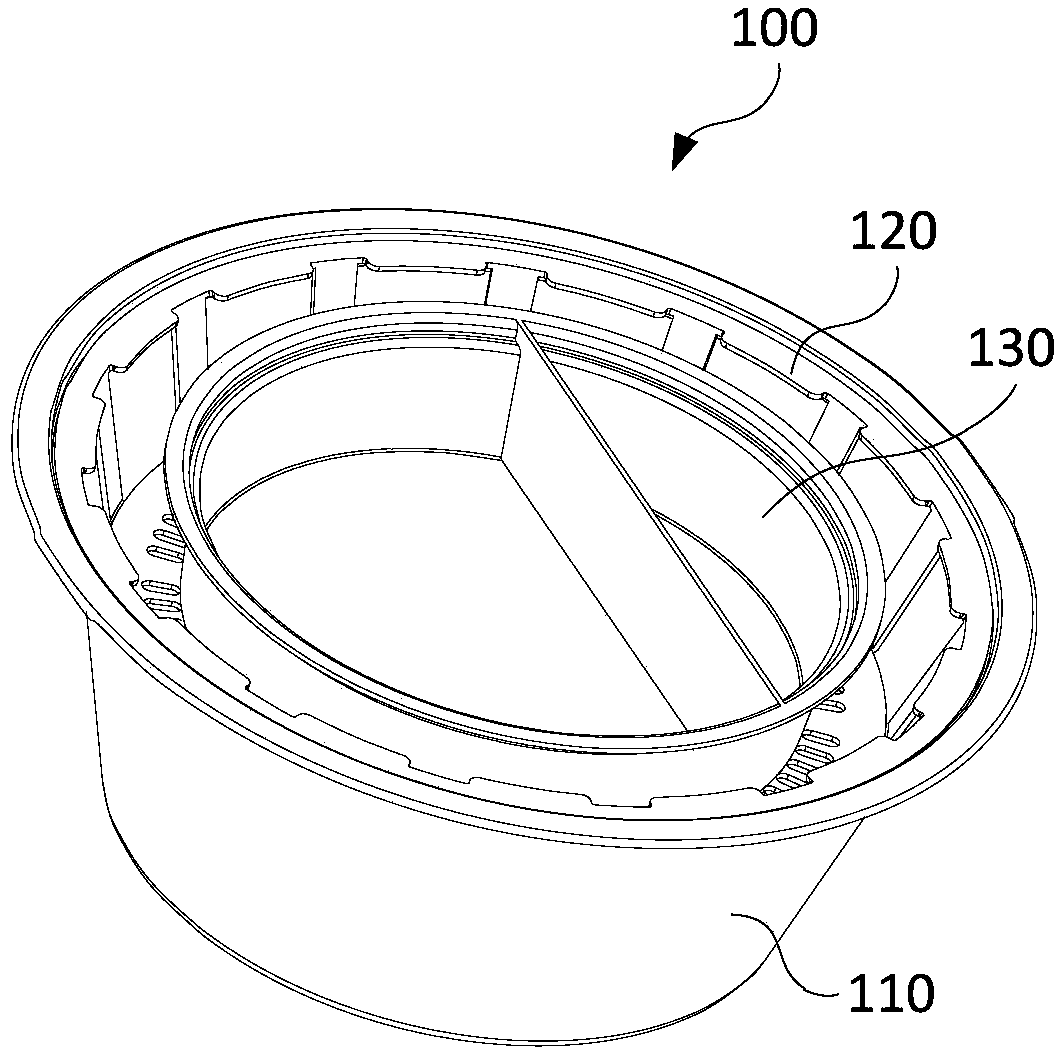

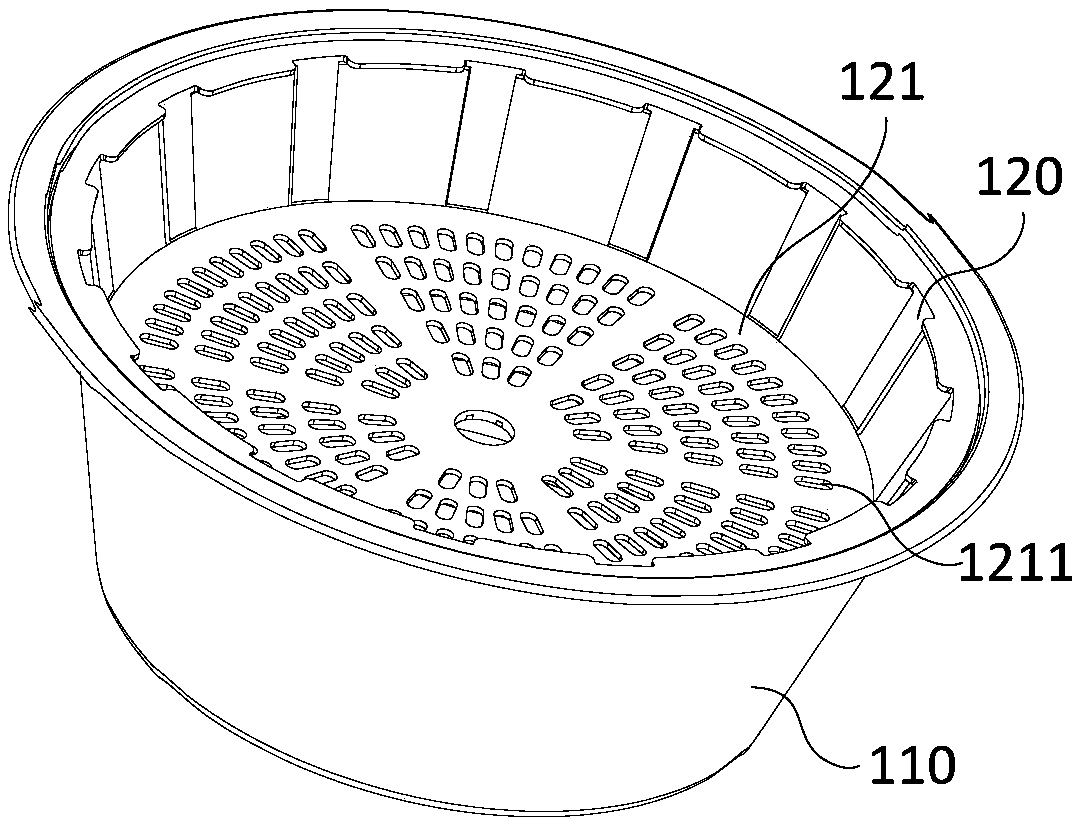

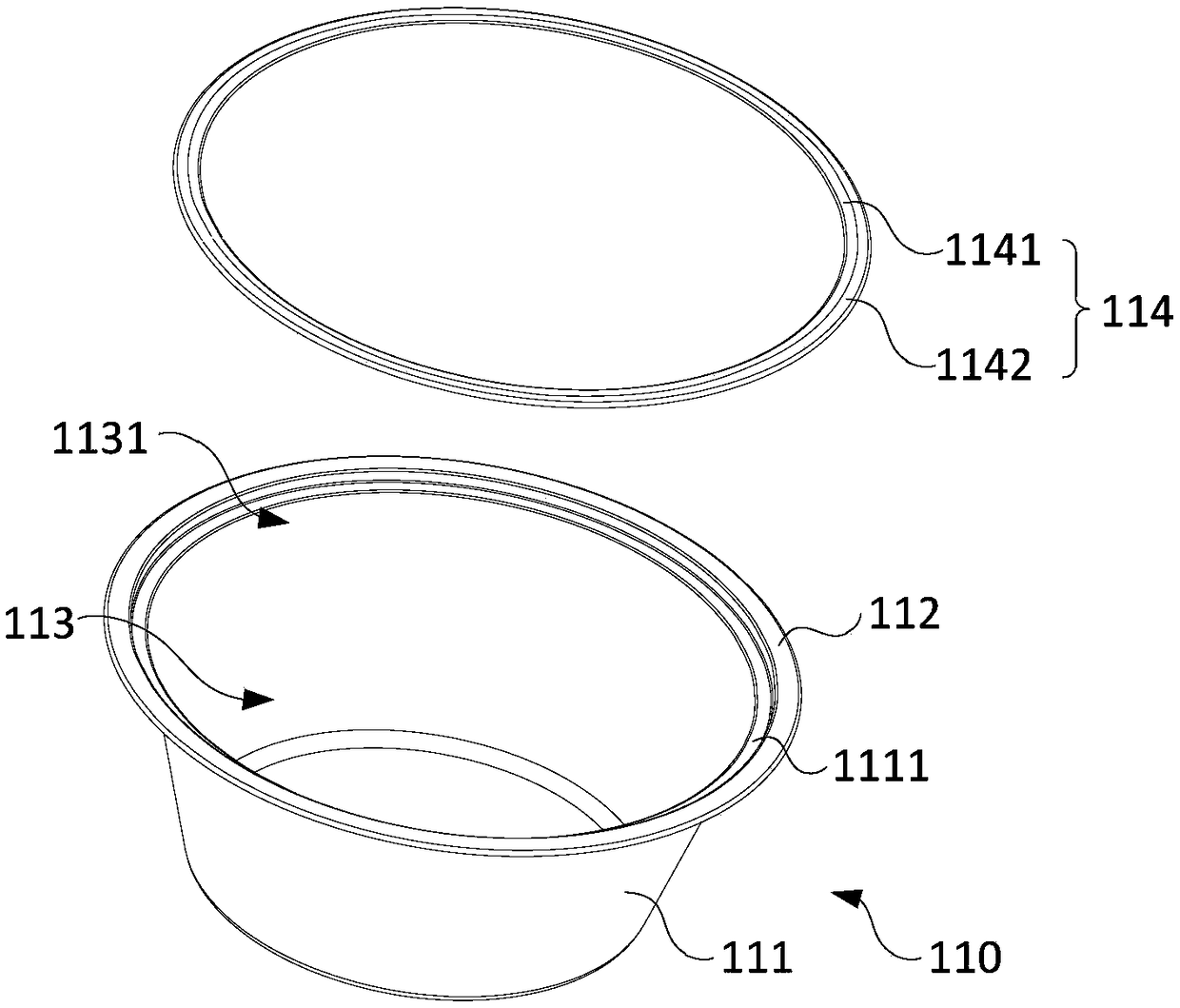

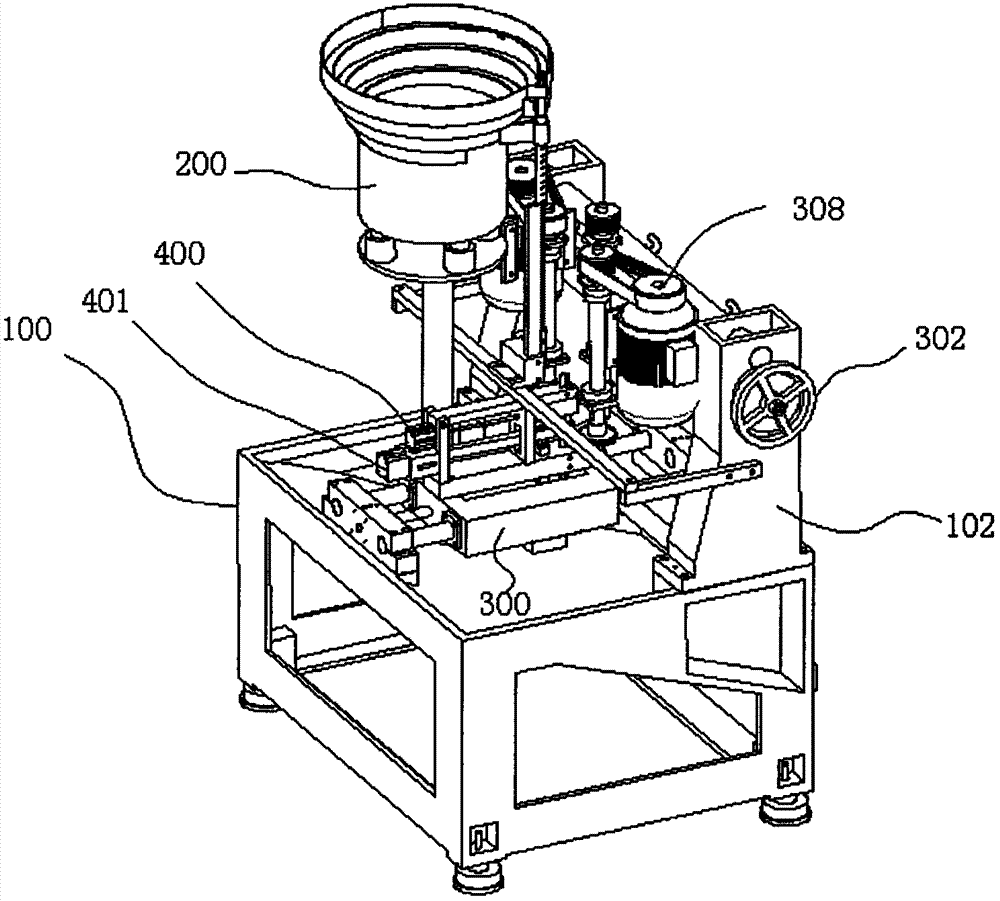

Automated kitchen system

PendingCN108851948ARealize fully automatic processingGuarantee processing qualityCooking vessel constructionsProcess engineeringFood products

The invention discloses an automated kitchen system. The automated kitchen system comprise an extraction station, first and second cooking stations and a mixing station, wherein the extracting stationis used for extracting an inner container from an outer container of food containers, the outer container contains first cooking materials, and the inner container contains second cooking materials;the first and second cooking stations are used for cooking the first cooking materials and the second cooking materials respectively; the mixing station is used for pouring the cooked second cooking materials from the inner container into the outer container after cooking the first cooking materials is completed. The automated kitchen system can achieve fully-automated processing of different cooking materials in multiple containers and mix different cooked cooking materials, thereby saving labor cost and ensuring the food processing quality and hygiene.

Owner:长沙易爱智能科技有限公司

Lock cylinder post-machining device

InactiveCN102728888ARealize fully automatic processingGuaranteed machining accuracyMetal sawing devicesMetal working apparatusControl systemEngineering

The invention discloses a lock cylinder post-machining device, which comprises a main body bracket, a blocking setting device, a finishing device and tool aprons, wherein the finishing device comprises a vibrating tray, a vibrating motor and a guide rod; the vibrating motor is respectively fixedly connected with the vibrating tray and a base bracket, and the guide rod is arranged below a discharge hole of the vibrating tray; the blocking setting device comprises a limit discharging mechanism, a sliding table, a feeding mechanism and a control electric plate; and the sliding table is connected with the base bracket through a guide rail in a sliding mode, a workpiece enters the sliding table from the guide rod through the limit discharging mechanism, and the feeding mechanism is arranged on the main body bracket, so that the workpiece on the sliding table is machined close to a cutter. According to the device, full-automatic machining of a lock cylinder is realized through the finishing mechanism, the limit discharging mechanism, the blocking setting device and the cutter; by matching the control electric plate, efficient and high-precision machining of the lock cylinder is realized; due to reasonable structural design of parts, the whole device is simple in structure; through a control system of the control electric plate, the device is convenient to operate; and through an adjusting system of the tool aprons, the machining precision of the lock cylinder is ensured.

Owner:温岭市铭创机床有限公司

Fully-automatic workpiece processing line and running method thereof

PendingCN110303345ARealize fully automatic processingAvoid mistakesMeasurement/indication equipmentsOther manufacturing equipments/toolsNumerical controlProduct inspection

The invention discloses a fully-automatic workpiece processing line and a running method thereof. The processing line comprises a plurality of numerically-controlled machine tools and workpiece finished product inspection equipment which are arranged in sequence, a track is arranged above the multiple numerically-controlled machine tools and the workpiece finished product inspection equipment which are arranged in sequence, the track is provided with walking robot grippers, the walking robot grippers are used for serially connecting the numerically-controlled machine tools and the workpiece finished product inspection equipment which are arranged in sequence, and one control center coordinatively controls the walking robot grippers, the numerically-controlled machine tools and the workpiece finished product inspection equipment; a workpiece feeding section is also arranged together with the multiple numerically-controlled machine tools and the workpiece finished product inspection equipment which are arranged in sequence, the workpiece feeding section comprises a feeding section frame, a loading vehicle entering zone and a workpiece material blank size measurement and verificationzone are arranged at the front and back of the feeding section frame, and the workpiece material blank size measurement and verification zone is positioned on the vertical lower side of a linear track, so that the walking robot grippers are capable of extending downwards to grasp workpiece material blanks.

Owner:廊坊市钦纵机电产品制造有限公司

Full-automatic bending machine for producing circular ring

InactiveCN108080446ARealize fully automatic processingPrecise processingMetal-working feeding devicesPositioning devicesMachine partsEngineering

The invention relates to the field of bending machines, in particular to a full-automatic bending machine for producing a circular ring. The full-automatic bending machine comprises a base, a bendingmechanism and a feeding mechanism; the feeding mechanism comprises a conveying device, sliding rail devices and a feeding device; and the bending mechanism comprises a workbench, a power device, a positioning device and a discharging device, wherein the power device is arranged above the positioning device, and the discharging device is arranged at the top part of the workbench. According to the full-automatic bending machine, a folding block and a pressing rod are driven to move downwards through pressing a first air cylinder downwards; in the downward pressing process of the folding block, the folding block, a round tube and a groove are used for extruding a to-be-machined part so as to finish machining of the part; in the ascending process of the pressing rod, a pushing block pushes anejector rod so as to push an ejector to move, the ejector is used for pushing out the machined part, and then feeding is automatically carried out through the feeding device; and full-automatic machining of the circular ring is realized by the bending machine, the waste of manpower resources is reduced, and machining of the part is more accurate.

Owner:ZHEJIANG UNIV OF TECH FENGHUA SMART ECONOMY RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com