Solar module frame short side intelligent production line

A solar module and production line technology, applied in electrical components, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of unguaranteed processing quality of riveting points, low work efficiency, increased labor costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

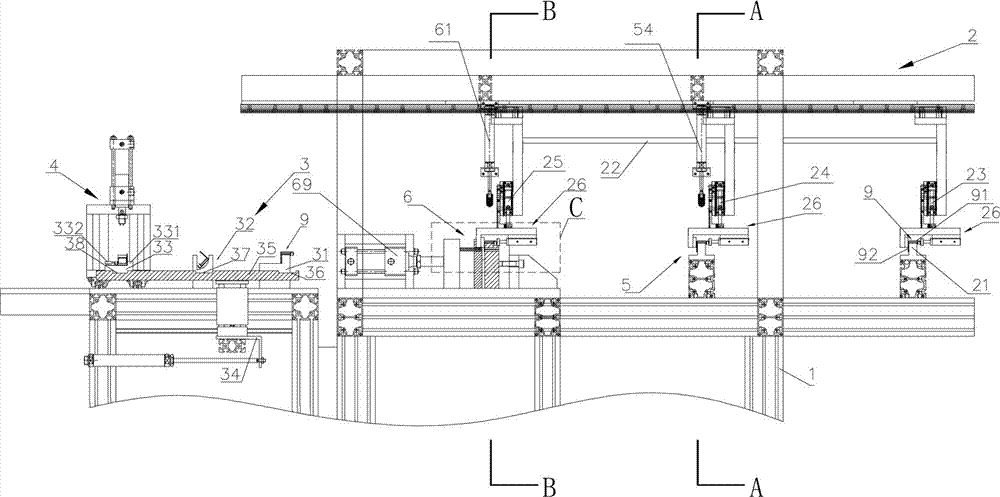

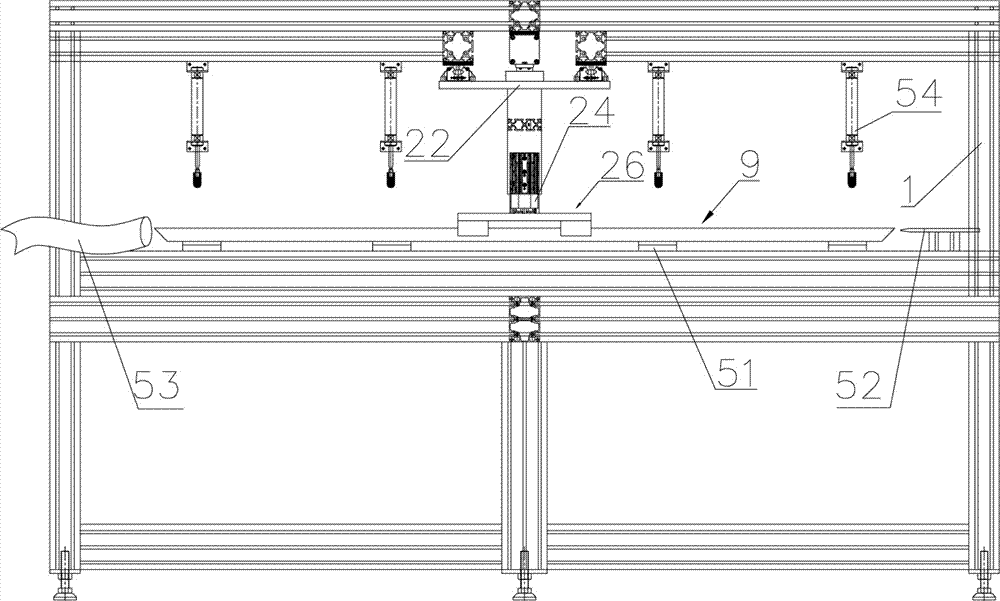

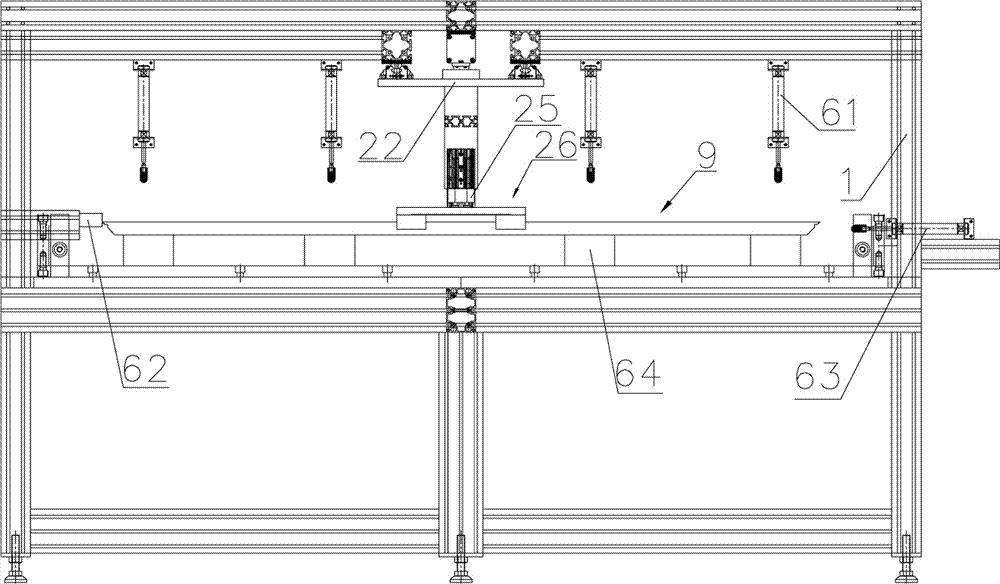

[0029] Such as figure 1 As shown, the intelligent production line for the short side of the solar module frame includes: a frame 1, and a chip blowing and punching device that can blow and punch chips on the short side 9 of the solar module frame is sequentially arranged on the frame 1 from front to back 2. A frame turning and transferring device that can turn over the short side 9 of the frame of the solar module that has been blown and punched and move it backwards. Code installation and riveting point device 4; the structure of chip blowing and punching device 2 is: in the frame 1 from front to back, there are arranged side by side and intervals that can be placed with the corner code installation side 91 facing forward and the punching side 92 facing forward. The frame carrier platform 21 of the short side 9 of the solar module frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com