Lock cylinder post-machining device

A technology for processing devices and lock cylinders, which is applied in the direction of sawing machine devices, metal processing, metal processing equipment, etc., can solve the problems of affecting the rigidity of lock cylinders, low processing accuracy, and high material costs, so as to achieve convenient operation, ensure processing accuracy, and equipment The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

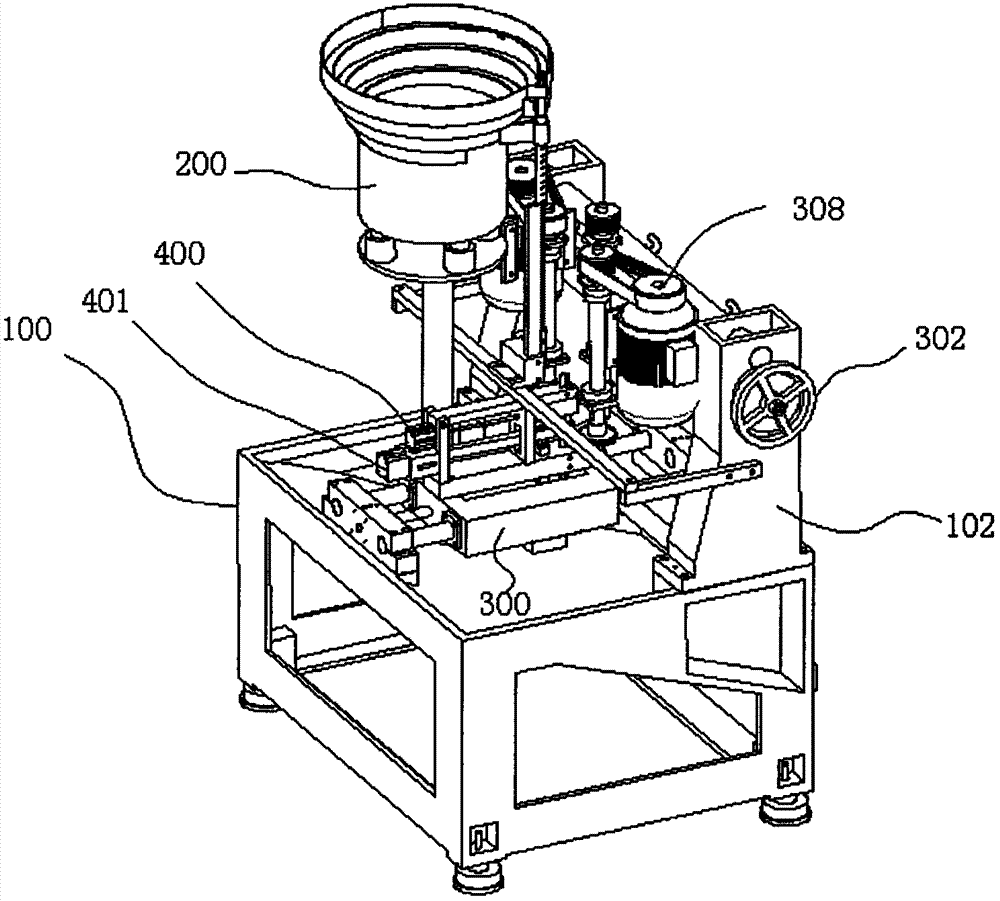

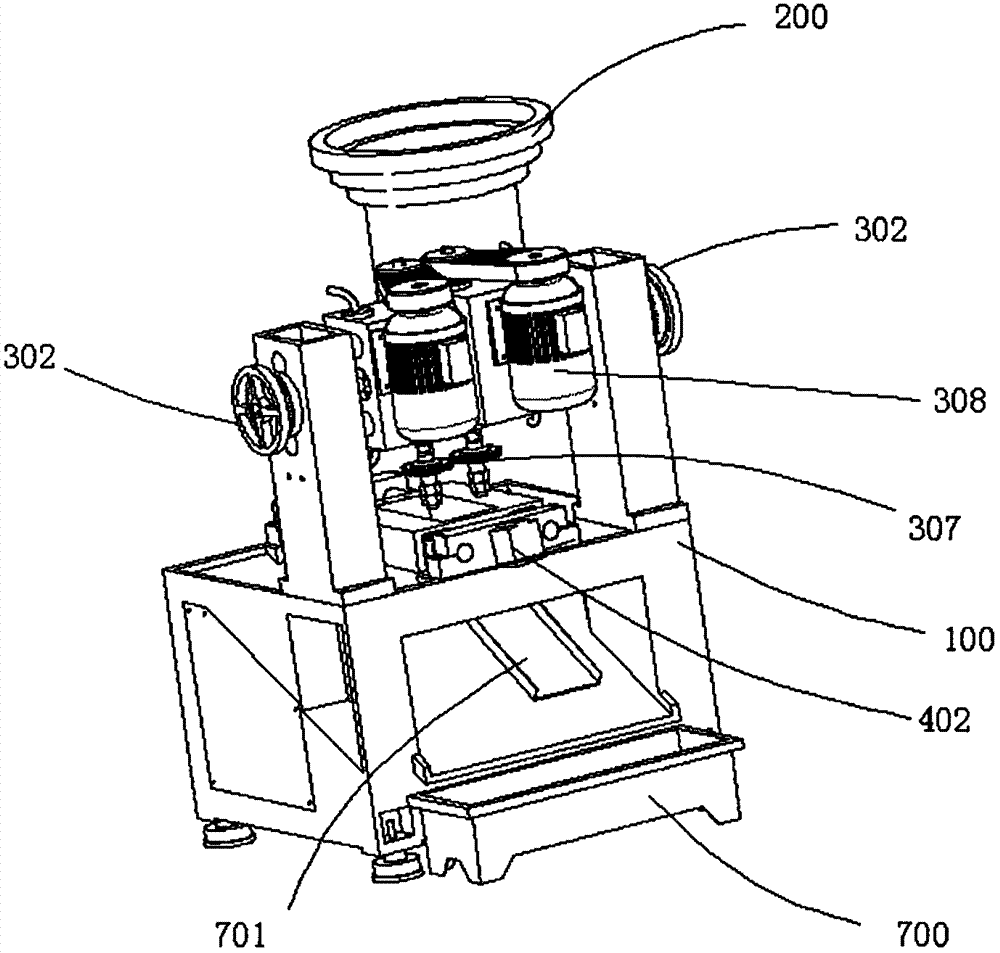

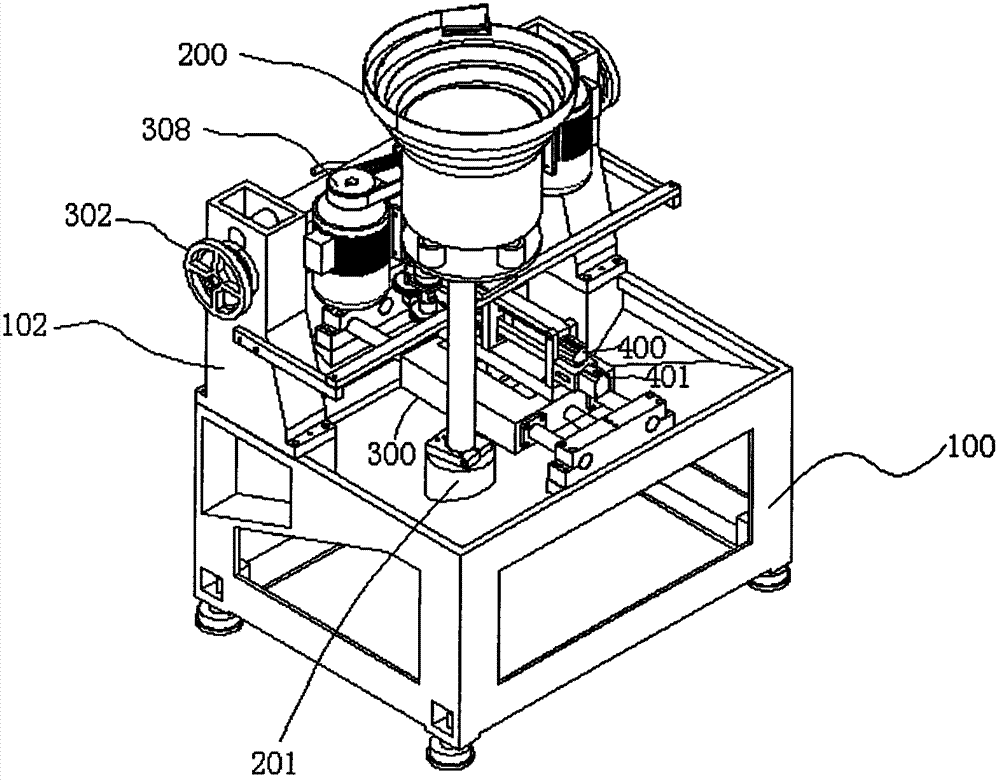

[0020] refer to Figure 1-Figure 7 A post-processing device for a lock cylinder, comprising a main body support, a positioning and material setting device, a monolithic device and two knife seats 306, wherein the knife seats 306 include two saw blades 307 and a motor 308 placed on both sides of the knife seat 306, and The saw blade 307 is connected to the motor 308; the monolithic device includes a vibrating disc 200, a vibrating motor 201 and a material guide rod, the vibrating motor 201 is fixedly connected to the vibrating disc 200 and the main body bracket 100 respectively, and the discharge port of the vibrating disc 200 and the upper material guide The rod 601 is connected; the position-fixing material device includes a limit feeding mechanism, a slide table 300, a feeding mechanism and a control electric board. The slide table 300 is slidably connected to the main body bracket through a guide rail, and the limit feed mechanism is placed on the upper guide rod 601 and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com