Fully-automatic workpiece processing line and running method thereof

A processing line, fully automatic technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of non-standard and consistent clamping, low production efficiency, no processing procedures, etc., to avoid the wrong billet , the effect of improving utilization and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

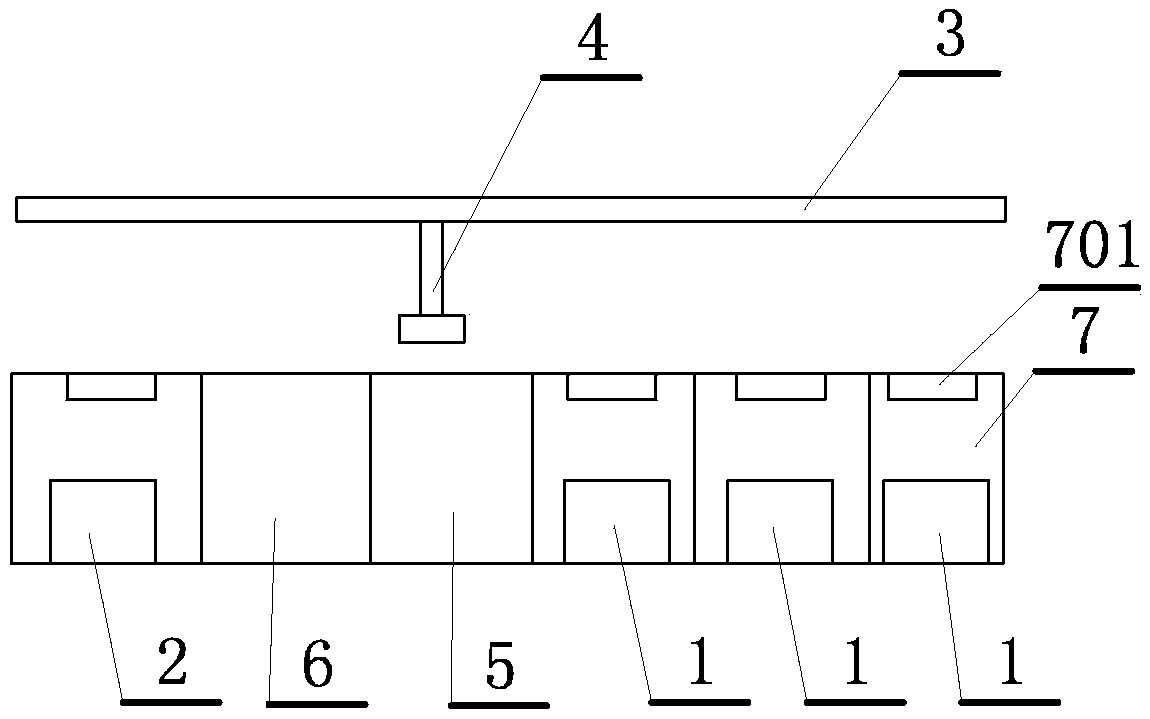

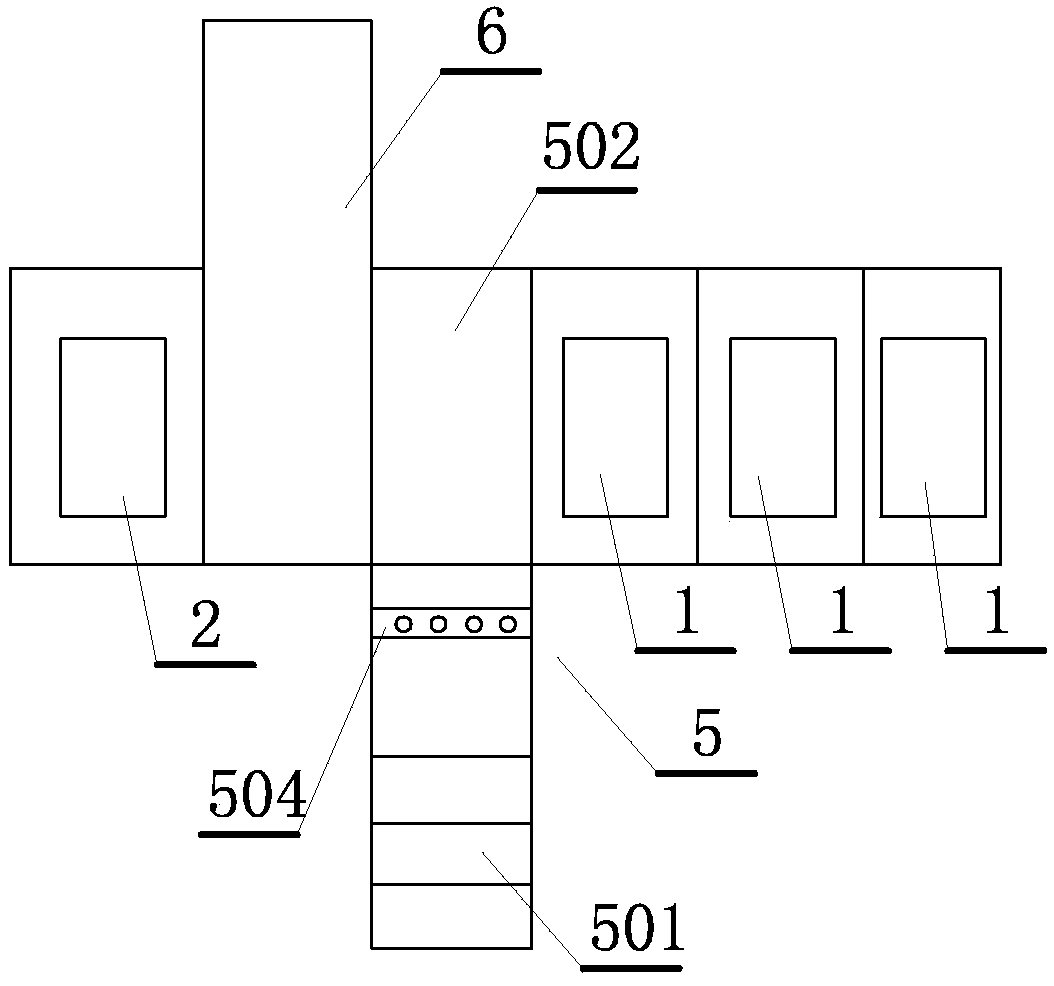

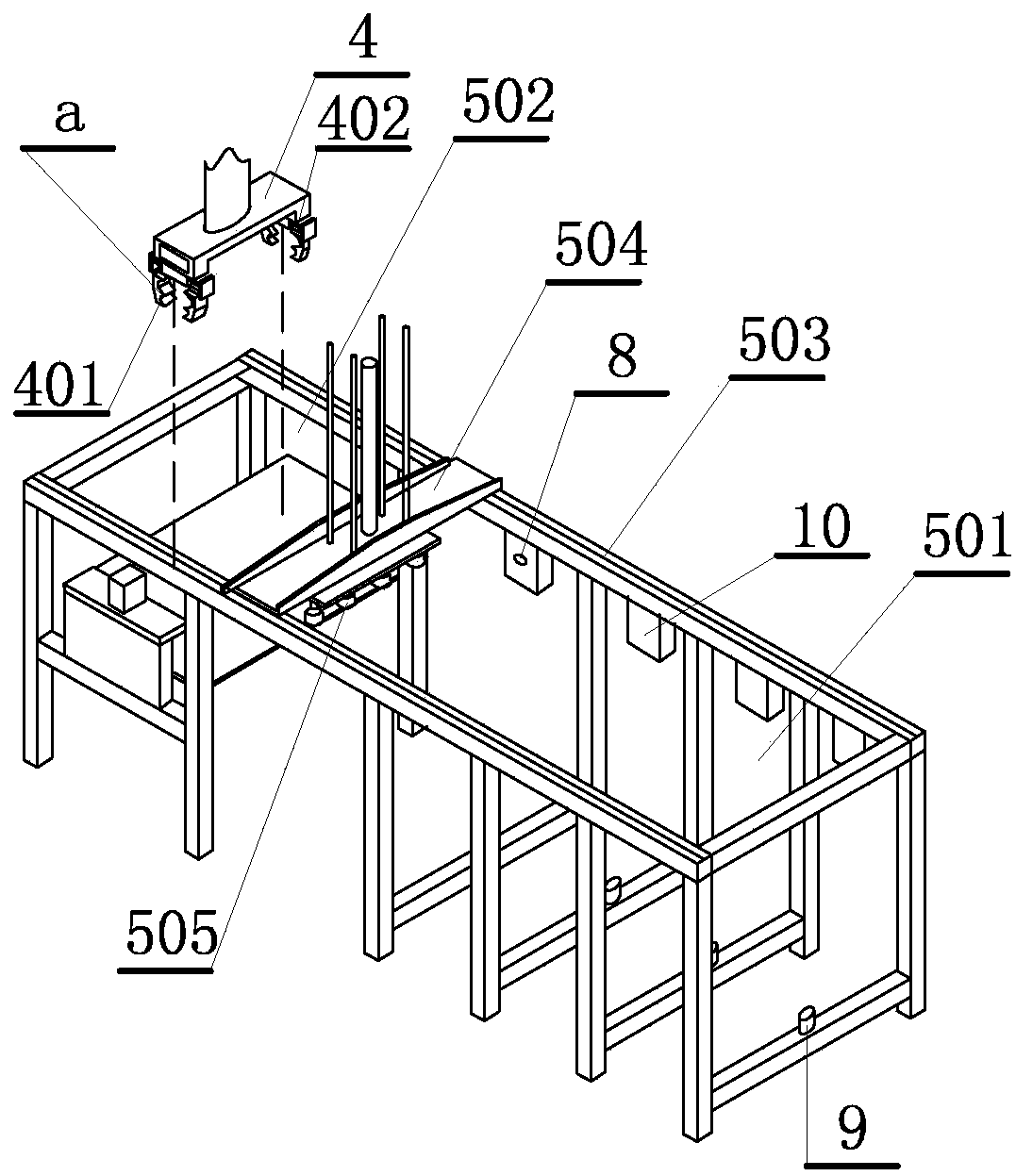

[0035] A fully automatic workpiece processing line, such as figure 1 and figure 2 As shown, it is a fully automatic workpiece processing line suitable for batch processing. The fully automatic workpiece processing line includes a plurality of numerically controlled machine tools 1 and finished workpiece inspection equipment 2 arranged in sequence. The finished workpiece inspection equipment adopts a three-dimensional Coordinate measuring machines, CNC machine tools are at least three or more, and the arrangement can be straight or curved; the CNC machine tools can be of the same type, such as CNC lathes, or different types of CNC machine tools, for example, both CNC lathes Lathes also include CNC milling machines or CNC grinding machines, which are combined and designed according to the needs of processing technology; multiple CNC machine tools 1 are used to complete the processing of workpieces, and workpiece inspection equipment 2 is used to measure and detect the processed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com