Full-automatic battery side processing production line

A production line, fully automatic technology, applied in battery pack parts, battery boxes/jackets, sustainable manufacturing/processing, etc., can solve problems such as inability to control product production cycles, poor product quality, and waste of space, etc. Achieve the effect of improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described below in conjunction with accompanying drawing.

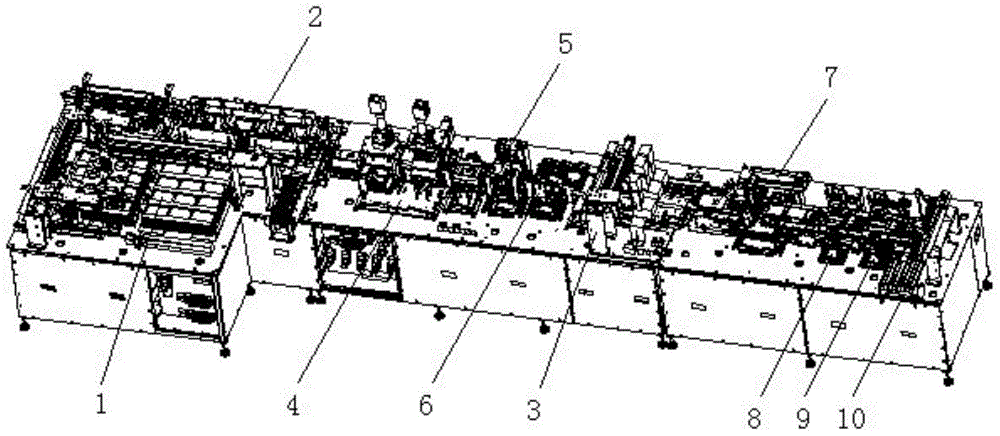

[0024] Such as figure 1 As shown, a fully automatic battery side edge processing production line according to the present invention includes an automatic feeding device 1, a feeding and waste discharging device 2, a handling device, a bending component, a gluing device 3, and a secondary bending post-processing component And unloading device 10.

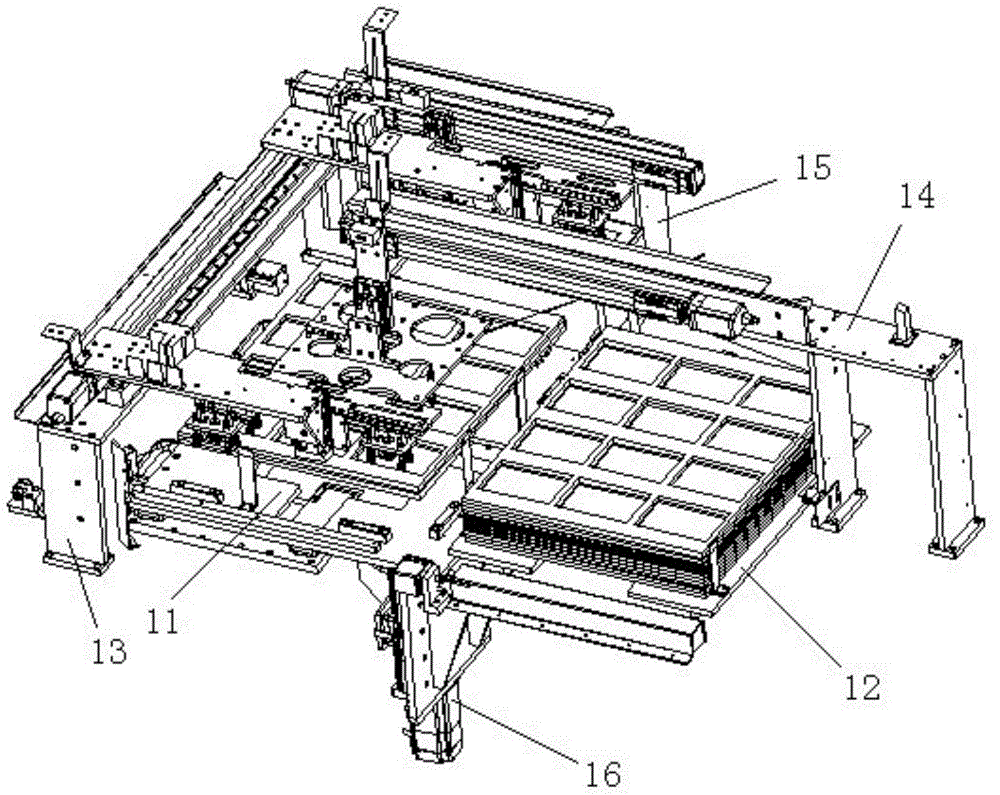

[0025] Such as figure 2 As shown, the automatic feeding device 1 includes a feeding frame and a feeding plate 11, a discharge plate 12, a longitudinal carriage 13, a first transverse carriage 14, a second transverse carriage arranged on the feeding frame Frame 15 and jacking device 16; Described feeding board 11 is slidably arranged on one side of feeding rack, and unloading board 12 is arranged on the other side of feeding rack; Described longitudinal carriage 13, the first A transverse carriage 14 and a second transverse carriage 15 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com