Full-automatic intelligent assembling and welding device

A welding equipment and fully automatic technology, applied in welding equipment, metal processing equipment, metal processing, etc., can solve problems such as unstable product placement, safety accidents, and low productivity, and achieve good market application value, precision equipment, and high productivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

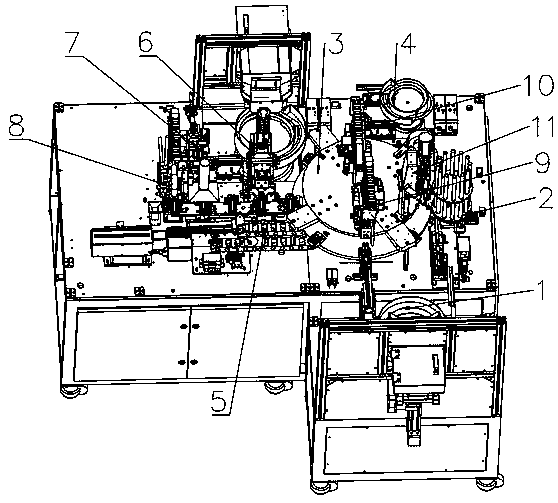

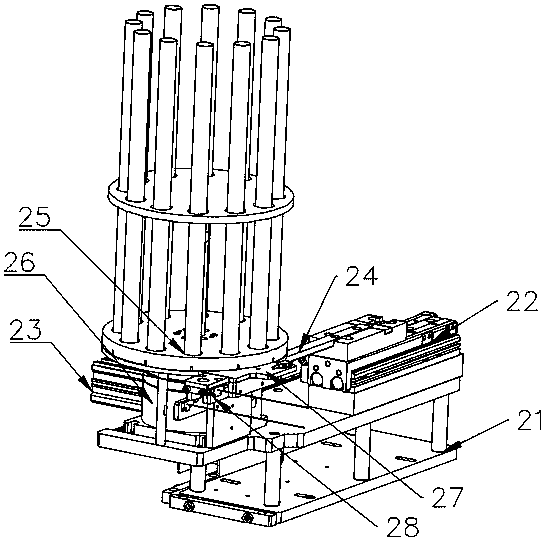

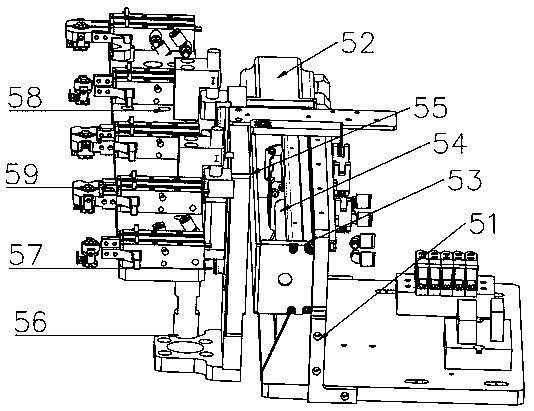

[0027] like Figure 1 to Figure 6 One embodiment described: a fully automatic intelligent assembly and welding equipment, including a workbench, a base feeding device 1 is arranged on the front side of the workbench, and a magnet feeding device 2 and a rotating device 3 are respectively arranged on the workbench , a top cover feeding device 4, a transplanting device 5, a welding device 6, a plug-in feeding device 7 and a detection device 8, the magnet feeding device 2 is arranged on the right side of the rotating device 3, and the rear side of the rotating device 3 The top cover feeding device 4 is set, the transplanting device 5 is arranged on the left side of the rotating device 3, the welding device 6 is arranged on the rear side of the transplanting device 5, and the welding device 6 is arranged on the left side of the welding device 6. A plug-in feeding device 7, the detection device 8 is arranged on the left side of the plug-in feeding device 7, and the first grabbing de...

Embodiment 2

[0034] Embodiment 2 is different from the above in that the rotating device 3 includes a rotating cylinder, a reduction box, a rotating shaft, a first rotating disk and a second rotating disk, the rotating cylinder is installed in the workbench, and the reducing The box is set on the workbench, the output end of the rotary cylinder is connected to the reduction box, one end of the rotation shaft is vertically arranged in the reduction box, and the other end of the rotation shaft passes through the first rotating disk vertically upwards It is vertically installed on the lower surface of the second rotating disk, and multiple groups of material carrier seats are installed on the first rotating disk.

Embodiment 3

[0035] The third embodiment differs from the above in that the multiple sets of loading seats and the multiple sets of transplanting parts 59 are set to be at least two or more.

[0036] The working principle of the present invention is: first, the base feeding device 1 transports the base to the bottom of the first grabbing device 9, and the first grabbing device 9 grabs and places the base on the rotating device 3, and then the rotating device 3 drives the base to the magnet The feeding device 2 is the processing position, the magnet feeding device 2 transports the magnet to the top of the base, and then the pressing device 11 presses the magnet above the base onto the base, and then the rotating device 3 rotates to the next station, and the top cover is loaded The device 4 starts to work, the top cover feeding device 4 transports the top cover under the second grabbing device 10, the second grabbing device 10 grabs and places the product on the base of the rotating device 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com