Full-automatic LED package machine

A packaging machine, fully automatic technology, applied in the direction of conveyor objects, transportation and packaging, electrical components, etc., can solve the problems affecting the accuracy and efficiency of LED packaging, the complex structure of LED packaging equipment, and the inability to achieve fully automatic processing. LED packaging efficiency and packaging accuracy, the effect of improving LED packaging efficiency and improving LED packaging accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

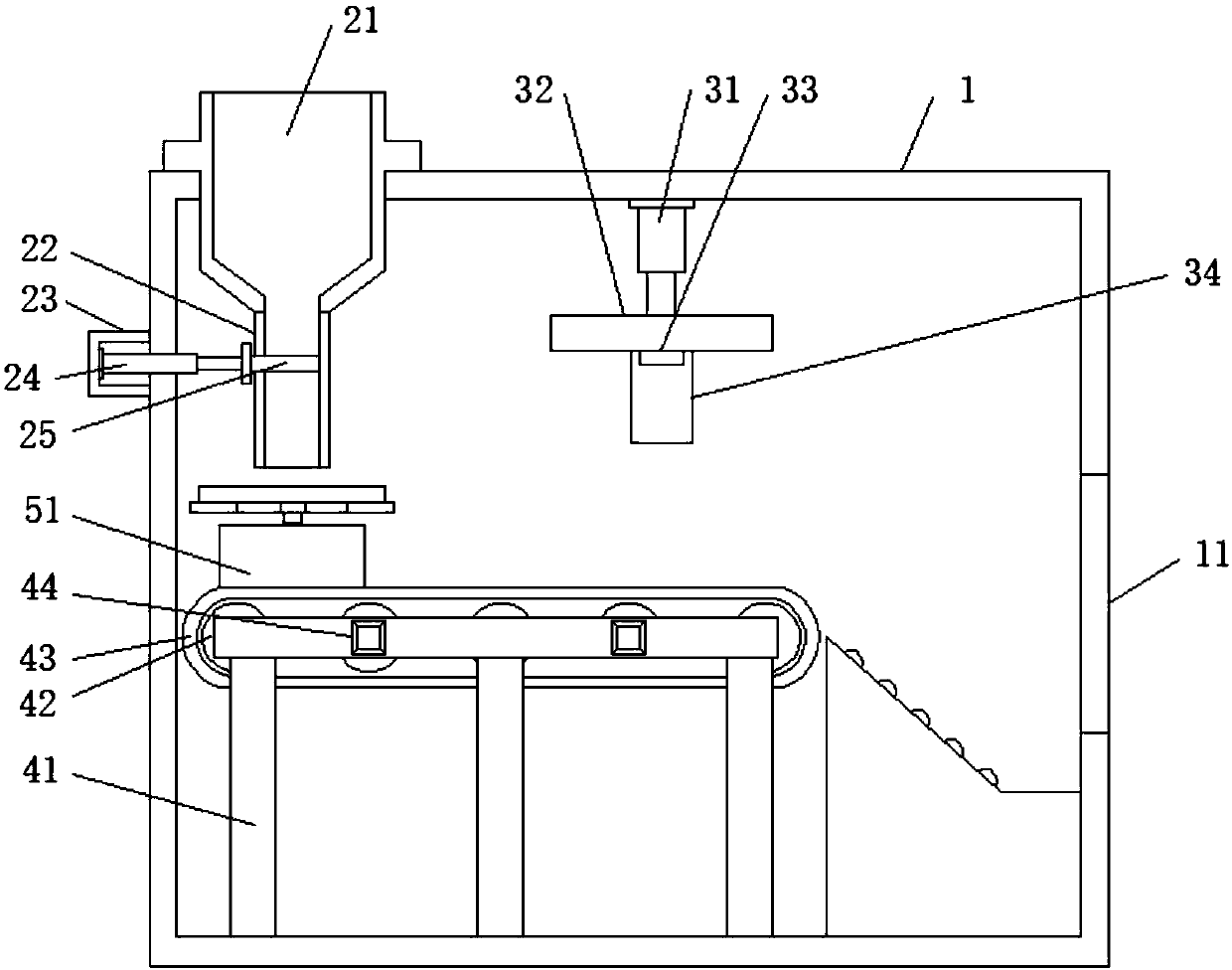

[0025] refer to Figure 1-5 , a fully automatic LED encapsulation machine, comprising a housing 1 with a cavity structure, a feeding mechanism arranged on one side of the top of the housing 1, a packaging mechanism on the inner wall of the other side of the top of the housing 1, a transmission mechanism, and a movement with the transmission mechanism The adjustment mechanism, the transmission mechanism is located directly below the feeding mechanism and the packaging mechanism. The transmission mechanism includes a support frame 41, a transmission shaft 42 that is rotatably connected to the top of the support frame 41, a conveyor belt 43 that is sleeved outside the transmission shaft 42, and drives the transmission shaft. 42 rotating third drive means 44;

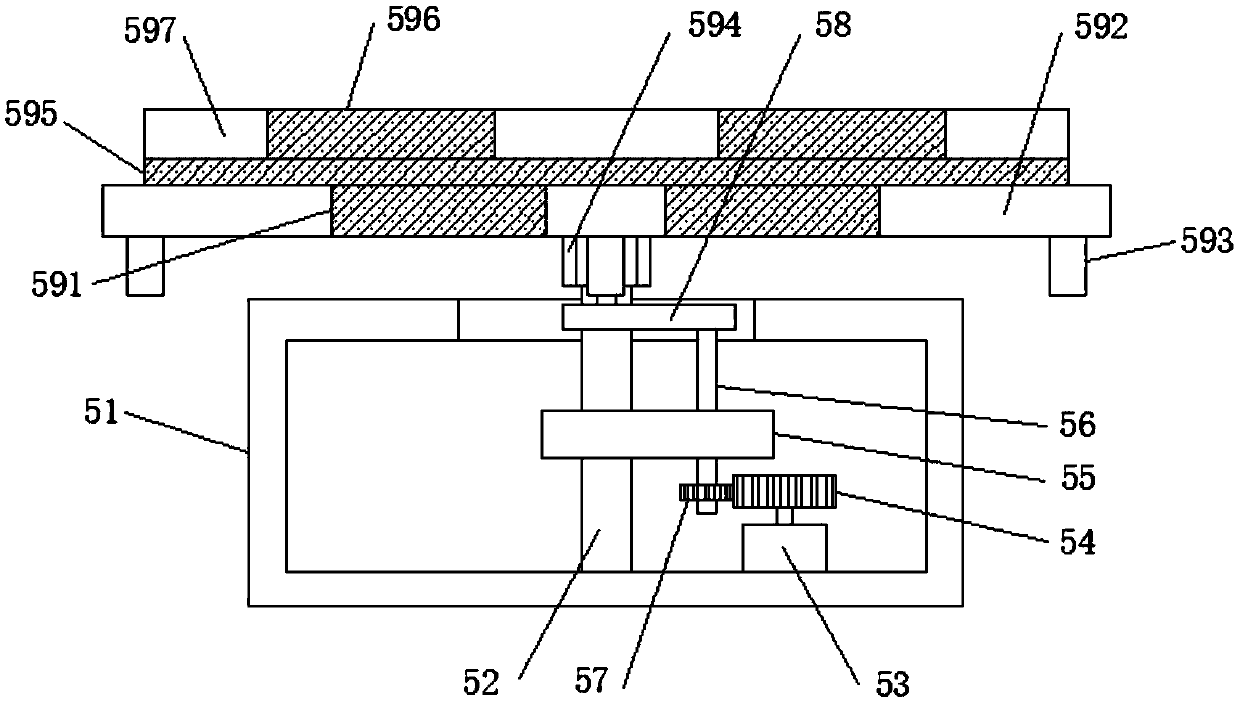

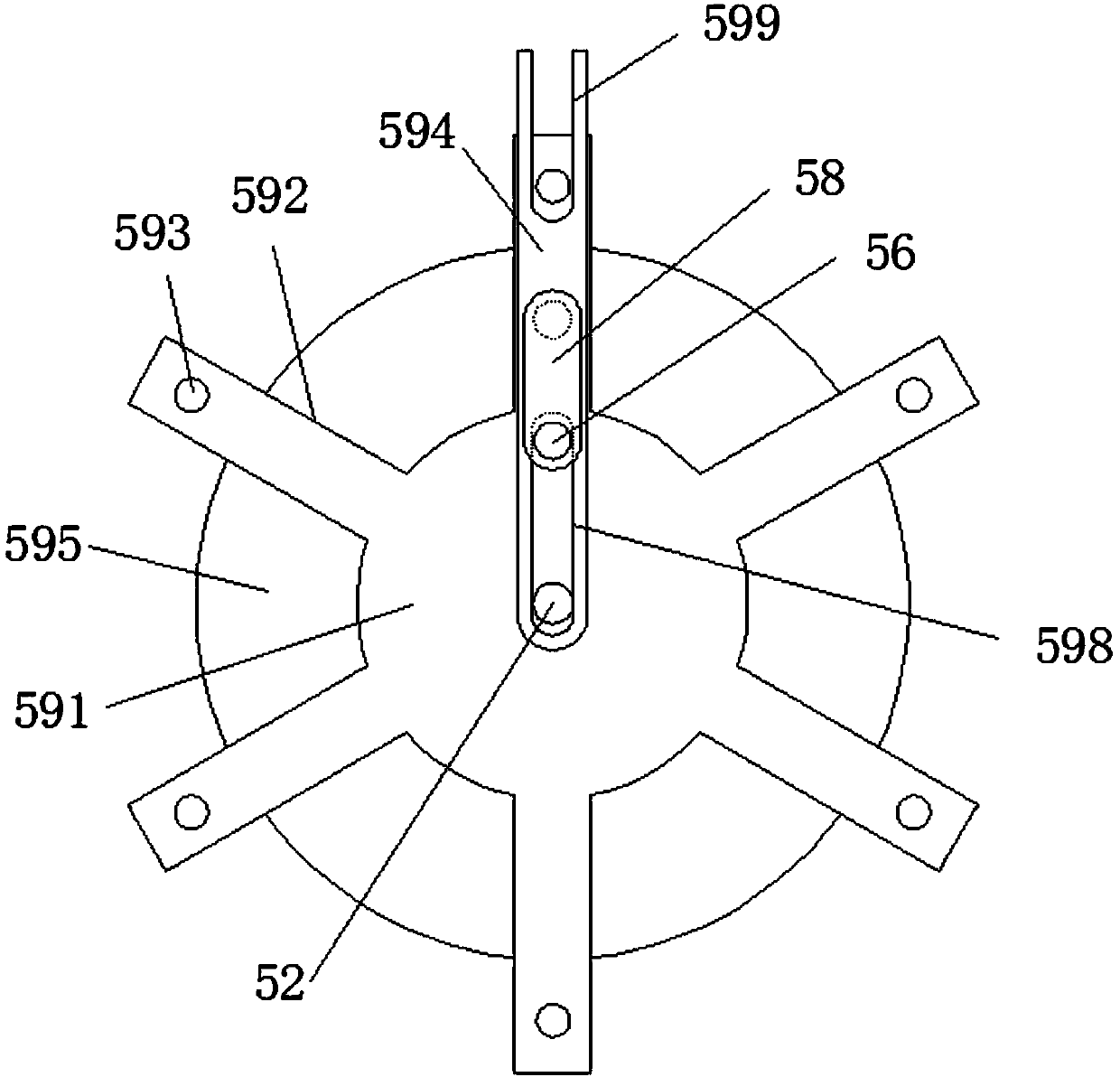

[0026] The adjustment mechanism includes a hollow fixed seat 51 fixedly installed on the top of the transmission shaft 42, a vertical positioning rod 52 and a fourth driving device 53 are installed on the bottom inner wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com