Patents

Literature

59results about How to "High packaging precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

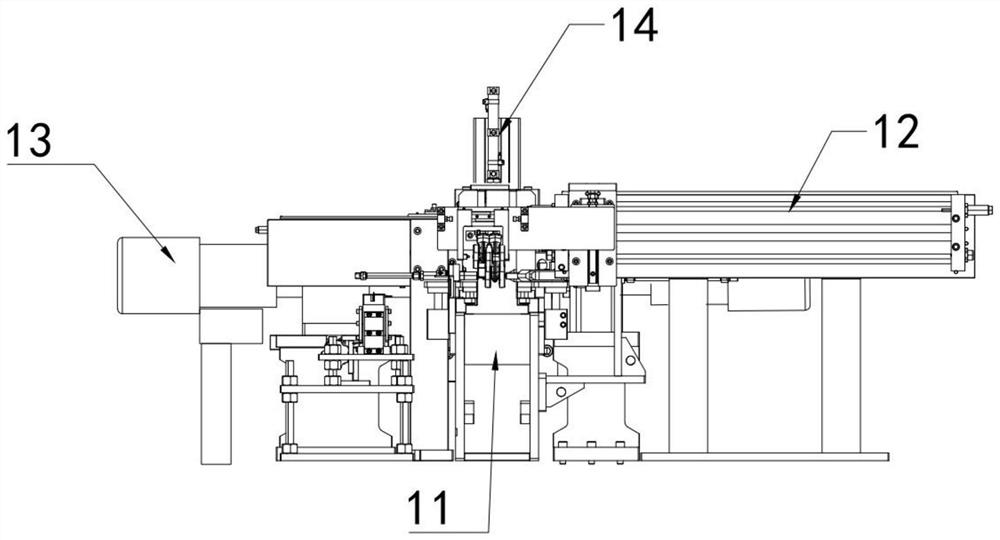

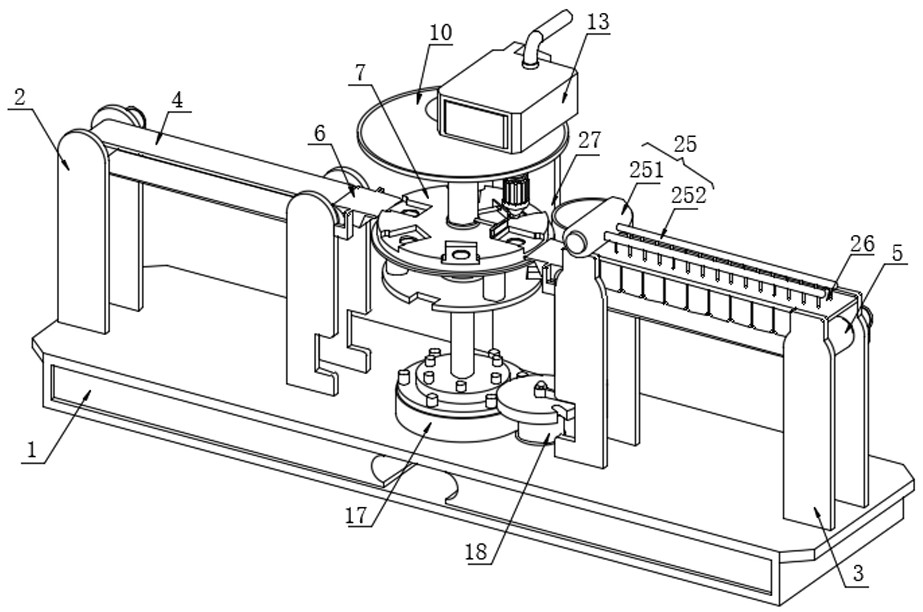

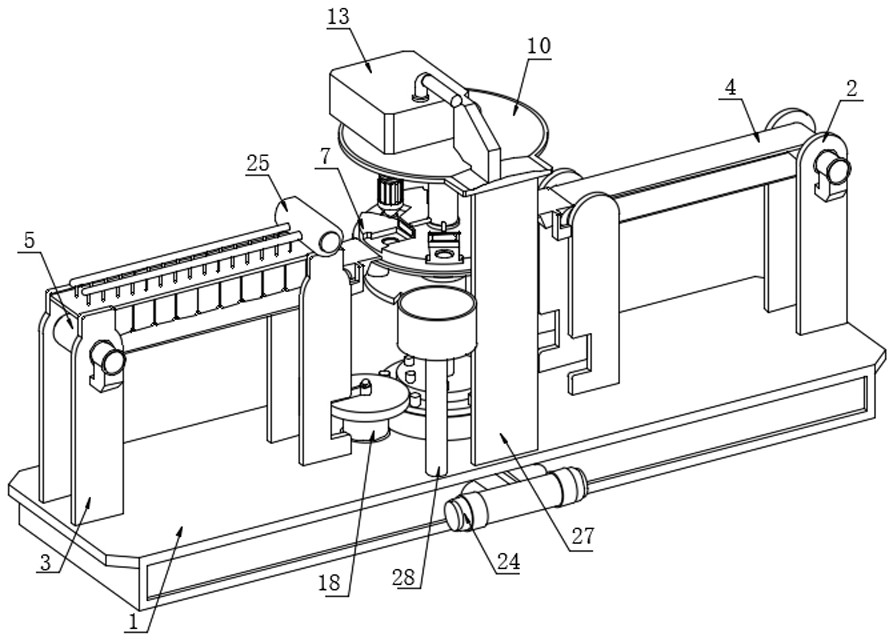

Servo double-surface heating vacuum packaging machine

ActiveCN102201592AQuality is not affectedGuarantee exclusionFinal product manufactureSecondary cells manufactureControl systemEngineering

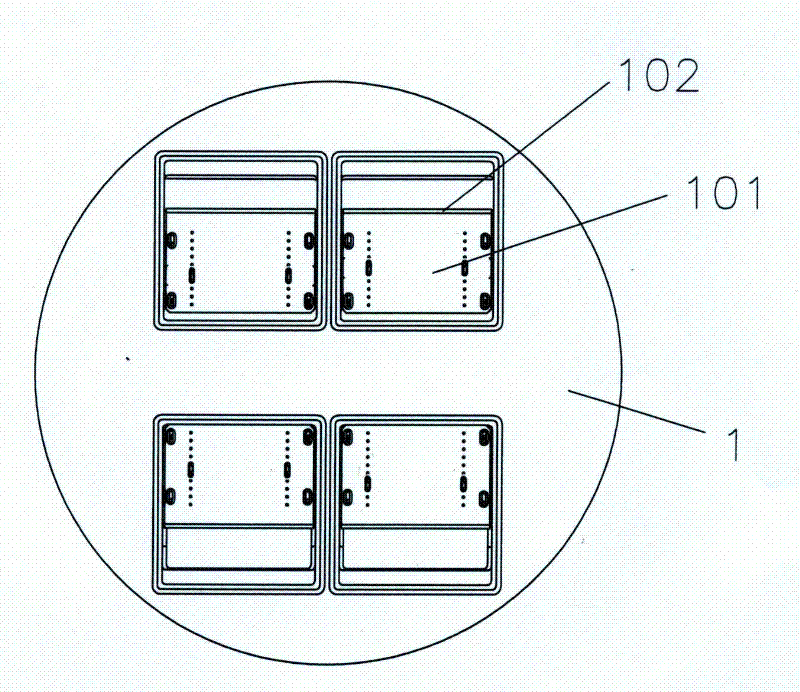

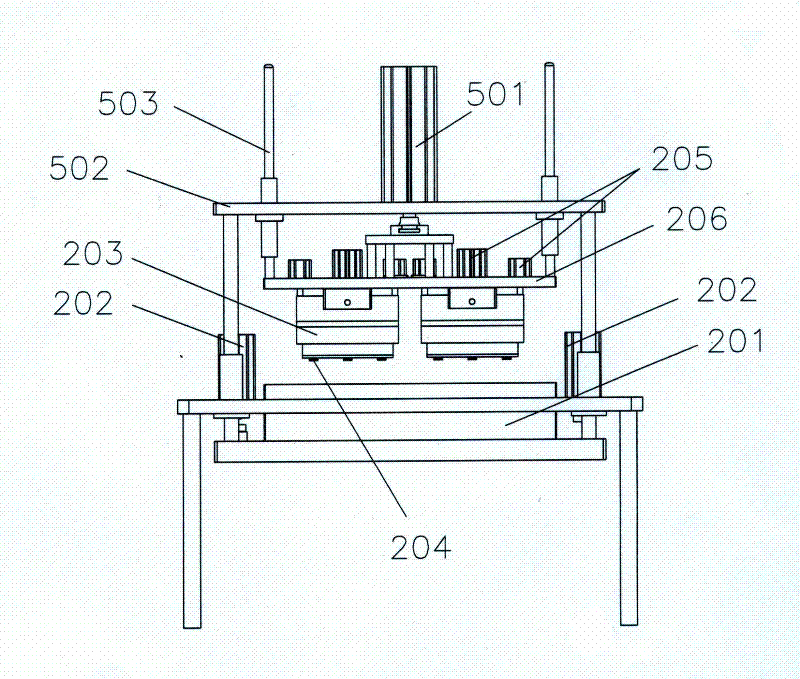

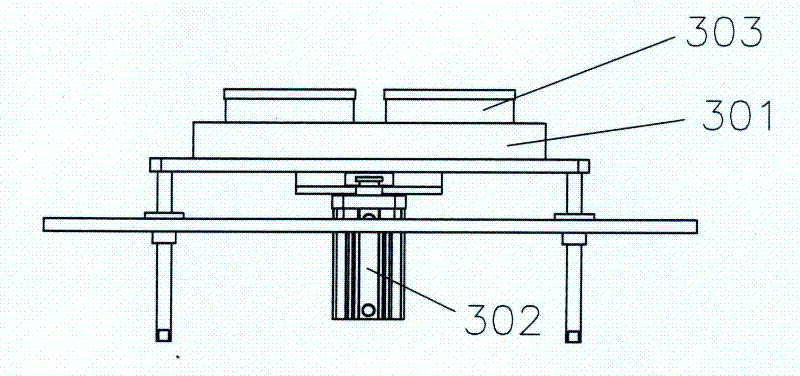

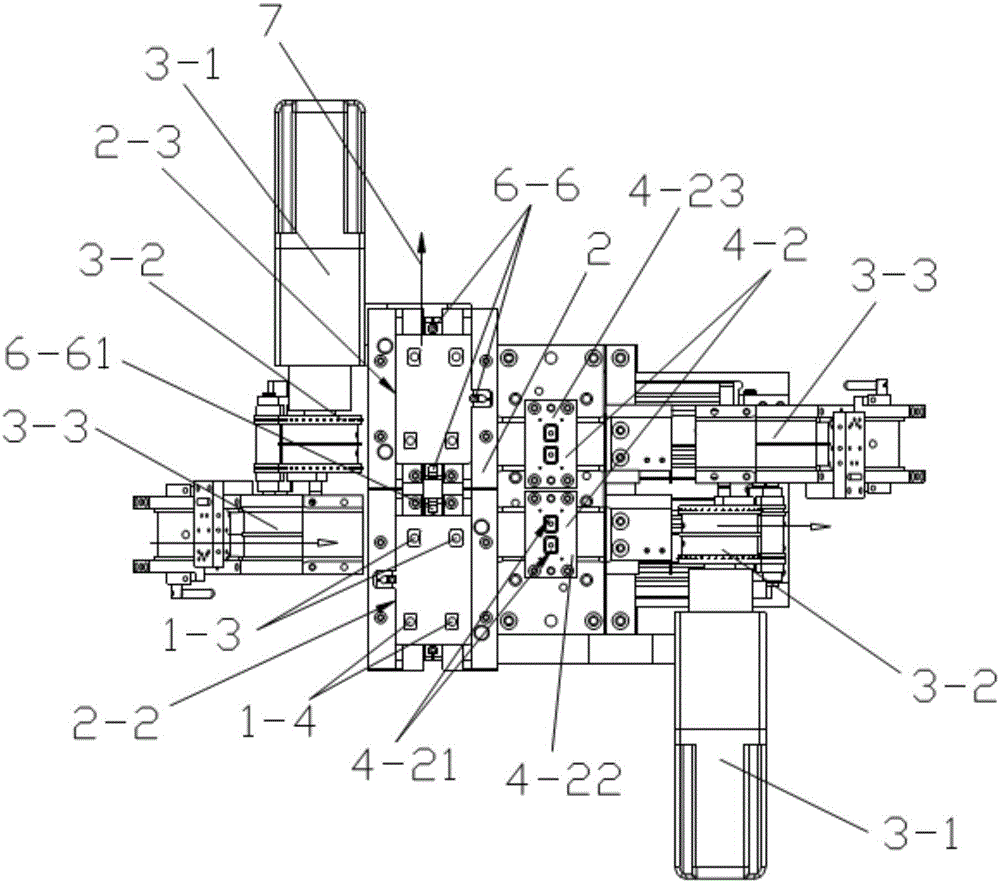

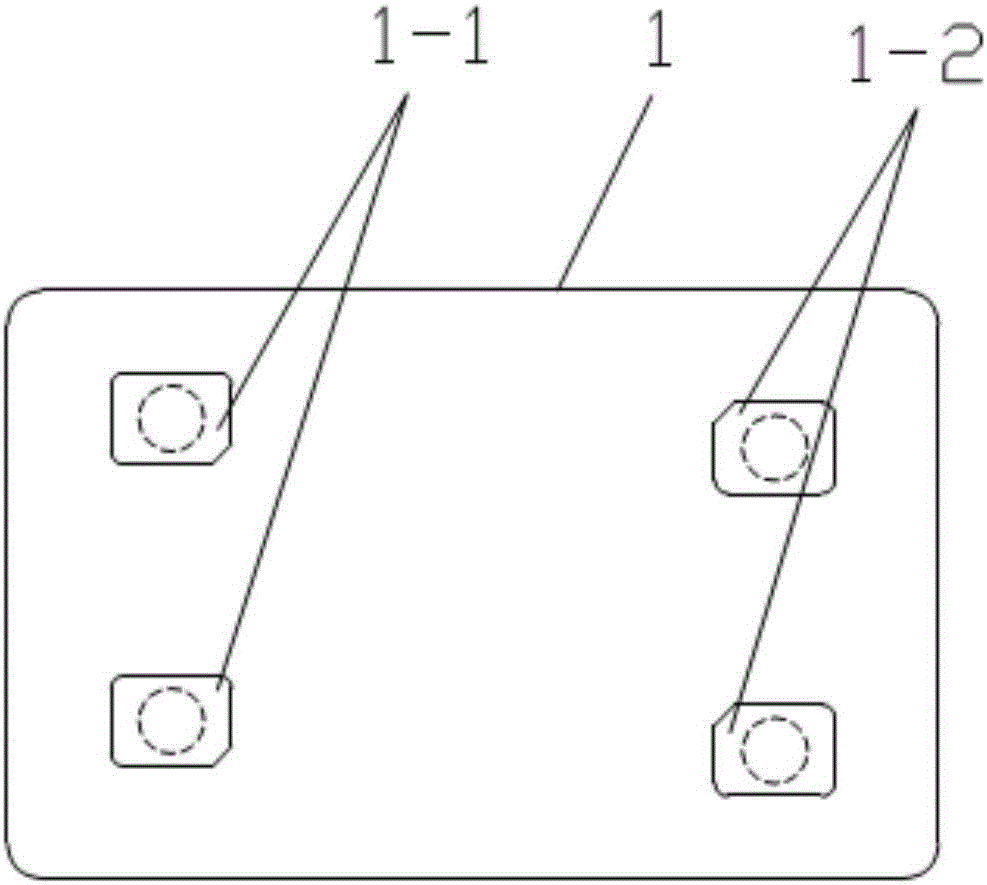

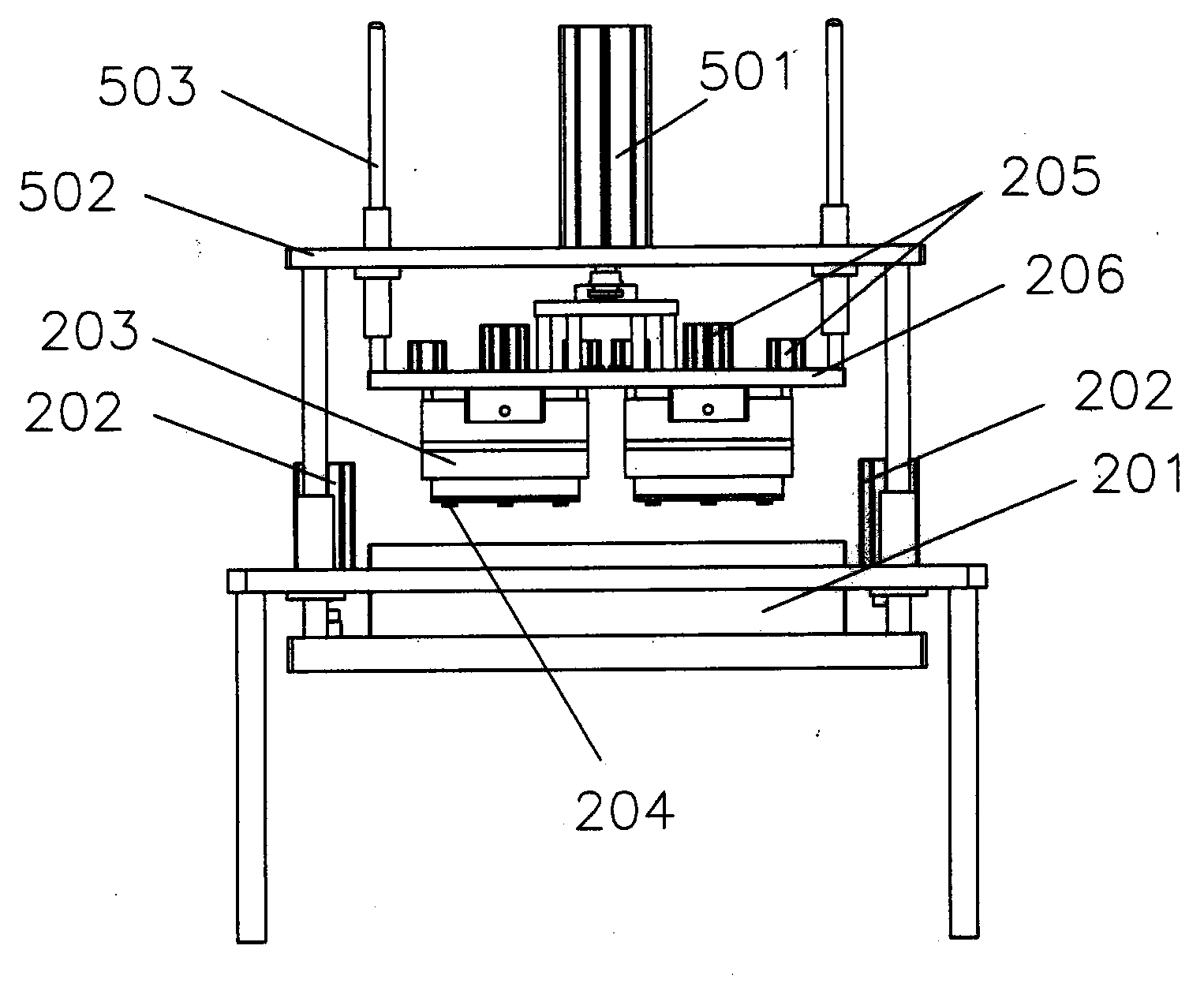

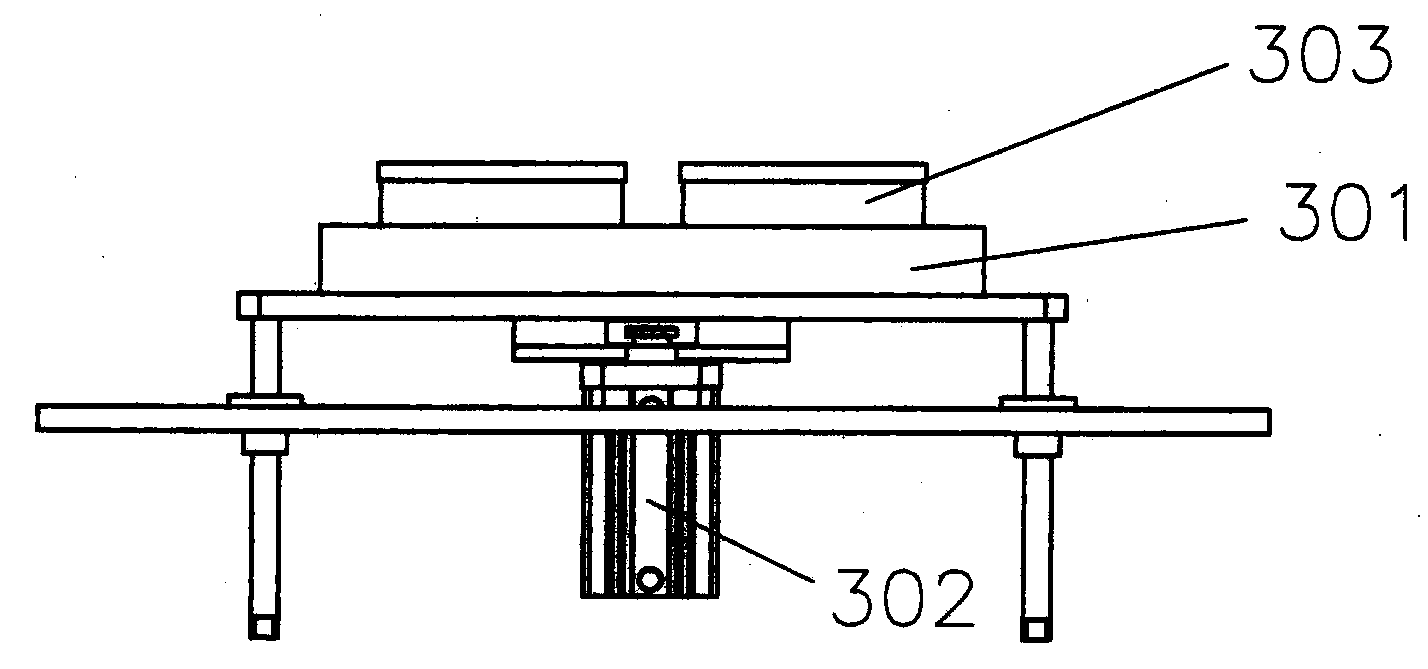

The invention discloses a servo double-surface heating vacuum packaging machine and belongs to liquid extraction seal secondary forming and packaging equipment of flexible packaged lithium batteries. The servo double-surface heating vacuum packaging machine comprises a double-station turntable feeding device driven by a cam partitioning device, a packaging mechanism with an up-and-down packaging device, and an electric control system, wherein the up-and-down packaging device comprises an upper cavity main body and a lower cavity main body; the opening directions of the upper cavity main body and the lower cavity main body are opposite to each other; the upper cavity main body and the lower cavity main body can clamp the turntable to form a sealed cavity body; a pressing board, an upper sealing head and a bayonet are arranged in the upper cavity main body; a lower sealing head and an aspirating hole are arranged in the lower cavity main body; the aspirating hole is communicated with an external vacuum source; the upper sealing head corresponds to the lower sealing head; and a heating body is arranged inside the servo double-surface heating vacuum packaging machine. The servo double-surface heating vacuum packaging machine has a compact structure and high efficiency; the electric core packaging quality is stable and the cost is low; vacuum liquid extraction can be realized; and pollution of the electrolyte to the equipment can be reduced to minimum.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

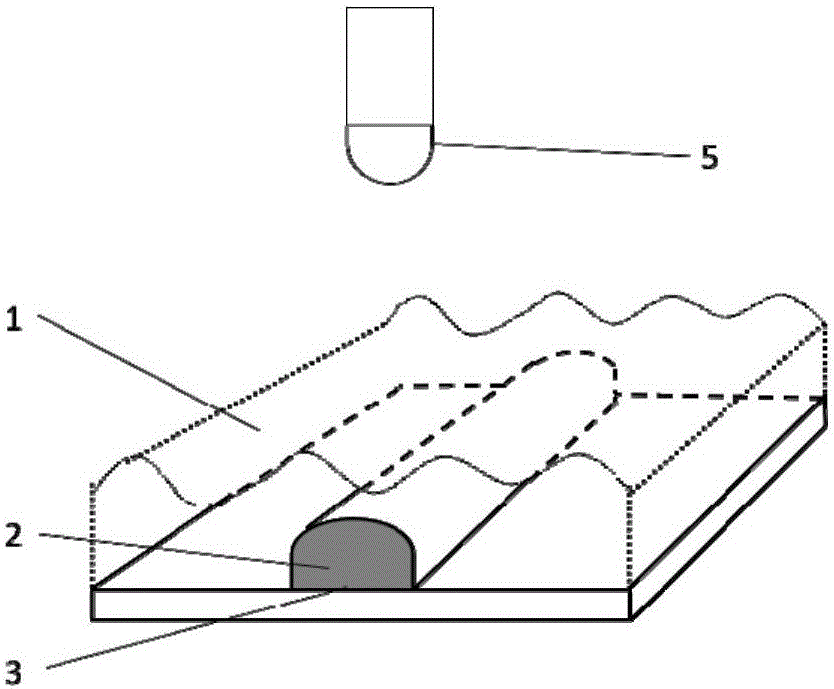

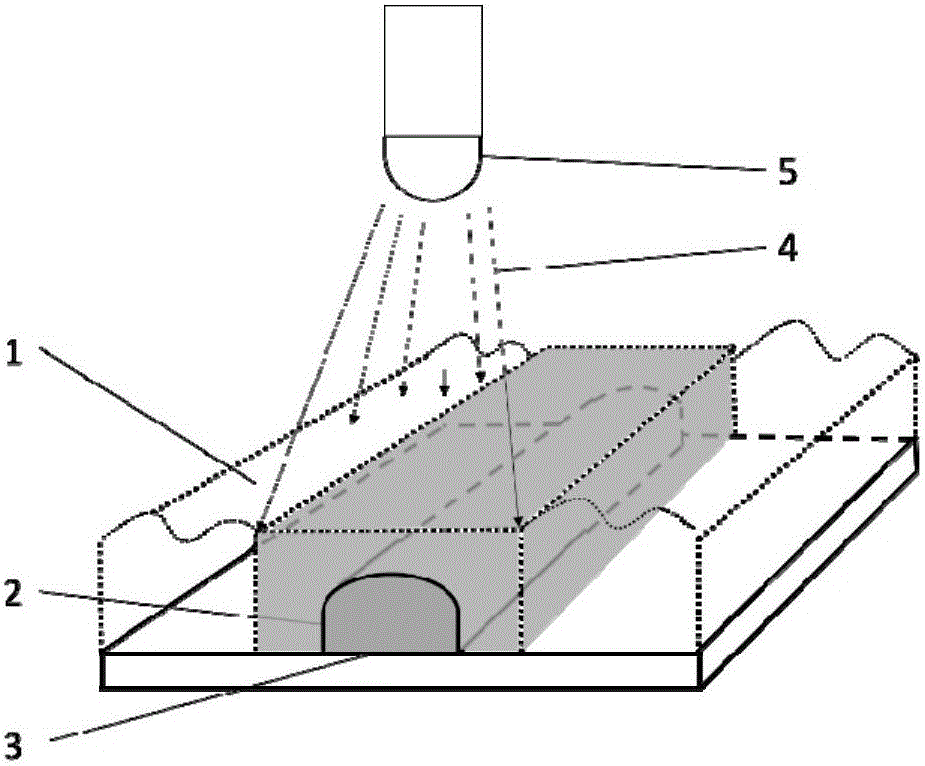

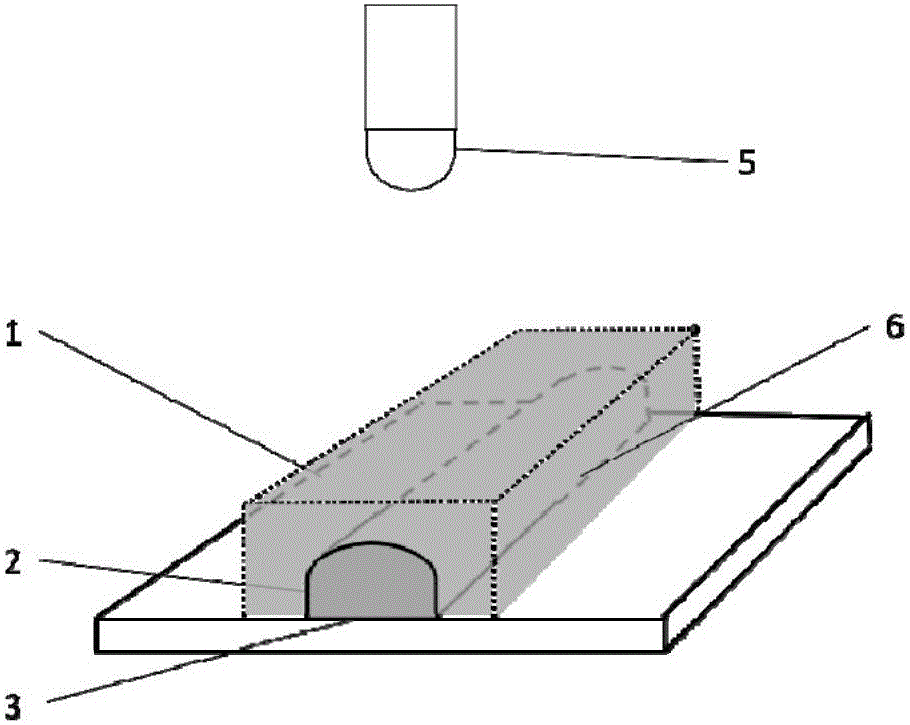

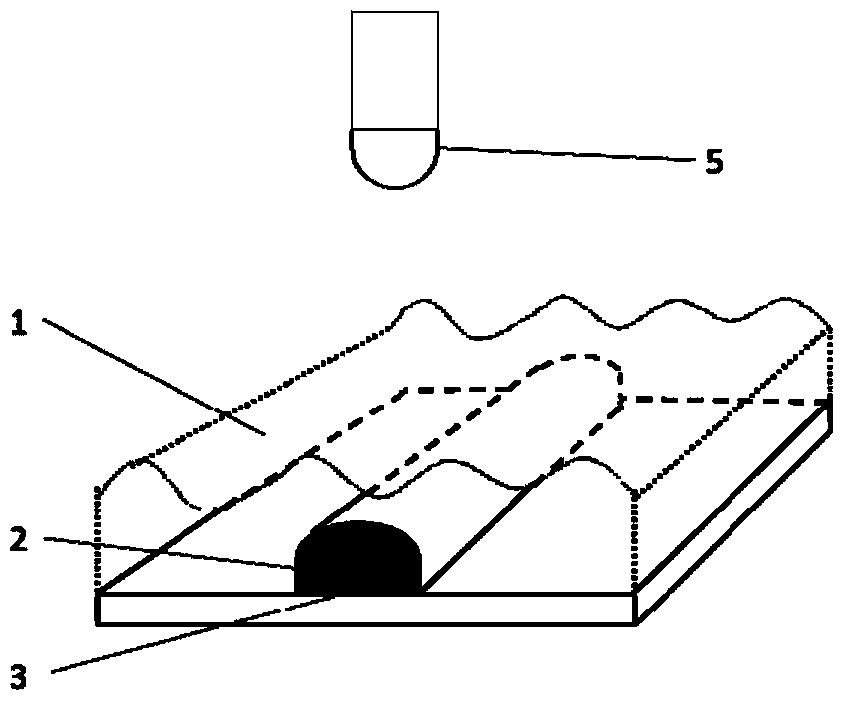

Method of light-cured resin packaging liquid-state metal printed circuit

ActiveCN105934105AImprove reliabilityImprove applicabilityNon-metallic protective coating applicationChemical reactionLight irradiation

The invention provides a method of a light-cured resin packaging liquid-state metal printed circuit. The method comprises the following steps: 1, a printed circuit to be packaged is a printed circuit taking liquid-state metal as a lead wire, a light-cured resin at a liquid state is coated to or adhered to the surface of the liquid-state metal printed circuit by use of an adhesive deposit device; and 2, an irradiation machine irradiates light to the light-cured resin on the surface of the liquid-state metal printed circuit, the irradiated light-cured resin is converted into a solid state from a liquid state through a chemical reaction, and thus the liquid-state metal printed circuit is packaged. The method for packaging the liquid-state metal printed circuit by use of the light-cured resin, brought forward by the invention, by use of the feature that the light-cured resin can be converted into the solid state from the liquid state under light irradiation, rapid and accurate packaging of the liquid-state metal printed circuit is realized, the circuit reliability is improved, and the adaptation scope is enlarged.

Owner:BEIJING DREAM INK TECH CO LTD

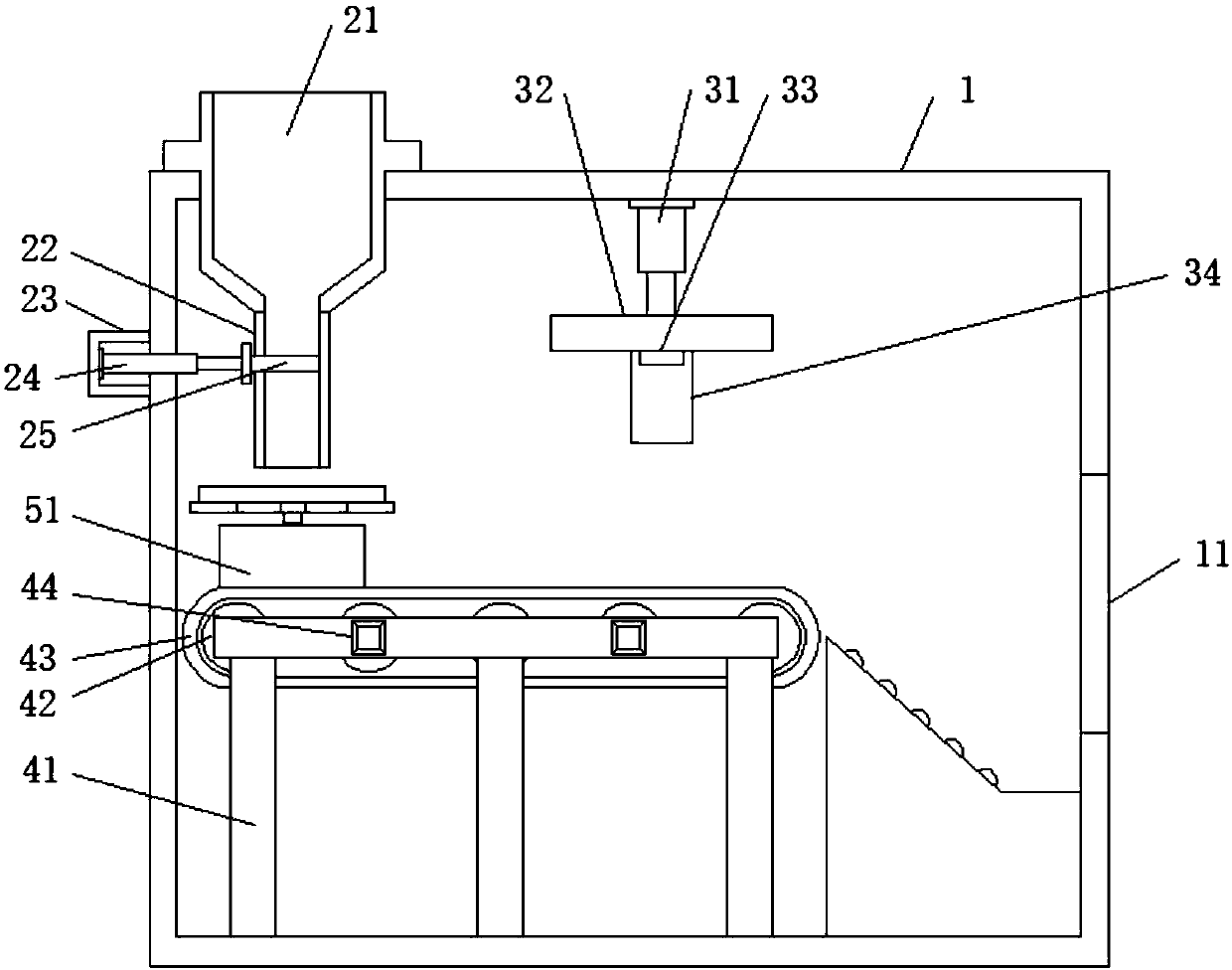

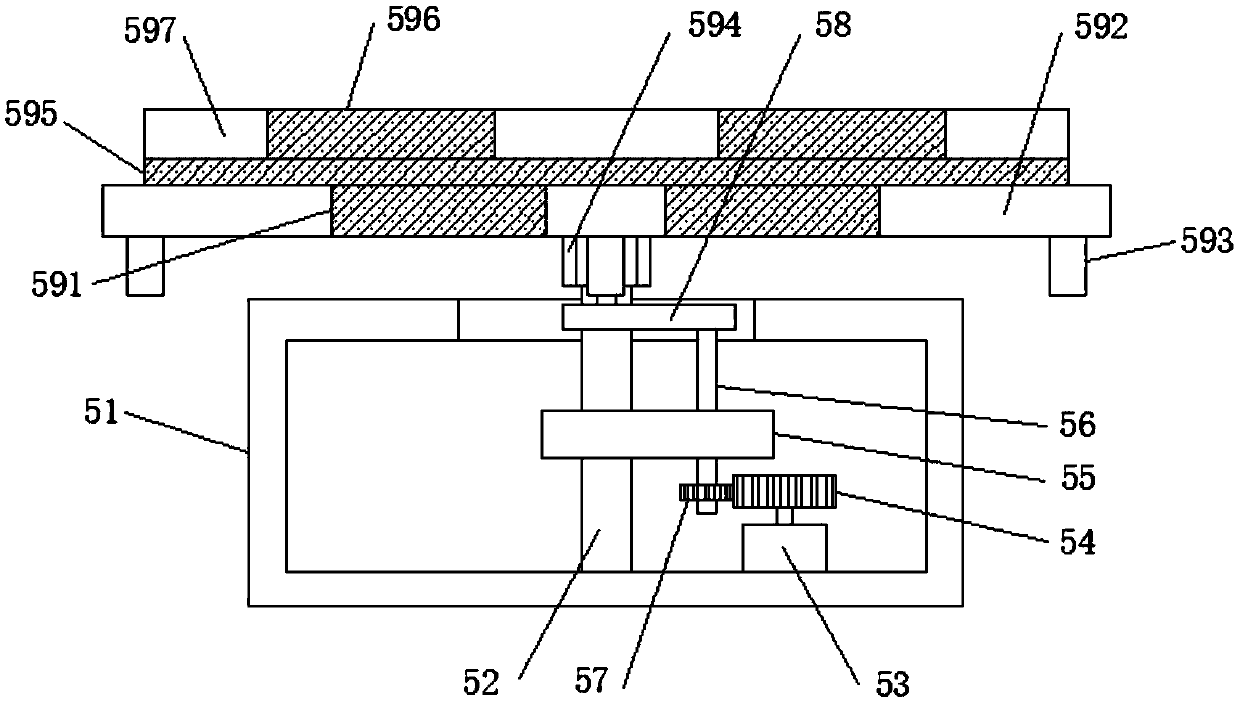

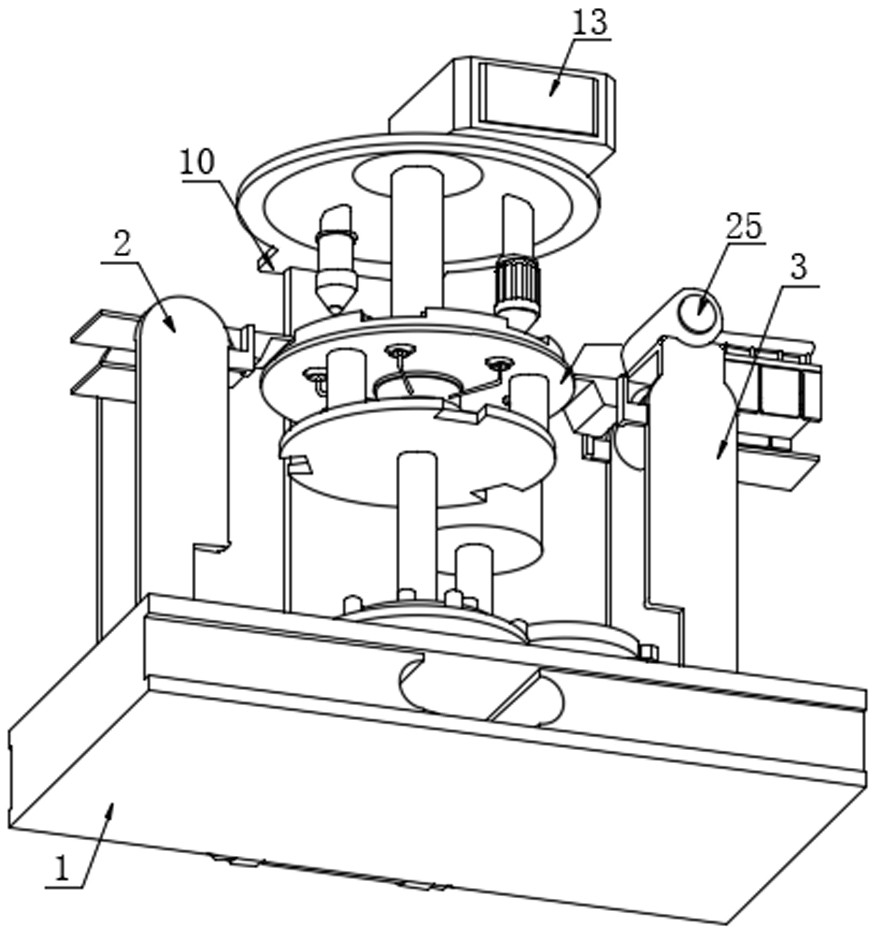

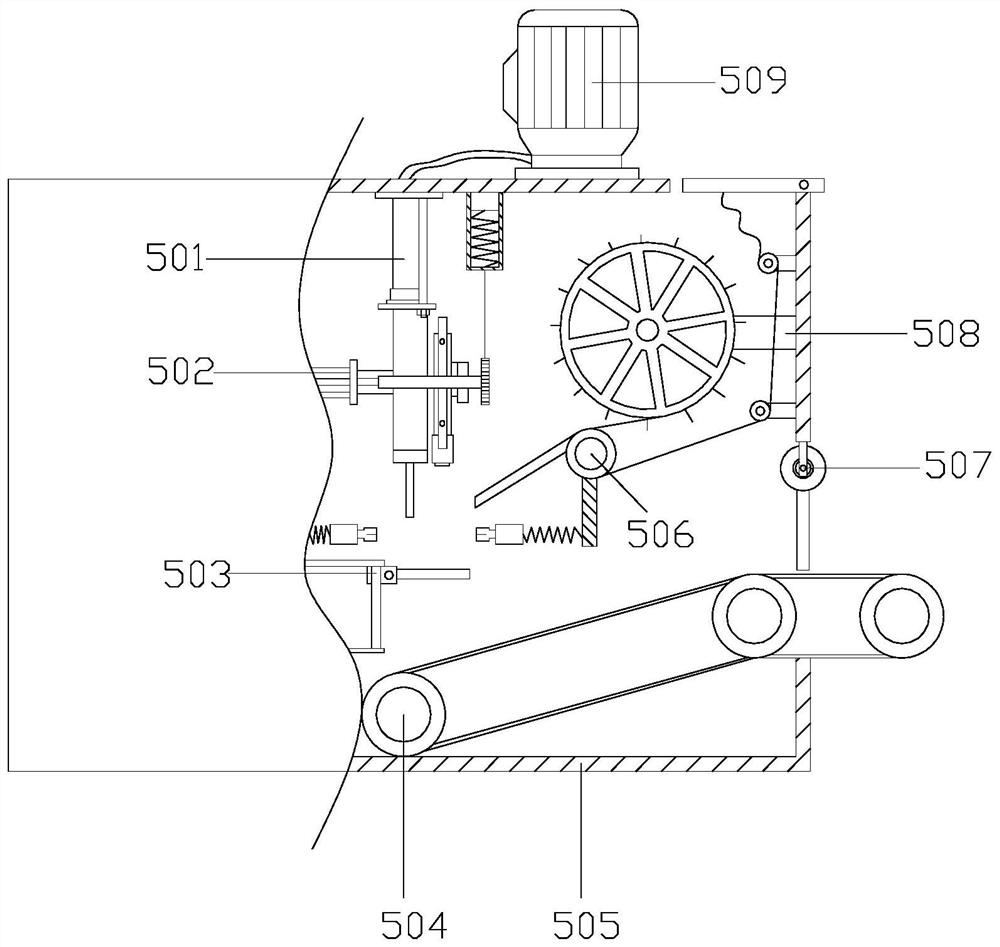

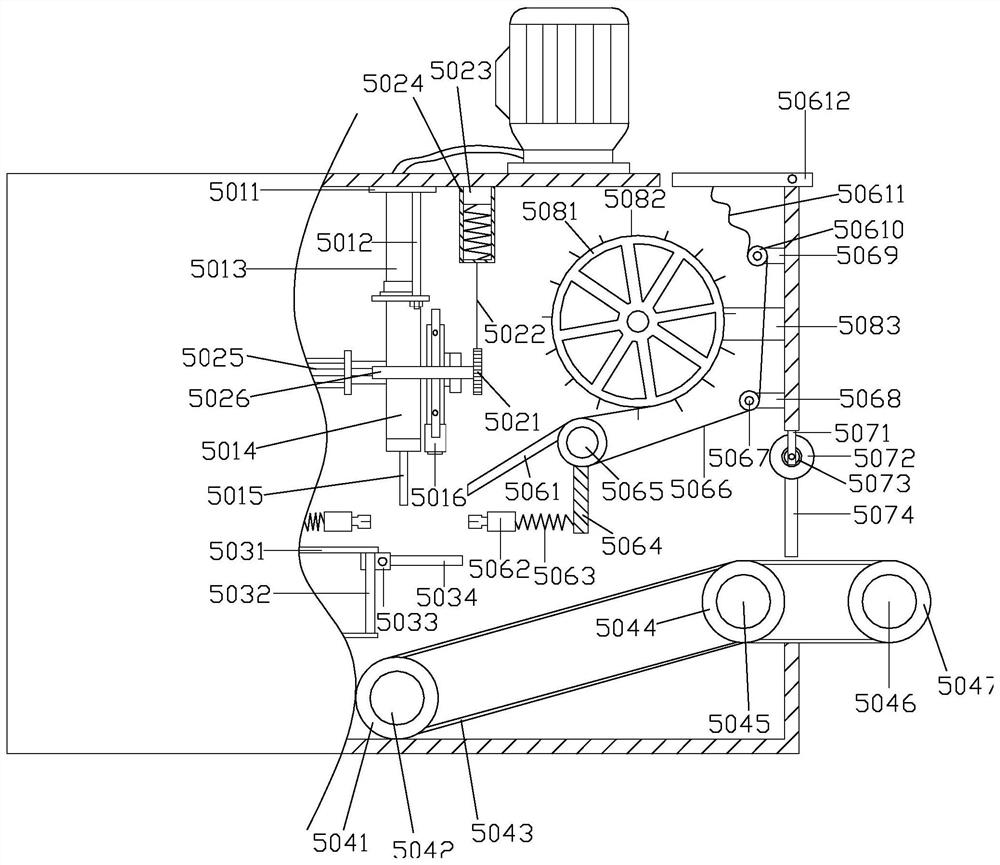

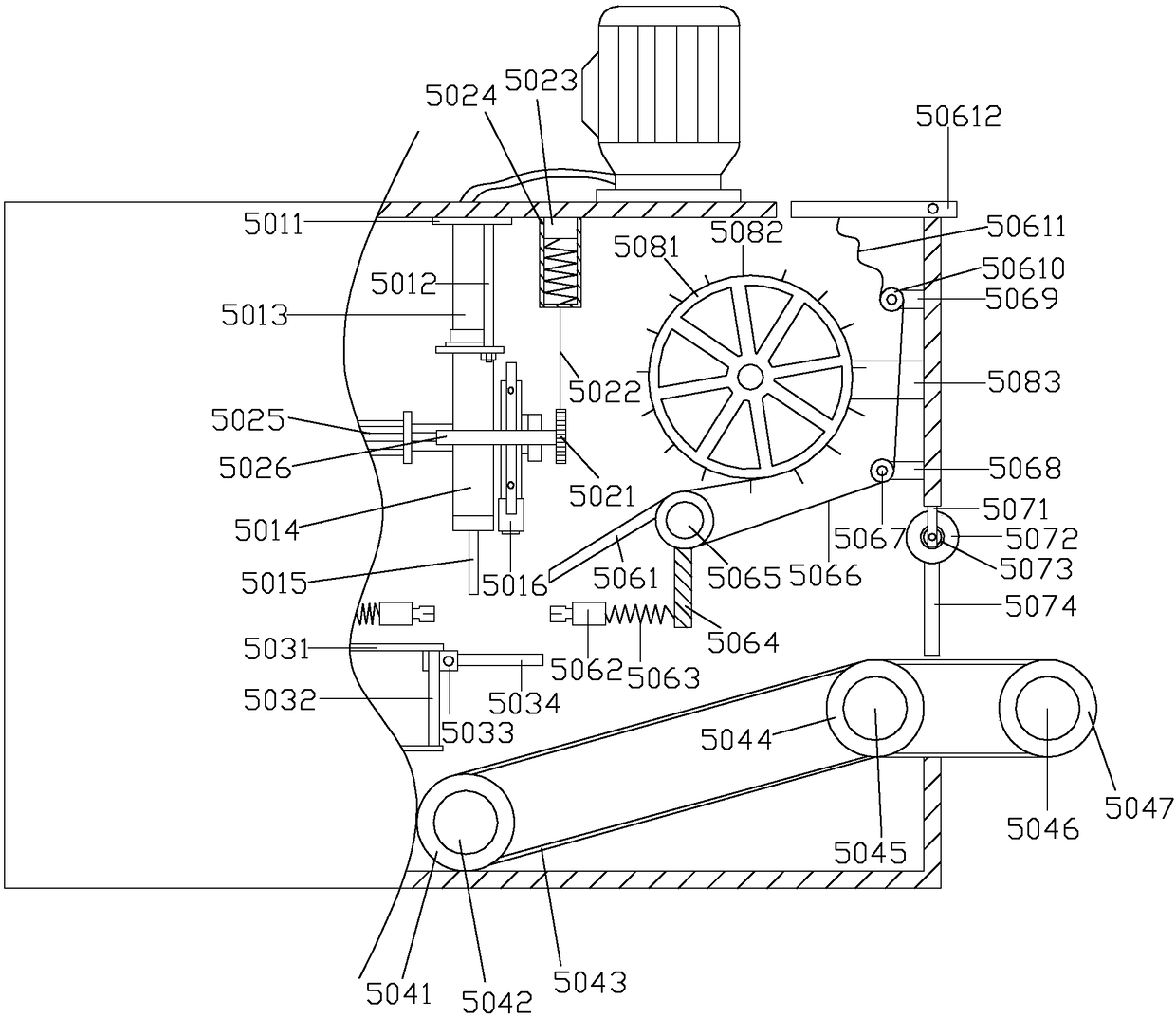

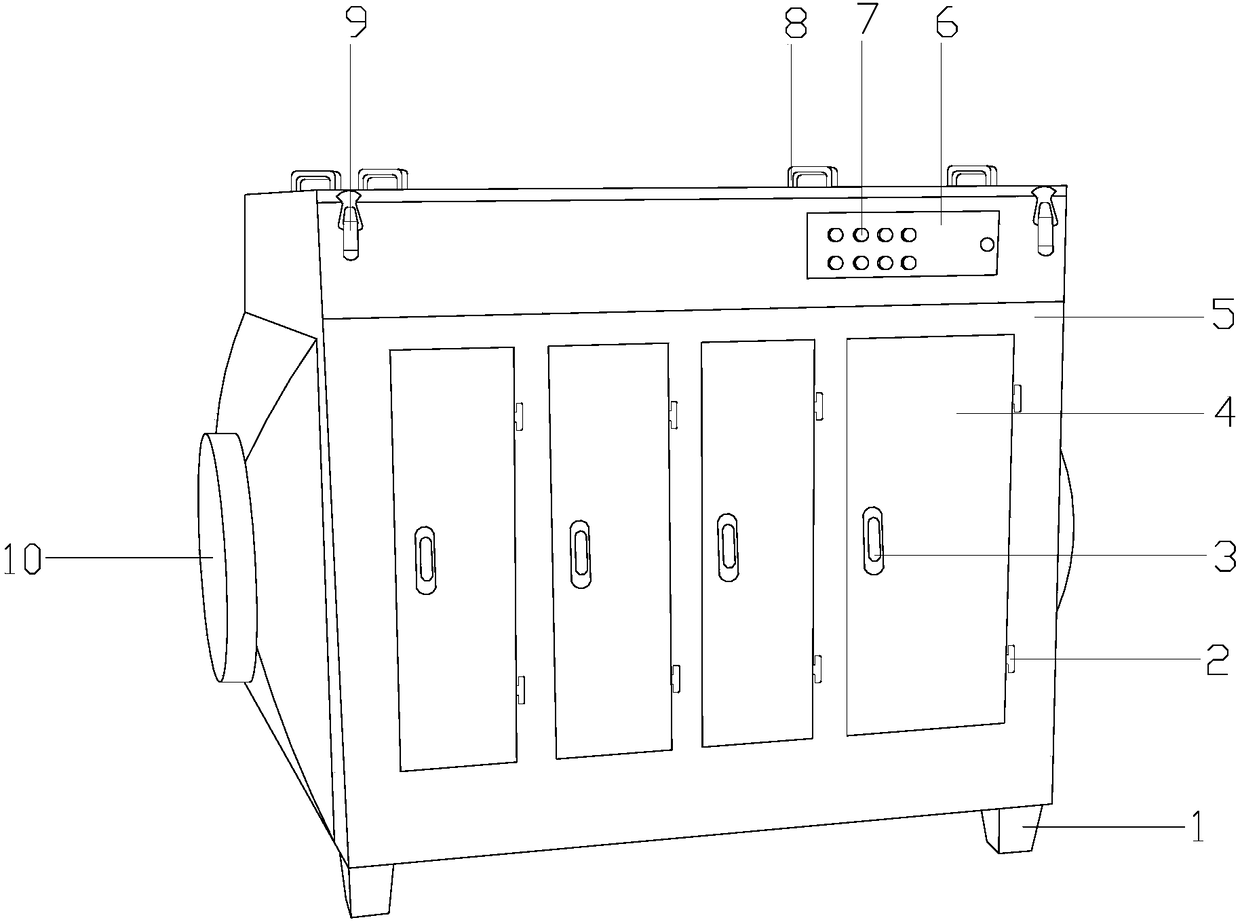

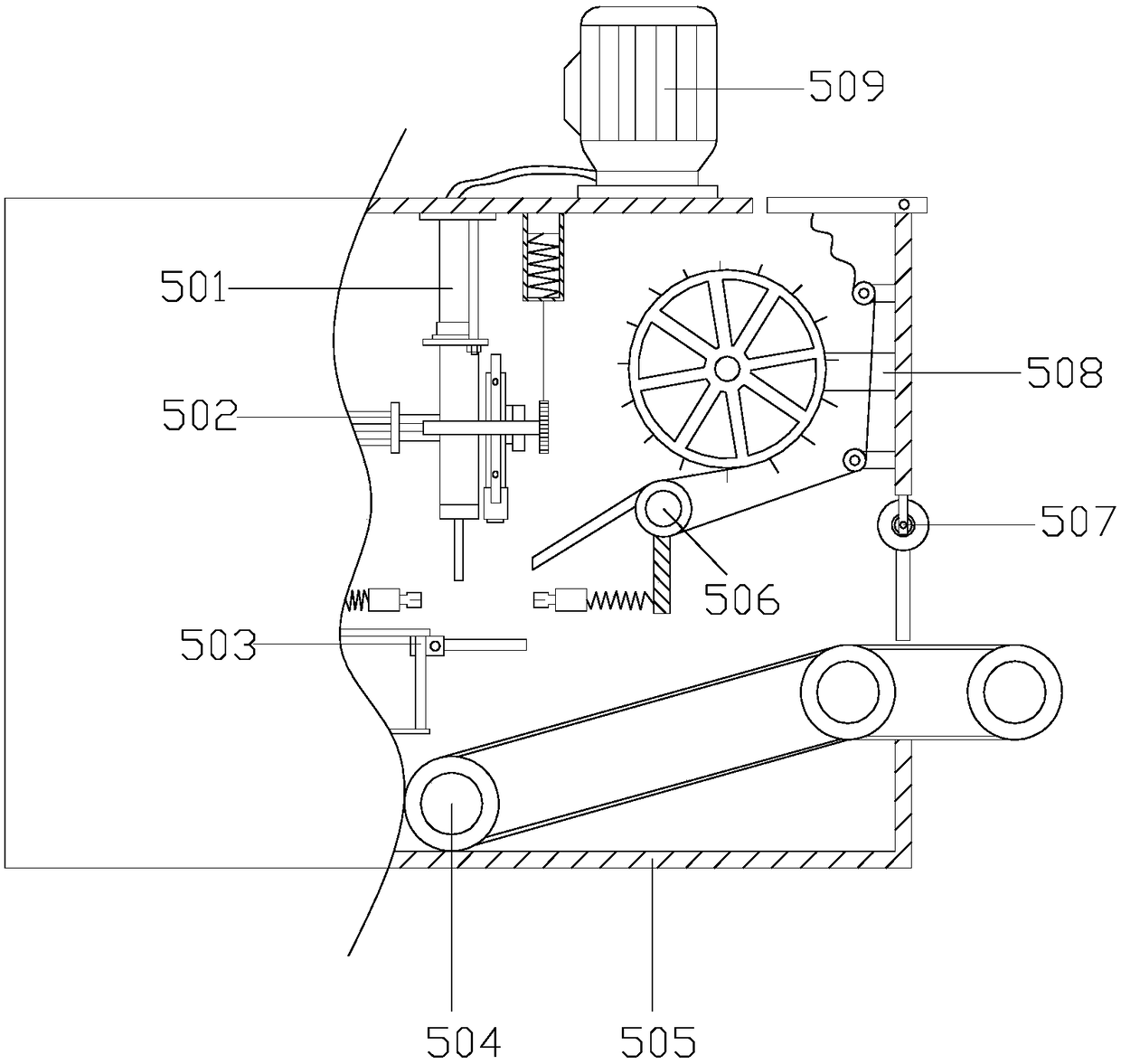

Full-automatic LED package machine

ActiveCN107910287AConvenient order placementEasy to moveSemiconductor/solid-state device manufacturingConveyor partsEngineeringAutomatic processing

The invention discloses a full-automatic LED package machine. The full-automatic LED package machine comprises a hollow-structure shell and also comprises a feeding mechanism, a package mechanism, a transmission mechanism and an adjustment mechanism, wherein the feeding mechanism is arranged at one side of the top of the shell, the package mechanism is arranged on an inner wall of the other side of the top of the shell, the adjustment mechanism moves with the transmission mechanism, the transmission mechanism comprises a support rack, a transmission shaft, a conveying belt and a third drivingdevice, the transmission shaft is rotatably connected to the top of the support rack, the conveying belt sleeves the transmission shaft, the third driving device drives the transmission shaft to rotate, the adjustment mechanism comprises a hollow fixed seat, the hollow fixed seat is fixedly arranged at the top of the transmission shaft, a positioning rod and a fourth driving device are arranged onan inner wall of the bottom of the hollow fixed seat, a first gear is arranged on an output shaft of the top of the fourth driving device, a fixed block is welded at a middle position of the positioning rod and is perpendicular to the positioning rod, and a rotation rod is rotatably connected with one side of the fixed block and is parallel to the positioning rod. The full-automatic LED package machine is reasonable in design and low in manual operation cost, full-automatic processing is achieved, the LED package efficiency and package accuracy are improved, and mass production is facilitated.

Owner:ZHONGSHAN MULINSEN ELECTRONICS CO LTD

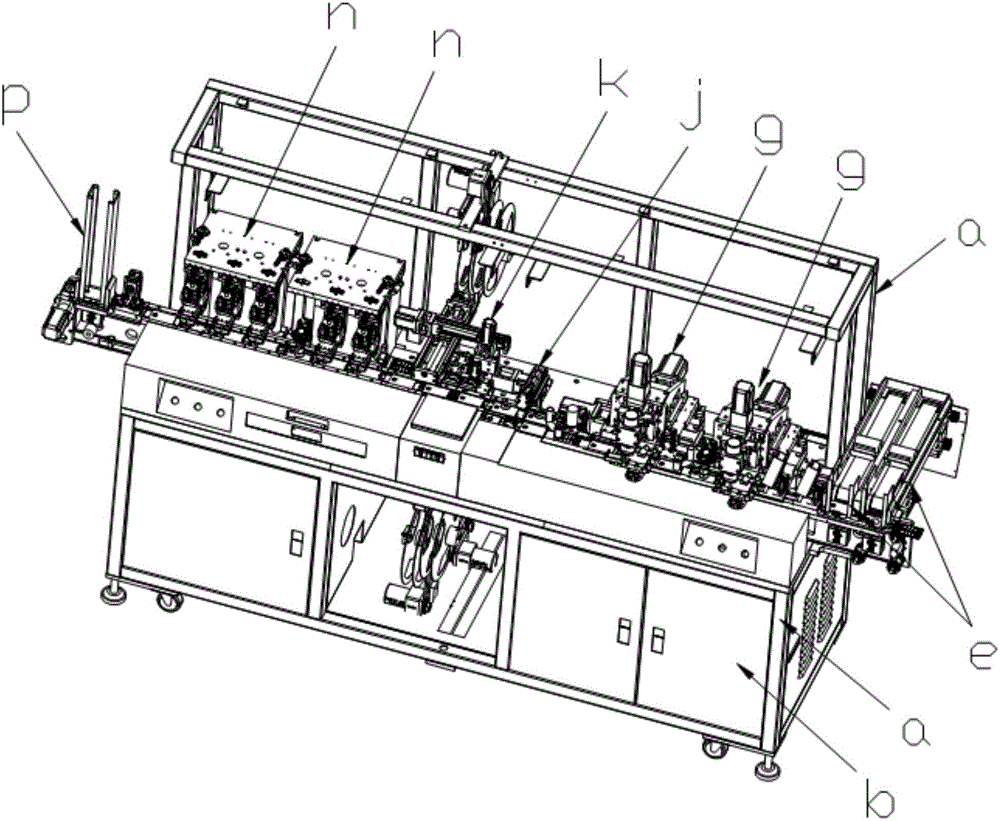

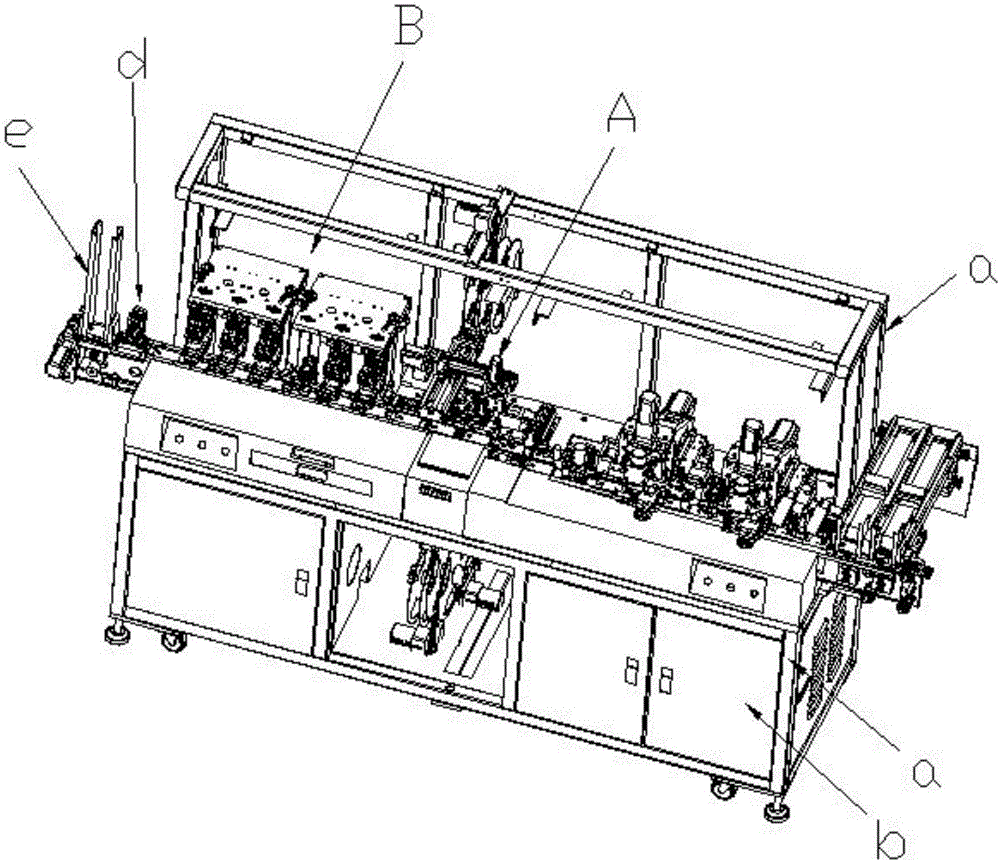

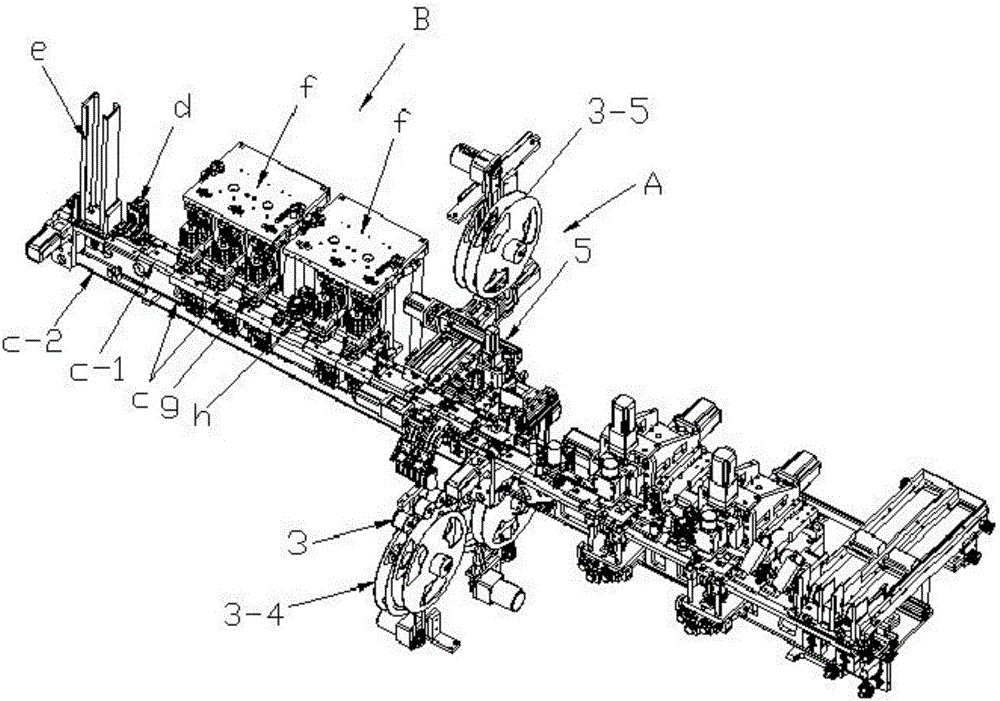

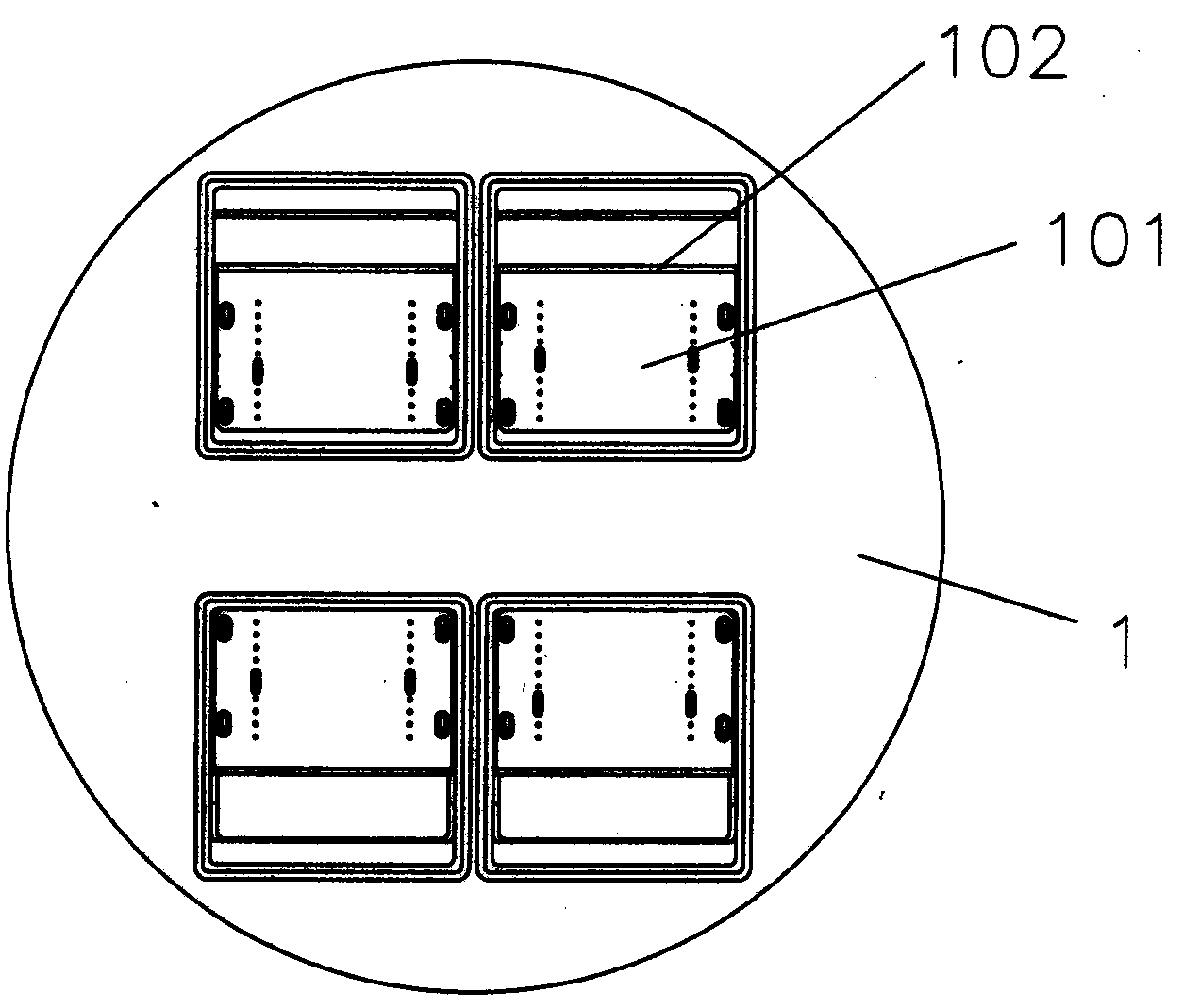

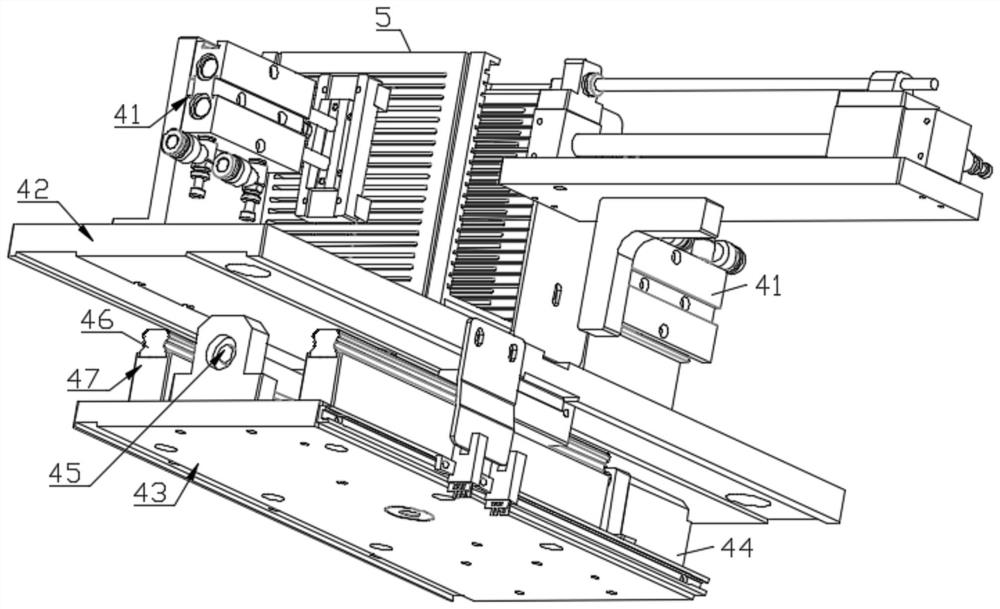

Multi-chip contact intelligent card groove milling packaging personalized production line

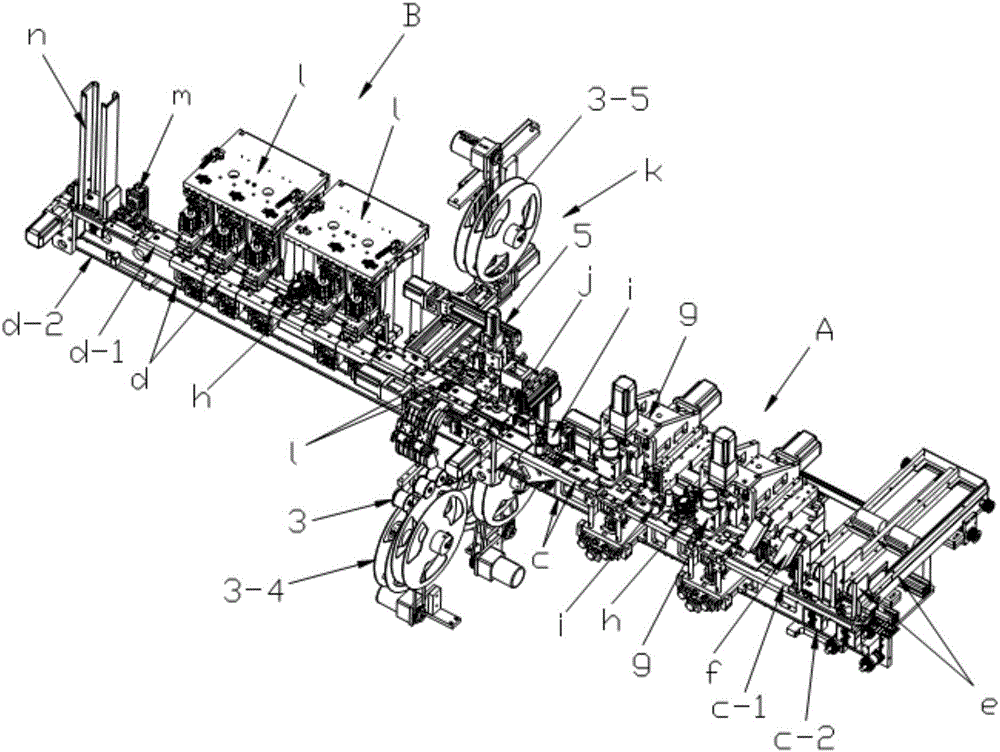

ActiveCN106447008AReduce transfer timeIncrease productivityCo-operative working arrangementsRecord carriers used with machinesPersonalizationProduction line

The invention discloses a multi-chip contact intelligent card groove milling packaging personalized production line. The production line comprises a groove milling device, a packaging device and a personalization device which are connected together, wherein the packaging device comprises a packaging module, the packaging module comprises two chip band supply mechanisms, a chip punching mechanism and a chip carrying packaging mechanism; two packaging work stations are arranged at positions, which are corresponding to the packaging module, in a chip carrying guide rail of the groove milling device, and each packaging work station is provided with a chip positioning mechanism; each of the two chip band supply mechanisms comprises a chip band and a chip band conveying mechanism; and the chip bands in the two chip band supply mechanisms extend in parallel along a direction vertical to a chip conveying direction, and the transmission directions of the chip bands in the two chip band supply mechanisms are opposite. The production line is applied to groove milling packaging of a single-chip card, is also applied to groove milling packaging of a multi-chip card, and has the advantages of fast packaging speed, high production efficiency, high packaging precision and the like.

Owner:GUANGZHOU MINGSEN TECH CO LTD

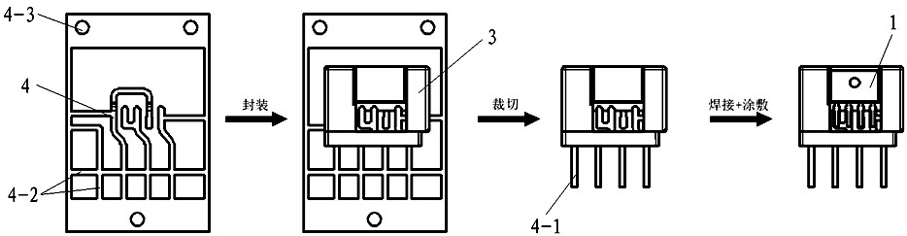

Novel integrated circuit (IC) package manufacturing process

ActiveCN102254838AFast packingHigh packaging precisionSemiconductor/solid-state device manufacturingNumerical controlEngineering

The invention discloses a novel integrated circuit (IC) package manufacturing process, which comprises the following steps of: manufacturing an IC carrier plate; preparing a packaging cover plate; gluing a reverse side of the packaging cover plate, and wholly pressing the reverse side of the packaging cover plate on the IC carrier plate mechanically; and carving and molding by adopting a + / -0.05mm high-precision carving machine, binding the IC carrier plate by using a binding machine, coating 50Um resin pure glue on a positive side of the packaging cover plate, wholly pressing packaging glass on the cover plate mechanically, and cutting and molding by using a cutting machine. The process has the advantages that: various parts are wholly pressed by resin pure glue, the traditional manual monomer package is replaced, and the packaging speed is greatly improved; the packaging cover plate is molded through high-precision computerized numerical control (CNC), a monomer plastic piece injection molding mode is replaced, and the packaging precision is improved; the wholly pressed products are cut by a wafer cutting machine, and the packaging precision is improved; and various parts are wholly pressed by the resin pure glue, the density among the various parts is improved, and the moistureproof function after package is improved.

Owner:宁波永旭丰泰电子科技有限公司

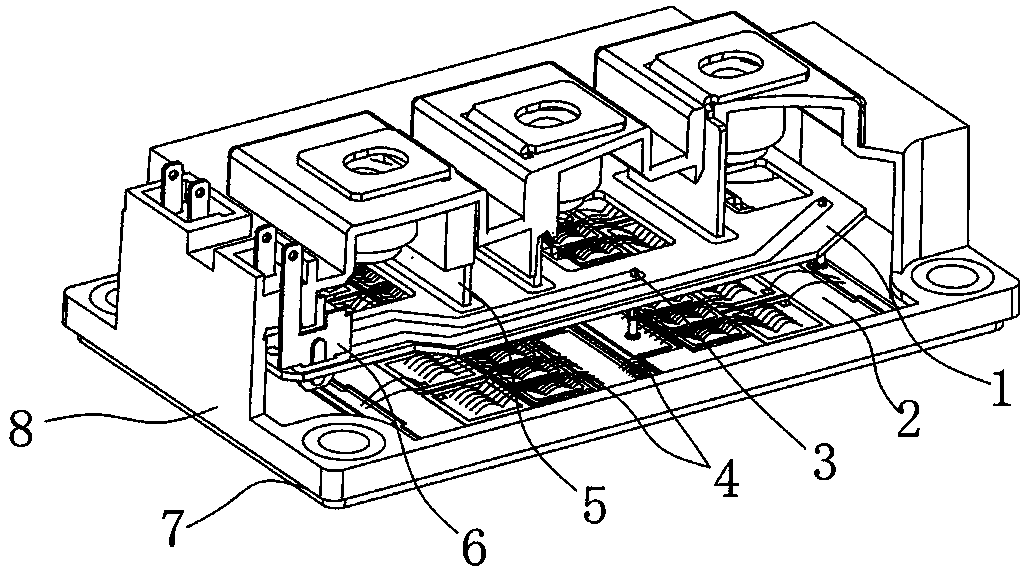

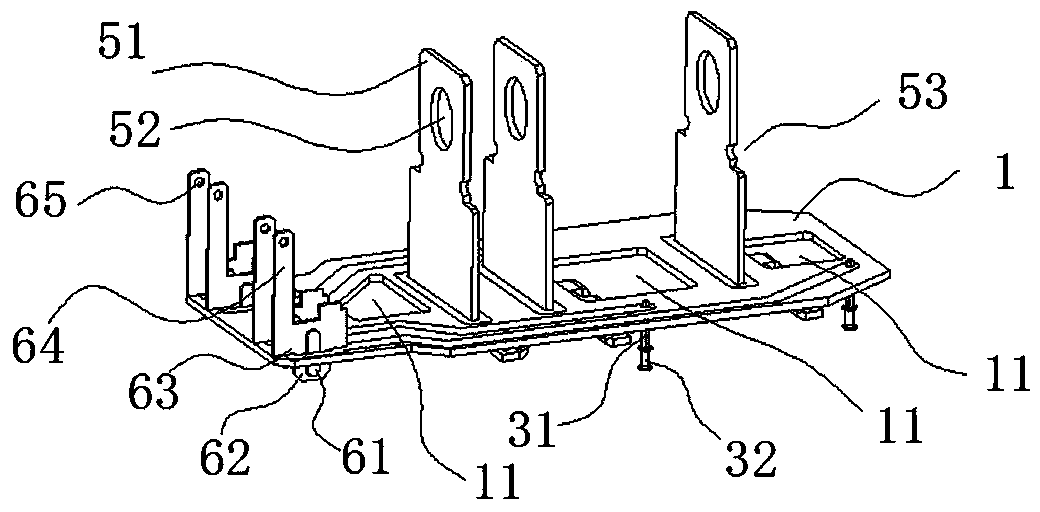

Power module encapsulating structure

ActiveCN103779344ASimple structureEasy to useSemiconductor/solid-state device detailsSolid-state devicesManufacturing technologyExternal application

A power module encapsulating structure mainly comprises DBC, the DBC is provided with chips and bonding wires and is welded on a substrate, power terminals, signal terminals and signal frames are fixed to a circuit board, the circuit board is welded on the DBC through power terminal pins and signal frame pins, an outer shell fixes and seals a whole module, and the outer shell is provided with an opening allowing the power terminals and signal terminals to stretch out and be connected with external application terminals. Two signal terminals are led to a gate electrode of an upper tube and a gate electrode of a lower tube respectively, and the other two signal terminals are led to an emitting electrode of the upper tube and an emitting electrode of the lower tube respectively. Circuits on the circuit board enable the signal terminals and the corresponding signal frames to be communicated, and the signal frames are welded and communicated with the corresponding positions on the DBC. Three power terminals are fixed through the circuit board and are welded and communicated with the corresponding positions on the DBC. The power module encapsulating structure has the advantages of being simple in structure, convenient to mount and use and simple in manufacturing technology, and improving encapsulating precision and using reliability.

Owner:STARPOWER SEMICON

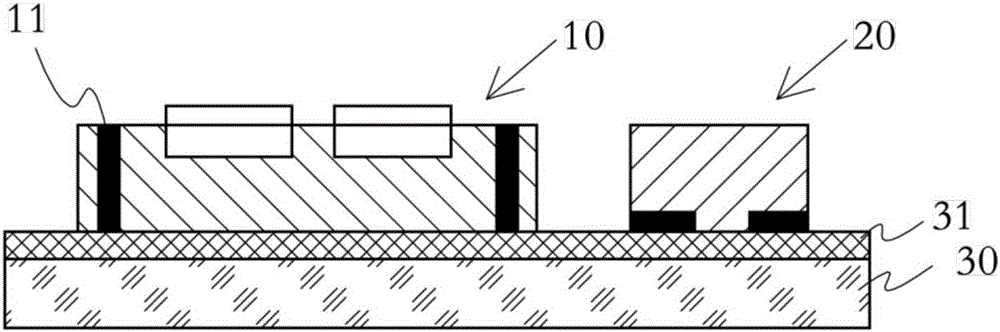

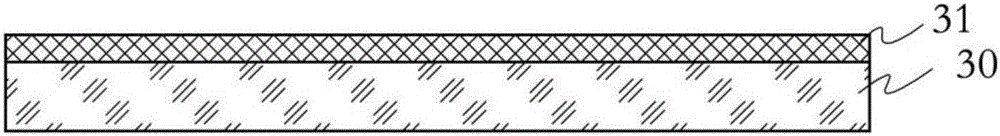

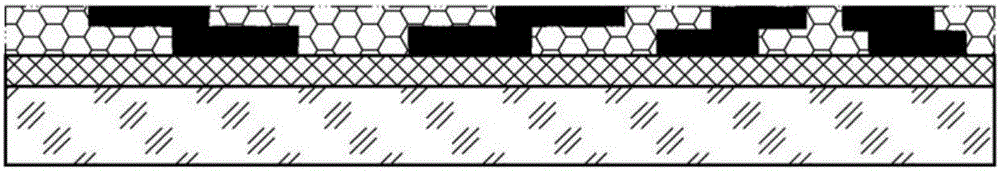

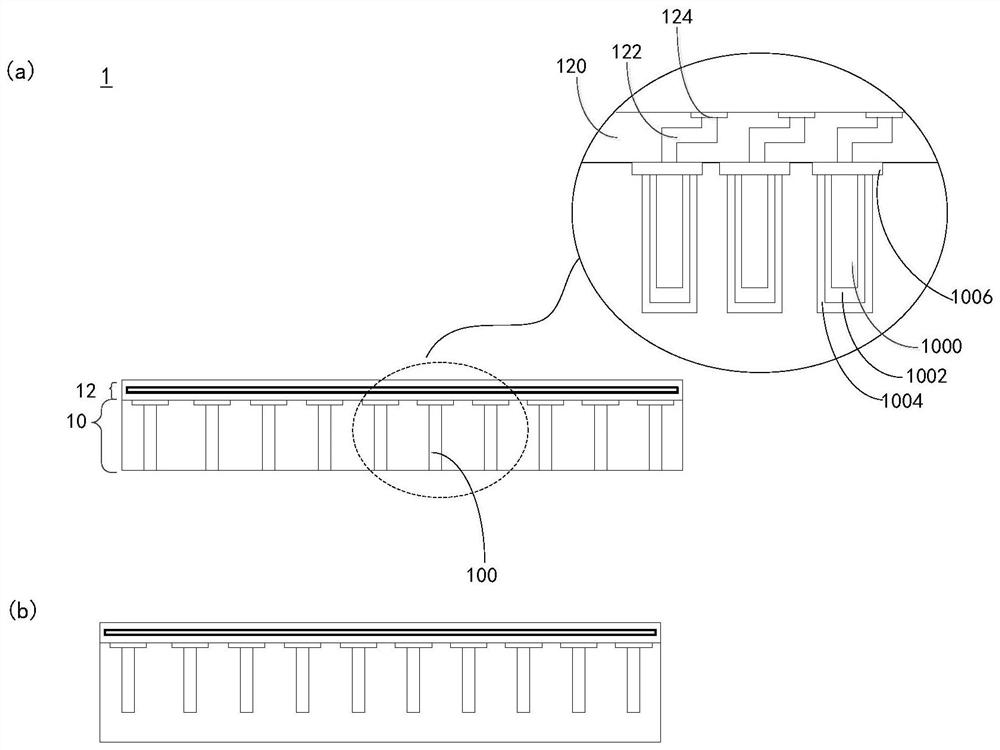

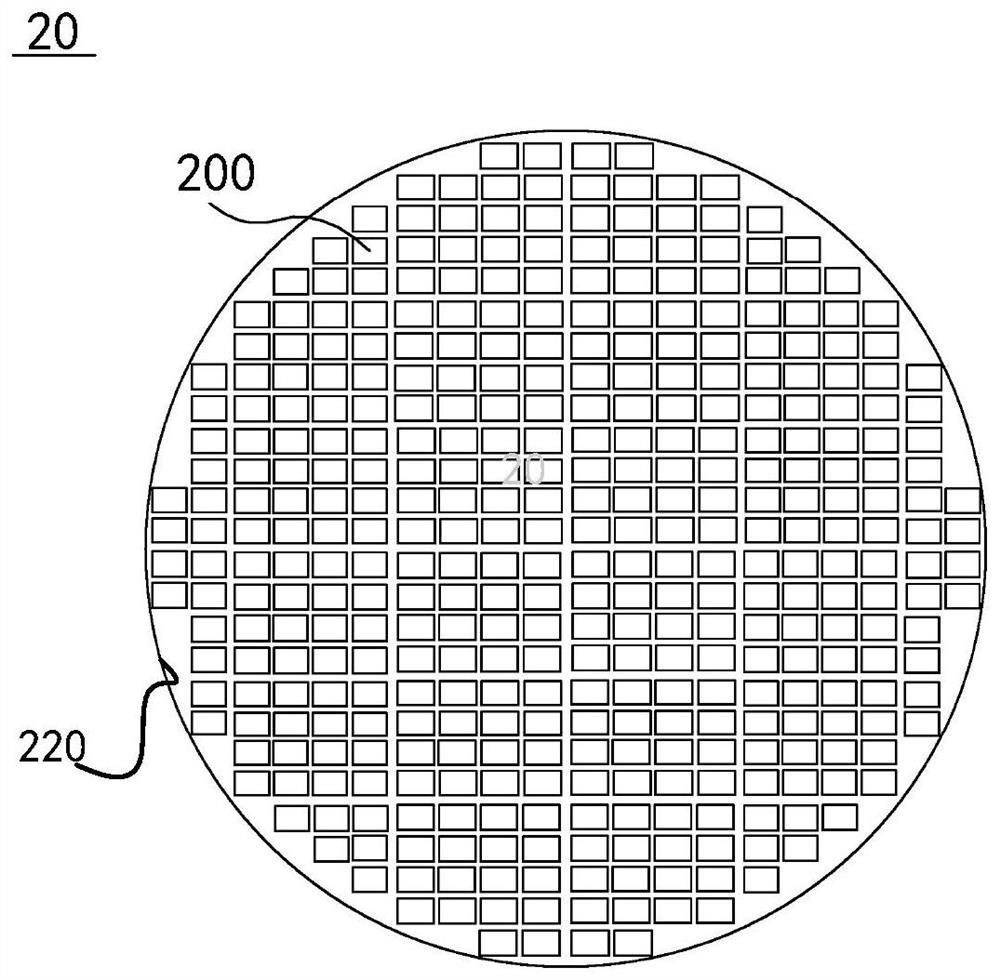

Ultra-thin ambient light and proximity sensor wafer level package and package method thereof

PendingCN106024649AConducive to thin designImprove routing densitySemiconductor/solid-state device detailsSolid-state devicesProximity sensorEngineering

The invention provides ultra-thin ambient light and proximity sensor wafer level package and a package method thereof. The method comprises the steps that a. a light-sensitive wafer with a silicon through-hole structure and a light-emitting wafer are placed on a forming carrier with a tape; b. the light-emitting wafer and the light-sensitive wafer are encapsulated by a light-transmitting material to form an optical cover; c. the optical cover is encapsulated by a non-light-transmitting material, and a light isolation belt is formed between the light-emitting wafer and the light-sensitive wafer to form a protection cover; d. the top of the protection cover is bonded to the processing fixture of an RDL wiring layer; e. the forming carrier and the tape are removed; and f. the RDL wiring layer is formed on the removed surface to realize the wafer level package. According to the invention, traditionally relying on the process of a PCB substrate is changed; the light-sensitive wafer with the silicon through-hole structure and the RDL wiring layer are combined to realize wafer level package; and thinning and efficient production are realized without the PCB substrate.

Owner:宁波德葳智能科技有限公司

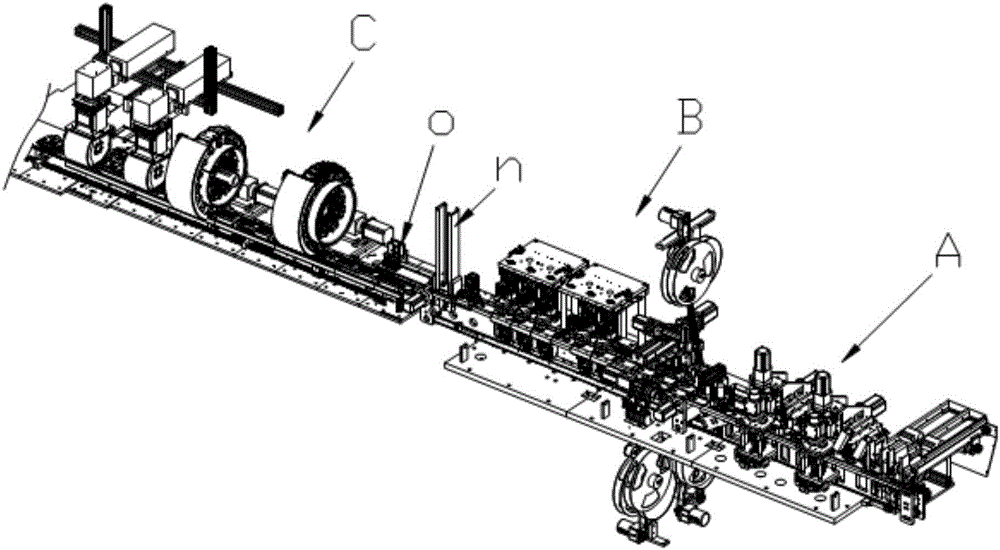

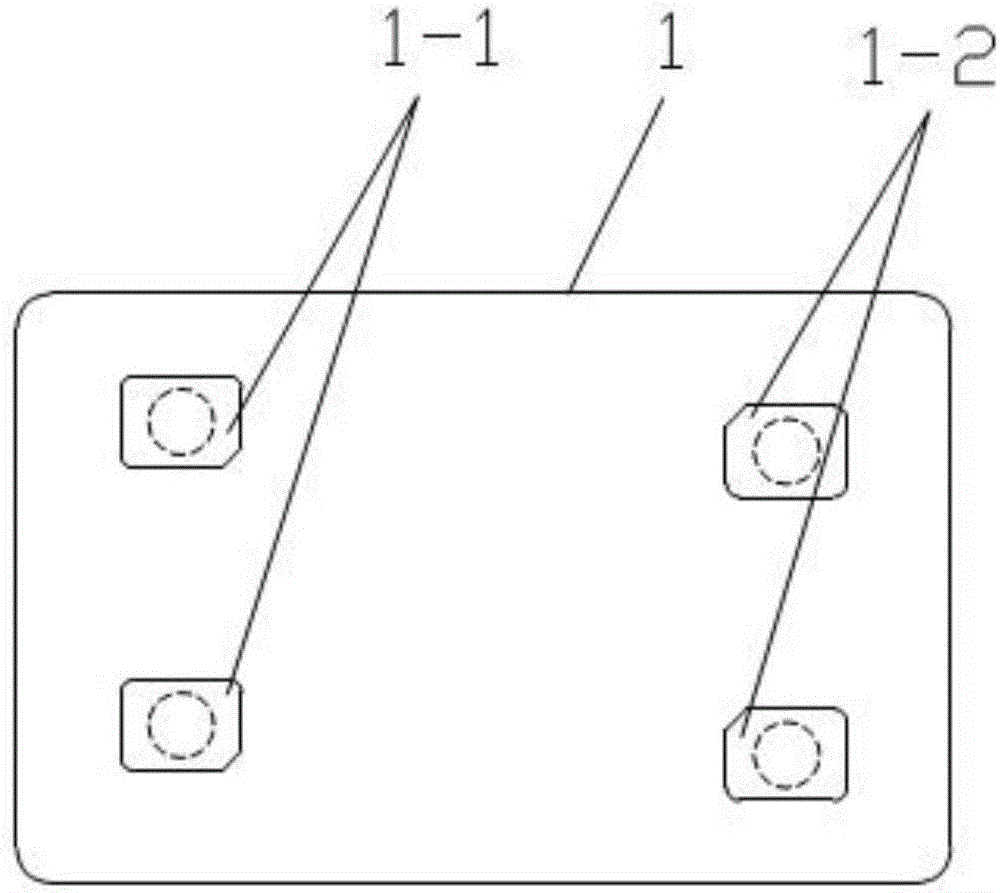

Chip package production line of multichip intelligent card

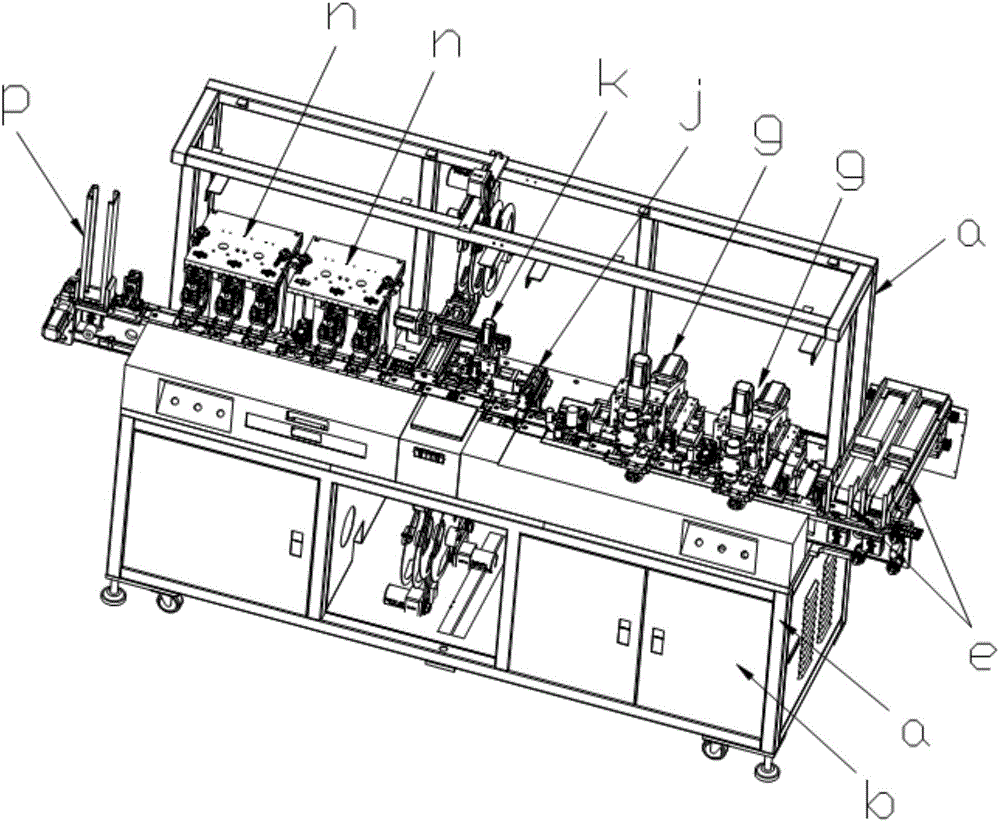

ActiveCN106328566AHigh packaging precisionSave packing timeSemiconductor/solid-state device manufacturingProduction lineThermal compression

The invention discloses a chip package production line of a multichip intelligent card, comprising a card conveying mechanism, a packaging module, a thermal compression module, a chip detection module and a card receiving module, wherein the modules are in sequence arranged along a card conveying direction; the packaging module comprises two chip belt supply mechanisms, a chip blanking mechanism and a chip carry packaging mechanism; two packaging stations are configured for the packaging module; a chip positioning mechanism is respectively arranged at each packaging station; chip belt supply mechanisms comprise chip belts and chip belt transmission mechanism; chip belts in two chip belt supply mechanisms in parallel extend along a direction perpendicular to the card conveying direction, and the transmission directions thereof are opposite. The equipment is applicable to package and fixation of the single-chip card and the multichip card and has the advantages of quick package and thermal compression fixation speed, high production efficiency and precision.

Owner:GUANGZHOU MINGSEN TECH CO LTD

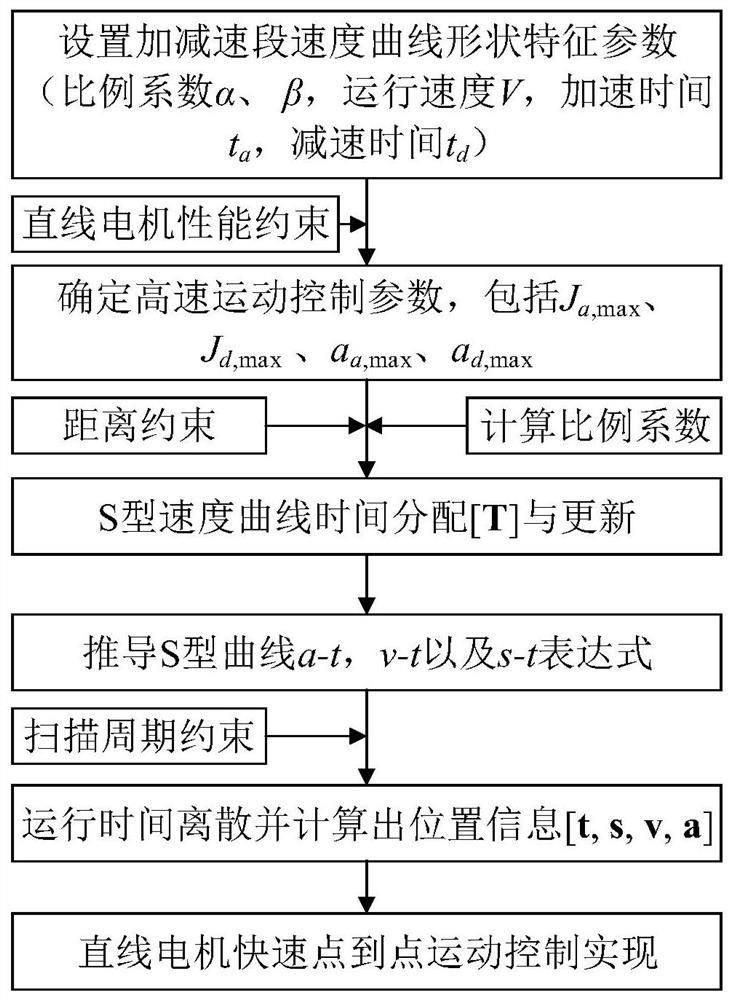

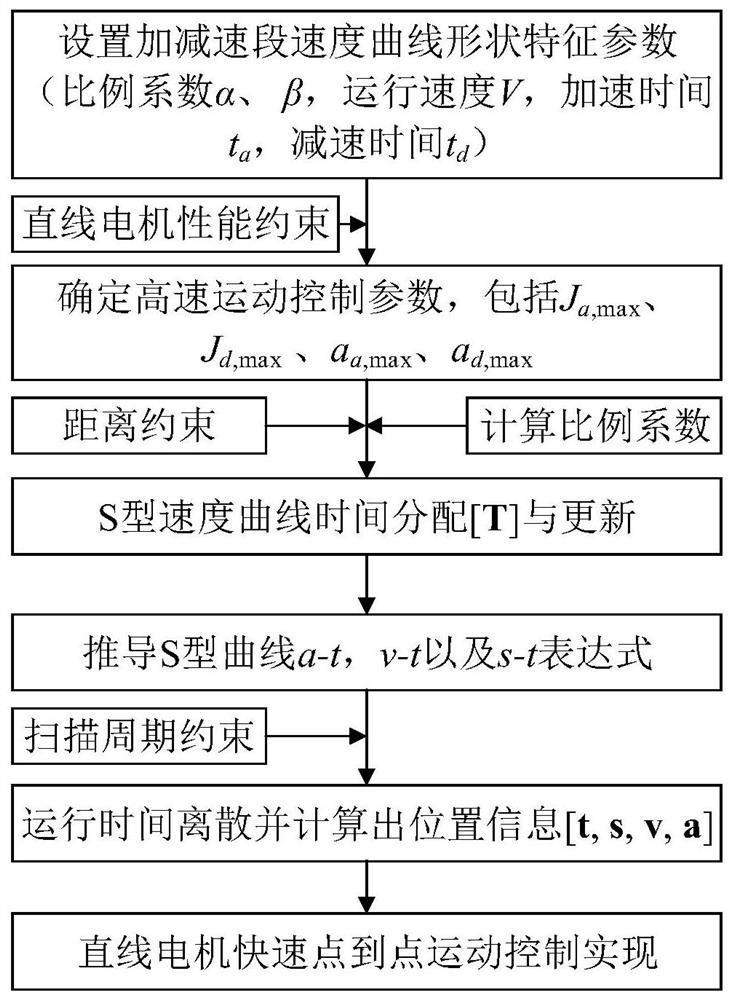

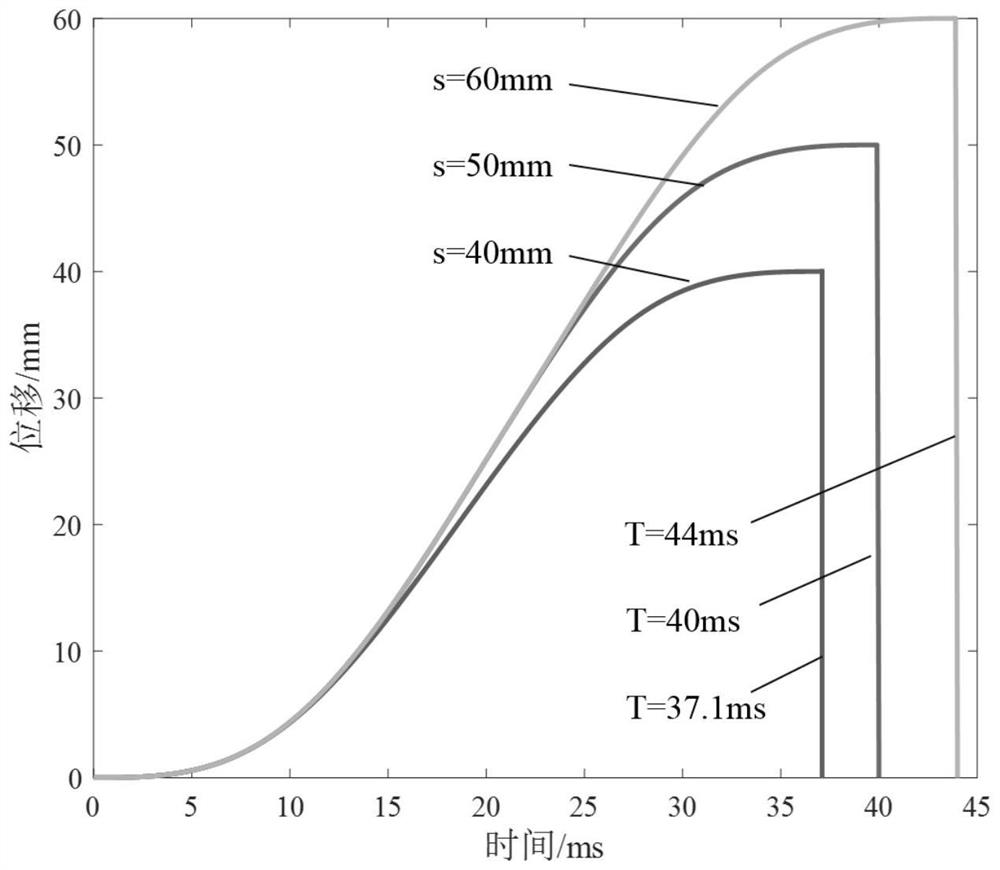

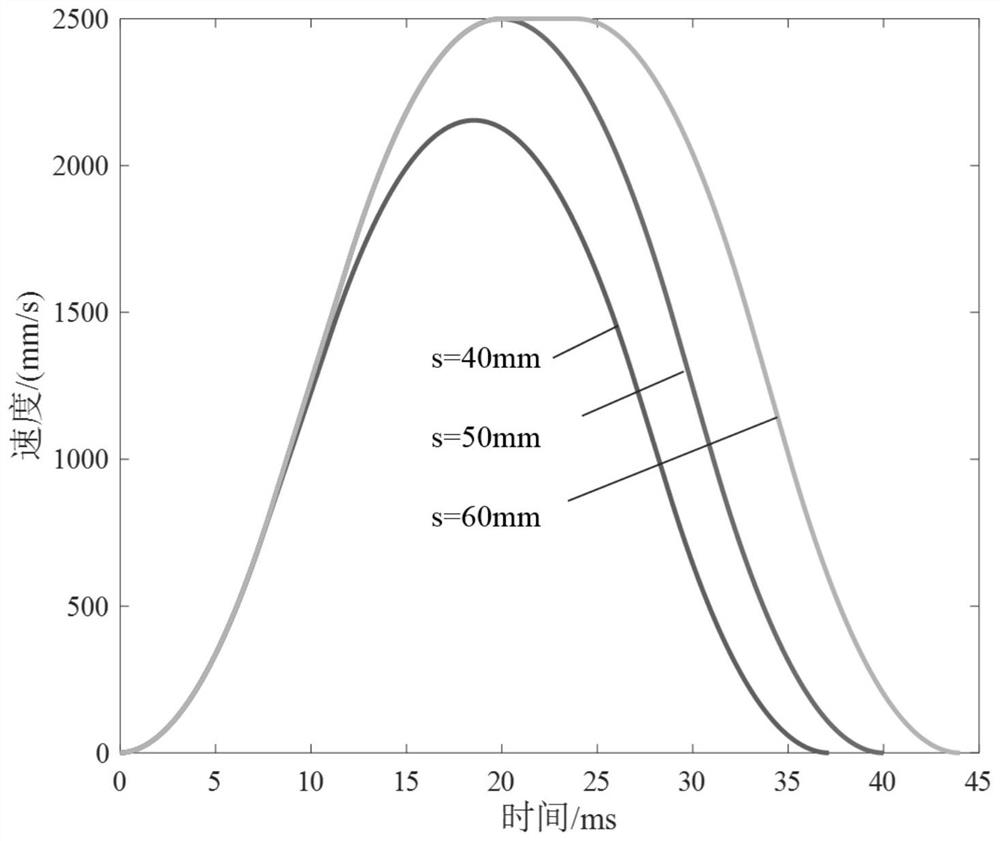

Linear motor high-precision positioning method based on asymmetric S-shaped speed curve control

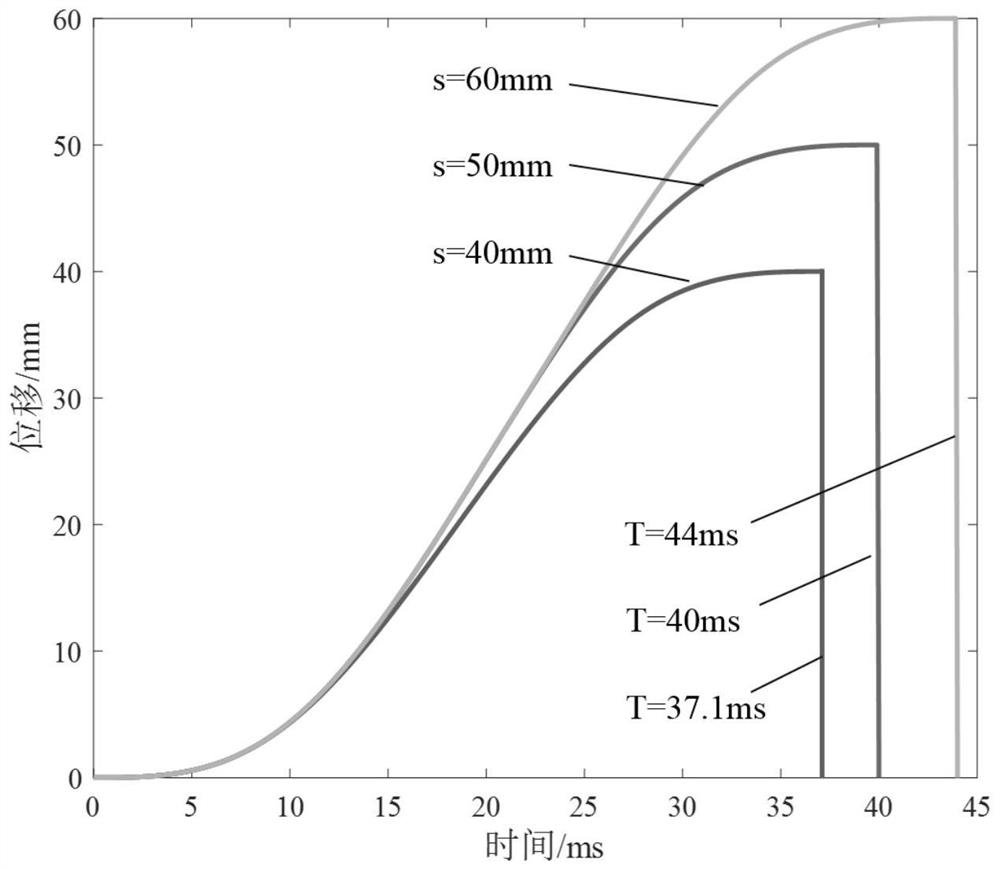

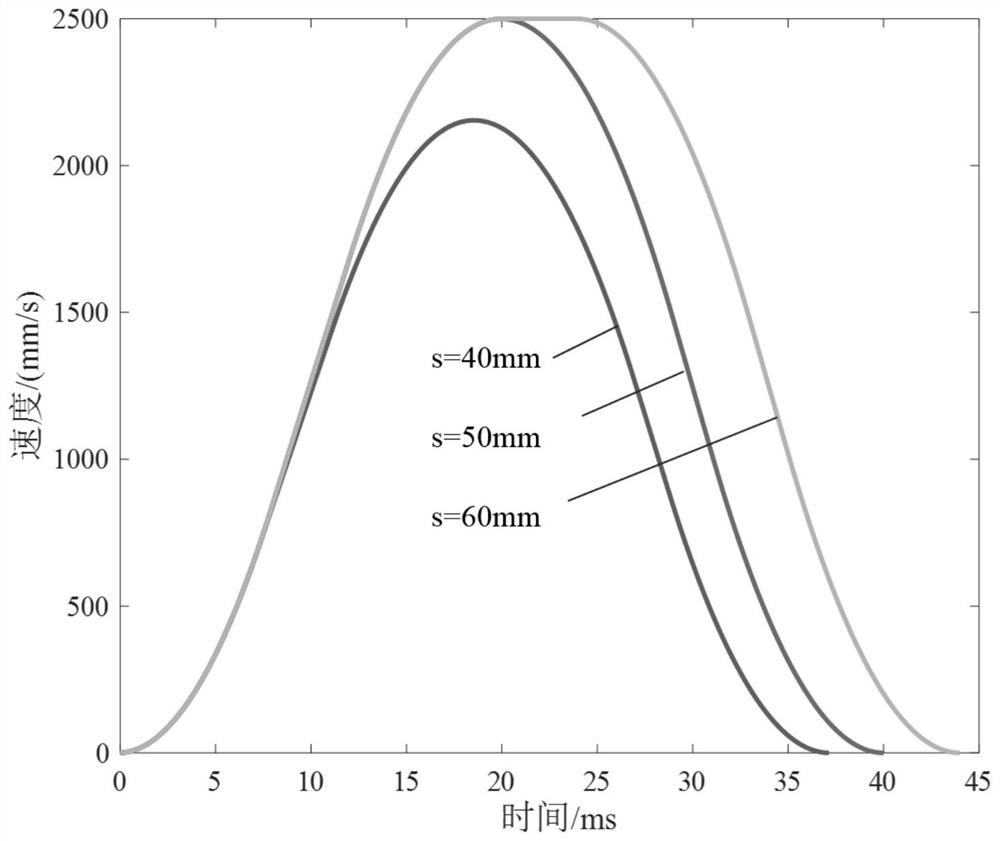

ActiveCN112327954AImprove impact performanceHigh positioning accuracySpeed/accelaration control using electric meansElectric machineClassical mechanics

The invention belongs to the field of high-precision and high-speed motion control, and relates to a linear motor high-precision positioning method based on asymmetric S-shaped speed curve control, inparticular to a linear motor high-precision positioning method based on asymmetric S-shaped speed curve control. The method includes: defininig a scaling factor and setting acceleration and deceleration section speed curve shape characteristics according to linear motor performance constraints, so as to determine appropriate motion control parameters; calculating an S-shaped speed curve time period matching relationship, and updating the S-shaped speed curve time period matching relationship based on point-to-point operation distance constraints; performing solving to obtain expressions of the acceleration and the time a-t, the speed and the time v-t and the displacement and the time s-t by adopting a successive integral method according to the relationship between the S-shaped speed curve plus the acceleration J and the time t; and dispersing the expression according to a PLC scanning period to obtain a motion instruction, transmitting the motion instruction to a driver in real time,and driving a motor to complete actions according to a set instruction to ensure the stability of the operation process.

Owner:DALIAN UNIV OF TECH

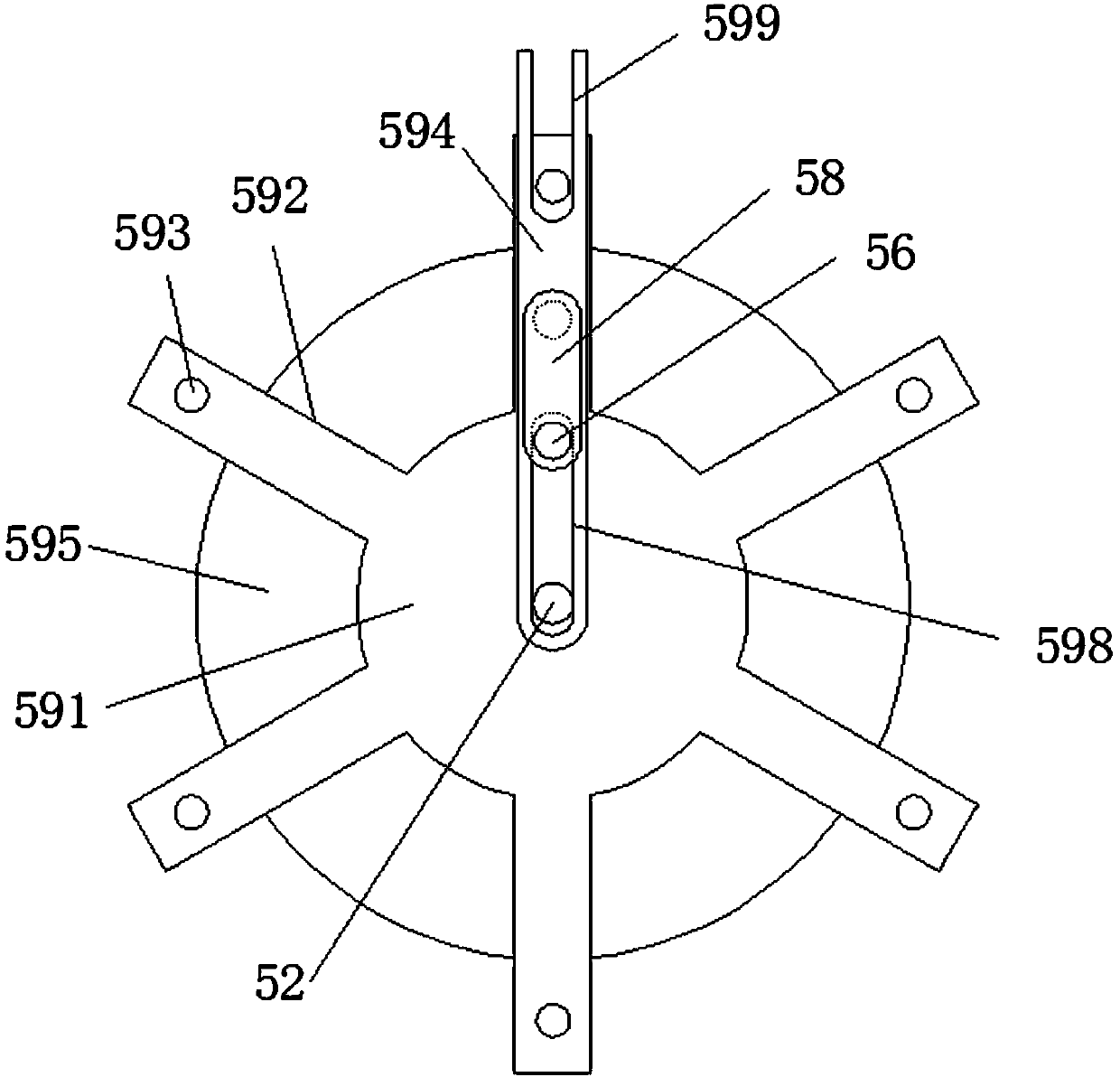

Chip packaging device of multi-chip intelligent card

ActiveCN106295766AHigh packaging precisionSave packing timeRecord carriers used with machinesPunchingEngineering

The invention discloses a chip packaging device of a multi-chip intelligent card. The chip packaging device of the multi-chip intelligent card comprises a card conveying guide track, two chip belt supply mechanisms, chip punching mechanisms and a chip carrying and packaging mechanism, wherein two packaging stations are arranged on the card conveying guide track; each chip belt supply mechanism comprises a chip belt and a chip belt conveying mechanism; the chip belts in the two chip belt supply mechanisms extend in parallel in the direction perpendicular to the card conveying direction; the conveying directions of the chip belts in the two chip belt supply mechanisms are opposite; each chip punching mechanism comprises a punching die and a punching actuating mechanism arranged below the punching die; two punching holes are formed in each punching die; and the two chip belts in the two chip belt supply mechanisms respectively pass through places below the punching die of one of the chip punching mechanisms. The chip packaging device has the advantages of high packaging speed, high production efficiency, high packaging precision and the like.

Owner:GUANGZHOU MINGSEN TECH CO LTD

Multi-chip contact type intelligent card slot milling packaging device

ActiveCN106601651AReduce transfer timeIncrease productivitySemiconductor/solid-state device manufacturingMilling equipment detailsEngineeringContact type

The invention discloses a multi-chip contact type intelligent card slot milling packaging device comprising a slot milling device and a packaging device, which are connected together. The packaging device comprises packaging modules, which comprises chip belt supply mechanisms, chip blanking mechanisms, and chip conveying packaging mechanisms. The card conveying guide rail of the slot milling device is provided with two packaging stations corresponding to the packaging modules, and each packaging station is provided with a card positioning mechanism. The two chi belt feeding mechanisms are provided, and each chip belt supply mechanism comprises a chip belt and a chip belt conveying mechanism. The chip belts of the two chip belt supply mechanisms are extended parallely along a direction vertical to the card conveying direction, and the conveying directions of the conveying belts of the two chip belt supply mechanisms are opposite to each other. The multi-chip contact type intelligent card slot milling packaging device is suitable for slot milling packaging of single-chip cards, and is suitable for slot milling packaging of multi-chip cards. When the multi-chip contact type intelligent card slot milling packaging device is used for the slot milling packaging of the multi-chip cards, the multi-chip contact type intelligent card slot milling packaging device has advantages of fast packaging speed, high production efficiency, and high packaging precision.

Owner:GUANGZHOU MINGSEN TECH CO LTD

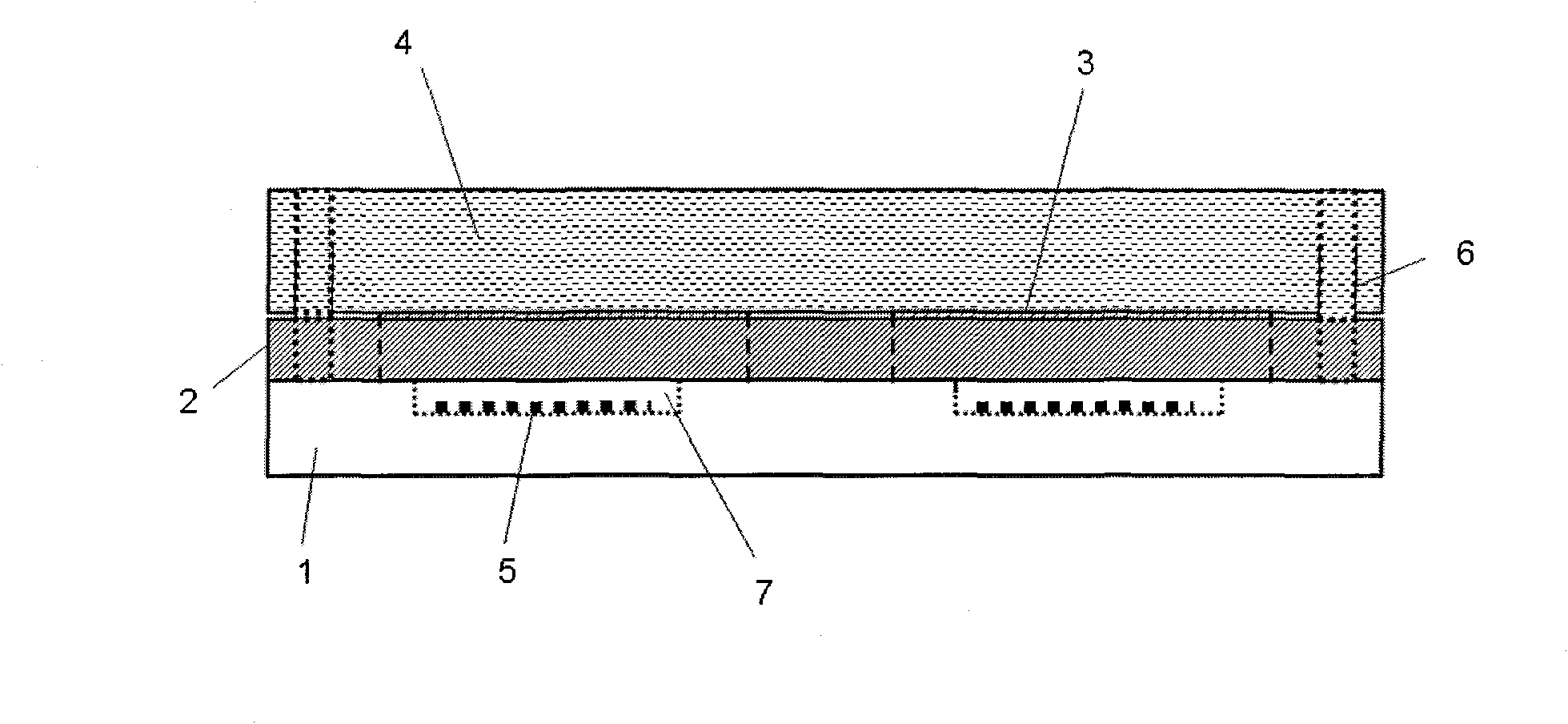

Solar photovoltaic tile and manufacture method thereof

ActiveCN102912946AReduce surface temperatureReduce indoor temperaturePhotovoltaic supportsRoof covering using slabs/sheetsSolar cellWhite stripe

The invention relates to a solar photovoltaic tile and a manufacture method thereof. The solar photovoltaic tile comprises a substrate and a solar cell arranged on the substrate; and zebra stripes are arranged on the upper surface of the substrate. The manufacture method comprises the following steps of: manufacturing the substrate; coating dark glaze on the surface of the substrate to form dark stripes, wherein white stripes are formed on the discolored part of the substrate, and the dark stripes and the white stripes form the zebra stripes; and then adhering the solar cell on the substrate. The solar photovoltaic tile and the manufacture method provided by the invention can promote air flow on the upper surface of the substrate, and solves the problem of a poor heat insulation effect caused by a poor radiating effect of the conventional photovoltaic tile.

Owner:成卫亮

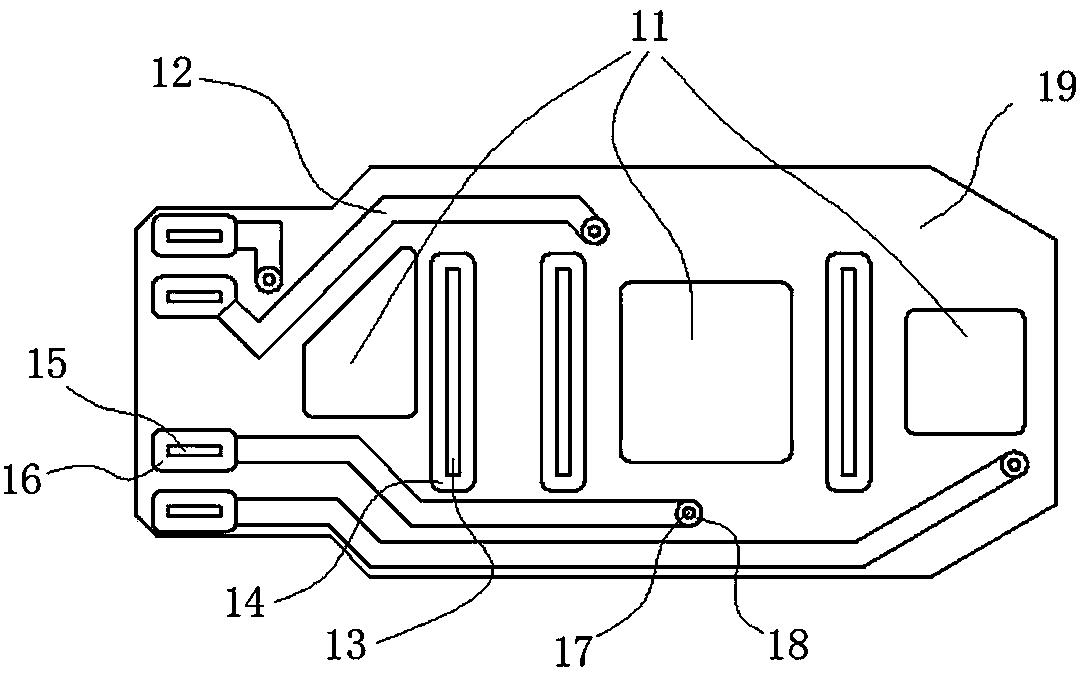

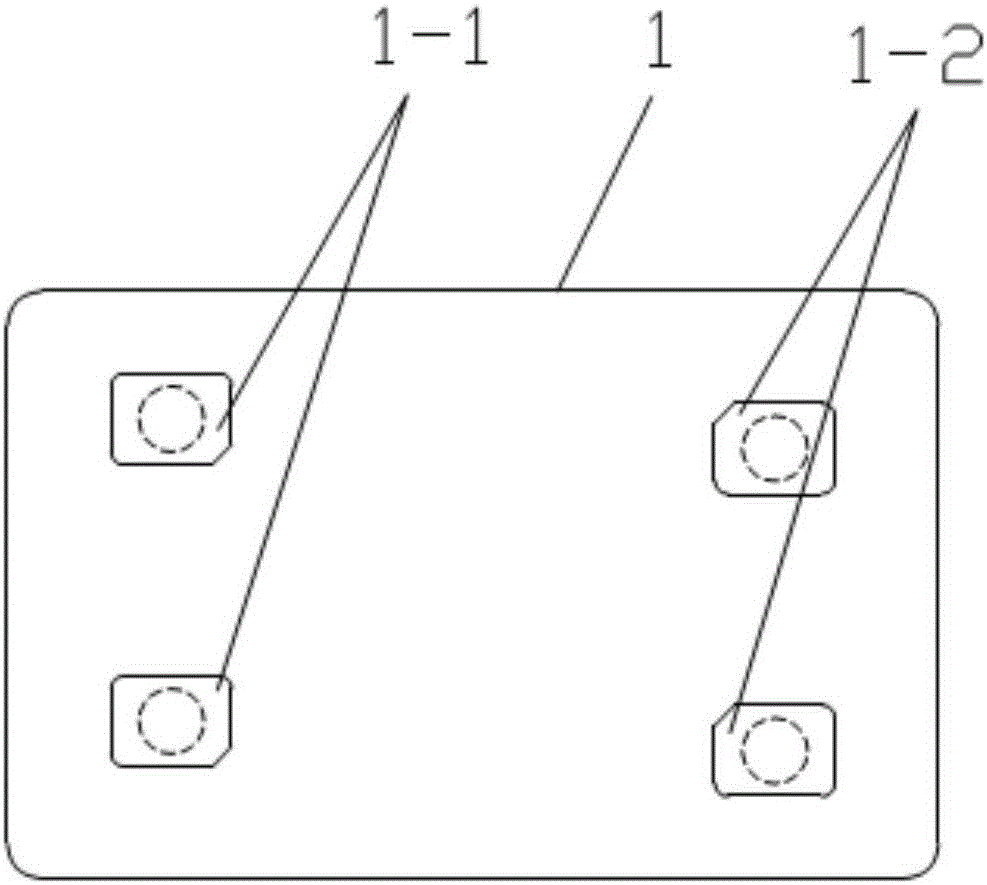

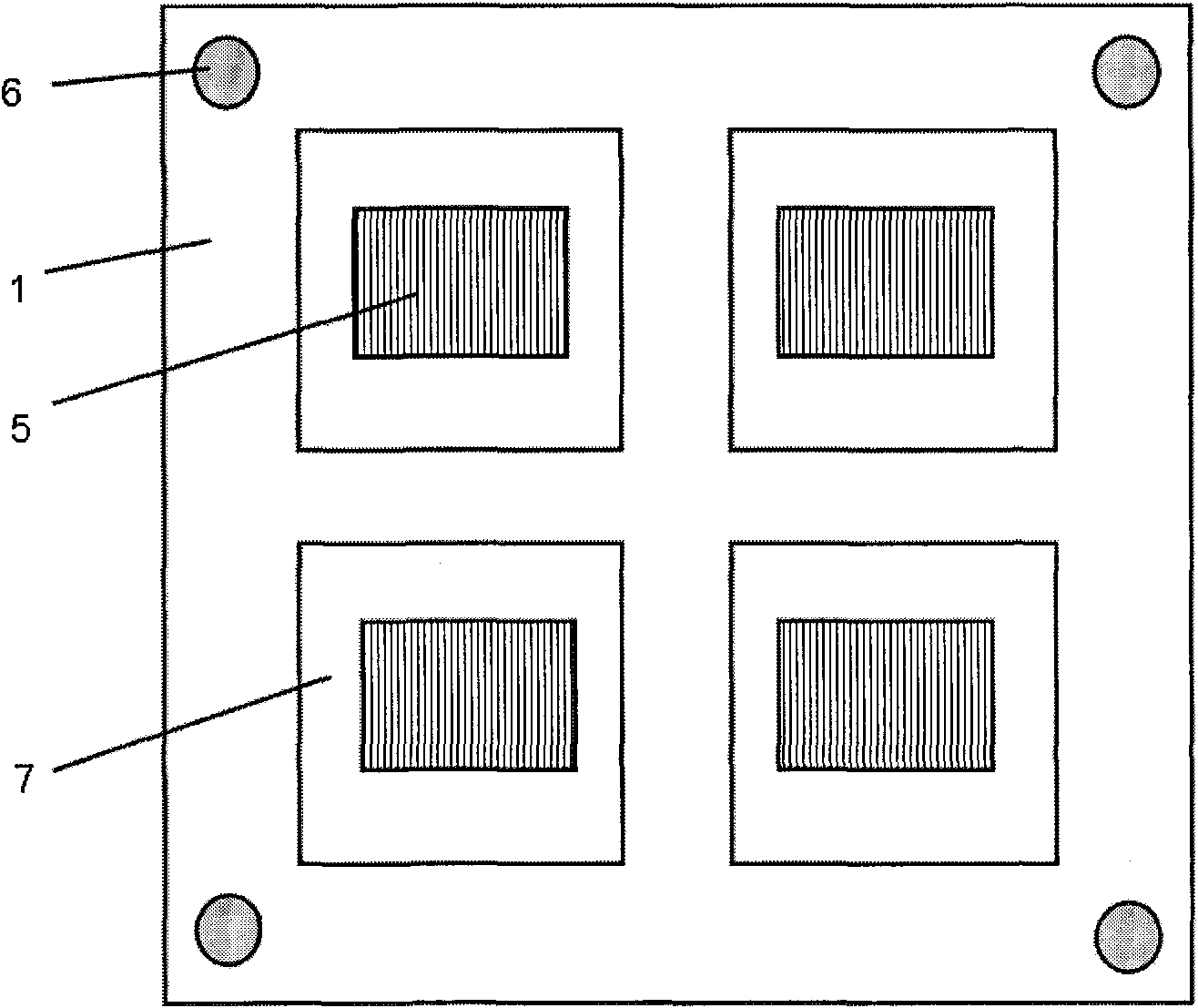

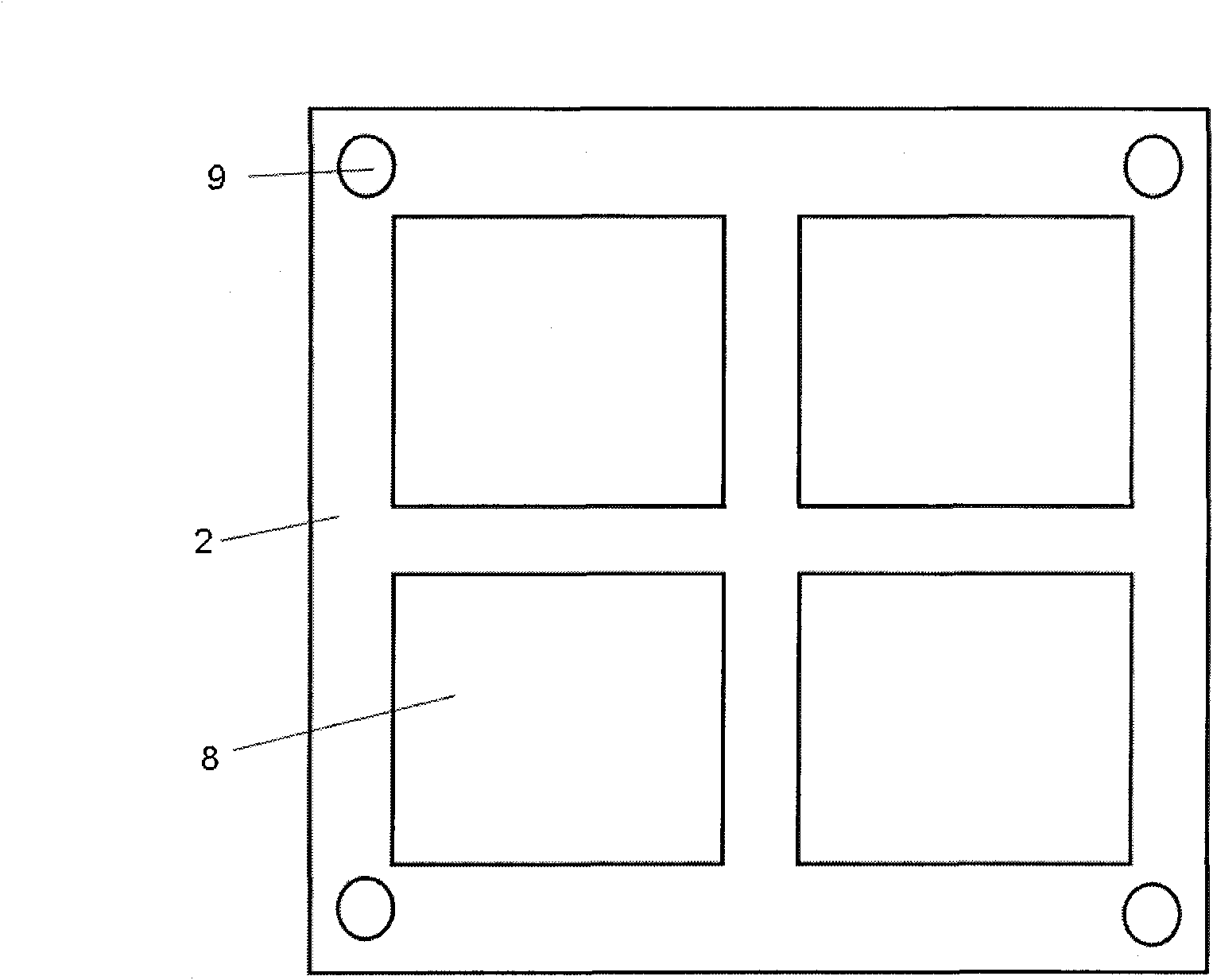

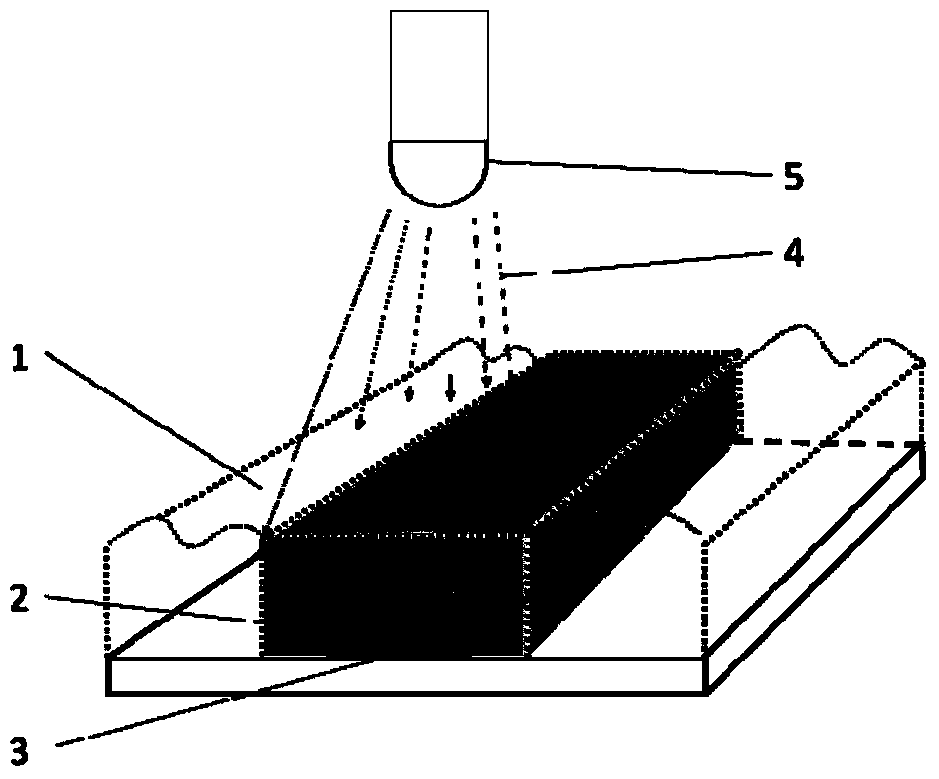

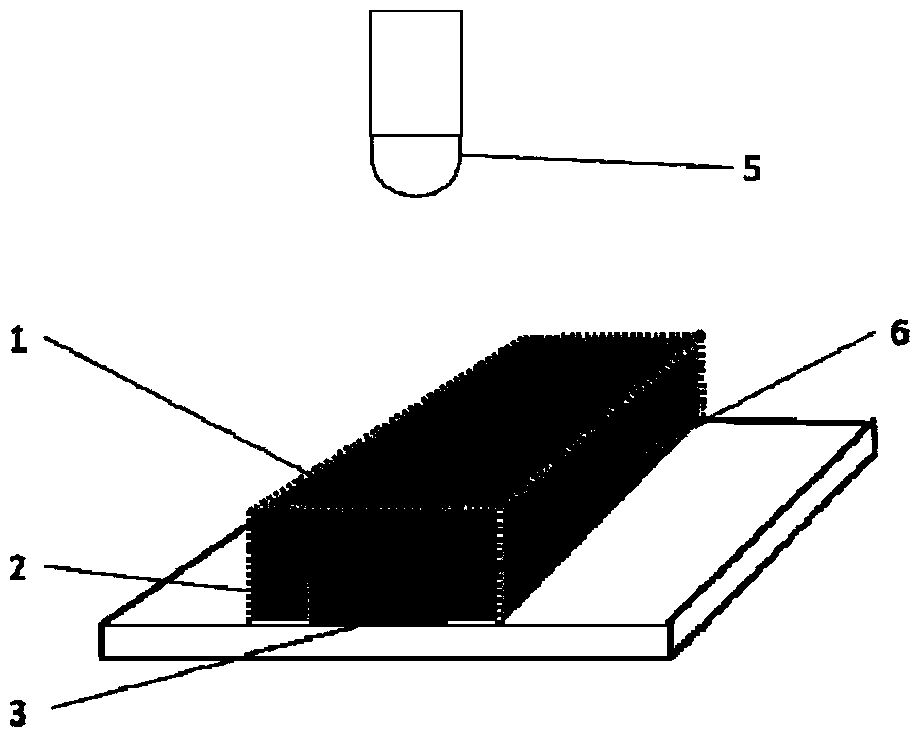

Packing alignment device for organic optoelectronic device and packing method thereof

InactiveCN101859872ASimple structureEasy to operateFinal product manufactureSolid-state devicesEngineeringPositioning system

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

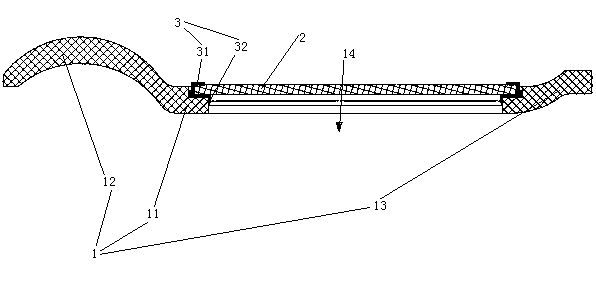

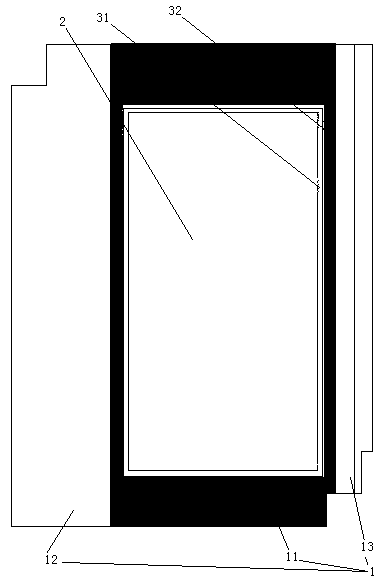

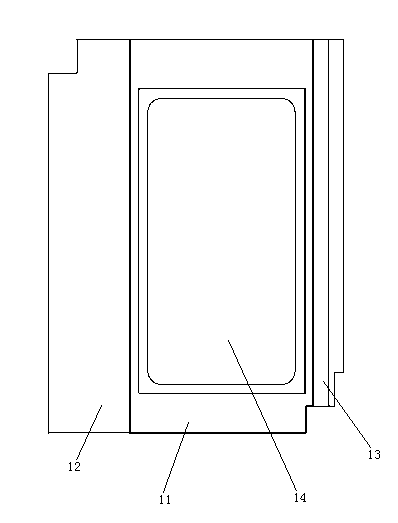

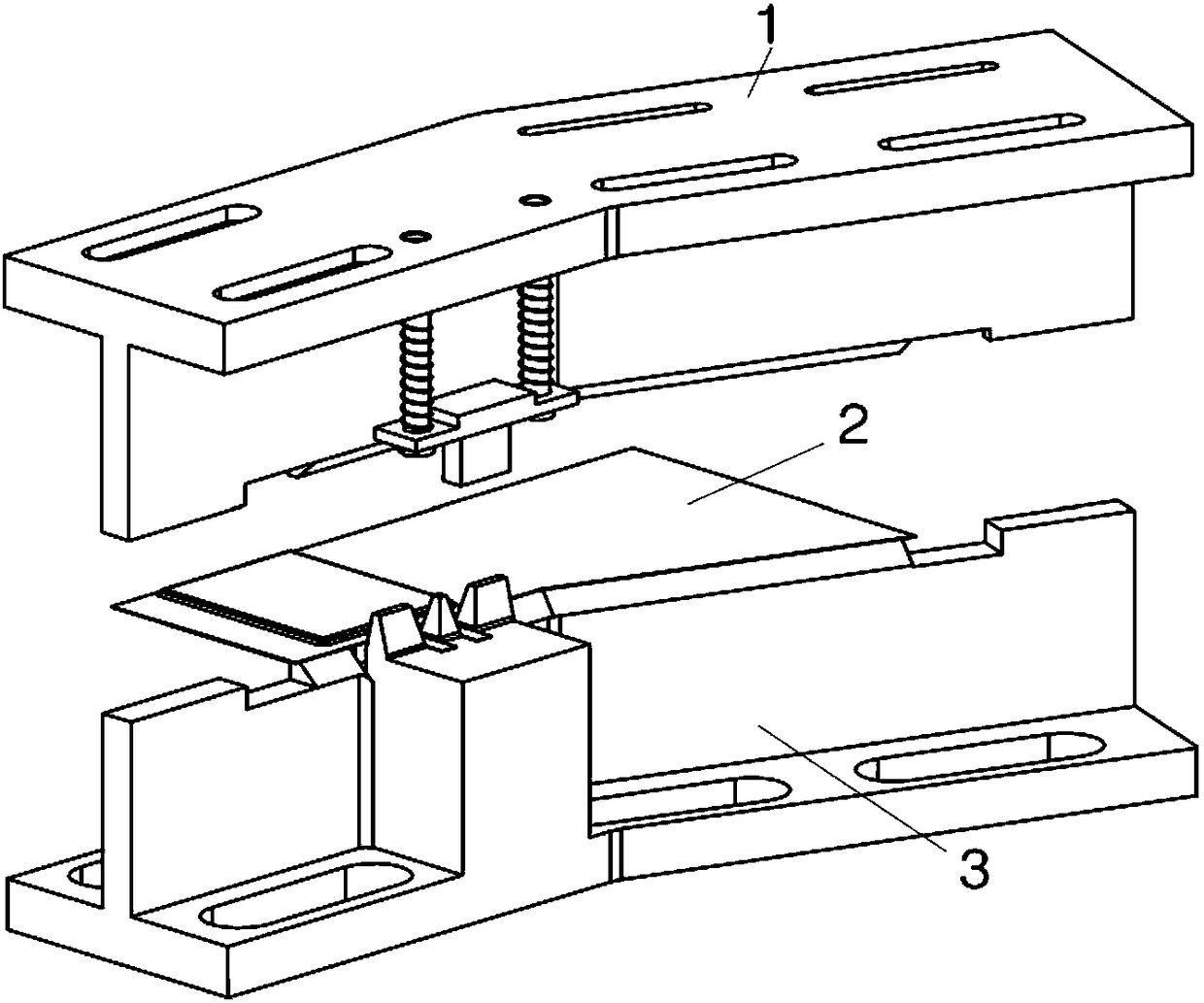

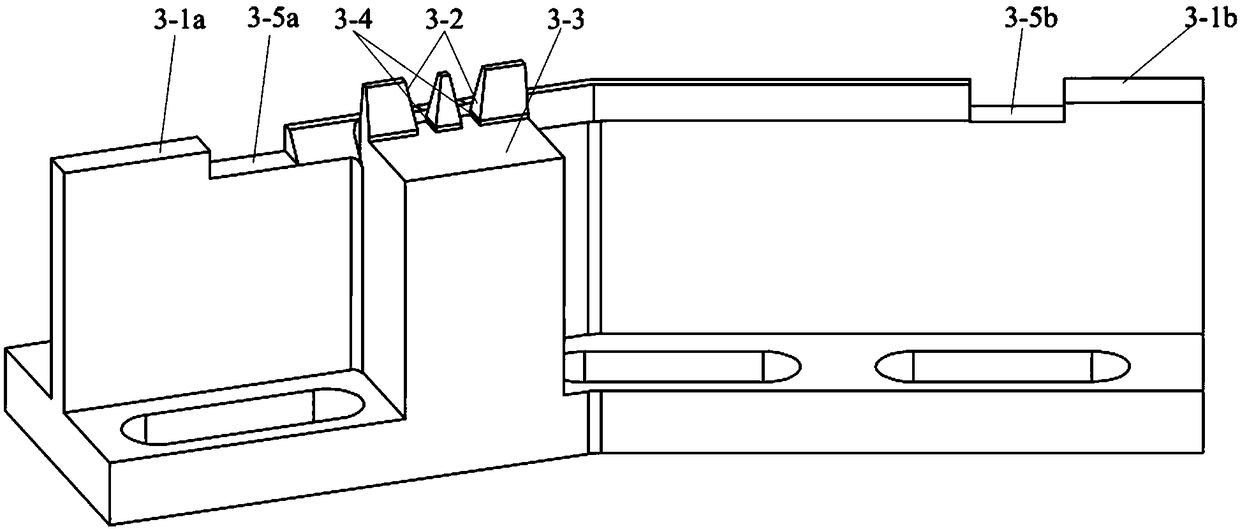

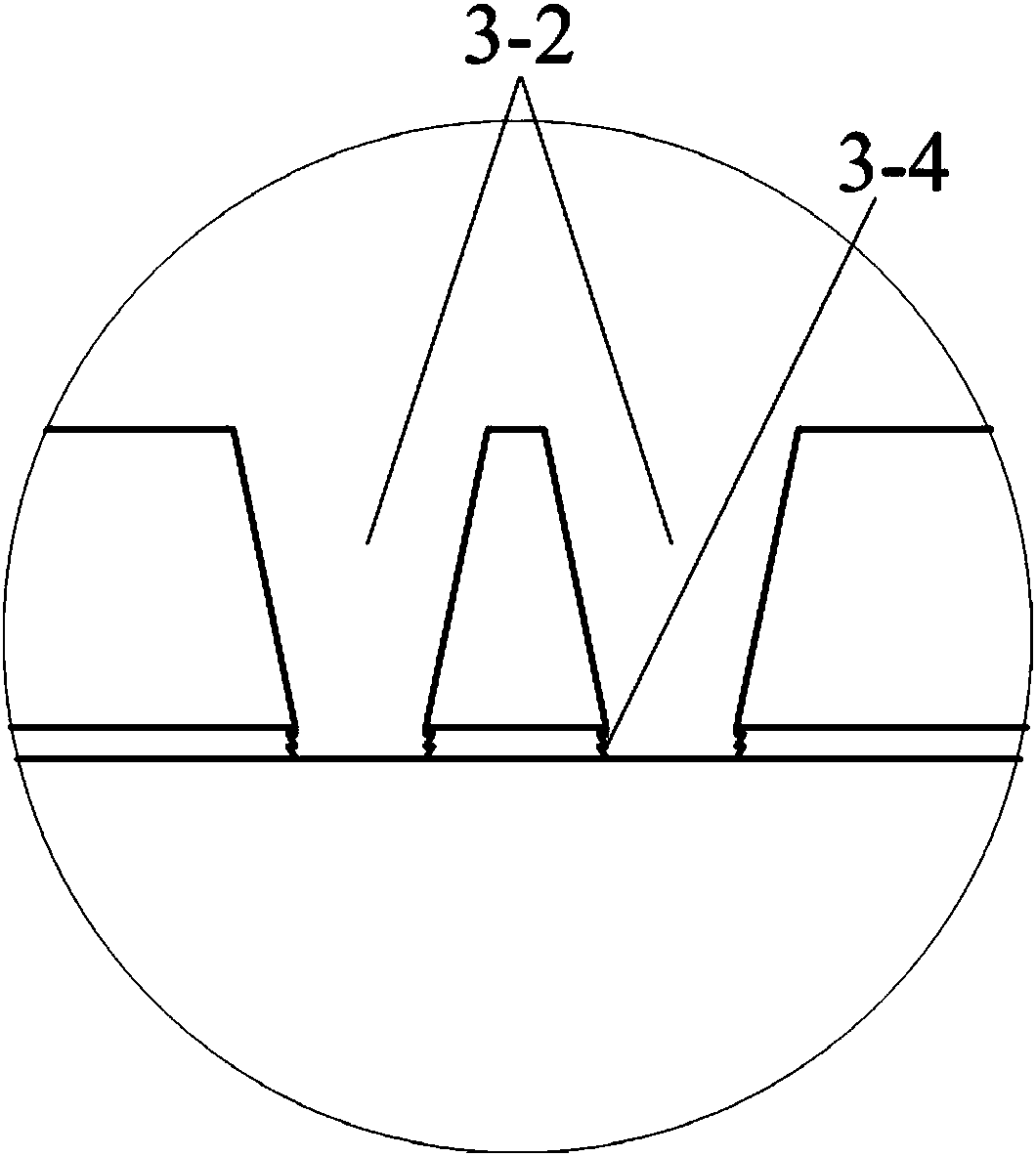

Specially-shaped end enclosure tool for sealing top of polymer softly-packaged battery specially-shaped airbag

InactiveCN108336415AResolve locationSolve the packaging problem of serious glue overflowFinal product manufactureElectrolyte accumulators manufactureEngineeringAirbag

The invention relates to a specially-shaped end enclosure tool for sealing the top of a polymer softly-packaged battery specially-shaped airbag. The specially-shaped end enclosure tool for sealing thetop of a polymer softly-packaged battery specially-shaped airbag is characterized by comprising a specially-shaped top sealing upper end enclosure and a specially-shaped top sealing lower end enclosure, an upper supporting seat and a lower supporting seat, wherein the specially-shaped top sealing upper end enclosure and the specially-shaped top sealing lower end enclosure are respectively fixed onto the upper supporting seat and the lower supporting seat to form an overall structure with the cross section being in a T shape, the upper end surfaces of the specially-shaped top sealing upper endenclosure and the specially-shaped top sealing lower end enclosure are respectively correspondingly provided with an end enclosure front end limiting platform and an end enclosure tail end limiting platform, the inner sides of the end enclosure front end limiting platform and the end enclosure tail end limiting platform are respectively provided with a glue overflow groove, a lug guiding mechanism is arranged between the two glue overflow groove of the specially-shaped top sealing lower end enclosure, and the specially-shaped top sealing upper end enclosure is provided with a lug compressionmechanism corresponding to the lug guiding mechanism. The specially-shaped end enclosure tool has the beneficial effects that various specially-shaped airbags can be sealed, the packaging difficultiessuch as poor lug position and severe leakage of glue can be solved, and the automation degree and the packaging precision of the battery production can be effectively improved.

Owner:TIANJIN LISHEN BATTERY

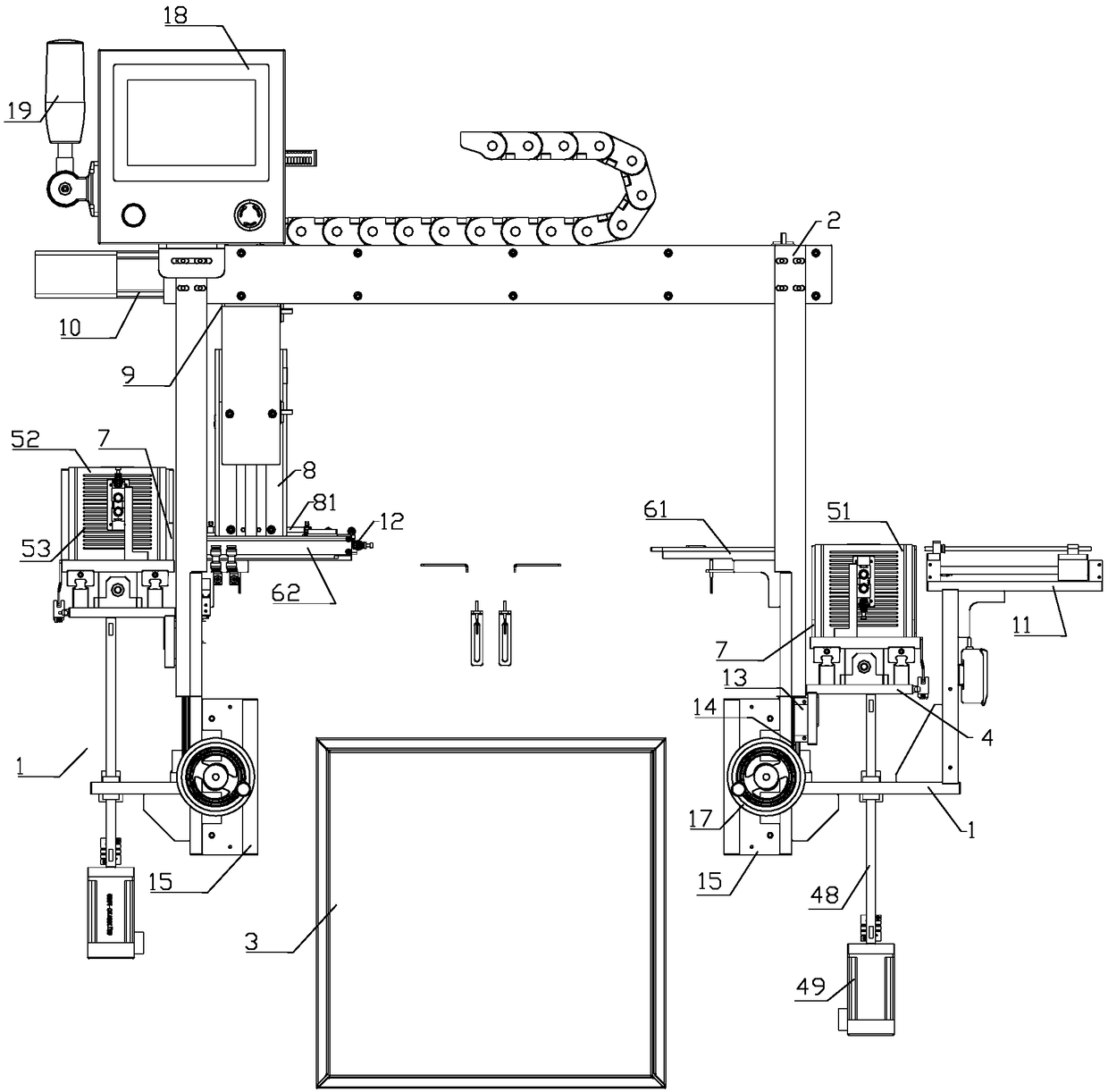

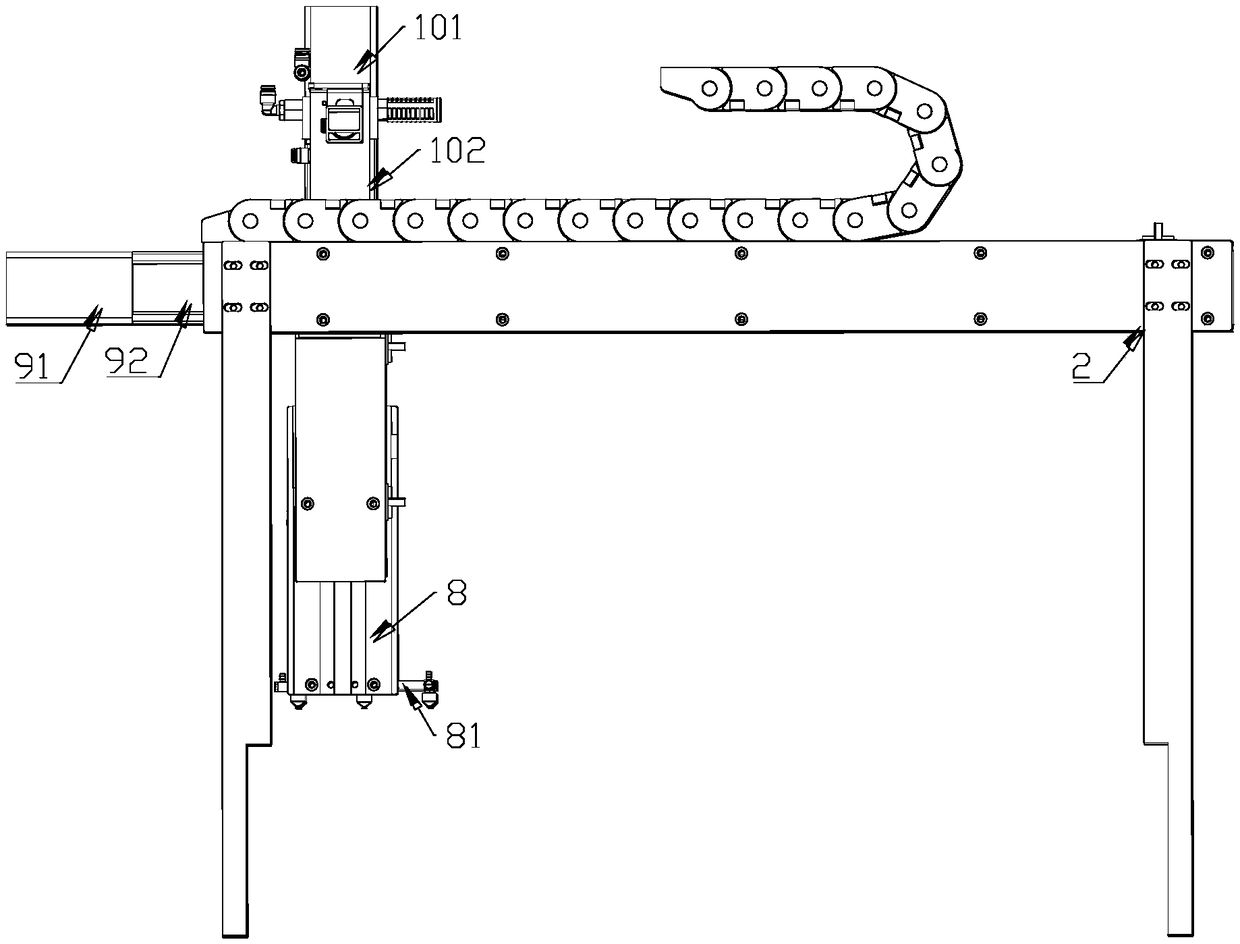

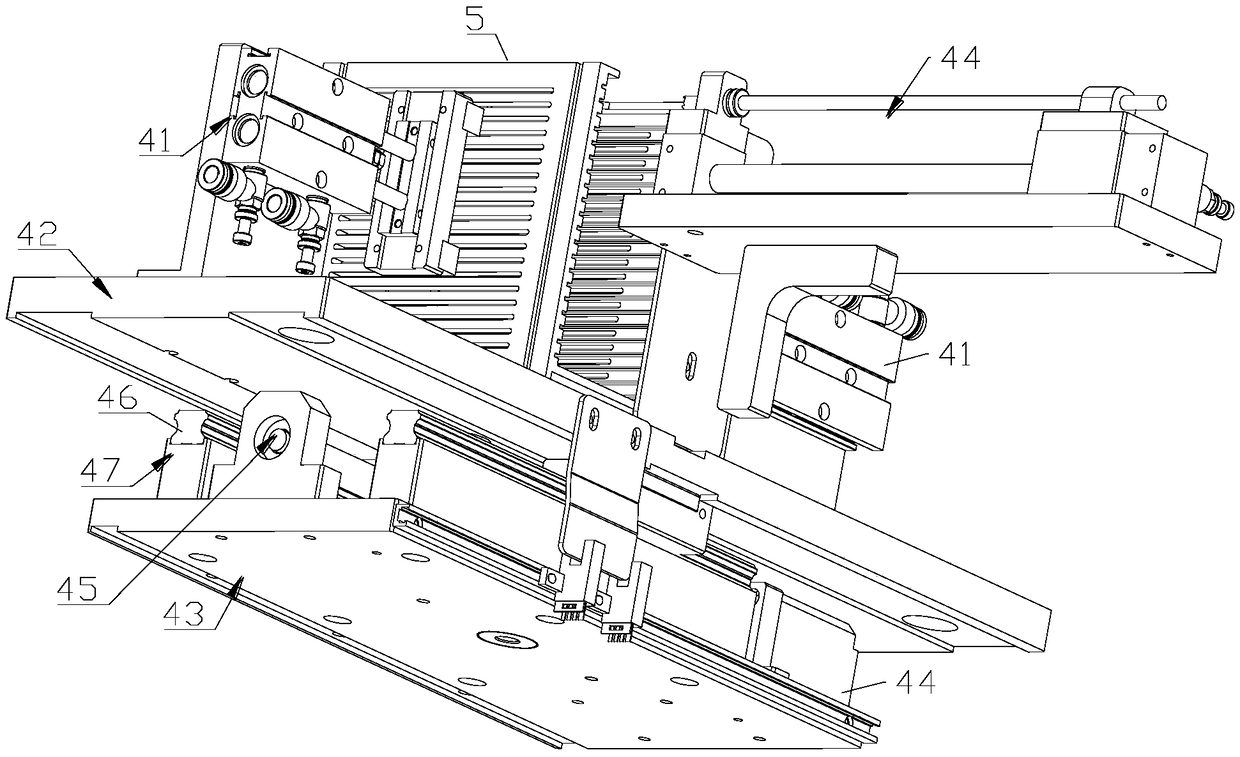

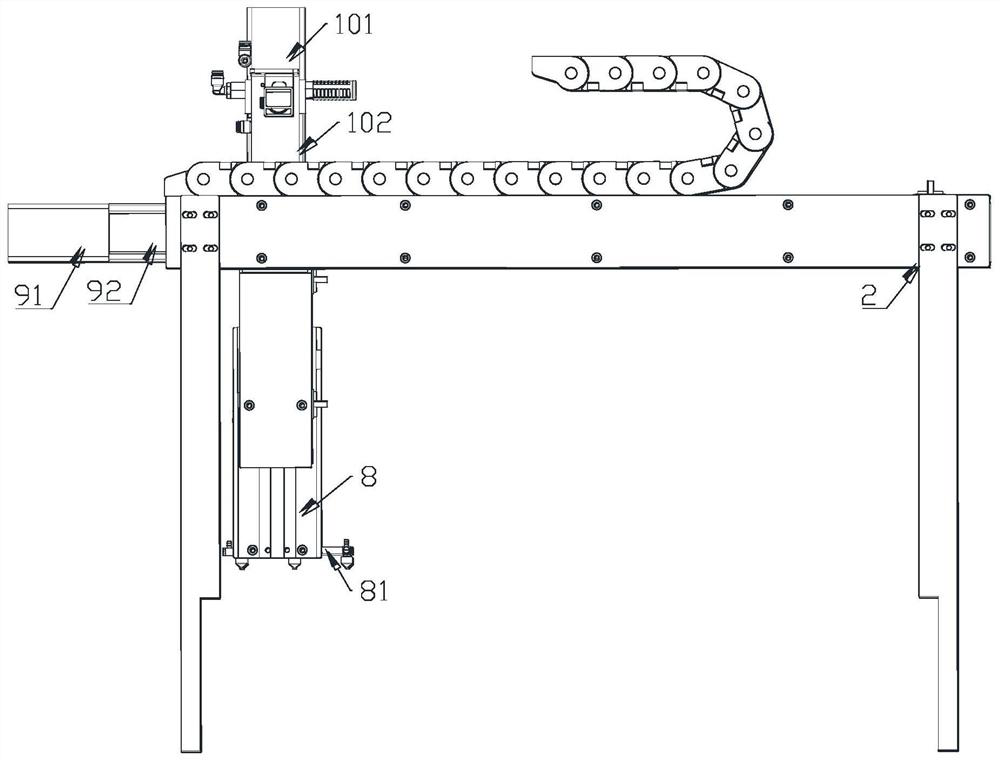

A feeding and discharging machine for semiconductor packaging

ActiveCN109390264ARealize automatic loading and unloadingReduce manual involvementSemiconductor/solid-state device manufacturingConveyor partsSemiconductor packageEngineering

A feeding and discharging machine for semiconductor packaging comprises material tables, a support and an electric control box. A movable seat is arranged on each material table; material boxes are mounted on the movable seats; the material boxes include a feeding box and a discharging box; semiconductors are placed in the feeding box; the support is positioned between the feeding box and the discharging box; tracks are installed on the support; feeding ports are arranged between the tracks and the material boxes and the tracks include a feeding track and a discharging track; the feeding box is located between the feeding track and a feeding cylinder; the feeding cylinder pushes the semiconductors in the feeding box into the feeding track; a movable grab block is installed on the support and a vacuum sucker is arranged under the movable grab block; the movable grab block grabs the semiconductors via the vacuum sucker; the discharging track is located between a discharging cylinder andthe discharging box; the discharging cylinder pushes the packaged semiconductors in the discharging track to the discharging box. The machine realizes automatic feeding and discharging of semiconductors, simplifies the operation processes, reduces the manual participation of workers, and improves the packaging efficiency, and has good safety and high packaging accuracy.

Owner:东莞胜镁特工业科技有限公司

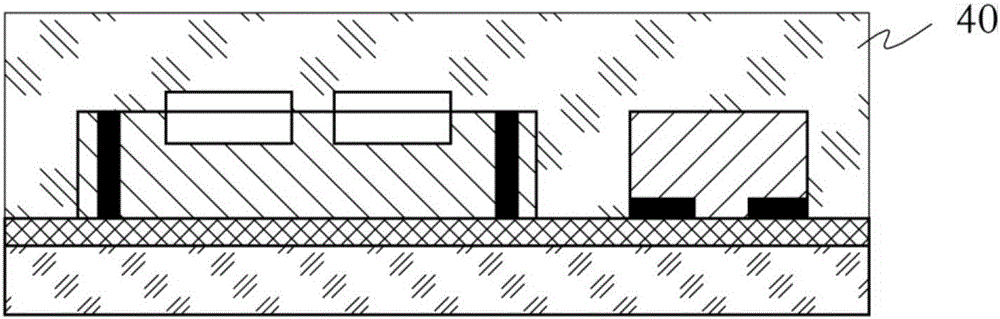

Improved method for realizing wafer-grade package of ultrathin environment light and proximity sensor, and package

PendingCN105977249AFirmly connectedConducive to thin designSolid-state devicesSemiconductor devicesWaferingProximity sensor

The invention provides an improved method for realizing a wafer-grade package of an ultrathin environment light and proximity sensor, and a package. A conventional technical process of realizing the wafer-grade package by reliance on a PCB substrate through combination of an RDL wiring layer and a wire bonding technology is changed; a wafer is locked by means of an optical sealing cover and a protective sealing cover; and a formation carry tool can simultaneously bear multiple wafer combinations to be processed, the optical sealing cover and the protective sealing cover can be manufactured simultaneously for all the wafer combinations on the formation carry tool, and besides, the RDL wiring layer formed on a temporary adhesive tape greatly facilitates thin-type design and also facilitates simultaneous processing of the multiple wafer combinations. The method provided by the invention and the package have such technical advantages, thereby achieving the purpose and effect of realizing thinning and efficient production by abandoning the PCB substrate.

Owner:宁波德葳智能科技有限公司

Servo double-surface heating vacuum packaging machine

ActiveCN102201592BQuality is not affectedGuarantee exclusionFinal product manufactureSecondary cells manufactureControl systemEngineering

The invention discloses a servo double-surface heating vacuum packaging machine and belongs to liquid extraction seal secondary forming and packaging equipment of flexible packaged lithium batteries. The servo double-surface heating vacuum packaging machine comprises a double-station turntable feeding device driven by a cam partitioning device, a packaging mechanism with an up-and-down packaging device, and an electric control system, wherein the up-and-down packaging device comprises an upper cavity main body and a lower cavity main body; the opening directions of the upper cavity main body and the lower cavity main body are opposite to each other; the upper cavity main body and the lower cavity main body can clamp the turntable to form a sealed cavity body; a pressing board, an upper sealing head and a bayonet are arranged in the upper cavity main body; a lower sealing head and an aspirating hole are arranged in the lower cavity main body; the aspirating hole is communicated with an external vacuum source; the upper sealing head corresponds to the lower sealing head; and a heating body is arranged inside the servo double-surface heating vacuum packaging machine. The servo double-surface heating vacuum packaging machine has a compact structure and high efficiency; the electric core packaging quality is stable and the cost is low; vacuum liquid extraction can be realized; and pollution of the electrolyte to the equipment can be reduced to minimum.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

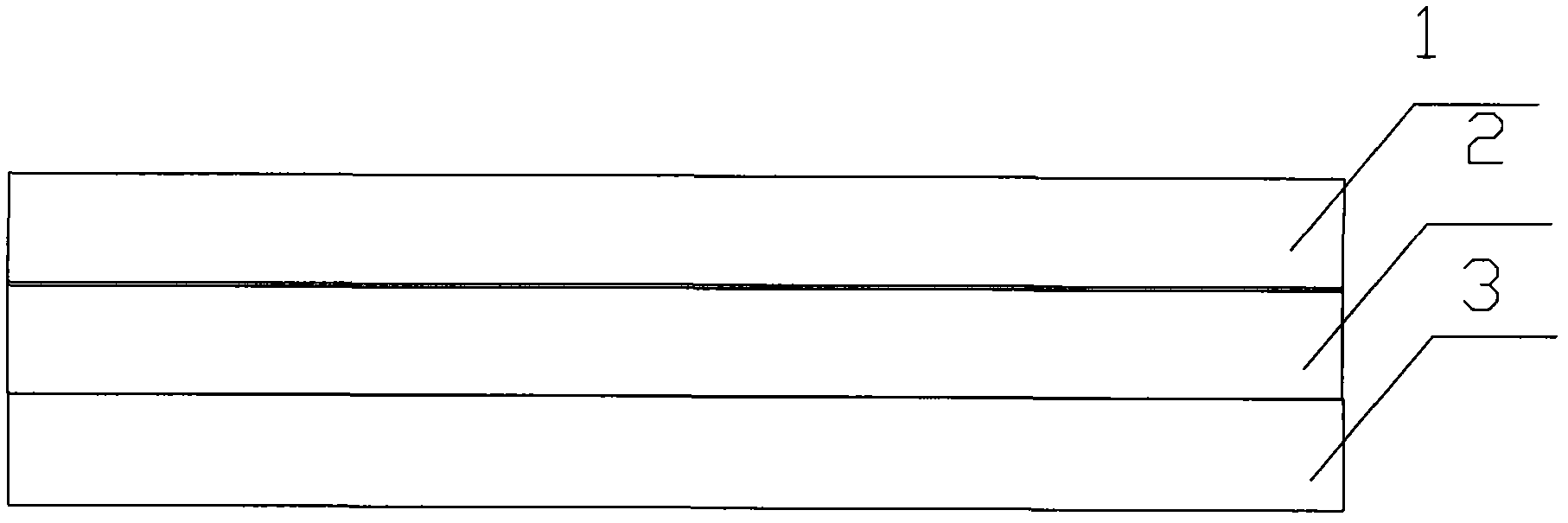

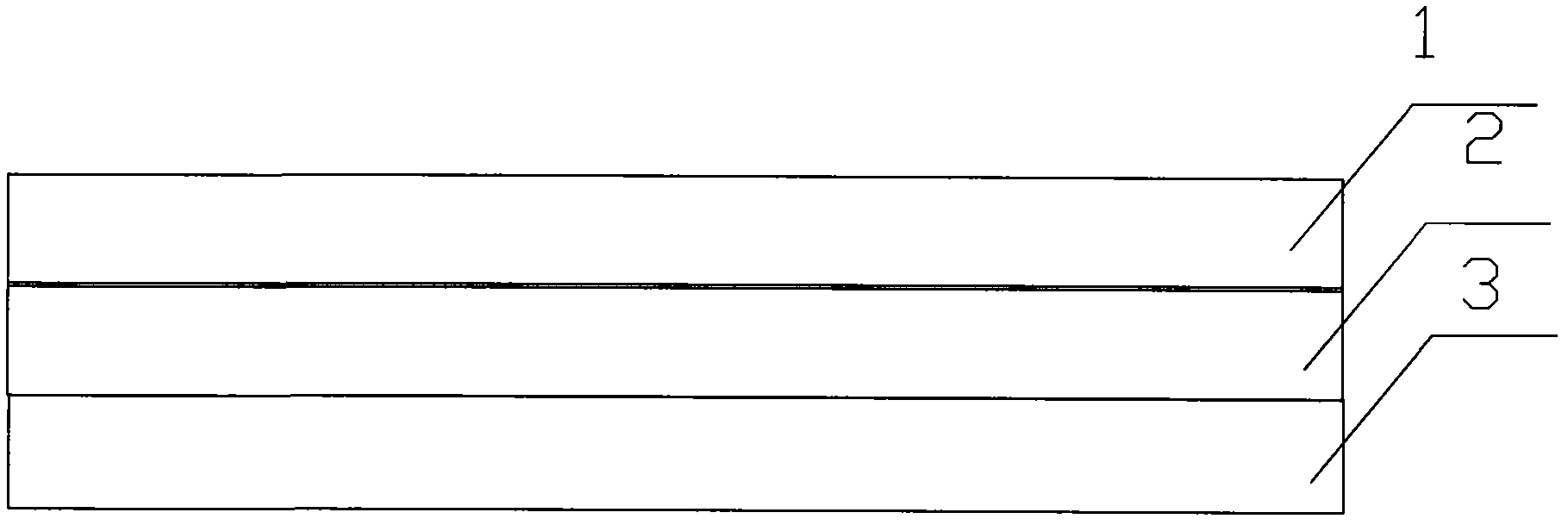

Metallization and heat sink integrated preparation method of AlN ceramic substrate

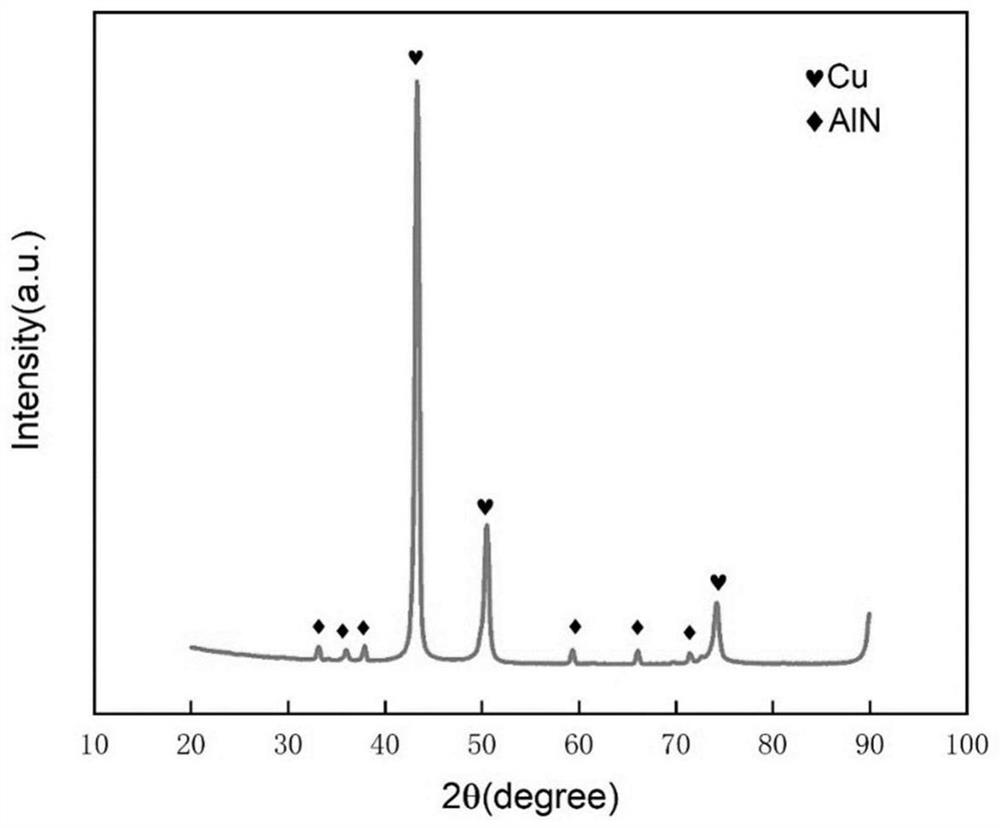

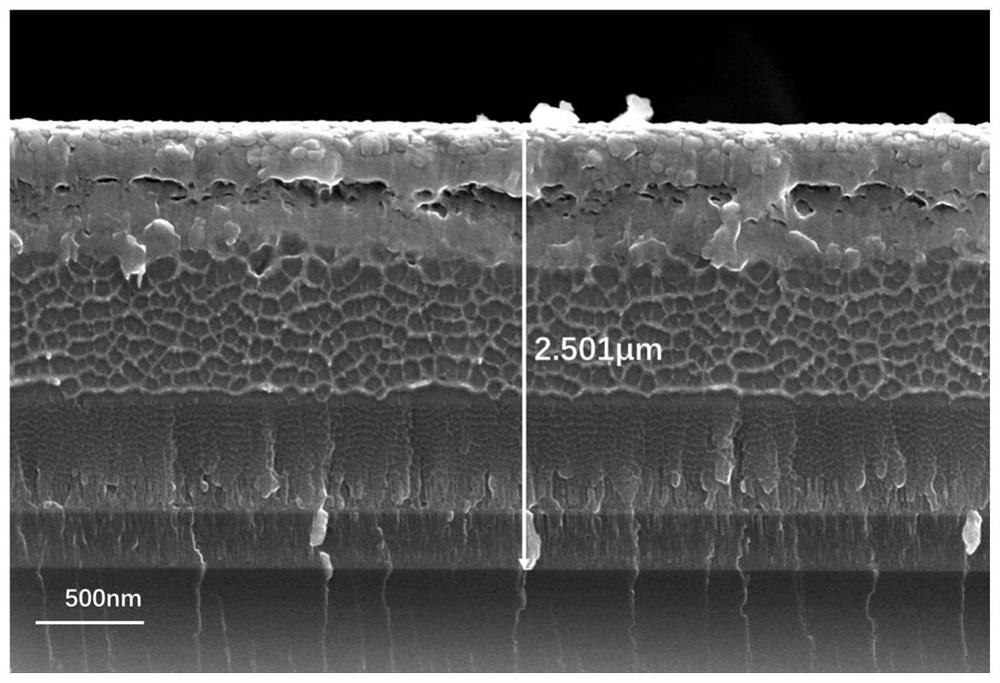

ActiveCN113174575AImprove package strengthReduce packaging process flowFinal product manufactureSemiconductor/solid-state device detailsDeposition processHeat sink

The invention discloses a metallization and heat sink integrated preparation method of an AlN ceramic substrate. According to the preparation method, a Ti metallization layer, a Ti-Cu gradient transition layer and a Cu heat sink layer are sequentially formed on the AlN ceramic substrate by the aid of a physical vapor deposition technology, and a transition layer Al3Ti+TiN is formed between an AlN layer and a Ti layer in the deposition process. The method specifically comprises the steps that surface polishing treatment is performed on the AlN ceramic substrate; the polished AlN ceramic substrate is soaked, cleaned and then dried; the surface of the cleaned AlN ceramic substrate is sequentially plated with the Ti metallization layer, the Ti-Cu gradient transition layer and the Cu heat sink layer by the aid of a magnetron sputtering deposition method, in the deposition process, the transition layer Al3Ti+TiN is automatically formed between the AlN layer and the Ti layer, and finally, the metallization and heat sink integrated AlN ceramic substrate is formed. According to the method, the metallization and heat sink integrated plating layer is deposited on the AlN ceramic substrate by the aid of the high vacuum magnetron sputtering technology, so that the overall packaging strength is greatly improved, the packaging process flow is shortened, the packaging consumption is reduced, and the production cost is remarkably reduced.

Owner:XI AN JIAOTONG UNIV

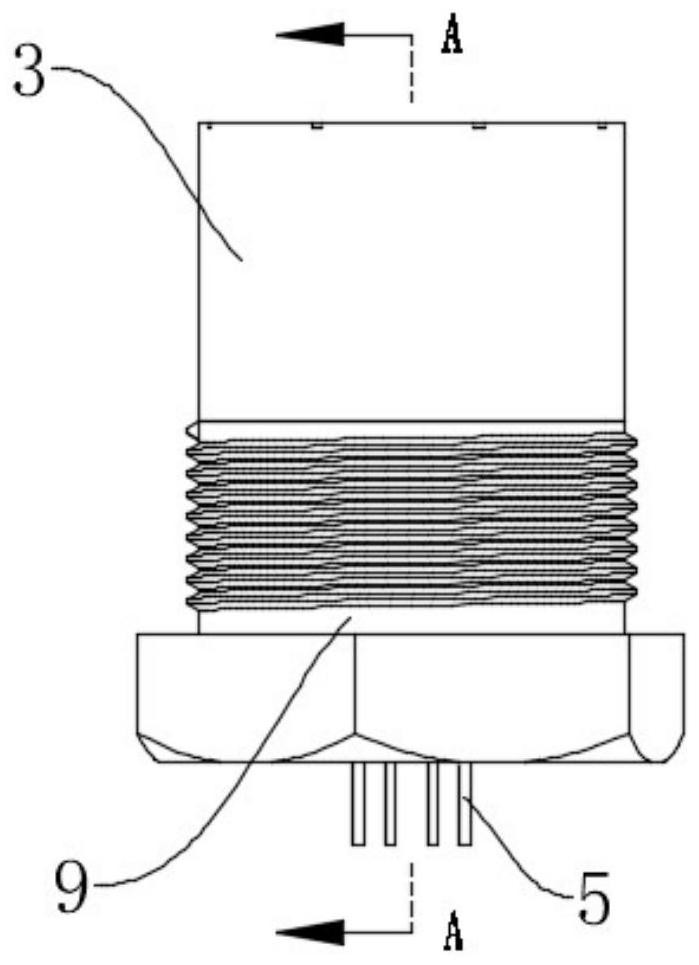

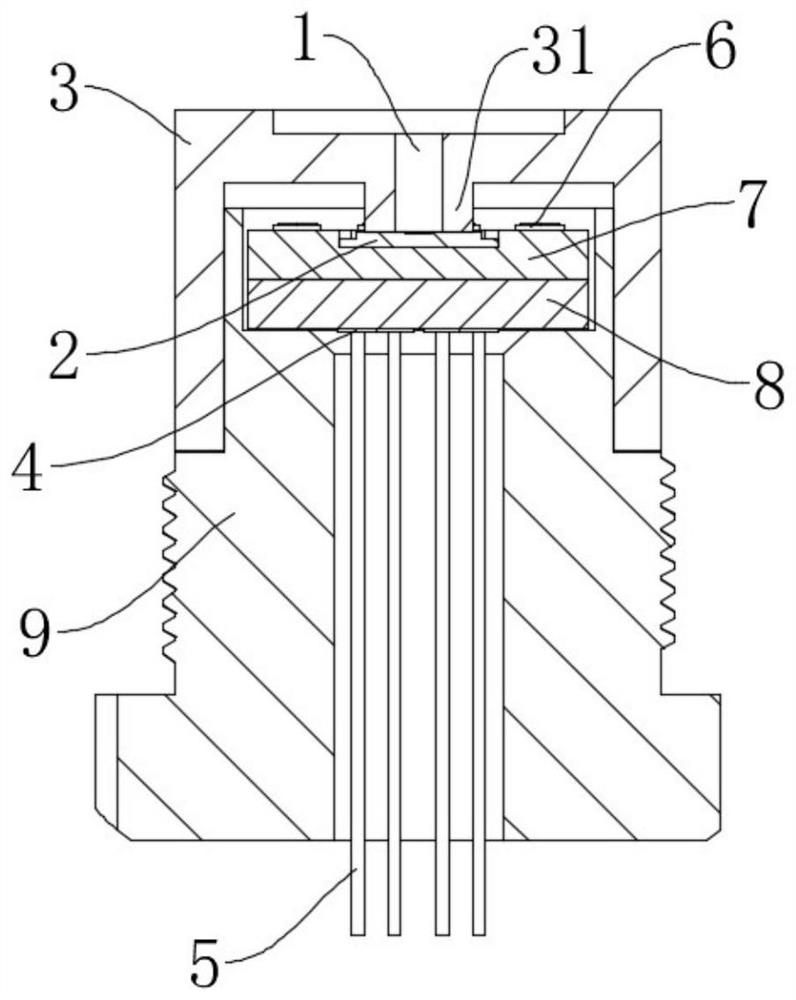

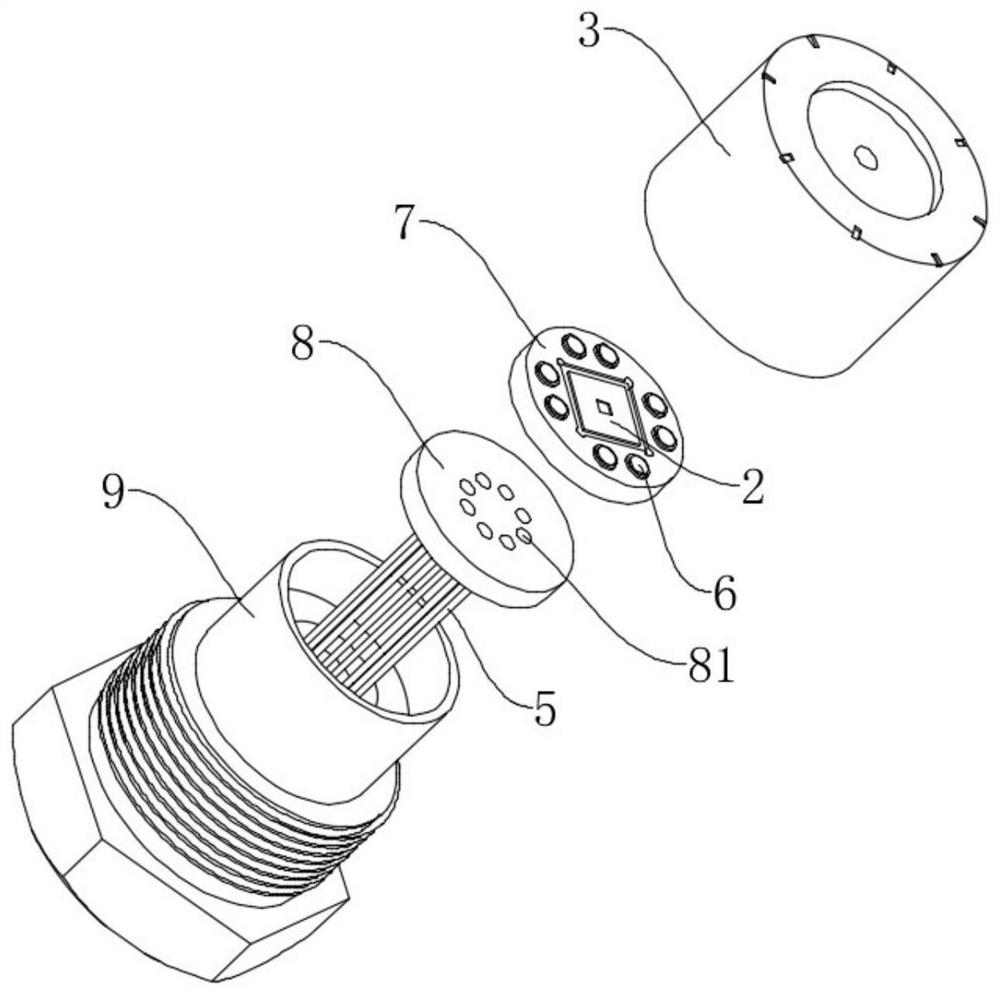

High-temperature pressure sensor packaging structure

PendingCN112504550AReduce volumeReduce contact areaFluid pressure measurementAir tightnessCeramic substrate

A high-temperature pressure sensor packaging structure comprises a packaging base, a packaging end cover, a sensor chip and a ceramic substrate assembly, a first mounting groove used for containing the ceramic substrate assembly is formed in the packaging base, the ceramic substrate assembly is arranged in the first mounting groove, the sensor chip is arranged on the ceramic substrate assembly, the packaging end cover is buckled on the packaging base, and the sensor chip and the ceramic substrate assembly are sealed in a containing space formed by the packaging base and the packaging end cover. The beneficial effects of the invention are that the second through holes in the second ceramic substrate can effectively reduce the distribution of the rear ends of the lead pins through reducing the layout range, the chamfers on the third through holes can reduce the welding area so as to reduce the thermal stress at a high temperature, and the circular grooves formed in the four corners of the second installation groove can enable the solder not to be accumulated during compression sintering. The structure is low in sintering difficulty, good in airtightness, high in packaging precision and capable of bearing severe environments such as high temperature and high pressure, and performance of the pressure sensor in high-temperature environments is guaranteed.

Owner:ZHONGBEI UNIV

A semiconductor package loading and unloading machine

ActiveCN109390264BRealize automatic loading and unloadingReduce manual involvementSemiconductor/solid-state device manufacturingConveyor partsSemiconductor packageElectric control

Owner:东莞胜镁特工业科技有限公司

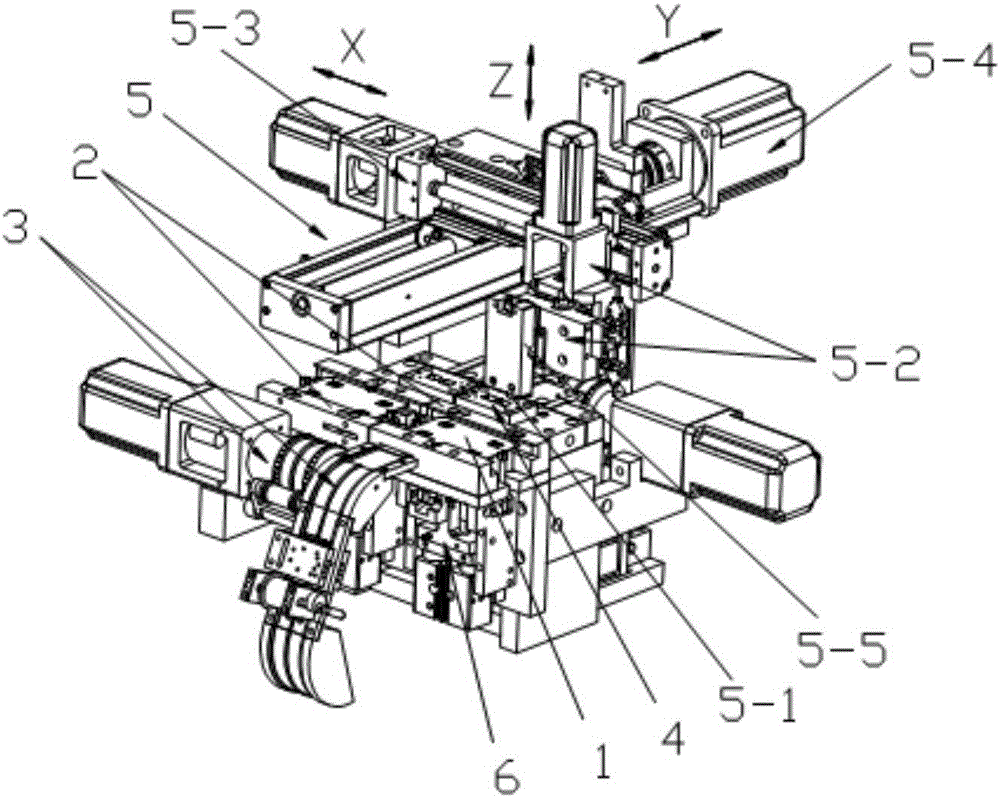

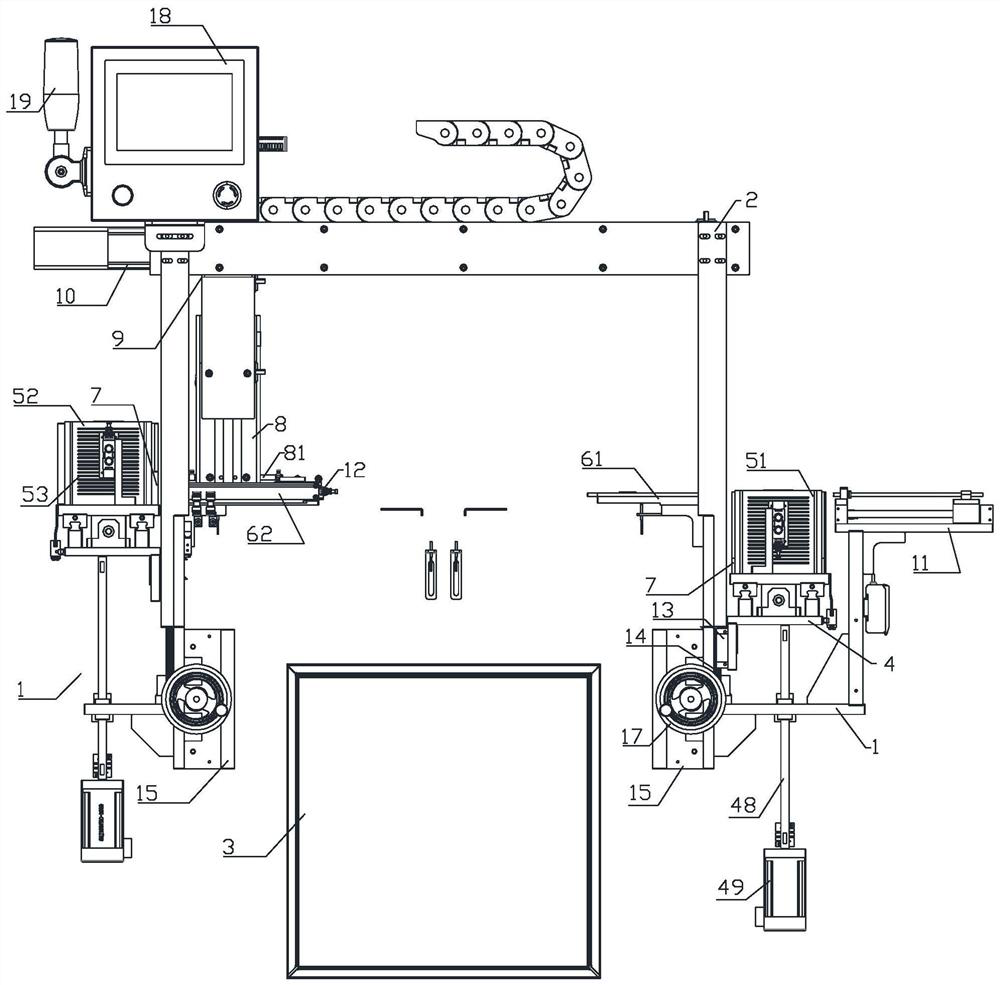

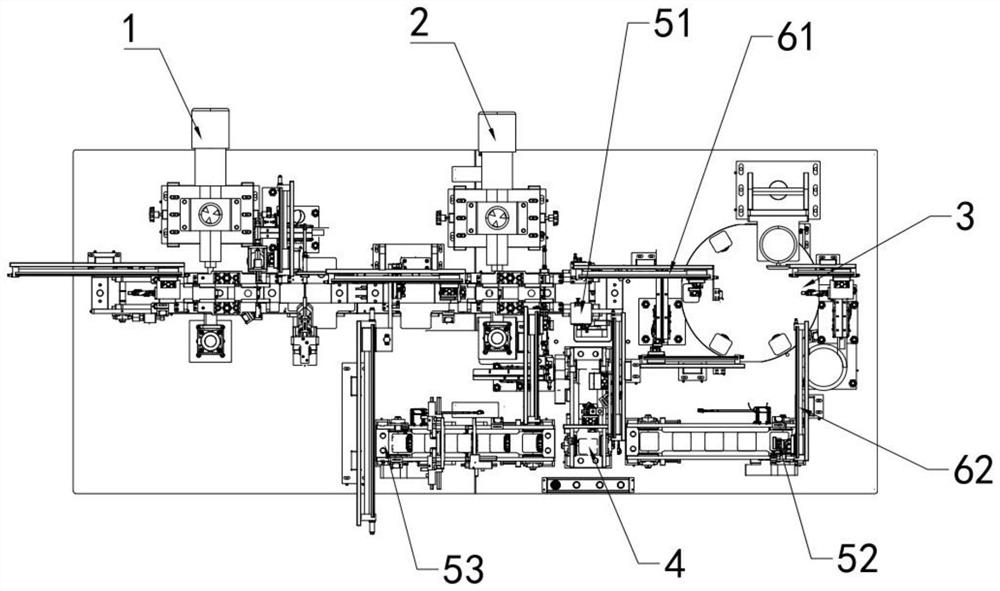

5G radio frequency front end assembling equipment and assembling method thereof

ActiveCN112770619AHigh packaging precisionImprove curing effectPrinted circuit assemblingElectrical componentsPlastic packagingHemt circuits

The invention discloses 5G radio frequency front end assembling equipment, which comprises a module assembling unit and a circuit forming unit which are sequentially arranged along an assembling sequence, wherein the module assembling unit comprises a substrate forming device and a chip mounting device; the circuit forming unit comprises a chip plastic packaging device and a circuit etching device; and the chip plastic packaging device comprises a sealing box body, a first sealing isolation layer and a sealing cavity, and a workpiece rotating device, a plastic packaging forming device and a high-pressure generating device are arranged in the sealing cavity. The invention further discloses an assembling method of 5G radio frequency front end assembling equipment. According to the invention, through the arrangement of the module assembling unit, under a streamlined assembling mode, high-precision and high-efficiency completion of compounding of multiple layers of substrates and assembling of chips is realized, the chip plastic packaging device adopts organic matter solidification to form a plastic packaging layer with the planarization reaching the standard, and the circuit etching device prepares a circuit network through a selective etching process. Quality requirements are strictly controlled, and good assembling precision of the substrate and the chip is guaranteed.

Owner:北京华迅通信技术有限公司

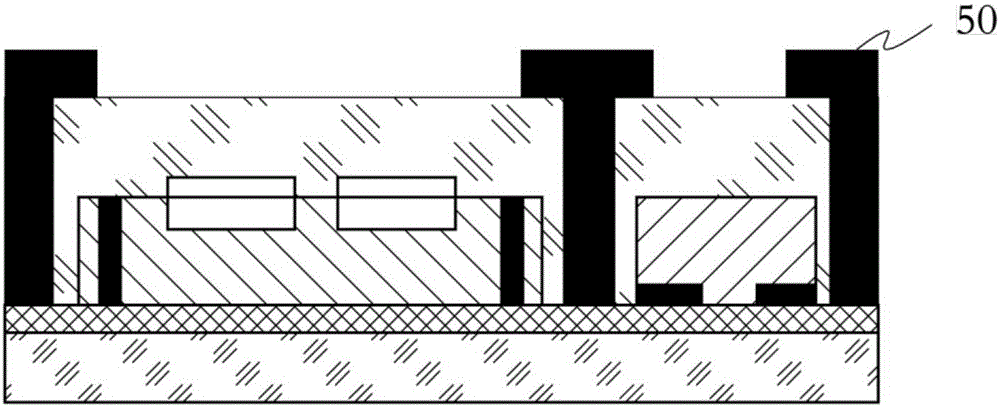

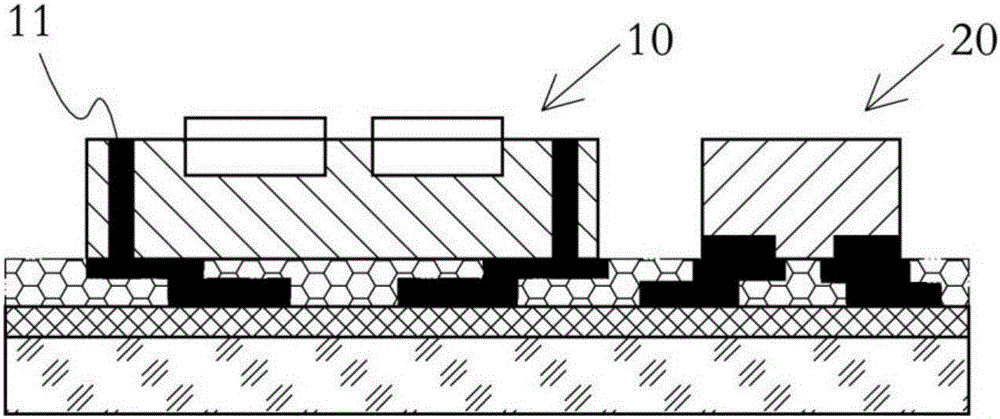

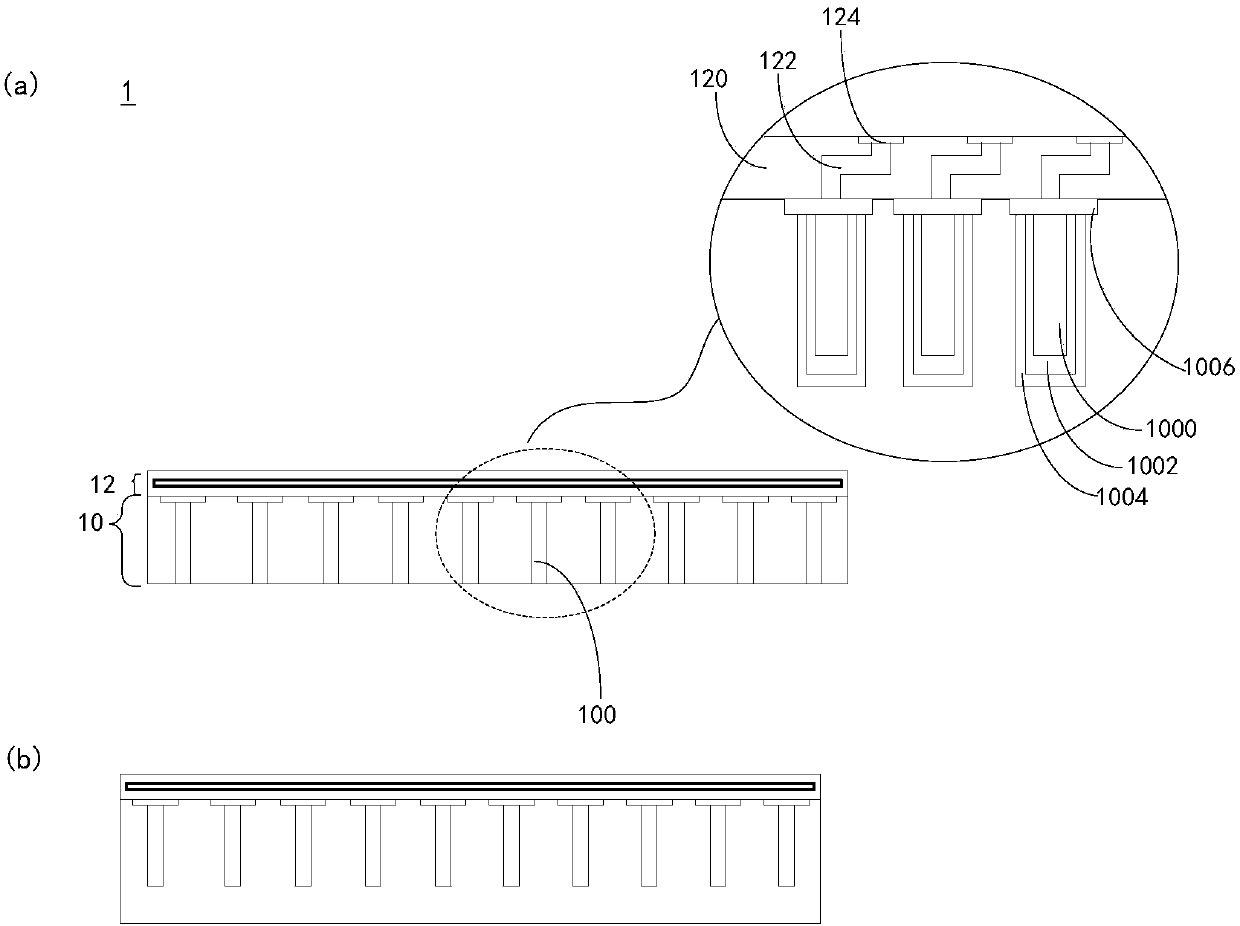

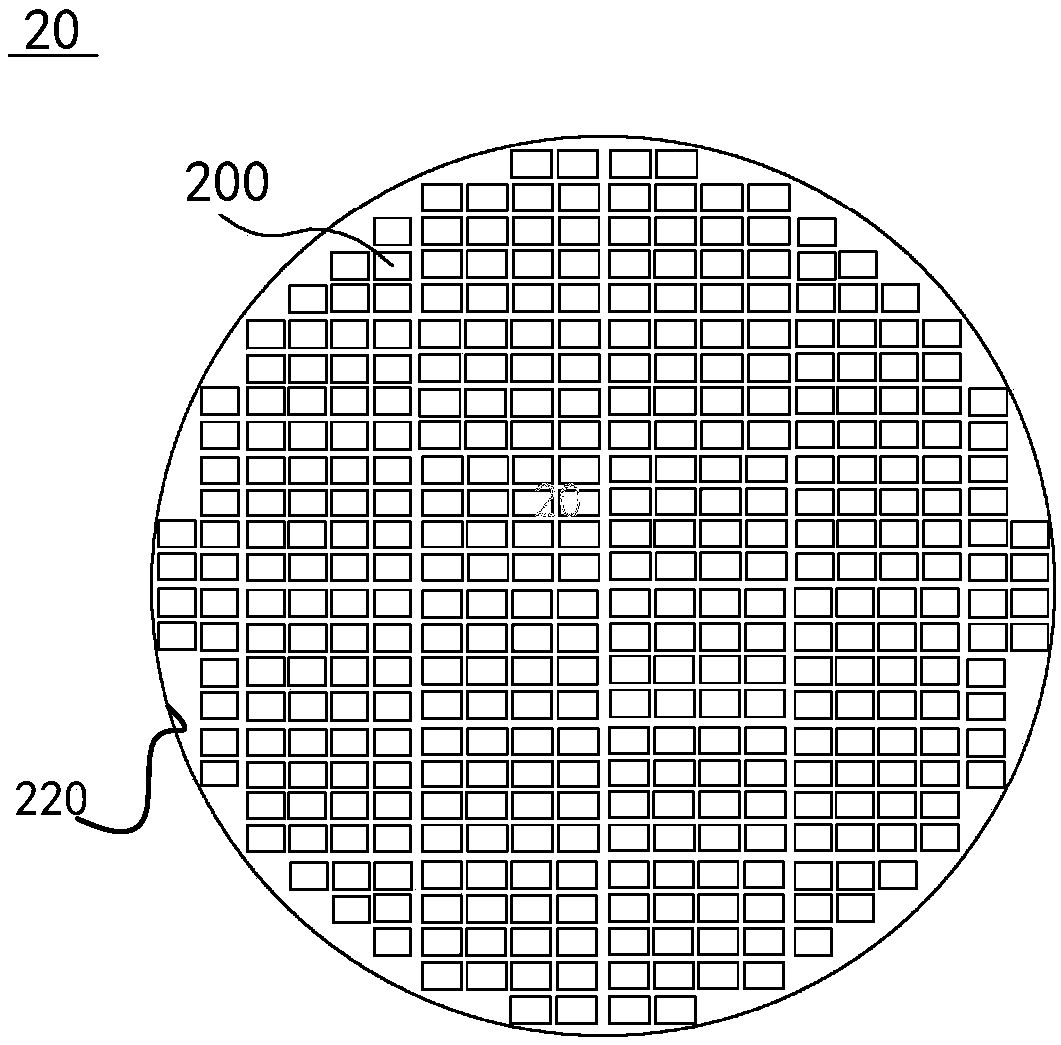

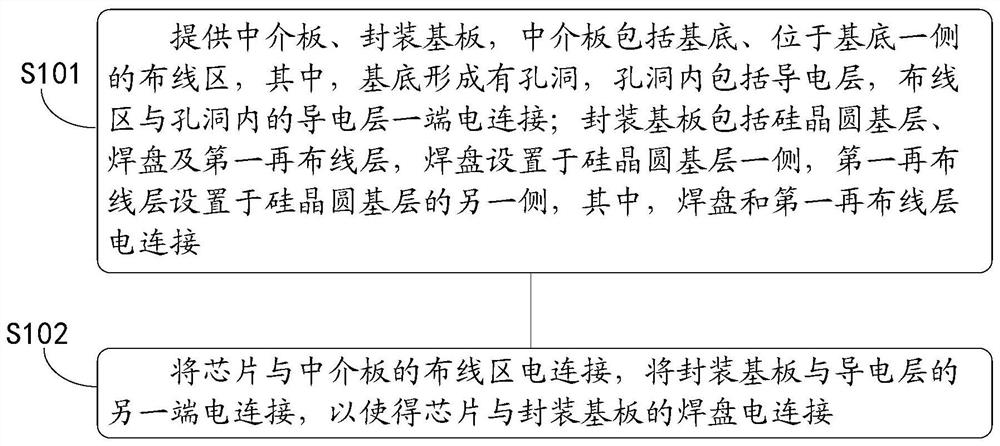

Fan-out packaging device

InactiveCN107564880AHigh packaging precisionGood thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesElectrical and Electronics engineeringSilicon

The invention discloses a fan-out packaging device, which comprises an intermediate board, a packaging substrate and a chip, wherein the intermediate board comprises a substrate and a routing area located at one side of the substrate; a hole is formed in the substrate and comprises a conductive layer; the routing area is electrically connected with one end of the conductive layer in the hole; thepackaging substrate comprises a silicon wafer base layer, a bonding pad and a first rerouting layer; the bonding pad is arranged at one side of the silicon wafer base layer; the first rerouting layeris arranged at the other side of the silicon wafer base layer, wherein the bonding pad is electrically connected with the first rerouting layer; the chip is electrically connected with the routing area of the intermediate board; the packaging substrate is electrically connected with the other end of the conductive layer, so that the chip is electrically connected with the bonding pad of the packaging substrate. According to the fan-out packaging device, the fan-out package accuracy can be improved and the chip is prevented from shifting.

Owner:NANTONG FUJITSU MICROELECTRONICS

High-precision positioning method for linear motors controlled by asymmetrical s-shaped speed curves

ActiveCN112327954BImprove impact performanceHigh positioning accuracySpeed/accelaration control using electric meansElectric machineClassical mechanics

The invention relates to a high-precision positioning method for a linear motor controlled by an asymmetrical S-shaped speed curve, belonging to the field of high-precision and high-speed motion control, and relates to a high-precision positioning method for a linear motor controlled by an asymmetrical S-shaped speed curve. According to the performance constraints of the linear motor, the method defines the proportional factor and sets the shape characteristics of the speed curve of the acceleration and deceleration section, so as to determine the appropriate motion control parameters; calculates the matching relationship of the S-shaped speed curve time period, and based on the point-to-point running distance constraints. Update; according to the relationship between jerk J and time t of the S-shaped velocity curve, the expressions of acceleration and time a-t, velocity and time v-t, and displacement and time s-t are obtained by using the successive integration method; according to the PLC scan cycle The movement command obtained by discrete expression is sent to the driver in real time, and the drive motor completes the action according to the set command to ensure the smooth operation process.

Owner:DALIAN UNIV OF TECH

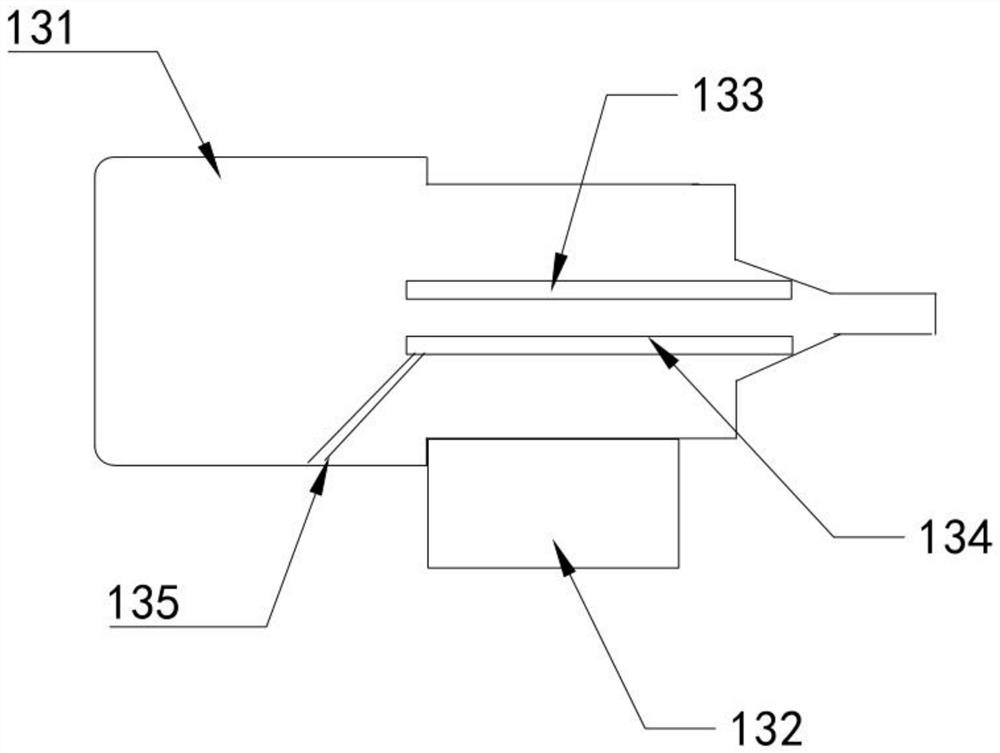

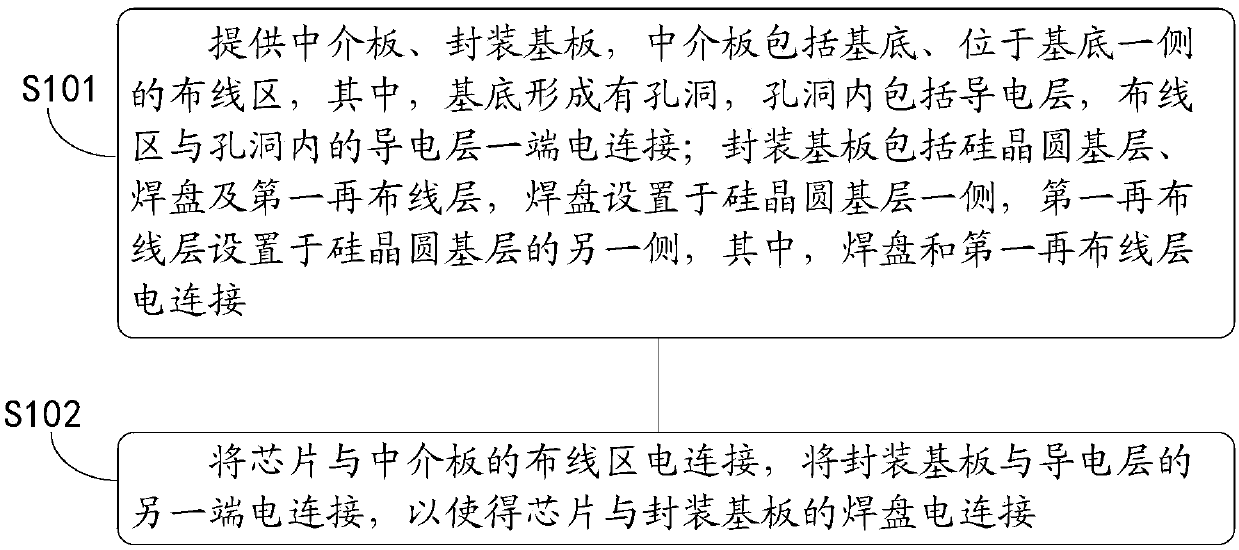

A fan-out packaging method

ActiveCN107611042BAvoid offsetImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesElectrical connectionEngineering

Owner:NANTONG FUJITSU MICROELECTRONICS

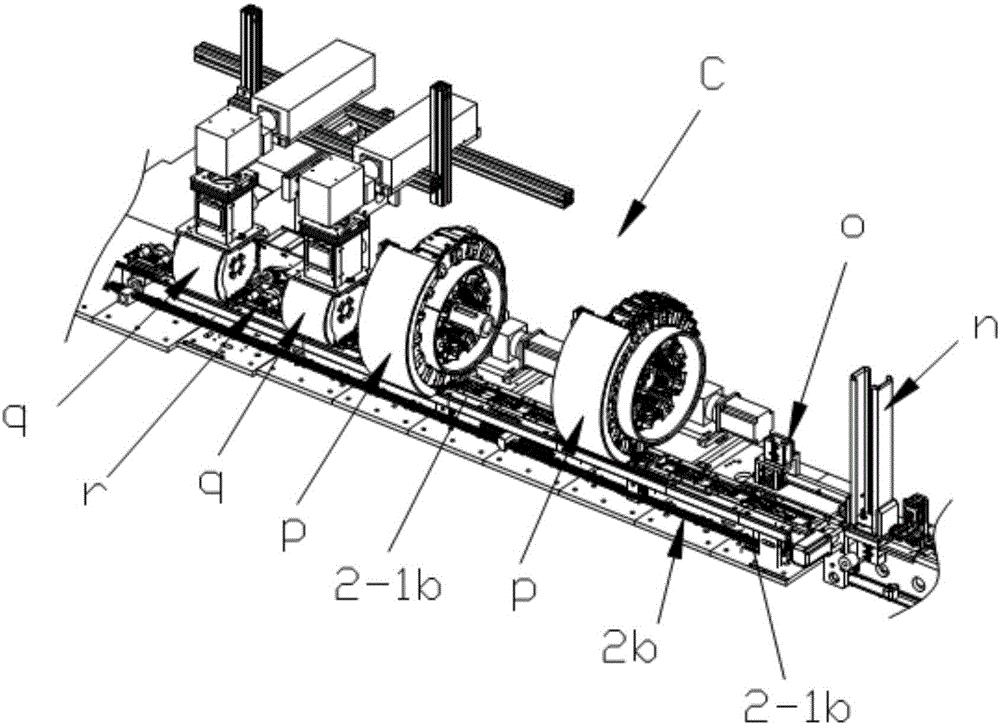

A multi-station turntable chip packaging production line

ActiveCN114093794BEfficient packagingAvoid damageSemiconductor/solid-state device manufacturingConveyor partsProduction lineCircular disc

The invention discloses a multi-station turntable type chip packaging production line, which belongs to the technical field of chip production and includes a bottom plate, and four first baffles and four second baffles are respectively fixedly connected to the left and right sides of the upper surface of the bottom plate. , corresponding to the four first baffles and the four second baffles are respectively provided with a first transmission mechanism and a second transmission mechanism, the opposite surfaces of the two first baffles and the two second baffles that are close to each other are A material guide table is provided. In the present invention, compared with the traditional processing method, the scheme will load, detect And the sealing glue is combined into a complete processing line, and at the same time, it avoids the damage caused by the position of the transferred chip, which is conducive to the efficient packaging of the chip and improves the packaging accuracy.

Owner:WUHAN FINEMEMS

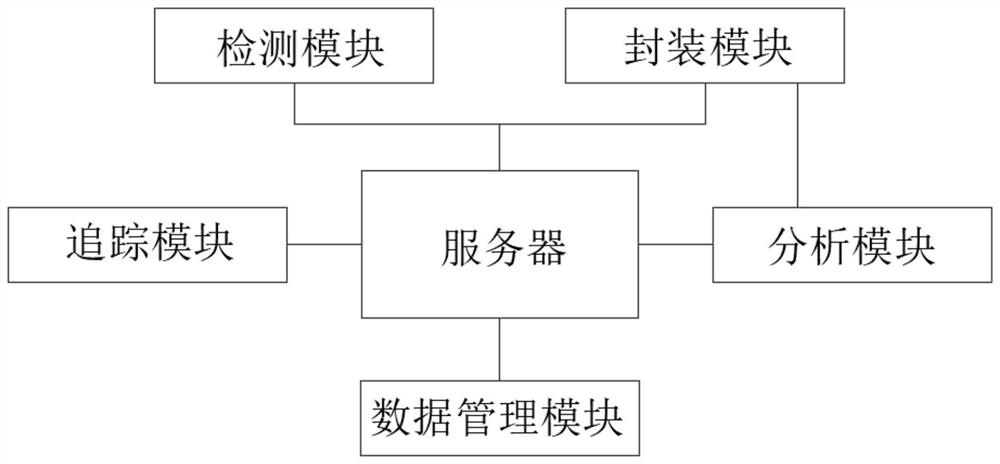

Packaging transmission control system of photovoltaic module chip

ActiveCN114724985AFacilitate data analysisEasy to refine againSemiconductor/solid-state device manufacturingPhotovoltaic energy generationComputer hardwareData ingestion

The invention discloses a packaging transmission control system of a photovoltaic module chip, and belongs to the technical field of chip packaging, the packaging transmission control system comprises a packaging module, a detection module and a server, the packaging module and the detection module are both in communication connection with the server; the server is also in communication connection with a tracking module, a data management module and an analysis module; the tracking module is used for tracking the packaging process of the chip and uploading collected packaging monitoring data to the cloud for storage; the data management module is used for carrying out data acquisition management, obtaining analysis data and sending the analysis data to the analysis module; the analysis module is used for analyzing the received analysis data, and the specific method comprises the steps that a data extraction unit is arranged, a data filling template is arranged in the data extraction unit, data extraction is conducted on detection data through the data extraction unit, the data filling template is filled with the extracted data, and the data extraction unit is used for extracting the detection data; and marking the data filling template filled with the data as selected data, and performing coordinate processing on the selected data.

Owner:安徽钜芯半导体科技有限公司

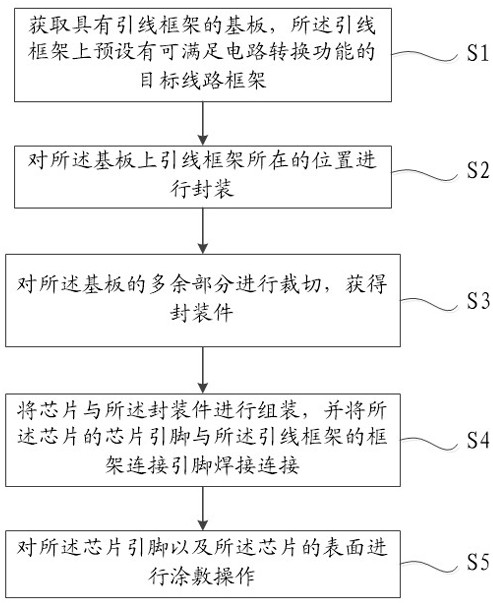

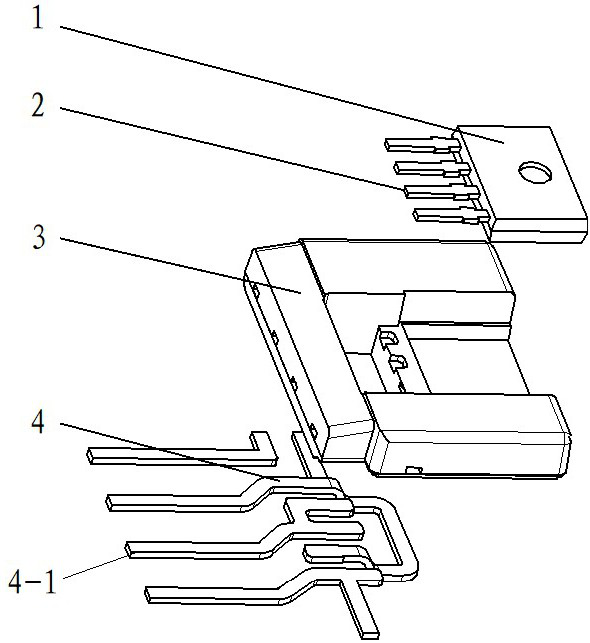

Chip packaging process

InactiveCN113808962AStable supportAvoid position deviationSemiconductor/solid-state device detailsSolid-state devicesHemt circuitsLead frame

The invention discloses a chip packaging process, which comprises the steps of obtaining a substrate with a lead frame, and presetting a target circuit frame capable of meeting a circuit conversion function on the lead frame; packaging the position of the lead frame on the substrate; cutting the redundant part of the substrate to obtain a packaging piece; assembling a chip and the packaging piece, and welding and connecting the chip pins of the chip with the frame connecting pins of the lead frame; and carrying out coating operation on the chip pins and the surface of the chip. According to the process provided by the invention, the target circuit frame is preset on the lead frame and can achieve a circuit conversion function; and a chip molding and packaging process is canceled, after the lead frame is directly packaged and molded, the chip and the packaging piece are welded and fixed, then coating treatment and single packaging are performed, and the chip pins and the frame connecting pins are connected by welding. The welding heat is low, the bonding strength is high, the connection strength is high after coating treatment, the insulation effect is good, and the reliability of the chip can be effectively improved.

Owner:NINGBO CRRC TIMES TRANSDUCER TECH CO LTD

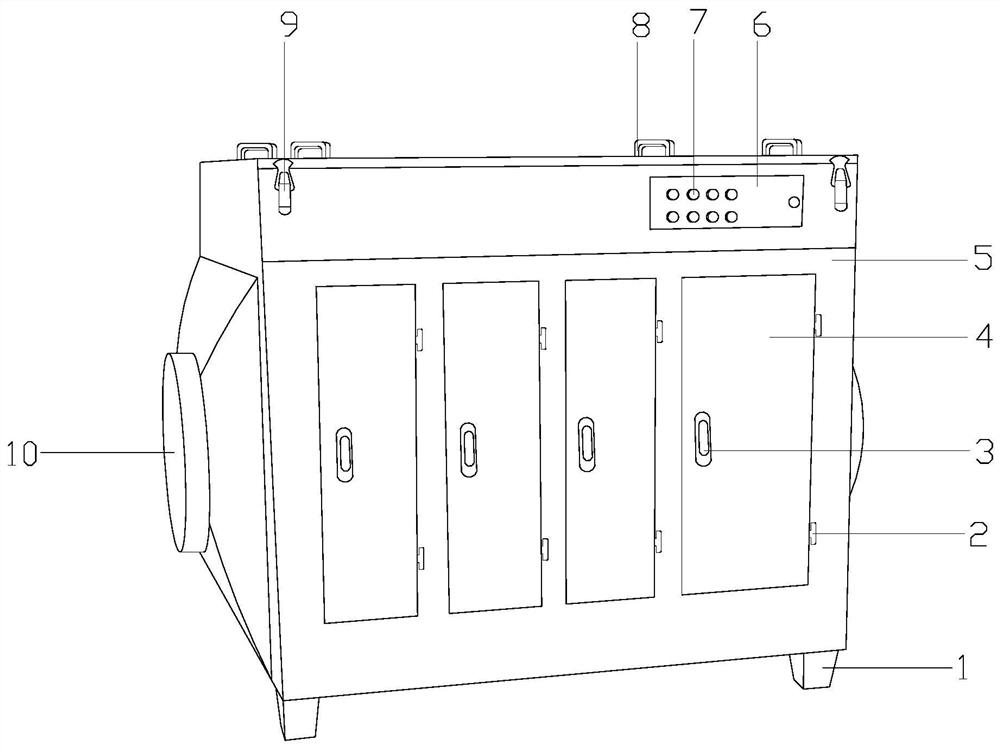

A plug-in packaging device for an automobile three-way catalytic converter

ActiveCN108408113BReduce workloadIncrease productivityExhaust apparatusSilencing apparatusStructural engineeringCatalytic converter

The invention discloses a plug-in encapsulation device for a three-way catalyst converter of an automobile. The plug-in encapsulation device structurally comprises fixed bottom legs, connectors, doorlocks, cabinet doors, an encapsulation processing mechanism, a control panel, a control button, a handle, a lock catch, and observation windows, wherein more than two fixed bottom legs are arranged and are respectively welded to four corners of the encapsulation processing mechanism; the cabinet doors are arranged at the front end of the encapsulation processing mechanism through a plurality connectors and are connected to the front end in a reinforcement manner through bolts; four door locks are arranged and are consistent in size; the door locks are fixedly embedded into the front ends of the cabinet doors; two observation windows are arranged and are respectively welded to left and right ends of the encapsulation processing mechanism. The plug-in encapsulation device has the benefits that the encapsulation accuracy is improved while improving the production efficiency, and workload of working personnel is reduced.

Owner:苏州因知成新能源有限公司

Plug-in encapsulation device for three-way catalyst converter of automobile

ActiveCN108408113AReduce workloadIncrease productivityExhaust apparatusSilencing apparatusEngineeringMechanical engineering

The invention discloses a plug-in encapsulation device for a three-way catalyst converter of an automobile. The plug-in encapsulation device structurally comprises fixed bottom legs, connectors, doorlocks, cabinet doors, an encapsulation processing mechanism, a control panel, a control button, a handle, a lock catch, and observation windows, wherein more than two fixed bottom legs are arranged and are respectively welded to four corners of the encapsulation processing mechanism; the cabinet doors are arranged at the front end of the encapsulation processing mechanism through a plurality connectors and are connected to the front end in a reinforcement manner through bolts; four door locks are arranged and are consistent in size; the door locks are fixedly embedded into the front ends of the cabinet doors; two observation windows are arranged and are respectively welded to left and right ends of the encapsulation processing mechanism. The plug-in encapsulation device has the benefits that the encapsulation accuracy is improved while improving the production efficiency, and workload of working personnel is reduced.

Owner:苏州因知成新能源有限公司

A method for encapsulating liquid metal printed circuits with light-curing resin

ActiveCN105934105BImprove reliabilityImprove applicabilityNon-metallic protective coating applicationPhoto irradiationChemical reaction

The invention provides a method of a light-cured resin packaging liquid-state metal printed circuit. The method comprises the following steps: 1, a printed circuit to be packaged is a printed circuit taking liquid-state metal as a lead wire, a light-cured resin at a liquid state is coated to or adhered to the surface of the liquid-state metal printed circuit by use of an adhesive deposit device; and 2, an irradiation machine irradiates light to the light-cured resin on the surface of the liquid-state metal printed circuit, the irradiated light-cured resin is converted into a solid state from a liquid state through a chemical reaction, and thus the liquid-state metal printed circuit is packaged. The method for packaging the liquid-state metal printed circuit by use of the light-cured resin, brought forward by the invention, by use of the feature that the light-cured resin can be converted into the solid state from the liquid state under light irradiation, rapid and accurate packaging of the liquid-state metal printed circuit is realized, the circuit reliability is improved, and the adaptation scope is enlarged.

Owner:BEIJING DREAM INK TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com