Linear motor high-precision positioning method based on asymmetric S-shaped speed curve control

A technology of speed curve and linear motor, which is applied in the direction of electric speed/acceleration control, etc., and can solve problems such as inability to meet high-precision positioning at the end

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The specific embodiment of the present invention will be described in detail in conjunction with the technical scheme and the accompanying drawings

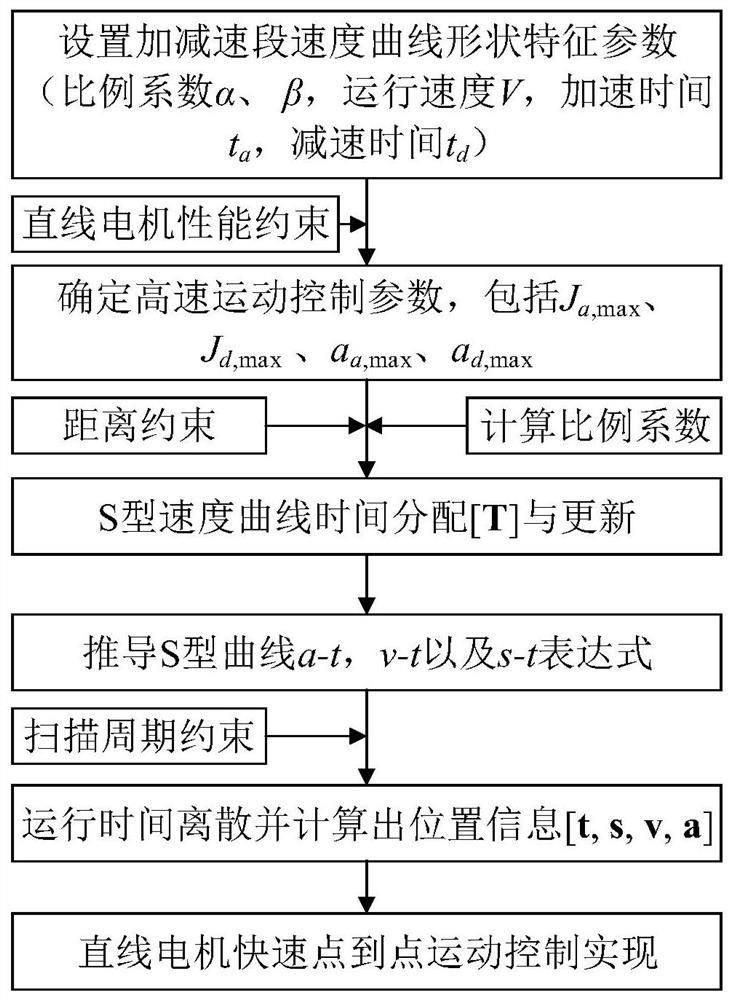

[0054] In the high-speed and high-precision packaging process of semiconductors, reasonable motion speed planning can avoid the impact or large vibration of the motor mover due to high-speed movement, which will affect the placement accuracy of the high-speed placement machine, and improve the stability of the placement process and improve the placement. The film speed and accuracy are of great significance. Based on this, a high-precision positioning method for linear motors controlled by an asymmetrical S-shaped speed curve was invented. The flow of the method is shown in Figure 1.

[0055] In the present invention, the TwinCAT2 software in the Beckhoff industrial computer is used as the soft PLC. According to the method proposed in the text, the position, speed, acceleration and time instructions are transmitted to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com