5G radio frequency front end assembling equipment and assembling method thereof

A technology of radio frequency front-end and assembly equipment, which is applied in the direction of assembling printed circuits, printed circuits, electrical components, etc. with electric components, which can solve the problem of affecting the quality and reliability of workpieces, the surface of the plastic sealing layer cannot be flattened, and the plastic sealing layer is easy to appear Defects and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

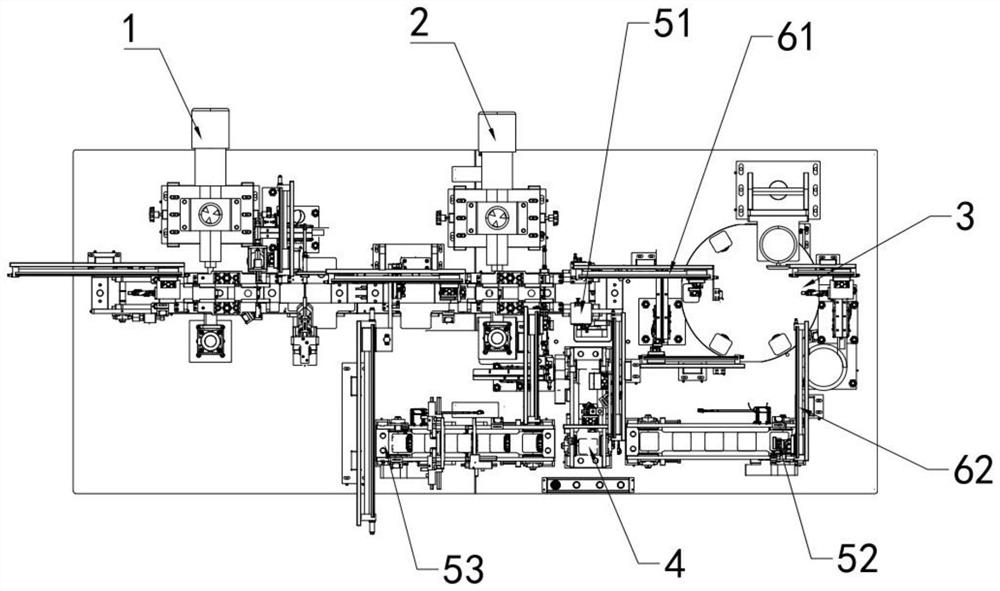

[0041]Example: SeeFigure 1 to 6The assembly apparatus of a 5G RF front end provided in this embodiment includes a module assembly unit, and a circuit forming unit that are sequentially set along the order of assembly.

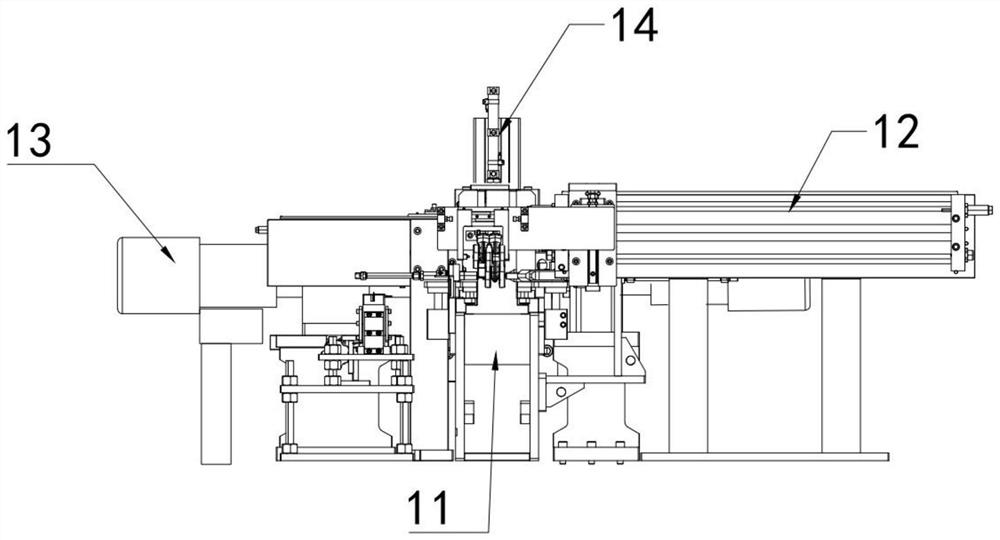

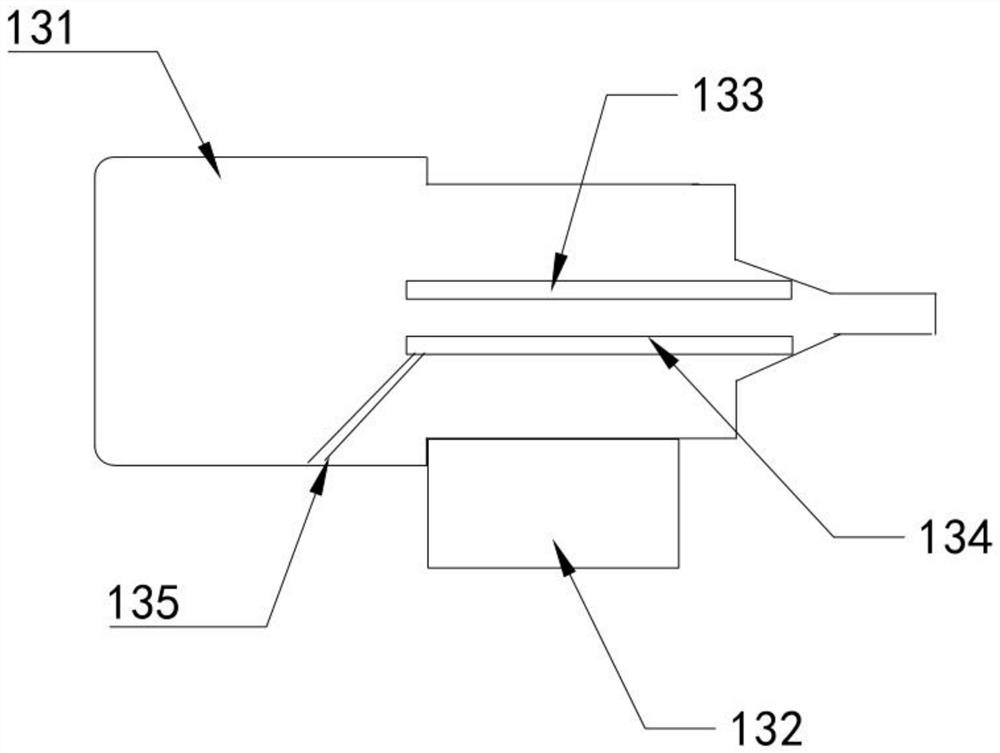

[0042]The module assembly unit includes a substrate molding device 1 for close fitting composite substrate, and a chip mounting device 2 for assembling each of the chips; module assembly units composed of the substrate molding device 1 and the chip mounting device 2. In the flow rate assembly method, high-precision and high efficiency is achieved, and the assembly of the chip of the multilayer substrate is achieved, and the device integration is high;

[0043]The circuit forming unit includes a chip plastic device 3 for plasticizing the assembled chip, and a circuit etching apparatus 4 for selective etching surface circuit network; the plastic sealing device 3 will be mounted to composite. The chip on the substrate is used to form a plastic layer of a flattened compass, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com