Patents

Literature

68results about How to "Guarantee exclusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

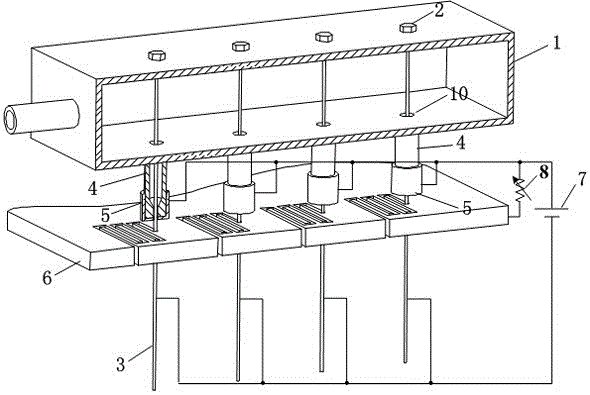

Servo double-surface heating vacuum packaging machine

ActiveCN102201592AQuality is not affectedGuarantee exclusionFinal product manufactureSecondary cells manufactureControl systemEngineering

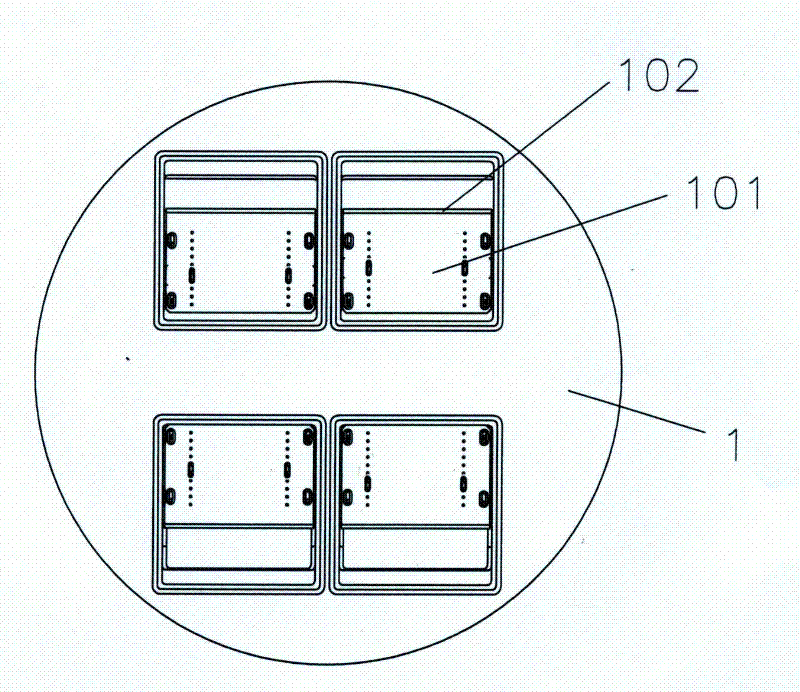

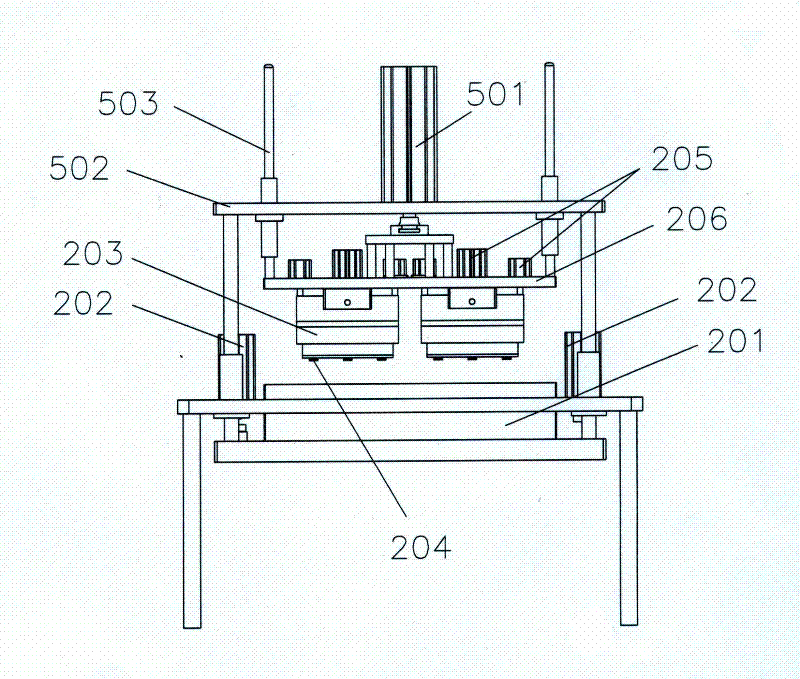

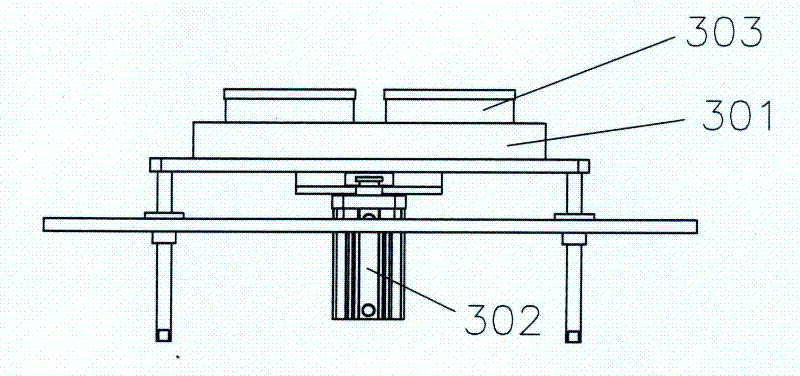

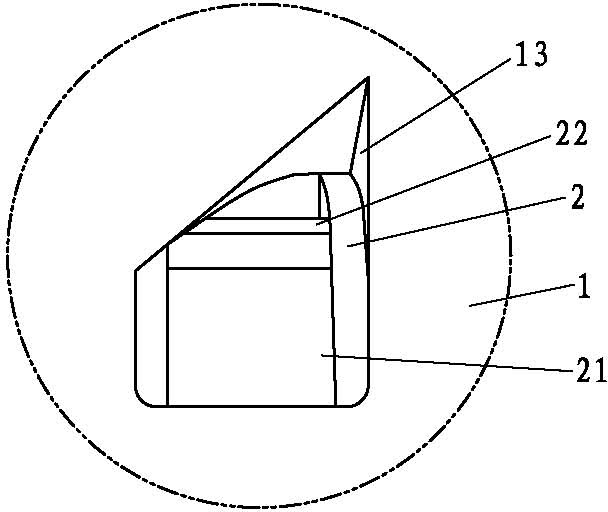

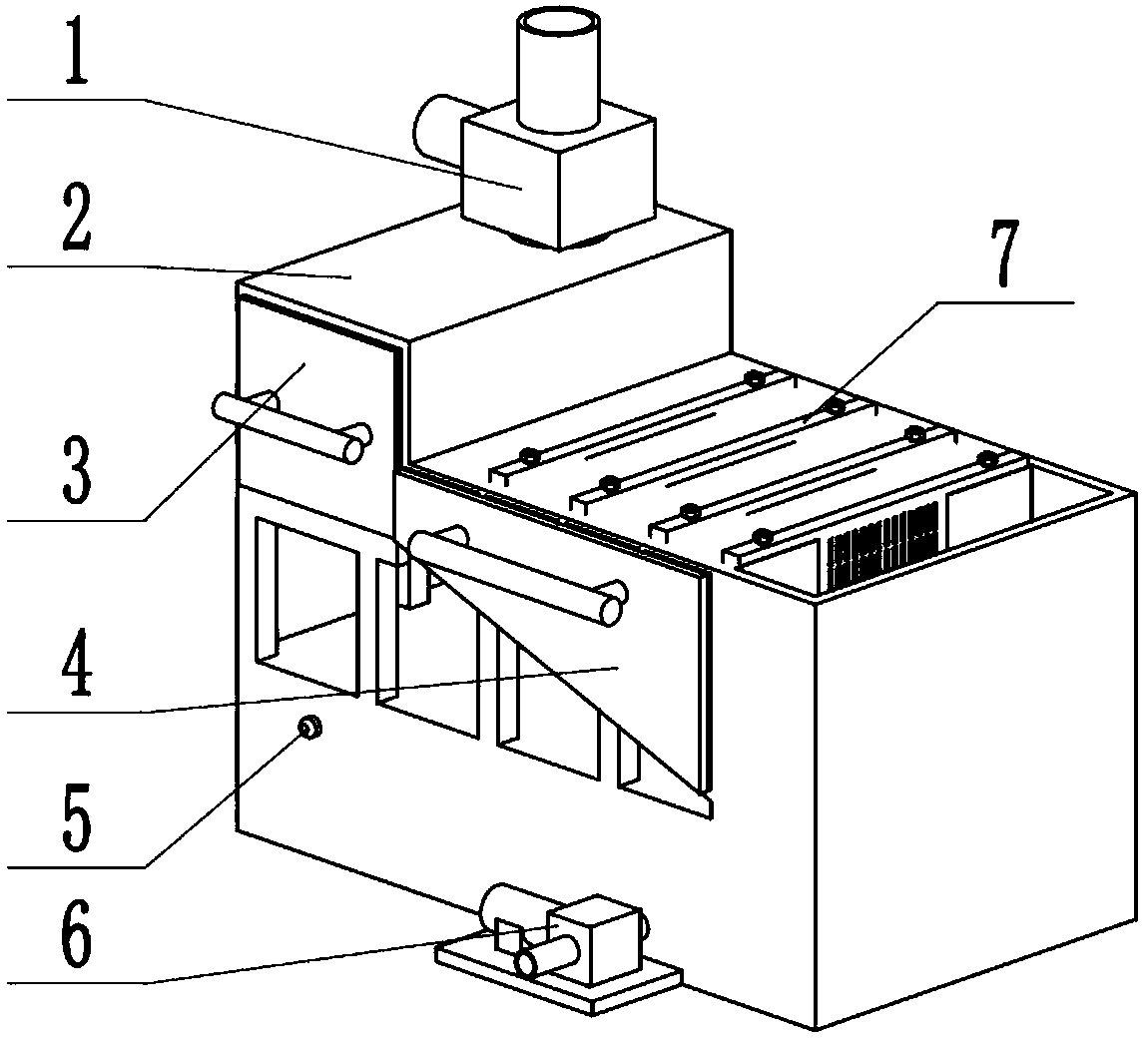

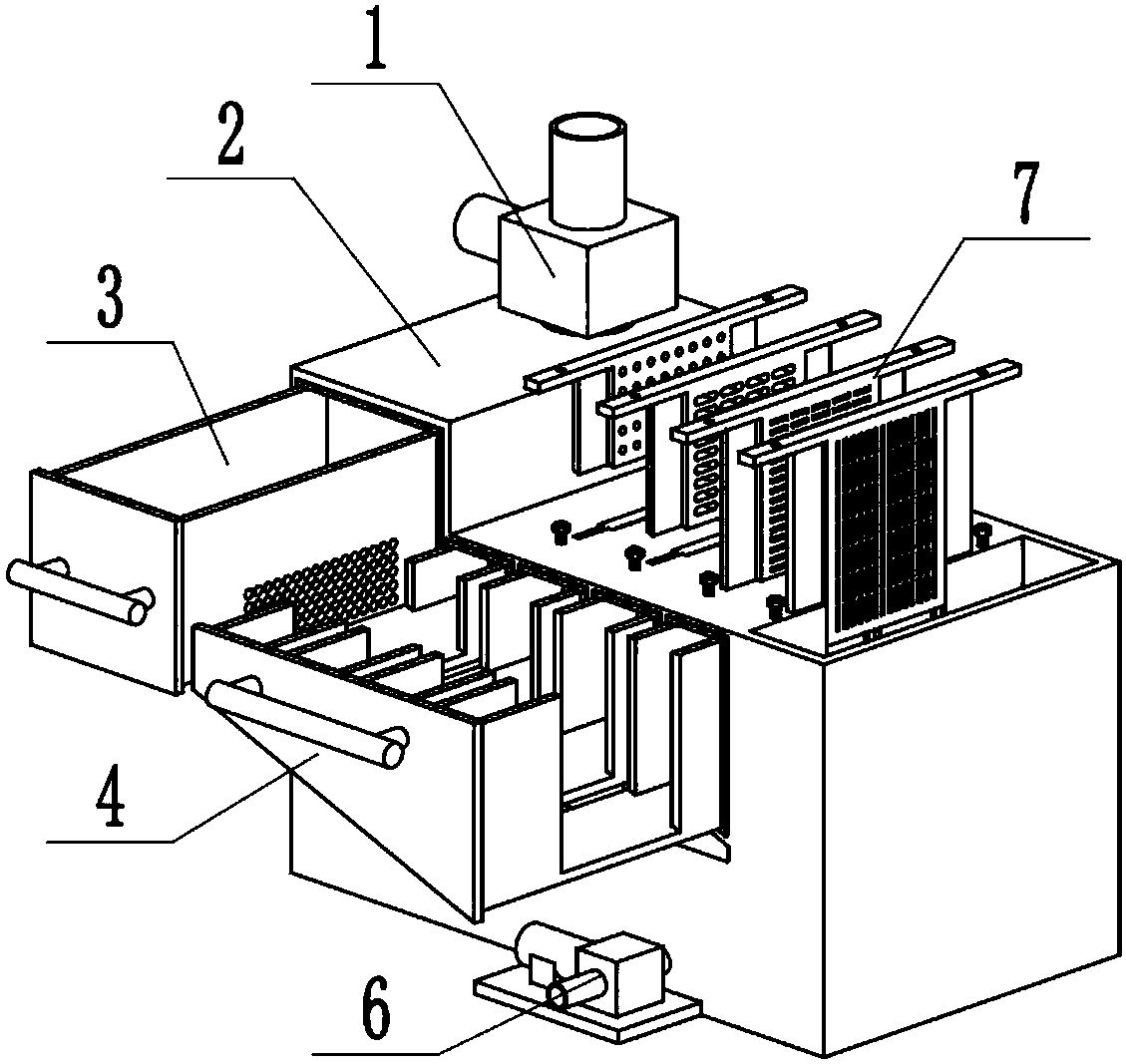

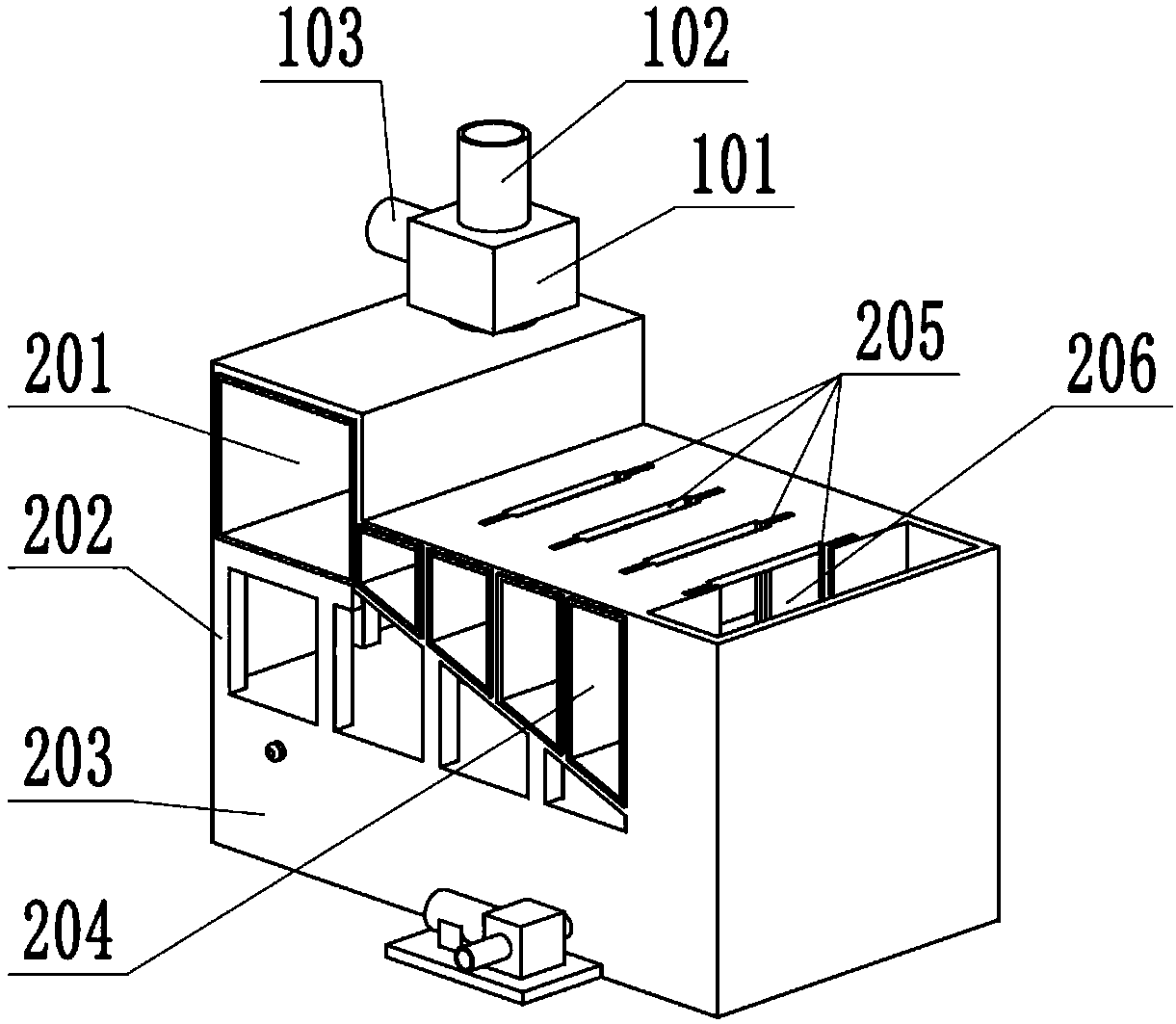

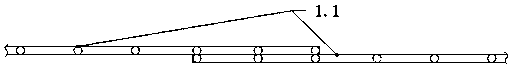

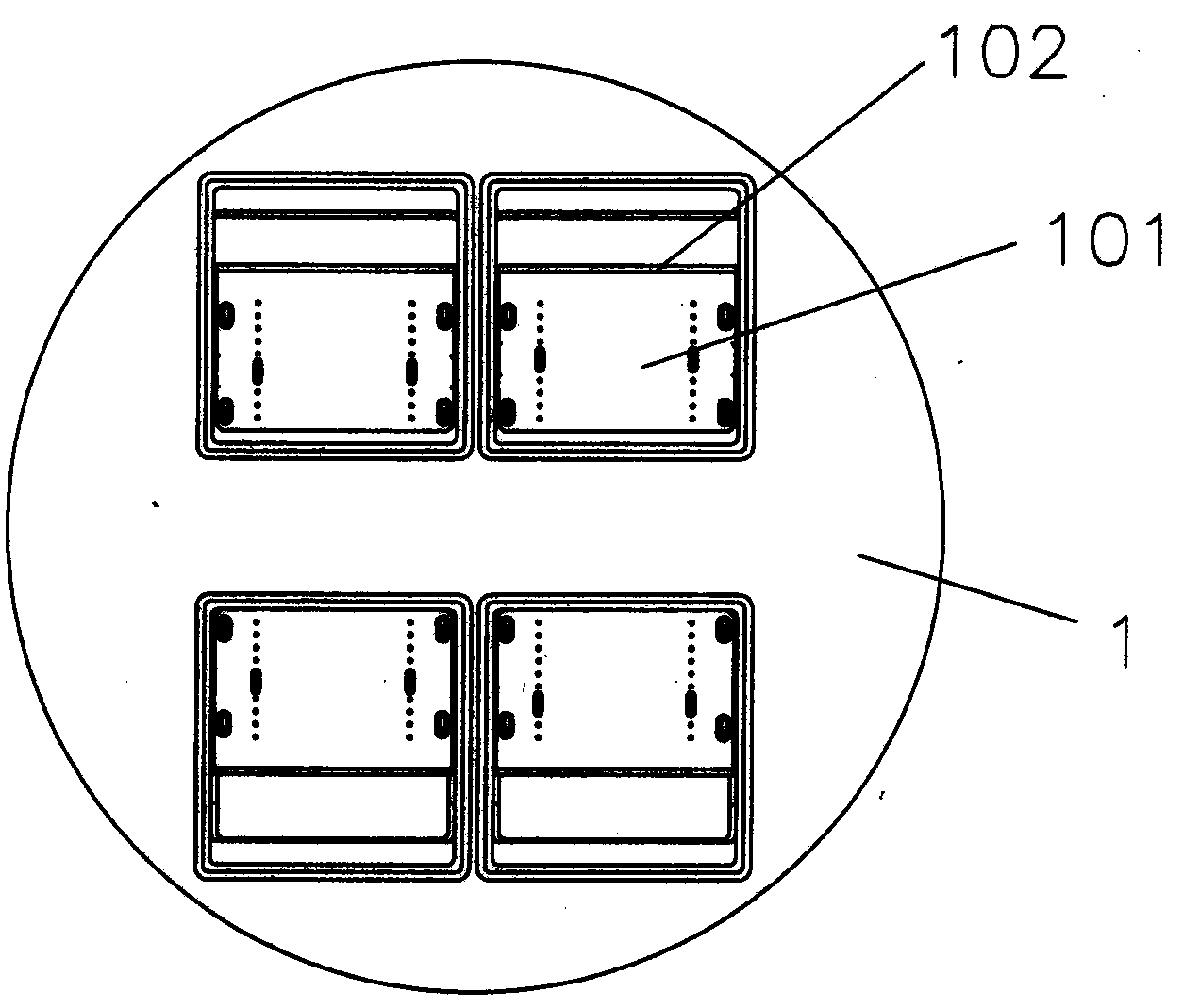

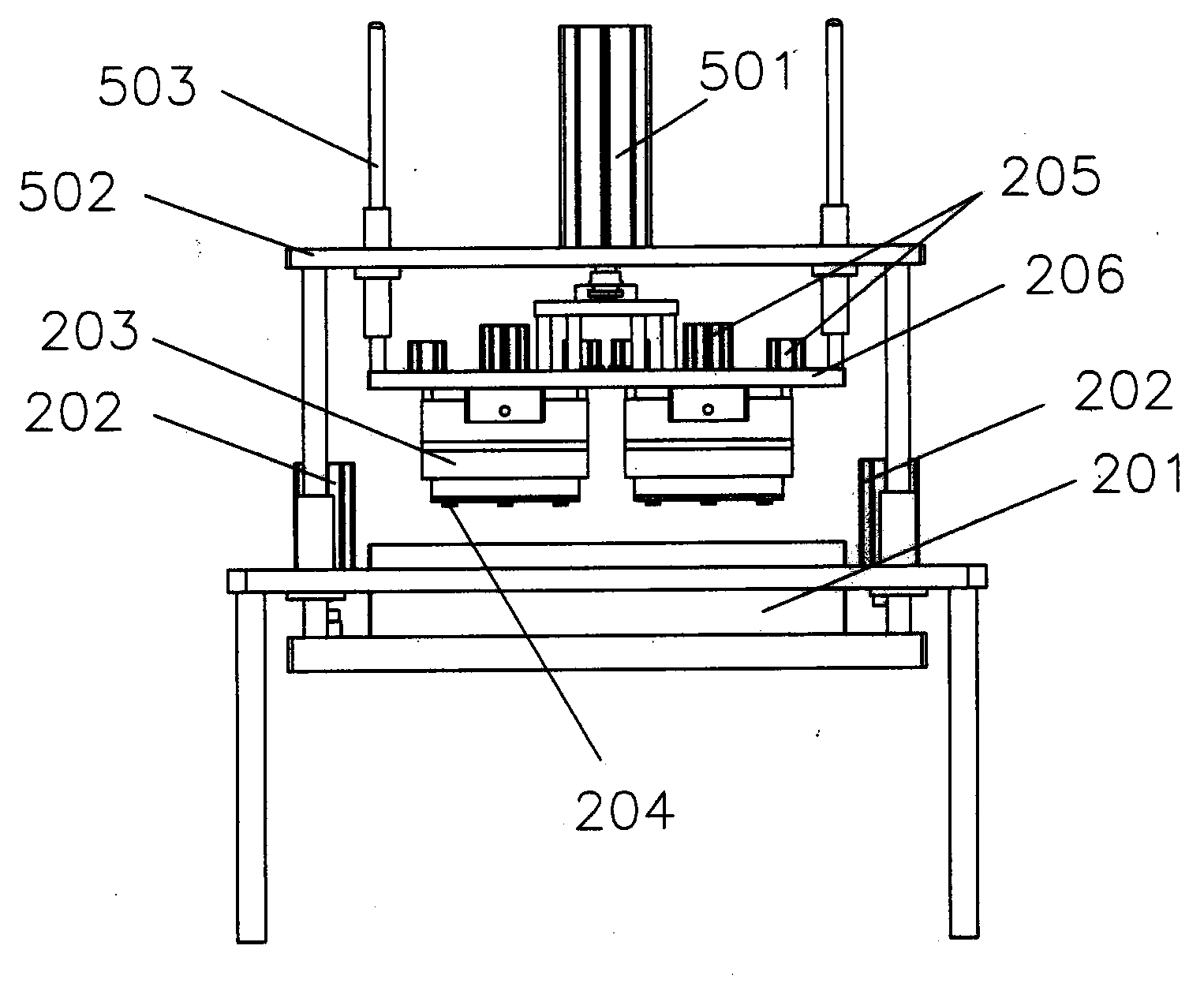

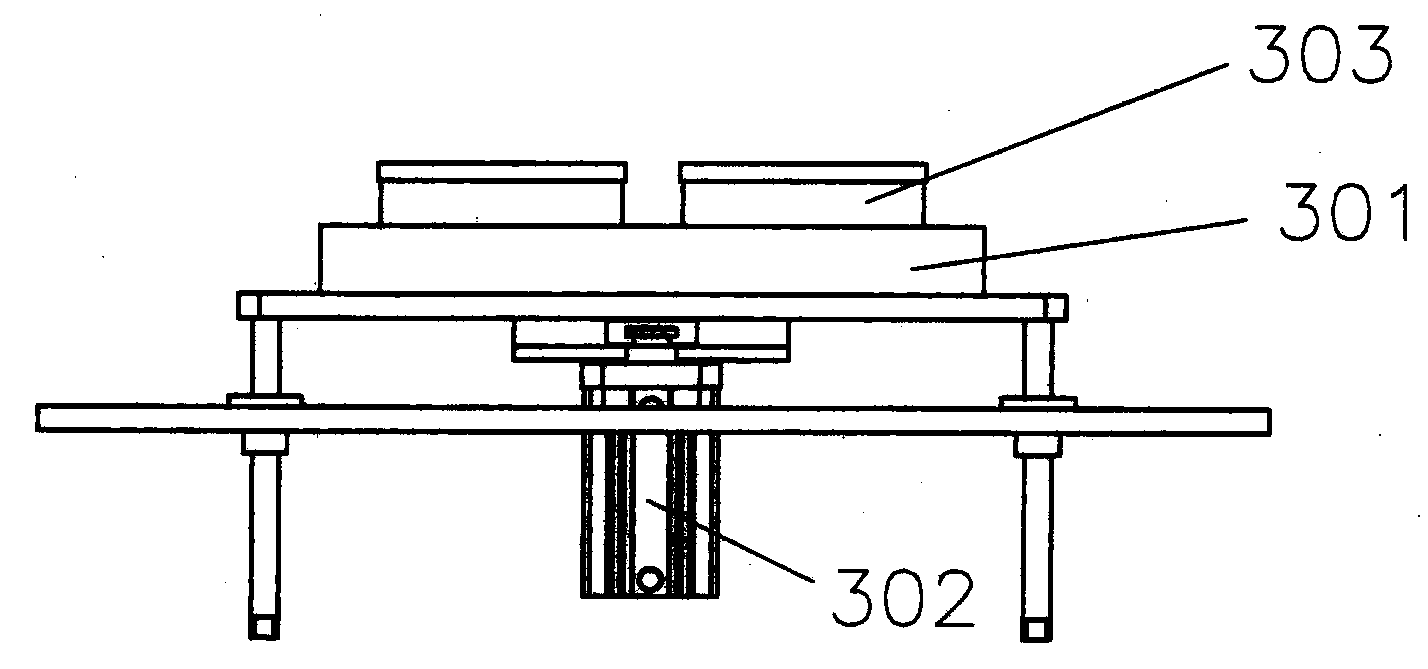

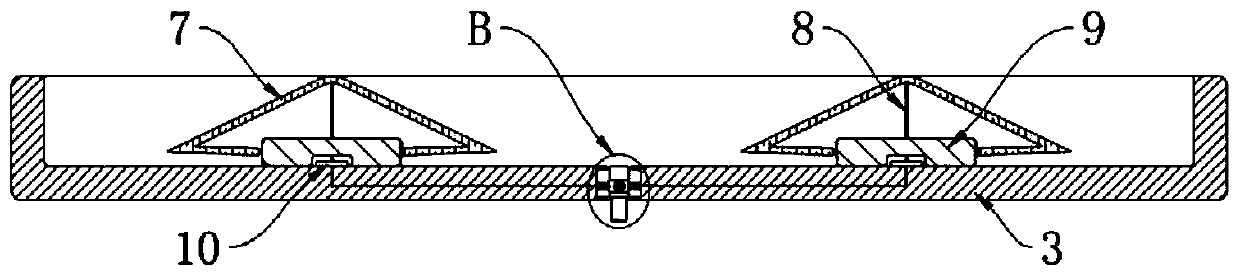

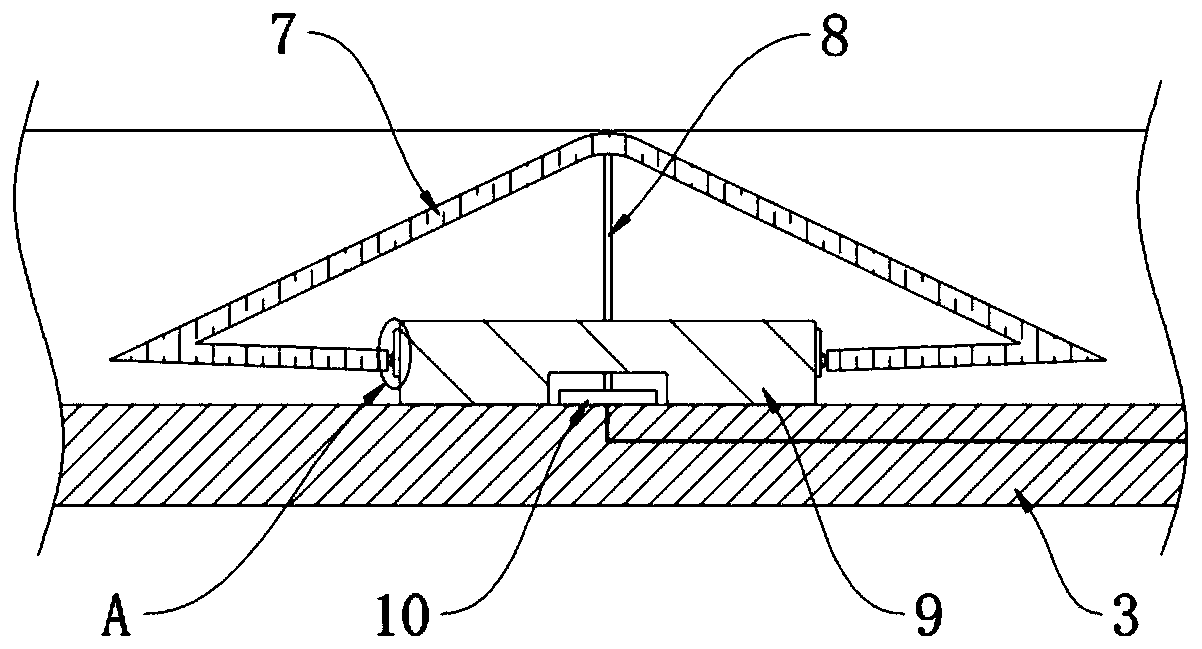

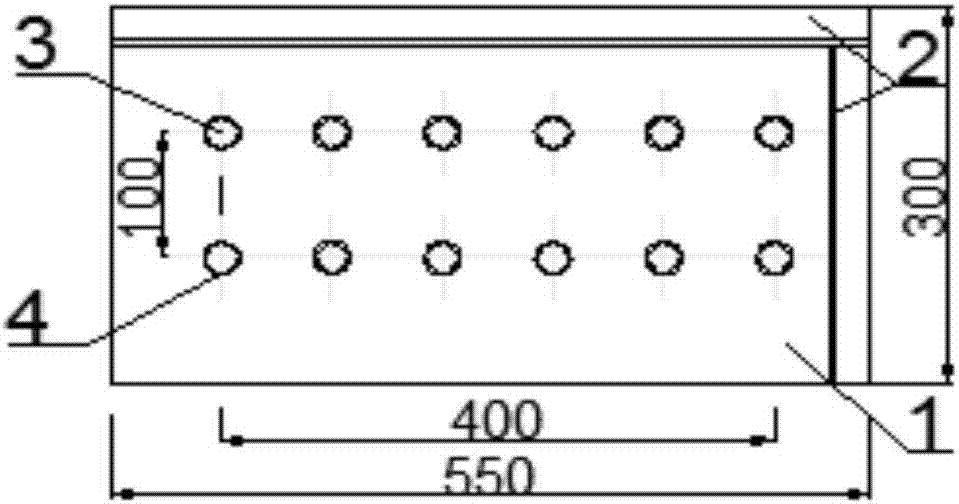

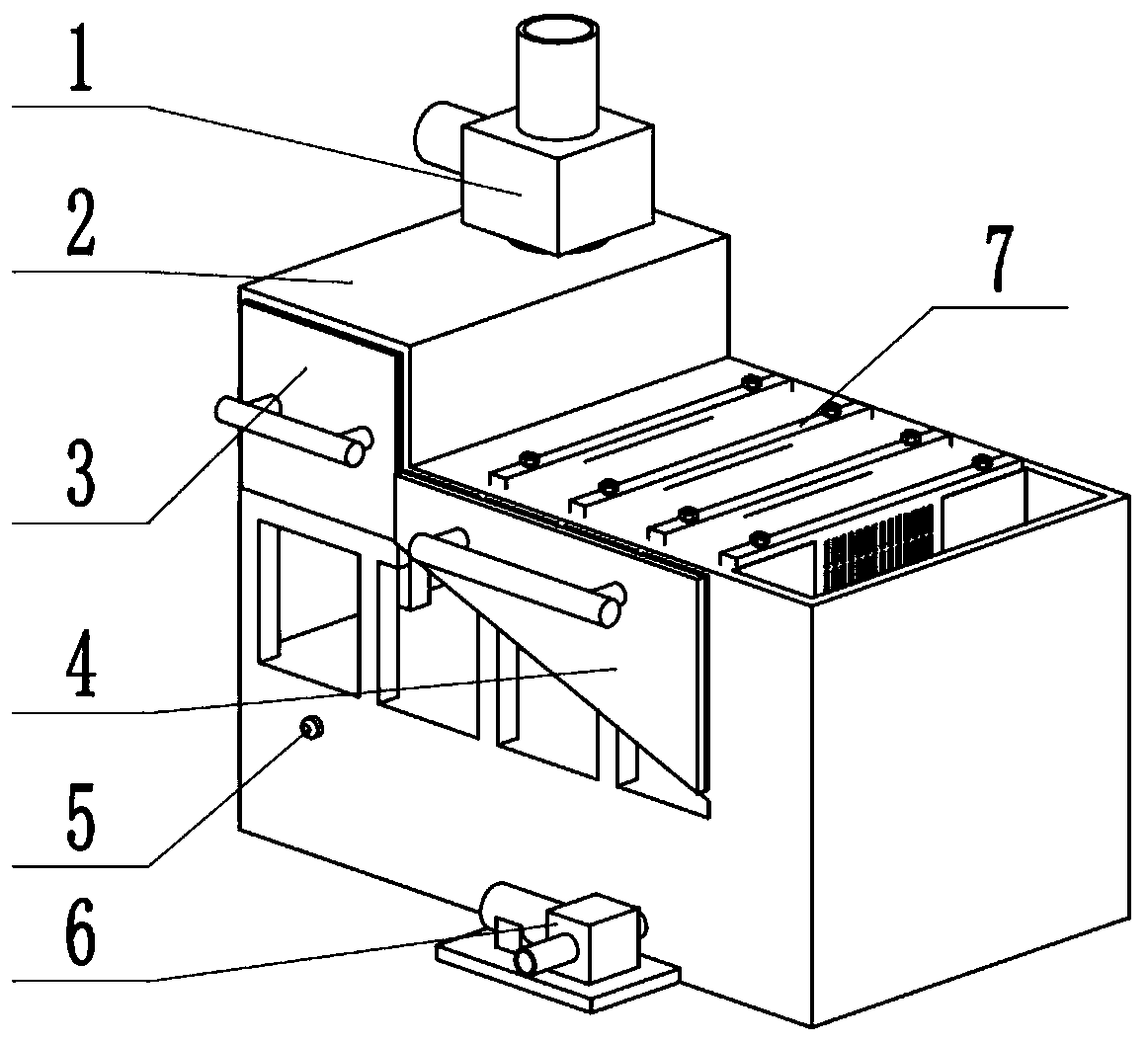

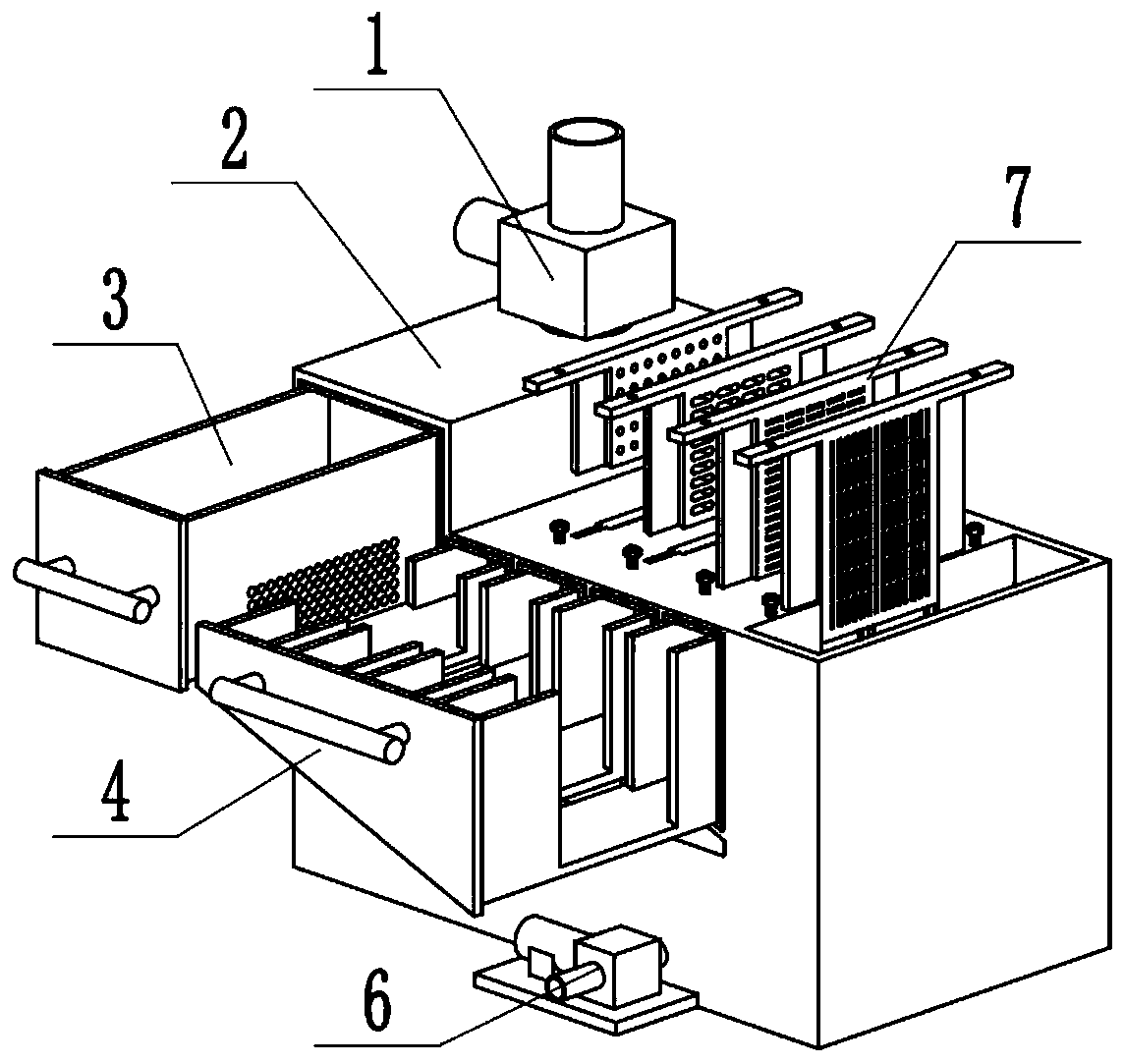

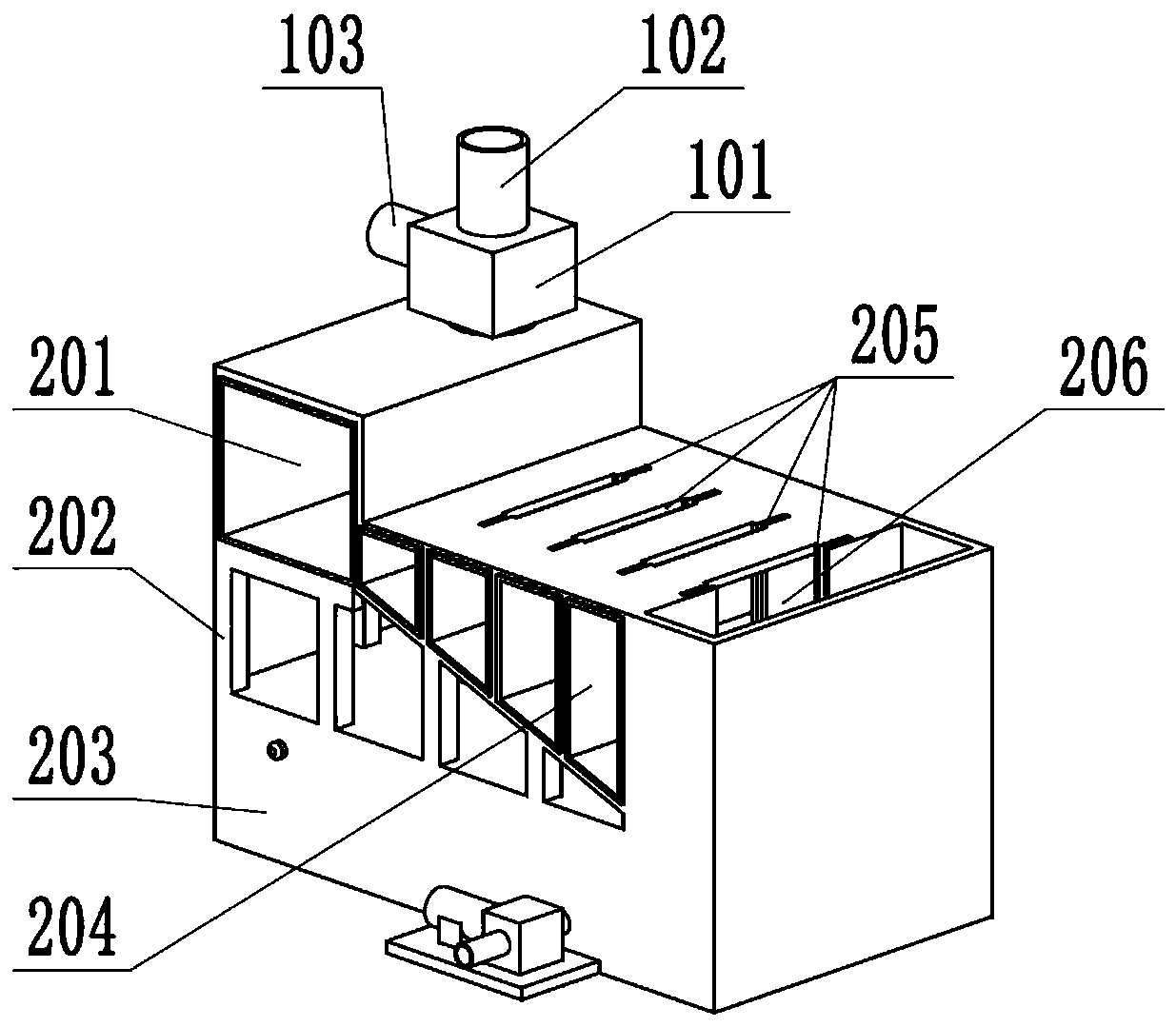

The invention discloses a servo double-surface heating vacuum packaging machine and belongs to liquid extraction seal secondary forming and packaging equipment of flexible packaged lithium batteries. The servo double-surface heating vacuum packaging machine comprises a double-station turntable feeding device driven by a cam partitioning device, a packaging mechanism with an up-and-down packaging device, and an electric control system, wherein the up-and-down packaging device comprises an upper cavity main body and a lower cavity main body; the opening directions of the upper cavity main body and the lower cavity main body are opposite to each other; the upper cavity main body and the lower cavity main body can clamp the turntable to form a sealed cavity body; a pressing board, an upper sealing head and a bayonet are arranged in the upper cavity main body; a lower sealing head and an aspirating hole are arranged in the lower cavity main body; the aspirating hole is communicated with an external vacuum source; the upper sealing head corresponds to the lower sealing head; and a heating body is arranged inside the servo double-surface heating vacuum packaging machine. The servo double-surface heating vacuum packaging machine has a compact structure and high efficiency; the electric core packaging quality is stable and the cost is low; vacuum liquid extraction can be realized; and pollution of the electrolyte to the equipment can be reduced to minimum.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

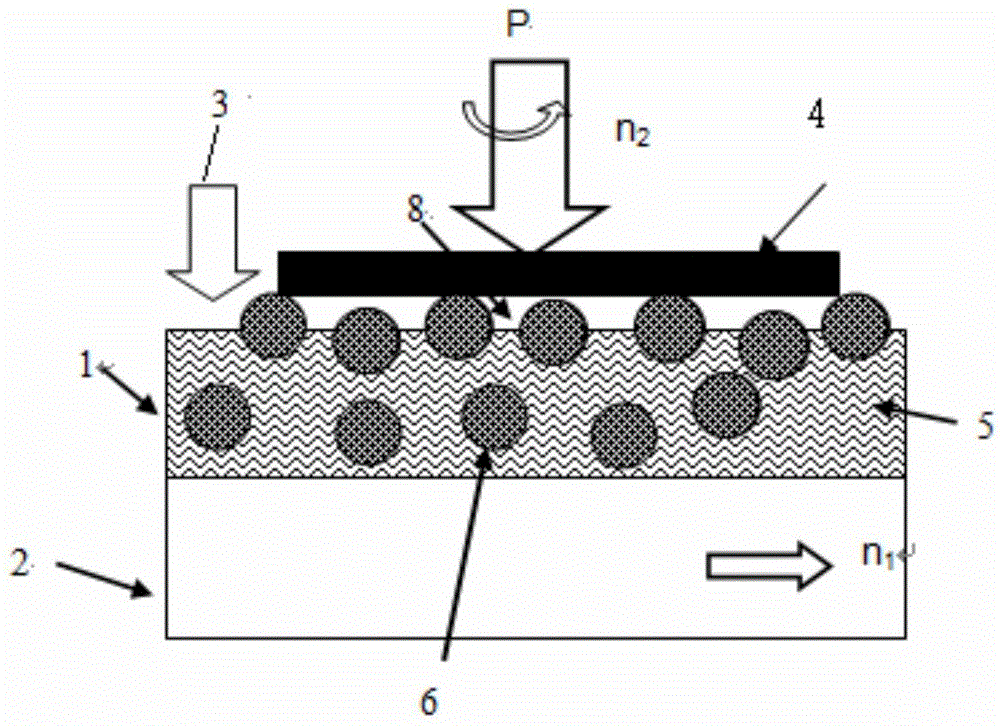

SiC/epoxy resin composite material and method for manufacturing pump components with it

ActiveCN102408677AImproved erosion and wear resistanceClosely arrangedPump componentsPumpsEpoxyEpoxy resin composite

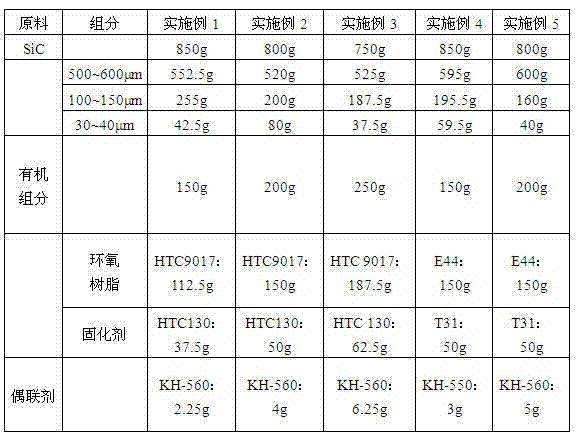

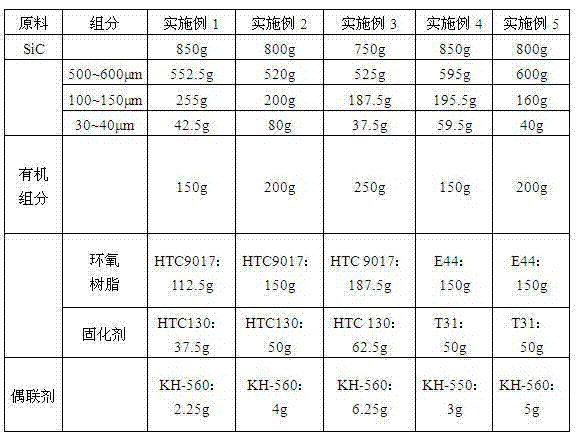

The invention discloses a SiC / epoxy epoxy resin composite material, wherein raw material components based on weight percentages are as follows: 75-85 wt% of SiC particles, 15-25 wt% of organic component and coupling agent with a mass of 1.5-2.5% of the organic component; the particle size distributions of the SiC particles are as follows: 500-600 microns taking up 65-75 wt%, 100-150 microns taking up 2-30 wt% and 30-40 microns taking up 5-10wt%; the organic component is composed of epoxy resin and curing agent; the mass ratio of the epoxy resin to the curing agent is 3: 1. A preparation method for pump component with SiC / epoxy epoxy resin composite material, comprising the following steps: (1), heating and stirring in vacuum way; (2), pressure pouring; (3), vacuum vibrating and forming; (4), heating and curing. The invention is characterized by simple technology and low production cost. The prepared SiC / epoxy epoxy resin composite material pump component can resist abrasion and corrosion.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY

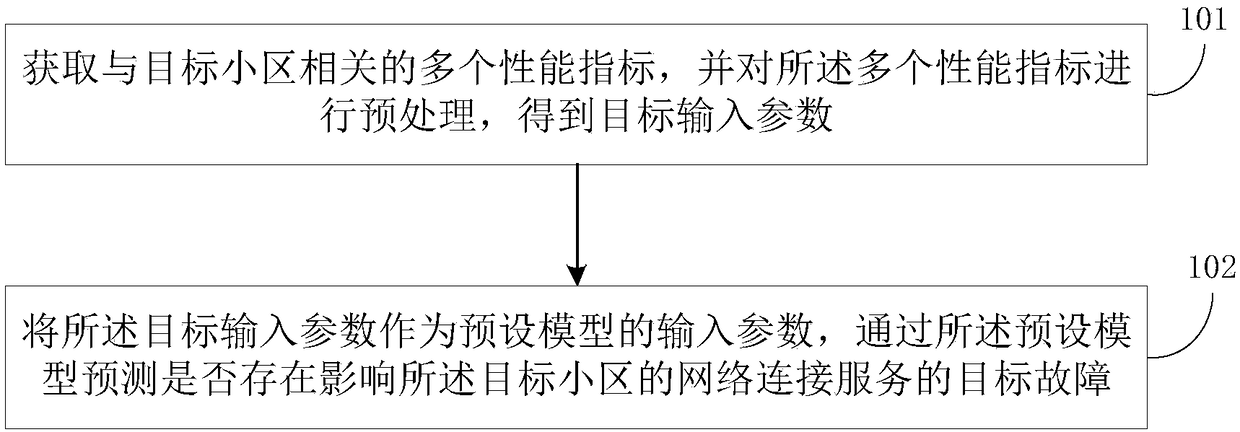

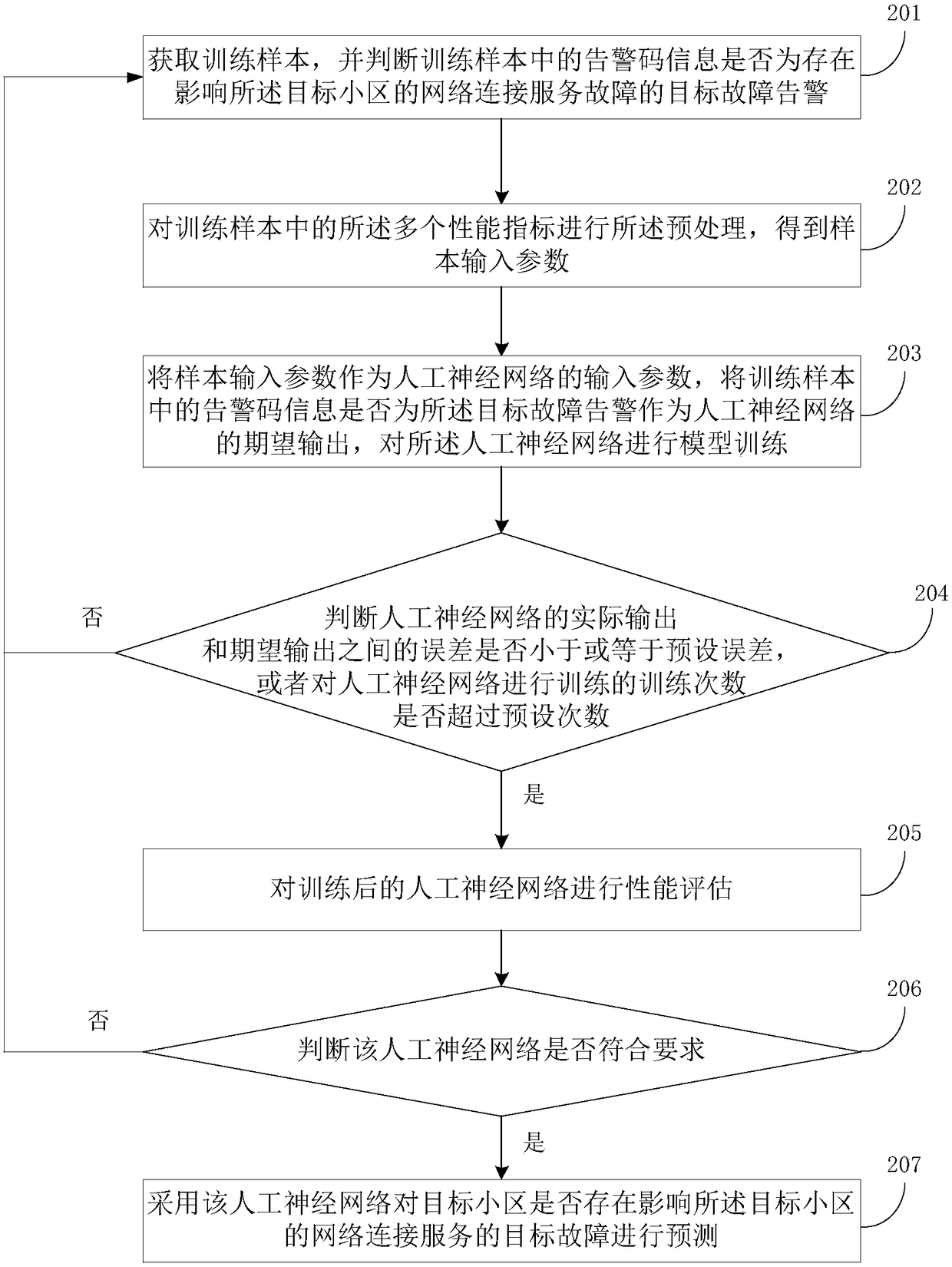

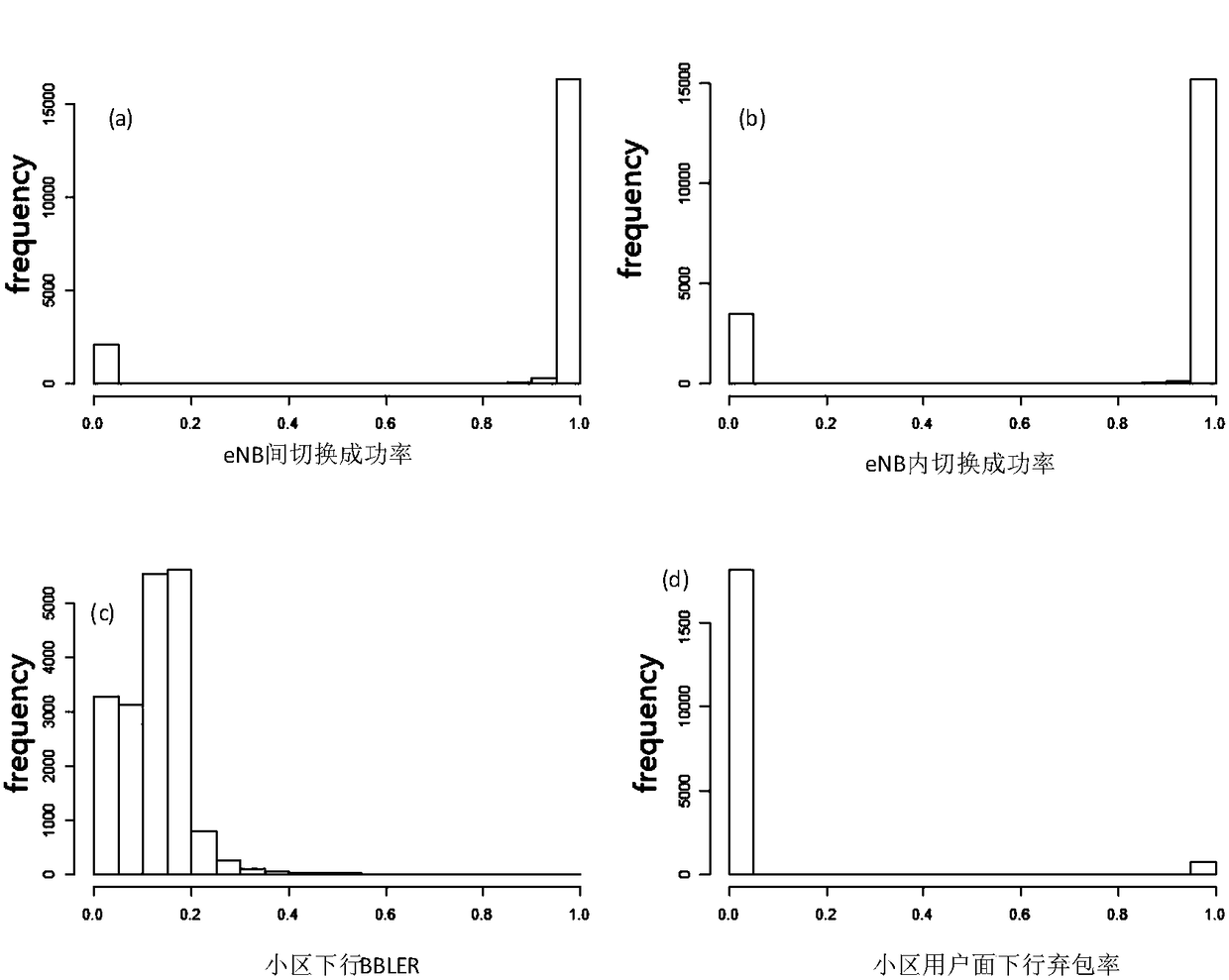

Prediction method and device for cell failure warning

The embodiments of the present invention disclose a prediction method and device for cell failure warning. The method includes the following steps that: a plurality of performance indicators related to a target cell are acquired, the plurality of performance indicators are pre-processed, so that target input parameters are obtained; and with the target input parameters adopted as the input parameters of a preset model, the preset model is adopted to predict whether a target fault that affects the network connection service of the target cell exists. According to the method, the trained presetmodel is adopted to abstract the connotations of the performance indicators so as to obtain data features of the generation of a warning by means of fitting, wherein the warning indicates that the network connection service of the target cell is affected, and therefore, whether the warning which indicates that the network connection service of the target cell is affected is generated can be predicted according to the performance indicators; and troubleshooting can be performed on the network of the target cell according to the prediction result of the preset model before the warning which indicates that the network connection service of the target cell is affected is generated, and a fault corresponding to the warning can be eliminated before a user perceives the fault.

Owner:CHINA MOBILE GRP GUANGDONG CO LTD +2

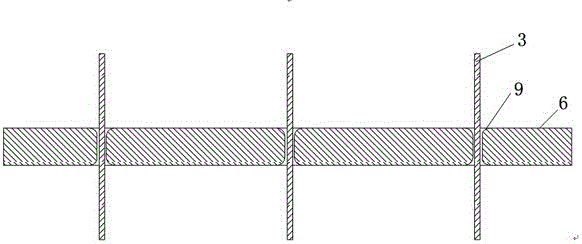

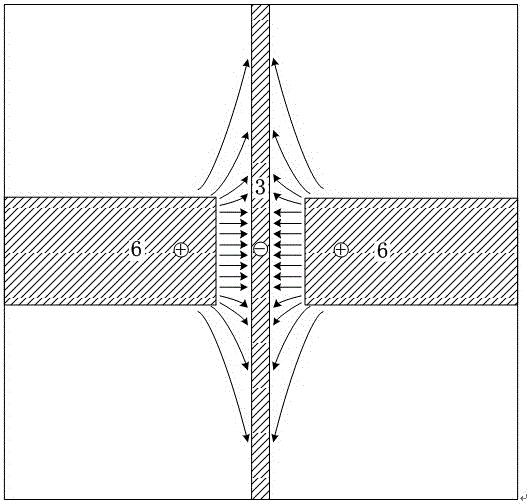

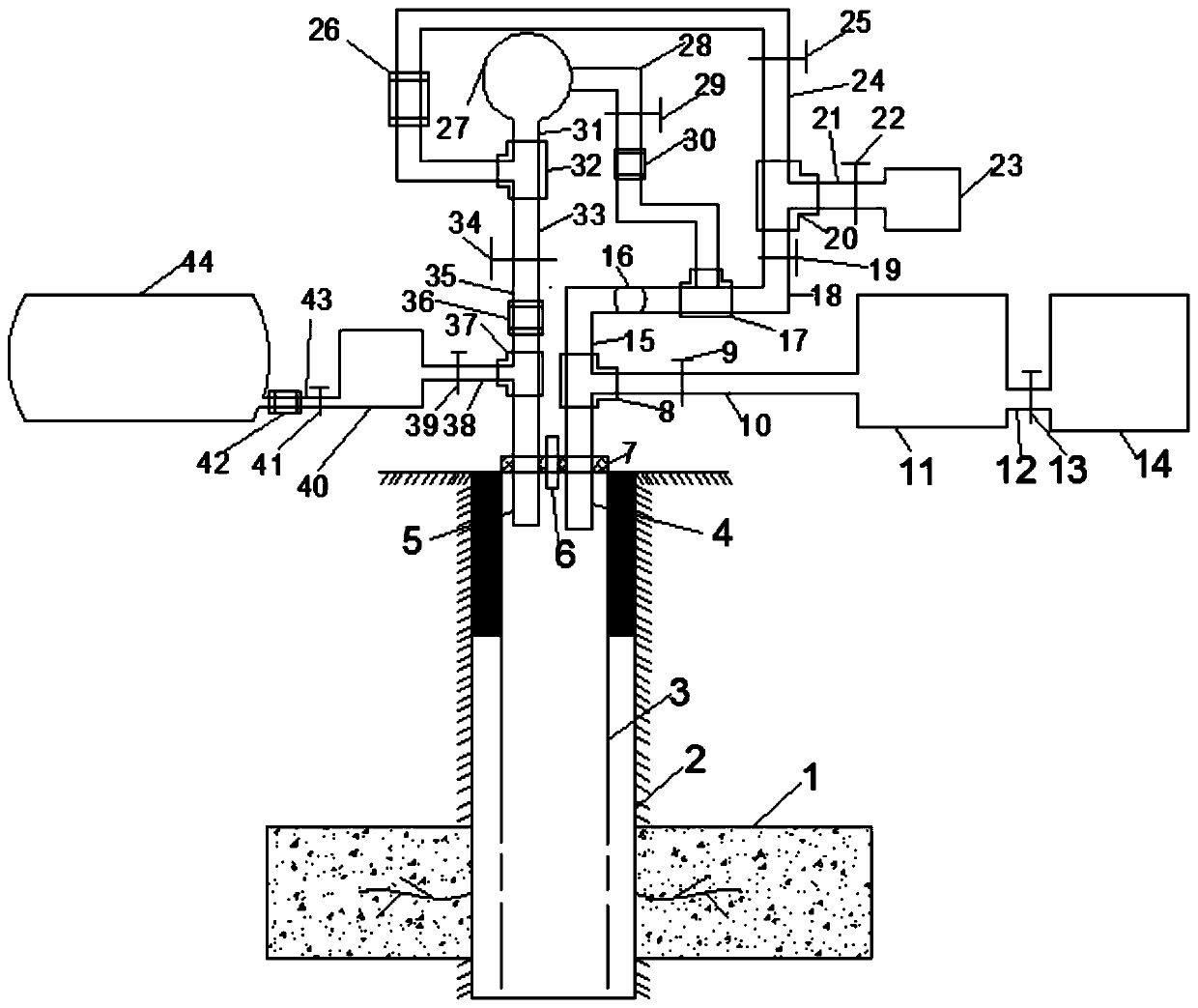

Follow-up auxiliary anode electrolytic wire cut machining system and method

ActiveCN106041235AInhibition of stray corrosion phenomenaQuality improvementElectric circuitsElectrical-based auxillary apparatusElectrolysisElectronic load

The invention relates to a follow-up auxiliary anode electrolytic wire cut machining system and a method and belongs to the technical field of electrolytic machining. The follow-up auxiliary anode electrolytic wire cut machining system comprises a workpiece anode (6), auxiliary anodes (5), an electronic load (8), tool wire electrodes (3) and a machining power supply (7), wherein the auxiliary anodes (5) are fixed relative to and follow the tool wire electrodes (3); the positive pole of the machining power supply (7) is connected with one end of each auxiliary anode (5) and one end of the electronic load (8), and the negative pole of the machining power supply (7) is connected with the tool wire electrodes (3); and the other end of the electronic load (8) is connected with the workpiece anode (6). During machining, the potentials of the auxiliary anodes are higher than that of a workpiece. In the non-machining areas of the upper surface and the lower surface of the workpiece, most of potentials of the tool wire electrodes are attracted by the auxiliary anodes, so that stray corrosion in the non-machining areas of the upper surface and the lower surface of the anode of the workpiece are inhibited.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

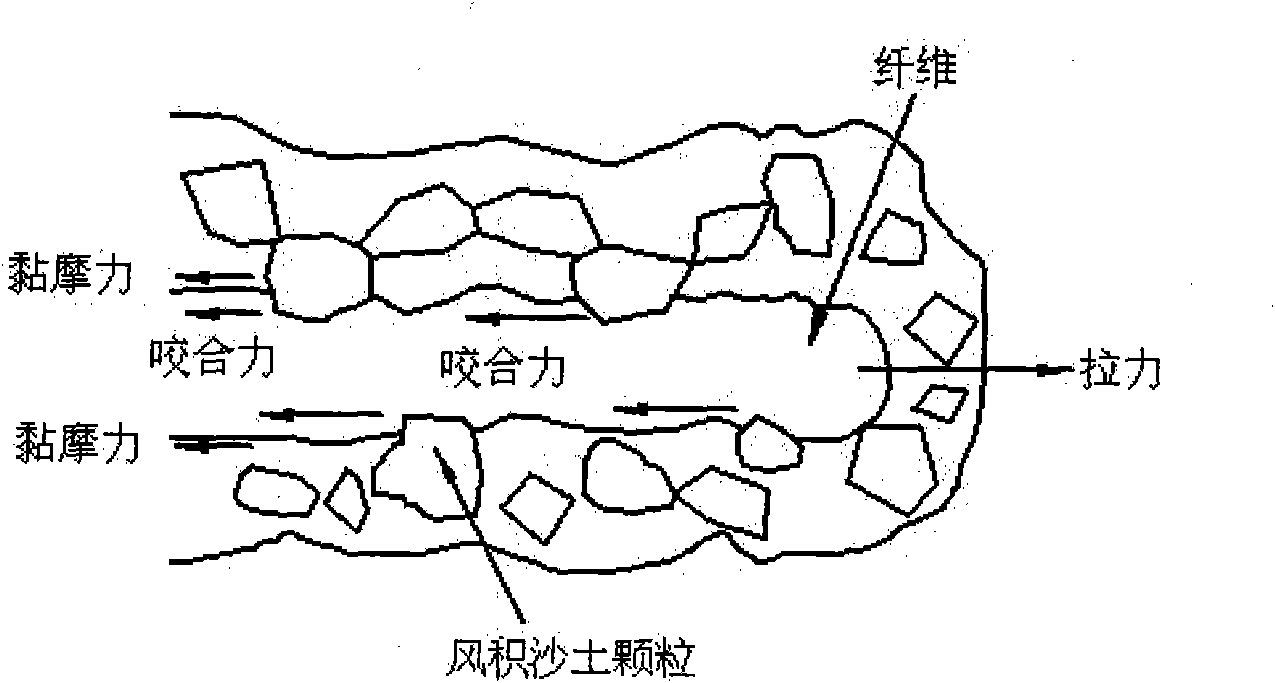

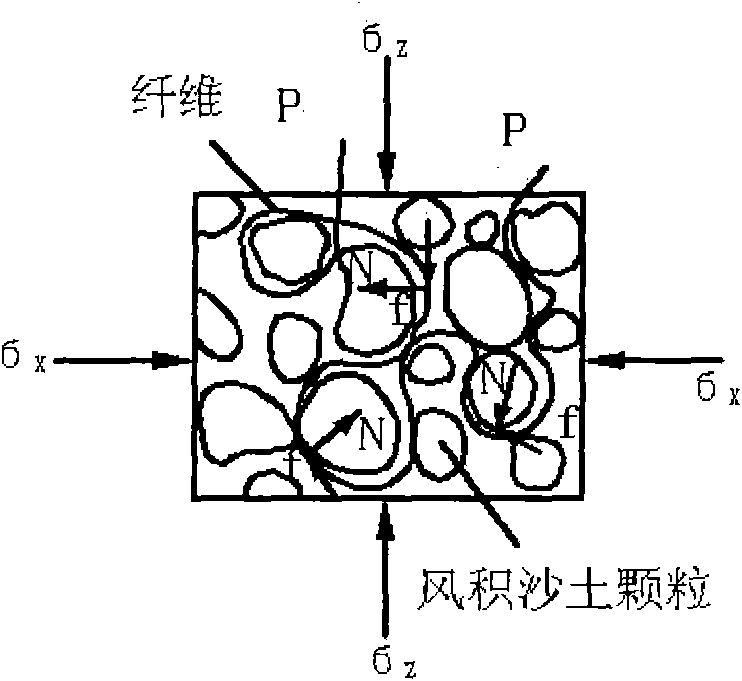

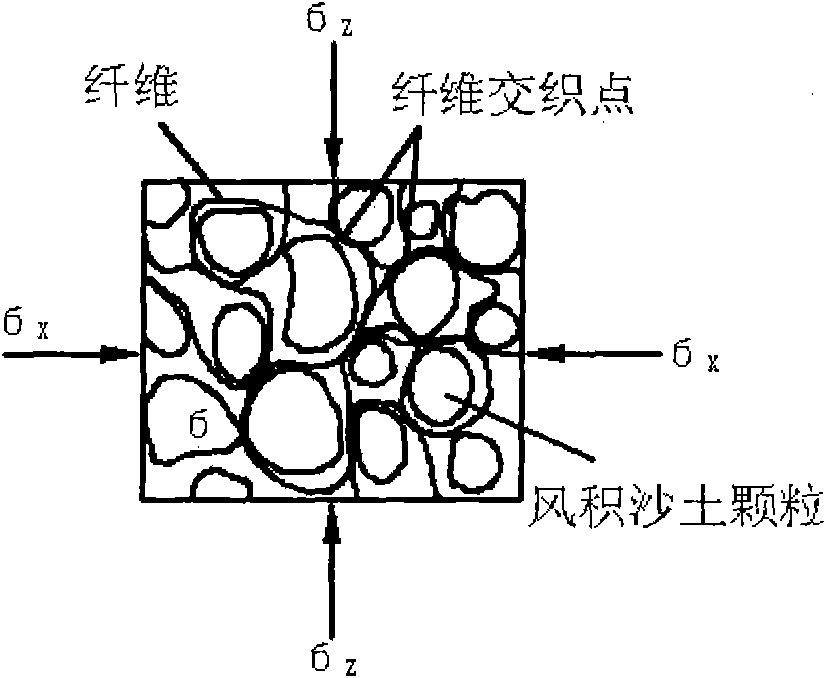

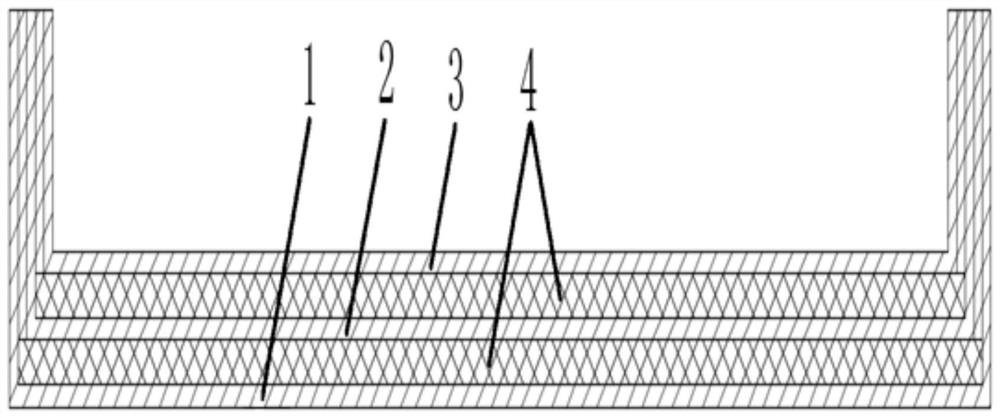

Method for reinforcing aeolian sandy soil by polypropylene fibers

The invention discloses a method for reinforcing aeolian sandy soil by polypropylene fibers. The method comprises the following steps: selecting materials for preparing fiber aeolian sandy soil, wherein the length of the polypropylene fiber is 18mm, the mix ratio of the fiber is 0.3 percent, and the aeolian sandy soil materials are air-dried aeolian sand or aeolian sandy soil (the moisture content accounts for 11.2wt%); according to the proportioning scheme, closely and completely mixing fine TEXSOL with aeolian sandy soil particles by way of spraying, so that a composite three-dimensional spatial structure is formed by the TEXSOL and the aeolian sandy soil; and carrying out mechanical compaction on the composite fiber aeolian sandy soil subjected to spraying, wherein the compaction method and standard of the composite fiber aeolian sandy soil are same as those of common soil, so that the compaction density of the aeolian sandy soil reaches 100 percent of the standard compaction density, and the fiber aeolian sandy soil is compacted closely. By utilizing the method in earth-filled dams, retaining walls and the drainage works of the earth-filled dams, the water stability of the interior of the soil body can be effectively improved, the shearing strength and tensile strength of the soil body can be obviously improved, and the construction process is simple; and because the fiber content of the fiber aeolian sandy soil is very low, the method has the advantages of cheapness and environmental protection.

Owner:HARBIN INST OF TECH

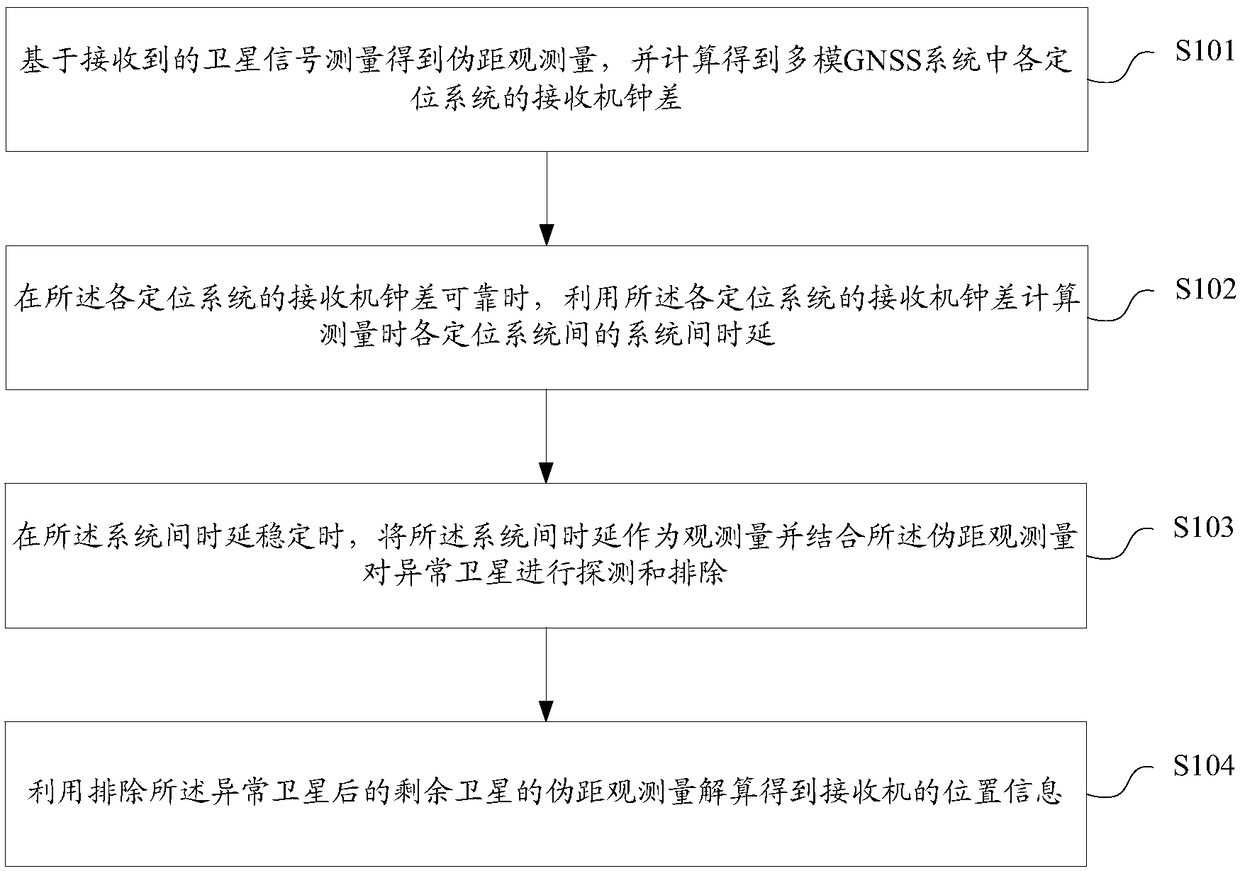

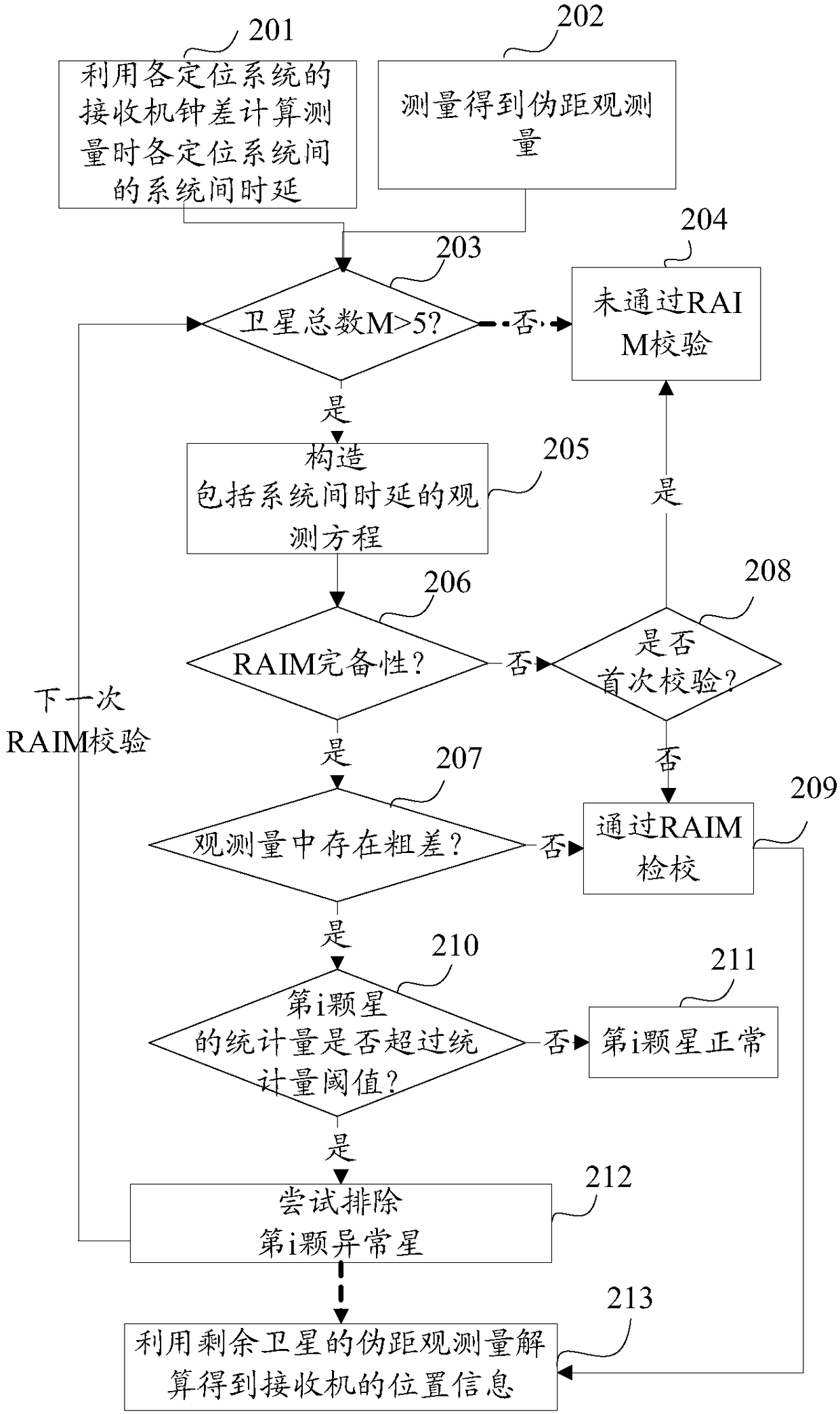

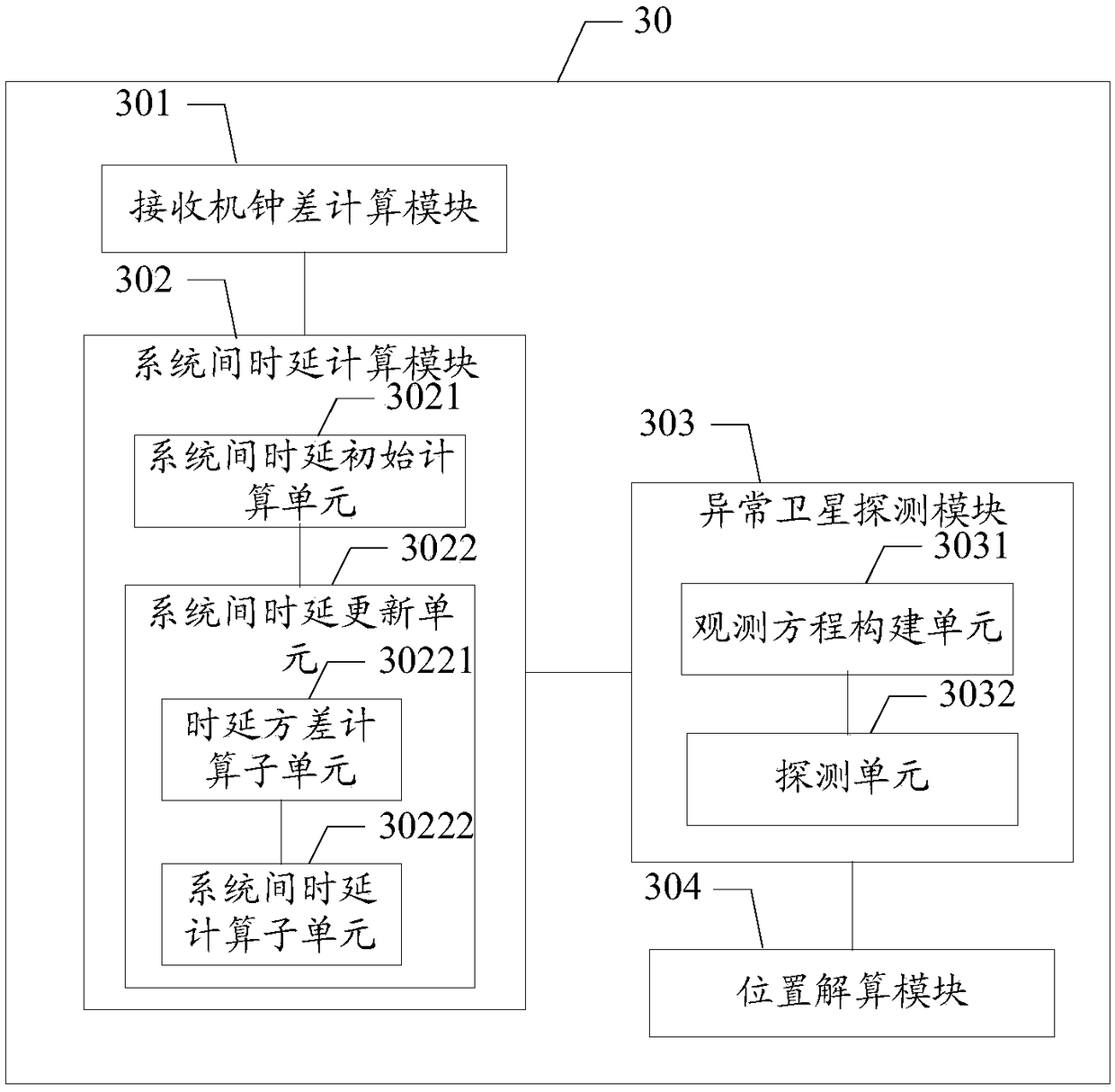

Positioning method and device of multimode GNSS system, storage medium and receiver

ActiveCN109085619AImprove stabilityGuaranteed detectionSatellite radio beaconingSystem timePositioning system

The invention discloses a positioning method and a device of a multimode GNSS system, a storage medium and a receiver. The positioning method comprises the following steps: measuring a pseudo-range observation quantity based on the received satellite signal, and calculating a receiver clock difference of each positioning system in the multimode GNSS system; using the receiver clock difference of each positioning system to calculate the inter-system time delay between each positioning system during the measurement when the receiver clock difference of each positioning system is reliable; usingthe inter-system time delay as an observation quantity and combining the pseudo-range observation quantity to detect and exclude the abnormal satellite when the inter-system time delay is stable; andusing the pseudo-range observation quantity of the remaining satellites after excluding the abnormal satellite to obtain the position information of the receiver . According to the positioning methodof the multimode GNSS system, the positioning accuracy of the receiver can be improved in a severe environment.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

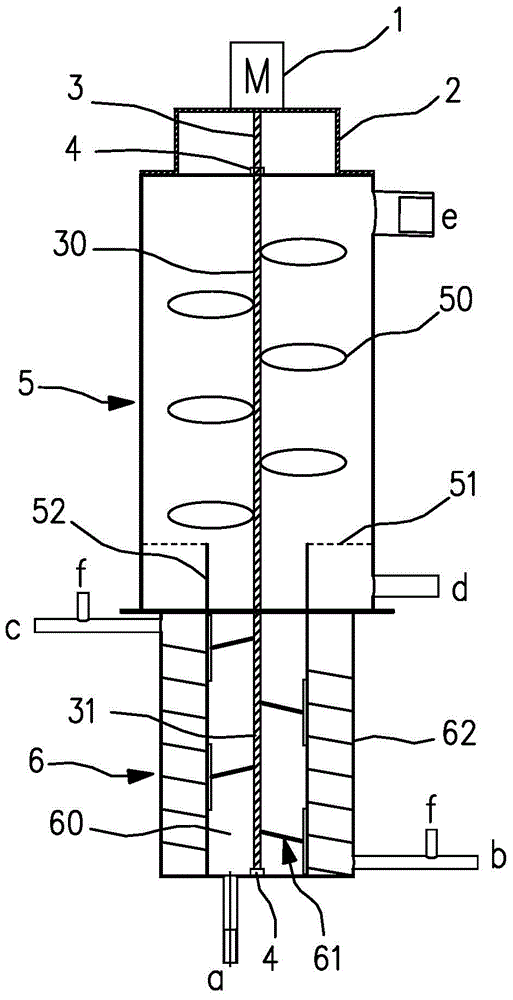

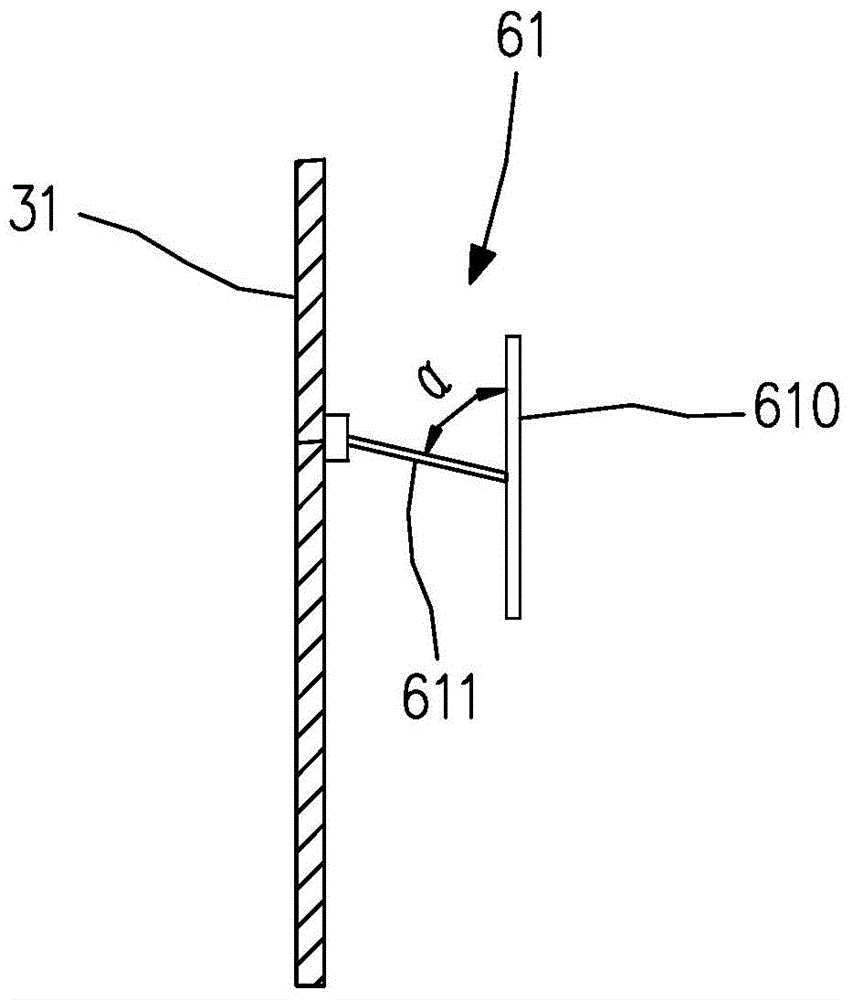

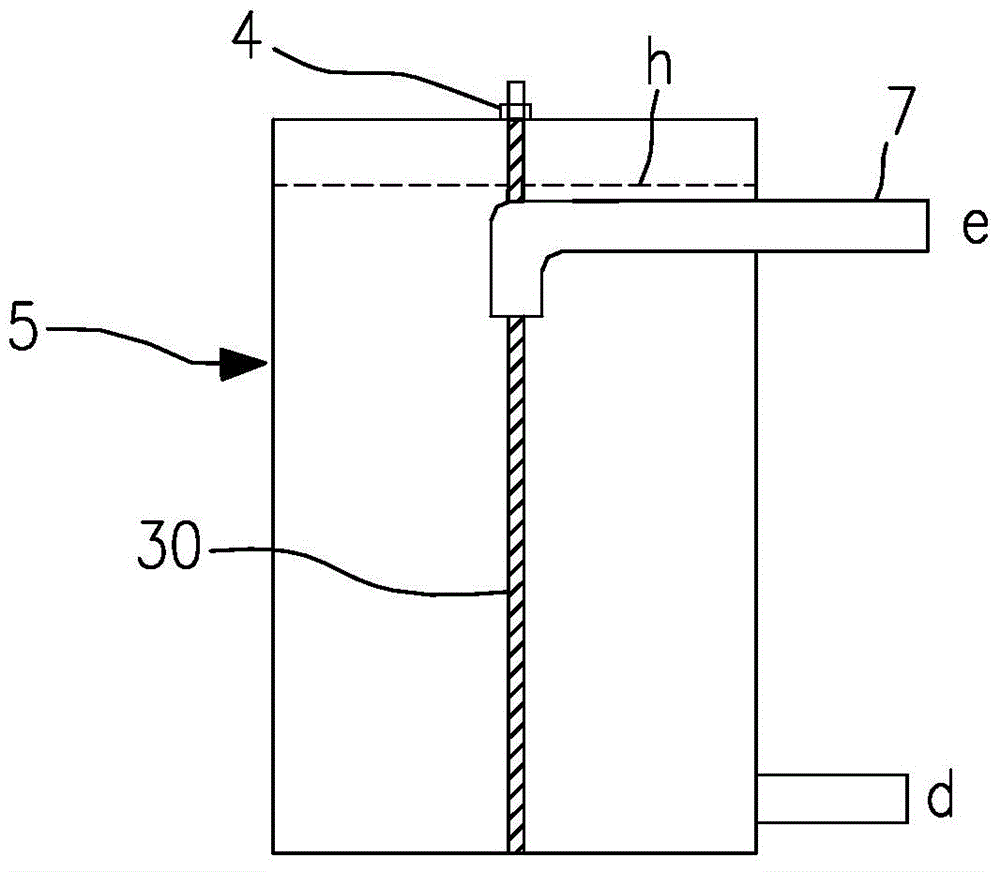

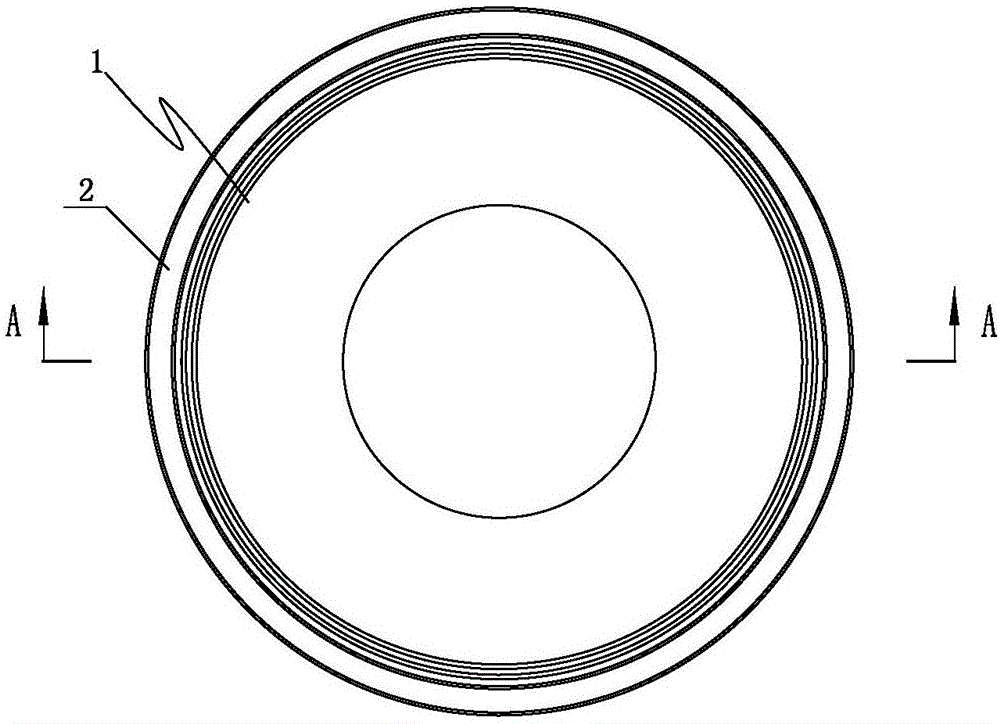

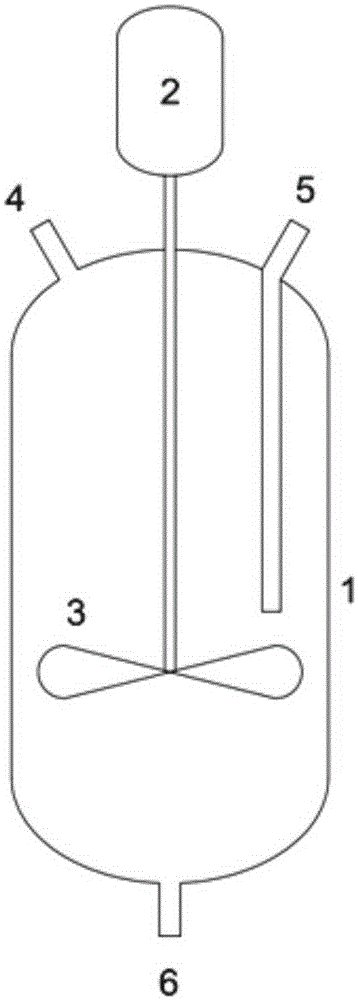

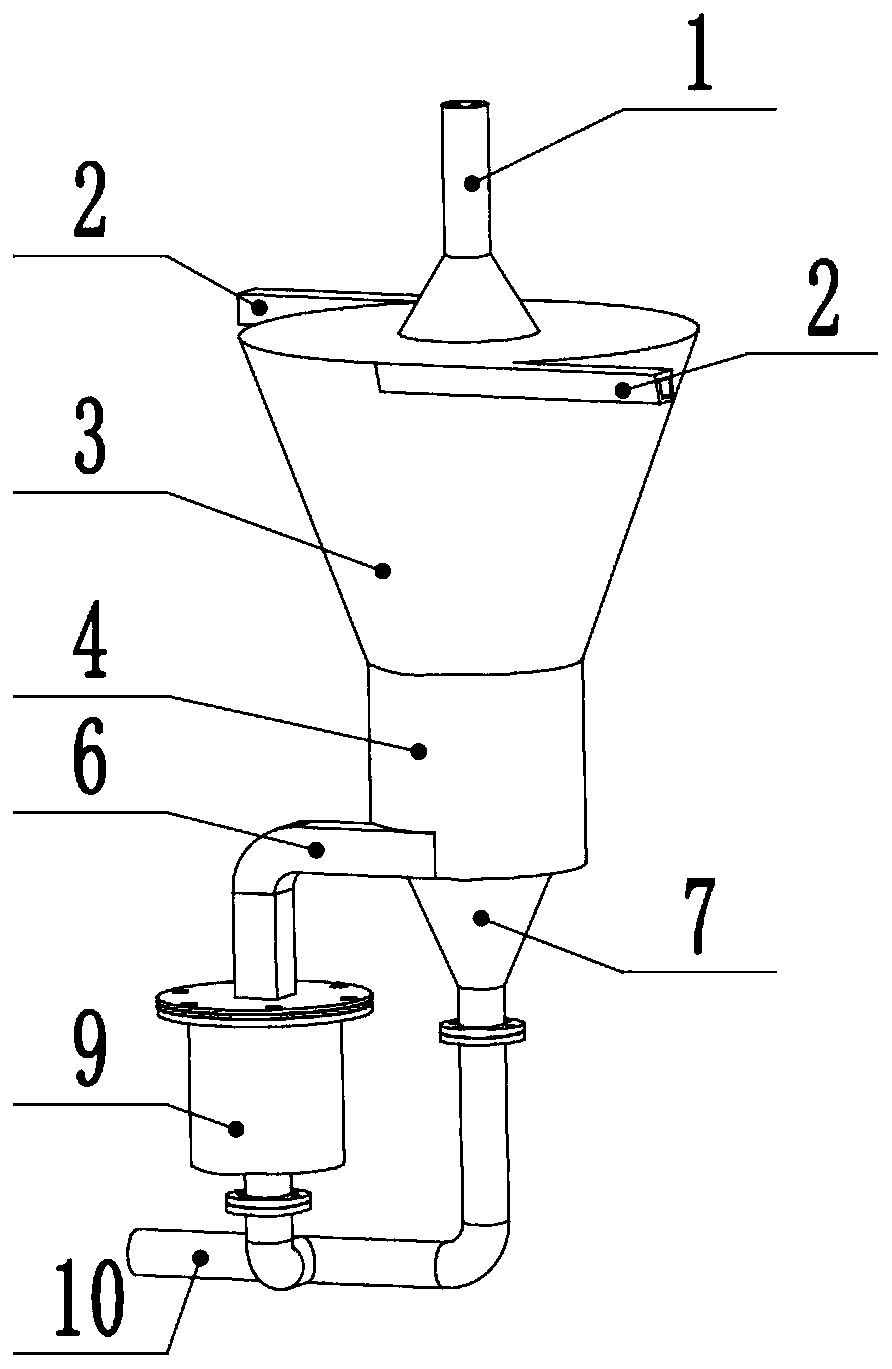

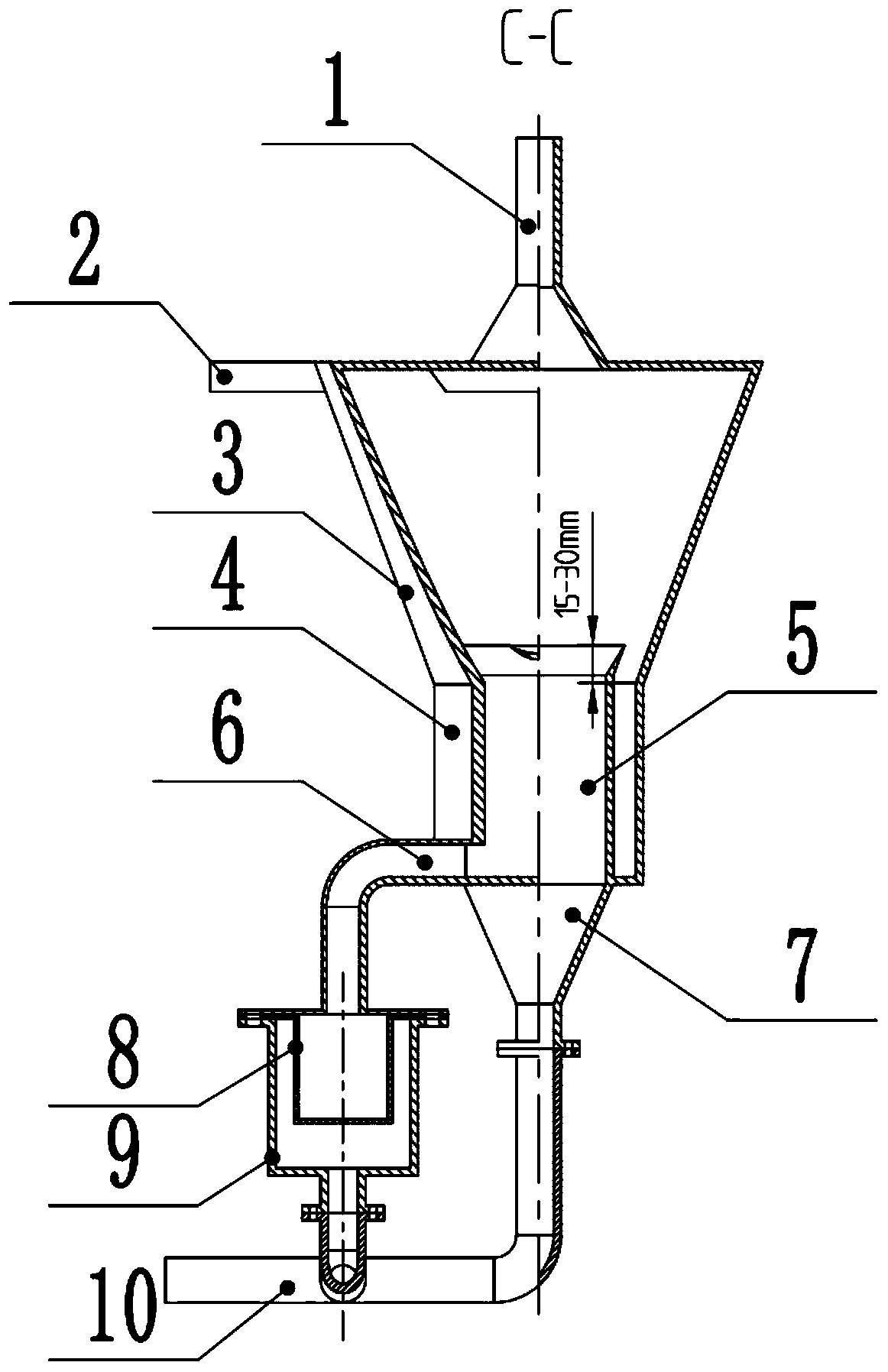

Crystal growth tank used for freezing and concentration

ActiveCN104689596ASmooth dischargeAvoid energy consumptionSolution crystallizationWhole bodyEngineering

The invention relates to a crystal growth tank used for freezing and concentration. The crystal growth tank comprises a barrel-shaped crystal tank body and a growth tank body, wherein a feeding hole is formed in the bottom of the crystal tank body; a cold medium water inlet located at the bottom end of the crystal tank body and a cold medium water outlet located at the top end of the crystal tank body are formed in the two symmetrical side edges of the crystal tank body; the crystal tank body is located on the lower side of the growth tank body, and the crystal tank body and the growth tank body are connected to form a communicated whole body, and a rotary shaft penetrates through the centers of the crystal tank body and the growth tank body; and the rotary shaft is rotationally and fixedly sealed between the top of the growth tank body and the bottom of the crystal tank body through sealing bearings at the two ends. A rotary shaft section in a material barrel of the crystal tank body, namely a scraping knife shaft, is movably connected with mutually-staggered scraping knives; a rotary shaft section in the growth tank body, namely a stirring shaft, is fixedly provided with hollow annular stirrers which are uniformly distributed; and the part, which is close to the center of the top, of the growth tank body is further provided with an ice discharging hole in a manner of extending out of the tank. The crystal growth tank is simple in structure, low in energy consumption and stable to operate, and can effectively guarantee the concentration effect.

Owner:HEFEI GENERAL MACHINERY RES INST

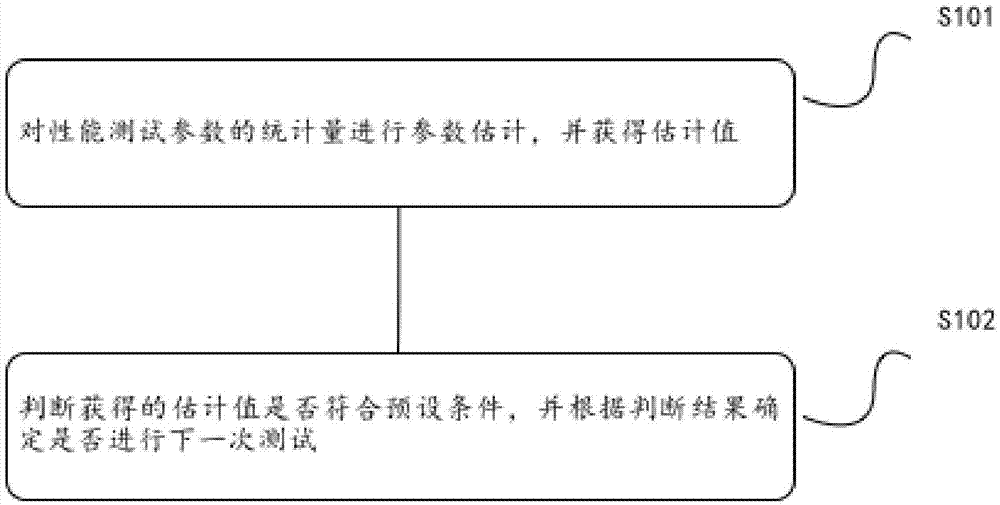

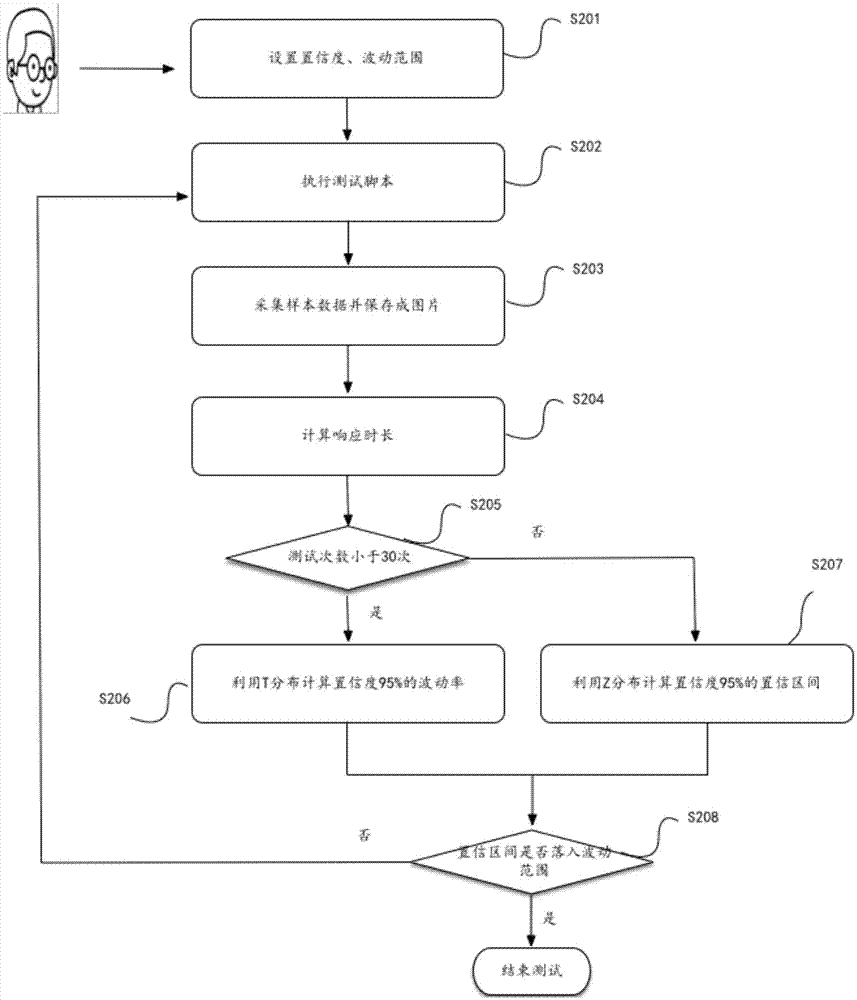

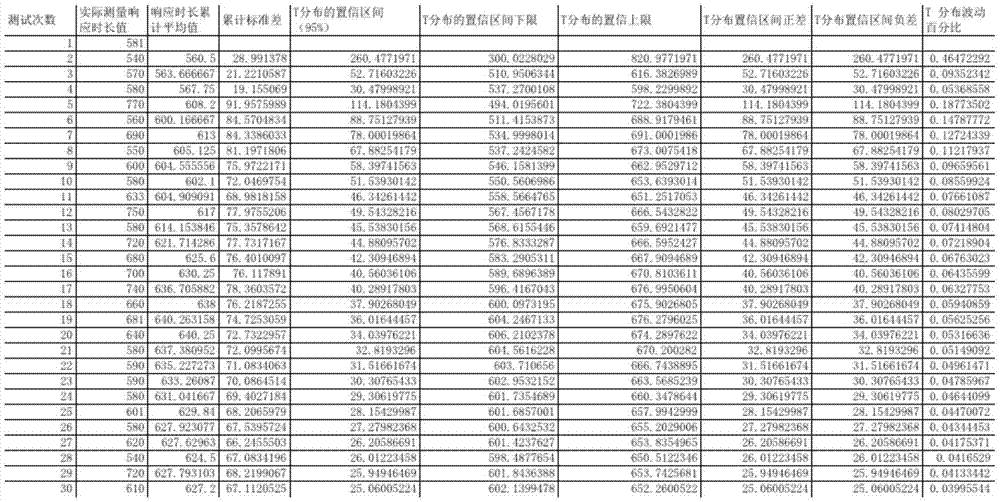

Performance testing method and device

InactiveCN106908258AGuarantee exclusionReduce testing costsStructural/machines measurementTest efficiencyReal-time computing

The application discloses a performance testing method and device. The method comprises the following steps: conducting parameter estimation of statistics of performance testing parameters, and obtaining an estimated value; and determining whether the obtained estimated value accords with a preset condition, and determining whether the next test is conducted on the basis of a determination result, wherein the preset condition is set on the basis of the preset fluctuation range of the performance testing parameters. The testing efficiency is increased.

Owner:ALIBABA GRP HLDG LTD

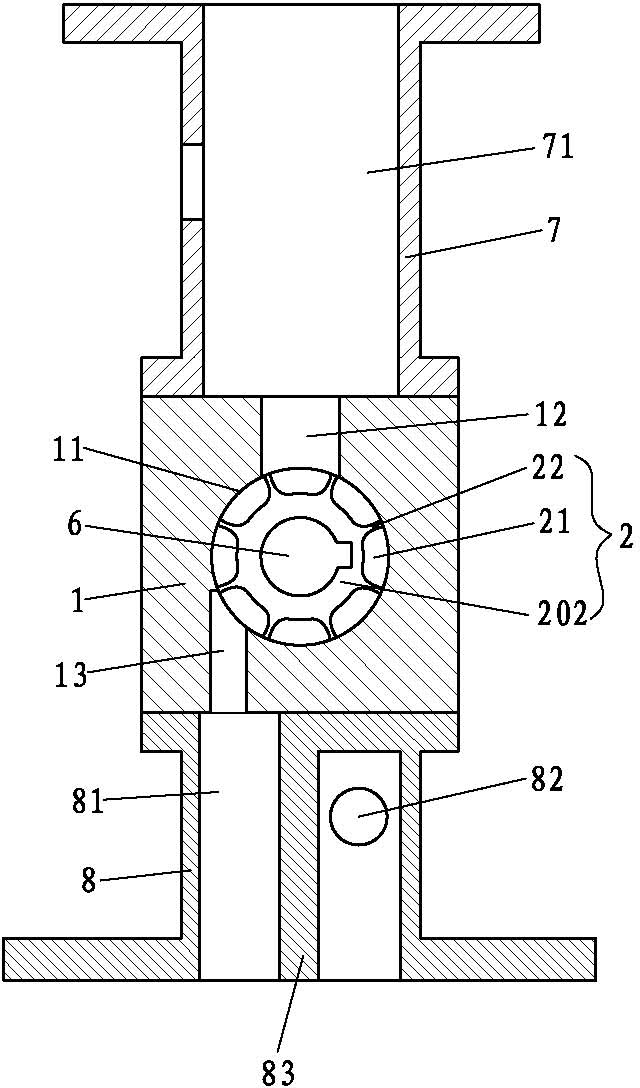

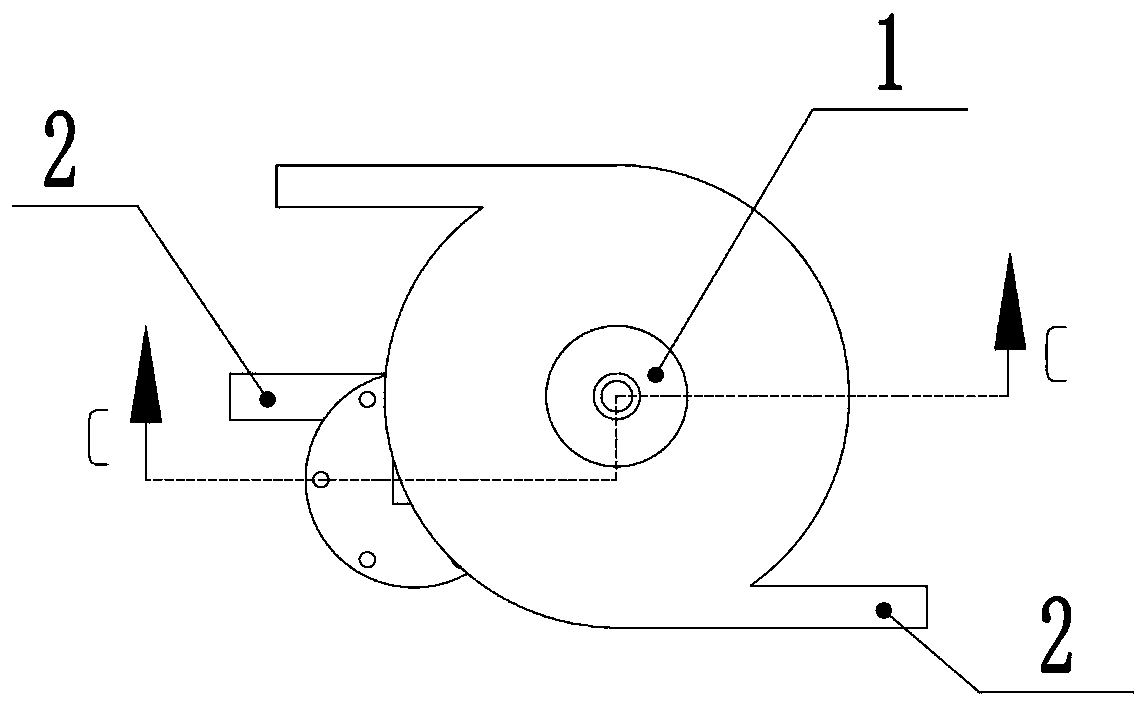

Automatic metering structure and automatic feeding device

ActiveCN102602671AGuaranteed feeding speedGuaranteed measurement accuracyRotary conveyorsMechanical engineeringControl engineering

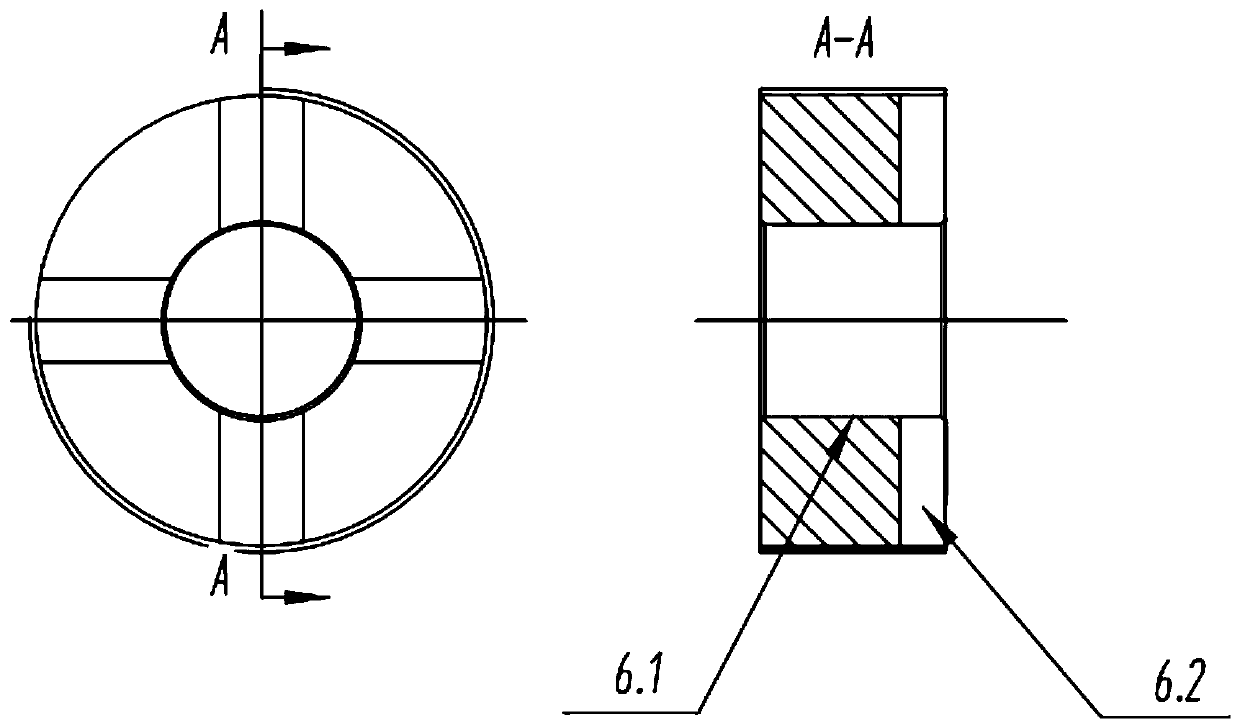

The invention discloses an automatic metering structure comprising a shell and a rotor; a rotor drum, and a feed opening and a discharge opening communicated with the rotor drum are formed on the shell; the rotor is inserted in the rotor drum, the rotor and the rotor drum are in sealed fit, a metering groove corresponding to the feed opening and the discharge opening is formed on the outer wall of the rotor, and the rotor is connected with a motor and is driven by the motor to rotate in the rotor drum to realize automatic and precise metering. The invention further discloses an automatic feeding device comprising an upper connecting seat, a lower connecting seat and the automatic metering structure; the upper connecting seat is installed above the shell, and a feed opening formed on the upper connecting seat is communicated with the feed opening of the shell; the lower connecting seat is installed between the lower side of the shell and a cabinet, a blanking opening formed on the lower connecting seat is communicated with the discharge opening of the shell and the cabinet, an extract opening further formed on the lower connecting seat is communicated with the cabinet, and a baffle is arranged between the blanking opening and the extract opening to realize automatic feeding, guarantee the blanking speed and improve the quality and the yield of the product.

Owner:XIAMEN BANGZHONG TECH

A horizontal and vertical deformation combined testing method for deep-layer rock bodies or soil bodies

ActiveCN106918322AGood free slidingGuarantee exclusionEarth material testingHeight/levelling measurementRing deviceDeformation monitoring

A horizontal and vertical deformation combined testing method for deep-layer rock bodies or soil bodies is disclosed. The method includes drilling a testing hole, mounting a horizontal and vertical displacement combined testing device for the deep-layer rock bodies or soil bodies, backfilling and protecting the testing hole, and performing measurement with instruments. The combined testing hole is utilized in the method, and therefore half of the testing cost is saved, and a horizontal and vertical three-dimensional deformation at a point of a rock body or a soil body can be obtained. In addition, a novel vertical settlement magnetic ring device and a backfilling method can greatly increase the testing precision. The method can meet safety monitoring projects requiring high precision, such as deformation monitoring of tunnels, high slopes, deep foundation pits and dam bodies.

Owner:CENT SOUTH UNIV

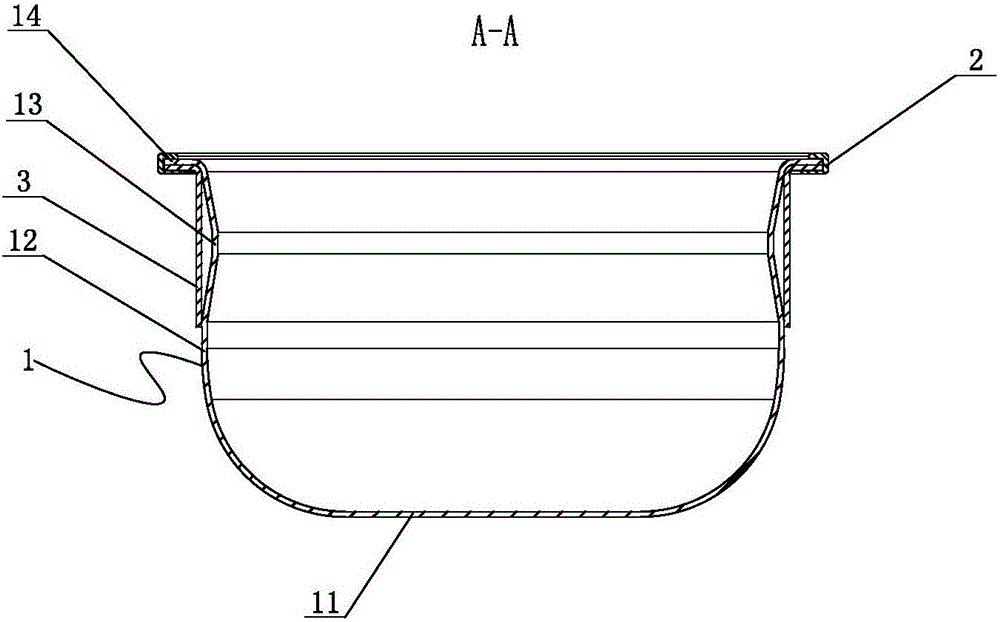

Vacuum non-stick pan and production method thereof

InactiveCN106820938ANot easy to loseTo achieve the effect of dullnessCooking-vessel materialsCooking vessel constructionsEngineeringInsulation layer

Owner:宁波华宝食为天电器科技有限公司

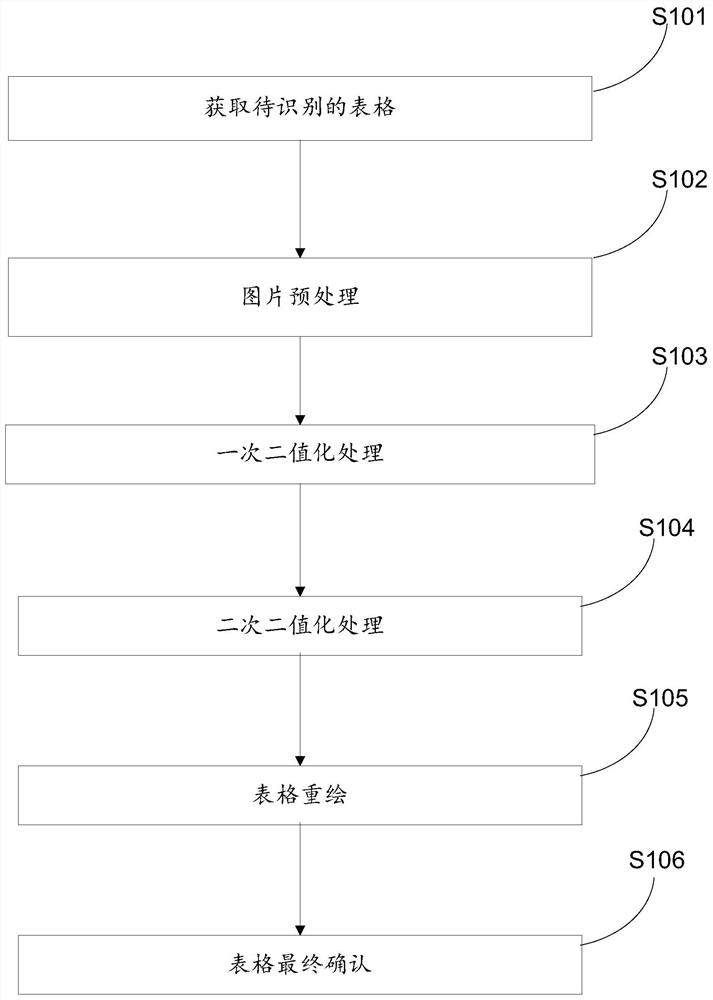

Positioning segmentation method and device for graphic table

ActiveCN111611783AImprove accuracyImprove recognition accuracyImage enhancementImage analysisGraphicsComputer graphics (images)

The invention discloses a positioning segmentation method and device for a graphic table. The method comprises the steps of performing binarization processing on the graphic table to obtain a first graph; performing morphological corrosion expansion on the first graph, and determining table composition lines in the first graph to obtain a first table; performing Gaussian blur and binarization processing on the first table to obtain a second graph; and performing morphological corrosion expansion on the second graph, and determining a table composition line segmentation graph table based on thesecond graph. According to the invention, two times of binarization processing and two times of morphological corrosion expansion are adopted, and composition lines of the graphic table are effectively processed; the first binarization is that the picture becomes black and white, a target area and a background area can be separated, interference is reduced, and subsequent processing is facilitated; the second binarization is that a table line can be thickened and dotted lines, fine lines and broken lines can be complemented after the second binarization and expansion; and the table area blockpositioning accuracy is improved.

Owner:山东旗帜信息有限公司

Preparation method of EVA elastomer

The invention discloses a preparation method of an EVA elastomer. In a single polymerization kettle, ethylene and vinyl acetate carry out free radical copolymerization in a solvent in the presence of an initiator; the free radical copolymerization comprises a pre-polymerization phase, a chain propagation phase, and a chain termination phase; and the controlled pre-polymerization phase, the chain propagation phase, and the chain termination phase are performed at different temperatures to prepare the EVA elastomer. According to the method, the controlled pre-polymerization phase, the chain propagation phase, and the chain termination phase are performed at different temperatures, thus the chance of implosion is largely reduced; the temperature runaway of polymerization and initiator loss caused by once heating are relieved, the reactions of polymerization monomers carry out completely, higher monomer conversion rate and copolymerization yield can be obtained; the copolymerization speed is guaranteed, at the same time, the solid content of products is increased, and the VAc content of polymerization products is adjusted to produce EVA elastomer products for satisfying different needs.

Owner:CHINA PETROLEUM & CHEM CORP +1

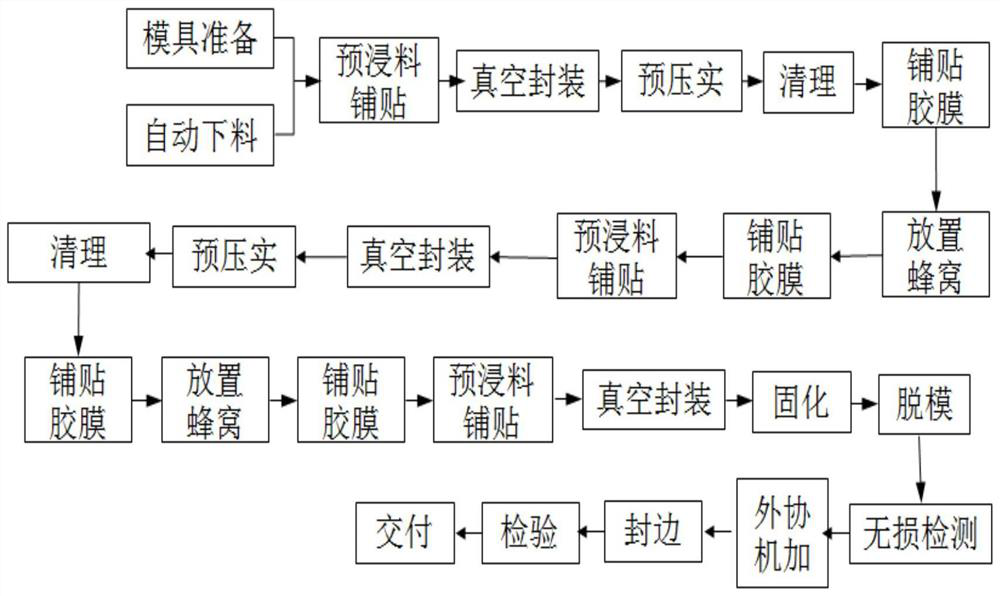

Method for integrally forming C sandwich panel antenna housing

The invention discloses a method for integrally forming C sandwich panel antenna housing. The method comprises the following steps: (1), preparing prepregs; (2), carrying out die pretreatment; (3), laying and pasting an outer skin; (4), laying and pasting honeycombs and a middle skin; (5), laying and pasting honeycombs and an inner skin; (6), curing; (7), demolding; and (8), machining and formingholes. According to the method for integrally forming the C sandwich panel antenna housing is simple; mixed materials with glass fibers or quartz fibers and epoxy resin or cyanic acid resin or bismaleimide resin are used as prepregs; aramid paper honeycombs and same-system adhesive films are used as main raw materials; a pre-compaction step is added after the skins are laid and pasted; bubbles among the prepregs are completely eliminated; meanwhile, resin fusion is more sufficient; curing is carried out after three layers of skins and two layers of honeycombs are laid and pasted; the thermal expansion coefficients of the prepregs are consistent; the stress in the curing process is small; the planeness of the panel antenna housing can be guaranteed; the method has few operation steps; the usage of autoclaves can be reduced; the energy consumption is reduced; and the production cost is reduced.

Owner:JIANGSU XINYANG NEW MATERIALS CO LTD

Device for treating and reusing household sewage

ActiveCN108149756AGuarantee exclusionImprove convenienceFatty/oily/floating substances removal devicesSpecific water treatment objectivesWater storageWastewater

The invention provides a device for treating and reusing household sewage and belongs to the field of household environment protection tools. The device comprises a water inlet structure, a box body,a coarse impurity filtering box, graded filtering boxes, a liquid level sensor, a small water pump and graded filtering screens, wherein the water inlet structure is located at the upper side of a coarse impurity filtering box groove of the box body; the coarse impurity filtering box is mounted in the coarse impurity filtering box groove of the box body; the graded filtering boxes are mounted in graded filtering box grooves; graded filtering screens are mounted in graded filtering screen grooves; the liquid level sensor is mounted at the upper middle part of a water storage box of the box body; the small water pump is connected with the bottom of the water storage box at a 3 / 4 position of the height of water storage volume; the other end of the small water pump is connected with a flush toilet. The device is capable of achieving secondary utilization of the household sewage on the basis that the convenience and the environmental friendliness are ensured.

Owner:睿得水资源科技开发有限公司

SiC/epoxy resin composite material and method for manufacturing pump components with it

ActiveCN102408677BImproved erosion and wear resistanceClosely arrangedPump componentsPumpsEpoxyEpoxy resin composite

The invention discloses a SiC / epoxy epoxy resin composite material, wherein raw material components based on weight percentages are as follows: 75-85 wt% of SiC particles, 15-25 wt% of organic component and coupling agent with a mass of 1.5-2.5% of the organic component; the particle size distributions of the SiC particles are as follows: 500-600 microns taking up 65-75 wt%, 100-150 microns taking up 2-30 wt% and 30-40 microns taking up 5-10wt%; the organic component is composed of epoxy resin and curing agent; the mass ratio of the epoxy resin to the curing agent is 3: 1. A preparation method for pump component with SiC / epoxy epoxy resin composite material, comprising the following steps: (1), heating and stirring in vacuum way; (2), pressure pouring; (3), vacuum vibrating and forming; (4), heating and curing. The invention is characterized by simple technology and low production cost. The prepared SiC / epoxy epoxy resin composite material pump component can resist abrasion and corrosion.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY

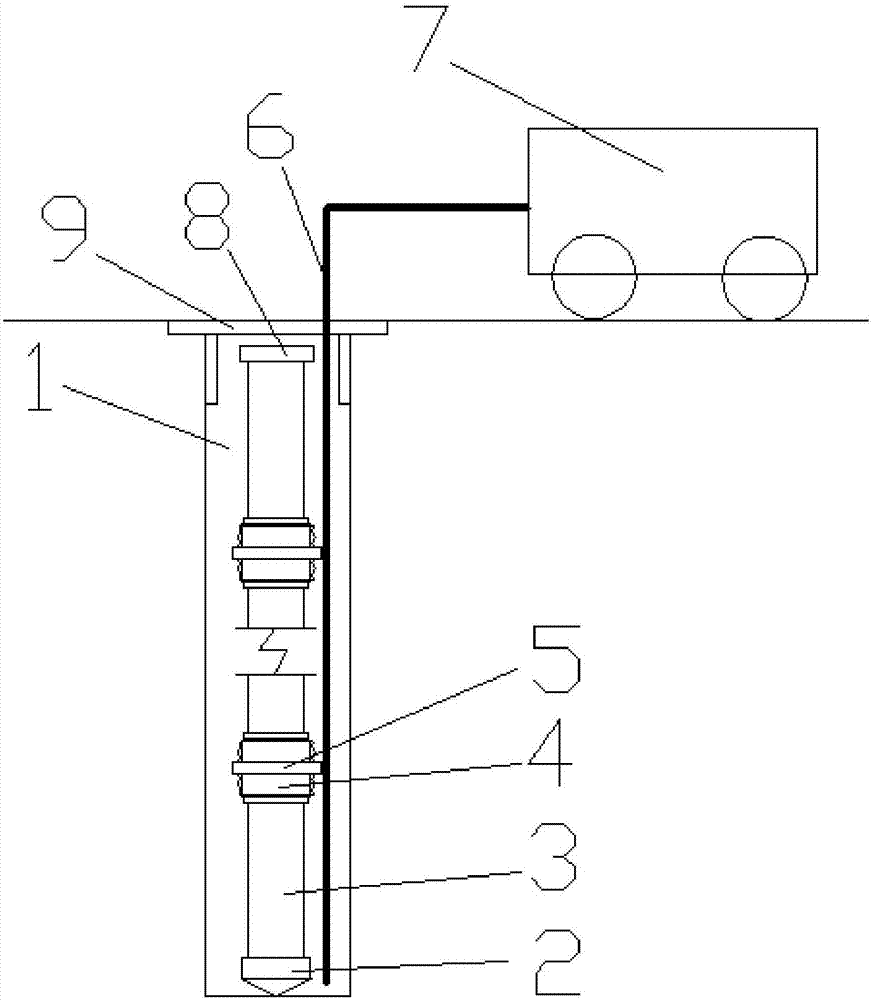

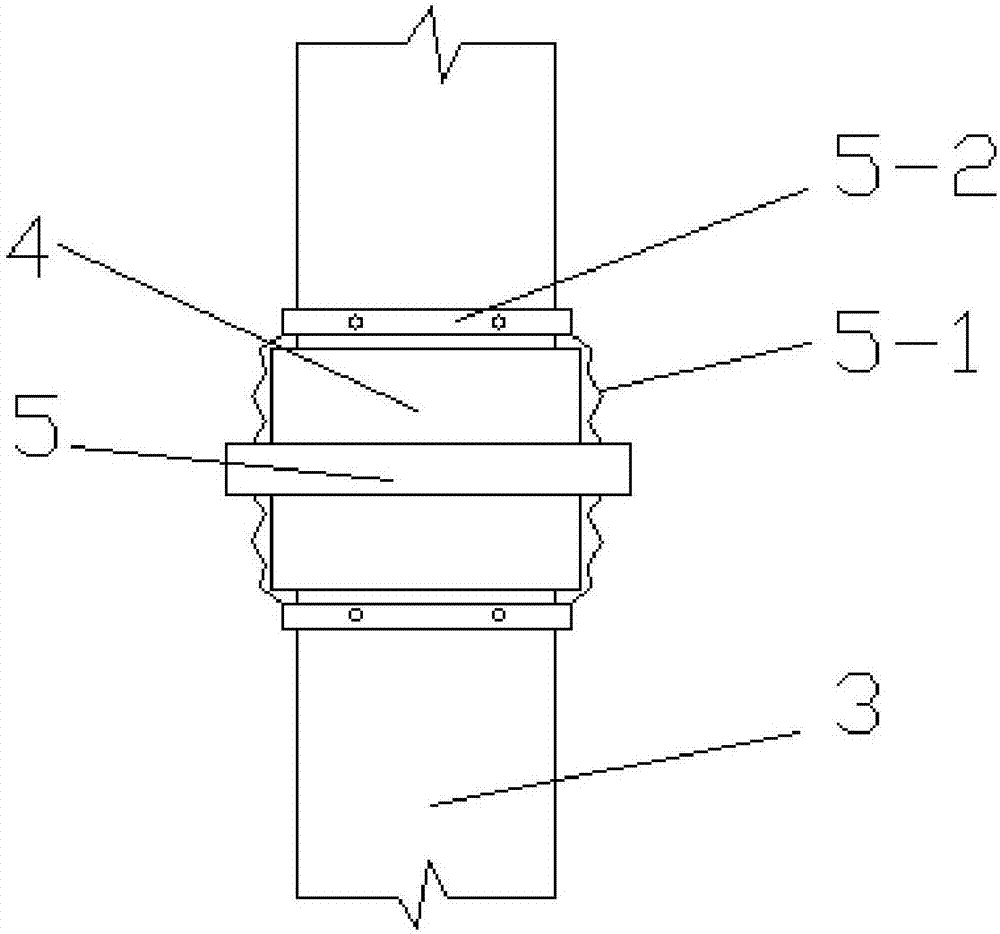

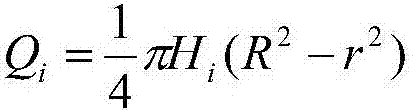

Method for enhancing shale gas exploitation through large-temperature-difference freeze-thaw cycle

ActiveCN109577939AImprove water absorptionGood cracking effectFluid removalHigh concentrationFreezing thawing

The invention discloses a method for enhancing shale gas exploitation through a large-temperature-difference freeze-thaw cycle. The method comprises the following steps of firstly, injecting magnetized water into a shale gas exploitation pipe of a shale gas well through pulsation; secondly, driving the magnetized water to move into shale as much as possible through high-pressure nitrogen, and thenconducting liquid-nitrogen freezing and high-temperature nitrogen melting on the magnetized water several times to fully utilize the permeability of the magnetized water, the driving property of thehigh-pressure nitrogen, the expansion force of the frozen magnetized water and an ultra-large-temperature-difference freeze-thaw cycle formed by the liquid nitrogen and the high-temperature nitrogen in order to cause complete cracking of the shale. Moreover, the high-temperature nitrogen can also provide energy for the shale gas to be separated from the shale, correspondingly the cracking effect of the shale can be effectively improved, the crack expansion range of the shale can be effectively expanded, and the shale permeability is increased, so that large-flow, high-concentration and long-time exploitation of the shale gas is improved.

Owner:XUZHOU UNIV OF TECH

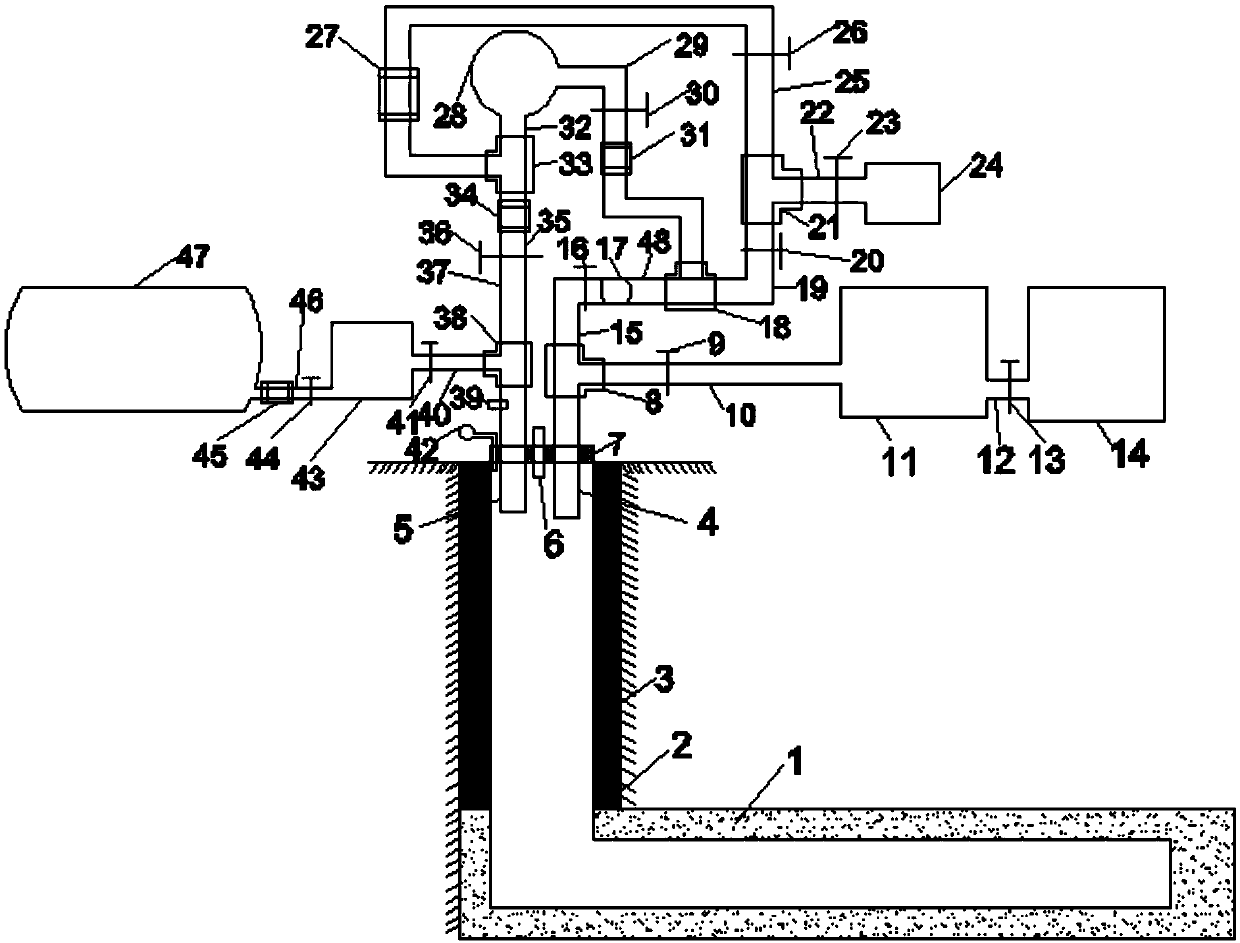

Split-flow filtration type gas-liquid-solid three-phase cyclone separation apparatus

ActiveCN110251998AGuarantee exclusionImprove cleanlinessLiquid degasificationCentrifugal force sediment separationCycloneFiltration

The invention discloses a split-flow filtration type gas-liquid-solid three-phase cyclone separation apparatus, and is applied in the field of hydraulic fluid cleaning. The apparatus comprises a swirling barrel, an exhaust pipe installed on the top of the barrel, inflow pipes tangential to the upper wall of the barrel, a split-flow baffle plate inside the barrel, a lateral outflow pipe tangential to the lower wall of the barrel, a filtering apparatus with a filtering net arranged inside the filtering apparatus, and connected with the lateral outflow pipe, a funnel-shaped vertical outflow port communicating with the inside of the split-flow baffle plate, and a confluence pipeline. The apparatus firstly uses swirling centrifugal force to realize boundary aggregation of contamination impurities and formation of a gas core center, then separation of boundary impurity oil is completed by the split-flow baffle plate, and at the same time a high-speed swirling state required for bubble elimination is maintained, so that oil filtration is completed, bubble elimination is ensured, and three-phase synchronous efficient separation is realized. At the same time, the boundary contamination oil after filtration participates in the system oil circulation, and thus stability of a system flow is ensured. The apparatus structure is simple, separation is efficient, the equipment manufacturing cost is low, and application ranges are wide.

Owner:YANSHAN UNIV

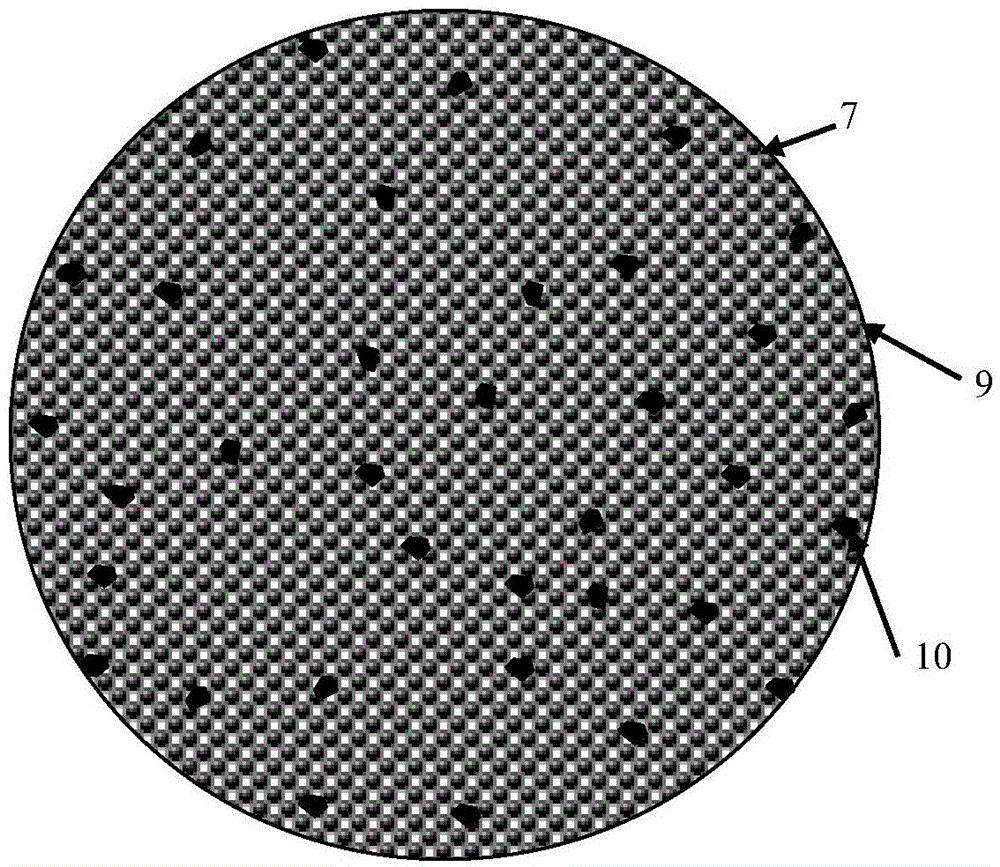

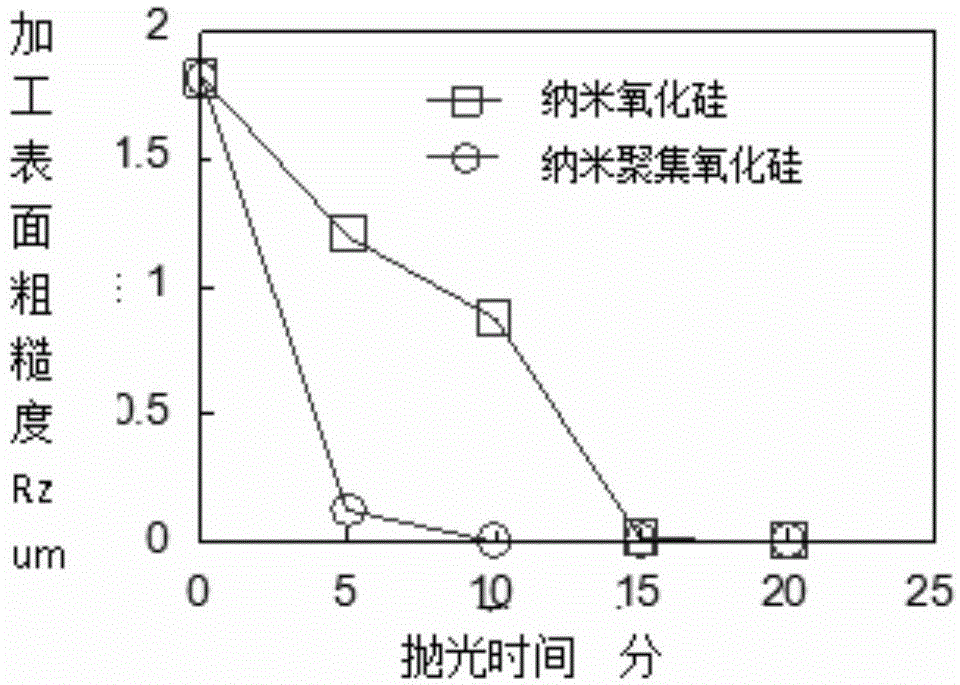

Fixed abrasive polishing cloth adopting nanometer aggregation structure adhesive

The invention relates to fixed abrasive polishing cloth adopting a nanometer aggregation structure adhesive. The fixed abrasive polishing cloth is characterized by consisting of a polishing cloth substrate and an abrasive uniformly distributed in the polishing cloth substrate, wherein the fixed abrasive is the nanometer aggregation structure adhesive; the nanometer aggregation structure adhesive is a micro-grade spherical abrasive formed by aggregating nanometer particles. The adopted nanometer aggregation structure adhesive is the micro-grade spherical abrasive formed by aggregating the nanometer particles, so that the nanometer particles can be prevented from easily falling into the polishing cloth substrate made of a sticky elastic material, and the machining effect is brought into full play while high surface smoothness is ensured.

Owner:TIANJIN VOCATIONAL INST

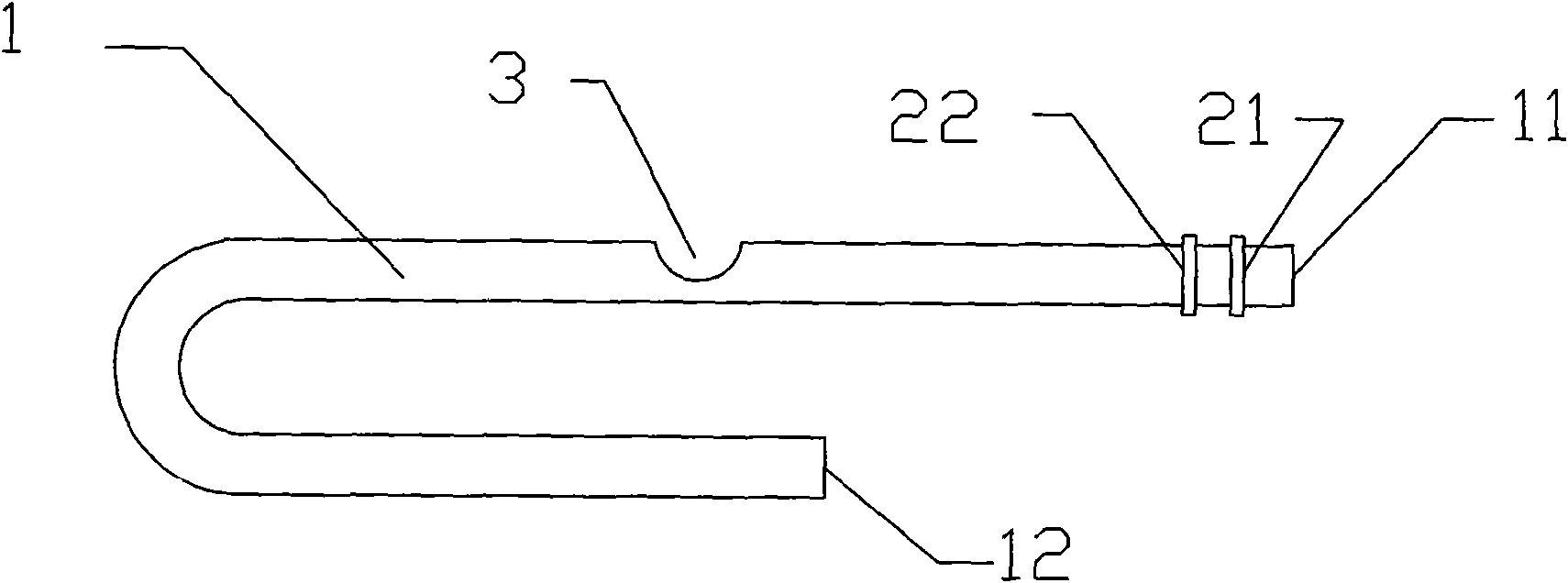

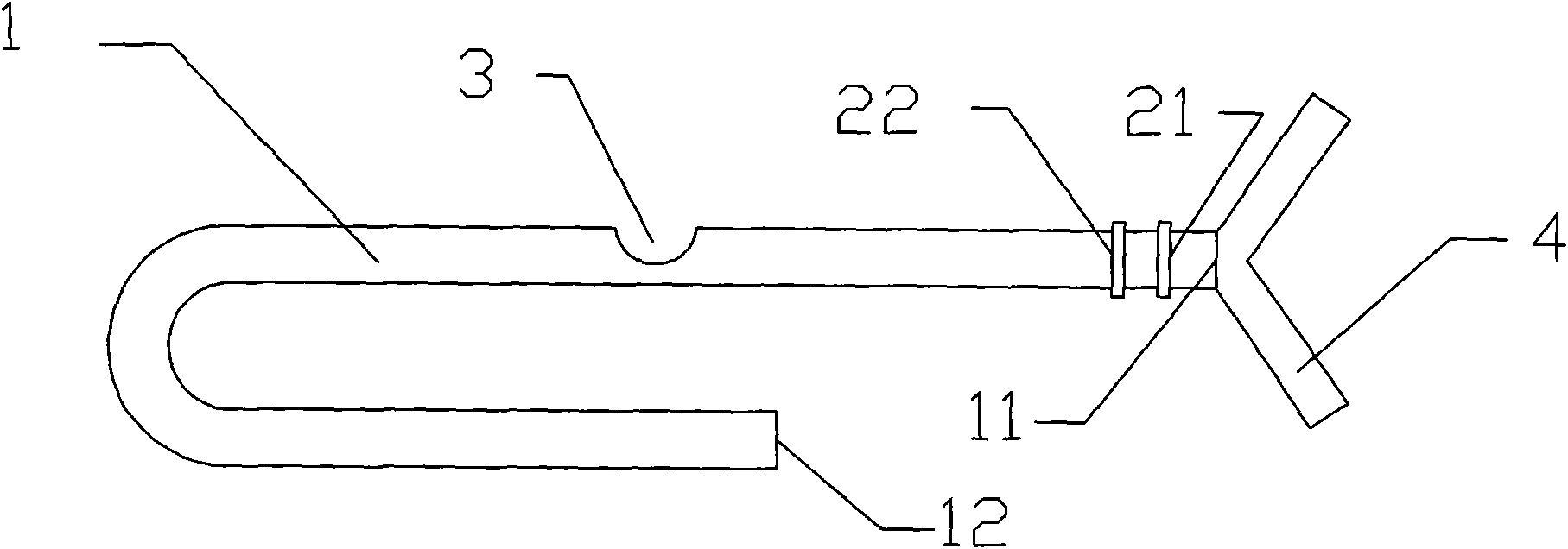

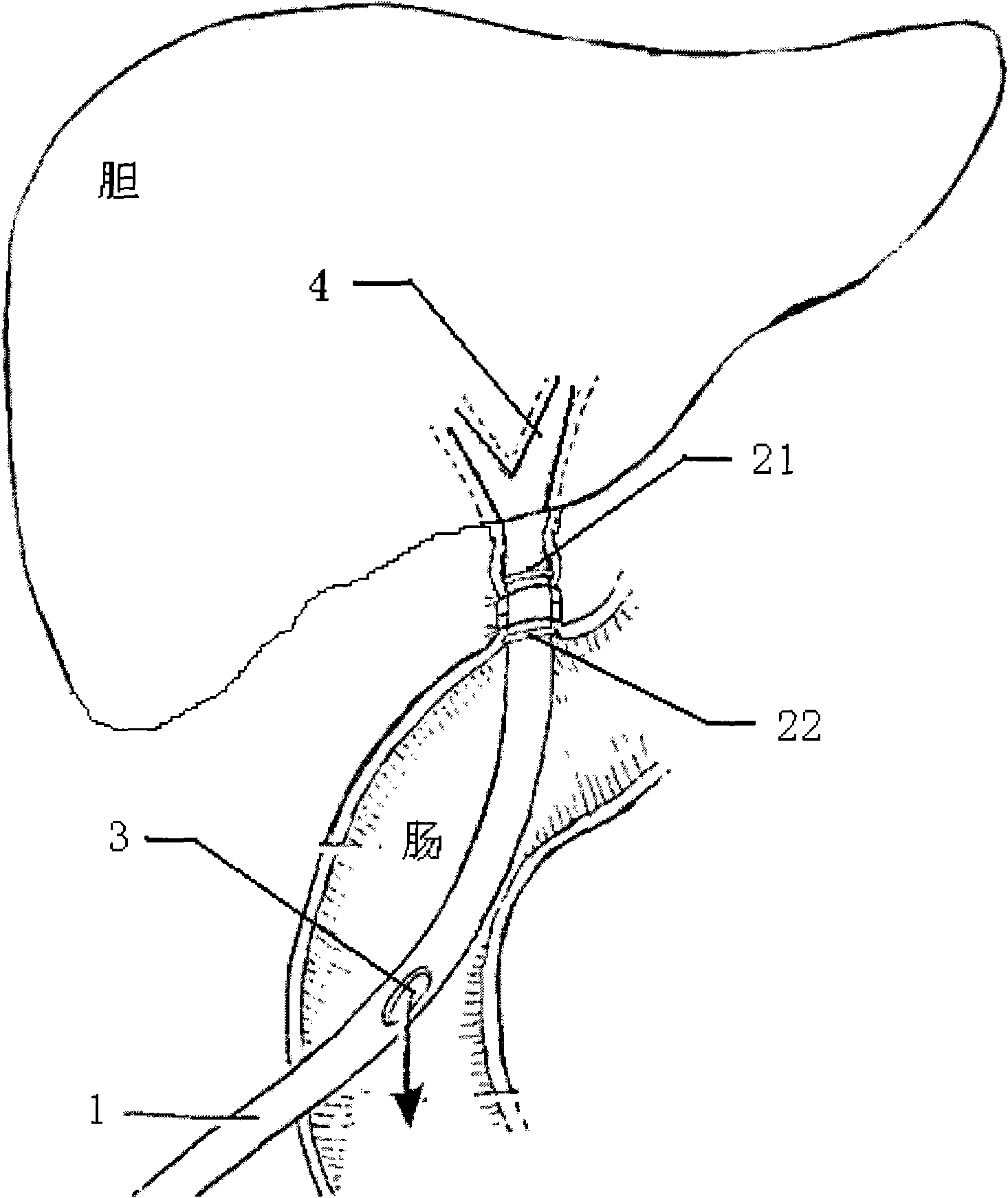

Biliary-enteric anastomosis support tube

ActiveCN101548903APromote growthPrevent stenosisSurgical staplesPostoperative complicationSmall intestine

A biliary-enteric anastomosis support tube, includes a siphunculus made from silicagel, the siphunculus includes an anastomosis end for anastomosing bile duct with small intestine and a drainage end for communication with vitro. The external surface of the siphunculus in the anastomosis end is provided with a first prominent ring for banding the bile duct and a second prominent ring for banding the small intestine, part of the siphunculus lies in the small intestine is provided with a side opening, the anastomosis end of the siphunculus is connected with a breeches pipe corresponding to bifurcation structure of the bile duct. The invention is provided with advantages of simplification of the biliary-enteric anastomosis, shorting anastomosis time, reducing postoperative complications.

Owner:ZHEJIANG UNIV

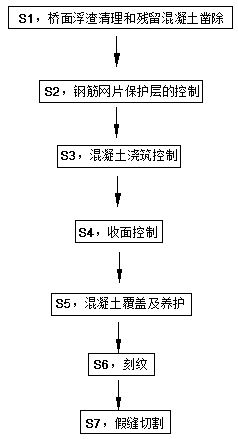

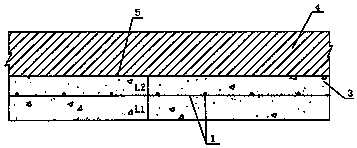

Bridge deck pavement surface crack control method

InactiveCN111576253AImprove construction qualityGuaranteed flatnessBridge erection/assemblyBridge strengtheningSurface finishArchitectural engineering

The invention belongs to the technical field of highway bridge deck pavement construction, particularly relates to a bridge deck pavement surface crack control method, and solves problems that bridgeconstruction quality is seriously influenced, construction cost is increased and construction efficiency is reduced due to pavement layer surface cracking caused by defects of a traditional bridge deck pavement construction process. The invention comprises a claim 1 and the like. The method comprises the following steps that S1, bridge deck scum is removed, and residual concrete is chiseled away;S2, a reinforcing mesh protective layer is controlled; S3, concrete pouring control is performed; S4, surface finishing control is performed; S5, concrete covering and curing are performed; S6, linesare carved; and S7, false seam cutting is performed. Cracks generated on the pavement surface are effectively controlled, rework is not needed, the bridge construction quality is improved, the construction cost is greatly reduced, and the construction efficiency is improved; and flatness and overall appearance quality of bridge deck pavement are also ensured.

Owner:CHINA RAILWAY SIXTH GROUP

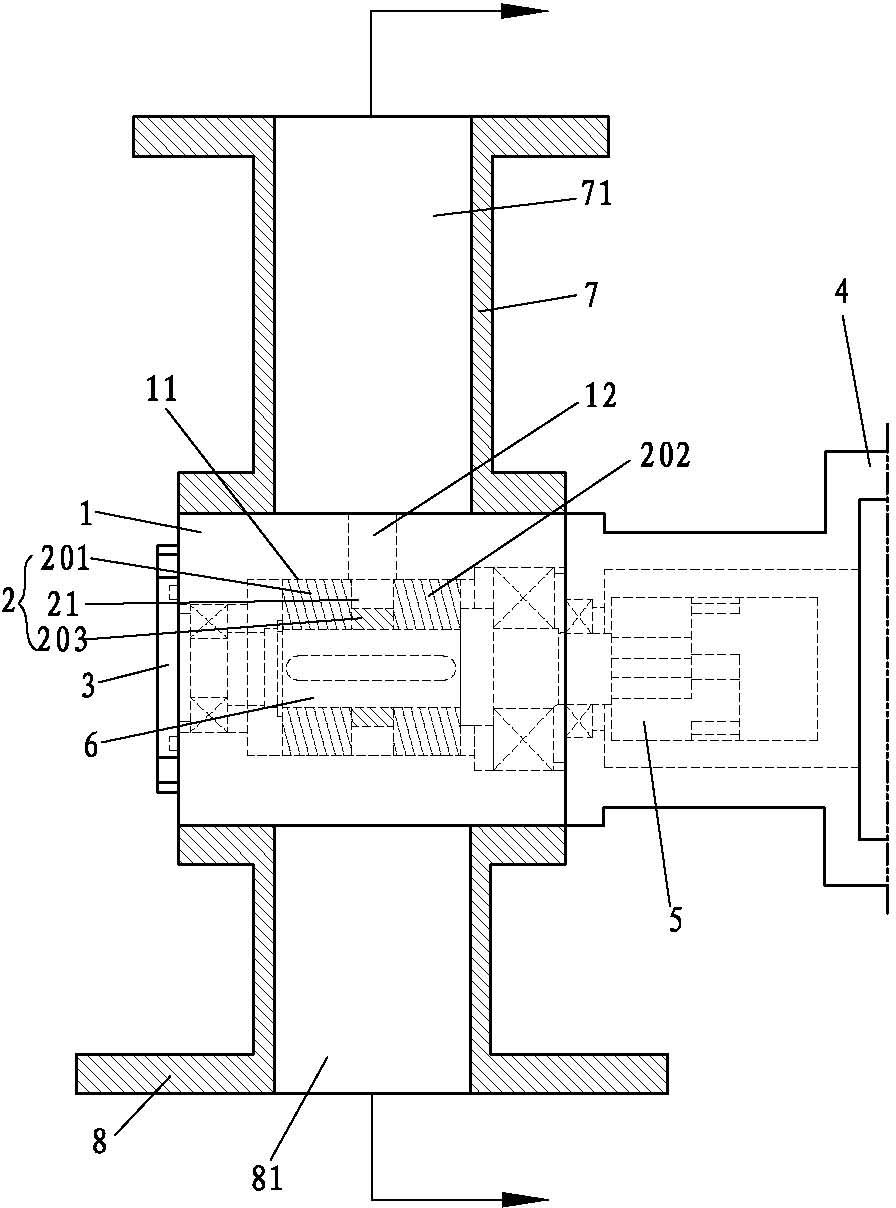

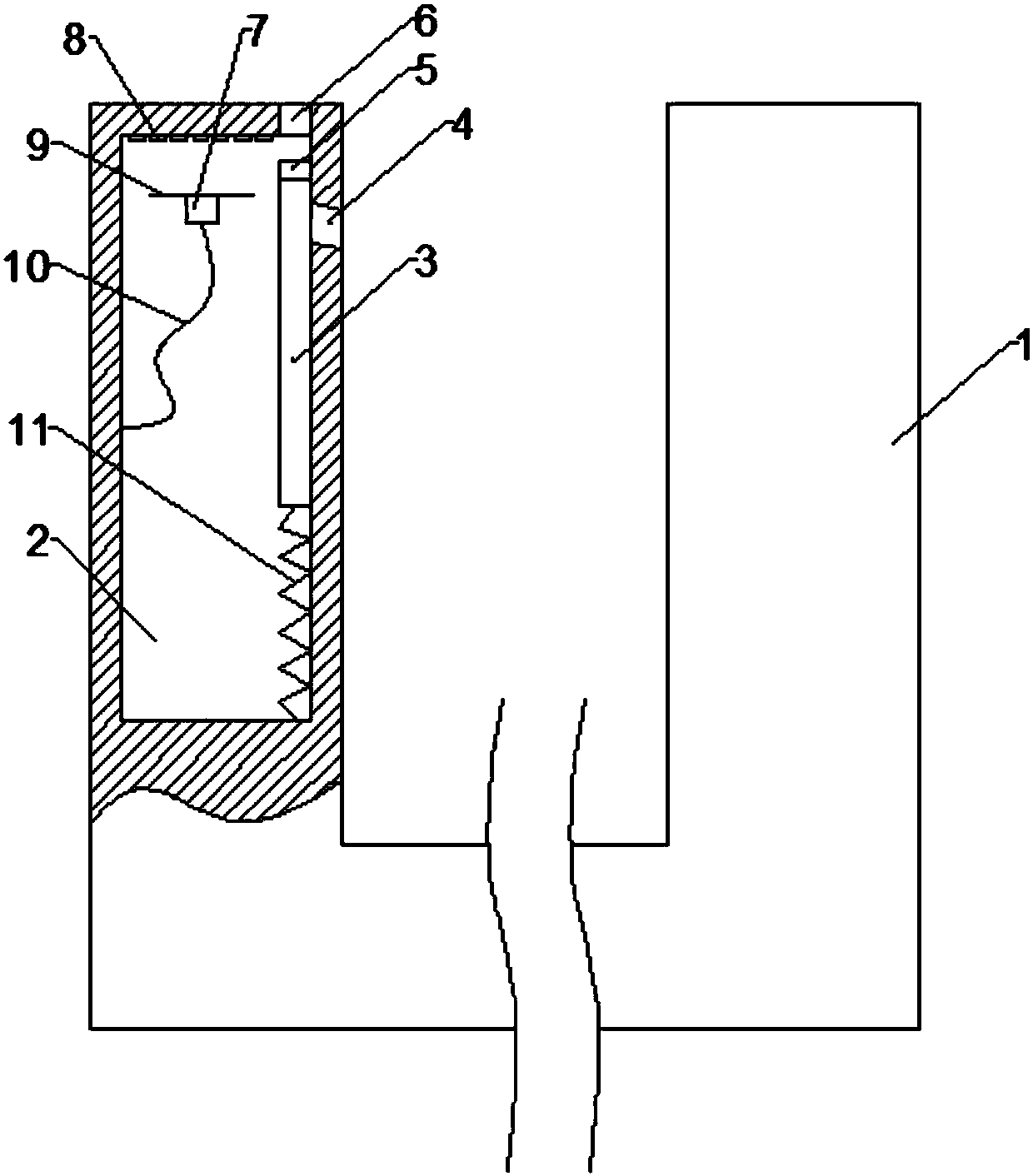

Servo double-surface heating vacuum packaging machine

ActiveCN102201592BQuality is not affectedGuarantee exclusionFinal product manufactureSecondary cells manufactureControl systemEngineering

The invention discloses a servo double-surface heating vacuum packaging machine and belongs to liquid extraction seal secondary forming and packaging equipment of flexible packaged lithium batteries. The servo double-surface heating vacuum packaging machine comprises a double-station turntable feeding device driven by a cam partitioning device, a packaging mechanism with an up-and-down packaging device, and an electric control system, wherein the up-and-down packaging device comprises an upper cavity main body and a lower cavity main body; the opening directions of the upper cavity main body and the lower cavity main body are opposite to each other; the upper cavity main body and the lower cavity main body can clamp the turntable to form a sealed cavity body; a pressing board, an upper sealing head and a bayonet are arranged in the upper cavity main body; a lower sealing head and an aspirating hole are arranged in the lower cavity main body; the aspirating hole is communicated with an external vacuum source; the upper sealing head corresponds to the lower sealing head; and a heating body is arranged inside the servo double-surface heating vacuum packaging machine. The servo double-surface heating vacuum packaging machine has a compact structure and high efficiency; the electric core packaging quality is stable and the cost is low; vacuum liquid extraction can be realized; and pollution of the electrolyte to the equipment can be reduced to minimum.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

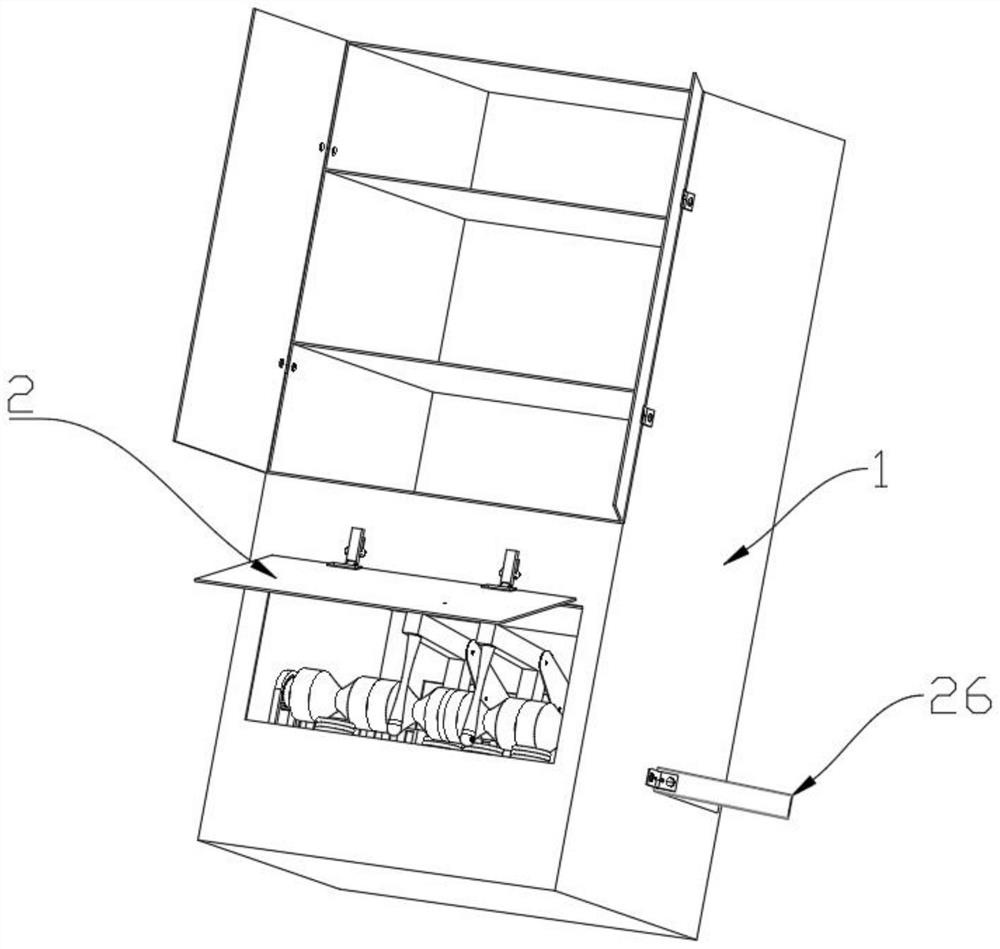

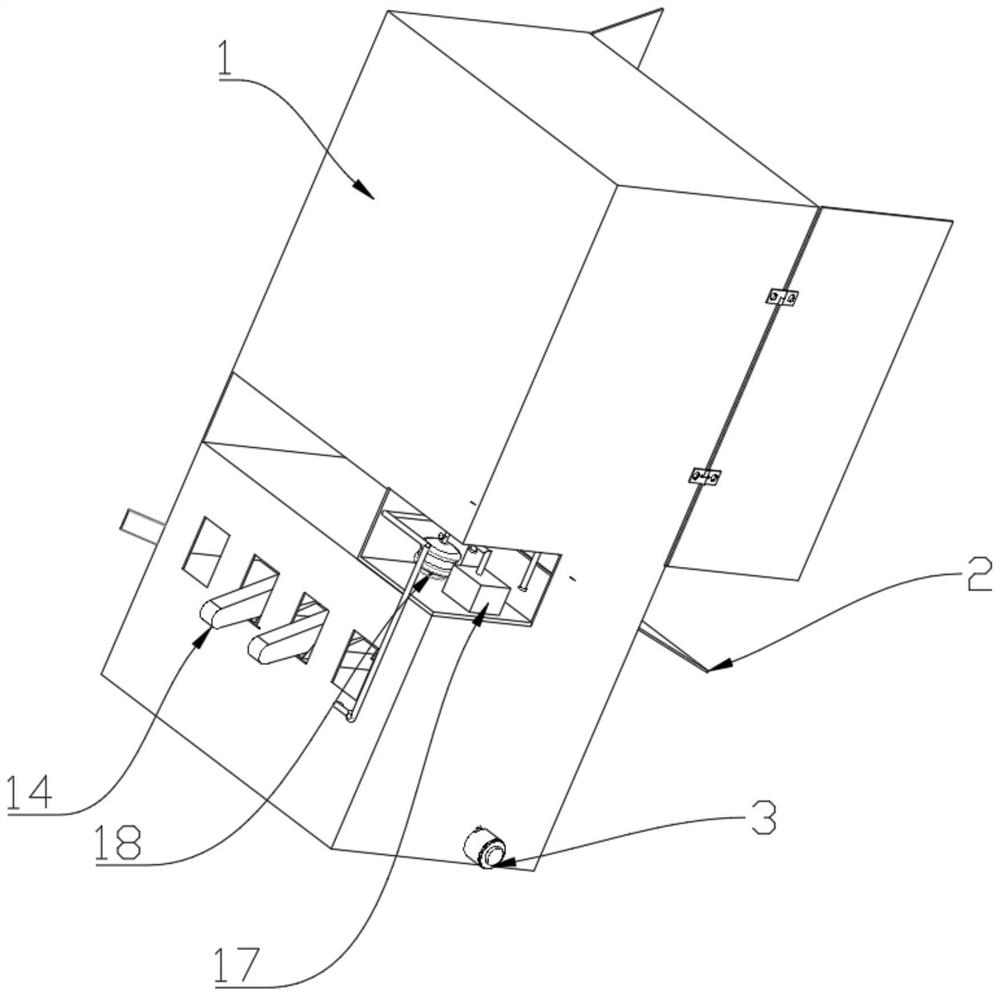

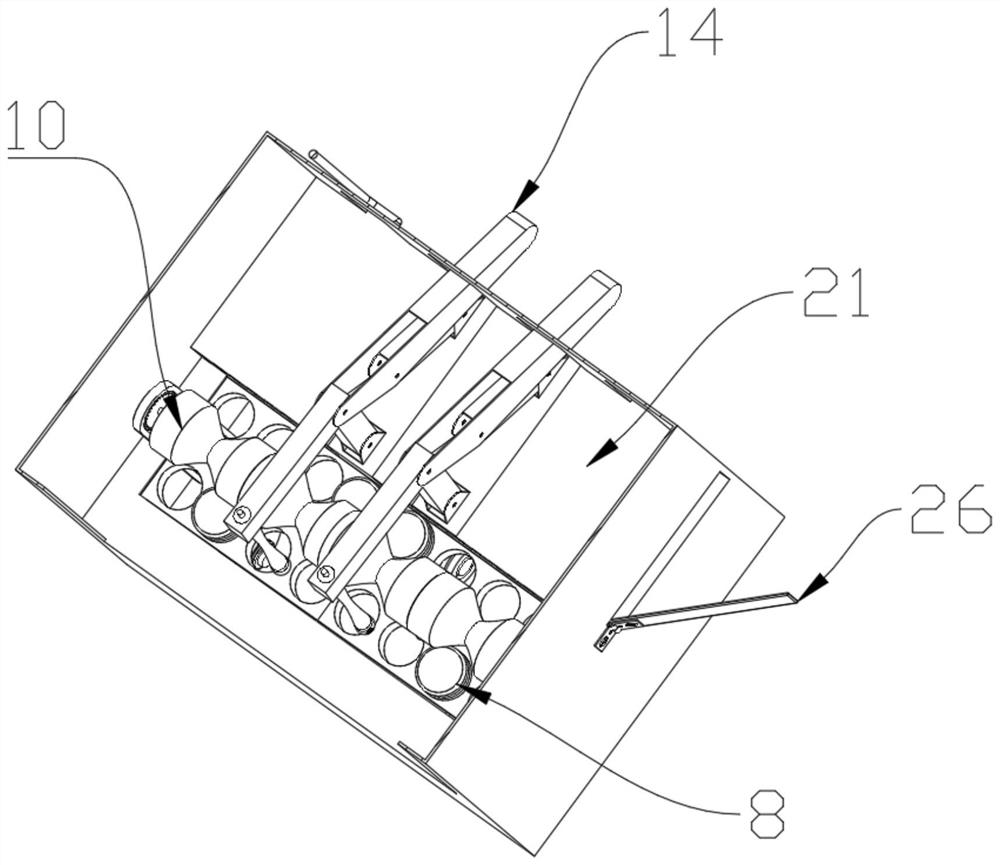

Vibration type dust removal shoe cabinet

PendingCN114304915ASimple structureWith vibration dust removalWardrobesFootwear cleanersDust controlStructural engineering

The invention discloses a vibration type dust removal shoe cabinet which comprises a shoe cabinet body, a vibration device is arranged in the shoe cabinet body, a dust removal bin door is arranged on the shoe cabinet body, the dust removal bin door is arranged at the position, where the vibration device is arranged, in the shoe cabinet body, and the dust removal bin door is connected with the shoe cabinet body in an opening and closing mode. Shoes needing dust removal are placed on the vibration device. The device is simple in structure and has the functions of vibration dust removal, disinfection and dust brushing; dust on the shoe sole is removed in an irregular vibration mode, compared with traditional ultrasonic pen dust removal and brush dust removal, the cost of the vibration dust removal mode is lower than that of ultrasonic dust removal, damage to the shoe body is small, and compared with brush dust removal, secondary mud feeding caused by brush strain is eliminated, so that the shoe sole dust removal efficiency is improved. And coarse dust at the bottom is fully shaken off, and fine dust on the shoe body is loosened, so that a satisfactory dust removal effect is achieved.

Owner:CHENGDU UNIV

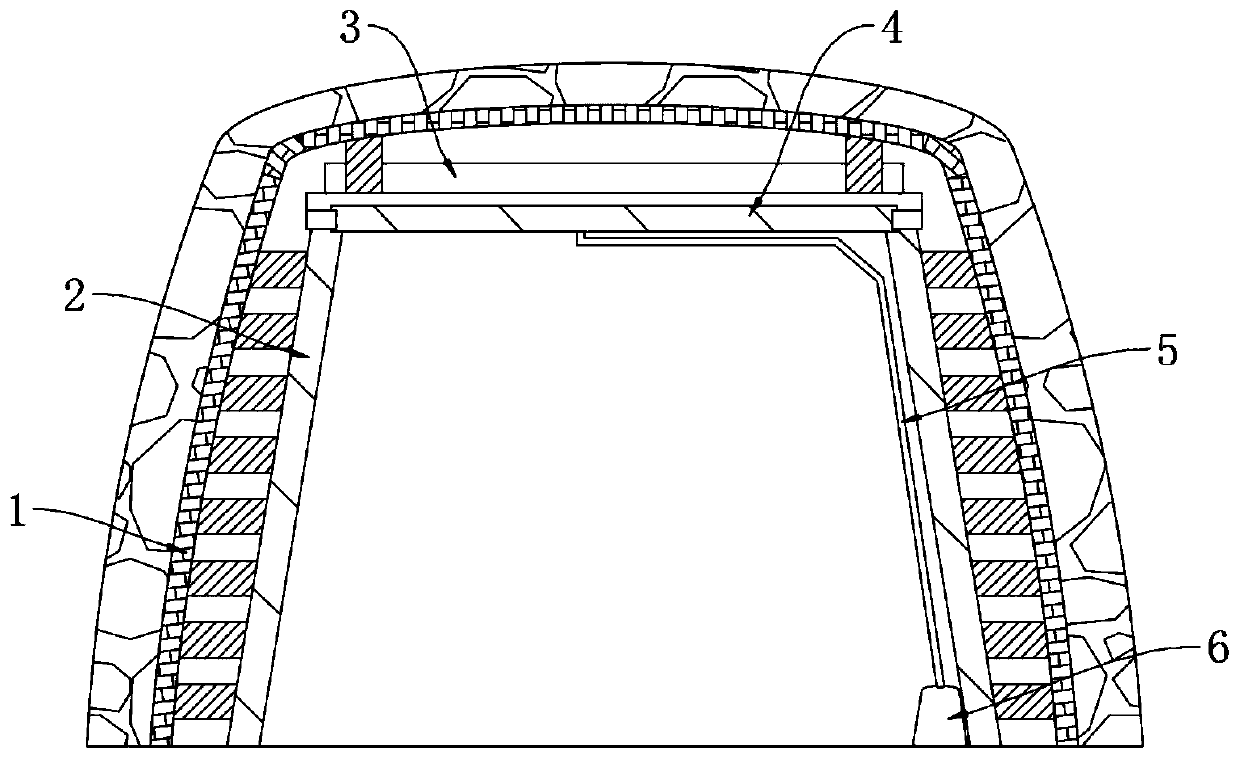

Coal mine roadway with water seepage warning function

ActiveCN110925023ARealize self-powered functionAvoid accumulationMining devicesDrainageMining engineeringStructural engineering

The invention discloses a coal mine roadway with a water seepage warning function. The coal mine roadway comprises an anchor net fixedly arranged on the inner wall of the roadway; a top plate is supported by the anchor net through a supporting layer; a water collecting tank is arranged between the anchor net and the top plate; two electrode plates are symmetrically arranged on the inner bottom wall of the water collecting tank; each electrode plate is slidably connected with a drainage support, and a rectangular groove is formed in the bottom wall of each electrode plate; each rectangular groove is internally provided with an electrode sheet; each electrode sheet is connected with the corresponding drainage support through a traction rope; a drainage alarm mechanism is arranged in the middle of the water collecting tank; and the drainage alarm mechanism comprises an installation groove arranged in the water collecting tank. The coal mine roadway can give an alarm in time when the waterseepage problem occurs at the surrounding rock above the top plate so as to warn construction personnel to block leakage and drain water in time, and the coal mine roadway can automatically drain water when the construction personnel do not drain water and too much water is accumulated in the water collecting tank so as to prevent water from accumulating at the top plate for a long time.

Owner:内蒙古蒙泰不连沟煤业有限责任公司

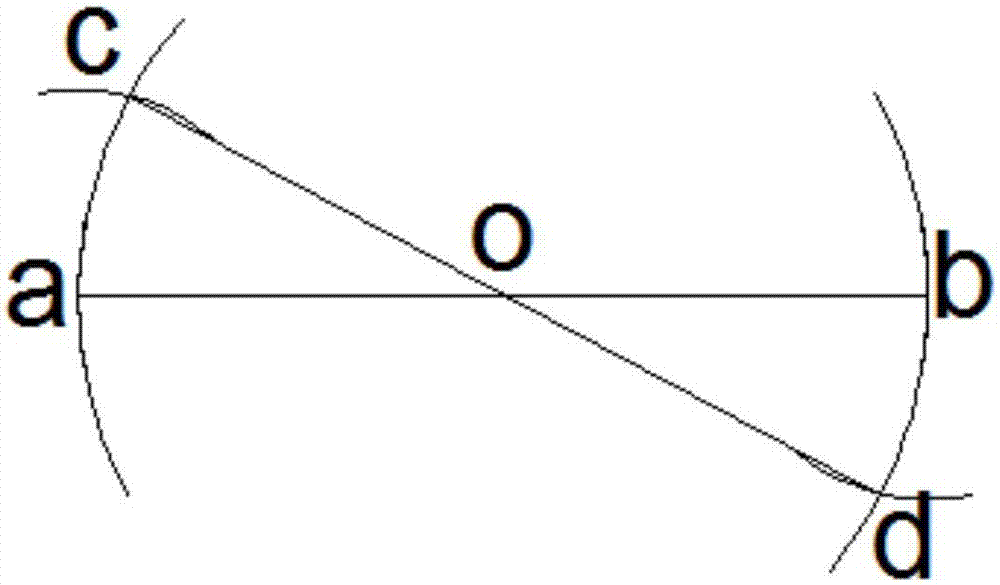

Method for rapidly manufacturing high-strength bolt holes

The invention discloses a method for rapidly manufacturing high-strength bolt holes. The method comprises the steps that 1, according to the dimensions of a bolt hole set, the length of a diagonal line of a rectangle formed by two rows of bolt hole sets is determined, a thin zinc-plated steel plate is selected, and the rectangle diagonal line is drawn; 2, a standard rectangular line frame is determined; 3, according to the positions of all the bolt holes, mark points are drilled; 4, after center points of the bolt holes are determined, blanking is carried out on the zinc-plated steel plate according to the dimension in a bolt hole template legend, one steel plate with the equal size and the thickness delta being 12-20 mm is taken and completely covered with a zinc-plated template, small holes are led out, then the bolt holes are drilled, and a bolt hole template is manufactured; and 5, auxiliary bolt hole machining is carried out through the bolt hole template manufactured in the step 4. Bolt hole distance control precision is high, the repeated service life is prolonged, it is ensured that machining scrap iron is effectively removed, and fixing is convenient.

Owner:CHINA FIRST METALLURGICAL GROUP

Secondary fine grinding process for processing of sweet dumpling powder

The invention discloses a secondary fine grinding process for processing of sweet dumpling powder in the field of sweet dumpling powder processing, wherein the secondary fine grinding process comprises the steps of screening, cleaning, demildewing, soaking, pulp grinding, homogenizing, press filtration, crushing and drying. The pulp grinding includes primary pulp grinding and secondary pulp grinding, and glutinous rice pulp obtained from primary pulp grinding directly flows into a secondary pulp grinding machine by a stainless steel guide groove and is subjected to secondary pulp grinding; thesweet dumpling powder produced by the process is boiled into sweet dumpling with no turbidity of soup, no sticking to a basin, no sticking of teeth, good swelling, fineness, smoothness, softness, opalescent and bright color, obvious glutinous rice clear and fragrant taste, comfortable taste, high gelatinization degree, and good rehydration, and effectively solves the problems that the granularityof sweet dumpling powder is not fine enough and not conducive to eating.

Owner:重庆源源龙脉食品有限公司

Large-temperature-difference freeze-thaw cycle method for production increase of surface borehole

InactiveCN109779590AImprove water absorptionGood cracking effectFluid removalGas removalHigh concentrationFreezing thawing

The invention discloses a large-temperature-difference freeze-thaw cycle method for production increase of a surface borehole. Firstly, magnetized water is injected into a gas extraction pipe of the surface borehole in a pulsating manner; high-pressure nitrogen drives the magnetized water to enter the coal body; liquid nitrogen freezing is carried out on the magnetized water for many times and themagnetized water and high-temperature nitrogen are melted; the freezing expansion force of the magnetized water and the direct large-temperature-difference effect of the liquid nitrogen and the high-temperature nitrogen are utilized to jointly crack the coal body; by means of interaction of high-temperature and high-pressure nitrogen, liquid nitrogen and magnetized water, an ultra-large temperature difference effect is formed, the coal cracking effect is achieved, finally, the coal cracking effect and the crack expansion range can be effectively improved, the coal permeability is increased, and therefore large-flow, high-concentration and long-time gas extraction through ground drilling is achieved.

Owner:XUZHOU UNIV OF TECH

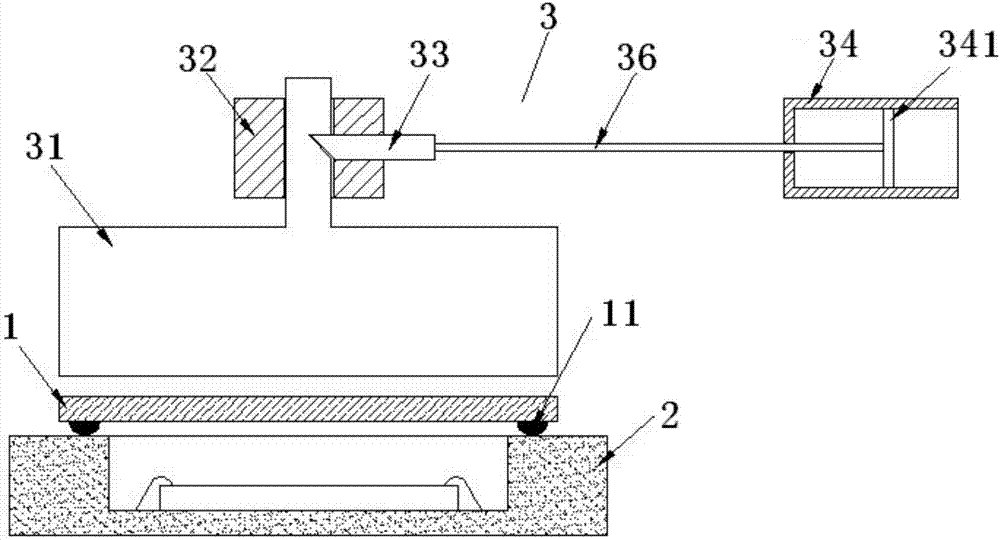

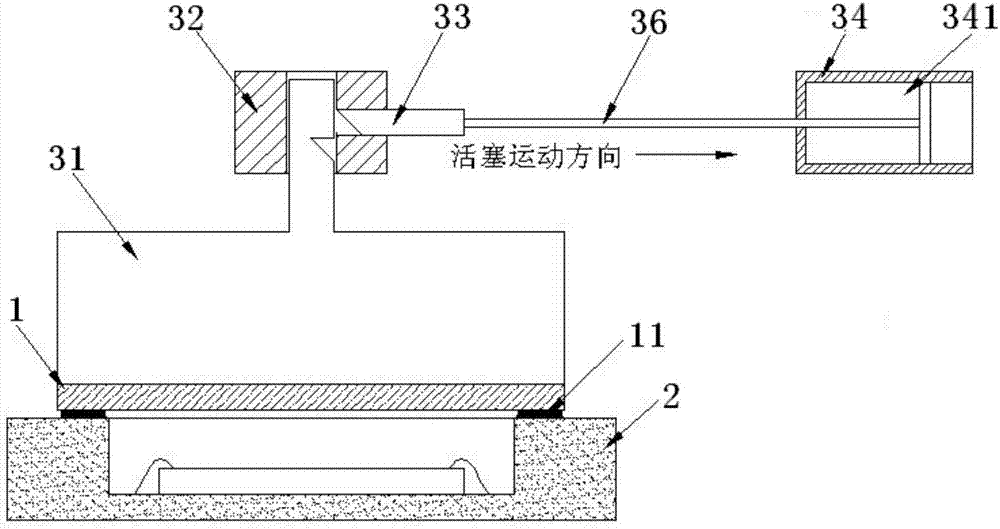

Pressing block trigger device and epoxy resin vacuum low pressure packaging process method

PendingCN107958857AAvoid damageEasy to operateSolid-state devicesSemiconductor/solid-state device manufacturingEpoxyOperating temperature

The invention discloses a pressing block trigger device and an epoxy resin vacuum low pressure packaging process method. The device comprises a pressing block, a movable pin and a cylinder. The upperpart of the pressing block has a slide rod, and a front end of the movable pin can be embedded into a dovetail groove in a side of the slide rod. An end of the movable pin is connected to a piston inthe cylinder through a connecting rod, and the moving pin is driven by the movement of the piston to be embedded into the slide rod or withdrawn from the sliding rod. A pre-cured epoxy resin is used as a bonding material, the operation is more convenient than that of a traditional epoxy resin, the cost is lower than that of a soldering mode, and the operating temperature is low and has small damage to the device. A vacuum oven is used to cure epoxy resin, a vacuum / low pressure state in a sealed cavity is ensured, and the formation of sealed interface pores due to internal expansion during curing is avoided. An epoxy resin curing process is designed, vacuumizing is carried out in a preheating stage, the pressing block trigger device is used to control the pressing block to press a cover plate in falling, the discharge of gas inside the cavity is ensured, and the pre-cured epoxy resin can effectively bond.

Owner:NORTH ELECTRON RES INST ANHUI CO LTD

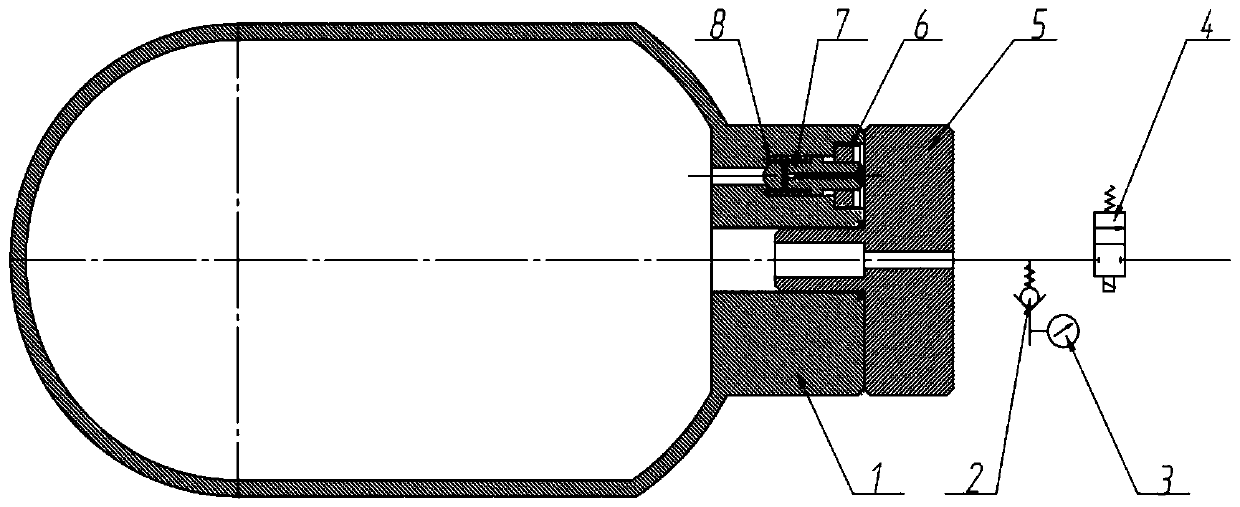

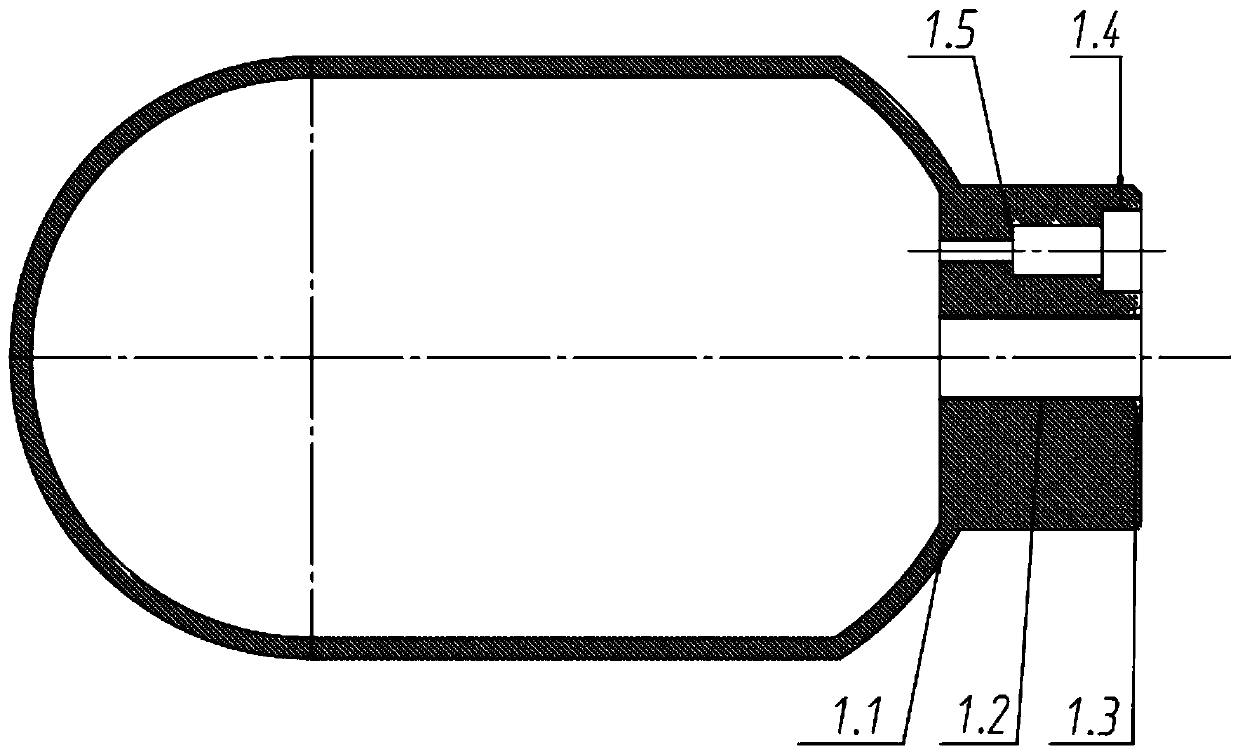

Opening self-pressure relief type gas storage bottle device

ActiveCN110715165AEnsure safetyGuarantee exclusionContainer discharging methodsContainer filling under pressureThermodynamicsGas cylinder

The invention relates to an opening self-pressure relief type gas storage bottle device, and belongs to the technical field of pneumatic transmission control. A valve port is formed in an end cover ofa gas storage bottle through the corresponding structural design, and a corresponding exhaust hole is formed in a valve element to rapidly discharge gas in the gas bottle, so that the situation thata gas storage bottle opening is opened under the condition of unknown pressure in the gas storage bottle, and damage of the field personnel anda gas storage device is caused is avoided.

Owner:BEIJING INST OF SPECIALIZED MACHINERY

A household sewage treatment and reuse device

ActiveCN108149756BGuarantee exclusionImprove convenienceFatty/oily/floating substances removal devicesSpecific water treatment objectivesWater storageWater storage tank

The invention provides a device for treating and reusing household sewage and belongs to the field of household environment protection tools. The device comprises a water inlet structure, a box body,a coarse impurity filtering box, graded filtering boxes, a liquid level sensor, a small water pump and graded filtering screens, wherein the water inlet structure is located at the upper side of a coarse impurity filtering box groove of the box body; the coarse impurity filtering box is mounted in the coarse impurity filtering box groove of the box body; the graded filtering boxes are mounted in graded filtering box grooves; graded filtering screens are mounted in graded filtering screen grooves; the liquid level sensor is mounted at the upper middle part of a water storage box of the box body; the small water pump is connected with the bottom of the water storage box at a 3 / 4 position of the height of water storage volume; the other end of the small water pump is connected with a flush toilet. The device is capable of achieving secondary utilization of the household sewage on the basis that the convenience and the environmental friendliness are ensured.

Owner:睿得水资源科技开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com