Method for reinforcing aeolian sandy soil by polypropylene fibers

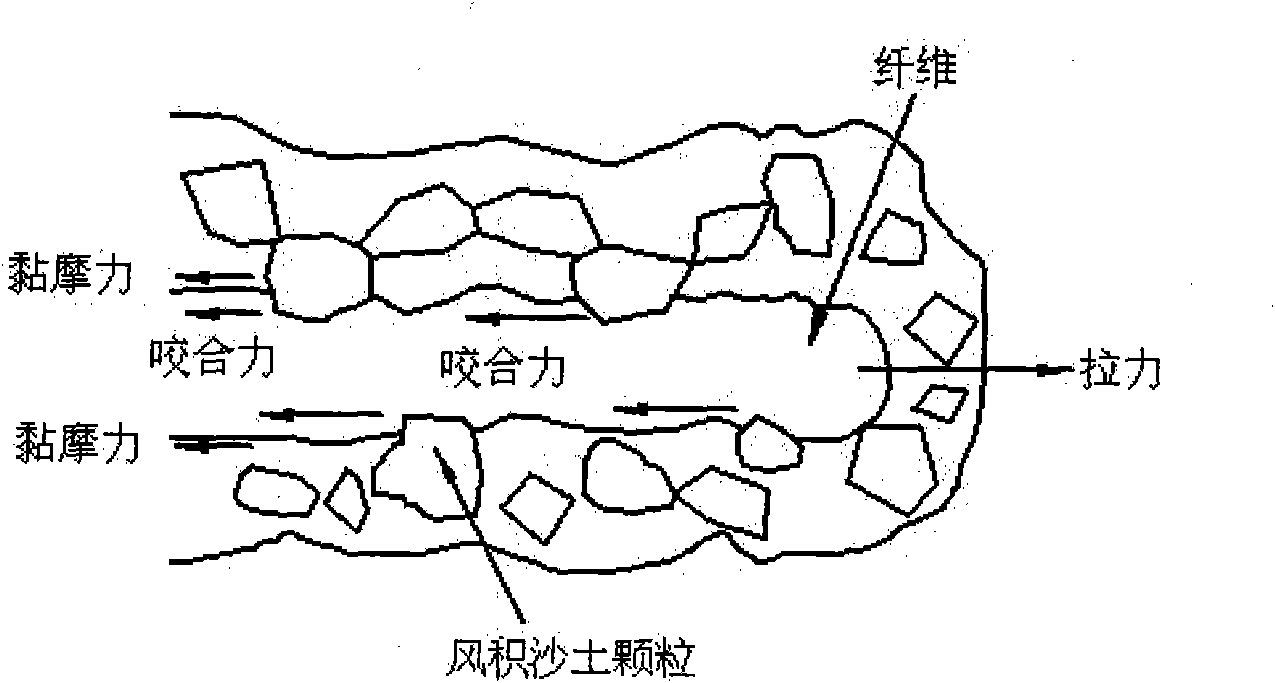

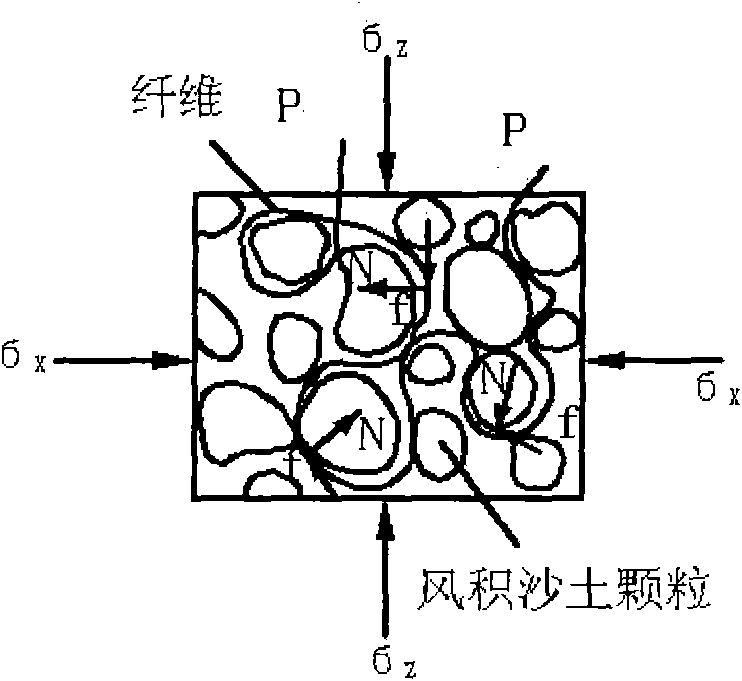

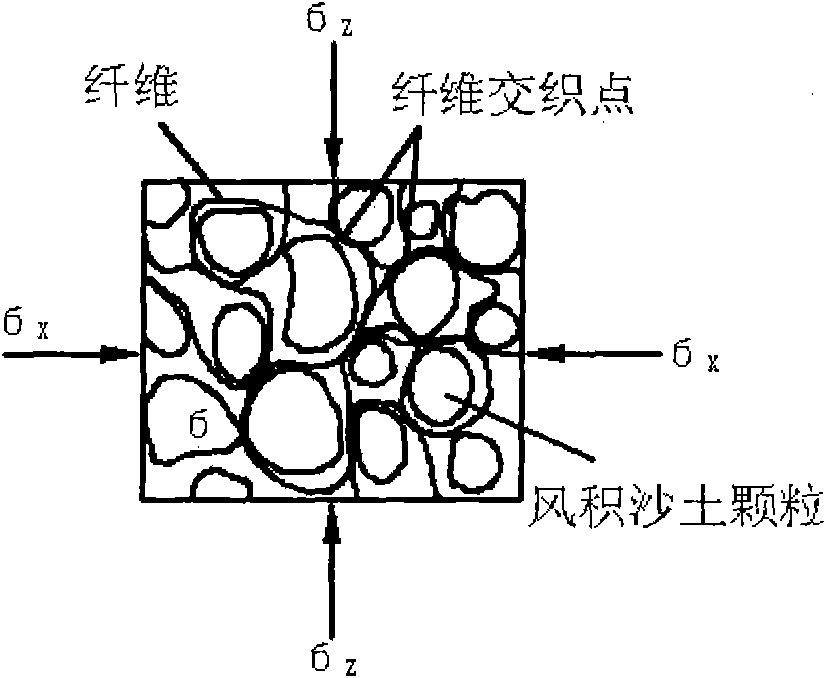

A technology of polypropylene fiber and aeolian sand, which is applied in the fields of soil protection, construction, and infrastructure engineering, etc. It can solve the problems that cannot completely cure the hazards of aeolian sand and soil engineering, and achieve enhanced plasticity, reduced noise, and improved strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The polypropylene fiber is rolled into a cylinder with a height of 25cm and a diameter of 30cm, and each cylinder weighs 15kg of polypropylene fiber ingots. The aeolian sand is transported to the construction height through the conveyor belt, and the polypropylene fiber ingot is placed in a sealed box with a creel and lifted to the construction height by a lift. The pressure of the polypropylene fiber and the aeolian sand is 2 to 3 bar. Jet machine spraying operation, generally set 10-20 nozzles to spray polypropylene fiber, the spray speed is 20-25 meters per second, the flow rate of aeolian sand is 6-7t / h, the ratio of polypropylene fiber weight to aeolian sand weight 0.3%, spray the fiber and aeolian sand rubber tube back and forth, so that the polypropylene fiber is evenly distributed in the aeolian sand, layered construction, both sides manually cooperate with the repair of the slope, layered rolling, cohesive soil wrapping the slope, The protection thickness is 5-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com