Energy dissipation and vibration reduction rolling rock shed-tunnel structure with assembled lightweight steel structure

A light steel structure and assembled technology, applied in construction, protective equipment, etc., can solve the problems of slow construction speed, increase the weight of the shed structure, and increase project investment, so as to reduce the amount of work, facilitate transportation, and reduce project investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

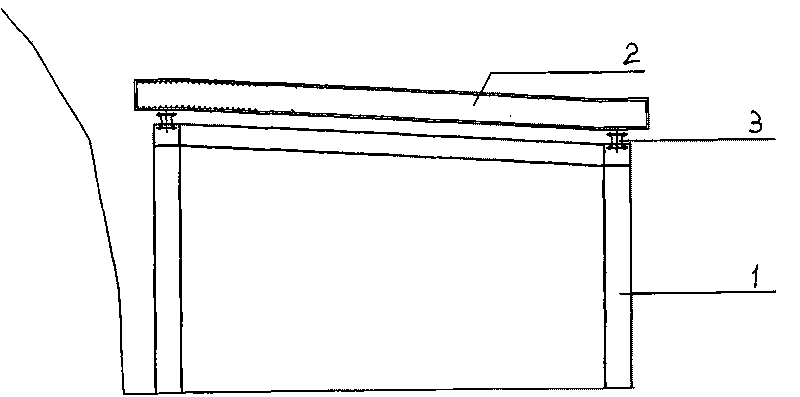

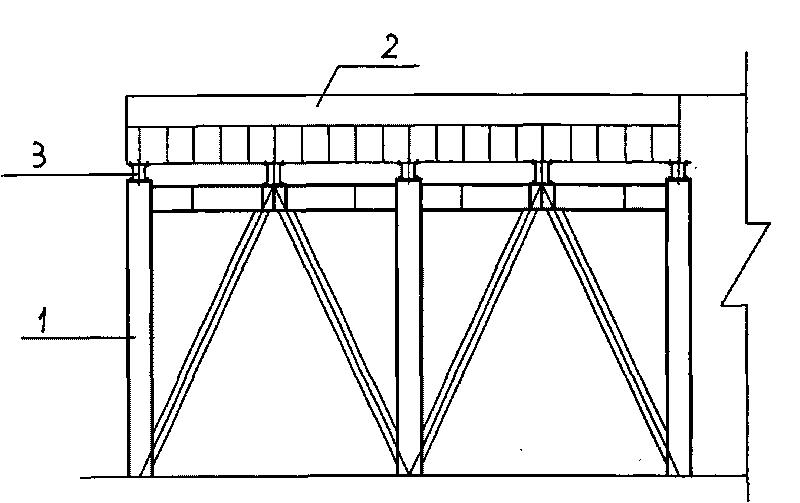

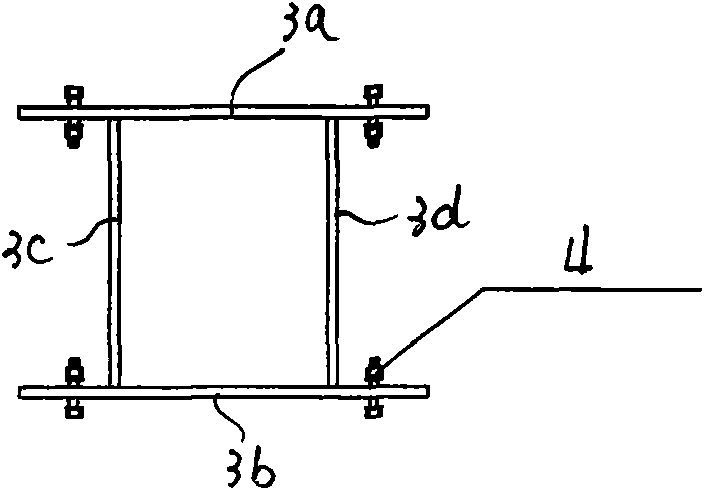

[0018] figure 1 figure 2 It is shown that the present invention includes a rock shed tunnel frame 1 and a concrete shed tunnel slab 2 arranged on the light steel structure frame, and also has an energy dissipation shock absorber 3: left and right vertical plates 3c, 3d welded on the upper and lower horizontal The plates 3a and 3b are formed between the plates 3a and 3b, and the upper and lower horizontal plates are provided with bolt connection holes; a plurality of energy dissipation shock absorbers are connected between the rock shed cave frame 1 and the concrete shed cave plate 2 by bolts 4. The rolling stone shed cave frame 1 is an H-shaped steel structure frame of the rolling stone shed cave. The concrete shed hole slab 2 is a prefabricated C30 reinforced concrete slab.

[0019] Refer to the attached drawings, the rolling stone shed frame 1 is made of H-shaped steel, and (prefabricated C30) reinforced concrete shed slab 2 is arranged on it, and Q235B material is set between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com