Secondary fine grinding process for processing of sweet dumpling powder

A technology of secondary refining and round powder, which is applied in the fields of food mechanical processing and food science, and can solve the problems of unfavorable eating and insufficient particle size of rice balls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

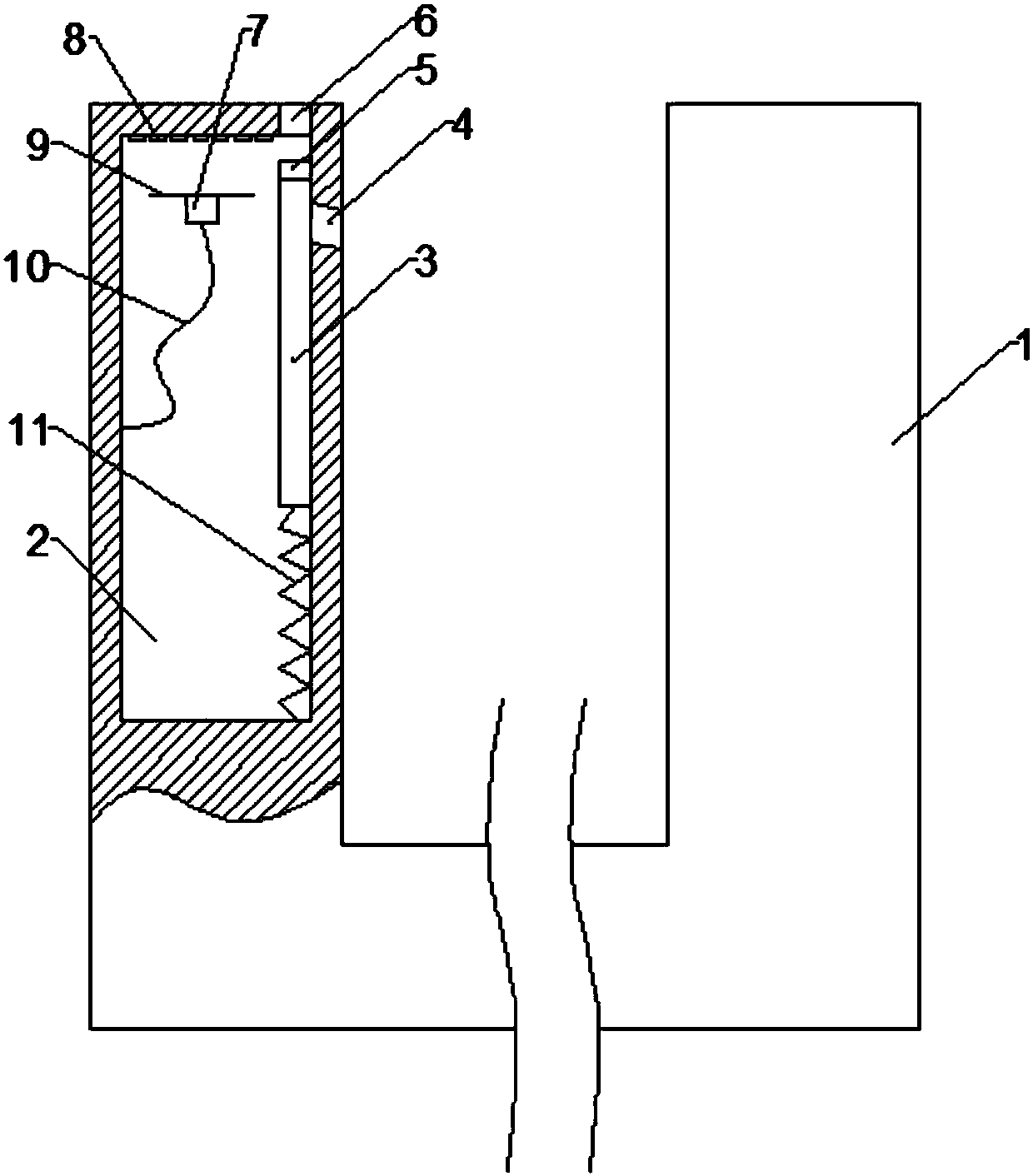

Image

Examples

Embodiment 1

[0025] Embodiment 1: glutinous rice ball powder processing secondary fine grinding technique, comprises the following steps:

[0026] Screening, select glutinous rice with white color, uniformity and no peculiar smell, select glutinous rice to remove impurities, and control the moisture content of glutinous rice below 14%;

[0027] Cleaning, digging and building an elutriation pool underground to clean the glutinous rice with tap water;

[0028] Mildew removal, physical removal of Aspergillus flavus from the cleaned glutinous rice; including pumping the cleaned glutinous rice and water into the vertical mold removal pipe with a suction pump for extrusion and transportation, and the inner wall of the mold removal pipe is integrally formed There are several spherical protrusions distributed in a spiral shape, and the mildew removal pipe is made of galvanized steel pipe;

[0029] Screening, connecting the outlet of the mildew removal tube to a three-stage filter sieve for screen...

Embodiment 2

[0040] Example 2, the difference between this example and Example 1 is that in the soaking step, the volume of the glutinous rice is expanded to 1.2 times, the glutinous rice is soaked in the soaking pool for 15 hours in winter, and the glutinous rice is soaked in the soaking pool for 13 hours in spring and autumn , Soak the glutinous rice in the soaking pool for 11 hours in summer.

Embodiment 3

[0041] Example 3, the difference between this example and Example 1 is that in the soaking step, the volume of glutinous rice is expanded to 1.3 times, the glutinous rice is soaked in the soaking pool for 16 hours in winter, and the glutinous rice is soaked in the soaking pool for 14 hours in spring and autumn , Soak the glutinous rice in the soaking pool for 12 hours in summer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com