Pressing block trigger device and epoxy resin vacuum low pressure packaging process method

A trigger device, epoxy resin technology, applied in electrical components, electric solid state devices, semiconductor/solid state device manufacturing, etc., can solve the problems of affecting product appearance, high operating temperature, large solder stress, etc., and achieve a simple and reliable control method. Low operating temperature and small device damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

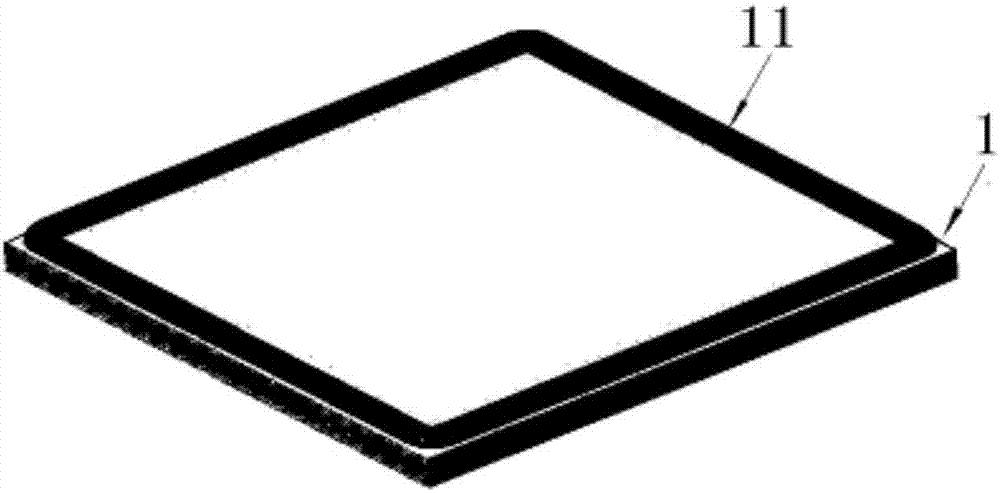

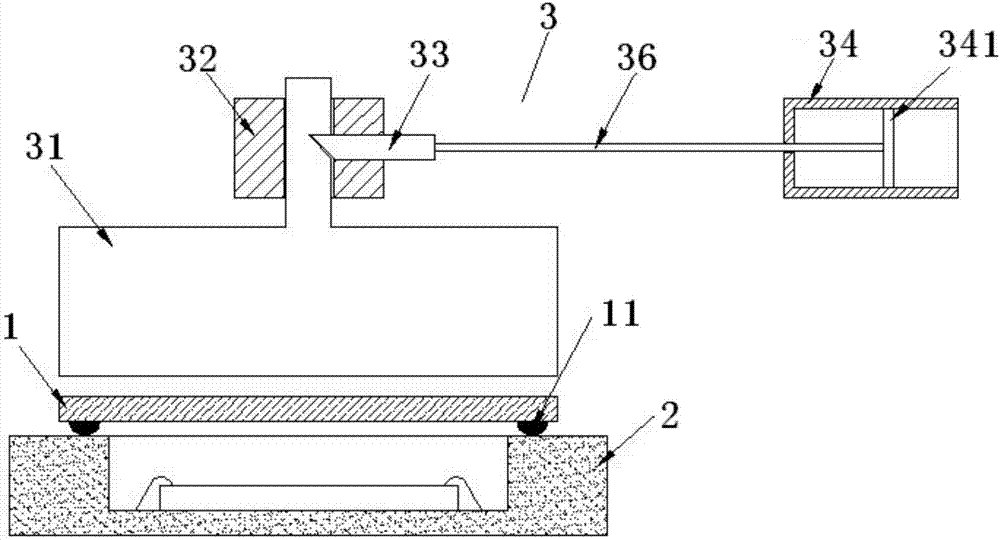

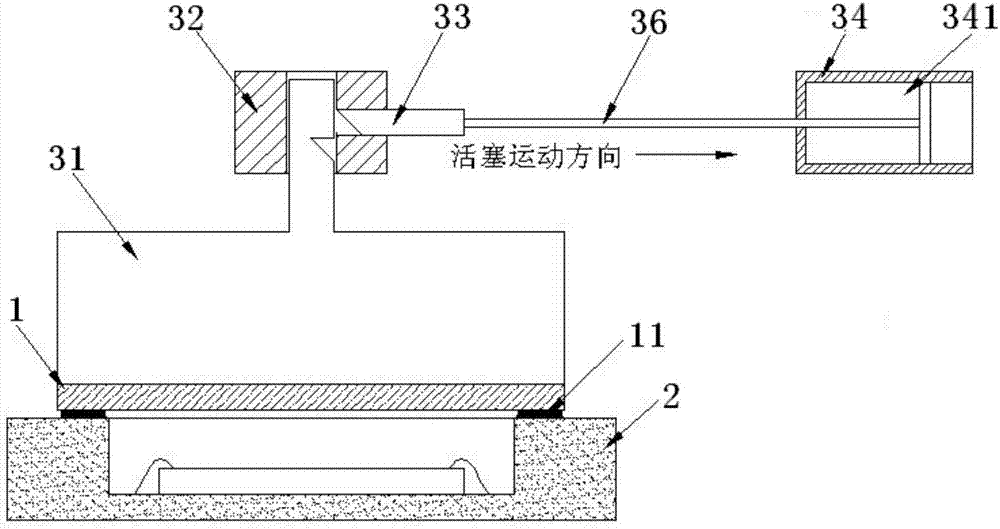

[0031] Such as figure 1 - image 3 As shown, the present invention uses pre-cured epoxy resin to realize the packaging of the cover plate 1 and the housing 2, covers the cover plate 1 pre-coated and cured epoxy resin 11 on the housing 2, and coats the epoxy resin 11 The face faces the housing 2 and fits with the housing. Place the casing 2 of the upper cover and the briquetting trigger device 3 in a vacuum oven. The oven is heated up. After reaching a certain temperature, the oven starts to vacuumize and triggers the briquetting to drop onto the cover 1, and then raises the temperature to the curing temperature and completes the curing.

[0032] Epoxy resin coating steps: choose pre-cured epo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com