Patents

Literature

42results about How to "Excluded" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

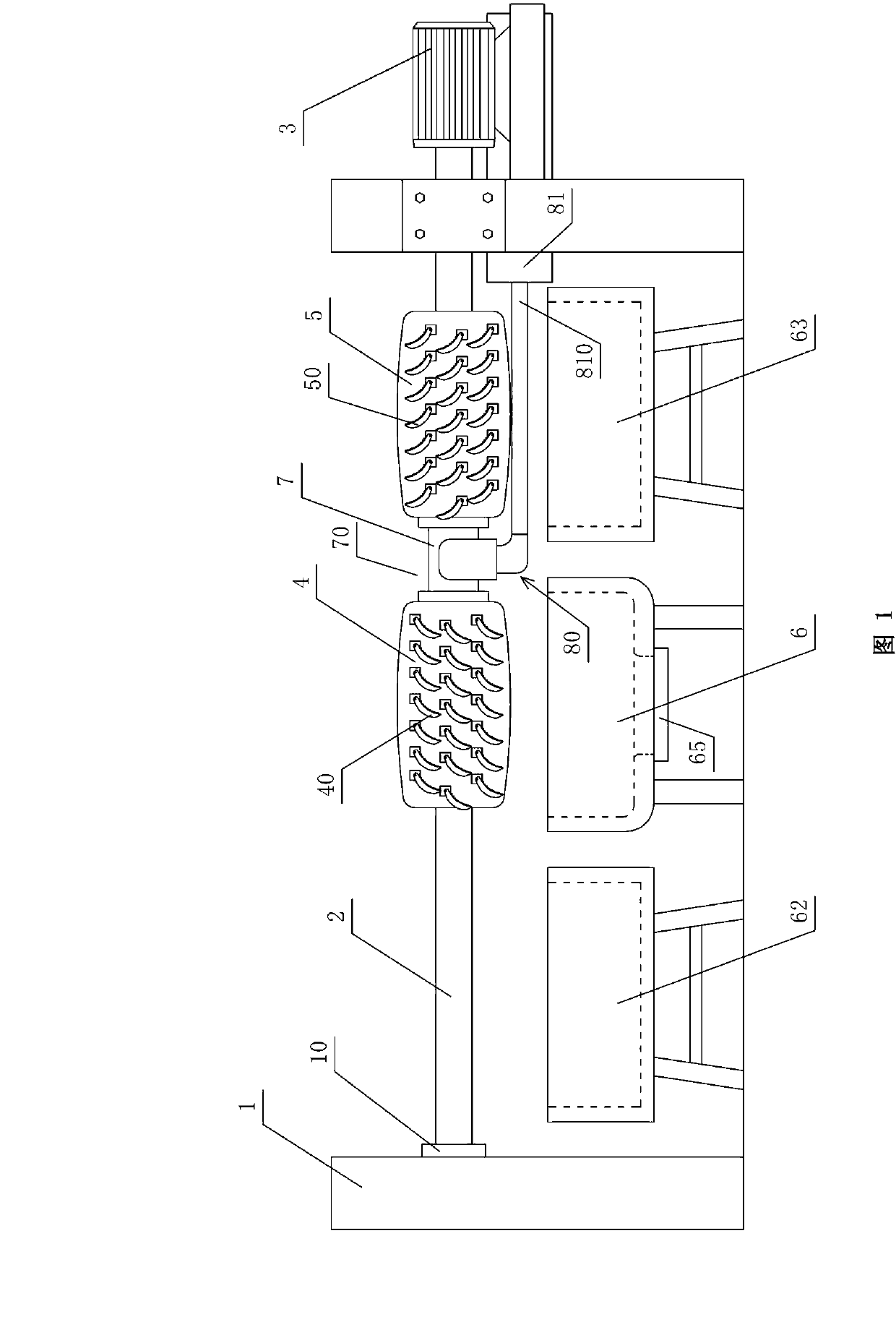

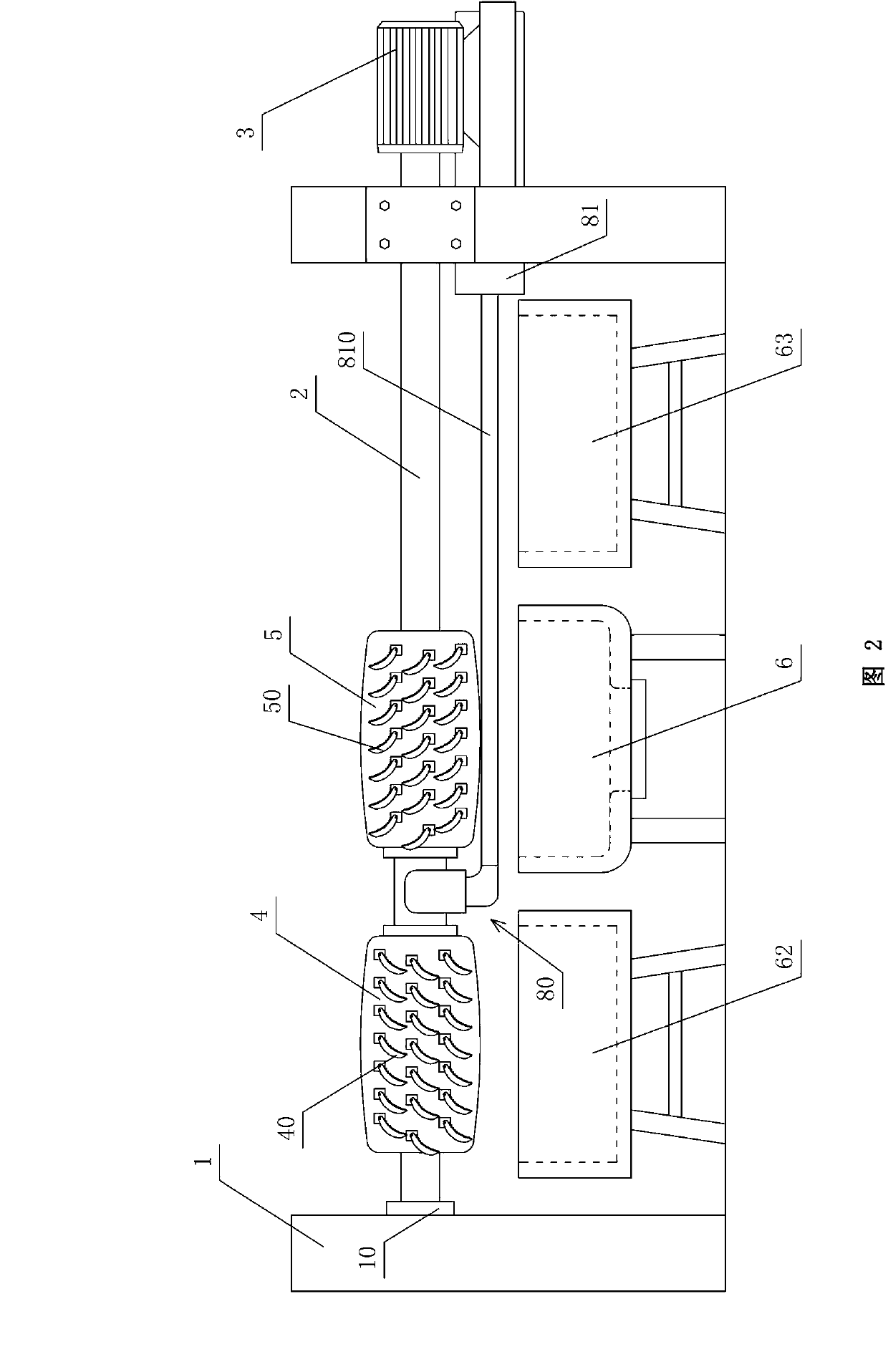

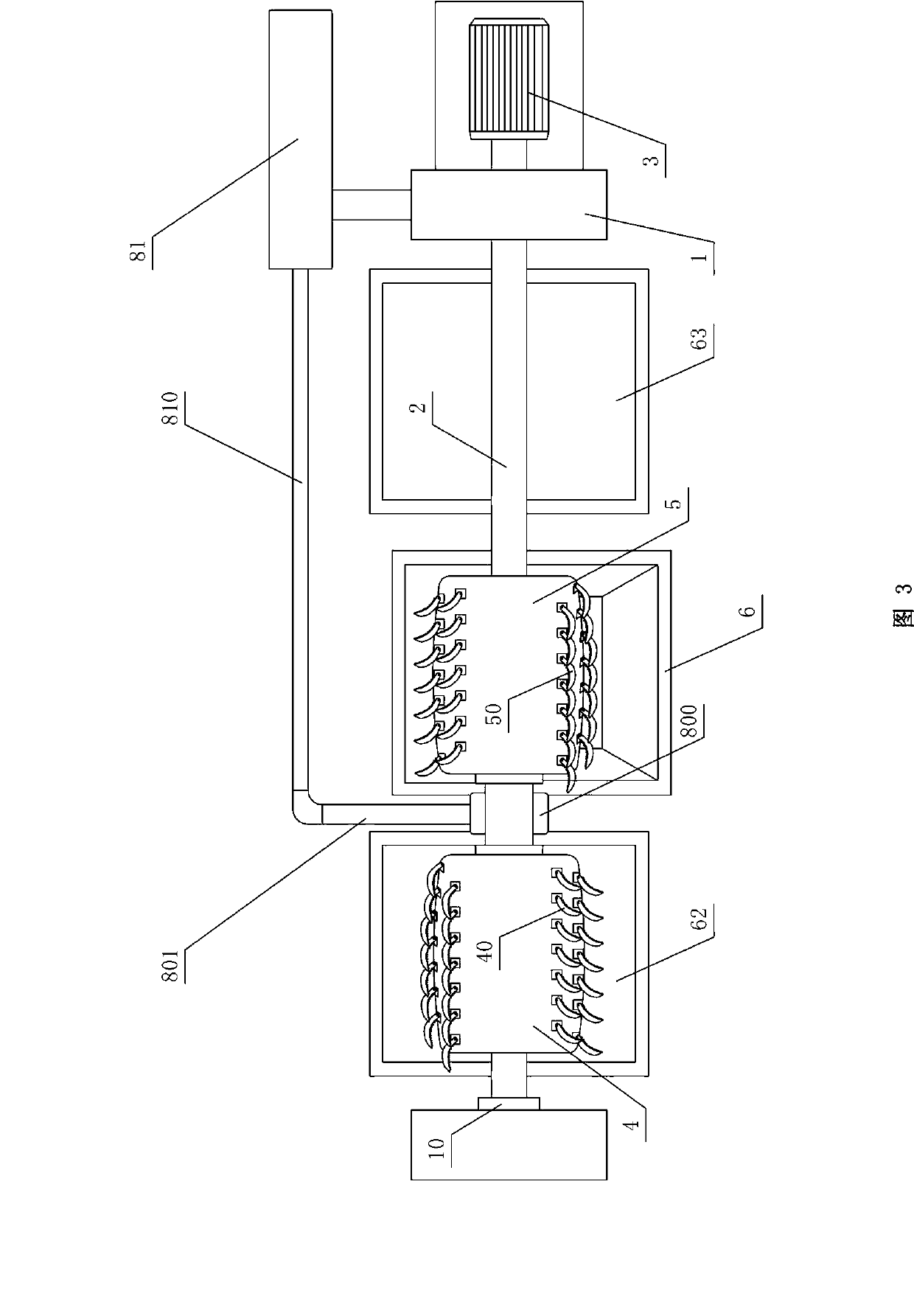

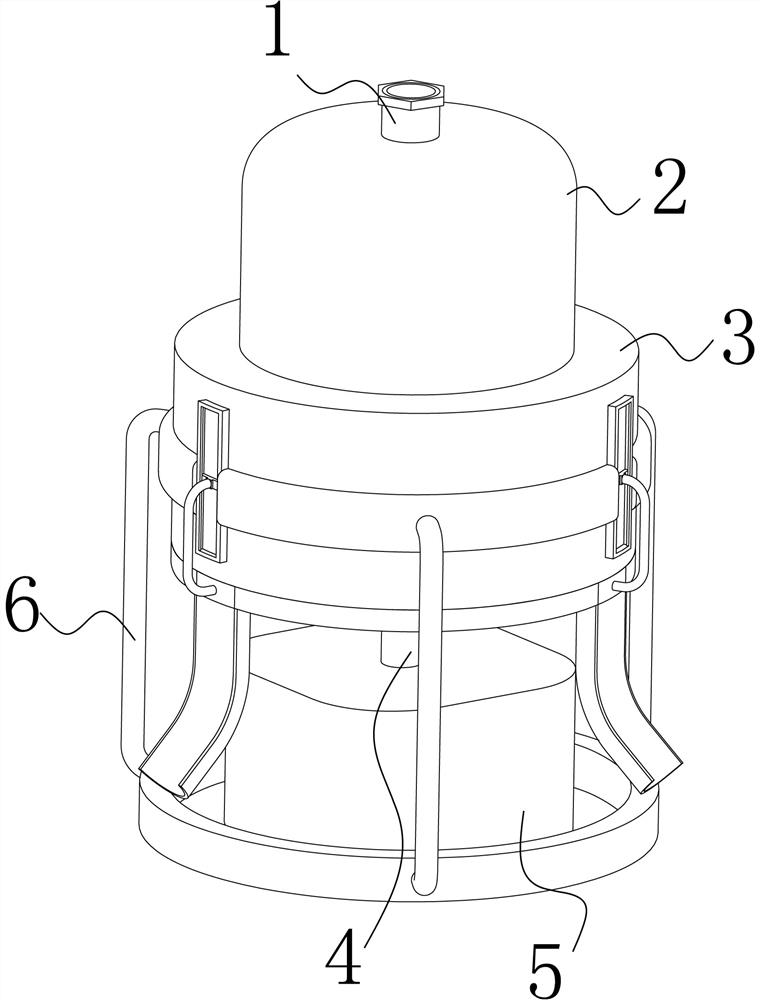

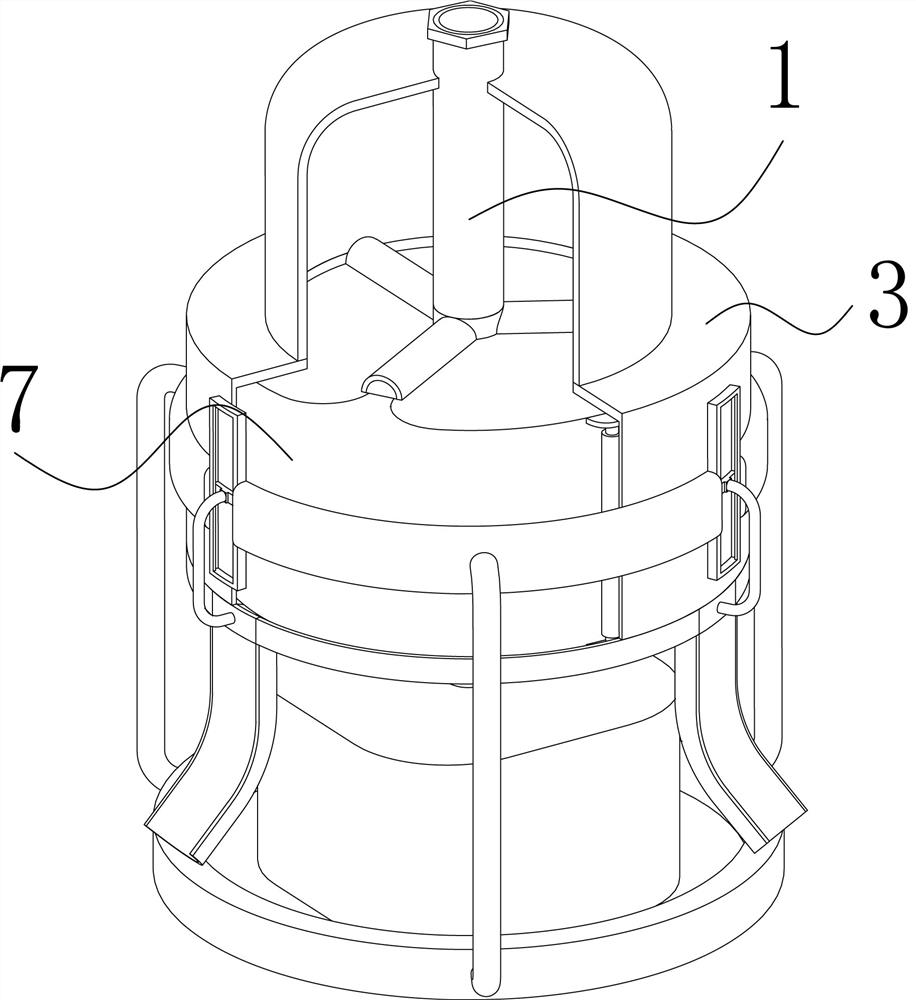

Servo double-surface heating vacuum packaging machine

ActiveCN102201592AQuality is not affectedGuarantee exclusionFinal product manufactureSecondary cells manufactureControl systemEngineering

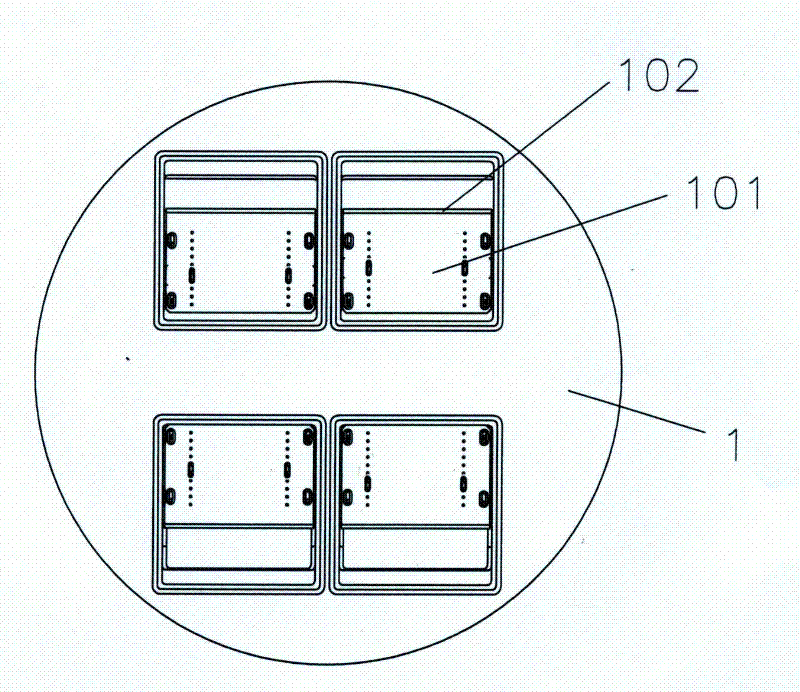

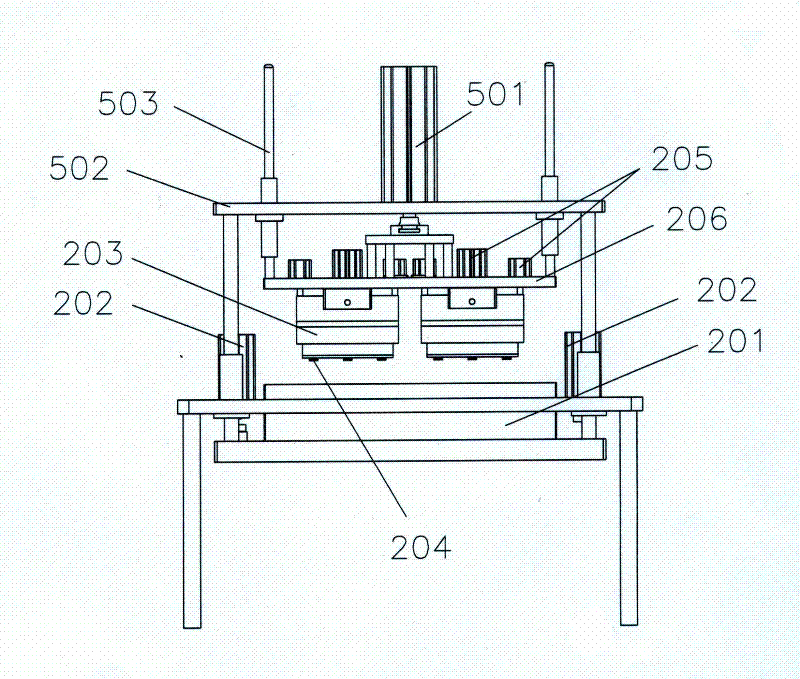

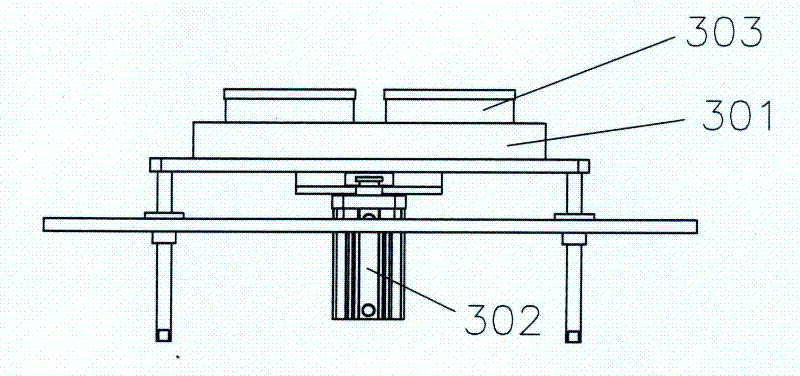

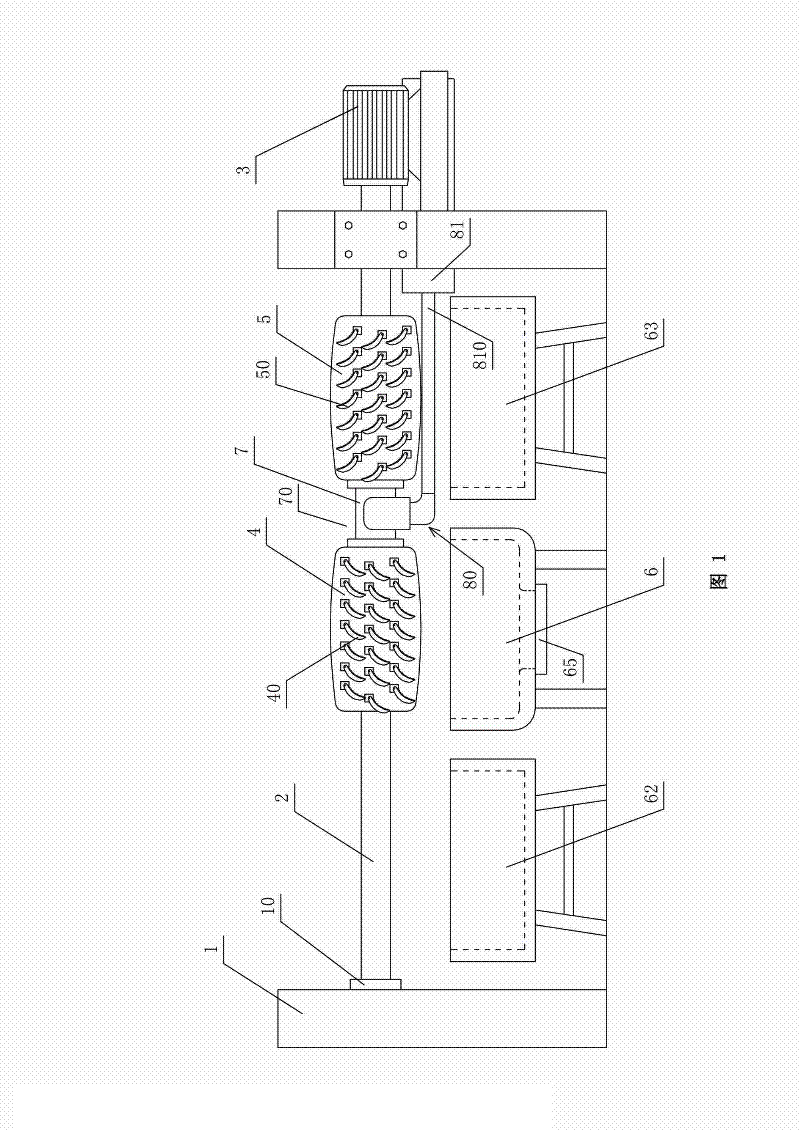

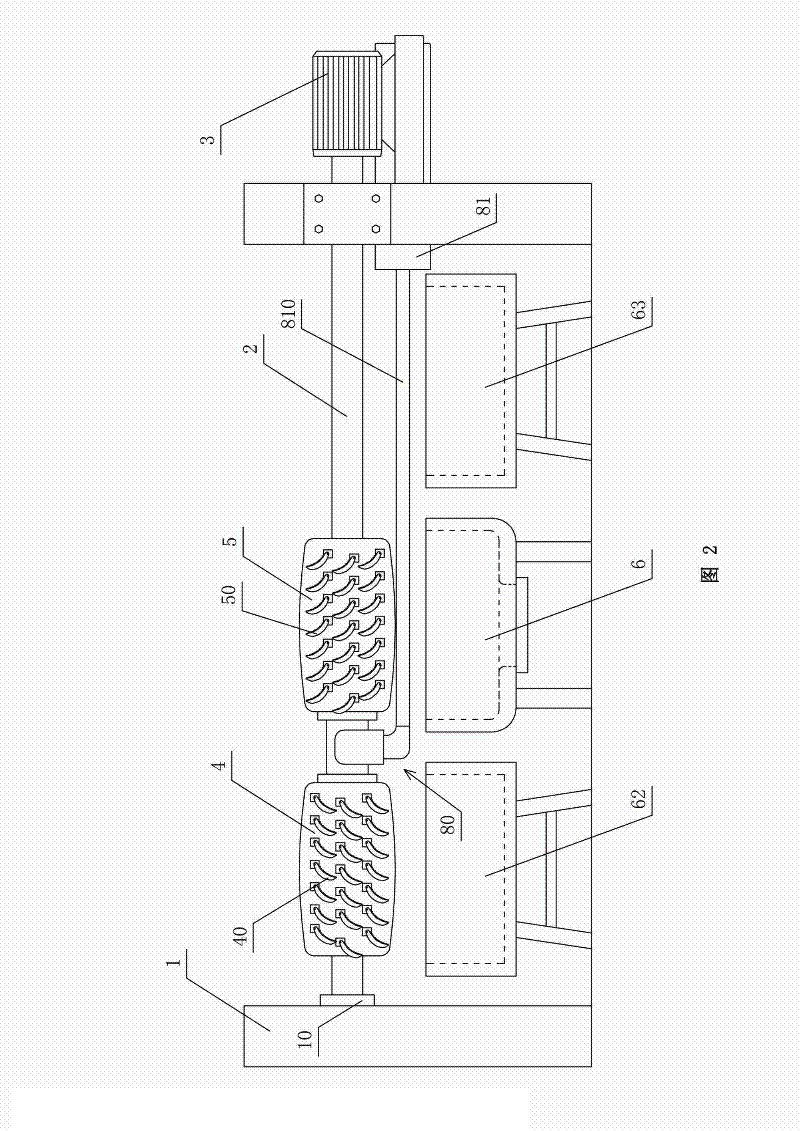

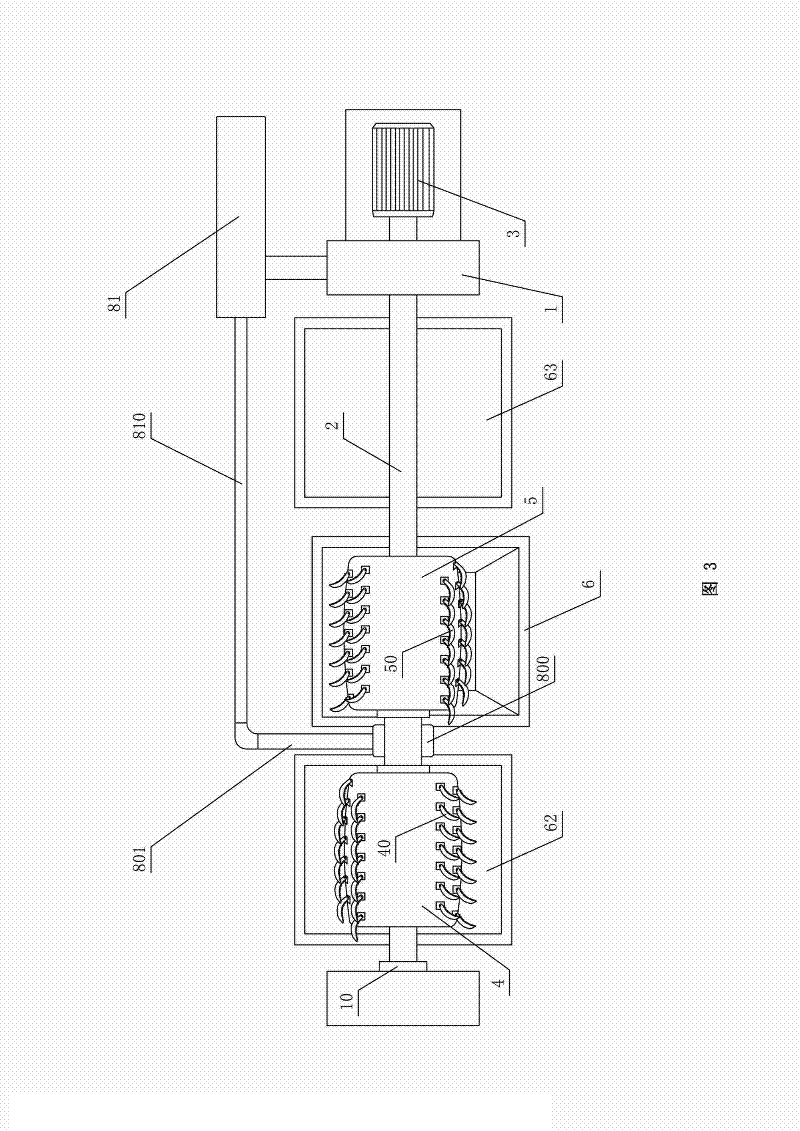

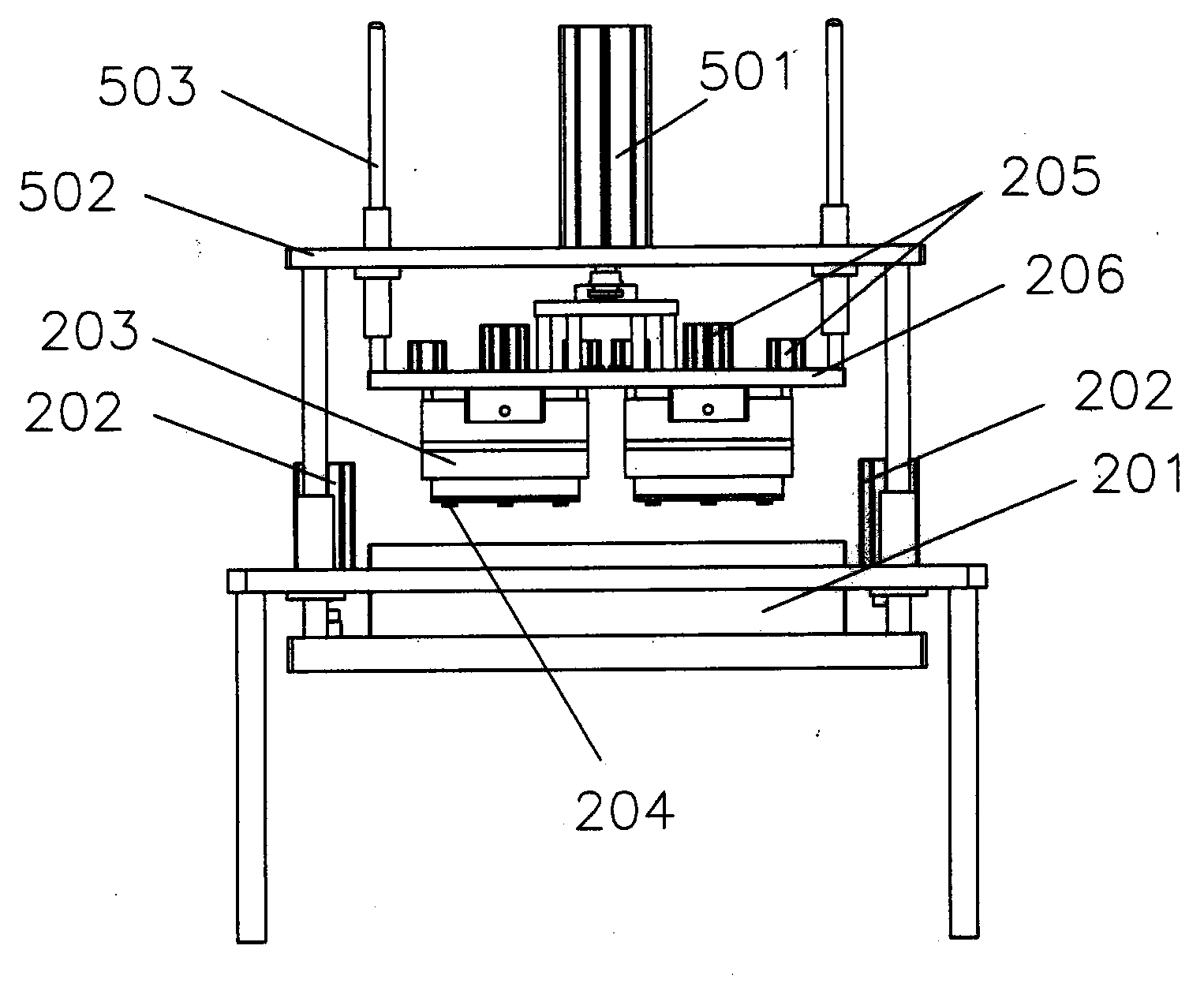

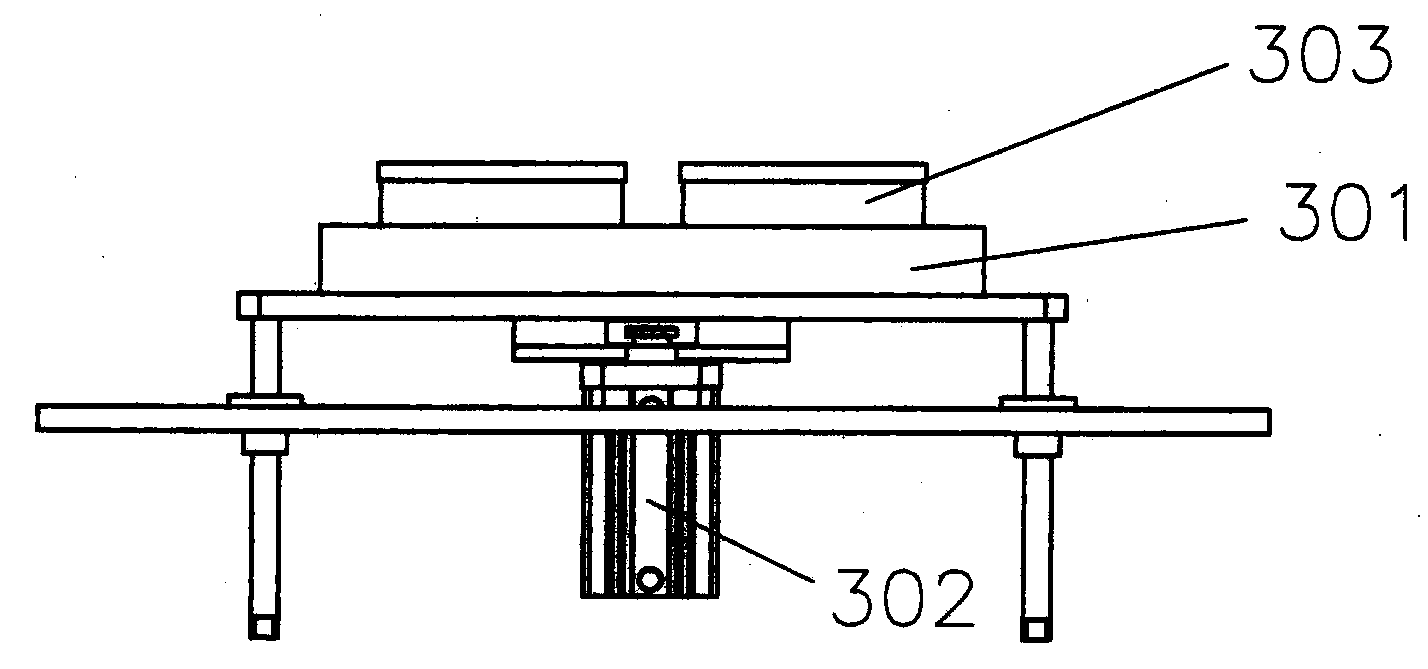

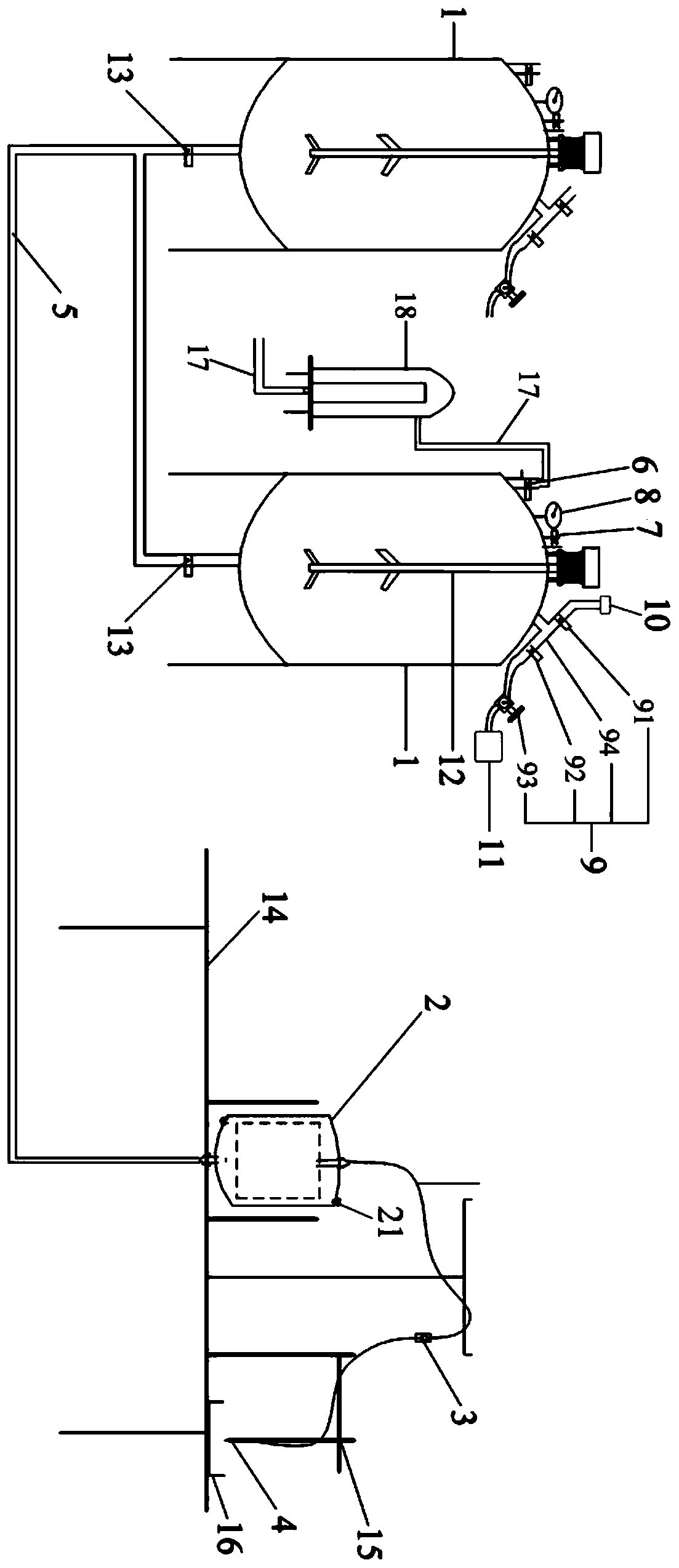

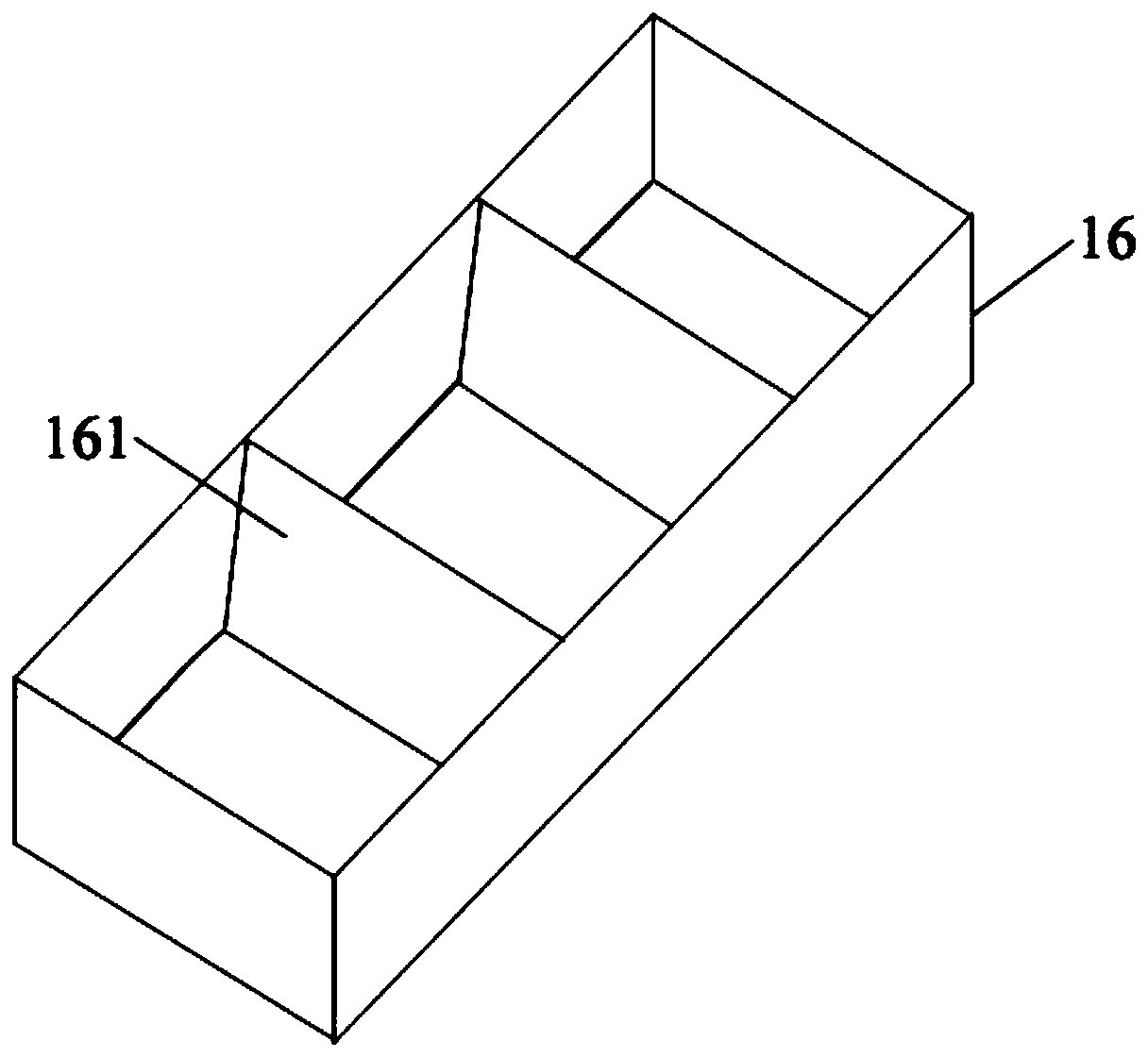

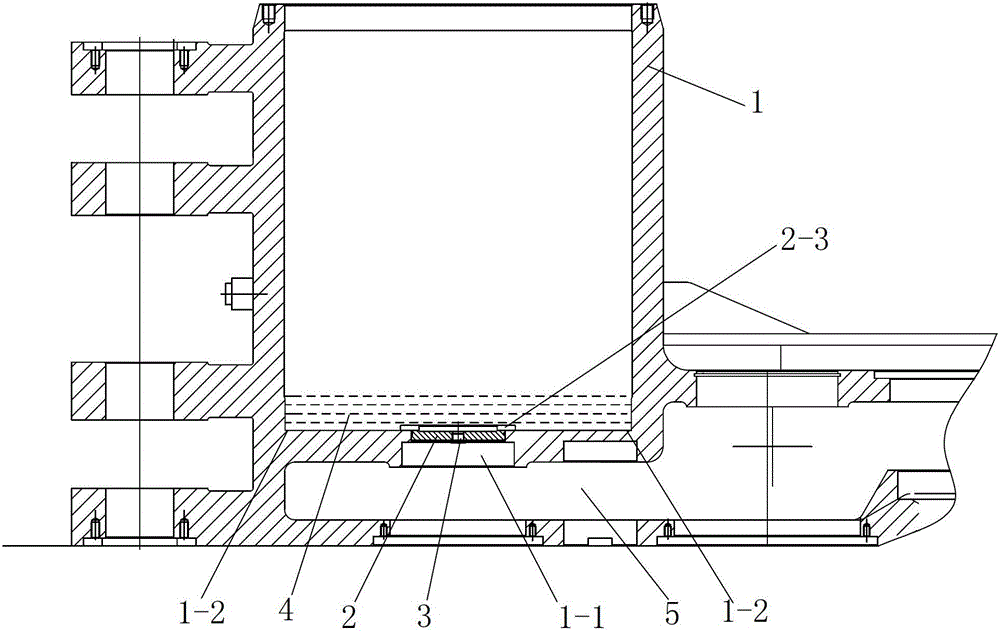

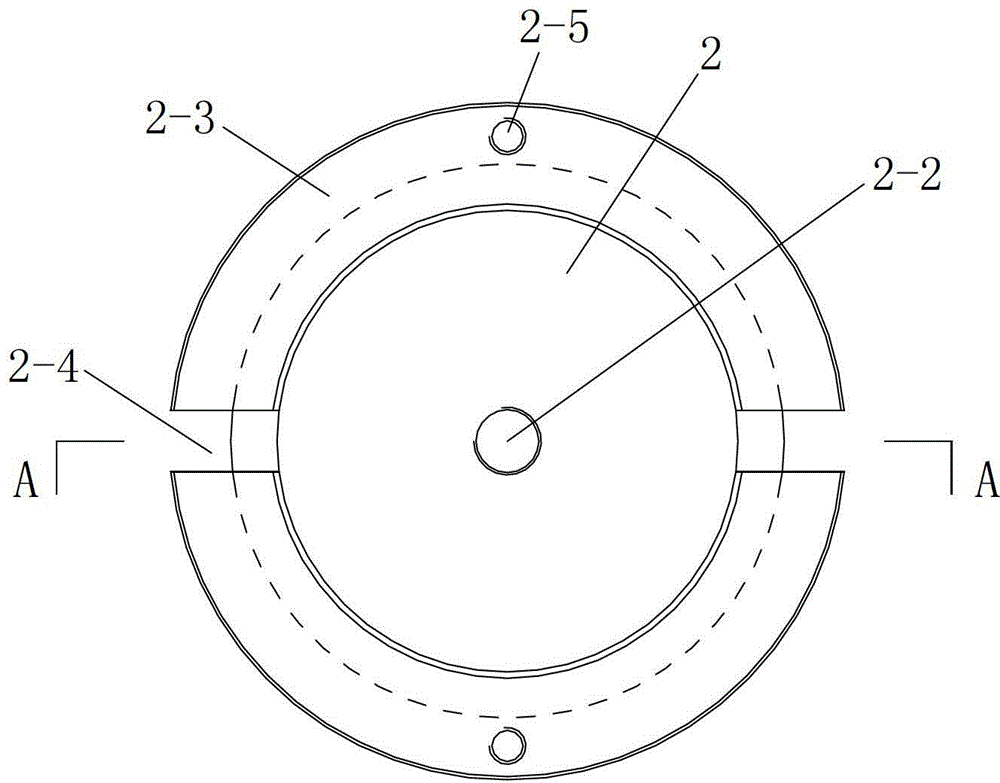

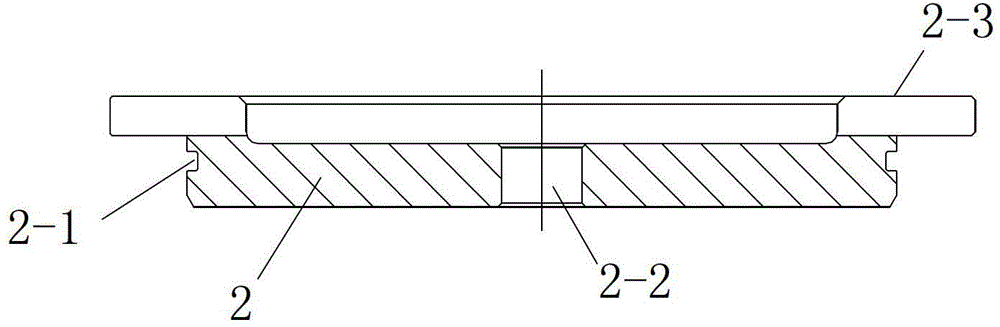

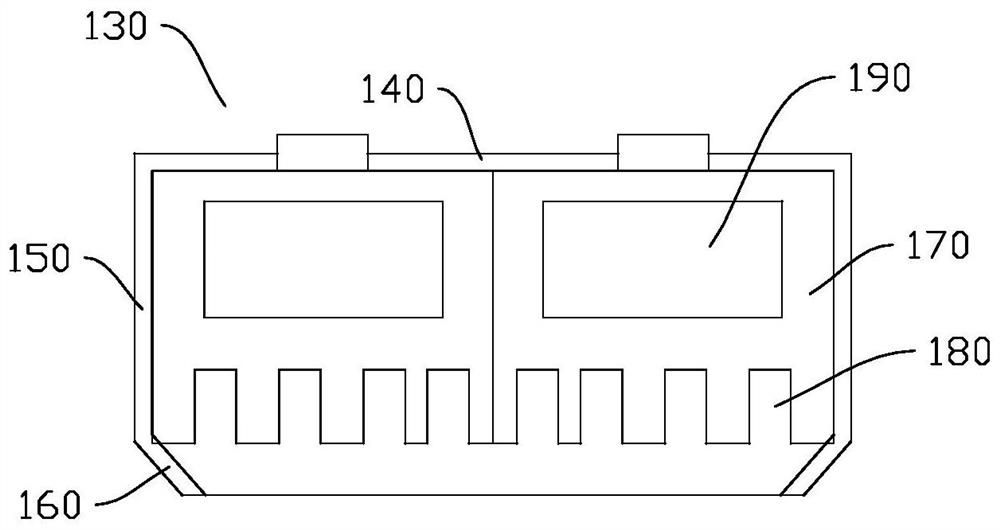

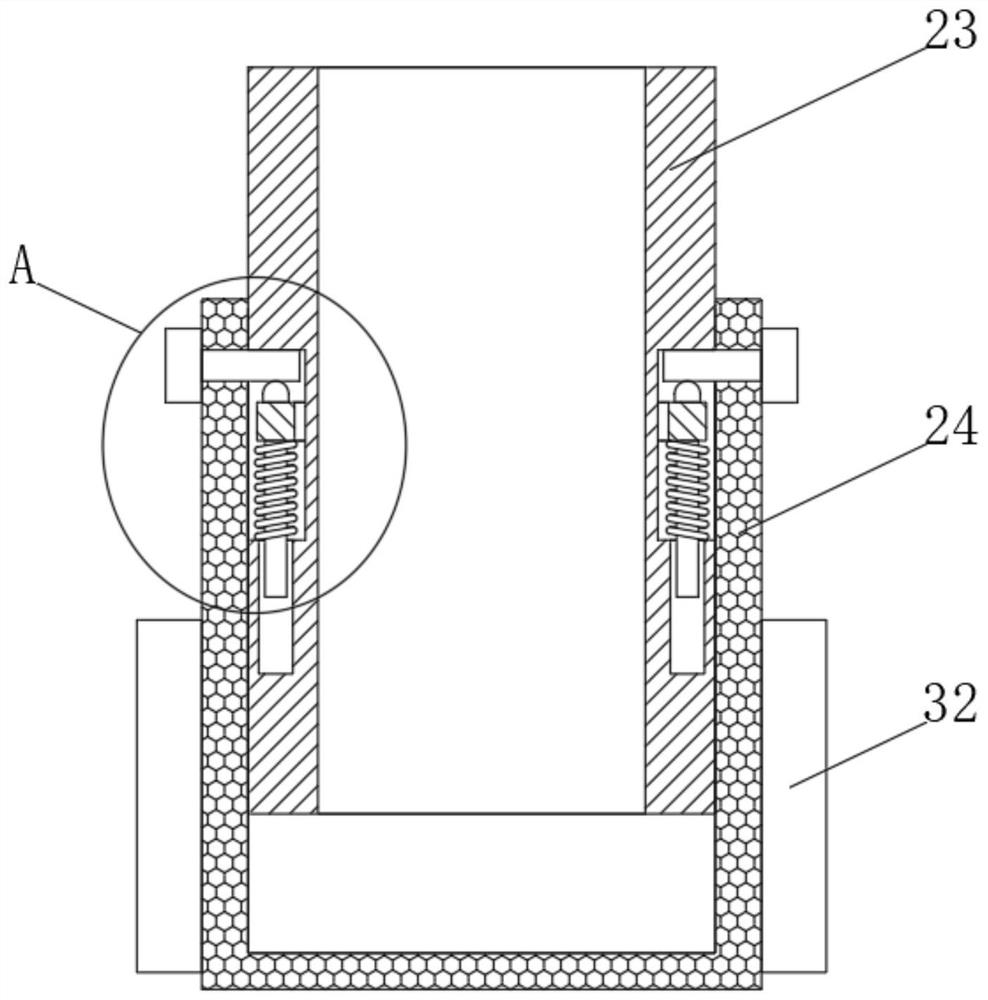

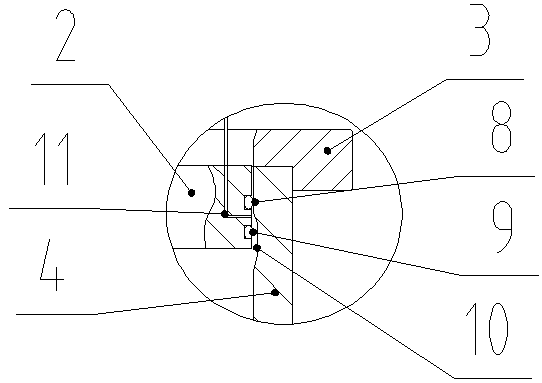

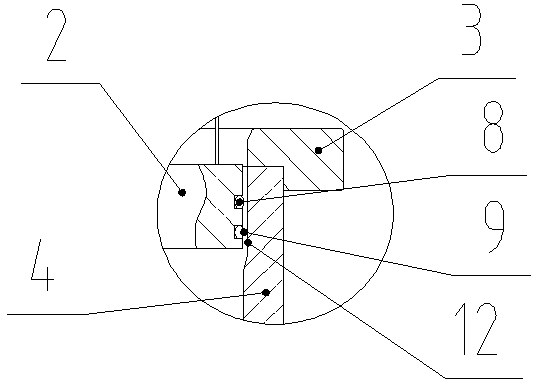

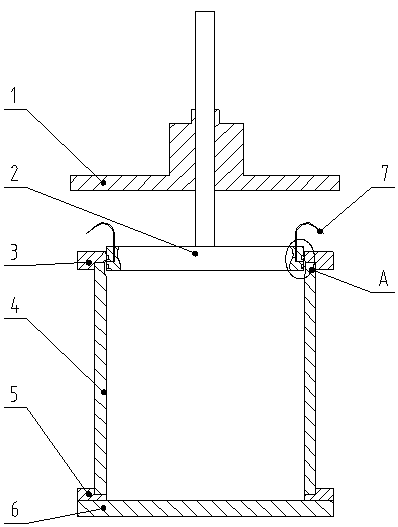

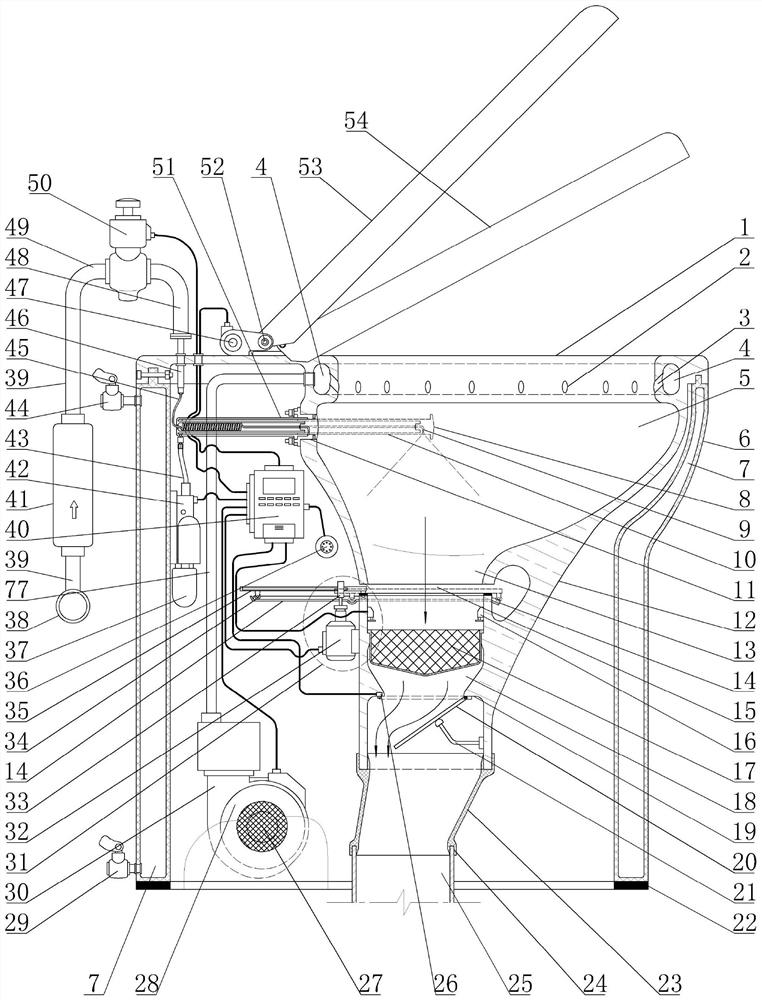

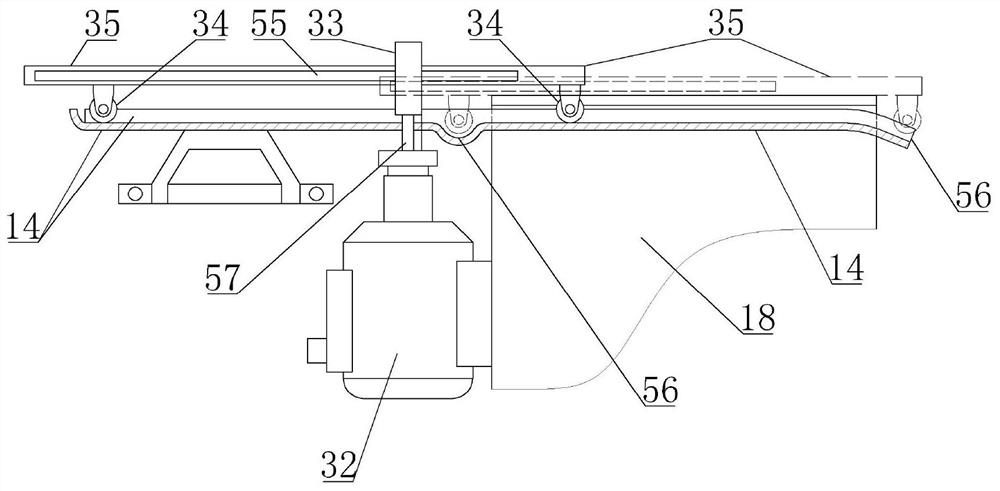

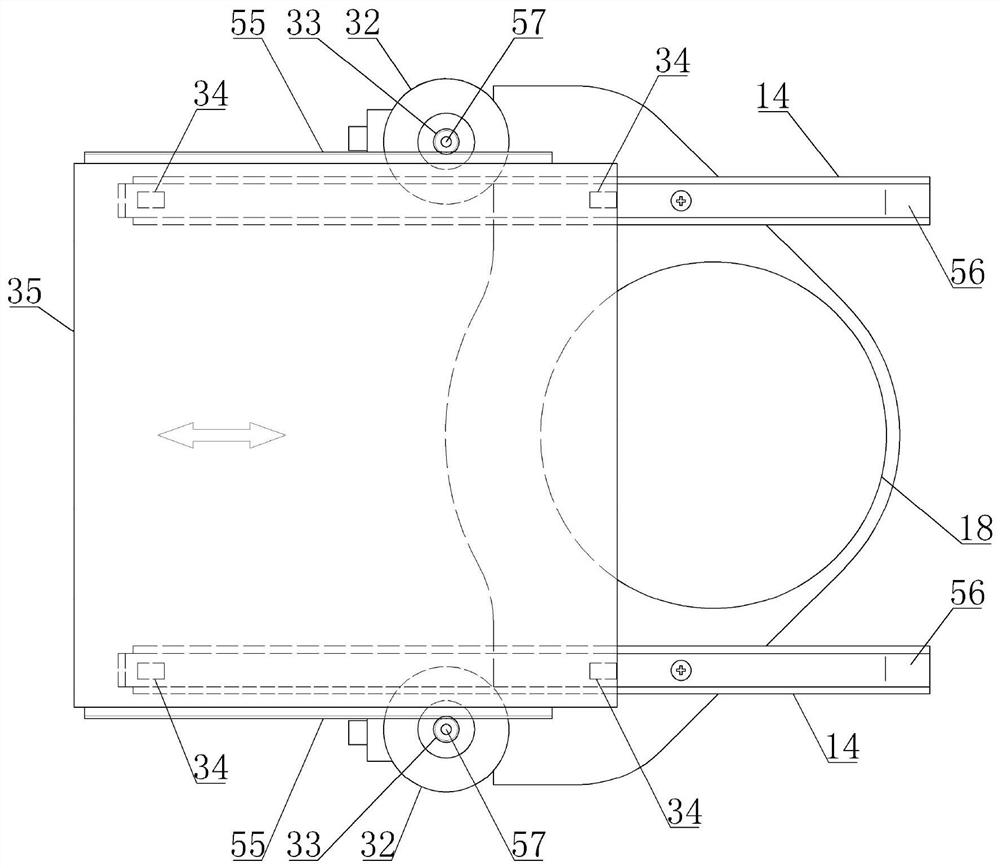

The invention discloses a servo double-surface heating vacuum packaging machine and belongs to liquid extraction seal secondary forming and packaging equipment of flexible packaged lithium batteries. The servo double-surface heating vacuum packaging machine comprises a double-station turntable feeding device driven by a cam partitioning device, a packaging mechanism with an up-and-down packaging device, and an electric control system, wherein the up-and-down packaging device comprises an upper cavity main body and a lower cavity main body; the opening directions of the upper cavity main body and the lower cavity main body are opposite to each other; the upper cavity main body and the lower cavity main body can clamp the turntable to form a sealed cavity body; a pressing board, an upper sealing head and a bayonet are arranged in the upper cavity main body; a lower sealing head and an aspirating hole are arranged in the lower cavity main body; the aspirating hole is communicated with an external vacuum source; the upper sealing head corresponds to the lower sealing head; and a heating body is arranged inside the servo double-surface heating vacuum packaging machine. The servo double-surface heating vacuum packaging machine has a compact structure and high efficiency; the electric core packaging quality is stable and the cost is low; vacuum liquid extraction can be realized; and pollution of the electrolyte to the equipment can be reduced to minimum.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

Polymer lithium ion battery formation process

InactiveCN110896154AFully contactedExcludedFinal product manufactureSecondary cells charging/dischargingElectrolytic agentLithium-ion battery

The invention discloses a formation process of a polymer lithium ion battery. The formation process comprises hot pressing before formation, hot pressing formation and hot pressing after formation, hot pressing before formation can completely discharge gas between battery roll core layers, so that the positive plate, the negative plate, the diaphragm and the electrolyte are in full contact, and preparation is made for formation; hot-pressing formation is adopted during formation, a stable and compact SEI film can be formed on the surface of the negative plate at a proper temperature, and expansion of the positive plate and the negative plate can be effectively inhibited under a certain pressure, so that the thickness of the battery is reduced, and the capacity of the battery is improved; according to the method, proper temperature and pressure are adopted after formation, so that the flatness and hardness of the battery cell can be improved, the formed SEI film can quickly tend to be stable, and the cycle life of the battery is prolonged. The method is simple in process and easy to operate, and industrialization is easy to achieve.

Owner:SHENZHEN GPC ENERGY GRP CO LTD

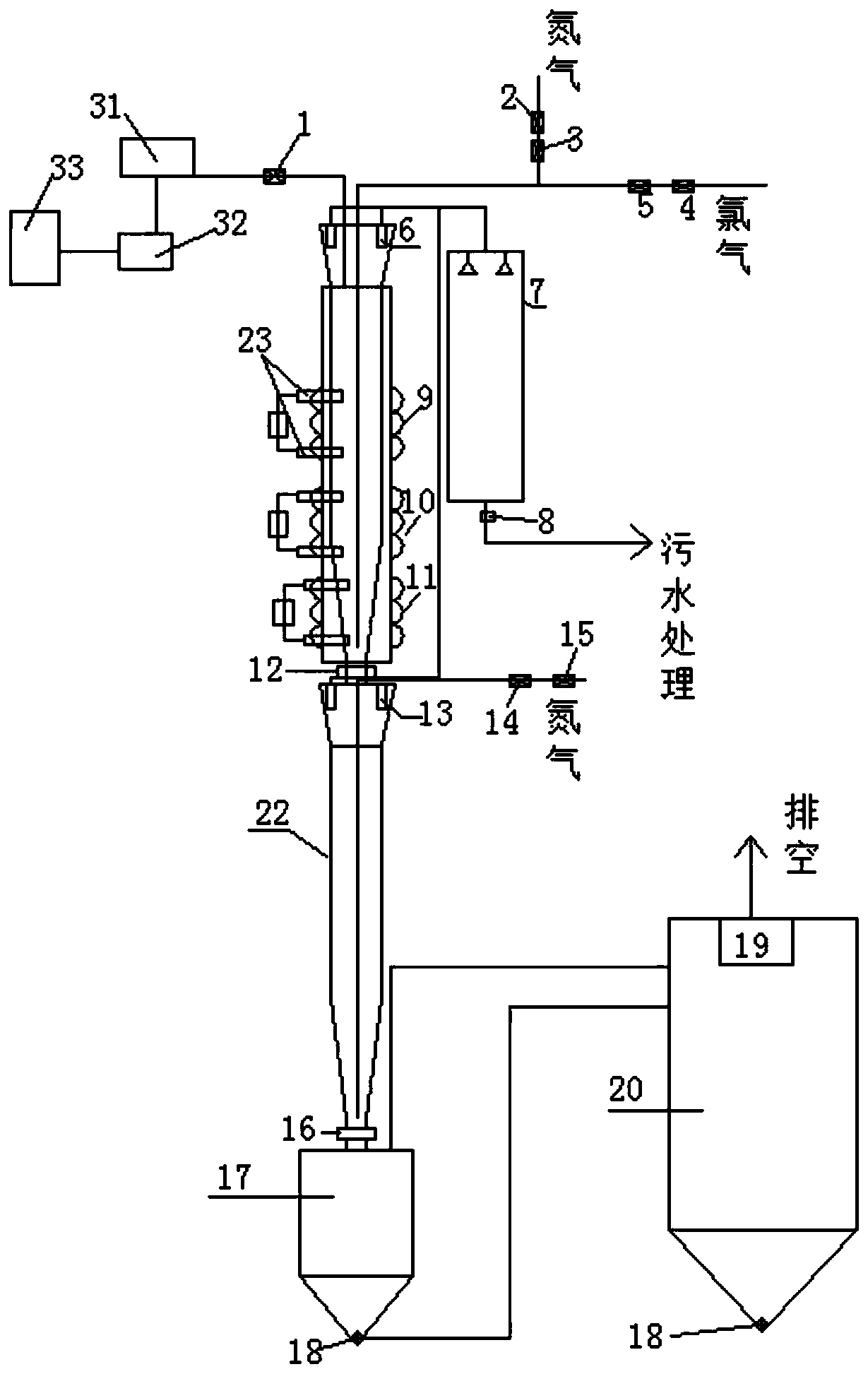

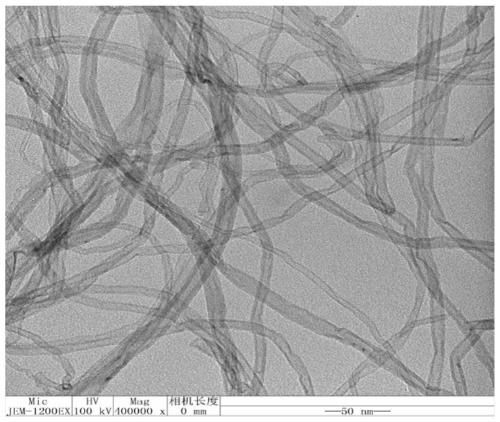

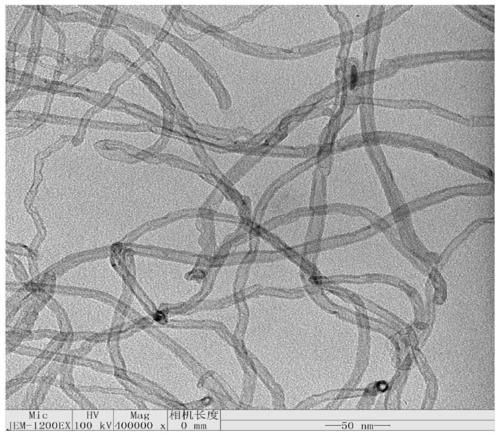

Device and method for directly electrifying and purifying carbon nano tube

InactiveCN111410188ASimplify complex structuresSave a lot of spaceCarbon nanotubesChemistryProcess engineering

The invention relates to the technical field of carbon nano tube purification, in particular to a device and a method for directly electrifying and purifying a carbon nano tube. The device comprises amain reactor, the main reactor comprises a material preheating section, a low-temperature heating reaction section, a high-temperature heating reaction section and a material cooling section which are sequentially arranged from top to bottom, the upper end of the main reactor is connected with a feeding valve, the feeding valve is connected with a feeding weighing device, the feeding weighing device is connected with a constant-pressure tank, and the constant-pressure tank is connected with a carbon nano tube storage tank; the invention discloses a device and a process method for directly electrifying and heating a carbon nano tube material in a reactor and then continuously purifying carbon nano tubes by adopting chlorine or hydrogen chloride gas. According to the continuous industrial purification device, graphite is adopted as an inner container of a reactor, a pouring material frame is combined, carbon nano tubes in the reactor are directly powered on, and acid gas and granular carbon nano tubes are used for reaction purification.

Owner:甘海半导体材料(上海)有限公司 +1

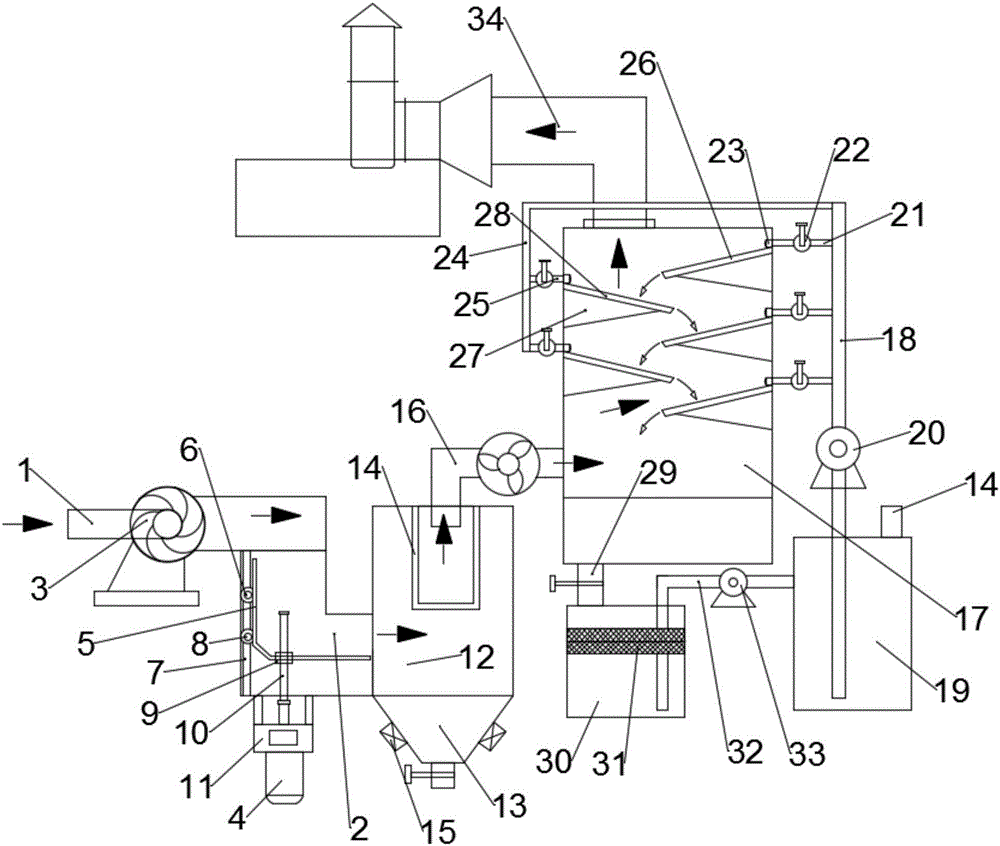

Water curtain check-type super-purification smoke exhaust dedusting and desulfurization system

InactiveCN106693650AAffect the effect of dust removalAffect the purification effectCombination devicesGas treatmentExhaust fumesEngineering

The invention discloses a water curtain check-type super-purification smoke exhaust dedusting and desulfurization system, which comprises a smoke exhaust inlet tube, wherein the end part of the smoke exhaust inlet tube is connected to a flow rate control tube; the left side wall of a tube body of the flow rate control tube is provided with a guide rail; the internal thread of a lifting nut is adaptively provided with a rotating screw rod; two side walls of a conical extrusion cavity are respectively provided with one vibrating motor; the left side wall of the upper side of an inner cavity in a case body of an ultra-clean desulfuration case is provided with first diversion water curtain boards; the two first diversion water curtain boards and three second diversion water curtain boards are staggered; the bottom end of a tube body of a drainage through tube is communicated with a circulating filter box pump. The system is capable of solving the problem of weakened desulfuration effect caused by uncontrollable smoke feeding velocity in a traditional process, ensuring that sulfides in the smoke are fully absorbed and removed and the treated solvent also can be recycled, and further saving the solvent resource.

Owner:合肥图腾龙企业管理事务所(有限合伙)

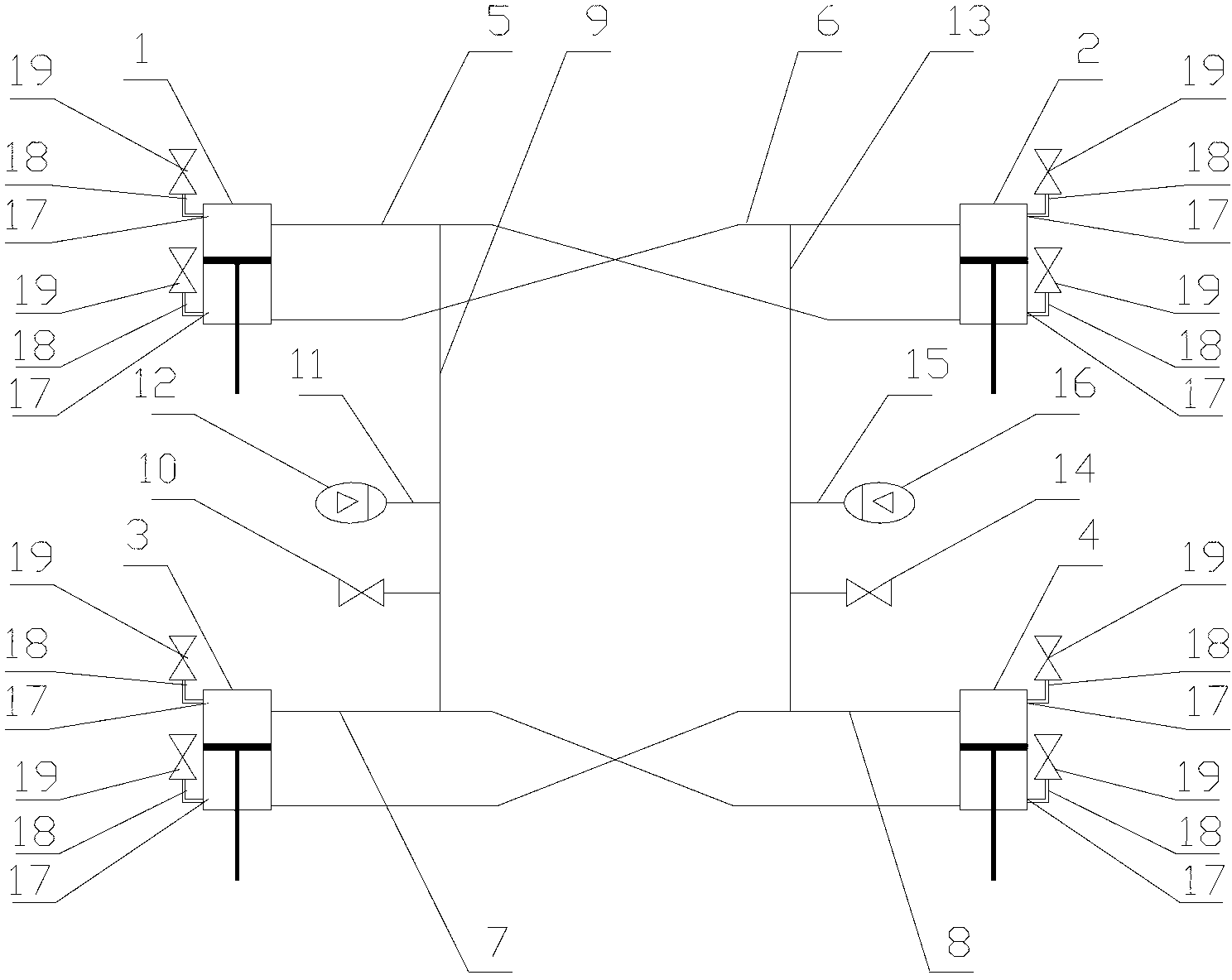

Hydraulic interconnection suspension system and exhausting and sealing method for same

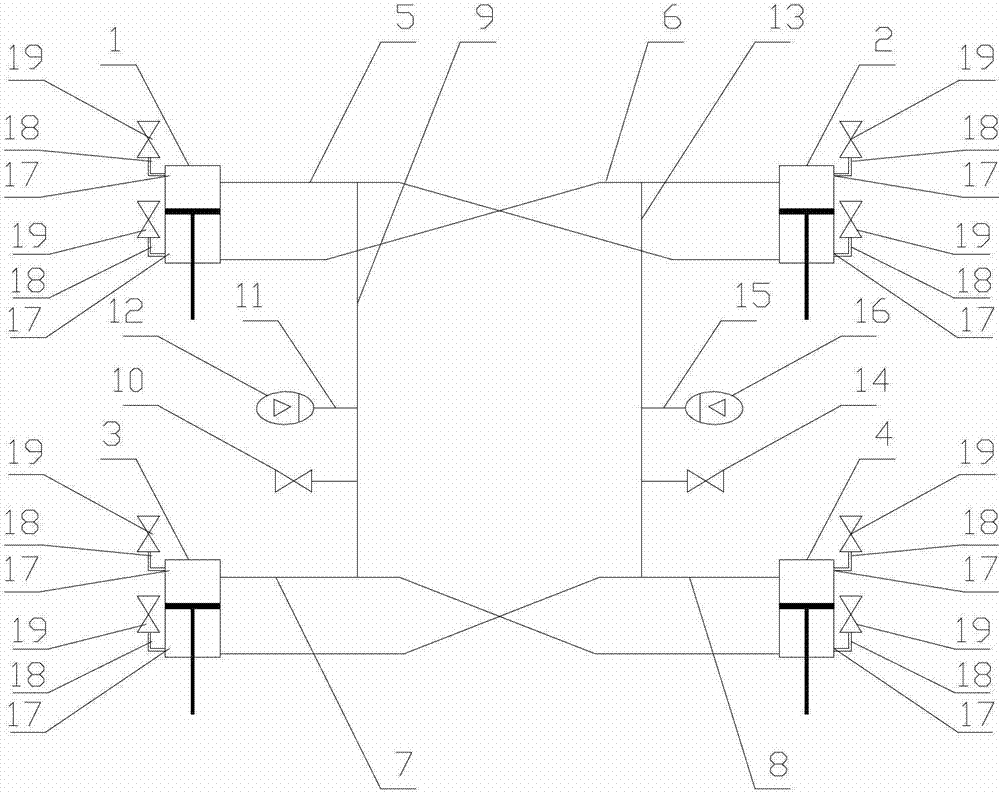

InactiveCN103273820AWork lessExcludedInterconnection systemsFluid-pressure actuator componentsHydraulic cylinderHydraulic pump

The invention discloses a hydraulic interconnection suspension system. Four hydraulic cylinders, two energy storages, two spherical valves and hydraulic pipes are connected with one another to form two hydraulic branches of the hydraulic interconnection suspension system. The invention further provides an exhausting and sealing method for the hydraulic interconnection suspension system. The hydraulic interconnection suspension system and the exhausting and sealing method have the advantage that bubbles are prevented in the hydraulic branches when the hydraulic interconnection suspension system is used.

Owner:苏州友邦汽车底盘科技有限公司

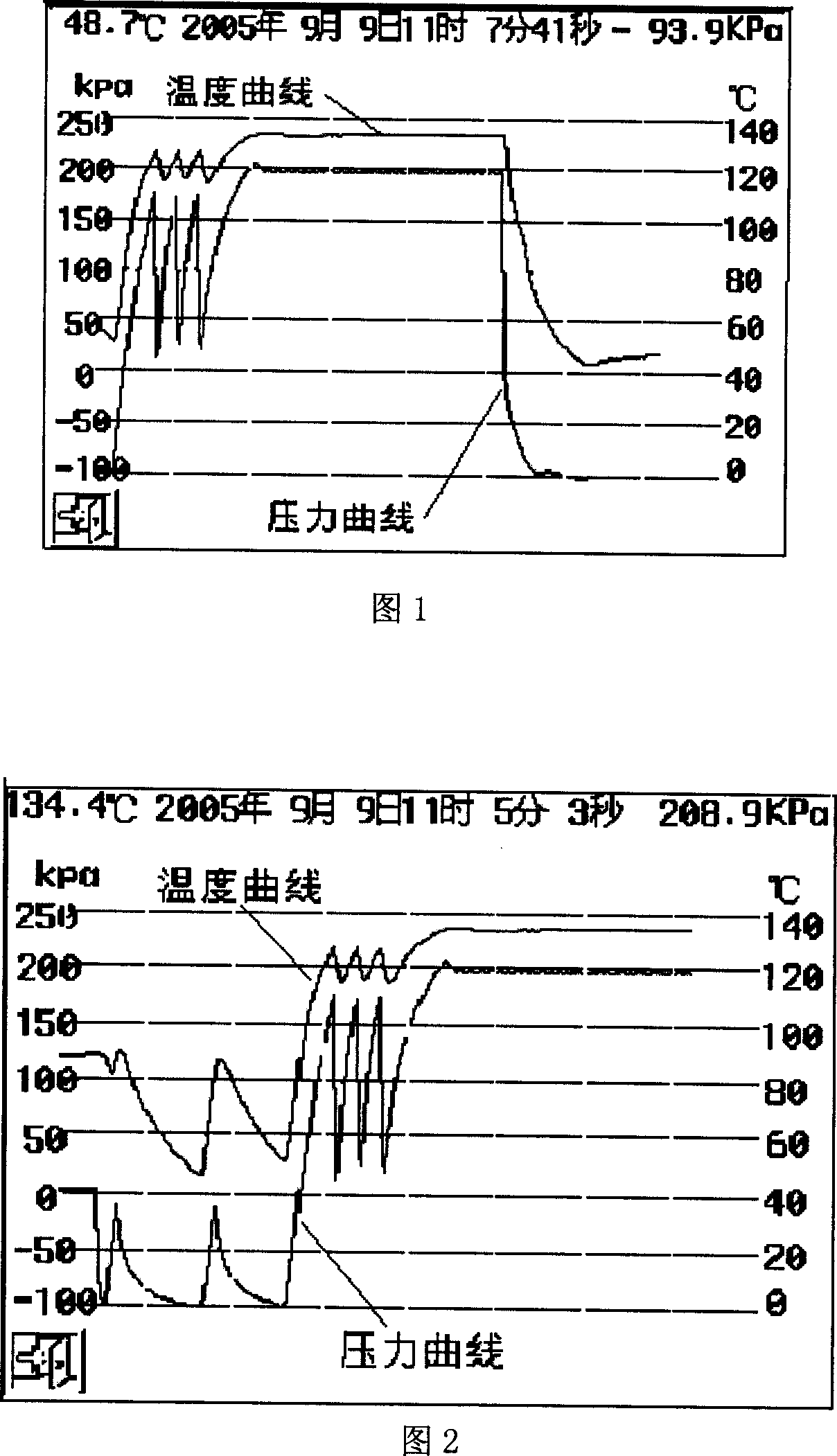

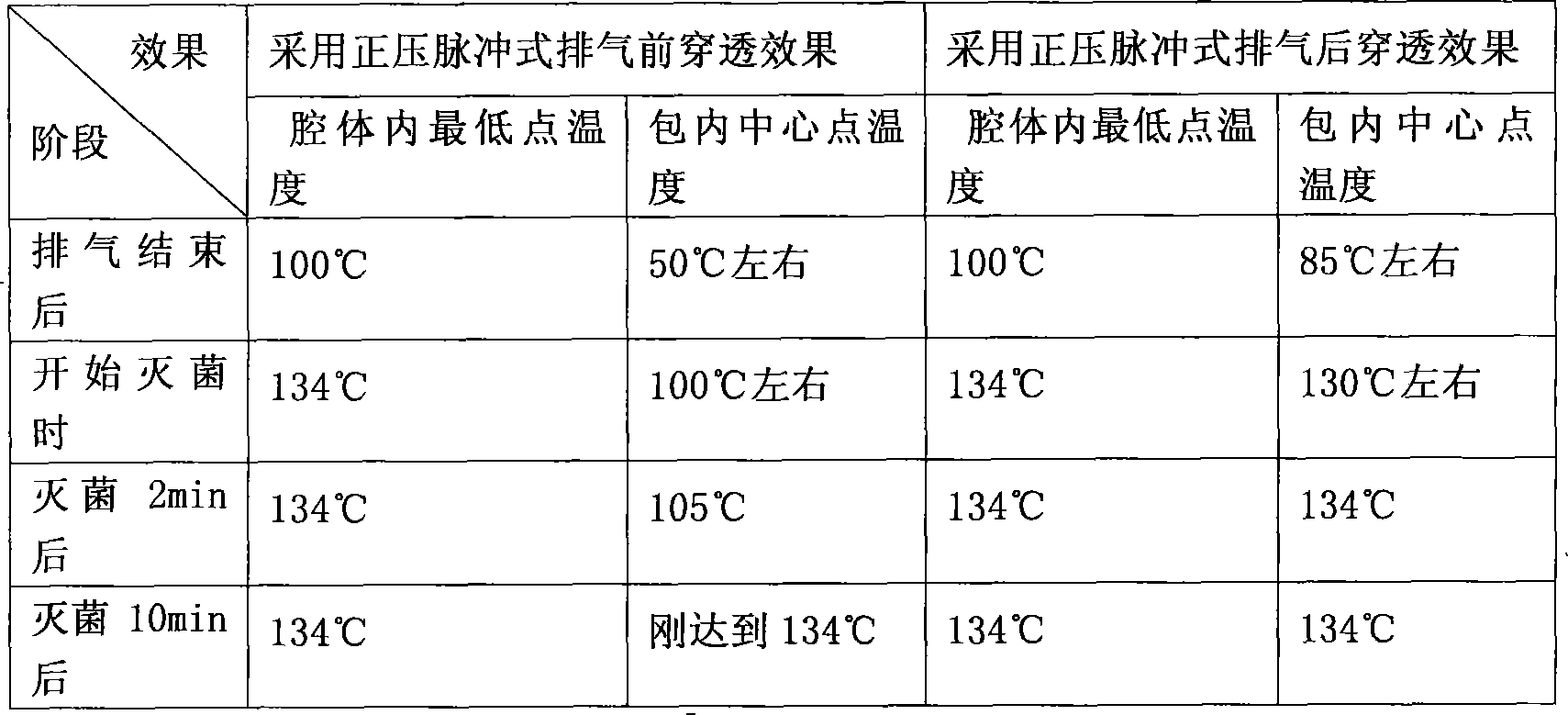

Pressure steam sterilizer dynamic pulse type gas exhausting method

The invention relates to a dynamic pulse type exhaust method of a pressure steam sterilizer, which is used for improving the cold air exhaust effect of the pressure steam sterilizer, firstly, the pretreatment exhaust of the pressure steam sterilizer need to be conducted, the variables of the sterilizer body need to be gathered, the upper limit value and the lower limit value need to be set, and then one to nine times of intermittent process of repetitive steam inlet and outlet are added, the steam inlet raises the variable of the sterilizer body all the way to the upper limit value, and then the steam exhaust outlet reduces the variable of the body gradually to the lower limit value. The invention can further exhaust the residual cold air in the sterilizer body as much as possible, then the temperature of the steam inlet raises continuously until coming to the sterilization process, so the sterilization begins, then the cold air exhaust effect is good, the penetration of steam is excellent, so the sterilization effect is largely improved.

Owner:SHINVA MEDICAL INSTR CO LTD

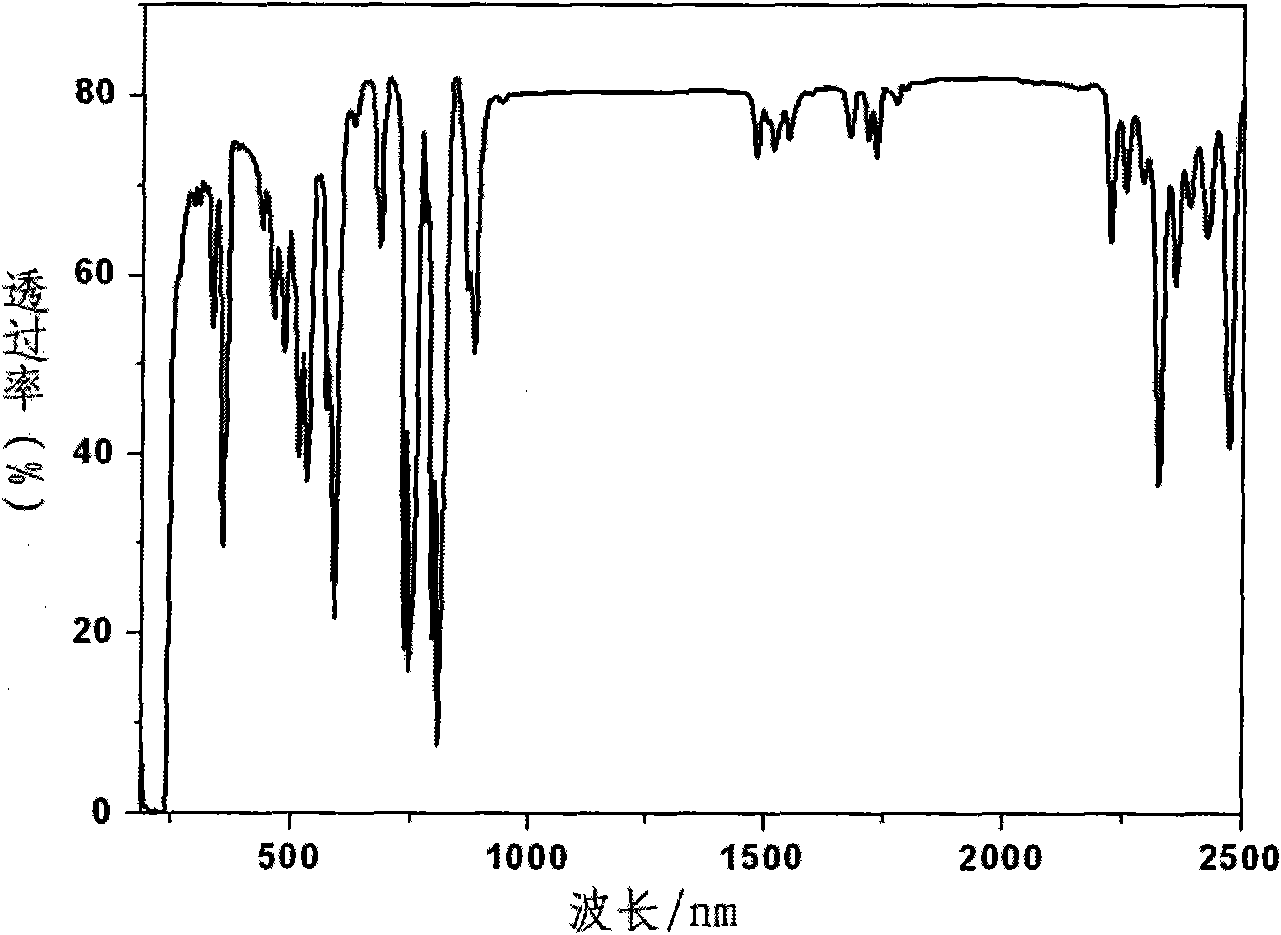

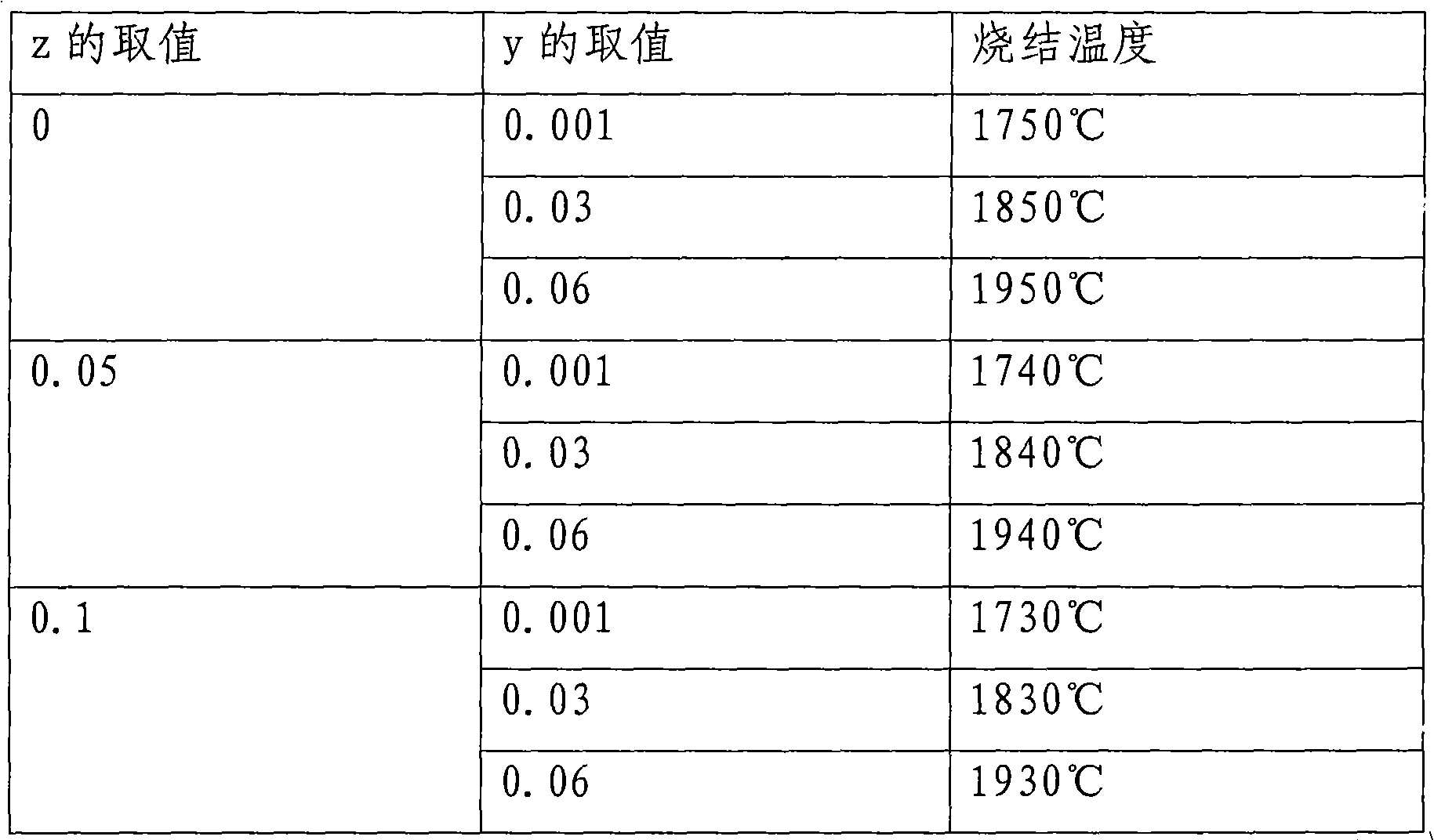

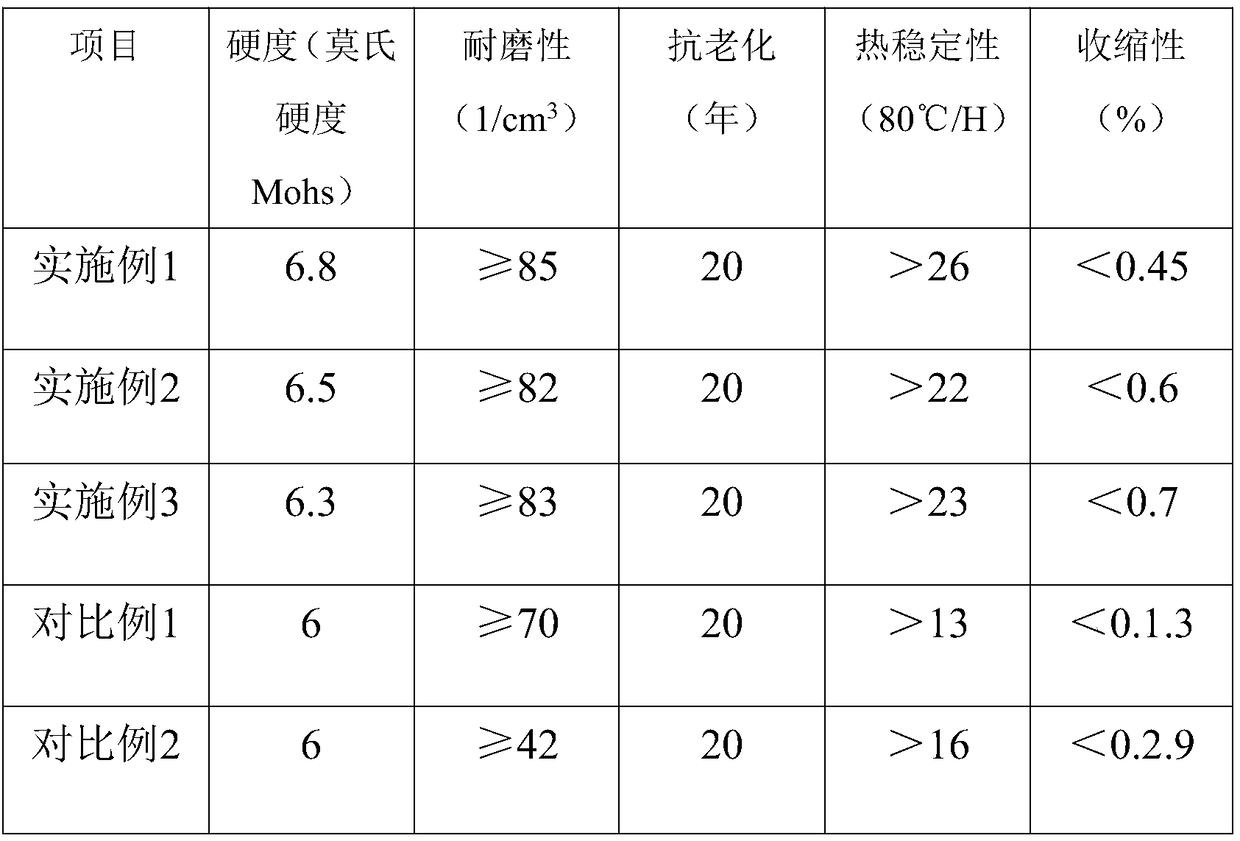

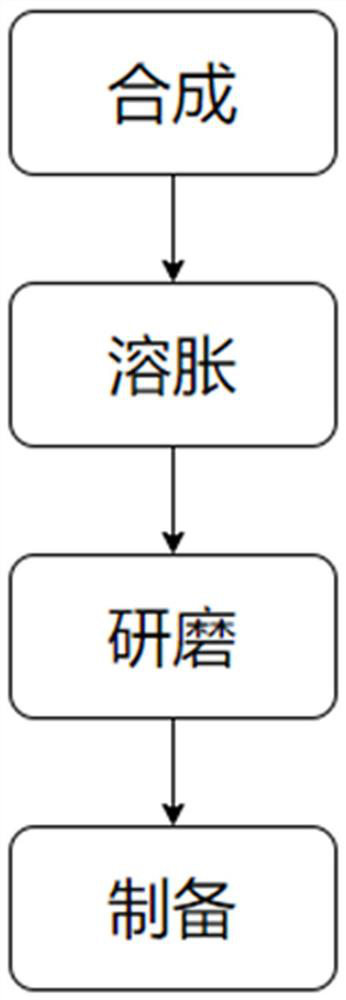

Lanthanum-zirconium codoped rare-earth sesquioxide transparent ceramic and preparation method thereof

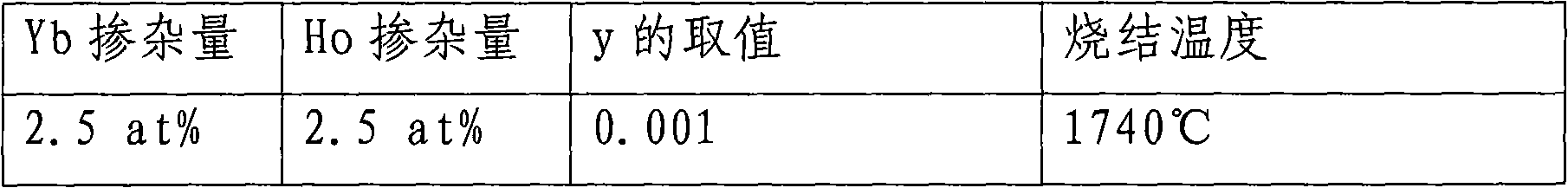

The invention discloses lanthanum-zirconium codoped rare-earth sesquioxide transparent ceramic and a preparation method thereof. The chemical formula of the lanthanum-zirconium codoped rare-earth sesquioxide transparent ceramic is R(2-2X-2Y-2Z)La2xZr2yLn2zO3, wherein x is more than or equal to 0.01 and less than or equal to 0.2; y is more than or equal to 0.001 and less than or equal to 0.06; z is more than or equal to 0 and less than or equal to 0.1; R refers to one of rare-earth elements such as Y, Lu, Sc and Gd which are usually taken as doping substrates; and Ln refers to one or the combination of a plurality of lanthanum-series elements such as Nd, Tm, Ho, Er, Yb, Tb and Pr which are usually taken as activated ions. Due to the adoption of lanthanum-zirconium codoping in the method for preparing transparent ceramic with a lanthanum-zirconium codoping method, the growth of crystal grains is suppressed to a certain degree while sintering is facilitated, and transparent ceramic with fine crystal grains, a single size and low porosity is finally obtained.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Full-automatic removing machine for concrete sundries

The invention relates to a full-automatic removing machine for concrete sundries, which comprises a bracket, a rotating shaft, a rotating motor, left and right cylinders and a material groove, wherein the rotating shaft is rotatably arranged on the bracket; the rotating motor is used for driving the rotating shaft to rotate; the left and right cylinders are sleeved on the rotating shaft and are capable of sliding; the material groove is alternately matched with the left and right cylinders; the material groove is located under the rotating shaft; the left and right cylinders are synchronouslyconnected by a linkage sleeve; the cross sections of the left and right cylinders are oval-shaped; bent material rakes are arranged on outer side walls of the left and right cylinders; the bent material rake on the left cylinder and the bent material rake on the right cylinder are bent along reverse directions; and the full-automatic removing machine further comprises a horizontal driving mechanism which is used for driving the left and right cylinders to move left and right horizontally on the rotating shaft. The full-automatic removing machine has the advantages of high capability of removing sundries such as rags, broken timbers and the like from construction rubbishes, high working efficiency, reasonable structural design, high practical applicability, and convenience in application and popularization in the construction rubbish recycling projects.

Owner:QUANGONG MACHINERY

Vacuum glue-replenishing method for marble

ActiveCN102794824AGuaranteed solid stabilityExcludedStone-like material working toolsVacuum pumpingPulp and paper industry

The invention relates to a vacuum glue-replenishing method for marble, which comprises the following steps: cleaning the marble surface and the interiors of cracks and drying; preparing a vacuum tank and mounting two sets of 5.5kW rotary-vane vacuum pumps on the vacuum tank; injecting glues on the surface and cracks of the marble; placing the marble injected with the glues into the vacuum tank for performing vacuum pumping treatment; extracting air from the cracks and glue layers of the marble, thereby causing the glue layers to be further compressed and permeated; keeping a pressure value in the vacuum tank within a scope from -0.1MPa to 0.15 MPa; taking the marble out, injecting the glues to the cracks again and repeating the vacuum pumping treatment till the glue layers no longer sink and permeate; and grinding and polishing the glue-replenished marble. The vacuum glue-replenishing method is simple in technology. The waste phenomenon caused by using the marble as a building material is effectively eliminated.

Owner:天下石仓(天津)有限公司

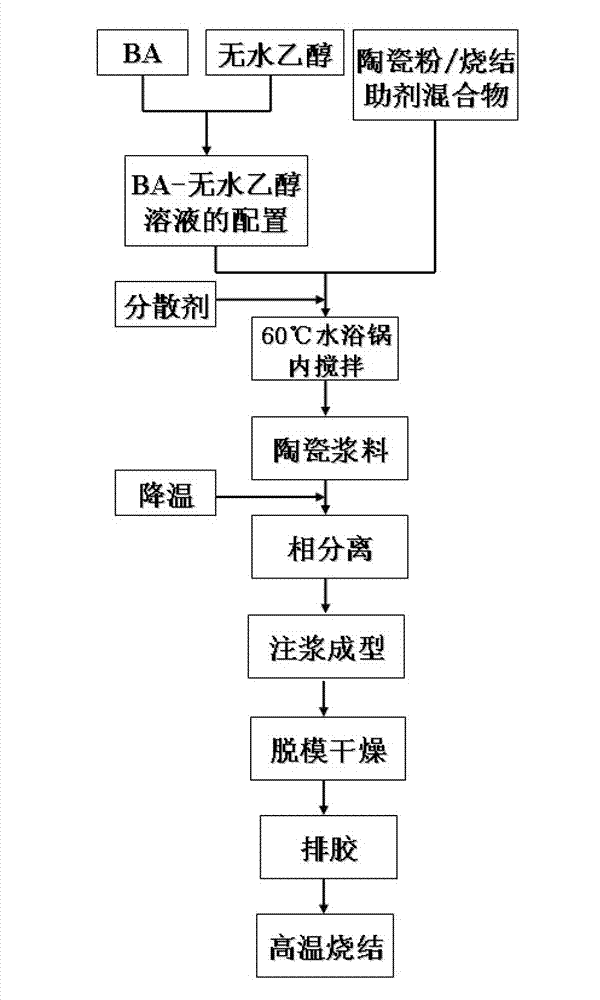

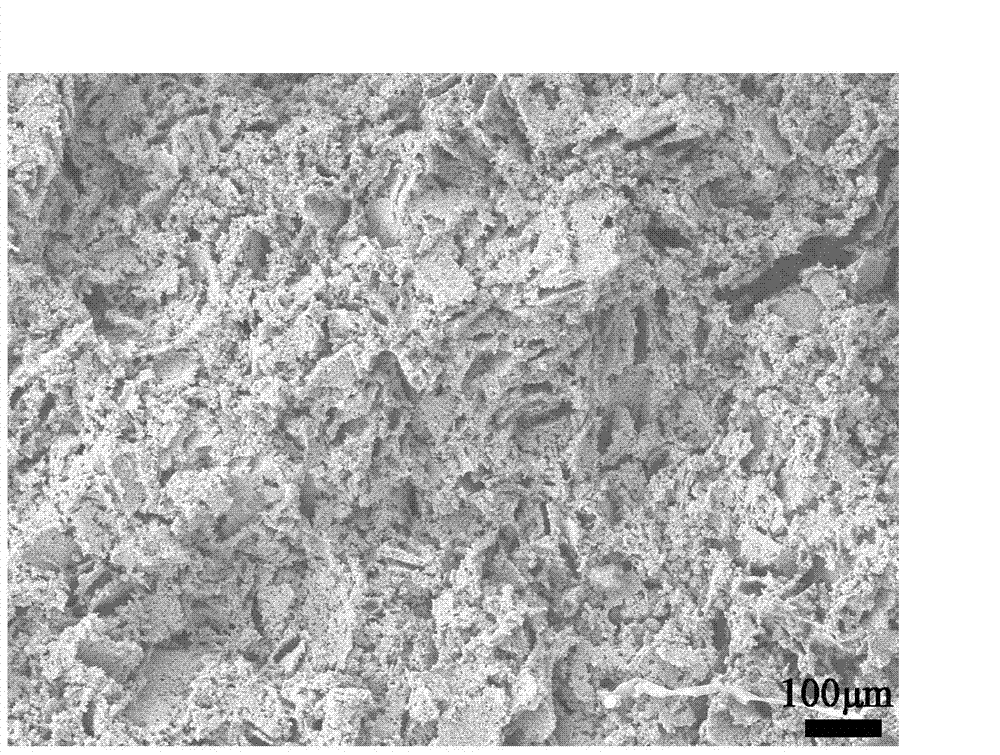

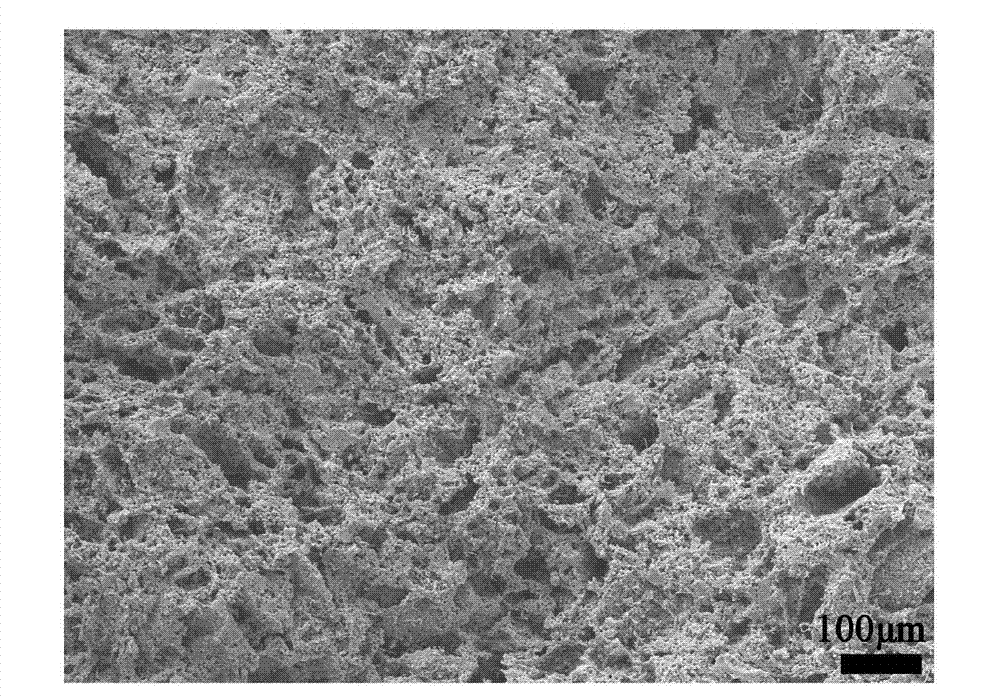

Method for utilizing thermally induced phase separation technology to prepare porous ceramic

The invention discloses a method for utilizing a thermally induced phase separation technology to prepare porous ceramic. The method comprises the following steps of: utilizing easily-volatilized benzoic acid BA as a pore forming agent; dissolving the pore forming agent into absolute ethyl alcohol; utilizing the thermally induced phase separation technology to control the quantity and the shape of the pore forming agent; and utilizing a traditional slip casting molding method to prepare a ceramic blank. According to the method disclosed by the invention, a phase separation temperature, a temperature reduction speed and a solution viscosity are controlled to control the quantity, the size and the shape of the phase separation pore forming agent, so that the size of the porosity and the pore shape of the porous ceramic are controlled; and the method has the advantages of controlling the shape of an air pore and the size of the air pore, and can carry out low-temperature hole formation.

Owner:XI AN JIAOTONG UNIV

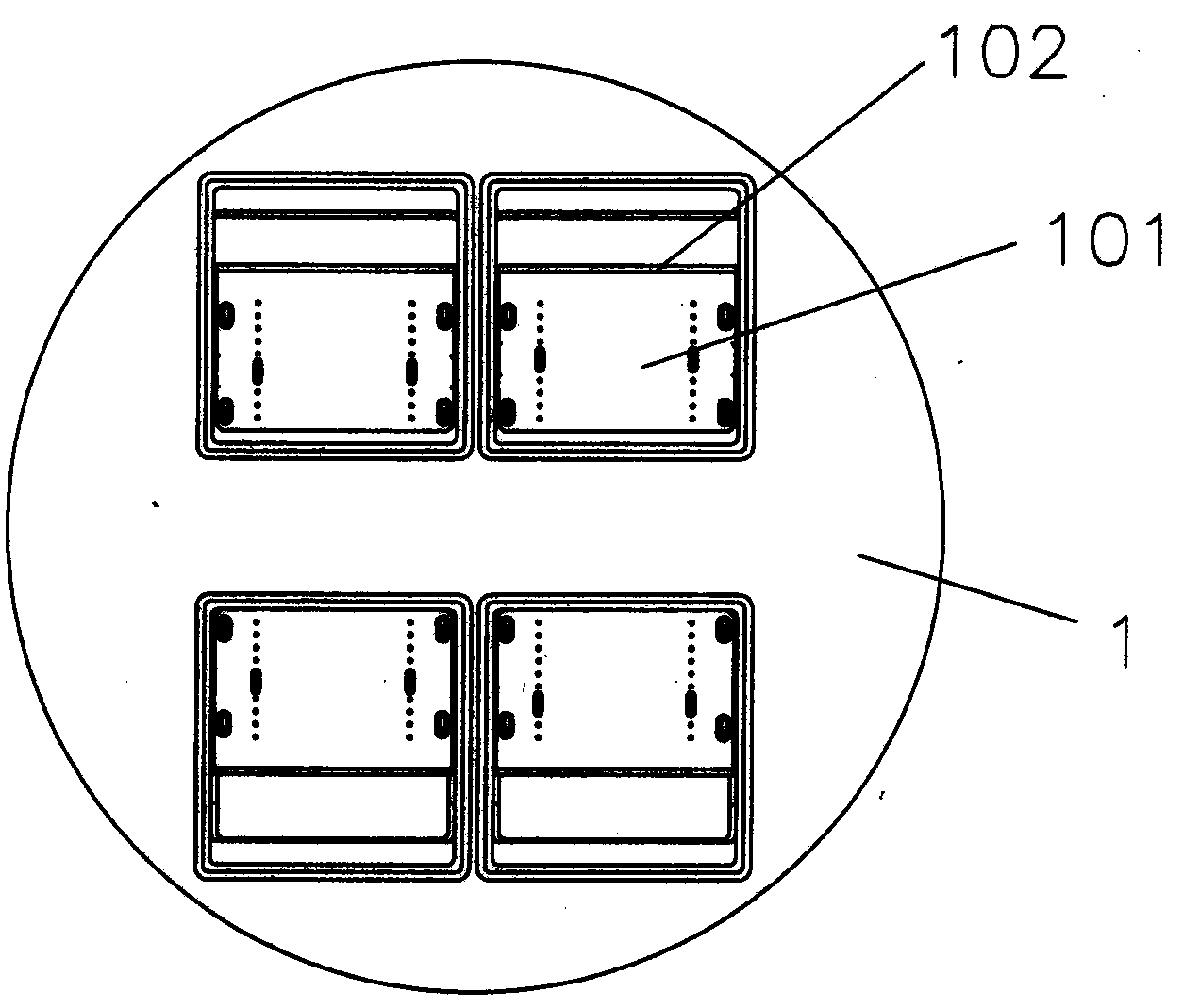

Servo double-surface heating vacuum packaging machine

ActiveCN102201592BQuality is not affectedGuarantee exclusionFinal product manufactureSecondary cells manufactureControl systemEngineering

The invention discloses a servo double-surface heating vacuum packaging machine and belongs to liquid extraction seal secondary forming and packaging equipment of flexible packaged lithium batteries. The servo double-surface heating vacuum packaging machine comprises a double-station turntable feeding device driven by a cam partitioning device, a packaging mechanism with an up-and-down packaging device, and an electric control system, wherein the up-and-down packaging device comprises an upper cavity main body and a lower cavity main body; the opening directions of the upper cavity main body and the lower cavity main body are opposite to each other; the upper cavity main body and the lower cavity main body can clamp the turntable to form a sealed cavity body; a pressing board, an upper sealing head and a bayonet are arranged in the upper cavity main body; a lower sealing head and an aspirating hole are arranged in the lower cavity main body; the aspirating hole is communicated with an external vacuum source; the upper sealing head corresponds to the lower sealing head; and a heating body is arranged inside the servo double-surface heating vacuum packaging machine. The servo double-surface heating vacuum packaging machine has a compact structure and high efficiency; the electric core packaging quality is stable and the cost is low; vacuum liquid extraction can be realized; and pollution of the electrolyte to the equipment can be reduced to minimum.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

Production process for novel artificial stone

The invention discloses production process for a novel artificial stone. The process comprises the following steps: 1) material preparation: a step of weighing main raw materials consisting of granular sand, quarry waste materials, pigment stones and calcium carbonate, and mixing the main raw materials in a tank A under stirring; weighing auxiliary materials consisting of glue, a curing agent and an accelerant, and mixing the auxiliary materials in a tank B under stirring; and weighing a filler--unsaturated resin and pouring the unsaturated resin into a tank C for subsequent usage; 2) stirring the mixed raw materials in the tank B and the tank C in a mixer with a frequency of 12 Mhz for 20 seconds each time until the mixed raw materials are of a mud shape; 3) separately pouring the mixed raw materials in the tank B and the tank C treated in the step 2) into the tank A at a speed of 30 to 50 Mhz / m; 4) casting the mixed slurry obtained in the step 3) in a mold so as to form a blank material; and 5) extracting the air in the blank material with an evacuator, and after curing of the blank material in the mold, carrying out demolding, maintenance at normal temperature and normal pressure, cutting and flat grinding. The artificial stone produced by using the production process in the invention has the advantages of high density, complete removal of air bubbles and high quality.

Owner:谢秋鸿

Lens continuous pouring system and process thereof

InactiveCN110884007AContinuous Pouring GuaranteeGuaranteed continuous flowOptical articlesExhaust valveStructural engineering

The invention discloses a lens continuous pouring system and a pouring process thereof. The system comprises a material tank, a filtering device capable of easily discharging bubbles, a material pouring valve and a material pouring needle head which are sequentially connected through a material pouring pipeline. The pouring needle head is fixed on a pouring frame on a pouring table; a template push disc with a plurality of empty grids is placed on the pouring table at a lower end of the pouring needle head, a feeding port, an exhaust valve and a pressure control assembly are arranged at the top of the material tank, a discharging valve is arranged at a bottom of the material tank, one end of the pressure control assembly is connected with a vacuum generation device, and the other end is connected with a compressed air device. A stirrer is mounted in the material tank. By means of the system and process, lens feed liquid can be effectively and continuously poured, the production efficiency is improved, and the product quality is improved.

Owner:JIANGSU CONANT OPTICS +1

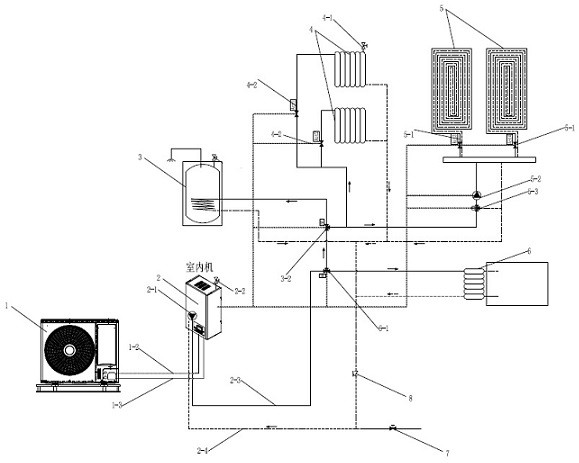

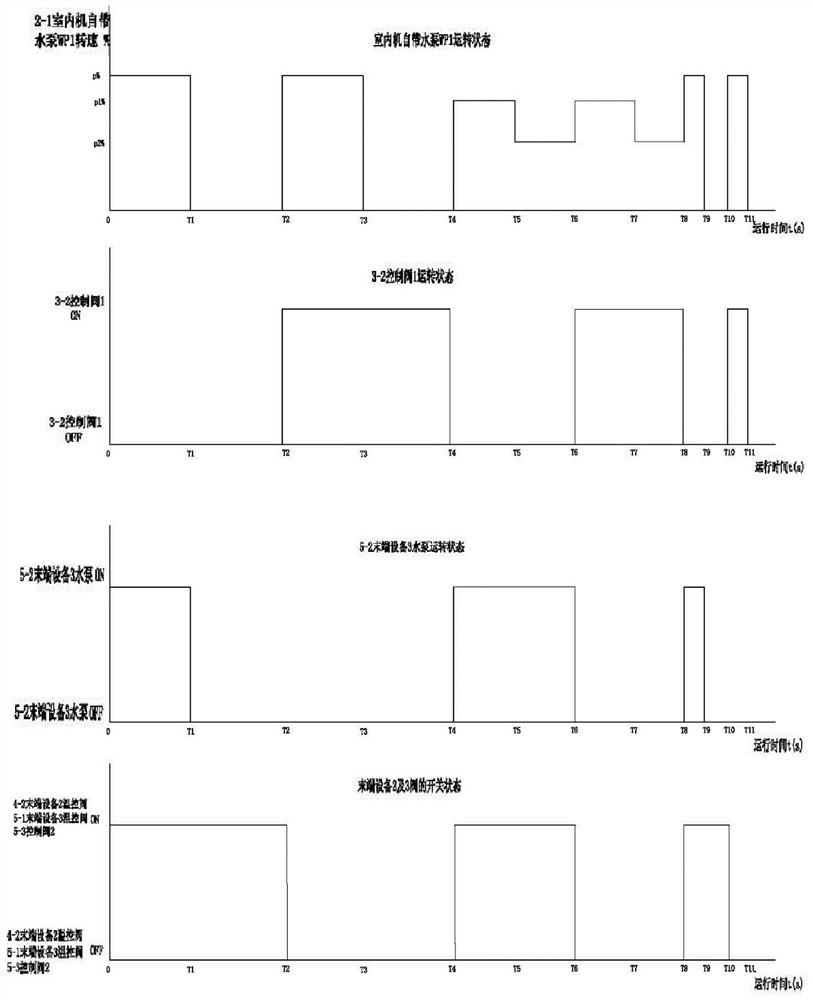

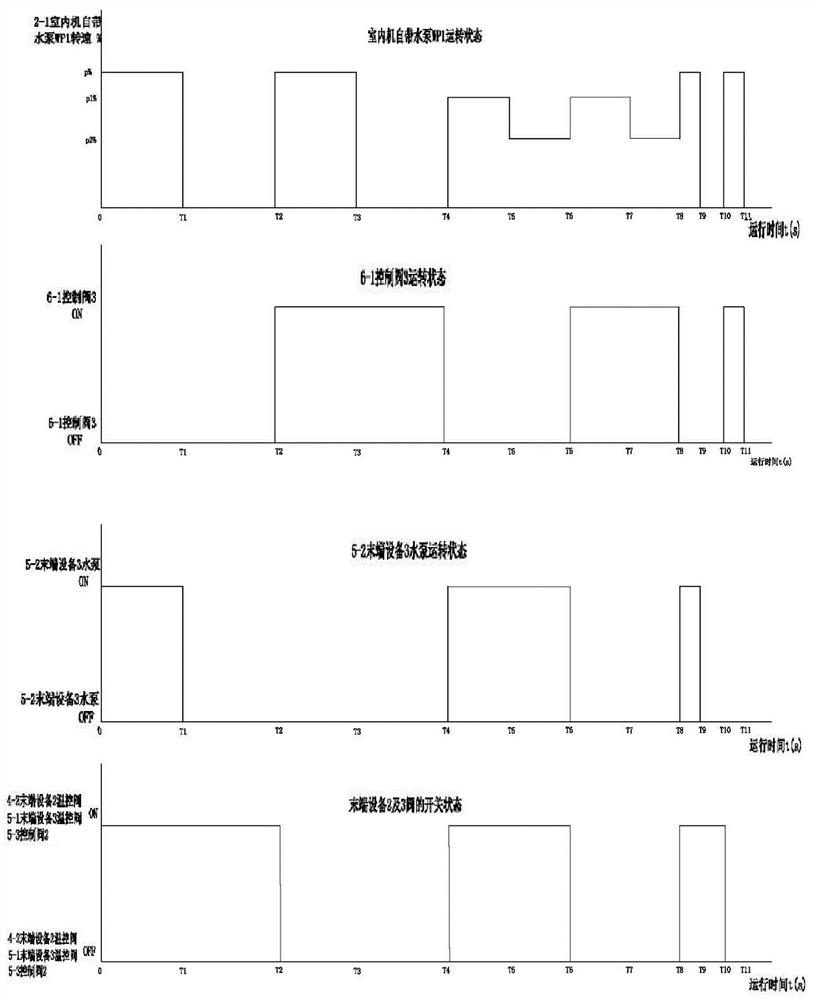

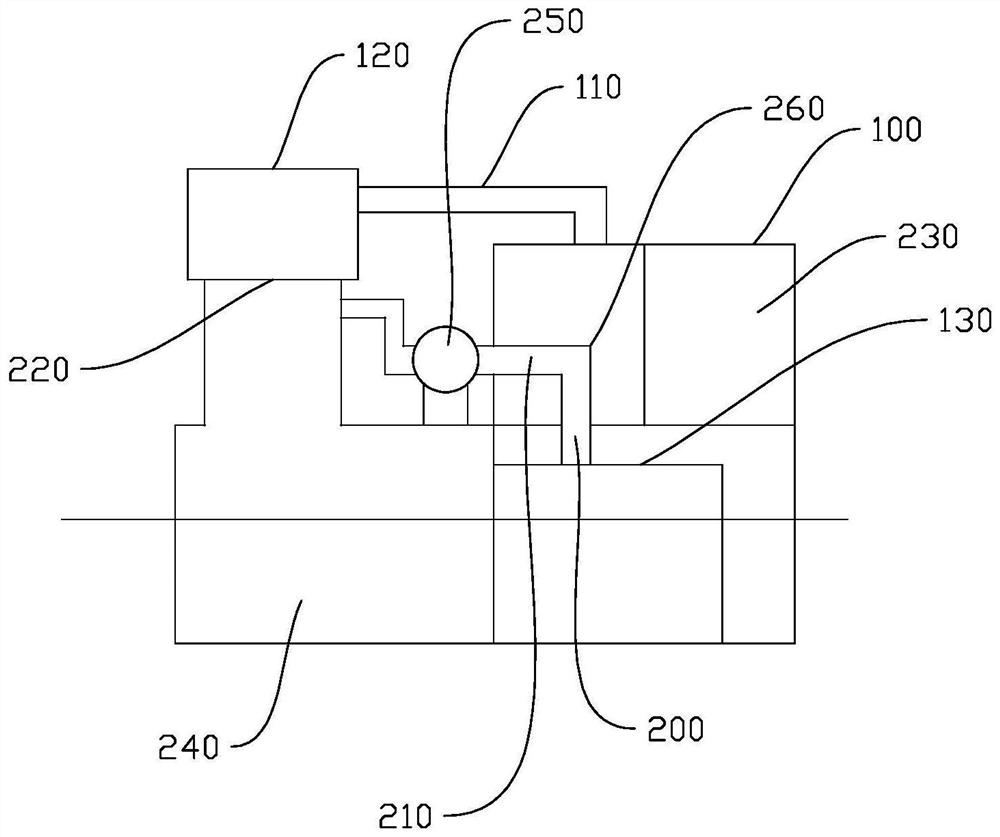

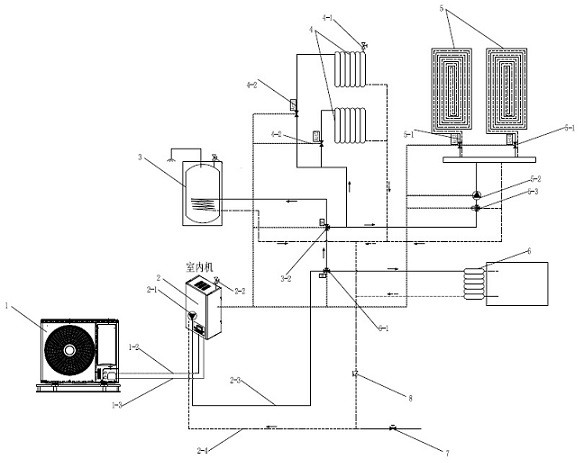

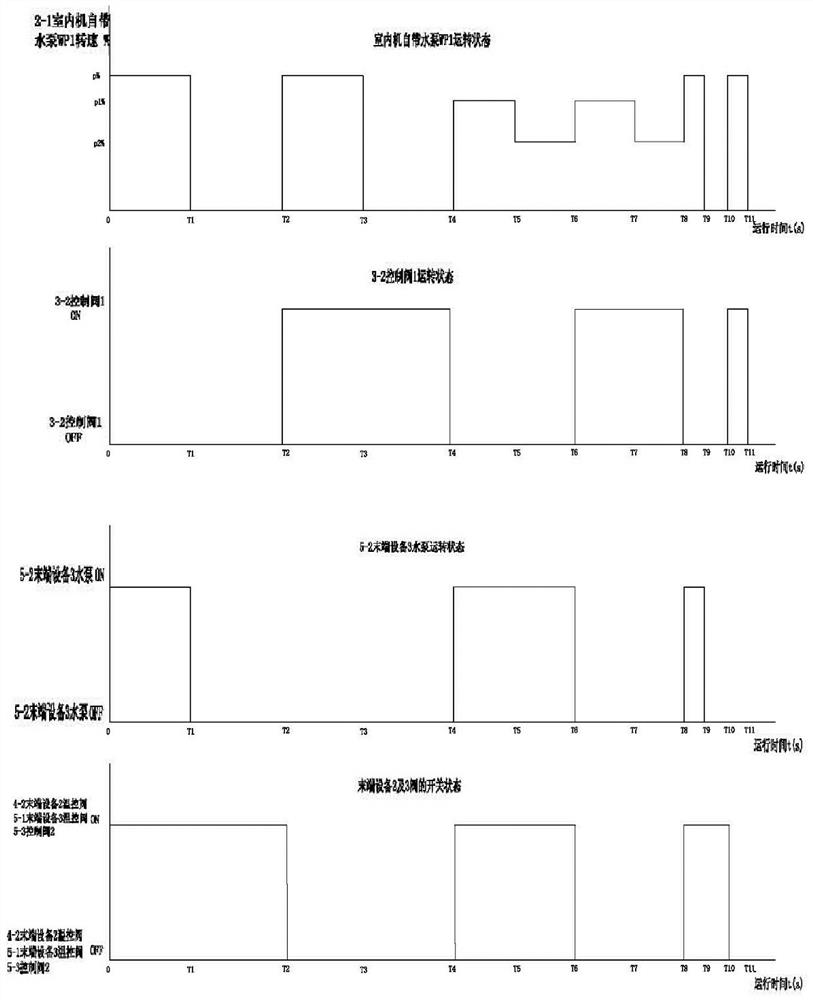

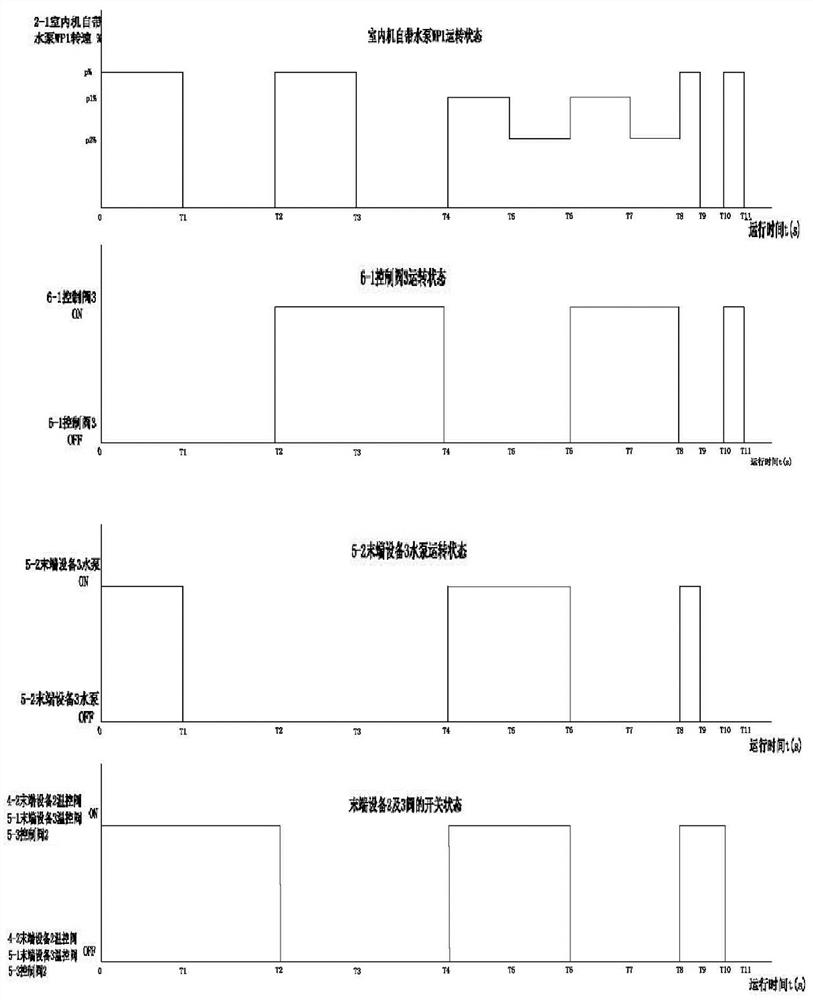

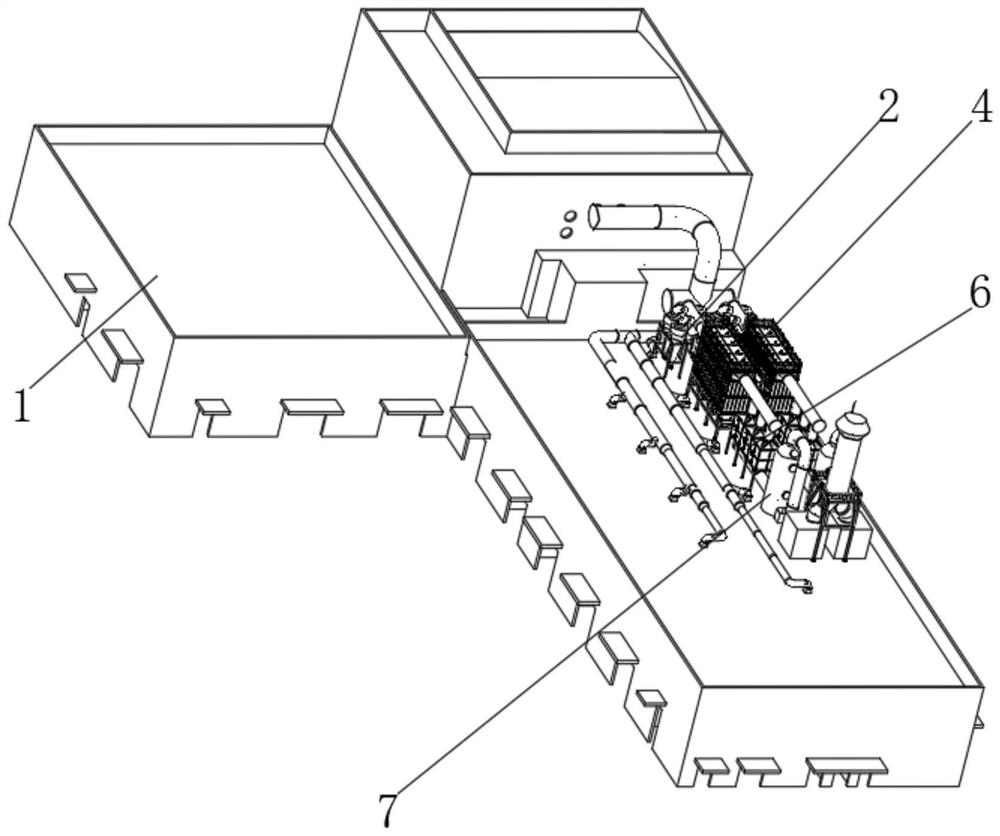

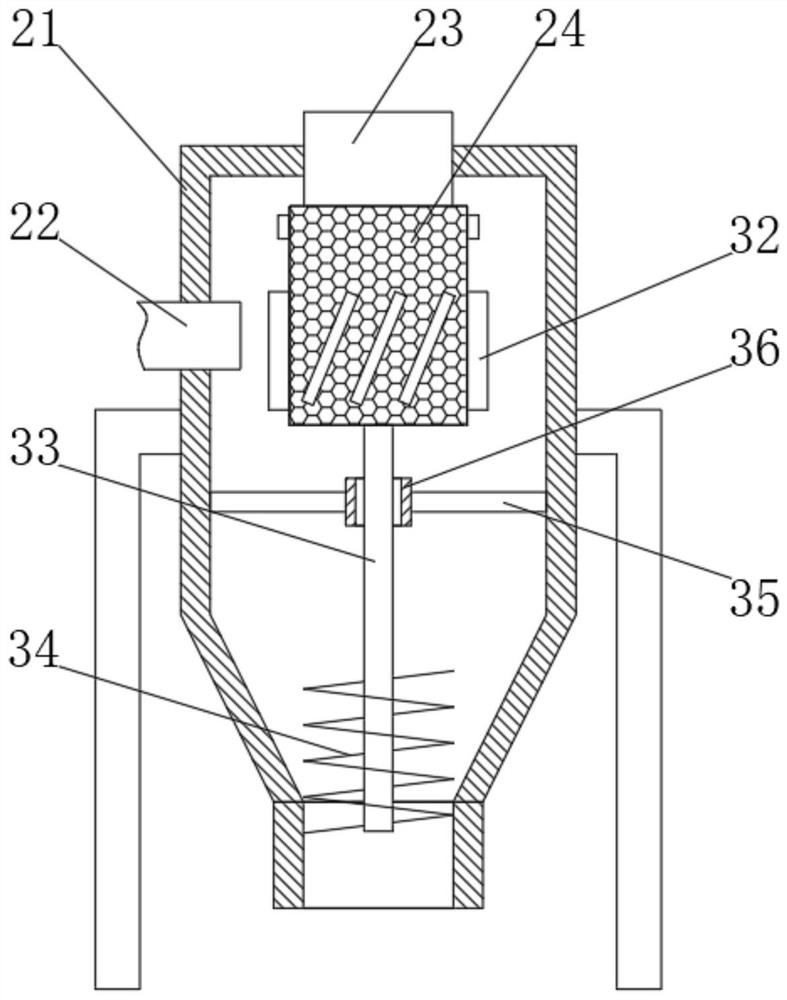

Air source heat pump unit

ActiveCN112728765AExcludedNo manual operationFluid heatersEnergy efficient heating/coolingThermodynamicsEngineering

The invention relates to an air source heat pump unit which comprises an outdoor unit, an indoor unit, at least two pieces of end equipment and a control module, wherein the at least two pieces of end equipment are connected with the indoor unit; the control module can divide the end equipment into first and second end equipment. When an automatic emptying function is started, emptying is carried out according to an emptying period circularly. The emptying period comprises at least two first end equipment emptying times, at least two first end equipment system water path stabilizing times, at least two second end equipment emptying times and at least two second end equipment system water path stabilizing times. The air source heat pump unit comprises control of emptying air of a hot water system intactly without manual operation, so that air in the water system can be excluded thoroughly and air frustration is avoided.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

Toilet manufacturing process

The invention relates to the technical field of sanitary appliances and in particular relates to a toilet manufacturing process. The process comprises the following steps: S1, making a toilet seat glass fiber reinforced plastic mold, a liner glass fiber reinforced plastic mold and a wooden base mold according to the shape and size of the toilet seat, a liner and a base, and making an artificial stone toilet seat, an artificial stone liner and a PVC (Polyvinyl Chloride) base according to the molds; S2, connecting the seat ring of the toilet seat and the liner in a casting manner. Thus, the toilet prepared by utilizing a filling material provided by the invention has high glossiness, moisture resistance and excellent aging resistance. Moreover, since a luminous filler is arranged in the filling material, the prepared toilet has a luminous function, light storage is saturated by irradiating in the light for 5-20 minutes only, the toilet starts to give light when a light source does not exist, and the lighting time can reach 6-15 hours. After the toilet absorbs enough light in the daytime, a user can go to the toilet at night without turning on the light. The toilet has illuminating and indicating effects. Meanwhile, since the light does not need to be turned on, the energy-saving effect is achieved.

Owner:安徽雅诺卫浴科技有限公司

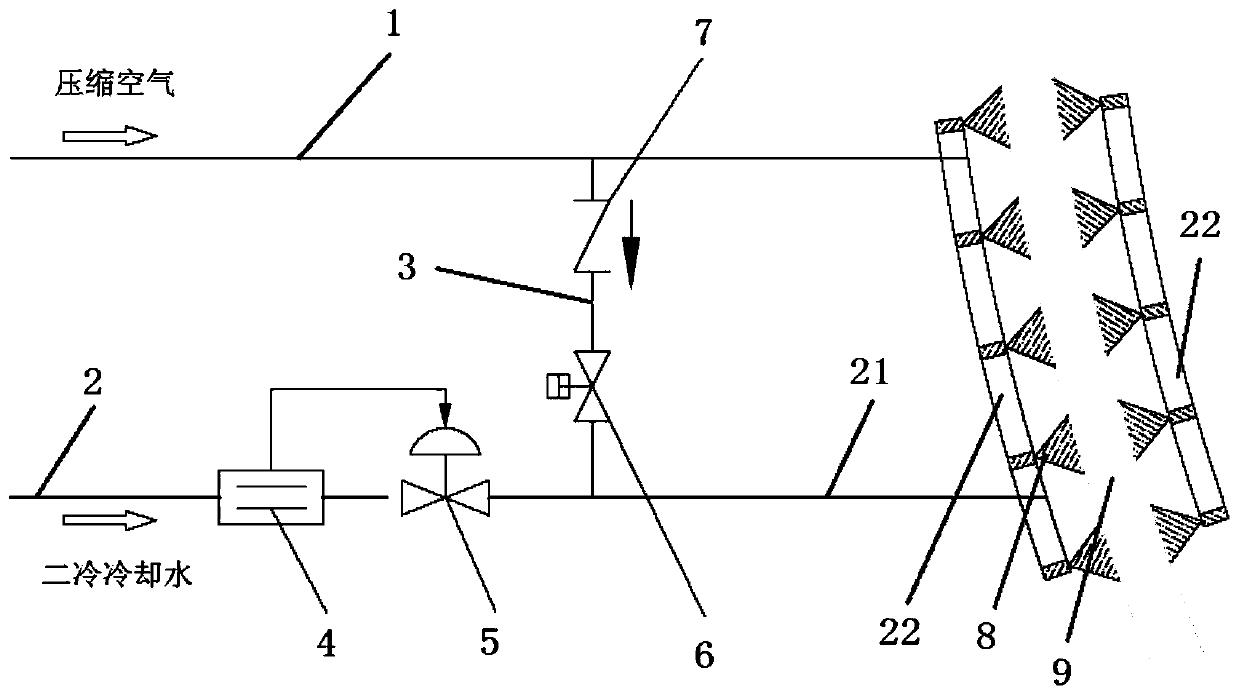

System and method for preventing continuous casting secondary cooling nozzle from being blocked

The invention relates to a system and method for preventing a continuous casting secondary cooling nozzle from being blocked, and belongs to the technical field of steelmaking continuous casting. Before the pulling speed of a continuous casting machine is reduced to zero, a pneumatic flow adjusting valve arranged on a secondary cooling water pipeline is closed, secondary cooling water is closed, and cooling is paused; a middle pipeline communicating with a compressed air pipeline and the secondary cooling water pipeline is arranged between the compressed air pipeline and the secondary coolingwater pipeline, a rapid cut-off valve is arranged on the middle pipeline, compressed air is introduced into the compressed air pipeline, the rapid cut-off valve is opened, the compressed air in the compressed air pipeline enters the secondary cooling water pipeline through the middle pipeline, and residual water in the secondary cooling water pipeline is discharged; before the pulling speed is increased, the compressed air is closed, and the rapid cut-off valve is closed; and the pneumatic flow adjusting valve is opened, the secondary cooling water is opened, the pulling speed is increased, and cooling is continued. According to the system and method, the situation that the nozzle is blocked after water remaining in the water pipeline forms water scale is effectively prevented, the uniformity of secondary cooling is guaranteed, the utility period of the nozzle is prolonged, and the maintenance cost is reduced.

Owner:CISDI RES & DEV CO LTD

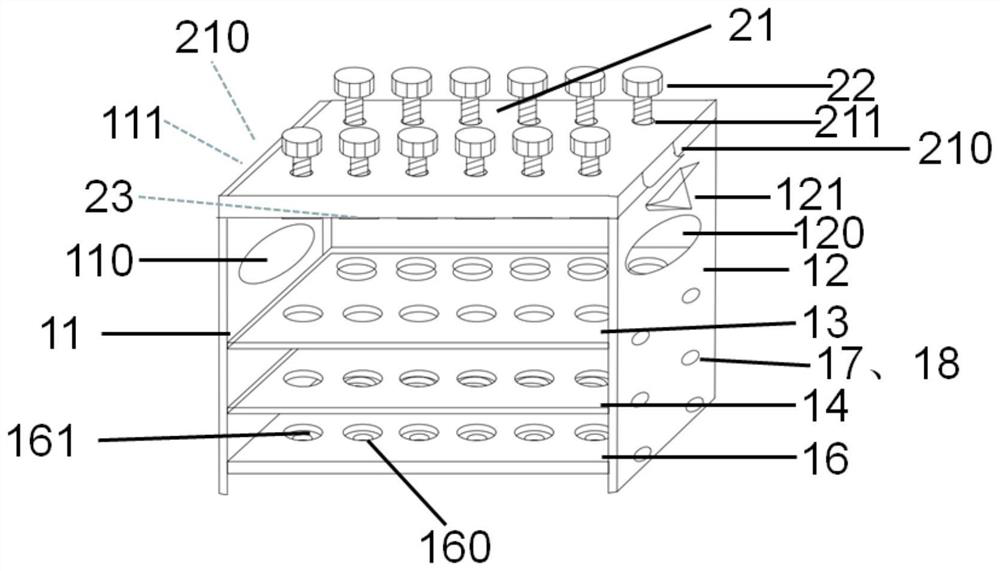

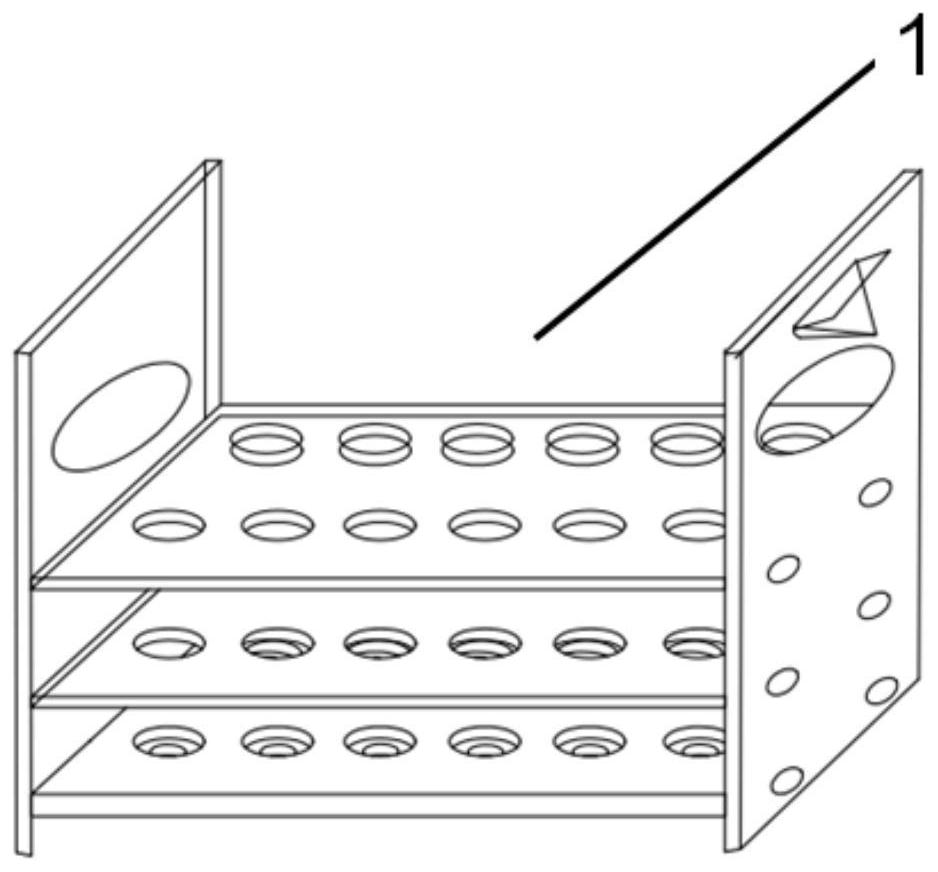

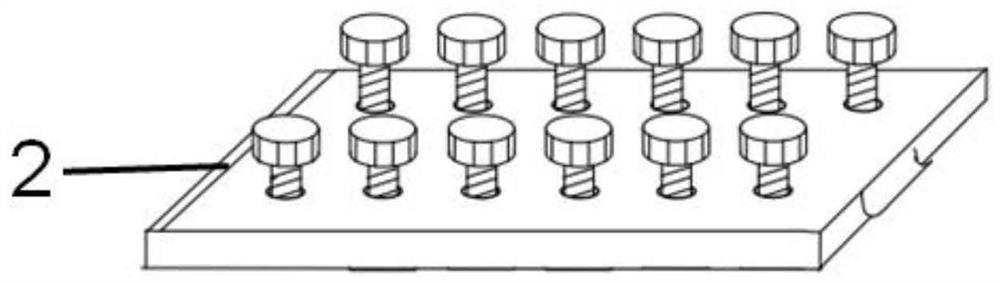

Colorimetric tube rack

InactiveCN112058341AEasy to fixPlay the role of diversion holeTest tube stands/holdersMechanical engineeringFluid Leak

The invention relates to a colorimetric tube rack, which is provided with a colorimetric tube rack main body and a top plate assembly arranged at the top of the main body. The colorimetric tube rack main body comprises a bottom plate which is provided with clamping grooves and liquid leakage holes; a left side plate and a right side plate which are firmly fixed to the left side and the right sideof the bottom plate respectively; and horizontal positioning plates which are parallel to the bottom plate, are firmly fixed between the left side plate and the right side plate and are provided withthrough holes for colorimetric tubes to pass through. The top plate assembly comprises a top plate with more than two through holes; and more than two rods correspondingly arranged in the through holes of the top plate, wherein each rod can abut against the plug of the corresponding colorimetric tube in the working process and is used for adjusting the displacement of the plug of the colorimetrictube in the axial direction of the rod. By utilizing the colorimetric tube rack disclosed by the invention, the digestion operation becomes convenient; and the accuracy of a detection result can be guaranteed, and the probability of repeated experiments is reduced.

Owner:北京华准检测技术有限公司

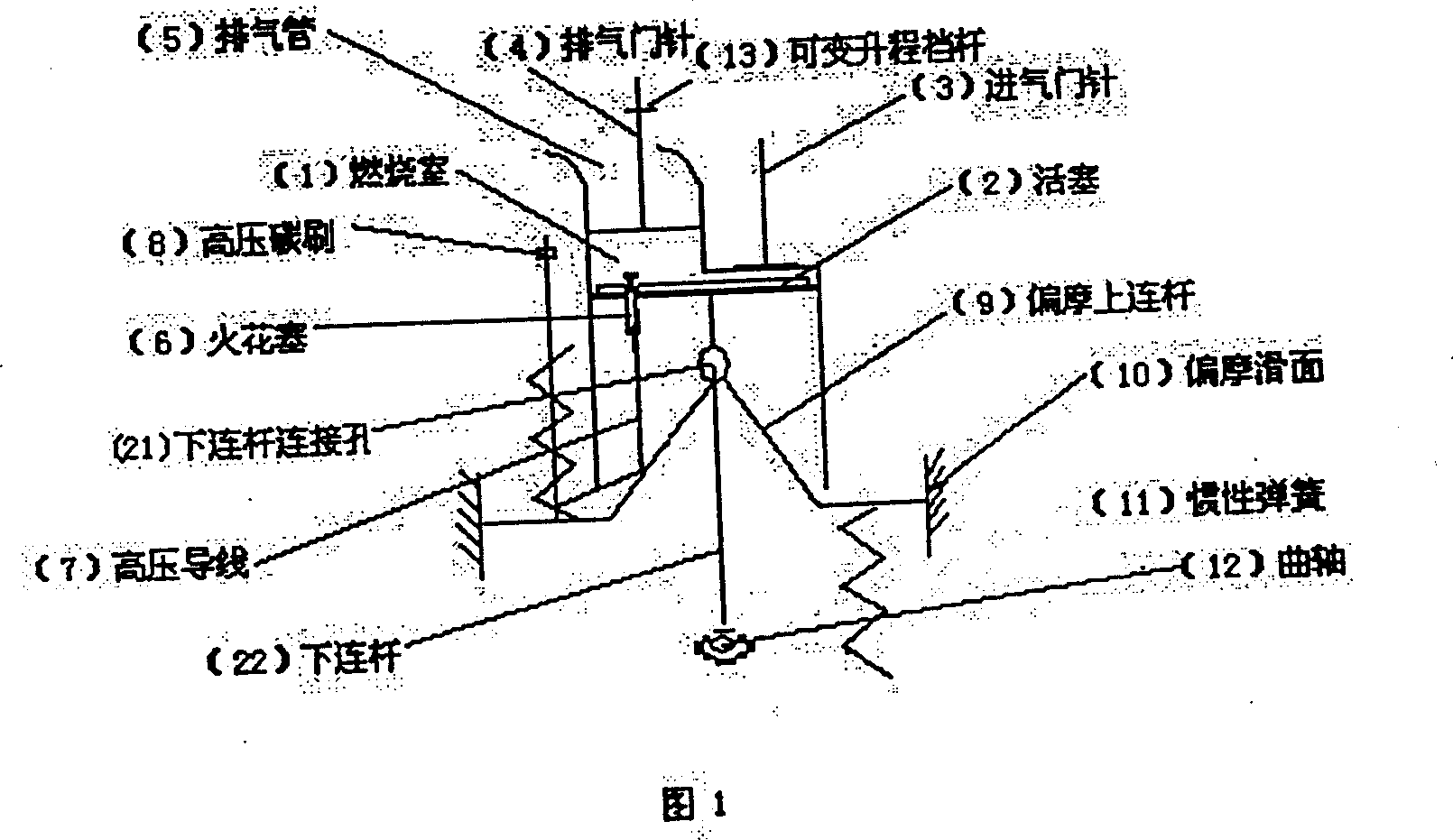

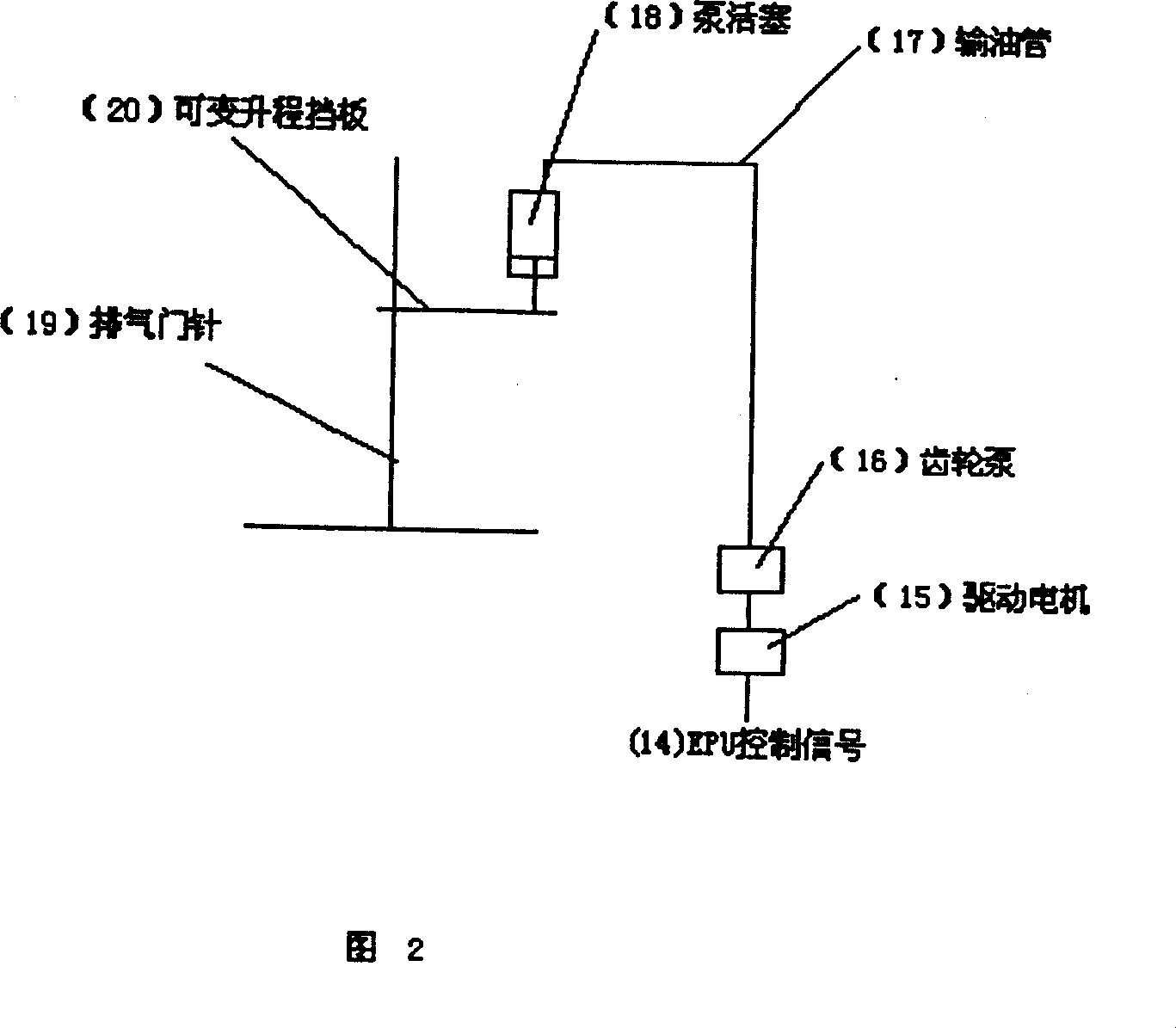

Improved internal combustion engine burner

InactiveCN101100955AExcludedExchange evenlyInternal combustion piston enginesCombustorCombustion chamber

The improved-type internal combustion engine combustor is made up of exhausting valve needle; a part of exhaust pipe; variable lift stop bar; offset friction upper link rod and inertial spring. It has advantage of adjustable internal space of combustion room and capable of discharging empty of waste gas. It is adapted to using in internal combustion engine system.

Owner:张勤祥

Method for detecting shrinkage porosity hole of root of motor barrel of rocker arm of cutting unit of coal mining machine

ActiveCN102680179BEasy to operateEasy to implementDetection of fluid at leakage pointEngineeringRocker arm

Owner:XIAN COAL MINING MACHINERY

Hydraulic interconnection suspension system and exhausting and sealing method for same

InactiveCN103273820BWork lessExcludedInterconnection systemsFluid-pressure actuator componentsHydraulic cylinderHydraulic pump

The invention discloses a hydraulic interconnection suspension system. Four hydraulic cylinders, two energy storages, two spherical valves and hydraulic pipes are connected with one another to form two hydraulic branches of the hydraulic interconnection suspension system. The invention further provides an exhausting and sealing method for the hydraulic interconnection suspension system. The hydraulic interconnection suspension system and the exhausting and sealing method have the advantage that bubbles are prevented in the hydraulic branches when the hydraulic interconnection suspension system is used.

Owner:苏州友邦汽车底盘科技有限公司

Paint waste gas treatment device

The invention discloses a paint waste gas treatment device. The paint waste gas treatment device comprises a waste gas treatment mechanism and an auxiliary exhaust mechanism. The waste gas treatment mechanism is provided with protective cover, a first air suction pipe and a treatment device, wherein the protective cover is arranged on a wire inlet side of a painting machine, the first air suctionpipe is connected to the top of the protective cover, and the treatment device is connected to the first air suction pipe. The auxiliary exhaust mechanism is provided with a cover body, a second air suction pipe and a fan, wherein the cover body is located in the protective cover, the second air suction pipe is connected to the cover body and penetrates through the protective cover, and the secondair suction pipe and the treatment device are connected through the first fan. With the paint waste gas treatment device, the capacity of removing waste gas by suction can be improved, less waste gasleaks out, and environmental pollution is reduced.

Owner:鹤山市江磁线缆有限公司

Full-automatic removing machine for concrete sundries

The invention relates to a full-automatic removing machine for concrete sundries, which comprises a bracket, a rotating shaft, a rotating motor, left and right cylinders and a material groove, wherein the rotating shaft is rotatably arranged on the bracket; the rotating motor is used for driving the rotating shaft to rotate; the left and right cylinders are sleeved on the rotating shaft and are capable of sliding; the material groove is alternately matched with the left and right cylinders; the material groove is located under the rotating shaft; the left and right cylinders are synchronouslyconnected by a linkage sleeve; the cross sections of the left and right cylinders are oval-shaped; bent material rakes are arranged on outer side walls of the left and right cylinders; the bent material rake on the left cylinder and the bent material rake on the right cylinder are bent along reverse directions; and the full-automatic removing machine further comprises a horizontal driving mechanism which is used for driving the left and right cylinders to move left and right horizontally on the rotating shaft. The full-automatic removing machine has the advantages of high capability of removing sundries such as rags, broken timbers and the like from construction rubbishes, high working efficiency, reasonable structural design, high practical applicability, and convenience in application and popularization in the construction rubbish recycling projects.

Owner:QUANGONG MACHINERY

An air source heat pump unit

ActiveCN112728765BExcludedNo manual operationFluid heatersEnergy efficient heating/coolingThermodynamicsTerminal equipment

The invention relates to an air source heat pump unit including an outdoor unit, an indoor unit, at least two terminal devices and a control module, at least two terminal devices connected to the indoor unit, and the control module can divide the terminal devices into a first group of terminal devices and a control module. The second group of terminal equipment; when the automatic emptying function is turned on, it is emptied according to the emptying cycle cycle. The emptying cycle includes at least two emptying times of the first group of terminal equipment, at least two first group of terminal equipment system waterway stabilization times, At least two second group of terminal equipment system waterway emptying time, at least two second group of terminal equipment system waterway stabilization time. The air source heat pump unit of the present invention includes a complete hot water system air exhaust control, without manual operation, and can completely remove the air in the water system to avoid air pockets.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

Power battery test smoke and exhaust gas treatment system and its treatment method

ActiveCN113244726BAvoid easy cloggingImprove filtration efficiencyCombination devicesGas treatmentCombustion chamberElectrical battery

Owner:重庆鑫协环保设备有限公司

A New Chromatographic Column with Exhaust

Owner:JIANGSU HANBON SCI & TECH CO

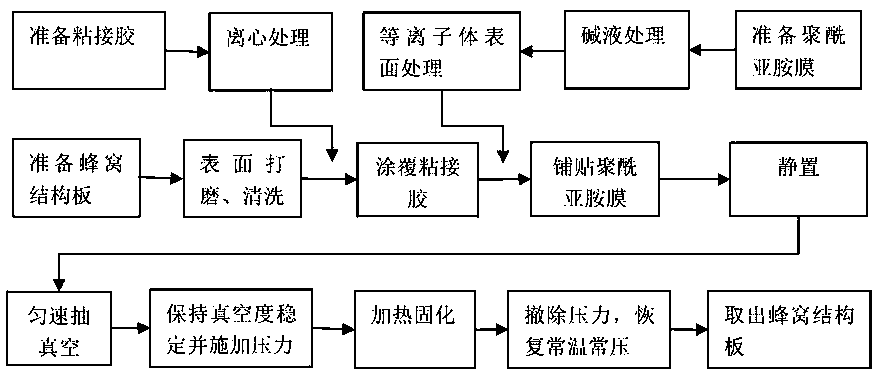

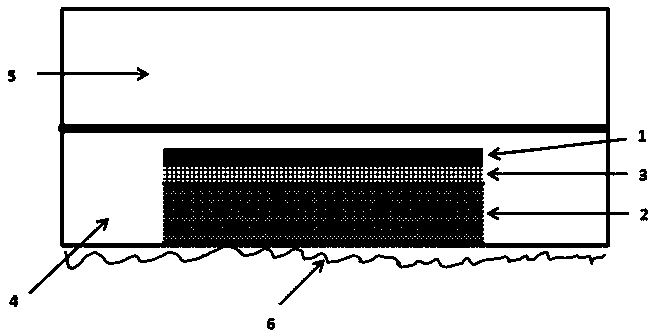

Pasting process of polyimide film on the surface of honeycomb structure board

ActiveCN107825818BWill not overflowEfficient exclusionLamination ancillary operationsLaminationAccelerated curingAdhesive

The invention discloses a technology for pasting a polyimide film on the surface of a honeycombed plate. The technology comprises the following steps: laying the polyimide film on an adhesive on the surface of the honeycombed plate, standing the polyimide film and the honeycombed plate, performing uniform-speed vacuumizing, keeping the stability of the vacuum degree and applying a pressure to thesurface of the honeycombed plate, and performing heat-curing to complete the pasting of the polyimide film. The time window of the adhesive having a large viscosity and low fluidity when being surface-dry and the uniform gas flow uniform-speed vacuumizing are used to effectively remove bubbles between the honeycombed plate and the polyimide film without flowing and overflowing of the adhesive during air extraction, so the good pasting quality is guaranteed; the pressure is applied to the surface of the honeycombed plate to accelerate the removal of the bubbles, so the bubble removal efficiencyis improved, and the bonding strength is improved; and curing is performed under vacuum, pressurizing and heating conditions, so the bubbles are effectively prevented from infiltrating the internal of the polyimide film again, the curing is accelerated, the curing efficiency is increased, and the production cost is reduced.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

a toilet

ActiveCN111155616BReduce pollutionSpill will notWater closetsFlushing devicesWater savingStraight tube

The invention relates to a toilet, an annular main air duct is arranged in a closestool ring, a plurality of air outlets are formed in the inner wall of the closestool ring, each air outlet is communicated with the main air duct through a branch air duct, and the main air duct is communicated with an air outlet of a draught fan through an air pipe. A downpipe of the toilet is a straight pipe, a gap is formed between an upper opening of the downpipe and a lower opening of a urinal, the two sides of the downpipe are each provided with a sliding way, the two sliding ways are transversely arrangedin parallel, and a partition plate is arranged above the two sliding ways and connected with the sliding ways in a sliding mode; when the partition plate is positioned at one end of the slideway, theupper opening of the downpipe is relatively communicated with the lower opening of the urinal, and when the partition plate is positioned at the other end of the slideway, the partition plate is positioned in the gap to cover an orifice of the downpipe and is provided with a sliding driving device; wherein the first flushing device comprises a first high-pressure nozzle and a first water valve, the first high-pressure nozzle is fixedly arranged on the bottom surface of a closestool cover of the toilet, and the first high-pressure nozzle is communicated with a water outlet pipe of the first water valve through a first water supply pipe; and the toilet is water-saving, sanitary and odorless in use.

Owner:崔太明

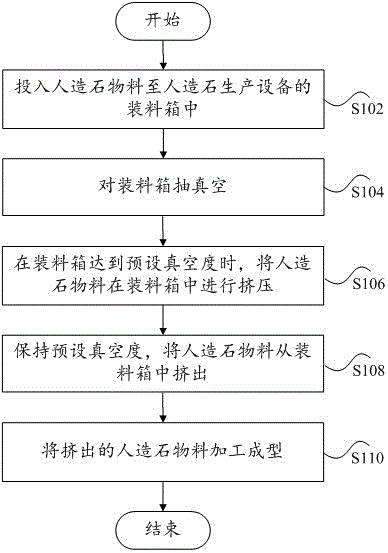

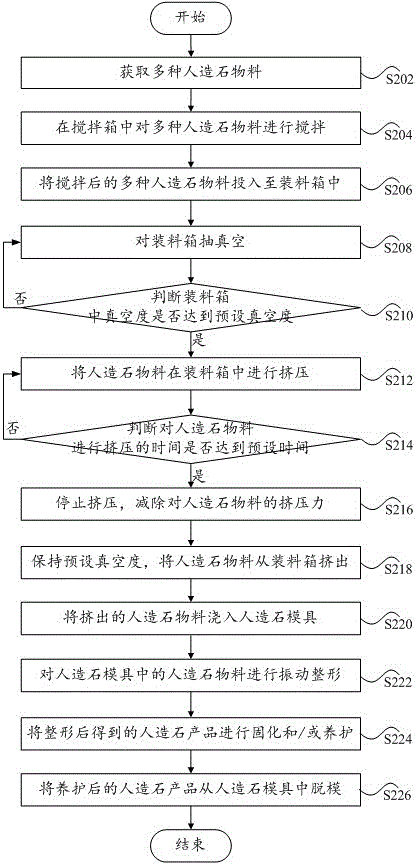

A kind of production method of artificial stone

InactiveCN103909557BExcludedImprove product qualityFeeding arrangmentsArtificial stoneMaterials science

The invention discloses a production method for an artificial stone. The production method for the artificial stone includes: adding artificial stone materials to a material box of artificial stone production equipment; vacuumizing the material box; extruding the artificial stone materials in the material box when the material box achieves a preset vacuum degree; keeping the preset vacuum degree, and extruding the artificial stone materials from the material box; machining and shaping the extruded artificial stone materials. The production method for the artificial stone is capable of lowering the artificial stone production equipment cost and improving the artificial stone product quality.

Owner:余以富

Efficient antibacterial formaldehyde-removing composite additive as well as preparation method and application thereof

The invention belongs to the field of additives, and particularly relates to an efficient antibacterial formaldehyde-removing composite additive and a preparation method and application thereof.The efficient antibacterial formaldehyde-removing composite additive comprises a feeding device, a closed cylinder is arranged on the outer surface of the feeding device, the outer surface of the feeding device is fixedly connected with the inner wall of the closed cylinder, and a processing cylinder is arranged at the bottom of the closed cylinder; the bottom of the closed cylinder is fixedly connected with the top of the machining cylinder, a conduction column is arranged at the bottom of the machining cylinder, the bottom of the machining cylinder is movably connected with the top of the conduction column, a power source is arranged at the bottom of the conduction column, the bottom of the conduction column is fixedly connected with the top of the power source, and a supporting device is arranged on the outer surface of the machining cylinder. In order to overcome the defects in the prior art, the efficient antibacterial formaldehyde-removing composite additive and the preparation method and application thereof are provided, and the problem that the antibacterial effect of a traditional additive is poor due to the fact that mixing is insufficient during preparation of the traditional additive is solved.

Owner:中山市森林家新材料科技有限公司

Technique for heat treatment by mixing core self-heating and external heating

ActiveCN106504913AReduce wrinklesEliminate interlayer gapsDrying/impregnating machinesEngineeringVoltage modulation

The invention discloses a technique for heat treatment by mixing core self-heating and external heating. The technique comprises the steps as follows: a capacitor core is put into a temperature-controlled box body and is connected with a power supply for voltage modulation and frequency modulation; the power supply applies certain AC voltage to the capacitor core, so that the capacitor core loses power and generates heat for internal heating; and the temperature-controlled box body is heated to carry out external heating on the capacitor core, so that the heat treatment process is achieved through cooperation of internal heating and external heating. The whole capacitor core can be uniformly heated during heat treatment through cooperation of an internal heating effect and an external heating effect; the condition that inside original bubbles and moisture can be eliminated is ensured; an internal medium of the capacitor core can shrink at the same time; creases are effectively reduced; an interlayer gap is eliminated; and new bubbles and moisture which cannot be eliminated are avoided.

Owner:安徽华威新能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com