Patents

Literature

39results about How to "Guaranteed continuous flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

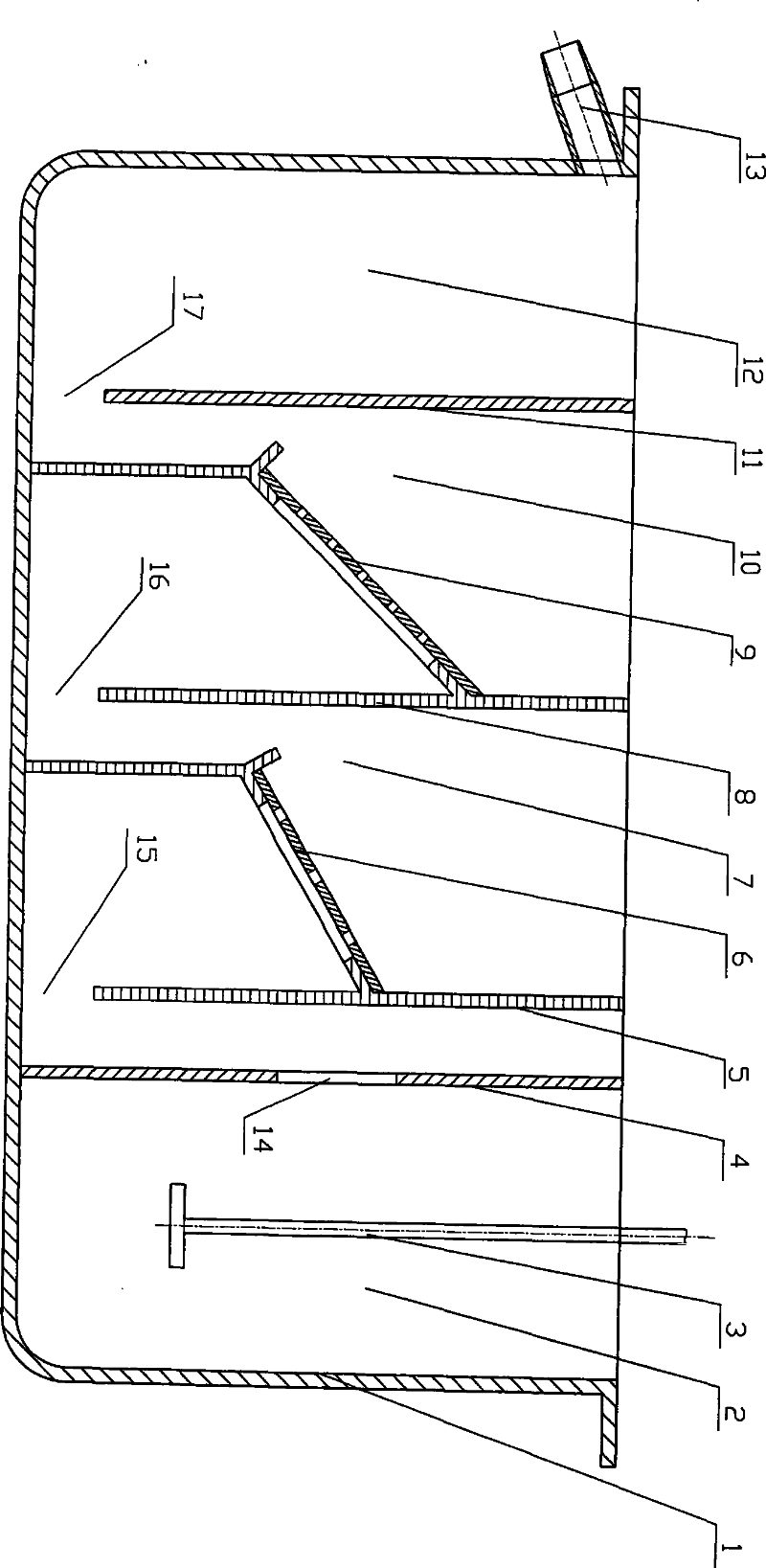

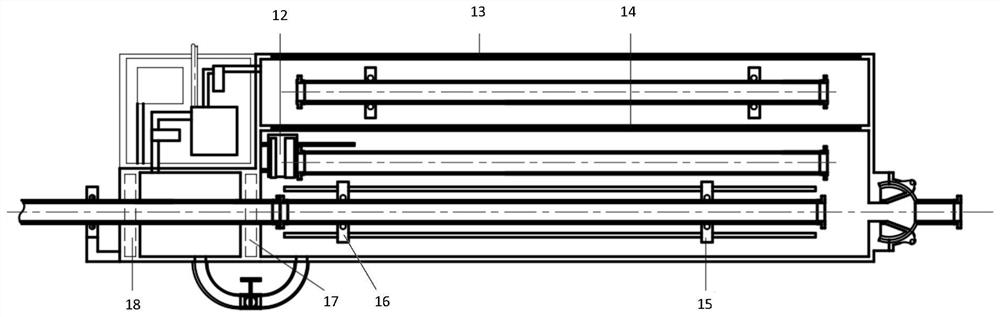

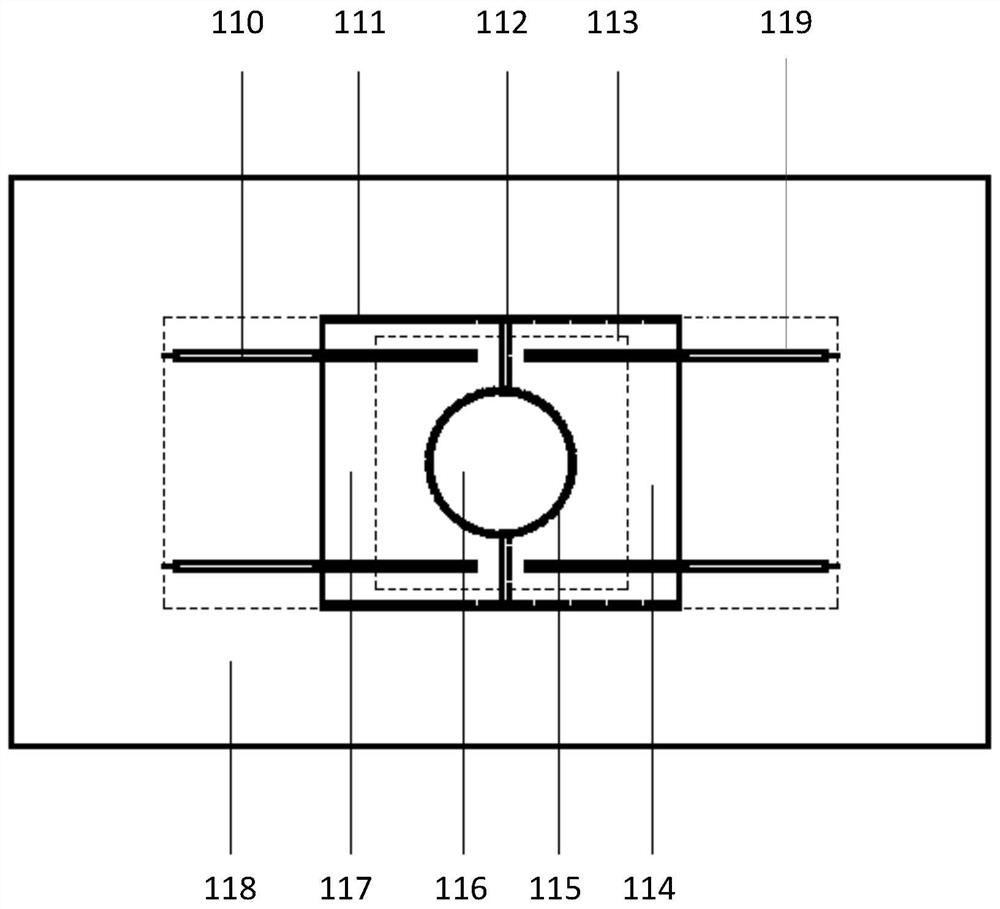

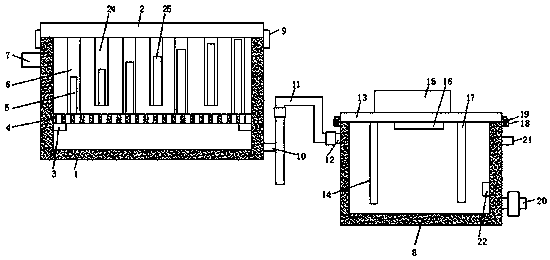

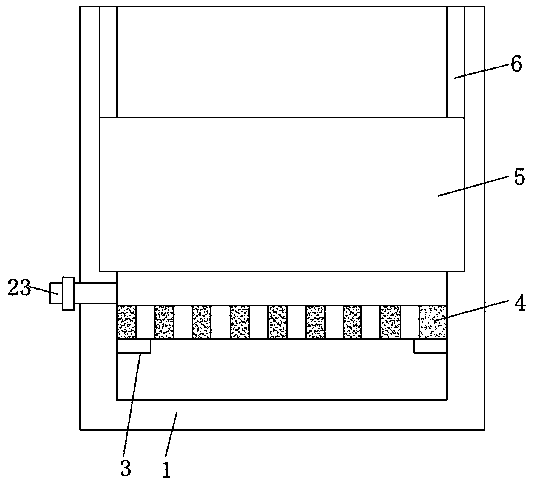

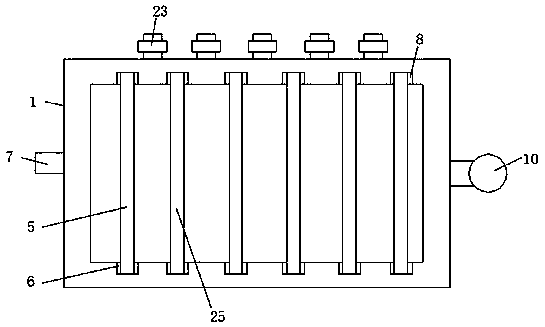

Magnesium alloy furnace material fluxless remelting refining method and device

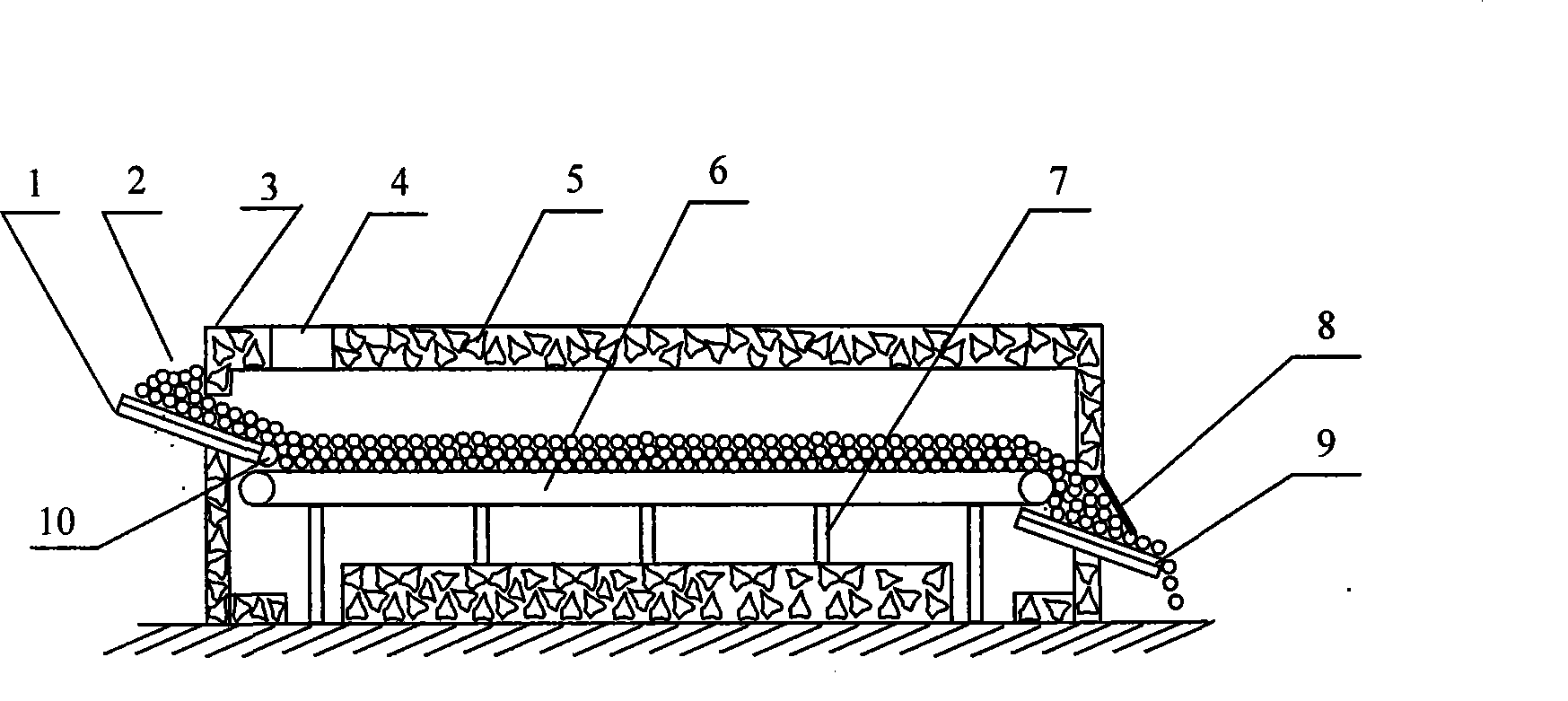

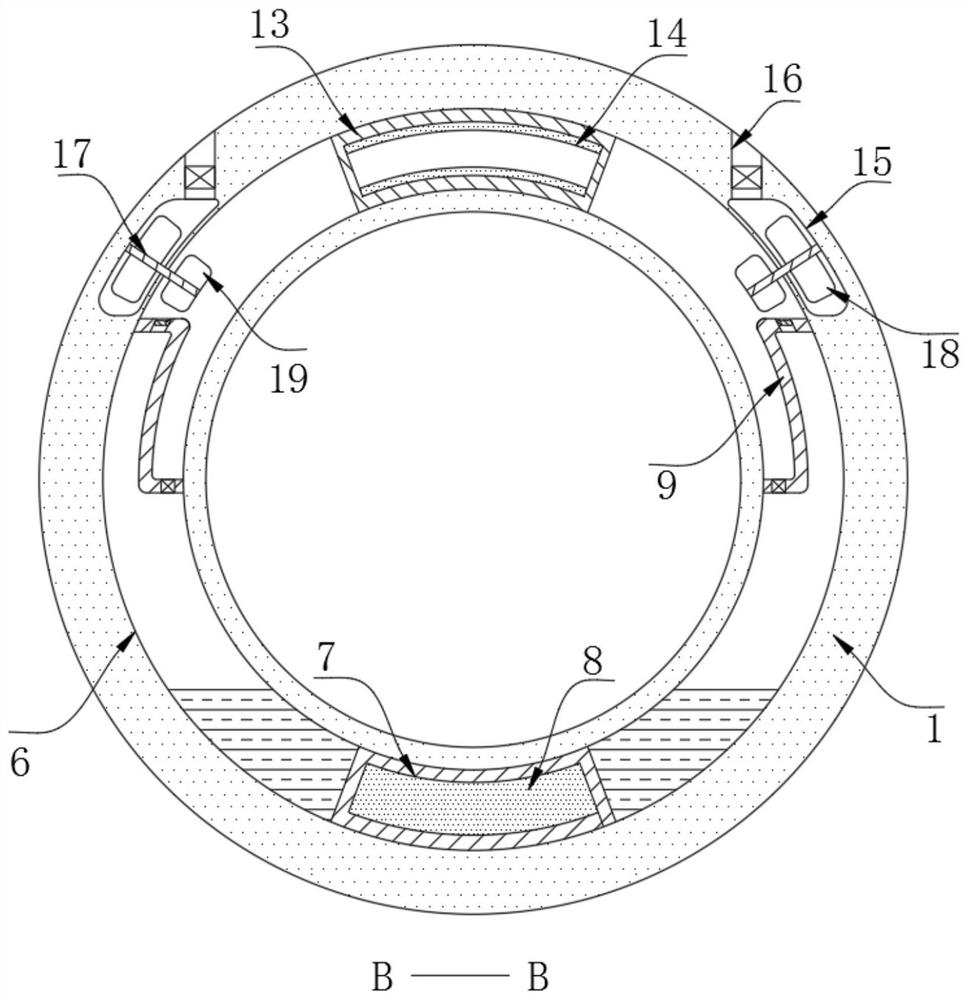

The invention relates to a method of refusion refining for magnesium alloy furnace charge without the fluxing agent and its apparatus. Magnesia fused mass is refined using complex multi-refining method after preheating and drying magnesium alloy furnace charge, including the steps of: fusing furnace charge, stirring refining or (and blowing refining), forced sedimentating, filter refining, static refining, discharging and casting, accordingly the high-quality purification of fusing body is performed by efficiently eliminating all kinds of impurity and gas in the magnesium alloy furnace charge. The apparatus mostly includes crucibles, pretreatment chambers in order fixed in the crucibles, one or more filter chamber and casting chambers, each adjacent two chambers communicated by fused mass flowing channels, stirring units or (and blowing units) in the pretreatment chambers, first-order filter unit airproofed and fixed in each filter chamber. The apparatus can perform continuous complex multi-refining and casting / producing of magnesia fused mass, with greatly-improved refining quality and purified effect of magnesium alloy fused mass, while the problem that the filter apparatus is easy to be blocked in the process of filtering is solved.

Owner:重庆硕龙科技有限公司

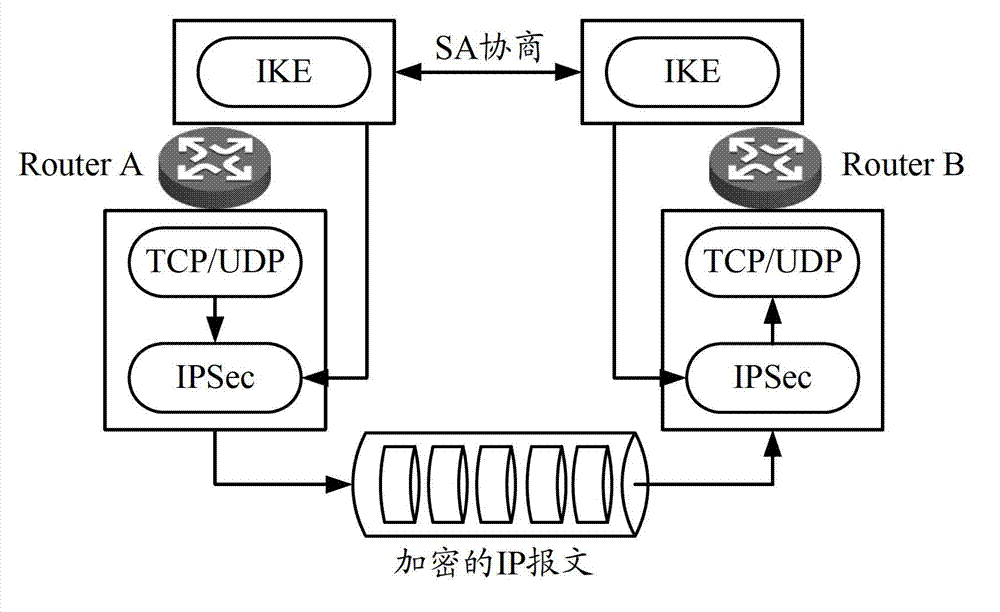

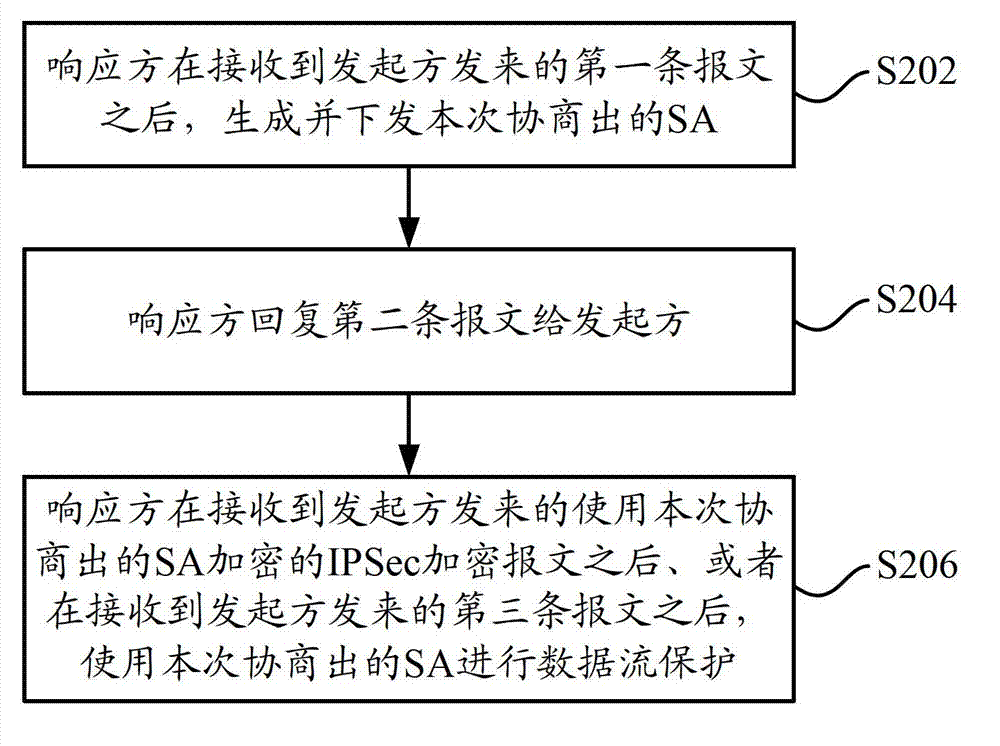

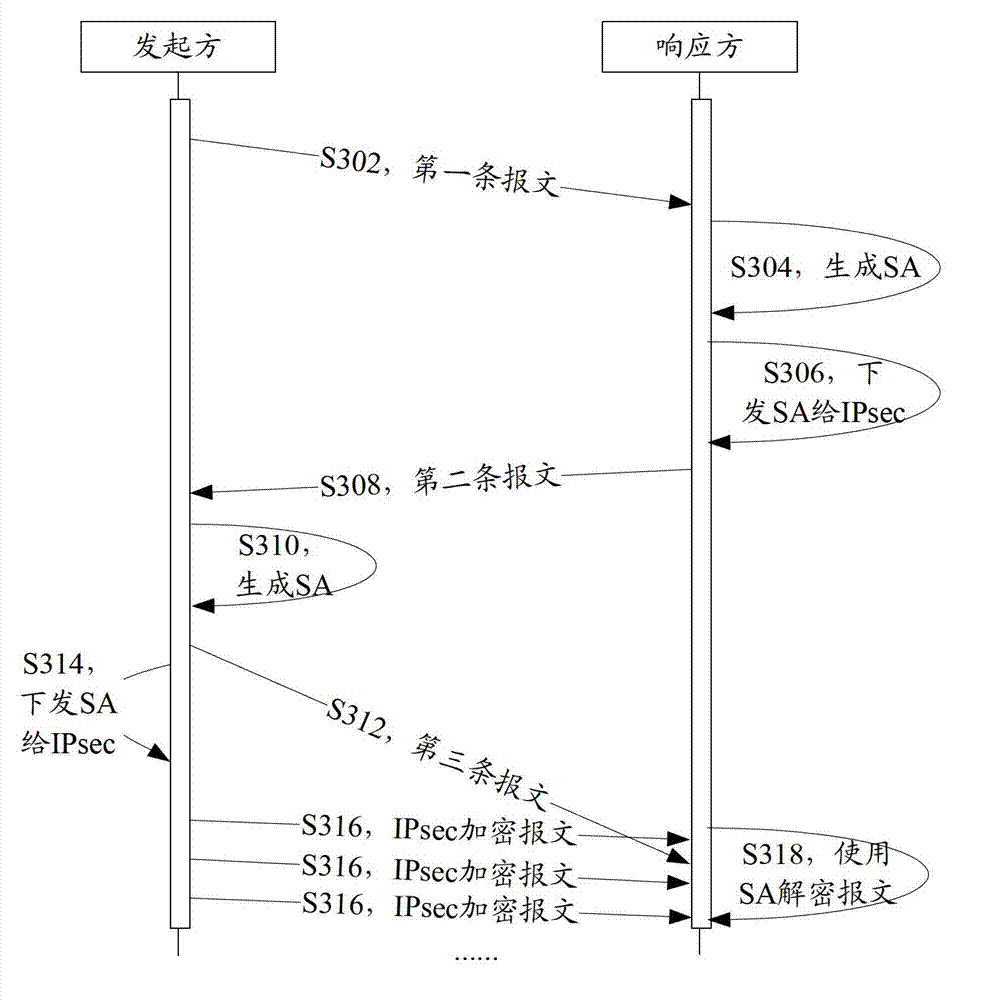

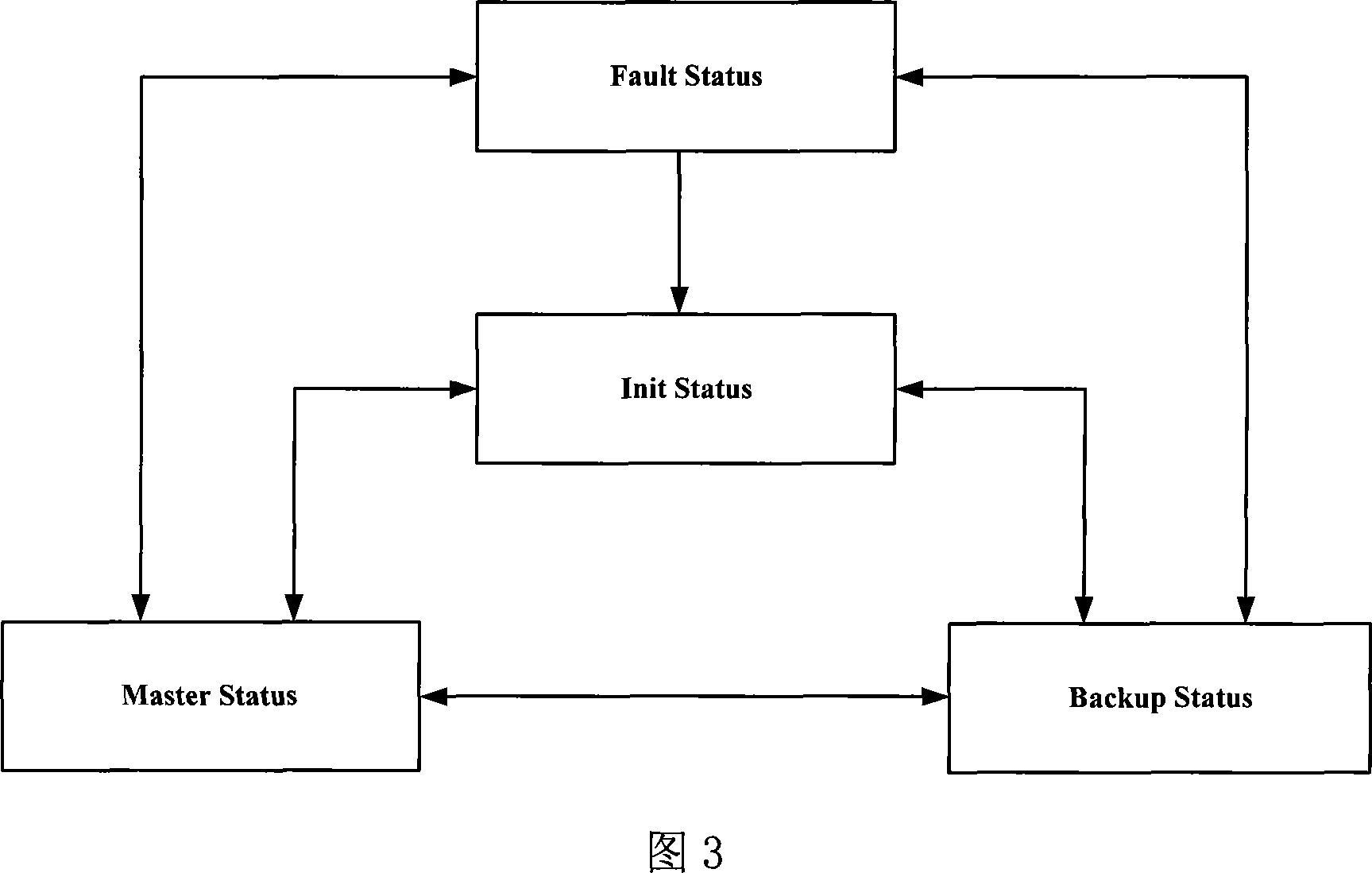

IPSec SA consultation method and device

The invention discloses an IPSec (Internet Protocol Security) SA (Security Association) consultation method and an IPSec SA consultation device. The method comprises the following steps: generating and issuing a consulted SA when a responder receives a first message sent by an initiator; replying a second message to the initiator by the responder; and when the responder receives the IPSec encrypted message which is sent by the initiator and encrypted by the consulted SA, or receives a third message sent by the initiator, carrying out data flow protection utilizing the consulted SA, wherein the first message, the second message and the third message are three messages which are used to complete the IPSec SA consultation by the initiator and the responder together in a fast mode. According to the invention, through changing the issuing time and effective time of responder's consulted SA, the problems of jitter or interruption of instant flows during the IPSec SA initial consultation or re-consultation process in the prior art are solved.

Owner:NEW H3C TECH CO LTD

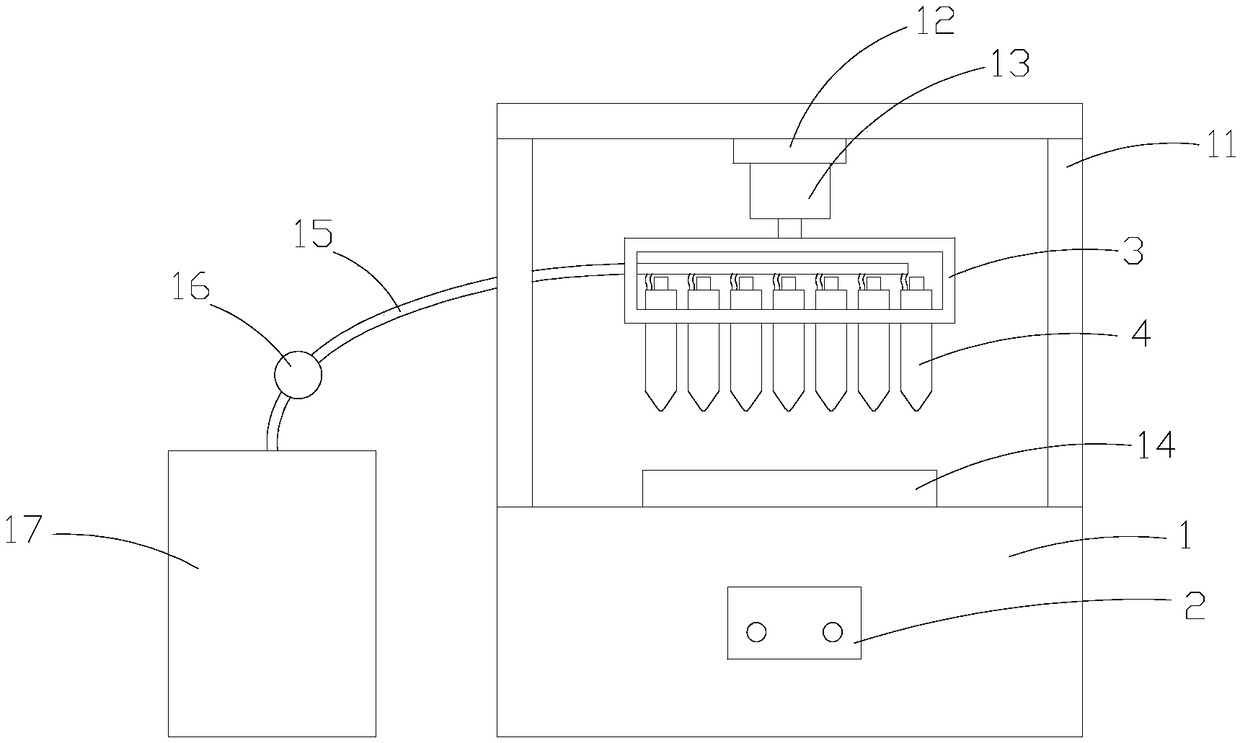

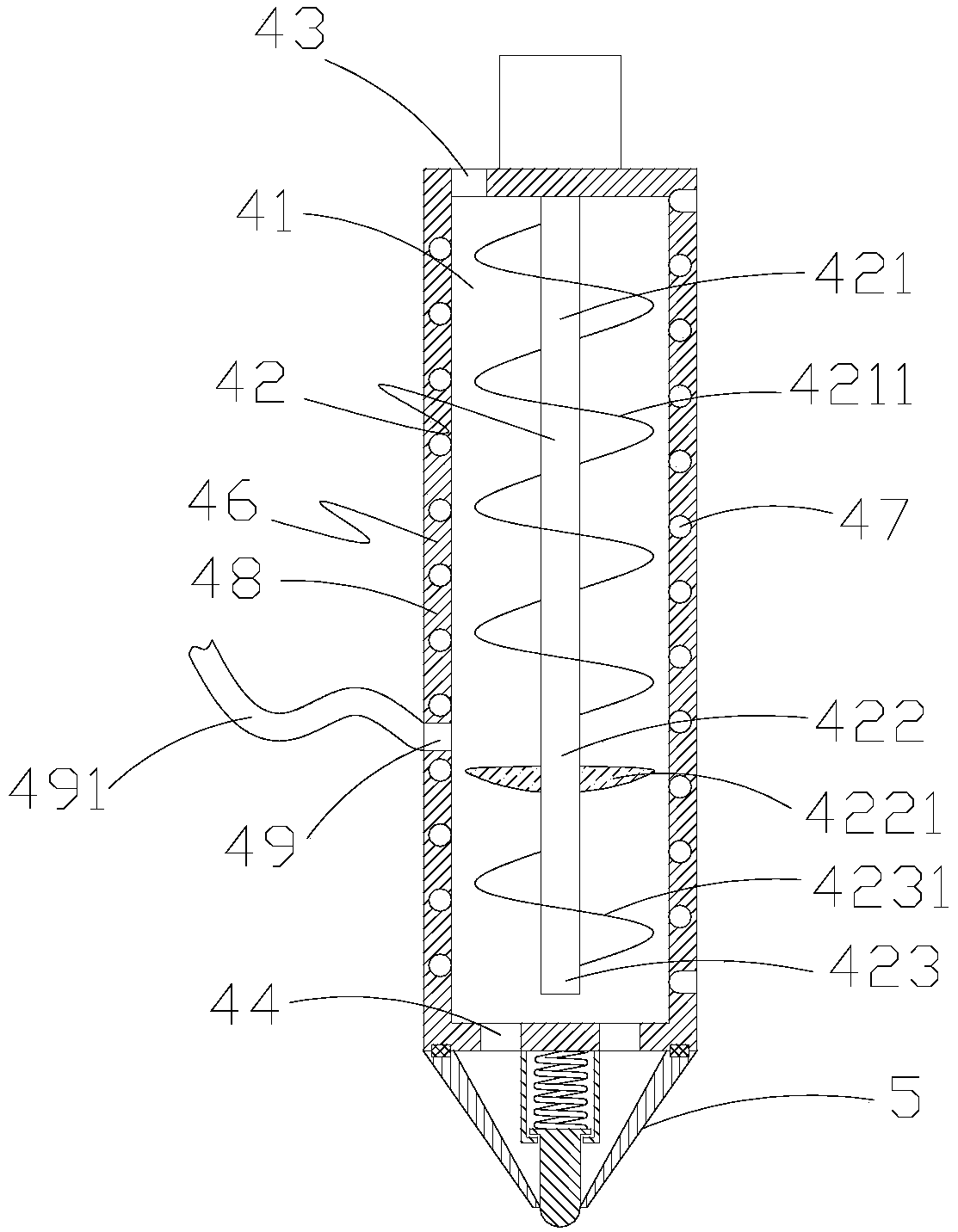

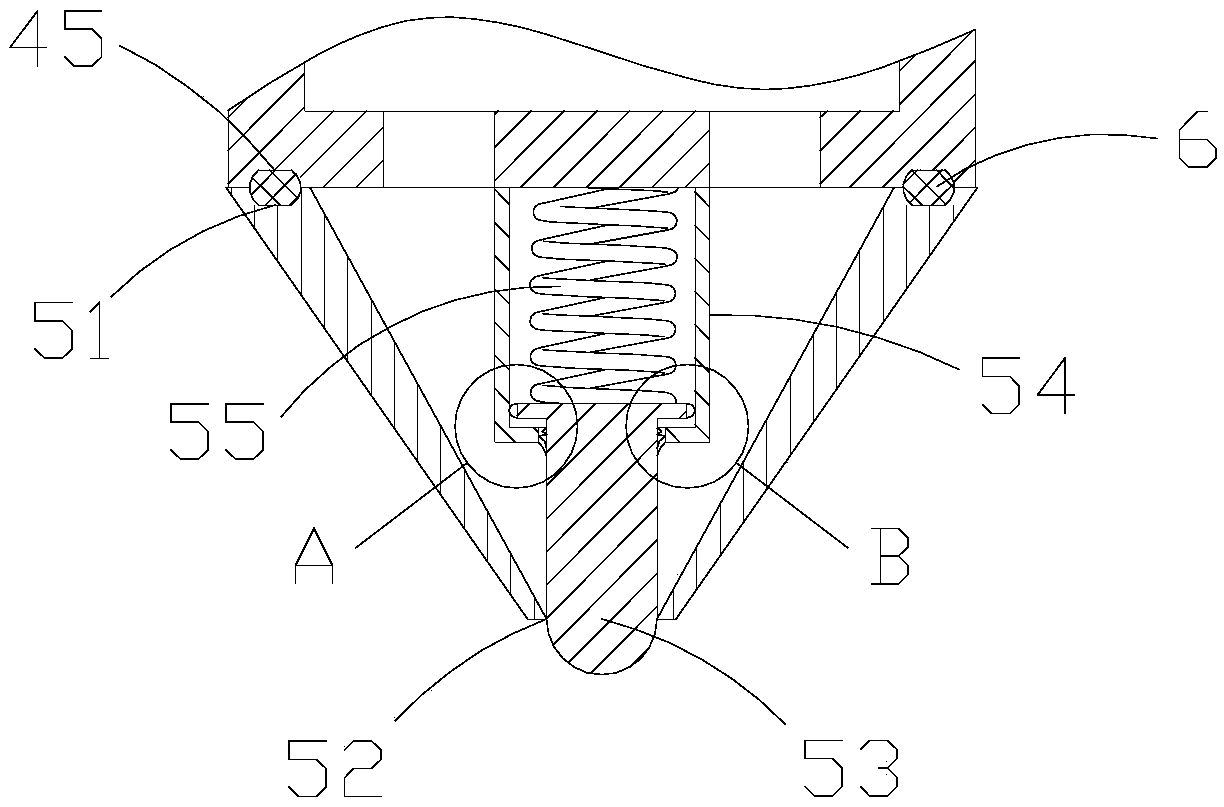

LED chip glue dispensing machine

InactiveCN109465153ANot easy to solidifyPrevent solidificationLiquid surface applicatorsSpraying apparatusEngineeringMechanical engineering

The invention discloses an LED chip glue dispensing machine. The LED chip glue dispensing machine comprises a base, a control device arranged on the base, a glue gun rack capable of moving up and down, a glue gun arranged on the glue gun rack and a feeding device connected with the glue gun. The glue gun is internally provided with a stirring cavity. A stirring shaft is arranged in the stirring cavity. The top of the stirring cavity is provided with a feed port. According to the LED chip glue dispensing machine, the stirring cavity and the stirring shaft are arranged in the glue gun to conductstirring on glue in the glue gun, and then the glue is made to flow continuously. Accordingly, the phenomenon that the glue gun gets blocked due to glue solidification is avoided.

Owner:HANGZHOU XIAOCHENG IND DESIGN CO LTD

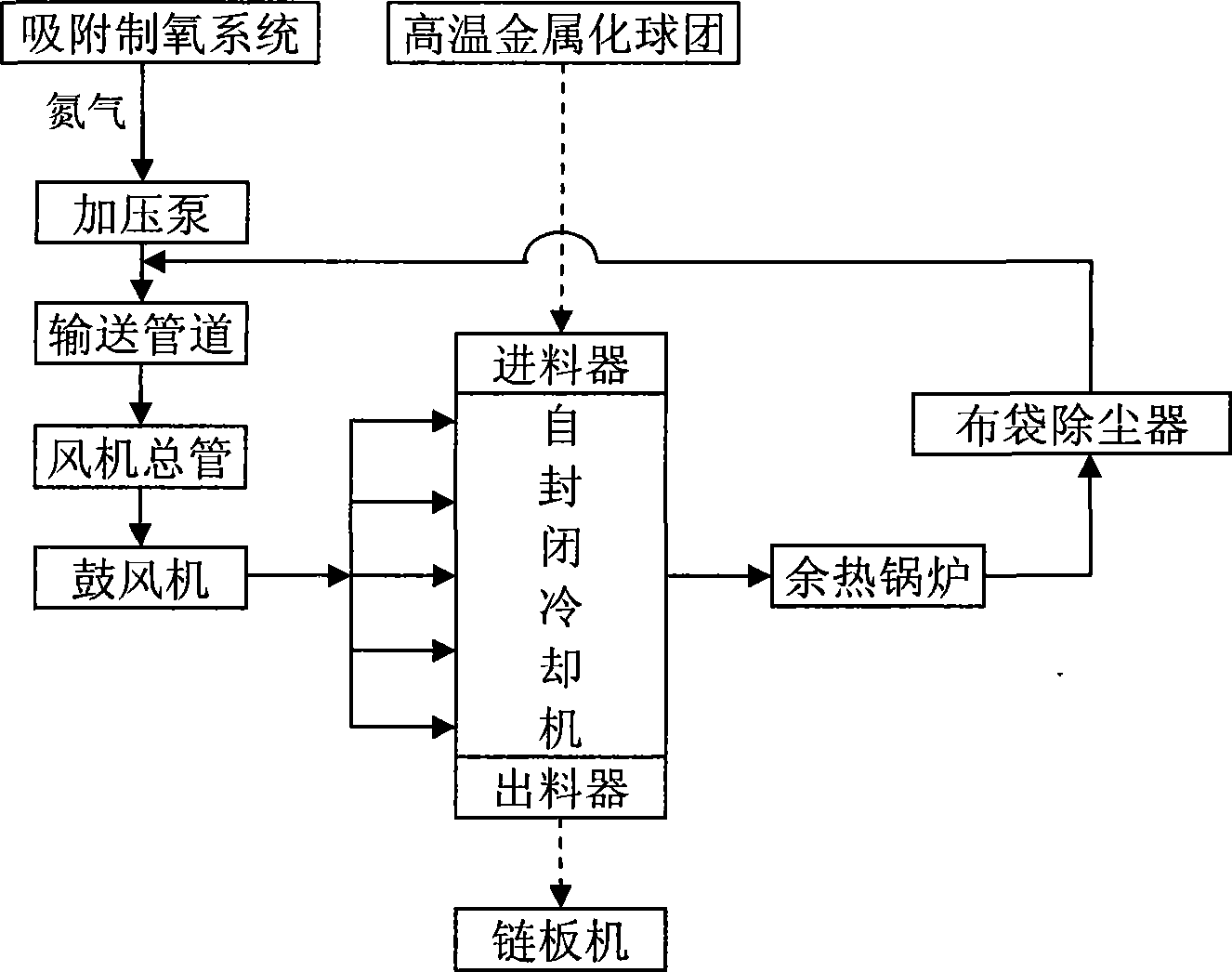

Self-sealing nitrogen circulating cooling method and apparatus

The invention provides a self-sealing nitrogen circulating cooling method which comprises the following steps: a. nitrogen discharged after oxygen generation through the absorption oxygen-generation technology in a steel plant is delivered to a blower header pipe through a pressure pump and a delivery pipeline, and the nitrogen in the blower header pipe is mixed with a recycle gas after recovery of heat; b. after pressure is applied to the mixed gas by a blast blower, the mixed gas is delivered to an air inlet pipe of a cooler, enters a material layer zone of a self-cooler through the air inlet pipe, and then is output through a large flue after heat exchange with a high temperature mass at the temperature of 1000 DEGC; and c. the temperature of waste gas in the large flue reaches up to 500-600 DEG C, and then is reduced to 180-230 DEG C after recovery of heat, and the waste gas is again led to the blower header pipe as a recycle gas for mixed cycle utilization with supplementary nitrogen. The technology can realize continuity, stability, recovery of high temperature waste gas and metallization rate of products in production, meet the national policy requirements for energy conservation, emission reduction and cyclic economy, and provide space for reducing production cost.

Owner:LAIWU IRON & STEEL GRP

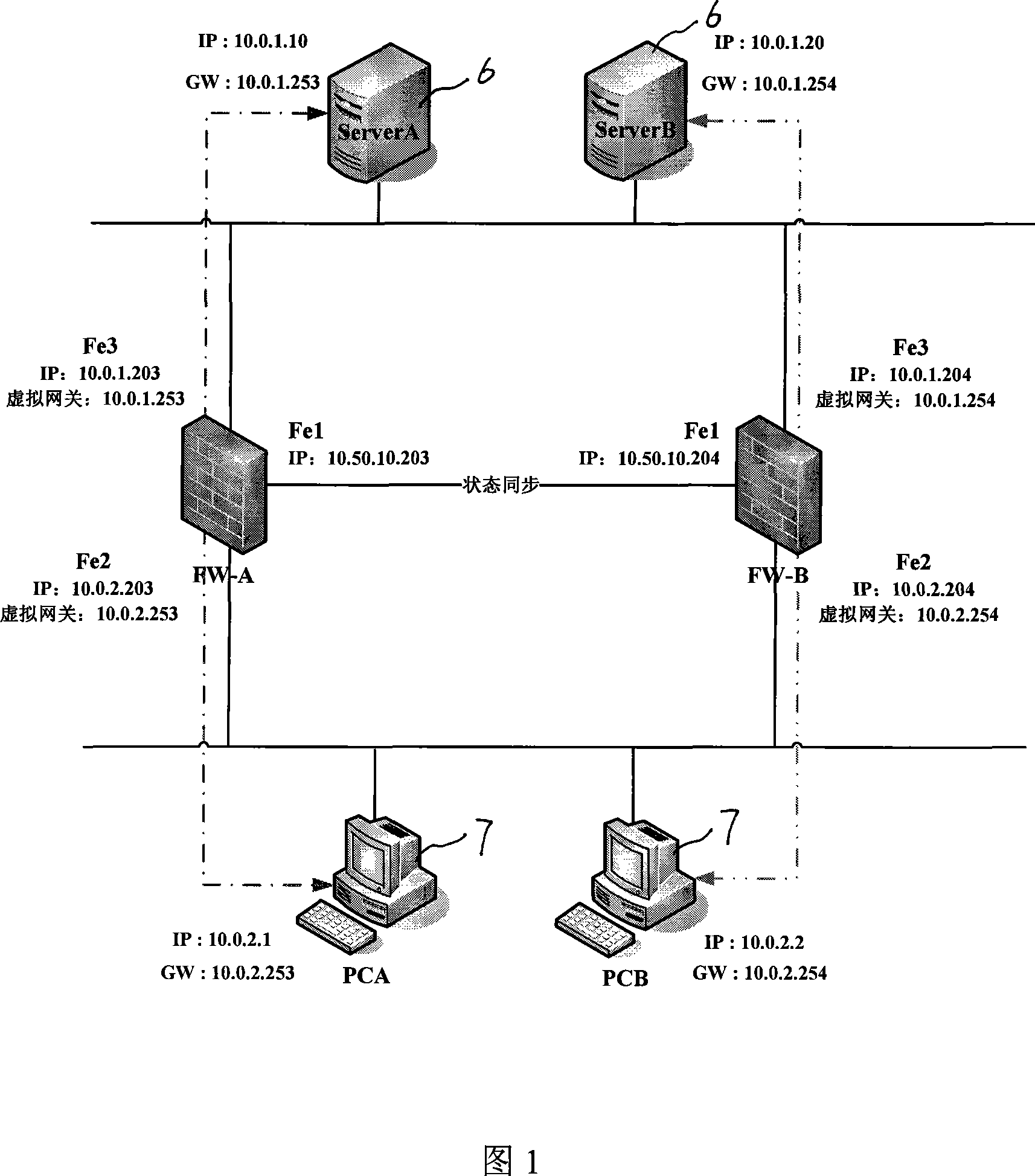

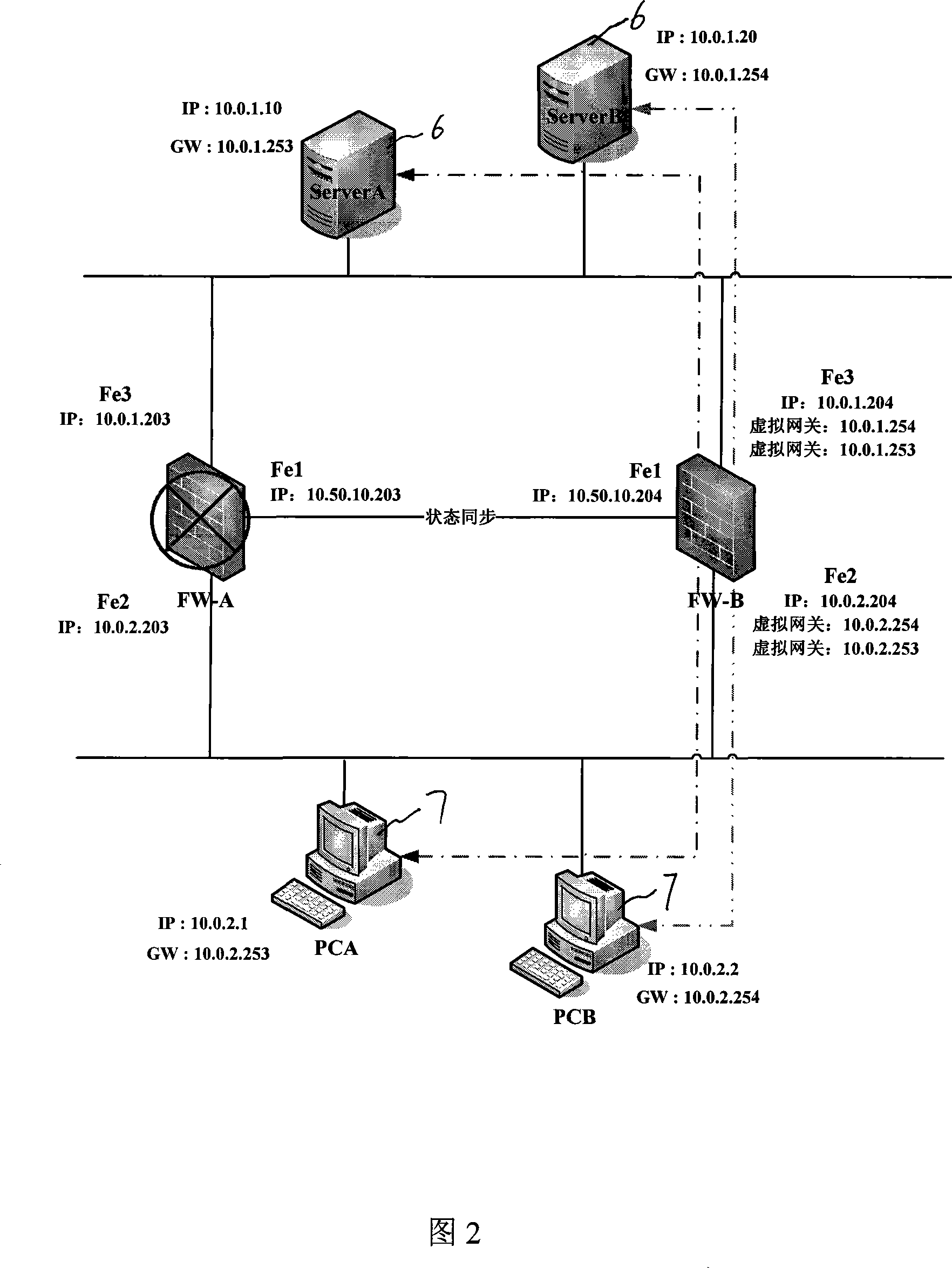

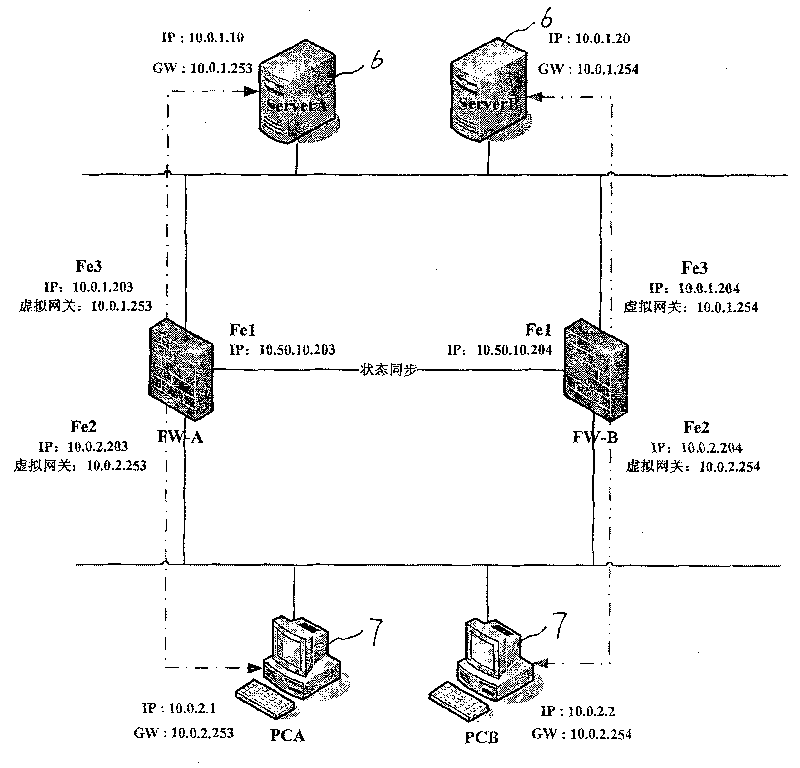

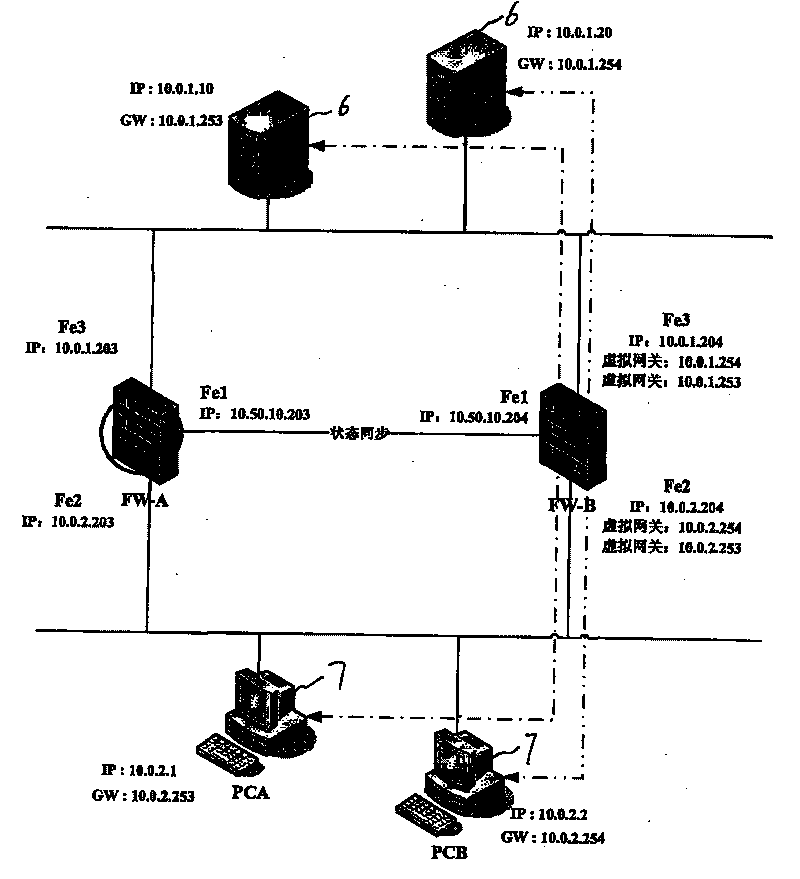

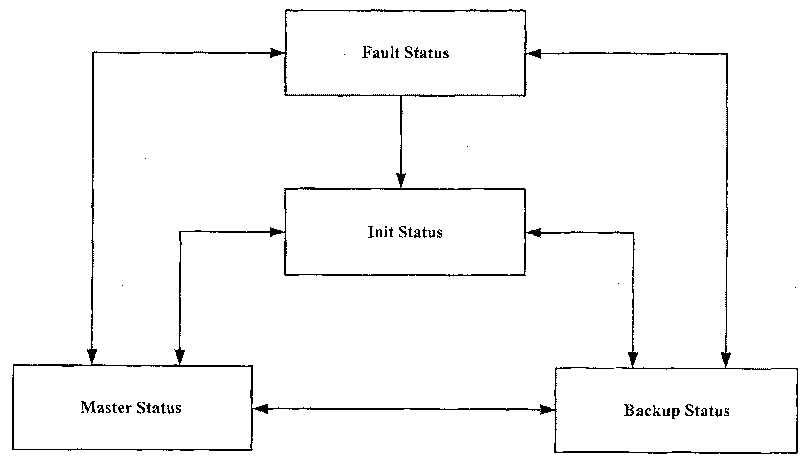

Load equalizing method and device for multiple fire-proof wall

ActiveCN101052047AImprove reliabilityImprove usabilityError preventionData switching by path configurationHigh availabilitySwitching time

The invention uses multi firewalls to construct a highly efficient and stable route link. The invention also provide an apparatus thereof used for providing a virtual gateway address for each firewall; each client is pointed to different virtual gateway so as to balance the traffic on each firewall; when one firewall fails, other firewalls can take over the address of the failure firewall to keep the network traffic in normal state.

Owner:QI-ANXIN LEGENDSEC INFORMATION TECH (BEIJING) INC +1

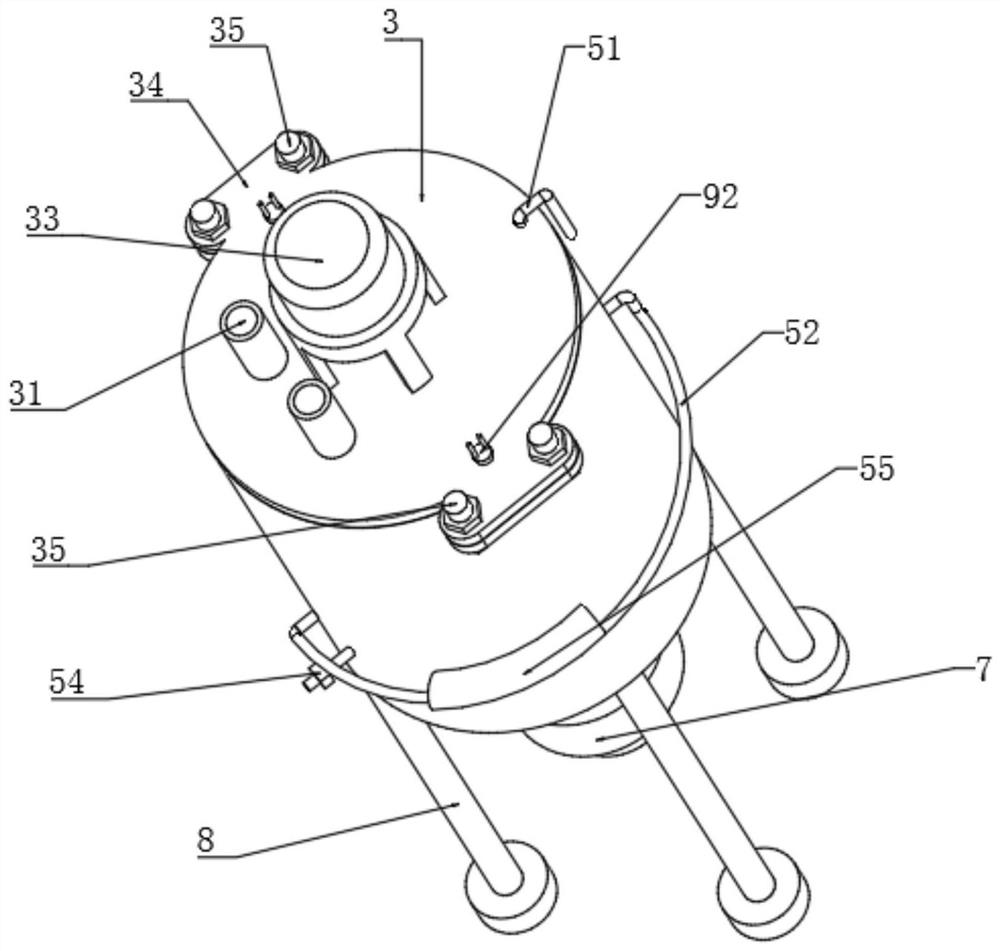

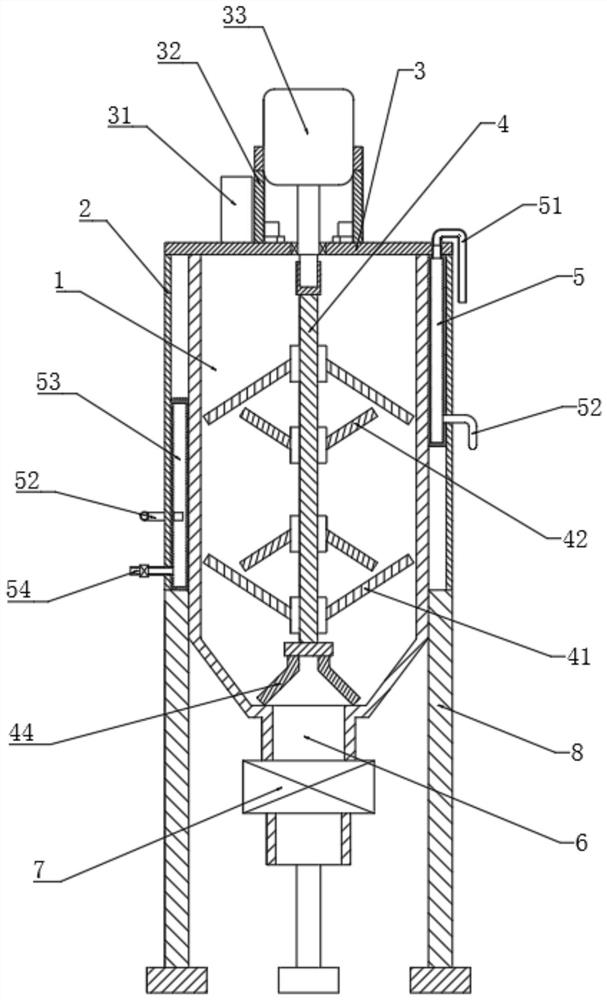

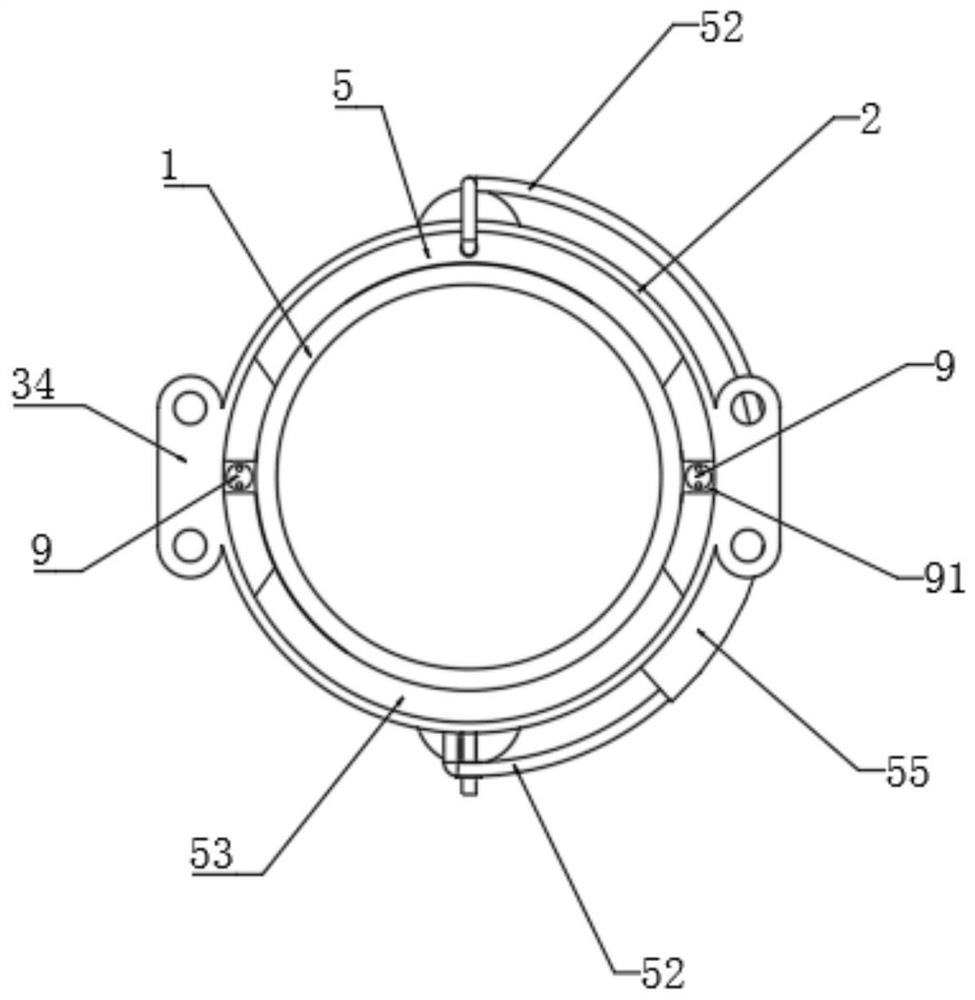

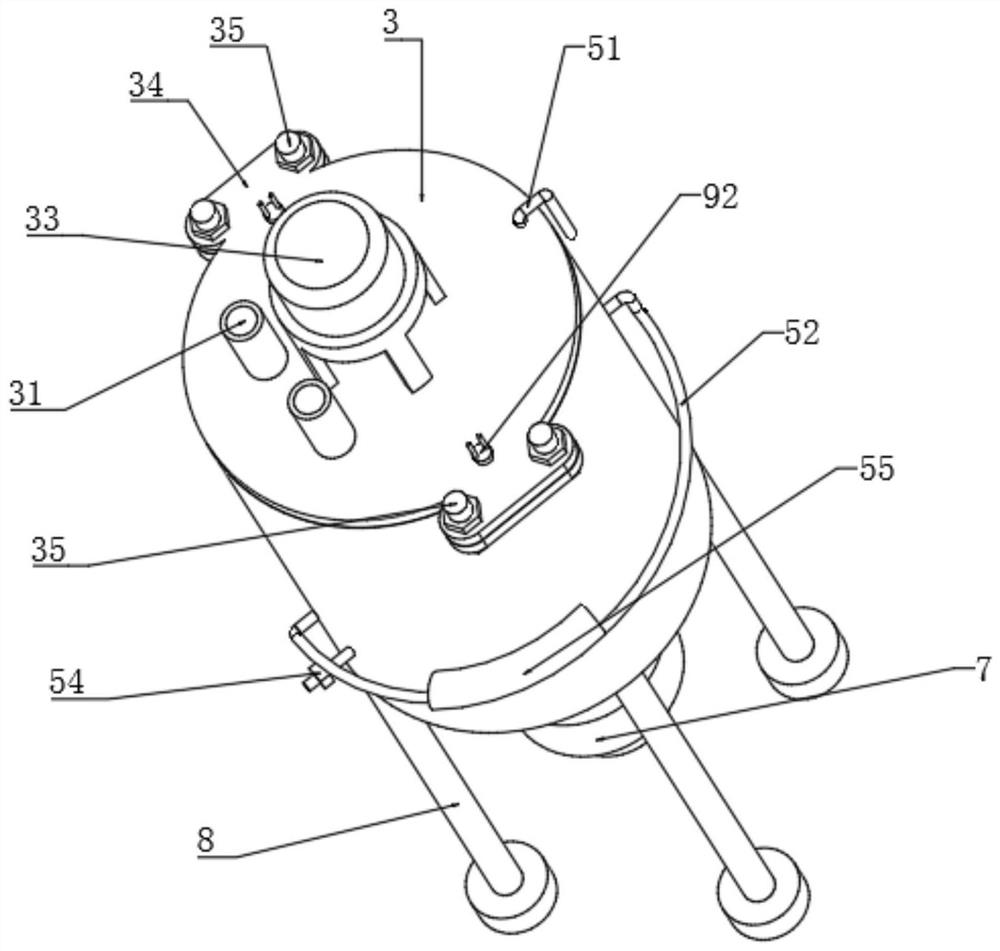

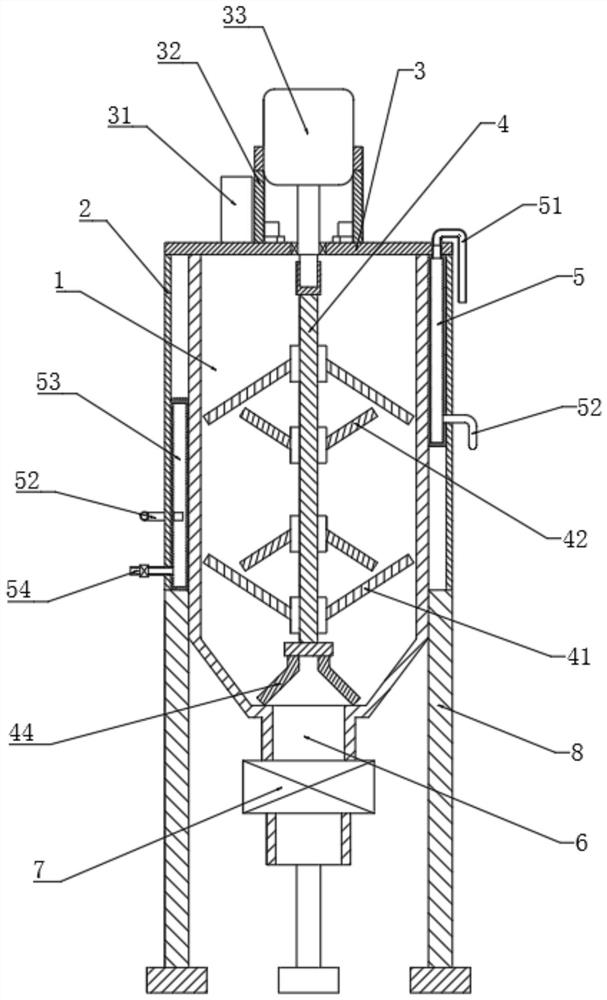

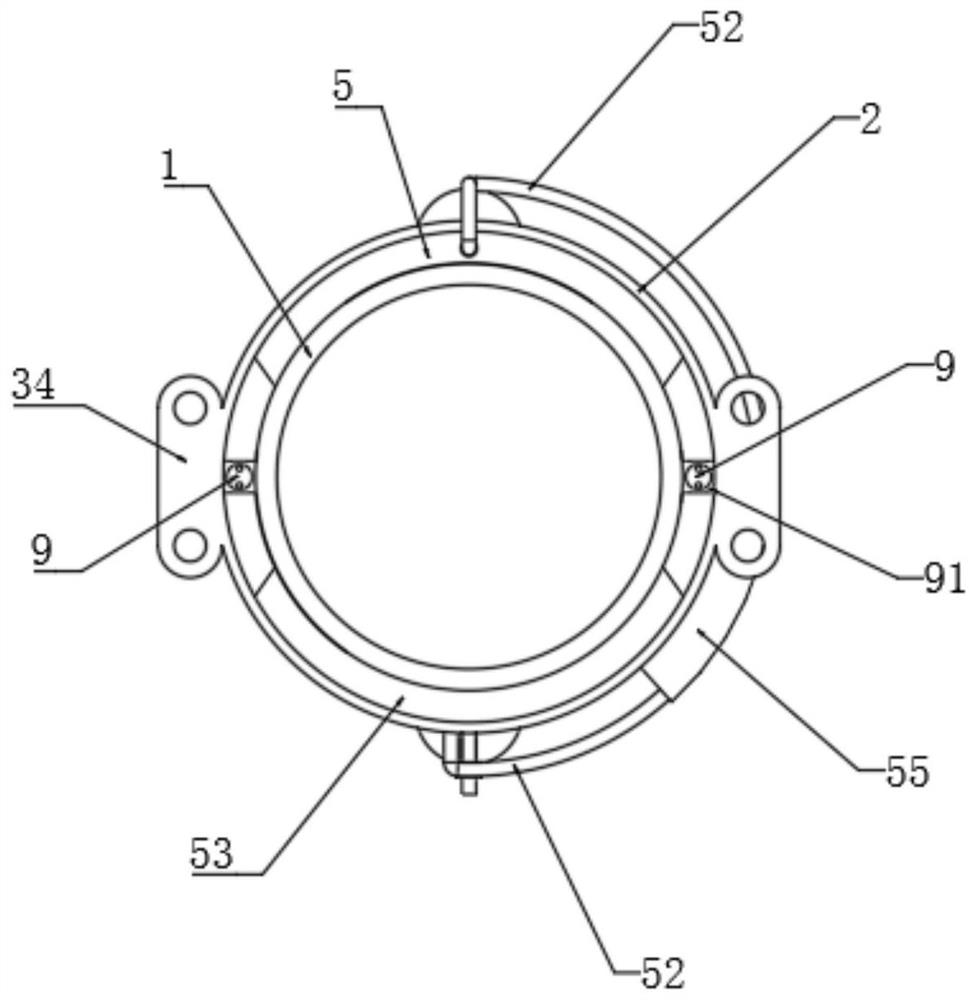

Preparation method and equipment of magnetic nanocomposite material

ActiveCN111790288AReduce resistanceImprove stirring efficiencyRotary stirring mixersTransportation and packagingElectric machineCooling effect

The invention discloses a preparation method and equipment of a magnetic nanocomposite material, belonging to the technical field of magnetic nanomaterial preparation. The equipment comprises an agitating tank, wherein a heating cavity is formed in the outer wall of the upper part of the agitating tank; a feeding pipe is arranged on the upper end surface of the upper cover; the middle part of theupper end surface of the upper cover is fixedly connected with a stirring motor through a mounting frame; the output shaft end of the stirring motor is fixedly connected with a stirring shaft; the lower part of the stirring shaft is fixedly connected with long stirring blades and short stirring blades respectively; a first cooling cavity and a second cooling cavity are formed in an inner cavity ofthe heating cavity; and irradiation heating devices are symmetrically arranged in the inner cavity of the heating cavity. According to the invention, the problems that existing magnetic nanocompositematerial preparation equipment is low in liquid raw material and powder mixing efficiency and poor in heating and cooling effect, and consequently the whole magnetic nanomaterial production efficiency is not high are solved.

Owner:JINHUA VOCATIONAL TECH COLLEGE

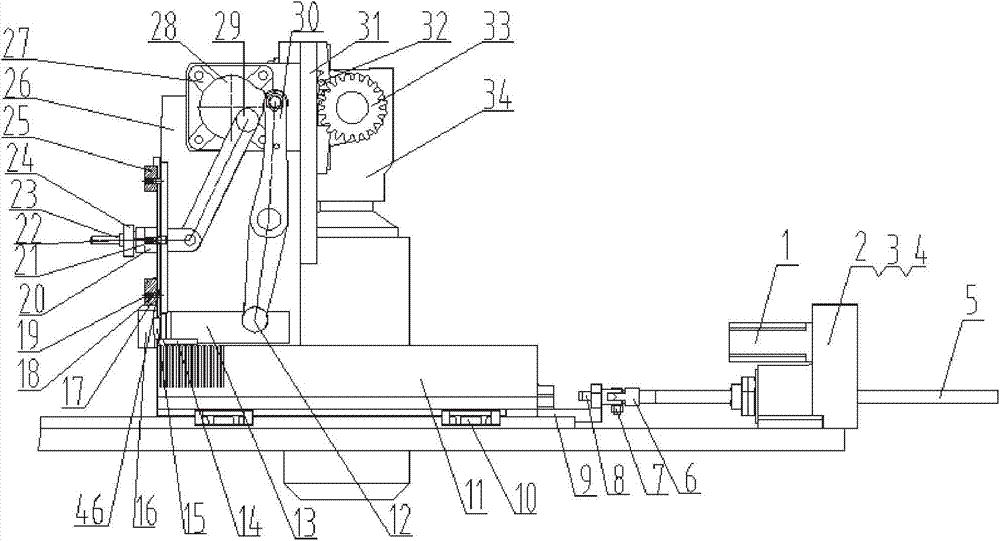

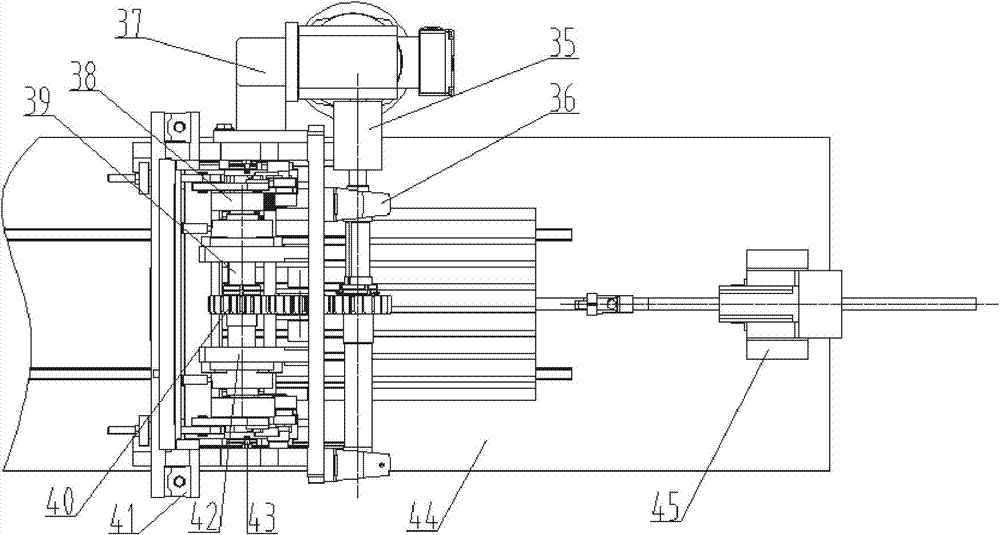

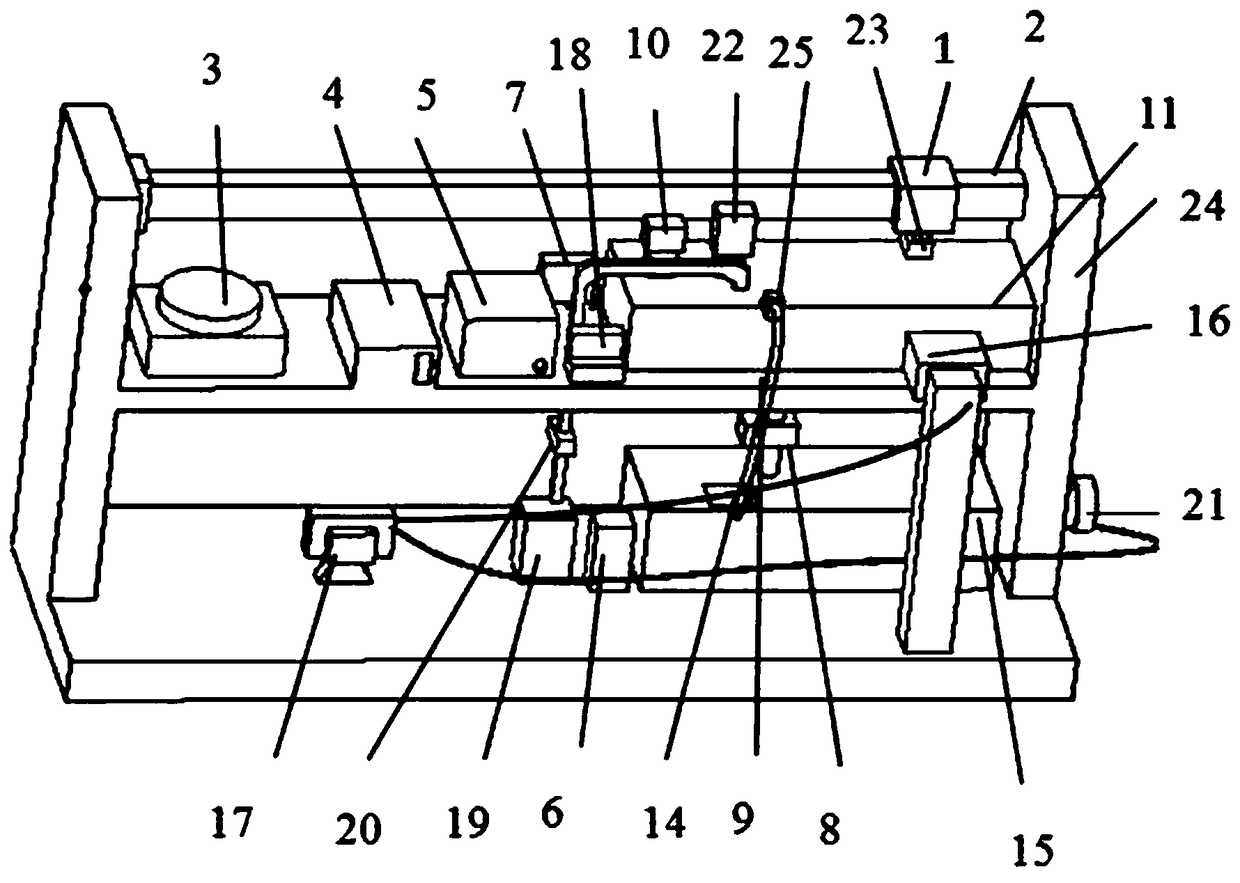

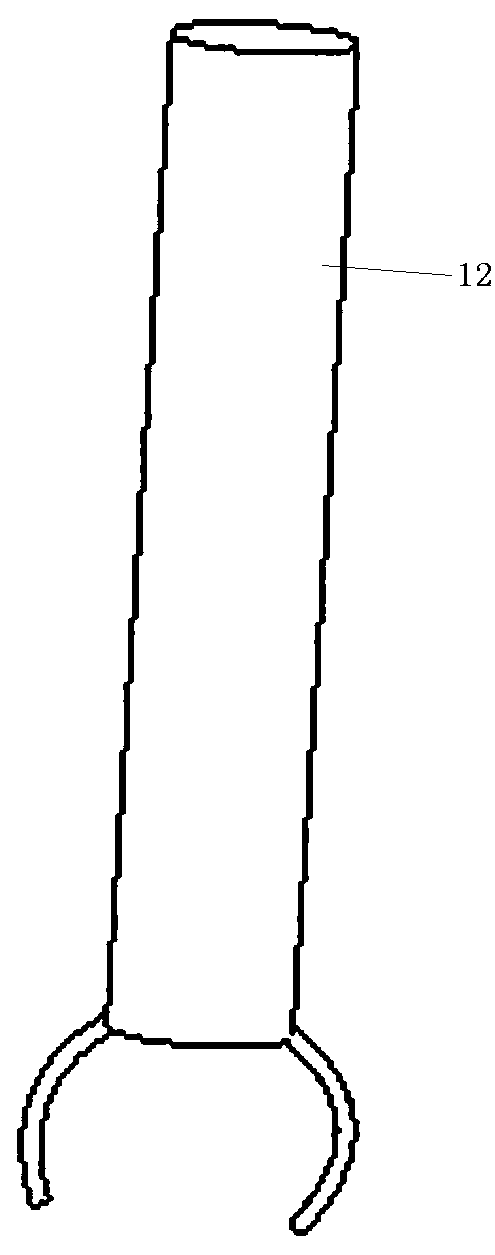

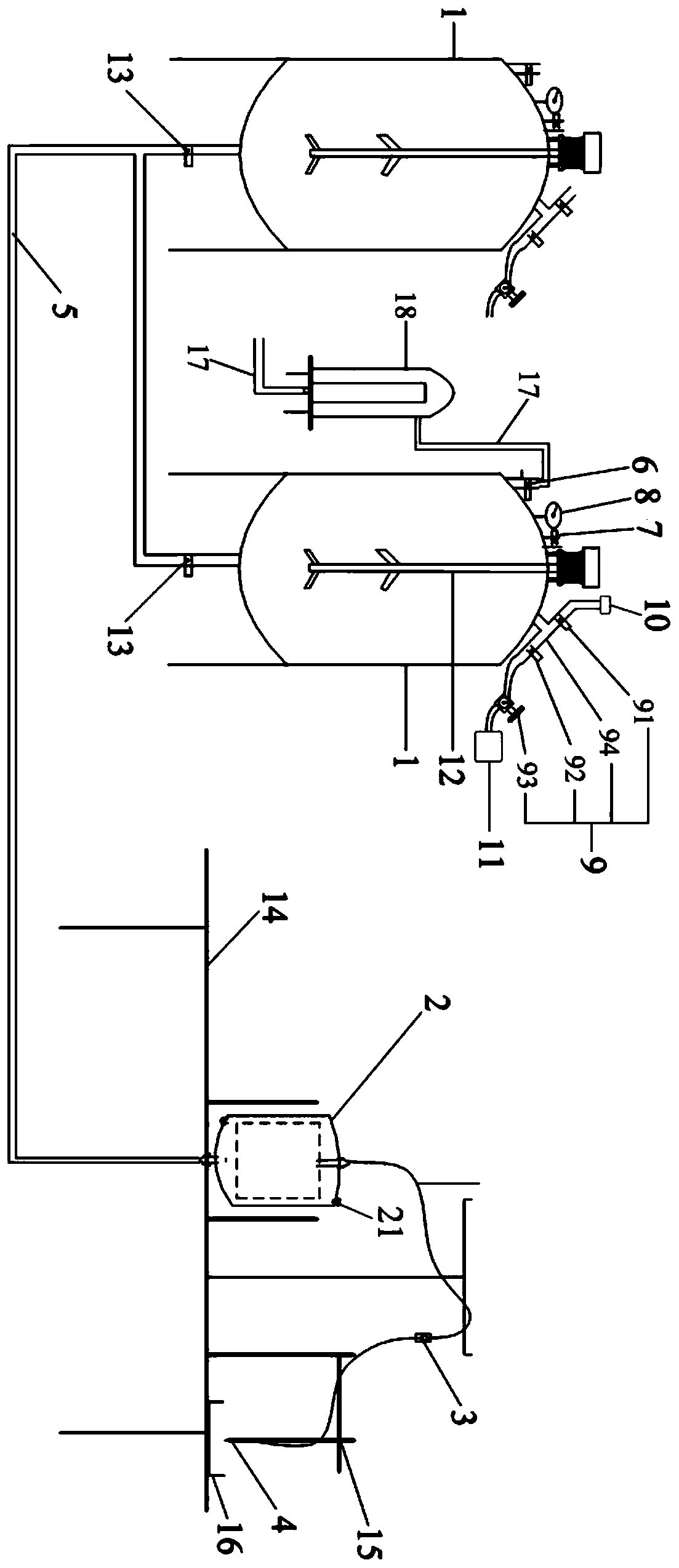

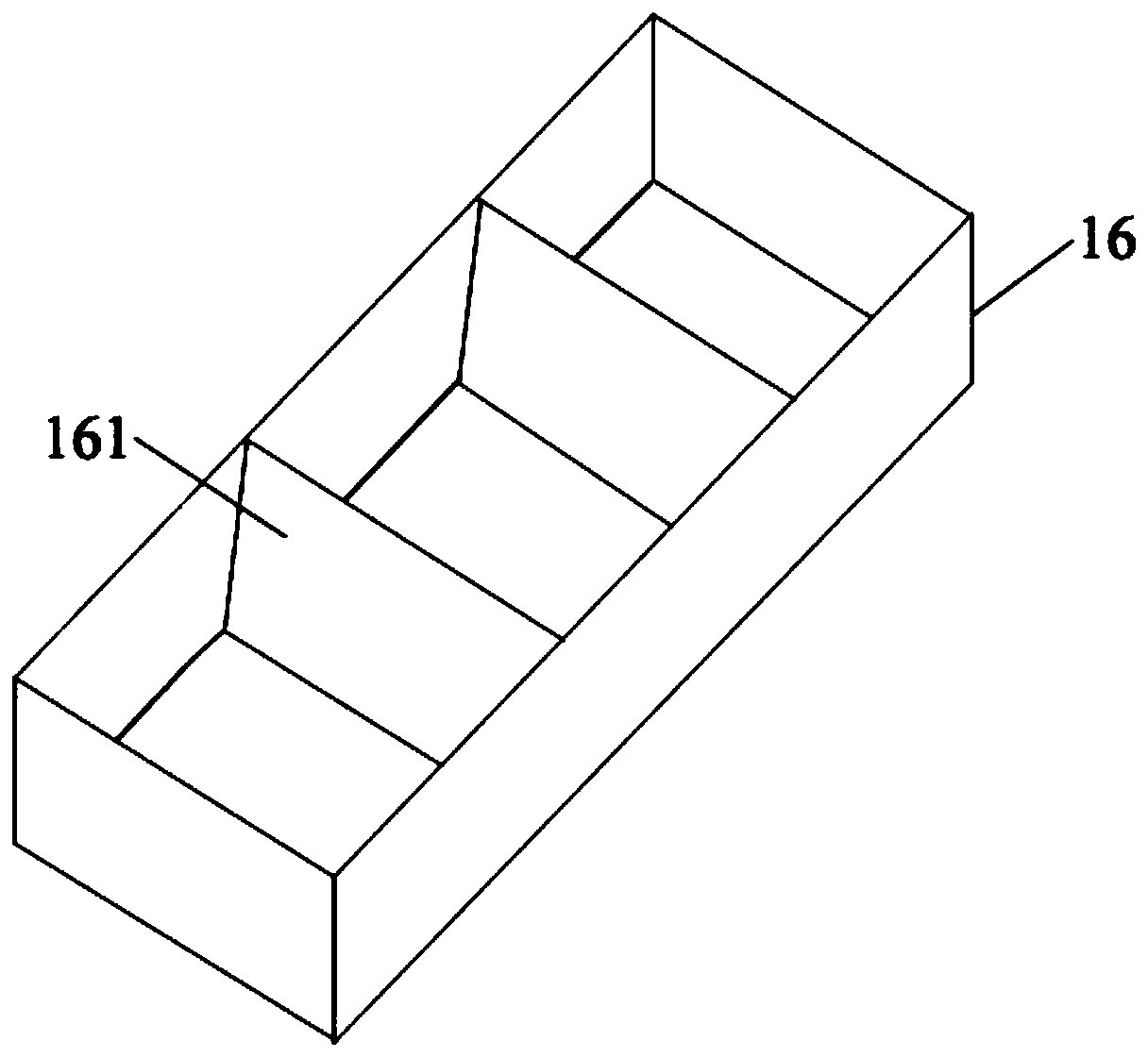

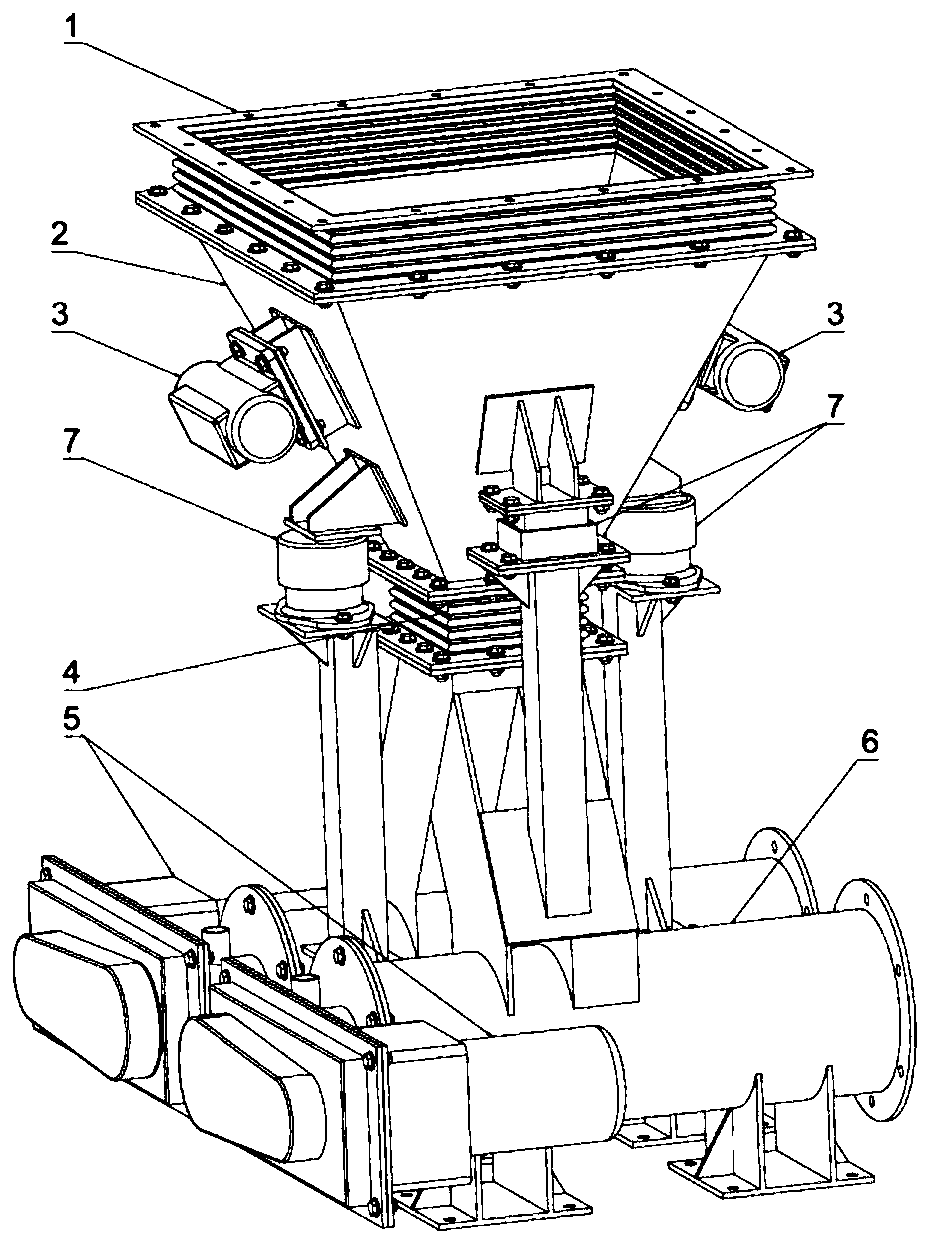

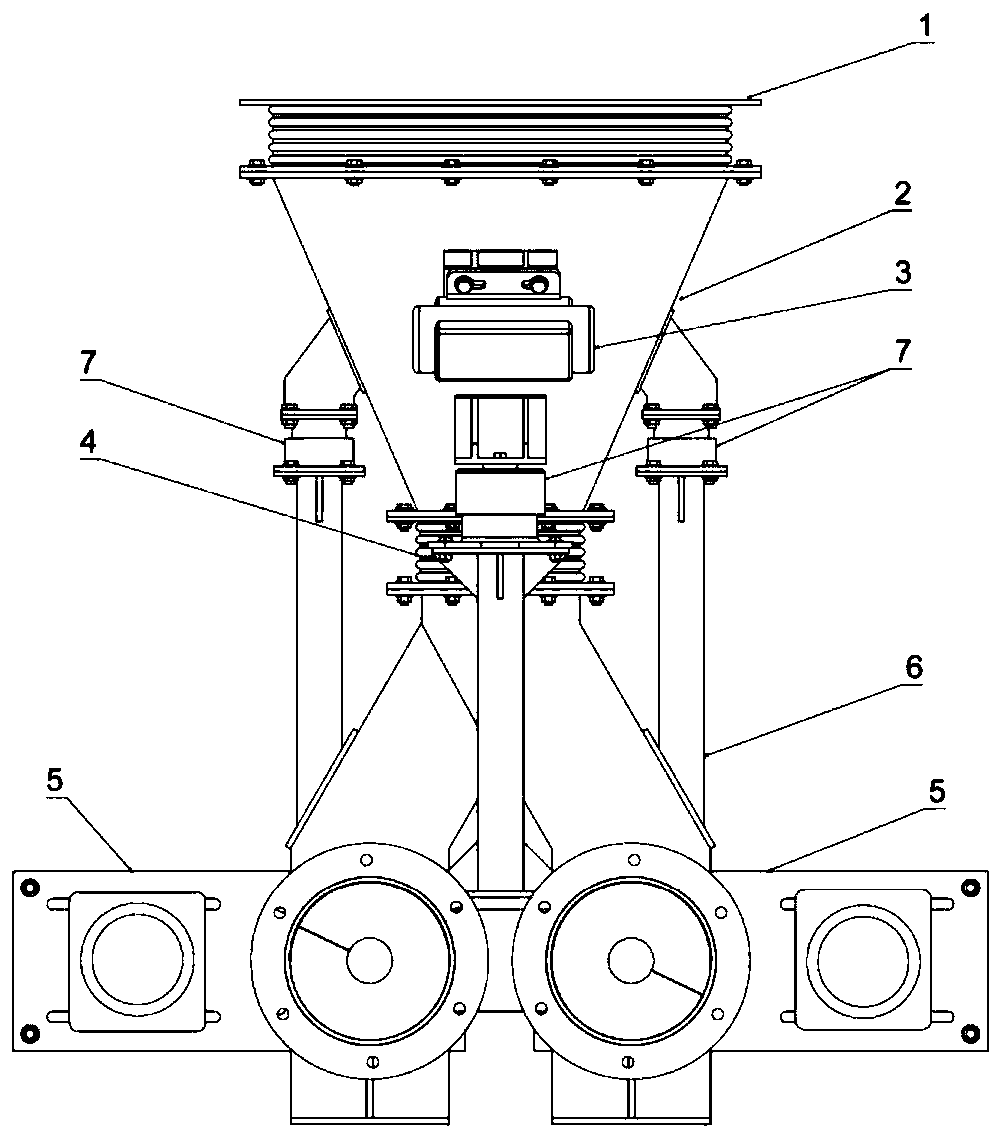

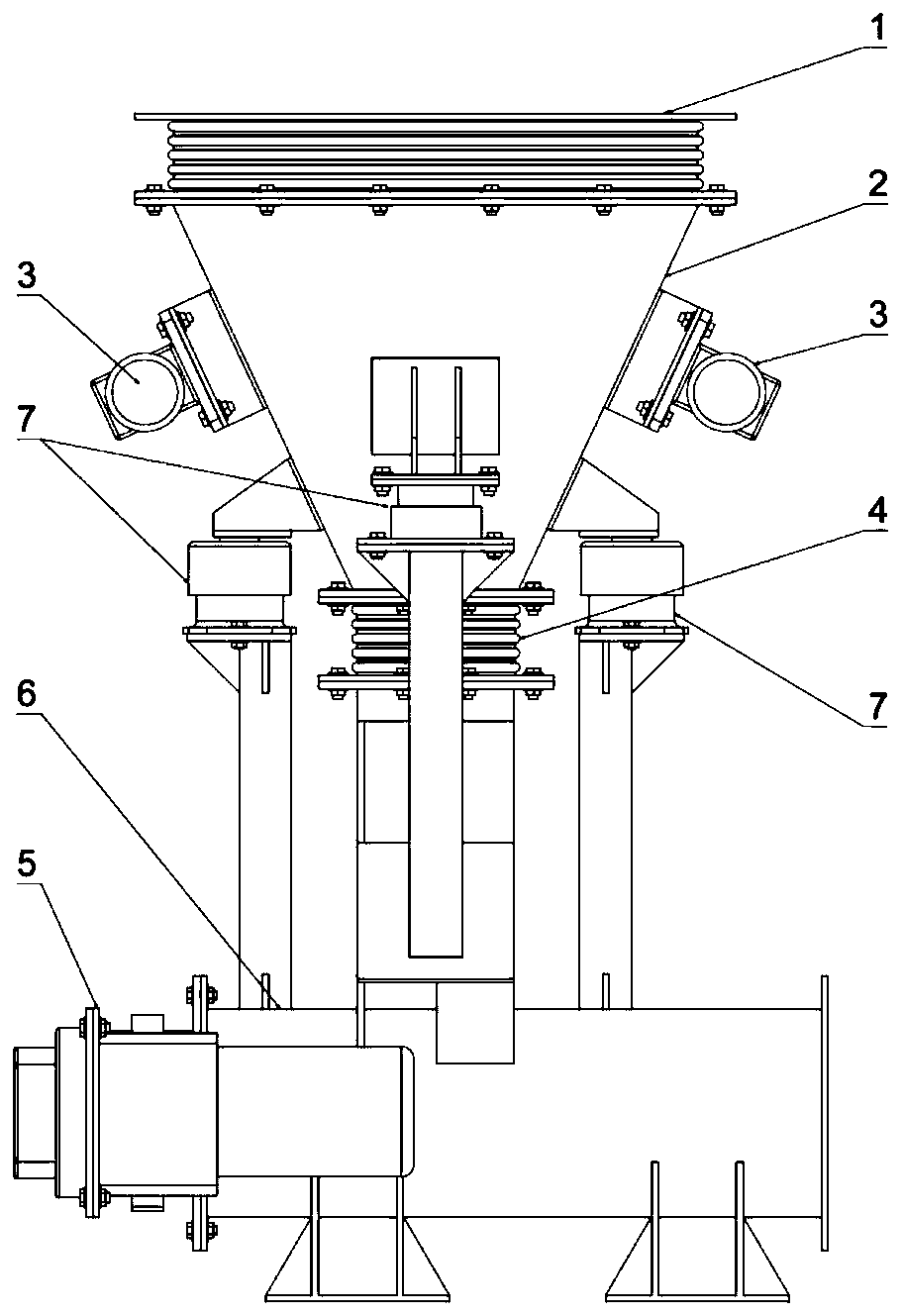

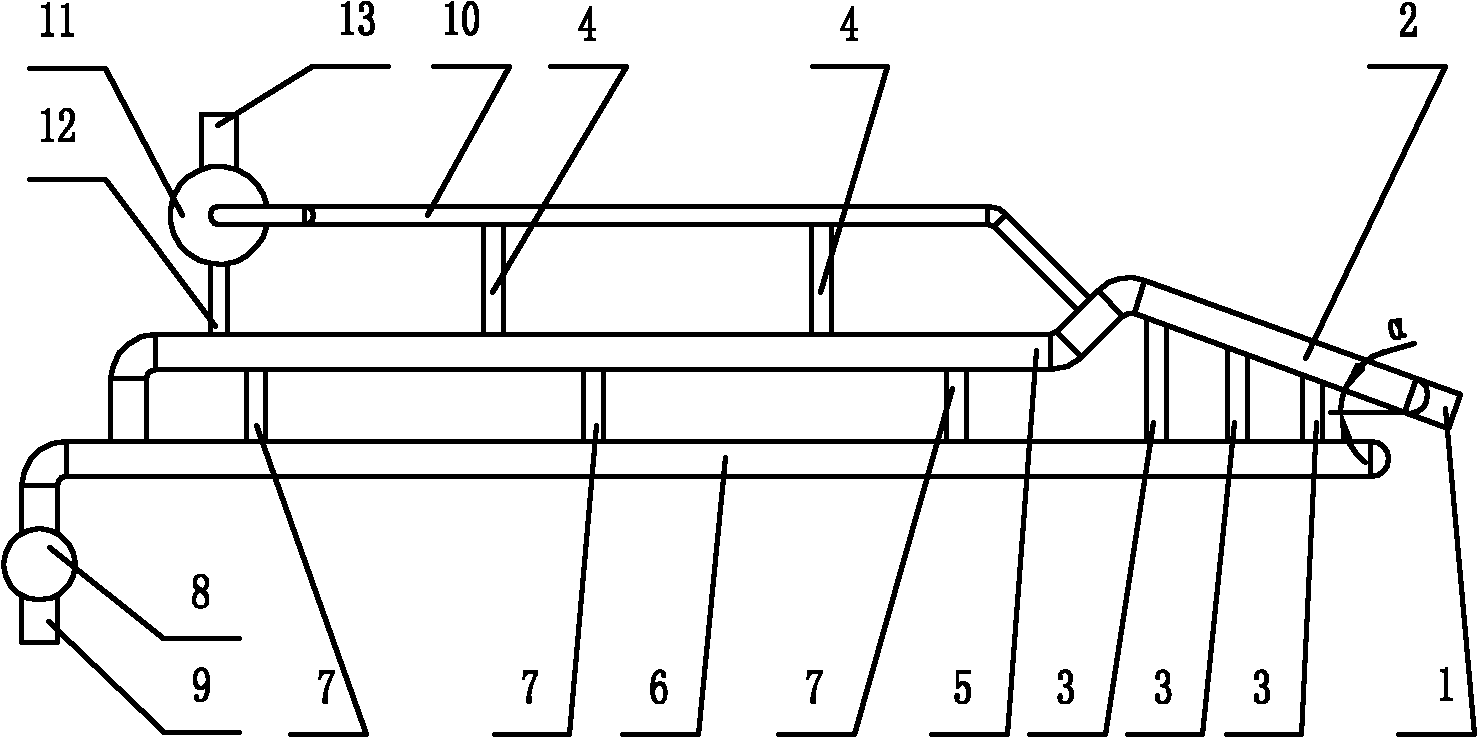

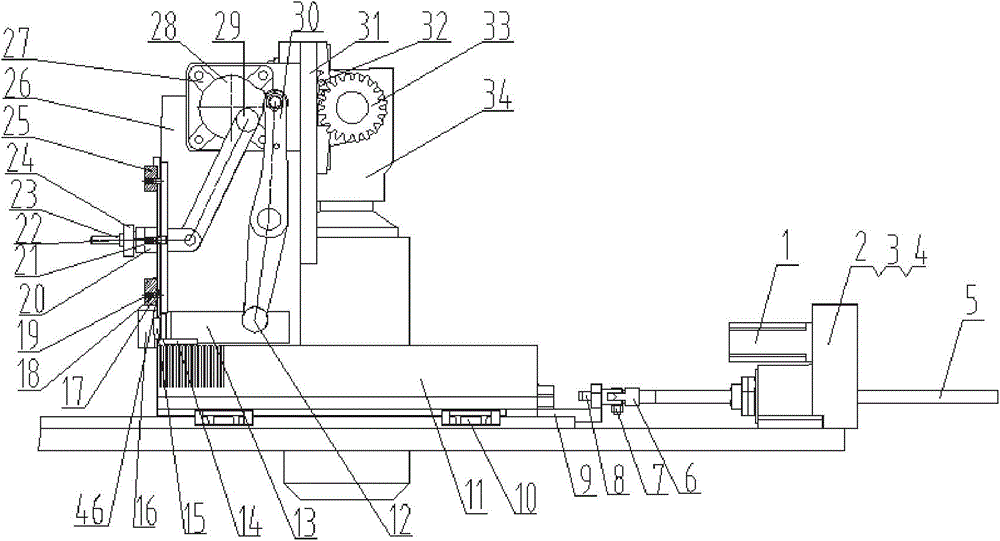

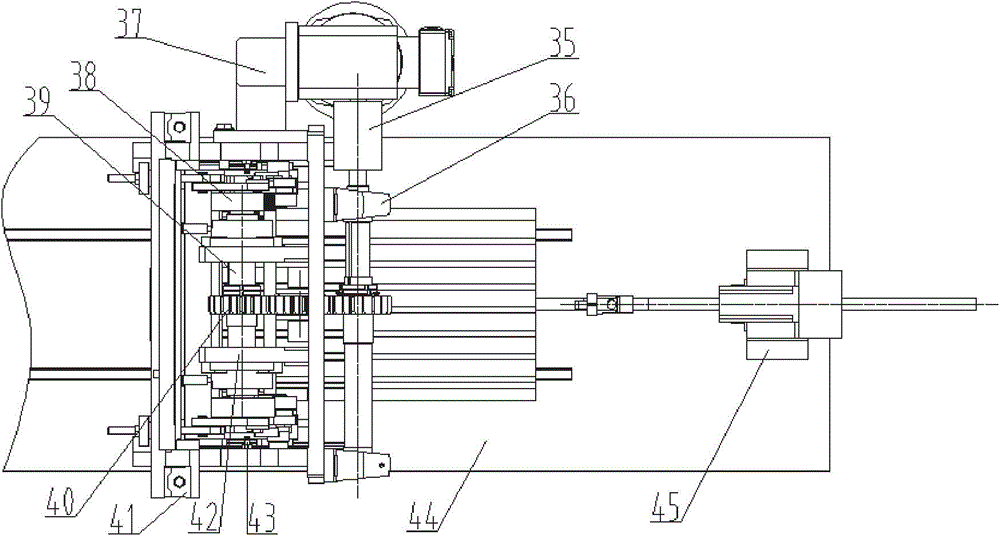

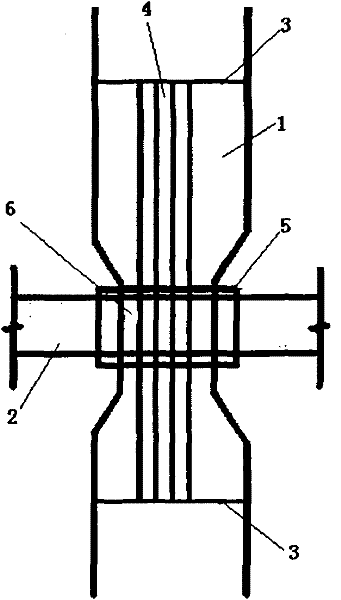

Automatic fin cut-off device and work process thereof

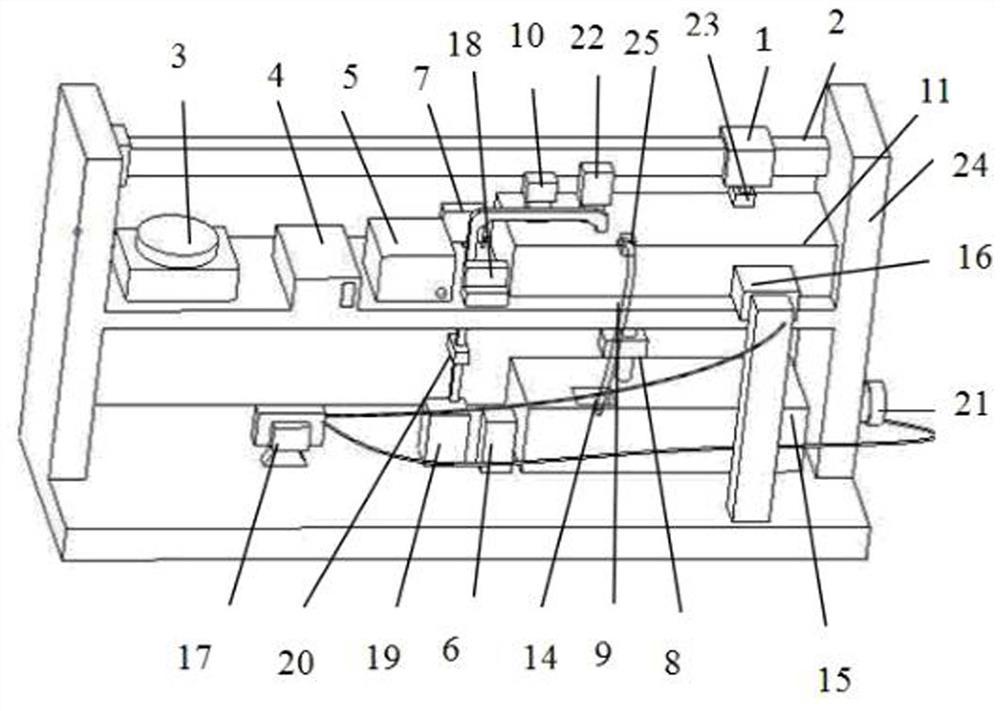

InactiveCN103786179AGuaranteed continuous flowRealize fully automatic controlMetal working apparatusAutomatic controlEngineering

The invention provides an automatic fin cut-off device and a work process of the device. The automatic fin cut-off device comprises a machine frame and a fin cut-off mechanism arranged on the machine frame and further comprises a fin bearing mechanism arranged on the machine frame. The fin bearing mechanism comprises a fin base arranged on the machine frame in a sliding mode and a fin base driving mechanism, a fin bearing groove is formed in the fin base, the fin cut-off mechanism comprises a cutter, and the fin bearing groove is formed below the cutter. The device comprises a fin pushing mechanism, the fin cut-off mechanism and the fin bearing mechanism, full-automatic control over feeding, cutting-off and discharging of fins can be achieved, continuous flowing of the fins is ensured, and the production requirements for high speed and high precision are met.

Owner:上海英集斯自动化技术有限公司

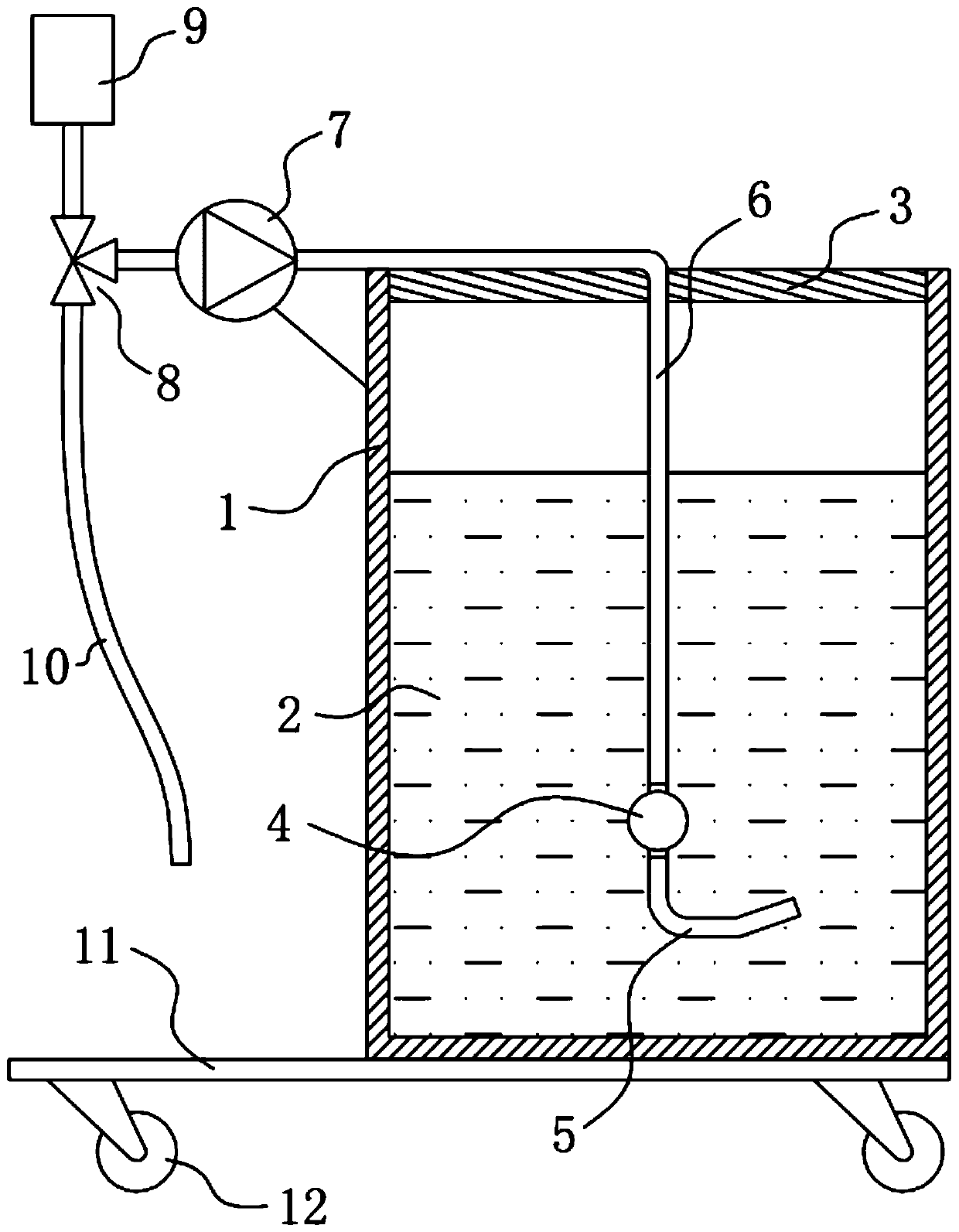

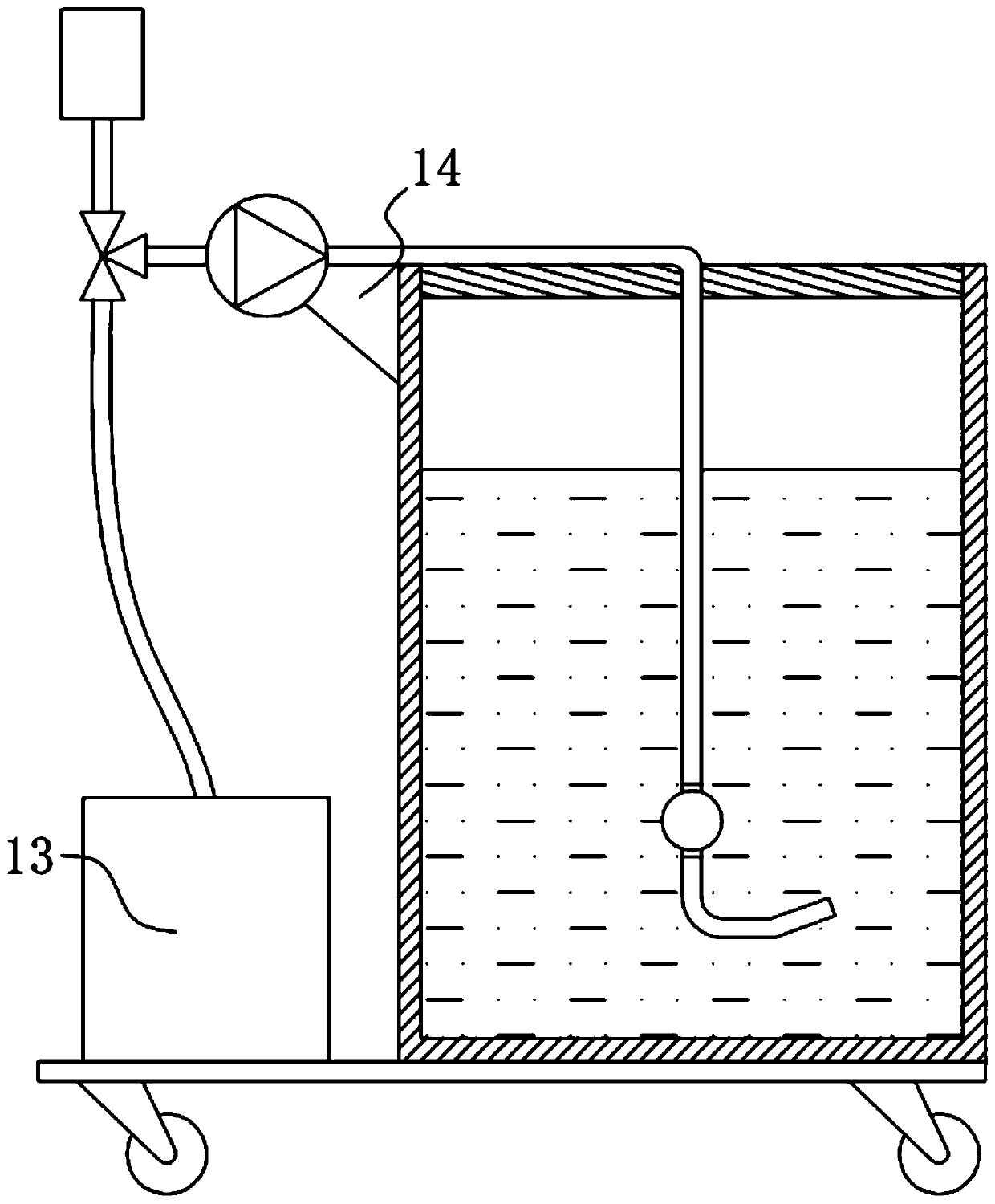

Glue storage barrel with stirring function

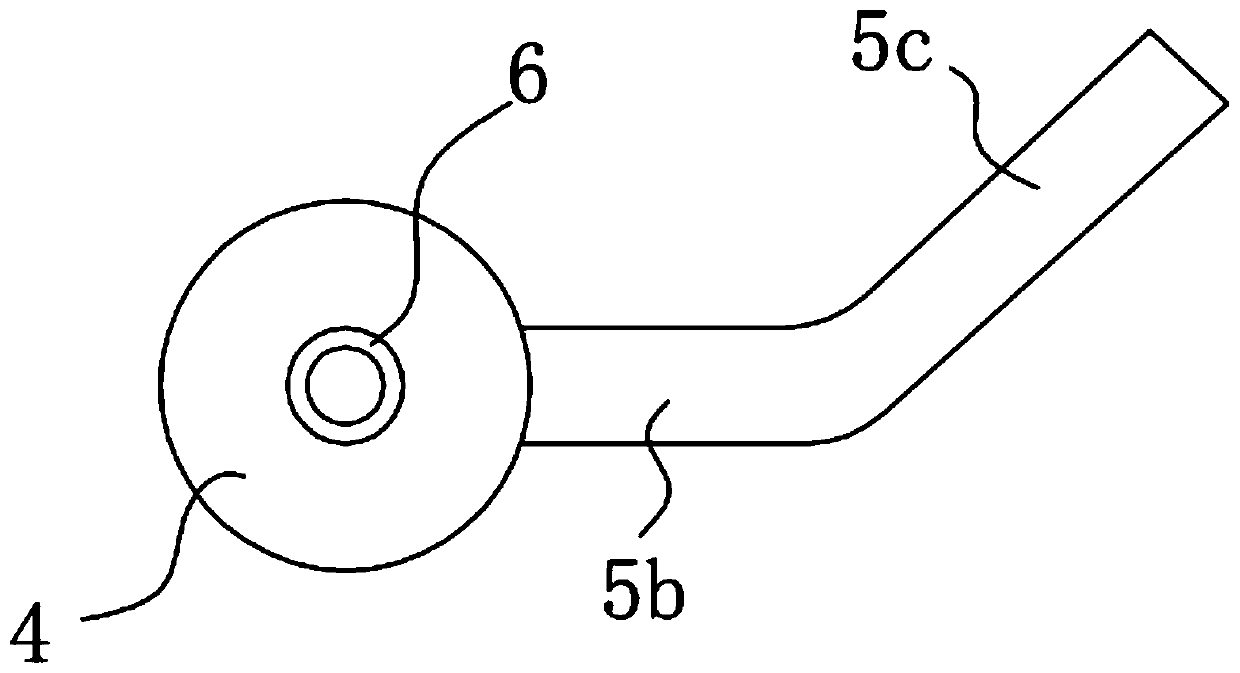

The invention discloses a glue storage barrel with a stirring function. The glue storage barrel comprises a barrel body, an input output part, and a soaking tube, wherein the barrel body comprises a glue storage barrel with a glue solution; the input output part comprises a pump body with a two-way conveying function, one end of the pump body is connected with a hollow tube; the hollow tube is provided with a vertical section which is suspended in the glue storage barrel; the other end of the pump body is connected with a three-way valve; the other two ends of the three-way valve are separately connected with an air filter and a glue conveying tube; the soaking part is positioned at one end, back to the pump body, on the hollow tube; the soaking part is soaked in the glue solution of the glue storage barrel, and the soaking part comprises an elbow tube which is axially connected to the hollow tube; the hollow tube has a rotation freedom around a plumb line; the outlet section of the elbow tube is an inclined tube; the center line of the inclined tube and the horizontal plane are arranged at an included angle; the center line of the inclined tube and the center line of the verticalsection of the hollow tube are mutually different-surface straight lines. The glue storage barrel utilizes the glue solution or gas bubbles to realize stirring and mixing of the glue solution, so thatuniformity of the glue solution in the glue storage barrel is improved, the integral stirring range is wide, and equipment cost is low.

Owner:昆山金红凯包装制品有限公司

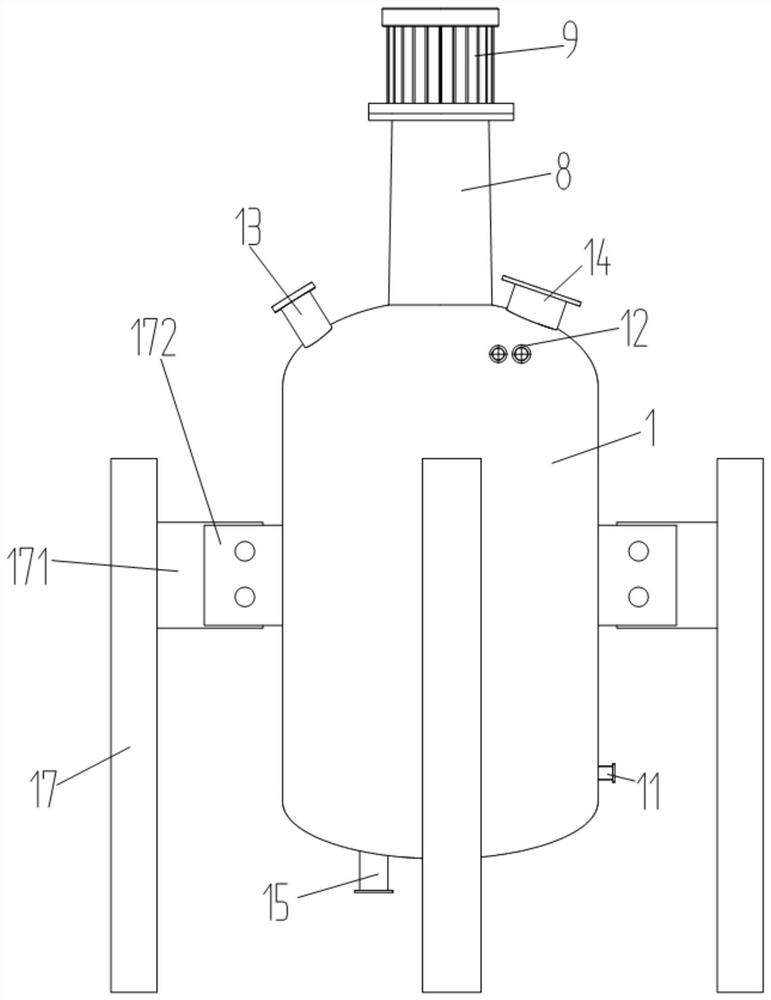

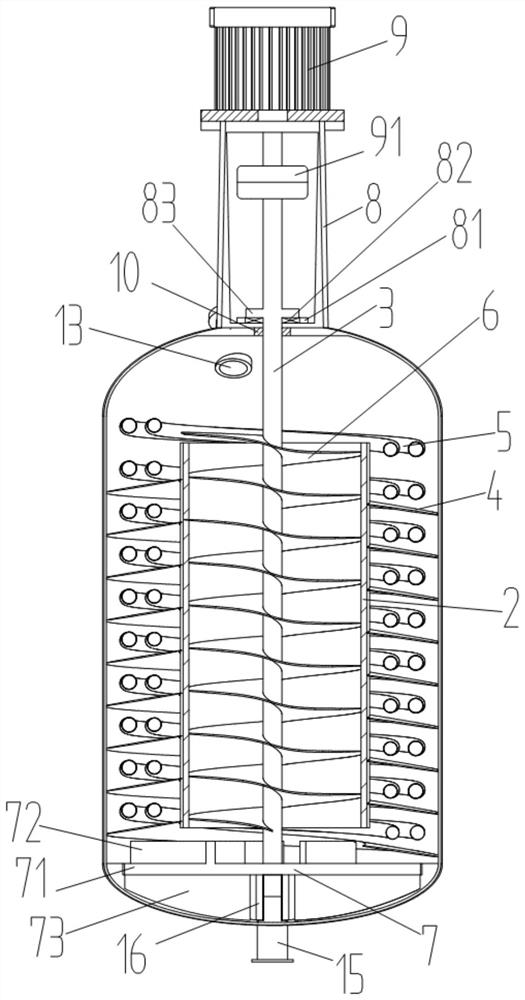

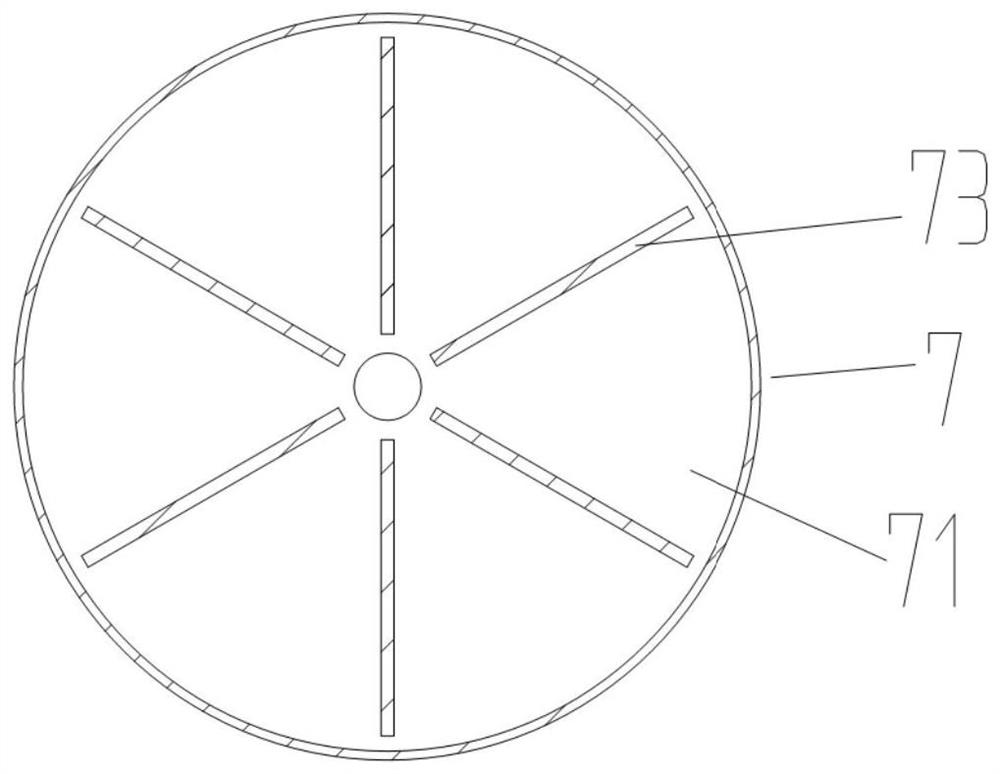

Reaction kettle for producing chlorine ether rubber

PendingCN113041985AAvoid material agglomerationSufficient heat exchangeChemical/physical/physico-chemical stationary reactorsElectric machineryDrive motor

The invention discloses a reaction kettle for producing chlorine ether rubber, which comprises a tank body, an inner cylinder body, a rotating shaft, a spiral blade I, a coil pipe, a spiral blade II, an impeller, an end socket seat and a driving motor, and an output shaft of the driving motor downwards penetrates through a through hole I formed in an upper cover of the end socket seat and then is coaxially inserted into the cylinder body of the end socket seat; and the lower end of the driving motor is connected with the upper end of the rotating shaft through a coupler to drive the rotating shaft to rotate, a bearing seat is arranged at the bottom in the end socket seat, a bearing is arranged in the bearing seat, and the rotating shaft is sleeved with an inner ring of the bearing and rotationally supported on the bearing through a shaft shoulder of the rotating shaft. Materials in the reaction kettle form a circulating mixing reaction structure from bottom to top and then from top to bottom, mixing is uniform, reaction is sufficient, and the materials can be prevented from caking. The cooling effect is good by introducing a refrigerant medium into the coil pipe.

Owner:宁夏博远橡胶有限公司

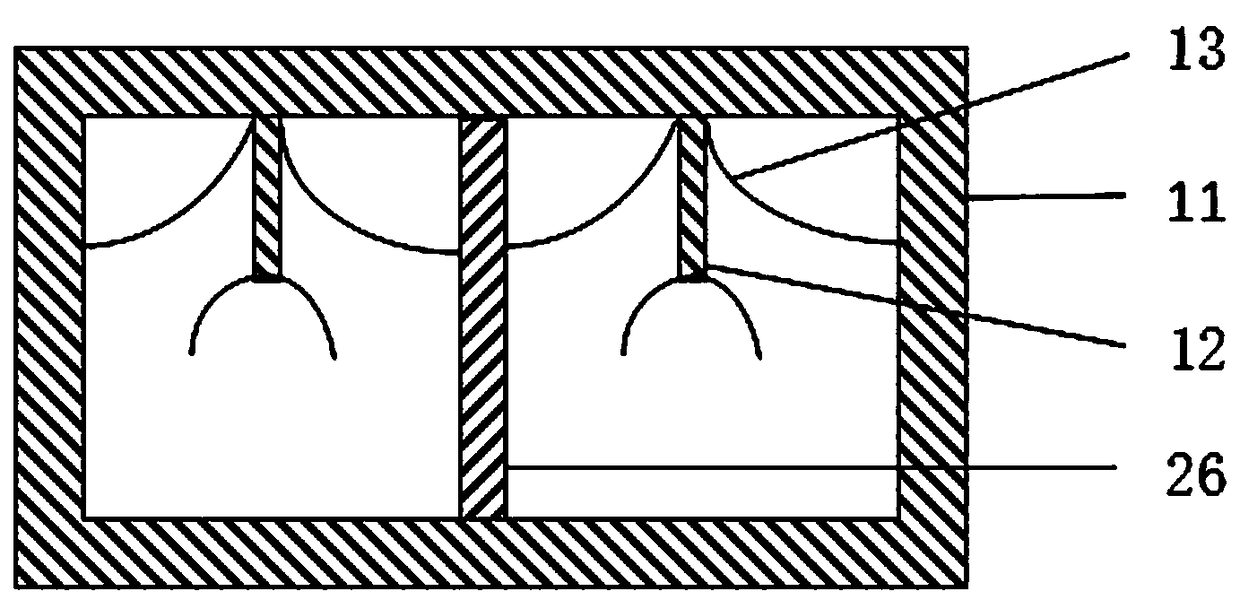

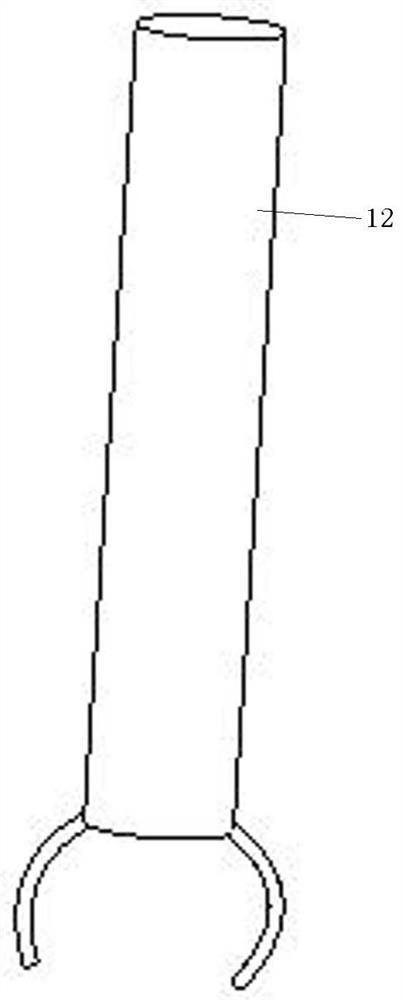

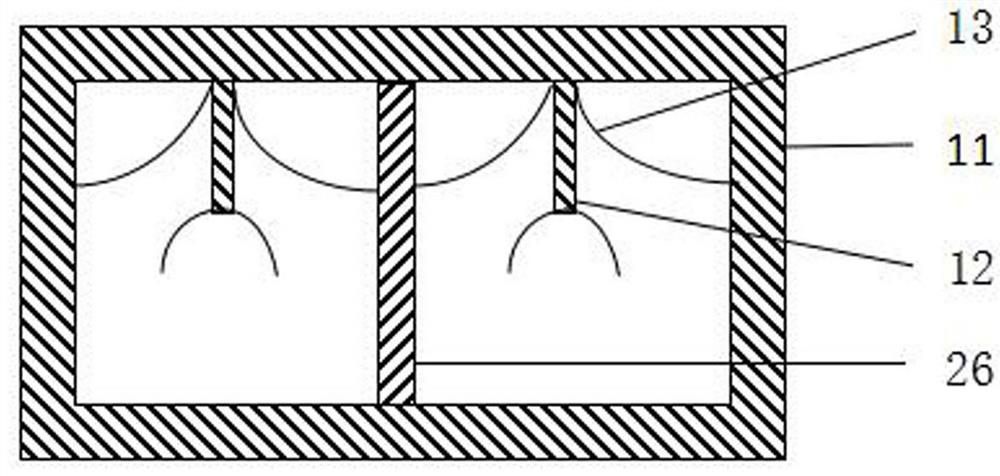

Degradability test device for 3D printing magnesium alloy material and application thereof

ActiveCN108593489AIncreased durabilityGood compatibilityWeighing by removing componentMaterials scienceArtificial valve

The invention discloses a degradability test device for 3D printing magnesium alloy material, comprising a cardiac artificial chamber fixed on a support, a sample carrier, and a pretreatment device; the cardiac artificial chamber is divided into two independent regions by a no-pore artificial valve plate; a porous artificial valve plate is arranged in each independent region; the cardiac artificial chamber is also connected with a temperature detector, a hydrogen detector, a pressure sensor, a gas storage cylinder, a PH auto-control system and an alarm; a rotary shaft is arranged on the support; the sample carrier is mounted on the rotary shaft; the sample carrier includes a speed adjusting motor; a drill chuck is fixed to one end of an output shaft of the speed adjusting motor; a sample carrying unit is mounted on the drill chuck; the pretreatment device comprises an ultrasonic device, a drying box, and a weigher. The degradability test device for 3D printing magnesium alloy materialis high in automation level and enables degrading action of an implant material in a human body to be simulated more accurately, testing is convenient and fast, and the results are accurate and visual.

Owner:ZHONGBEI UNIV

Pipeline extension equipment and slurry circulation system for slurry shield

ActiveCN113202498AExtend your lifeAvoid pollutionMining devicesTunnelsHigh elevationProcess engineering

The invention discloses pipeline extension equipment and a slurry circulation system for a slurry shield. The pipeline extension equipment comprises a relay sealed cabin, a pipeline clamping and moving device and a pipeline mounting device, and the two ends of the relay sealed cabin correspondingly communicate with an upper pipeline and a lower pipeline, and the relay sealed cabin can temporarily store a fluid medium; the pipeline clamping and moving device is used for clamping a pre-stored pipeline to move to be aligned with the lower pipeline; and the pipeline mounting device is used for fixing the pre-stored pipeline and the lower pipeline, and the pre-stored pipeline and the lower pipeline form a new-stage lower pipeline and can move relative to the relay sealed cabin so as to release the new-stage lower pipeline from the relay sealed cabin. By applying the pipeline extension equipment, the pipeline extension operation is realized under the condition that the slurry circulation system is not stopped, the medium supply equipment does not need to be started and stopped for many times, the service life of system elements is effectively prolonged, the overhaul interval is prolonged, and the operation economy is improved; meanwhile, continuous flowing of media in the pipeline is guaranteed, and operation in high-altitude or alpine regions is achieved; and the construction environment pollution caused by slurry leakage or overflow in the pipeline extension operation is effectively avoided.

Owner:CHINA RAILWAY CONSTR HEAVY IND

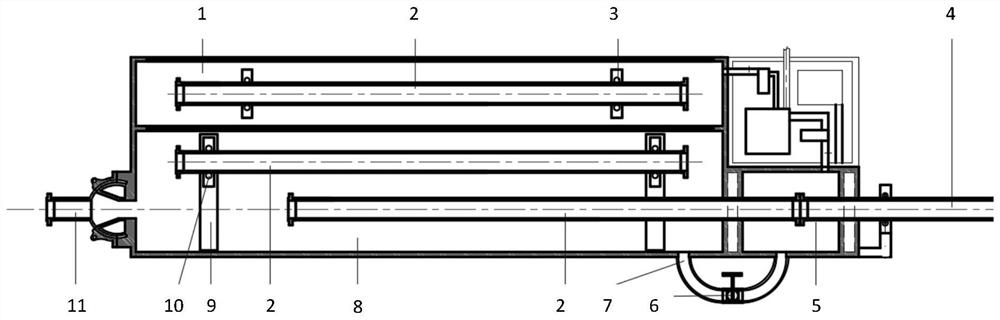

Lens continuous pouring system and process thereof

InactiveCN110884007AContinuous Pouring GuaranteeGuaranteed continuous flowOptical articlesExhaust valveStructural engineering

The invention discloses a lens continuous pouring system and a pouring process thereof. The system comprises a material tank, a filtering device capable of easily discharging bubbles, a material pouring valve and a material pouring needle head which are sequentially connected through a material pouring pipeline. The pouring needle head is fixed on a pouring frame on a pouring table; a template push disc with a plurality of empty grids is placed on the pouring table at a lower end of the pouring needle head, a feeding port, an exhaust valve and a pressure control assembly are arranged at the top of the material tank, a discharging valve is arranged at a bottom of the material tank, one end of the pressure control assembly is connected with a vacuum generation device, and the other end is connected with a compressed air device. A stirrer is mounted in the material tank. By means of the system and process, lens feed liquid can be effectively and continuously poured, the production efficiency is improved, and the product quality is improved.

Owner:JIANGSU CONANT OPTICS +1

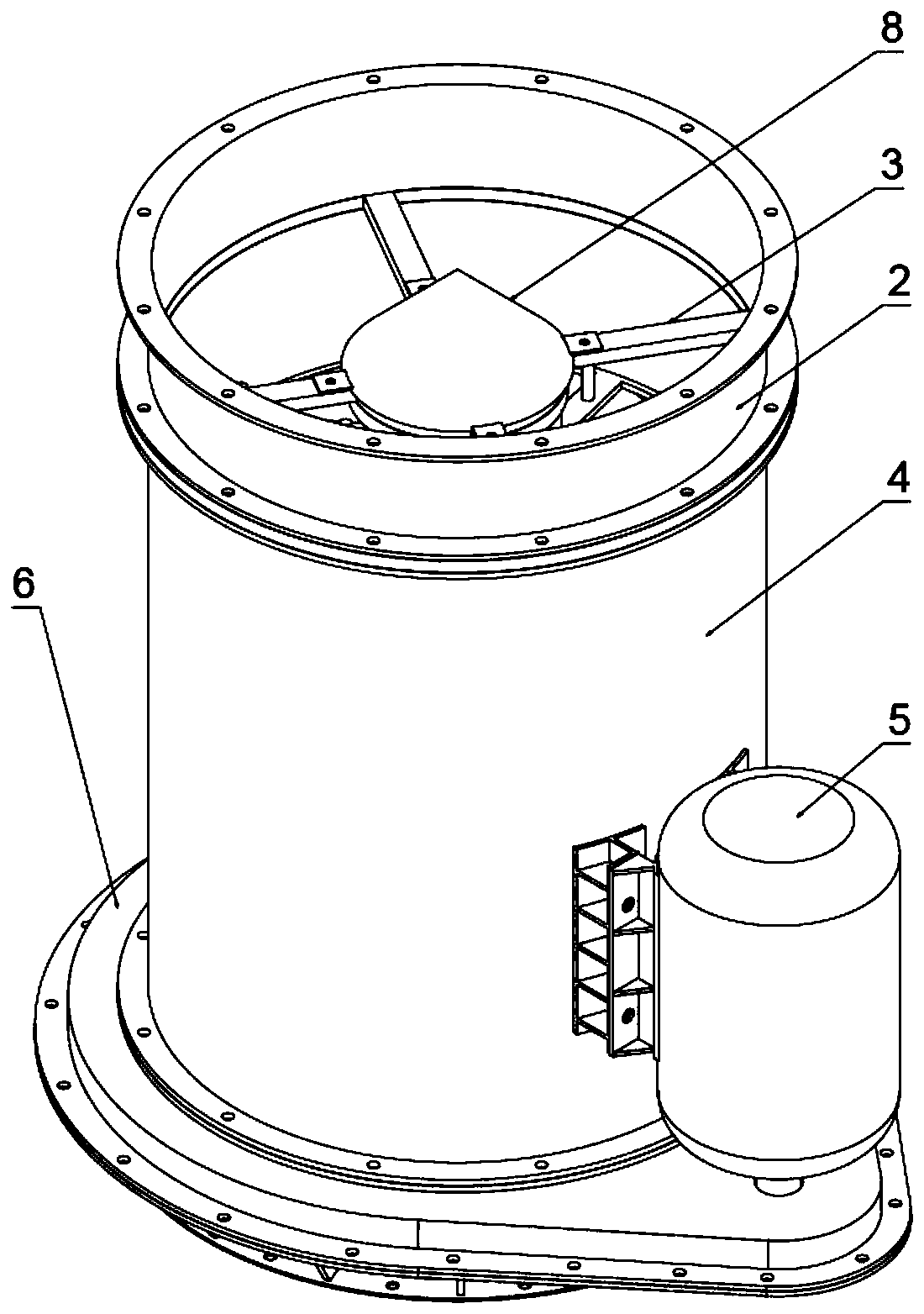

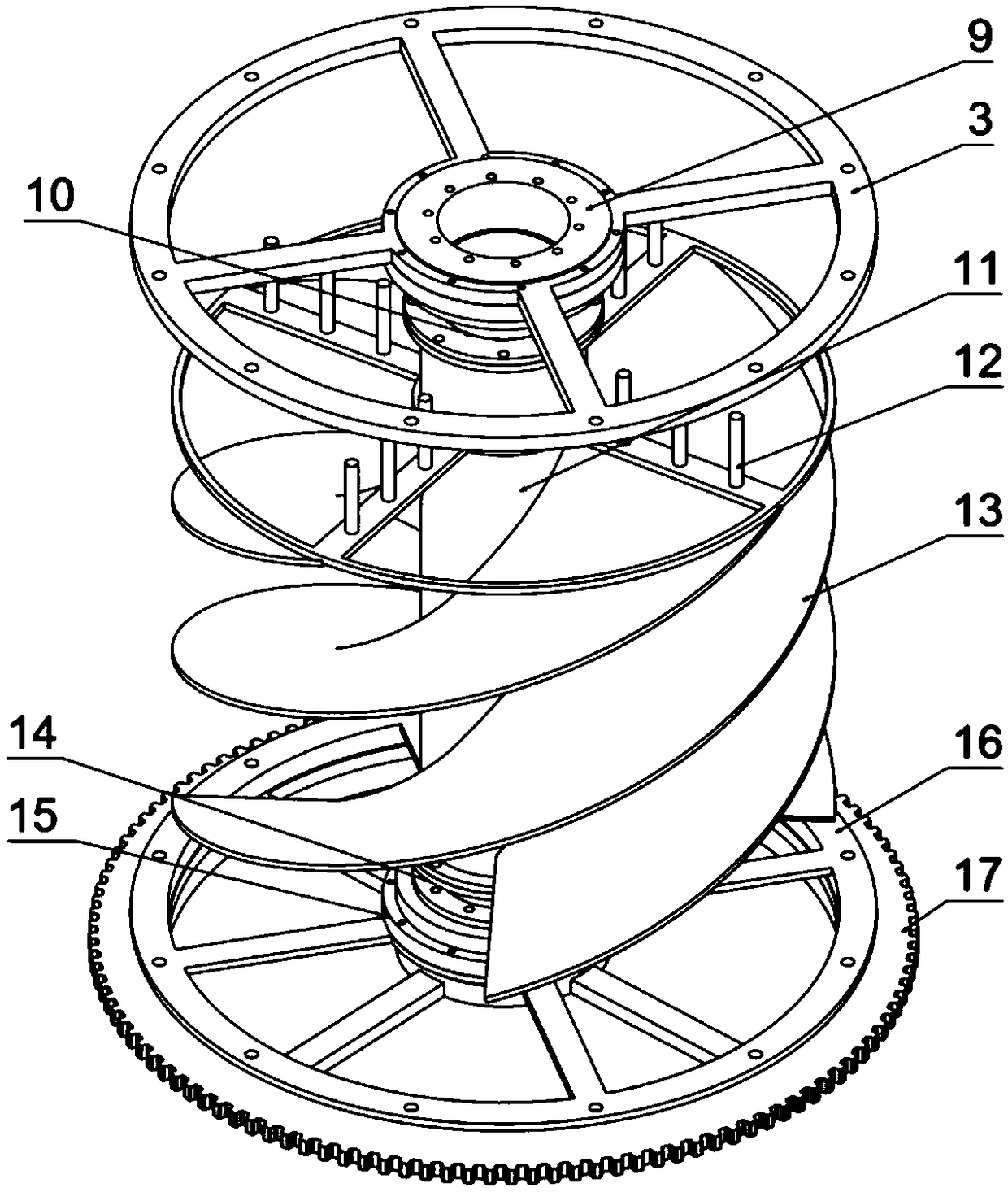

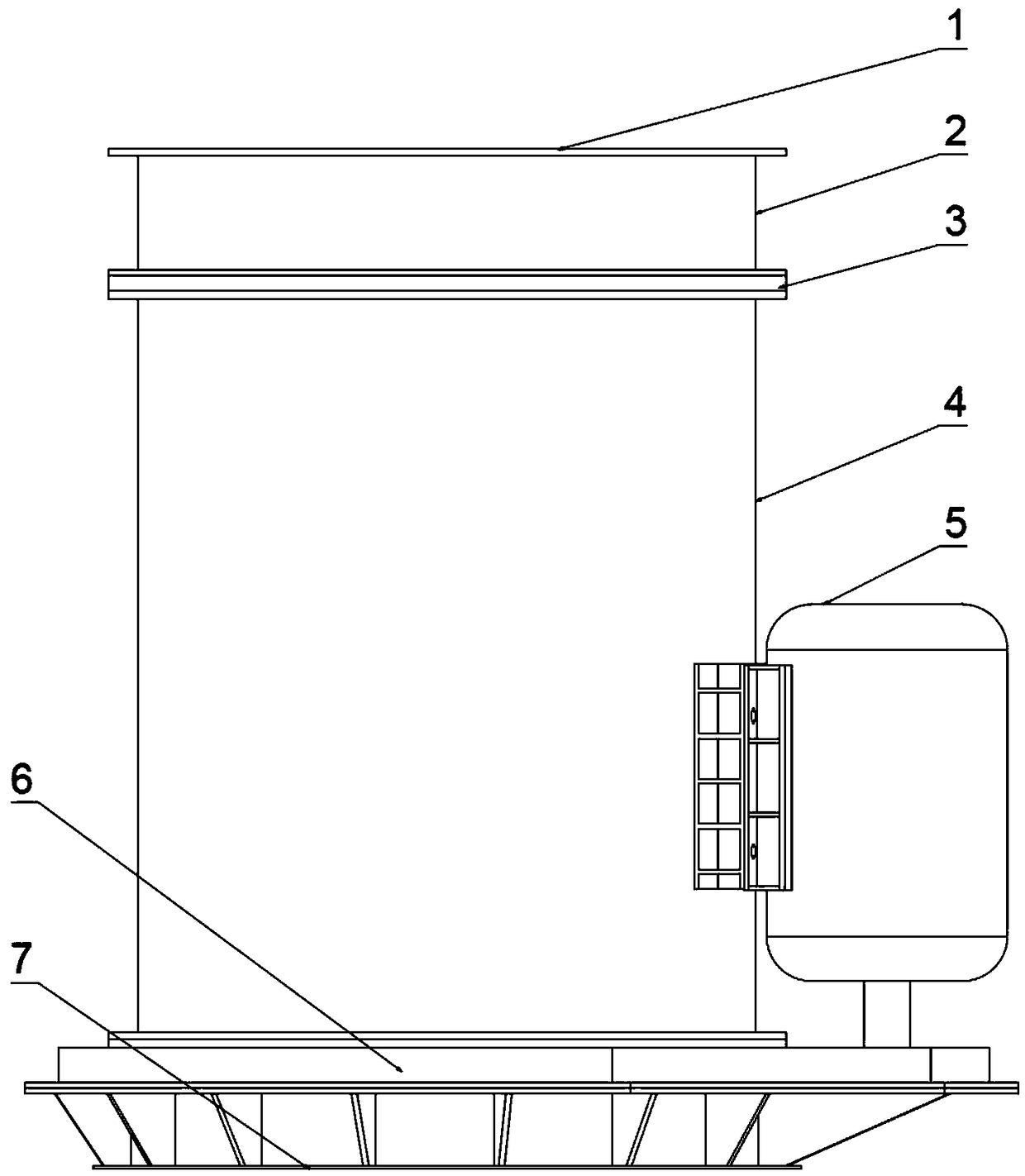

Device for stably and continuously discharging solid bulk material

InactiveCN109384057AStrong granularityAdaptableLarge containersLoading/unloadingSpiral bladeDrive motor

The invention relates to a device for stably and continuously discharging a solid bulk material, which comprises a multi-blade spiral flow controller, wherein the multi-blade spiral flow controller isformed by circularly arraying a plurality of spiral blades along a rotating shaft, and a bulk material disturbing device is arranged at the top of the multi-blade spiral flow controller so as to prevent a material bridge from being blocked. The bottom of the multi-blade spiral flow controller is provided with a driving gear disc which is used for driving the multi-blade spiral flow controller torotate. The outer side of the multi-blade spiral flow controller is provided with a shell of a discharging device, a driving motor is fixed on the shell, and one end of the driving motor is connectedwith the gear disc. The device can achieve the integral flow of the bulk material at the upper part of the discharging device without material deflection or intermittent discharging. The discharging device can achieve continuous discharging of the material and can change the spiral rotating speed according to the flow speed of the materials with different requirements, the number of spiral bladesand the pitch length can be designed according to different bulk flow characteristics, the device has wide control range of the flow speed of the materials, and can achieve millimeter-level flow speedcontrol of the materials.

Owner:XI AN JIAOTONG UNIV

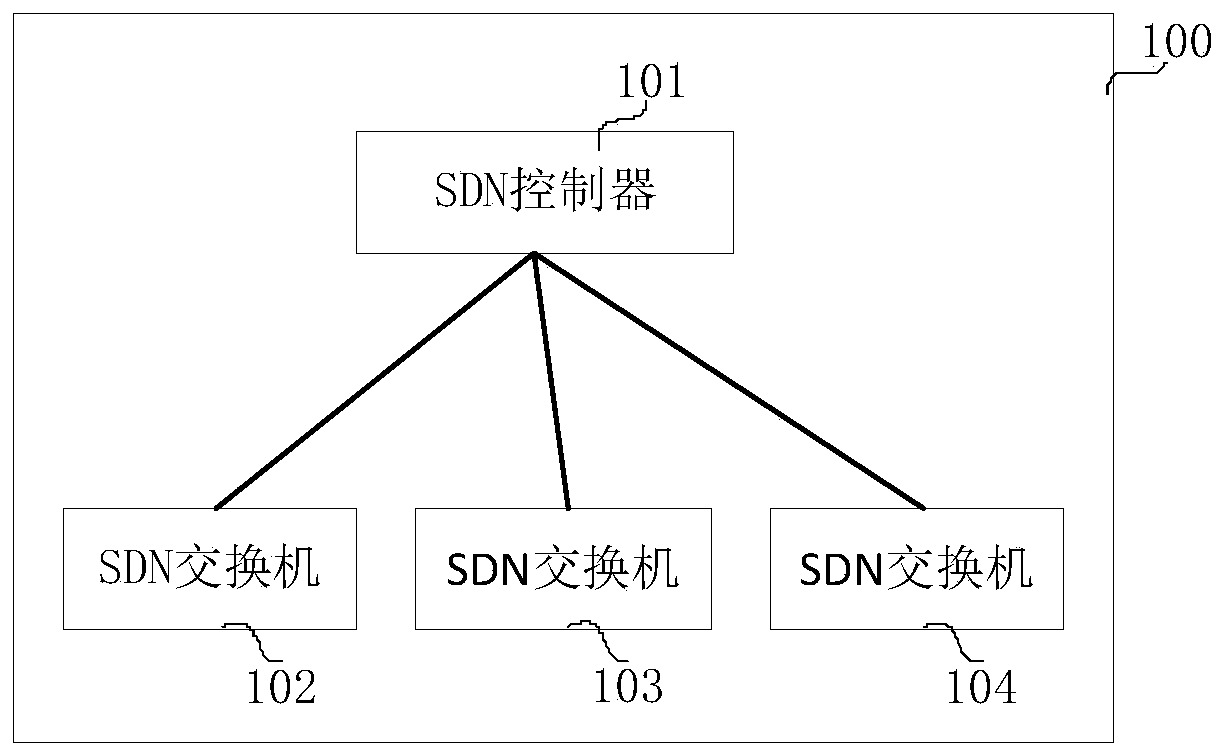

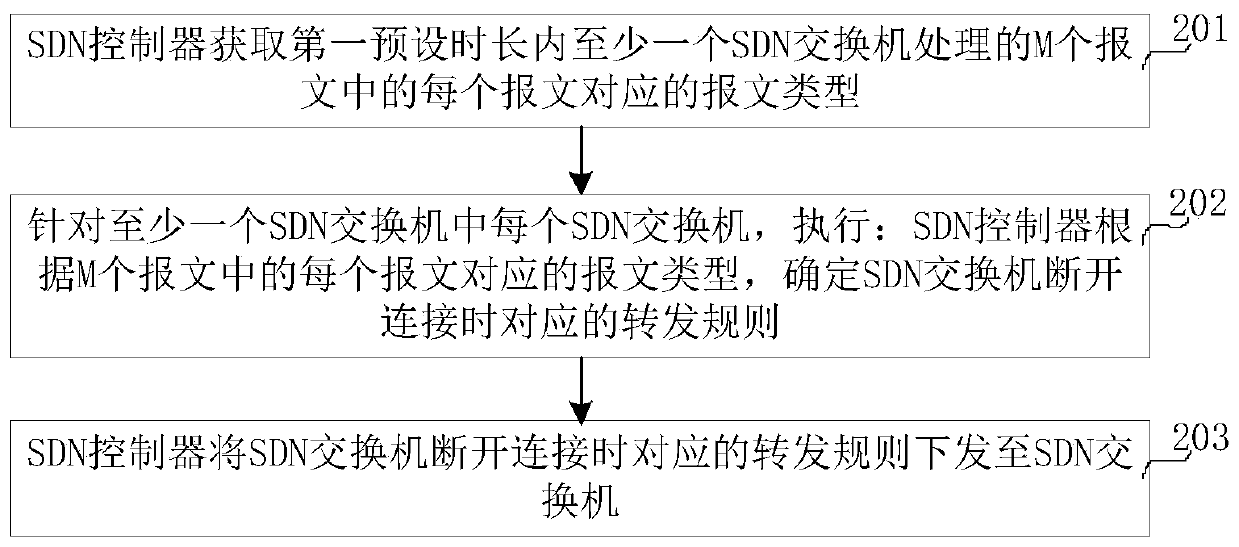

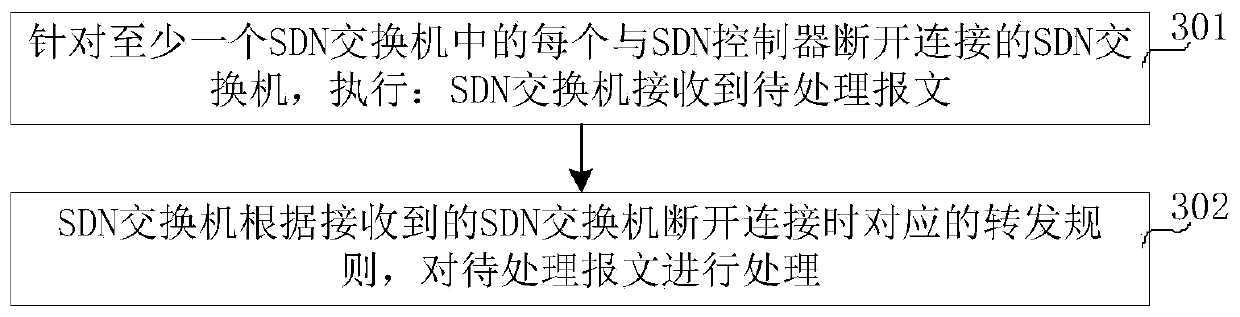

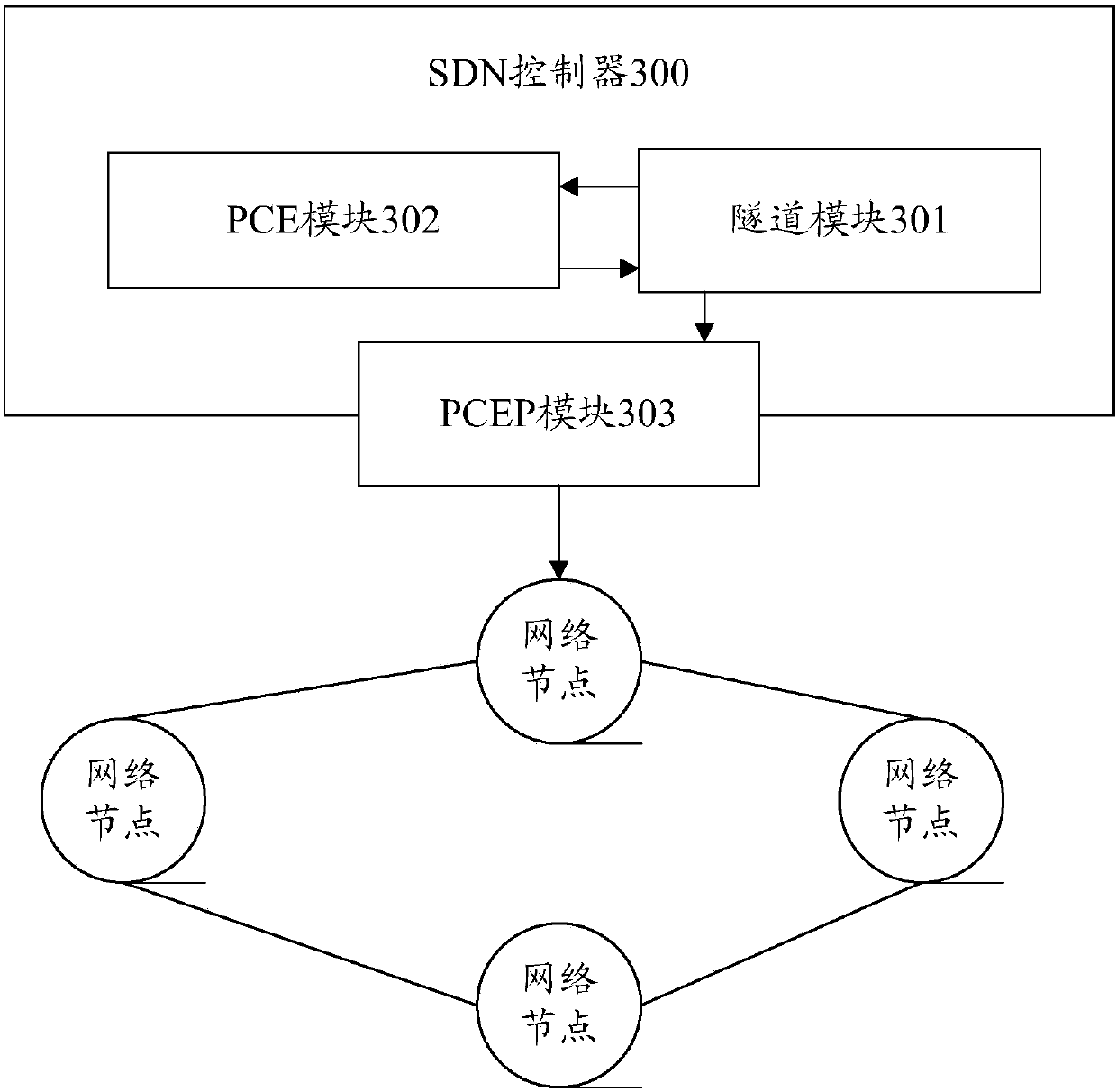

A kind of SDN switch operation method, controller and switch

ActiveCN106936720BGuaranteed continuous flowData switching networksDistributed computingPacket forwarding

Owner:KYLAND TECH CO LTD

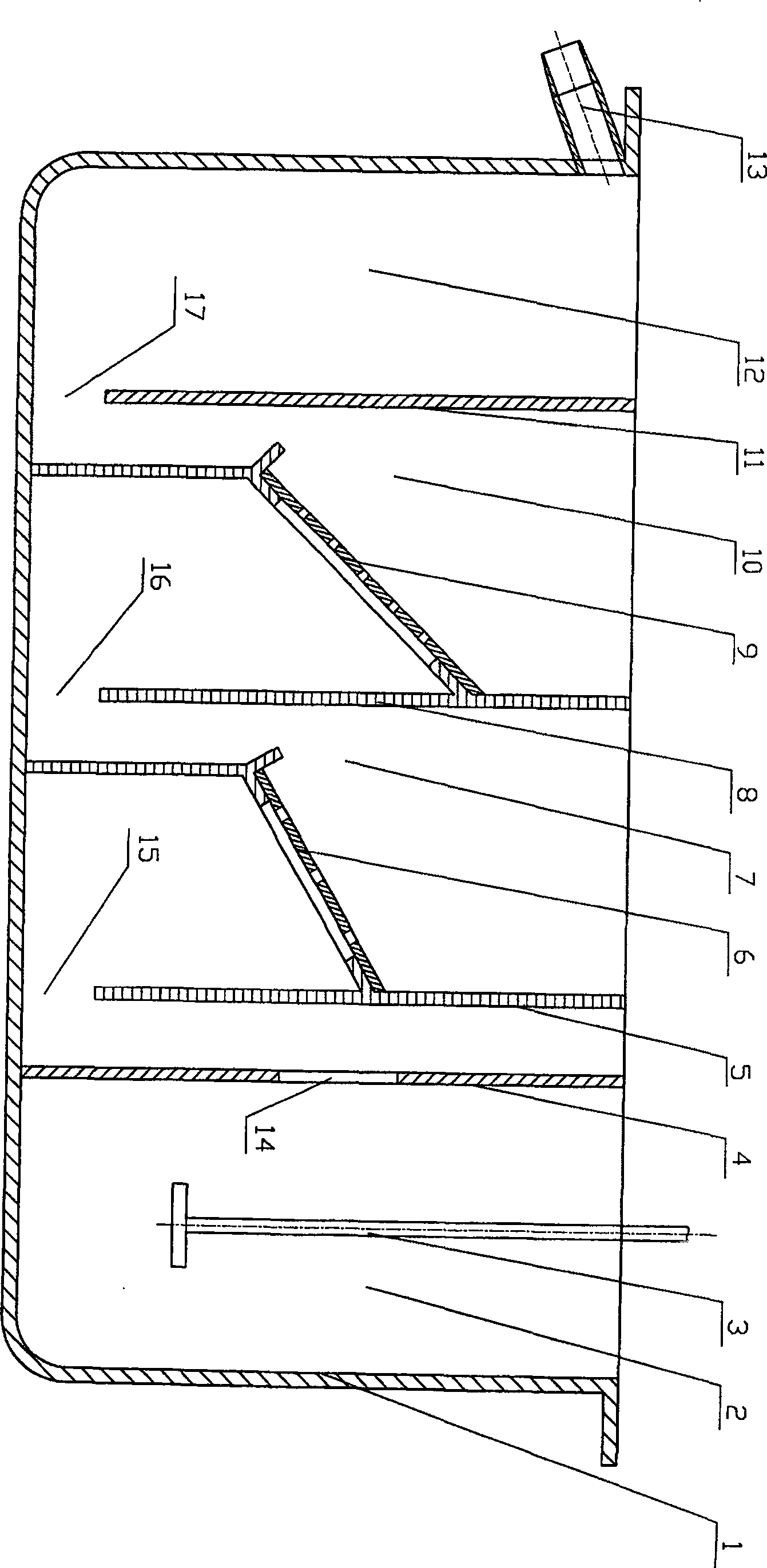

Magnesium alloy furnace material fluxless remelting refining method and device

The invention relates to a method of refusion refining for magnesium alloy furnace charge without the fluxing agent and its apparatus. Magnesia fused mass is refined using complex multi-refining method after preheating and drying magnesium alloy furnace charge, including the steps of: fusing furnace charge, stirring refining or (and blowing refining), forced sedimentating, filter refining, static refining, discharging and casting, accordingly the high-quality purification of fusing body is performed by efficiently eliminating all kinds of impurity and gas in the magnesium alloy furnace charge. The apparatus mostly includes crucibles, pretreatment chambers in order fixed in the crucibles, one or more filter chamber and casting chambers, each adjacent two chambers communicated by fused mass flowing channels, stirring units or (and blowing units) in the pretreatment chambers, first-order filter unit airproofed and fixed in each filter chamber. The apparatus can perform continuous complex multi-refining and casting / producing of magnesia fused mass, with greatly-improved refining quality and purified effect of magnesium alloy fused mass, while the problem that the filter apparatus is easy to be blocked in the process of filtering is solved.

Owner:重庆硕龙科技有限公司

Solid scattered material discharging controlling device

InactiveCN109941777ALow risk of blockage of bulk material flowReduced risk of cloggingLarge containersLoading/unloadingSpiral bladeEngineering

The invention relates to a solid scattered material discharging controlling device. The device comprises a feeding hopper, a scattered material driving device and a discharging controlling device housing. The feeding hopper is externally provided with a vibrator, and a conical guiding hood is arranged in the feeding hopper. The discharging controlling device housing is mainly composed of a scattered material conveying pipe and a scattered material feeding passage which is arranged on the top of the housing, the scattered material conveying pipe is composed of two circular pipes with the same diameter, and the scattered feeding passage is composed of two rectangular pipes. The feeding hopper and the scattered material feeding passage are connected and fixed by a soft connecting flange and ashock-absorbing device. The scattered material driving device is provided with spiral blades and a driving motor, and two groups of the spiral blades are fixed in the scattered material conveying pipe. The device has the advantages that the scattered material in the upper portion of the discharging device can flow approximately as a whole without obvious material flowing deflecting, blocking andnonuniform speed distribution, the device can be operated at a higher temperature, and therefore the continuous and stable movement of the scattered material at a lower flow rate is achieved.

Owner:XI AN JIAOTONG UNIV

Aquaculture device

InactiveCN110250045AStructural solutionSolve functionClimate change adaptationPisciculture and aquariaAquatic productWater quality

The invention relates to the field of aquaculture, and discloses an aquaculture device. For solving the problem that in the prior art, an existing aquaculture device is simple in structure and single in function, the device comprises a cultivation box and a water collecting device, the cultivation box is of a cuboid structure, the cultivation box comprises a box cover, a partition plate, a plurality of first baffles and a plurality of second baffles, the box cover is fixedly connected with the top of the cultivation box, a plurality of mesh holes are evenly formed in the partition plate, the partition plate is located inside the cultivation box, the inner walls of the two sides of the cultivation box are each fixedly provided with a limiting block, the partition plate is located at the tops of the two limiting blocks, a plurality of first clamping grooves and a plurality of second clamping grooves are evenly formed in the inner walls of the two sides of the cultivation box, and the first clamping grooves and the second clamping grooves are distributed at intervals. The device is reasonable in structure, exquisite in design, easy to operate, capable of ensuring continuous flowing of water and saving energy, capable of adopting running water for driving excrement at the bottom of a tank and capable of achieving concentrated management and real-time monitoring, and easy to popularize.

Owner:DALIAN OCEAN UNIV

Load equalizing method and device for multiple fire-proof wall

ActiveCN101052047BImprove reliabilityImprove usabilityError preventionData switching by path configurationHigh availabilitySwitching time

The invention uses multi firewalls to construct a highly efficient and stable route link. The invention also provide an apparatus thereof used for providing a virtual gateway address for each firewall; each client is pointed to different virtual gateway so as to balance the traffic on each firewall; when one firewall fails, other firewalls can take over the address of the failure firewall to keepthe network traffic in normal state.

Owner:QI-ANXIN LEGENDSEC INFORMATION TECH (BEIJING) INC +1

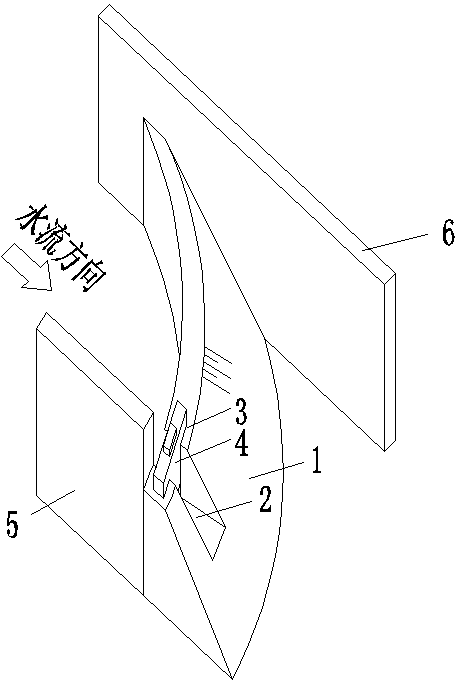

An arc-shaped rolling dam capable of automatically washing sand and reducing silt and its operation method

ActiveCN106702968BImprove desilting effectLow desilting costBarrages/weirsDry seasonReinforced concrete

The invention discloses an arc type overflow dam capable of automatically washing away sand and reducing siltation and a running method of the arc type overflow dam. The arc type overflow dam capable of automatically washing away sand and reducing siltation comprises a dam body, a flow releasing and sand discharging hole, gate slots, gates, a guide wall and a protection bank. The arc type overflow dam capable of automatically washing away sand and reducing siltation is characterized in that the dam body is of an arc reinforced concrete structure; the flow releasing and sand discharging hole is formed in the right side of the dam body; the gate slots are formed in the inner walls of the two sides of the flow releasing and sand discharging hole; the gates are manual steel gates and are installed on the gate slots; the guide wall is of an anti-scouring reinforced concrete structure and is arranged on the upstream right bank; and the protection bank is of an anti-scouring reinforced concrete structure and is arranged on the downstream left bank. In the water season, the steel gates are opened, bend transverse ring flow formed by the arc dam body is utilized for automatically conducting flow releasing and sand washing; and in the dry season, the steel gates are closed, the water level is elevated, and water is stored. Compared with traditional mountainous area overflow dams, the arc type overflow dam has the beneficial effects that the form is decent and attractive, little mud and little sand are deposited in front of the dam, the siltation reducing cost is low, and the comprehensive benefits of the project are more obvious.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

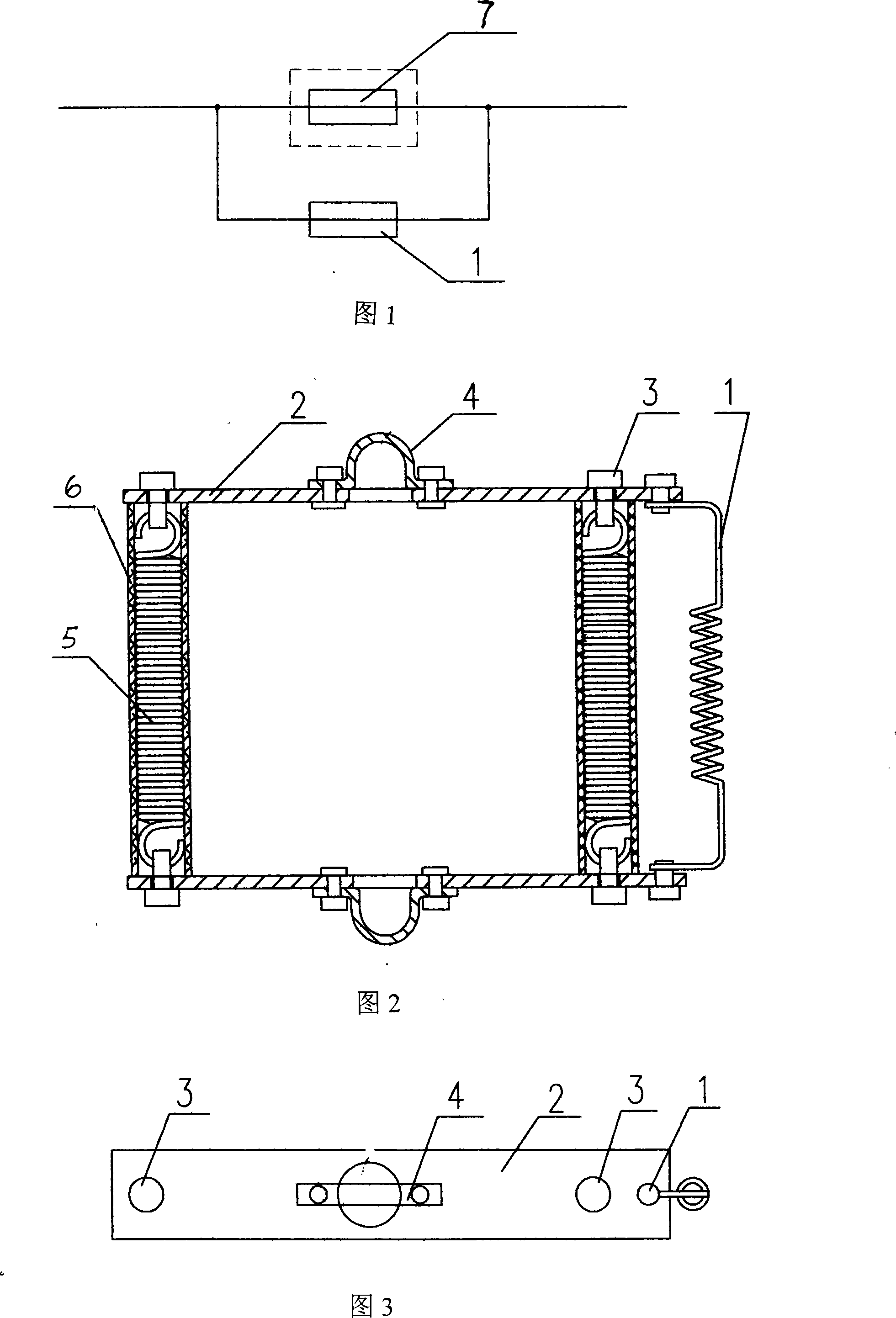

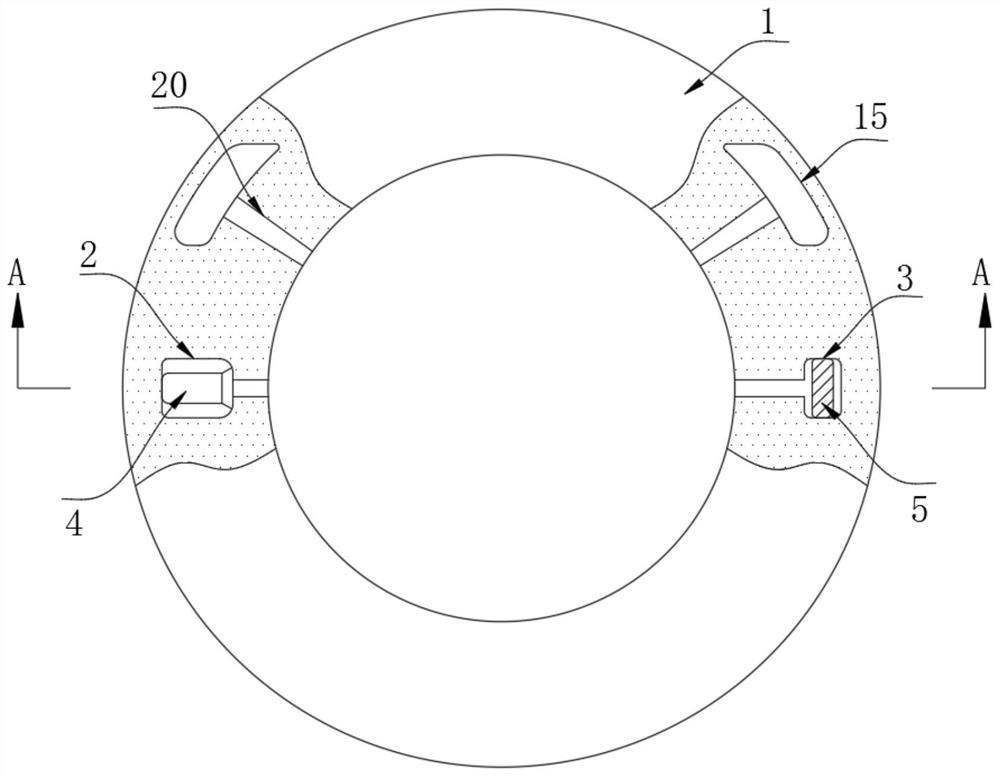

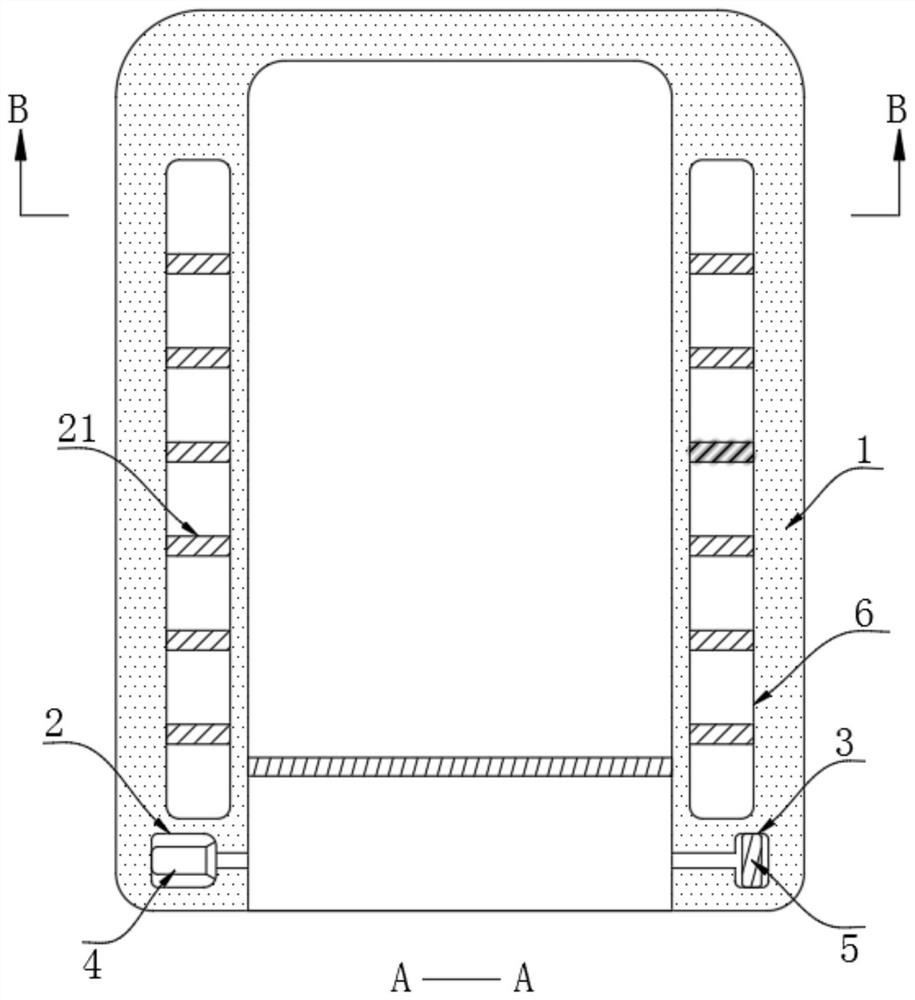

High voltage splitflow type fuse

ActiveCN101202187AGuaranteed continuous flowPlay the role of shunt fuse protectionEmergency protective devicesPower gridHigh pressure

The invention provides a high voltage distribution fuse, mainly comprising a distribution rubber-sheathed fuse, two copper conductive contact boards, insulation columns, an upper hanging ring, a lower hanging ring, a pulling spring and an insulation bushing. The insulation columns are respectively arranged at the two ends of the copper conductive contact board. The insulation columns which correspond to each other from bottom to top are hooked by the pulling spring to be connected. The outer part of the pulling spring is sleeved with the insulation bushing. Two ends of the distribution rubber-sheathed fuse are respectively connected with the ends of the upper and lower copper conductive contact boards to form a distribution branch. The invention is in parallel connection with the wiring screws at the two ends of a failed high voltage drop-out fuse and can displace the a failed high voltage drop-out fuse to work, so as to guarantee a constant work of the grid. The design of the invention is novel, the structure is simple, the operation is safe and easy and the use is convenient.

Owner:GUILIN ZIZHU LATEX PROD

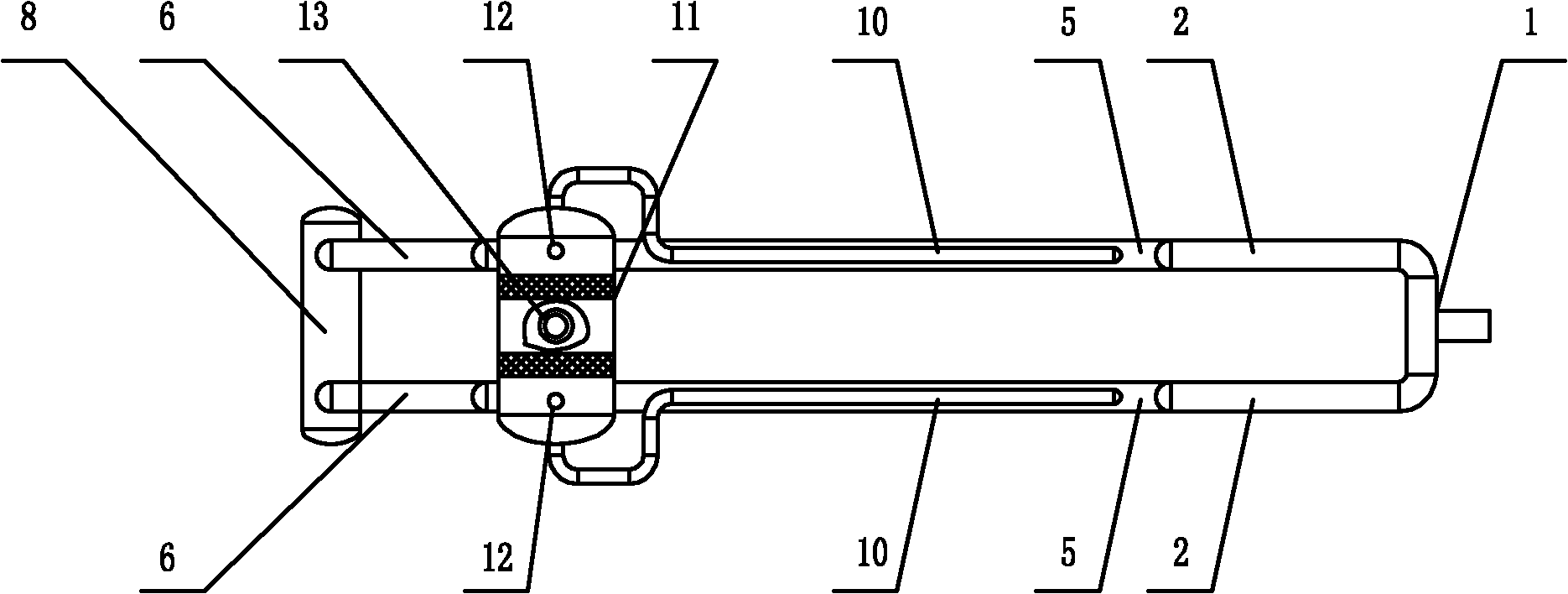

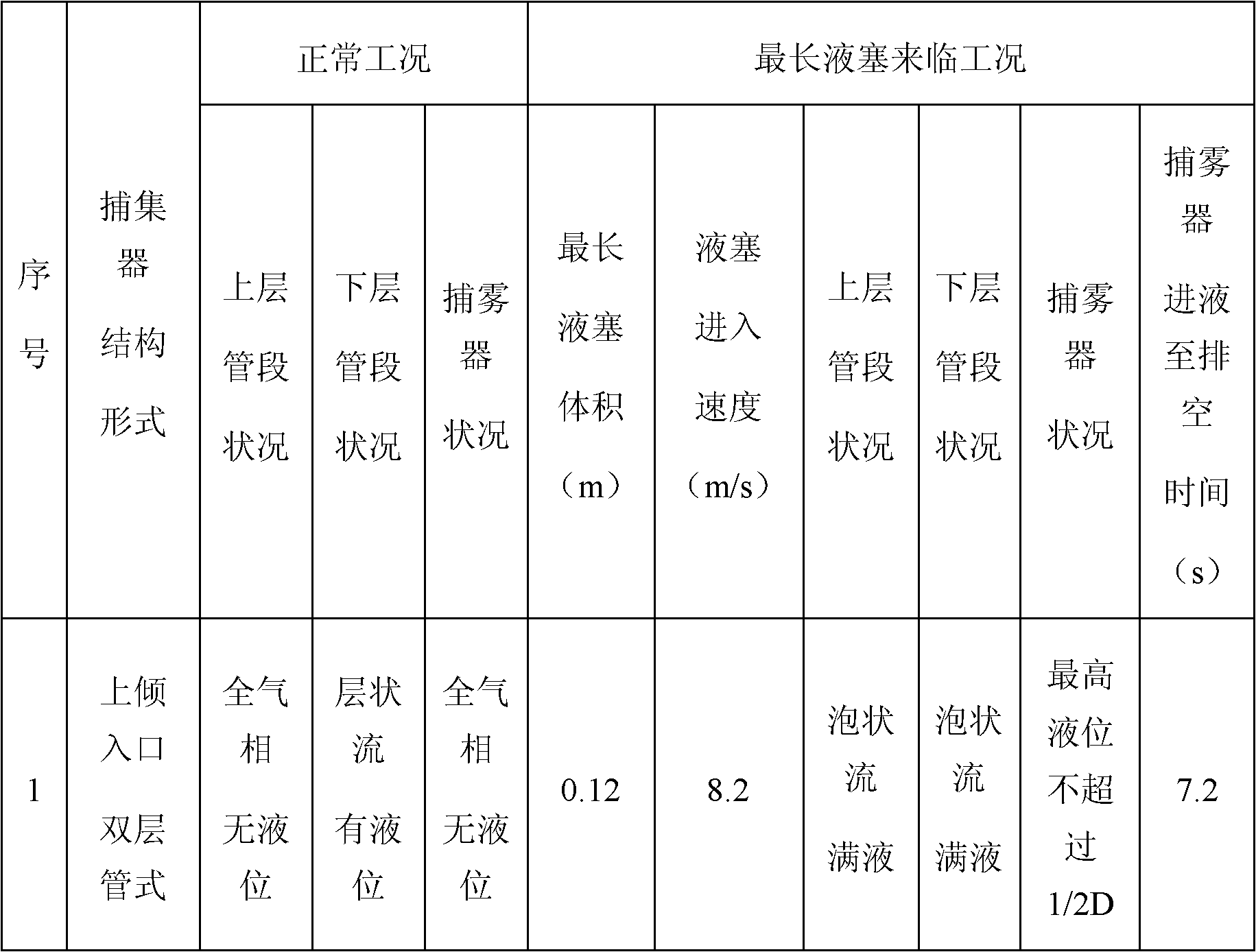

Updip entrance double-layer tubular slug flow catcher

ActiveCN102174991BSmall footprintPlay the role of gas-liquid separationPipeline systemsSurface engineeringGas phase

The invention relates to an updip entrance double-layer tubular slug flow catcher, and relates to a slug flow catcher, aiming to solve the problems of large floor space, large liquid carrying amount in gas and no gas phase fog catching function for the existing finger-type tubular slug flow catcher. Two upper-layer pipe sections and two lower-layer pipe sections are all horizontally arranged in parallel; the head end of each upper-layer pipe section is communicated with the tail end of an updip pipe section; the head end of the updip pipe section is communicated with an inlet pipe; the tail end of each upper-layer pipe section is communicated with the tail part of each lower-layer pipe section; the tail end of each lower layer pipe section is communicated with a liquid collecting pipe; two gas collecting pipes are horizontally arranged in parallel; the head end of the gas collecting pipe is communicated with the tail of the updip pipe section; the tail end of the gas collecting pipe is communicated with a bidirectional inlet fog catching device; the gas collecting pipe is communicated with the upper pipe section through a gas guide pipe; the upper-layer pipe sections are communicated with the lower-layer pipe sections through communicating pipes; the updip pipe section is communicated with the lower-layer pipe section through a downspout; and the bidirectional inlet fog catching device is communicated with the tail of each upper-layer pipe section through a liquid discharge pipe. The slug flow catcher provided by the invention is used for oil gas treatment of oil gas field surface engineering.

Owner:DAQING OILFIELD CO LTD +2

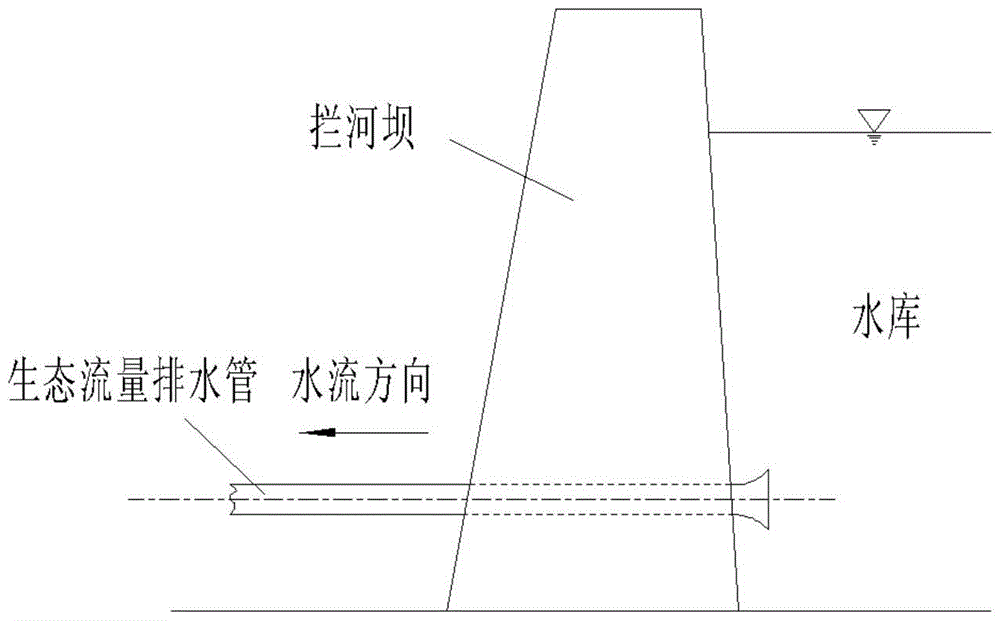

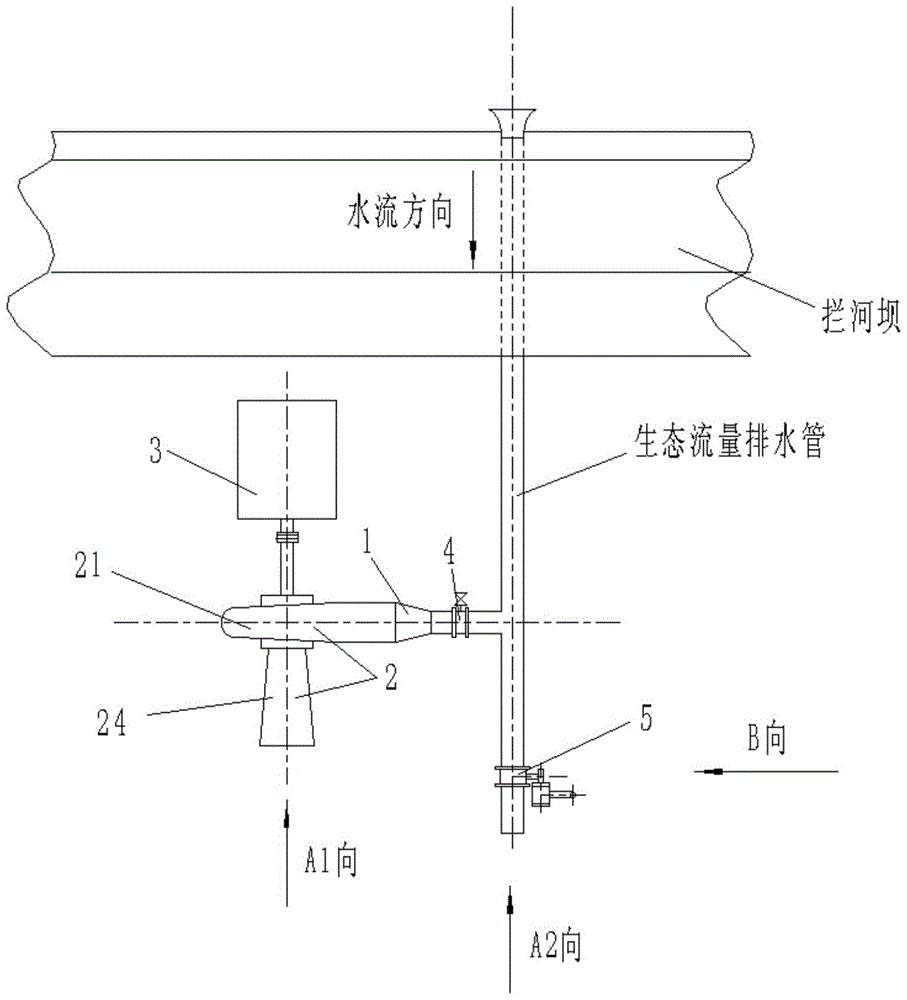

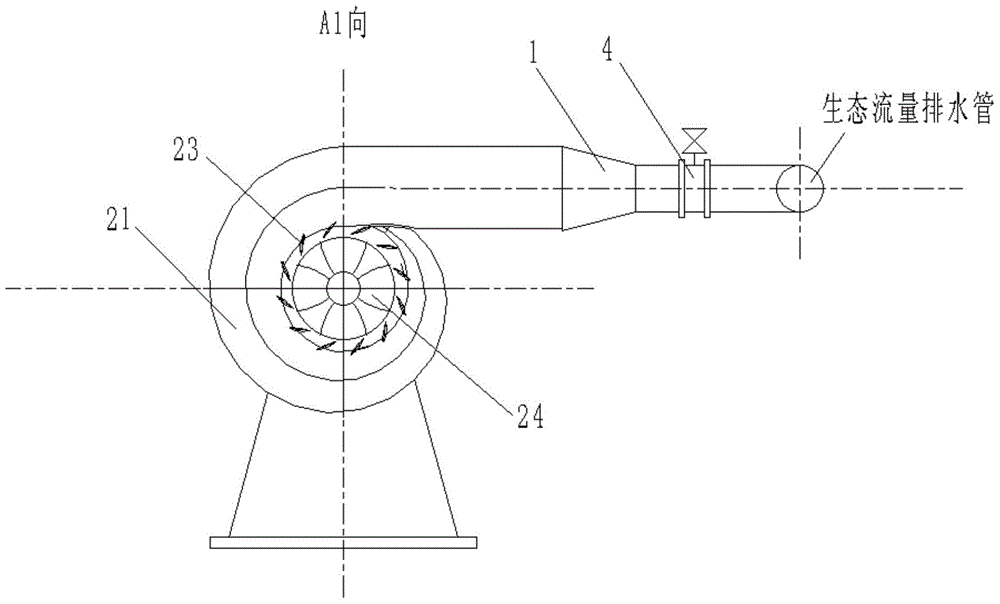

An open-air hydroelectric generator set that utilizes the ecological flow of a hydropower station to generate electricity

ActiveCN104481779BGuaranteed continuous flowSmall sizeHydro energy generationReaction enginesElectricityWater turbine

The invention relates to an outdoor hydroelectric generating set generating electricity through hydropower station ecological flow. The outdoor hydroelectric generating set generating electricity through the hydropower station ecological flow is characterized by comprising a water turbine, a horizontal type asynchronous generator, a water inlet valve, a diffusion pipe and a hammer type butterfly valve; the diffusion pipe is arranged at the tail end of a branched pipeline which is perpendicularly connected with a main pipeline of an ecological flow drainage pipe; the convergence end of the diffusion pipe is connected with the tail end of the branched pipeline; the diffusion end of the diffusion pipe is connected with a water inlet of the water turbine; the water turbine is connected with an asynchronous motor to drive the asynchronous motor to generate electricity; the water inlet valve is arranged on the branched pipeline which is connected with the diffusion pipe; the hammer type butterfly valve is arranged at a water outlet of the ecological flow drainage pipe; the water inlet valve is opened and the hammer type butterfly valve is closed when the water turbine drives the asynchronous generator to generate electricity, the ecological flow sequentially passes the main pipeline, the water inlet valve and the diffusion pipe to flow into the water turbine, the water turbine drives the asynchronous generator to generate electricity, and the ecological flow after work is discharged through the water turbine; when the asynchronous motor does not generate electricity, the hammer type butterfly valve is opened and the ecological flow is discharged through the hammer type butterfly valve.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +1

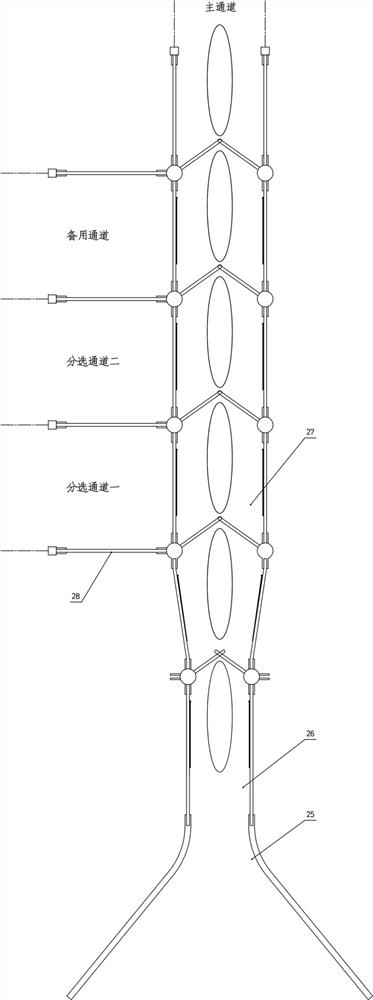

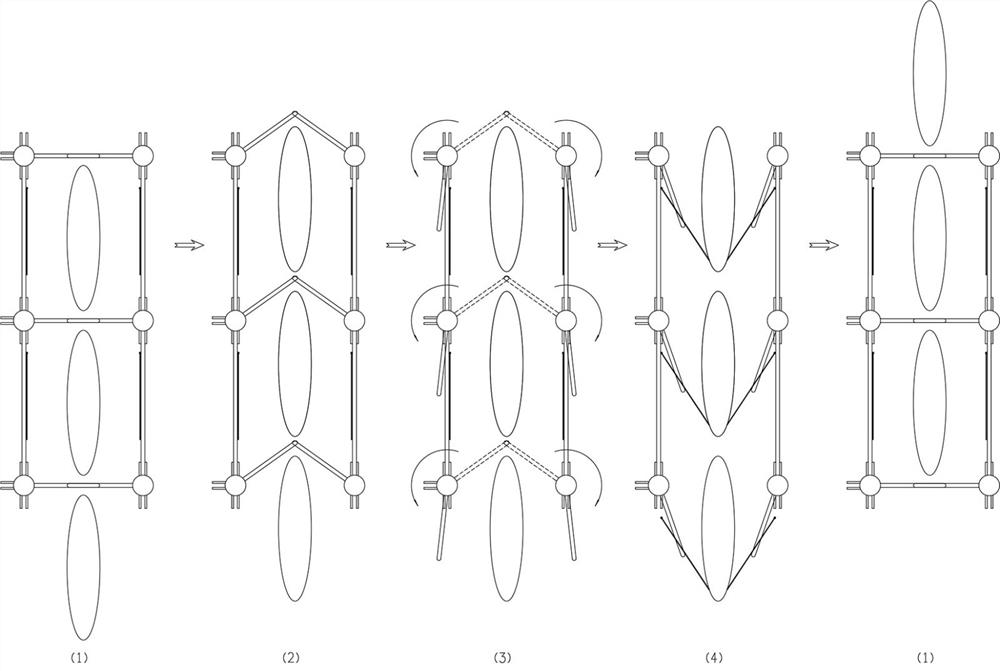

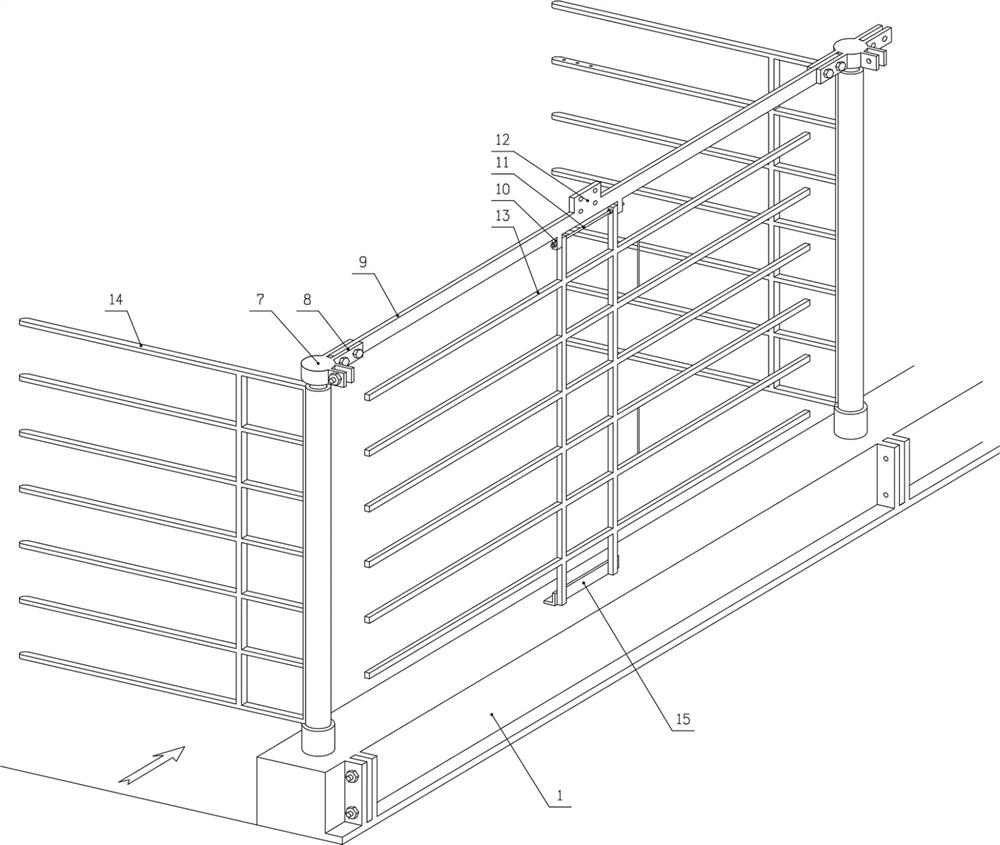

Flock breeding individual sorting system

ActiveCN111838006BAbility to improve sorting accuracyGuaranteed continuous flowPasturing equipmentOther apparatusDiseaseAlgorithm

The invention discloses a sorting system for flock breeding individuals, which includes a main channel and a sorting channel. The main channel has a plurality of detection areas, and each detection area has a pair of revolving door systems in front of each detection area. Through the revolving door system, adjacent The detection areas are connected, and each detection area includes two side walls. The side walls corresponding to the sorting channel are provided with a controllable opening mechanism, and the main channel is connected with the corresponding sorting channel through the controllable opening mechanism. An RFID tag detection mechanism for identifying individual sheep is installed within the scope of each detection area. The present invention is used for individual sorting of different individuals such as body weight differences, different disease conditions, etc. And the ability to change the number of sorting channels by increasing or decreasing the number of corresponding detection areas can improve the sorting accuracy.

Owner:民勤县中信牧业养殖专业合作社

A fin automatic cutting device and its working process

InactiveCN103786179BGuaranteed continuous flowRealize fully automatic controlMetal working apparatusAutomatic controlEngineering

The invention provides an automatic fin cut-off device and a work process of the device. The automatic fin cut-off device comprises a machine frame and a fin cut-off mechanism arranged on the machine frame and further comprises a fin bearing mechanism arranged on the machine frame. The fin bearing mechanism comprises a fin base arranged on the machine frame in a sliding mode and a fin base driving mechanism, a fin bearing groove is formed in the fin base, the fin cut-off mechanism comprises a cutter, and the fin bearing groove is formed below the cutter. The device comprises a fin pushing mechanism, the fin cut-off mechanism and the fin bearing mechanism, full-automatic control over feeding, cutting-off and discharging of fins can be achieved, continuous flowing of the fins is ensured, and the production requirements for high speed and high precision are met.

Owner:上海英集斯自动化技术有限公司

A kind of preparation method of magnetic nanocomposite material and its equipment

ActiveCN111790288BReduce resistanceImprove stirring efficiencyRotary stirring mixersTransportation and packagingMaterials preparationCooling effect

The invention discloses a preparation method and equipment of a magnetic nano-composite material, and relates to the technical field of preparation of magnetic nano-materials. The preparation method and equipment of the magnetic nanocomposite material include a stirring tank, the outer wall of the upper part of the stirring tank is provided with a heating cavity, the upper end surface of the upper cover is provided with a feeding pipe, and the middle part of the upper end surface of the upper cover passes through The mounting frame is fixedly connected with a stirring motor, the output shaft end of the stirring motor is fixedly connected with a stirring shaft, the lower part of the stirring shaft is fixedly connected with a long stirring blade and a short stirring blade, and the inner cavity of the heating chamber is respectively provided with The first cooling cavity and the second cooling cavity, the inner cavity of the heating cavity is symmetrically arranged with irradiation heating devices, which solves the problems of low mixing efficiency of liquid raw materials and powder, and poor heating and cooling effects in the existing magnetic nanocomposite material preparation equipment. This leads to the problem of low production efficiency of the entire magnetic nanomaterials.

Owner:JINHUA VOCATIONAL TECH COLLEGE

Construction method of structural system of river under no-cutoff working condition

ActiveCN101892632BKeep the water flowingGuaranteed continuous flowArtificial islandsBuilding repairsSupporting systemCofferdam

The invention relates to a construction method of a structural system of a river under a no-cutoff working condition, comprising the specific steps as follows: 1, constructing cofferdams and shortcuts; 2, removing river channel bridges and pile foundation; 3, constructing a base pit of the river channel segment; 4, constructing the parts at both sides of a new river bridge; and 5, removing the cofferdams and recovering water transportation of the river. The invention has the advantages that: 1, the road or underground pipeline is ensured to be uninterrupted in the construction period; 2, the pile foundation is arranged or fillers are filled below a drainage pipe in the paving process of the drainage pipe to ensure that the drainage pipe maintains the water-on state at the preset height after the cofferdam is gathered; 3, the drainage pipe is cut in the connection-after-disconnection manner when the underground passage ground wall is constructed to cut separately for alternative construction so as to ensure that the river is not cutoff in the construction process of an enclosing structure; and 4, the drainage pipe is supported by a lattice column support system during construction of the underground structures and bridges so as to ensure the stability of the drainage pipe and no cutoff of the river in the construction process of the underground structure.

Owner:SHANGHAI FOUND ENG GRP

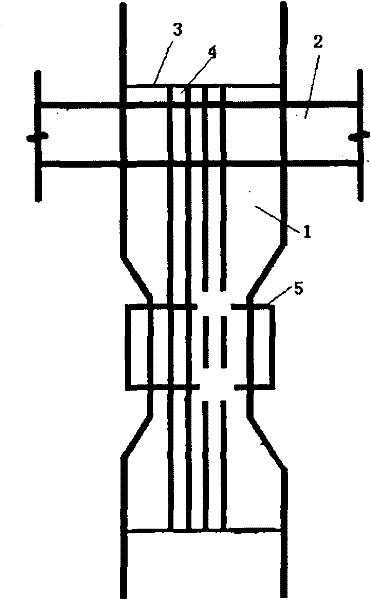

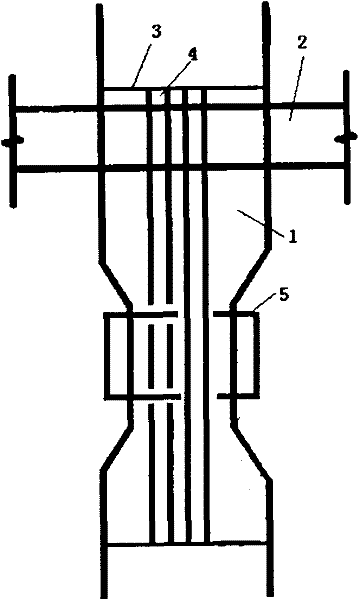

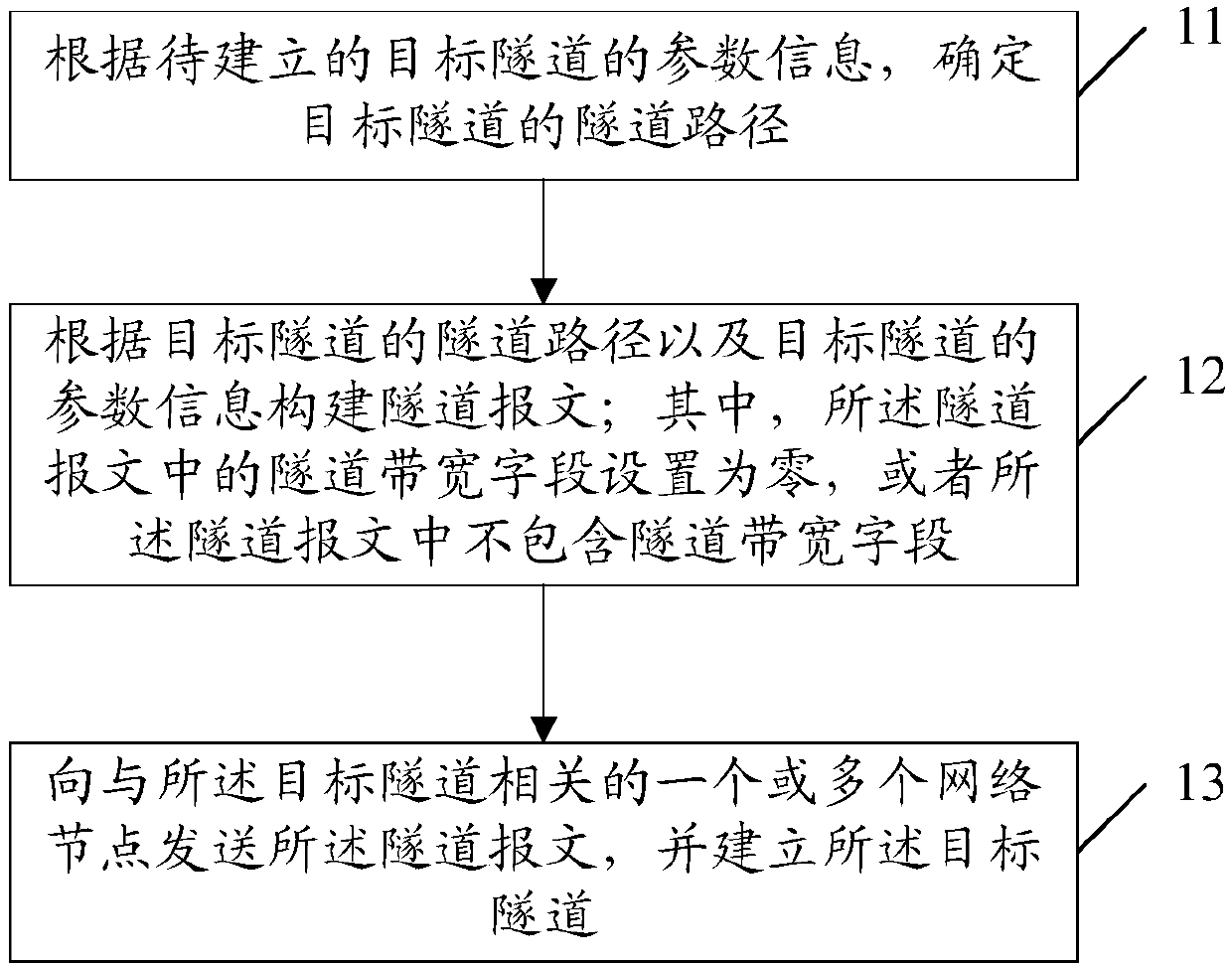

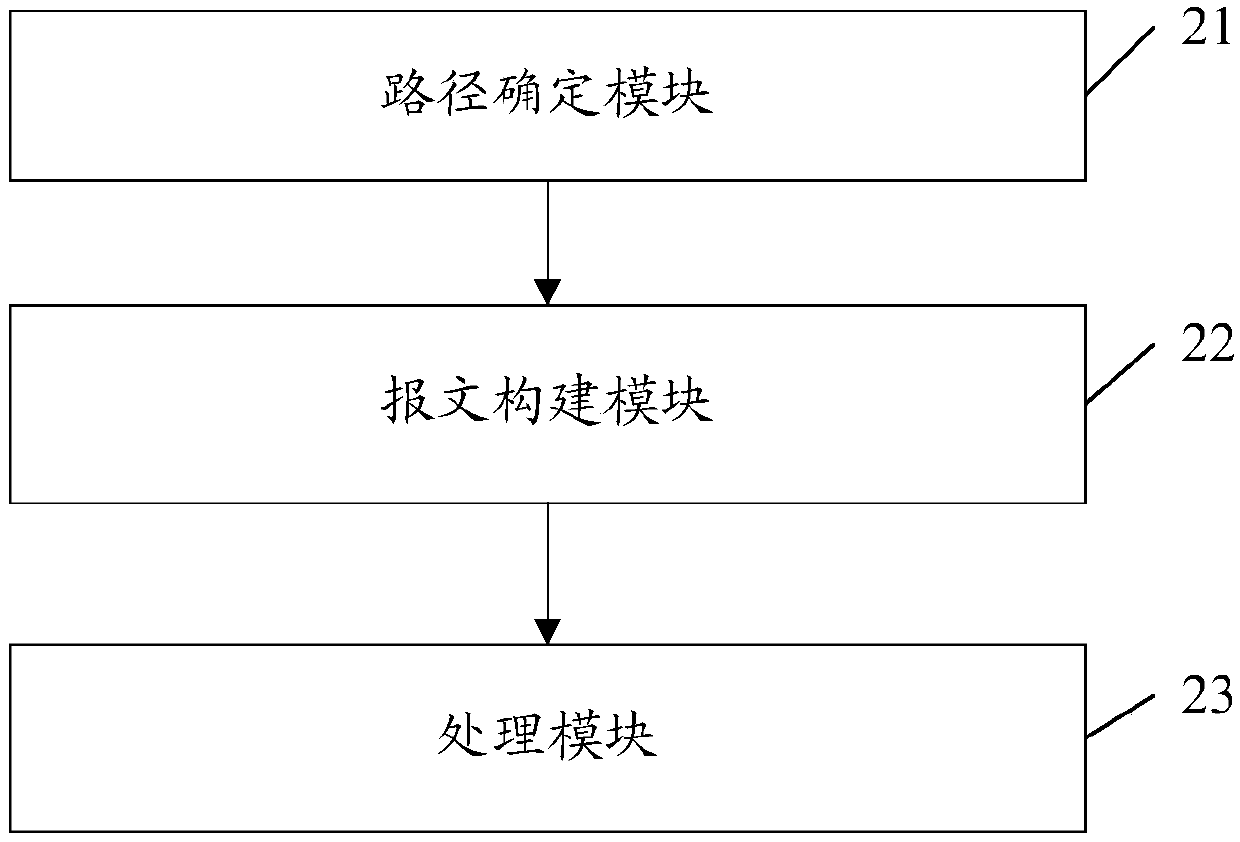

Tunnel establishing method and apparatus

ActiveCN107864103AImprove efficiencyGuaranteed continuous flowData switching networksTraffic volumeContinuous flow

The invention provides a tunnel establishing method and an apparatus. The method comprises the following steps of according to parameter information of a target tunnel to be established, determining atunnel path of the target tunnel; according to the tunnel path of the target tunnel and the parameter information of the target tunnel, constructing a tunnel message, wherein a tunnel bandwidth fieldin the tunnel message is set to be zero, or the tunnel message does not contain the tunnel bandwidth field; and sending the tunnel message to one or more network nodes related to the target tunnel, and establishing the target tunnel. In the invention, when tunnel bandwidth soft preemption is generated, because the established tunnel does not need to occupy a bandwidth, the tunnel can be immediately established successfully and does not need to wait for a preempted tunnel to complete migration. Efficiency of tunnel establishing in a network through a SDN controller can be greatly increased. Simultaneously, compared with a condition that the preempted tunnel is directly dismantled, a flow of the preempted tunnel is allowed to go through an original path before preempted tunnel migration iscompleted so as to maximumly guarantee the continuous flow.

Owner:ZTE CORP

A dust-removing and heat-dissipating monitor

ActiveCN111541836BEasy to useClean up in timeTelevision system detailsColor television detailsThermodynamicsEngineering

Owner:淮北中易光电科技有限公司

3D printing magnesium alloy material degradation test device and application

ActiveCN108593489BIncreased durabilityGood compatibilityWeighing by removing componentMg alloysEngineering

The invention discloses a degradability test device for 3D printing magnesium alloy material, comprising a cardiac artificial chamber fixed on a support, a sample carrier, and a pretreatment device; the cardiac artificial chamber is divided into two independent regions by a no-pore artificial valve plate; a porous artificial valve plate is arranged in each independent region; the cardiac artificial chamber is also connected with a temperature detector, a hydrogen detector, a pressure sensor, a gas storage cylinder, a PH auto-control system and an alarm; a rotary shaft is arranged on the support; the sample carrier is mounted on the rotary shaft; the sample carrier includes a speed adjusting motor; a drill chuck is fixed to one end of an output shaft of the speed adjusting motor; a sample carrying unit is mounted on the drill chuck; the pretreatment device comprises an ultrasonic device, a drying box, and a weigher. The degradability test device for 3D printing magnesium alloy materialis high in automation level and enables degrading action of an implant material in a human body to be simulated more accurately, testing is convenient and fast, and the results are accurate and visual.

Owner:ZHONGBEI UNIV

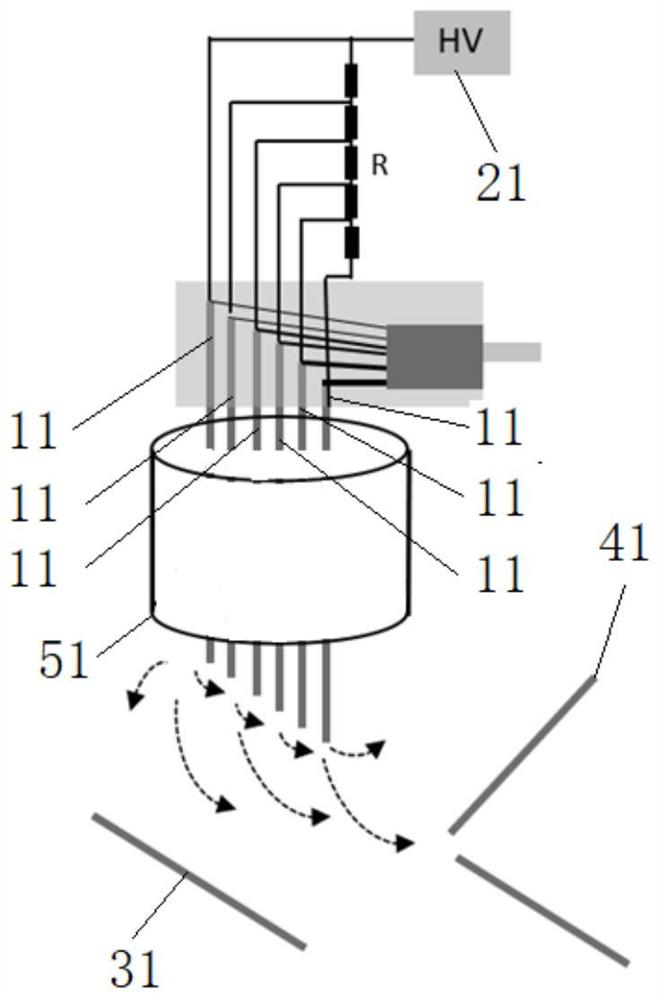

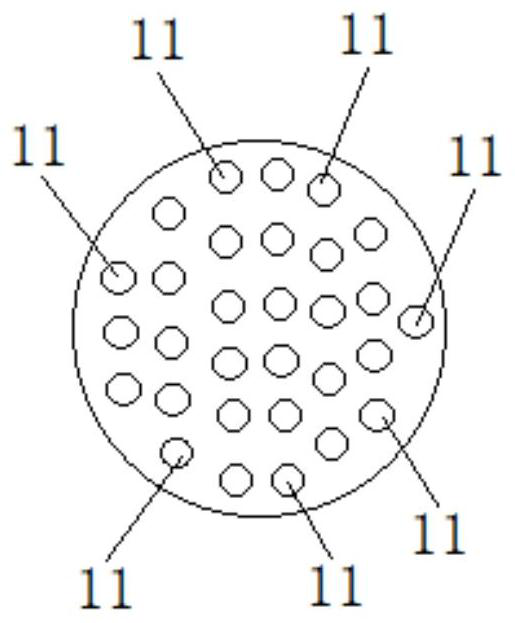

Electrospray ion source and ionization method based on electrospray technology

PendingCN114256055AGood desolvation effectGuaranteed continuous flowIon sources/gunsPhysical chemistryCapillary Tubing

The invention provides an electrospray ion source and an ionization method, the electrospray ion source comprises a plurality of vertically arranged capillary tubes arranged in a plurality of columns, and the heights of the bottom ends of the capillary tubes in each column are gradually reduced from left to right; the power supply applies voltage to the capillary tubes, the voltage of each column of capillary tubes is the same, and the voltage of each column of capillary tubes is gradually reduced from left to right. The method has the advantages of wide application range and the like.

Owner:HANGZHOU PUYU TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com