Glue storage barrel with stirring function

A technology of glue storage and function, applied in the field of glue storage barrels, can solve the problem of insufficient uniformity of the physical properties of glue liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

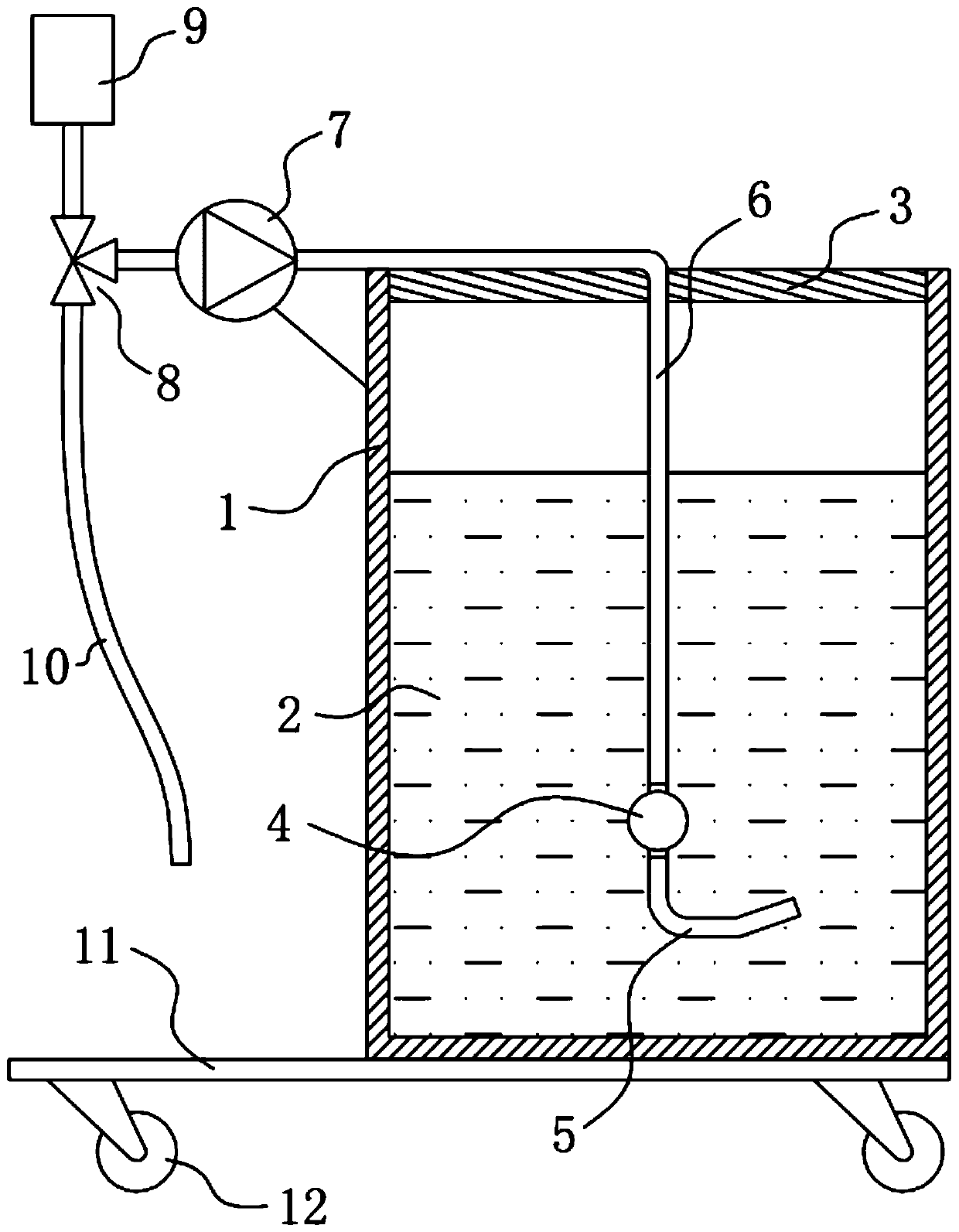

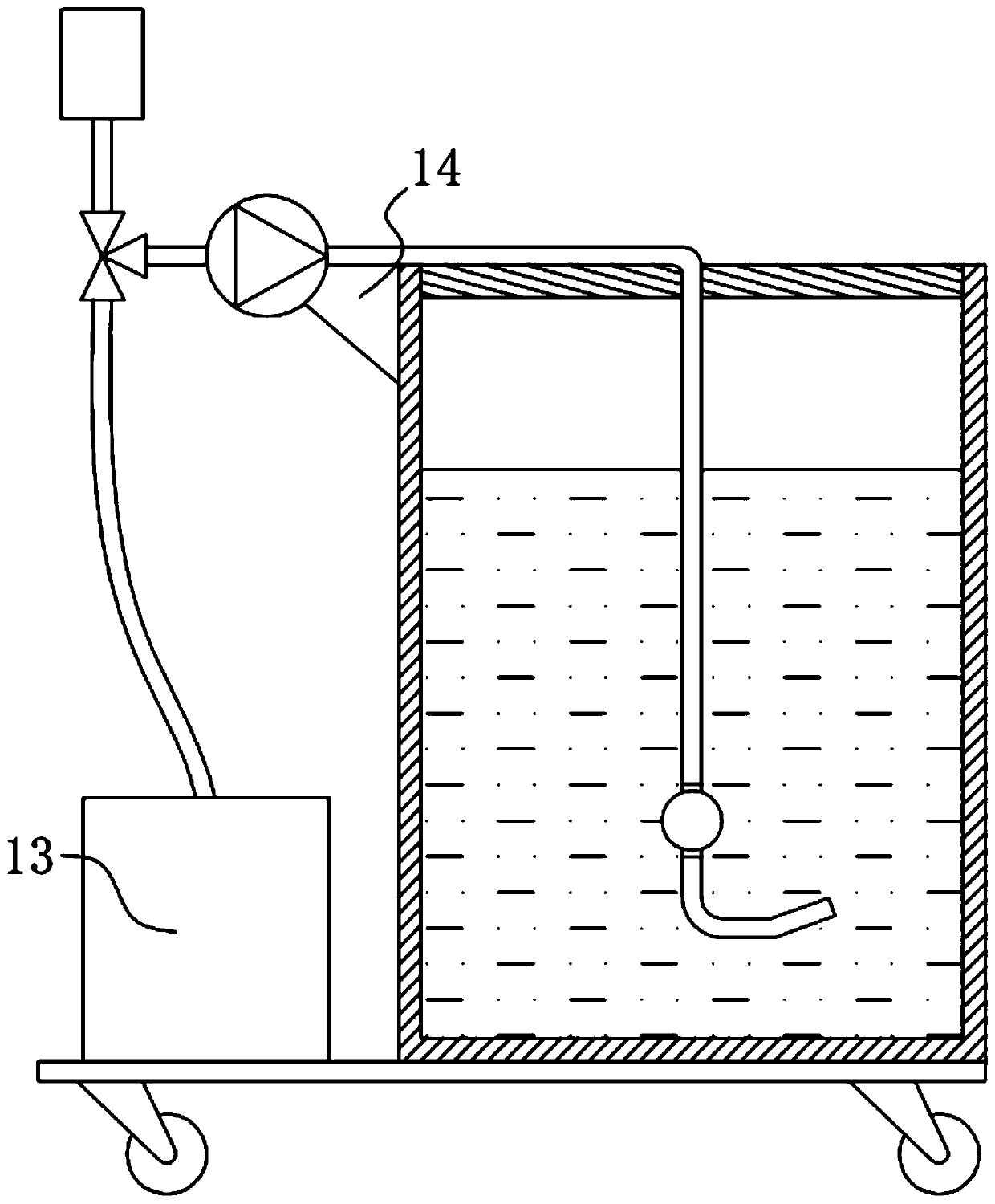

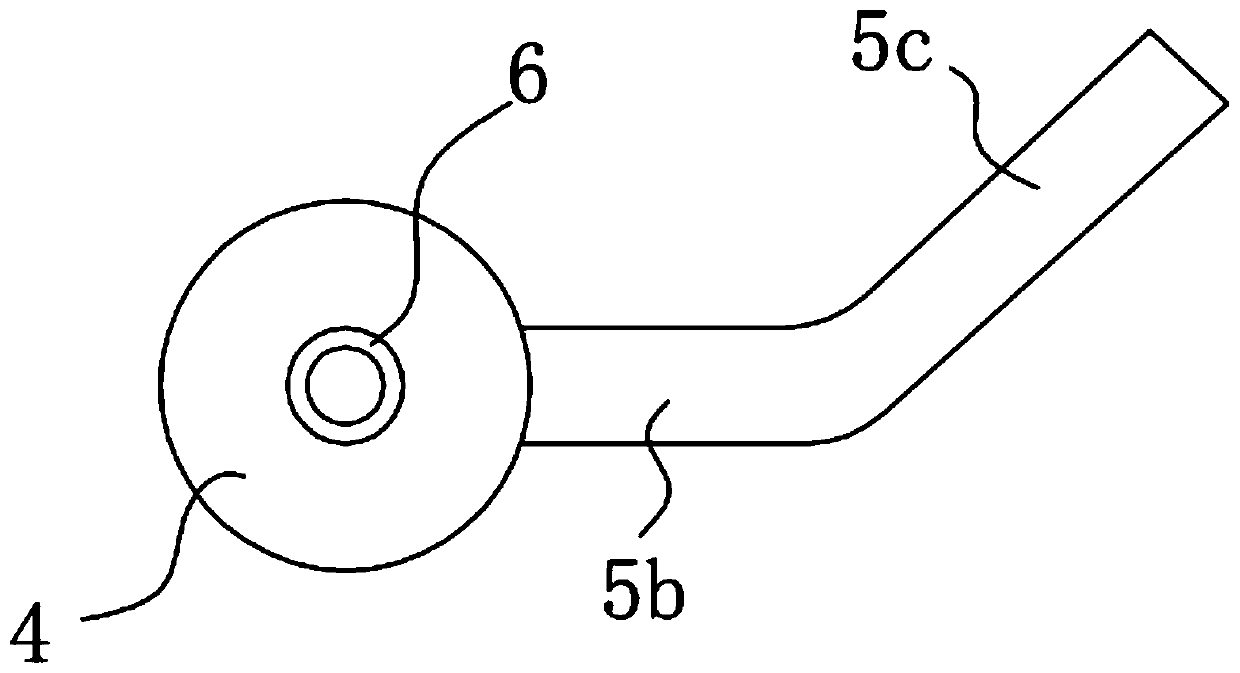

[0034] In order to achieve the purpose of the present invention, a rubber storage barrel with stirring function includes: a barrel body, including a glue storage barrel 1 containing glue 2; an input and output part, including a pump body 7 with a two-way delivery function, One end of the pump body 7 is connected with a hollow pipe 6, the hollow pipe 6 has a vertical section suspended in the rubber storage barrel 1, the other end of the pump body 7 is connected with a three-way valve 8, and the other two ends of the three-way valve 8 are respectively connected with empty The filter 9 and the rubber delivery tube 10; the submerged part is located at the end of the hollow tube 6 away from the pump body 7, the submerged part is submerged in the glue liquid 2 of the glue storage barrel 1, and the submerged part includes the elbow 5, and the elbow 5 and the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com