Patents

Literature

82results about How to "Good hangability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

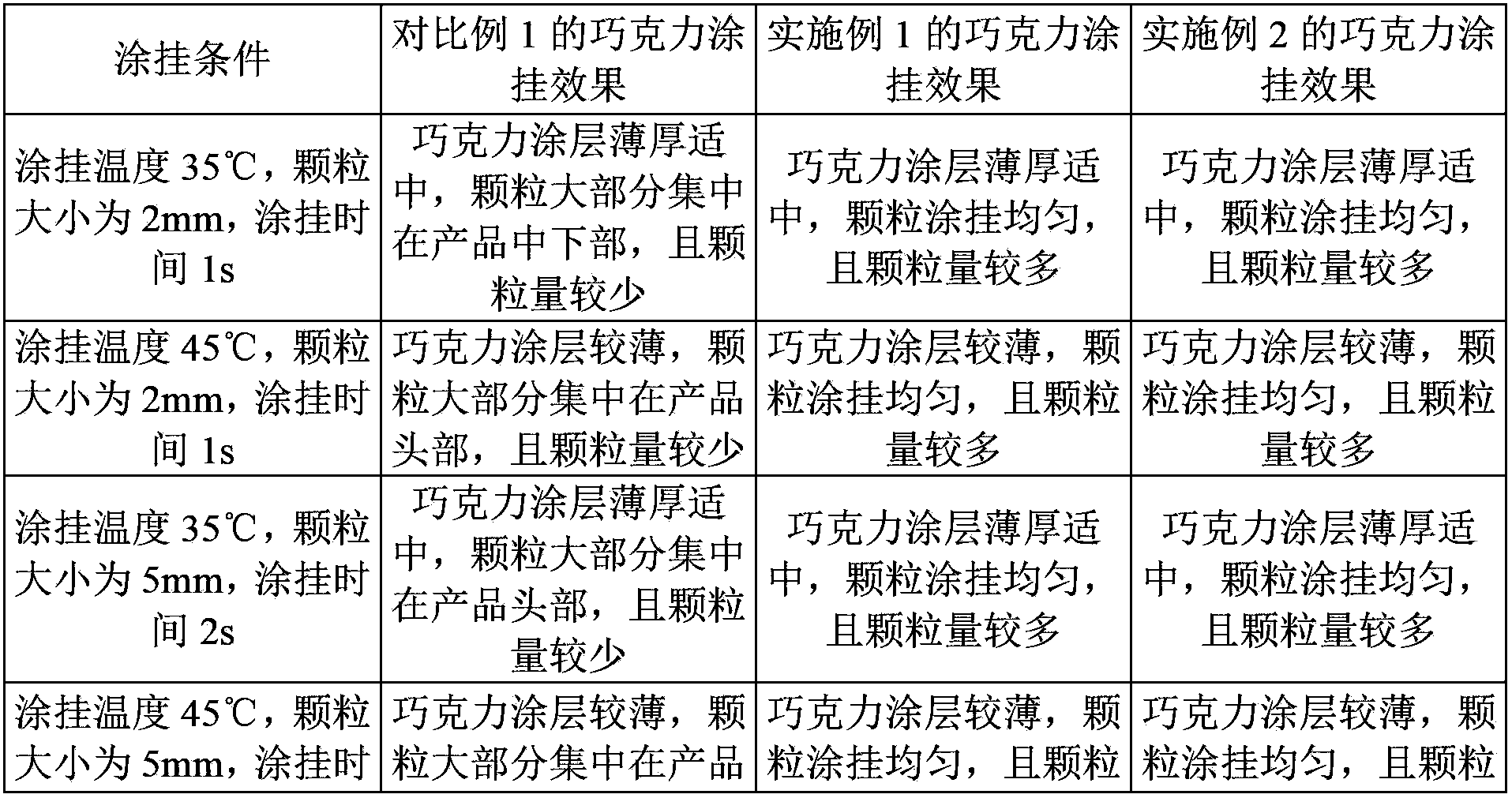

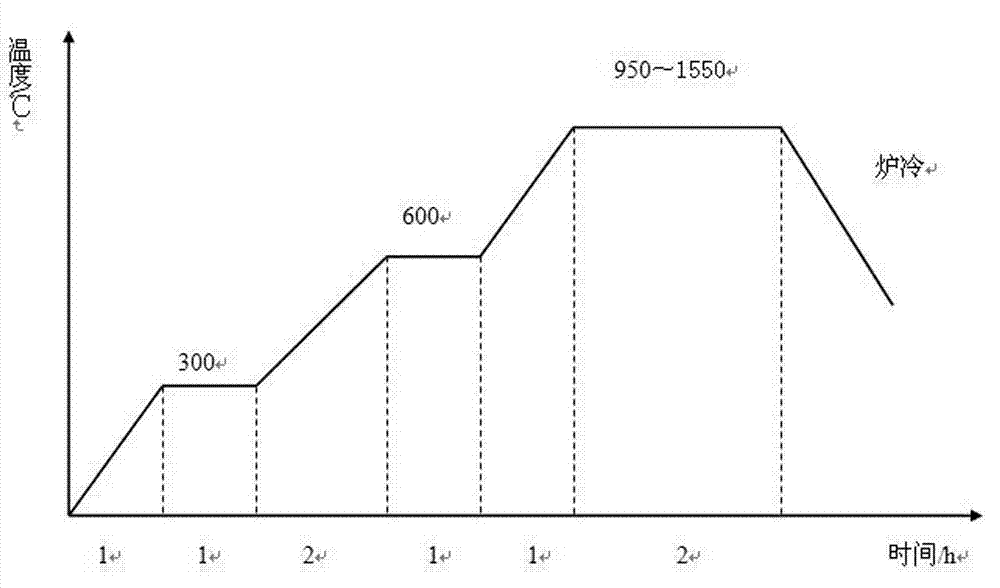

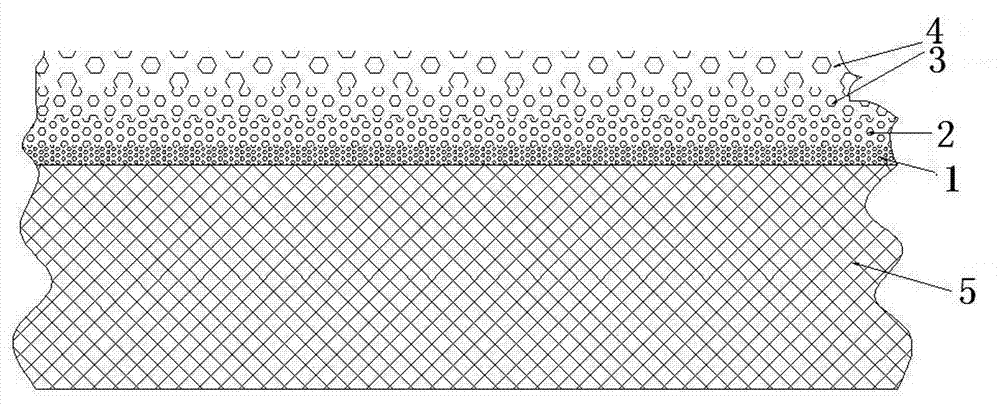

Chocolate used for external coating of cold drink, and particle-containing chocolate coat

The invention relates to the food field, and concretely relates to a chocolate used for the external coating of a cold drink, and a particle-containing chocolate coat. The chocolate used for the external coating of a cold drink comprises 33-37wt% of white granulated sugar, 9-11wt% of whole milk power, 23-25wt% of coconut oil, 3-5wt% of anhydrous cream, 4-6wt% of cocoa powder, 9-11wt% of natural cocoa butter, 8-10wt% of cocoa liquor, and 2.5-3.5wt% of an emulsifier, wherein the sum of the weight percentages of all the above components is 100%. Particles can suspend in the chocolate, so the particles can be uniformly distributed in the surface of a product in the coating process, the proper mouthfeel of the externally coated chocolate is guaranteed, and the coating amount of the chocolate can be effectively controlled in order to realize an ideal coating effect.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

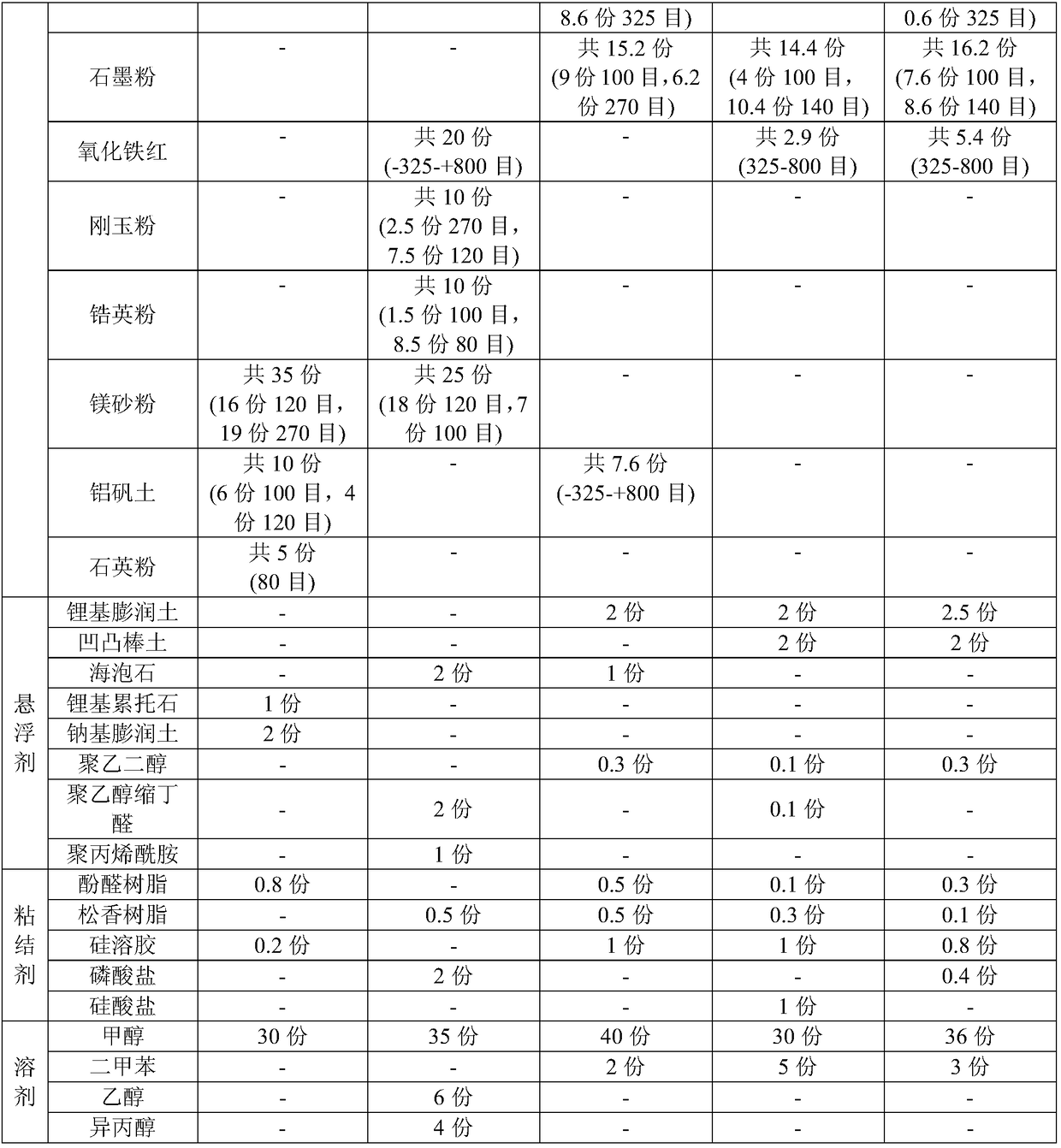

High-temperature wear-resisting coating for casting and preparation method thereof

ActiveCN104325067AHigh refractorinessLow thermal conductivityFoundry mouldsFoundry coresWear resistantSuspending Agents

The invention discloses a high-temperature wear-resisting coating for casting and a preparation method thereof. The coating comprises the following components: a fireproof material, a carrier, a bonding agent, a suspension agent and an auxiliary agent. The invention further designs the preparation method of the high-temperature wear-resisting coating for casting. The preparation method comprises the following steps: putting the suspension agent and the carrier into a dispersion machine and uniformly agitating; then adding the fireproof material and continually agitating; and slowly adding the bonding agent and the auxiliary agent in sequence under an agitating state; and agitating uniformly to obtain the high-temperature wear-resisting coating for casting. The high-temperature wear-resisting coating for casting is low in price, and is clean and is free from pollution; the preparation method is simple and the coating is high temperature resistant and wear resistant and is not easy to release; and a die for casting can be protected and the quality of a casting piece can be improved.

Owner:YANCHENG AOTONG TESCO FOUNDRY CO LTD

Intumescent Fireproofing Systems and Methods

InactiveUS20130331489A1Eliminate the potential for VOC releaseImprove performanceCoatingsEthyl groupFibre composition

Water-based intumescent fireproofing formulations are provided that exhibit excellent fireproofing properties while simultaneously significantly reducing and / or eliminating the potential for VOC release and exhibiting excellent hangability properties. The intumescent fireproofing formulation includes a coalescent that significantly reduces and / or eliminates the potential for VOC release and fiber constituents, e.g., fibers of greater than 0.2 mm in length. Exemplary coalescents have a boiling point of at least 180° C. and include bis(2-ethylhexanoate)triethyleneglycol, 2,2,4-trimethyl-1,3-pentanediolmono(2-methylproponate) and 2,2,4-trimethyl-1,3-pentanedioldi(2-methylpropanoate). Intumescent fireproofing formulations are also provided that include clay to further improve performance.

Owner:US MINERAL PRODS

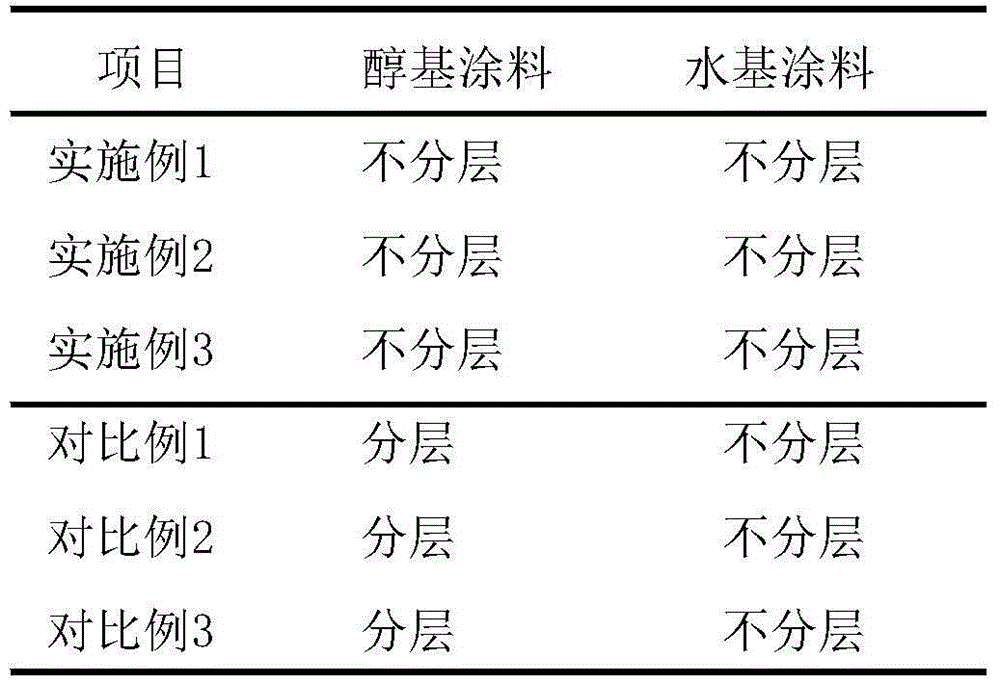

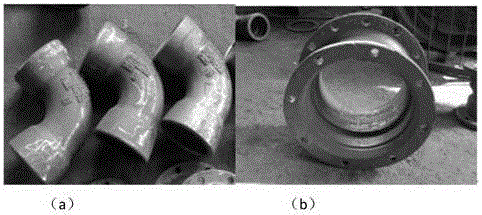

Cast iron evaporative pattern coating and preparation method thereof

ActiveCN104353777AGood hangabilityImprove thermal performanceFoundry mouldsFoundry coresCelluloseAdhesive

The invention relates to the technical field of evaporative pattern coatings, and in particular relates to a cast iron evaporative pattern coating and a preparation method thereof. The cast iron evaporative pattern coating comprises the following components in parts by weight: 100 parts of refractory aggregate, 2-4 parts of a suspending agent, 1.2-1.6 parts of an adhesive, 0.4-1 part of a thickening agent, 0.5-1.2 parts of a sintering agent, 0.2-0.6 part of an antioxidant and 0.2-0.5 part of an anti-foaming agent, wherein the thickening agent is one or two of sodium carboxymethyl cellulose and xanthan gum; the sintering agent is sodium tripolyphosphate. The coating is good in coating property, a coated layer is free of flow marks or drain marks and good in thermal property and air permeability and is not infiltrated with a molten metal liquid; a cast piece is smooth in surface and free of sand adhesion defect. The preparation method comprises the following steps: uniformly mixing the powder-like components, pouring water into a stirring bucket, pouring the mixed components into the stirring bucket, and stirring for 30-40 minutes by using a stirring machine, wherein the weight of the water accounts for 80% that of the coating. The coating does not need to be prepared for a second time when be used, thus being convenient to use.

Owner:襄阳聚力新材料科技有限公司

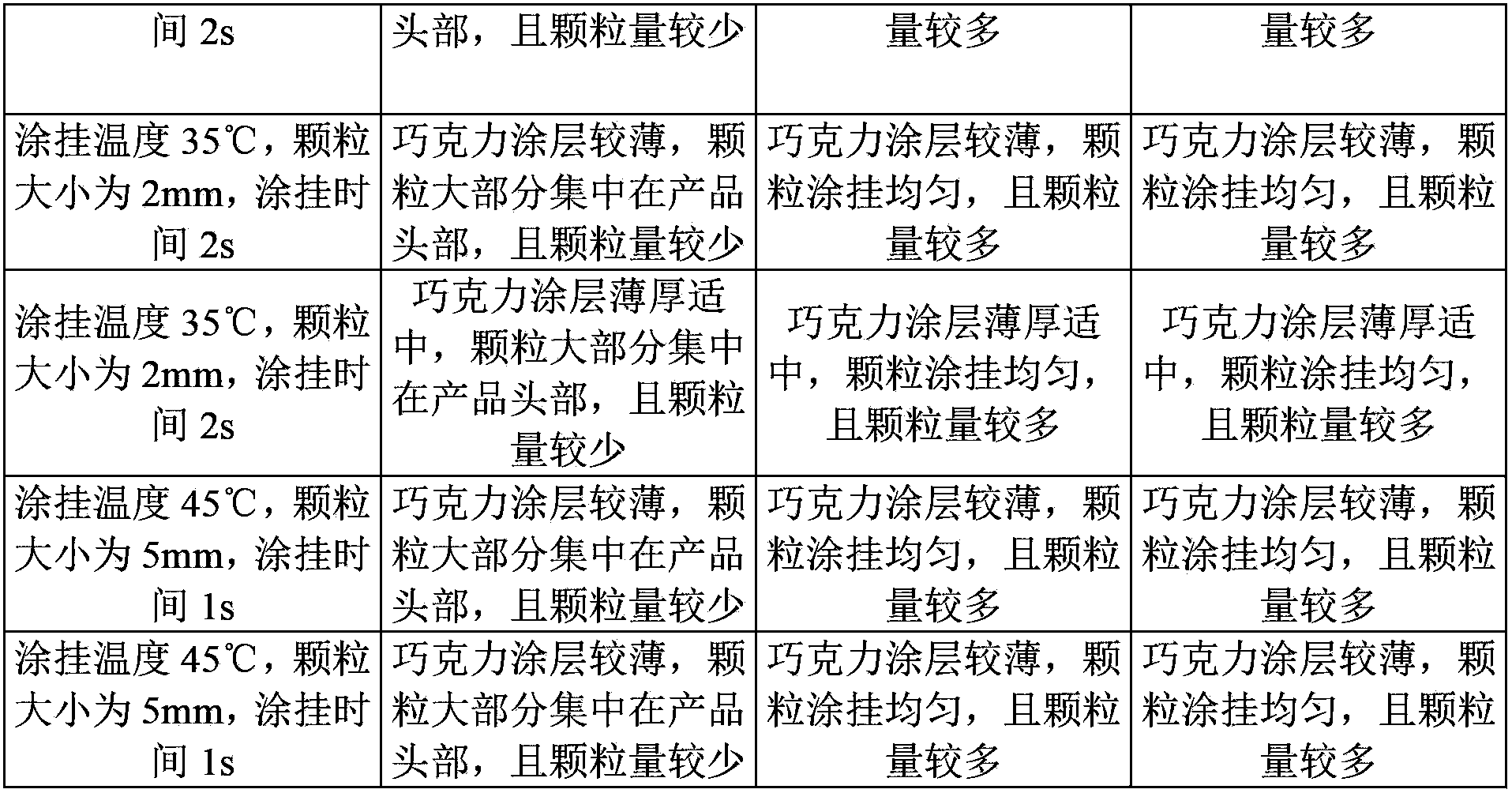

Method for preparing surface molded shell cast by high-temperature titanium alloy melting mold

The invention discloses a method for preparing a surface molded shell cast by a high-temperature titanium alloy melting mold, and relates to a method for preparing a surface molded shell. The method solves the problems that the molded shell prepared by the conventional method has high cost during de-waxing and easily pollutes the environment. The method comprises the following steps: 1, preparing mixed adhesive; 2, preparing surface slurry; 3, coating and hanging, scattering sand and drying to obtain the surface molded shell. The molded shell prepared by the method can be used for steam de-waxing, has low de-waxing cost, and is environmentally-friendly and easy to operate.

Owner:HARBIN INST OF TECH

Anti-interface reaction composite ceramic shell

The invention relates to an anti-interface reaction composite ceramic shell. The shell consists of a surface layer and a reinforcing layer, the surface layer is made of yttria powder as refractory powder, yttria sand as refractory aggregate and silica sol as binder by adopting a multi-coating method, the reinforcing layer is made of electro-fused mullite powder as refractory powder, electro-fused corundum sand as refractory aggregate and silica sol as binder by adopting the multi-coating method, the reinforcing layer is fixed on the top surface of the surface layer, and the reinforcing layer and the surface layer are of an integrated structure; the total thickness of the shell is 5mm to 13mm, wherein the thickness of the surface layer is 0.15mm to 1.4mm. After the shell produced by the method is roasted, the surface of the cavity of the shell is smooth and does not have cracks, the surface does not have floating sand and floating powder, and the shape of a blade wax pattern is completely and clearly copied.

Owner:SHENYANG RES INST OF FOUNDRY

Mold casting method

InactiveCN105312500AHigh dimensional accuracyFlat surfaceFoundry mouldsFoundry coresPolyvinyl alcoholSodium phosphates

The invention relates to a mold casting method. The mold casting method comprises the following steps that 1 a foam plate is machined into a foam model; 2 a fire-proof coating is smeared on the surface of the foam model; 3 the foam model smeared with the fire-proof coating is dried; 4 the foam model in the step 3 is buried in molding sand for vibration molding; 5 liquid metal is poured at negative pressure so that the foam model can be gasified; and 6 when the poured model in the step 5 is cooled, a casting inside a sand box is separated from dry sand, and a mold casting is obtained. The fire-proof coating in the step 2 is composed of the following raw materials of bauxite, quartz powder, corundum powder, kieselguhr, talcum powder, cryolite, carboxymethyl cellulose (CMC), polyvinyl alcohol, water glass and sodium phosphate. The mold casting method is suitable for lost foam casting, sand burning is not prone to occur, and an obtained mold is high in size precision and has a bright and clean surface.

Owner:广西博白县三田机械制造有限公司

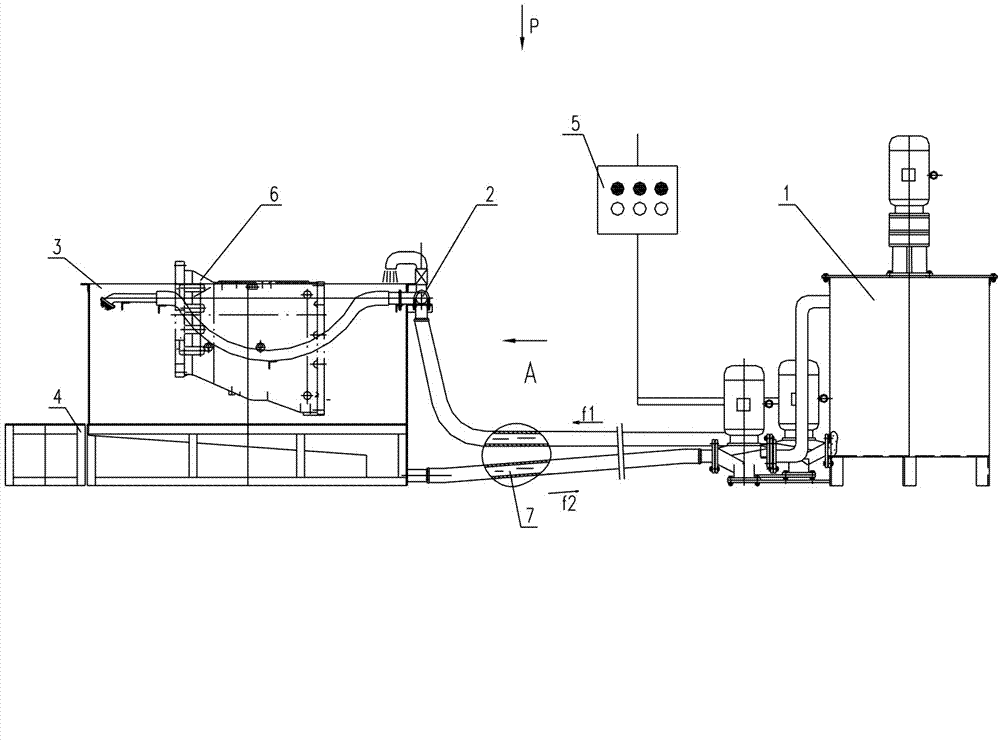

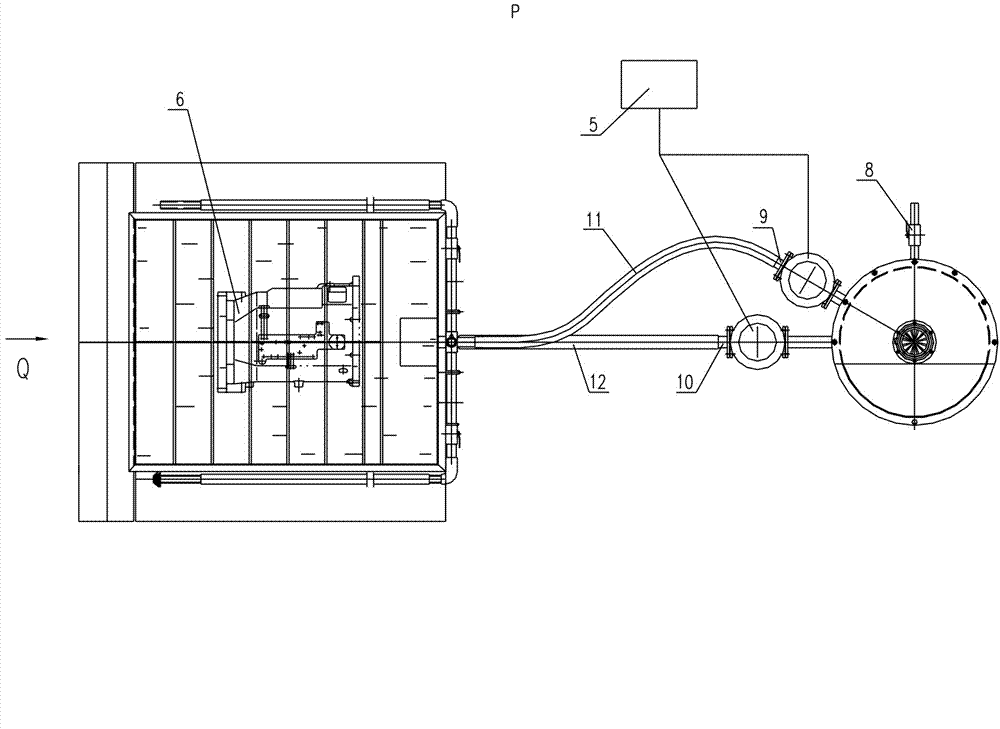

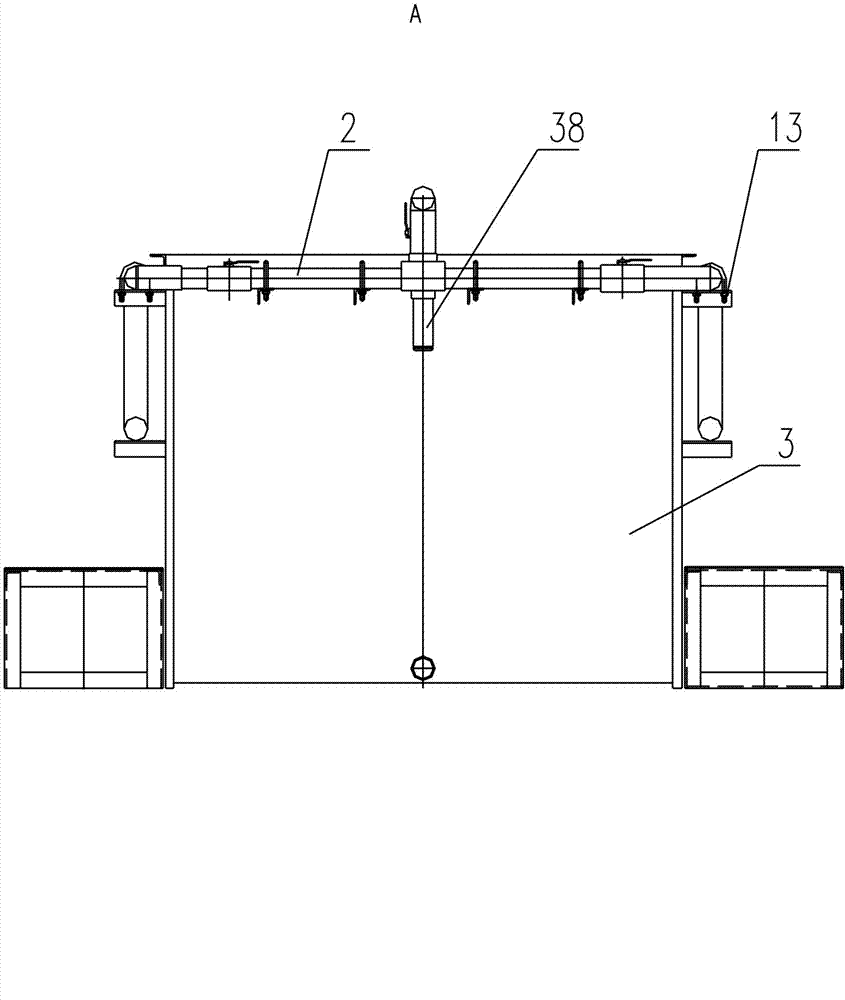

Coating device and method for evaporative pattern sample of thin-wall shell piece

InactiveCN102784894AImprove application efficiencyAvoid deformationMoulding toolsFoundry mouldsAgricultural engineeringUltimate tensile strength

The invention belongs to the field of machine manufacturing, and particularly relates to a coating device and a method for an evaporative pattern sample of a thin-wall shell piece. The coating device for the evaporative pattern sample of the thin-wall shell workpiece comprises a stirring mechanism (1), a spraying mechanism (2), a coating tank mechanism (3), an auxiliary mechanism (4) and a power controlling cabinet (5), wherein the stirring mechanism (1) is fixedly connected with the spraying mechanism (2); the spraying mechanism (2) is fixedly connected to the coating tank mechanism (3); the coating tank mechanism (3) is fixedly connected with the stirring mechanism (1); a foot table in the auxiliary mechanism (4) is placed beside the coating tank mechanism (3); and the dynamical power of each mechanism is independent. According to the invention, the method integrates spraying and curtain coating, the stirring mechanism, the spraying mechanism, the coating tank mechanism and the auxiliary mechanism are utilized for coating of a large-sized and complex-structured evaporative pattern sample of the thin-wall shell workpiece, so that the deformation or fracture of the sample is avoided during the coating process, the work intensity is reduced, and the normal operation is guaranteed.

Owner:CHINA YITUO GROUP

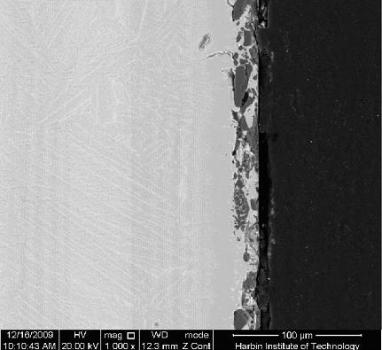

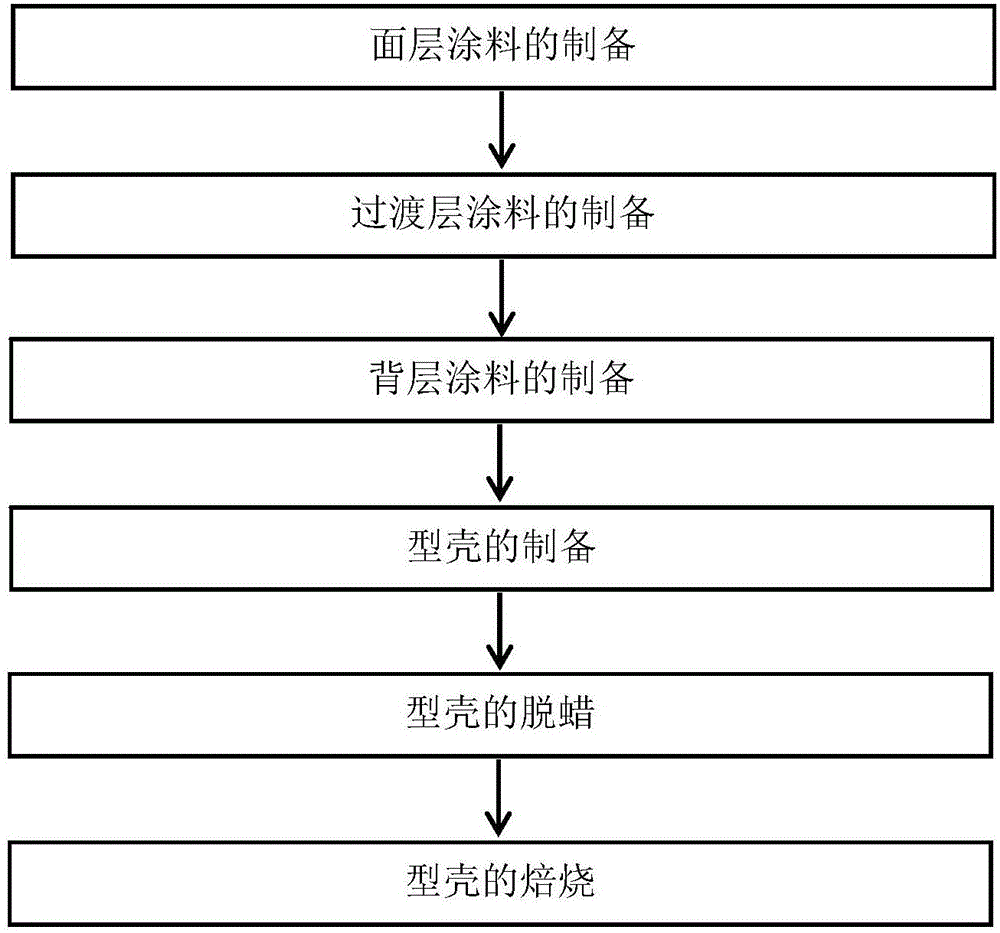

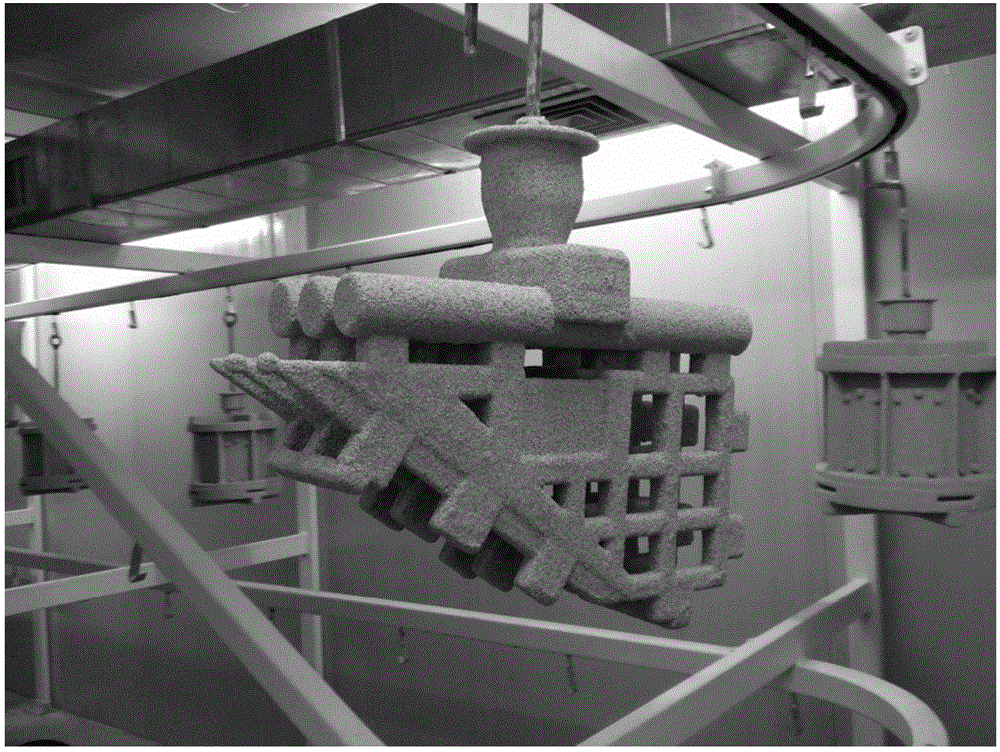

Preparation method of yttrium oxide moulding shell used for casting

ActiveCN106493287ASolve the problem of water back dissolutionSolve the breathability problemFoundry mouldsFoundry coresHuman healthTitanium alloy

The invention discloses a preparation method of an yttrium oxide moulding shell used for titanium alloy precision casting. A moulding shell surface layer coating comprises yttrium oxide refractory powder, ammonium zirconium carbonate binder, a wetting agent and a defoaming agent. The preparation method includes the steps of preparation of the surface layer coating, preparation of a back layer coating, preparation of the moulding shell, dewaxing, calcinations and the like. By means of the yttrium oxide moulding shell used for titanium alloy precision casting and the preparation method thereof, the problems that an existing moulding shell is prone to redissolution under the influence of water in the preparation and dewaxing processes, and steam dewaxing cannot be achieved are solved. The binder used for the coating is made of ammonium zirconium carbonate and is low in price, and the prepared coating is stable and reliable and cannot generate redissolution after being dried under the influence of water. The prepared surface layer coating is good in smearing performance and high in refractoriness, steam dewaxing is adopted, no pollution is caused to the environment, and the prepared surface layer moulding shell has no influence on the human health. The prepared yttrium oxide moulding shell is wide in application range, an interface reaction layer is small, titanium alloy casts are high in precision, performance is excellent, and later-period finishing is conducted easily.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

Fired mold low-pressure casting process of integral type compressor impeller

InactiveCN103658536AReduce labor intensityIncrease pressureFoundry mouldsFoundry coresImpellerStaining

The invention provides a fired mold low-pressure casting process of an integral type compressor impeller. The process comprises the following steps of preparing coating with silica sol binder for fired mold casting, wherein a fireproofing surface layer and a second layer are made of fused alumina powder and sand, and a reinforced layer is made of mullite powder and sand special for fired mold casting; when coating the coating on the reinforced layer, adopting a two-time slurry staining method, i.e. firstly staining thin coating and secondly staining thick coating; and after dewaxing a shell, roasting at the low temperature of 500 DEG C, storing, and roasting at high temperature before pouring, wherein the temperature of high-temperature roasting is 1000 DEG C, the heat preservation time is 4h, and the temperature of the shell during pouring is 100-150 DEG C. The prepared shell is high in strength, low-pressure pouring can be carried out by utilizing a single shell, the pouring temperature of molten aluminum is 670-680 DEG C, the mold-filling pressure is 0.03 MPa, the mold-filling time is 10s, the solidification holding pressure is 0.35 MPa, and the holding pressure time is 5min. The integral type compressor impeller produced by adopting the fired mold low-pressure casting process is good in mold-filling and feeding effect, compact in casting tissue, good in product mechanical property and inner quality, high in production efficiency, and low in labor intensity, and has no need to be modeled through binning.

Owner:SHANDONG JIANZHU UNIV

High-temperature-resistant environment-friendly metal casting coating and preparation method thereof

InactiveCN105642821AImprove high temperature resistanceImprove crack resistanceFoundry mouldsFoundry coresSodium BentoniteCrack resistance

The invention discloses high-temperature-resistant environment-friendly metal casting coating and a preparation method thereof. The coating comprises, by weight, 3-5 parts of attapulgite clay, 12-15 parts of quartz powder, 5-12 parts of talcum powder, 4-10 parts of superfine glass powder, 1.5-4 parts of sodium silicate, 3-5 parts of bauxite, 3-8 parts of diatomaceous earth, 2-4 parts of bentonite, 6-10 parts of polyethylene glycol, 3-9 parts of organic siloxane, 5-9 parts of silicon resin, 6-12 parts of linseed oil water-soluble alkyd resin, 4-6 parts of triphenyltin hydroxide, 2-6 parts of lignosulfonic acid, 1-3 parts of oxidizing agents, 1-2 parts of wetting agents, 2-5 parts of defoaming agents, 4-9 parts of preservatives, 2-6 parts of bonding agents, 5-8 parts of curing agents and 75-90 parts of deionized water. Compared with the prior art, the casting coating prepared through the method has excellent high temperature resistance, crack resistance and scouring resistance, and is good in adhesiveness and air permeability; meanwhile, the produced coating is uniform, environmentally friendly, free of pollution, good in stability and adsorbability, and capable of meeting the requirements for mass production of large castings, and improves the surface quality of the castings.

Owner:TONGLING ANDONG CAST STEEL

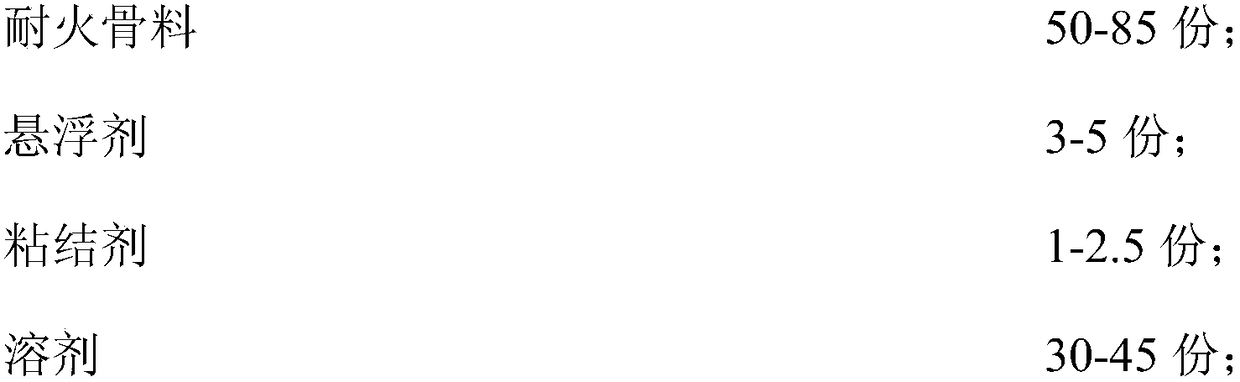

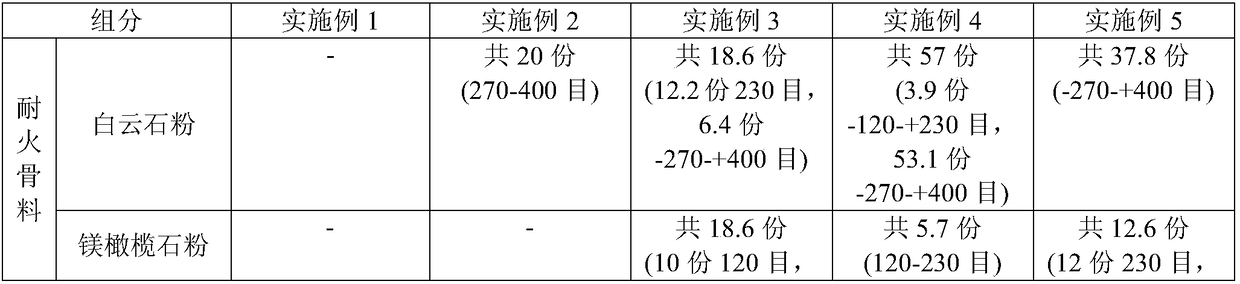

Cast iron sand mold protecting coating coated to surface of 40-120-mesh sand and preparation method thereof

The invention relates to a cast iron sand mold protecting coating coated to the surface of 40-120-mesh sand and a preparation method thereof. The cast iron sand mold protecting coating is prepared from the following components in parts by mass: 50-85 parts of a refractory aggregate, 3-5 parts of a suspender, 1-2.5 parts of an adhesive and 30-45 parts of a solvent, wherein the size distribution ofthe refractory aggregate is as follows: 5-15wt% of -100-+120 meshes, 25-45wt% of -120-+270 meshes and 30-50wt% of 270 meshes. The coating is good in coating effect and good in permeating effect on thesurface of 40-120-mesh mold sand. The surface structure of the cast iron mold sand is modified, the levelness is improved, and permeation to the mold sand by molten metal is shielded; moreover, sulfur released by the sand mold at a high temperature is absorbed by the coating, so that the under-nodularizing thickness of a cast iron part is reduced greatly.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Lost foam casting coating

ActiveCN106825389ALow film forming temperatureImprove initial tackFoundry mouldsFoundry coresNeopreneLost-foam casting

Disclosed is a lost foam casting coating. The lost foam casting coating comprises, by weight, 50-60 parts of quartz powder, 1-2 parts of vegetable glue powder, 10-15 parts of kaolin, 6-8 parts of bentonite, 4-6 parts of methyl methacrylate, 1-2 parts of neoprene latex and 0.2-0.4 part of catalyst. The lost foam casting coating with the structure has the advantages of being high in adhesive force, coating property and levelling property.

Owner:重庆市九明机械制造有限公司

Corrosion-resistant paint for hydraulic oil tanks and preparation method thereof

InactiveCN104774534AGood hangabilityImprove bonded stateAnti-corrosive paintsEpoxy resin coatingsAdhesiveActive agent

The invention discloses a corrosion-resistant paint for hydraulic oil tanks. The corrosion-resistant paint for hydraulic oil tanks is a double-component paint formed by mixing a component A and a component B, wherein the component A comprises a modified epoxy resin, a filler, a foaming agent, acetone, an adhesive, a suspending agent, sodium carbonate and a mildew preventive; and the component B comprises a bisphenol A polyetheretherketone resin, a defoaming agent, a leveling agent, a solvent, a cosolvent, a thixotropic agent and a surfactant. The invention also discloses a preparation method of the corrosion-resistant paint for hydraulic oil tanks, which comprises the following steps: preparation of the component A, preparation of the component B, and preparation of the corrosion-resistant paint for hydraulic oil tanks. The preparation method is simple and easy to implement, and has the advantage of low preparation cost. The prepared paint has the advantages of favorable abrasion resistance, favorable coating property, high impact resistance, favorable adhesive force, favorable flexibility, favorable water resistance and favorable chemical resistance.

Owner:SUZHOU JIN YUAN OIL MACHINERY

Production method of environment-friendly dual-purpose coating suspending agent

ActiveCN104923719AWith water immersion hydration expansion performancePrevent sinkingFoundry mouldsFoundry coresWater basedAlcohol

The invention relates to a production method of an environment-friendly dual-purpose coating suspending agent. The method comprises the following steps that 1, bentonite, sodium carbonate and water are stirred evenly, then roller-crushing and stacking are performed, the water content of a rolled-crushed piece is controlled to be 30-35% by weight, and modified bontonite is obtained; 2, the modified bontonite, attapulgite, lithium carbonate and water are mixed evenly, roller-crushing and stacking are performed, and the water content of the rolled-crushed piece is controlled to be 40-50% by weight; and 3, the product obtained in the second step is naturally aired or dried, crushed and ground into powder, and the environment-friendly dual-purpose coating suspending agent is obtained. The sodium bentonite is obtained by modifying the bentonite through the sodium carbonate firstly, then the sodium bentonite and the attapulgite are modified through the lithium carbonate, and the environment-friendly dual-purpose coating suspending agent containing no organic additive is obtained and can be directly used for water-based and alcohol-based coatings. Meanwhile, the production method is simple and suitable for large-scale industrial application.

Owner:江苏玖川纳米材料科技有限公司 +1

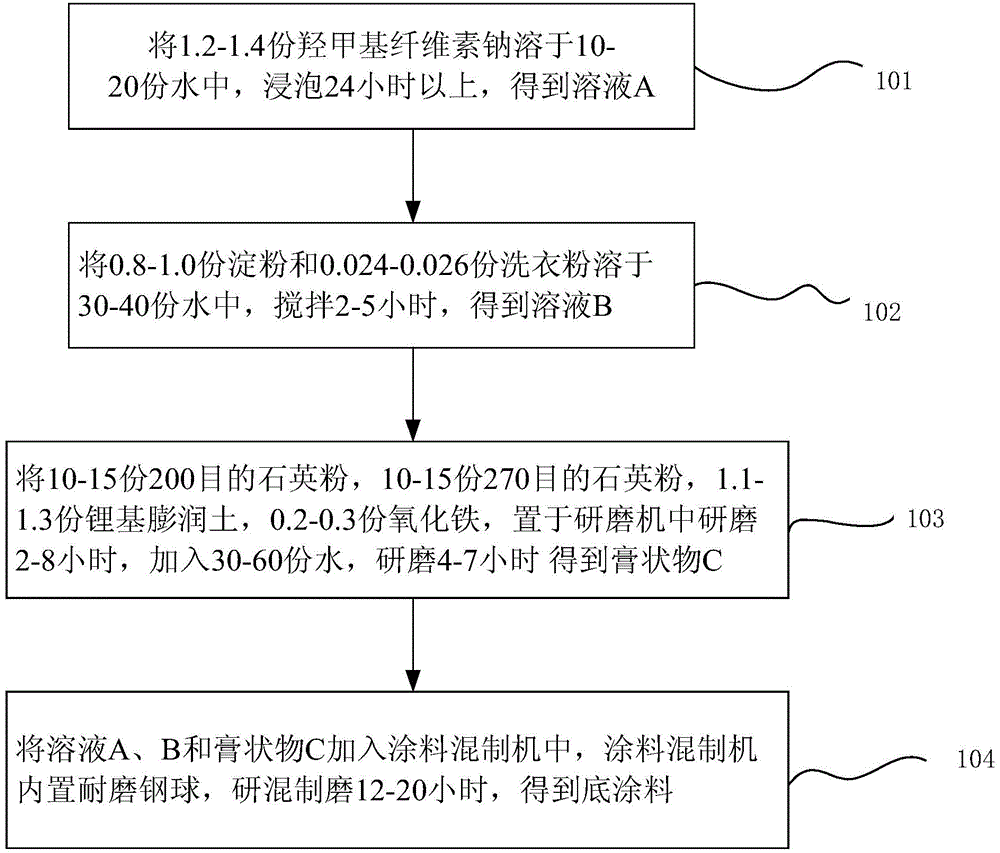

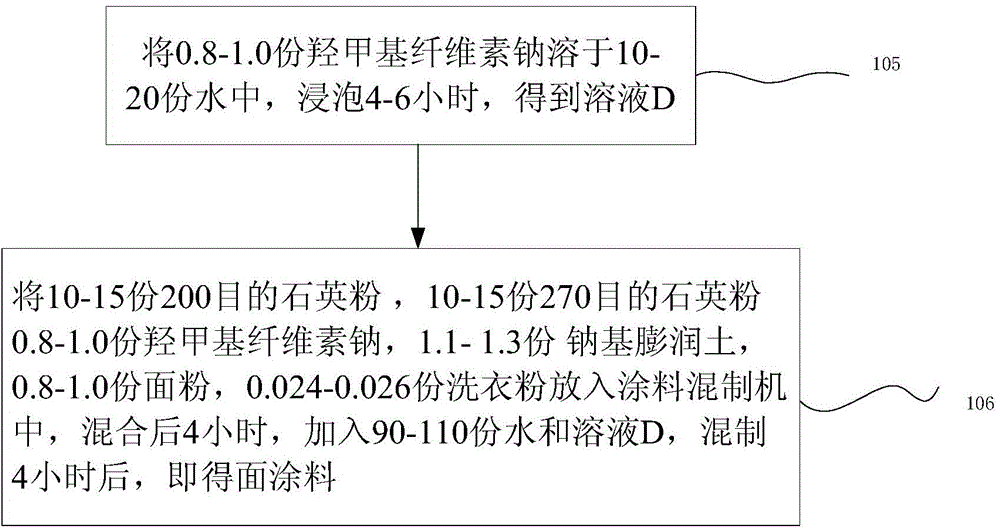

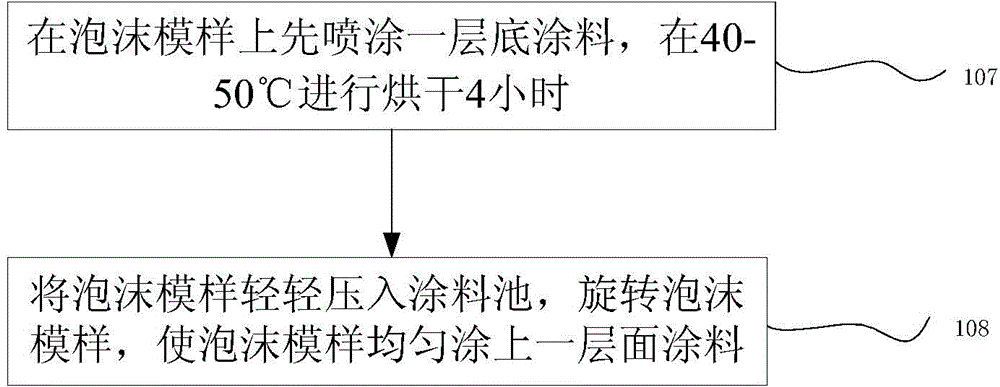

Water-based paint for full mold and preparation method and using method of water-based paint

InactiveCN105312487AWide variety of sourcesLow priceFoundry mouldsFoundry coresFull-mold castingOxide

The invention relates to special paint for full molds, in particular to water-based paint for a full mold. The water-based paint for the full mold comprises a primer and a surface paint. The primer comprises, by weight, 10-15 parts of 200-mesh quartz powder, 10-15 parts of 270-mesh quartz powder, 1.2-1.4 parts of carboxymethyl cellulose sodium, 1.2-1.4 parts of lithium-based bentonite, 0.8-1.0 part of starch, 0.024-0.026 part of detergents, 0.2-0.3 part of ferric oxide and 90-100 parts of water. The surface paint comprises, by weight, 10-15 parts of 200-mesh quartz powder, 10-15 parts of 270-mesh quartz powder,, 0.8-1.0 part of carboxymethyl cellulose sodium, 1.1-1.3 parts of sodium bentonite, 0.8-1.0 part of flour, 0.024-0.026 part of detergents and 110-120 parts of water. The water-based paint for the full mold has the beneficial effects that the range of raw material sources of the water-based paint for the full mold is wide, the price is low, and the production cost is low; in addition, by coating the surface of a foam mold sample with the paint prepared through the formula, the breathability is high, the smearing performance is good, the refractoriness is high, and the water-based paint can be widely applied to the full mold casting industry.

Owner:山东蒙凌工程机械股份有限公司

Water-based lost-foam casting coating

InactiveCN107952929AEasy to prepareRaw materials are easy to getFoundry mouldsFoundry coresWater basedEconomic benefits

The invention relates to water-based lost-foam casting coating. The water-based lost-foam casting coating consists of the following raw material components in parts by weight: 1.6-2.2 parts of latex powder, 0.2-0.5 part of xanthan gum, 3-4 parts of attapulgite, 0.3-1 part of CMC, 1-1.6 parts of curing starch, 50-60 parts of quartz powder, 80-100 parts of bauxite, and 0.010-0.015 part of a penetrating agent. Compared with the prior art, the water-based lost-foam casting coating has the beneficial effects that: the formula design is reasonable, the preparation process is fine, finished product performances are stable, and the economic benefits and the social value are good.

Owner:山东蒙沃变速器有限公司

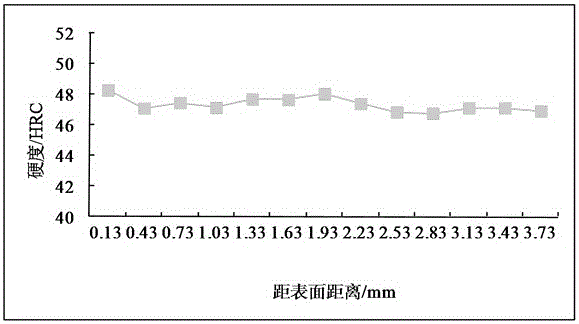

Anti-carburizing painting capable of being removed through washing after quenching and preparation method thereof

The invention discloses an anti-carburizing painting capable of being removed through washing after quenching. The anti-carburizing painting is prepared from, by mass, 25%-35% of boric acid, 15%-25% of filling, 15%-25% of aluminum dihydrogen phosphate, 1%-5% of tinting pigment and 30%-40% of water. The invention further discloses a preparation method of the anti-carburizing painting capable of being removed through washing after quenching. The anti-carburizing painting can be removed through washing after carburizing heat treatment, so that the problem that a traditional anti-carburizing painting is difficult to peel off after the carburizing heat treatment is solved. An inorganic heat-resisting material serves as an anti-carburizing agent in the formula of the anti-carburizing painting, so that an anti-carburizing coating formed after the anti-carburizing agent is brushed on the surface of a workpiece is good in cohesiveness, capable of not peeling and capable of not flowing at a high temperature, and the carburizing atmosphere is not influenced.

Owner:NANJING KERUN LUBRICANTS +1

Formula of pattern material prepared from paraffin and stearic acid

InactiveCN103382307AImprovement ingredientsImprove reusabilityFoundry moulding apparatusParaffin waxInvestment casting

The invention belongs to the field of investment casting, and specifically relates to a formula of a pattern material prepared from paraffin and stearic acid. The mass ratio of 56# semi-refined paraffin wax to first-grade triple pressed stearic acid is 1:0.95-1.05; the mass ratio of a recycled paraffin which contains no saponifiable matter to first-grade triple pressed stearic acid is 1.2:0.75-0.85. A mixture of semi-refined paraffin wax and stearic acid is prepared according to the mass ratio, and is added into clear water; a heating temperature is controlled at 75 to 90 DEG C, and the temperature is strictly prohibited from exceeding 90 DEG C. According to the formula, volume contraction and linear contraction of a casting are controlled in a dimensional tolerance range of the casting that is permitted, demoulding efficiency and surface quality of the casting are increased, and production cost is reduced.

Owner:JIANGSU BIAOXIN KUBOTA IND

Casting alcohol-based coating

InactiveCN108817311AGood viscosityHigh viscosityFoundry mouldsFoundry coresLeveling effectMetallurgy

The invention discloses a casting alcohol-based coating which comprises, by weight, 10-25 parts of a refractory aggregate, 50-60 parts of a carrier, 2-7 parts of a binder, 10-15 parts of a suspensionagent, and 8-49 parts of additives. The casting alcohol-based coating has high viscosity, brush-ability, anti-sagging effect, leveling effect, permeability, suspensibility, coatability and thixotropy.

Owner:江苏赫芝电气有限公司

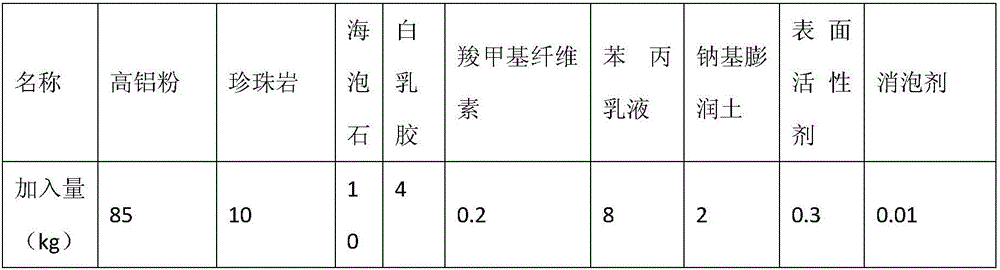

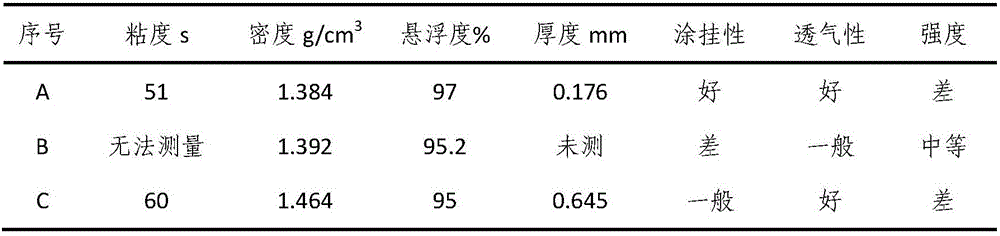

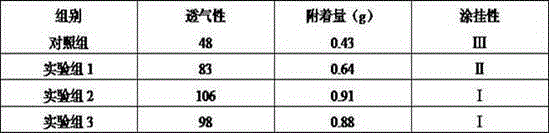

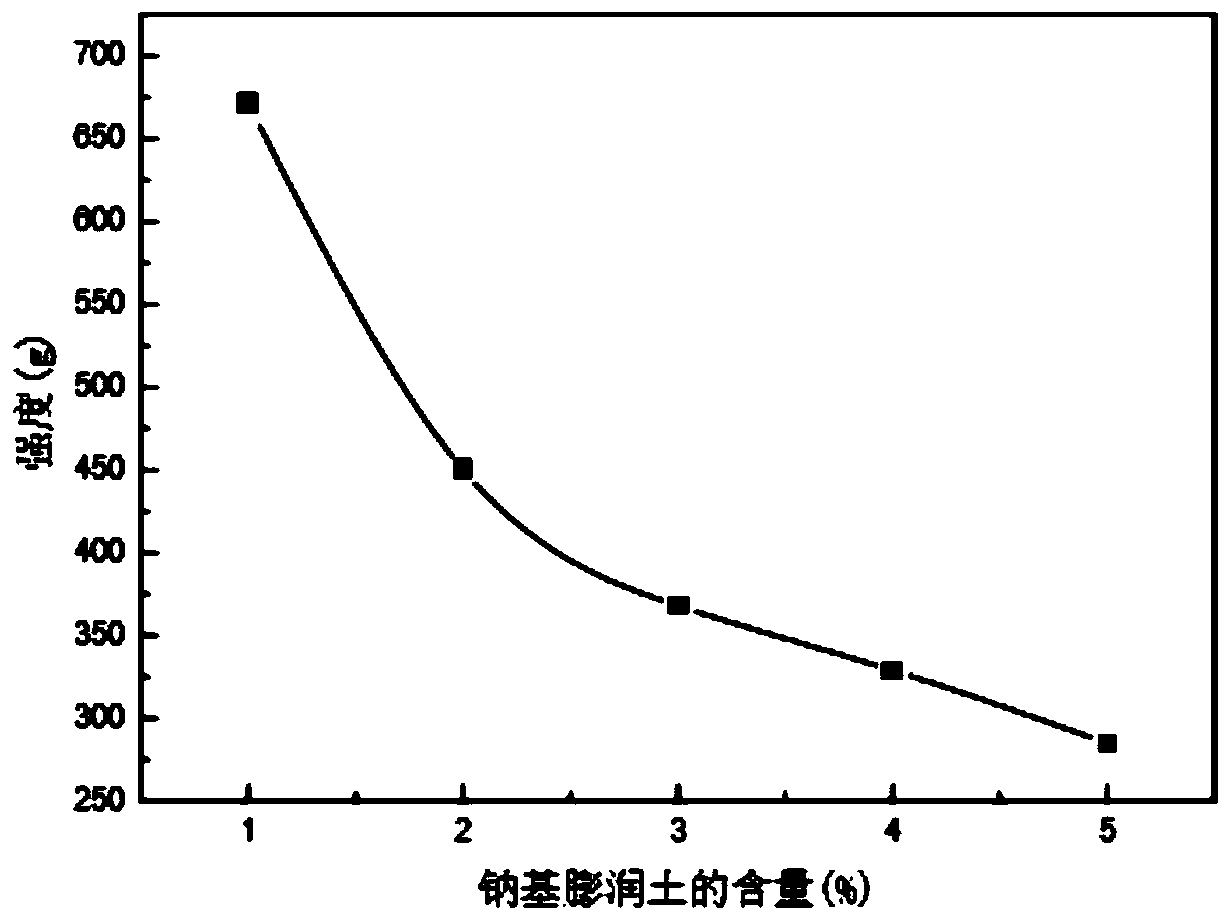

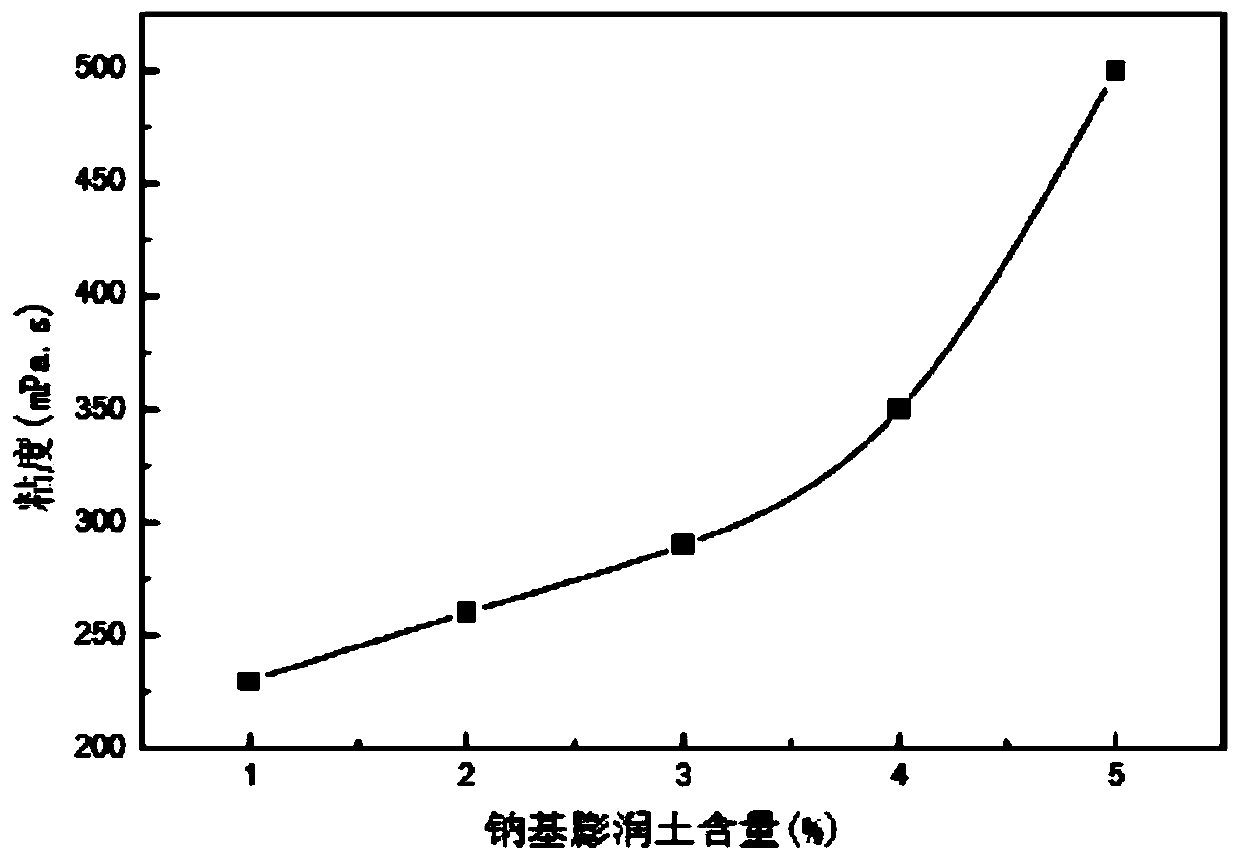

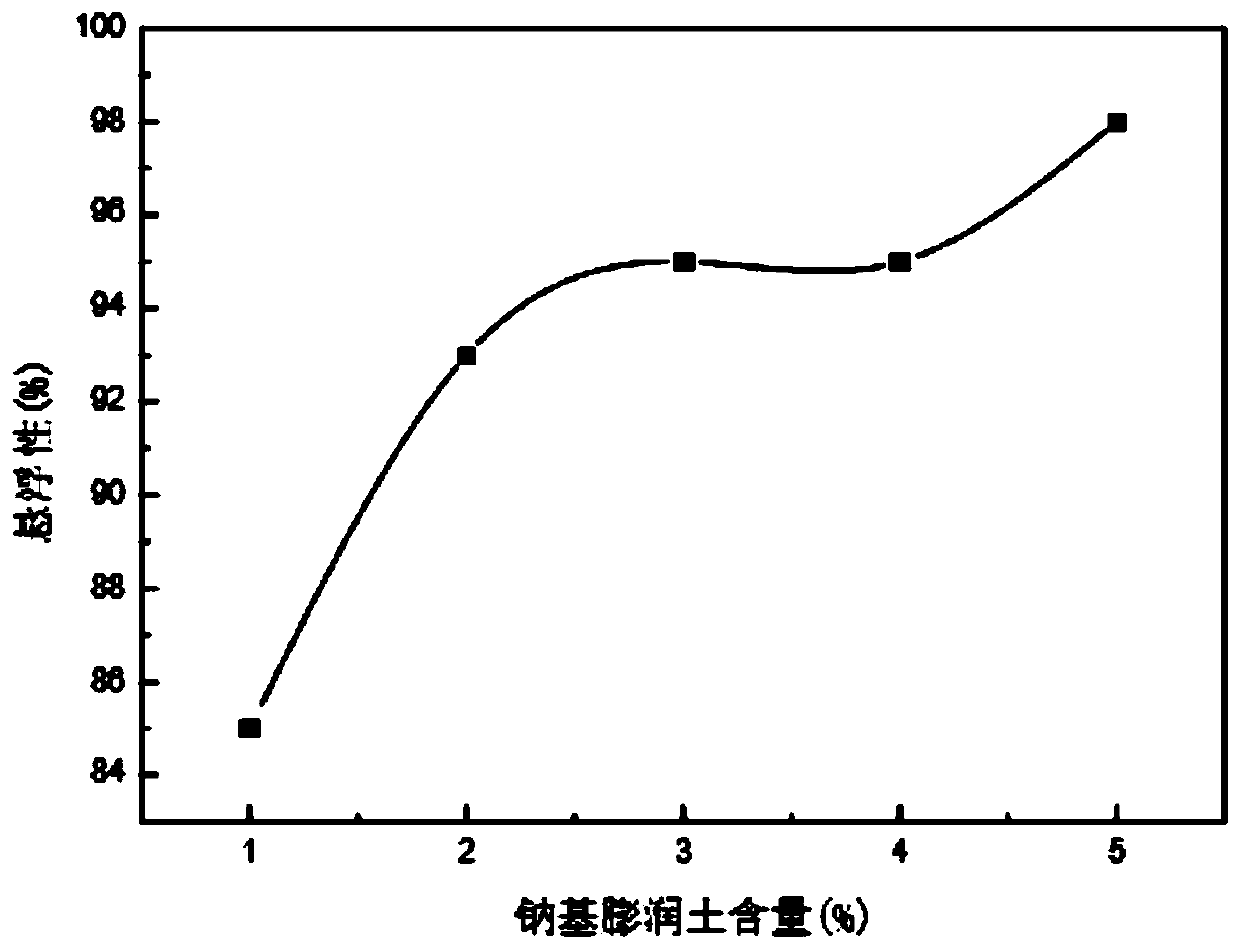

Cast-iron evaporative pattern coating and preparation method thereof

The invention provides a cast-iron evaporative pattern coating and a preparation method thereof. The cast-iron evaporative pattern coating comprises 84 to 88 parts of high aluminum powder, 8 to 12 parts of perlite, 8 to 12 parts of sepiolite, 6 to 10 parts of styrene-acrylic emulsion, 2 to 3 parts of sodium bentonite, 2 to 5 parts of white latex, 0.1 to 0.4 part of carboxymethylcellulose, 0.2 to 0.6 part of additive, and 105 to 120 parts of water. The coating of the invention has the advantages of uniformity and smoothness and good air permeability, and is easy to overcome the problems that the casting is easy to spray back and the local carbon is deficient, and the strength is high under the high temperature condition, which can eliminate the sticky sand and the collapse of the casting surface.

Owner:桃江新兴管件有限责任公司

Fire-proof coating used for die casting

InactiveCN105328114AImprove breathabilityImprove wettabilityFoundry mouldsFoundry coresPolyvinyl alcoholSodium phosphates

The invention relates to a fire-proof coating used for die casting. The fire-proof coating is prepared from bauxite, quartz powder, corundum powder, kieselguhr, talcum powder, cryolite, CMC, polyvinyl alcohol, water glass and sodium phosphate. The fire-proof coating is suitable for evaporative pattern casting, is high in breathability, and has the beneficial effects of having good wettability and adhesivity and being resistant to high temperature, good in coating performance, easy to dry, and the like.

Owner:广西博白县三田机械制造有限公司

Alcohol-based paint for sand casting and preparation method thereof

InactiveCN102873267BImprove high temperature strengthImprove high temperature stabilityFoundry mouldsFoundry coresSodium BentonitePolyvinyl alcohol

The invention discloses an alcohol-based paint for sand casting and a preparation method thereof. The density of the paint is 1200-1400 kg / m<3>, and the paint is composed of solutes and an organic solvent, wherein the organic solvent is one of methanol, ethanol and isopropanol or a mixture thereof; and the solutes include the following components in percentage by weight: 60-75% of alumina, 1-5% of attapulgite, 0.5-1.5% of sodium bentonite, 2-10% of amorphous graphite, 3-15% of lamellar graphite, 2-10% of iron red, 1-5% of polyvinyl butyral, 0.1-0.5% of surfactant, 0.1-0.5% of dispersant and 1-5% of hydrochloric acid solution. The alcohol-based paint is simple in preparation process, high in stability and easy to store.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Formula of cleaning agent of wax mould

InactiveCN1793308AStable washingGood hangabilitySurface-active detergent compositionsDetergent compounding agentsWaxOrganic solvent

The invention relates to dried model cleaning agent, especially for its formula in casting technique. Its technical proposal is as follows: its component amounts by weight are as follows: pure water 800-1000, sodium nitrite 8-10, and polyethenoxy ether 1. Its advantages are that it can clean organic matter surface; and it is nontoxic, stable, and has good coating effect.

Owner:东营恒诚机械有限公司

Evanescent mold coating for producing automobile coverage piece die and preparing method and application method of evanescent mold coating

The invention discloses an evanescent mold coating for producing an automobile coverage piece die and a preparing method and an application method of the evanescent mold coating. The evanescent mold coating for producing the automobile coverage piece die comprises the following raw materials including bauxite, quartz powder, silica sol, sodium bentonite, white emulsion, ZnO, KMnO4, organic bentonite, organic short fiber, CMC, iron oxide, polyoxyethylene ether, n-caprylic alcohol, formalin and water. The provided evanescent mold coating for producing the automobile coverage piece die has good high temperature resistance, breathability, wettability, adhesion, coating hanging performance, sintering performance and peeling performance, the formed coating is small in gas volume and high in drying speed, and when the evanescent mold coating is used for automobile coverage piece die producing, the obtained die is smooth in surface, and air holes, sand burning and other defects are overcome.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

3D printing sand mold water-based dip coating and preparation method thereof

InactiveCN108971419AImprove corrosion resistanceIncrease impactFoundry mouldsFoundry coresWater basedPreservative

The invention relates to the technical field of 3D printing sand casting, in particular to a 3D printing sand mold water-based dip coating and a preparation method thereof. The 3D printing sand mold water-based dip coating is prepared from the following components in percentage by weight: 50 to 75% of composite refractory aggregate, 3 to 6% of composite suspending agent, 0.8 to 1.2% of composite binder, 0.1 to 0.5% of penetrant, 0.2 to 0.6% of leveling agent, 0.05 to 0.2% of DL-T201 preservative, 2 to 5% of flux, 0.1 to 0.3% of defoamer, and 25 to 38% of water. The invention also discloses a preparation method of the 3D printing sand mold water-based dip coating. The coating has excellent performance, excellent coating property, proper permeability, good leveling property, high suspensionstability, suitable coating thickness, good sintering peeling property and superior anti-sticking property. Compared with conventional coatings, the coating can be applied only once by dip coating. The penetration depth and coating thickness can meet the requirements. After drying, the coating strength is very high. No flow mark, no dripping, and no accumulation exist.

Owner:贵阳灵峰铸造材料有限公司

Low-voltage extraction switchgear and anti-corrosion technology thereof

InactiveCN106654957AImprove bonded stateGood hangabilitySwitchgear with withdrawable carriageAnti-corrosive paintsRare-earth elementMetallurgy

The invention discloses a low-voltage extraction switchgear. The low-voltage extraction switchgear comprises, by mass, 3 to 6% of Zn, 1 to 1.5% of Mo, 1 to 1.2% of Ti, 0.02 to 0.03% of N , 8 to 11% of Cr, 0.01 to 0.03% of C, 0.5 to 0.7% of Mn, 0.3 to 0.6% of Nb, 0.7 to 0.9% of Mg, 0.3 to 0.4% of Cu, 0.5 to 0.7% of W, 0.3 to 0.5% of Si, 0.025 to 0.030% of P, 0.008 to 0.010% of S and 0.1 to 0.3% of rare earth elements. The balance is Fe and unavoidable impurities. The invention further relates to the anti-corrosion technology of the low-voltage extraction switchgear. The anti-corrosion technology is simple and practicable. The anti-corrosion performance of the switchgear can be effectively improved. The service life is prolonged. The cost is reduced.

Owner:SUZHOU NIUDONG PRECISION MFG TECH CO LTD

Coating for lost foam casting of engine cylinder blocks and preparing method thereof

The invention discloses a coating for lost foam casting of engine cylinder blocks and a preparing method thereof, belongs to the technical field of lost foam coating, and aims to provide a lost foam coating with fine coating property, fine breathability and high strength and a preparing method thereof. The technical scheme includes that the coating for lost foam casting of engine cylinder blocks is prepared by the following raw materials: by weight part, 100 parts of quartz sand powder, 5-10 parts of sodium bentonite, 0.1-1 part of cellulose, 5-15 parts of resin, 0.01-0.08 part of tween, 0.02-0.1 part of octanol, 1-5 parts of flour and 60-90 parts of pure water. The coating for lost foam casting of engine cylinder blocks and the preparing method thereof can be applied to various of lost foam casting fields in the prior art widely.

Owner:山西华尔动力机械有限公司

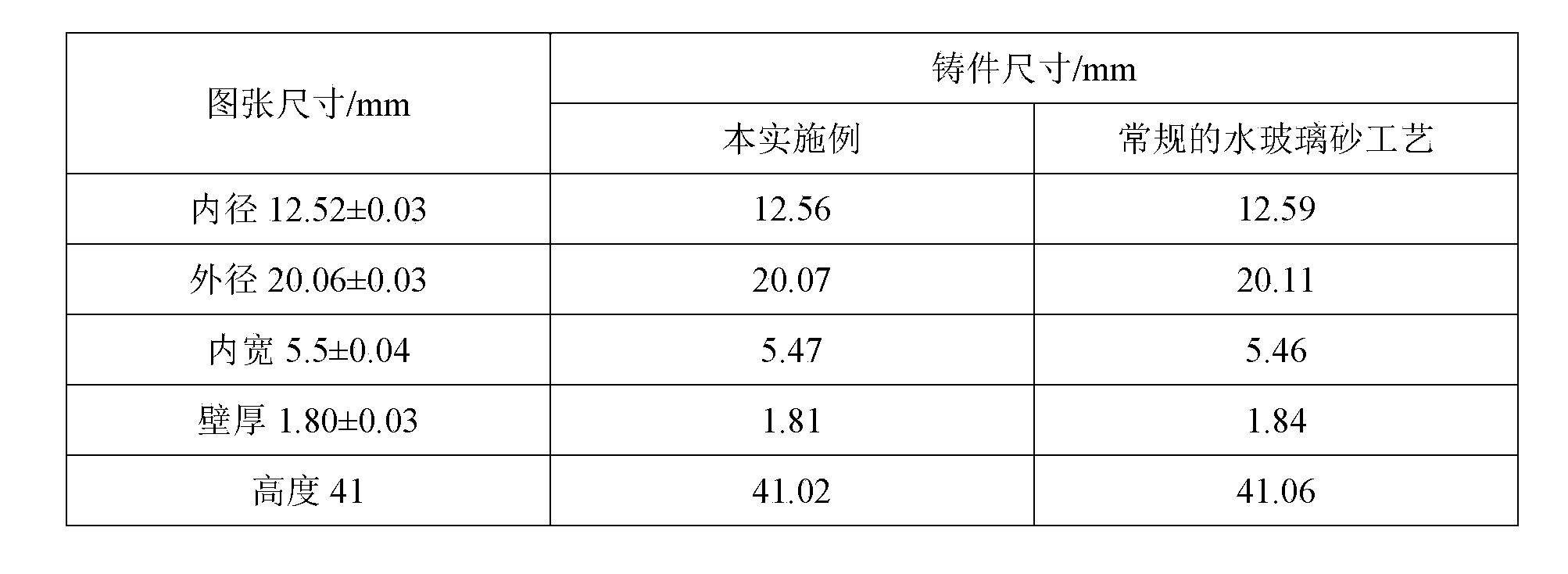

Novel water glass sand shell making technique for investment casting

InactiveCN103350192AGood miscibilityGood collapsibilityFoundry mouldsFoundry coresSurface layerInvestment casting

The invention discloses a novel water glass sand shell making technique for investment casting. The novel water glass sand shell making technique comprises the following steps: (1) smearing a surface layer; (2) smearing a transition layer; (3) smearing a third layer. The conventional water glass sand shell making technique is improved, special powder for precision casting and refining quartz sand are adopted, water glass and the special powder for precision casting are good in intersolubility, sizing agent flows smoothly, investment spreading mass is uniformly attached, the searing performance is good, and the stuccoing operability is good. The shell collapsibility after pouring is good, the surface roughness R of the casting is smaller than or equal to 6.3, and the surface quality and the dimensional accuracy of the casting are good.

Owner:TIANCHANG TIANXIANG GRP

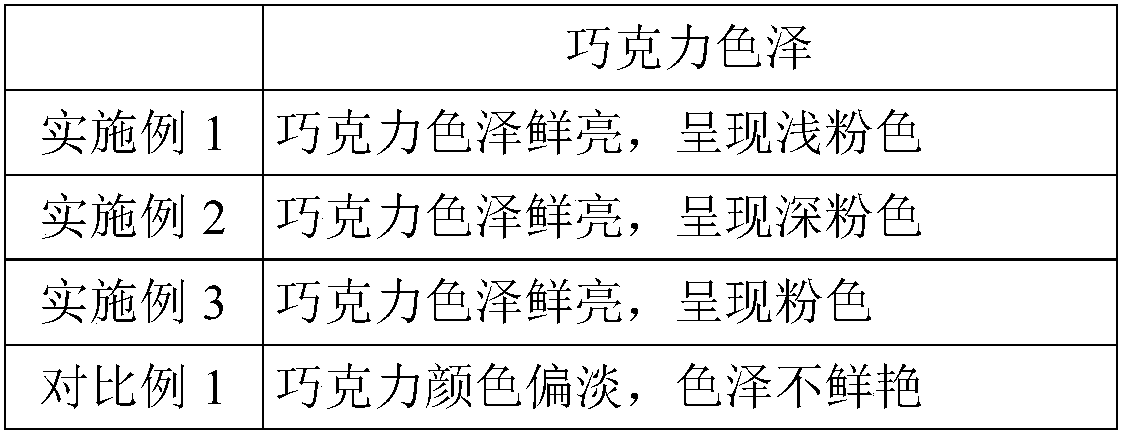

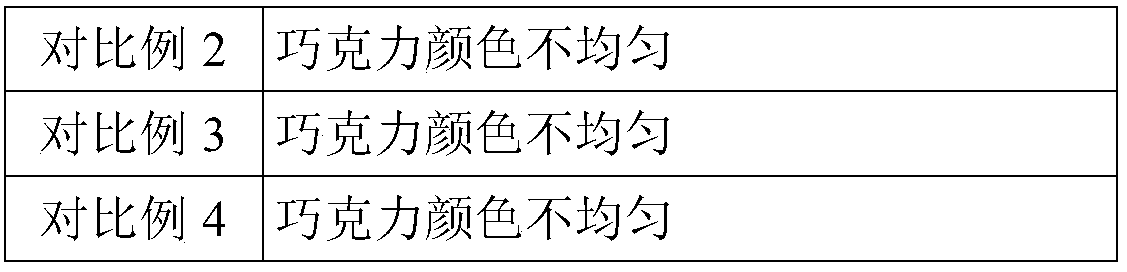

Coating chocolate added with beet juice powder and used for frozen drinks

PendingCN110574818AEvenly dispersedUniform colorFood ingredient as colourFrozen sweetsButter cocoaSugar

The invention provides coating chocolate added with beet juice powder and used for frozen drinks. Raw materials of the coating chocolate include (by weight): 330-400 parts of white granulated sugar, 130-170 parts of milk powder, 120-160 parts of cocoa mass, 40-60 parts of natural anhydrous butter, 260-300 parts of cocoa butter, 1-3 parts of lecithin and 1-10 parts of beet juice powder. According to the technical scheme, the beet juice powder can be uniformly dispersed in chocolate, so that a chocolate coating is uniform and bright in color, the due taste of externally coated chocolate is not influenced, the coating amount of the chocolate can be effectively controlled, and an ideal coating effect is achieved.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com