Evanescent mold coating for producing automobile coverage piece die and preparing method and application method of evanescent mold coating

A technology for automotive panels and lost foam, applied in coatings, manufacturing tools, casting and molding equipment, etc., can solve the problems of high temperature resistance, coating hangability and poor leveling of lost foam coatings, and achieve rich sources and good air permeability The effect of high temperature resistance and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

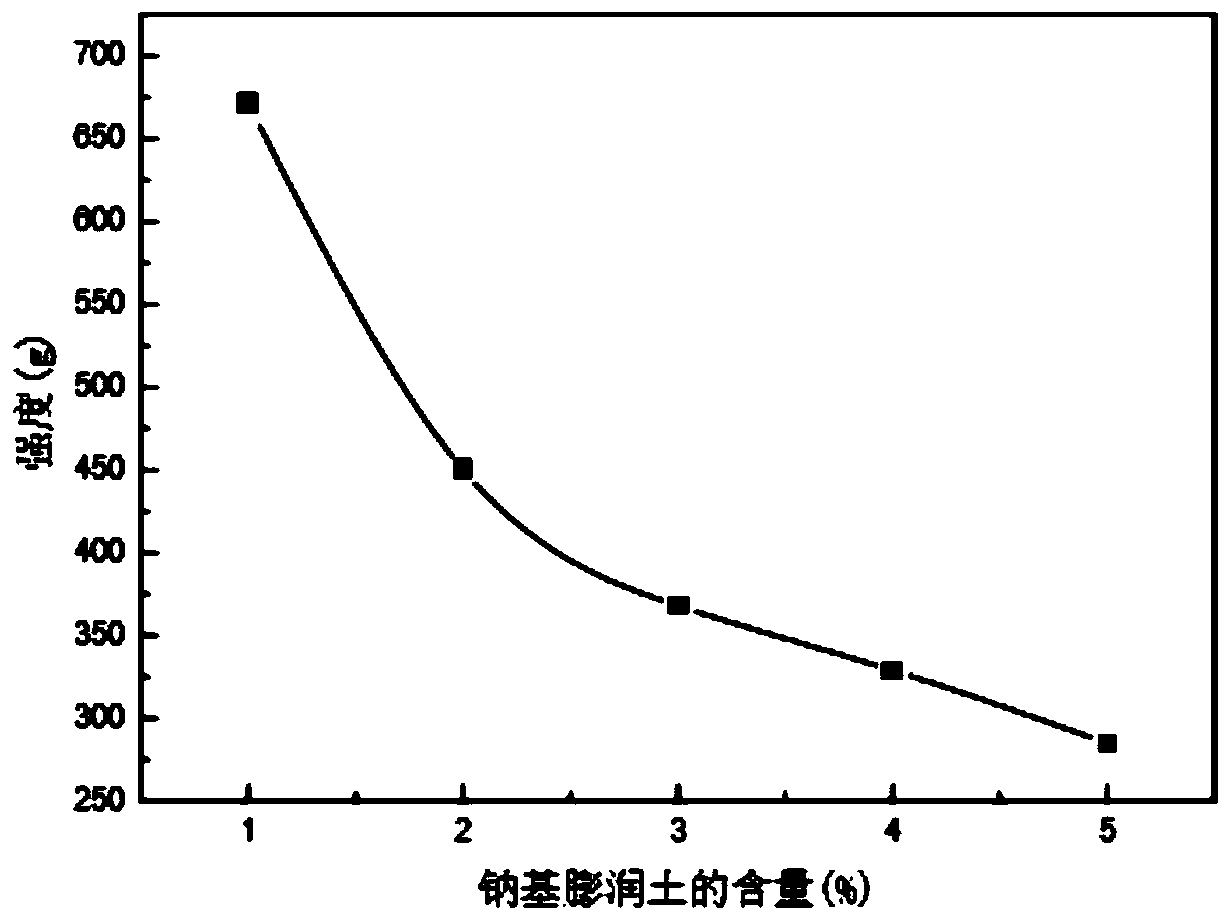

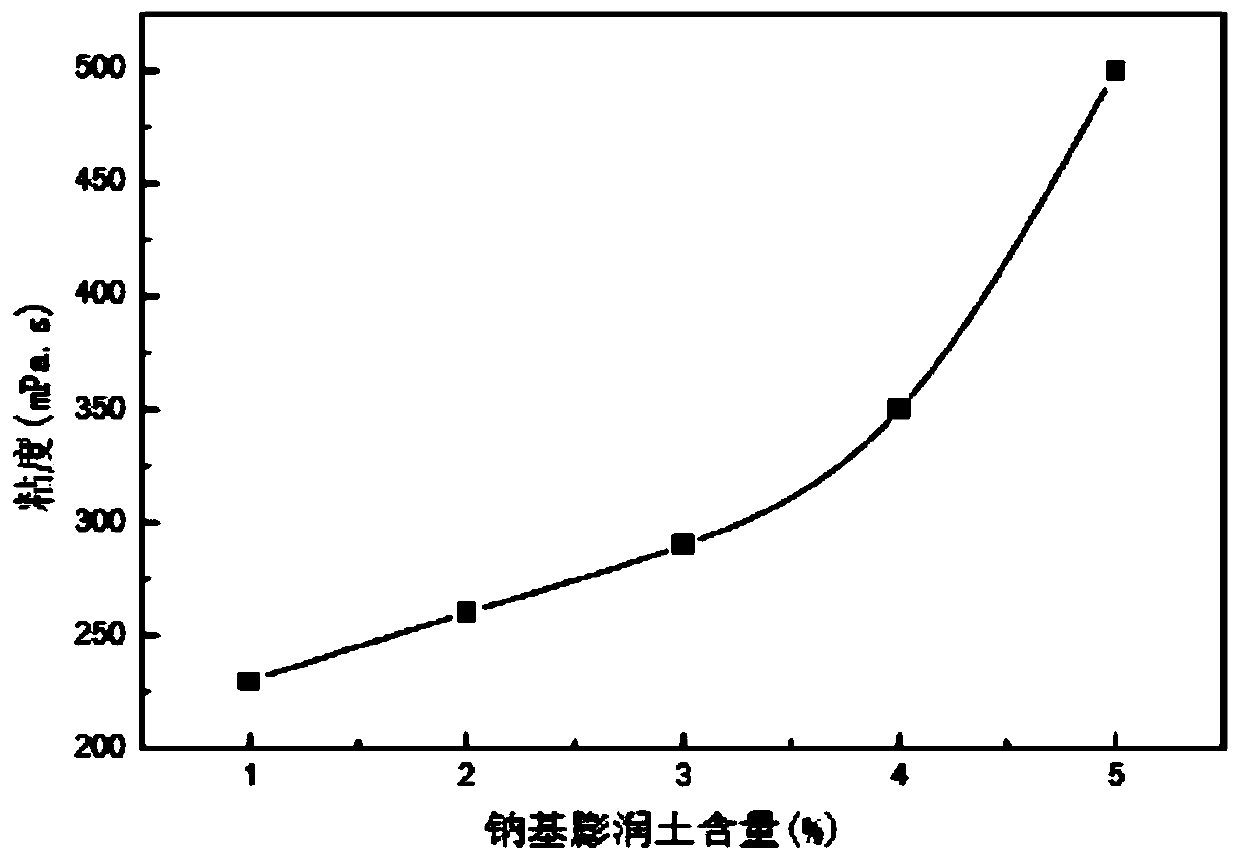

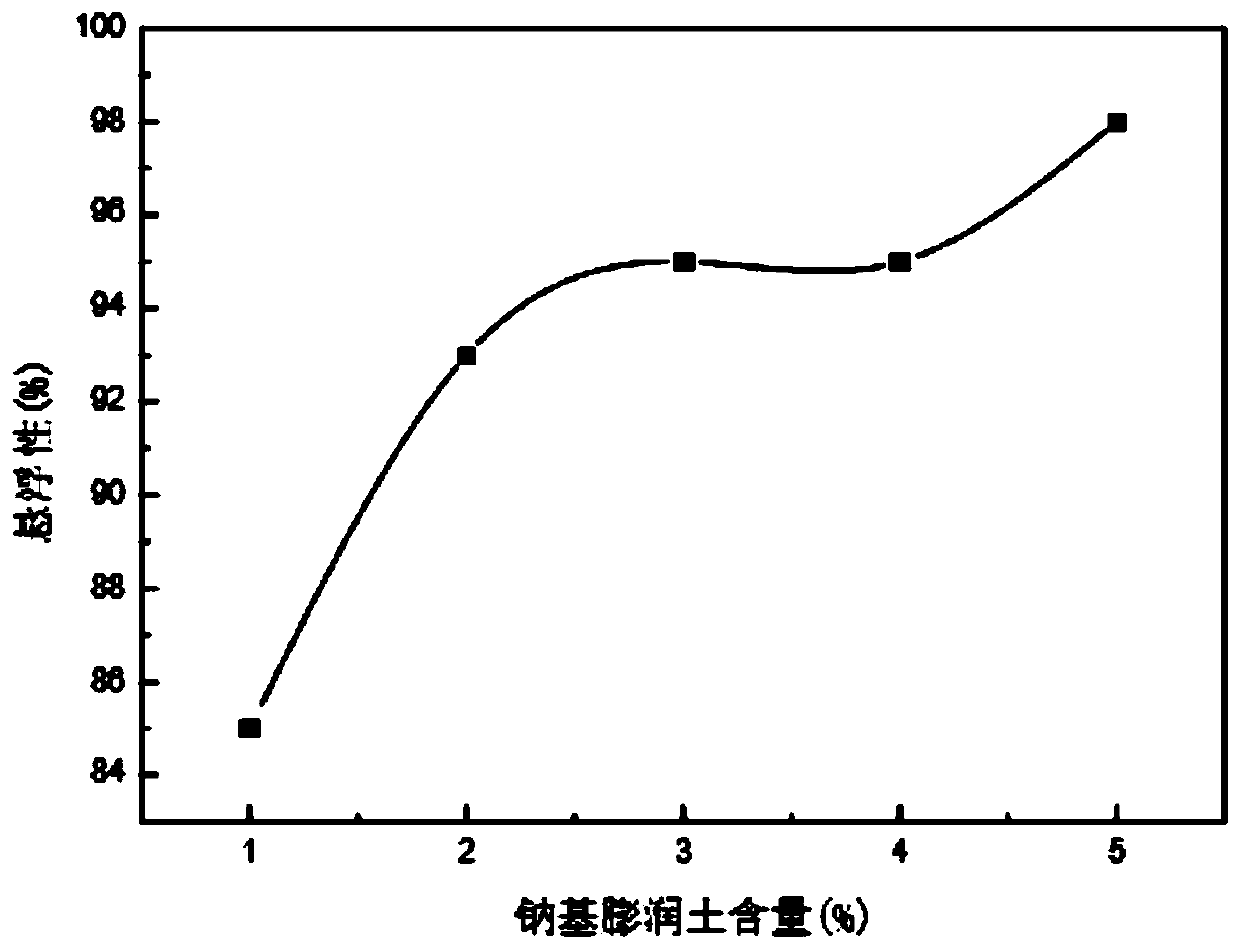

[0027] A kind of lost-foam coating used for producing automobile panel molds, comprising the following raw materials in percentage by weight: bauxite 50.94%, quartz powder 35%, silica sol 1.5%, sodium bentonite 3%, white latex 1.2%, ZnO 1.6 %, KMnO 4 0.5%, organic bentonite 1%, organic short fiber 0.6%, CMC 1.5%, iron oxide 3.0%, polyoxyethylene ether 0.1%, n-octanol 0.02%, formaldehyde aqueous solution 0.04%; -90% water as solvent.

[0028] The preparation method of the lost foam coating for the production of automobile panel molds is as follows: adding the raw materials of the formulation amount except bauxite and quartz powder into the water, stirring and mixing evenly, adding the formulation amount of bauxite, Quartz powder, stir and mix evenly, adjust the viscosity of the system to 22-26Pa.s, the lost foam coating for the production of automobile panel molds can be obtained, the Baume degree of the obtained coating is in the range of 65-68Be, and the density At 1.60-1.6...

Embodiment 2

[0030] A lost-foam coating for producing automobile panel molds, comprising the following raw materials in weight percent: bauxite 51%, quartz powder 34%, silica sol 2.3%, sodium bentonite 2%, white latex 1.3%, ZnO2. 26%, KMnO 4 0.5%, organic bentonite 1.2%, organic short fiber 0.7%, CMC 1.5%, iron oxide 3.0%, polyoxyethylene ether 0.2%, n-octanol 0.02%, formaldehyde aqueous solution 0.02%; -90% water as solvent.

[0031] The preparation method of the lost foam coating for the production of automobile panel molds is as follows: adding the raw materials of the formulation amount except bauxite and quartz powder into the water, stirring and mixing evenly, adding the formulation amount of bauxite, Quartz powder, stir and mix evenly, adjust the viscosity of the system to 22-26Pa.s, the lost foam coating for the production of automobile panel molds can be obtained, the Baume degree of the obtained coating is in the range of 65-68Be, and the density At 1.60-1.67g.cm 3 In the rang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com