Method for producing alkali-free glass fiber by albite serving as fluxible clarifying agent

A technology of alkali-free glass fiber and albite, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of affecting the uniformity of batch materials, mixed powder transportation, high price, easy moisture absorption and agglomeration, etc., to reduce industrial Production difficulty, small crystallization ability, and the effect of reducing production difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

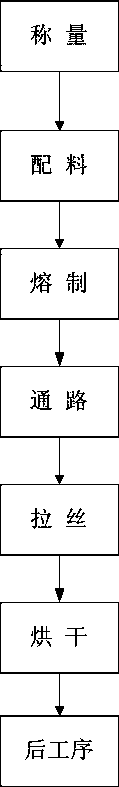

Method used

Image

Examples

Embodiment 1

[0029] To produce 100kg of alkali-free glass fiber, the amount of raw materials required is: kaolin: 10kg, of which: SiO 2 ≥44.0%, Al 2 o 3 ≥37.5%, Fe 2 o 3 ≤0.6%, H 2 O≤1%; pyrophyllite: 45kg, of which: SiO 2 ≥72%, Al 2 o 3 ≥16.5%, Fe 2 o 3 ≤0.45%, H 2 O≤1%; quicklime: 20㎏, of which: CaO≥85%, Fe 2 o 3 ≤0.15%, MgO≤3%, H 2 O≤1%; Dolomite: 9.5㎏, of which CaO≥30%, Fe 2 o 3 ≤0.15%, MgO≤21.0%, H 2 O≤1%; Colemanite: 8㎏, of which CaO≥27.5%, Fe 2 o 3 ≤0.10%, B 2 o 3 ≥38.0%, SiO 2 ≤6.5%, H 2 O≤1%; leucoporite: 20kg, of which SiO 2 ≥80.0%, Al 2 o 3 ≥10.0%, Fe 2 o 3 ≤0.50%, H 2 O≤1%; Fluorite: 3㎏, of which: CaF 2 ≥90%, H 2 O≤1%; Albite: 3.5㎏, of which: SiO 2 ≥69.0%, Al 2 o 3 ≥17.0%, Fe 2 o 3 ≤0.35%, Na 2O≥8.5%, H 2 O≤1%; the above percentages are mass percentages.

[0030] Before weighing, the composition content of CaO in quicklime should be detected every day, and the lime ratio should be adjusted according to the content of its composition.

[0031...

Embodiment 2

[0044] To produce 100kg of alkali-free glass fiber, the amount of raw materials required is: kaolin: 15kg, of which: SiO 2 ≥44.0%, Al 2 o 3 ≥37.5%, Fe 2 o 3 ≤0.6%, H 2 O≤1%; pyrophyllite: 36㎏, of which: SiO 2 ≥72%, Al 2 o 3 ≥16.5%, Fe 2 o 3 ≤0.45%, H 2 O≤1%; quicklime: 22㎏, of which: CaO≥85%, Fe 2 o 3 ≤0.15%, MgO≤3%, H 2 O≤1%; dolomite: 10kg, of which CaO≥30%, Fe 2 o 3 ≤0.15%, MgO≤21.0%, H 2 O≤1%; Colemanite: 8㎏, of which CaO≥27.5%, Fe 2 o 3 ≤0.10%, B 2 o 3 ≥38.0%, SiO 2 ≤6.5%, H 2 O≤1%; leucoporite: 25kg, of which SiO 2 ≥80.0%, Al 2 o 3 ≥10.0%, Fe 2 o 3 ≤0.50%, H 2 O≤1%; Fluorite: 2.6㎏, of which: CaF 2 ≥90%, H 2 O≤1%; Albite: 2.5㎏, of which: SiO 2 ≥69.0%, Al 2 o 3 ≥17.0%, Fe 2 o 3 ≤0.35%, Na 2 O≥8.5%, H 2 O≤1%; the above percentages are mass percentages.

[0045] Before weighing, the composition content of CaO in quicklime should be detected every day, and the lime ratio should be adjusted according to the content of its composition.

[00...

Embodiment 3

[0059] To produce 100kg of alkali-free glass fiber, the amount of raw materials required is: kaolin: 9.2kg, of which: SiO 2 ≥44.0%, Al 2 o 3 ≥37.5%, Fe 2 o 3 ≤0.6%, H 2 O≤1%; pyrophyllite: 46.4㎏, of which: SiO 2 ≥72.0%, Al 2 o 3 ≥16.5%, Fe 2 o 3 ≤0.45%, H 2 O≤1%; quicklime: 19.0㎏, of which: CaO≥85.0%, Fe 2 o 3 ≤0.15%, MgO≤3%, H 2 O≤1%; Dolomite: 8.2㎏, of which CaO≥30%, Fe 2 o 3 ≤0.15%, MgO≤21.0%, H 2 O≤1%; Colemanite: 9.0㎏, of which CaO≥27.5%, Fe 2 o 3 ≤0.10%, B 2 o 3 ≥38.0%, SiO 2 ≤6.5%, H 2 O≤1%; leucoporite: 16.8㎏, of which SiO 2 ≥80%, Al 2 o 3 ≥10%, Fe 2 o 3 ≤0.50%, H 2 O≤1%; Fluorite: 2.7㎏, of which: CaF 2 ≥90.0%, H 2 O≤1%; Albite: 2.5㎏, of which: SiO 2 ≥69.0%, Al 2 o 3 ≥17.0%, Fe 2 o 3 ≤0.35%, Na 2 O≥8.5%, H 2 O≤1%; the above percentages are mass percentages.

[0060] Before weighing, the composition content of CaO in quicklime should be detected every day, and the lime ratio should be adjusted according to the content of its compositi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com