Patents

Literature

46results about How to "Low refractoriness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature glaze coating, preparation method thereof, binder and using method of coating

The invention discloses a high-temperature glaze coating, a preparation method thereof, a binder and a using method of the coating, and aims at solving the problems of poor high-temperature resistance, low emissivity and absorptivity in a high-temperature zone, instability, and easiness of attenuation of the existing far-infrared energy-saving coating. The high-temperature glaze coating has the characteristics of good radiation heat transfer effect, high external blackness (the emissivity is greater than 0.95) and the like, and has the advantages of stable emissivity and absorptivity, non-attenuation performance and long service life in a long-term use process. Meanwhile, the coating can be tightly combined with a basal body by matching with the binder disclosed by the invention; the adhesive force is increased; a glazed ceramic polymer can be formed on the basal body after high-temperature sintering; the high-temperature glaze coating has the advantages of hardness, abrasive resistance, and long service life, and does not fall off; and the coating disclosed by the invention can also evenly coat the surface which cannot be covered by general coatings.

Owner:四川科达节能技术有限公司

Preparation method of ceramic bond for low-temperature high-strength cubic boron nitride (CBN) grinding tool

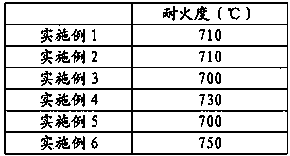

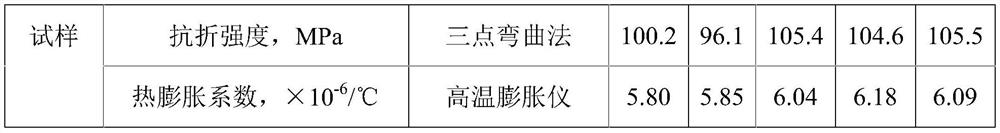

The invention discloses a preparation method of ceramic bond for a low-temperature high-strength cubic boron nitride (CBN) grinding tool, which comprises the following steps: evenly mixing 35-75% of a, 2-15% of b, 5-20% of c and 5-25% of d by weight percent, grounding and sieving, melting at 1200-1400 DEG C for 1-6h, carrying out water quench, drying, secondary grinding and secondary sieving to obtain basic ceramic bond, and evenly mixing the obtained basic ceramic bond with nano oxide the weight of which accounts for 0.2-15% of that of the basic ceramic bond to obtain the ceramic bond of theinvention, wherein the a is silica or silicon dioxide, the b is aluminum hydroxide or aluminum oxide, the c is anhydrous sodium carbonate or sodium oxide, and the d is boric acid or boron trioxide. Through adding nano oxide to the basic ceramic bond, the refractoriness of the basic ceramic bond is reduced by 10-50 DEG C, the fluidity is improved by 5-25%, and the breaking strength is improved by 5-45%.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Ceramic bond, preparation method thereof and manufacturing method of ceramic bond grinding tool

ActiveCN103624696ALow refractorinessHigh strengthAbrasion apparatusGrinding devicesLithium carbonateSilicon dioxide

The invention relates to a ceramic bond with low refractoriness and high strength. The ceramic bond comprises the following components in percentage by weight: 25%-45% of silicon dioxide, 15%-25% of ultrafine silicon dioxide with the particle size of not more than 5 microns, 14%-20% of sodium tetraborate, 8%-13% of aluminum oxide, 4%-8% of lithium carbonate, 5%-10% of zinc oxide, 1%-2% of magnesium oxide, 0%-1% of barium carbonate and 3%-5% of titanium oxide. As the ultrafine silicon dioxide is introduced into the component, the strength of the ceramic bond is improved and the refractoriness is simultaneously reduced. In addition, the invention further provides a preparation method of the ceramic bond and a method for manufacturing a ceramic bond grinding tool by utilizing the ceramic bond.

Owner:ZHUHAI JUXIN TECH DEV

Red mudstone porous granular-ceramics filter material and method for preparing same

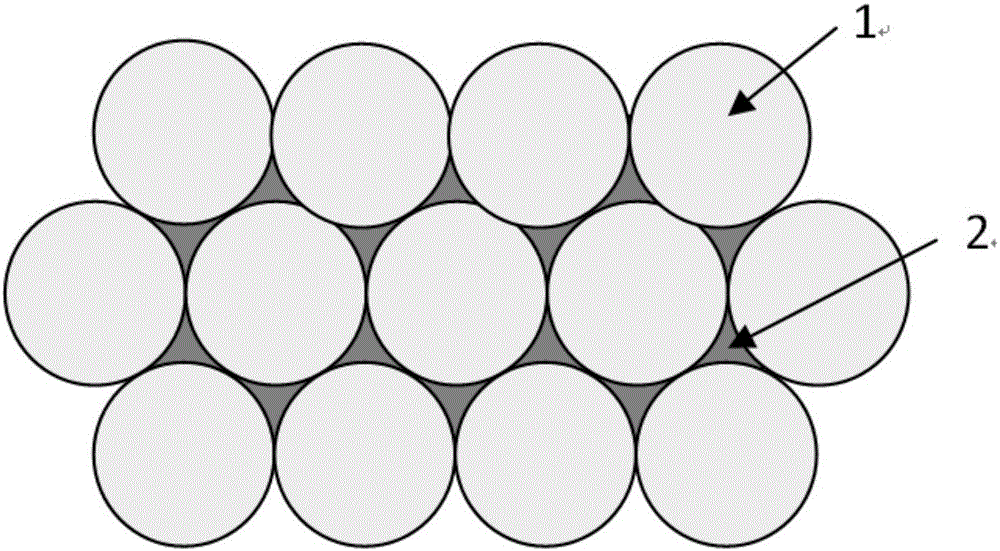

InactiveCN1883746AUniform distribution of poresSimple production processFiltration separationCeramicwareCeramicPulverised fuel ash

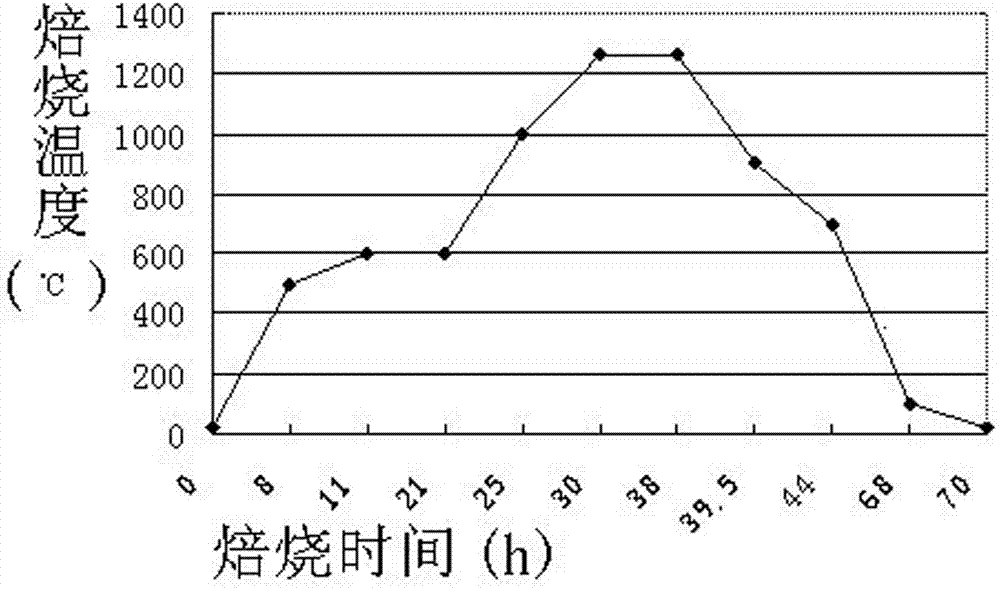

Light spherical ceramsite filter materials and their preparation method characterized in that red mudstone and fly ash is used as main materials, slight pore-forming agent is doped therein, wherein red mudstone in 40-70% by weight, fly ash in 28-55% by weight, and pore-forming agent in 1-5% by weight, and the products are given by grinding, mixing, palletizing to forming spherical particles with 3-10mm diameter and by dry prebraking for 10-20 min at a temperature of 300-500 DEG C., and by calcining for 10-30 min at a temperature of 1050-1180 DEG C. The products can be provided with evenly porousness, and by simply process.

Owner:NANCHANG UNIV

Ceramic and metal composite binding agent, preparation method and diamond grinding wheel

ActiveCN105397648ALow refractorinessSmall coefficient of thermal expansionAbrasion apparatusPorosityThermal expansion

The invention discloses a ceramic and metal composite binding agent, a preparation method and a diamond grinding wheel. The binding agent is composed of, by weight, 35-40 parts of SiO2, 25-30 parts of H3BO3, 10-15 parts of Li2B4O7, 3-10 parts of AlF3, 2-6 parts of Na2S, 2-5 parts of Fe2N, 3-8 parts of Mg3N2, 2-6 parts of CaF2 and 15-20 parts of lead-tin alloy or nickel-titanium alloy. The binding agent not only has the advantages that the degree of fire resistance is low (as low as 650 DEG C), the thermal expansion coefficient is small (3.0-4.0*10-6 / DEG C), the strength is high (the bending strength reaches 150-220 Mpa), the porosity is adjustable, the self-sharpening performance is good and the chemical stability is good, but also has the excellent properties of high heat conductivity (20-50 W / m.K) and good toughness, is suitable for molding of the diamond grinding wheel, and better meets the requirements of modern precision grinding machining.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Steel ladle edge refractory castable

The invention provides a steel ladle edge refractory castable which comprises the following raw materials in percentage by mass: 40-60% of flint clay aggregate, 15-25% of used magnesia carbon bricks, 15-25% of high aluminium bauxite, 1-3% of cement, 1-2% of borax glass, 2-3% of spodumene, 3-4% of kyanite, 2-3% of silicon micro-powder, 1-2% of steel fiber and 1-2% of binding agent, wherein the binding agent comprises at least one of sodium tripolyphosphate, sodium hexametaphosphate and explosion-proof fiber. According to the steel ladle edge refractory castable provided by the invention, high strength, bonded slag resistance and an excellent anti-heat shock stability property are taken into consideration, and the using quality of the steel ladle edge material is greatly improved.

Owner:莱芜钢铁集团泰东实业有限公司

Dry powder lost foam casting coating

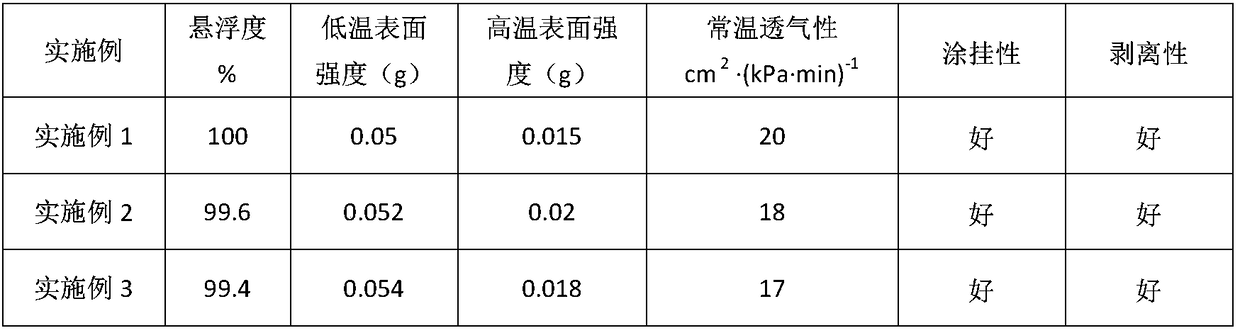

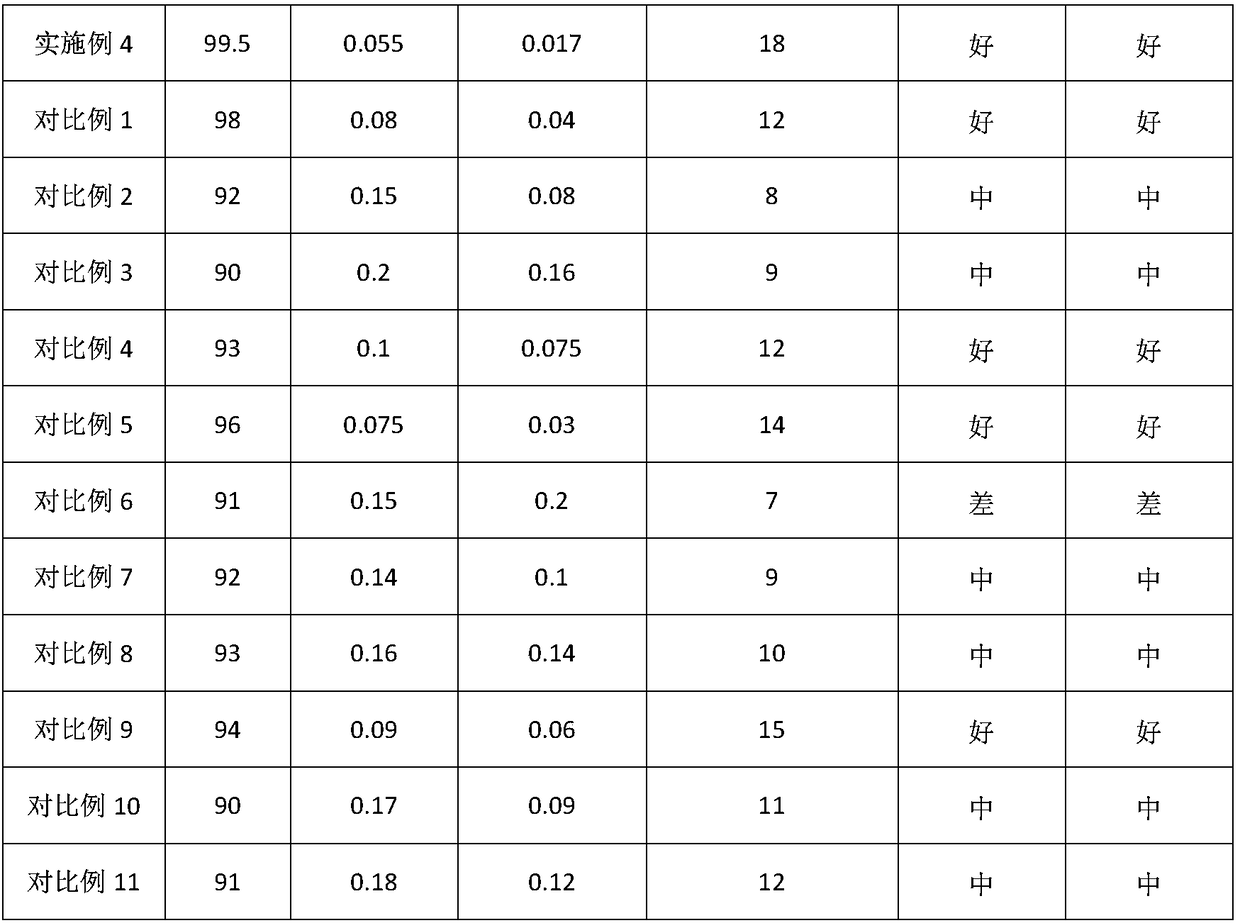

ActiveCN108296428AExtended shelf lifeDisperse fastFoundry mouldsFoundry coresPyrophosphateUltimate tensile strength

The invention discloses dry powder lost foam casting coating and a preparation method thereof. The dry powder lost foam casting coating is composed of following raw materials of, by weight, 70-76 parts of high aluminum powder, 15-19 parts of zircon powder, 7-9 parts of meerschaum, 1-3 parts of sodium bentonite, 0.6-1.5 parts of dispersing agents NNO, 1.2-3 parts of sodium pyrophosphate, 1.5-3 parts of yellow dextrin, 1-1.5 parts of potato powder, and 0.01-0.03 part of antifoaming agent. According to the obtained dry powder lost foam casting coating, the coating thickness is even, a coating isflat, the high-temperature strength is high, and the coating hanging performance is excellent.

Owner:桃江新兴管件有限责任公司

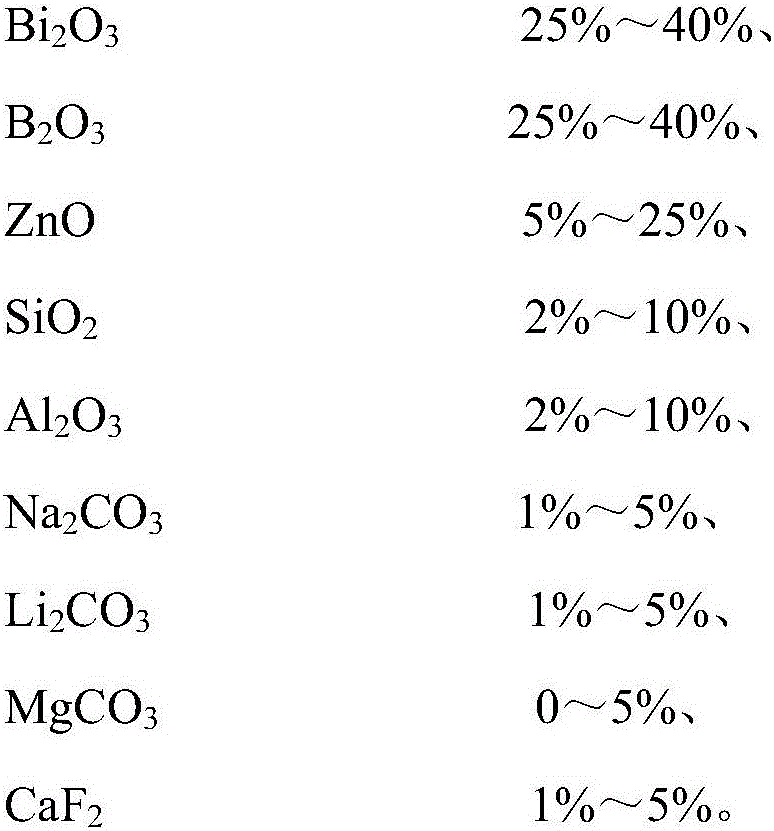

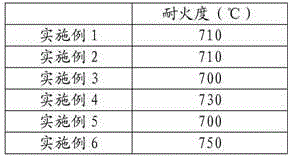

Additive raw material composite and additive for superhard material product, preparation method of additive, combined binder and superhard material product

ActiveCN106041759AEvenly dispersedReduced impact strengthAbrasion apparatusSuperhard materialMetal binding

The invention discloses an additive raw material composite and an additive for a superhard material product, a preparation method of the additive, a combined binder and the superhard material product. The raw material composite is composed of the following components including, by mass, 25%-40% of Bi2O3, 25%-40% of B2O3, 5%-25% of ZnO, 2%-10% of SiO2, 2%-10% of Al2O3, 1%-5% of Na2CO3, 1%-5% of Li2CO3, 0%-5% of MgCO3 and 1%-5% of CaF2. The additive prepared from the raw material composite has a microcrystal structure and is larger than 200 MPa in strength, the refractoriness of the additive is lower than 500 DEG C which is far lower than the sintering temperature of the metal binder superhard material product, the additive is uniformly dispersed and fine in structure among framework particles after sintering, the influence on the integral strength of the product is small, and accordingly, the grinding efficiency of the metal binder superhard material product can be remarkably improved and the service life of the metal binder superhard material product can be remarkably prolonged.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Lightweight high-strength ceramic particles manufactured by using urban sludge and manufacturing method for lightweight high-strength ceramic particles

InactiveCN102336580ALight weightHigh strengthSludge treatmentConstruction waste recoverySocial benefitsResource utilization

The invention belongs to the technical field of sludge reclaiming resource utilization, and in particular relates to lightweight high-strength ceramic particles manufactured by using urban sludge and a manufacturing method for the lightweight high-strength ceramic particles. The method comprises the following steps of: crushing 30 to 50 parts of building garbage to obtain crushed building garbage; and mixing the crushed building garbage, 40 to 60 parts of urban sludge and 40 to 60 parts of potassium feldspar powder uniformly, roasting the mixture for 20 to 120 minutes at the temperature of between 1,150 and 1,500 DEG C, cooling, and thus obtaining the lightweight high-strength ceramic particles. The urban sludge, the building garbage and the potassium feldspar powder are mixed in a certain ratio and coordinated, so that the strength of the lightweight high-strength ceramic particles reaches 60 to 120MPa, and the ceramic particles have more excellent physical and mechanical properties compared with common natural stones. According to the ceramic particles and the manufacturing method, wastes can be changed into valuable, environmental pollution is improved, and the innocent, reduction and recycle principles of Chinese solid waste treatment are met; and the invention has remarkable economic benefit and social benefit.

Owner:DONGGUAN BAOYUANDA REAL ESTATE DEV

High-temperature binder and preparation method thereof

The invention discloses a high-temperature ceramic binder and a preparation method thereof. The ceramic binder is composed of the following materials in parts by weight: 40-46 parts of SiO2, 35-45 parts of B2O3, 25-32 parts of TiO2, 5-10 parts of MgO, 8-15 parts of Li2O, 10-20 parts of CaCO3 and 2-8 parts of Na2O. By fully mixing all the raw materials in a ball mill, adding water, carrying out ball milling for 6-8 h, standing for 3-4 h, pouring out the water, drying at a temperature of 90-105 DEG C, and then carrying out ball milling and sieving the obtained product so as to prepare the ceramic binder. The ceramic binder prepared according to the invention has the characteristics of low refractoriness and high strength.

Owner:CHANGSHU HAIYU GRINDING WHEEL

Vitrified bond, preparation method and manufacturing method of vitrified bonded abrasive tool

ActiveCN103624696BLow refractorinessHigh strengthAbrasion apparatusGrinding devicesLithium carbonateSilicon dioxide

The invention relates to a ceramic bond with low refractoriness and high strength. The ceramic bond comprises the following components in percentage by weight: 25%-45% of silicon dioxide, 15%-25% of ultrafine silicon dioxide with the particle size of not more than 5 microns, 14%-20% of sodium tetraborate, 8%-13% of aluminum oxide, 4%-8% of lithium carbonate, 5%-10% of zinc oxide, 1%-2% of magnesium oxide, 0%-1% of barium carbonate and 3%-5% of titanium oxide. As the ultrafine silicon dioxide is introduced into the component, the strength of the ceramic bond is improved and the refractoriness is simultaneously reduced. In addition, the invention further provides a preparation method of the ceramic bond and a method for manufacturing a ceramic bond grinding tool by utilizing the ceramic bond.

Owner:ZHUHAI JUXIN TECH DEV

Alkali metal ceramic binding agent

The invention discloses an alkali metal ceramic binding agent. The alkali metal ceramic binding agent is composed of, by weight, 22 parts to 35 parts of TiO2, 26 parts to 31 parts of B2O3, 45 parts to 50 parts of Al2O3, 10 parts to 18 parts of SiO2, 6 parts to 10 parts of Fe2O3, 5 parts to 11 parts of KNO3, 3 parts to 7 parts of MgCO3 and 4 parts to 8 parts of CaCO3. All the raw materials are fully mixed in a ball mill, water is then added, ball milling is conducted for 6 hours to 8 hours, the mixture stands for 3 hours to 4 hours, water is poured out, drying is conducted at a temperature of 95 DEG C to 105 DEG C, and the ceramic binding agent is then prepared through ball milling and screening. Alkali metal such as Li2O, KNO3 and Na2CO3 is added to the alkali metal ceramic binding agent, the refractoriness of the ceramic binding agent is effectively lowered, and the service life of ceramic abrasive wheels is prolonged.

Owner:CHANGSHU HAIYU GRINDING WHEEL

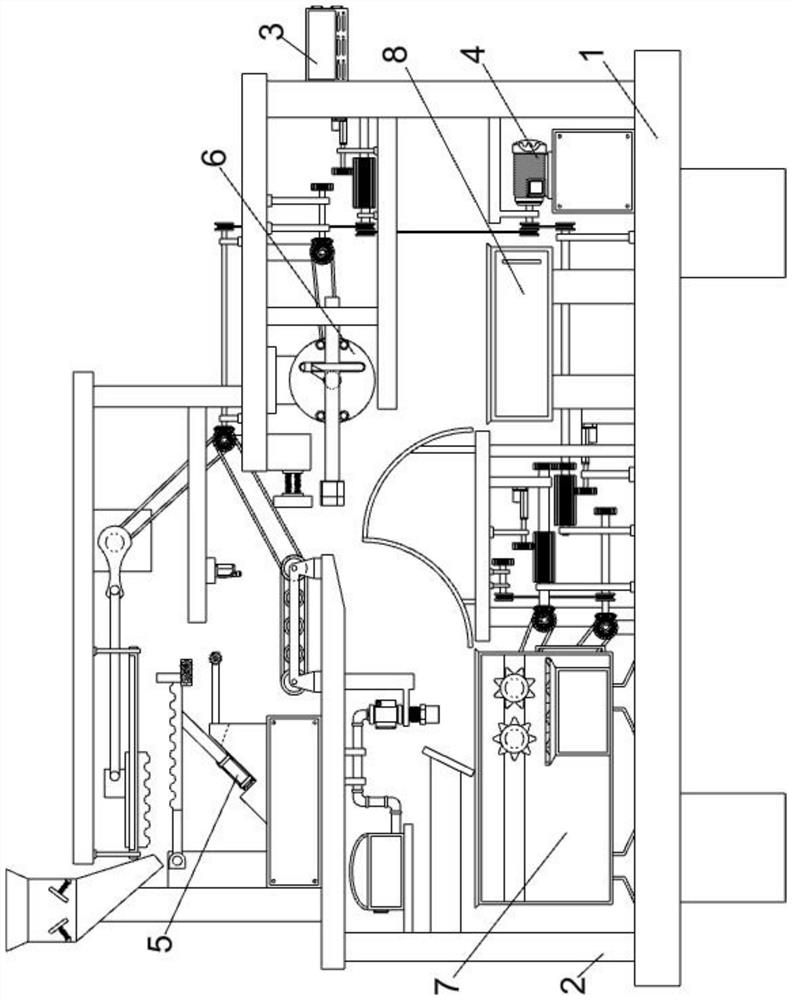

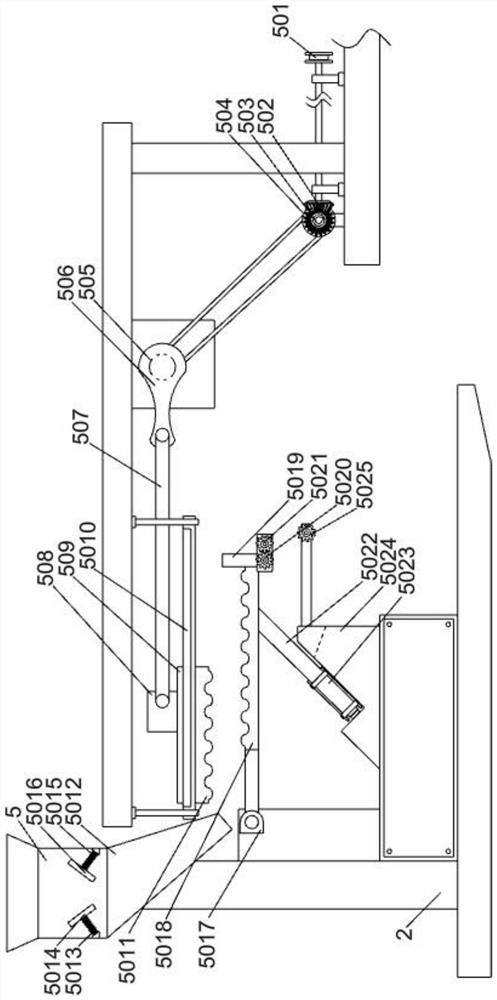

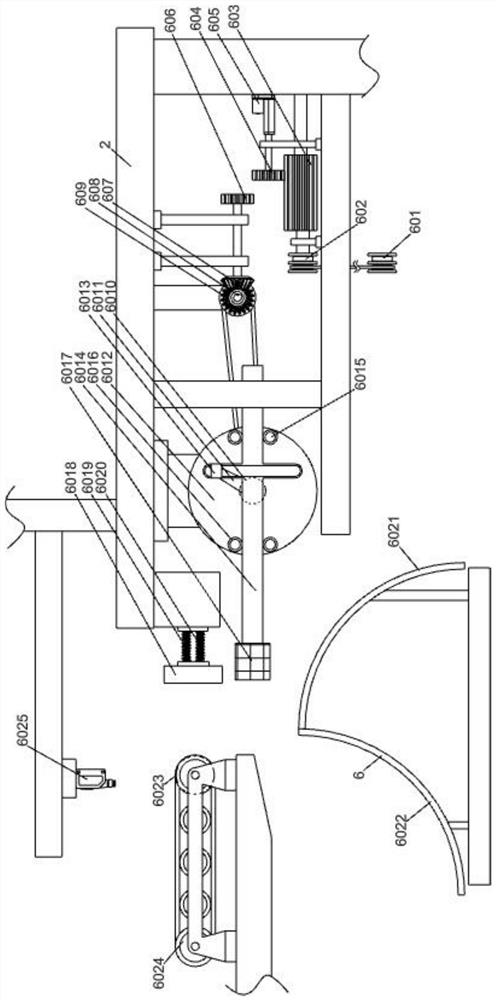

Silica processing pretreatment device

InactiveCN111843811ALow refractorinessIncrease costEdge grinding machinesPolishing machinesPhysical chemistryElectric machinery

The invention relates to the field of ore, in particular to a silica processing pretreatment device. The technical problem is to provide the silica processing pretreatment device. According to the technical scheme, the silica processing pretreatment device comprises a bottom frame, a supporting frame, a control display screen, a stepping motor, an edge grinding mechanism, a color system sorting mechanism, a film layer removing mechanism and a storage bin, wherein and the bottom frame is welded with the supporting frame. The device has the effects that the edge grinding treatment is carried outon silica with sharp edges and corners in advance, so that the abrasion to a machine during further processing is avoided; and meanwhile, machine chippings are mixed into silica raw materials, and the reddish-brown silica with iron oxide films is sorted out through color discrimination to be washed with acid liquor, so that the waste of a large amount of acid liquor and low treatment effect caused by treatment on all the silica raw materials are avoided, the removal of the iron oxide films is beneficial to further processing on the silica raw materials, and the quality of silica products is improved.

Owner:卢昌敏

Preparation method of hollow alumina ball thermal insulation refractory material

The invention which belongs to the technical field of refractory materials relates to a preparation method of a hollow alumina ball thermal insulation refractory material. The technical scheme of the preparation method is that the preparation method comprises the following steps: 1, adding an organic binder to hollow alumina balls, uniformly mixing, adding water, and stirring to make the surface of the hollow alumina balls be fully wet and adhered by the organic binder; 2, adding mixed powder of clay and alpha-Al2O3 micropowder, and uniformly mixing; and 3, drying the prepared formed product at 100-110DEG C, and carrying out thermal insulation sintering at 1550-1650DEG C. According to the invention, a mullite phase can be easily synthesized from clay and the alpha-Al2O3 micropowder, mullite has the characteristics of low thermal expansion rate, good thermal shock resistance, and good high temperature creep resistance, and the organic binder is adopted to effectively avoid the enrichment of impurities in clay in product drying and sintering processes, so the hollow alumina ball thermal insulation refractory material prepared through the method has the characteristics of uniform distribution of a small amount of the impurities, white appearance, good thermal shock resistance, low volume density, and low thermal conductivity.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

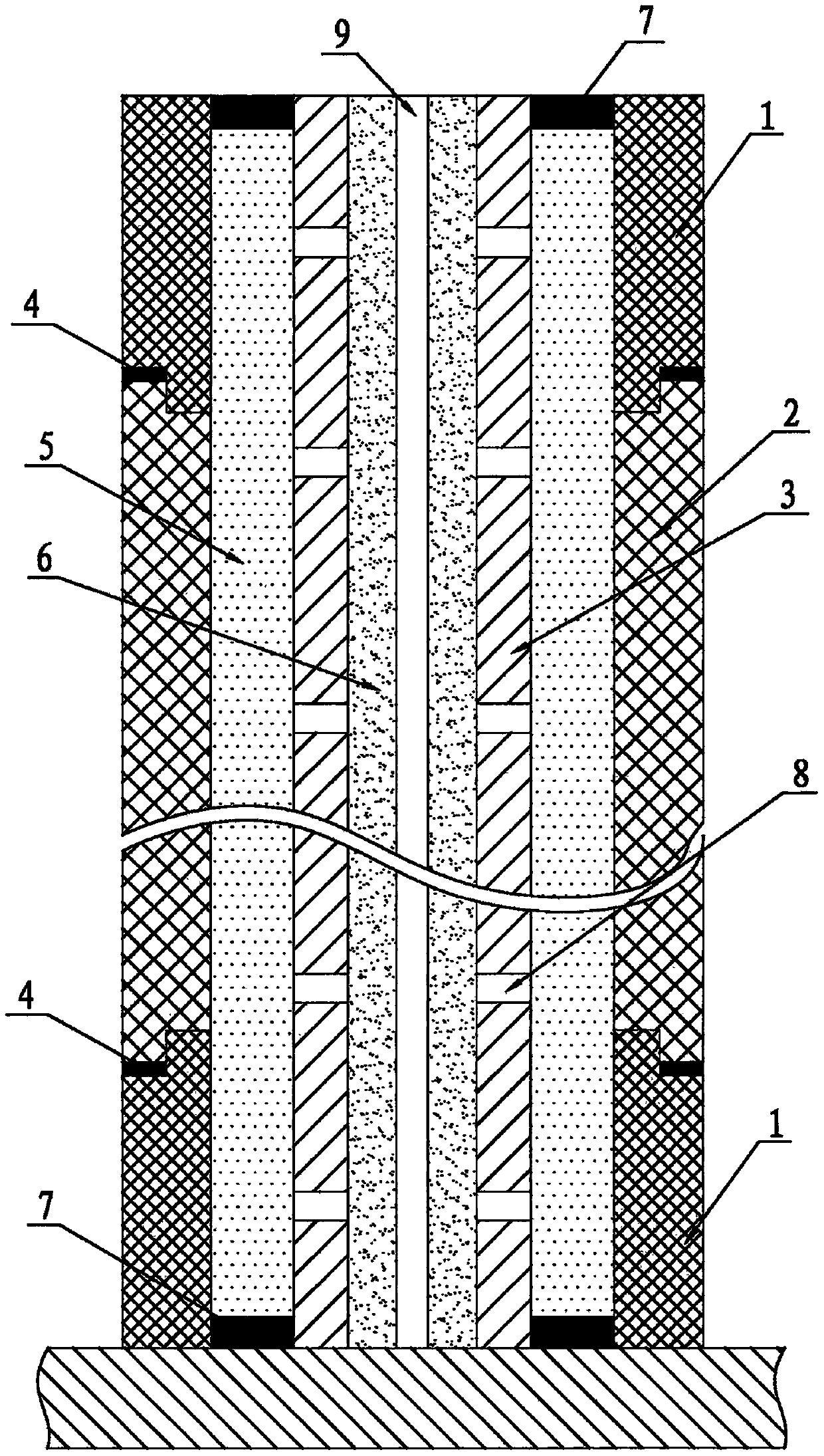

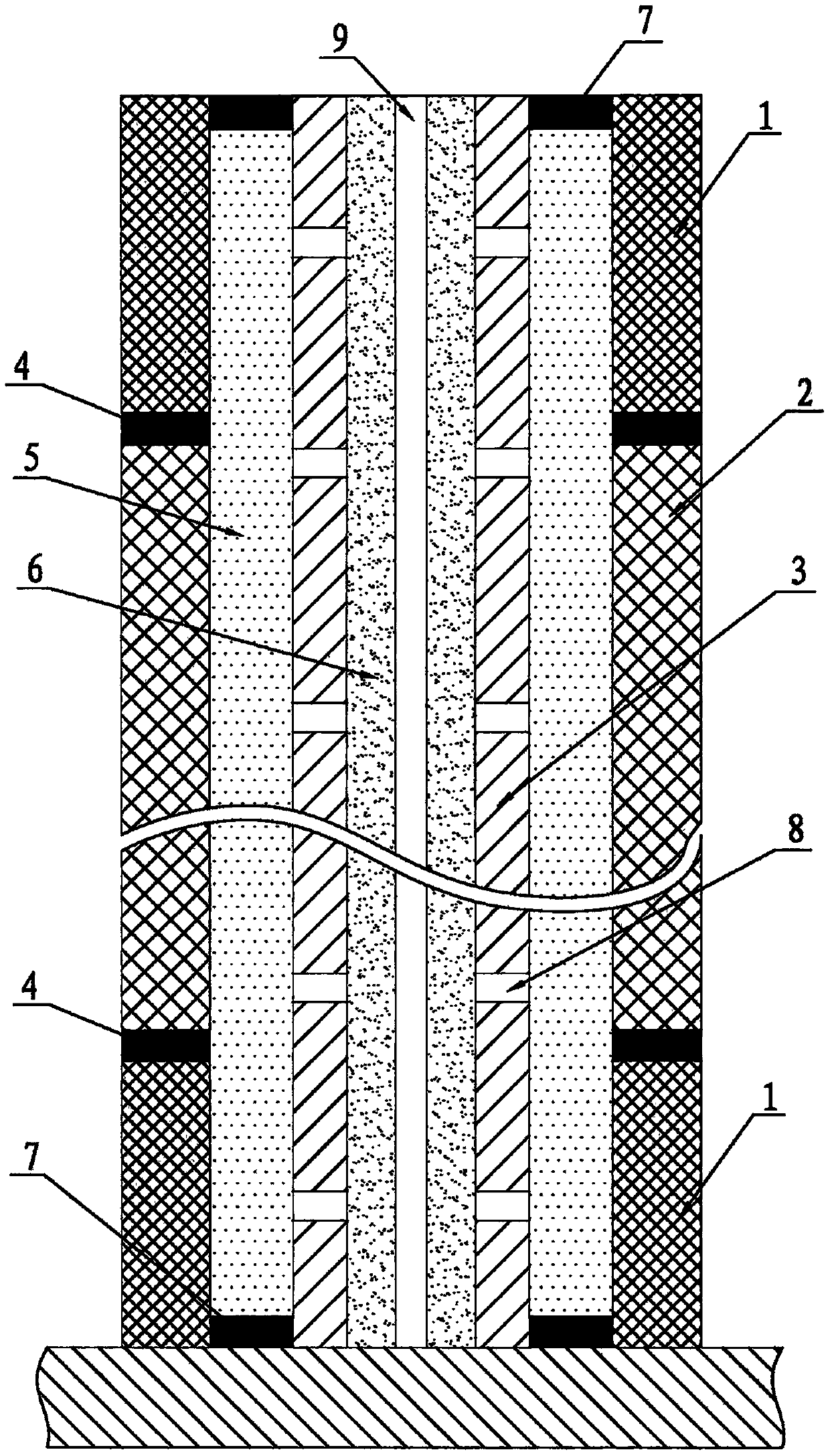

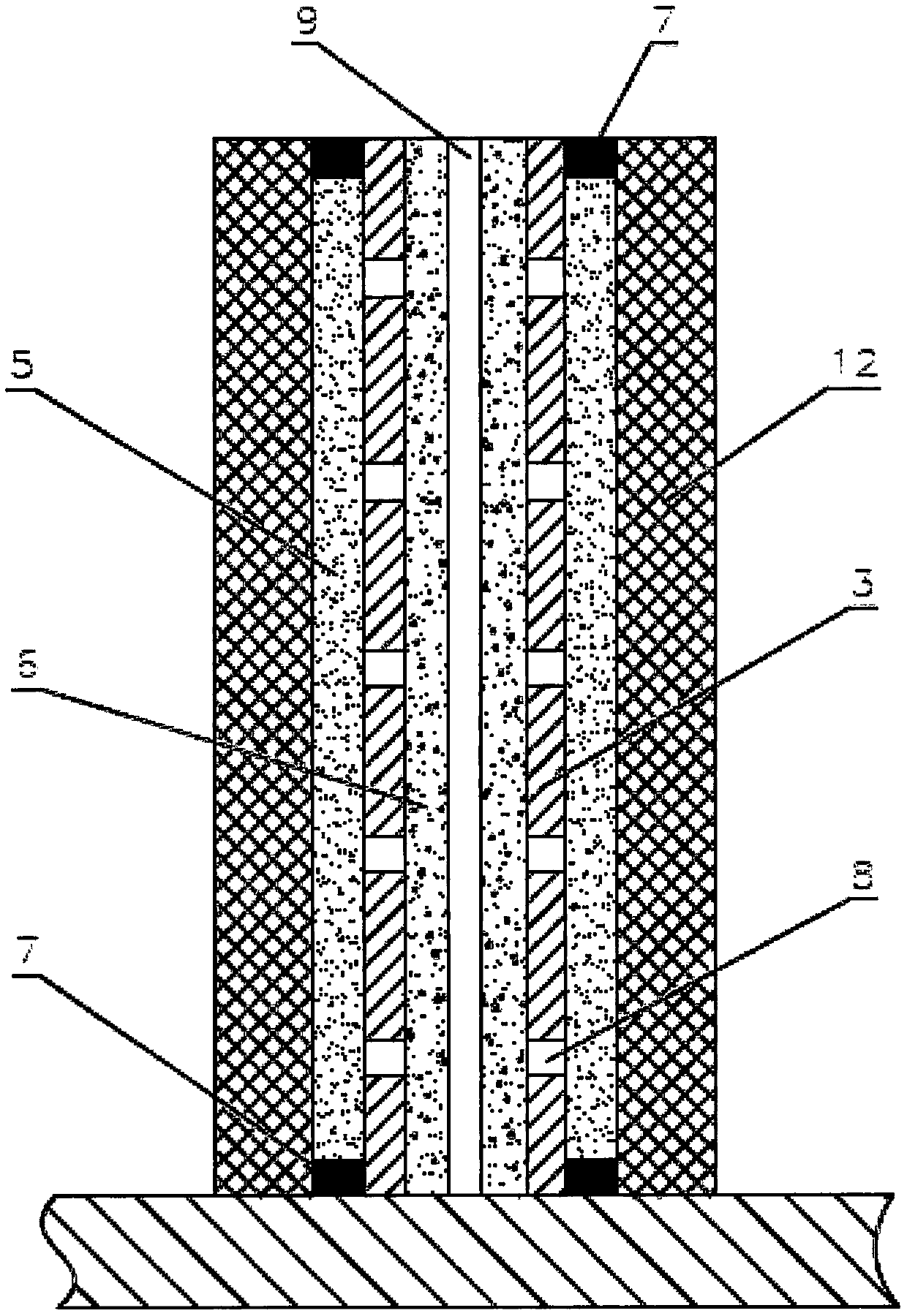

Casting long and thin hole forming sand core structure

InactiveCN109954838AGuarantee the shape qualityReduced dimensional accuracyFoundry mouldsFoundry coresButt jointSteel tube

The invention discloses a casting long and thin hole forming sand core structure. End portion fireproof casing pipes, a transition fireproof casing pipe, a process steel pipe, a casing pipe bonding resin layer, an outer sand core layer, an inner sand core layer and end face sealing layers are included. The transition fireproof casing pipe is arranged between the end portion fireproof casing pipes,the transition fireproof casing pipe and the end portion fireproof casing pipes are in butt joint through the casing pipe bonding resin layer to form a hollow fireproof casing pipe. The process steelpipe is coaxially arranged in an inner hole of the fireproof casing pipe. A ventilation hole is formed in a pipe body of the process steel pipe. The outer sand core layer is arranged between an innerhole of the process steel pipe and the inner hole of the fireproof casing pipe. The inner sand core layer is arranged in the inner hole of the process steel pipe. The end face sealing layers are arranged at the two ends of the outer sand core layer. An air outlet channel is arranged at the center of the inner sand core layer. According to a long and thin casting hole sand core of the structure, the defects that an ordinary sand core is low in surface fireproof degree and is prone to burning losses, burning through, washing damage or washing fracture through high-temperature molten iron can beeliminated, sand discharging and process steel pipe recycling and repeated usage are facilitated, the sand usage amount is small, and the casting cost is low.

Owner:KEHUA HLDG

Lightweight high-strength porcelain granule manufactured by utilizing paper mill sludge and manufacturing method thereof

ActiveCN102329146ALightweight and high bulk densityHigh strengthSludge treatmentConstruction waste recoverySocial benefitsResource utilization

The invention belongs to the technical field of sludge recovery and resource utilization and in particular relates to a lightweight high-strength porcelain granule manufactured by utilizing paper mill sludge and a manufacturing method thereof. The manufacturing method comprises the following steps: firstly grinding 30-50 parts of construction wastes to obtain ground construction wastes; and uniformly mixing the ground construction wastes with 50-60 parts of paper mill sludge and 40-60 parts of potassium feldspar powder, then roasting the mixture at 1150-1500 DEG C for 20-120 minutes and cooling the product to obtain the lightweight high-strength porcelain granule. According to the invention, by virtue of mixing the paper mill sludge, the construction wastes and the potassium feldspar powder in a certain proportion to give play to the synergistic actions among the materials, the strength of the manufactured lightweight high-strength porcelain granule is as high as 60-120MPa; the lightweight high-strength porcelain granule has better physical and mechanical properties than the common natural stones; and preparation method provided by the invention not only can be used for turning wastes into wealth, but also is beneficial to reduction of environmental pollution, conforms to the national harmlessness, quantitative reduction and resource principles in solid waste treatment and hasobvious economic and social benefits.

Owner:广东春天生态科技集团有限公司

Low-temperature ceramic bond and preparation method thereof

The invention discloses a low-temperature ceramic bond and a preparation method thereof. The ceramic bond is prepared from the following substances in parts by weight: 36-45 parts of SiO2, 23-33 parts of B2O3, 30-40 parts of Fe2O3, 2-8 parts of CaO, 7-10 parts of Li2CO3, 3-5 parts of KNO3 and 6-9 parts of Na2O. The preparation method comprises the following steps: sufficiently mixing all raw materials in a ball mill; adding water, carrying out ball milling for 10-15 hours, and standing for 3-4 hours; pouring the water out, and baking at 90-105 DEG C; and carrying out ball milling, and screening to prepare the ceramic bond. The prepared ceramic bond has the characteristics of low refractoriness and high strength.

Owner:CHANGSHU HAIYU GRINDING WHEEL

Light high-strength ceramic grains manufactured by utilizing pond sludge and manufacturing method thereof

The invention belongs to the technical field of sludge recycling, and particularly relates to light high-strength ceramic grains manufactured by utilizing pond sludge and a manufacturing method thereof. The manufacturing method comprises the following steps of: crushing 30 to 50 parts of building garbage to obtain building garbage crushed materials; and mixing the building garbage crushed materials, 30 to 40 parts of pond sludge and 40 to 60 parts of potash feldspar powder uniformly, roasting at the temperature of between 1,150 and 1,500 DEG C for 20 to 120 minutes, and cooling to obtain the light high-strength ceramic grains. In the method, the pond sludge, the building garbage and the potash feldspar powder are mixed in a certain ratio to play a synergetic role, so that the strength of the prepared light high-strength ceramic grains is 16 to 120 MPa, and the physical and mechanical properties are higher than those of the common natural stones. By the light high-strength ceramic grains, wastes can be changed into wealth, environmental pollution is easy to improve, and the principle of innocence, minimization and recycling of solid waste treatment in China is met, so the light high-strength ceramic grains have obvious economic and social benefits.

Owner:DONGGUAN BAOYUANDA REAL ESTATE DEV

Method for preventing crush of slag ladle when positioning furnace washing slag

ActiveCN103031403APrevent piercingDemonstrate technological progressManufacturing convertersSlagRotary furnace

The invention provides a method for preventing crush of a slag ladle when positioning furnace washing slag, which comprises the steps of: paving paint wasted by a tundish used by continuous casting steel at the bottom of the slag ladle, wherein the paved paint is 200-220 mm thick; then paving 800-820 kg of wasted oxidized steel slag of a rotary furnace, wherein the grain size of the steel slag is smaller than 100 mm; and carrying out slag positioning operation by using the slag ladle to effectively prevent damage caused by crush of the ladle when positioning furnace washing slag. The wasted paint used consists of 80% of powder and 20% of mixture of which the grain size is 30-50 mm.

Owner:XINJIANG BAYI IRON & STEEL

Ceramic bond and preparation method thereof

The invention discloses a ceramic bond and a preparation method thereof. The ceramic bond is prepared from the following substances in parts by weight: 20-30 parts of Na2O, 30-40 parts of B2O3, 45-50 parts of Al2O3, 15-30 parts of SiO2, 8-10 parts of Li2CO3, 1-5 parts of KNO3 and 5-10 parts of TiO2. The preparation method comprises the following steps: sufficiently mixing all raw materials in a ball mill; adding water, carrying out ball milling for 10-15 hours, and standing for 3-5 hours; pouring the water out, and baking at 90-110 DEG C; and carrying out ball milling, and screening to prepare the ceramic bond. The prepared ceramic bond has the characteristics of low refractoriness and high strength.

Owner:CHANGSHU HAIYU GRINDING WHEEL

Brick and manufacturing process thereof

The invention provides a brick. The brick mainly comprises plastic clay, quartz sand, wollastonite, feldspar, a toughening material, a ceramic pigment and the like. The brick can present complicated patterns, the colors and patterns of the brick are enriched, and the complicated beauty of Chinese blue-and-white is reproduced by utilizing the material of the clay brick to reproduce the skill of group fine work. In addition, the invention further relates to a manufacturing process of the brick, according to the process, a complicated pattern structure is divided into simple unit pieces, then the simple unit pieces are pressed and formed respectively, then the simple unit pieces are spliced into complicated patterns and fired, the preparation process of the complicated pattern structure is simplified, the requirement for the process technology is met, and the physical performance of the brick in the aspects of breaking strength and the like is improved.

Owner:汪强辉

High-strength ceramic bond and preparation method thereof

The invention discloses a high-strength ceramic bond and a preparation method thereof. The ceramic bond is composed of the following substances of, by weight, 1-3 parts of sodium pyrophosphate, 5-8 parts of borax, 2-3 parts of sodium silicate, 0.02-0.05 part of magnesium oxide, 1-2 parts of modified phenolic resin, 0.5-0.8 part of calcite, 0.2-0.4 part of barium sulfate and 0.1-0.5 part of calciumcarbonate. All raw materials are sufficiently mixed in a ball mill, then water is added, ball milling is conducted for 6-8 h, and then still standing is conducted for 3-4 h; and the water is poured out, drying is conducted under the condition of 95-105 DEG C, and then ball milling and sieving are conducted to prepared and obtain the ceramic bond. The prepared ceramic bond has the characteristicsof being low in fire resisting degree and high in strength.

Owner:房世俊

High-temperature ceramic bond and preparation method thereof

The invention discloses a high-temperature ceramic bond and a preparation method thereof. The high-temperature ceramic bond comprises the following substances in parts by weight: 2-6 parts of iron ore, 5-6 parts of zinc oxide, 5-10 parts of TiO2, 1-1.5 parts of MgO, 3-8 parts of clay, 1-3 parts of boron nitride, and 1-2 parts of barium oxide. The preparation method comprises the following steps: sufficiently mixing all the raw materials in a ball mill, adding water, performing ball milling for 6-8 h, then standing for 3-4 h, pouring water out, drying at the temperature of 90-105 DEG C, performing ball milling again, and sieving, thereby obtaining the high-temperature ceramic bond. The high-temperature ceramic bond prepared according to the preparation method has the characteristics of being low in degree of fire resistance and high in strength.

Owner:房世俊

Sol-gel preparation method of ceramic bonding agent

InactiveCN111975654AImprove stabilityEliminate concentration differencesAbrasion apparatusGel preparationEthylic acid

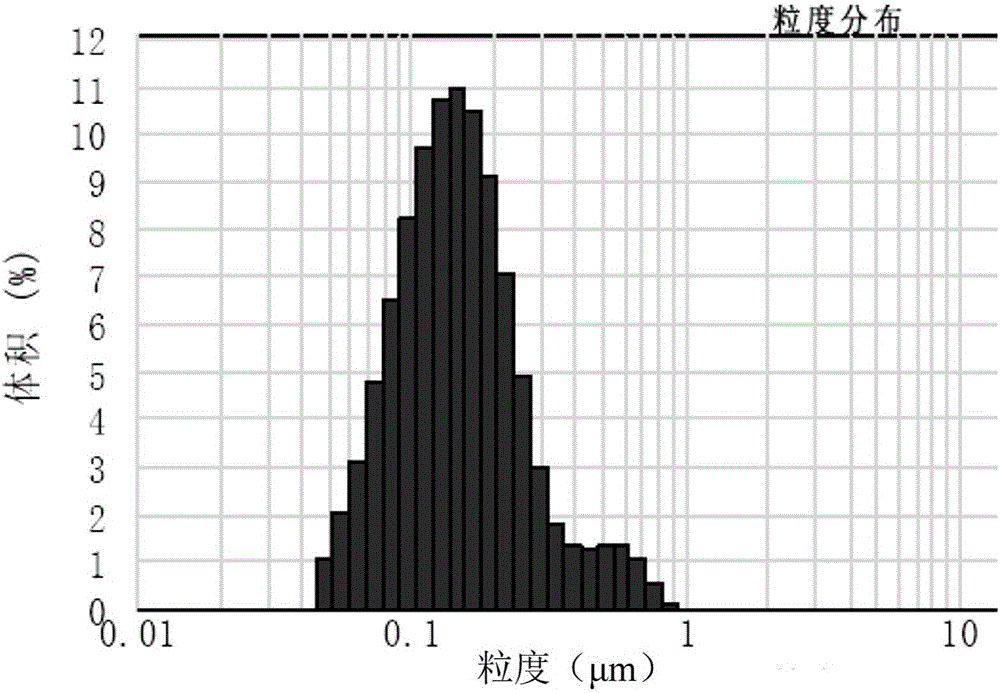

The invention relates to a sol-gel preparation method of a ceramic bonding agent. The preparation method comprises the steps that 1) zinc acetate and zirconium acetate are taken and dissolved in an acetic acid solution to prepare a mixed solution A, and sodium nitrate, lithium nitrate and aluminum nitrate are taken and dissolved in a boric acid solution to prepare a mixed solution B; 2) tetrabutyltitanate is taken and added into absolute ethanol to prepare a solution, the mixed solution A is added, and heat reaction is carried out under ultrasonic conditions to prepare sol A; 3) firstly the mixed solution B is added into acidic silica sol for mixing uniformly, and then the sol A is added to prepare mixed sol; 4) ammonia is added into the mixed sol under the ultrasonic conditions, so thatpH of a system reaches 5 or above, and wet gel is prepared; and 5) the obtained wet gel is dried, sintered and cooled to obtain the ceramic bonding agent. According to the preparation method, the uniform mixing of components of the ceramic bonding agent at the molecular level is promoted through smooth rubber alloy, the grain size is small, the reactivity is high, refractoriness is greatly reduced, and high-temperature fluidity is significantly improved; and formed pores after sintering are small and uniform, the structure is uniform without defects, and the mechanical strength is high.

Owner:卢俊杰

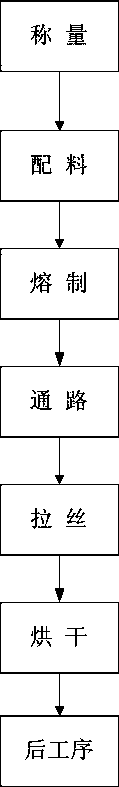

A method for producing glass fiber by using spodumene slag as flux clarifying agent

The invention discloses a method for producing glass fiber by using spodumene slag as a fluxing and clarifying agent, which comprises the steps of weighing, batching, melting, passing through, wire drawing, drying and the like; the components are weighed according to the following parts by weight: Kaolin: 100-120, pyrophyllite: 150-410, quicklime: 150-200, dolomite: 50-70, colemanite: 50-70, leucolite: 130-310, fluorite: 20-30, lithium 10-30 parts of pyroxene slag, the sum of parts by weight of each component is 1000. The present invention uses spodumene slag as a melting flux clarifying agent, which can prevent deliquescent agglomeration of the prepared glass fiber, and the spodumene slag can reduce the refractoriness of kaolin, and does not need to keep the melting temperature stable, thus reducing industrial production. difficulty. Adopting the method provided by the invention to produce glass fiber not only reduces the cost, but also reduces the environmental pollution caused by slag, and has good economic and social benefits.

Owner:NEIJIANG HUAYUAN ELECTRONICS MATERIALS

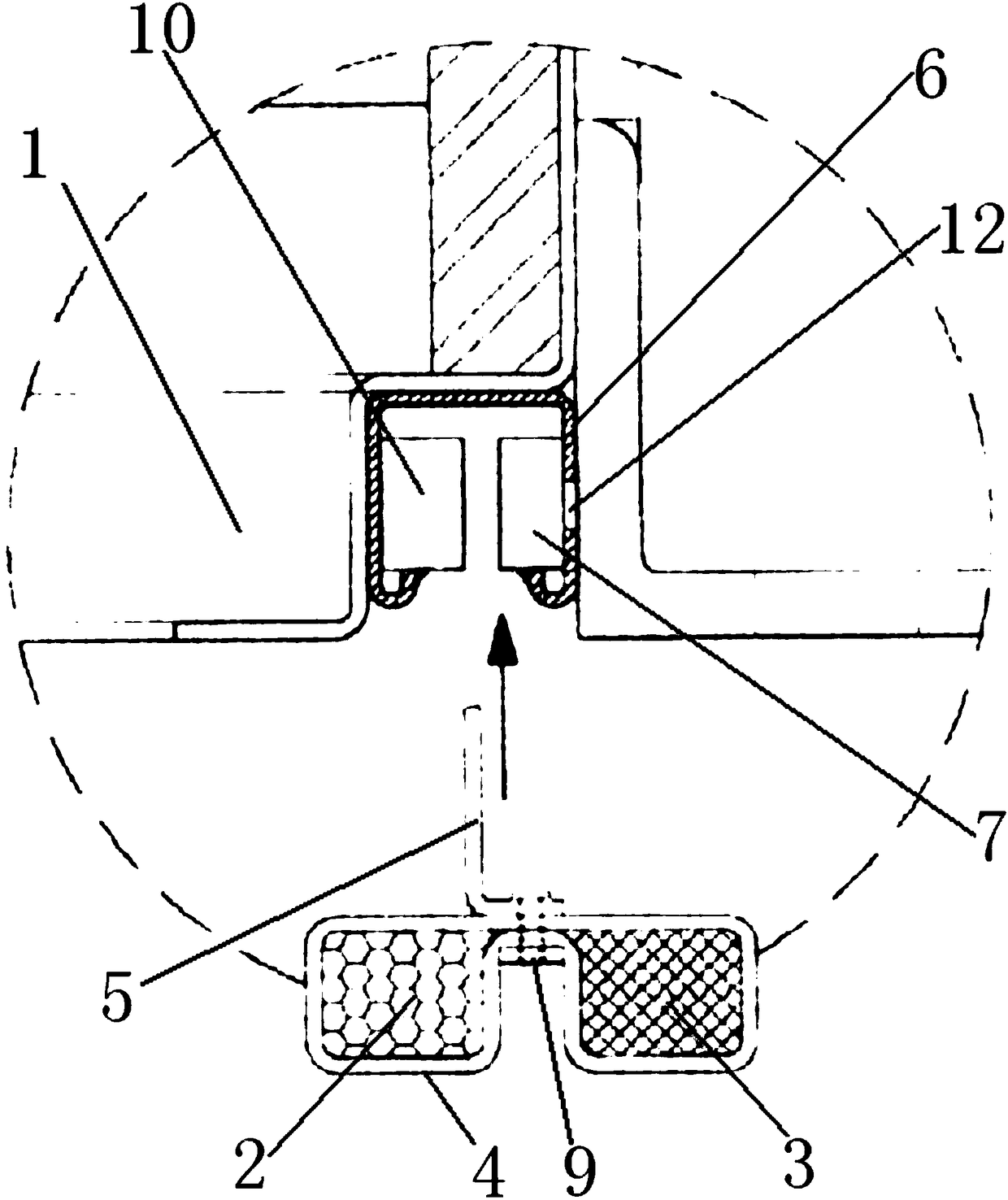

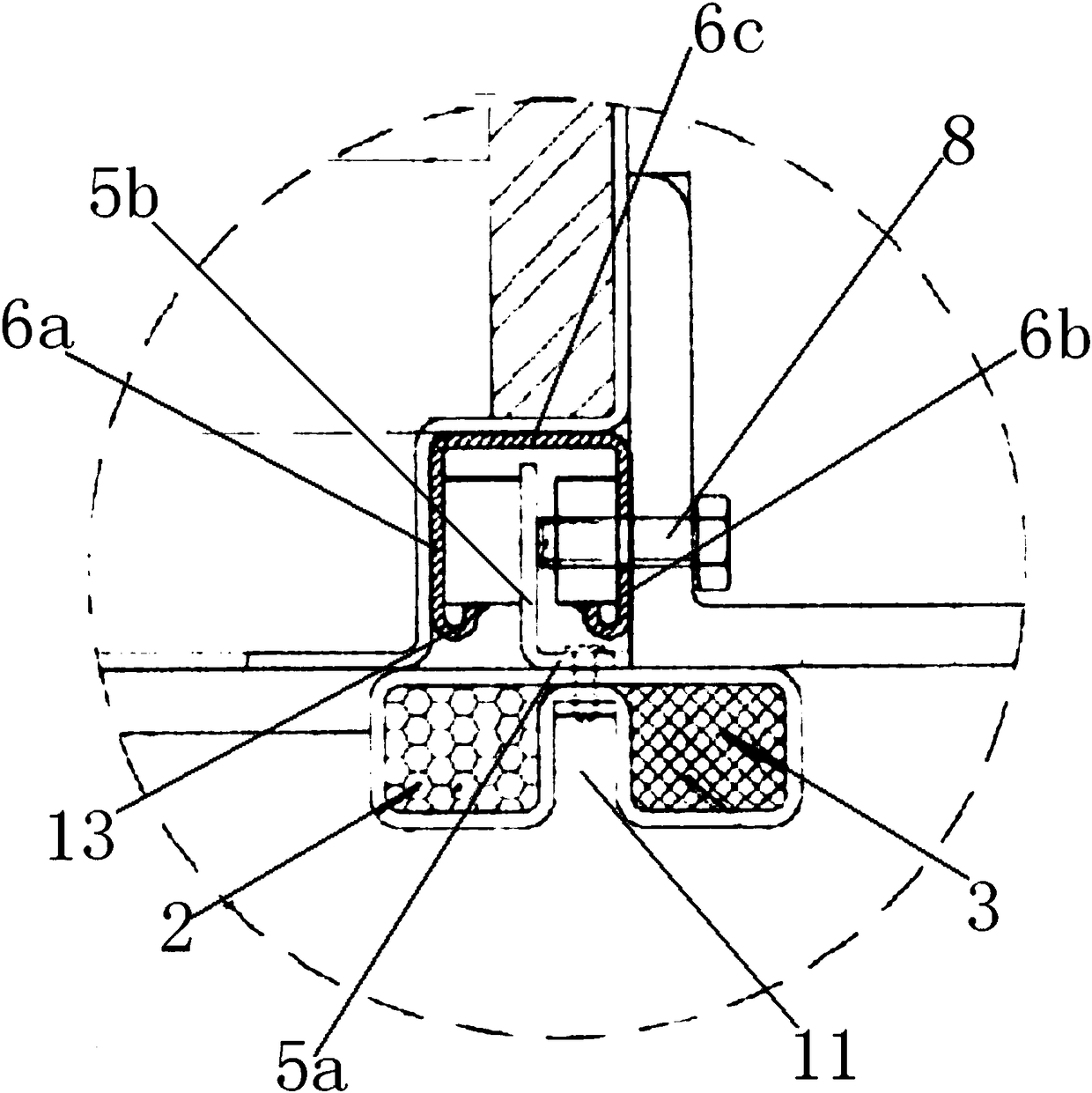

Dual-sealing mechanism for tank cover of aluminum melt degasification tank

ActiveCN108220622AEasy to fixImprove structural strengthCharge composition/stateThermal insulationAgricultural engineering

The invention discloses a dual-sealing mechanism for a tank cover of an aluminum melt degasification tank. The dual-sealing mechanism comprises an inner sealing strip, an outer sealing strip, wrappingcloth and an L-shaped part, wherein the outer sealing strip is away from a furnace chamber of the degasification tank relative to the inner sealing strip; the inner sealing strip and the outer sealing strip are wrapped with the wrapping cloth; the L-shaped part comprises a first flat plate and a second flat plate which are in vertical butted joint, the first flat plate is connected and fixed witha batten, so that the inner sides of the wrapping cloth are attached, the inner sealing strip and the outer sealing strip are separated to constitute a clearance groove, the batten is located at thebottom of the clearance groove, and the second flat plate is connected and fixed with the tank cover; channel steel is fixed on the tank cover and comprises a third flat plate and a fourth flat platewhich are parallel to each other, a fifth flat plate is vertically connected between the third flat plate and the fourth flat plate, a nut is fixed on the fourth flat plate, and a through hole coaxialwith the nut is formed in the fourth flat plate; a cushion block is fixed on the third flat plate. With the adoption of the dual-sealing mechanism, the thermal insulation effect of the tank cover isimproved, and the sealing strips are convenient to dismount and mount and are connected stably after being mounted.

Owner:SUZHOU BONENG FURNACE TECH CO LTD

Method for producing alkali-free glass fiber by albite serving as fluxible clarifying agent

The invention discloses a method for producing an alkali-free glass fiber by albite serving as a fluxible clarifying agent. The method comprises the following steps of: (a) weighing; (b) burdening; (c) melting; (d) accessing; (e) wire-drawing; (f) drying; and (g) subsequent working. The alkali-free glass fiber comprises the following components in parts by mass: 60 to 140 parts of kaolin, 280 to 450 parts of pyrophyllite, 150 to 200 parts of calcined lime, 60 to 90 parts of dolomite, 60 to 90 parts of colemanite, 130 to 230 parts of quartzitic sandstone, 15 to 30 parts of fluorite and 15 to 30 parts of albite, and the sum of the proportions of the components is 1,000. According to the method, the albite is used as a fluxible clarifying agent, so that crystals are prevented from being separated out and damaging a product during forming of the glass fiber. The albite can be used for reducing the fire resistance of the kaolin, so that the industrial production difficulty is reduced. According to the method for producing the alkali-free glass fiber, the cost and the production difficulty are reduced, the stability of melting temperature and the quality of the product are improved, and relatively high economic benefit is realized.

Owner:NEIJIANG HUAYUAN ELECTRONICS MATERIALS

Plastic refractory for repairing furnace lining of medium-frequency induction furnace and preparation method of plastic refractory

The invention relates to a plastic refractory for repairing a furnace lining of a medium-frequency induction furnace and a preparation method of the plastic refractory. According to the technical scheme, 63.0 wt%-78.0 wt% of vanadium iron slag, 12.0 wt%-17.0 wt% of basalt, 8.0 wt%-13.0 wt% of bauxite and 2.0 wt%-7.0 wt% of bentonite serve as raw materials, a binding agent accounting for 4.0 wt%-5.5 wt% of the raw materials is added, the raw materials are mixed to be uniform, and the plastic refractory for repairing the furnace lining of the medium-frequency induction furnace is obtained. The vanadium iron slag comprises the following main chemical components: more than or equal to 83.5 wt% of Al2O3, more than or equal to 9.0 wt% of MgO, less than or equal to 5.0 wt% of CaO, less than or equal to 0.3 wt% of SiO2, less than or equal to 0.2 wt% of Fe2O3 and less than or equal to 0.2 wt% of IL. Therefore, the method has the characteristics of environmental friendliness, simple process and low production cost; and the prepared plastic refractory for repairing the furnace lining of the medium-frequency induction furnace is convenient in construction mode, high in bonding strength, excellent in slag resistance and long in service life.

Owner:山东泰力克新材料科技有限公司

A kind of ceramic-metal composite binder, preparation method and diamond grinding wheel

ActiveCN105397648BLow refractorinessSmall coefficient of thermal expansionAbrasion apparatusPorosityThermal expansion

The invention discloses a ceramic and metal composite binding agent, a preparation method and a diamond grinding wheel. The binding agent is composed of, by weight, 35-40 parts of SiO2, 25-30 parts of H3BO3, 10-15 parts of Li2B4O7, 3-10 parts of AlF3, 2-6 parts of Na2S, 2-5 parts of Fe2N, 3-8 parts of Mg3N2, 2-6 parts of CaF2 and 15-20 parts of lead-tin alloy or nickel-titanium alloy. The binding agent not only has the advantages that the degree of fire resistance is low (as low as 650 DEG C), the thermal expansion coefficient is small (3.0-4.0*10-6 / DEG C), the strength is high (the bending strength reaches 150-220 Mpa), the porosity is adjustable, the self-sharpening performance is good and the chemical stability is good, but also has the excellent properties of high heat conductivity (20-50 W / m.K) and good toughness, is suitable for molding of the diamond grinding wheel, and better meets the requirements of modern precision grinding machining.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

A white corundum vitrified grinding wheel bond added with construction glass waste

ActiveCN104875127BLow firing temperatureAlleviate harsh requirementsAbrasion apparatusArchitectural glassManufacturing technology

The invention discloses a white corundum ceramic grinding wheel binder added with architectural glass wastes, and belongs to the technical field of bonded abrasive tool manufacturing. The white corundum ceramic grinding wheel binder is obtained through milling and mixing potassium feldspar, clay, talc and recycled architectural glass wastes according to a certain proportion, wherein all components are subjected to synergistic effect within a limited dosage range, so that the sintering temperature and use performance of the ceramic binder are ensured, the maximum sintering temperature does not exceed 1260 DEG C, and the white corundum ceramic grinding wheel binder is suitable for manufacturing ceramic grinding wheels by using milled white corundum. The white corundum ceramic grinding wheel binder is good in wettability to milled white corundum, strong in holding force, and good in abrasive tool self-sharpening property. The grinding wheel prepared by using the binder is high in rotating strength, has a use line viscosity of 63 m / s or more, and high in durability; a workpiece has no burn cracks; the recycled architectural glass wastes are milled and used for preparing the white corundum ceramic grinding wheel binder, so as to reduce the cost of raw materials of the binder and reduce non-renewable mineral resources.

Owner:白鸽磨料磨具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com