Patents

Literature

40results about How to "Eliminate concentration differences" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

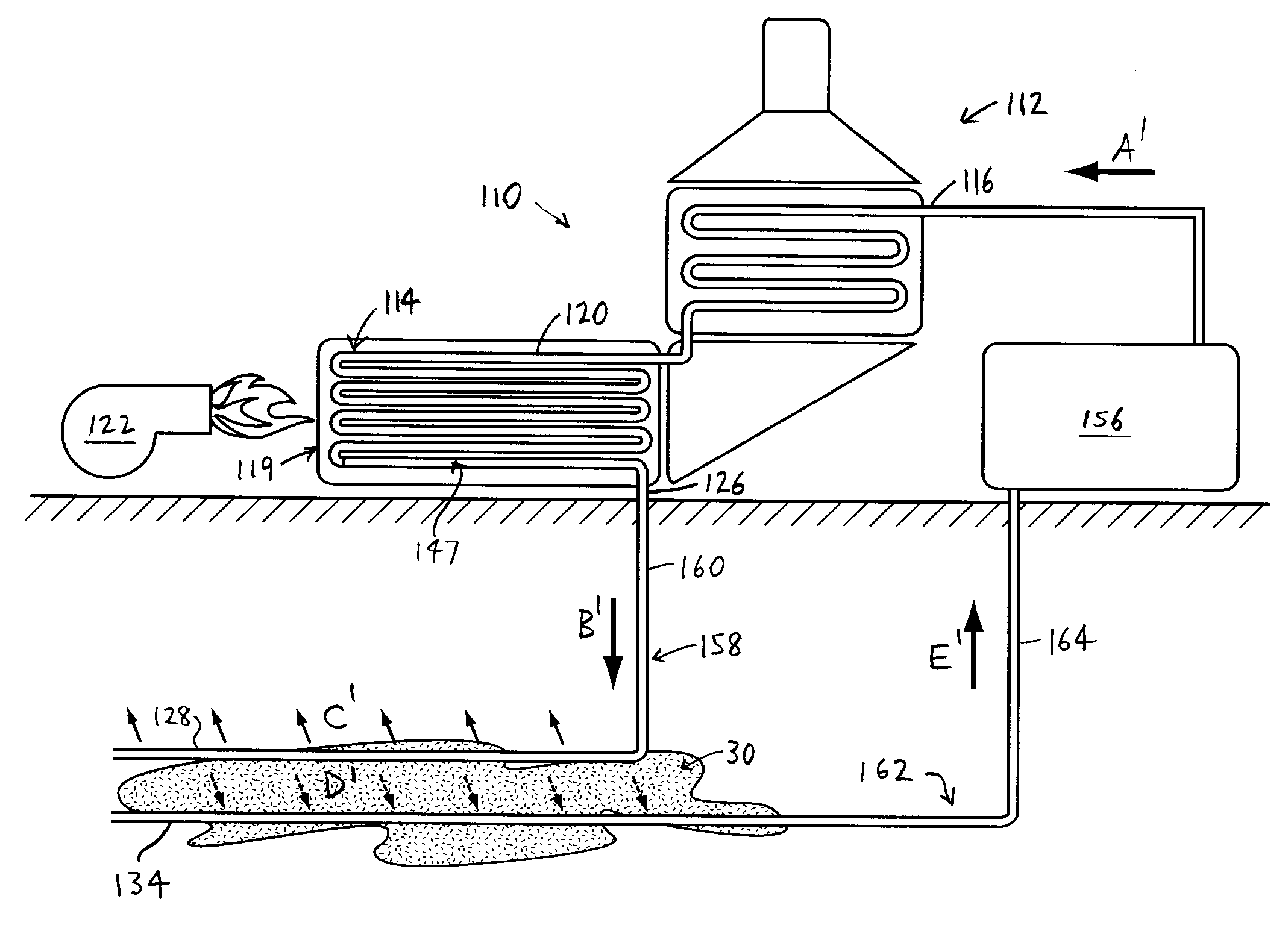

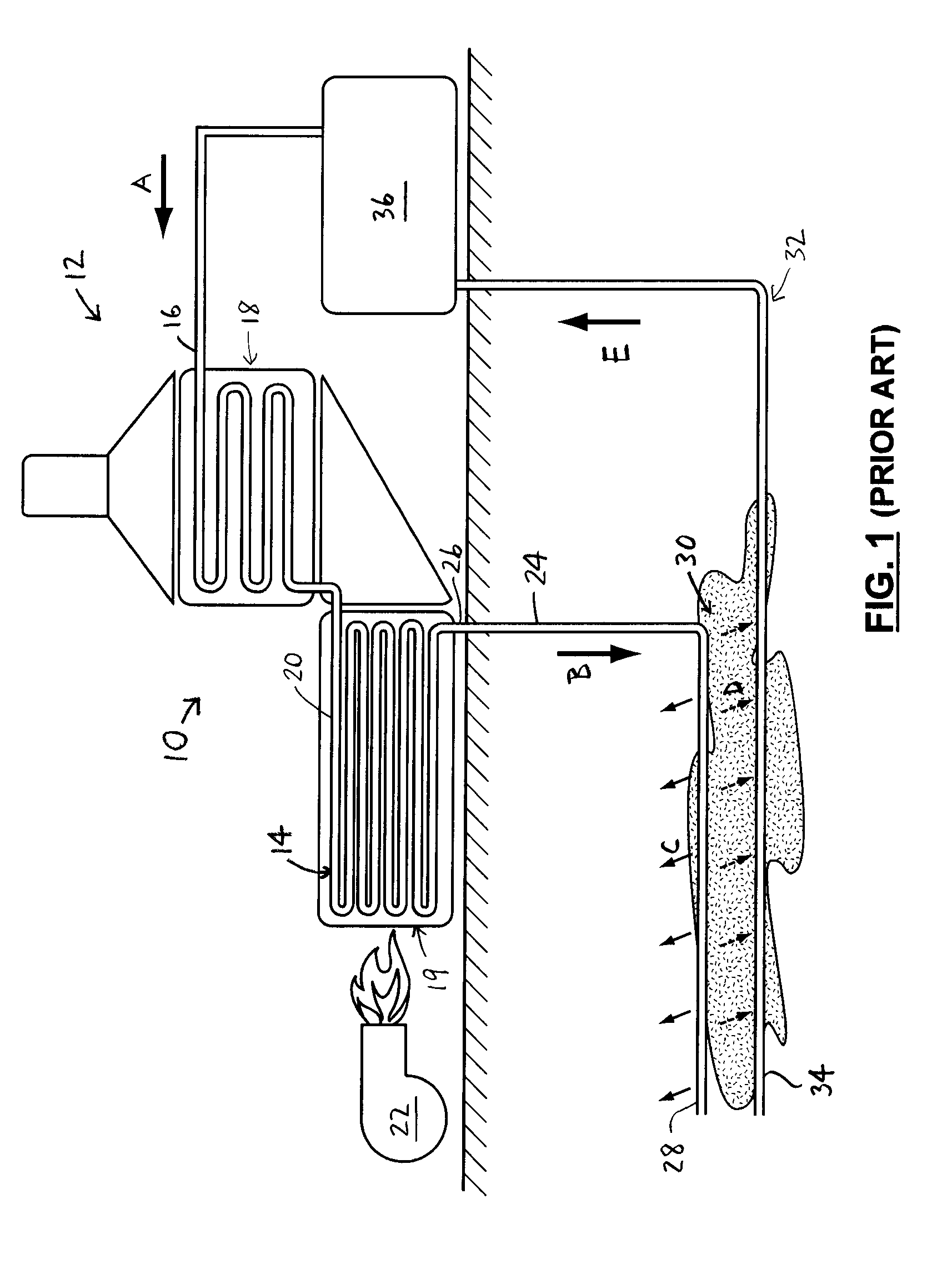

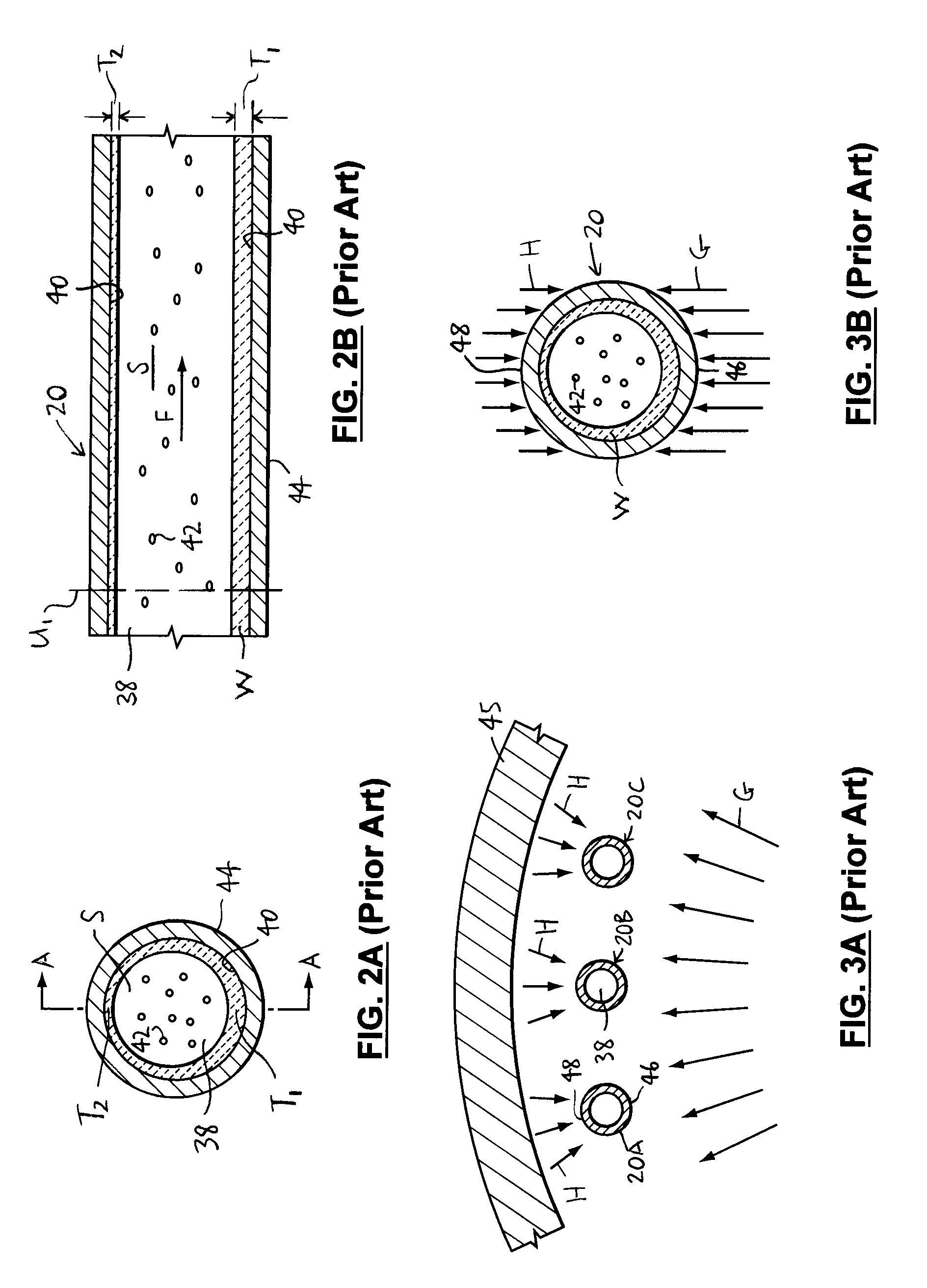

System and method for enhanced oil recovery with a once-through steam generator

ActiveUS20110017449A1High exit steam qualityEnhanced overall recoveryWater circulationInsulationEngineeringImpurity

A once-through steam generator including one or more steam-generating circuits extending between inlet and outlet ends thereof and including one or more pipes, the steam-generating circuit having a heating segment at least partially defining a heating portion of the once-through steam generator, and one or more heat sources for generating heat to which the heating segment is subjected. The steam-generating circuit is adapted to receive feedwater at the inlet end, the feedwater being subjected to the heat from the heat source to convert the feedwater into steam and water. The pipe has a bore therein at least partially defined by an inner surface, and at least a portion of the inner surface has ribs at least partially defining a helical flow passage. The helical flow passage guides the water therealong for imparting a swirling motion thereto, to control concentrations of the impurities in the water.

Owner:PROPAK SYST

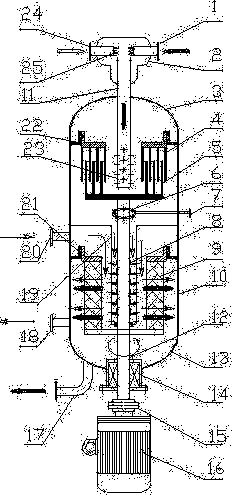

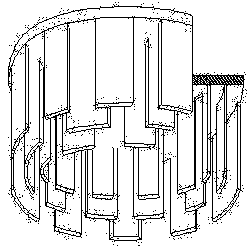

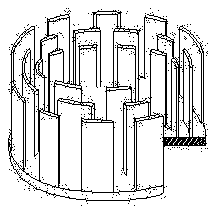

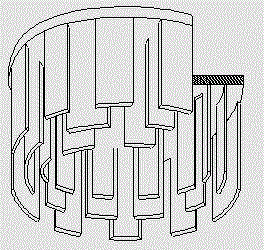

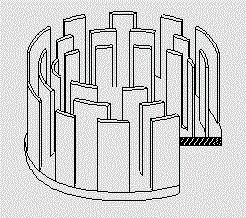

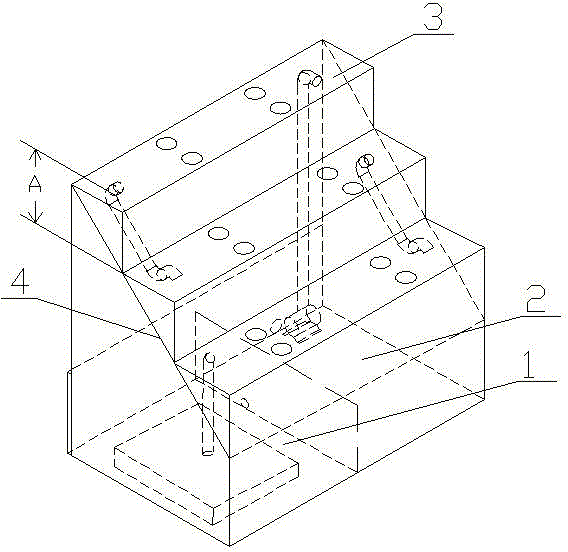

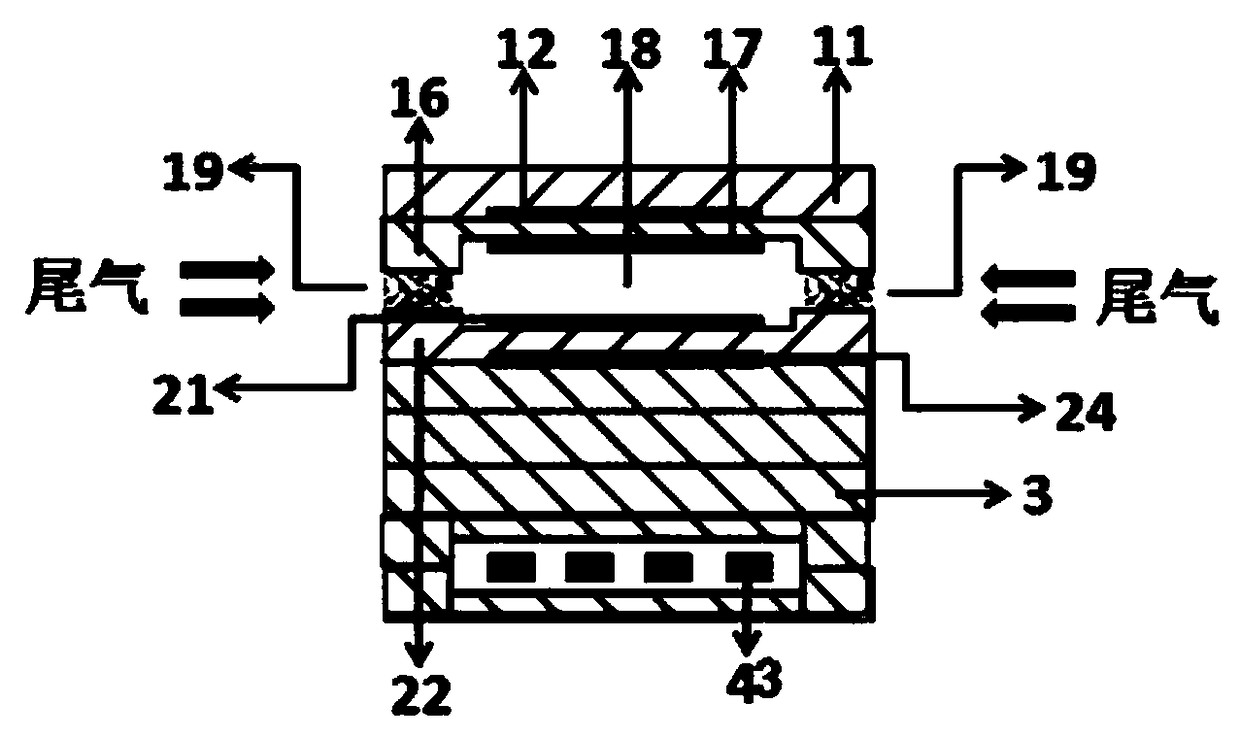

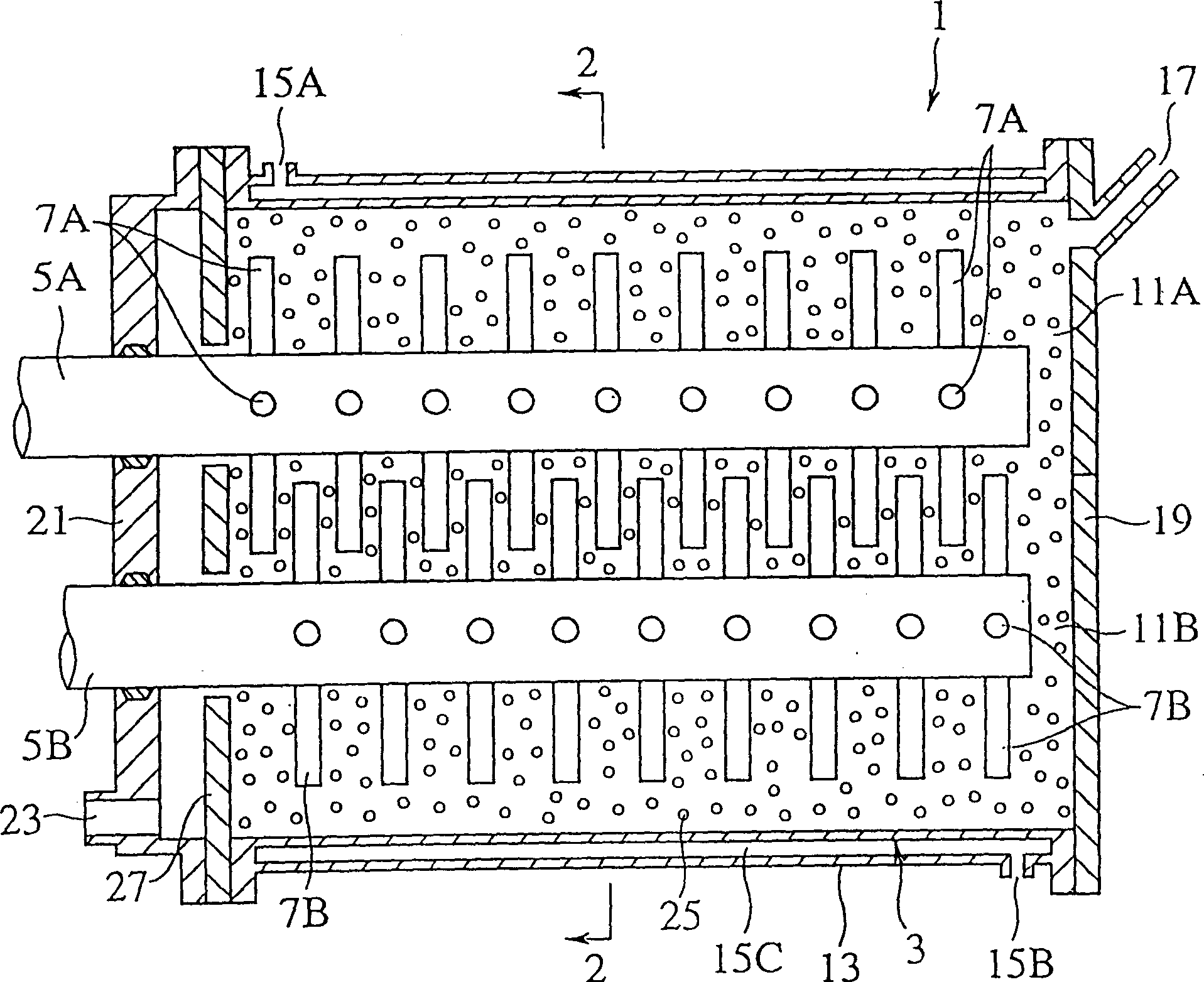

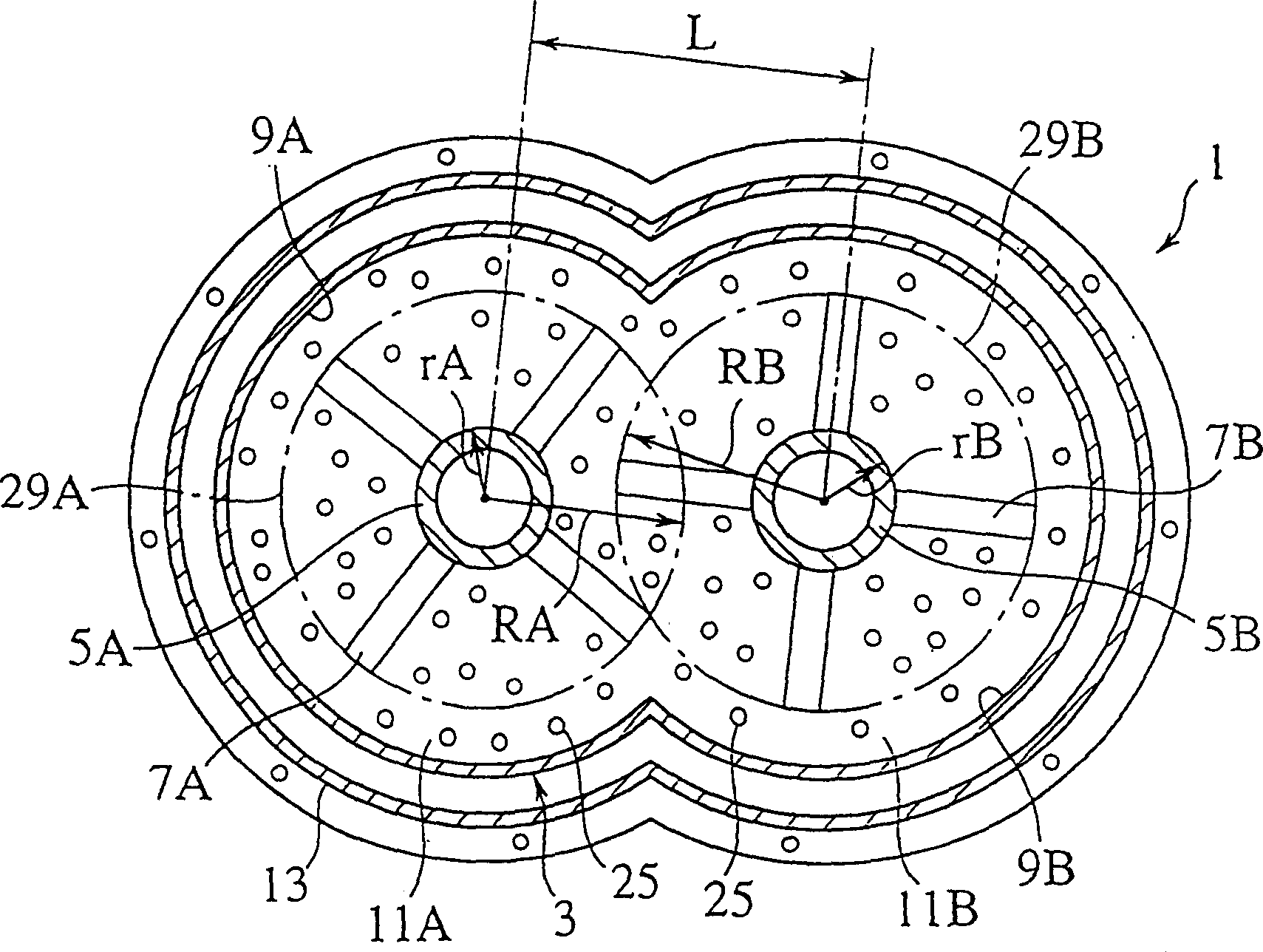

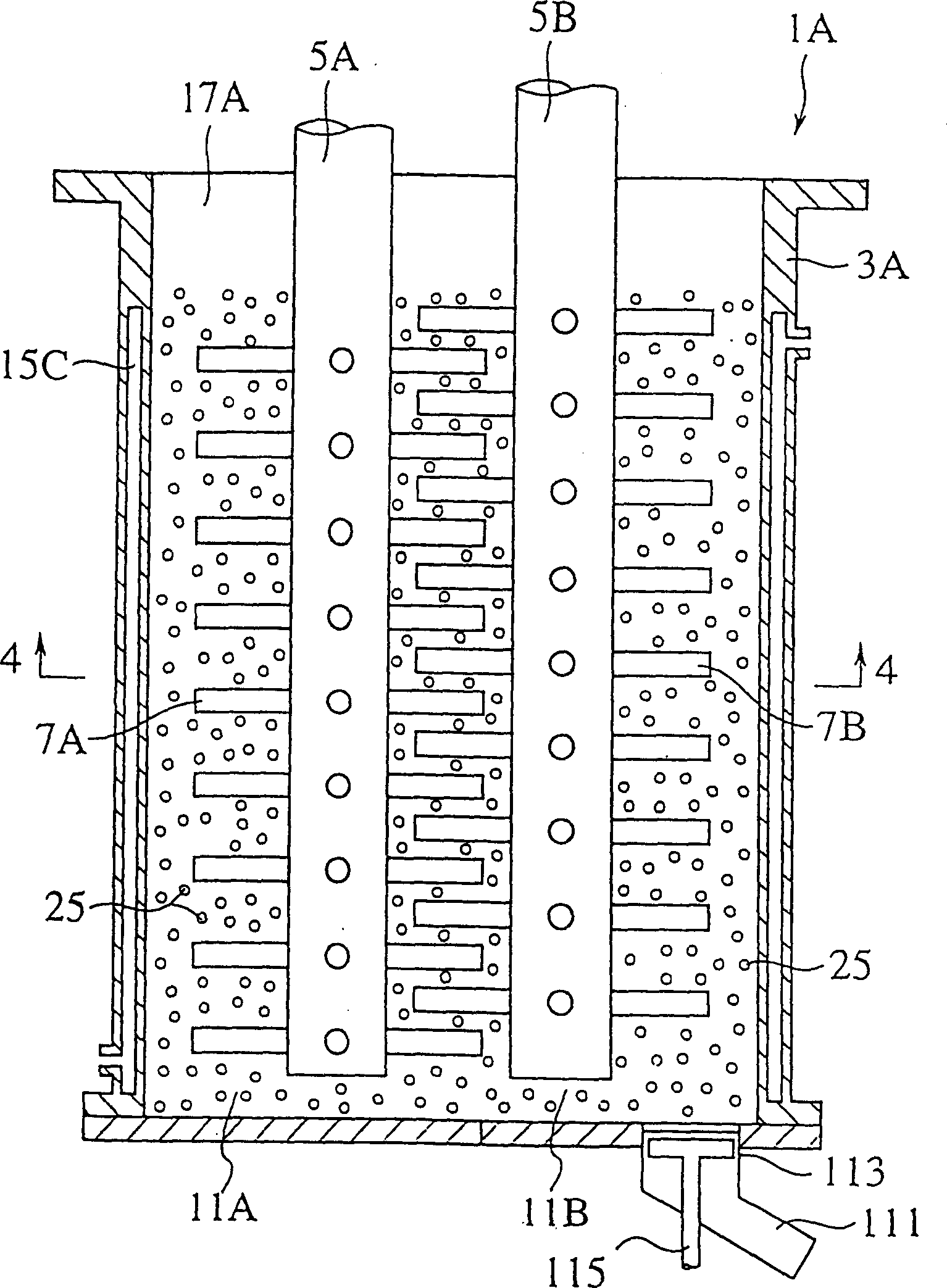

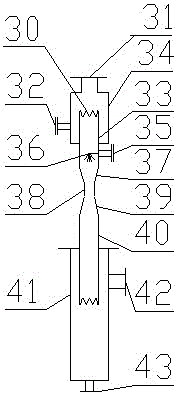

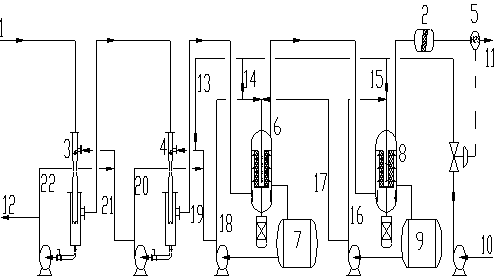

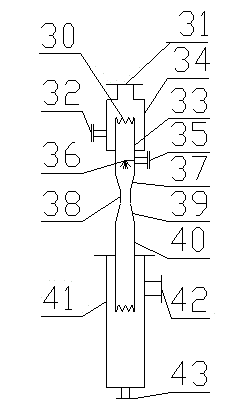

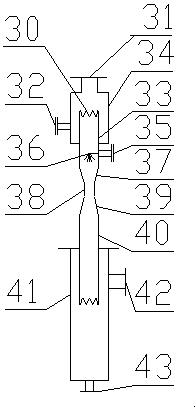

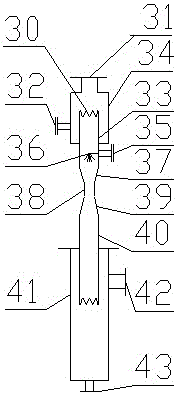

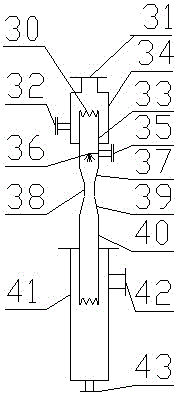

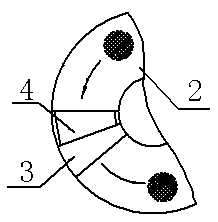

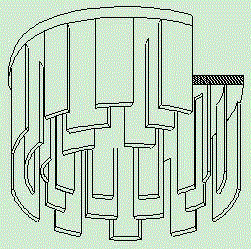

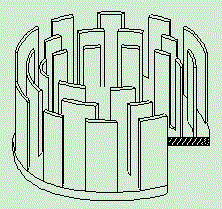

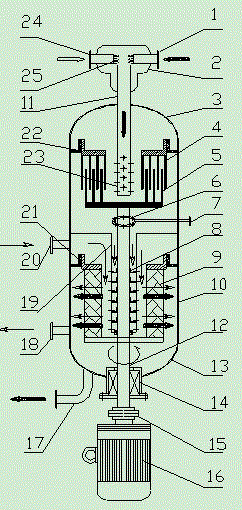

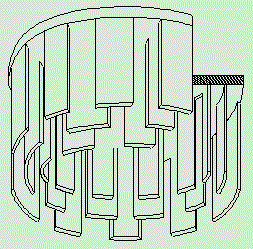

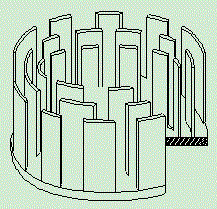

Sectional feeding type alkylation reactor and alkylation reaction method

ActiveCN104549087AEliminate concentration differencesImprove product qualityLiquid hydrocarbon mixtures productionMixersEmulsionSulfuric acid

The invention discloses a sectional feeding type alkylation reactor and an alkylation reaction method. The reactor comprises a reactor barrel body, a seal head, a separating plate, an upper bed layer, a lower bed layer, a feeding pipe, a fed material distributing pipe, a rotating shaft, a supplementing material inlet, a discharging opening, a circulating cooling air inlet and a circulating cooling air outlet. The invention further provides the alkylation reaction method adopting the sectional feeding type alkylation reactor. The alkylation reaction method comprises the following steps: preparing acid hydrocarbon emulsion through iso-butane and concentrated sulfuric acid in the upper bed layer, and then entering a rotating bed at the lower bed layer together with mixed hydrocarbon which enters through a supplemented material inlet, so as to perform alkylation reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Alkylation reactor and alkylation reaction method

ActiveCN104667856ASmall scaleFast scaleLiquid hydrocarbon mixtures productionChemical/physical/physico-chemical nozzle-type rreactorsPtru catalystEmulsion

The invention discloses a sectional feeding alkylation reactor and an alkylation reaction method. The reactor comprises a reactor barrel, seal heads, a partition plate, an upper bed layer, a lower bed layer, a feeding pipe, a feeding distributing pipe, a rotary shaft, a supplementing material inlet, a discharging opening, a circulating cooling gas inlet, a circulating cooling gas refrigerating system and a circulating cool gas outlet. The invention further provides the alkylation reaction method. The method comprises the following steps: as the sectional feeding alkylation reactor is adopted, firstly forming an acidic hydrocarbon emulsion in the upper bed layer from iso-butane and concentrated sulfuric acid; and then carrying alkylation reaction on the acidic hydrocarbon emulsion and mixed hydrocarbon entering from the supplementing material inlet in a lower bed layer rotary bed. According to the alkylation method disclosed by the invention, by taking the concentrated sulfuric acid as a catalyst and the iso-butane and olefin as raw materials, the alkylation reaction is carried out. The alkylation reaction disclosed by the invention can be carried out at a low temperature, so that the reactor is low in acid consumption and small in equipment scale.

Owner:CHINA PETROLEUM & CHEM CORP +1

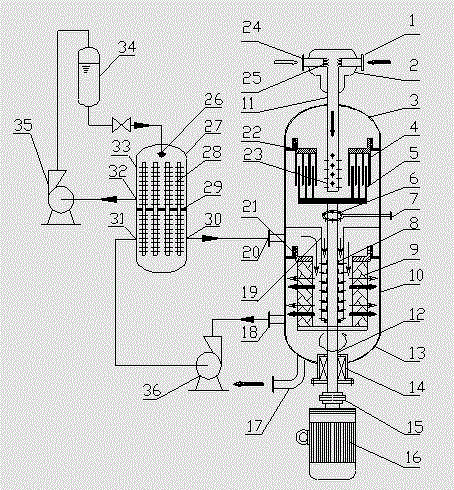

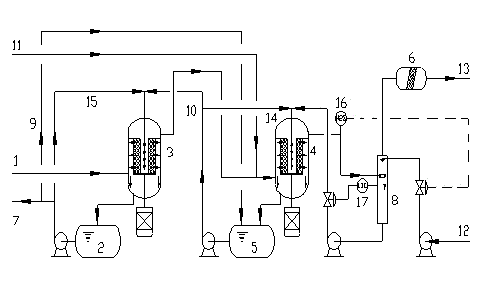

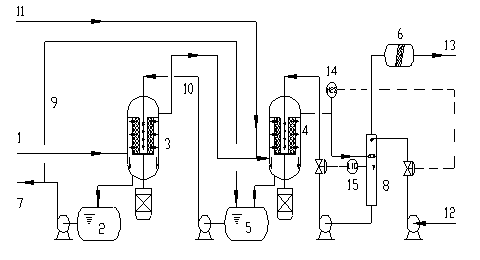

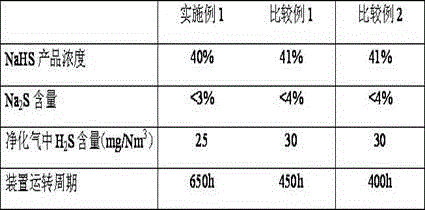

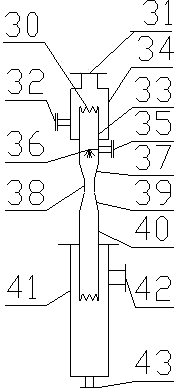

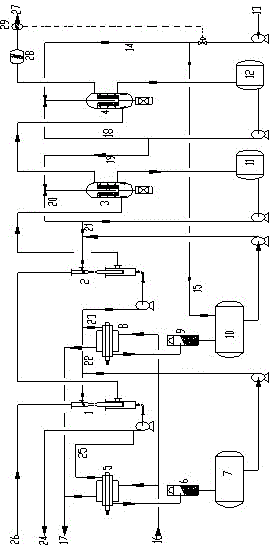

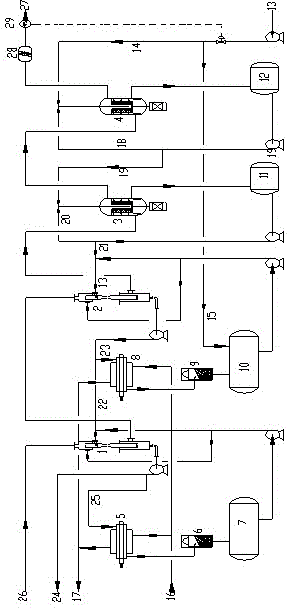

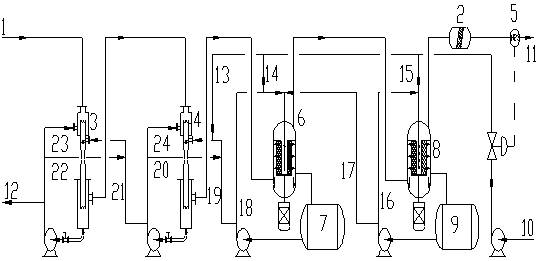

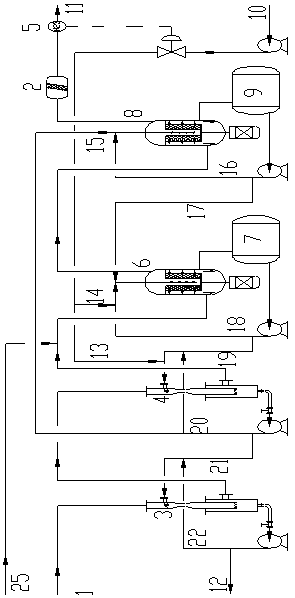

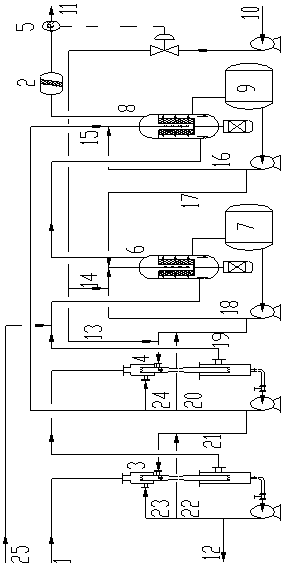

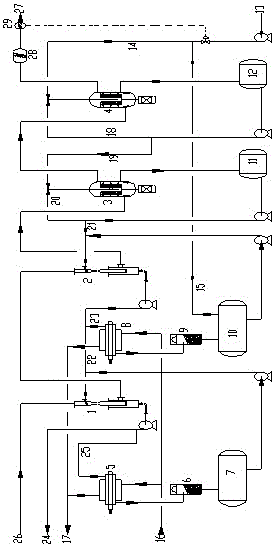

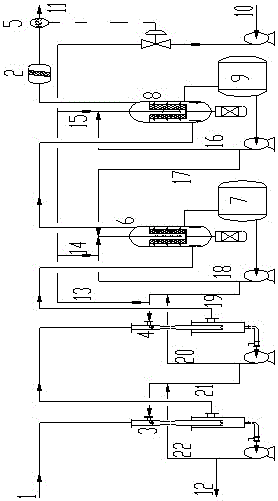

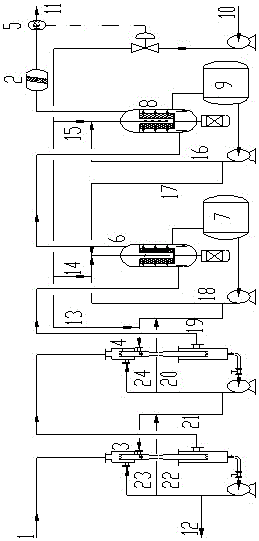

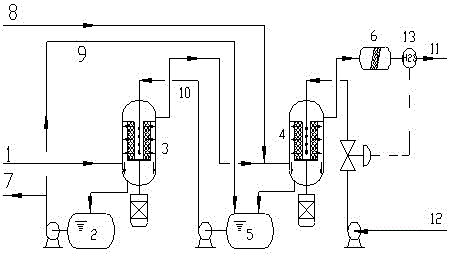

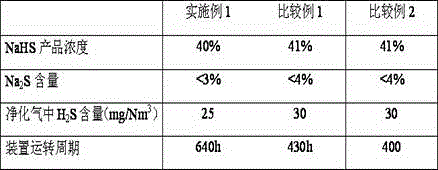

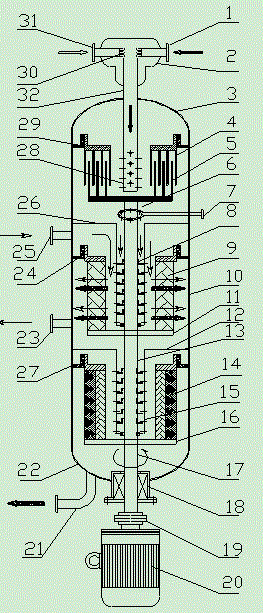

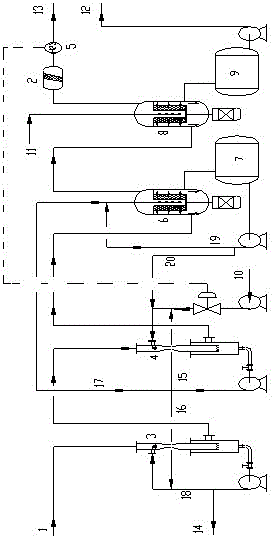

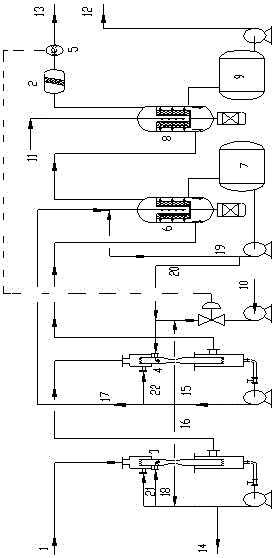

Process and apparatus for producing sodium hydrosulfide from acidic gas

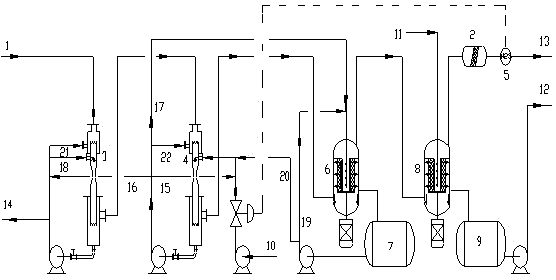

ActiveCN104826463AIncreased depth of responseGuaranteed long-term operationSulfur compoundsDispersed particle separationPollutantGas pipeline

The invention discloses a process and apparatus for producing sodium hydrosulfide from acidic gas. The acidic gas treating process employs a two-stage gas-liquid two-phase countercurrent absorption reaction and uses a NaOH solution as an absorption liquid to treat acidic gas so as to produce NaHS. According to the process, a primary liquid reaction product and a secondary liquid reaction product are cyclically used, and the primary liquid reaction product is circulated to a secondary intermediate tank and used as a diluent; and a supplementary carrier gas pipeline is arranged between two-stage rotating packed bed reactors to introduce supplementary carrier gas, so the concentration of CO2 in the acidic gases is reduced and most CO2 is taken out of the apparatus together with the carrier gas, and thus, the contents of Na2CO3 and NaHCO3 are controlled, obstruction of the pipeline due to crystallization caused by production of a great amount of Na2CO3 is prevented, and long cycle operation of the apparatus is guaranteed. The rotating packed bed reactors are used as gas-liquid reactors which have high mass transfer and reaction efficiency. The acidic gas treating process provided by the invention is simple and can achieve the dual objectives of purification of acidic gas and reclamation of pollutants; and an acidic gas treating system has the advantages of small scale, low energy consumption and low proneness to obstruction.

Owner:CHINA PETROLEUM & CHEM CORP +1

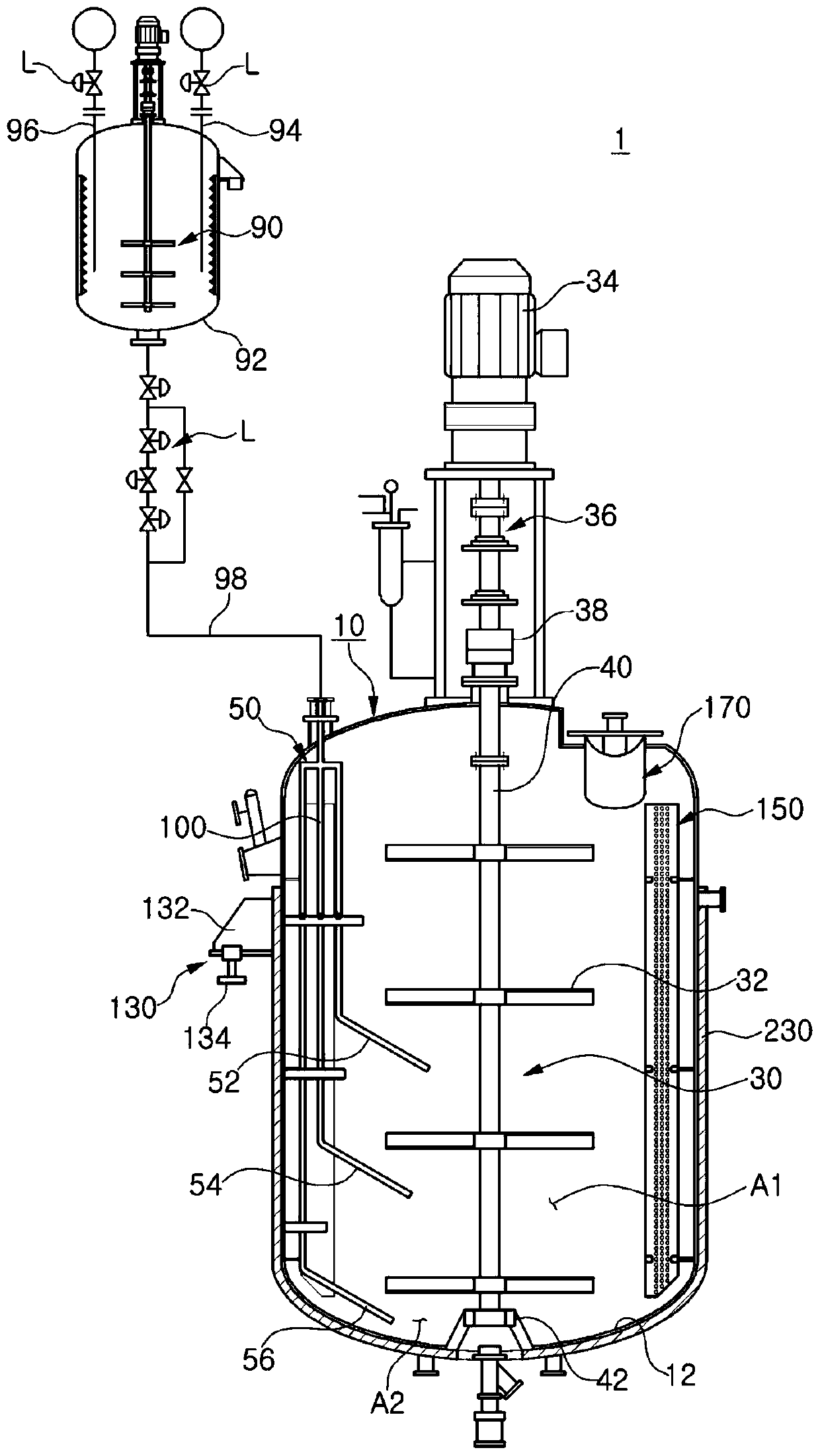

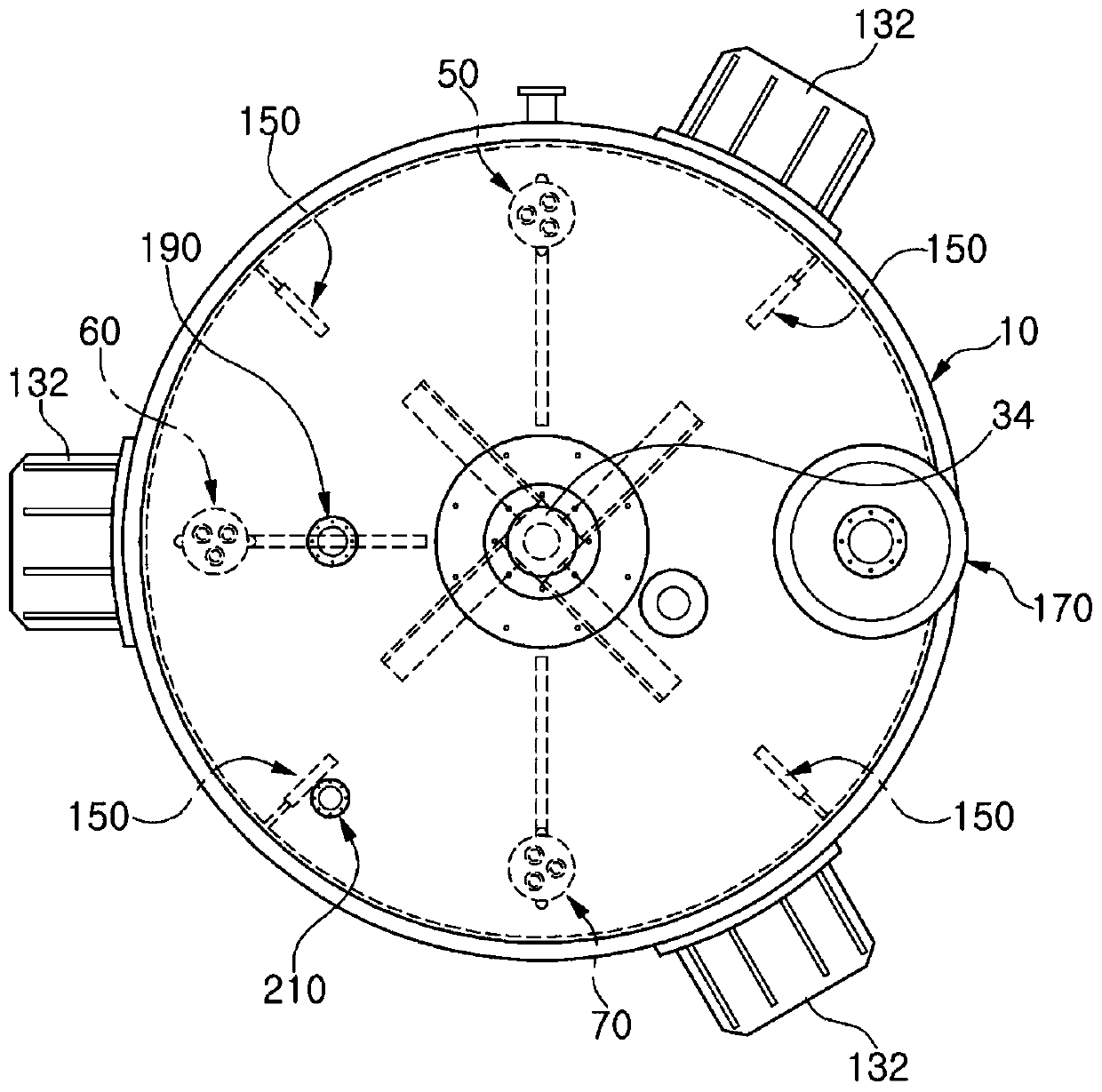

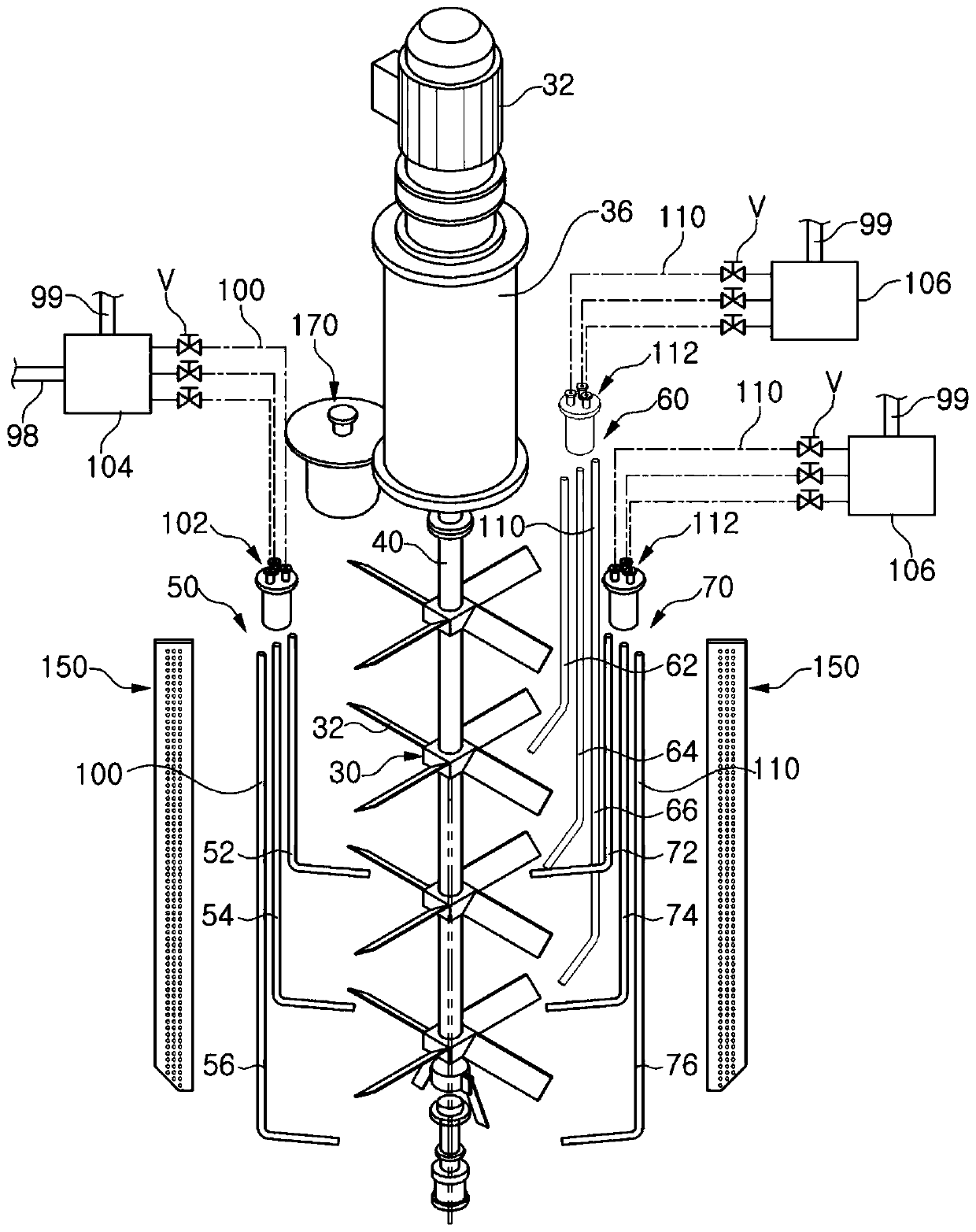

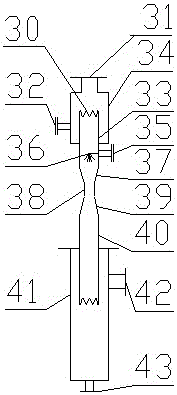

Apparatus and method for reaction

ActiveCN110678254AReduce or suppress the concentration differenceFast growthFlow mixersCell electrodesThermodynamicsPtru catalyst

Provided are an apparatus and a method for reaction for use in a co-precipitation reaction for producing a catalyst or a cathode active material for a lithium secondary battery, which injects a raw material (a solution) at least between impellers according to the level in a vessel, thereby making a stirring speed uniform and, in particular, minimizing a concentration difference between solutions.The apparatus for the reaction may comprise: a reaction vessel; a stirring means provided inside the reaction vessel and having multi-staged impellers; and a raw material injecting means, comprising at least one injection nozzle connected to the reaction vessel, for injecting a raw material at least between impellers.

Owner:浦项控股股份有限公司 +2

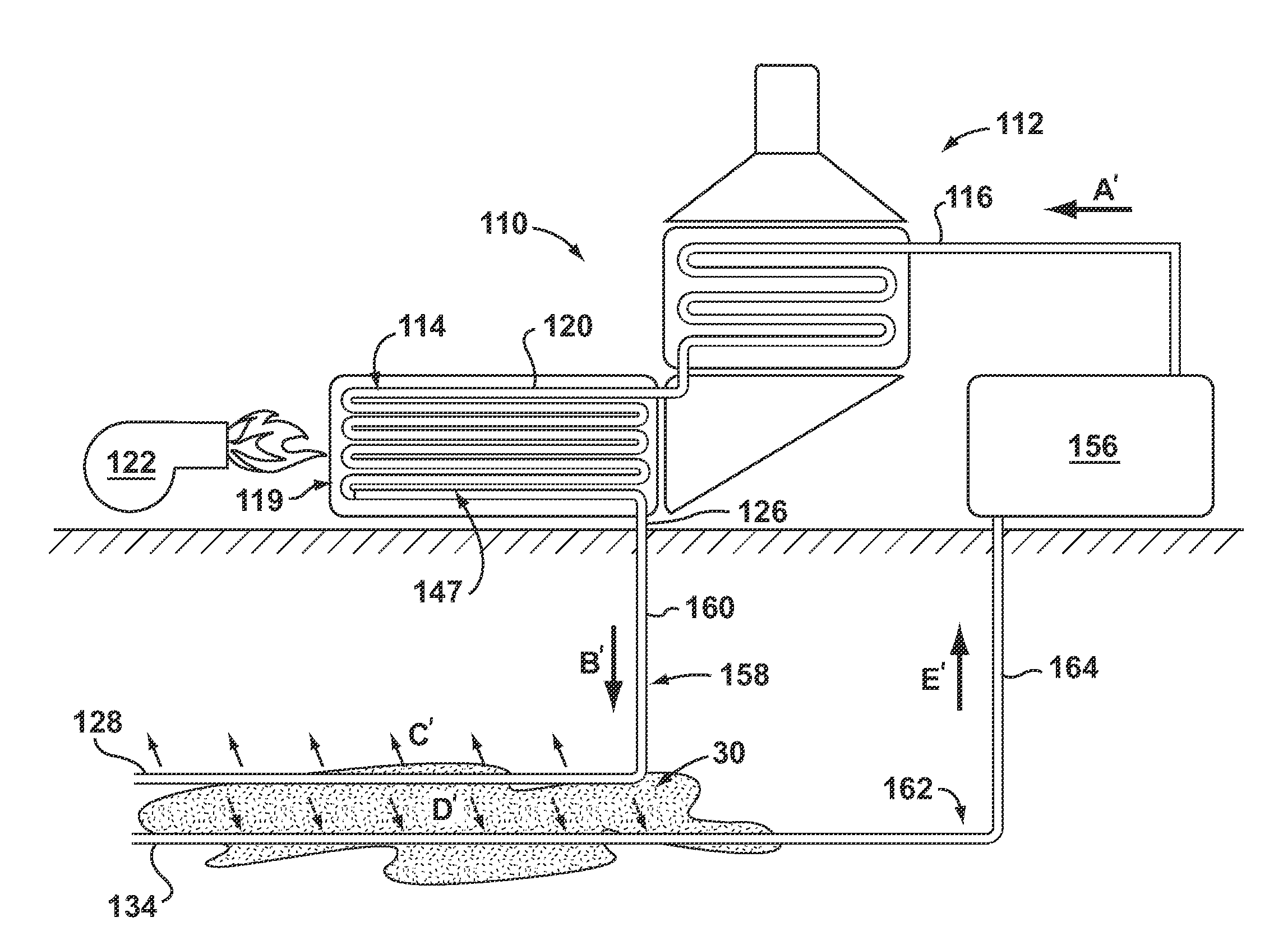

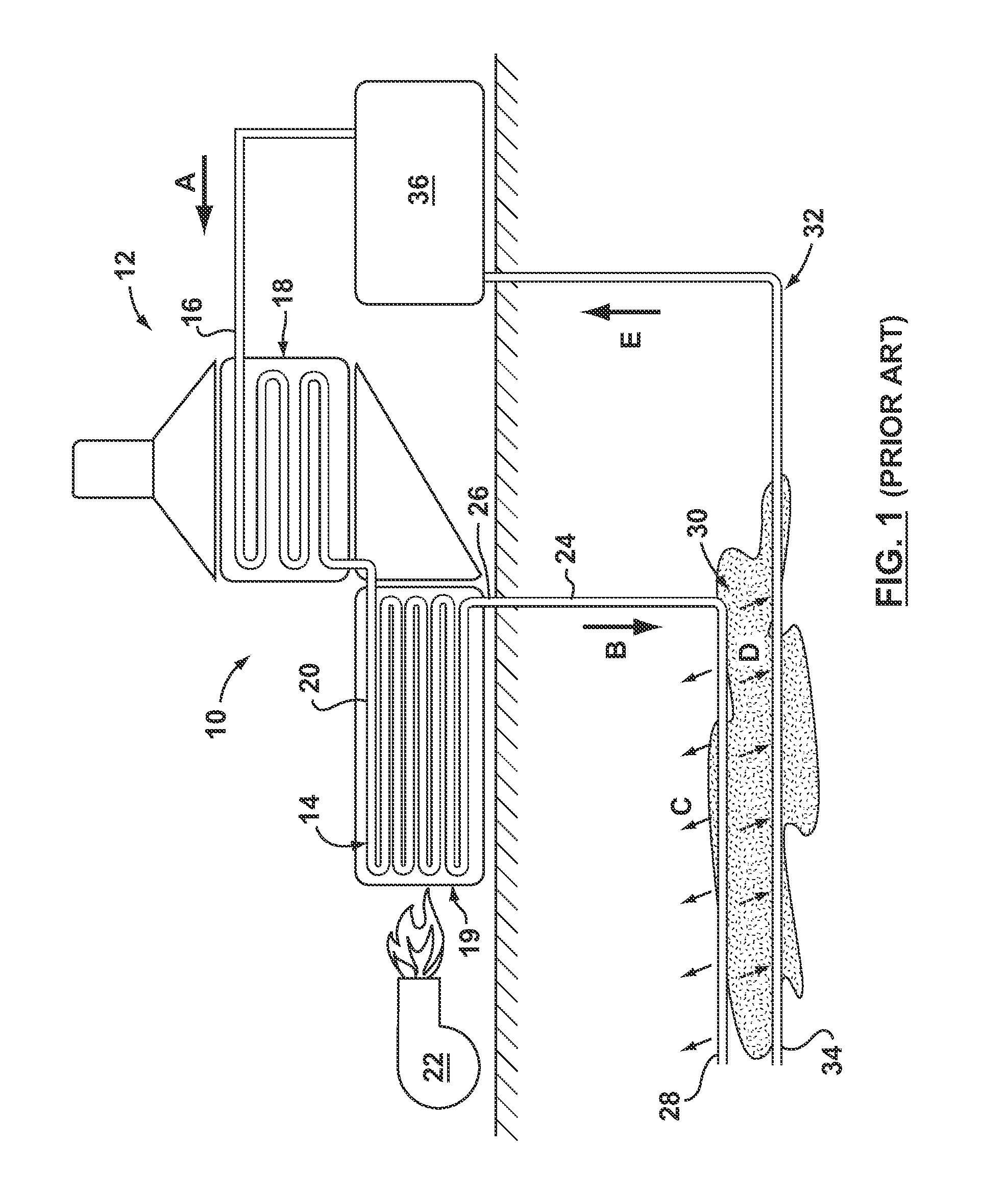

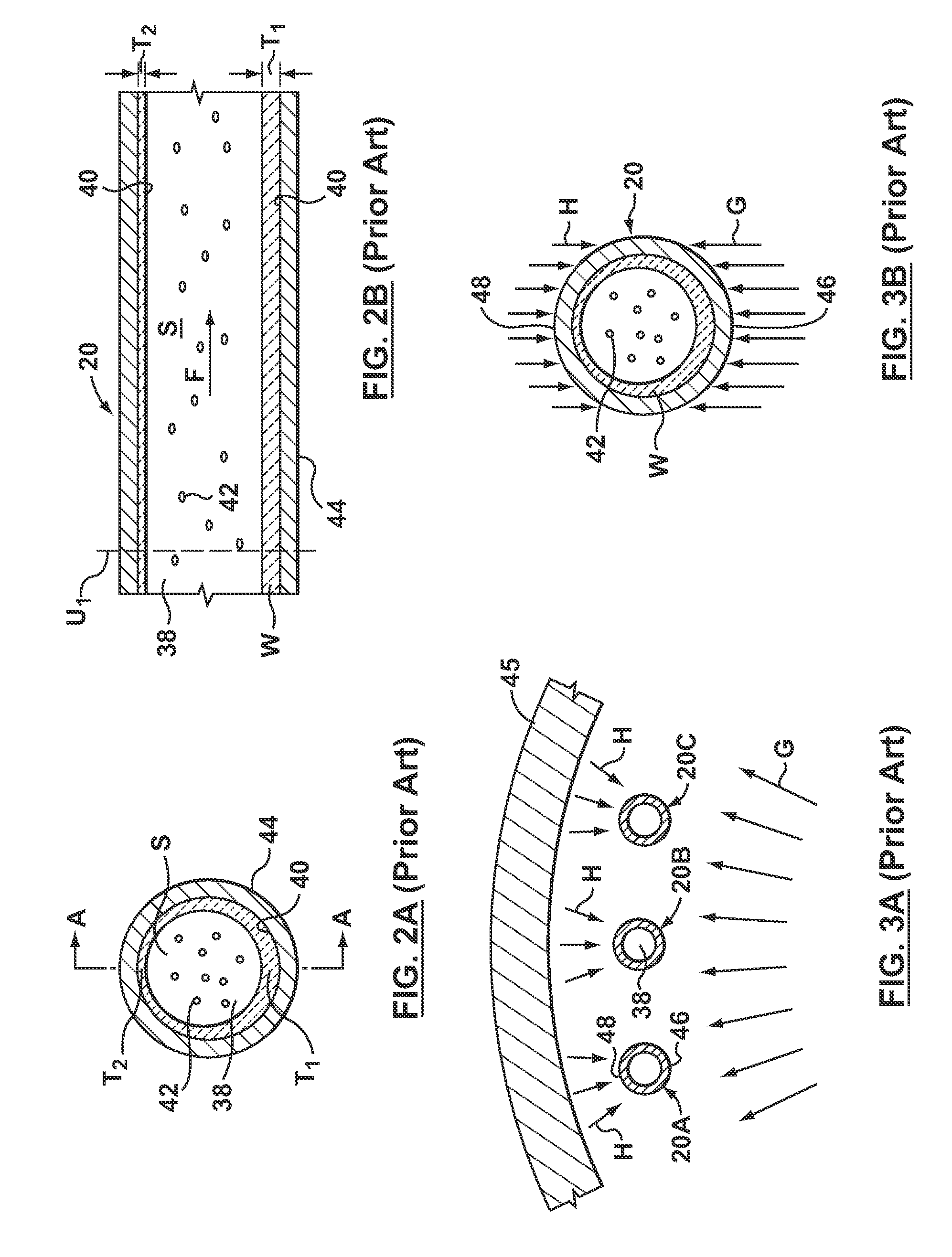

System and method for enhanced oil recovery with a once-through steam generator

ActiveUS8631871B2High exit steam qualityEnhanced overall recoveryWater circulationInsulationEngineeringImpurity

A once-through steam generator including one or more steam-generating circuits extending between inlet and outlet ends thereof and including one or more pipes, the steam-generating circuit having a heating segment at least partially defining a heating portion of the once-through steam generator, and one or more heat sources for generating heat to which the heating segment is subjected. The steam-generating circuit is adapted to receive feedwater at the inlet end, the feedwater being subjected to the heat from the heat source to convert the feedwater into steam and water. The pipe has a bore therein at least partially defined by an inner surface, and at least a portion of the inner surface has ribs at least partially defining a helical flow passage. The helical flow passage guides the water therealong for imparting a swirling motion thereto, to control concentrations of the impurities in the water.

Owner:PROPAK SYST

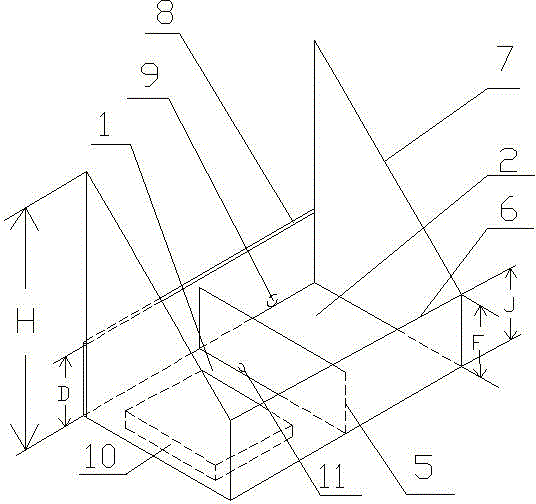

Experimental vitreous deep flow circulating hydroponic device

InactiveCN102972279AEasy to observeRecord growth dataAgriculture gas emission reductionCultivating equipmentsNutrient solutionEngineering

The invention discloses an experimental vitreous deep flow circulating hydroponic device. An inclination, which has a lower front part and a higher rear part, is arranged at the top end of a rectangular vessel of the device; an inner side board is connected with the interior of the rectangular vessel; the rectangular vessel is divided into a purified water tank and a water supply tank by the inner side board; a water pump is arranged in the water supply tank; a sloping plate is arranged at the top end of the rectangular vessel; at least two layers of hydroponic pools are arranged in a stepped form on the sloping plate; a perforated fix planting plate is arranged at the top of each hydroponic pool; a water circulating pipe is arranged between the two adjacent hydroponic pools; the distance between the lowest part of a hole of the water circulating pipe and the lowest part of the bottom surface of the hydroponic pool is greater than 10 cm to ensure that the depth of nutrient solution in the hydroponic pool is greater than 10 cm; the hydroponic pool at the lowest part is connected with a water outlet pipe; the hydroponic pool at the highest part is connected with a water supply pipe; and the lower end of the water supply pipe is connected with the water pump. The device achieves the deep flow hydroponic purpose and forms a favorable deep flow circulating system, so as to be convenient to observe the root system growth of the plants and test the fertilizer efficiency, is low in cost, can meet the experimental requirement for deep flow hydroponic plants, and is convenient to use.

Owner:云南省农业科学院经济作物研究所

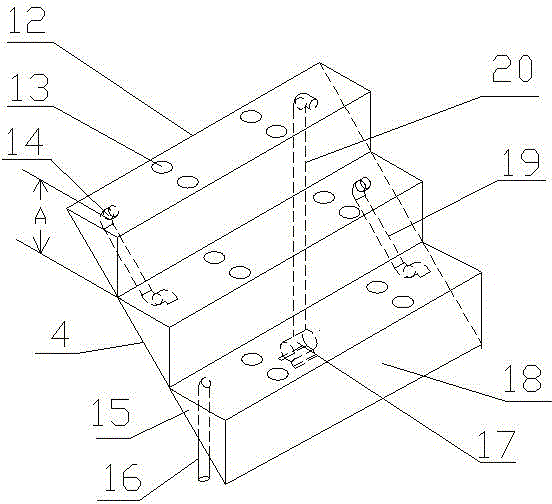

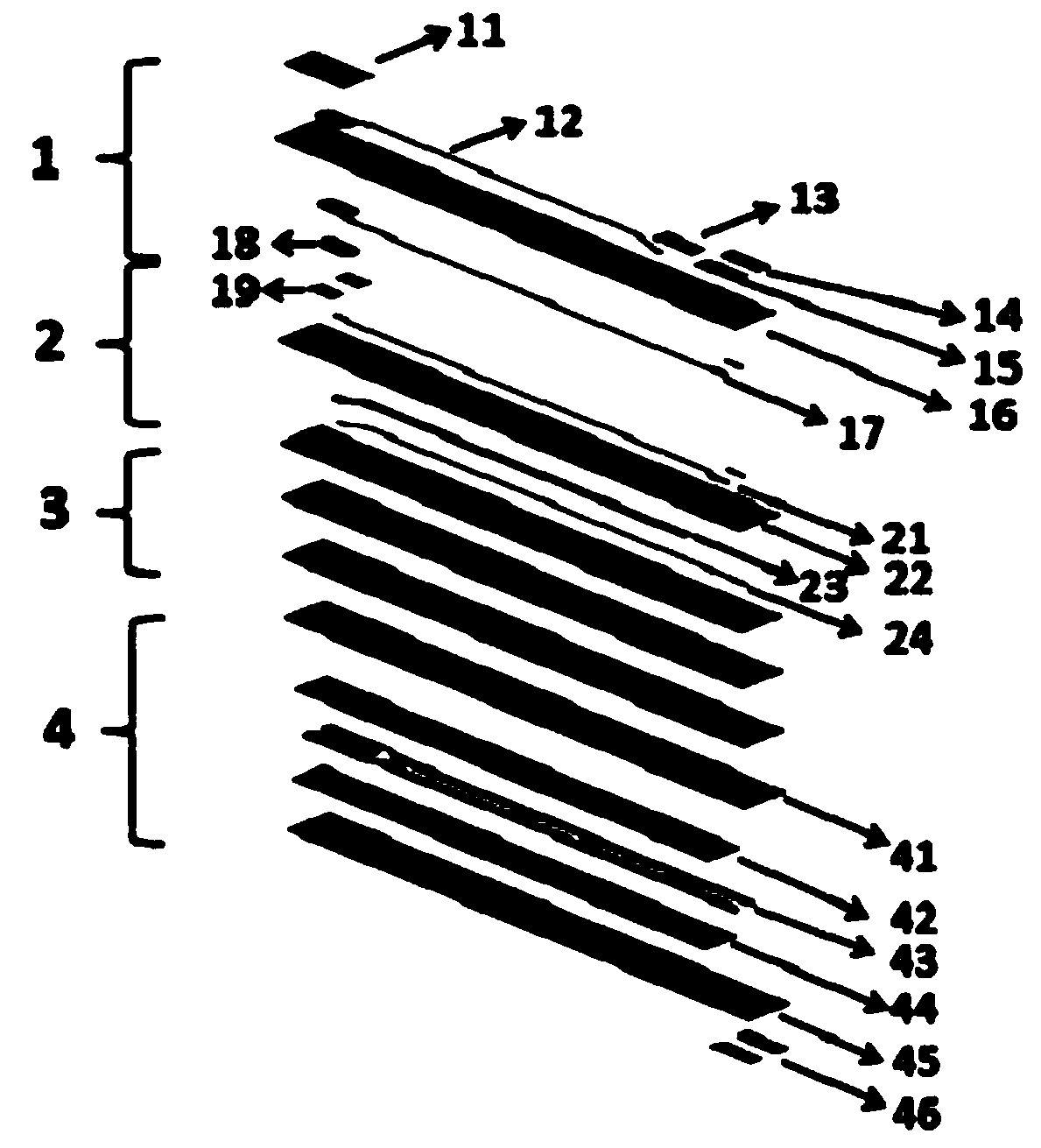

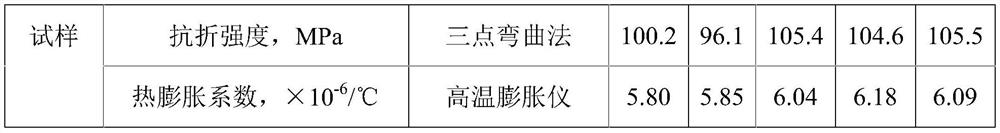

Novel double-battery type sheet wide-area oxygen sensor and preparation method thereof

ActiveCN108732224AImprove test accuracyEliminate the preparation processMaterial electrochemical variablesWide areaInsulation layer

The invention discloses a novel double-battery type sheet wide-area oxygen sensor. The novel double-battery type sheet wide-area oxygen sensor is formed by laminating and sintering an oxygen pump battery, a reference battery, a structure layer and a heating layer, wherein the oxygen pump battery comprises a first zirconium oxide tape casting substrate, an oxygen pump outer electrode and an oxygenpump inner electrode; the reference battery comprises a second zirconium oxide tape casting substrate, a testing electrode and a reference electrode; a diffusion cavity is located between the first zirconium oxide tape casting substrate and the second zirconium oxide tape casting substrate; diffusion barriers are arranged at two sides of the diffusion cavity; the structure layer comprises a thirdzirconium oxide tape casting substrate; the heating layer comprises a fourth zirconium oxide tape casting substrate, a third insulation layer and a heater. The invention further provides a preparationmethod of the novel double-battery type sheet wide-area oxygen sensor; the preparation method comprises the following steps: preparing the zirconium oxide tape casting substrates by adopting a tape casting method; preparing the oxygen pump inner electrode, the oxygen pump outer electrode, the diffusion barriers and the diffusion cavity by adopting screen printing; then laminating in sequence andsintering. According to the novel double-battery type sheet wide-area oxygen sensor, an internal reference ratio of pump current is adopted so that changes of oxygen concentration of reference gas areavoided and the testing precision of the sensor is improved.

Owner:成都科锐传感技术有限公司

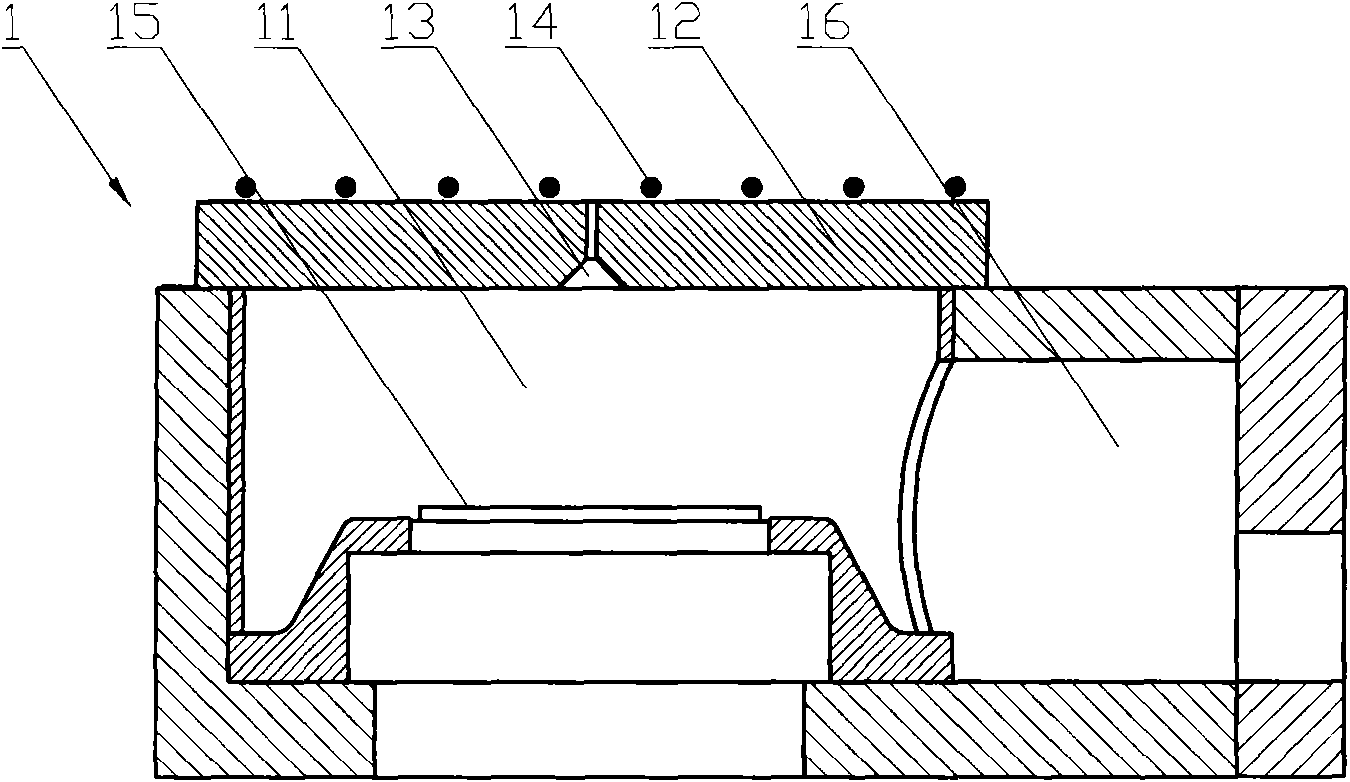

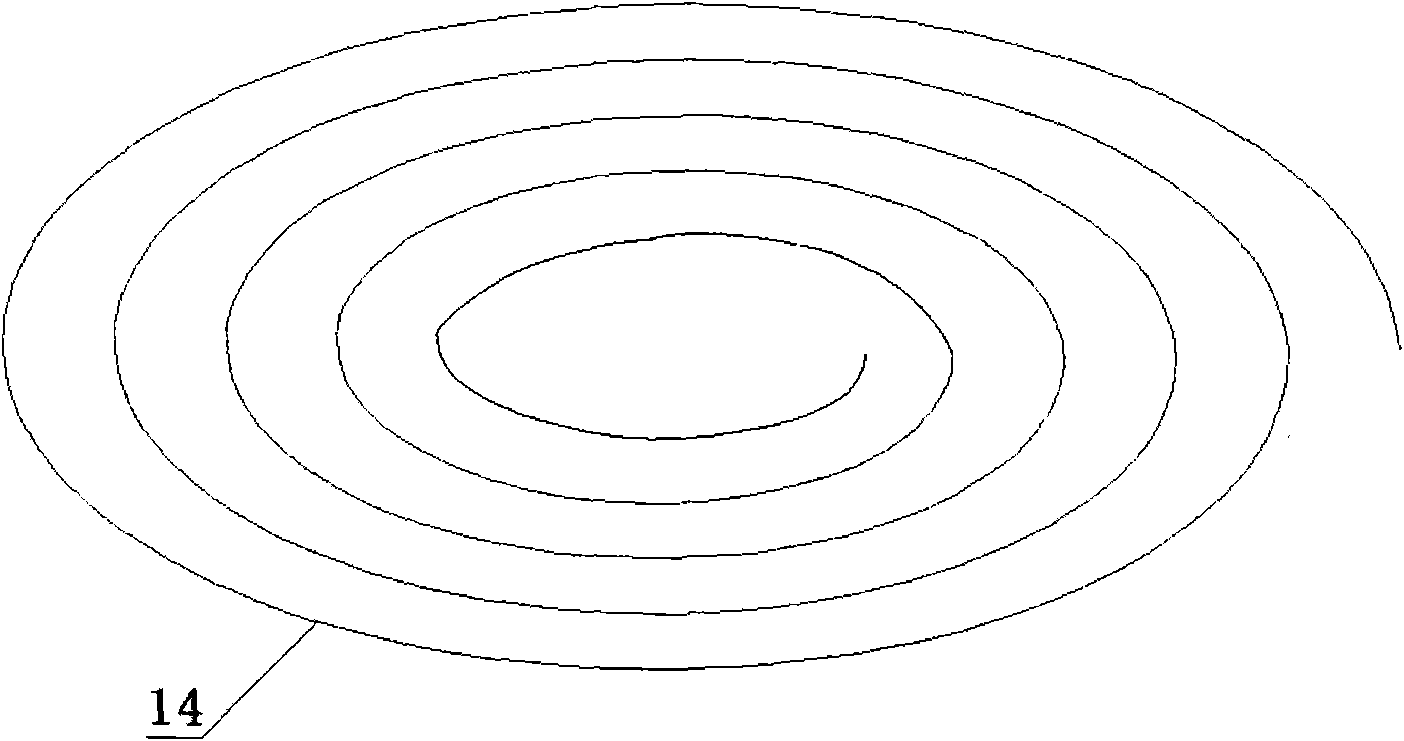

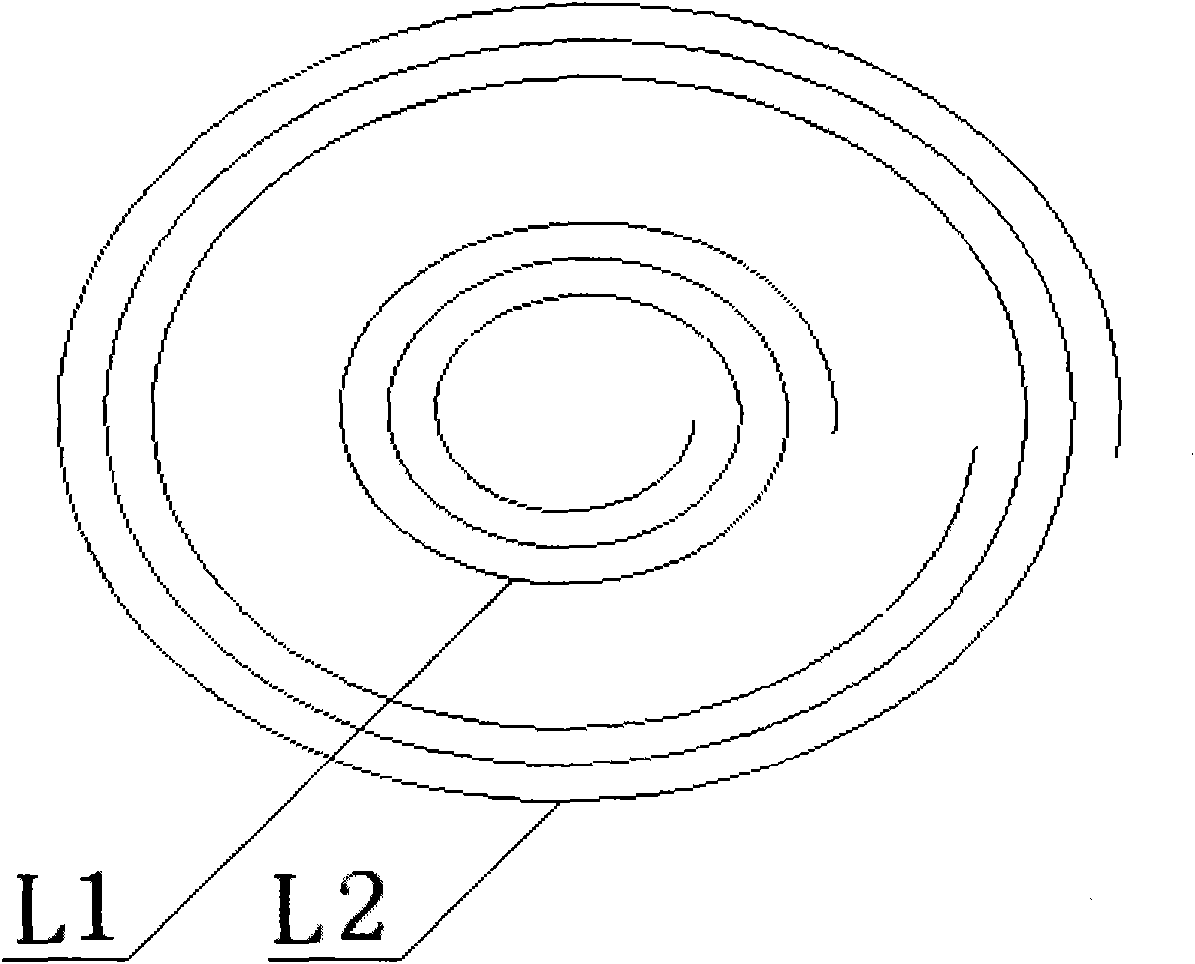

Plasma processing equipment, its radio frequency apparatus and radio frequency conveying method

InactiveCN101677485AEliminates differences in plasma concentration in the radial directionEliminate concentration differencesElectric discharge tubesPlasma techniqueRadio frequency energyEngineering

The invention discloses a radio frequency apparatus, includes a radio frequency power supply, a radio frequency adapter and an inductance coupling coil connected in order, wherein the inductance coupling coil includes a center coil and at least a group of peripheral coils surrounding the center coi;l the center coil and the peripheral coils are in mutual independence, and the proportion of radio frequency current in these coils can be regulated. The invention also discloses a plasma processing equipment including the radio frequency apparatus. In the radio frequency conveying method disclosedby the invention, radio frequency energies are respectively input to the center position and peripheral position of the reaction chamber through at least two mutually independent inductance coupling coils, and the proportion of radio frequency current in these coils can be regulated according to the plasma concentration at these positions. As subarea conveying and subarea control of the radio frequency energy is realized, the uniformity of the plasma in the radial direction of the reaction chamber can be improved, thereby ensuring the smooth completion of the fine processing to the workpiece by the plasma processing equipment.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

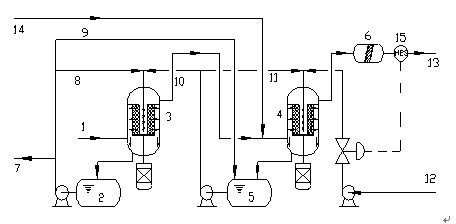

Three-stage countercurrent absorption process and apparatus for acidic gases

ActiveCN104826466AReduce concentrationAvoid cloggingSulfur compoundsDispersed particle separationGas phaseProcess engineering

The invention discloses a three-stage countercurrent absorption process and apparatus for acidic gases. The absorption process employs a gas-liquid two-phase countercurrent absorption reaction and uses a NaOH solution as an absorption liquid to treat acidic gases so as to produce NaHS. According to the process, a supplementary carrier gas pipeline is arranged on a connection pipeline located between a gas phase outlet and an inlet of a two-stage rotating bed reactor to introduce a supplementary carrier gas, so the concentration of CO2 in the acidic gases is reduced; most CO2 is taken out of the apparatus; thus, the contents of Na2CO3 and NaHCO3 are controlled, obstruction of the pipelines due to crystallization caused by production of a great amount of Na2CO3 is prevented, and long cycle operation of the apparatus is guaranteed. The absorption process for acidic gases provided by the invention is simple and can achieve the dual objectives of purification of acidic gases and reclamation of pollutants; and an acidic gas treating system has the advantages of small scale, low energy consumption and low proneness to obstruction.

Owner:CHINA PETROLEUM & CHEM CORP +1

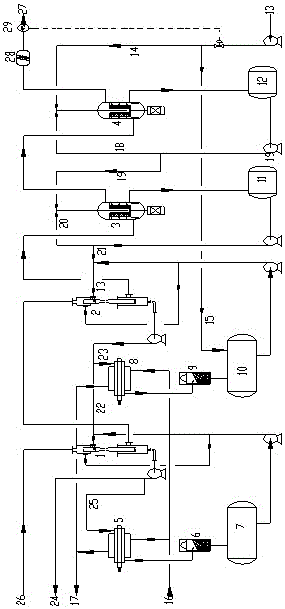

Acidic gas treating process and system

ActiveCN104826468AIncreased depth of responseFully contactedSulfur compoundsDispersed particle separationGas liquid reactionPhysical chemistry

The invention discloses an acidic gas treating process and system. The acidic gas treating process employs a two-stage gas-liquid two-phase countercurrent absorption reaction and uses a NaOH solution as an absorption liquid to treat acidic gas so as to produce NaHS. According to the process, a primary liquid reaction product and a secondary liquid reaction product are cyclically used, and the primary liquid reaction product is circulated to a secondary intermediate tank and used as a diluent. The acidic gas treating system adopts a rotating bed reactor as a gas-liquid reactor; CO2 in the acidic gas reacts with NaOH to produce nanometer Na2CO3 crystal, so obstruction of a pipeline by the Na2CO3 crystal during fluid conveying is prevented. The acidic gas treating process provided by the invention is simple and can achieve the dual objectives of purification of acidic gas and reclamation of pollutants; and the acidic gas treating system has the advantages of small scale, low energy consumption and low proneness to obstruction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Novel acidic gas treating process and apparatus

ActiveCN104826464AIncreased depth of responseFully contactedDispersed particle separationPhysical chemistryPrecipitation

The invention provides a novel acidic gas treating process and apparatus. The acidic gas treating process employs a gas-liquid two-phase countercurrent absorption reaction and uses a NaOH solution as an absorption liquid to treat acidic gas so as to produce NaHS. According to the process, a primary liquid reaction product and a secondary liquid reaction product are cyclically used, the secondary liquid reaction product is used a tertiary reaction absorption liquid, and an MDEA solution is used as a fourth-stage reaction absorption liquid; thus, the purpose of replacement of CO2 with H2S is achieved, the generation amounts of Na2CO3 and NaHCO3 in a liquid phase product are reduced, precipitation of crystals is prevented, and long cycle operation of the apparatus is guaranteed. The acidic gas treating process provided by the invention is simple and can achieve the dual objectives of purification of acidic gas and reclamation of pollutants.

Owner:CHINA PETROLEUM & CHEM CORP +1

Dispersing apparatus

InactiveCN1118330CPrevent rotationEliminate concentration differencesGrain treatmentsEngineeringPigment

Owner:TOYO INK SC HOLD CO LTD

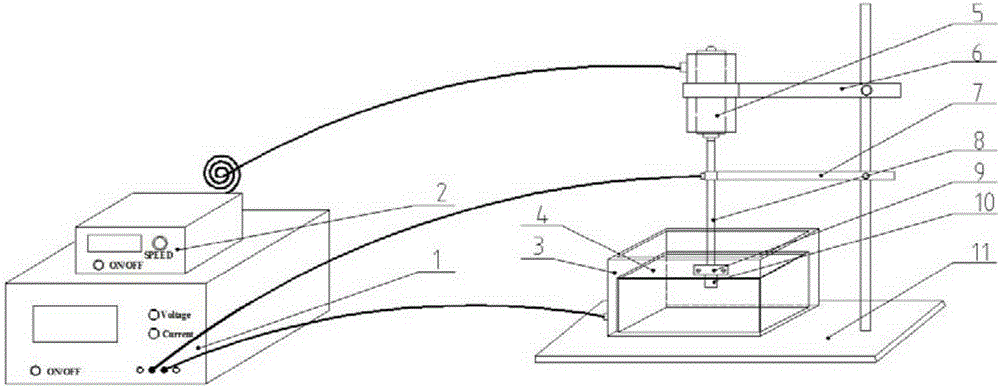

Electroplating device and electroplating structure based on tin-silver-copper alloy plating

ActiveCN105220207ASimple structureEliminate concentration differencesCellsTanksControl systemTin-silver-copper

The invention relates to an electroplating device and an electroplating structure based on tin-silver-copper alloy plating. The electroplating device and the electroplating structure comprise an electroplating bath and a control system, wherein a tin layer is arranged on the inner wall of the electroplating bath in a surrounding mode; an electrode rotating mechanism is arranged above the electroplating bath; the control system comprises a rotary speed controller; and the rotary speed controller controls the electrode rotating mechanism to rotate so as to drive a plating article to rotate in the area which the tin layer surrounds. Therefore, according to the electroplating device and the electroplating structure based on tin-silver-copper alloy plating, a stirring device is not required to be installed; only a stationary electrode of a traditional electroplating device is converted into a rotary electrode; besides, the tin layer is arranged around the inner wall of the electroplating bath; in an electroplating process, the plating article can rotate, the concentration difference of electroplating liquids is effectively eliminated, and the structure of the electroplating bath is extremely simplified, so that a disordered state of electrolyte flowing cannot occur in the electroplating process, furthermore, the electroplating effect is enhanced, and the plating layer is enabled to be more flat and uniform; and the structure is simple, the operation is convenient and the enablement is high.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

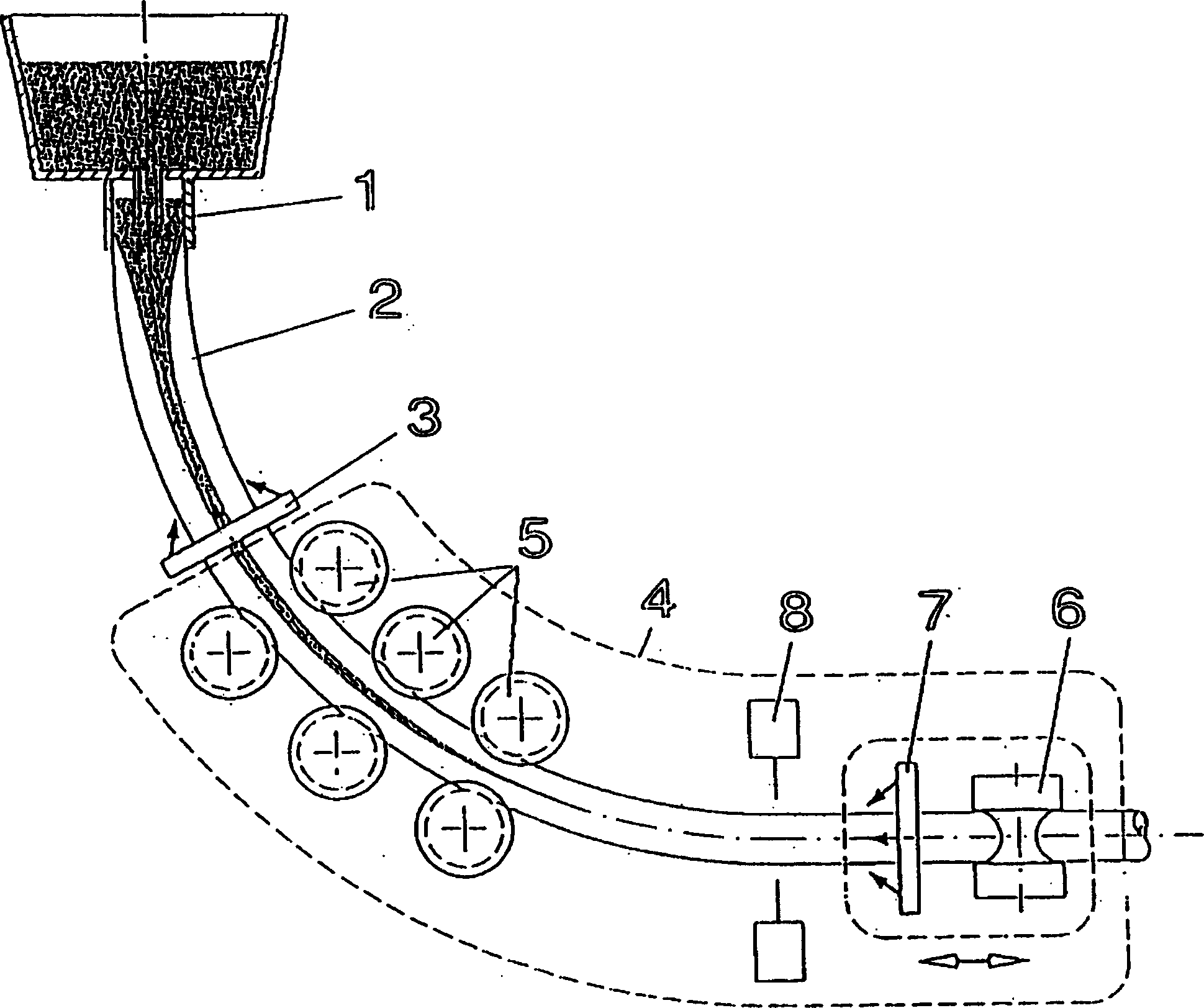

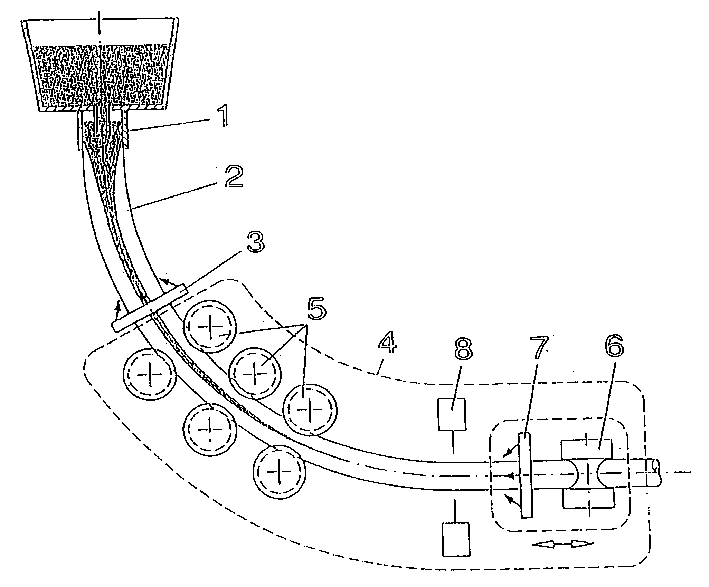

Method of producing round billets and its equipment

InactiveCN1170646CRegulating pressureConvenient distanceWork treatment devicesMetal rolling arrangementsIt equipmentMaterials science

The invention relates to a process and device for the production of continuously cast billets in a production plant employs a vertical, round strand-casting machine with horizontal run-out, at least one descaling device, and several following roll stands. For the production of round billets with diameters in the range of 90-300 mm, after the solidifying round billet has left the mold but before it has entered the following rolling unit, its surface is descaled and the area near the surface is cooled in defined manner to a temperature which is optimum for the grade of steel in question before the round billet is worked, first over the course of at least three successive horizontal passes then in a vertical pass, the surface of the preworked billet being descaled again before the last pass.

Owner:SMS DEMAG AG

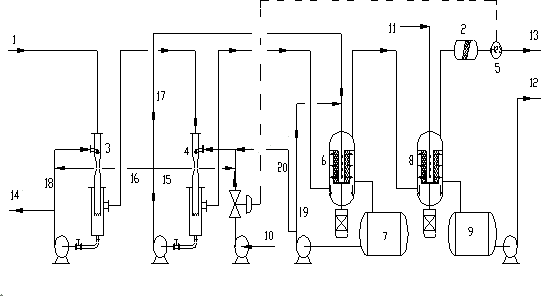

Multi-stage countercurrent absorption process and system for acidic gas

ActiveCN104826465AReduce contentIncreased depth of responseDispersed particle separationPhysical chemistryCrystallization

The invention provides a multi-stage countercurrent absorption process and system for acidic gas. The absorption process employs a gas-liquid two-phase countercurrent absorption reaction and uses a NaOH solution as an absorption liquid to treat acidic gas so as to produce NaHS. According to the process, a crystallizer and a separator are arranged in a primary reaction and a secondary reaction, and heat is taken out of a reactor; and through filling of the NaOH solution in stages, peak clipping of reaction heat is realized, and local crystallization caused by generation of heat spots is prevented. A combination of a Venturi reactor and a rotating packed bed reactor is used as a reaction apparatus which is flexible to operate and has high mass transfer efficiency. The acidic gas absorption process provided by the invention is simple and can achieve the dual objectives of purification of acidic gas and reclamation of pollutants; and the acidic gas absorption system has the advantages of small scale, low energy consumption and low proneness to obstruction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Comprehensive utilization process and system for acidic gas

ActiveCN104826560AIncreased depth of responseFully contactedSulfur compoundsLiquid-gas reaction processesPollutantChemistry

The invention provides a comprehensive utilization process and system for acidic gas. The comprehensive utilization process employs a NaOH solution as an absorption liquid to treat acidic gases so as to produce NaHS. According to the process, a liquid reaction product obtained in each stage is cyclically used; and through filling of the NaOH solution in stages and adjusting of reaction intensity in each stage, peak clipping of reaction heat is realized, and local crystallization caused by generation of heat spots is prevented. A combination of a Venturi reactor and a rotating packed bed reactor is used as a reaction apparatus which is flexible to operate and has high mass transfer efficiency. The acidic gas treatment process provided by the invention is simple and can achieve the dual objectives of purification of acidic gas and reclamation of pollutants.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of sodium hydrosulfide production process and device

ActiveCN105642091BIncreased depth of responseFully contactedDispersed particle separationSulfur compoundsSulfurGas phase

Owner:CHINA PETROLEUM & CHEM CORP +1

Sol-gel preparation method of ceramic bonding agent

InactiveCN111975654AImprove stabilityEliminate concentration differencesAbrasion apparatusGel preparationEthylic acid

The invention relates to a sol-gel preparation method of a ceramic bonding agent. The preparation method comprises the steps that 1) zinc acetate and zirconium acetate are taken and dissolved in an acetic acid solution to prepare a mixed solution A, and sodium nitrate, lithium nitrate and aluminum nitrate are taken and dissolved in a boric acid solution to prepare a mixed solution B; 2) tetrabutyltitanate is taken and added into absolute ethanol to prepare a solution, the mixed solution A is added, and heat reaction is carried out under ultrasonic conditions to prepare sol A; 3) firstly the mixed solution B is added into acidic silica sol for mixing uniformly, and then the sol A is added to prepare mixed sol; 4) ammonia is added into the mixed sol under the ultrasonic conditions, so thatpH of a system reaches 5 or above, and wet gel is prepared; and 5) the obtained wet gel is dried, sintered and cooled to obtain the ceramic bonding agent. According to the preparation method, the uniform mixing of components of the ceramic bonding agent at the molecular level is promoted through smooth rubber alloy, the grain size is small, the reactivity is high, refractoriness is greatly reduced, and high-temperature fluidity is significantly improved; and formed pores after sintering are small and uniform, the structure is uniform without defects, and the mechanical strength is high.

Owner:卢俊杰

A multi-stage countercurrent absorption process method and system for acid gas

ActiveCN104826465BReduce contentIncreased depth of responseDispersed particle separationPhysical chemistryProcess engineering

The invention provides a multi-stage countercurrent absorption process and system for acidic gas. The absorption process employs a gas-liquid two-phase countercurrent absorption reaction and uses a NaOH solution as an absorption liquid to treat acidic gas so as to produce NaHS. According to the process, a crystallizer and a separator are arranged in a primary reaction and a secondary reaction, and heat is taken out of a reactor; and through filling of the NaOH solution in stages, peak clipping of reaction heat is realized, and local crystallization caused by generation of heat spots is prevented. A combination of a Venturi reactor and a rotating packed bed reactor is used as a reaction apparatus which is flexible to operate and has high mass transfer efficiency. The acidic gas absorption process provided by the invention is simple and can achieve the dual objectives of purification of acidic gas and reclamation of pollutants; and the acidic gas absorption system has the advantages of small scale, low energy consumption and low proneness to obstruction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process method and system for comprehensive utilization of acid gas

ActiveCN104826560BIncreased depth of responseFully contactedSulfur compoundsLiquid-gas reaction processesPhysical chemistryProcess engineering

Owner:CHINA PETROLEUM & CHEM CORP +1

A process and system for preparing sodium hydrosulfide from acid gas

ActiveCN104826467BAvoid cloggingReduce concentrationSulfur compoundsDispersed particle separationSodium hydrosulfideDiluent

The invention discloses a process and system for producing sodium hydrosulfide from acidic gas. The process employs a gas-liquid two-phase countercurrent absorption reaction and uses a NaOH solution as an absorption liquid to treat acidic gases so as to produce NaHS. According to the process, a primary liquid reaction product is circulated to a secondary intermediate tank and used as a diluent; and a supplementary carrier gas pipeline is arranged to introduce supplementary carrier gas, so the concentration of CO2 in the acidic gases is reduced and most CO2 is taken out of the apparatus together with the carrier gas, thereby realizing control of the contents of Na2CO3 and NaHCO3, preventing obstruction of the pipelines due to crystallization caused by production of a great amount of Na2CO3 and guaranteeing long cycle operation of an apparatus. The acidic gas treating process provided by the invention is simple and can achieve the dual objectives of purification of acidic gas and reclamation of pollutants; and the system for producing sodium hydrosulfide from acidic gas has the advantages of small scale, low energy consumption and low proneness to obstruction.

Owner:CHINA PETROLEUM & CHEM CORP +1

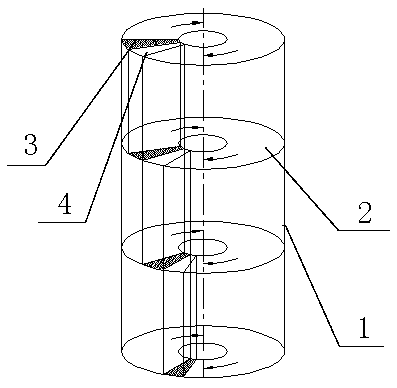

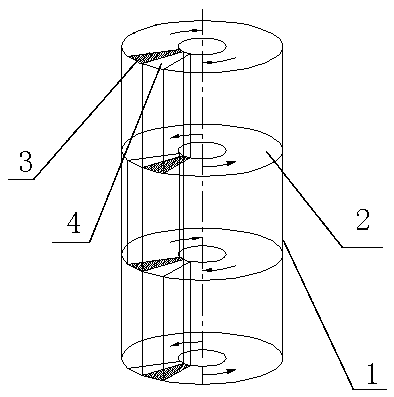

Staggered sieve plate installation structure of circular flowing type sieve plate tower

PendingCN108499150AEliminate concentration differencesImprove distillation efficiencyDistillation separationMarine engineeringTower

The invention relates to a staggered sieve plate installation structure of a circular flowing type sieve plate tower. The structure comprises a tower body; multiple circular flowing sieve plates are installed on the upper and lower sides of the interior of the tower body and comprise the clockwise circular flowing sieve plates and the counterclockwise circular flowing sieve plates; the flowing direction of every two sieve plates installed between the adjacent upper and lower layers is completely opposite, and that is to say that one of the two sieve plates is the clockwise circular flowing sieve plate, and the other one of the two sieve plates is the counterclockwise circular flowing sieve plate. Tower plate liquid receiving grooves are formed in the circular flowing sieve plates, tower plate downcomers are arranged adjacent to one sides of the tower plate liquid receiving grooves, and circular flowing liquid flows from the outer sides of the liquid receiving grooves to the outer sidesof the downcomers and then enter the downcomers; the downcomers of the circular flowing sieve plates on the upper layer are aligned with the liquid receiving grooves of the circular flowing sieve plates on the lower layer, and the liquid receiving grooves of the circular flowing sieve plates on the upper layer are aligned with the downcomers of the circular flowing sieve plates on the lower layer. The structure has the advantages that the structure is simple, installation is convenient, the rectification effect of a circular flowing type shunt tower can be substantially improved, correspondingly the energy consumption of the tower and peripheral equipment is reduced, and the production cost is saved.

Owner:杭州杭氧低温液化设备有限公司

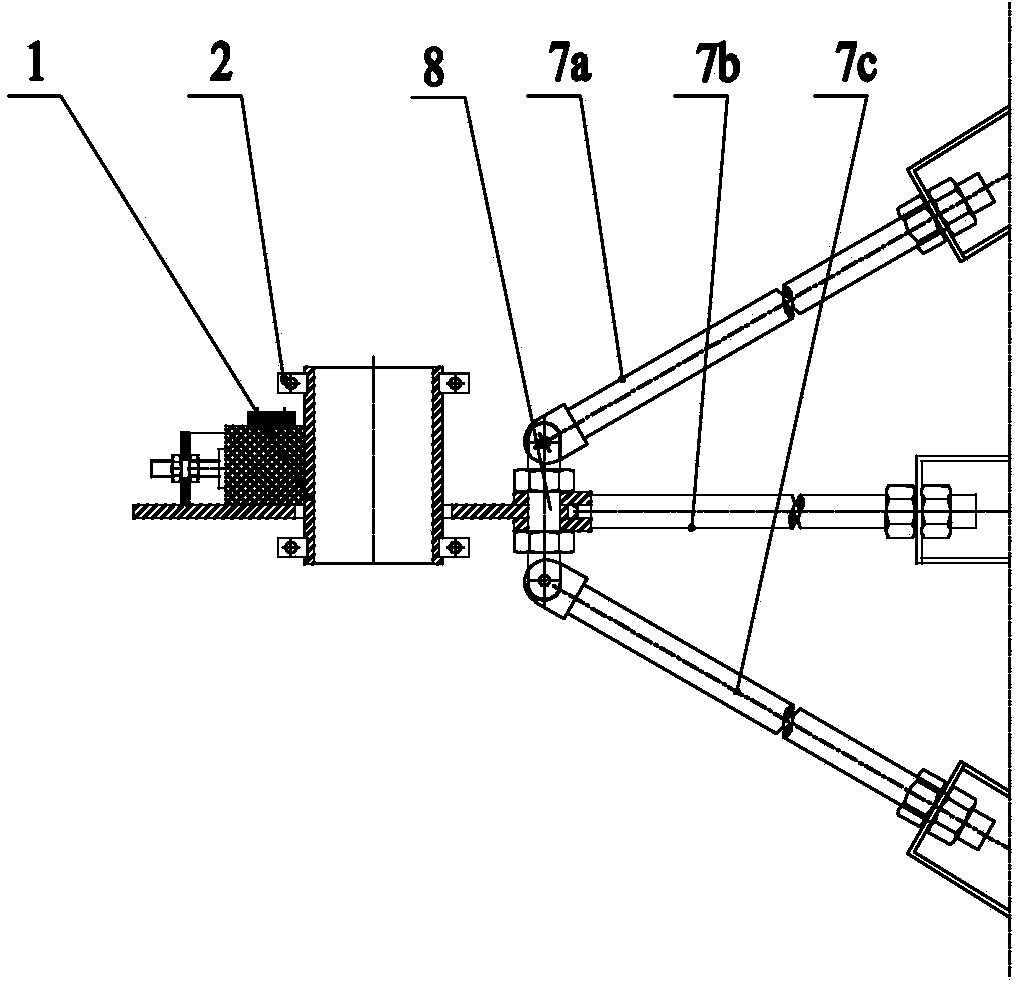

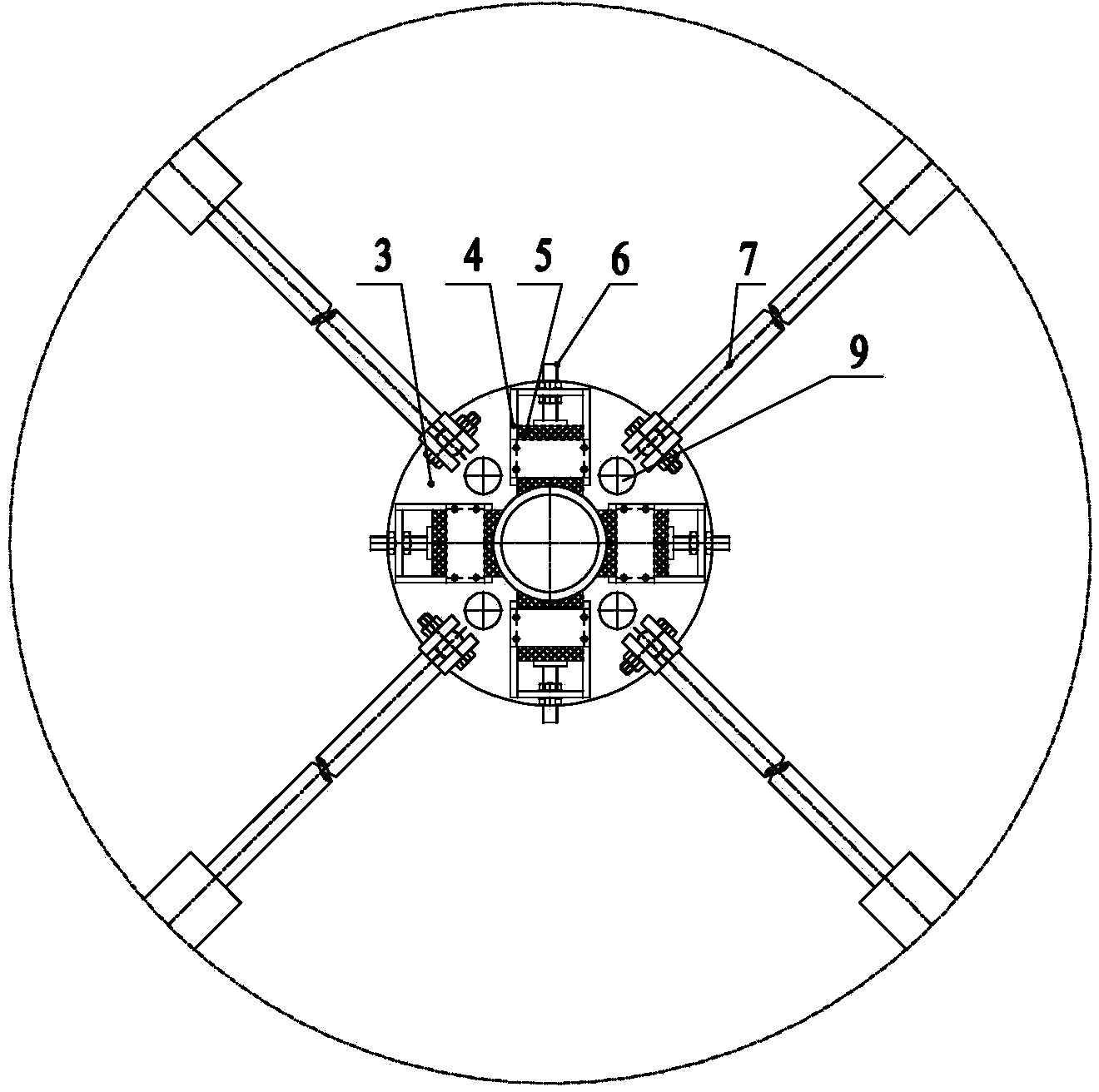

Large fermentation tank bearing

ActiveCN103642676BGuaranteed axial stabilityGuaranteed radial stabilityBioreactor/fermenter combinationsBiological substance pretreatmentsTransformerEngineering

The invention relates to a frock clamp used in a production process of transformers, and in particular relates to a large fermentation tank bearing. The large fermentation tank bearing comprises a disk base which is supported in a tank body through a plurality of groups of pull rod racks, wherein each group of pull rod racks comprises a first pull rod, a second pull rod and a third pull rod, the extension cord of the second pull rod and the center line of the tank body are vertically intersected, the first pull rod and the third pull rod are symmetrical relative to the second pull rod, a connecting pin penetrating through the disk base is arranged at the junction of the disk base and each pull rod rack, the upper end of the connecting pin is hinged with the first pull rod, and the lower end of the connecting pin is hinged with the third pull rod. With the adoption of the large fermentation tank bearing, the concentration difference at the middle bearing area in the tank during stirring is eliminated, and the mass transfer and mixing efficiencies of a high-viscosity fermentation tank are improved.

Owner:JIANGSU HAOTELONG MIX EQUIP

Staged Feed Alkylation Reactor and Alkylation Process

ActiveCN104549116BOvercoming wrapping forceAchieve hybridLiquid hydrocarbon mixtures productionChemical/physical/physico-chemical nozzle-type rreactorsEmulsionAlkylation

The invention discloses a segmented feeding alkylation reactor and an alkylation reaction method. The reactor comprises a reactor cylinder, a head, a partition, an upper bed, a rotary bed, a composite bed, and an Material pipe, feeding distribution pipe, rotating shaft, supplementary material inlet, material outlet, recirculating cooling air inlet and recirculating cooling air outlet. The present invention also provides an alkylation reaction method, which adopts the above-mentioned segmented feed alkylation reactor, wherein isobutane and concentrated sulfuric acid first form an acid hydrocarbon emulsion in the upper bed layer, and then mix with the The hydrocarbon enters the rotating bed for alkylation reaction, and the reacted material realizes the demulsification process of the emulsion in the composite bed layer.

Owner:CHINA PETROLEUM & CHEM CORP +1

A new type of acid gas treatment process method and device

ActiveCN104826464BIncreased depth of responseFully contactedDispersed particle separationFluid phasePhysical chemistry

The invention provides a novel acidic gas treating process and apparatus. The acidic gas treating process employs a gas-liquid two-phase countercurrent absorption reaction and uses a NaOH solution as an absorption liquid to treat acidic gas so as to produce NaHS. According to the process, a primary liquid reaction product and a secondary liquid reaction product are cyclically used, the secondary liquid reaction product is used a tertiary reaction absorption liquid, and an MDEA solution is used as a fourth-stage reaction absorption liquid; thus, the purpose of replacement of CO2 with H2S is achieved, the generation amounts of Na2CO3 and NaHCO3 in a liquid phase product are reduced, precipitation of crystals is prevented, and long cycle operation of the apparatus is guaranteed. The acidic gas treating process provided by the invention is simple and can achieve the dual objectives of purification of acidic gas and reclamation of pollutants.

Owner:CHINA PETROLEUM & CHEM CORP +1

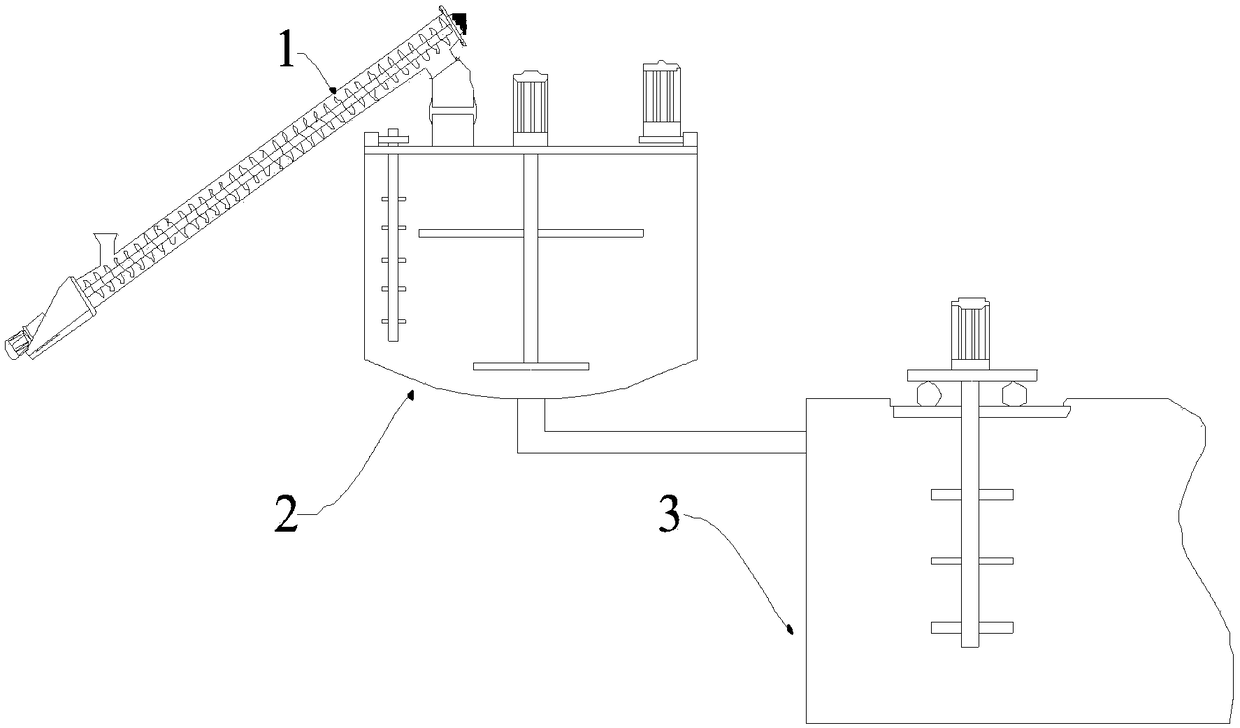

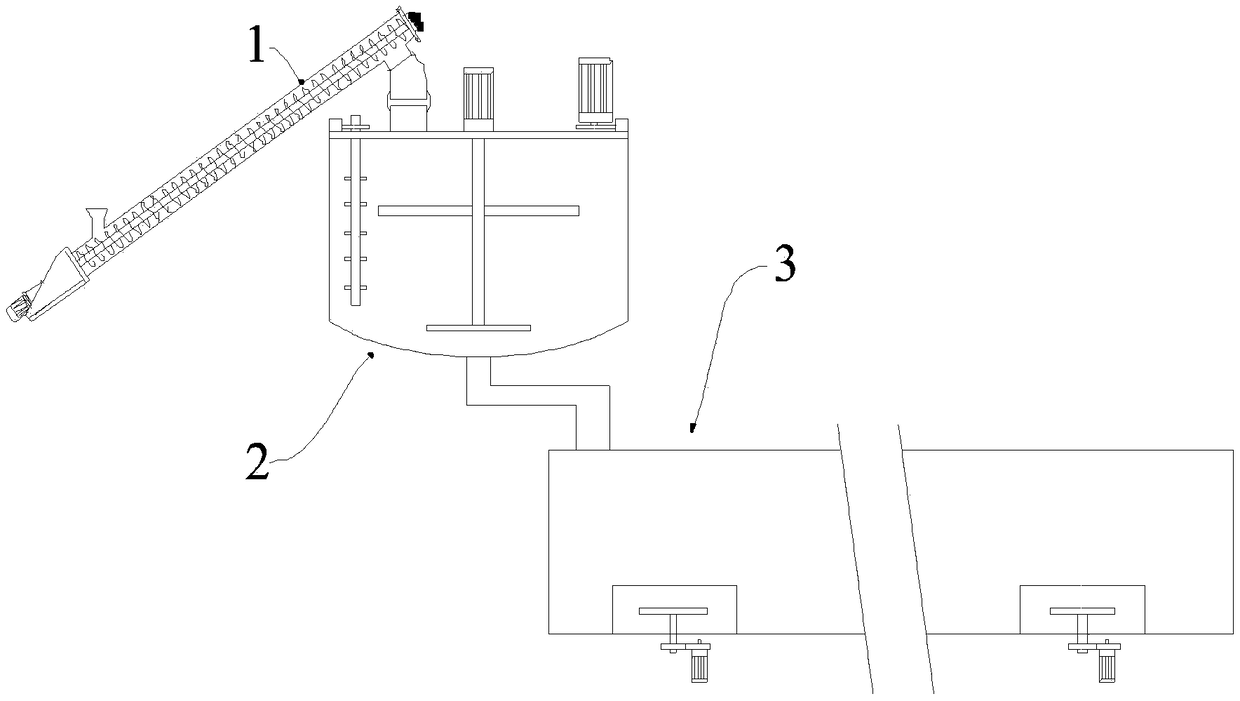

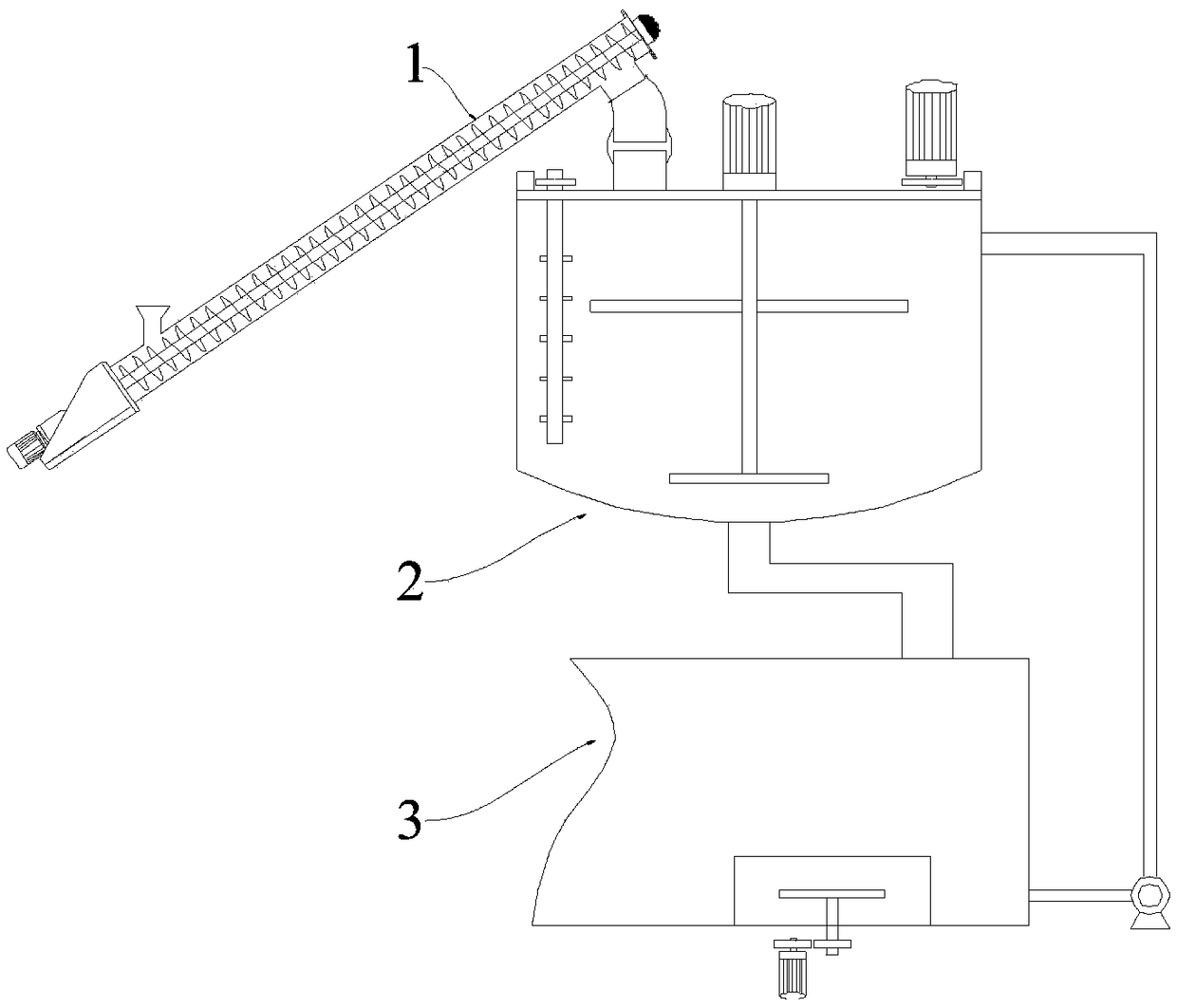

Lost-foam paint concentration real-time adjusting apparatus for exterior support production

InactiveCN109289679AStir wellImprove mix qualityFlow mixersRotary stirring mixersHigh volume manufacturingEngineering

The invention relates to the technical field of paint dip-coating equipment for production of engine parts and provides a lost-foam paint concentration real-time adjusting apparatus for exterior support production, comprising a screw feeder, a mixer and a dip-coating mechanism which are connected in sequence; the dip-coating mechanism comprises a dip-coating box connected with the mixer through acirculating pump; the mixer includes a stirring barrel in which a main stirrer is arranged; the top of the stirring barrel is also provided with a circular transmission component which is in serial transmission connection with a plurality of auxiliary stirrers. The feeder and the mixer are hermetically connected; therefore, dust caused during feeding is avoided. The circular transmission componentis in serial transmission connection with the multiple auxiliary stirrers; therefore, stirring dead corners are avoided. The dip-coating box is connected with the mixer via the circulating pump; therefore, the lost-foam paint concentration real-time adjusting apparatus for exterior support production is suitable for continuous batch production. A paint in a box is returned into the mixer in realtime to remix with a newly mixed paint before the mixture is returned to the dip-coating box; therefore, differences of paint concentrations due to differences of mixing batches are eliminated, and quality stability is improved for the dip-coating paint.

Owner:山东浩顺机械有限公司

A kind of electroplating device and electroplating structure based on tin-silver-copper alloy plating

ActiveCN105220207BSimple structureEliminate concentration differencesCellsTanksCopper platingControl system

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

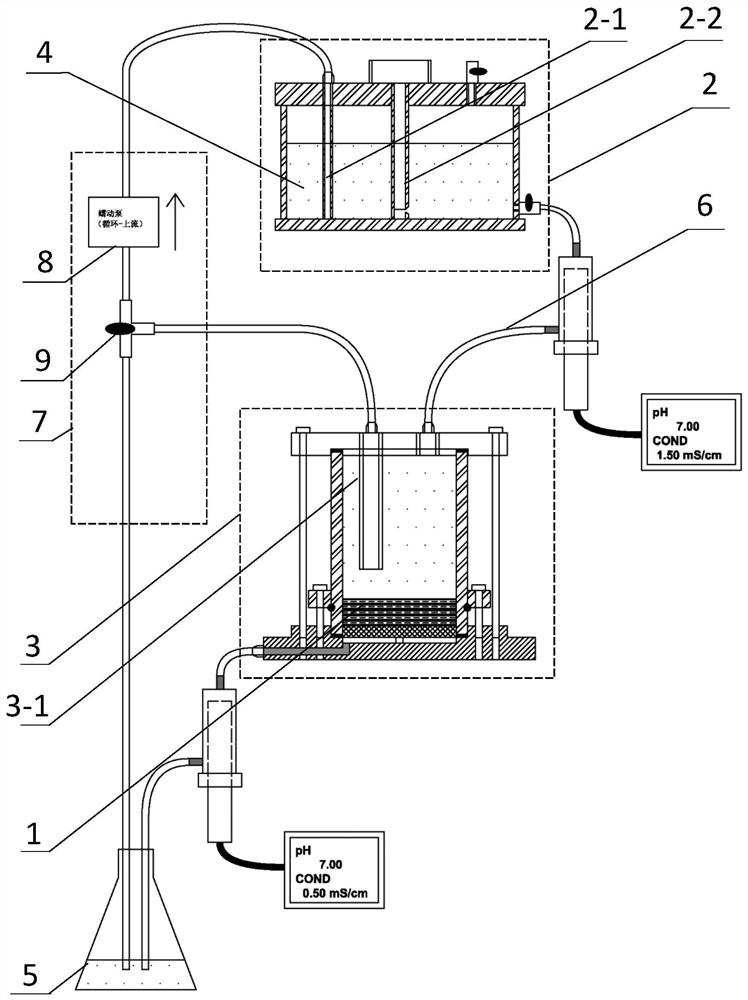

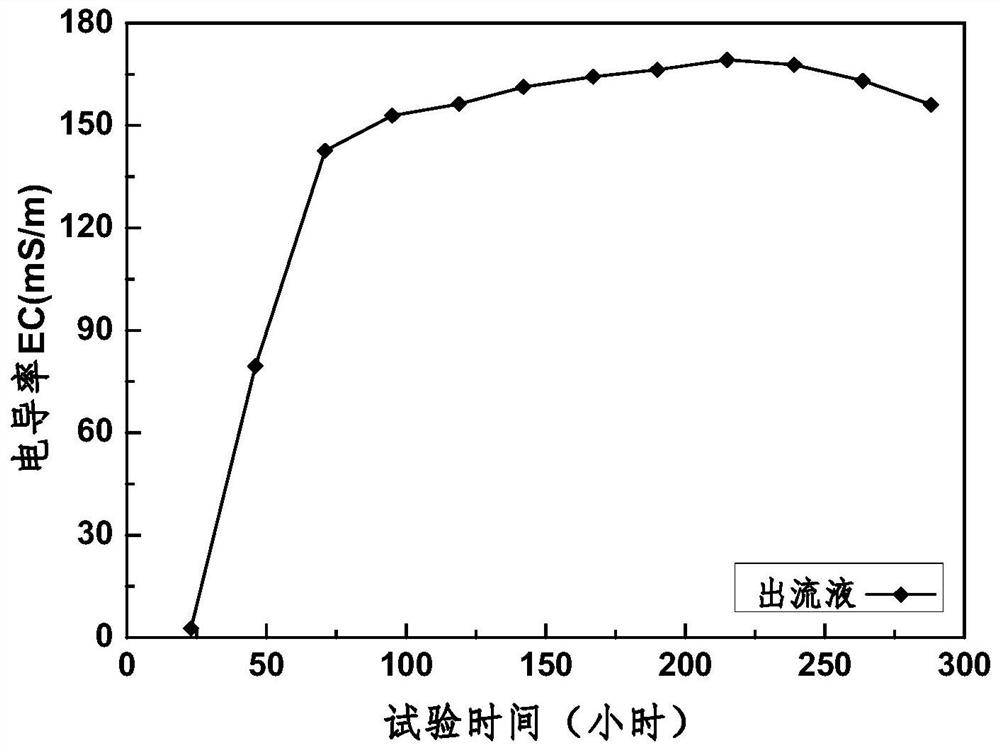

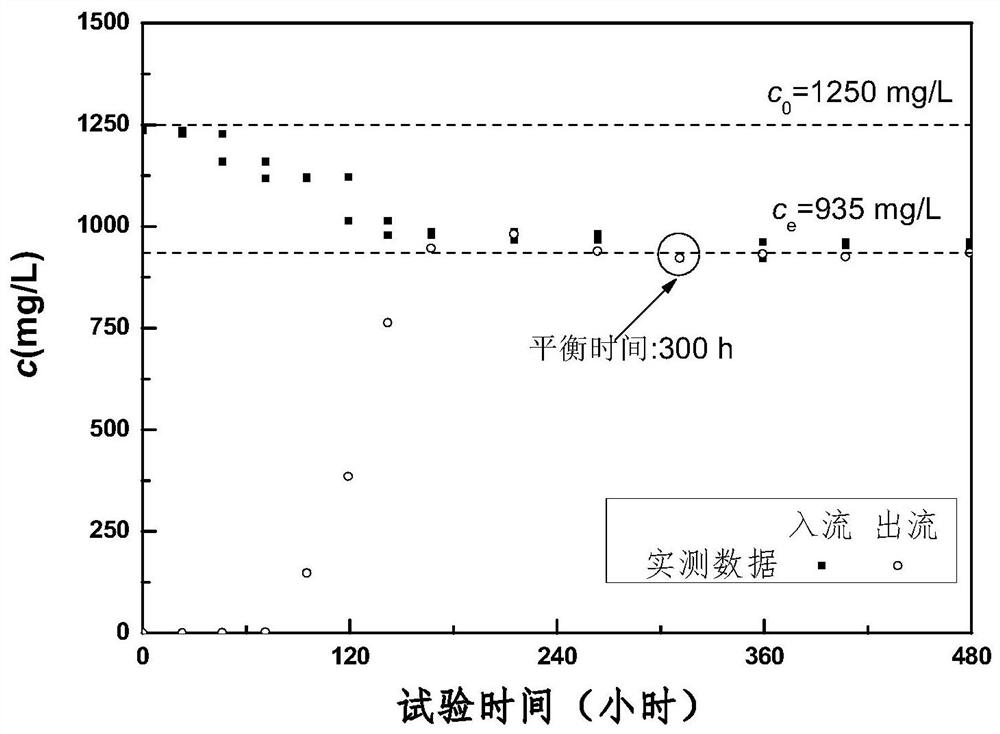

Cyclic closed system soil column test method for rapid determination of soil isotherm adsorption curve

ActiveCN113702618BReduce test equilibration timeEasy to judge adsorption equilibriumEarth material testingColor/spectral properties measurementsSoil scienceAdsorption equilibrium

Owner:ZHEJIANG UNIV

A kind of segmented feeding alkylation reactor and alkylation reaction method

ActiveCN104549087BAchieve hybridImprove responseLiquid hydrocarbon mixtures productionMixersAlkyl transferEmulsion

The invention discloses a sectional feeding type alkylation reactor and an alkylation reaction method. The reactor comprises a reactor barrel body, a seal head, a separating plate, an upper bed layer, a lower bed layer, a feeding pipe, a fed material distributing pipe, a rotating shaft, a supplementing material inlet, a discharging opening, a circulating cooling air inlet and a circulating cooling air outlet. The invention further provides the alkylation reaction method adopting the sectional feeding type alkylation reactor. The alkylation reaction method comprises the following steps: preparing acid hydrocarbon emulsion through iso-butane and concentrated sulfuric acid in the upper bed layer, and then entering a rotating bed at the lower bed layer together with mixed hydrocarbon which enters through a supplemented material inlet, so as to perform alkylation reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com