Large fermentation tank bearing

A fermentation tank and bearing technology, applied in the field of fixtures, can solve problems such as unsatisfactory effects, gaps, and the inability of stirring structures to meet the needs of high-viscosity fermentation, so as to improve mass transfer and mixing efficiency, eliminate concentration differences, and ensure axial The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

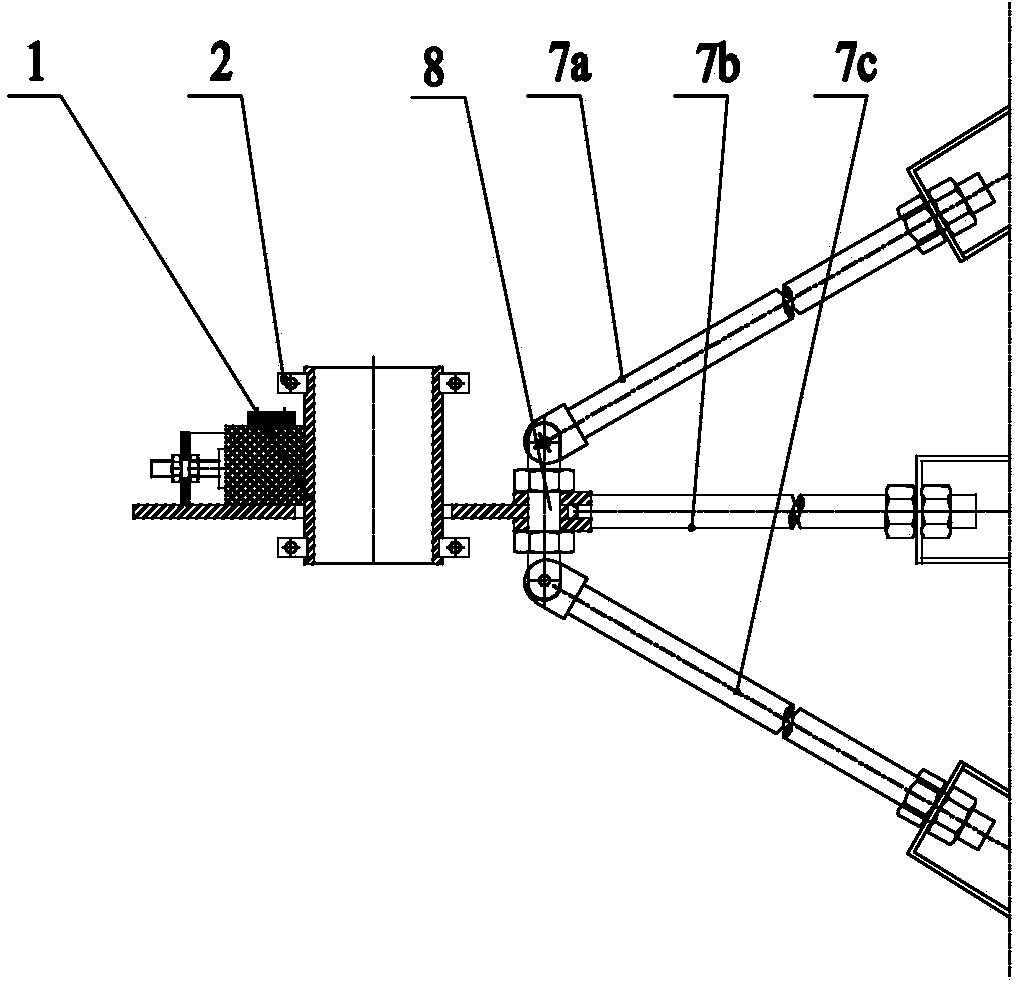

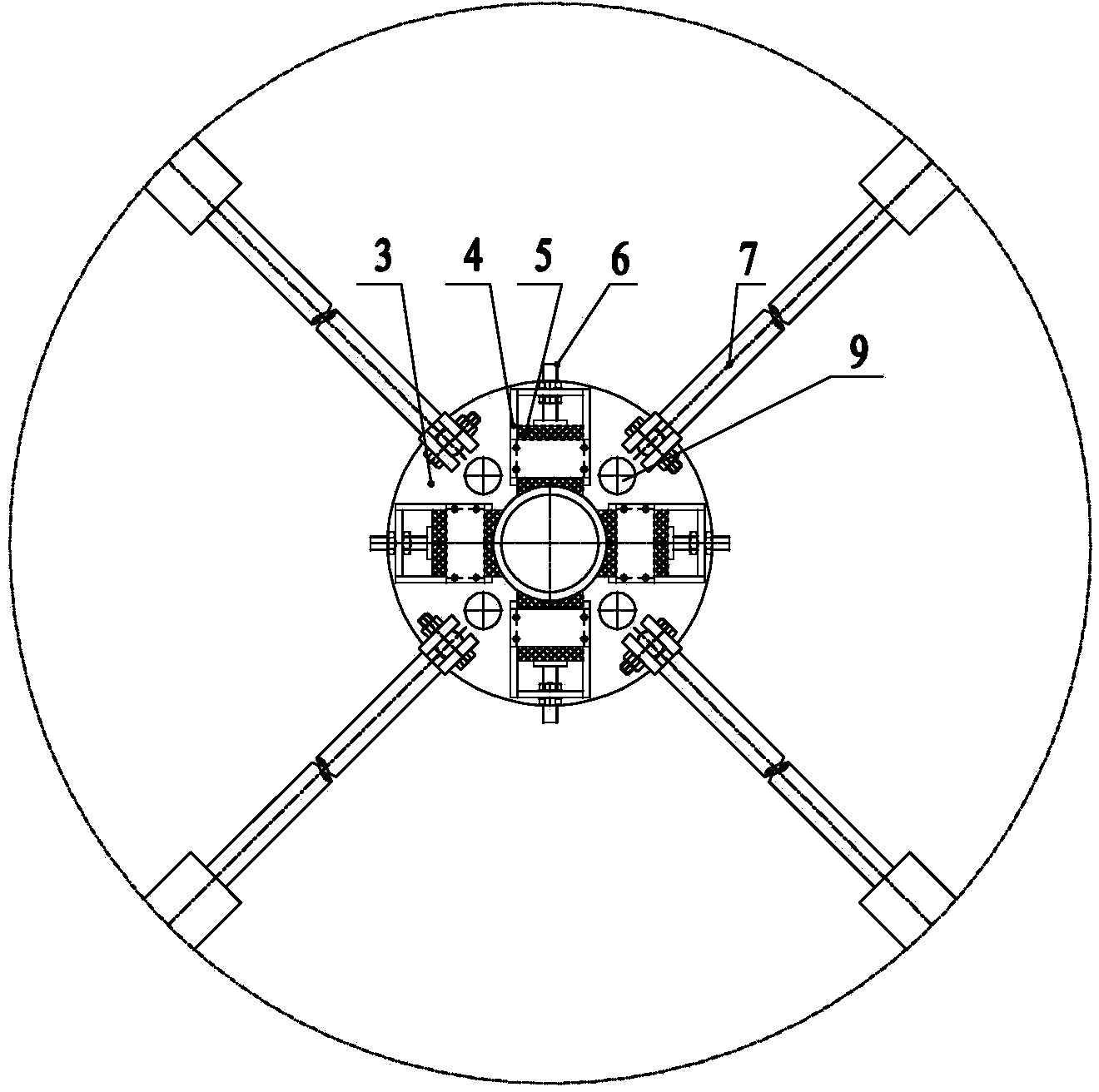

[0012] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] figure 1 , 2 Including the sheath 1, the clamp ring 2, the disc seat 3, the fixed box 4, the bearing bush 5, the adjusting screw 6, the rod frame 7, the first rod 7a, the second rod 7b, the third rod 7c, and the connecting pin 8 , Through hole 9 and so on.

[0014] Such as figure 1 , figure 2 As shown, the present invention is a large-scale fermenter bearing, including a disc seat 3, and the disc seat 3 is supported in the tank body by several groups of tie rod frames 7, and each group of pull rod frames 7 includes a first pull rod 7a, a second pull rod Pull rod 7b, the third pull rod 7c, wherein the extension line of the second pull rod 7b intersects vertically with the center line of the tank body, the first pull rod 7a and the third pull rod 7c are symmetrically arranged about the first pull rod 7a; the disc seat 3 and the pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com