Lost-foam paint concentration real-time adjusting apparatus for exterior support production

A technology of real-time adjustment and lost foam, applied in mixers with rotating stirring devices, transportation, packaging, dissolution, etc., can solve the problems of adhesive floating, affecting the use effect of coatings, and insufficient mixing of coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

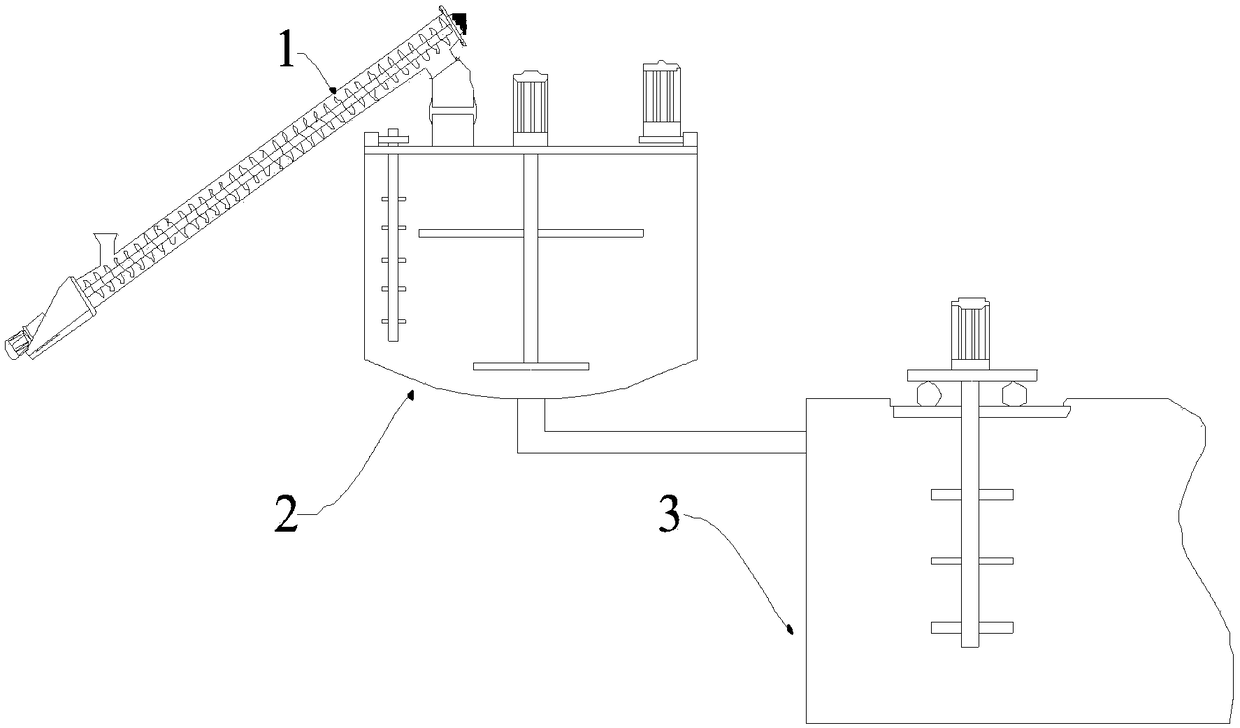

[0066] Example 1, see figure 1 , including a feeder 1, a mixer 2 and a dip coating mechanism 3 connected in sequence; the dip coating mechanism 3 includes a dip coating box 31, and a mobile stirring mechanism is arranged in the dip coating box 31.

[0067] This implementation is suitable for flexible production, without manual real-time mixing, reducing labor intensity and improving labor efficiency. The labor intensity of feeding is reduced, and the dust generated when feeding directly into the mixer 2 is also avoided.

Embodiment 2

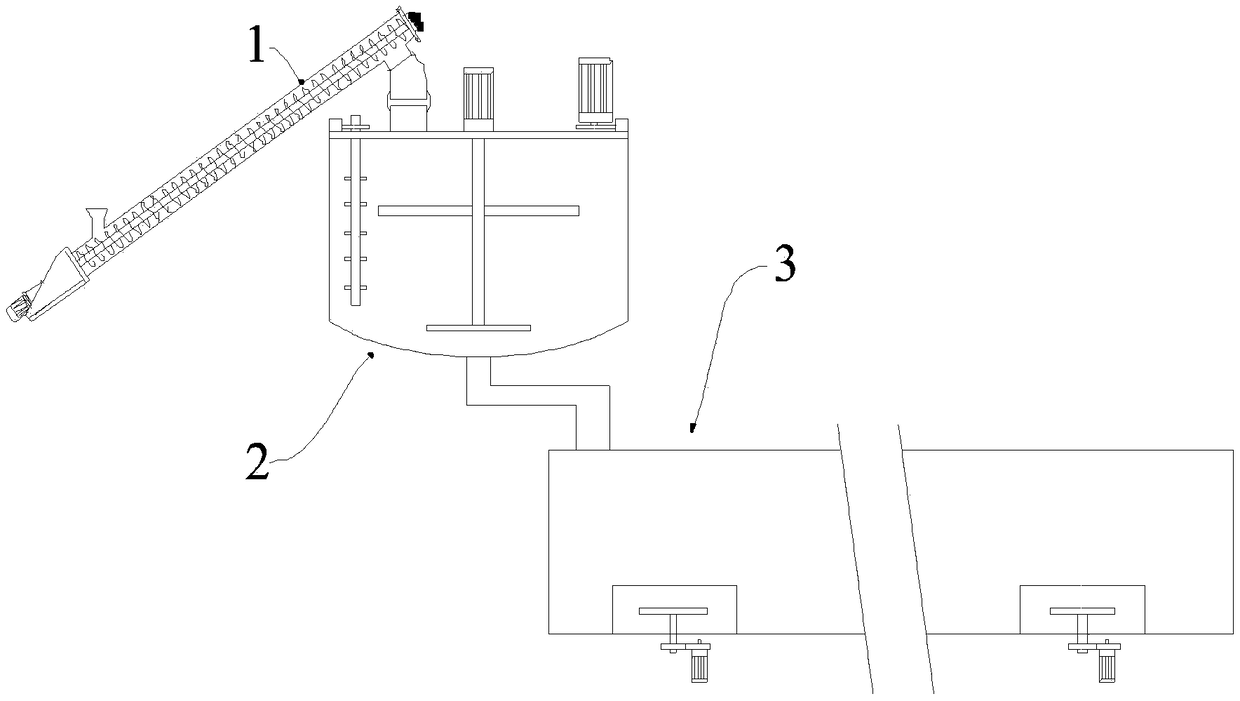

[0068] Example 2, see figure 2 , including a feeder 1, a mixer 2 and a dip coating mechanism 3 connected in sequence;

[0069] This implementation is suitable for continuous multi-person production. During the dip coating operation, the paint in the box is stirred in real time, which saves the manual stirring step, improves efficiency, and ensures the stability of dip coating quality. The labor intensity of feeding is reduced, and the dust generated when feeding directly into the mixer 2 is also avoided.

Embodiment 3

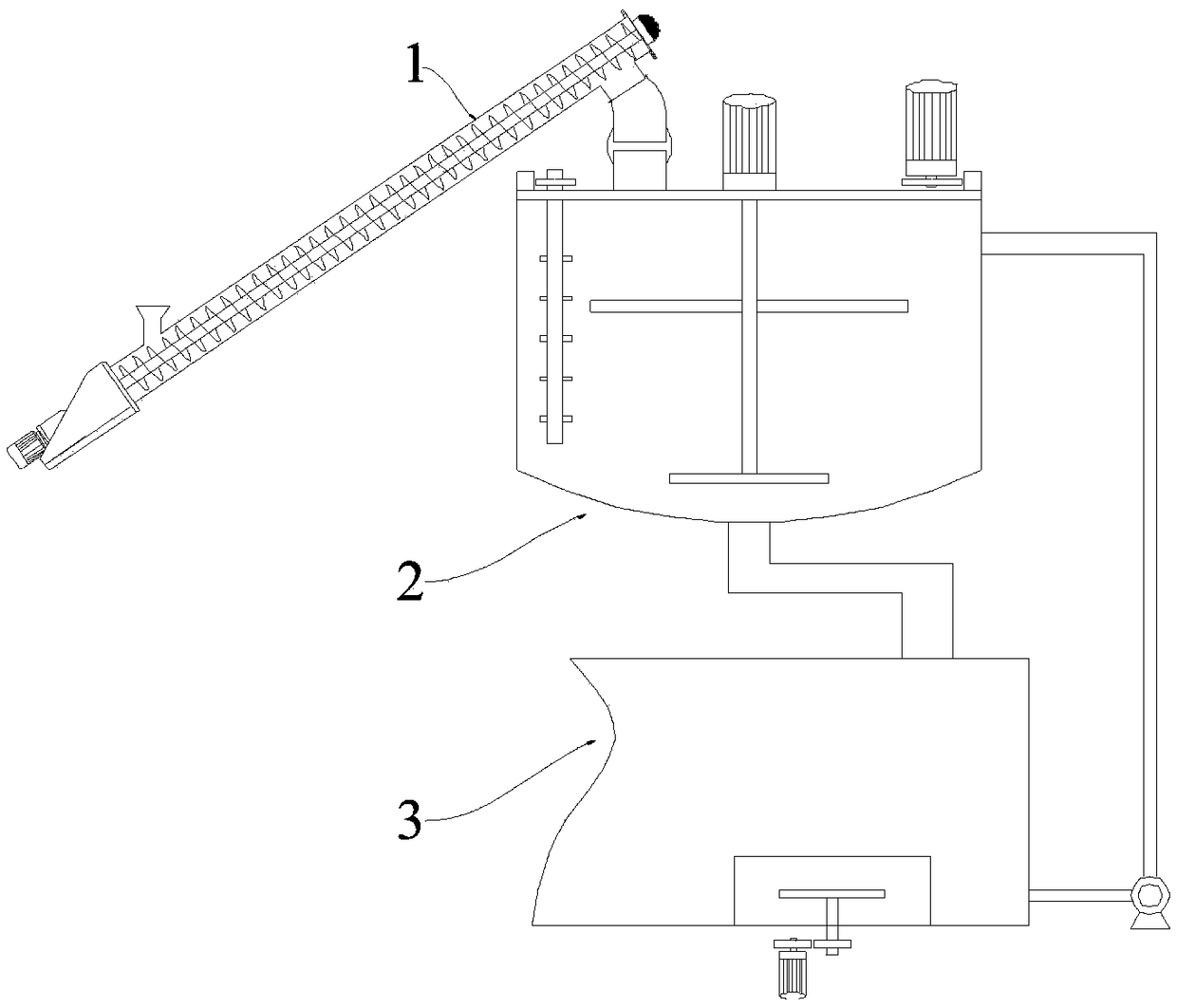

[0070] Example 3, see image 3 , including a feeder 1, a mixer 2 and a dip coating mechanism 3 connected in sequence; A bottom agitator 5 may be provided in the dipping tank 31, or a mobile agitating mechanism may be provided. The labor intensity of feeding is reduced, and the dust generated when feeding directly into the mixer 2 is also avoided.

[0071] This implementation is suitable for continuous mass production. The paint in the box returns to the mixer 2 in real time and remixes with the freshly mixed paint and then returns to the dip coating box 31, which ensures the consistency of the paint concentration in the box and eliminates the need for different mixing batches. The difference in paint concentration caused by the second time improves the quality stability of the dip coating.

[0072] In summary, the present invention connects feeder, mixer and dip-coating mechanism successively; Dip-coating mechanism comprises dip-coating box; Adopt sealing connection between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com