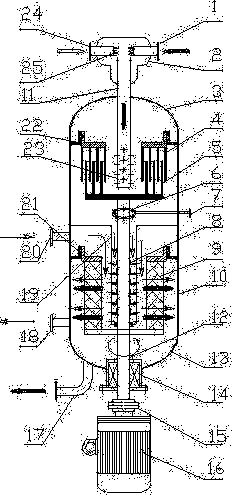

Sectional feeding type alkylation reactor and alkylation reaction method

An alkylation reactor and reactor technology, applied in chemical instruments and methods, chemical methods for reacting liquids and liquids, chemical/physical/physicochemical fixed reactors, etc., can solve the problem of increasing side reactions and inappropriate Heat release and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

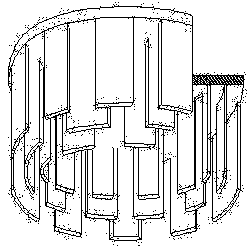

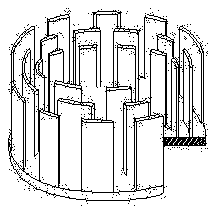

[0037] use as figure 1 For the reactor with the structure shown, the gap between the upper bed and the lower bed is 100mm. The total width of the slots of the upper bed static assembly and the rotating assembly is 1 / 3 of its circumference. The rotating assembly and the stationary assembly are respectively provided with 3 layers, the overlapping position of the stationary toothed ring assembly and the rotating toothed ring assembly is 1 / 2 of the total bed height, and the gap distance between the stationary toothed ring assembly and the reactor shell is 50mm. The gap distance between the stationary toothed ring assembly and the rotating toothed ring assembly is 50 mm, and the thickness of the stationary toothed ring assembly is 0.5 times the thickness of the rotating toothed ring assembly. The lower bed rotating bed is made of stainless steel mesh packing, the bed porosity of the stainless steel mesh packing is 0.95, and the specific surface area is 4000m 2 / m 3 , the wire d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com