Novel double-battery type sheet wide-area oxygen sensor and preparation method thereof

An oxygen sensor and dual-battery technology, which is applied in the field of new dual-battery chip wide-area oxygen sensor and its preparation, can solve problems affecting measurement accuracy, air concentration changes, exhaust gas pollution, etc., and eliminate the preparation process and chip thickness. The effect of thinning and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

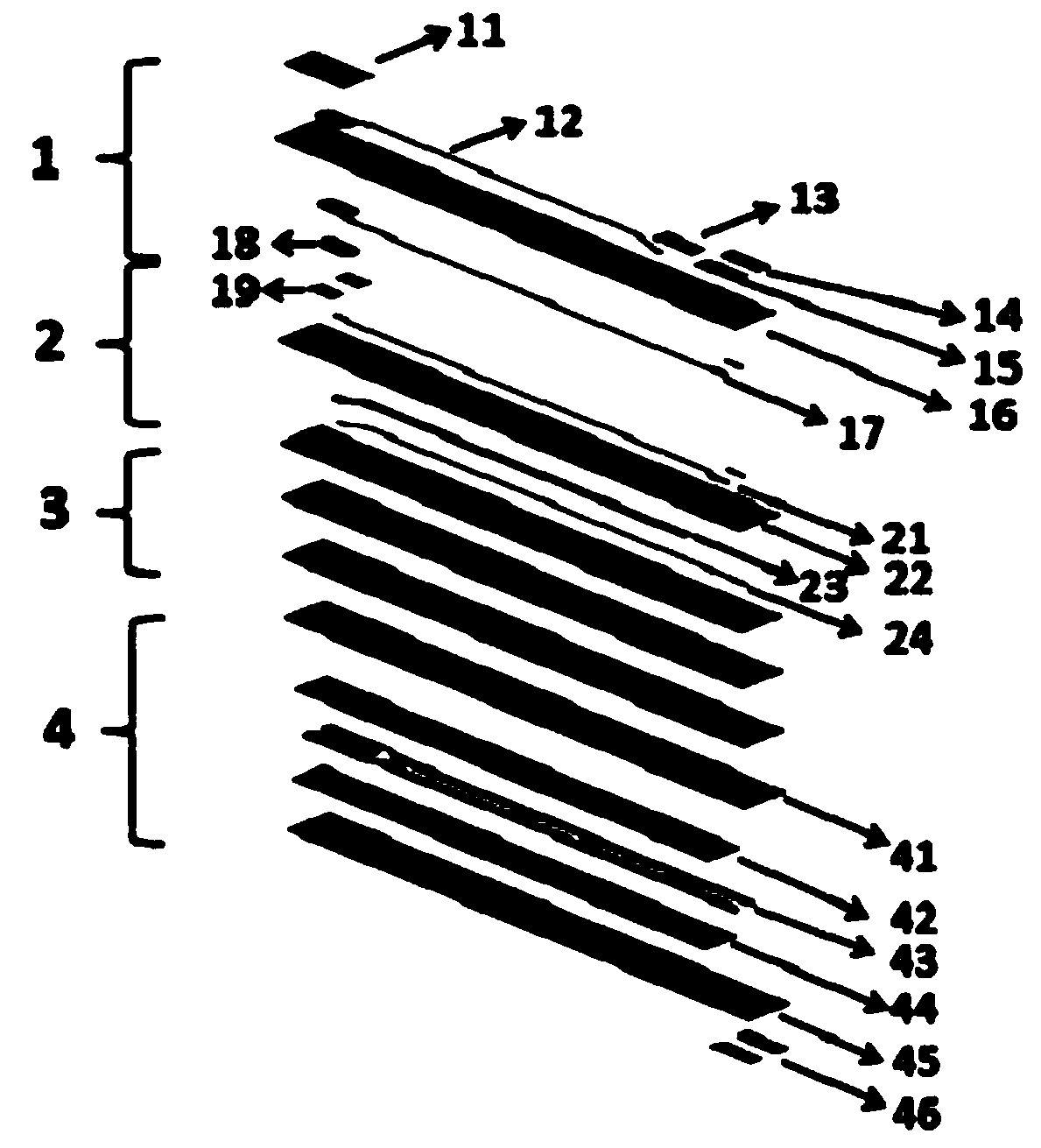

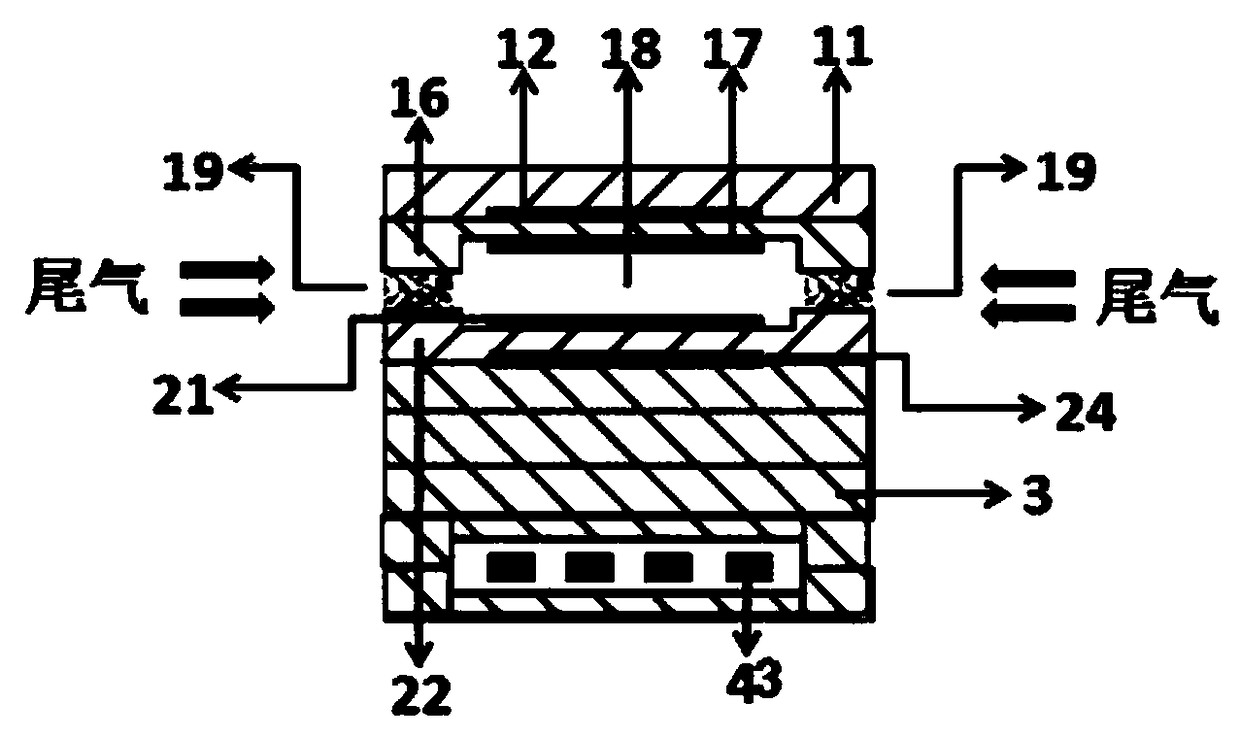

[0038] combined with figure 1 and figure 2 As shown, a new double-battery chip type wide-area oxygen sensor is sintered by stacking the oxygen pumping battery 1, the reference battery 2, the structural layer 3 and the heating layer 4 sequentially from top to bottom, wherein:

[0039] Oxygen pumping battery 1: a pump comprising a first zirconia casting substrate 16, an oxygen pumping external electrode 12 symmetrically arranged on the upper surface of the first zirconia casting substrate and a pump on the lower surface of the first zirconia casting substrate 16 The oxygen inner electrode 17, the oxygen pump outer electrode 12 is covered with a porous protective layer 11, and the oxygen pump outer electrode 12 is connected to the pin 13;

[0040]Reference cell 2: comprising a second zirconia cast substrate 22, a test electrode 21 and a reference electrode 24 arranged on the upper surface of the second zirconia cast substrate 22, the second zirconia cast substrate The lower su...

Embodiment 2

[0045] A preparation method of a novel dual-cell type chip wide-area oxygen sensor, comprising:

[0046] Step S1: Take 5 mol% yttrium oxide doped zirconia, and configure inorganic components with alumina according to the mass percentage of 88:12, and add dispersant, organic Solvent, binder and plasticizer are ball milled to form zirconia ceramic slurry;

[0047] A zirconia casting substrate is prepared by a casting method, and a first zirconia casting substrate, a second zirconia casting substrate, a third zirconia casting substrate and a fourth zirconia casting substrate are obtained;

[0048] Use mechanical punching to punch positioning holes, electrode lead-out holes and heater lead-out holes;

[0049] Step S2: prepare oxygen pump electrode slurry, diffusion barrier slurry and porous protective layer slurry: mix platinum powder and carbon at a mass percentage of 88:12, and then add an organic solvent to prepare pump electrode slurry; mix zirconia, carbon Mixing at a mass ...

Embodiment 3

[0056] Step S1: Take 8mol% yttrium oxide-doped zirconia, and configure inorganic components with alumina according to the mass percentage of 75:25, and add dispersant, organic Solvent, binder and plasticizer are ball milled to form zirconia ceramic slurry;

[0057] A zirconia casting substrate is prepared by a casting method, and a first zirconia casting substrate, a second zirconia casting substrate, a third zirconia casting substrate and a fourth zirconia casting substrate are obtained;

[0058] Use mechanical punching to punch positioning holes, electrode lead-out holes and heater lead-out holes;

[0059] Step S2: Prepare oxygen pump electrode slurry, diffusion barrier slurry and porous protective layer slurry: mix platinum powder and carbon at a mass percentage of 95:5, and then add an organic solvent to prepare pump electrode slurry; mix zirconia, carbon Mix at 50:50 by mass percentage, and then add an organic solvent to prepare a diffusion barrier slurry; mix zirconia a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com