Patents

Literature

800 results about "Signal analyzer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A signal analyzer is an instrument that measures the magnitude and phase of the input signal at a single frequency within the IF bandwidth of the instrument. It employs digital techniques to extract useful information that is carried by an electrical signal. In common usage the term is related to both spectrum analyzers and vector signal analyzers. While spectrum analyzers measure the amplitude or magnitude of signals, a signal analyzer with appropriate software or programming can measure any aspect of the signal such as modulation. Today’s high-frequency signal analyzers achieve good performance by optimizing both the analog front end and the digital back end.

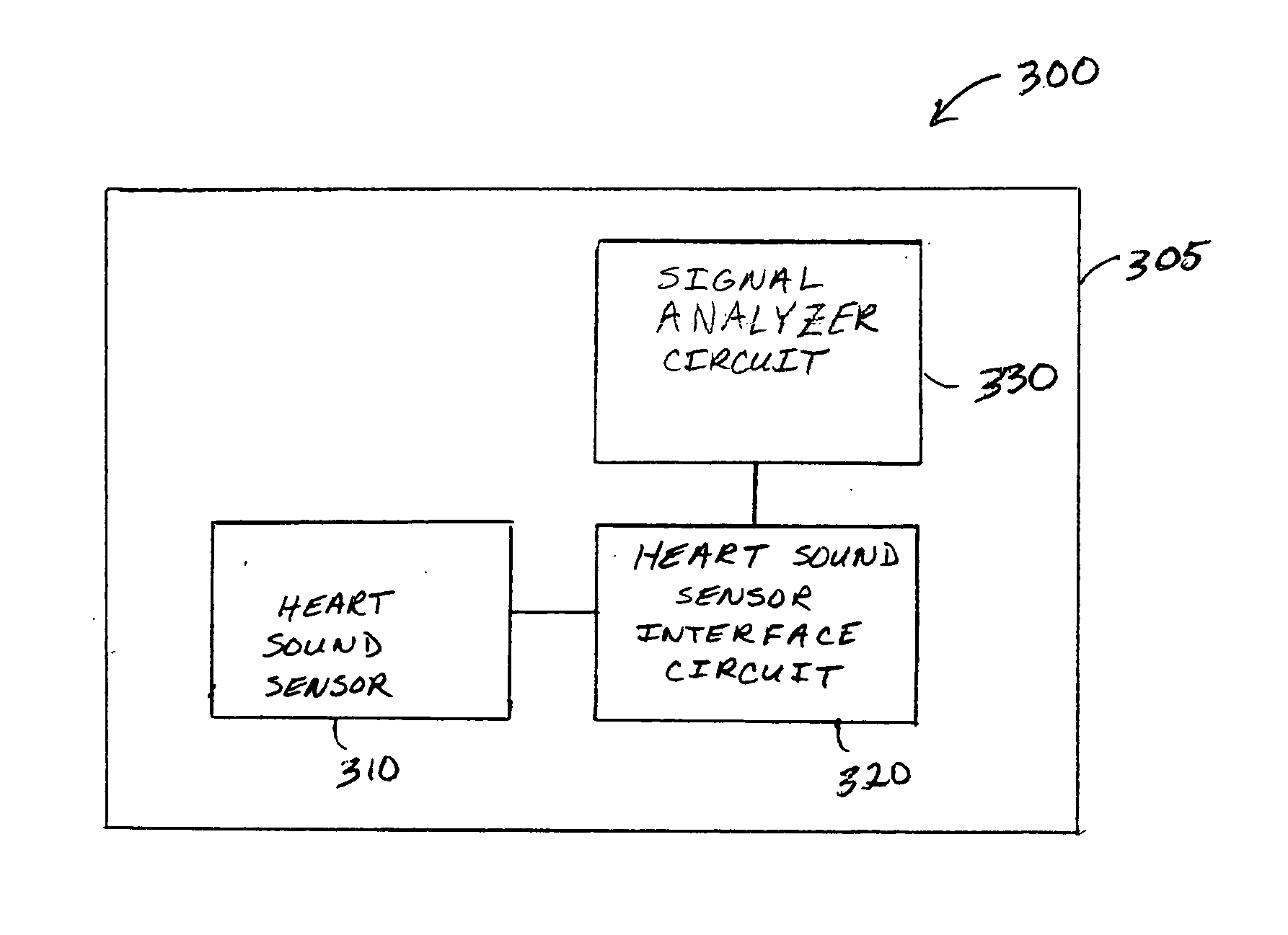

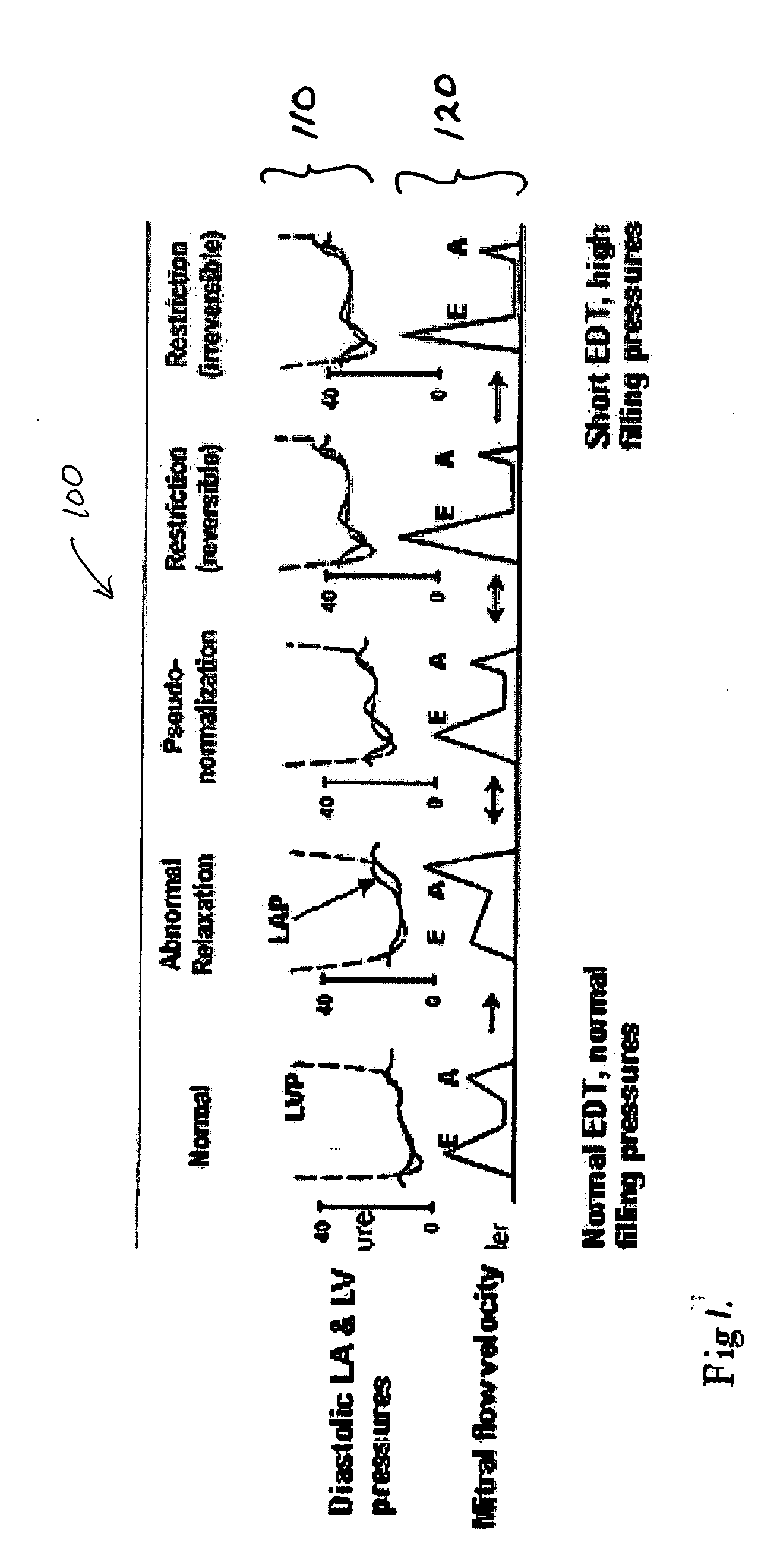

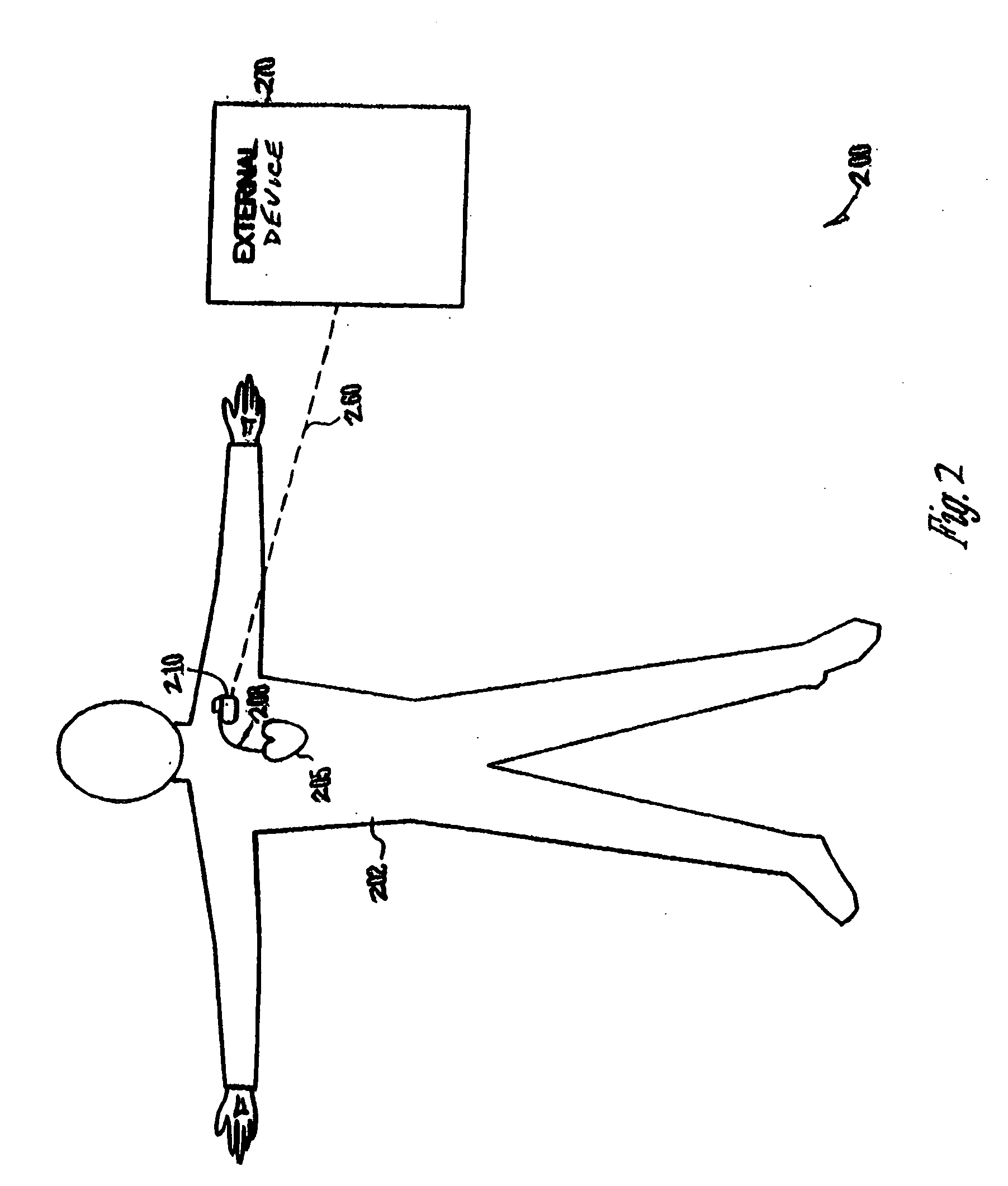

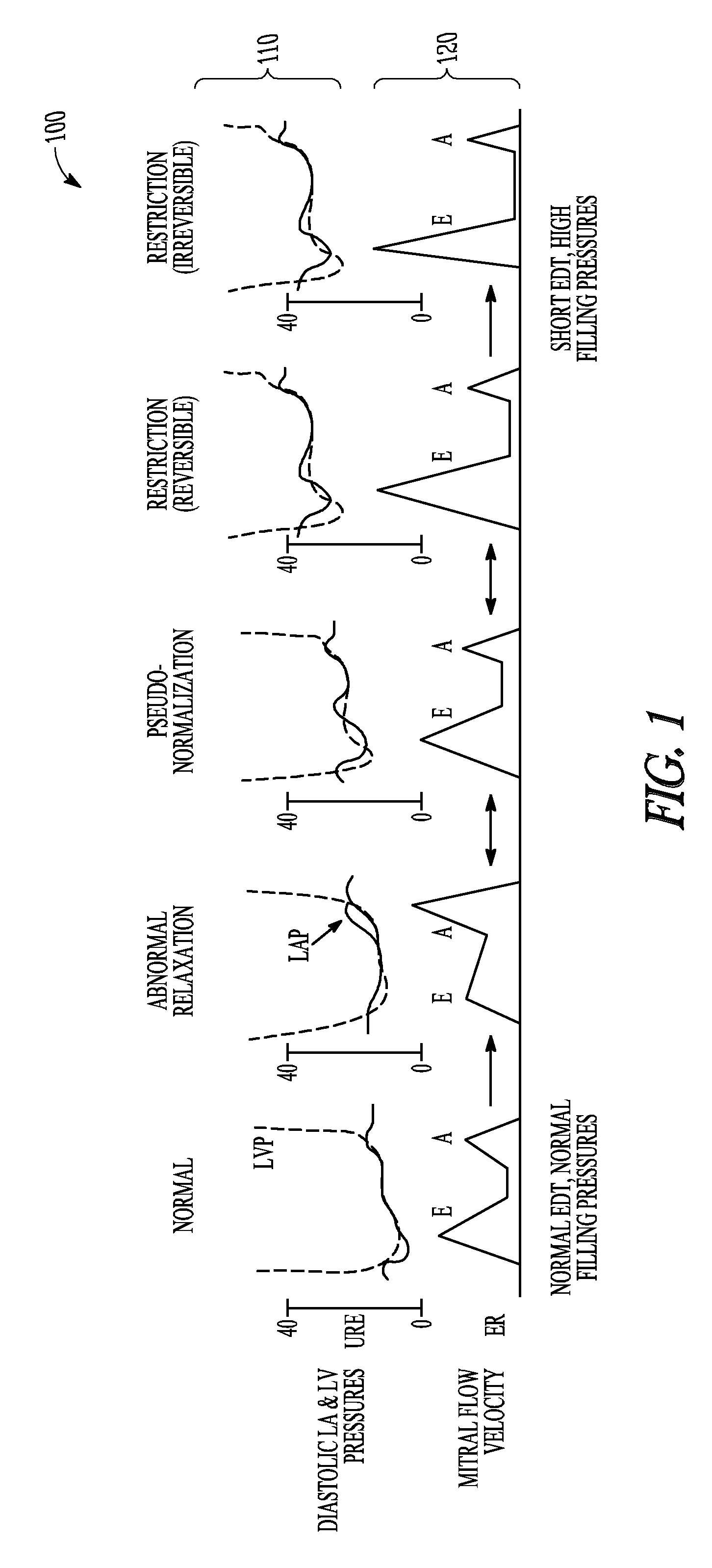

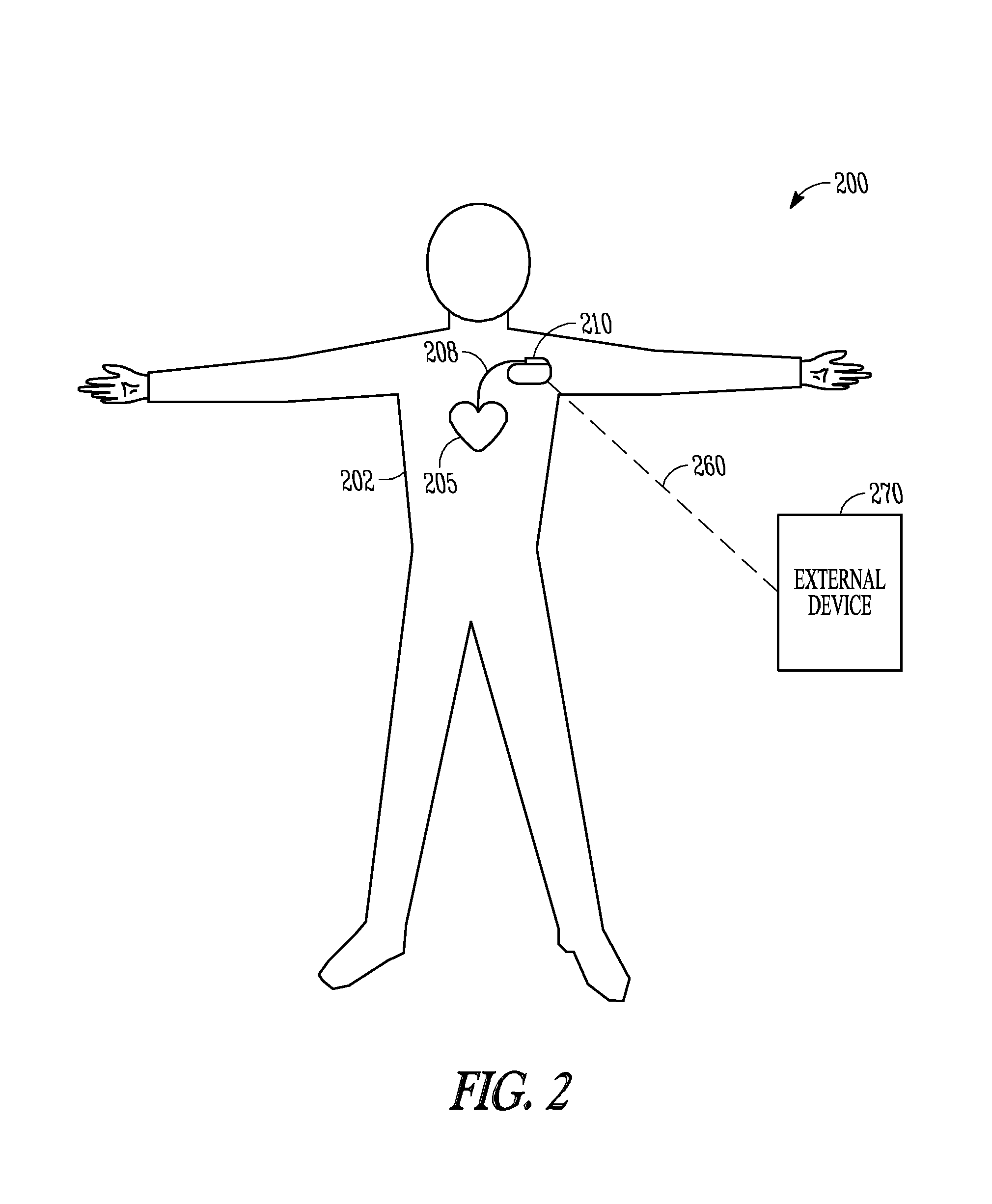

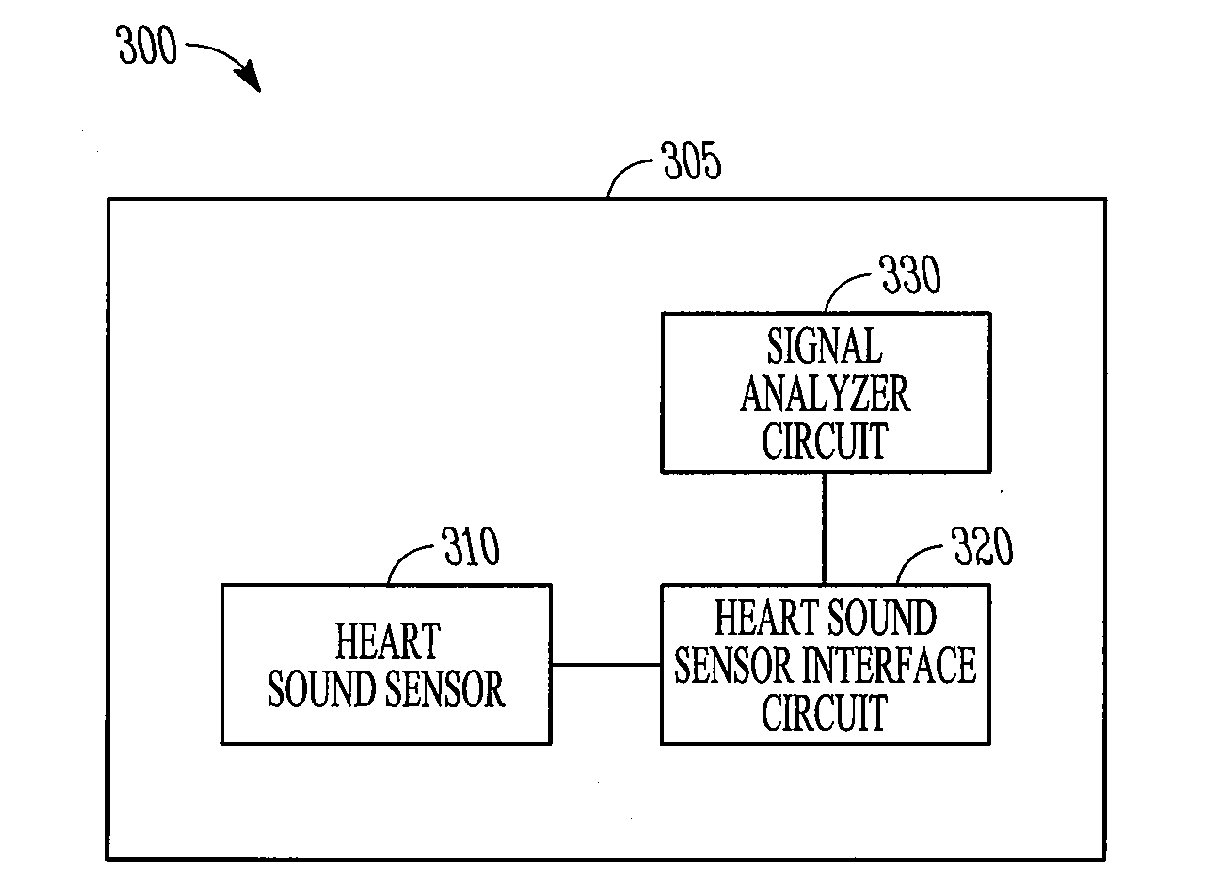

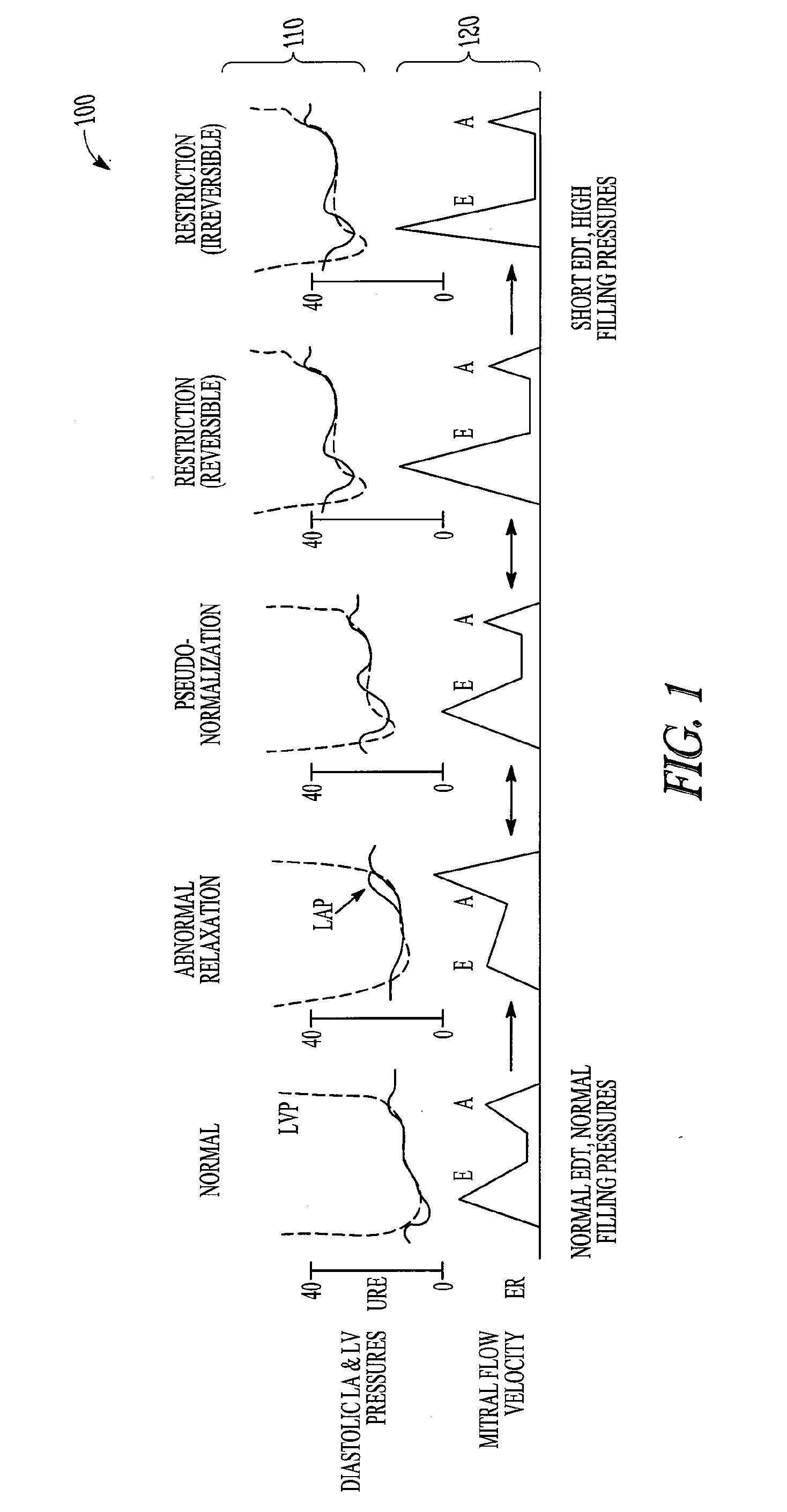

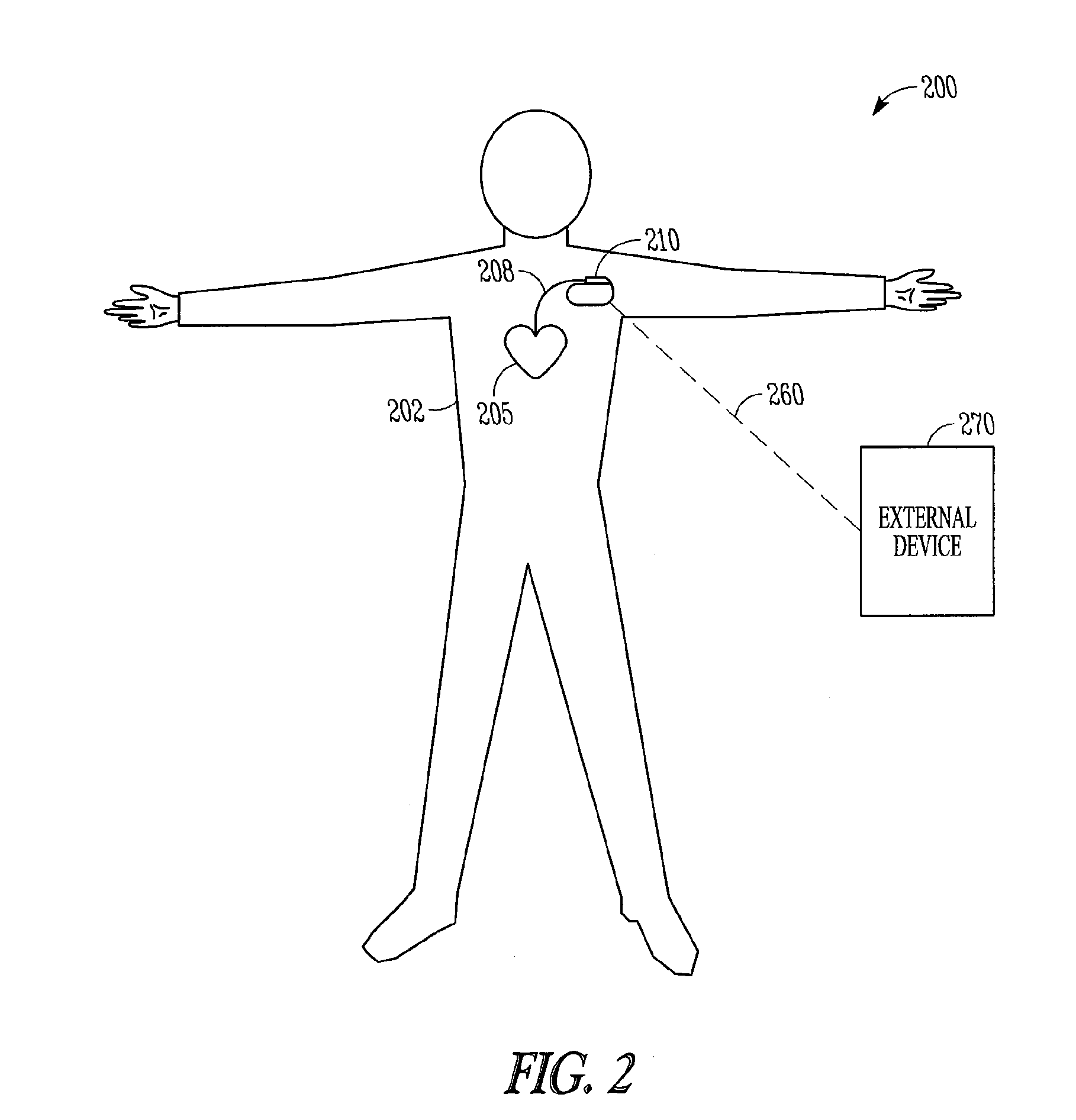

Ischemia detection using a heart sound sensor

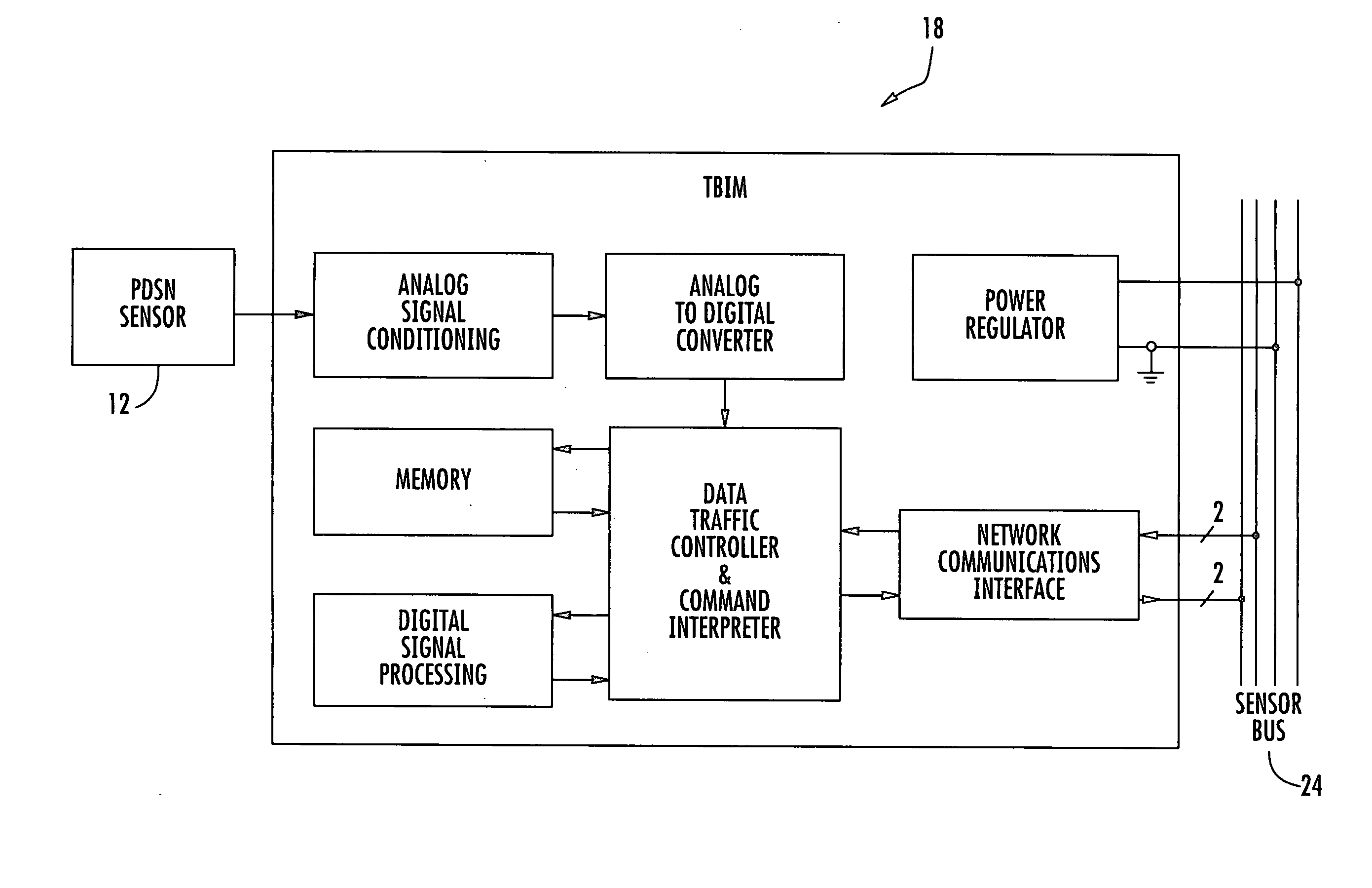

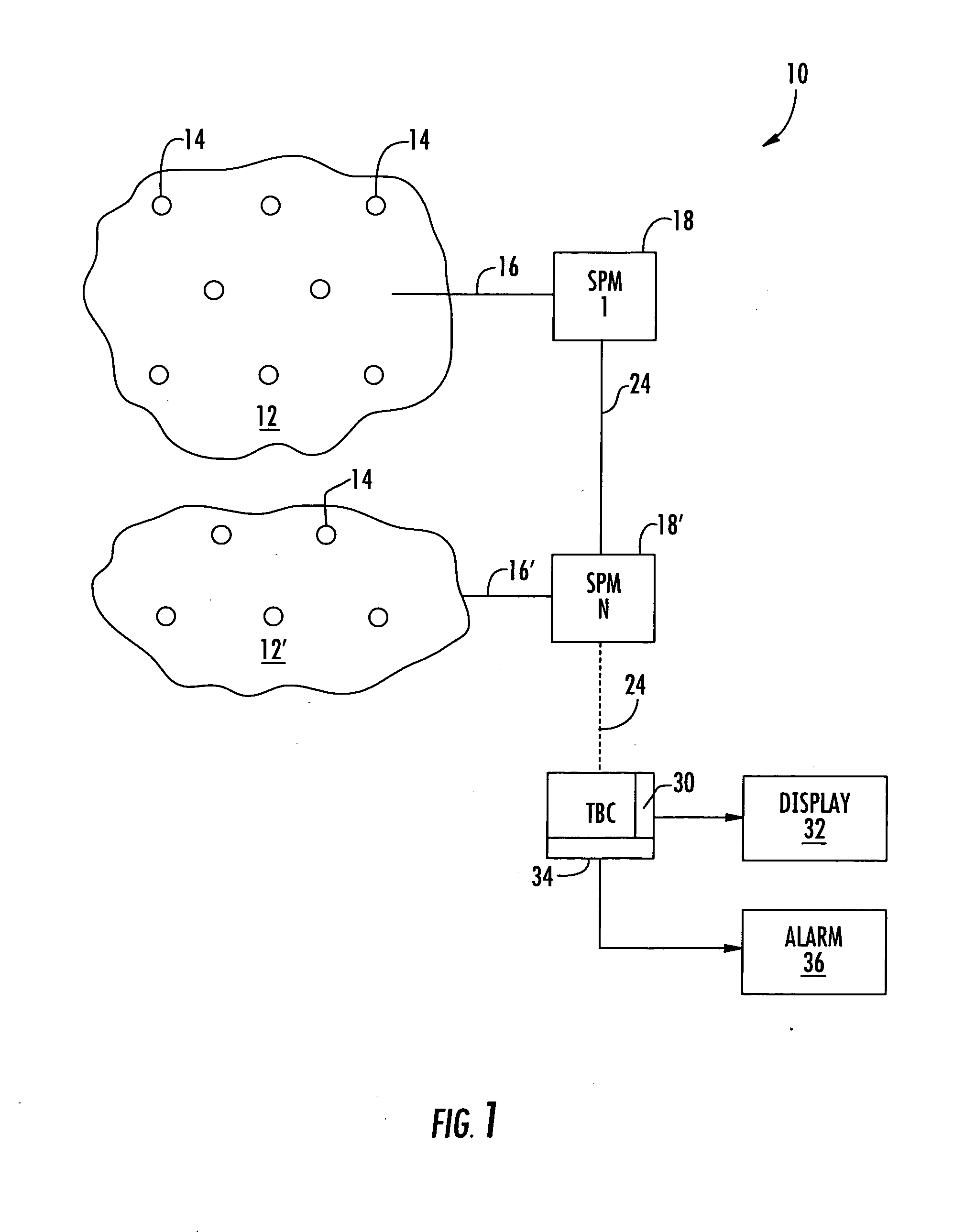

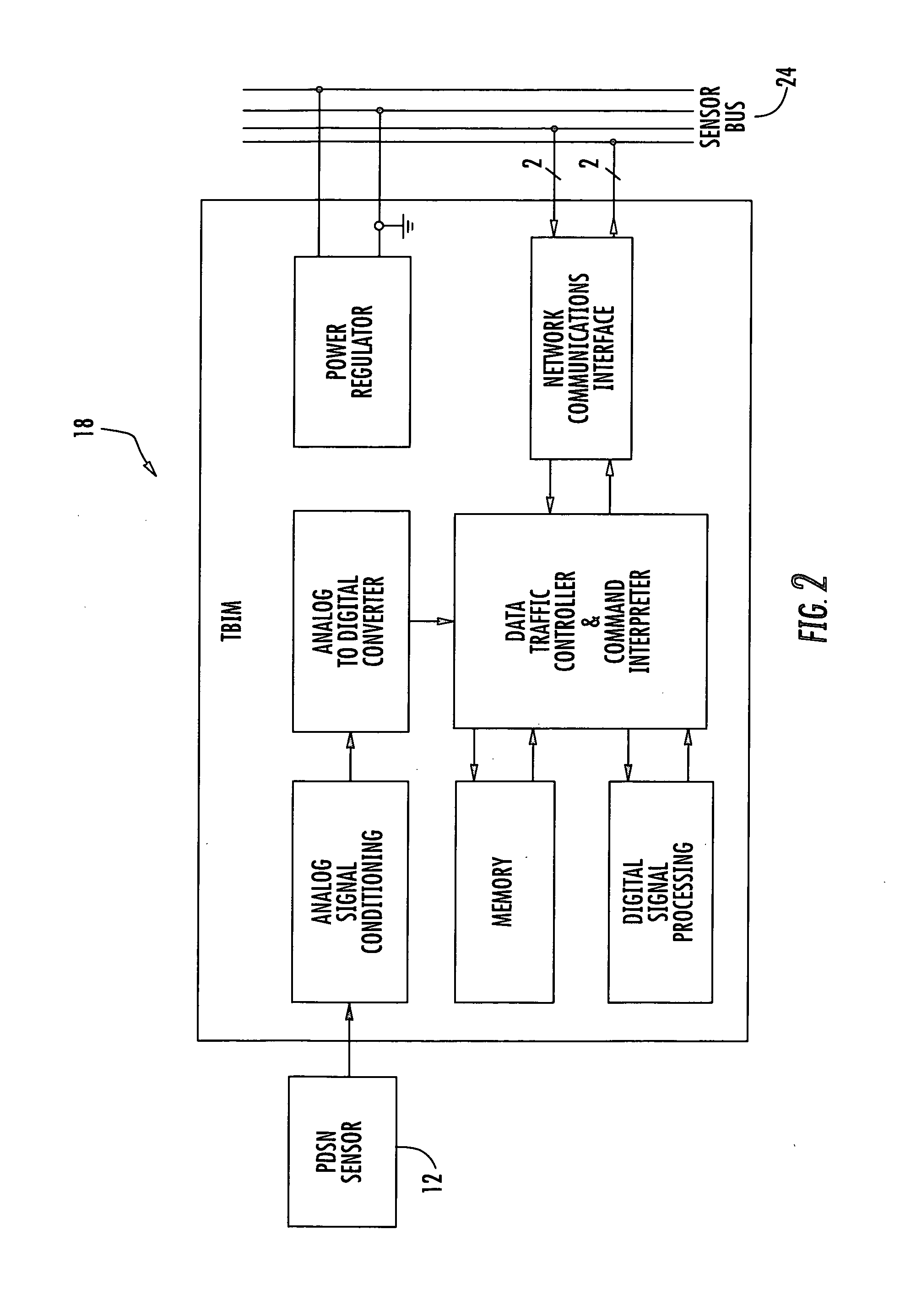

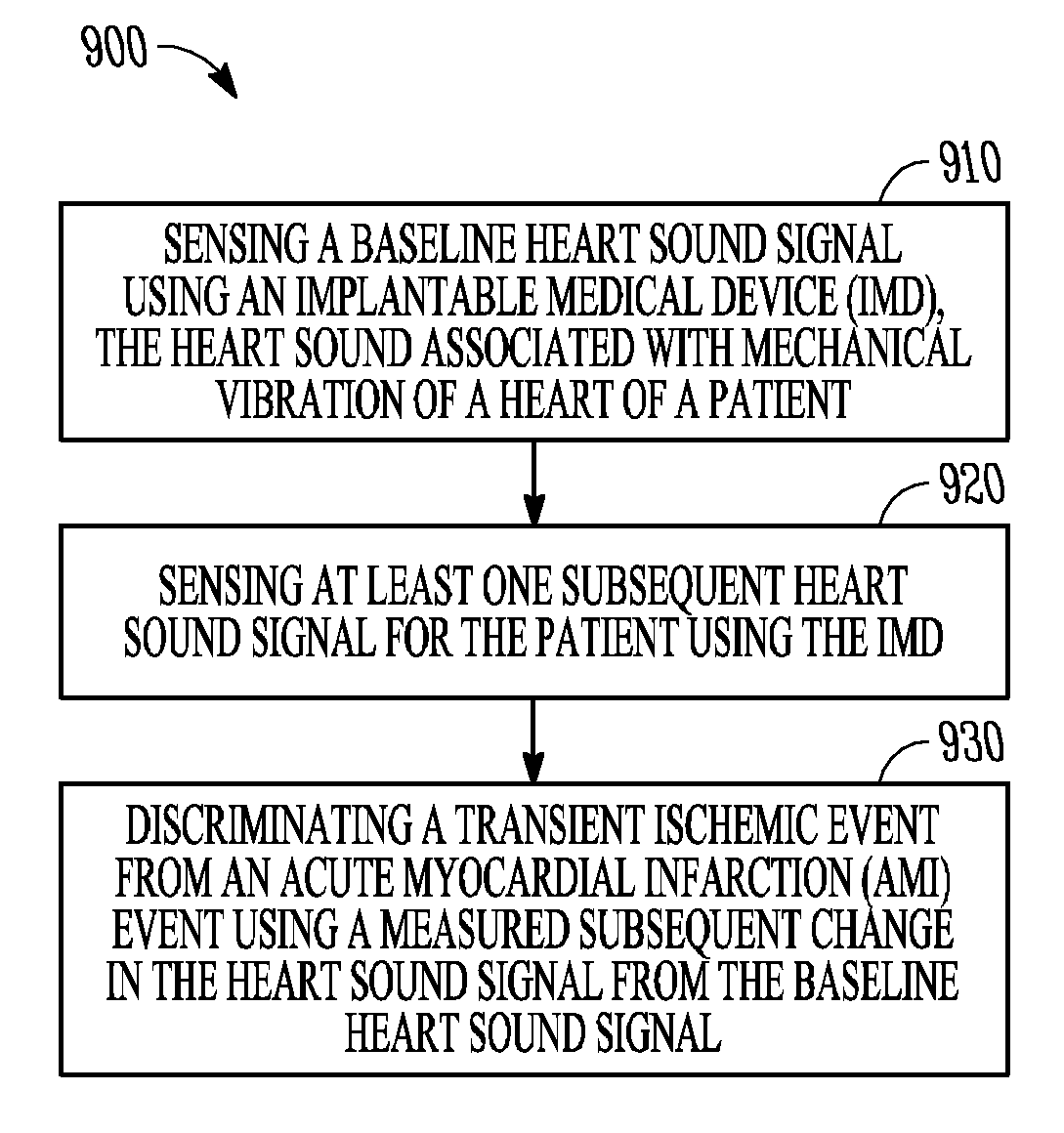

A system comprising an implantable medical device (IMD) includes an implantable heart sound sensor to produce an electrical signal representative of at least one heart sound. The heart sound is associated with mechanical activity of a patient's heart. Additionally, the IMD includes a heart sound sensor interface circuit coupled to the heart sound sensor to produce a heart sound signal, and a signal analyzer circuit coupled to the heart sound sensor interface circuit. The signal analyzer circuit measures a baseline heart sound signal, and deems that an ischemic event has occurred using, among other things, a measured subsequent change in the heart sound signal from the established baseline heart sound signal.

Owner:CARDIAC PACEMAKERS INC

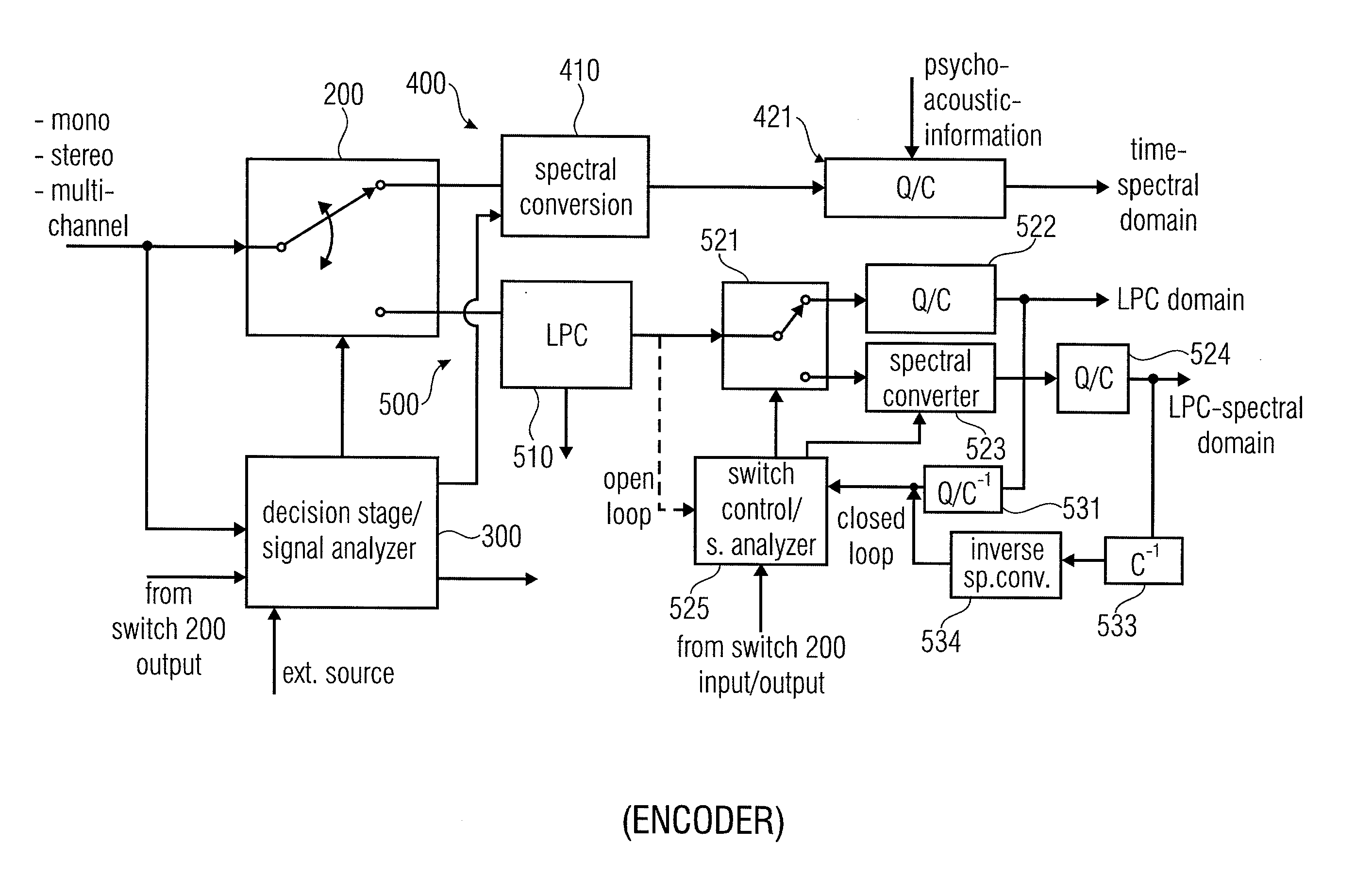

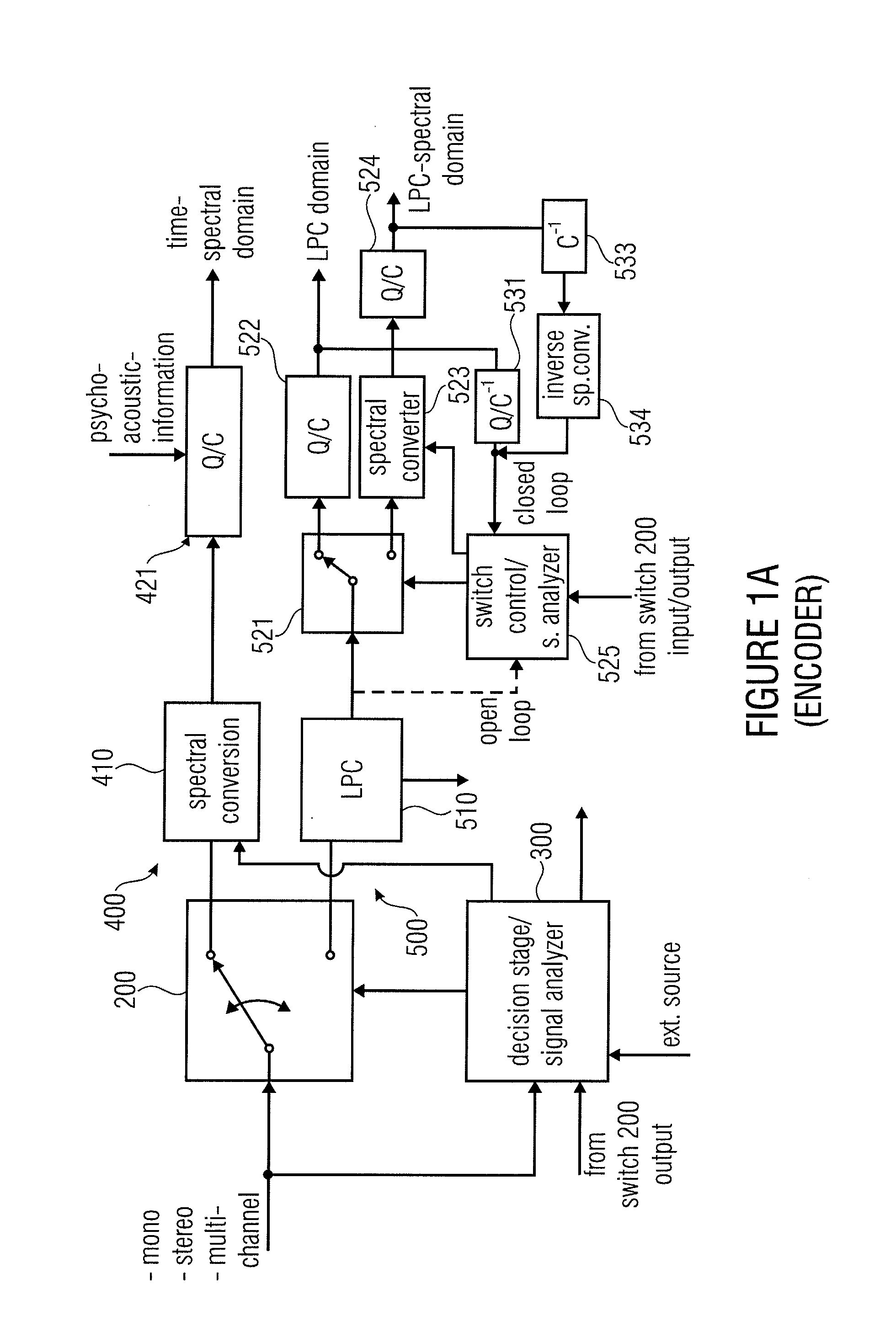

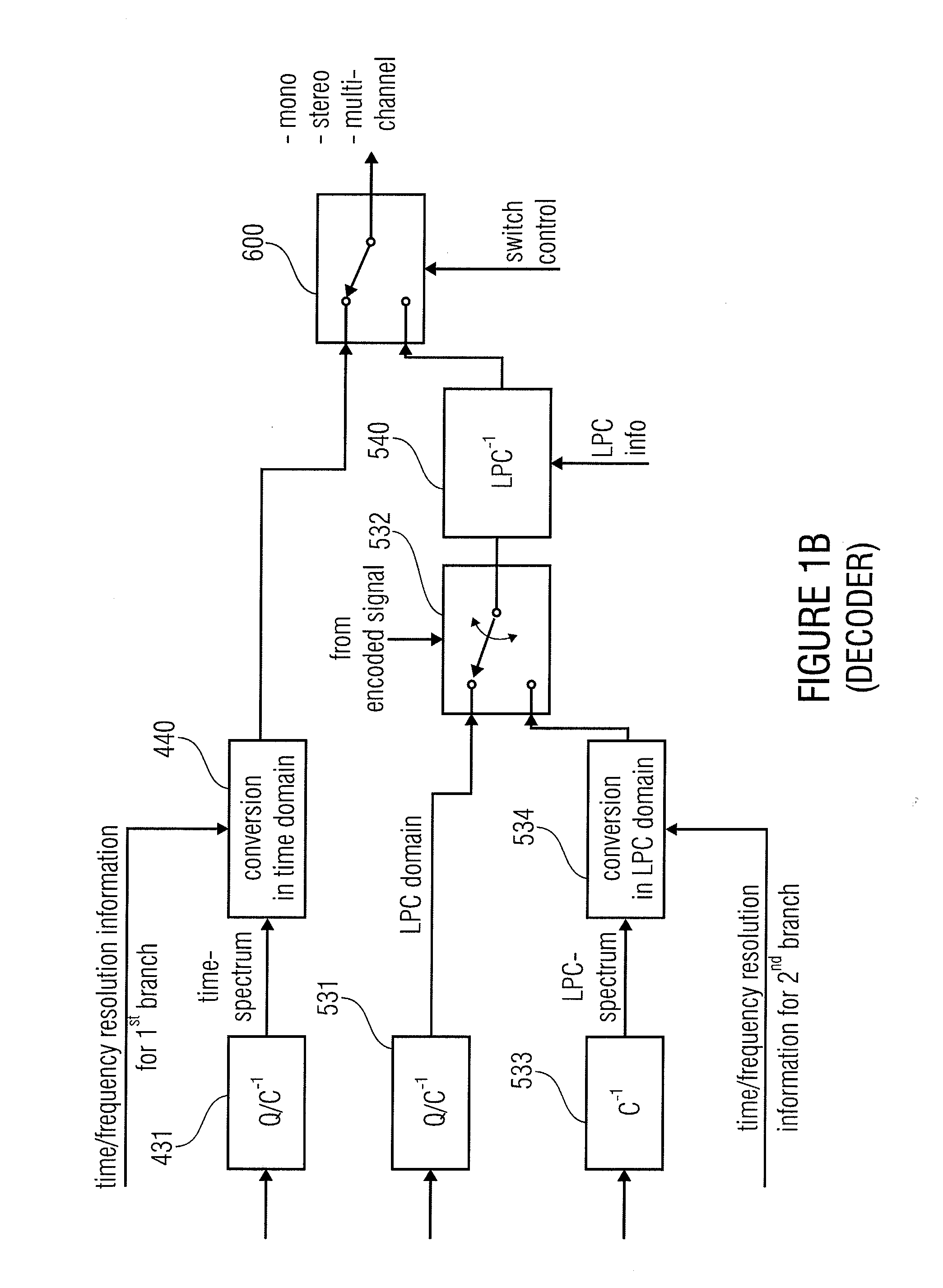

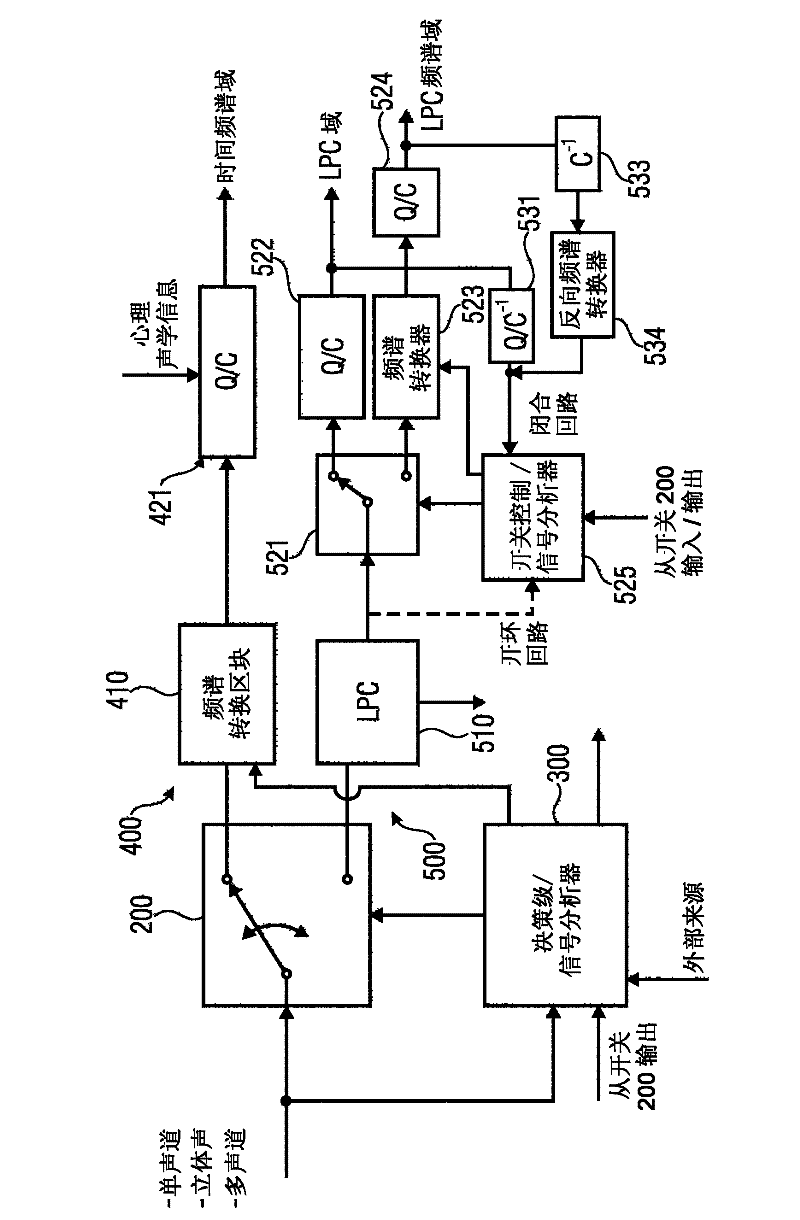

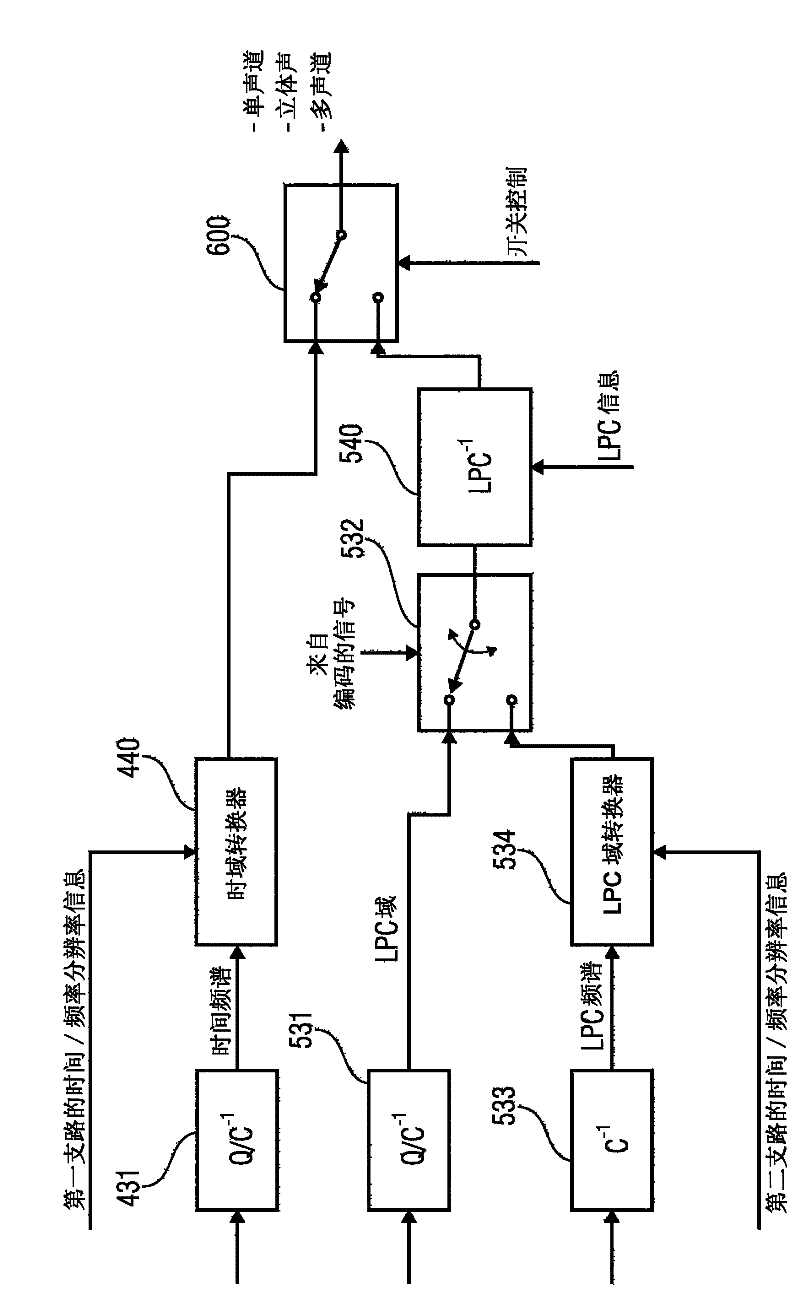

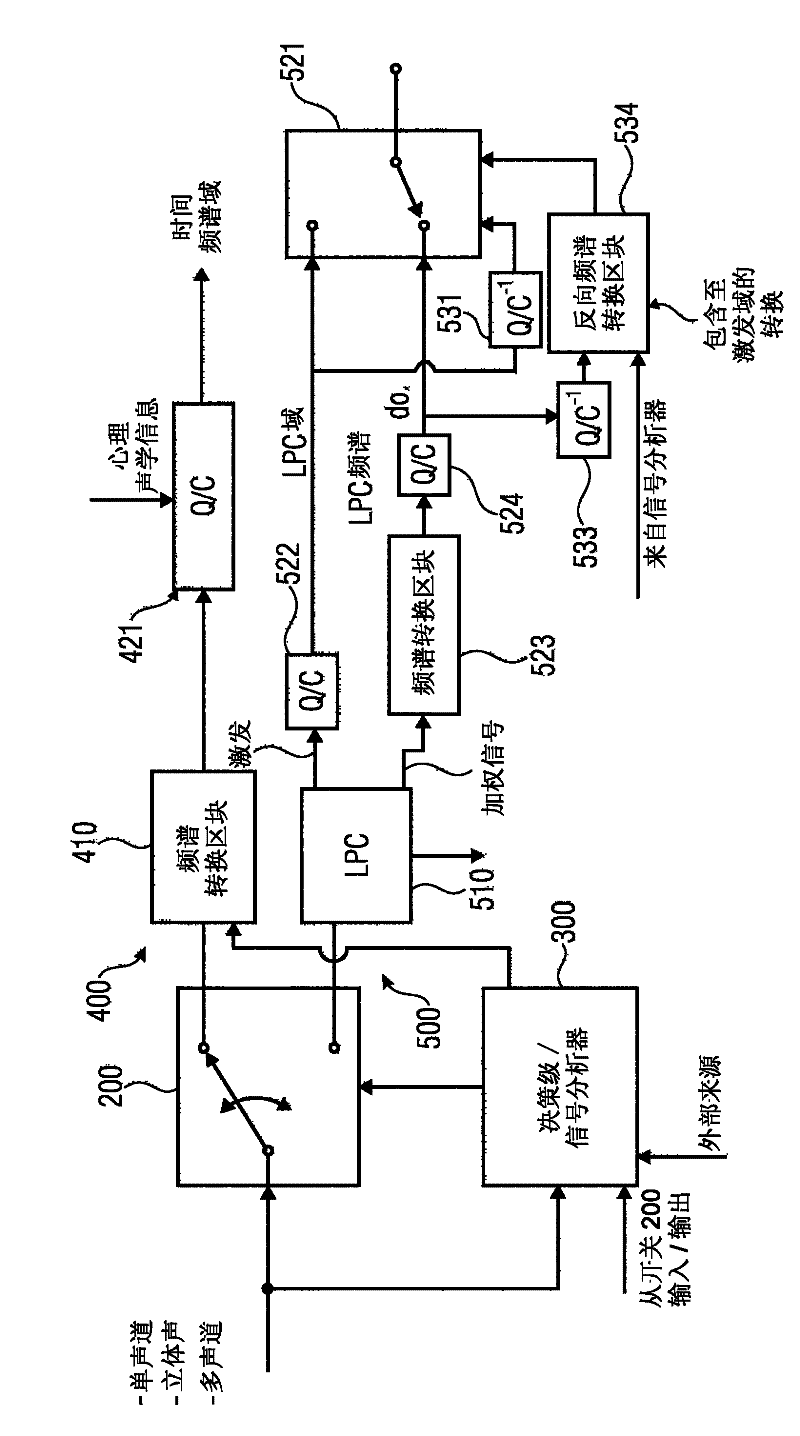

Multi-Resolution Switched Audio Encoding/Decoding Scheme

ActiveUS20110238425A1More biasedAvoid short lengthSpeech analysisCode conversionTime domainImage resolution

An audio encoder for encoding an audio signal has a first coding branch, the first coding branch comprising a first converter for converting a signal from a time domain into a frequency domain. Furthermore, the audio encoder has a second coding branch comprising a second time / frequency converter. Additionally, a signal analyzer for analyzing the audio signal is provided. The signal analyzer, on the hand, determines whether an audio portion is effective in the encoder output signal as a first encoded signal from the first encoding branch or as a second encoded signal from a second encoding branch. On the other hand, the signal analyzer determines a time / frequency resolution to be applied by the converters when generating the encoded signals. An output interface includes, in addition to the first encoded signal and the second encoded signal, a resolution information identifying the resolution used by the first time / frequency converter and used by the second time / frequency converter.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV +1

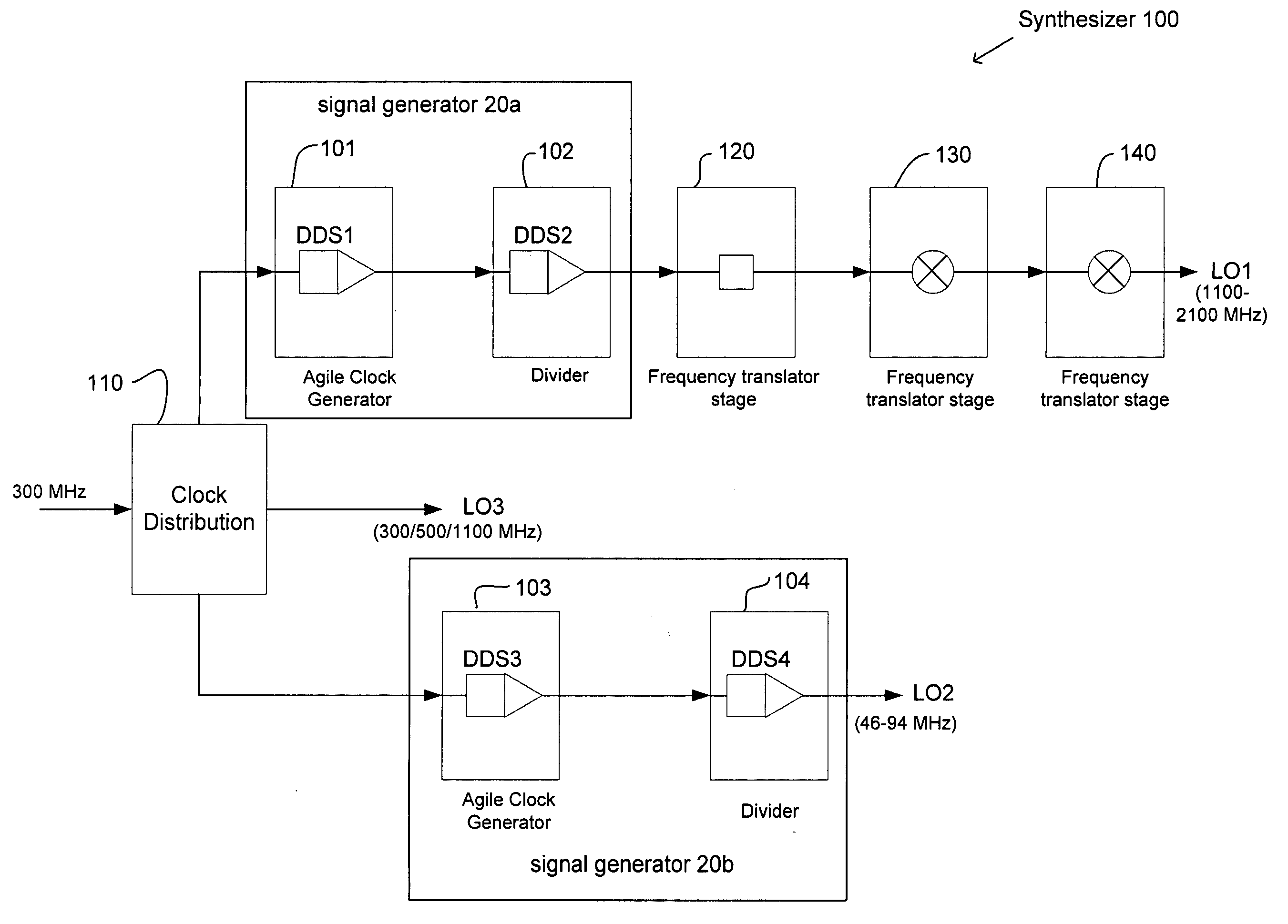

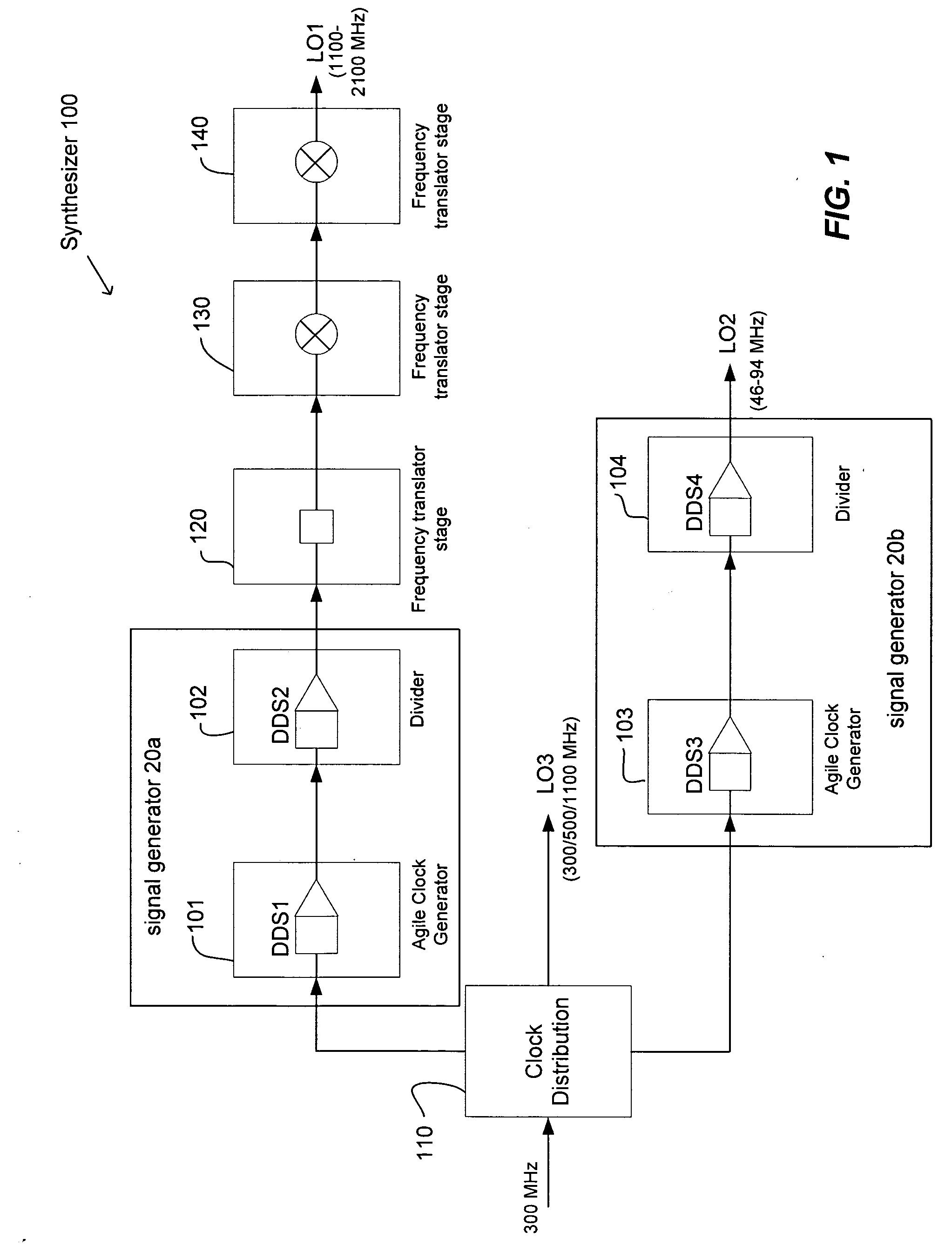

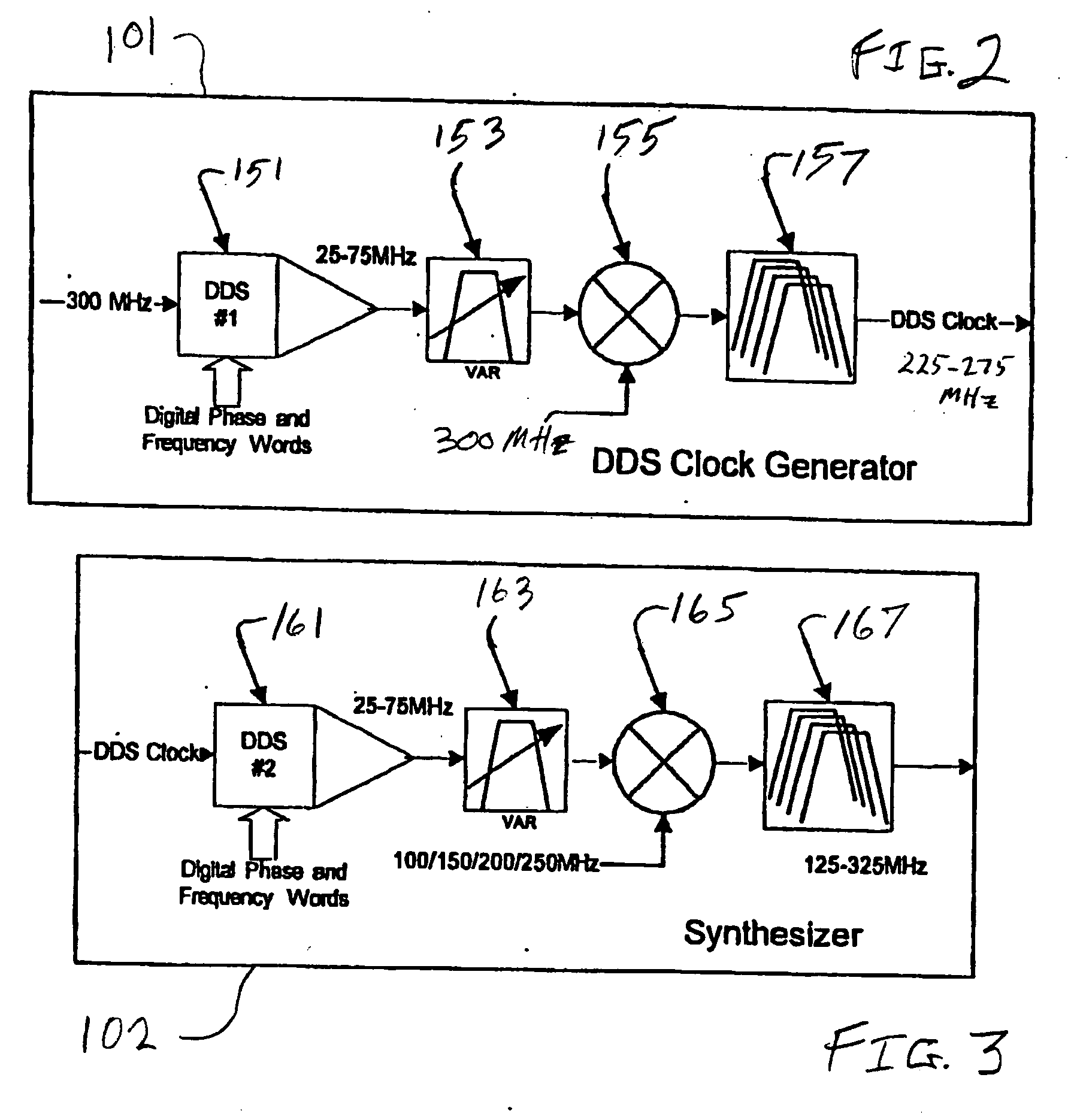

Wideband signal generators, measurement devices, methods of signal generation, and methods of signal analysis

ActiveUS20050003785A1Small sizeReducing or avoiding spurious DDS responsesPulse automatic controlContinuous to patterned pulse manipulationMeasurement deviceSignal analyzer

A wideband signal generator according to one embodiment of the invention includes a variable frequency source and a direct digital synthesizer. Local oscillators, signal analyzers, modulators, demodulators, and other equipment including one or more such generators are also disclosed.

Owner:MERCURY SISTEMS INC

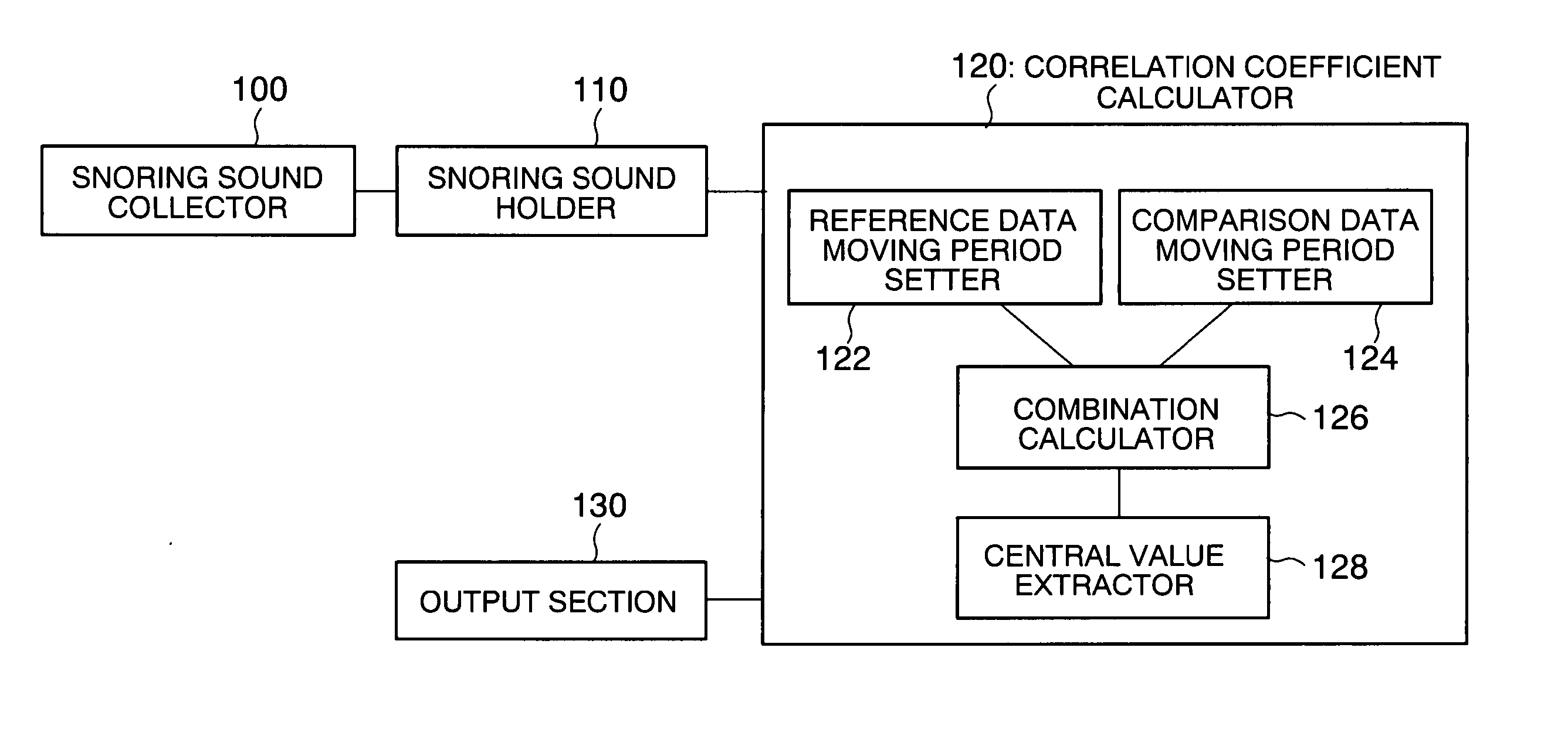

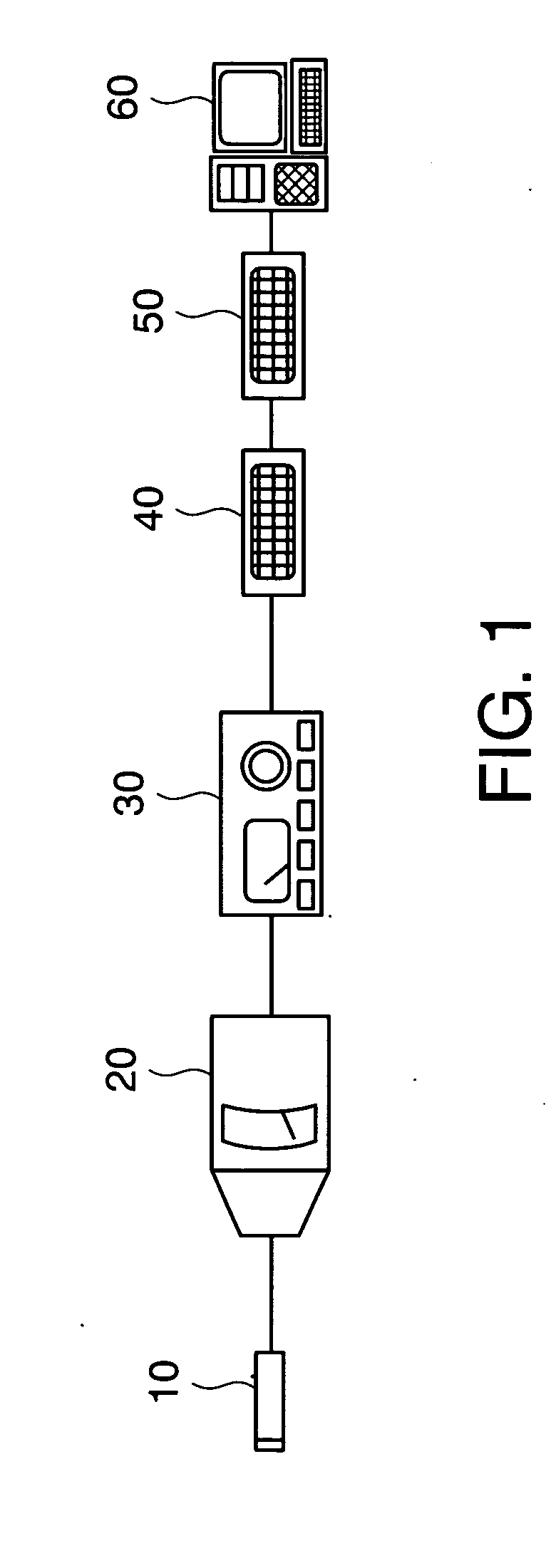

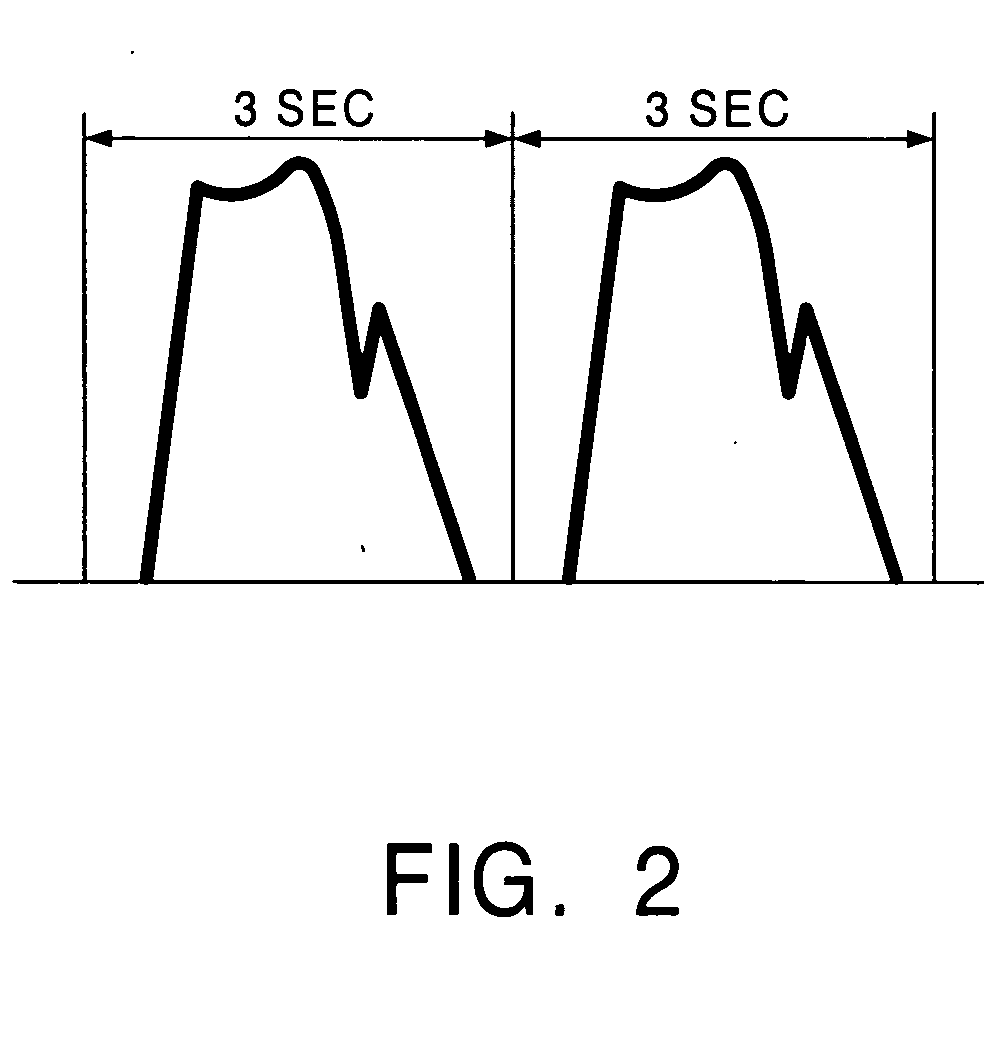

Sleep apnea syndrome diagnosing device and signal analyzer, and methods thereof

A sleep apnea syndrome diagnosing device disclosed herein comprises: a snoring sound collector which collects snoring sound; a snoring sound holder which holds the collected snoring sound; a correlation coefficient calculator which divides a time axis of the snoring sound held in the snoring sound holder into plural cycles and which sequentially calculates a correlation coefficient between the snoring sound of one cycle and the snoring sound of a cycle next to the one cycle; and an output section which outputs the correlation coefficient calculated by the correlation coefficient calculator.

Owner:SATO CO LTD

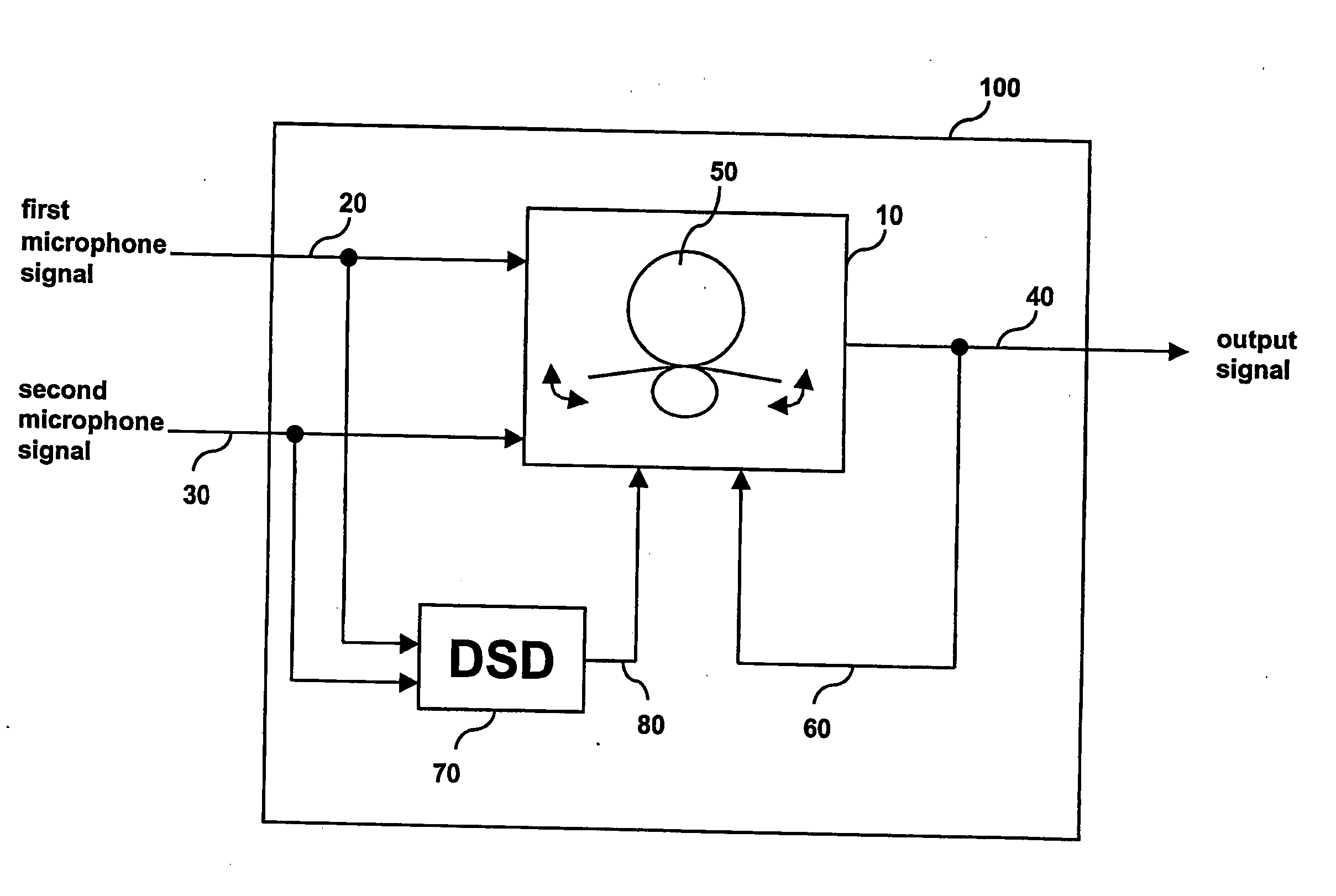

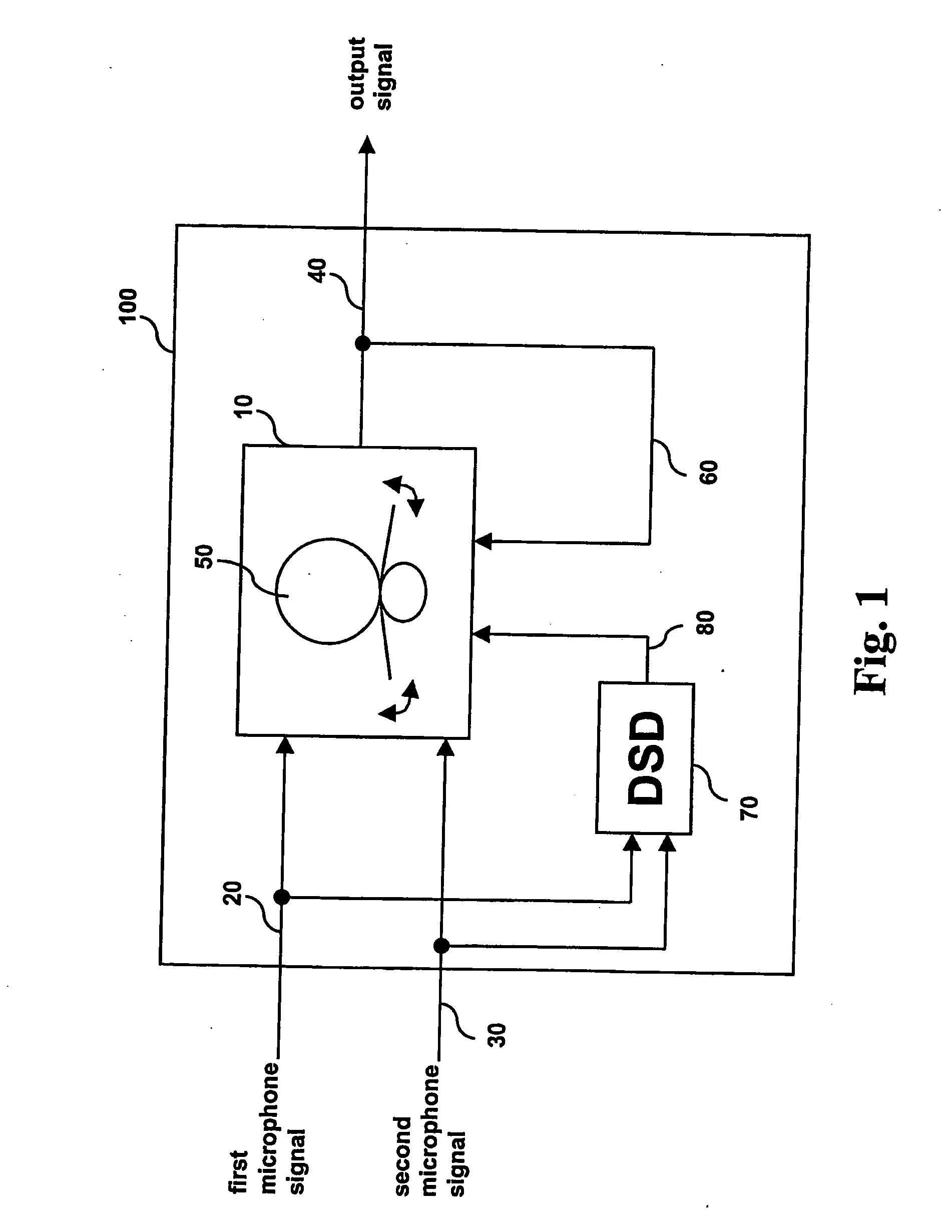

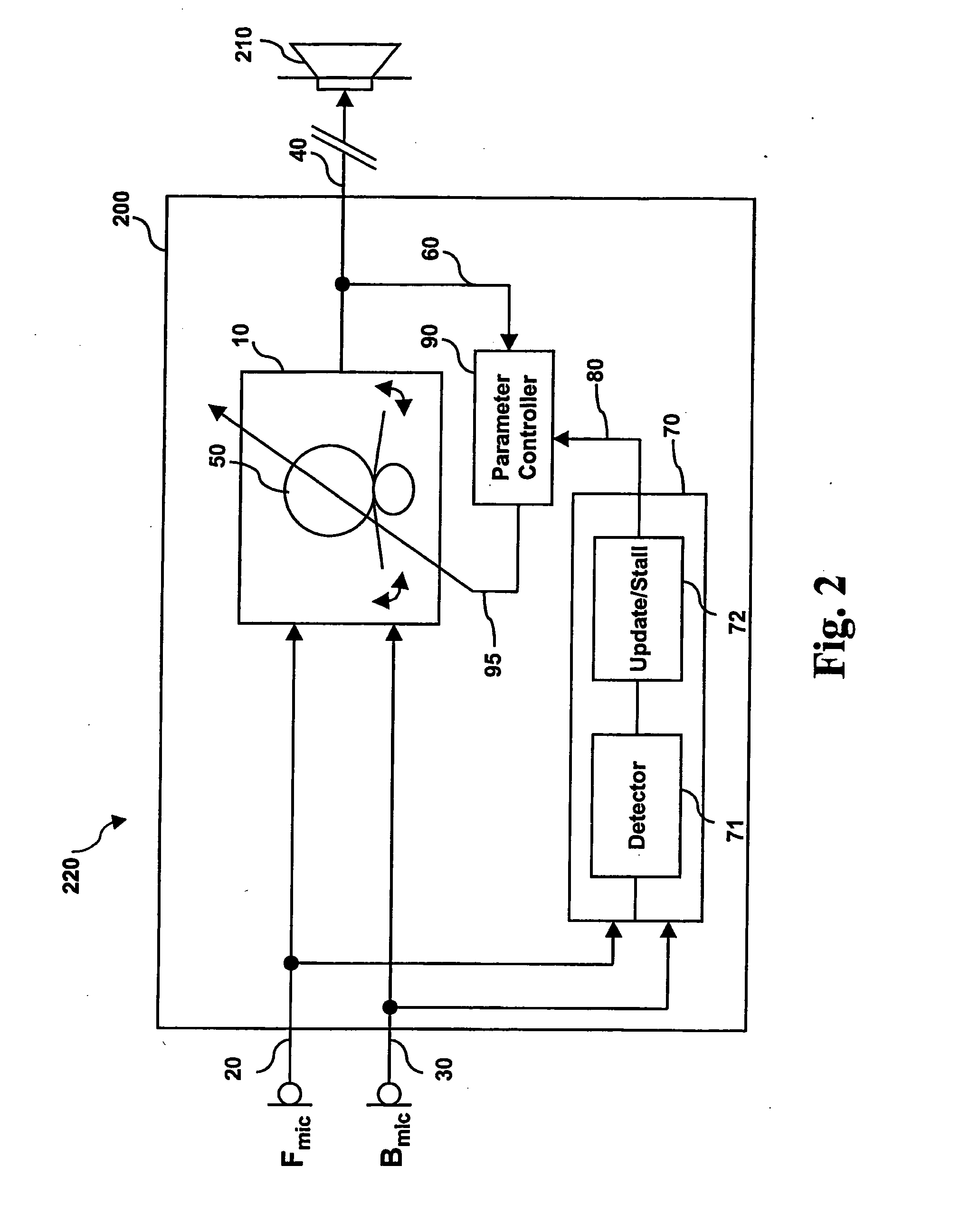

Method for controlling the directionality of the sound receiving characteristic of a hearing aid and a signal processing apparatus

ActiveUS20060177079A1Minimize output signalMinimize microphone noiseDoor/window protective devicesCurtain accessoriesSignal analyzerEngineering

A signal processing apparatus (100) for a hearing aid with a controllable directional characteristic is provided which comprises a directional controller (10) receiving first and second microphone signals (20, 30) and output an output signal (40), a signal analyzer (70) which detects whether at least one of said first and second microphone signals being undesired signals, and wherein said directional controller minimizes the output signal by adjusting the directional characteristic only if the signal analyzer has detected undesired signals.

Owner:WIDEX AS

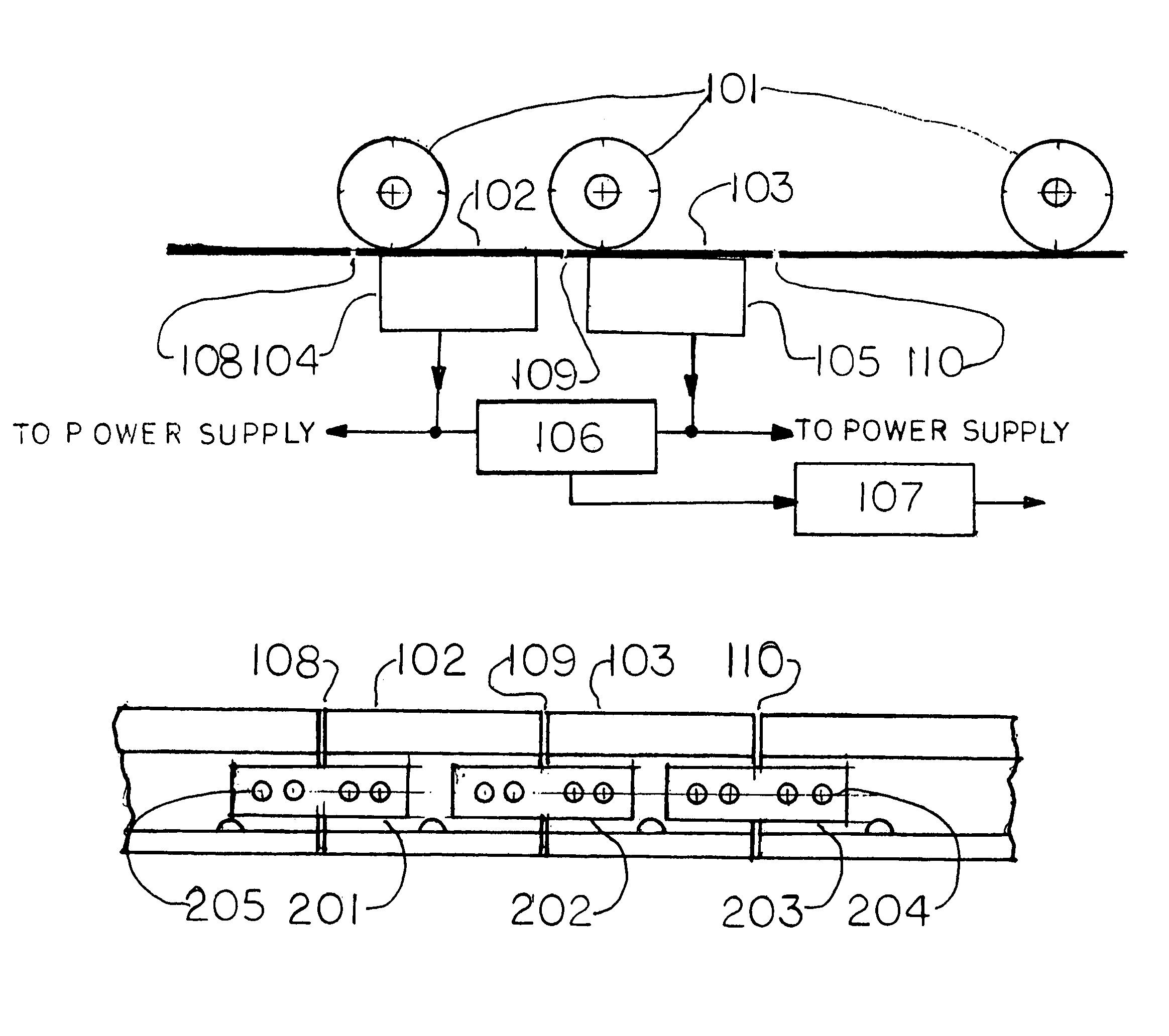

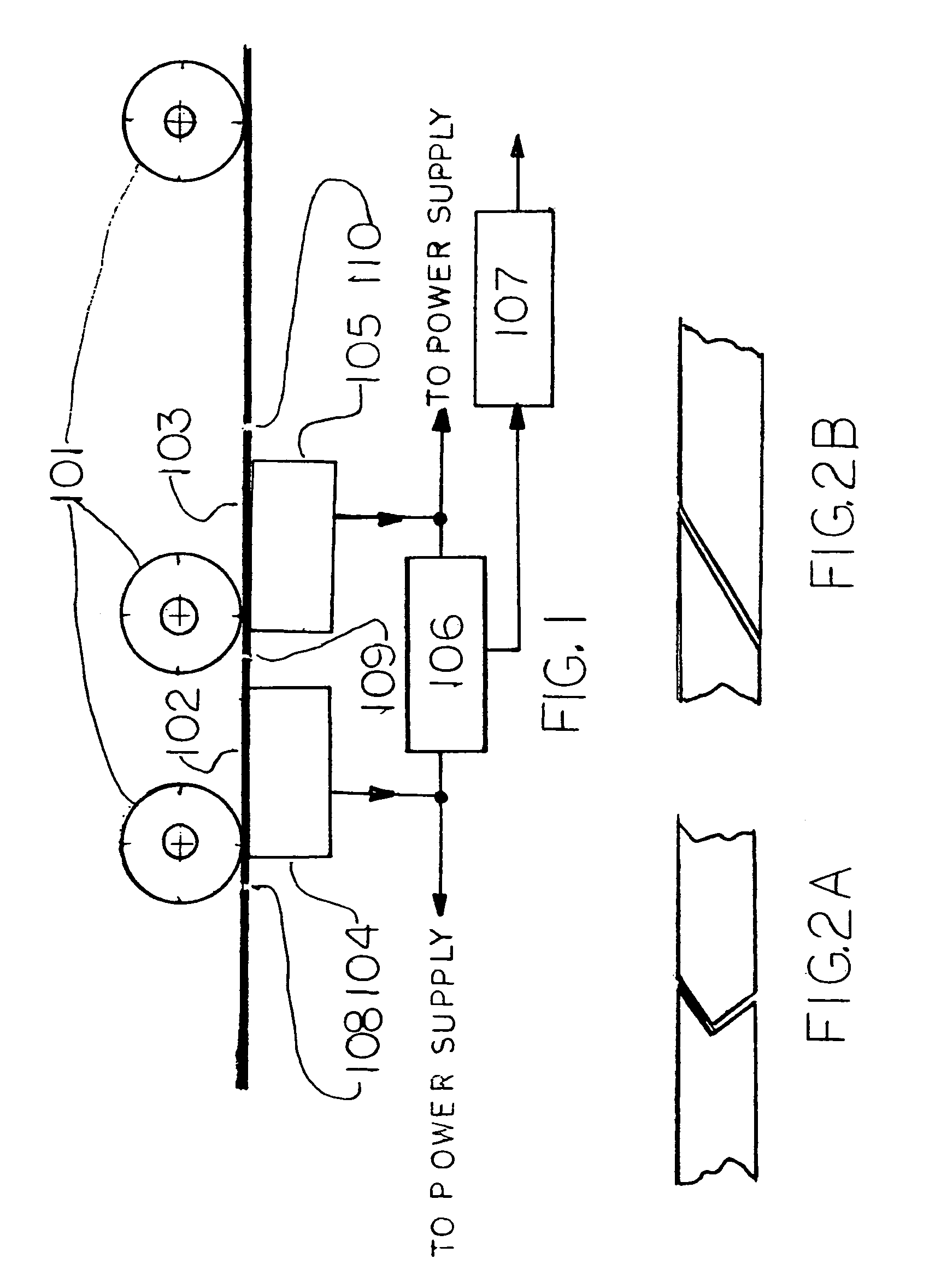

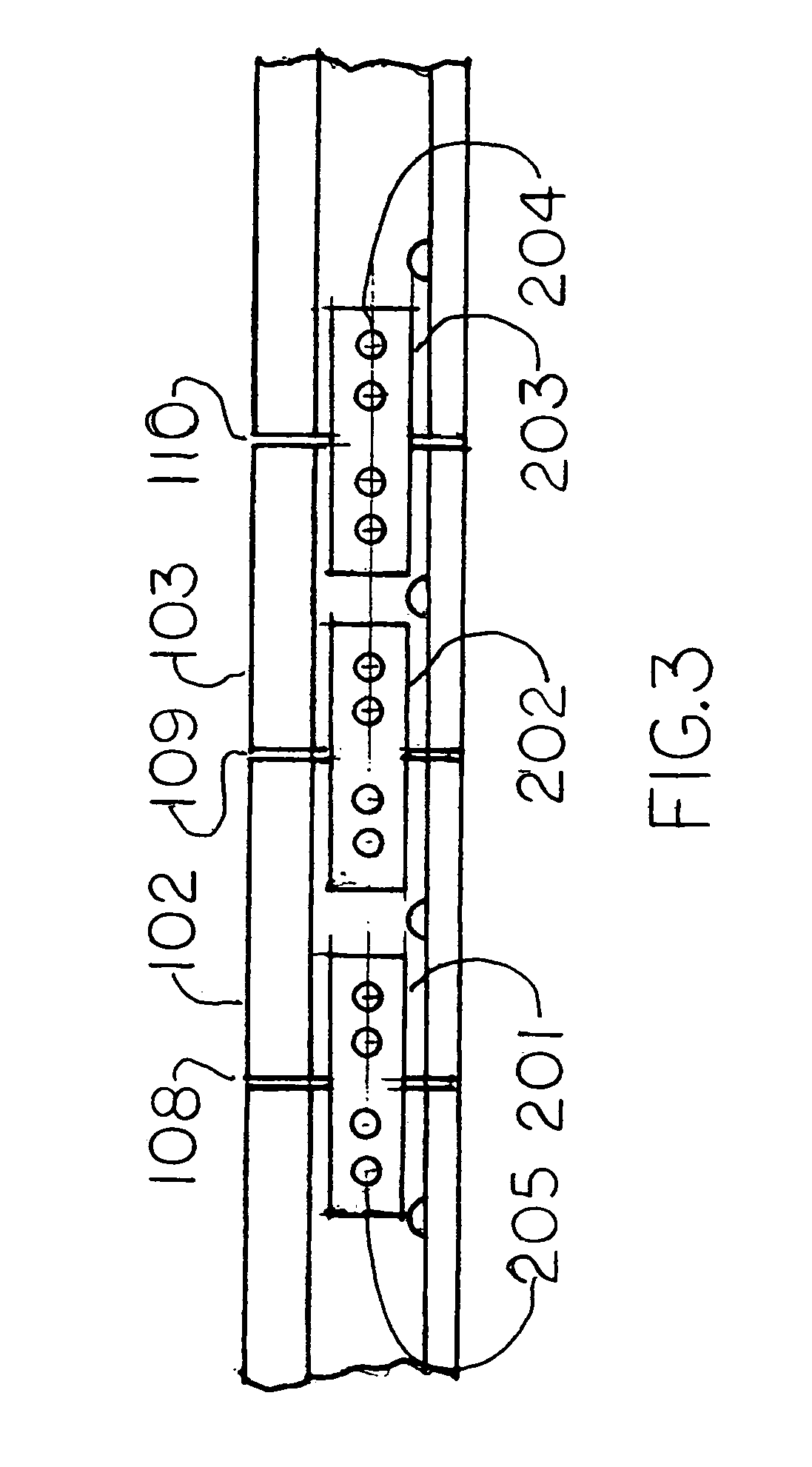

System for detection of defects in railroad car wheels

ActiveUS7213789B1Easy to modifyDefect locationWheel-rims surveying/measuringRailway vehicle testingFrequency spectrumSignal analyzer

A system for automatic detection of defects in railroad wheels, a system that is stationary and is installed in extended intervals in the rails uses stationary acoustical / vibration sensors installed at intervals in the rails. Rail segments associated with the detectors are acoustically isolated. The sensors acquire the sounds and vibrations generated by the wheels rolling over the rails. Signal analyzers identify rail defects from intensity vs., frequency distributions of acoustical spectra. Such spectra reflect the condition of the wheels and change their intensity vs. frequency distributions when the wheels pass the sensors installed in the rails. The acquired information on the condition of the wheels is transmitted to a central location. Any defective wheel is identified and marked for repair or replacement.

Owner:MATZAN EUGENE

Coil on plug signal detection

InactiveUS6396277B1Resistance/reactance/impedenceMachines/enginesSignal analyzerInternal combustion engine

An apparatus for measuring ignition charge signals produced by coils of coil-on-plug devices of an internal combustion engine. A signal detector comprises an insulating substrate having a first conductive planar layer on a first side and a second conductive planar layer on a second side. The first layer is coupled to a signal wire and the second layer is coupled to a ground wire. When the signal detector is held in close proximity to the coil of the coil-on-plug, ignition signals generated by the coil and passing to the plug are detected. The detected signals may be coupled to a signal analyzer for display and analysis. The amplitude of the signal that is output by the signal detector may be adjusted to different coils having different output signal strengths by modifying the ratio of the surface areas of the first layer and the second layer.

Owner:SNAP ON INC

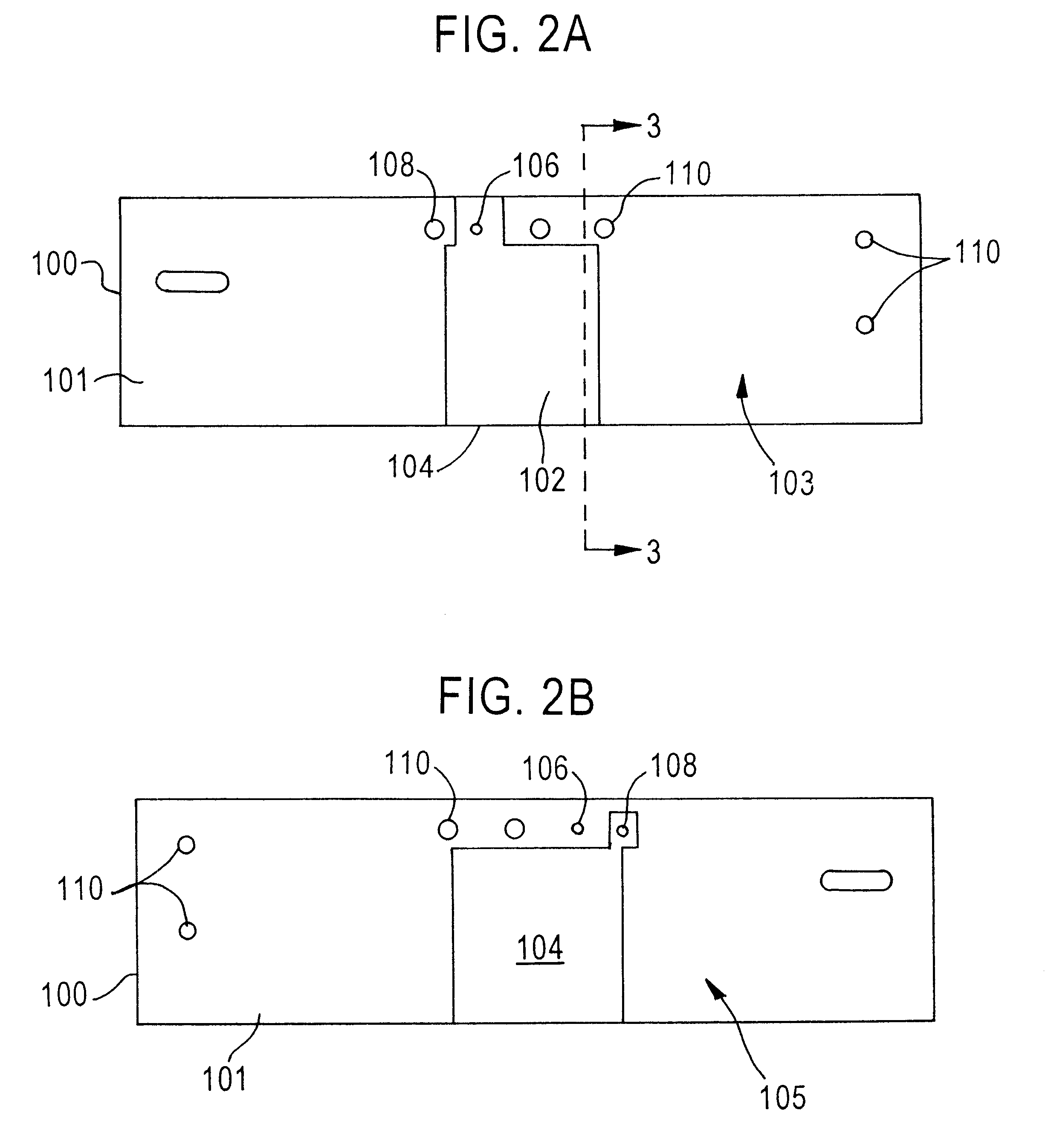

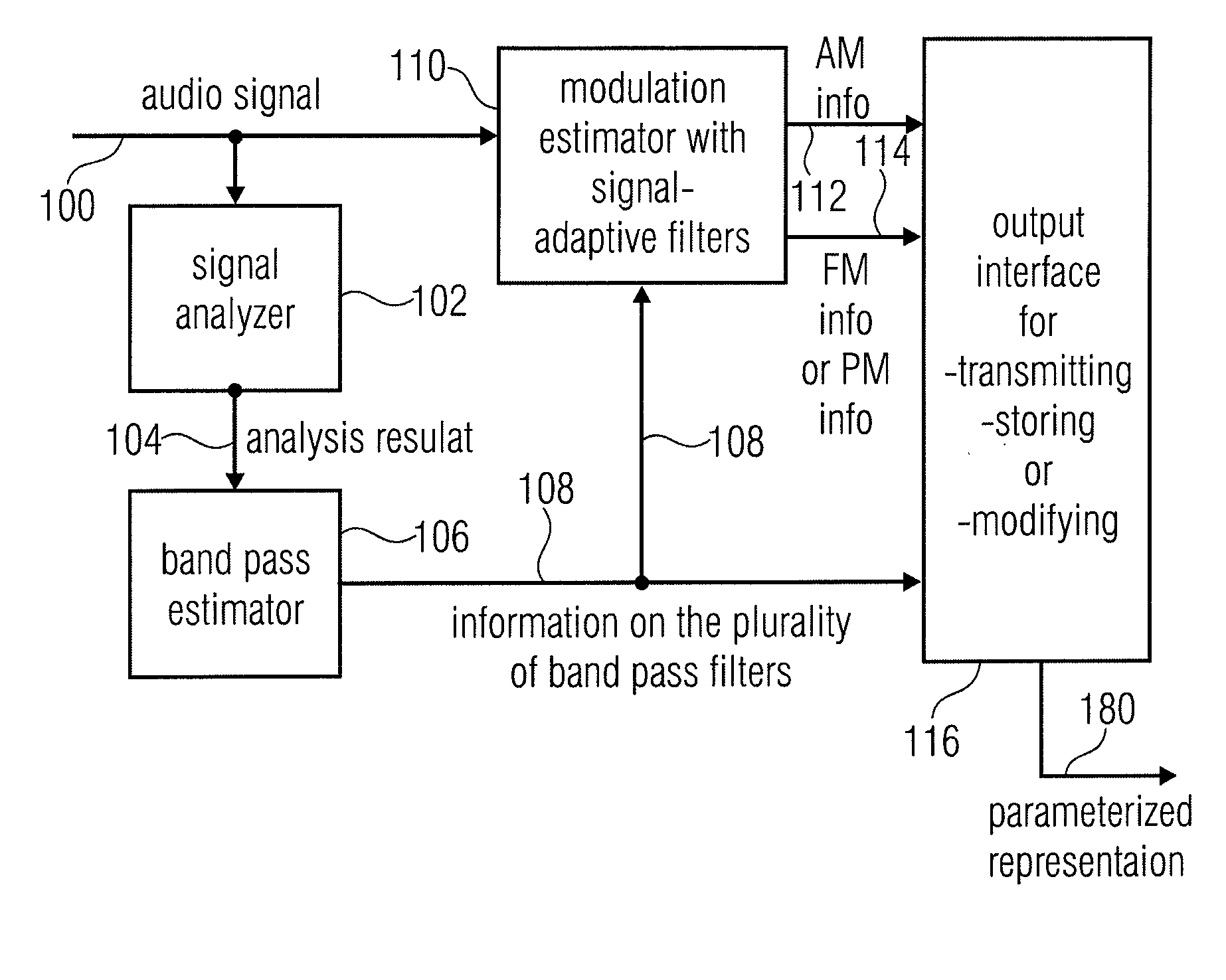

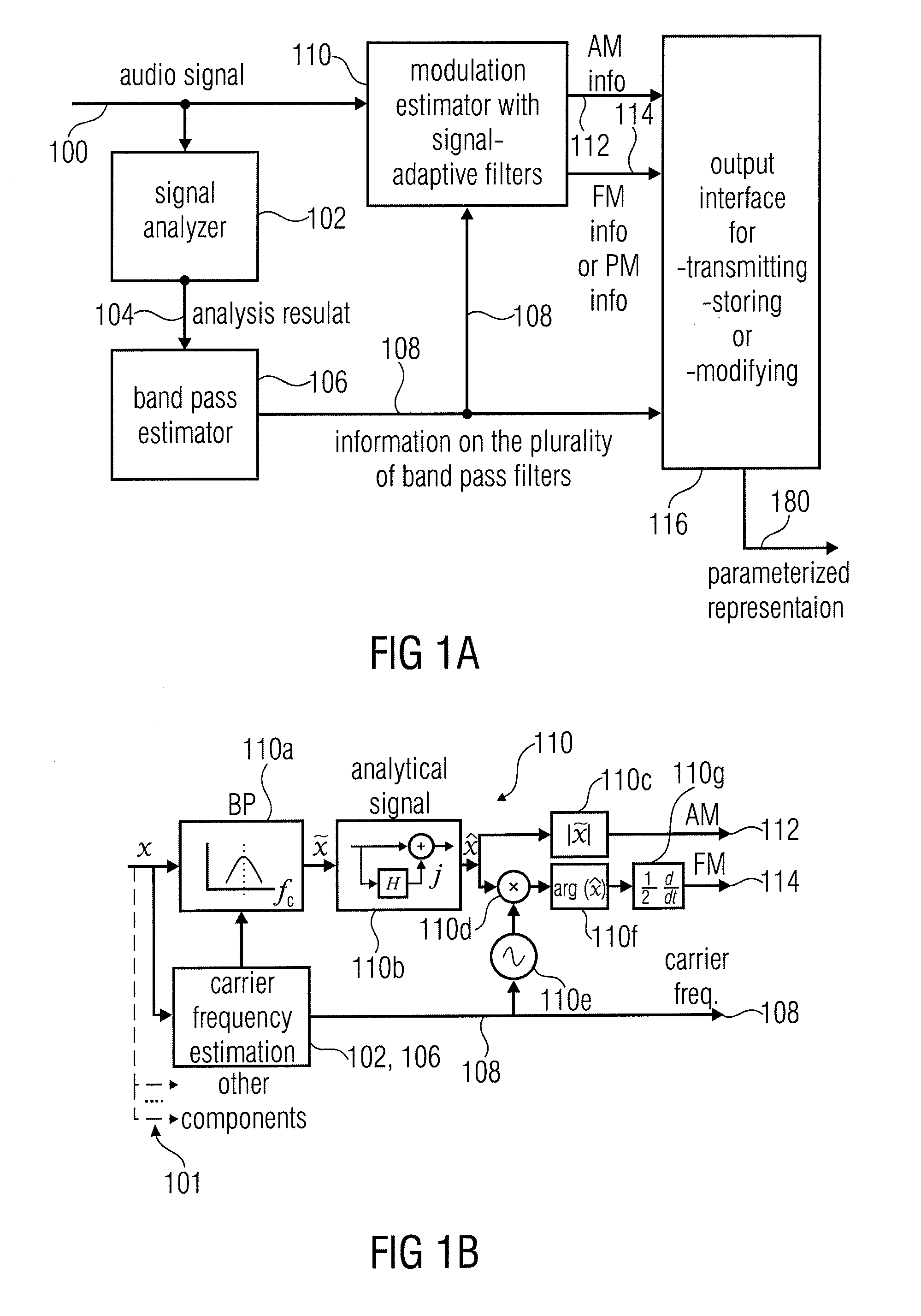

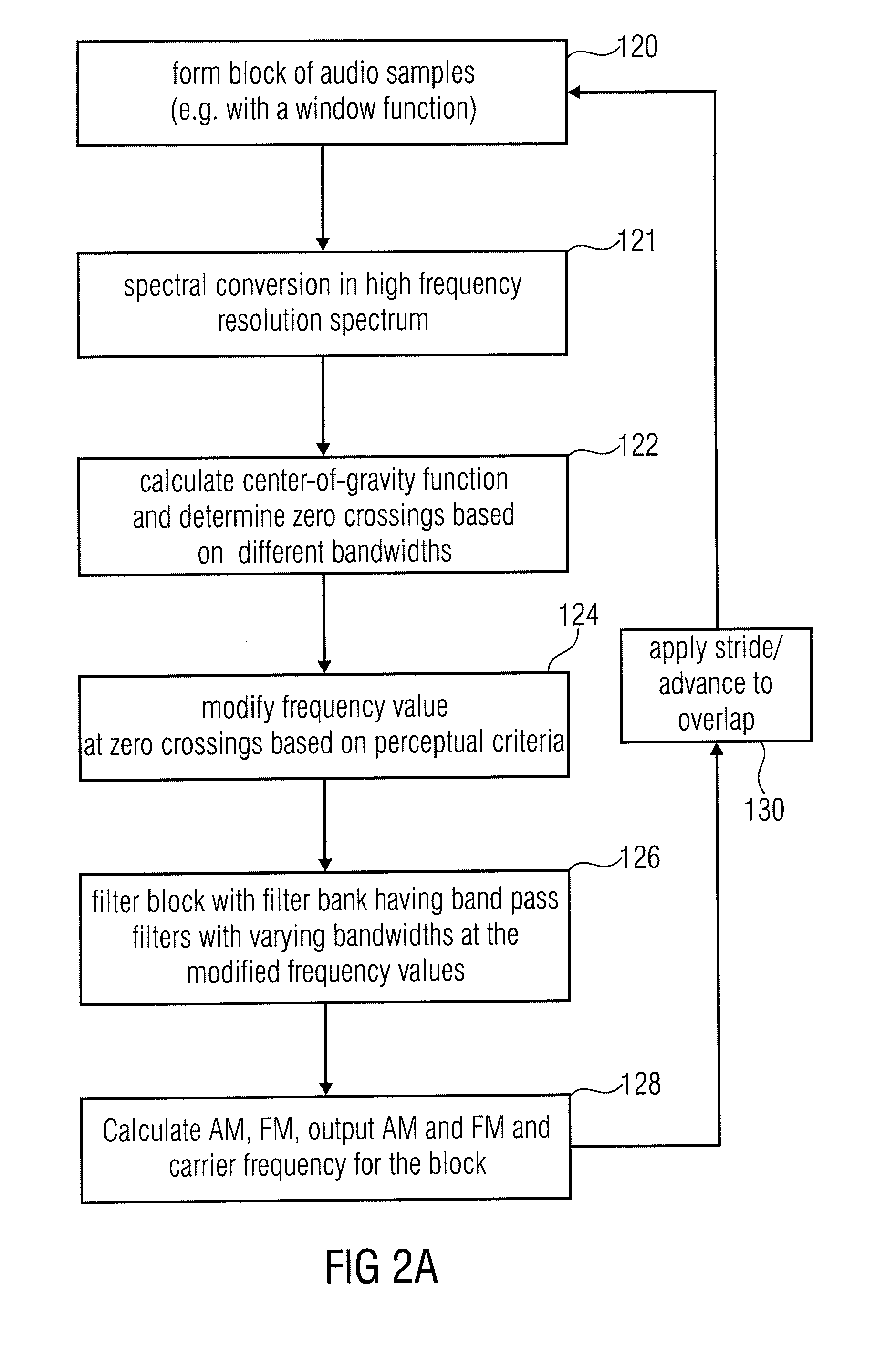

Apparatus and method for converting an audiosignal into a parameterized representation, apparatus and method for modifying a parameterized representation, apparatus and method for synthesizing a parameterized representation of an audio signal

ActiveUS20110106529A1High resolutionImprove representationSpeech analysisFrequency spectrumSignal analyzer

Apparatus for converting an audio signal into a parameterized representation, has a signal analyzer for analyzing a portion of the audio signal to obtain an analysis result; a band pass estimator for estimating information of a plurality of band pass filters based on the analysis result, wherein the information on the plurality of band pass filters has information on a filter shape for the portion of the audio signal, wherein the band width of a band pass filter is different over an audio spectrum and depends on the center frequency of the band pass filter; a modulation estimator for estimating an amplitude modulation or a frequency modulation or a phase modulation for each band of the plurality of band pass filters for the portion of the audio signal using the information on the plurality of band pass filters; and an output interface for transmitting, storing or modifying information on the amplitude modulation, information on the frequency modulation or phase modulation or the information on the plurality of band pass filters for the portion of the audio signal.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

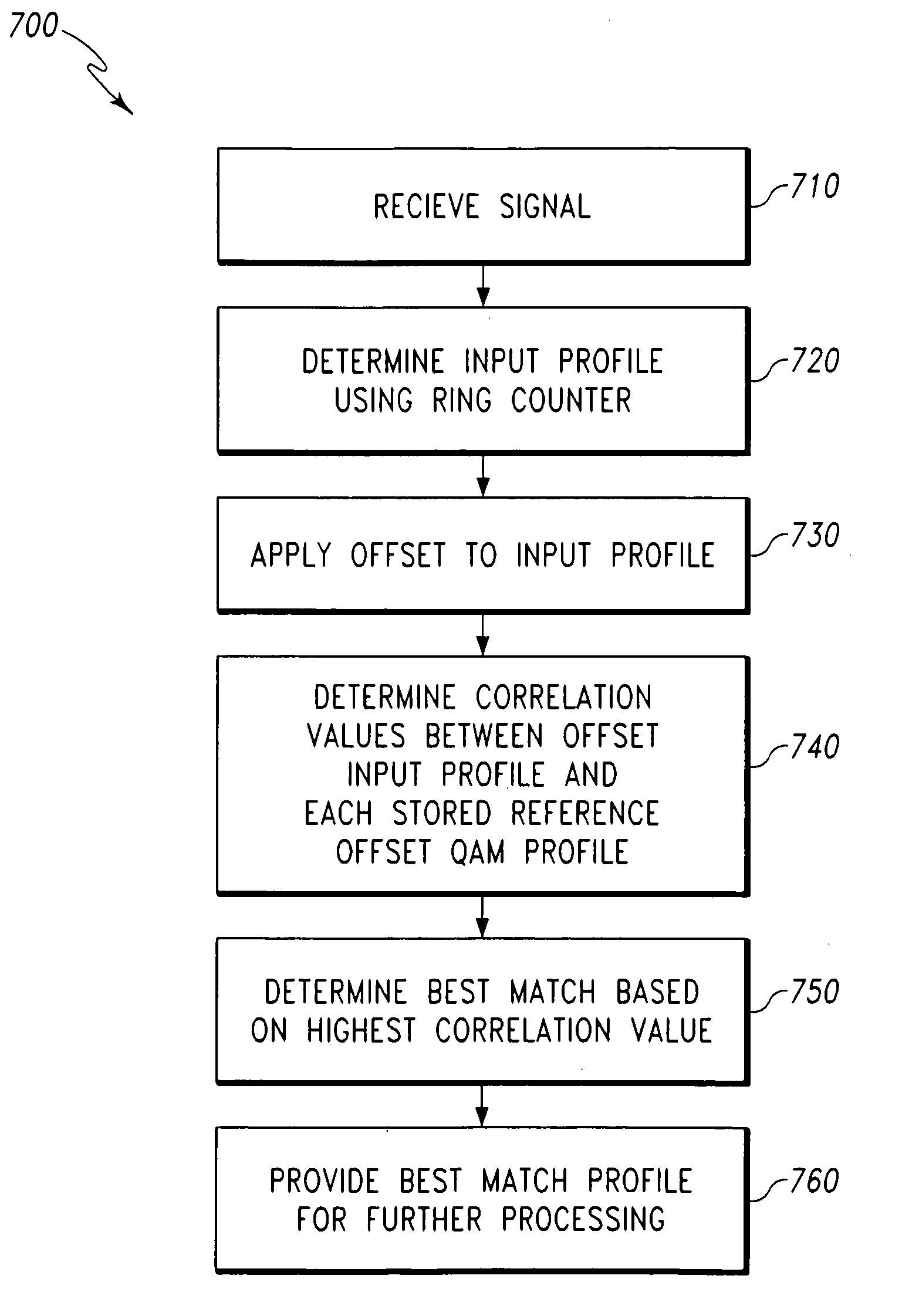

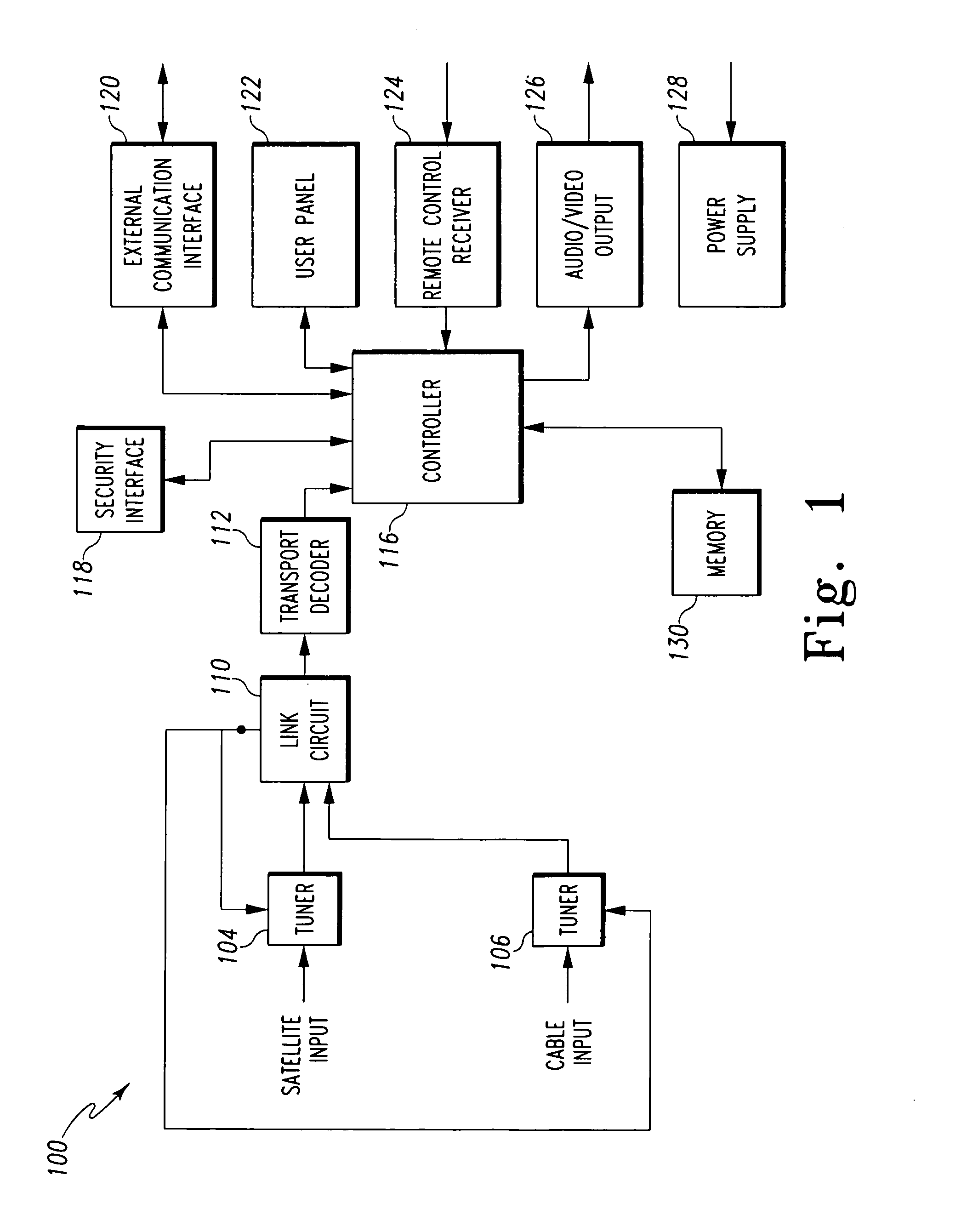

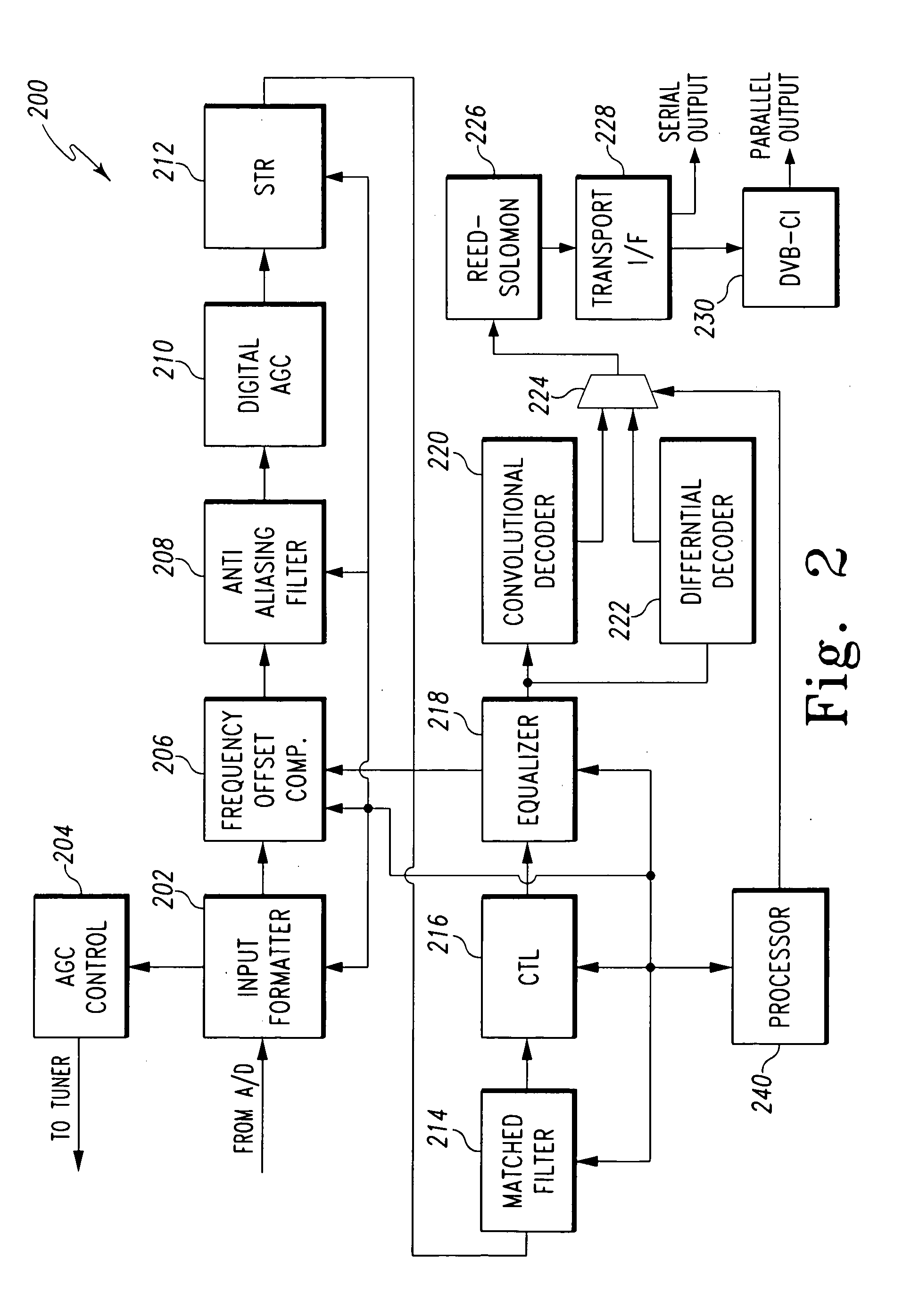

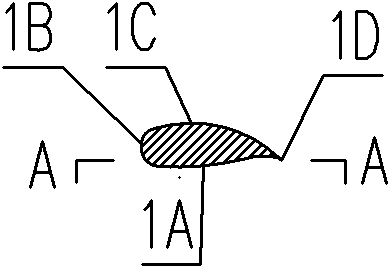

Apparatus and method for determination of signal format

InactiveUS20110074500A1Multiple input and output pulse circuitsMultiple modulation transmitter/receiver arrangementsRing counterSignal analyzer

The determination of the signal modulation format for a channel is an important aspect of the operation of a signal receiver. A method (700) is described including the steps of receiving (710) a signal, comparing (720) a sample of the received signal to a first threshold value and a second threshold value, creating (720) a signal profile based on the comparison, and selecting (750) a modulation format for the received signal based on the signal profile. An apparatus (500) is also described including a ring counter (510) that receives a sample of an input signal, compares the sample to a first threshold value and a second threshold value, and creates a signal profile for the input signal, a signal profiler (550) that compares the signal profile for the input signal to at least two reference profiles, and a detector (560) that determines a modulation format for the input signal based on the comparison in the signal profiler (550).

Owner:MAGNOLIA LICENSING LLC

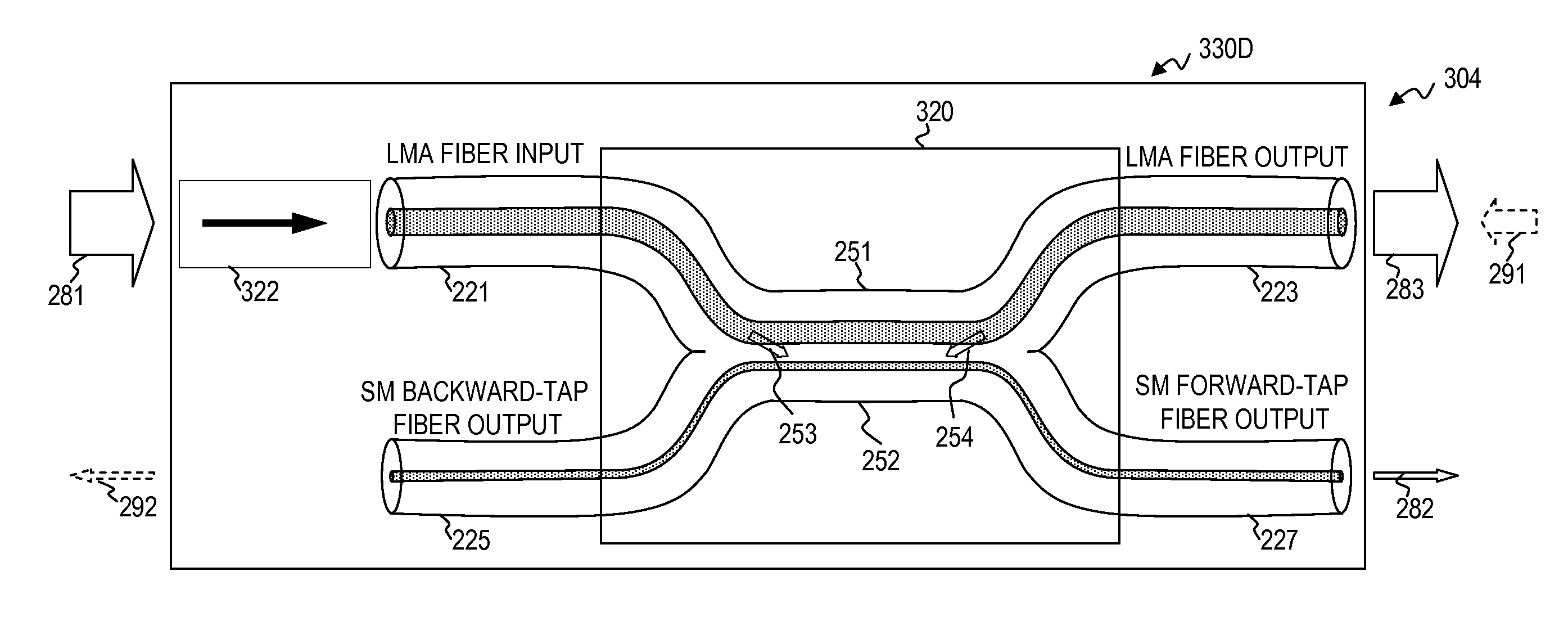

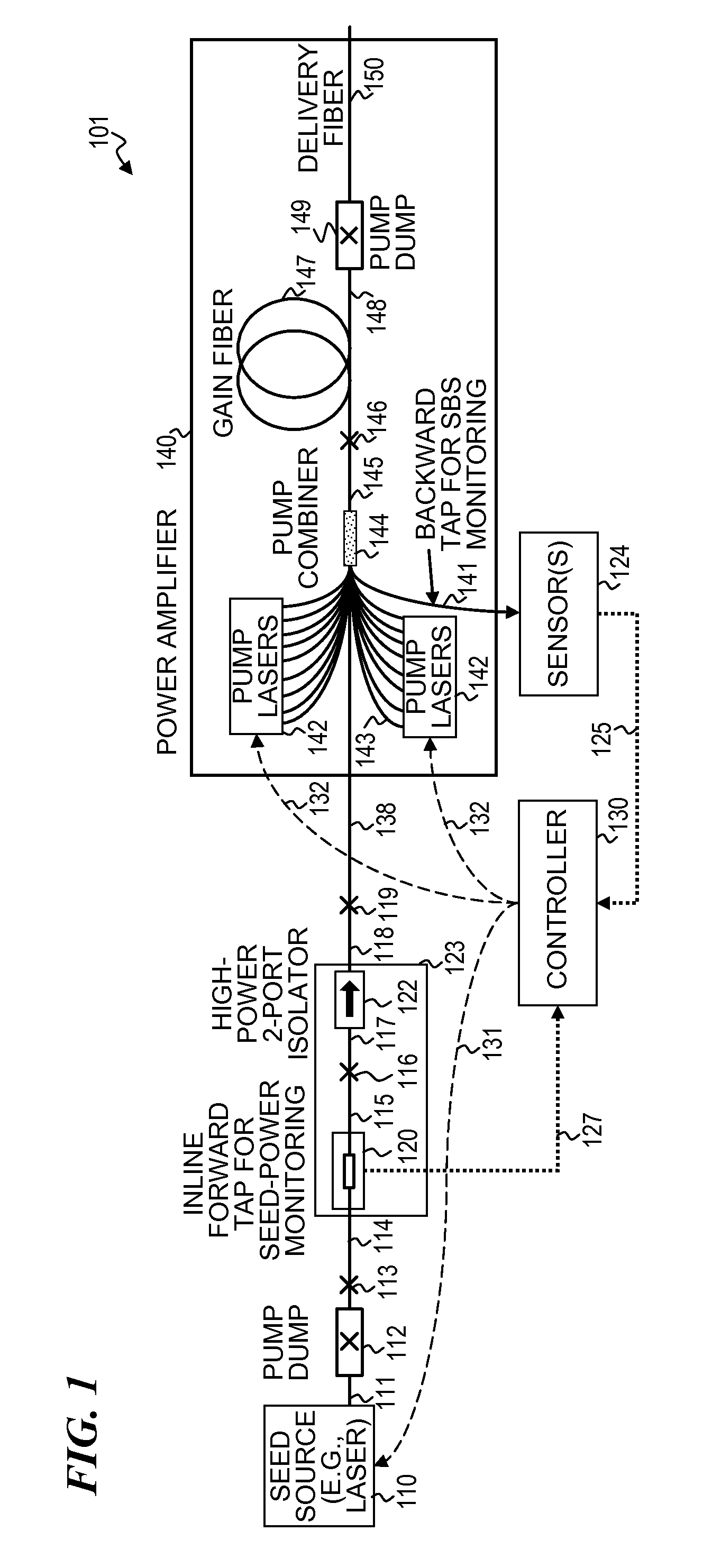

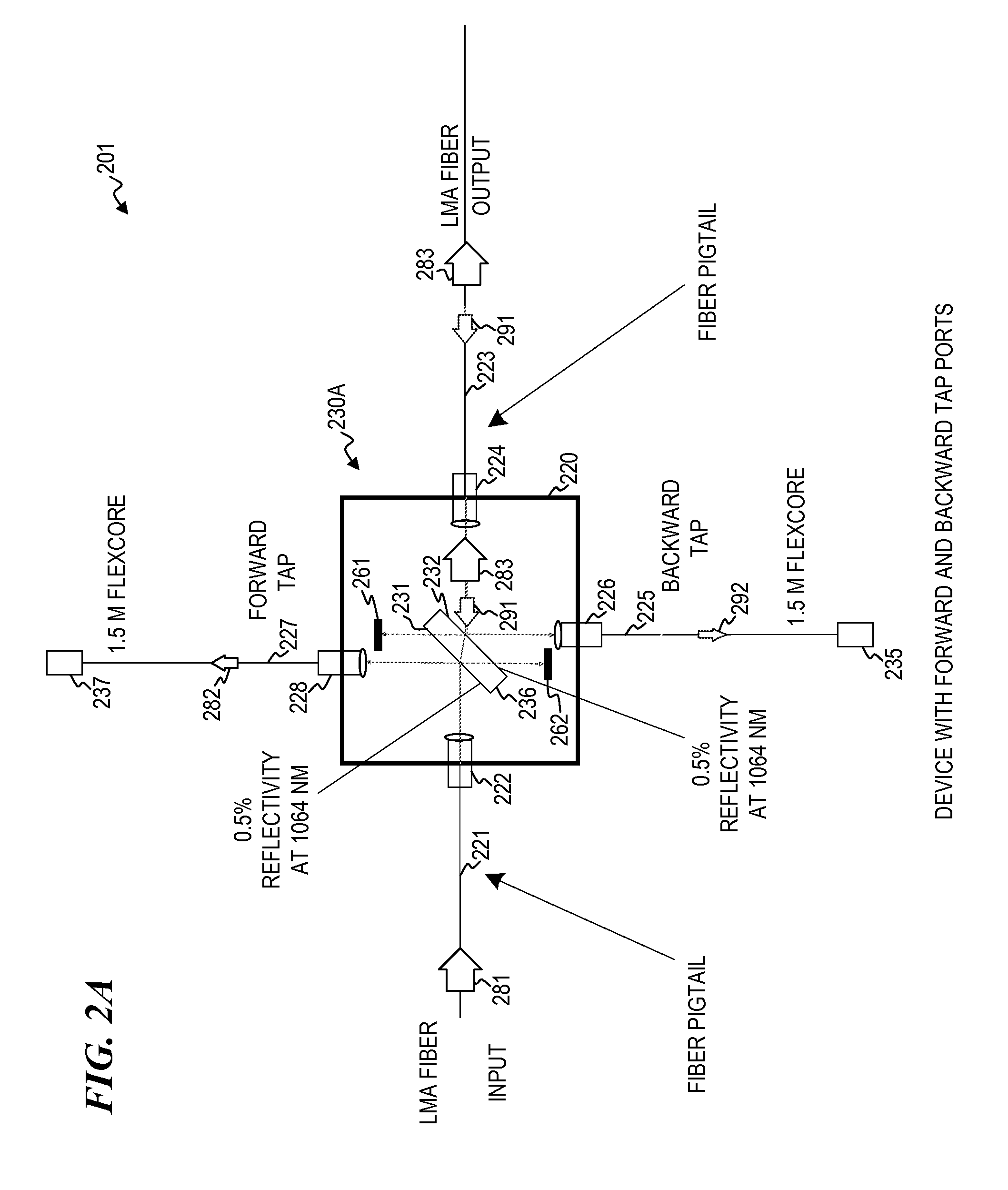

In-line forward/backward fiber-optic signal analyzer

ActiveUS20110091155A1Reduce catastrophic damageAvoid damageExcitation process/apparatusFibre transmissionAudio power amplifierSignal analyzer

An optical connector having a plurality of directional taps and connecting between a plurality of optical waveguides (e.g., such as a connector between a waveguide that is part of, or leads from, a seed laser and / or an initial optical-gain-fiber power amplifier, and a waveguide that is part of, or leads to, an output optical-gain-fiber power amplifier and / or a delivery fiber), wherein one of the directional taps extracts a small amount of the forward-traveling optical output signal from the seed laser or initial power amplifier (wherein this forward-tapped signal is optionally monitored using a sensor for the forward-tapped signal), and wherein another of the directional taps extracts at least some of any backward-traveling optical signal that may have been reflected (wherein this backward-tapped signal is optionally monitored using a sensor for the backward-tapped signal).

Owner:LOCKHEED MARTIN CORP

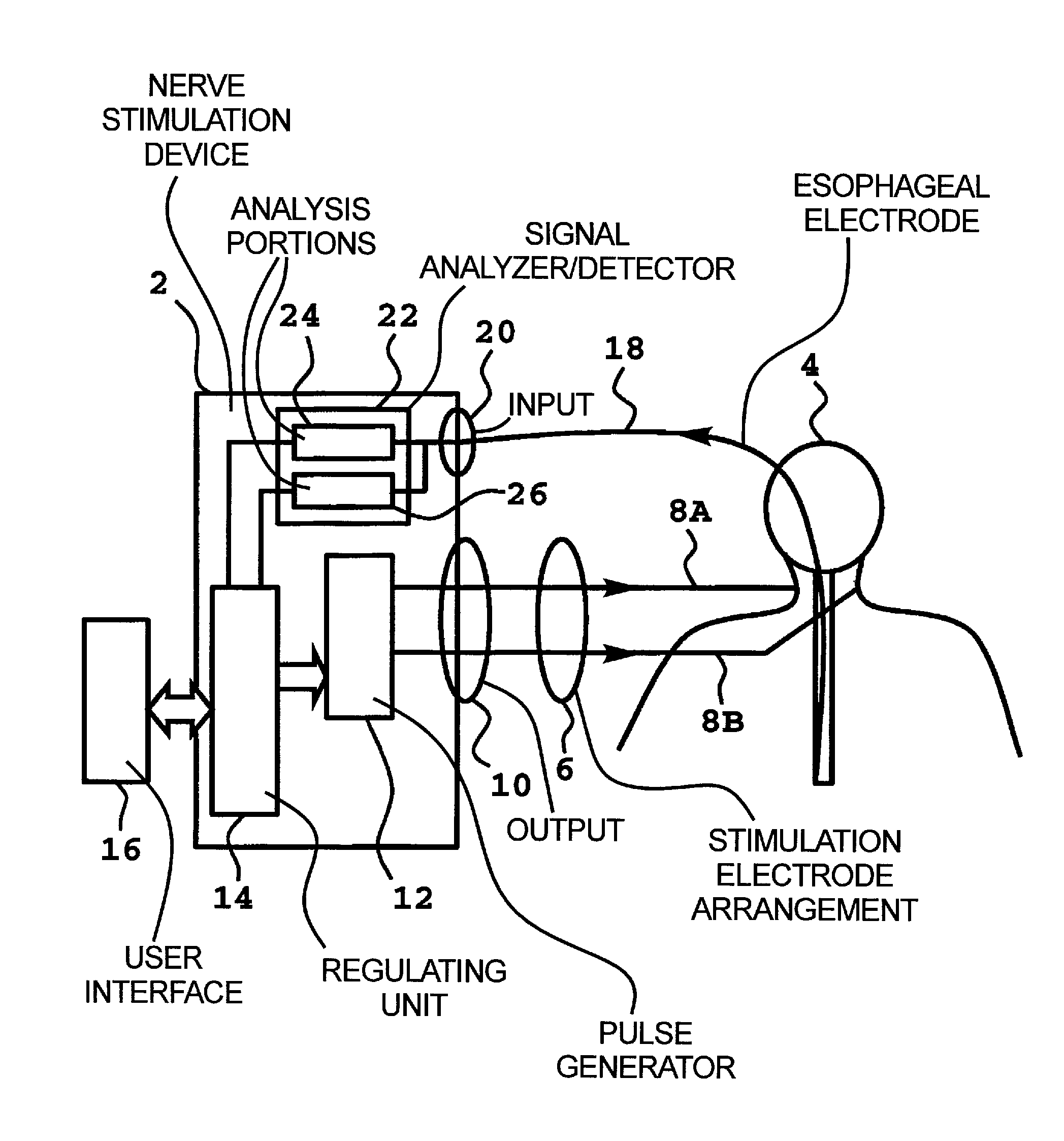

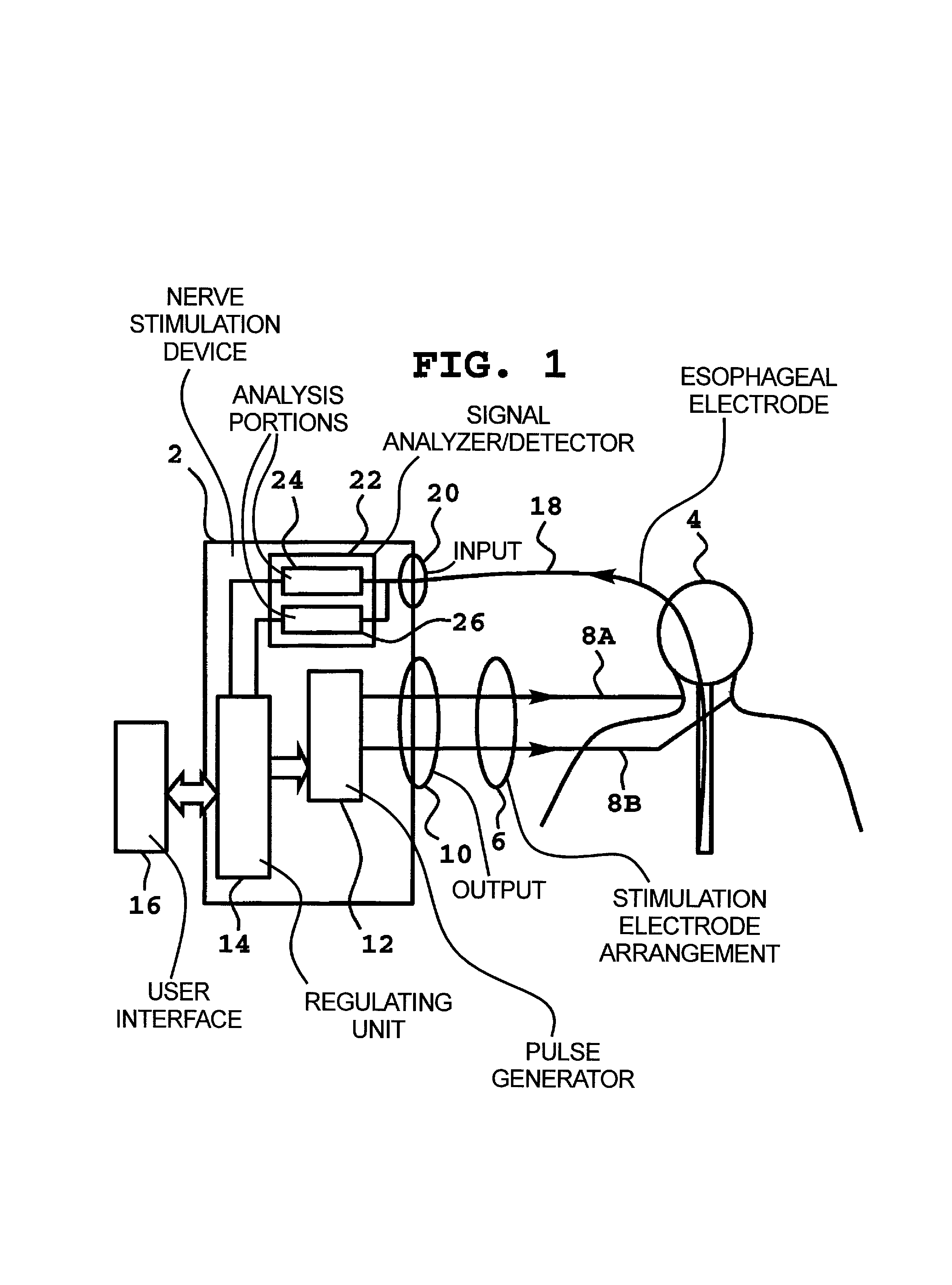

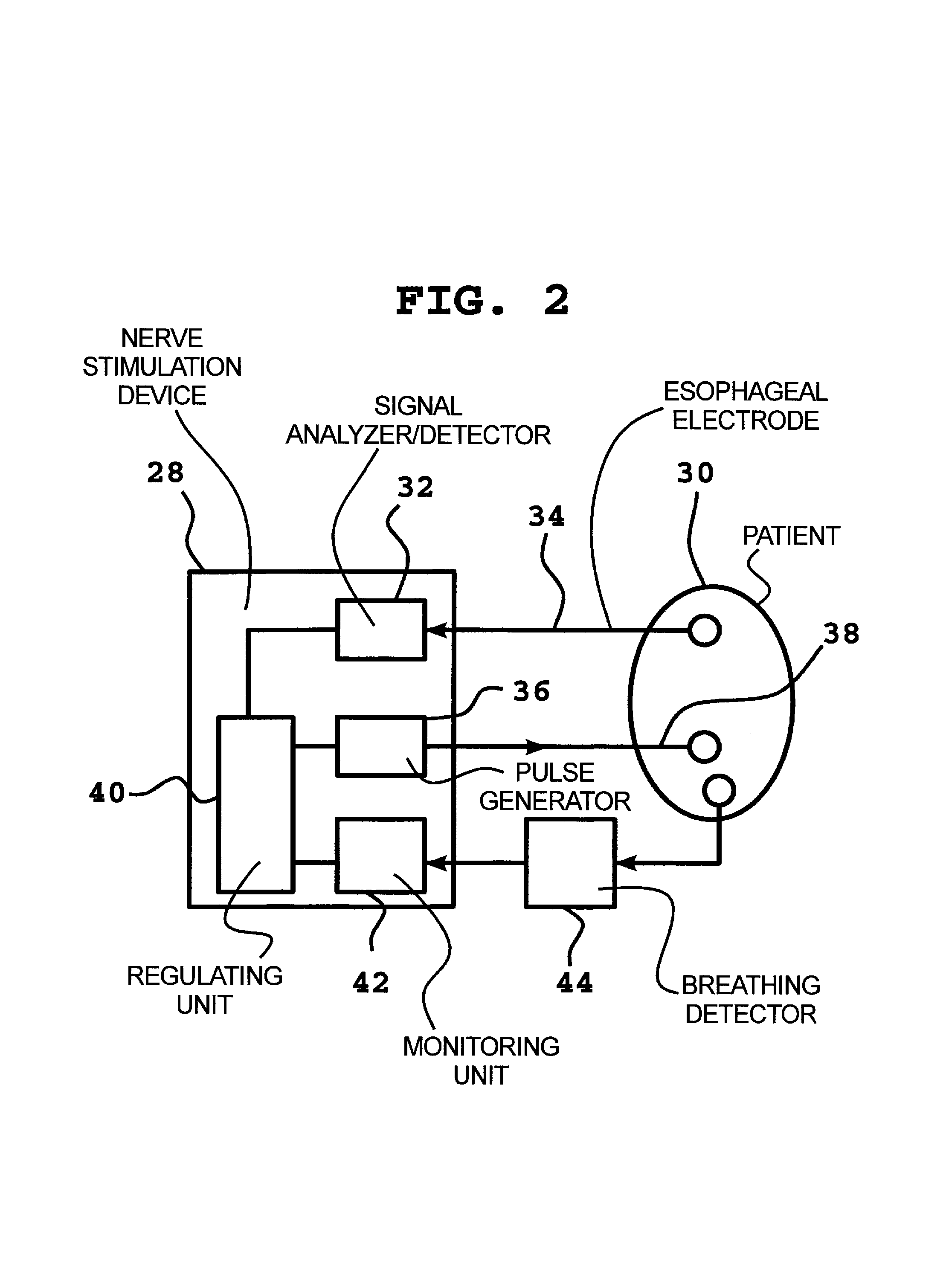

Nerve stimulation device

InactiveUS7283875B2Increase supplyElectrocardiographyElectromyographyEsophageal electrodeSignal analyzer

A nerve stimulation device has a pulse generator for generating stimulation pulses and an output for the stimulation pulses from the pulse generator, which is connectable to an electrode arrangement adapted for interaction with a living being to stimulate the phrenic nerve. The nerve stimulation device is made more safe and effective by the provision of an input connectable to an esophageal electrode for the reception of measurement signals. The esophageal electrode is adapted to be inserted in the esophagus of the living being for obtaining measurement signals. A signal analyzer filters myo-electrical signals from the diaphragm out of the measurement signals and a regulating unit regulates the pulse generator dependent on the myo-electrical signals.

Owner:MAQUET CRITICAL CARE

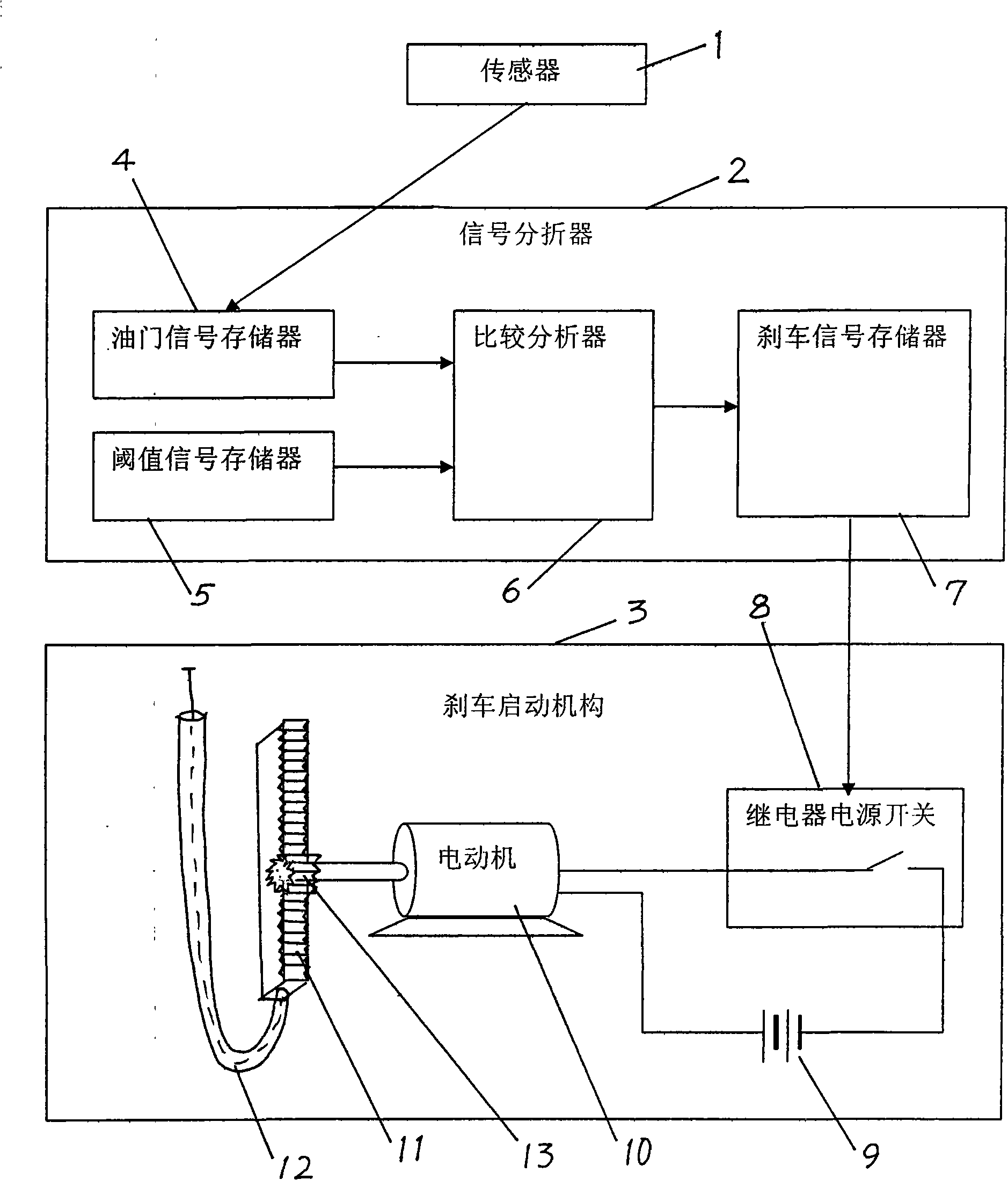

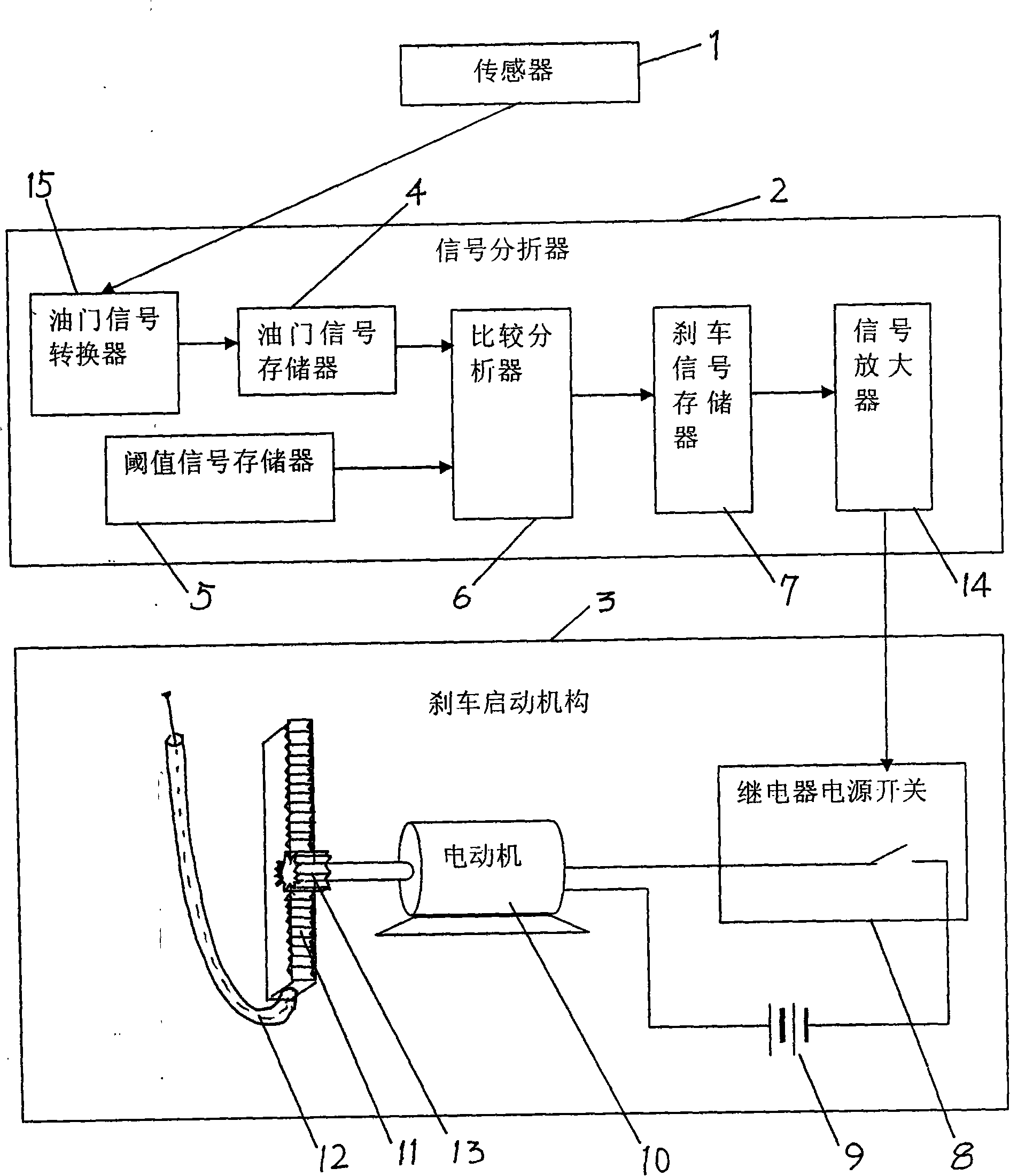

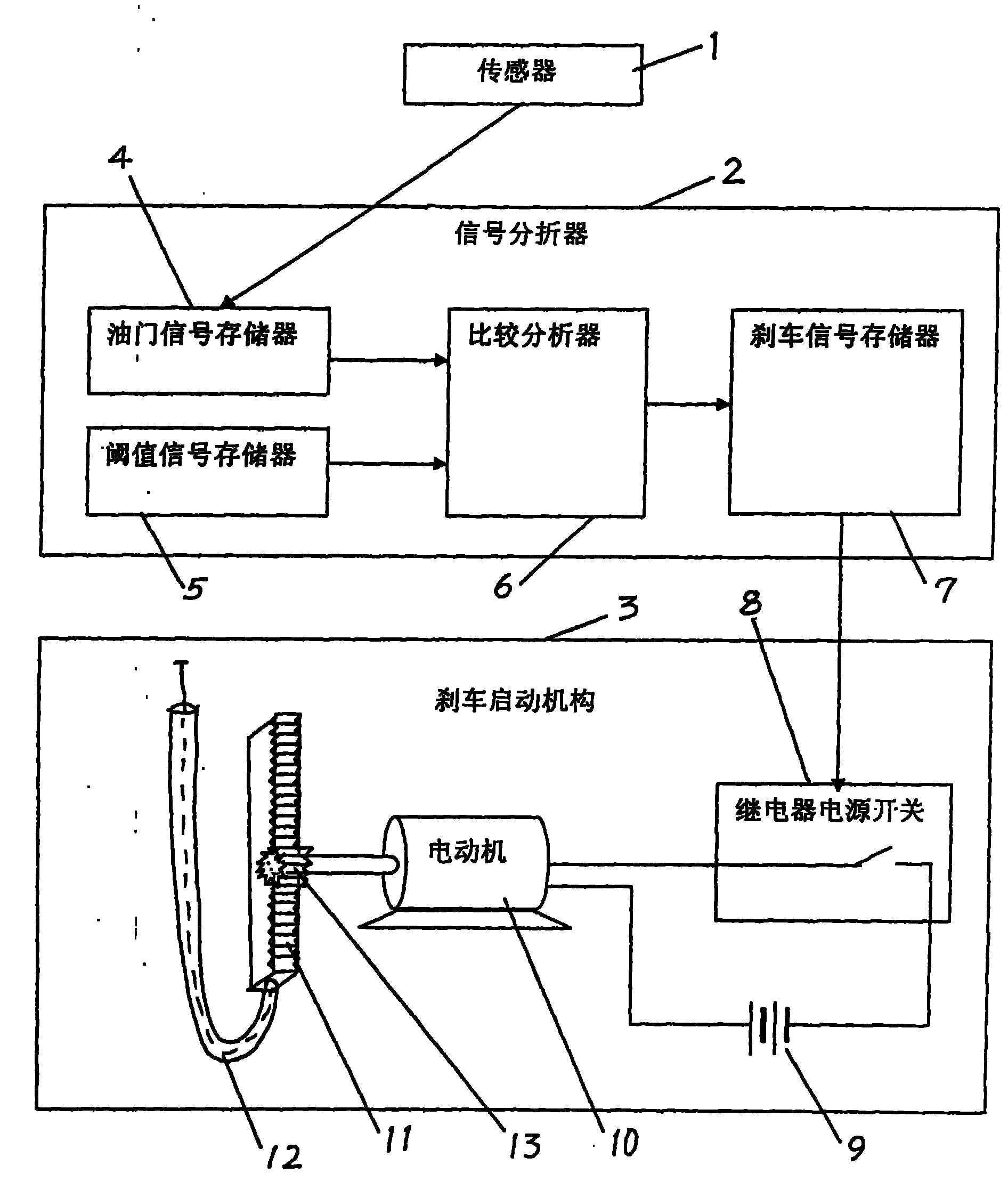

Device for automatically correcting accelerator pedal misoperation to braking operation by electrical and mechanical combination

InactiveCN102114776AAvoid nasty accidentsAvoid Vicious Traffic AccidentsFoot actuated initiationsPropulsion unit arrangementsElectricitySignal analyzer

The invention relates to a device for automatically correcting an accelerator pedal misoperation to a braking operation by electrical and mechanical combination, which belongs to a device capable of obtaining a mechanical operation for driving a brake device by means of electrical signal conversion of a mechanical operation of stepping on an accelerator pedal by mistake. The device comprises a sensor and is characterized in that the device further comprises a signal analyzer and a brake starting mechanism, wherein the sensor is connected with the signal analyzer to transmit an accelerator signal from the sensor to the signal analyzer, the signal analyzer is connected with the brake starting mechanism and transmits a brake start-up signal to the brake starting mechanism. The invention has the advantages that the mechanical operation of stepping on the accelerator pedal by mistake is converted into an accelerator electrical signal through the sensor, an electrical signal of serious accelerator pedal misoperation is analyzed, then the electrical signal of serious accelerator pedal misoperation is converted into an electrical signal for starting the brake device, and the brake starting mechanism generates a braking mechanical operation, as a result, the mechanical operation of stepping on the accelerator pedal by mistake is automatically converted into the braking operation of thevehicle, which prevents the occurrence of serious vehicle accidents caused by the misoperation of the accelerator pedal.

Owner:ZHEJIANG XIANAN AUTOMOBILE BREAKING SYST

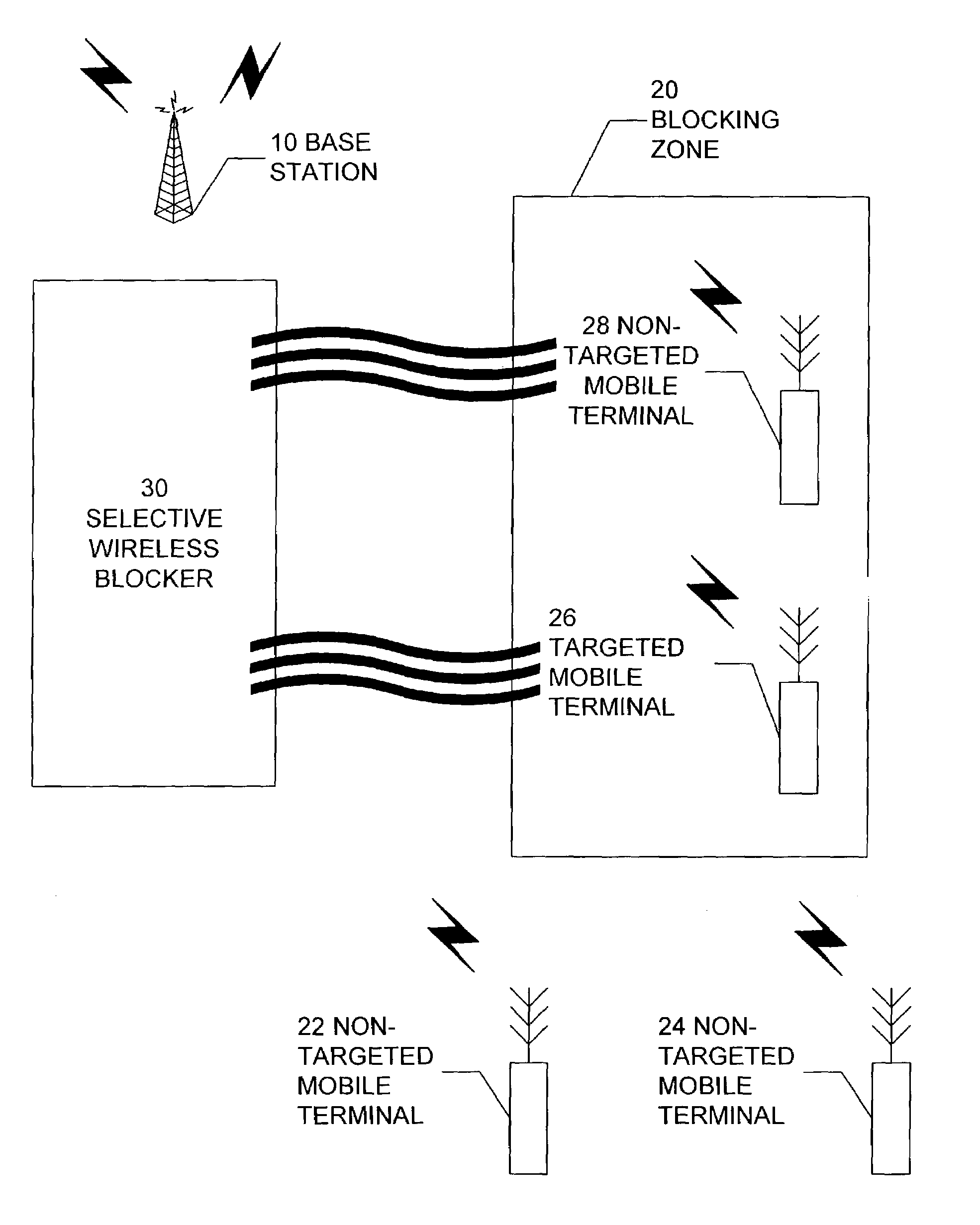

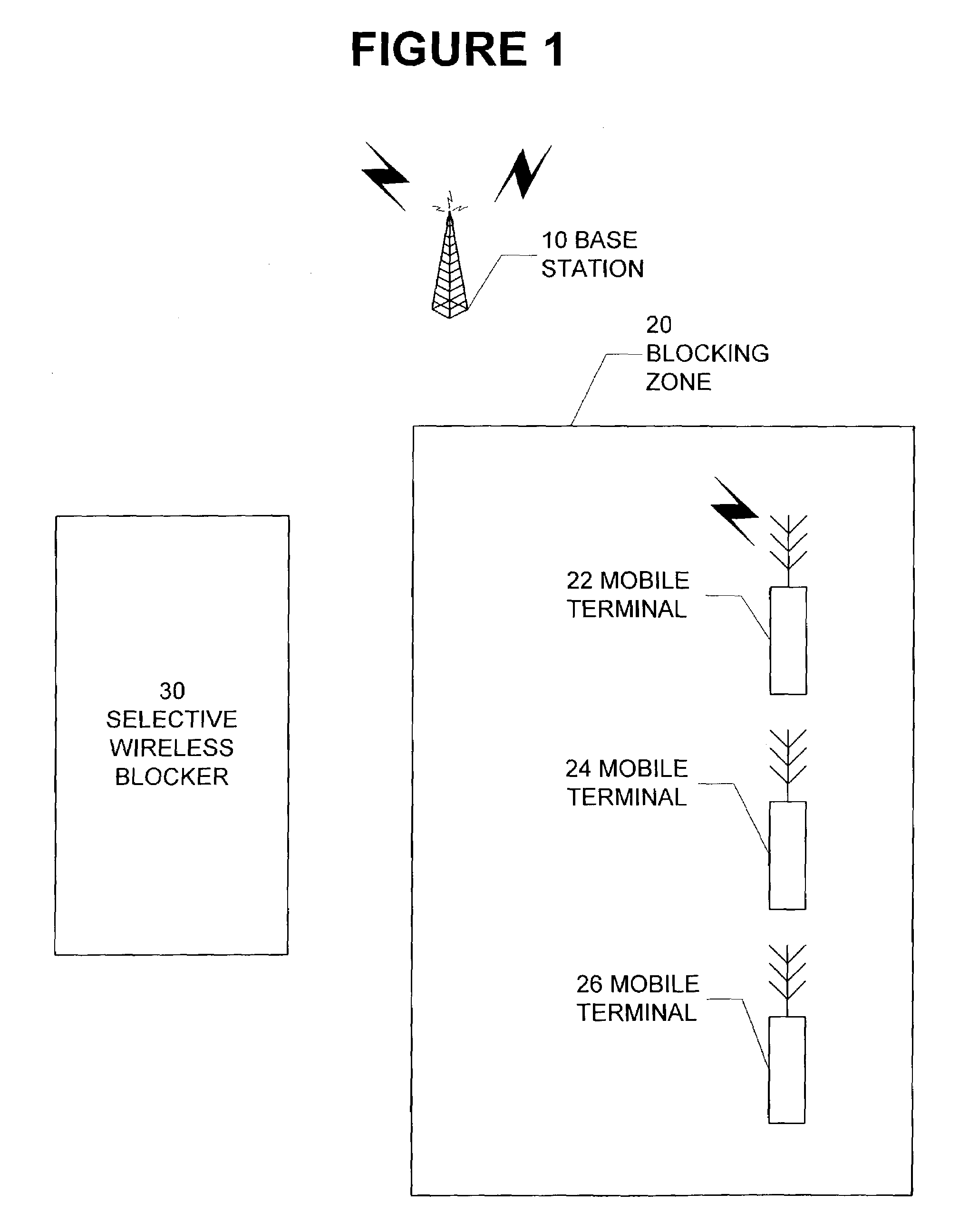

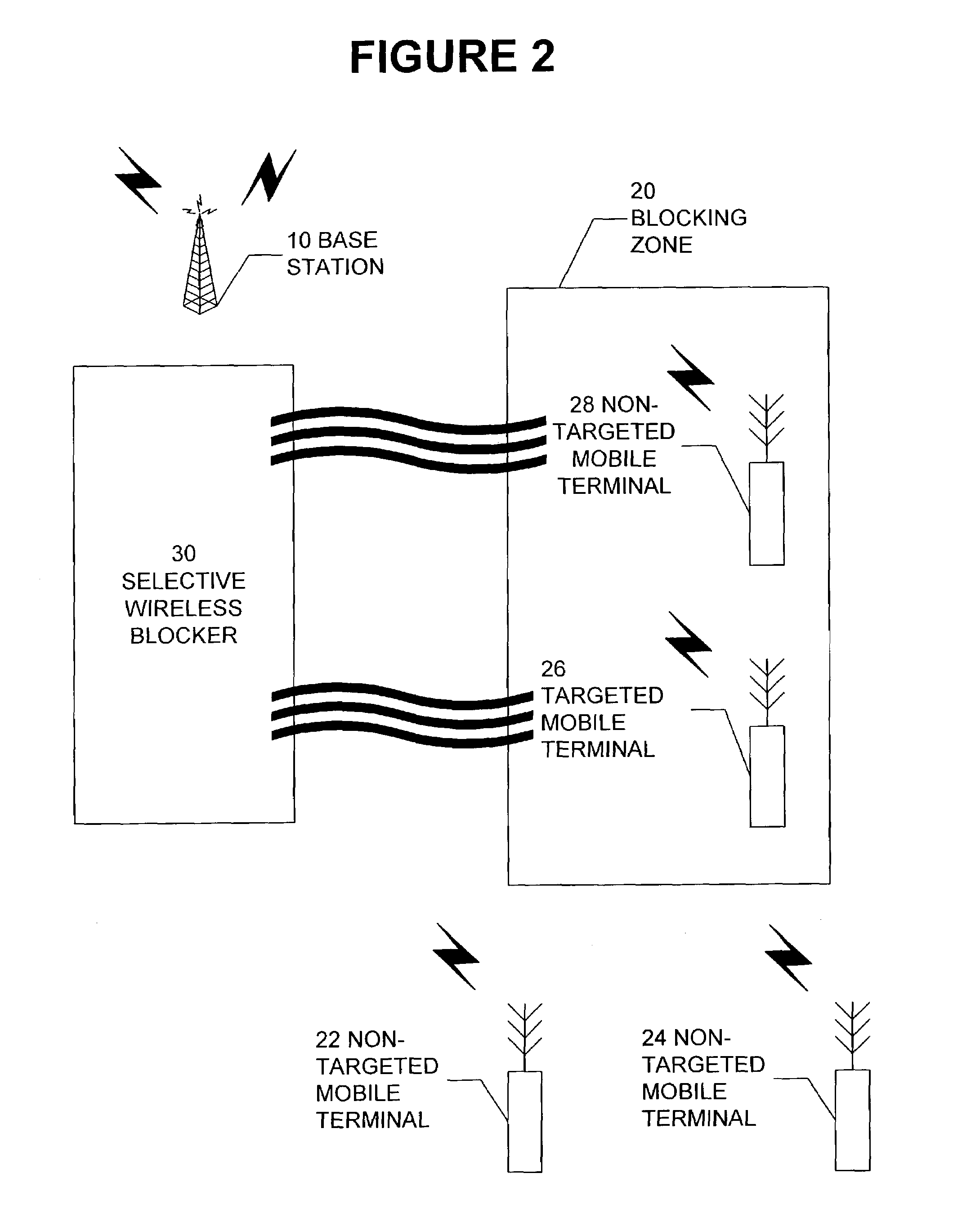

Targeted mobile terminal communication blocker

InactiveUS7050755B2Interference minimizationMinimize interferencePower managementEnergy efficient ICTSignal analyzerNon targeted

A selective blocker for targeted mobile terminals. A signal monitor determines when a targeted mobile terminal is transmitting a signal to a base station. A signal analyzer identifies characteristics of the terminal signal and a processor produces a blocking response based on one or more characteristics. The blocking response is transmitted to the targeted mobile terminal to block communications between the targeted mobile terminal and the base station using the minimum power needed to effectively block the terminal signal so as to limit interference with non-targeted mobile terminals.

Owner:PCTEL INC

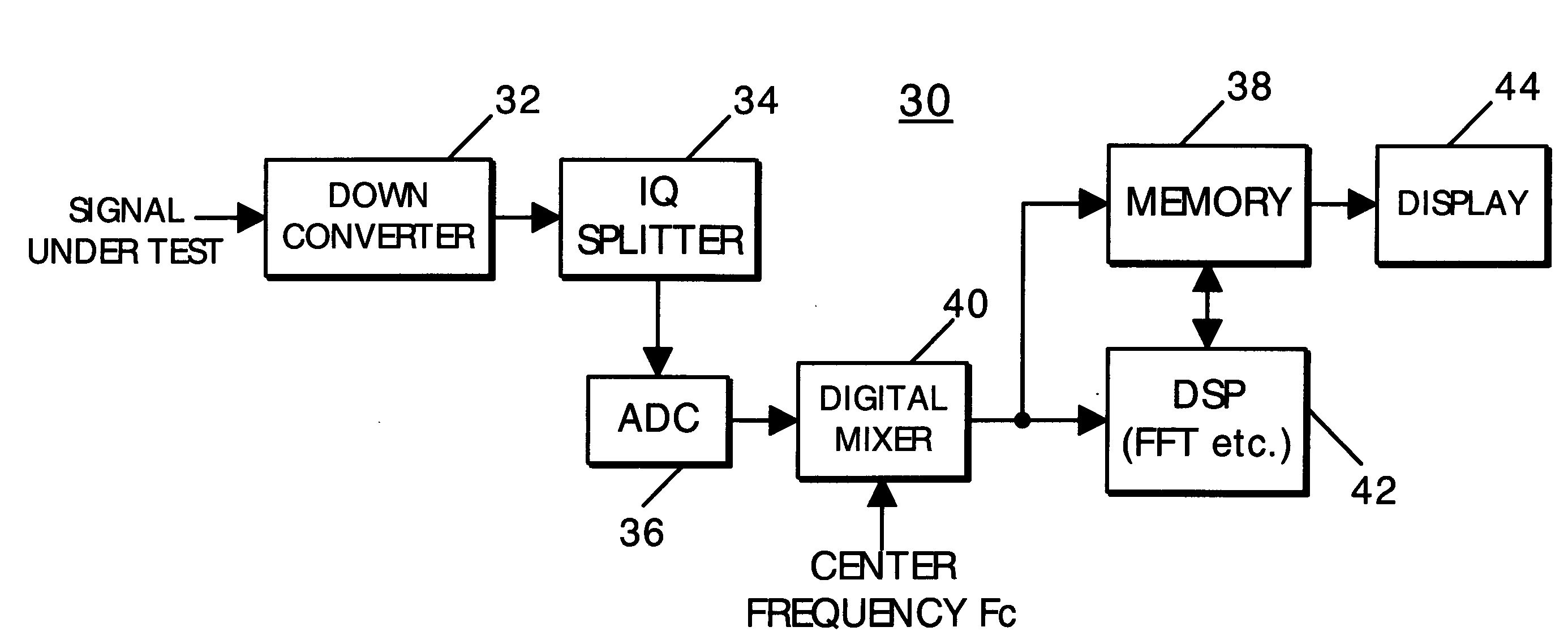

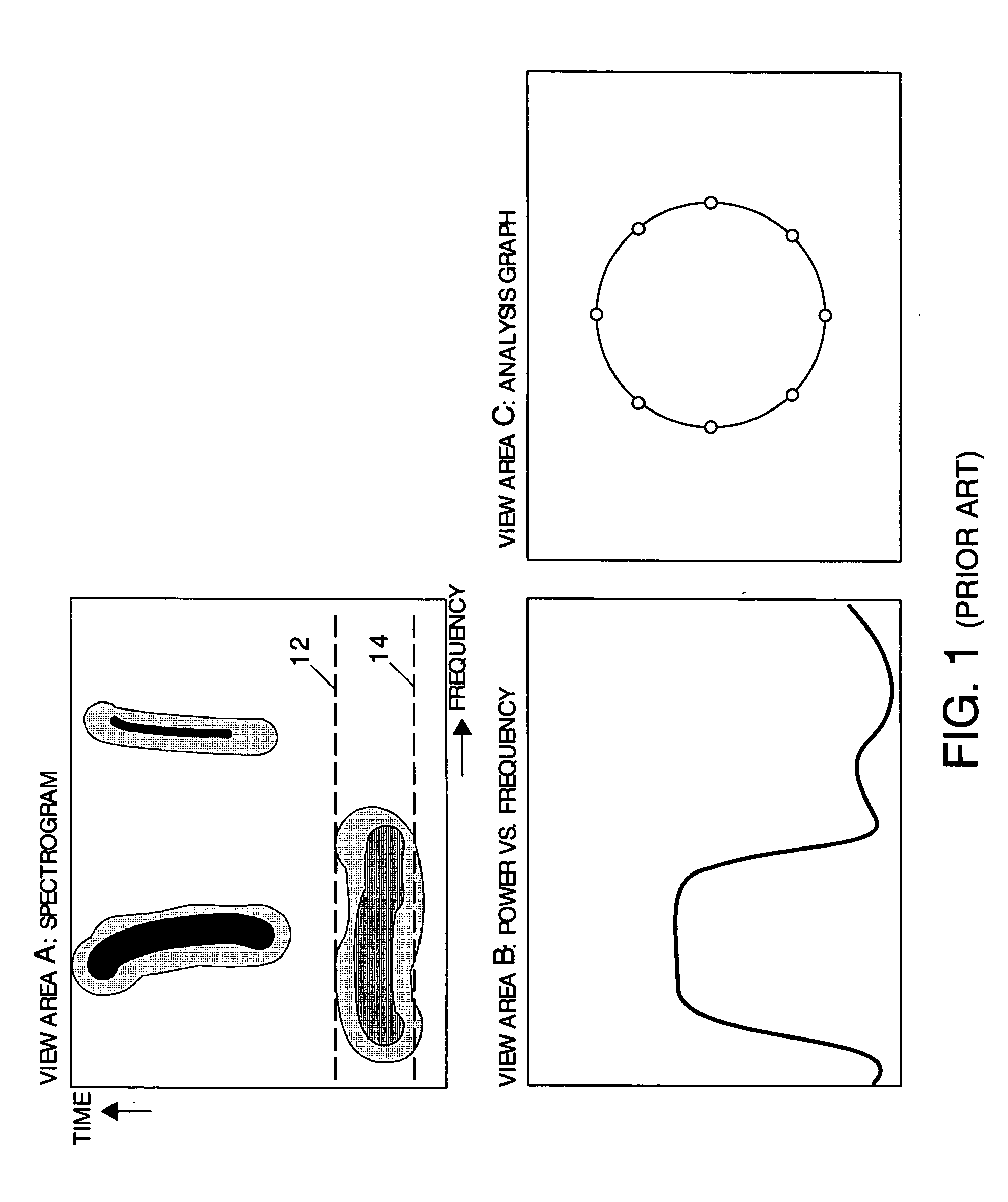

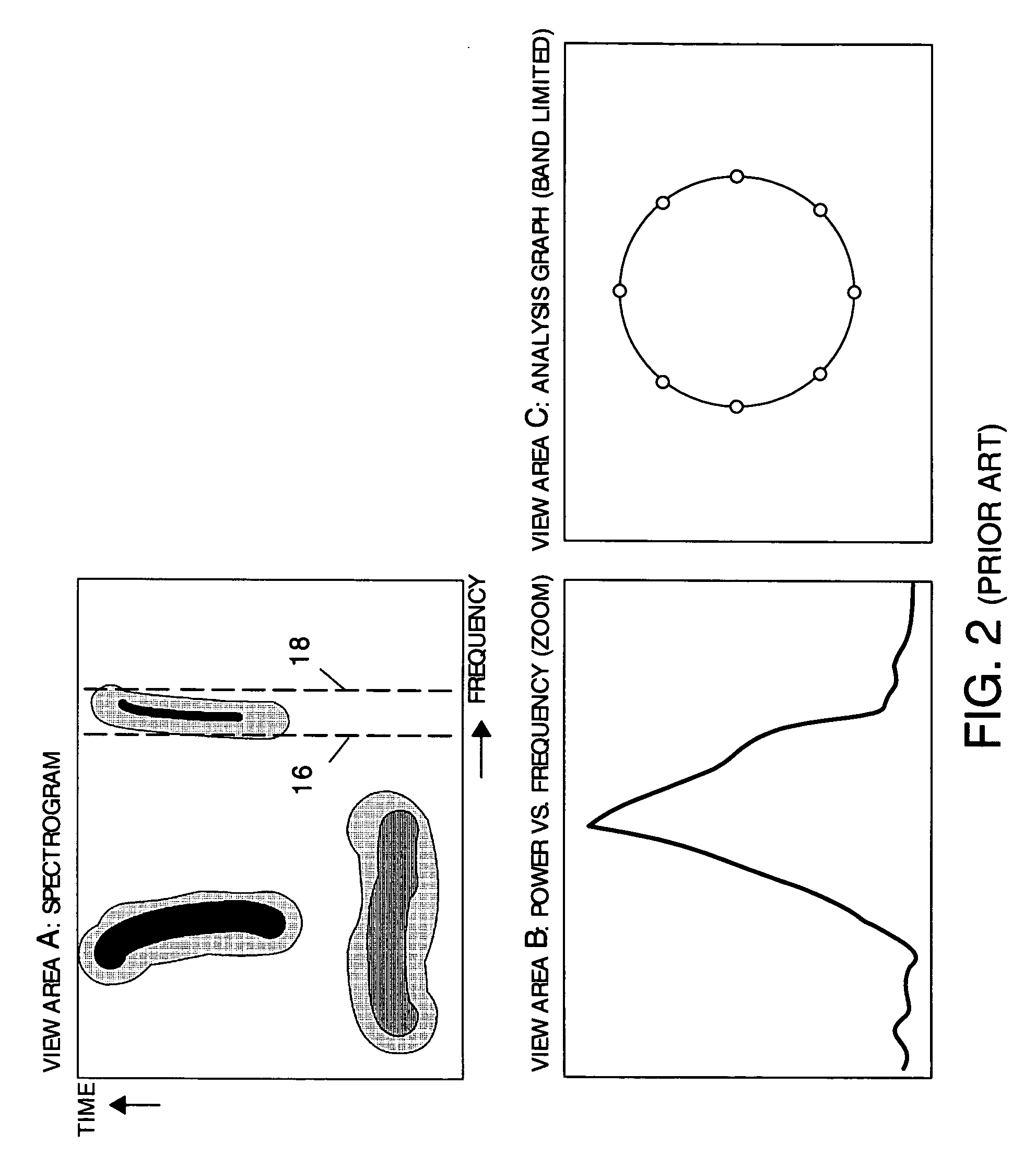

Display method for signal analyzer

A rectangle marker on a display of a signal analyzer simultaneously designates time and frequency intervals of data from a signal under test for analysis. The data of the signal under test is displayed as a graph having time and frequency axes. Sub-graphs show data designated by the rectangle marker as processed in the time domain, frequency domain and modulation domain. The resulting display provides an overview of the signal under test and simultaneously provides displays of measurements and analyses for a designated portion of the data.

Owner:TEKTRONIX INC

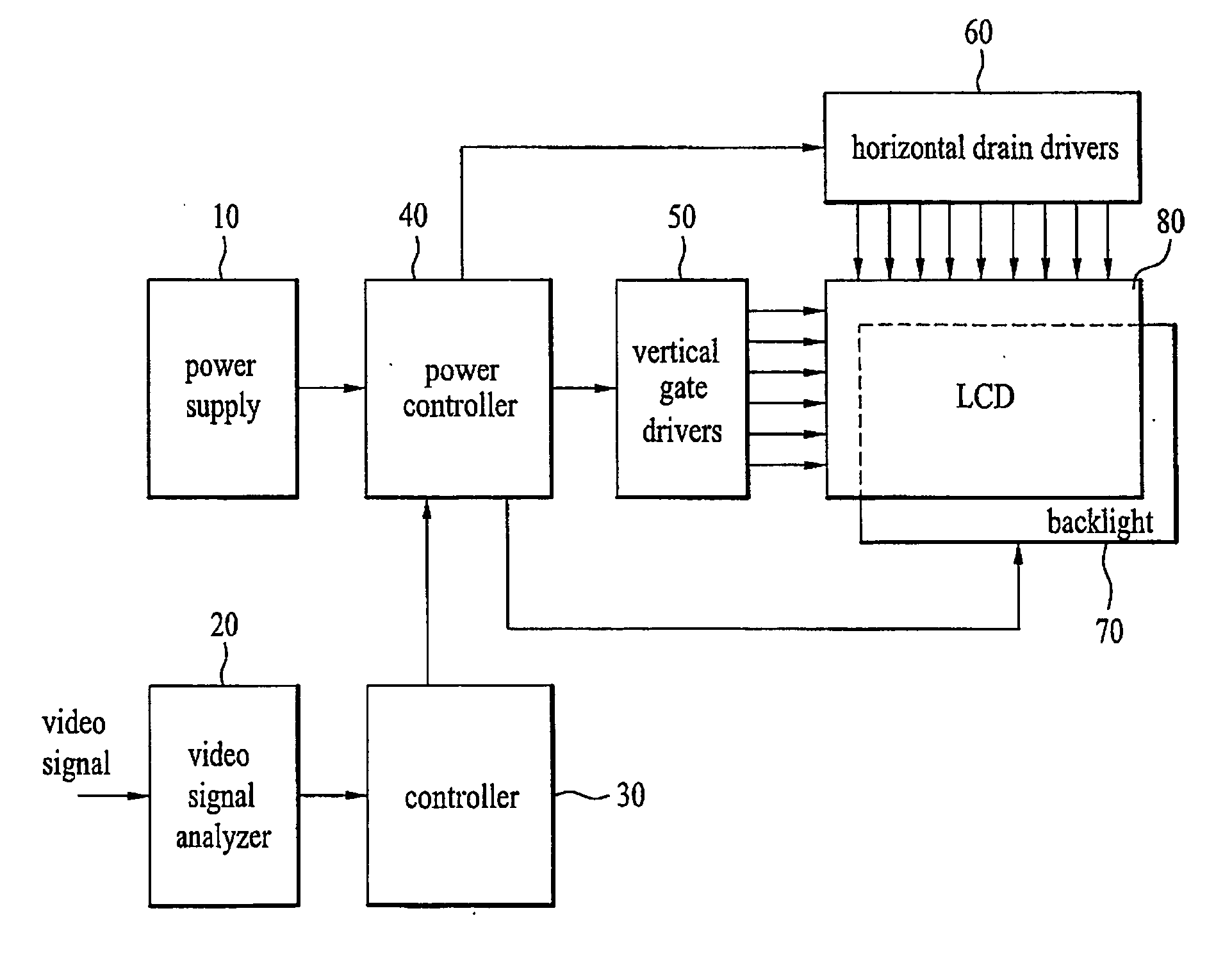

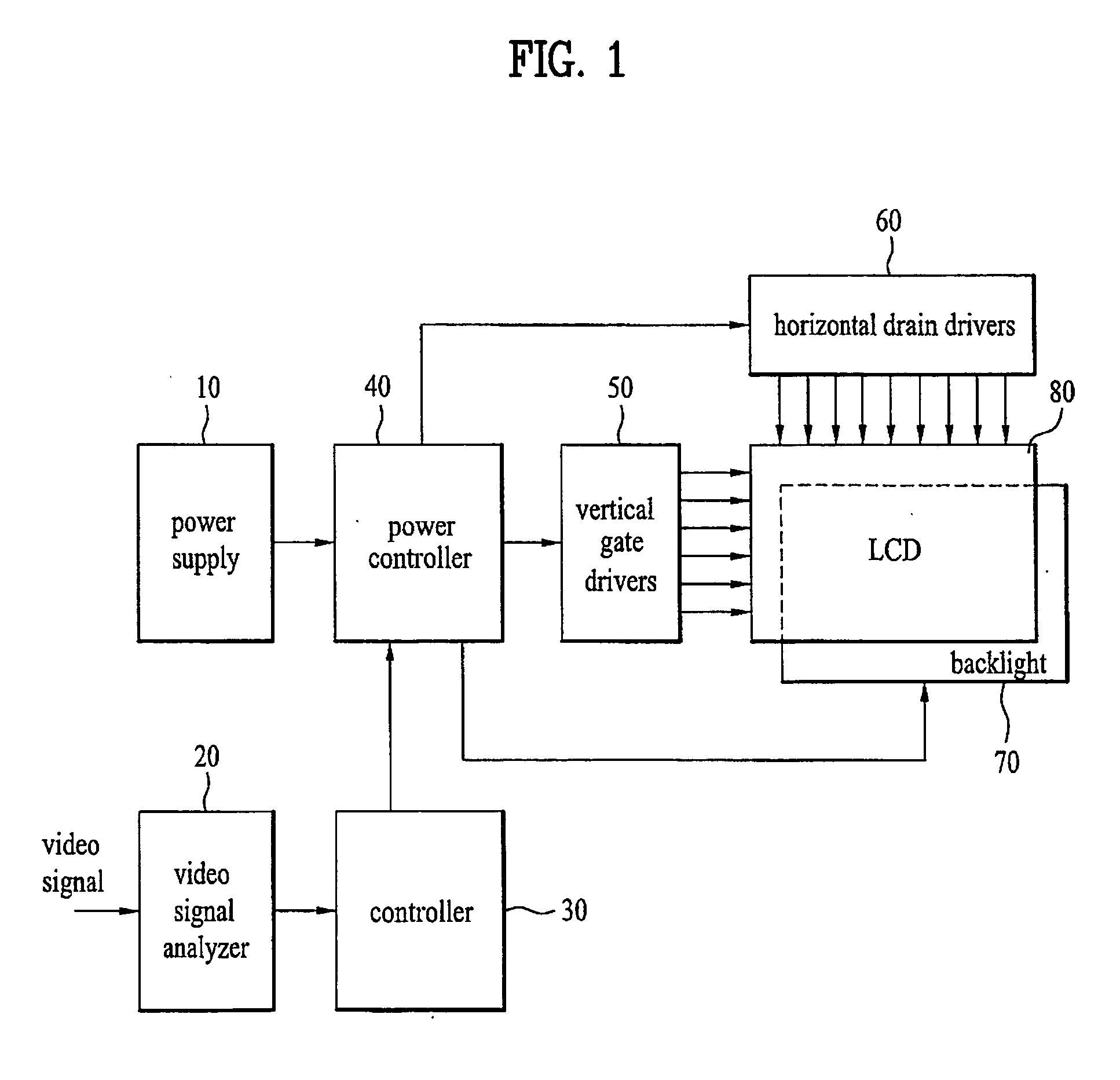

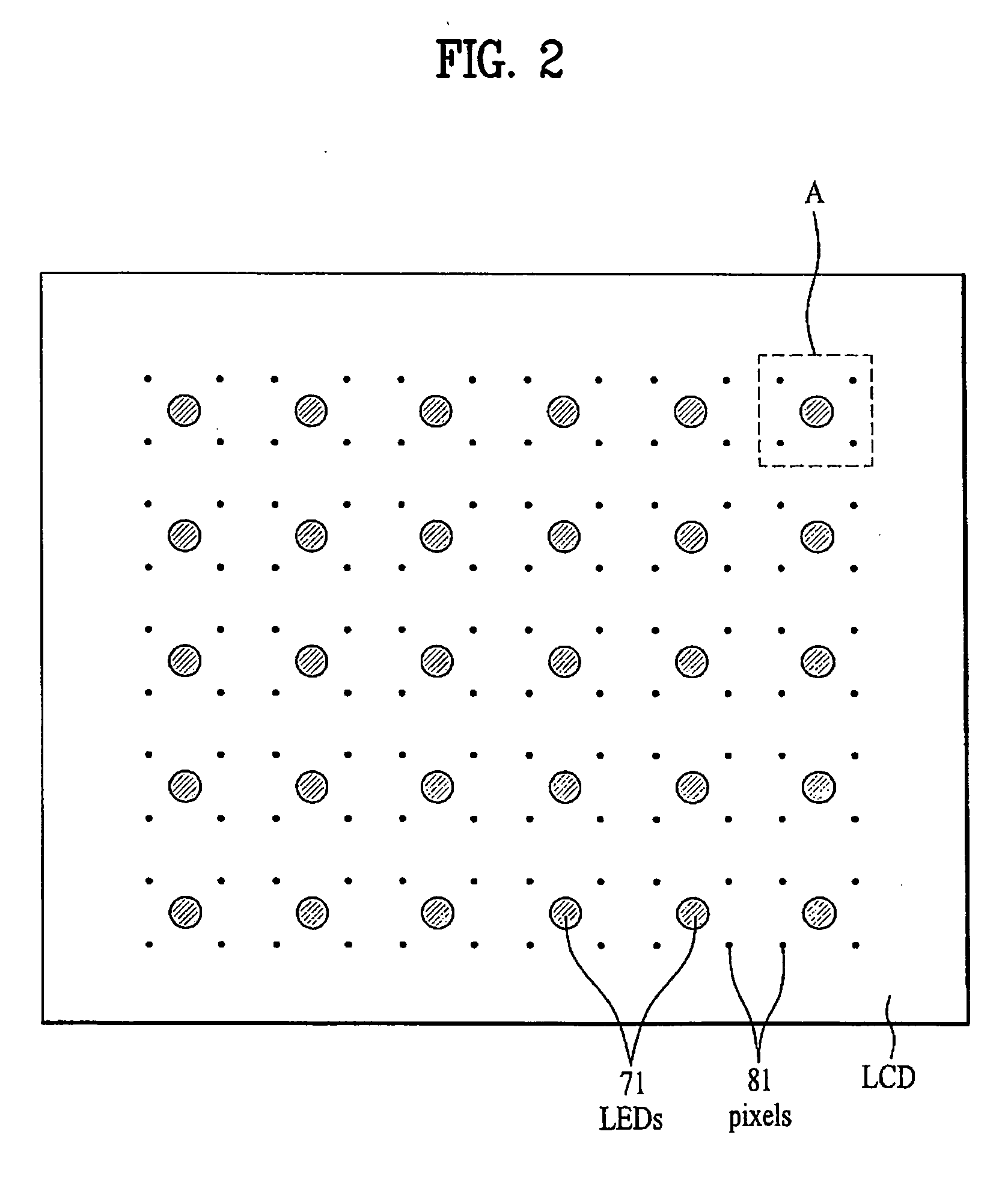

Apparatus and method for controlling power of a display device

InactiveUS20070002004A1Clearer video signalLow dissipation powerStatic indicating devicesNon-linear opticsPower controllerControl power

An apparatus and method for controlling power of a display device is disclosed. Dynamic contrast is widened by controlling contrasts of each LED in the backlight of the display device. The apparatus comprises a video signal analyzer, a liquid crystal display (LCD), vertical gate drivers and horizontal drain drivers, a backlight, a power controller, and a controller. By controlling each LED, clearer video signal, lower dissipating power, and lower heat can be achieved.

Owner:LG ELECTRONICS INC

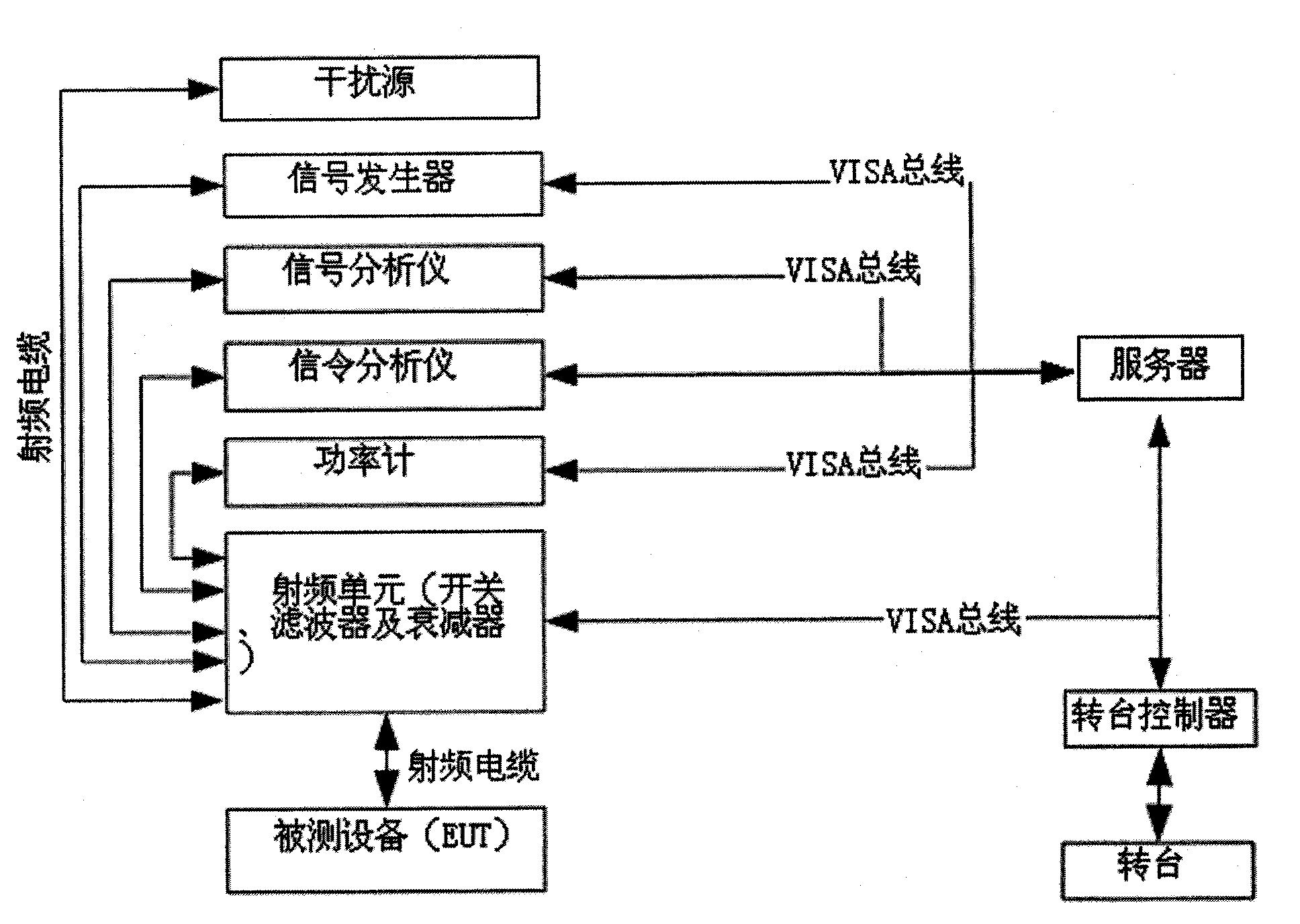

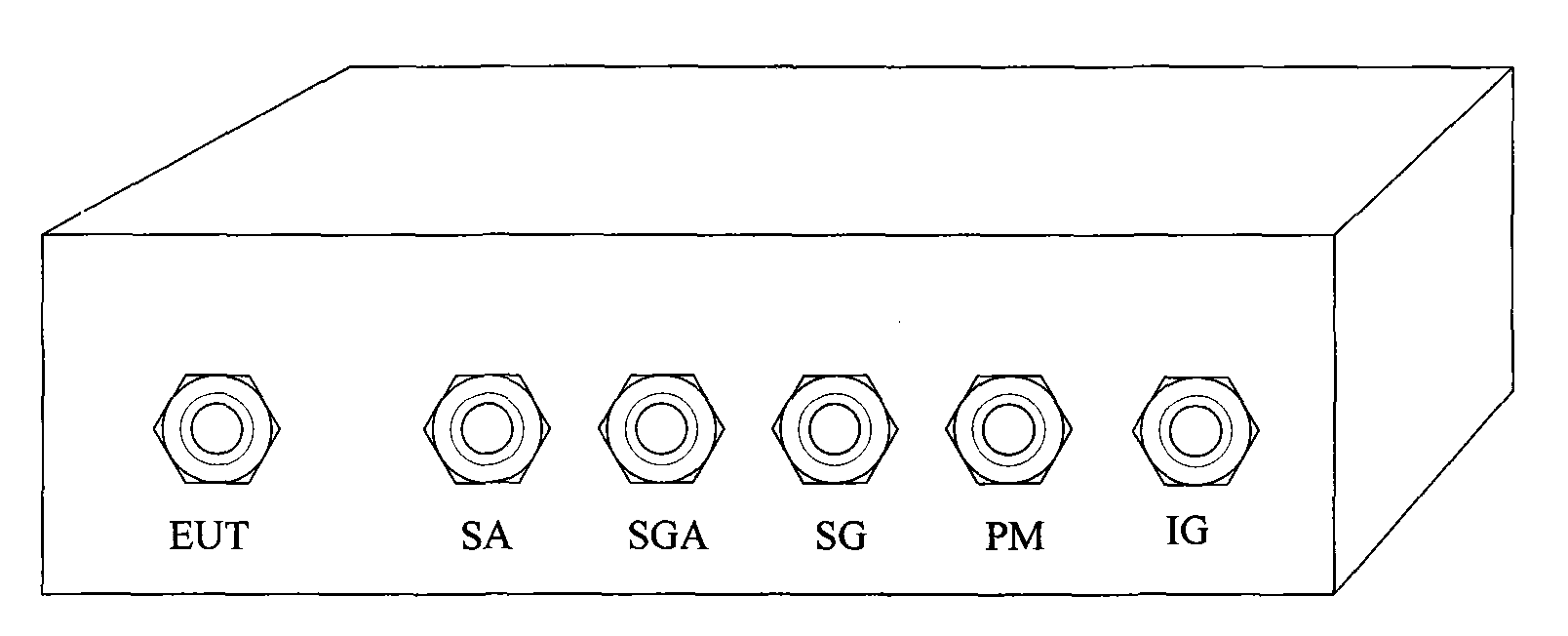

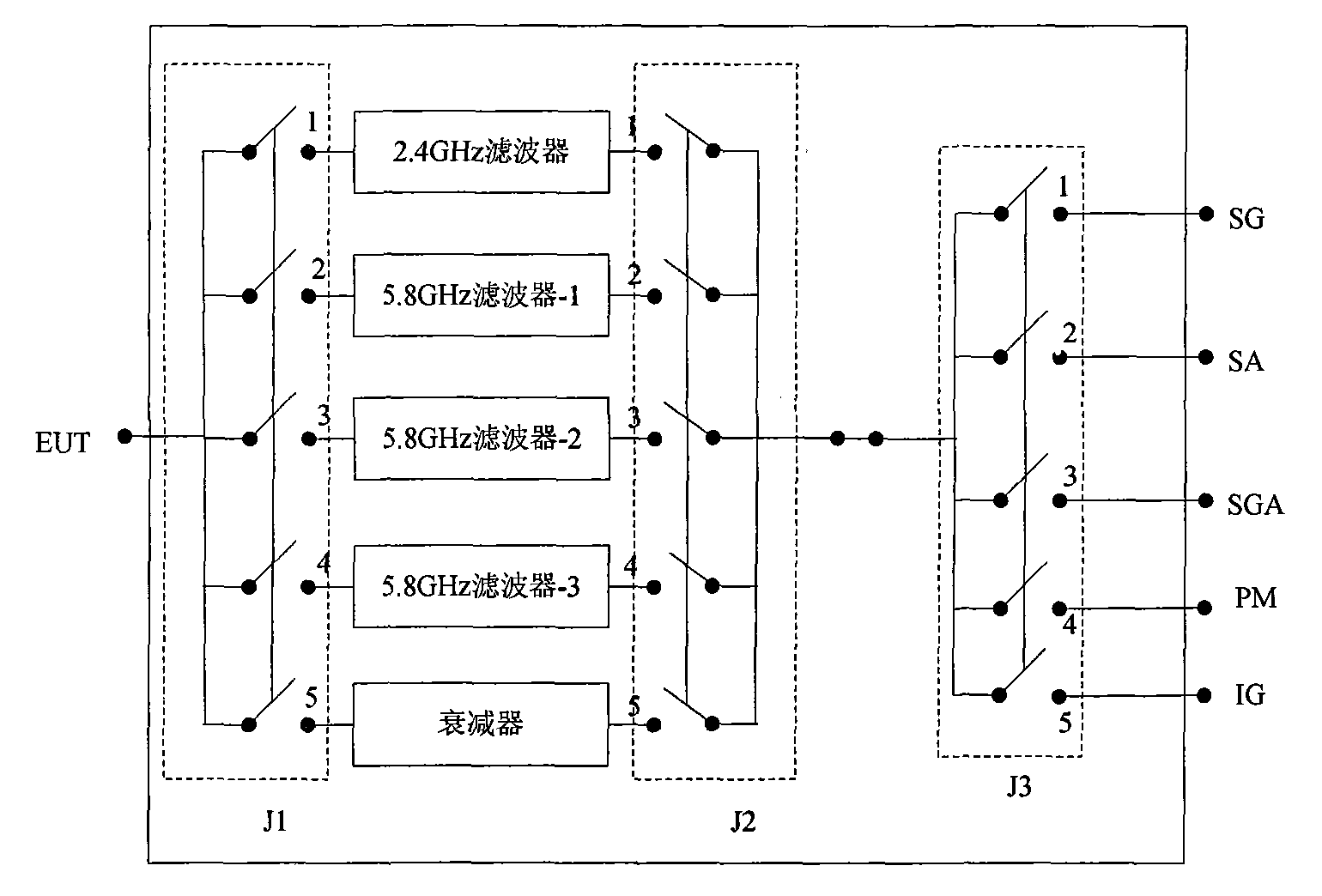

WLAN/WAPI wireless device radio frequency/over-the-air performance testing system

A WLAN / WAPI wireless device radio frequency / over-the-air performance testing system, used for radio frequency performance test of a WLAN / WAPI wireless device, comprises a signal generator, a signal analyzer, a signaling analyzer, a power meter, a radio frequency switch, a filter and an attenuator unit, a turntable / turntable controller and a server provided with automatic testing software. The radio frequency performance testing system is arranged in a large-sized testing cabinet, the operation of the system is centralizedly controlled by a high-performance server, the testing software can test the radio frequency performance and over-the-air performance according to user's requirement and related standard / technologies(CE,FCC standard and WAPI technology) and over-the-air performance requirement. The WLAN / WAPI wireless device radio frequency / over-the-air performance testing system can fully cover various tests and OTA tests of WLAN / WAPI wireless device of 802.11a / 802.11b / 802.11g standard under CE / FCC / WAPI standard, and can realize automation of tests utmostly.

Owner:TELECOMM METROLOGY CENT OF MINIST OF IND & INFORMATION TECH

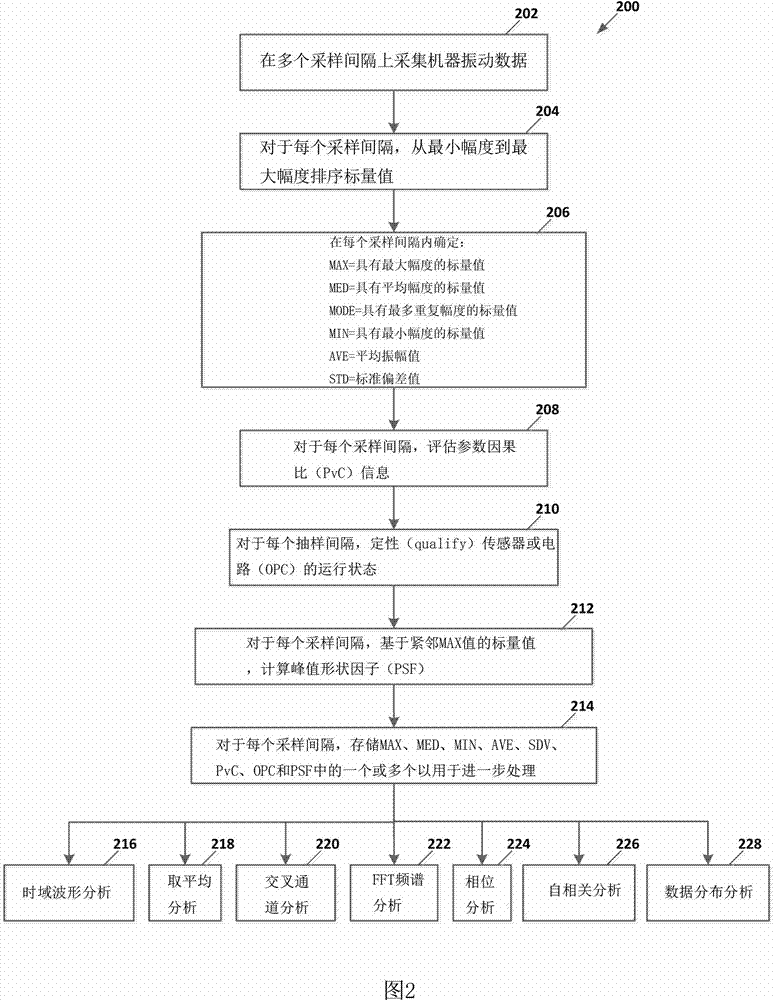

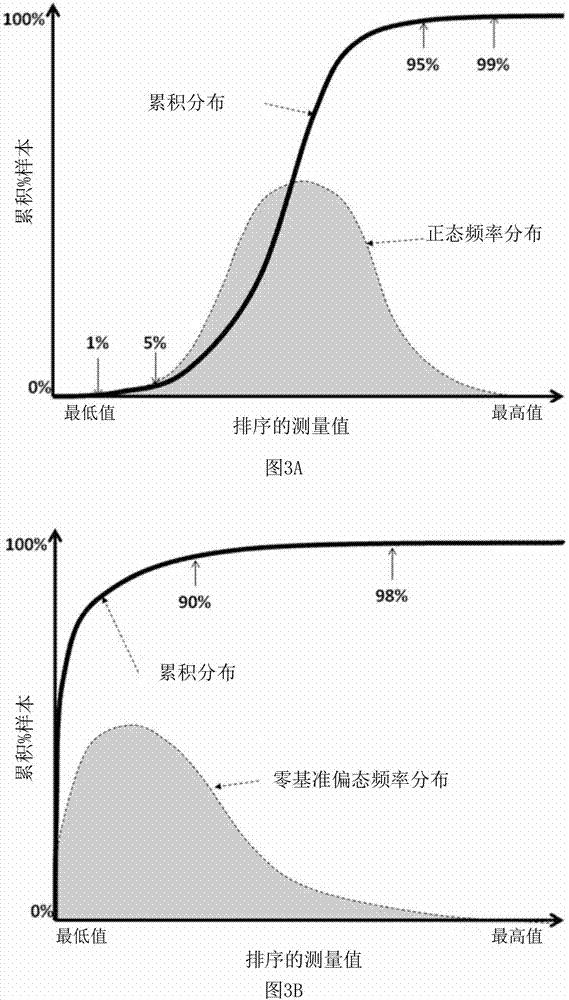

Selective decimation and analysis of oversampled data

Useful and meaningful machine characteristic information may be derived through analysis of oversampled digital data collected using dynamic signal analyzers, such as vibration analyzers. Such data have generally been discarded in prior art systems. In addition to peak values and decimated values, other oversampled values are used that are associated with characteristics of the machine being monitored and the sensors and circuits that gather the data. This provides more useful information than has previously been derived from oversampled data within a sampling interval.

Owner:EMERSON ELECTRIC US HLDG CHILE

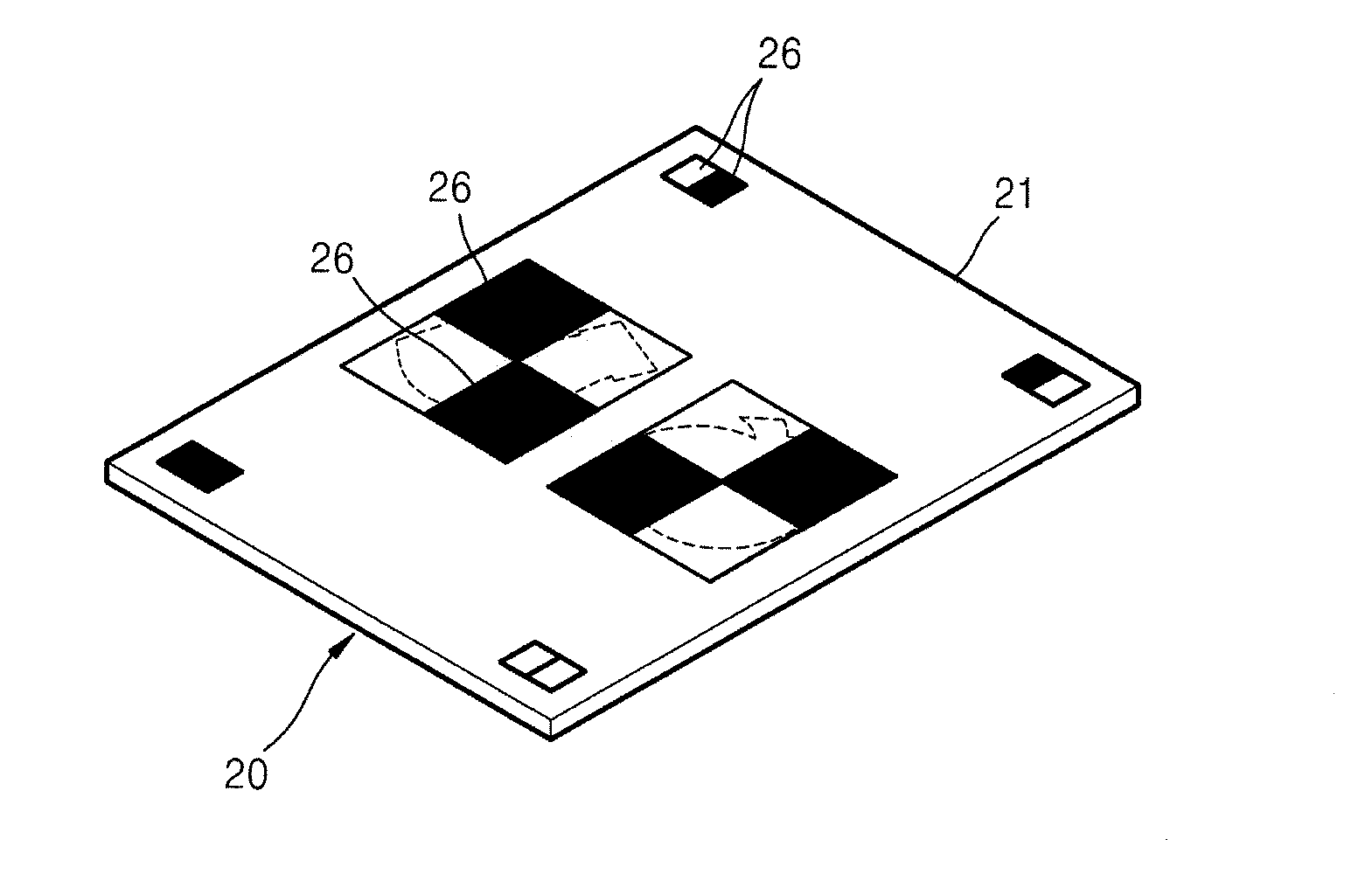

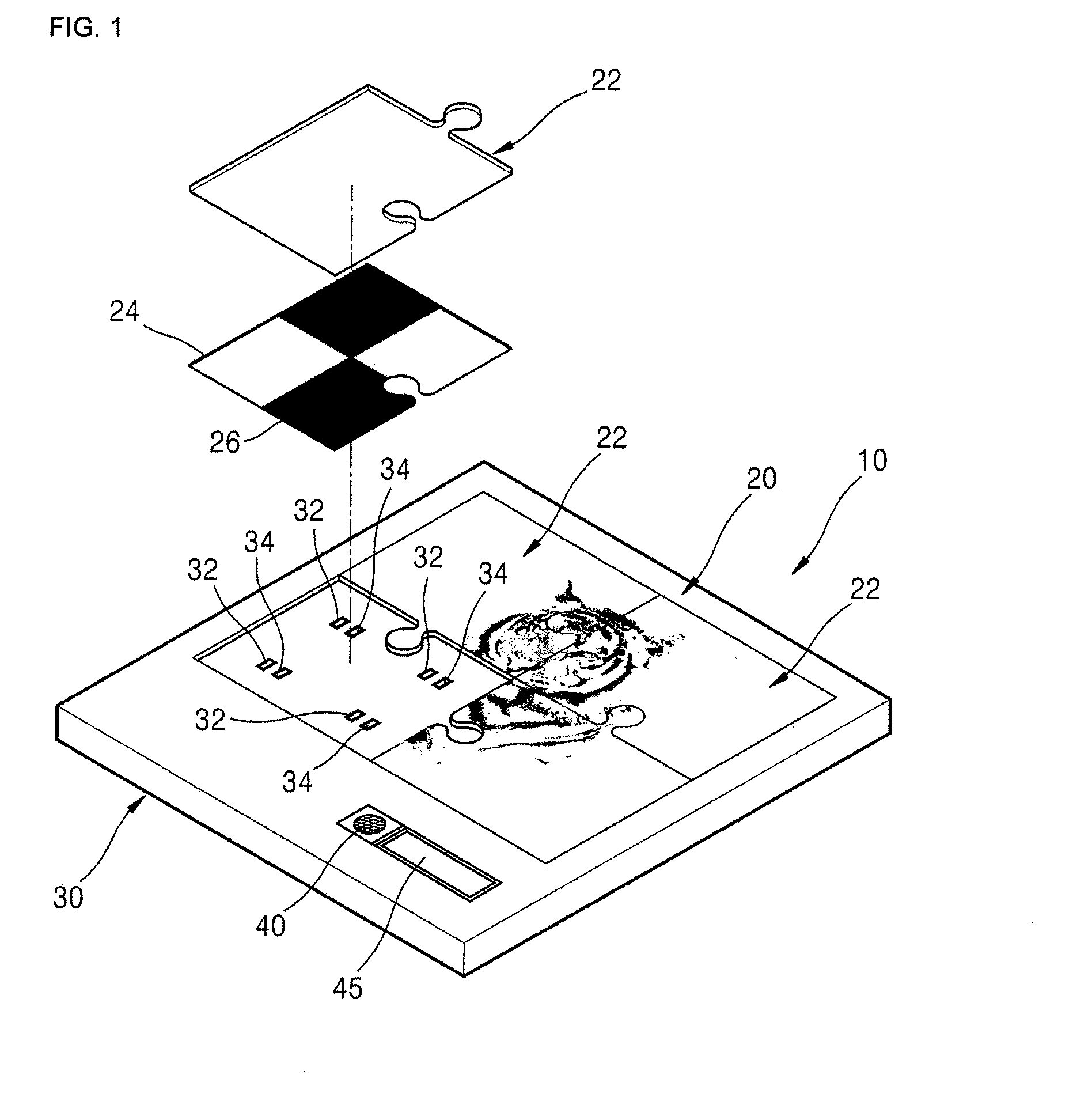

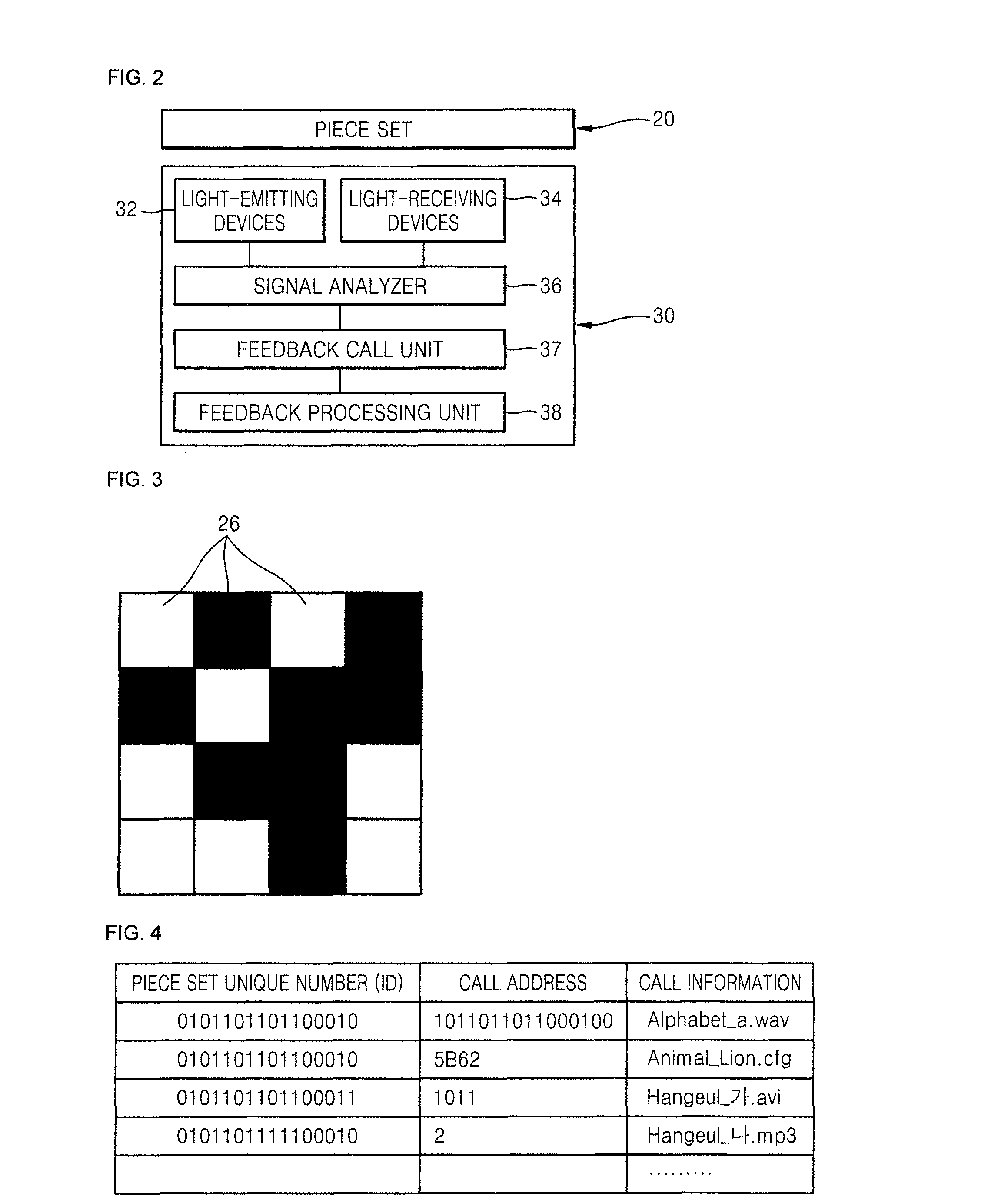

Puzzle toy

A puzzle toy including: a piece set containing a plurality of component pieces; and a main body for accommodating the piece set therein, wherein each of the plurality of component pieces has a rear surface on which a plurality of lattices is formed, and the main body includes: light-emitting devices, which are arranged to correspond to the respective lattices and emit light towards the lattices, and light-receiving devices for detecting light reflected from the lattices; a signal analyzer for determining colors of the lattices by signals detected by the light-receiving devices and generating output signals for the lattices; a feedback call unit for analyzing the output signals for the lattices, recognizing the lattice arrangement of the piece set, and determining the assembly success / failure of the piece set and a type of the piece set; and a feedback processing unit for outputting information regarding the assembled piece set.

Owner:SELLO AZUL

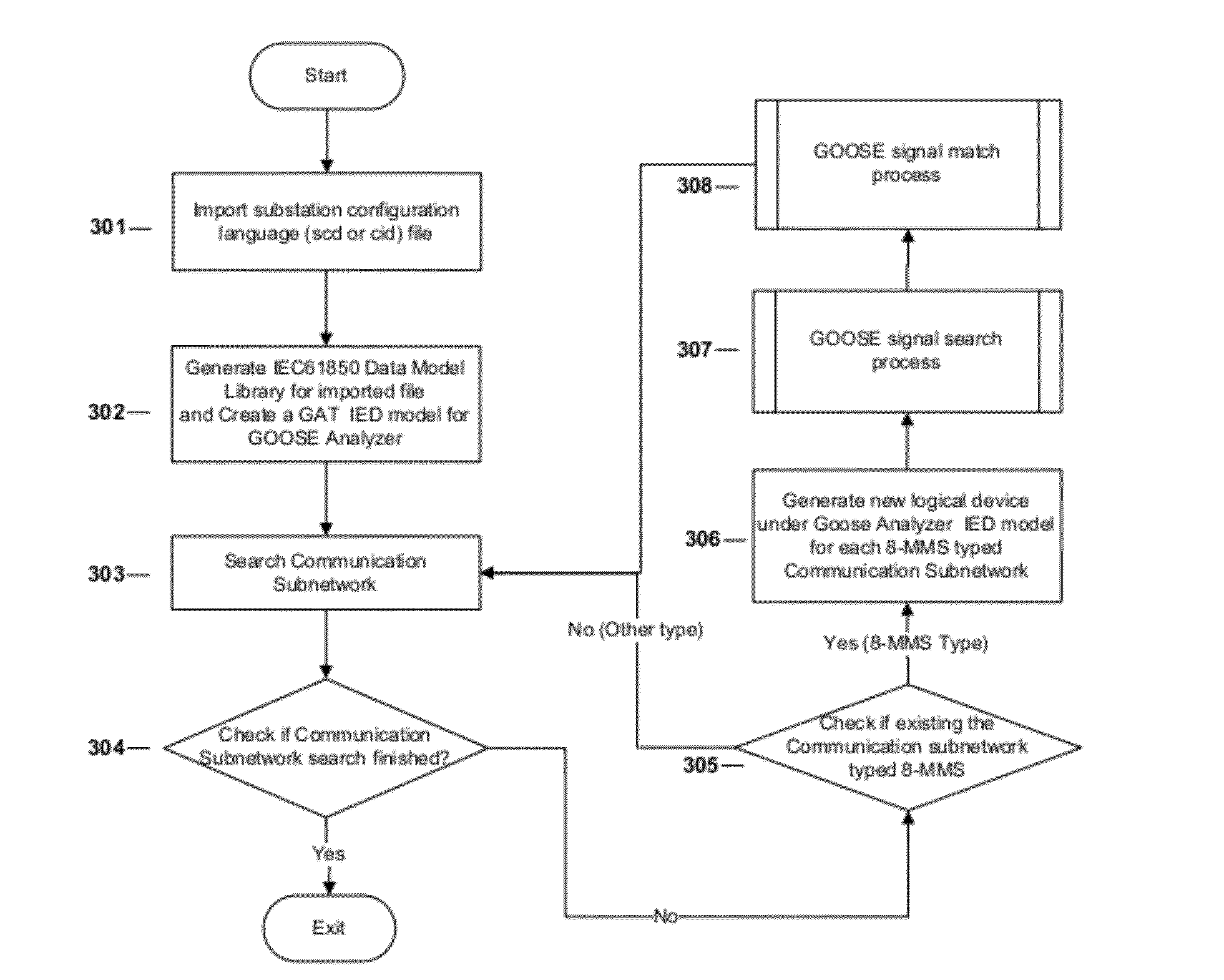

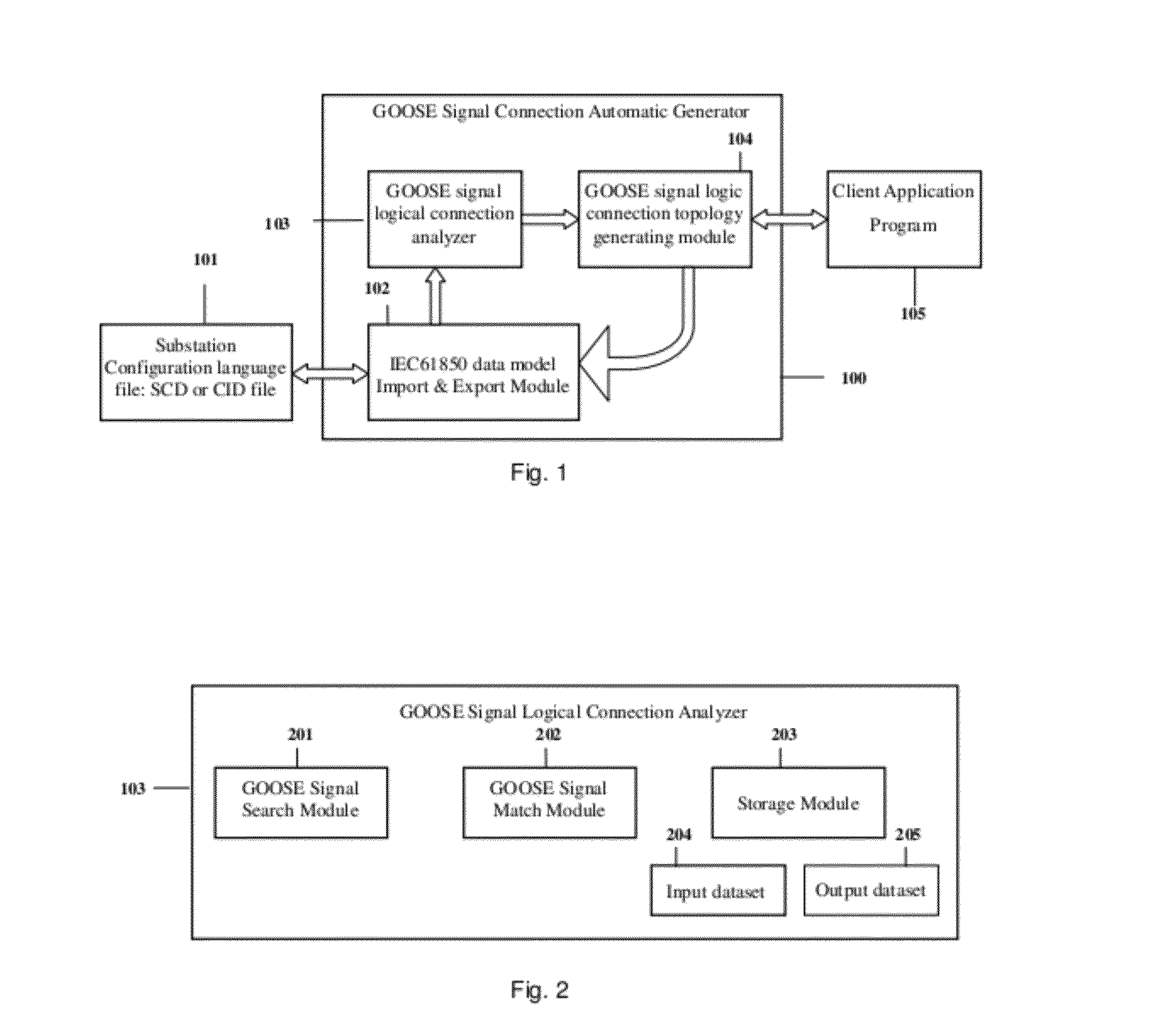

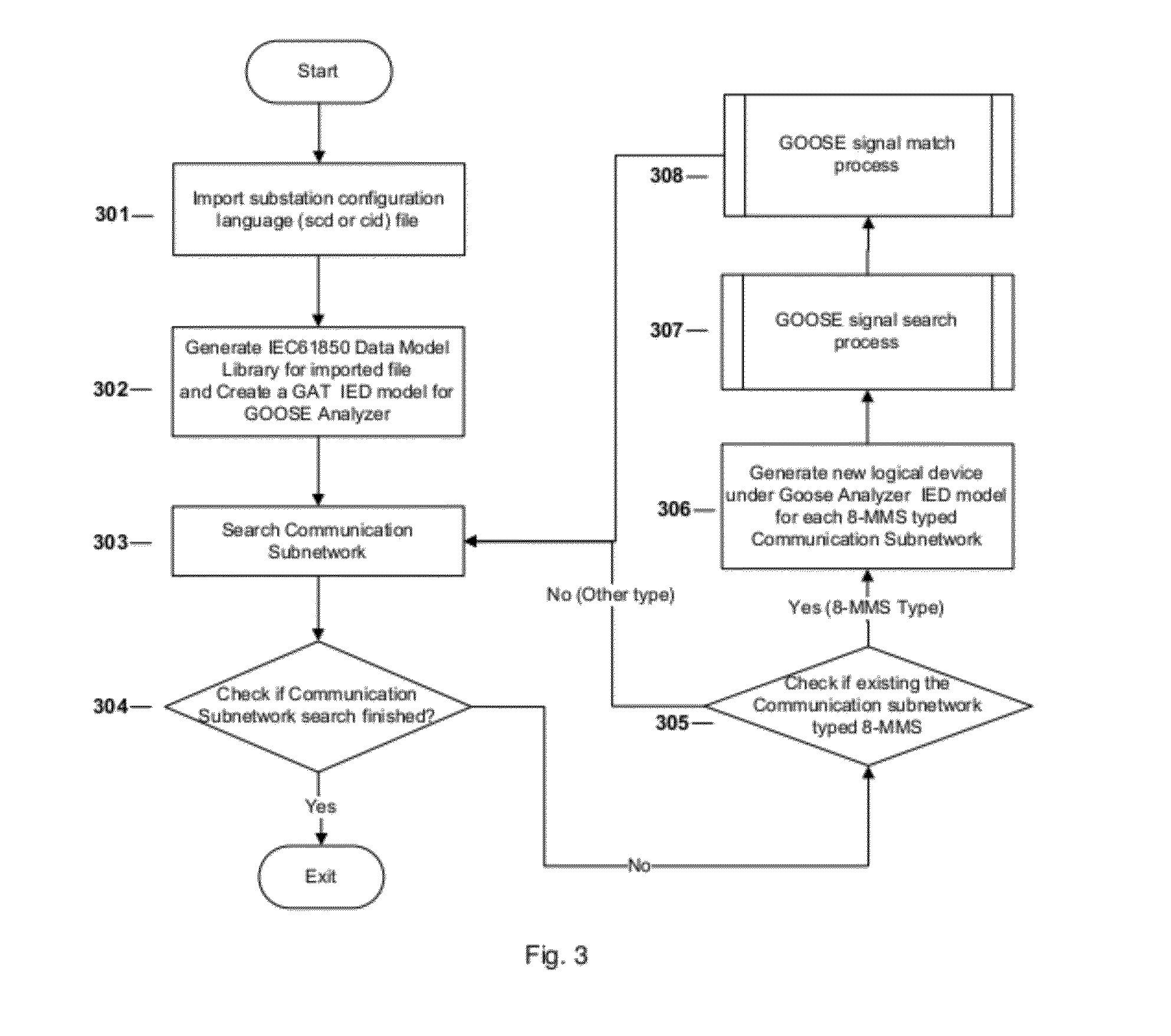

Method and Device for Auto-Generating Goose Signal Connection Topology from Substation Level

The invention provides a method and device for auto-generating GOOSE signal connection topology from substation level based on IEC61850 standard. The method comprises the following steps: import substation configuration language (SCL) file; search all GOOSE input and output signals under each access point; match the output signals to the input signals; and generate GOOSE signal connection topology based on the result of said matching. The device comprises an importing module for importing substation configuration language file; a GOOSE signal analyzer for searching all of GOOSE input and output signals under each access point, and matching said GOOSE output signals to said GOOSE input signals; and topology data module for generating GOOSE signal connection topology based on said matching. The device comprises a storage module. The storage module comprises an input dataset for storing GOOSE input signals and an output dataset for storing GOOSE output signals and their matching input signals.

Owner:HITACHI ENERGY SWITZERLAND AG +1

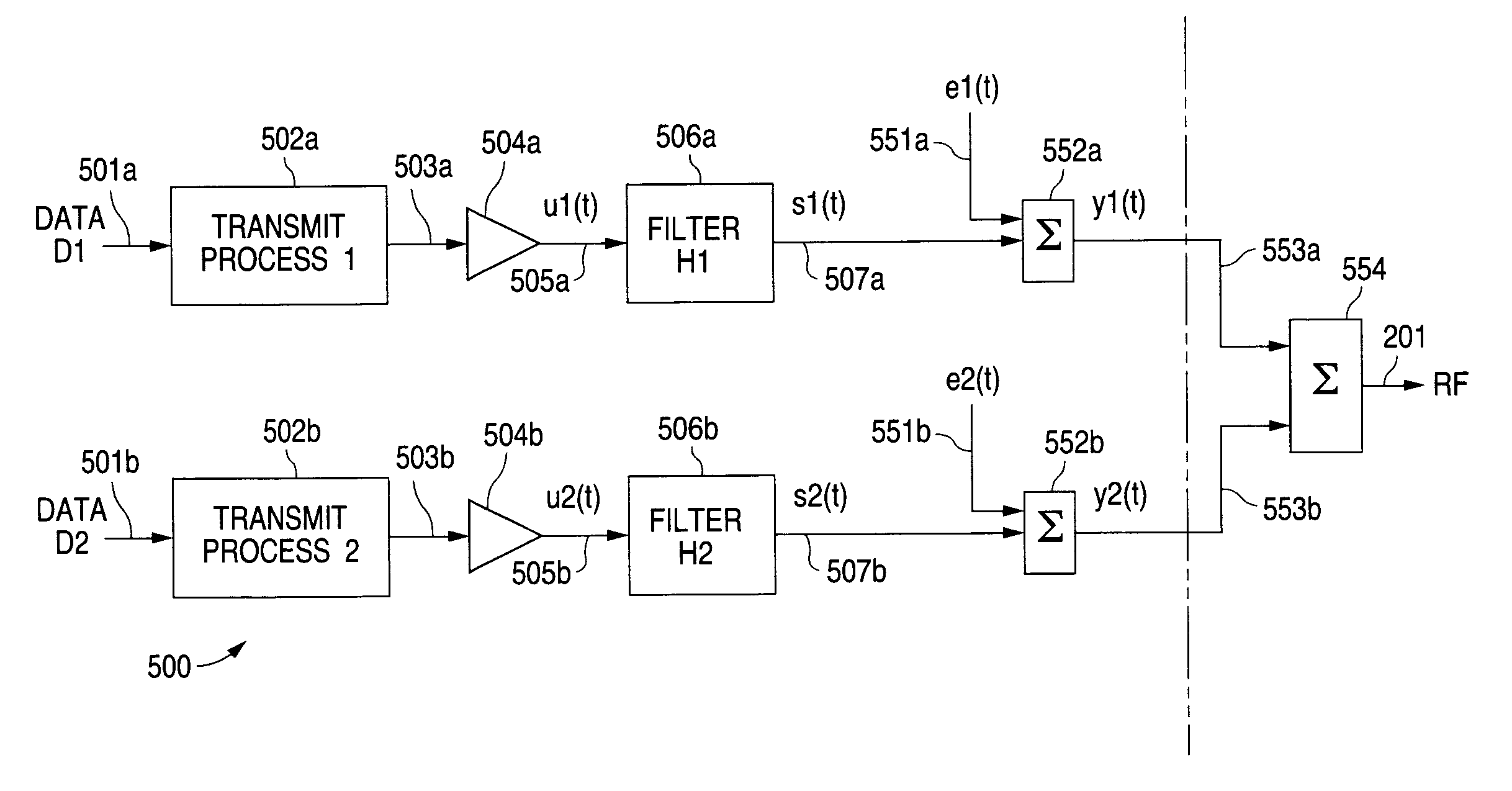

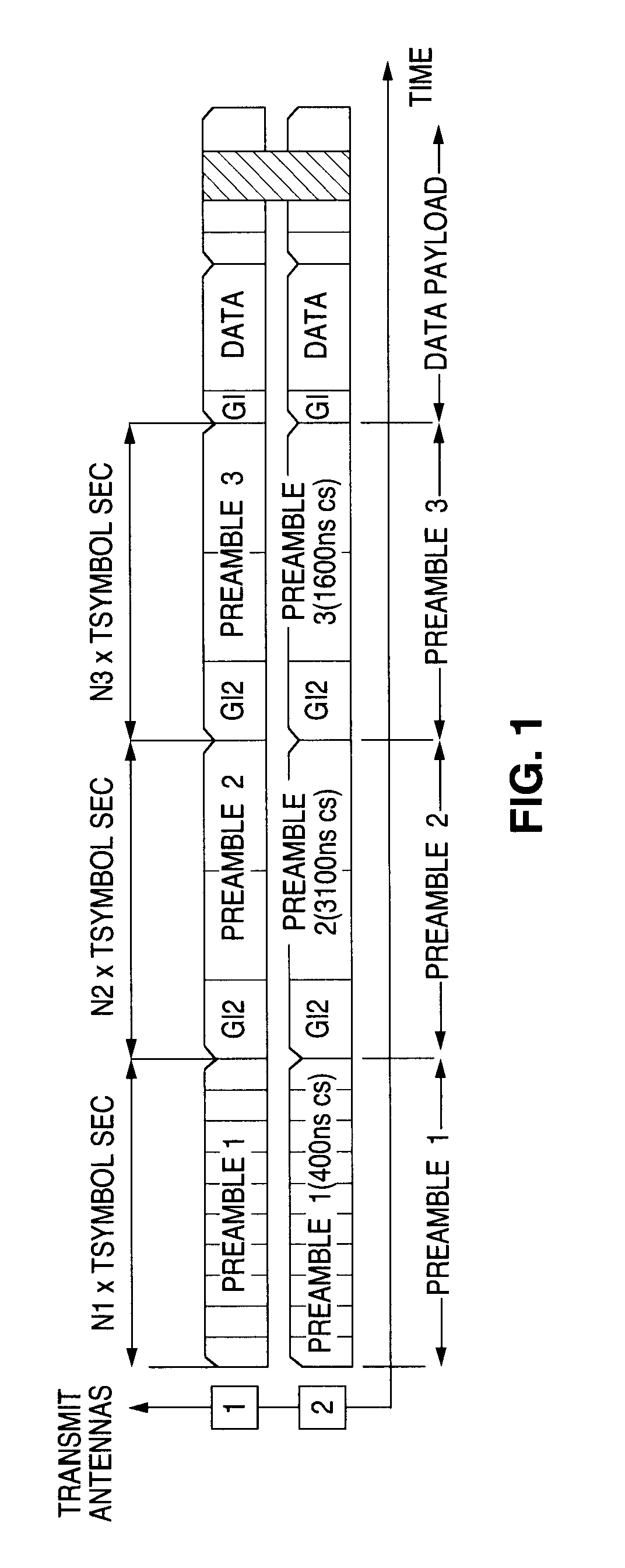

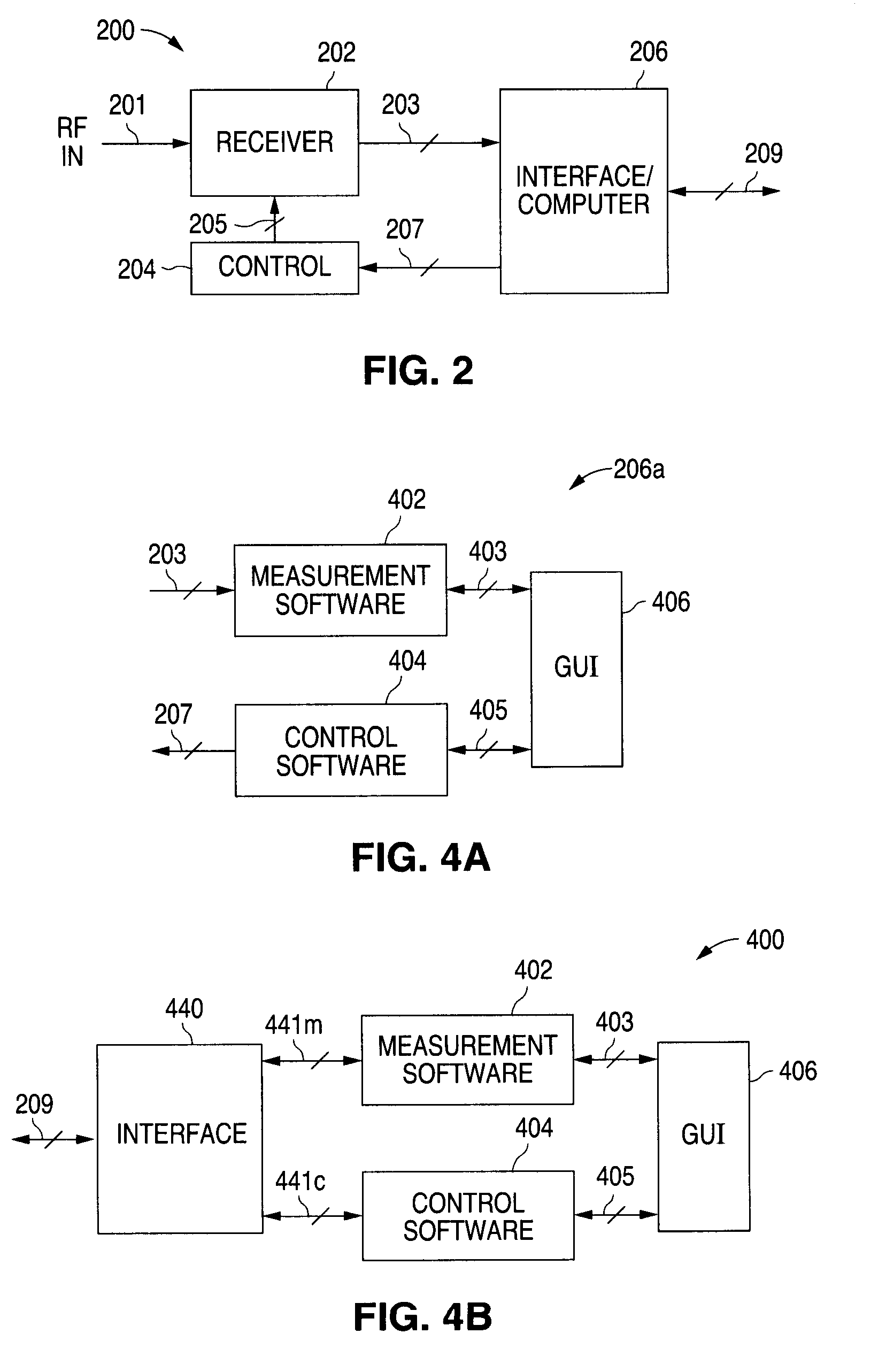

Apparatus and method for simultaneous testing of multiple orthogonal frequency division multiplexed transmitters with single vector signal analyzer

A signal analyzer and method for measuring signal compression levels of one or more individual orthogonal frequency division multiplexed (OFDM) signals among a plurality of OFDM signals within a composite signal.

Owner:LITEPOINT

Systems, methods and computer program products for characterizing structural events

Sensor assemblies for non-destructively monitoring a structure to detect a structural event include a plurality of sensor nodes configured to provide at least one sensor signal responsive to a structural event. A signal analyzer is configured to compare the sensor signal to a reference database of signal characteristics corresponding to respective structural events.

Owner:NORTH CAROLINA AGRICULTURAL AND TECHNICAL STATE UNIVERSITY

Ischemia detection using a heart sound sensor

Owner:CARDIAC PACEMAKERS INC

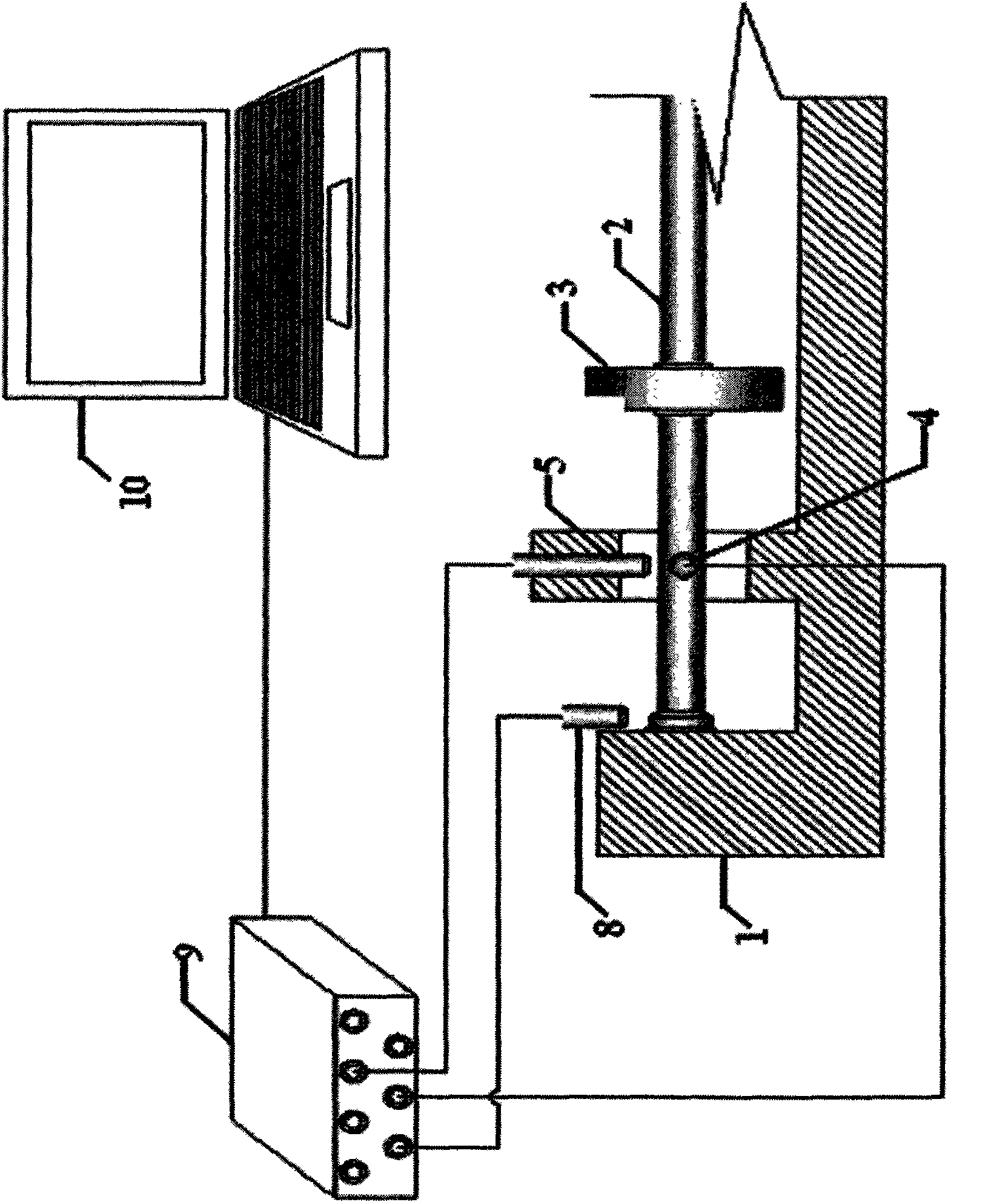

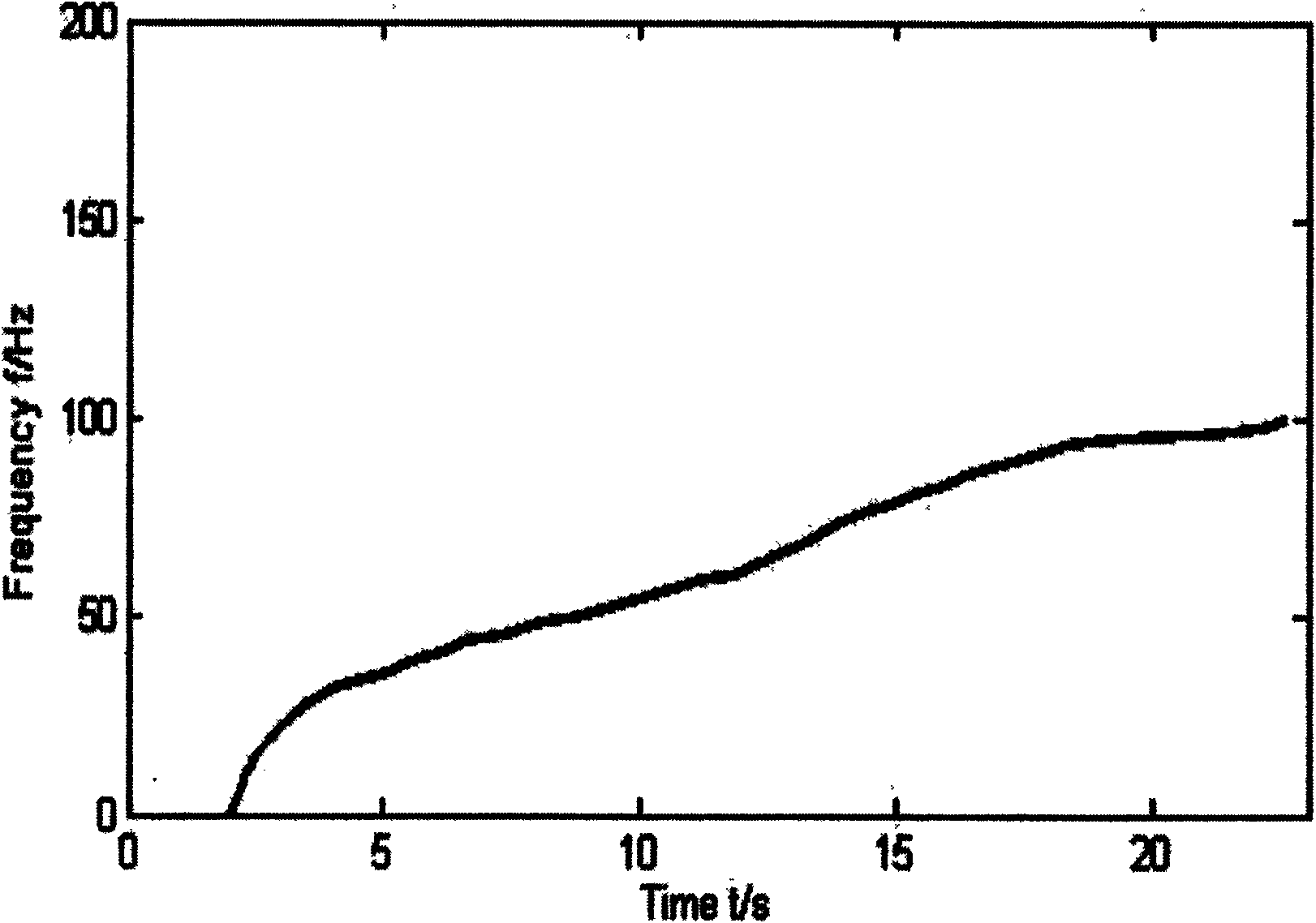

Non-stationery vibration signal instantaneous frequency estimation algorithm in start and stop period of rotating machinery

InactiveCN101603854AEliminate dependenciesImplementing Order Analysis TechniquesVibration measurement in solidsSubsonic/sonic/ultrasonic wave measurementFrequency counterTime frequency spectrum

The invention relates to a non-stationery vibration signal instantaneous frequency estimation algorithm in a start and stop period of rotating machinery; firstly, an experiment table working model of a rotor of the rotating machinery is built, a non-stationery vibration signal sensor for measuring vibration signal, and a photo-electric sensor for measuring the rotating speed of a reference axis are arranged along the horizontal and vertical direction of the reference axis; after the obtained signal is analyzed by an order analysis software of an upper computer through a dynamic signal analyzer, STFT time-frequency spectrum containing multi-level component is obtained; the working frequency of the rotating machinery is used as an estimated starting frequency point, according to the requirements of sampling frequency and calculation accuracy, the frequency obtained by the STFT time-frequency analysis is equally divided into M groups, the start and stop period is equally divided into N time points for building grid meshes of N time points and M groups of frequency points; the route of minimum-deviation frequency point from the start point to the stop point is computed through Viterbi algorithm, after fitting is carried out, the instantaneous frequency estimation function value of the reference axis of the non-stationery vibration signal of the rotating machinery in the start and stop period is obtained.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Ischemia detection using a heart sound sensor

A system comprising an implantable medical device (IMD) includes an implantable heart sound sensor to produce an electrical signal representative of at least one heart sound. The heart sound is associated with mechanical activity of a patient's heart. Additionally, the IMD includes a heart sound sensor interface circuit coupled to the heart sound sensor to produce a heart sound signal, and a signal analyzer circuit coupled to the heart sound sensor interface circuit. The signal analyzer circuit measures a baseline heart sound signal, and deems that an ischemic event has occurred using, among other things, a measured subsequent change in the heart sound signal from the established baseline heart sound signal.

Owner:CARDIAC PACEMAKERS INC

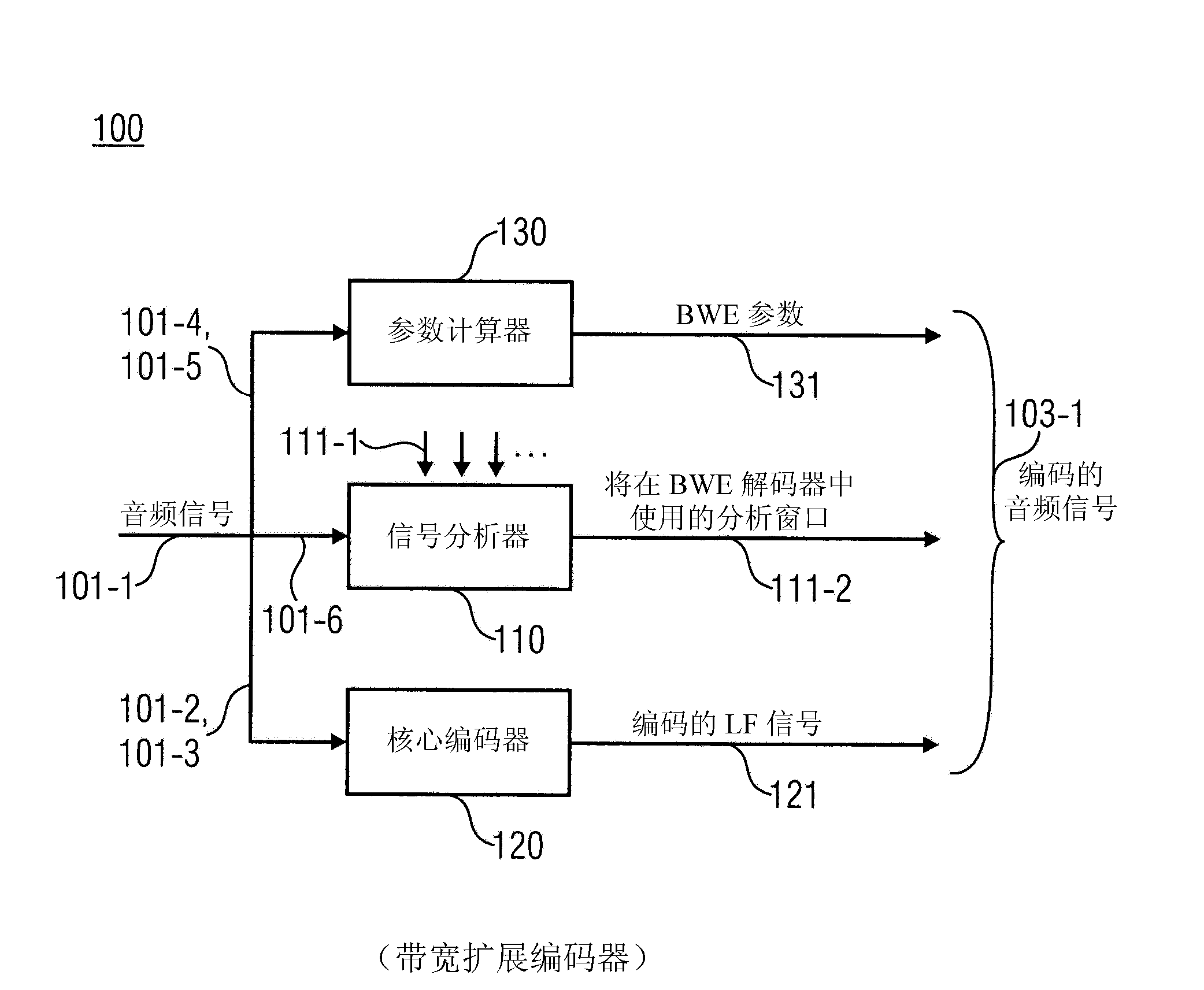

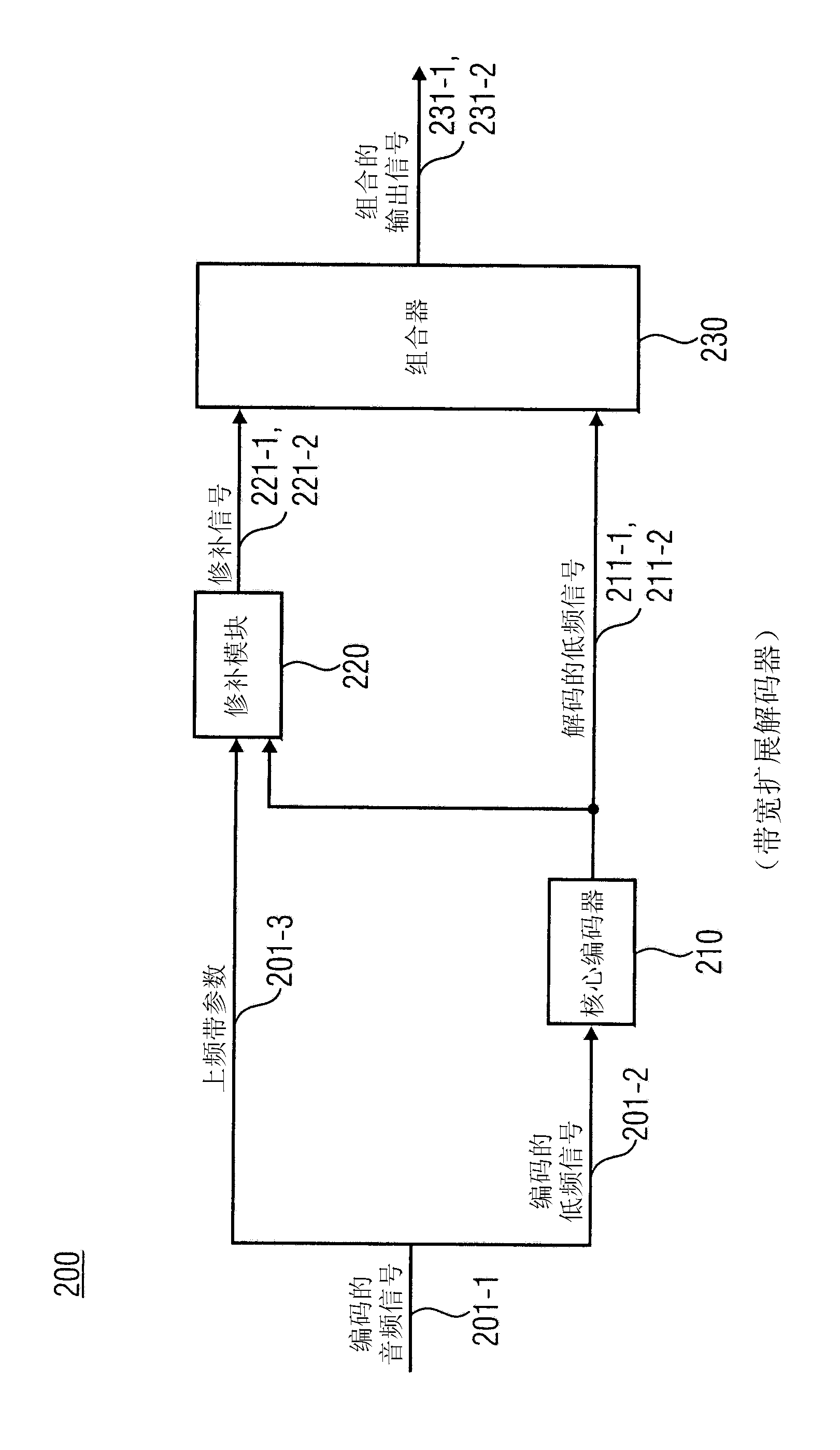

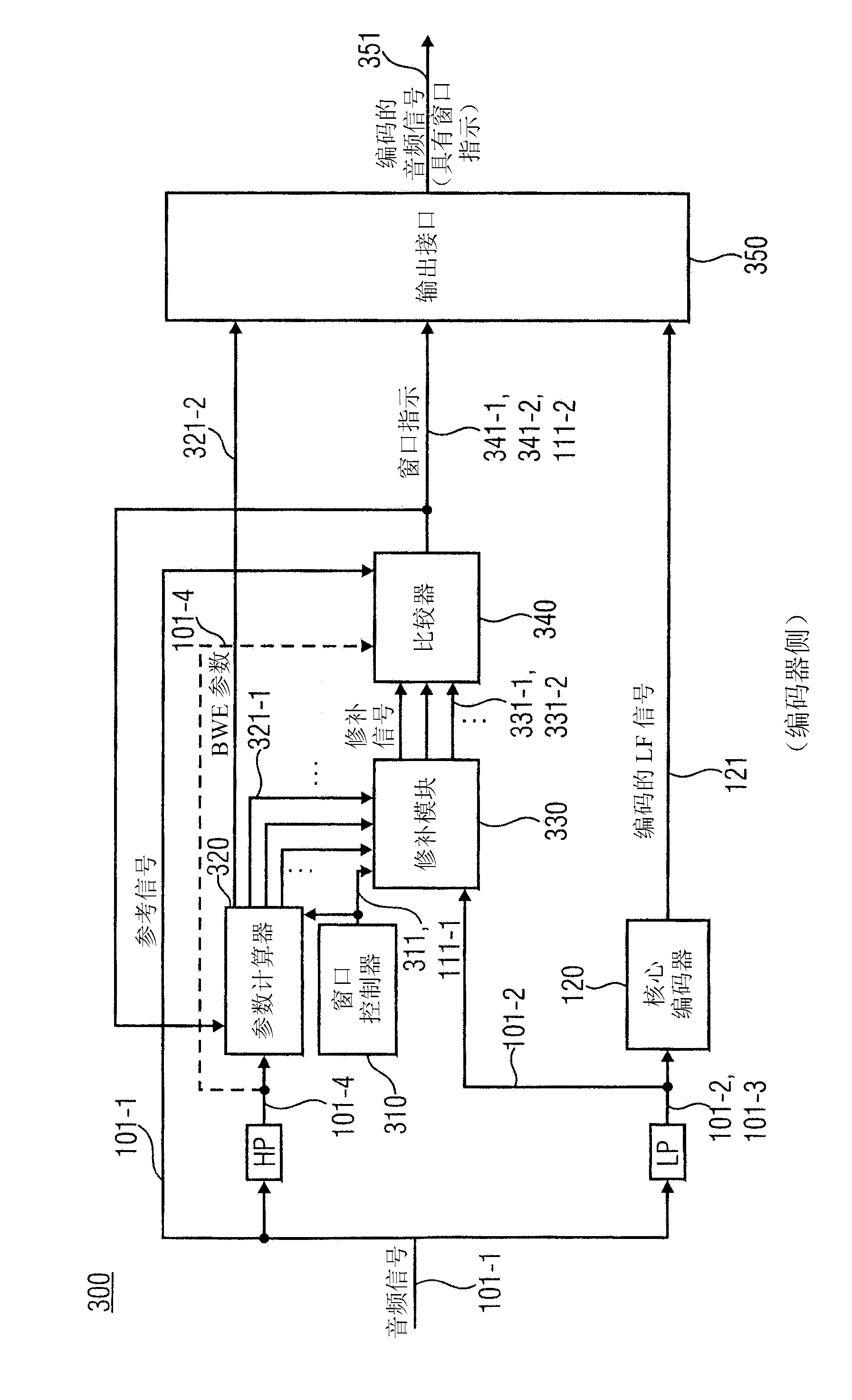

Bandwidth extension encoder, bandwidth extension decoder and phase vocoder

A bandwidth extension encoder for encoding an audio signal comprises a signal analyzer, a core encoder and a parameter calculator. The audio signal comprises a low frequency signal comprising a core frequency band and a high frequency signal comprising an upper frequency band. The signal analyzer is configured for analyzing the audio signal, the audio signal having a block of audio samples, the block having a specified length in time. The signal analyzer is furthermore configured for determining from a plurality of analysis windows an analysis window to be used for performing a bandwidth extension in a bandwidth extension decoder. The core encoder is configured for encoding the low frequency signal to obtain an encoded or frequency signal. The parameter calculator is configured for calculating bandwidth extension parameters from the high frequency signal.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

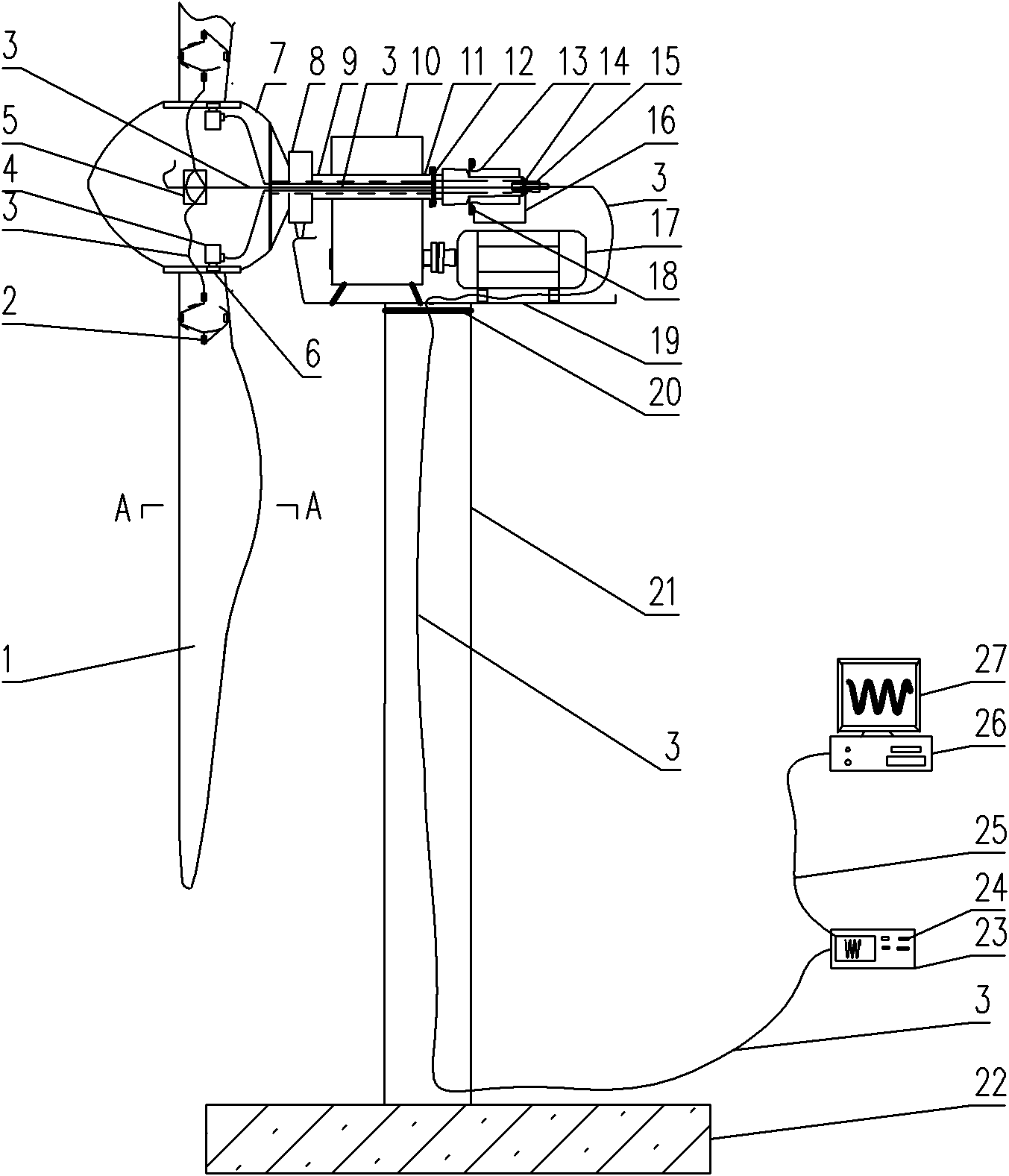

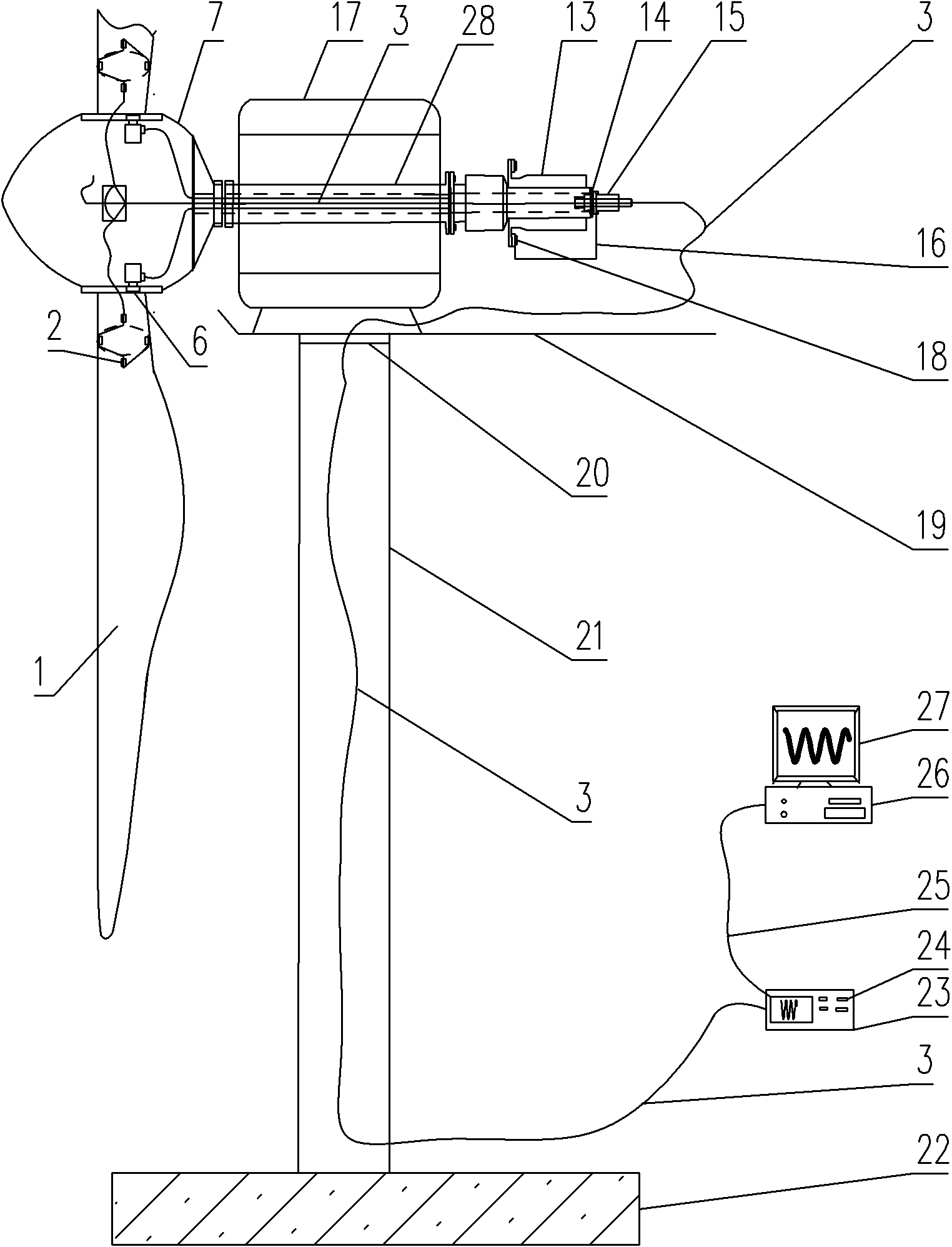

Intelligent monitoring device for blades of wind driven generator

InactiveCN102588213AAvoid working sickReduce generationWind motor controlOptically investigating flaws/contaminationWind drivenFiber

The invention discloses an intelligent monitoring device for blades of a wind driven generator, which comprises a blade body, a power generator, a plurality of fiber bragg grating sensors and a fiber bragg grating signal analyzer. The blade body is mounted on a hub, the power generator is connected with the hub through a gear box and a spindle or is directly connected with the hub, the fiber bragg grating sensors are arranged on the blade body, and the fiber bragg grating signal analyzer is connected with the fiber bragg grating sensors through optical fibers and an optical fiber coupler. Besides, wavelengths of different fiber bragg grating sensors on the blade body are different, the fiber bragg grating signal analyzer measures amplitude and frequency relations of corresponding temperature, vibration and dependent variables of optical signals of different wavelengths to acquire information about vibration, dynamic balance, fatigue, deformation, load and damage of the blade body, thereby assisting working staff to handle accidents in time.

Owner:孙首泉

Multi-resolution switched audio encoding/decoding scheme

An audio encoder for encoding an audio signal comprises a first coding branch (400), the first coding branch comprising a first converter (410) for converting a signal from a time domain into a frequency domain. Furthermore, the audio encoder comprises a second coding branch (500) comprising a second time / frequency converter (523). Additionally, a signal analyzer (300 / 525) for analyzing the audio signal is provided. The signal analyzer, on the hand, determines whether an audio portion is effective in the encoder output signal as a first encoded signal from the first encoding branch or as a second encoded signal from a second encoding branch. On the other hand, the signal analyzer determines a time / frequency resolution to be applied by the converters (410, 523) when generating the encoded signals. An output interface includes, in addition to the first encoded signal and the second encoded signal, a resolution information identifying the resolution used by the first time / frequency converter and used by the second time / frequency converter.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV +1

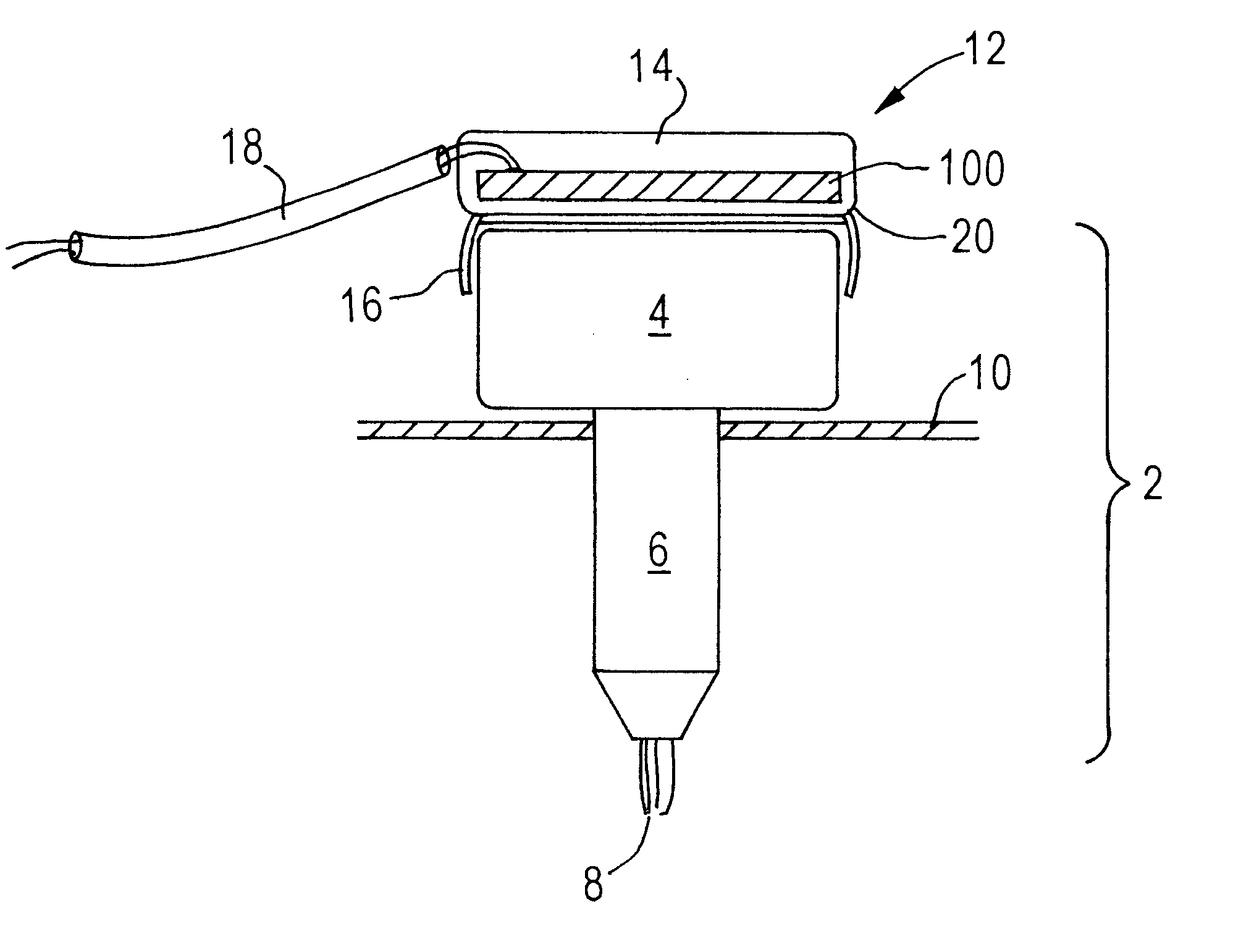

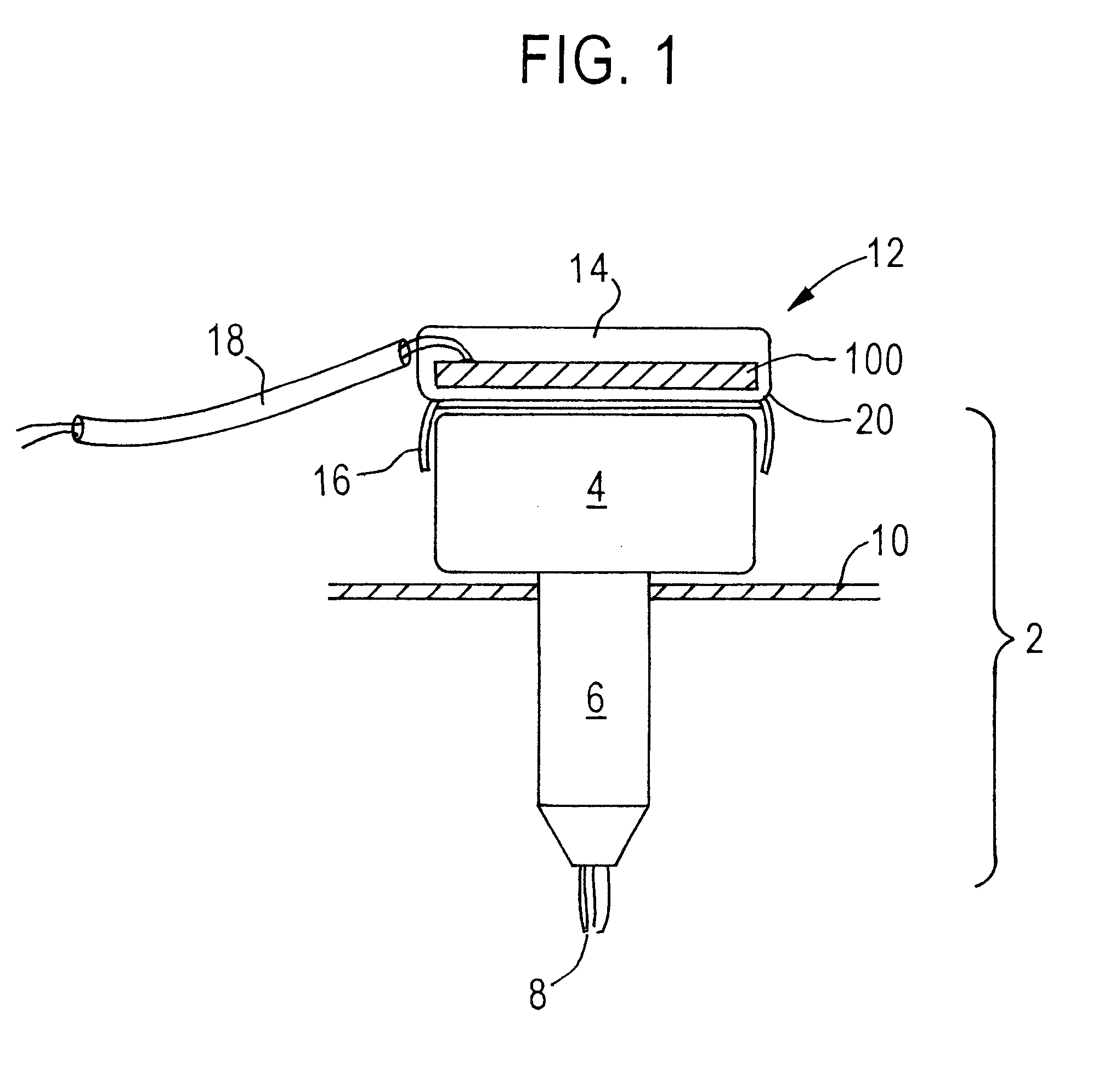

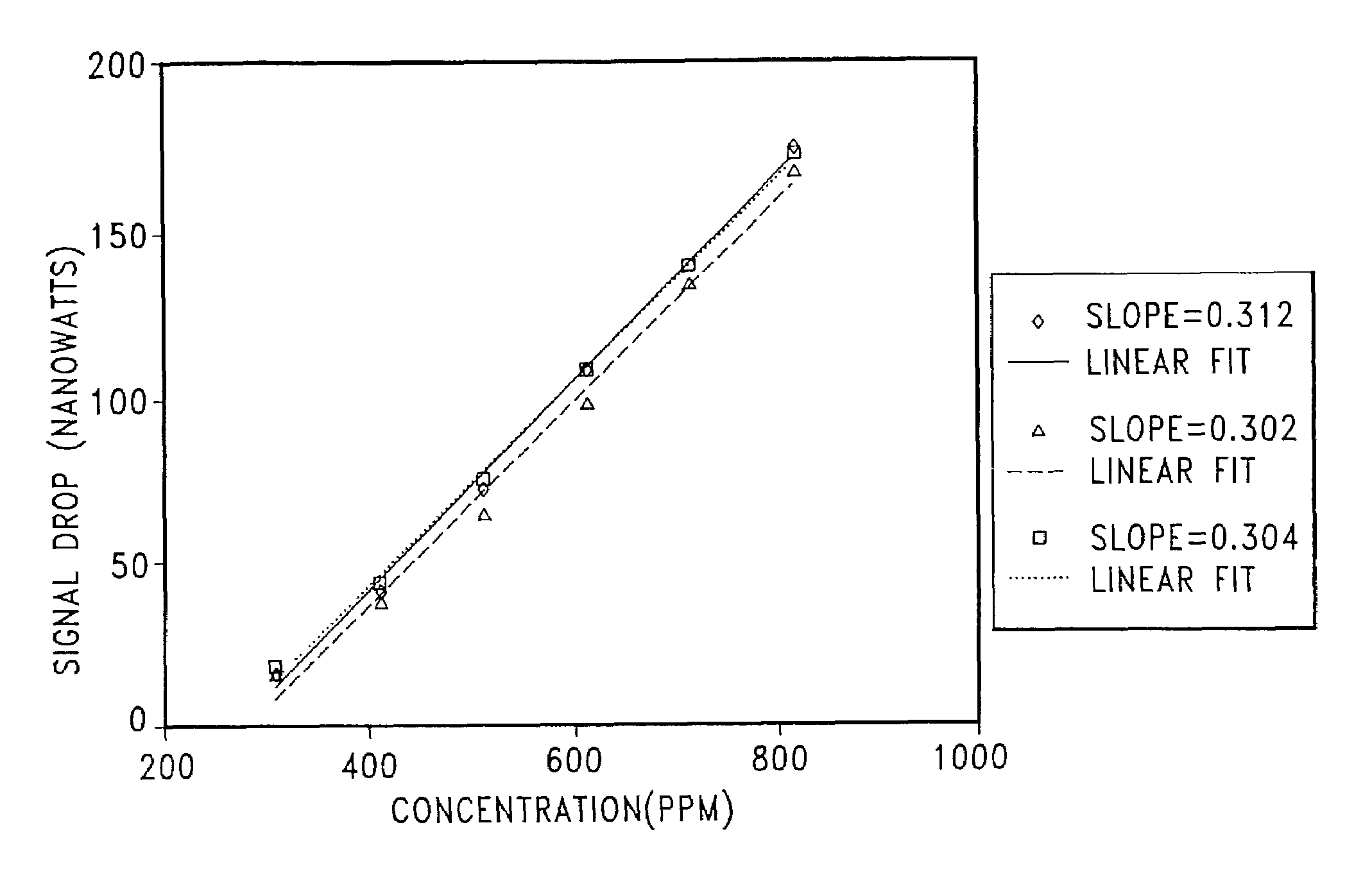

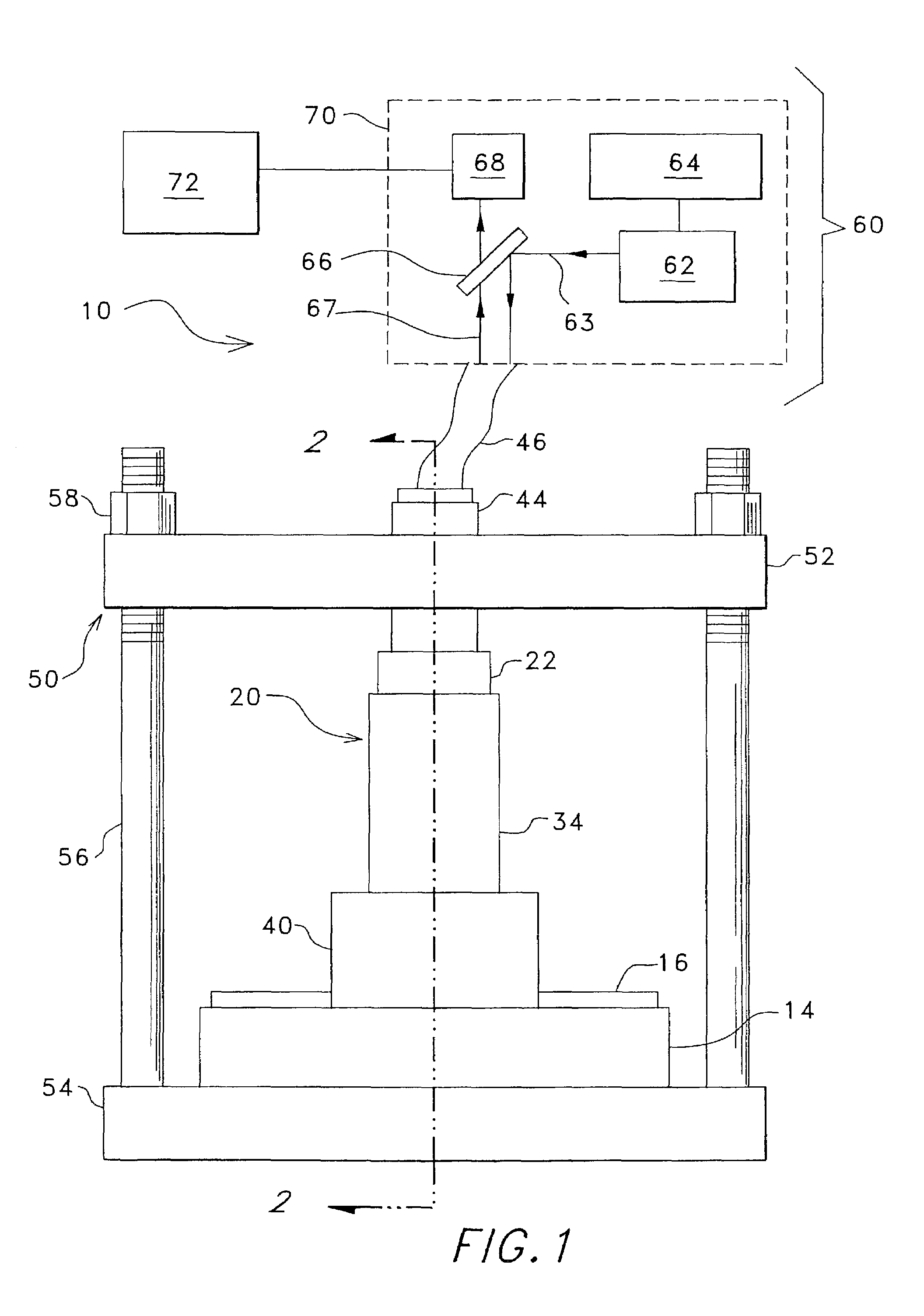

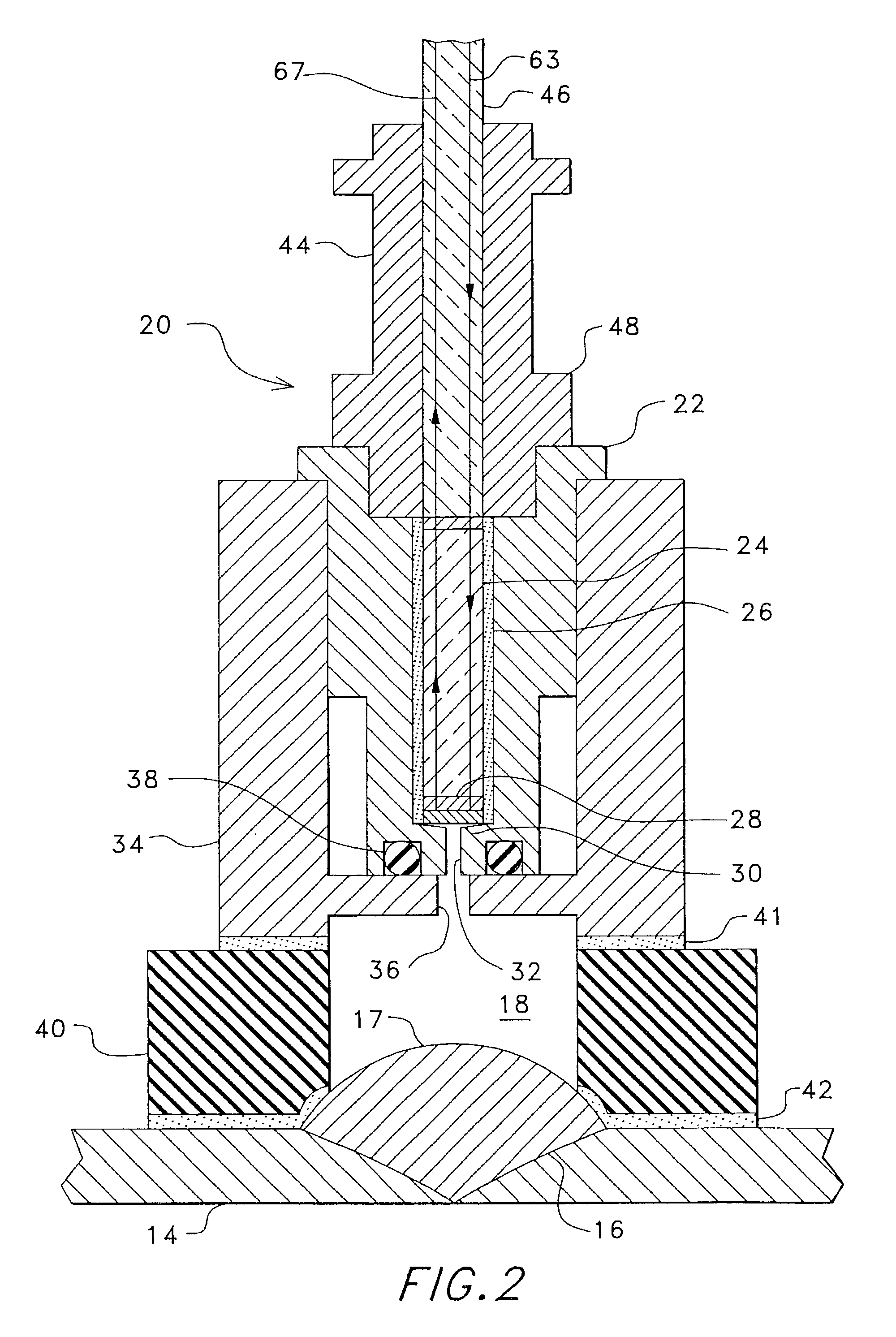

Method and apparatus for determining diffusible hydrogen concentrations

InactiveUS7306951B1Accurate and reliable processLess timeAnalysing fluids using sonic/ultrasonic/infrasonic wavesSamplingHydrogen concentrationSignal analyzer

A measuring apparatus and method for use in measuring diffusible hydrogen concentrations in materials, structures, and other objects. In an embodiment of the invention for use in welding applications, the measuring apparatus (10) includes a sensor assembly (20) that, with an included sealing member (40), defines a sample area (17) on a weld bead (16) from which hydrogen evolves into a sample volume (18) defined by the sealing member (40), a sensor housing (34) and a sensor (22) of the sensor assembly (20). The hydrogen reacts with a sensing layer (28) and a reflector layer (30) positioned on the end of an optical fiber (24), all of which are included in the sensor assembly (20) and are sealably positioned within the sensor (22). The sensing layer (28) comprises a chemochromic material that undergoes changes in physical properties, such as optical transmission properties, when it reacts with hydrogen and these changes are measured by the measuring apparatus (10) to determine the amount of hydrogen evolving from the sample area (17). An optical fiber (46) is joined to the sensor optical fiber (24) to direct light (63) transmitted by a light source (62) in a hydrogen monitoring assembly (60) through the sensing layer (28) to strike the reflector layer (30) which reflects light (67) back through optical fiber (46) to a detector (68) in the hydrogen monitoring assembly (60). A signal analyzer (72) is included in the hydrogen monitoring assembly (60) and is calibrated and configured to measure the diffusible hydrogen concentration in the weld bead (16) based on measured changes in the optical transmission properties of the sensing layer (28).

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

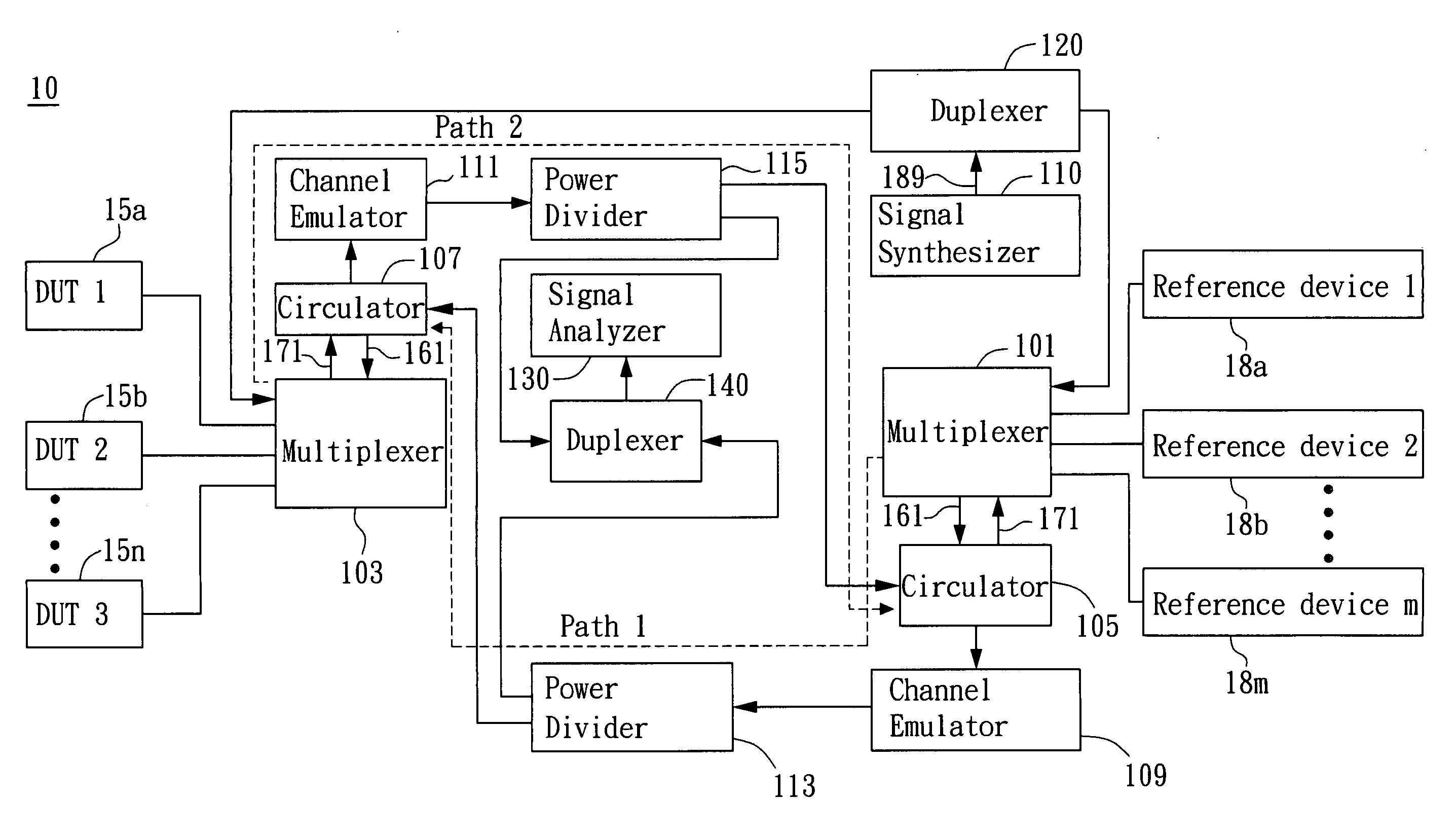

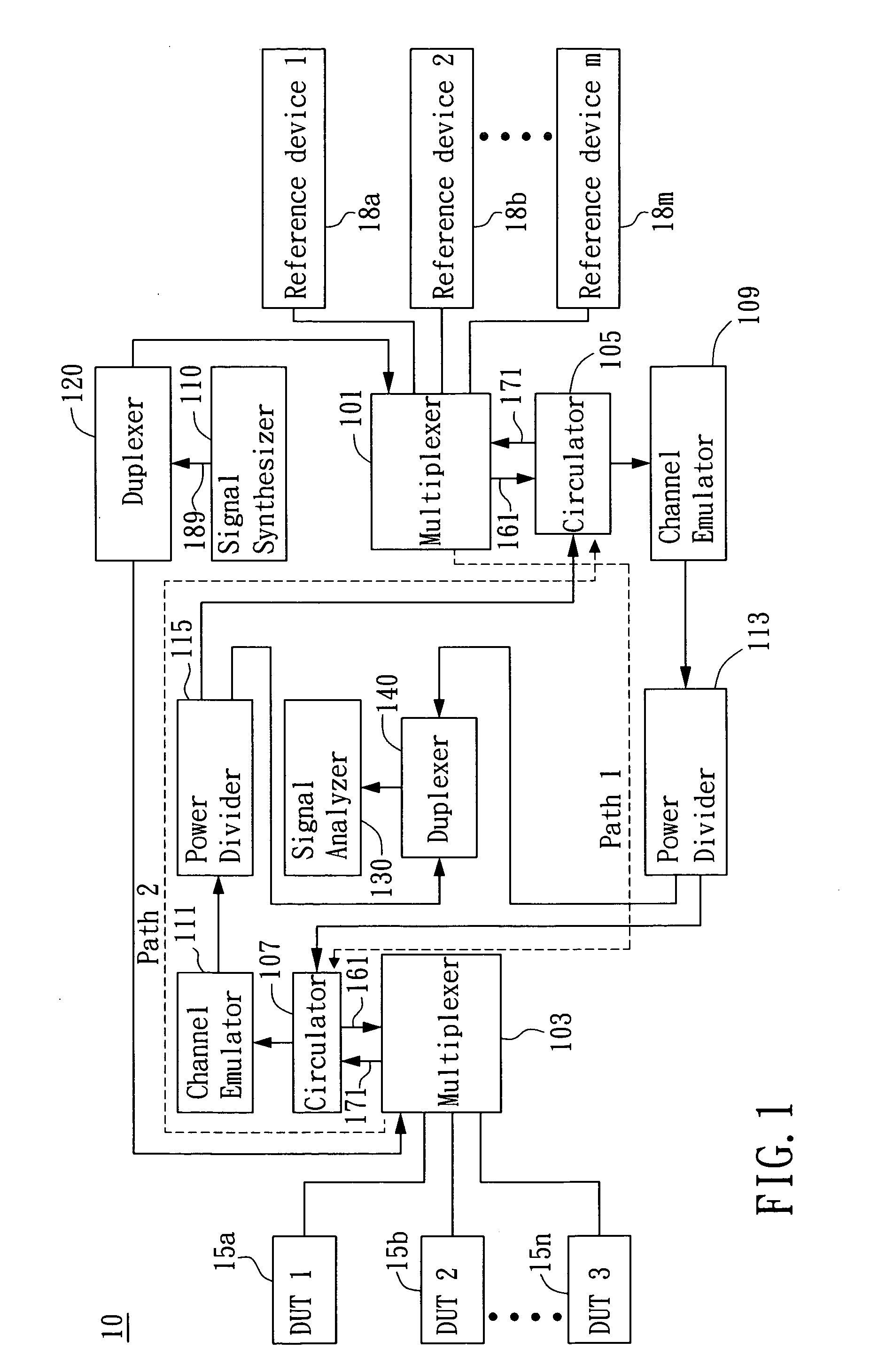

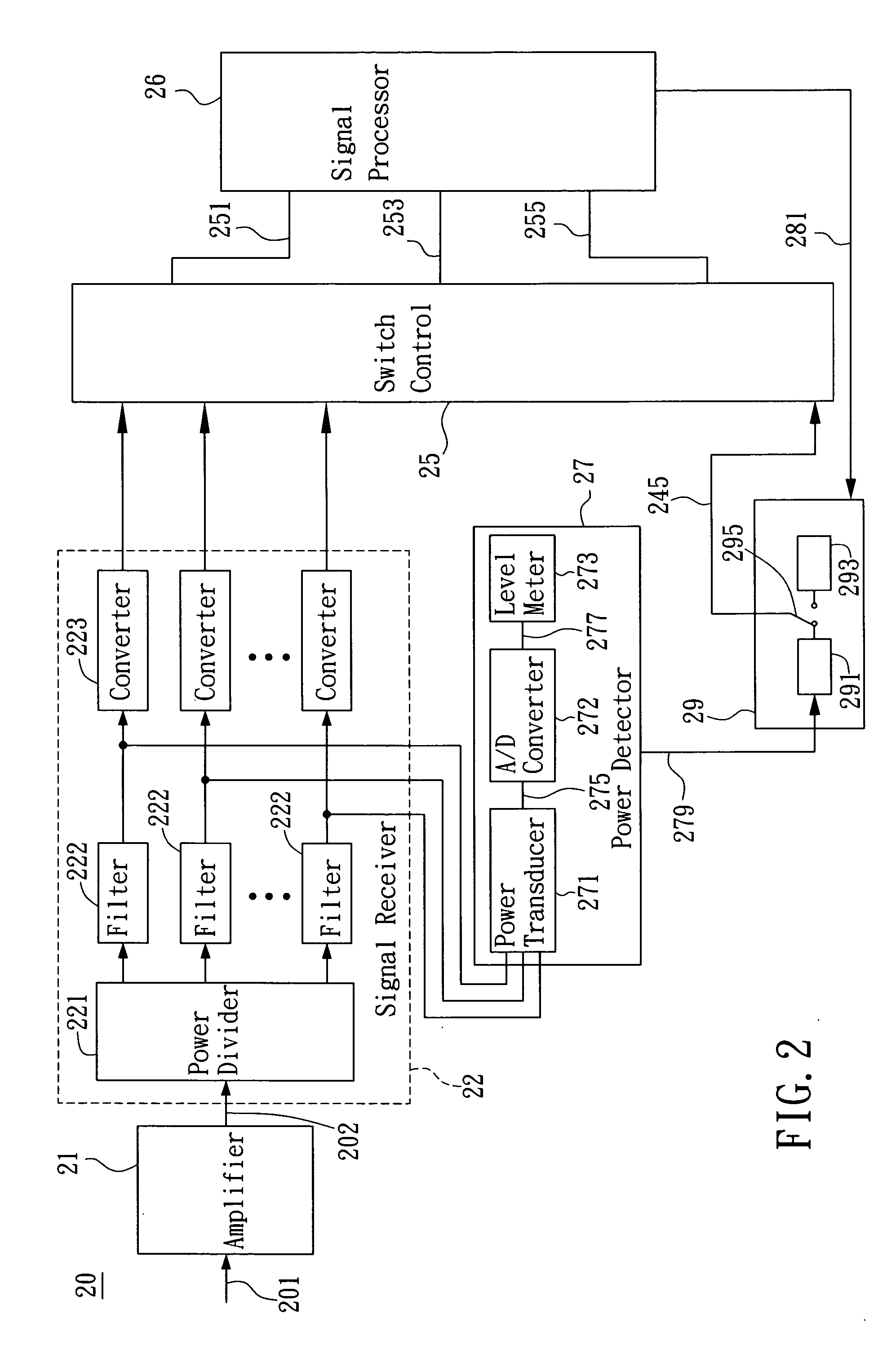

Signal testing system

InactiveUS20060252419A1Radio/inductive link selection arrangementsTransmission monitoringWireless transmissionMultiplexer

A signal testing system is disclosed, which is capable of achieving a bi-directional wireless transmission measurement enabling mutual testing between device-under-tests and reference devices by configuring a symmetrical structure with circulators and multiplexers. Moreover, the signal testing system not only is capable of fetching signal out of a test path by the use of power dividers and then transmitting the fetched signal to a signal analyzer to be analyzed so as to enable the system to support multiple testing, but also is capable of generating a signal used for referencing by a signal synthesizer so as to enable the system to support numerous tests. In addition, both the signal analyzer and the signal synthesizer have a switch control integrated therein, which enables the signal analyzer to perform analysis on signals of different frequency bandwidth, and enables the signal synthesizer to generate signals of different frequency bandwidth as require.

Owner:ARCADYAN

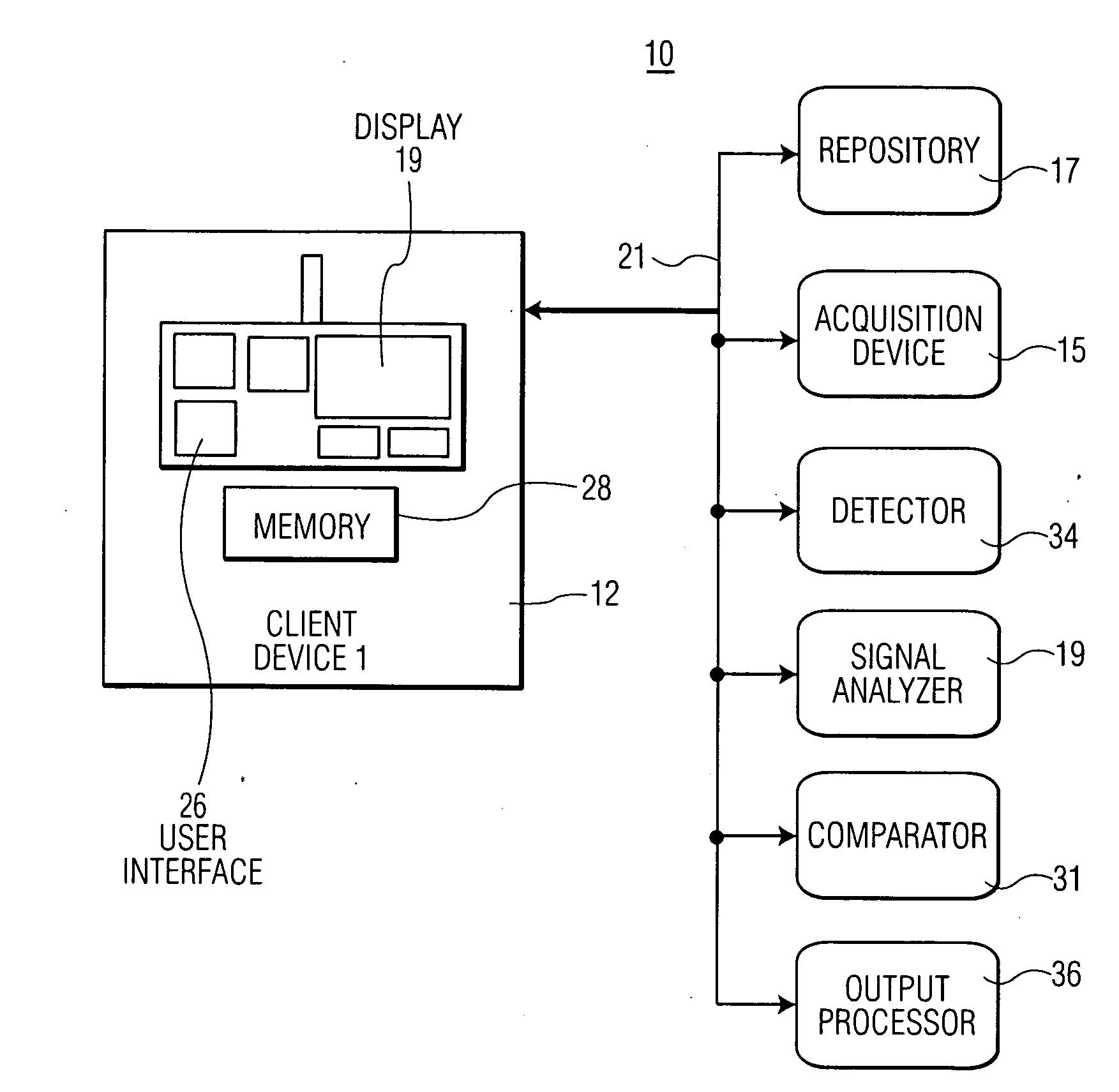

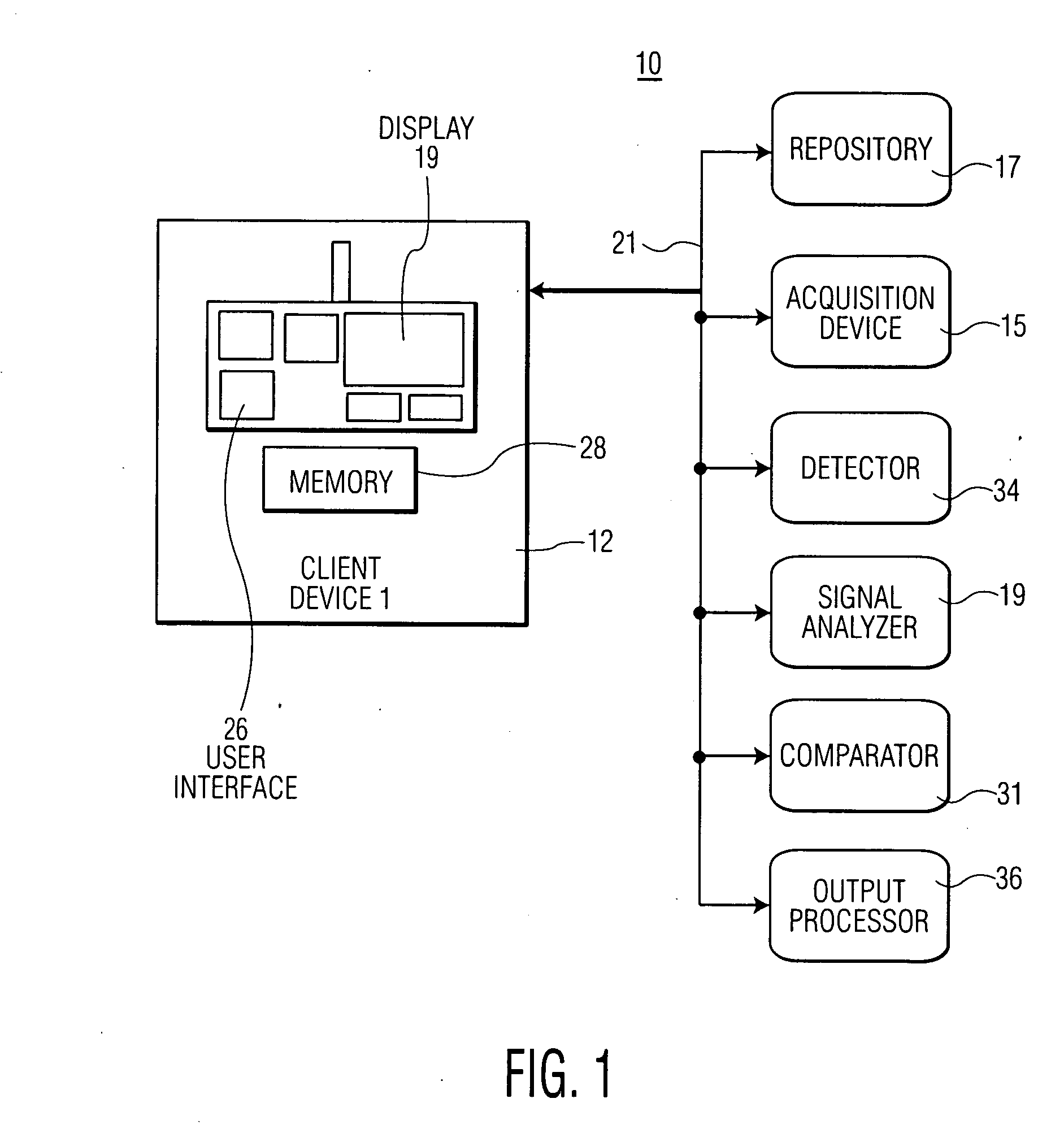

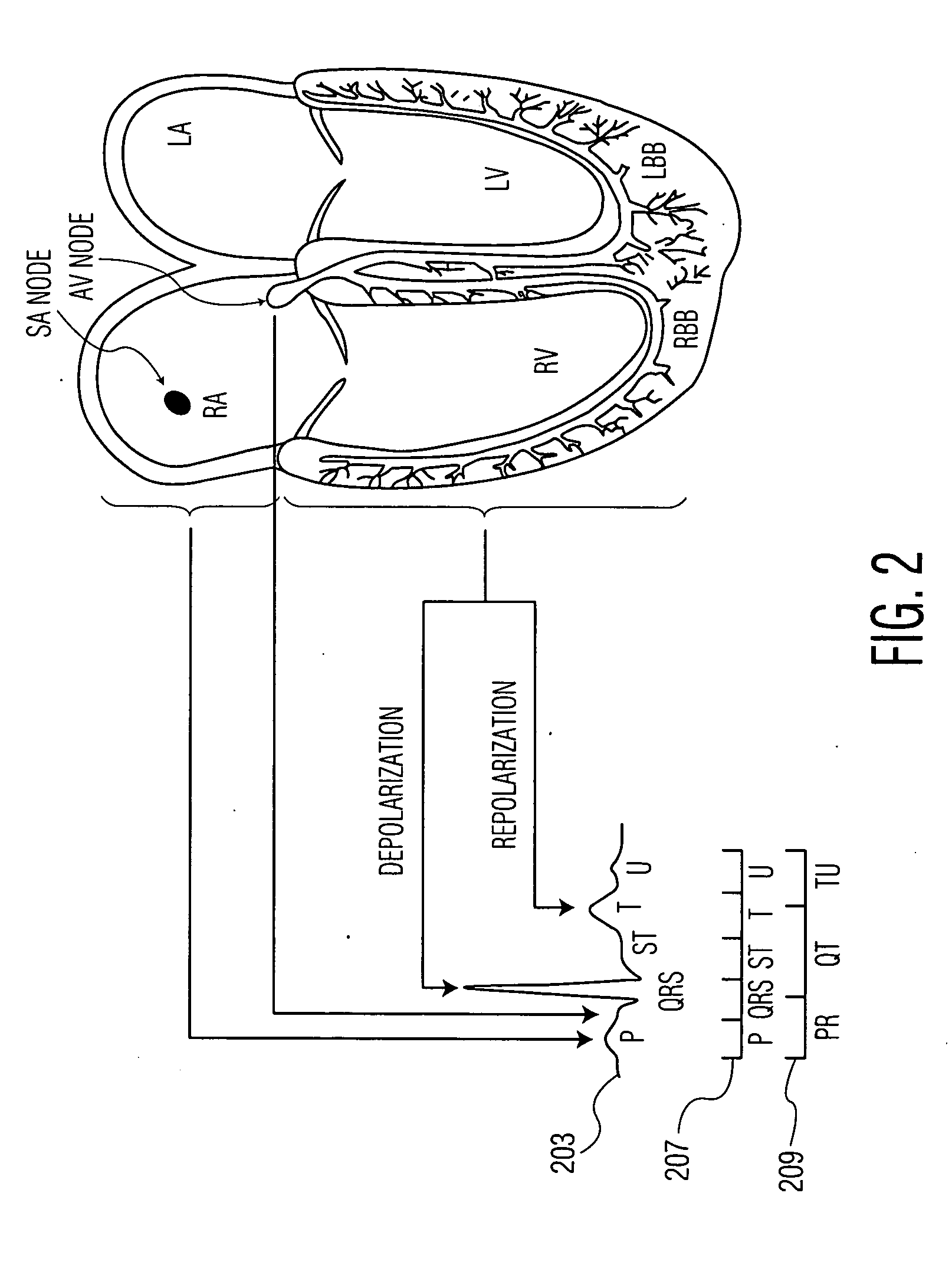

System for Heart Performance Characterization and Abnormality Detection

ActiveUS20090281441A1Improve precisionImprove reliabilityElectrocardiographyMedical devicesT wavePeak value

A system for heart performance characterization and abnormality detection includes an acquisition device for acquiring an electrophysiological signal representing heart beat cycles of a patient heart. A detector detects one or more parameters of the electrophysiological signal of parameter type comprising at least one of, (a) amplitude, (b) time duration, (c) peak frequency and (d) frequency bandwidth, of multiple different portions of a single heart beat cycle of the heart beat cycles selected in response to first predetermined data. The multiple different portions of the single heart beat cycle being selected from, a P wave portion, a QRS complex portion, an ST segment portion and a T wave portion in response to second predetermined data. A signal analyzer calculates a ratio of detected parameters of a single parameter type of the multiple different portions of the single heart beat cycle. An output processor generates data representing an alert message in response to a calculated ratio exceeding a predetermined threshold.

Owner:PIXART IMAGING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com