Intelligent monitoring device for blades of wind driven generator

A technology for wind turbines and monitoring devices, applied in wind turbines, wind turbine control, wind power generation, etc., can solve the problems of blade fatigue and vibration, reduce power generation efficiency, stall and other problems, achieve anti-battery interference and avoid working with illness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

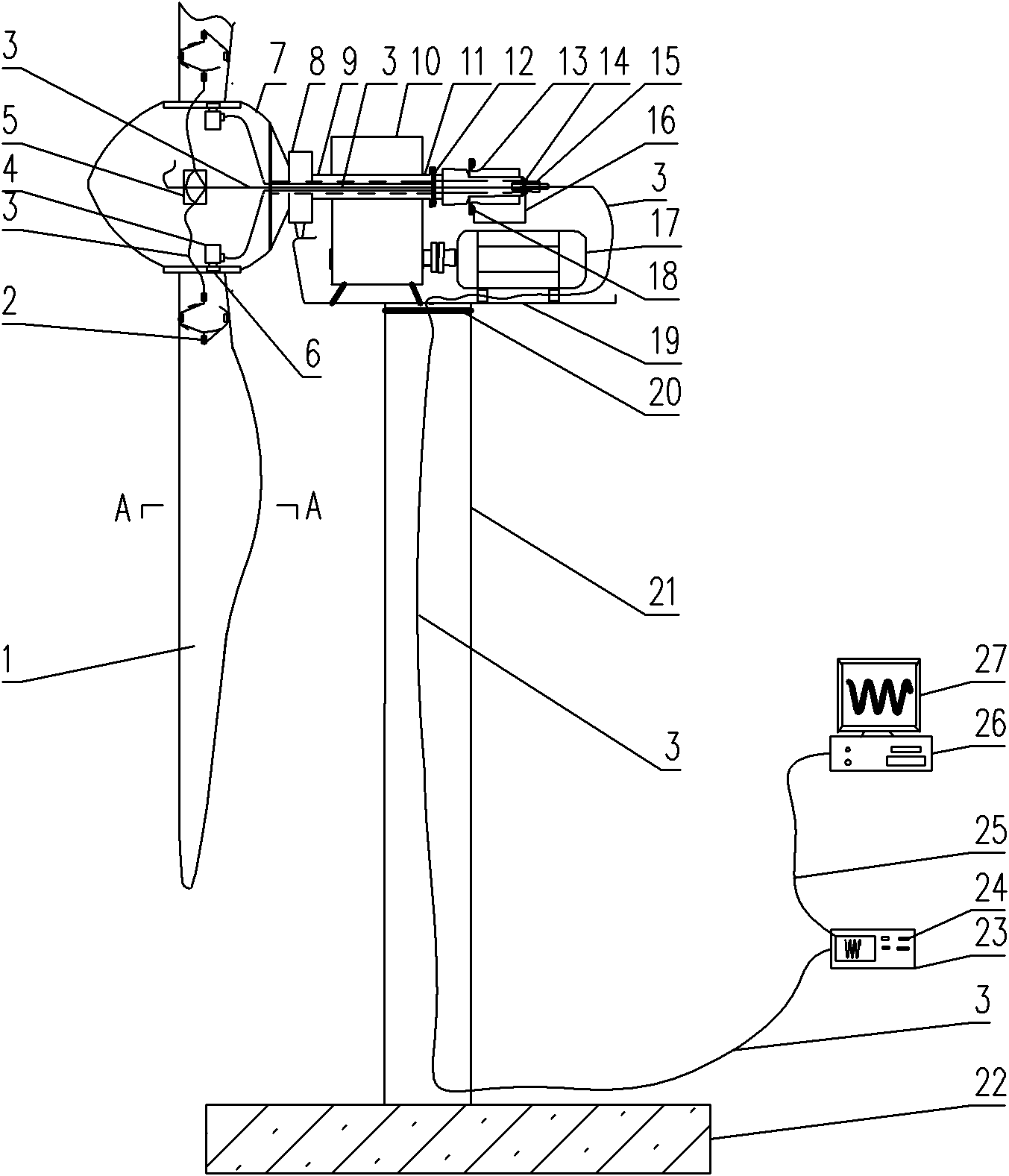

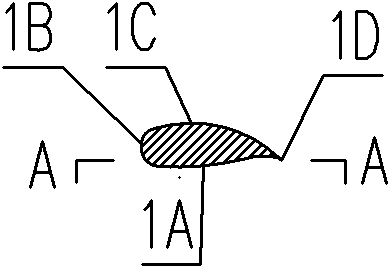

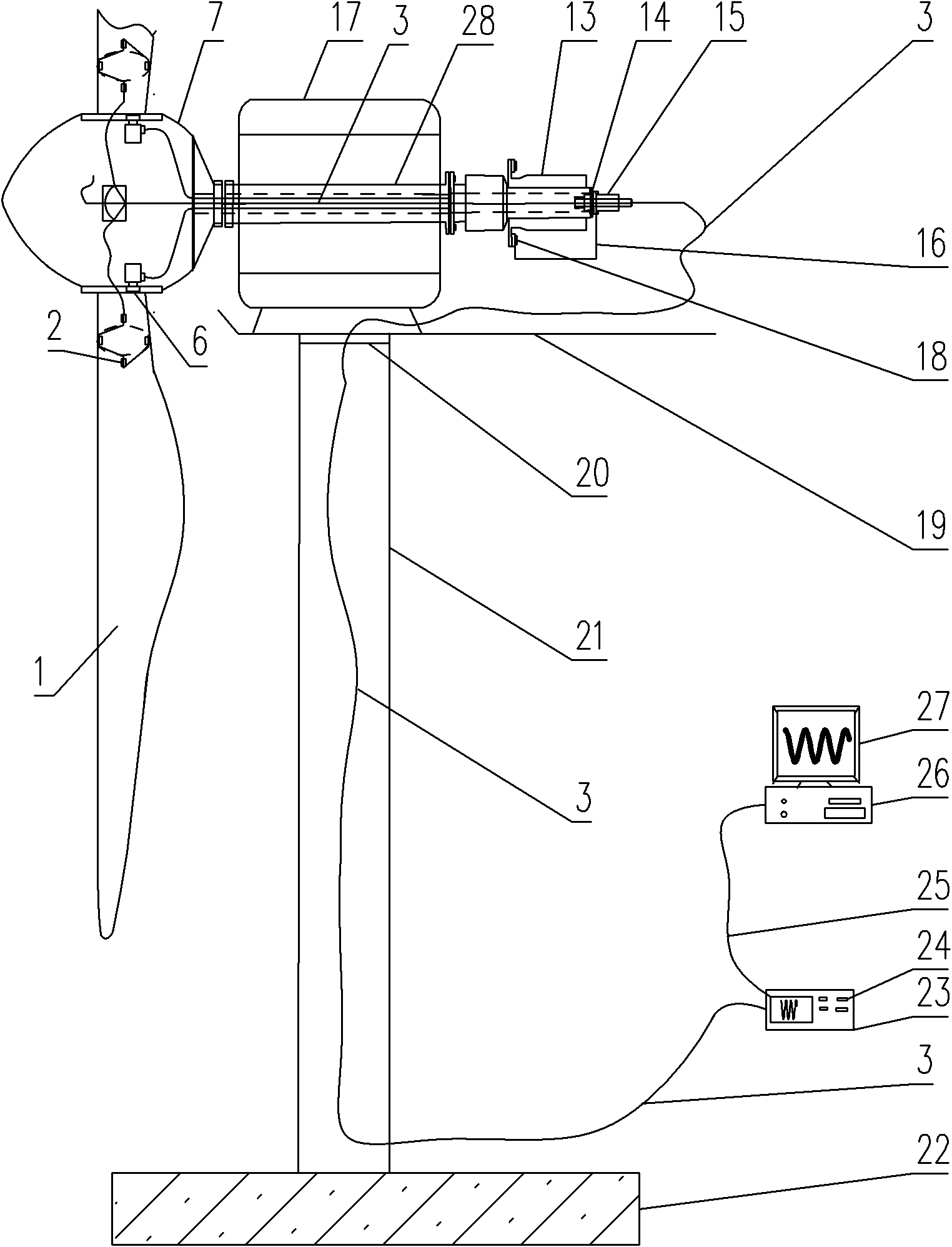

[0038] according to Figure 1a and figure 2 In the illustrated embodiment, the wind turbine blade intelligent monitoring device of the present invention includes:

[0039] The blade body 1 is installed on the hub 7;

[0040] The generator 17 is connected to the hub 7 via the gearbox 10 and the main shaft 9 or directly connected to the hub 7;

[0041] A plurality of fiber grating sensors 2 arranged on the blade body 1;

[0042] A fiber grating signal analyzer 23 is connected to the plurality of fiber grating sensors 2 through an optical fiber 3 and a fiber coupler 5; The refractive index of the fiber grating will change, so that the wavelength of the reflected light of the fiber grating will change accordingly. The fiber grating signal analyzer 23 can obtain the vibration, dynamic balance, fatigue, deformation, load, damage, etc. The information is output through the man-machine interface, so that the check-in personnel of the wind farm can get the health status of the bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com