Checking standard part and checking method of coordinate measuring machine

A technology of coordinate measuring machine and standard parts, applied in the field of checking standard parts, can solve problems such as the risk of detection work and the change of the state of the measuring machine, so as to achieve the effect of improving reliability, ensuring accurate calibration, and realizing the effect of grasping at any time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

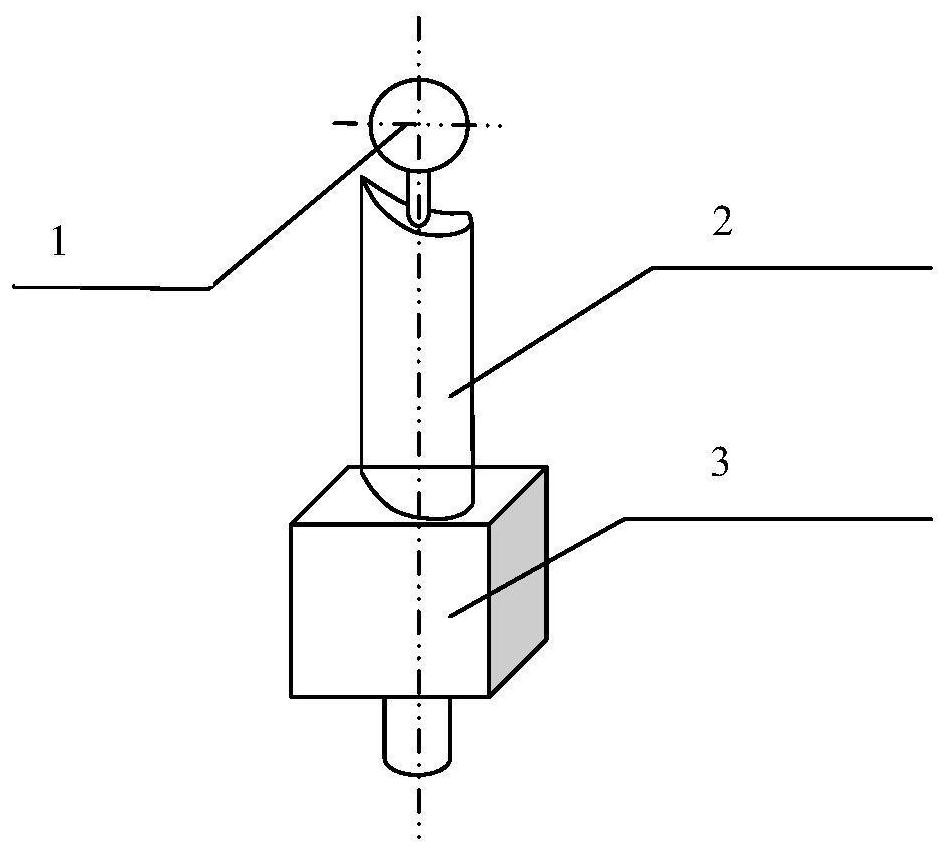

[0034] In the embodiment of the present invention, the simulated workpiece 2 is specifically a simulated blade. The simulated blade adopts a thicker and more rigid entity than the actual blade to be tested to ensure its stable state. The simulated blade is endowed by the metrology department with representative characteristic parameter values such as blade pot outline, blade back outline, leading and trailing edge thickness, blade body thickness, leading and trailing edge R, leading and trailing edge position, chord width, stacking point position, bending, torsion, etc. , take it as the standard value of the characteristic parameter, and store its value in the coordinate measuring machine system. When checking, the coordinate measuring machine automatically measures the corresponding characteristic parameter value according to the program and uploads it for analysis and comparison to determine the state of the coordinate measuring machine.

[0035] The specific implementatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com