Patents

Literature

185 results about "Probe calibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

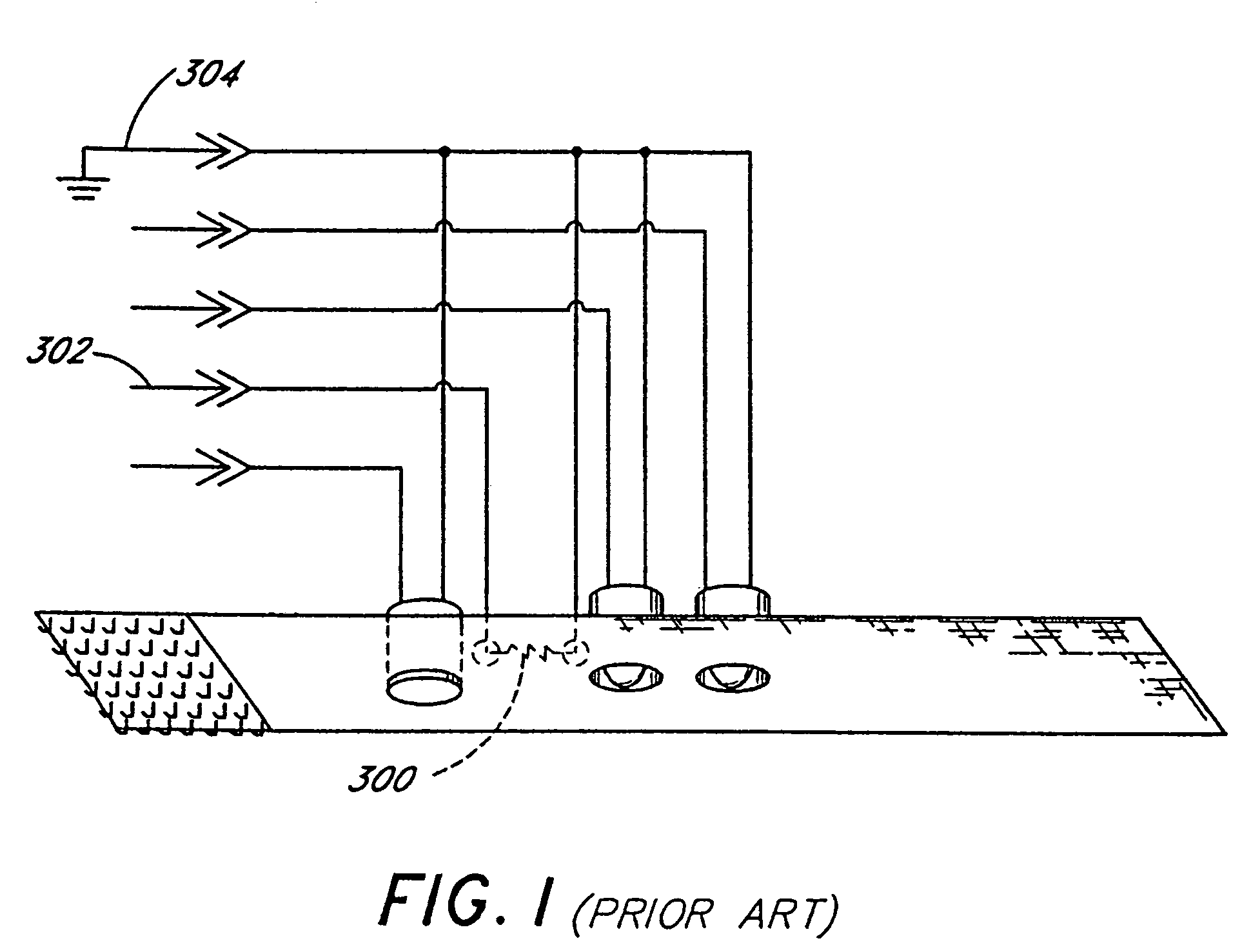

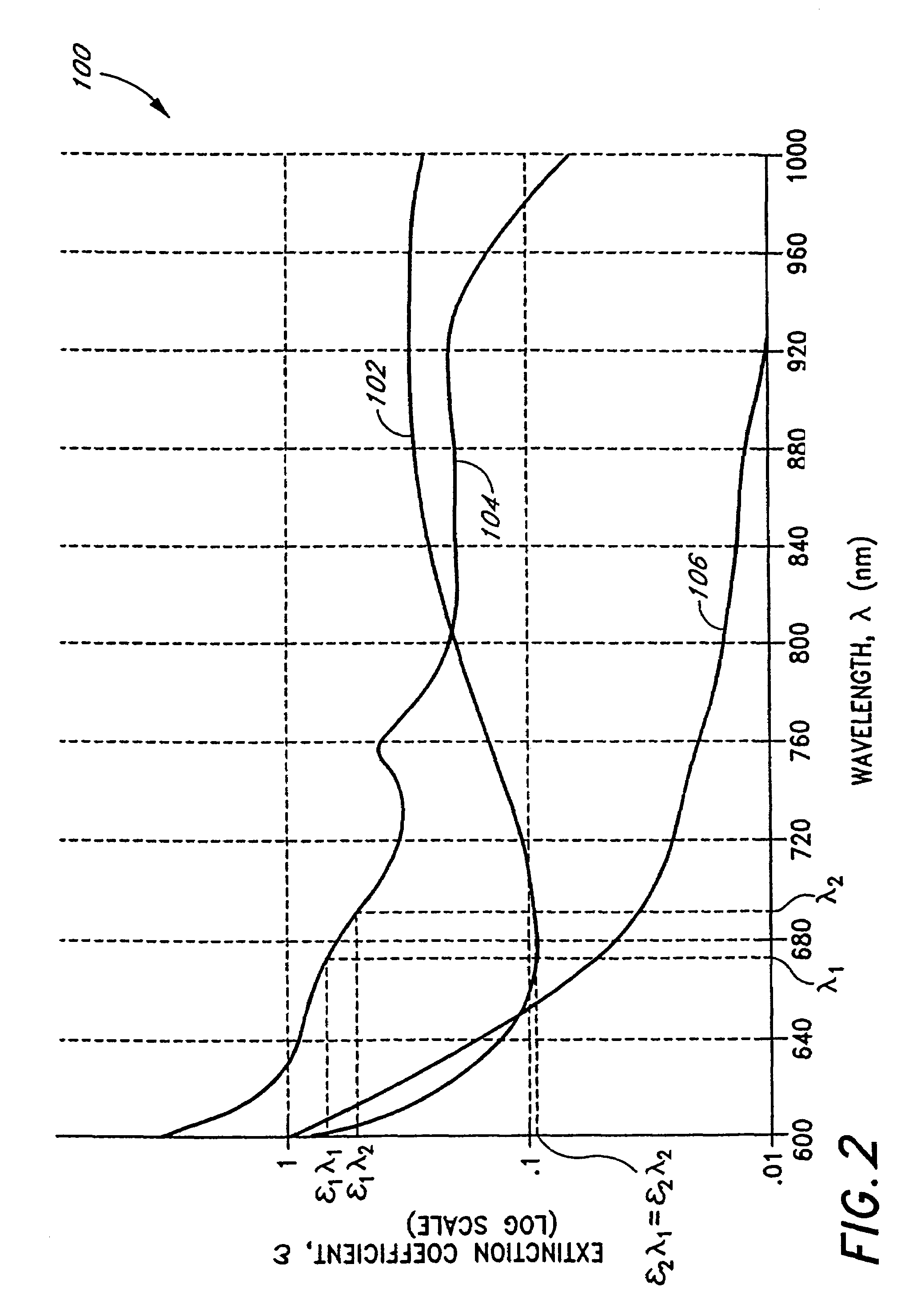

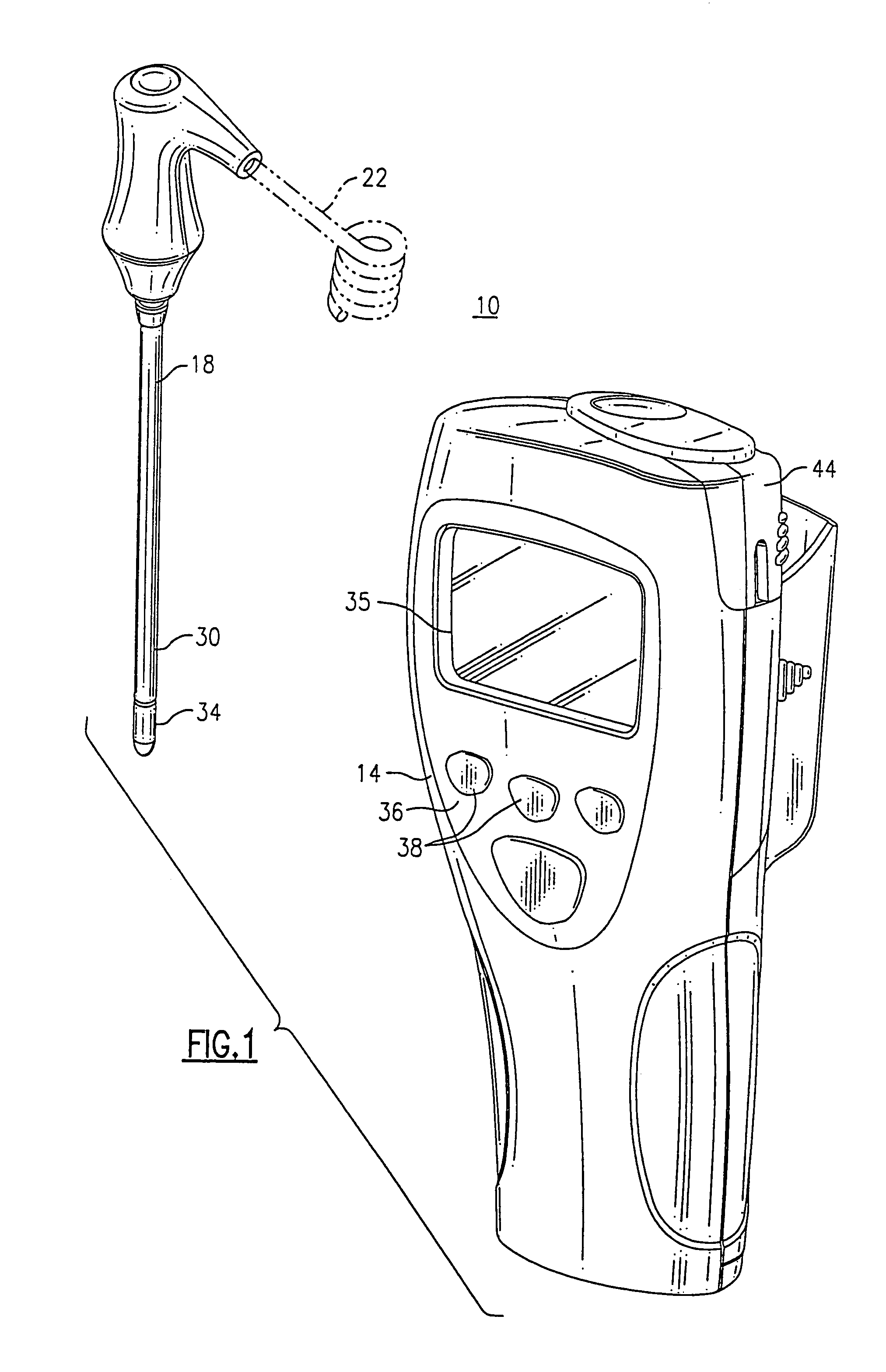

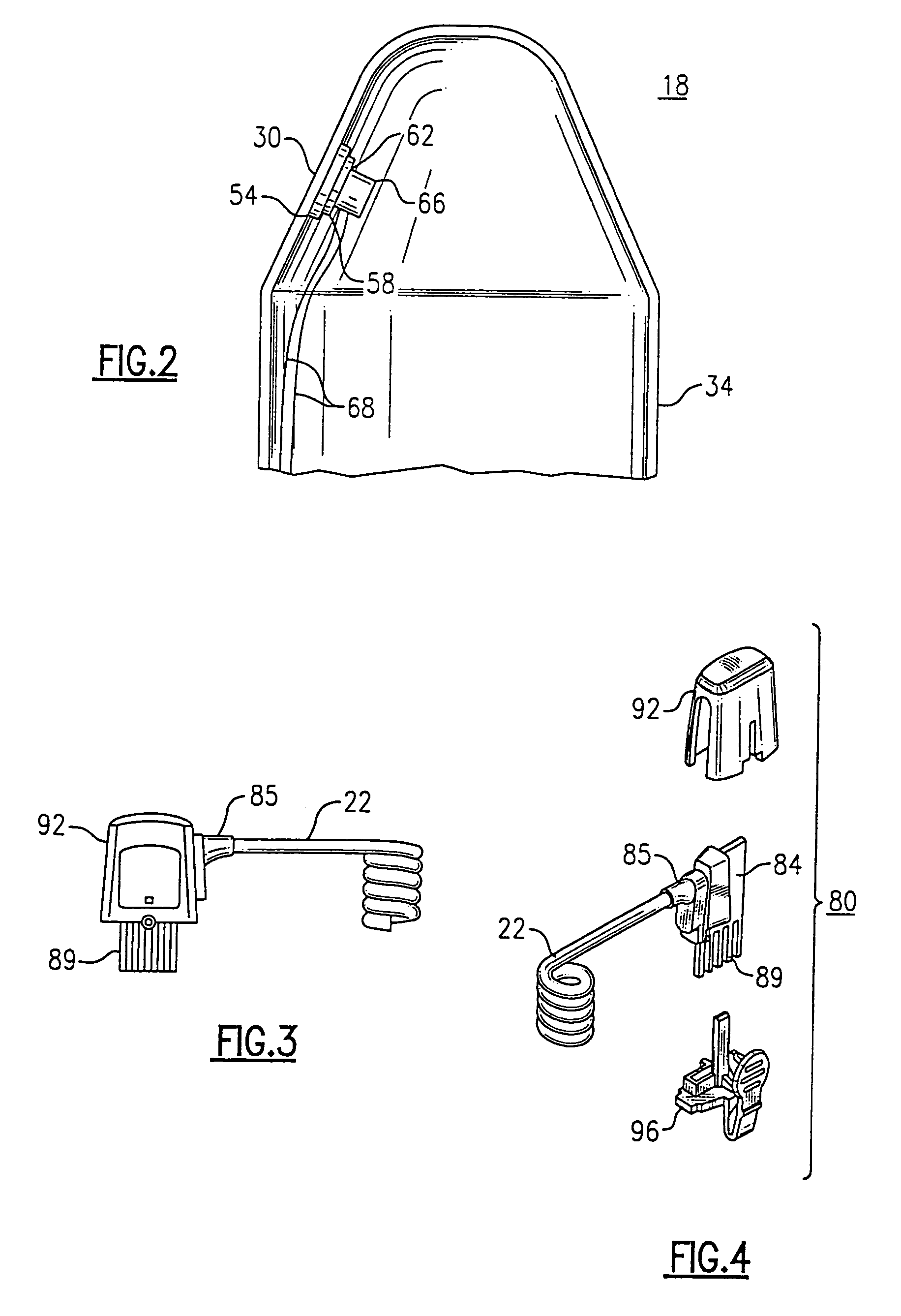

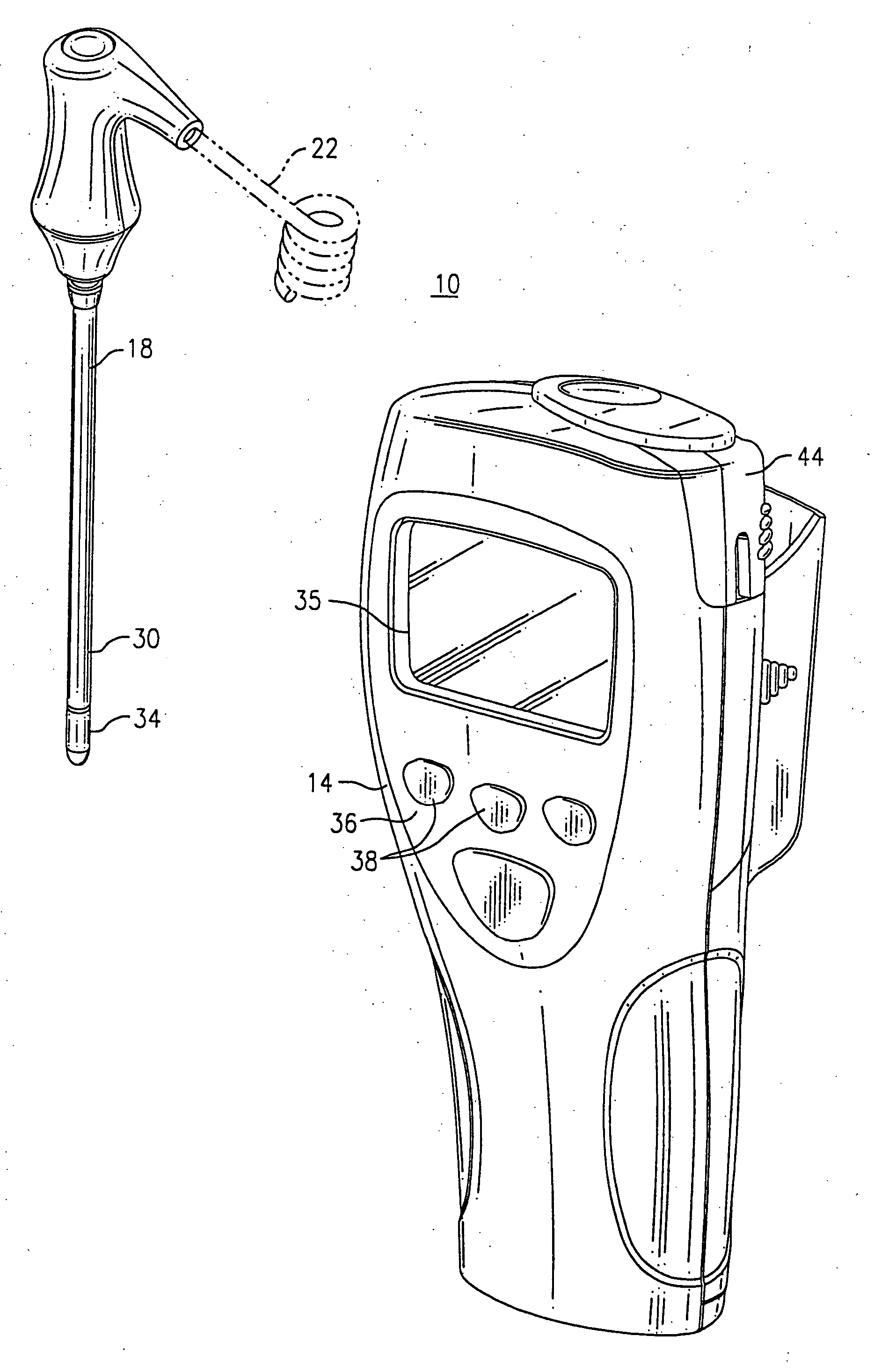

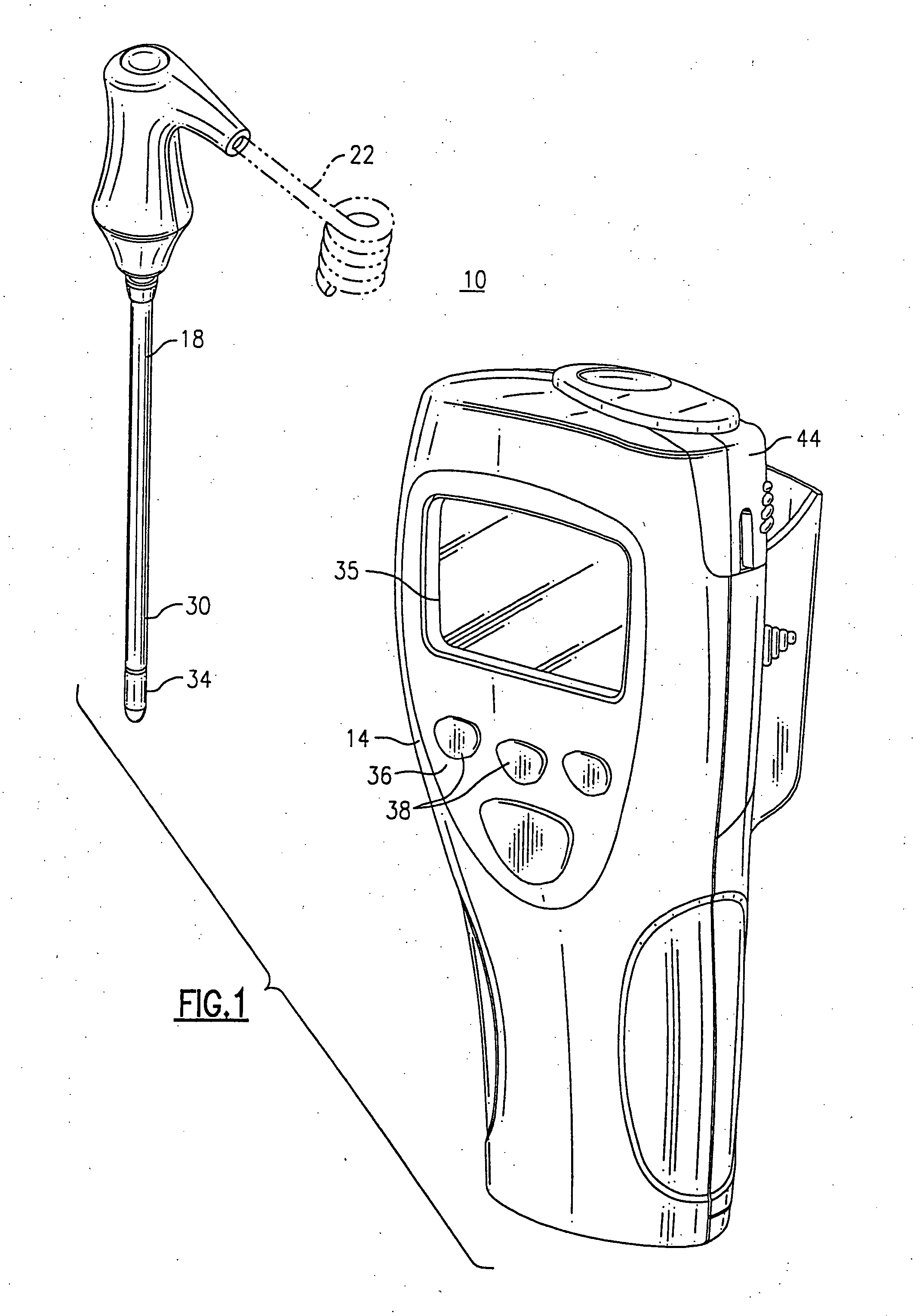

Manual and automatic probe calibration

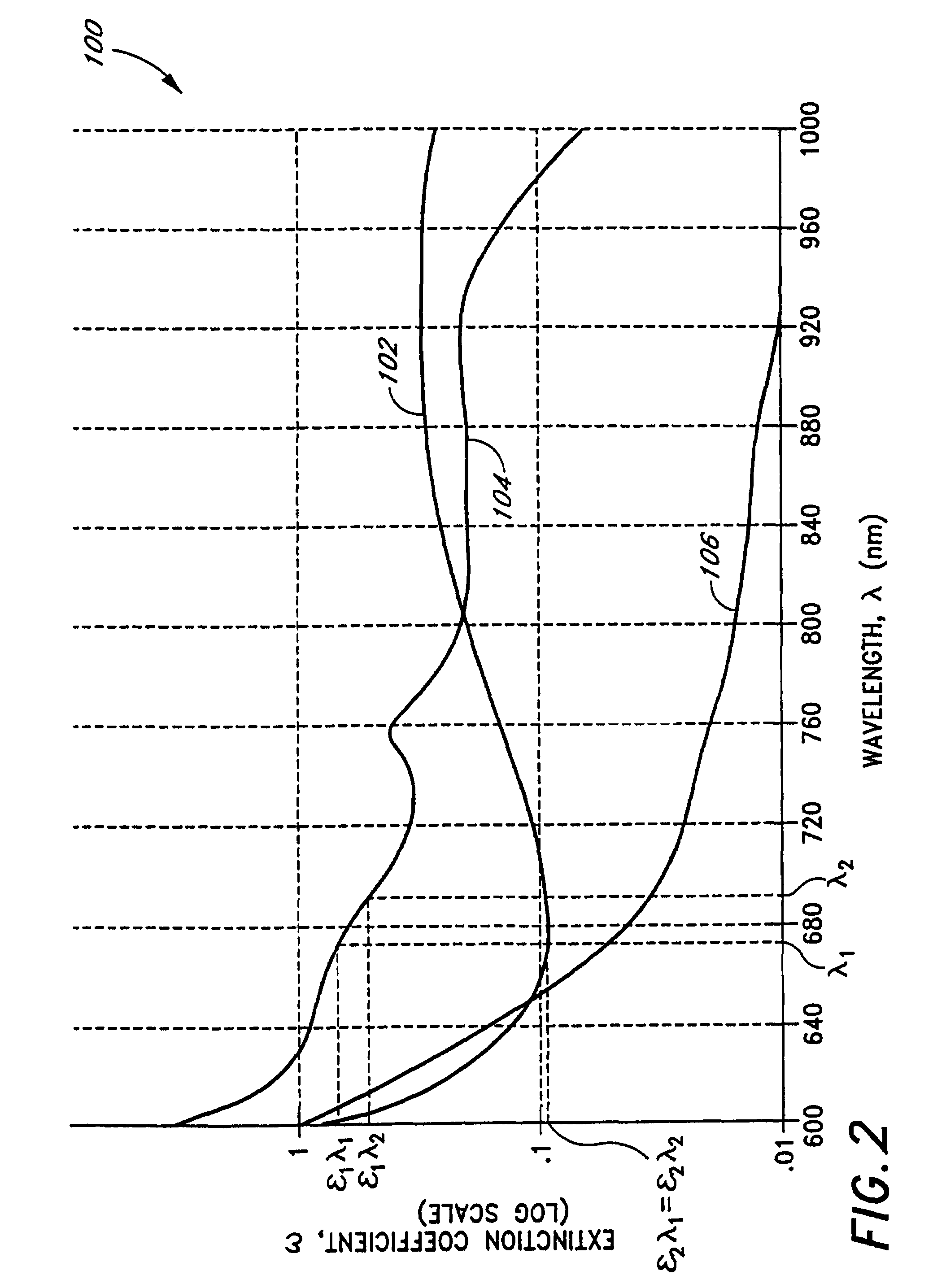

InactiveUS7496391B2Complicates designIncreased expenseRadiation pyrometrySpectrum investigationElectronic componentProbe calibration

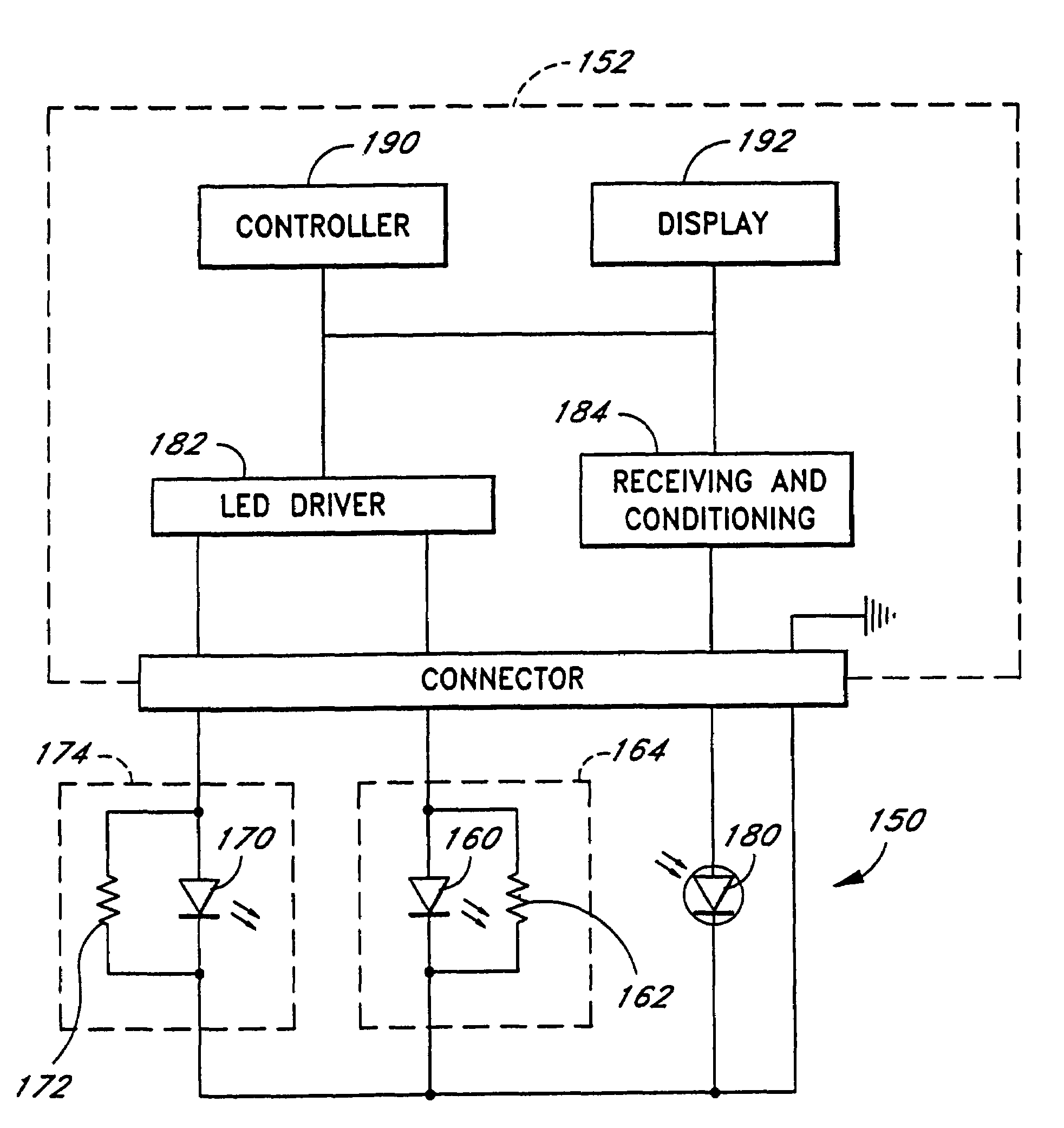

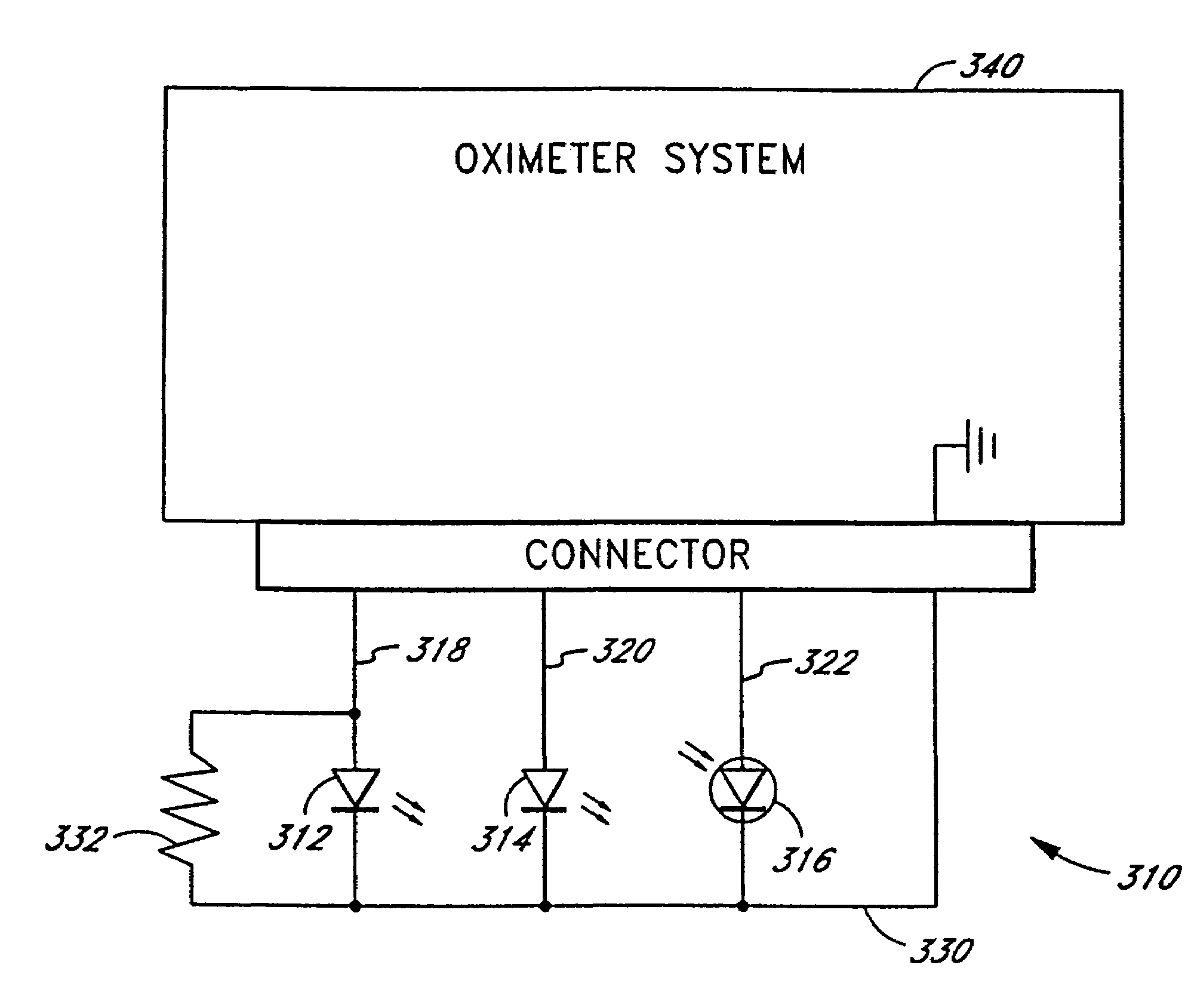

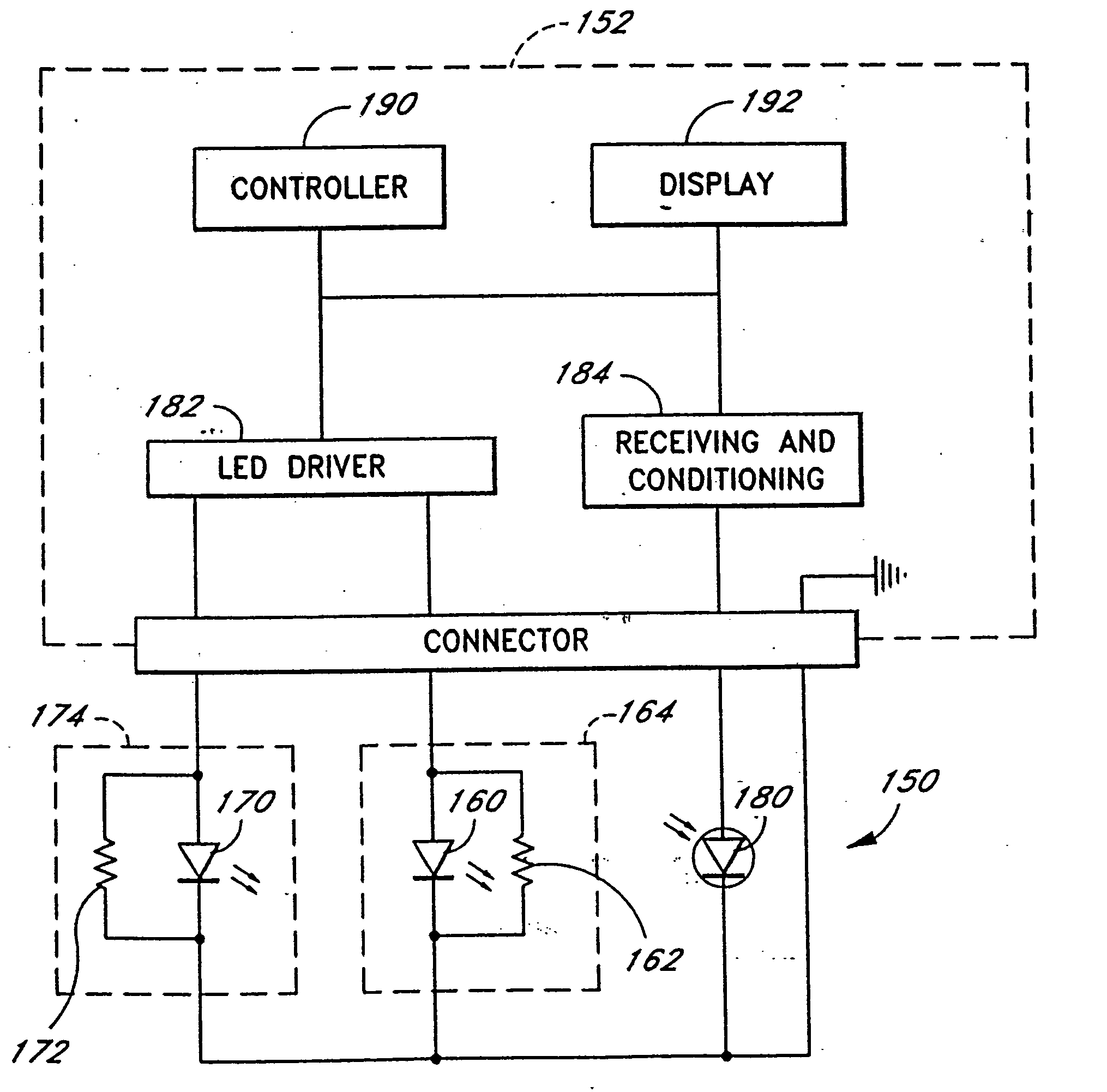

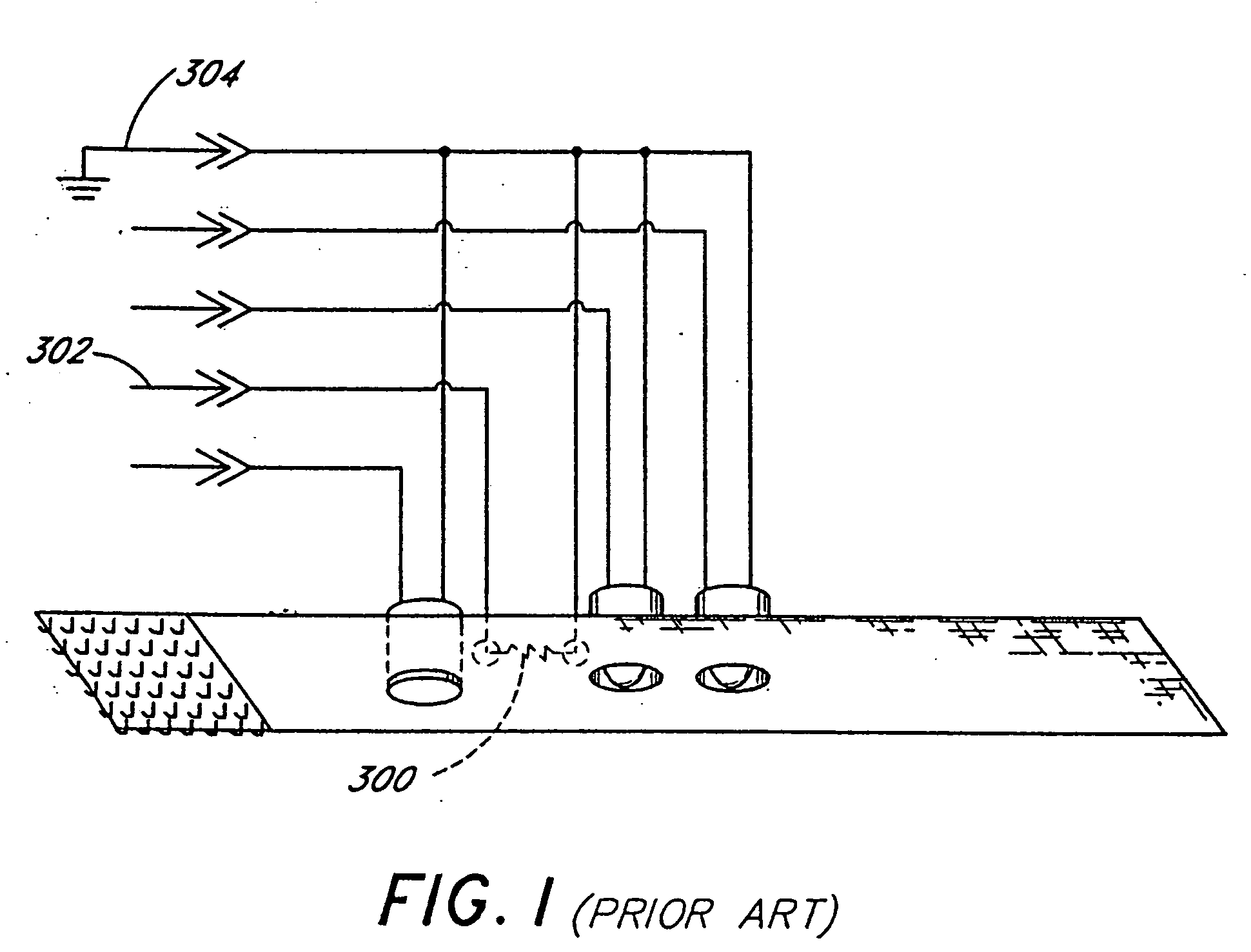

Embodiments of the present disclosure include an oximeter sensor system including a reusable portion including a substantially rigid connector connected to an end of a cable. The substantially rigid connector includes an electronic element housing at least one electronic component of a probe. The system also includes a disposable portion including a flexible wrap comprising a substantially rigid connection port shaped to receive the substantially rigid connector in a releasably securable manner.

Owner:JPMORGAN CHASE BANK NA

Manual and automatic probe calibration

InactiveUS7526328B2Complicates designIncreased expenseRadiation pyrometrySpectrum investigationFull Term NeonateEngineering

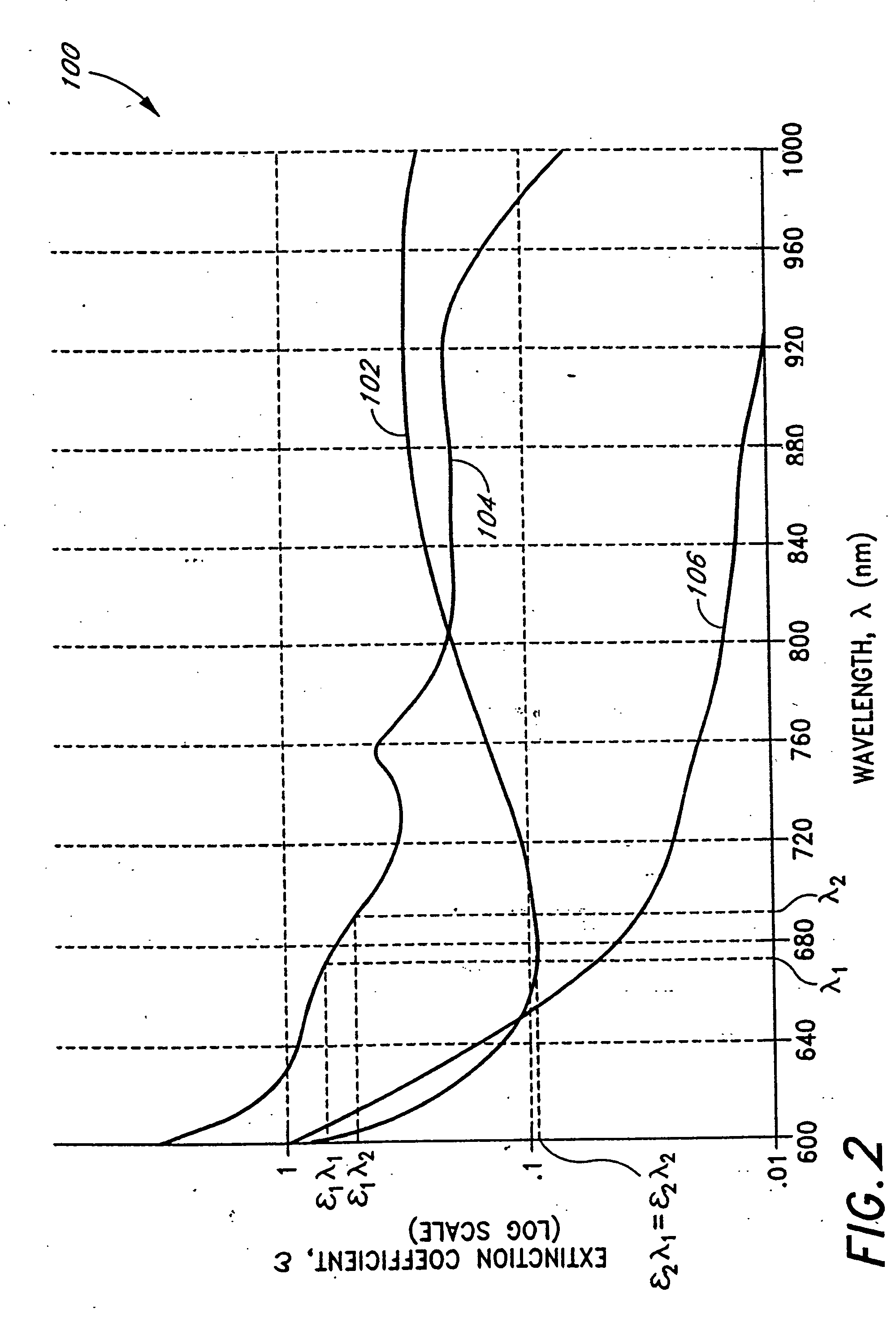

Embodiments of the present disclosure include an optical probe capable of communicating identification information to a patient monitor in addition to signals indicative of intensities of light after attenuation by body tissue. The identification information may indicate operating wavelengths of light sources, indicate a type of probe, such as, for example, that the probe is an adult probe, a pediatric probe, a neonatal probe, a disposable probe, a reusable probe, or the like. The information could also be utilized for security purposes, such as, for example, to ensure that the probe is configured properly for the oximeter, to indicate that the probe is from an authorized supplier, or the like. In one preferred embodiment, coding resistors could be provided across the light sources to allow additional information about the probe to be coded without added leads. However, any device could be used without it being used in parallel.

Owner:JPMORGAN CHASE BANK NA

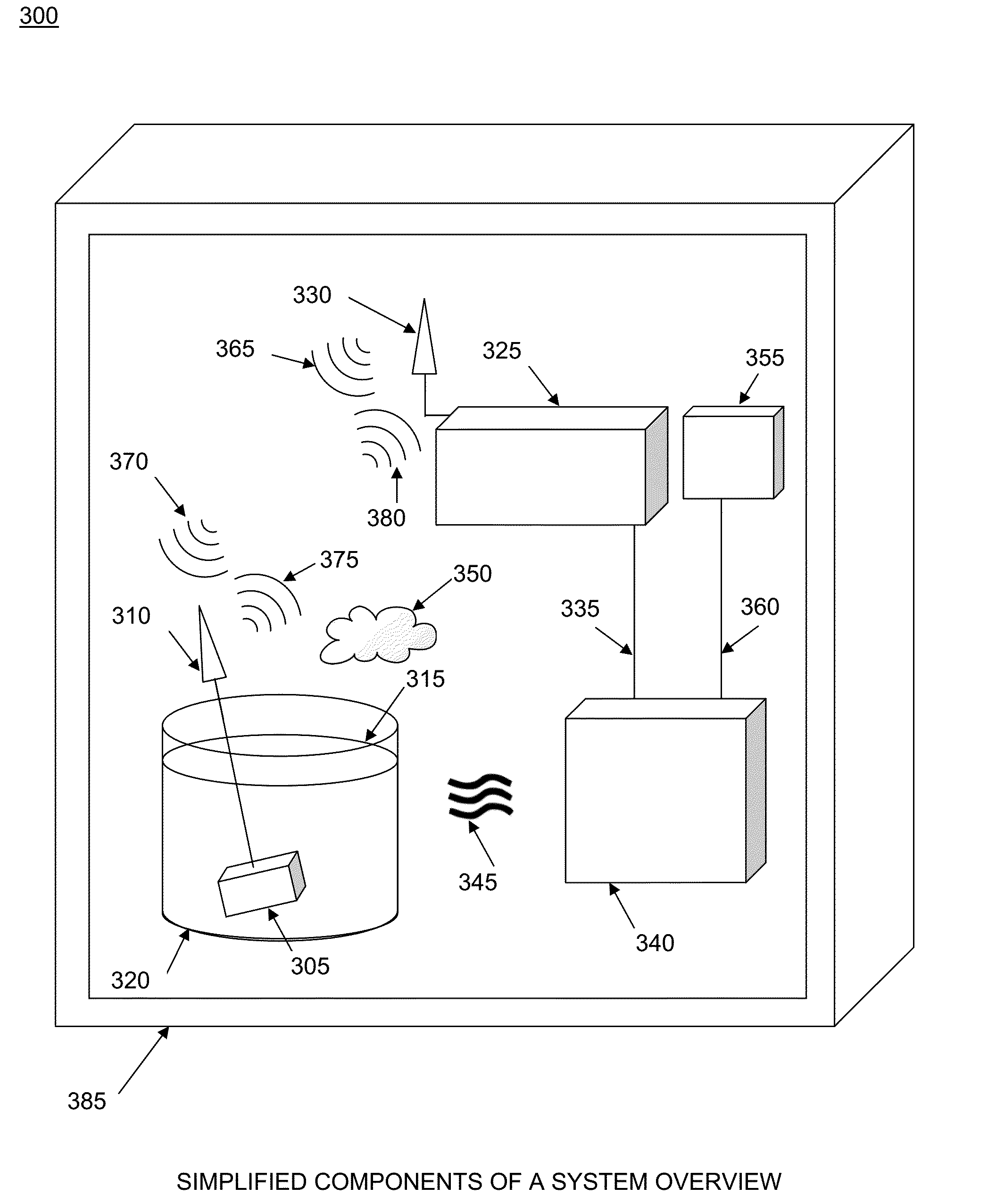

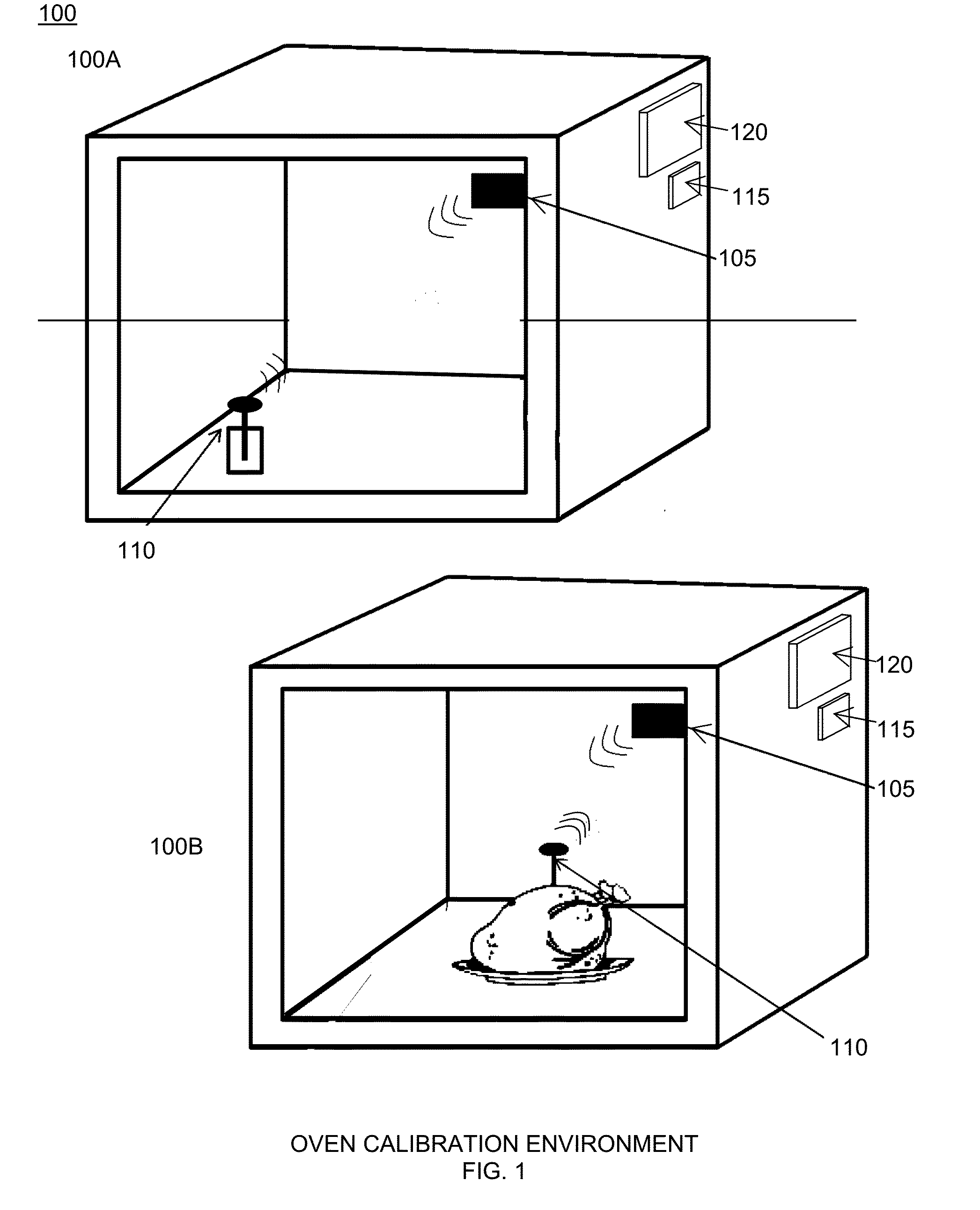

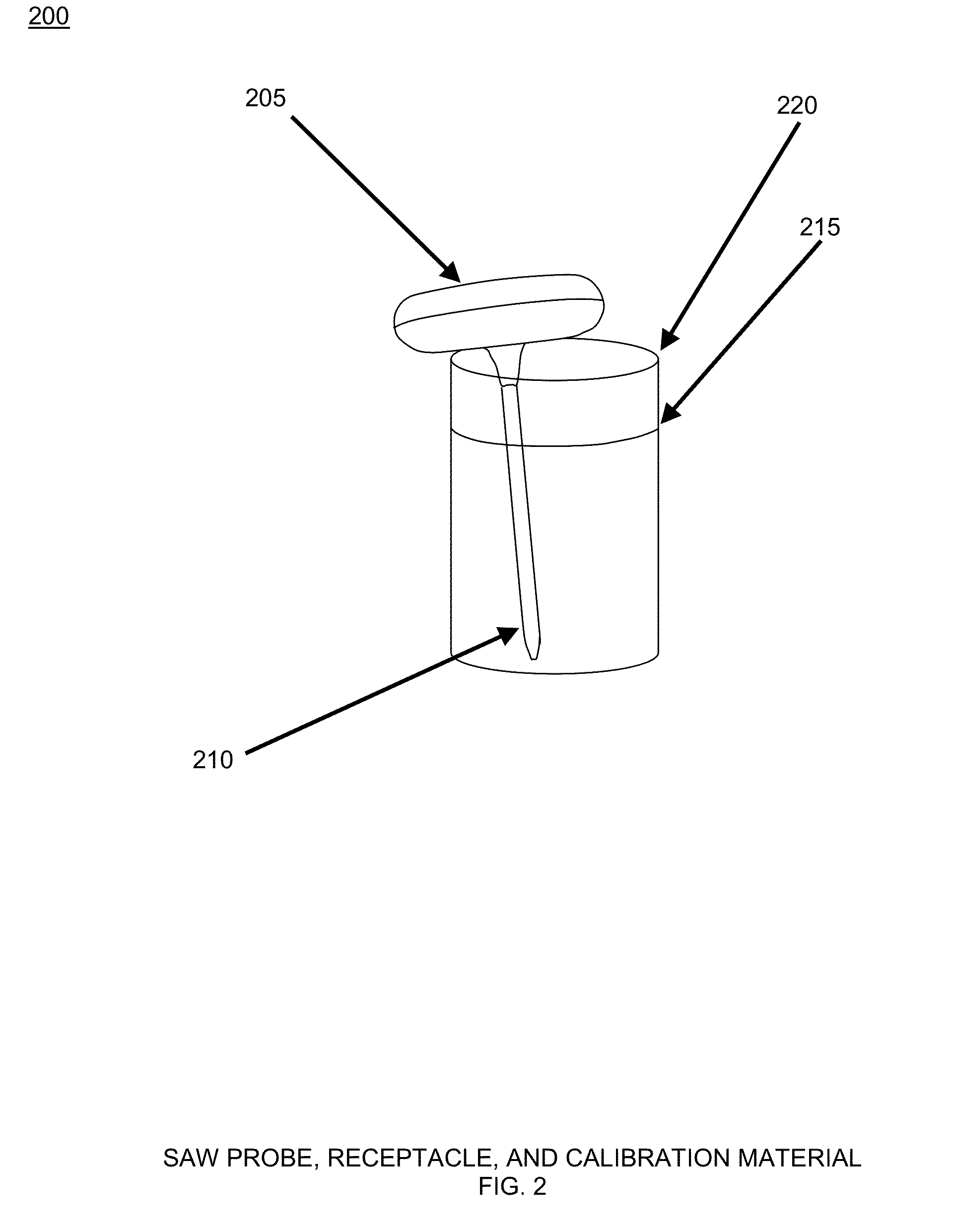

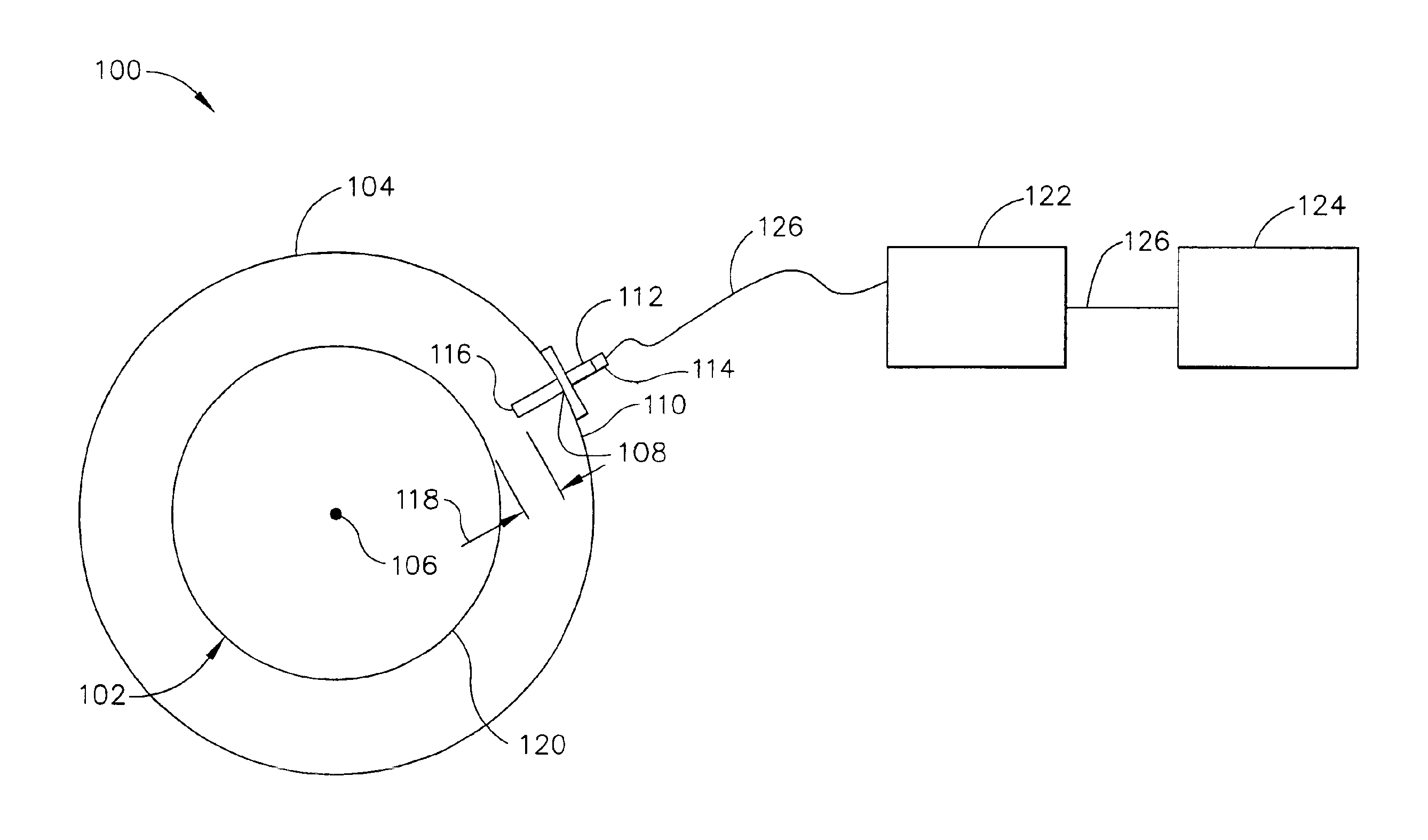

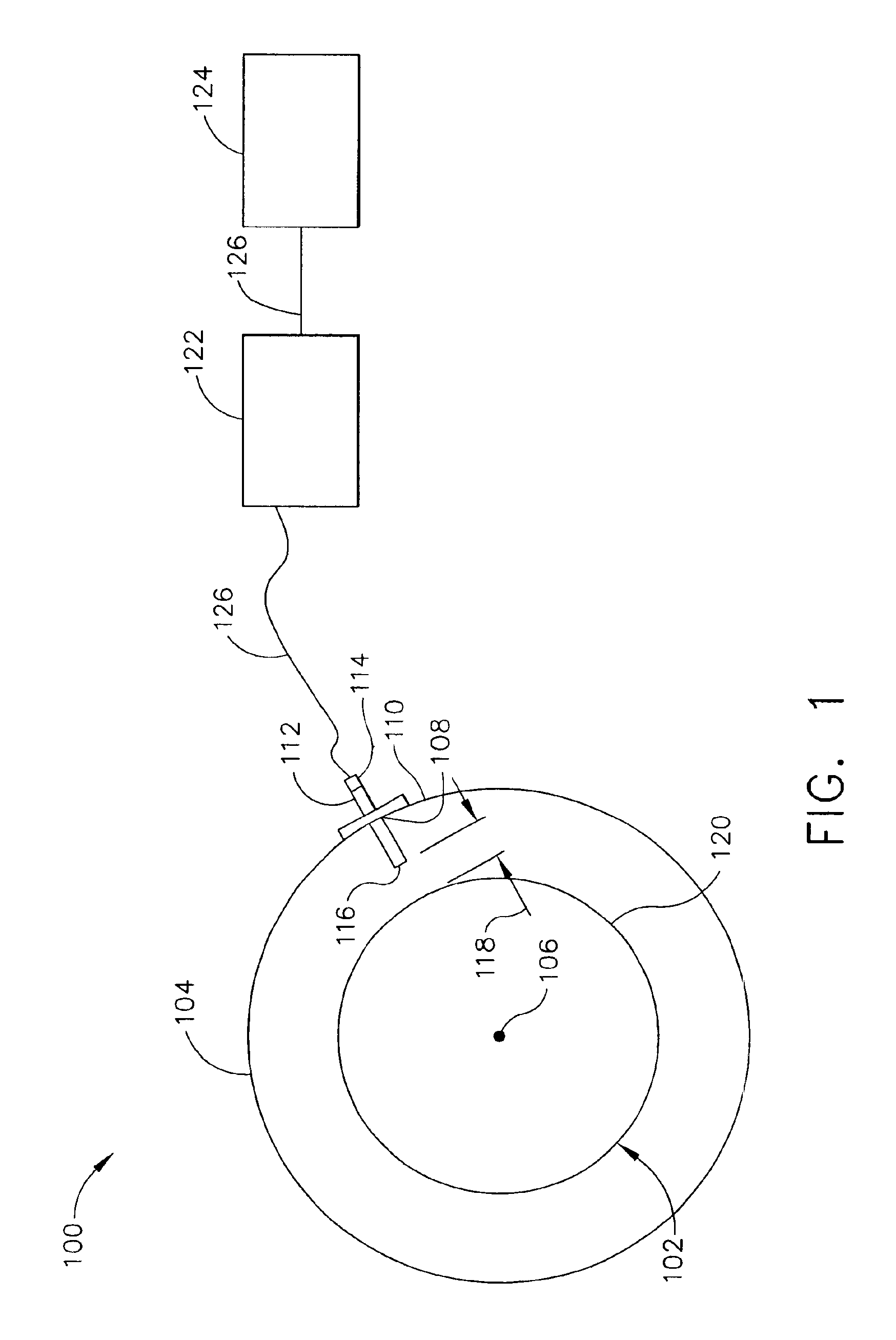

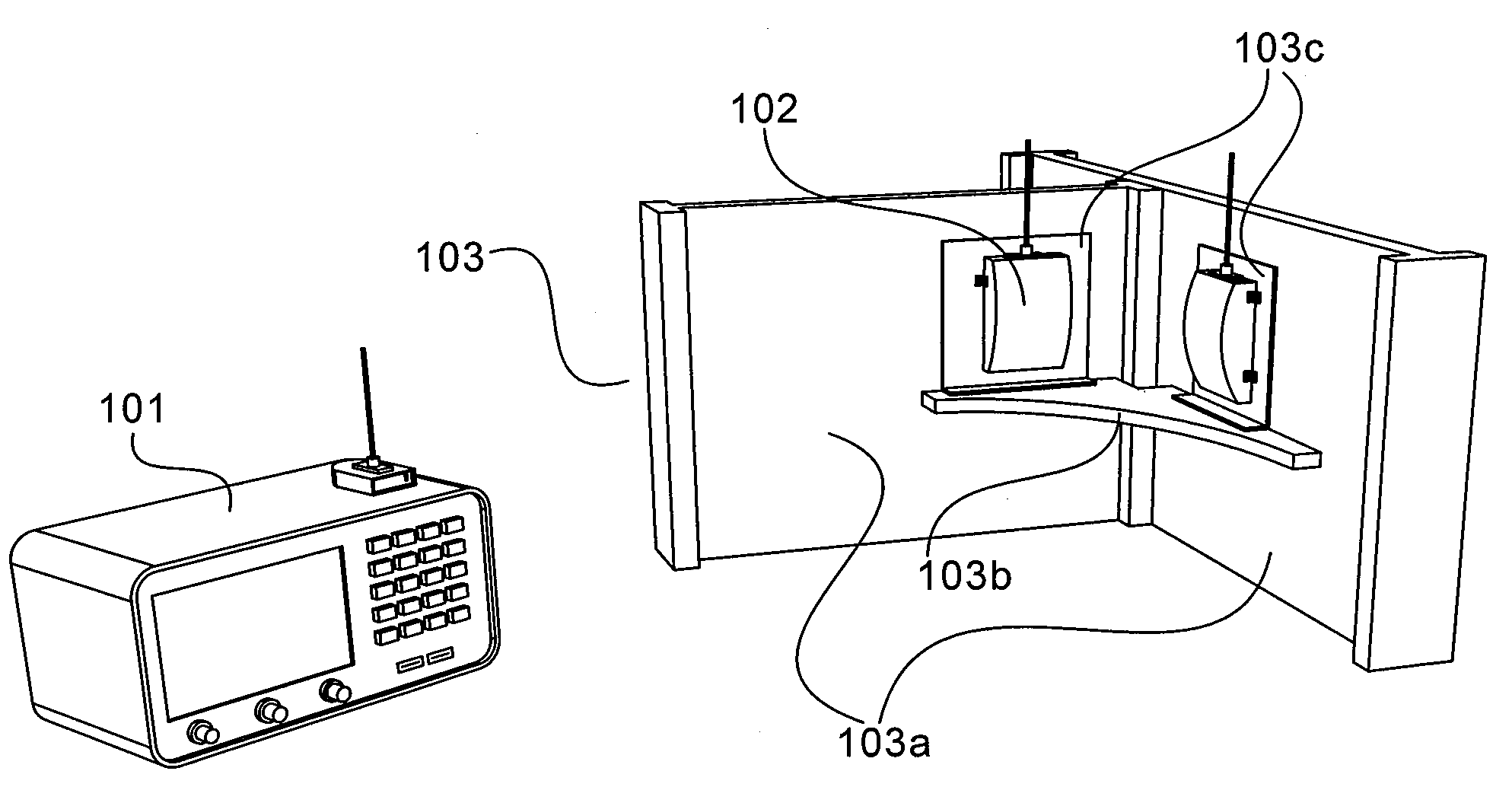

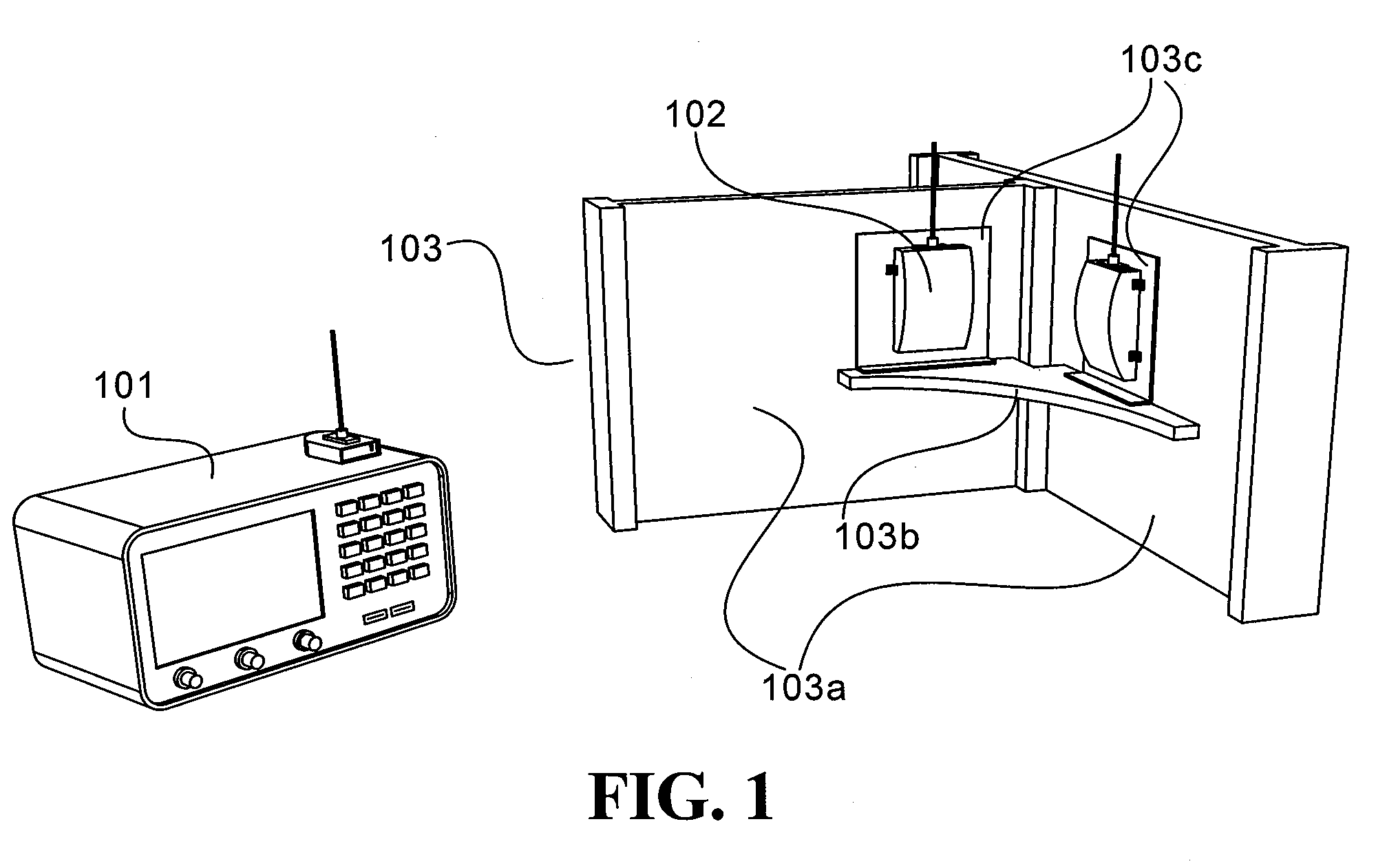

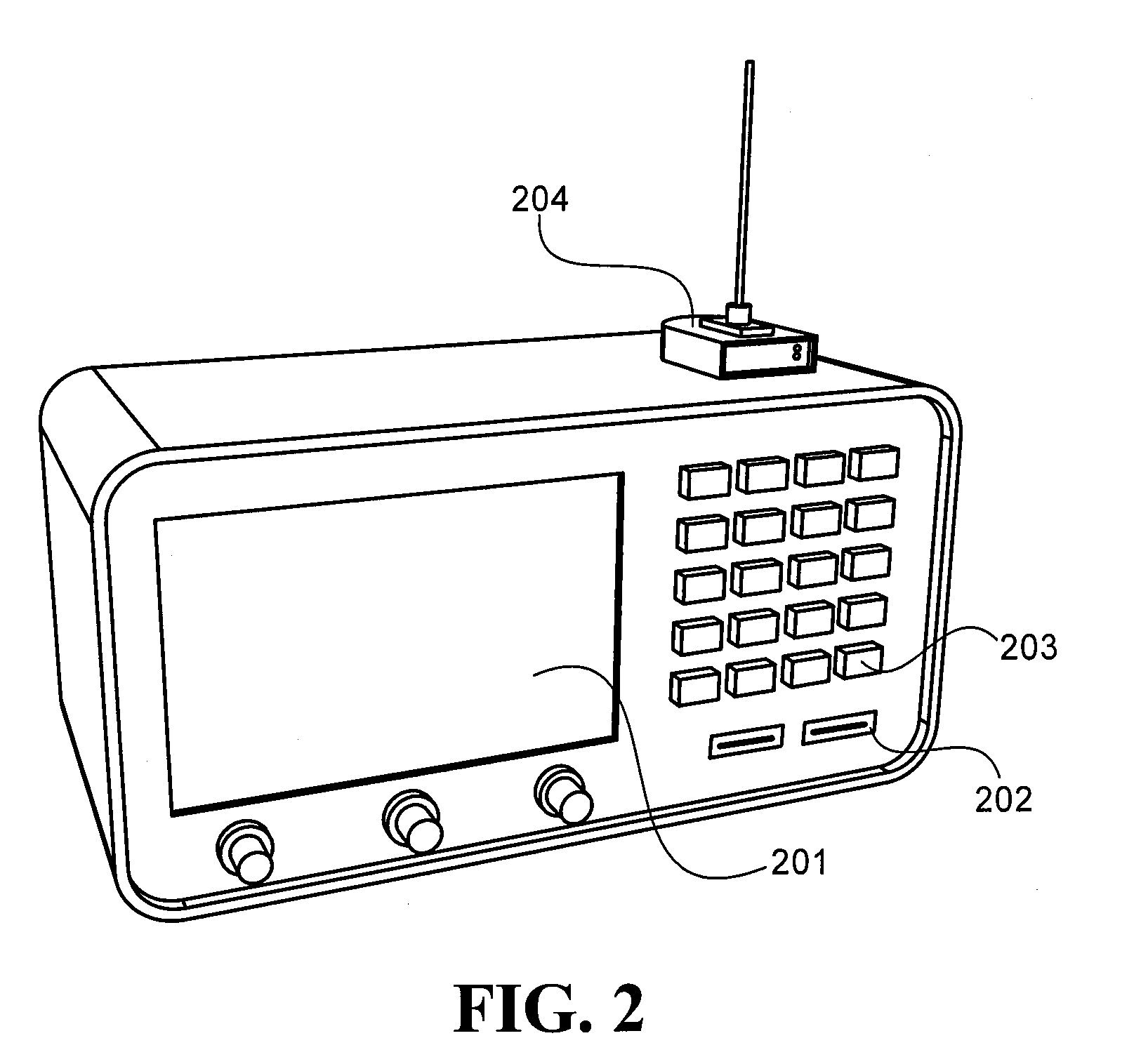

Wireless culinary probe calibration method and system

InactiveUS20160076949A1Quantity minimizationDomestic stoves or rangesLighting and heating apparatusSurface acoustic waveProbe calibration

A system and method to calibrate a temperature probe through immersion in a substance of known change of state temperature. The saturated Surface Acoustic Wave (SAW) probe temperature signal is calculated, overcoming oven reference temperature variability.

Owner:MICROSEMI CORP HIGH PERFORMANCE TIMING

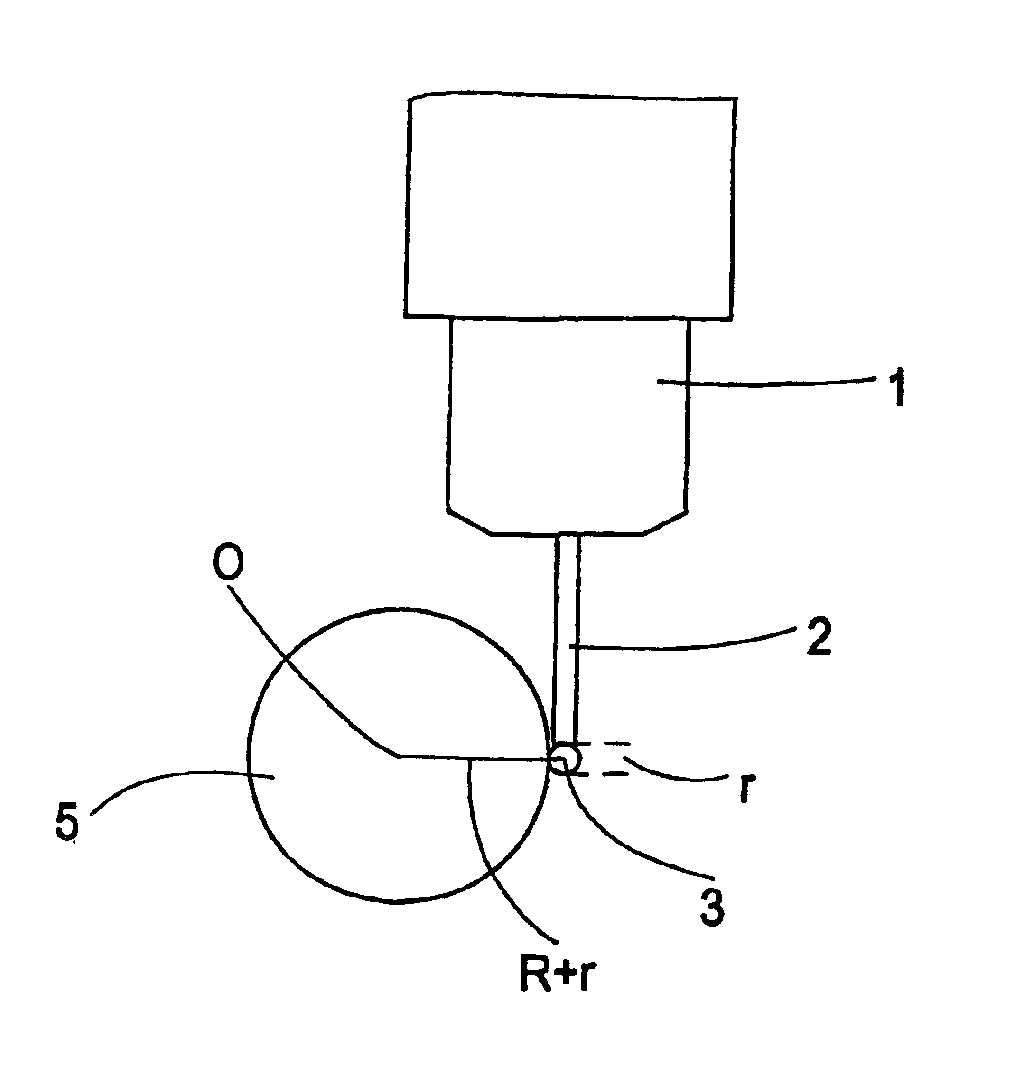

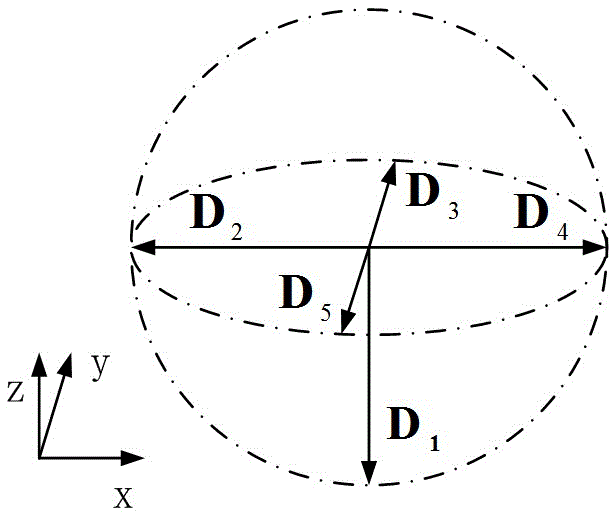

Calibration of an analogue probe

InactiveUS6909983B2Testing/calibration apparatusMechanical counters/curvatures measurementsClassical mechanicsZ-Coordinate

A method of calibrating a probe mounted on a machine in which the probe has a probe calibration matrix which relates the probe outputs in three orthogonal axes to the machine's X, Y and Z coordinate system. A datum ball mounted on the machine is bi-directionally scanned by the probe in one or more planes. For each plane, the mean direction of two approximate probe vectors in the plane is rotated about an axis orthogonal to that plane until the apparent material condition from the scan in each direction is the same. This process may be iterative. The mean values of the directions of the probe vectors for each plane are rotated, thus forming a corrected probe calibration matrix. The datum ball is preferably bi-directionally scanned in three orthogonal planes.

Owner:RENISHAW PLC

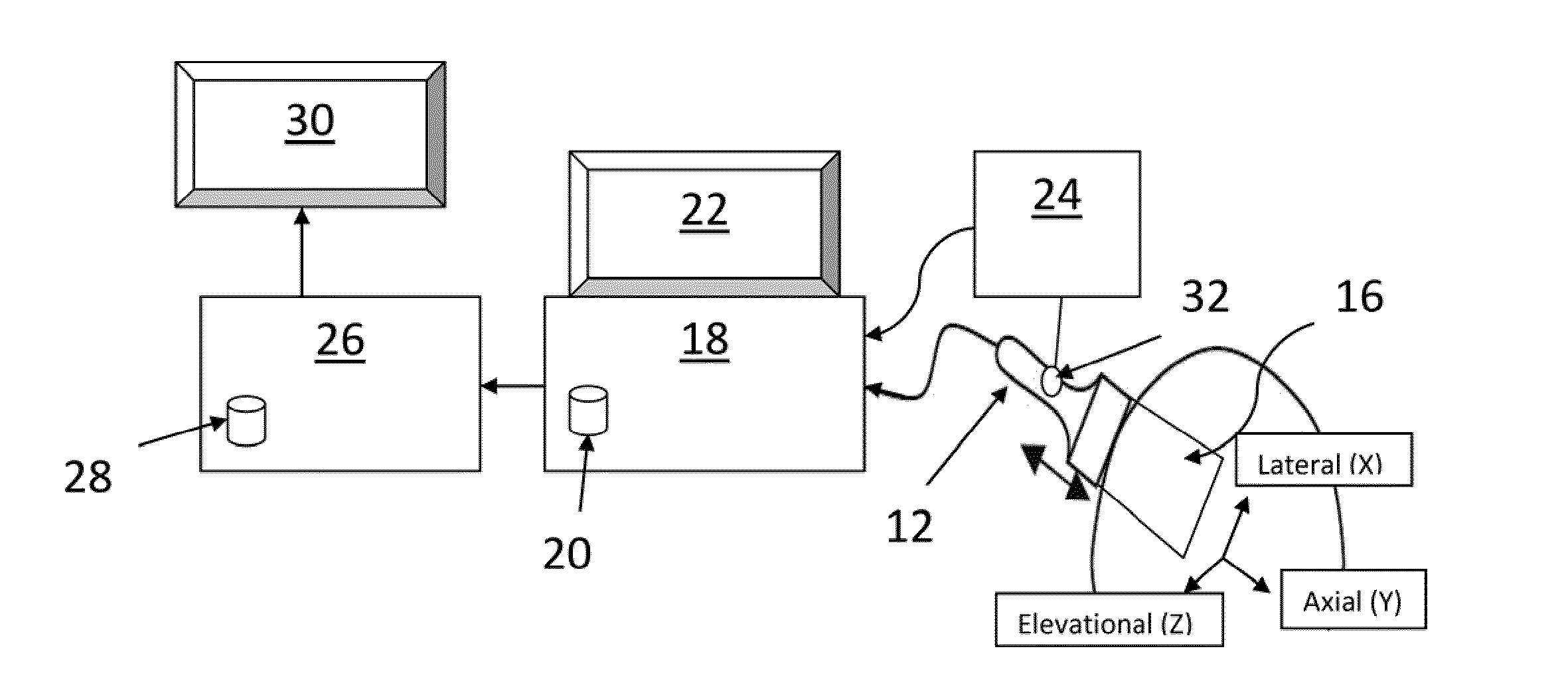

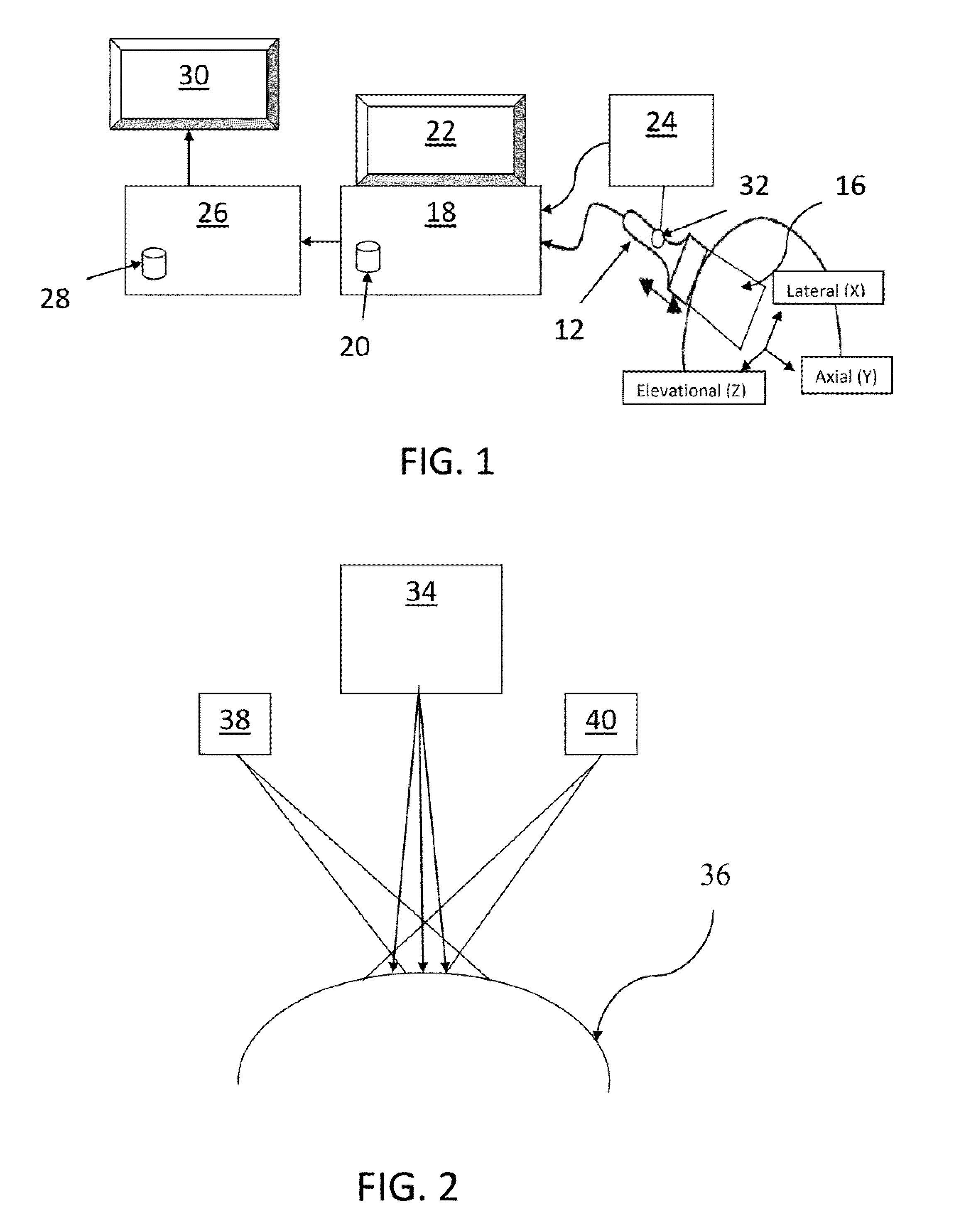

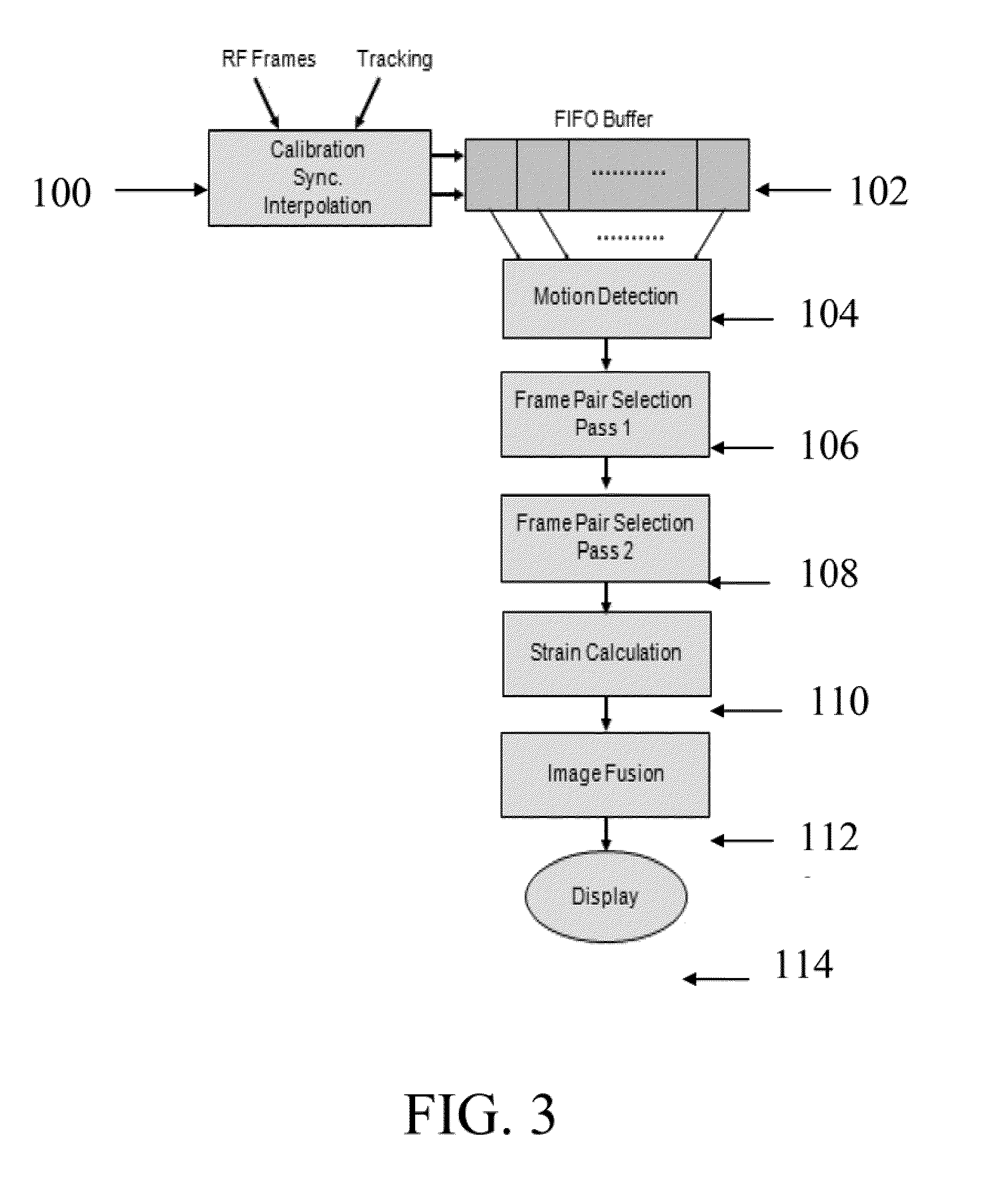

Methods and apparatus for ultrasound strain imaging

ActiveUS20110237945A1Minimize cost functionMedical automated diagnosisInfrasonic diagnosticsUltrasound imagingAccelerometer

A system and method for improved ultrasound strain imaging includes using data from a tracking system to enhance the quality of ultrasound strain image and to reduce the dependency of image quality of the user's expertise. The tracking information is synchronized with the RF frames and interpolated to find the transformation corresponding to each frame. The RF frames with their transformations are incorporated into calculation of ultrasound strain images. The tracking system may be an optical tracker, electromagnetic tracker, accelerometer, or a structured light system. The structured light system may also be used for probe calibration, by calibrating the surface of the probe pre-operatively. In addition, a relative Young's Modulus may be calculated using tracking information that is independent from the distribution of input force.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

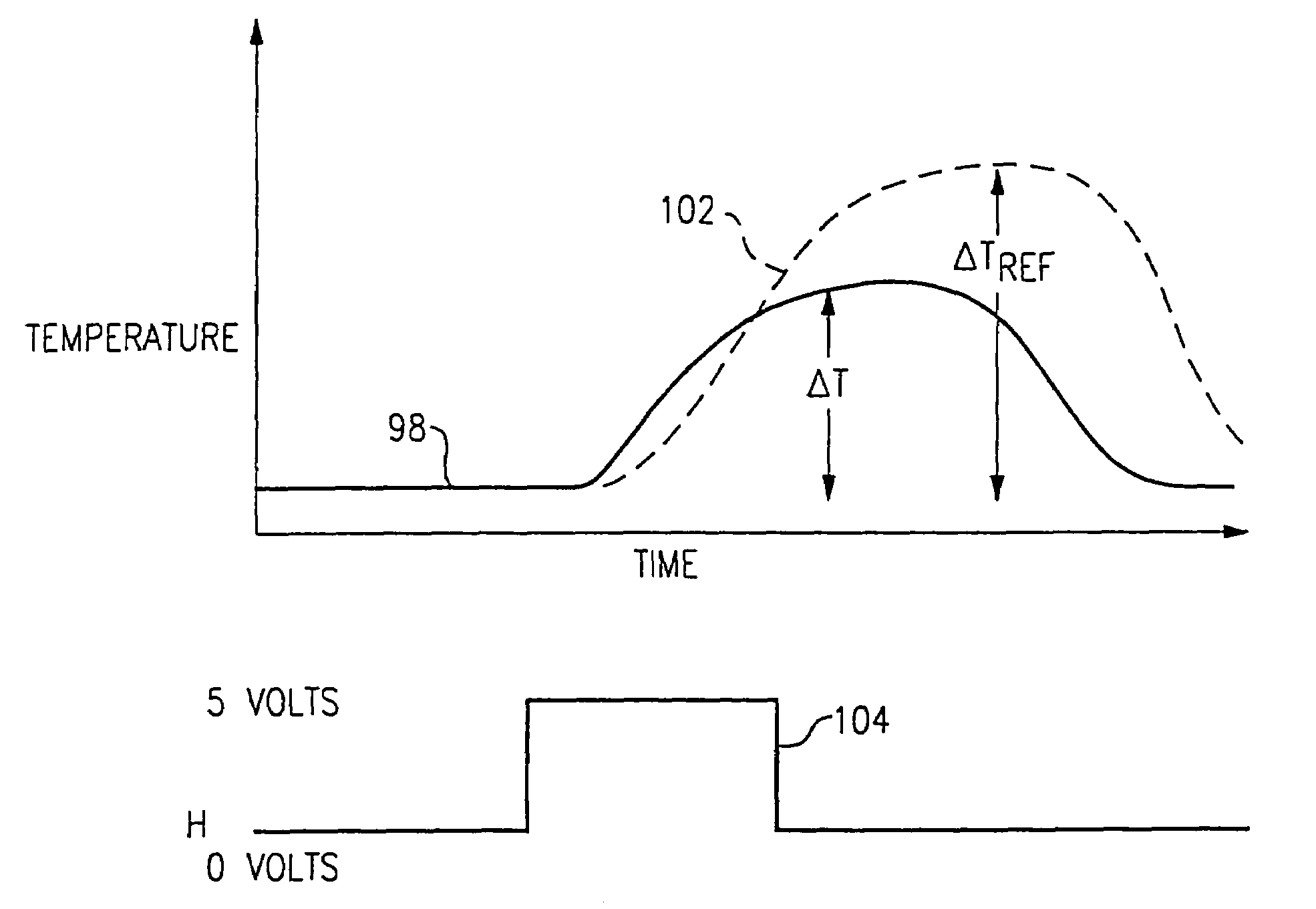

Thermometry probe calibration method

InactiveUS6971790B2Promote normalizationLow costThermometers using electric/magnetic elementsUsing electrical meansProbe calibrationThermal mass

A method in which thermal mass and manufacturing differences are compensated for in thermometry probes by storing characteristic data relating to individual probes into an EEPROM for each probe which is used by the temperature apparatus.

Owner:WELCH ALLYN INC

Methods and systems for machine monitoring system calibration

A method of measuring a clearance distance between a first member and a stationary member is provided. The method includes measuring the clearance distance using a first probe that is removably coupled at least partially within a mounting adapter, determining a first probe calibration based on the measured clearance distance, measuring a gauge clearance distance using a second probe, and modifying the first probe calibration based on the gauge clearance distance.

Owner:GENERAL ELECTRIC CO

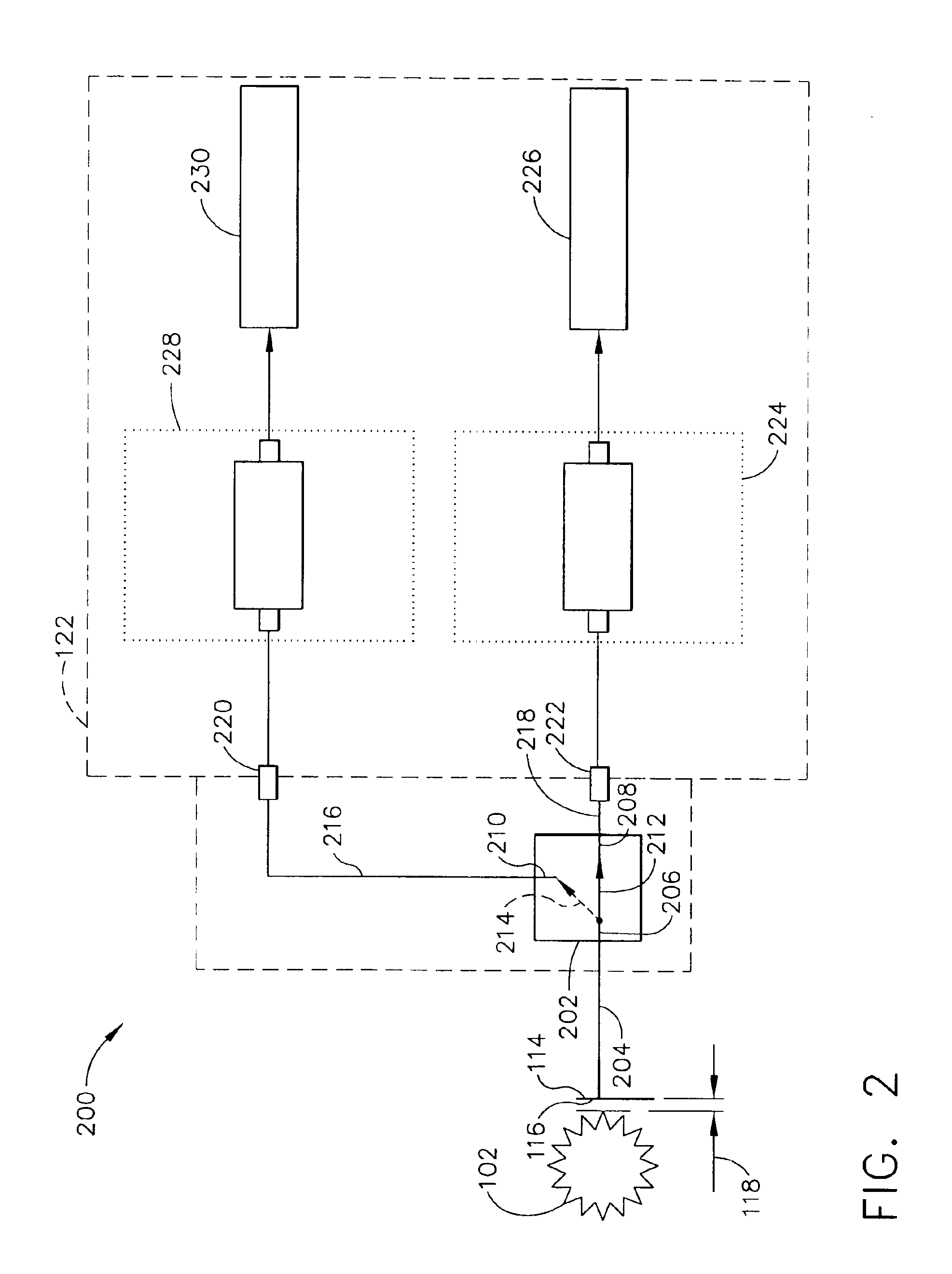

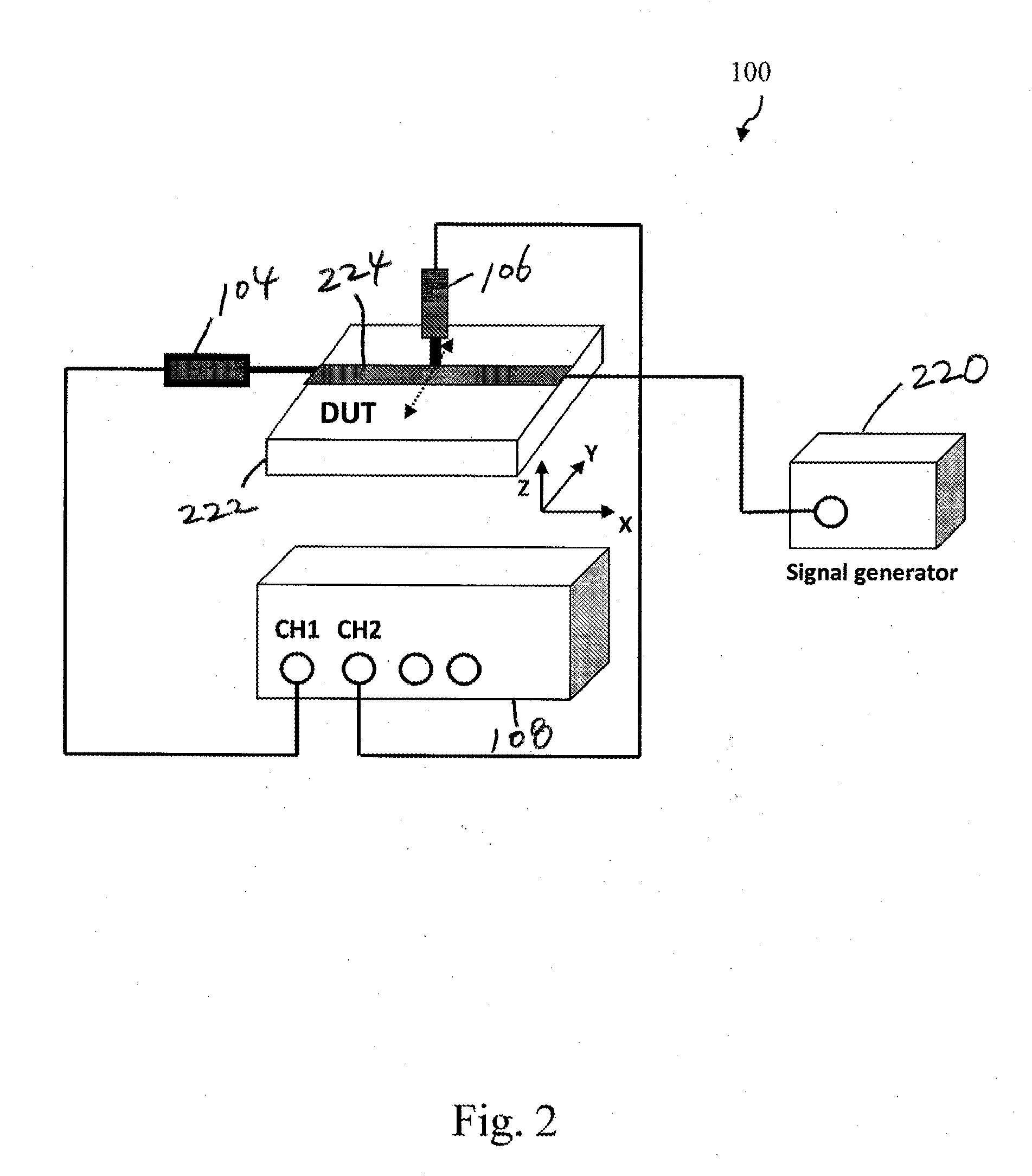

System and method for measuring near field information of device under test

A system and method for measuring near field information of a device under test (DUT) uses a reference probe and a measurement probe that are configured to sense a field. A probe calibration factor is used to determine corresponding field values for signals from the measurement probe at sampling locations about the DUT. The probe calibration factor is derived from measured signals about a conductive trace using a probe and simulated field information for the conductive trace when subjected to a simulated reference signal.

Owner:AMBER PRECISION INSTUMENTS

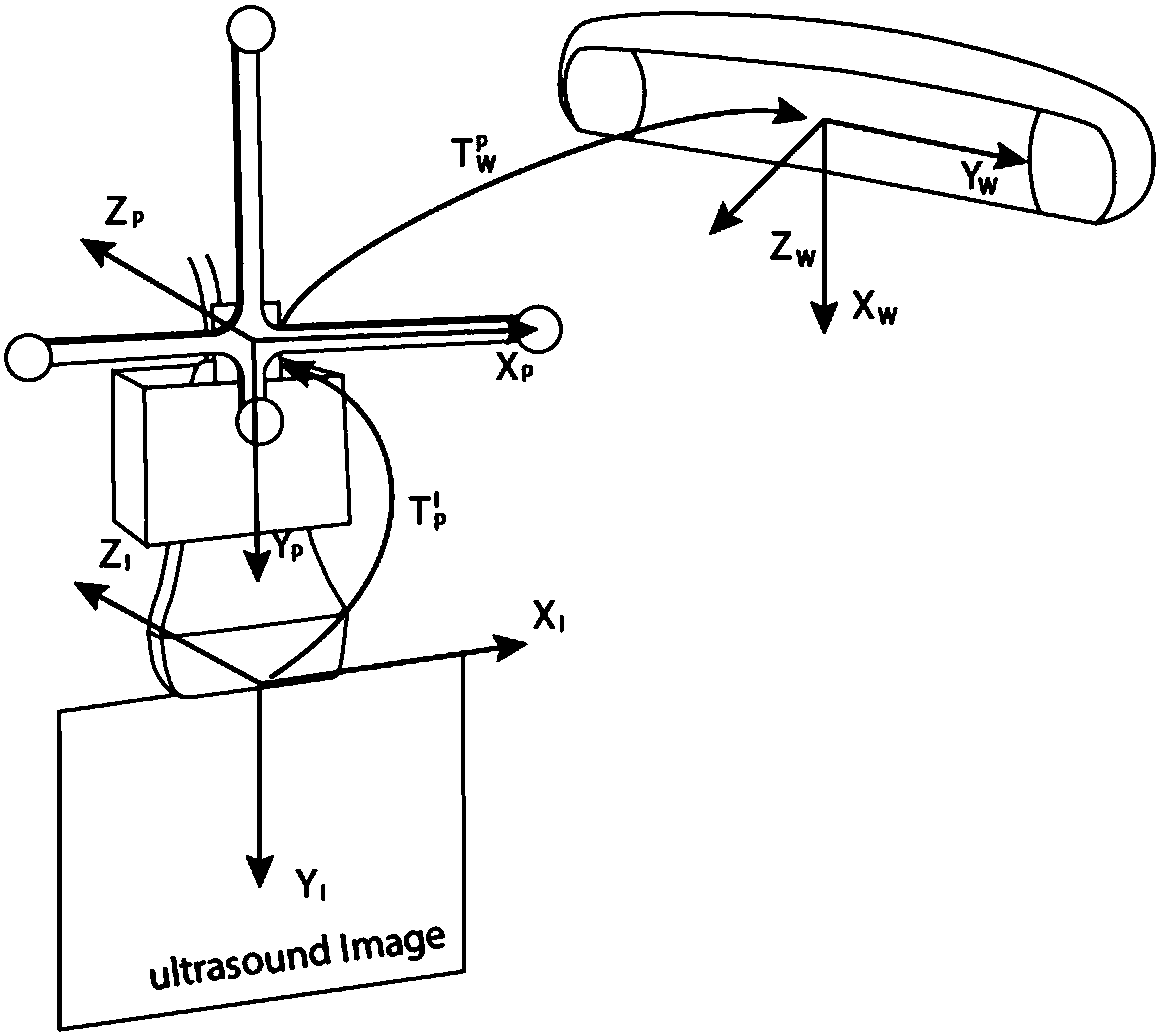

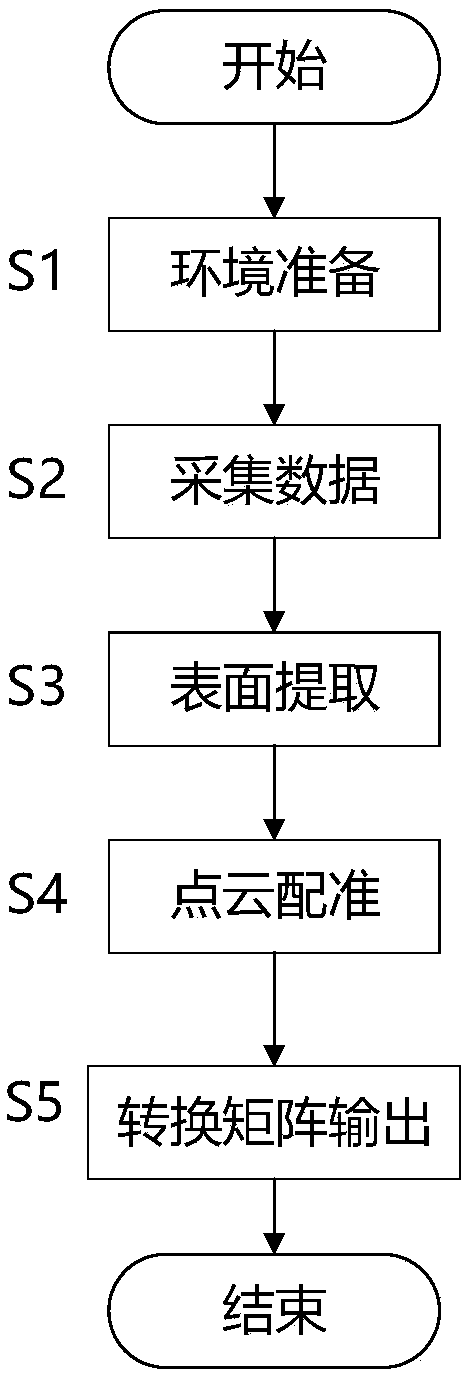

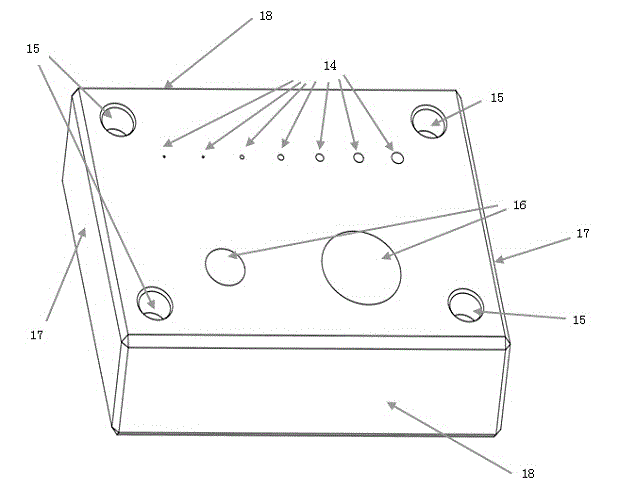

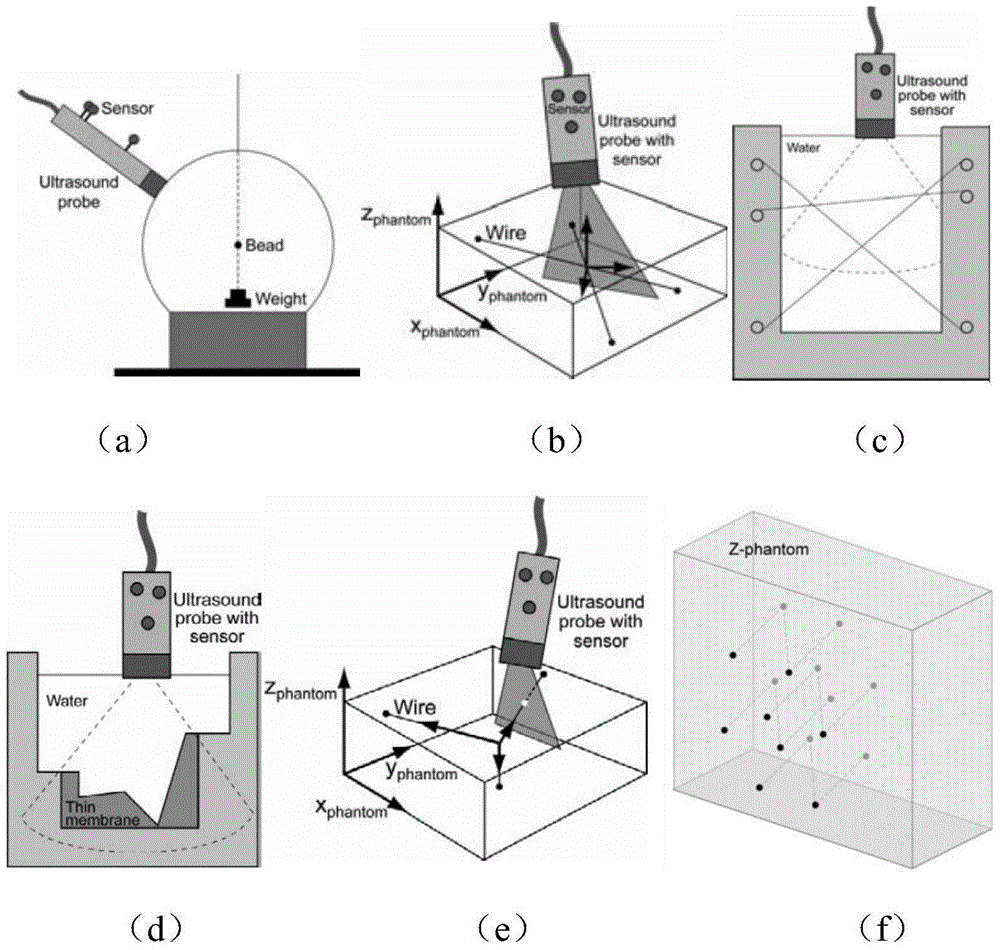

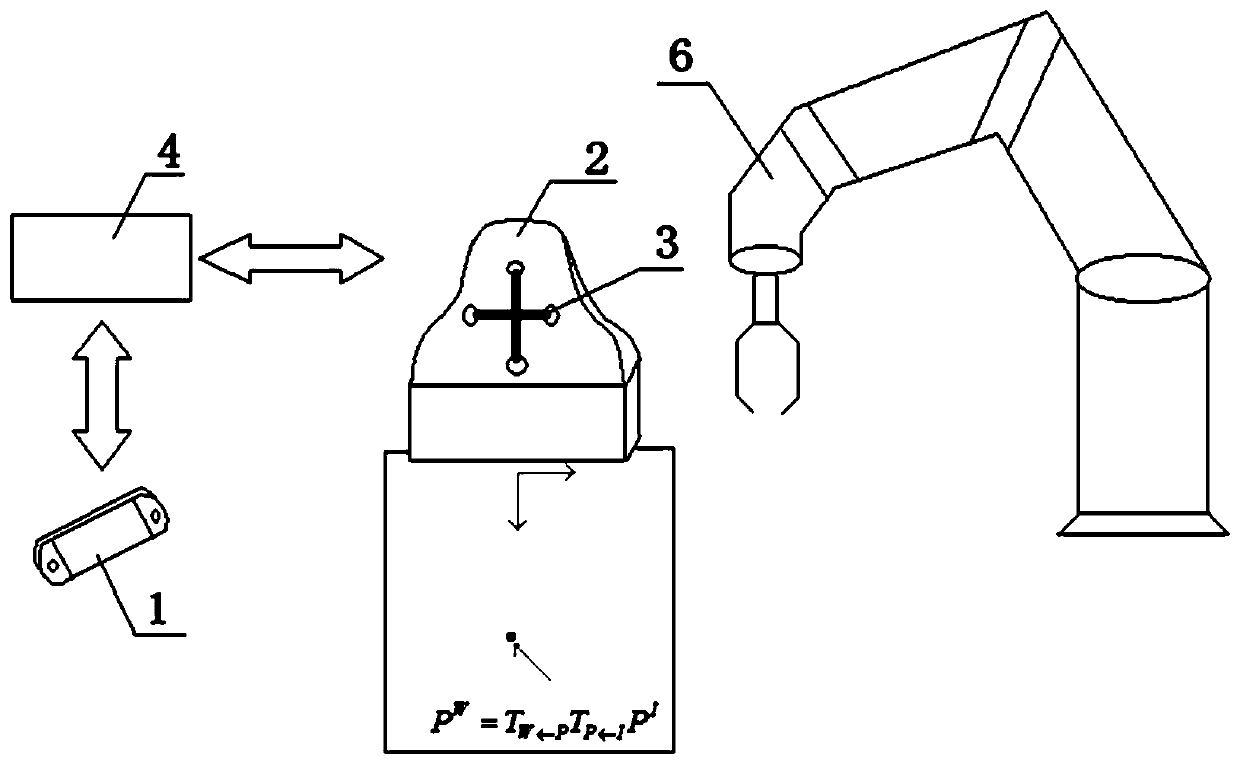

Ultrasonic probe calibration device and method based on optical positioning

InactiveCN107714082AEliminate the effects ofHigh precisionUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsPoint cloudThree-dimensional space

The invention relates to the field of medicine, and in particular relates to an ultrasonic probe calibration device and an ultrasonic probe calibration method based on optical positioning. The ultrasonic probe calibration device based on optical positioning is composed of a visual tracking device, an ultrasonic collecting device, a calibrator and a computer, wherein a tracking identification Marker 1 is fixed on an ultrasonic probe; the calibrator is a water tank with a plurality of trustums of different heights on the bottom, and one side of the calibrator is provided with a tracking identification Marker 2. An ultrasonic probe calibration method based on optical positioning comprises the following steps: segmenting a calibrator ultrasonic image collected by the ultrasonic probe, extracting the bottom picture contour of the calibrator, synchronously acquiring the coordinates of the Marker 1 and Marker 2 and the related position relation according to the visual tracking device, establishing the spatial position relation between the ultrasonic image and visual sense, and carrying out point cloud registration by adopting a coincidence point shift algorithm, and thus the coordinate transformation from the ultrasonic image pixel points to the three-dimensional space is realized. With the device and the method, the transformation precision from two-dimensional ultrasonic image information to three-dimensional space can be improved, and a basis is provided for the surgical navigation system based on the ultrasonic image.

Owner:BEIHANG UNIV

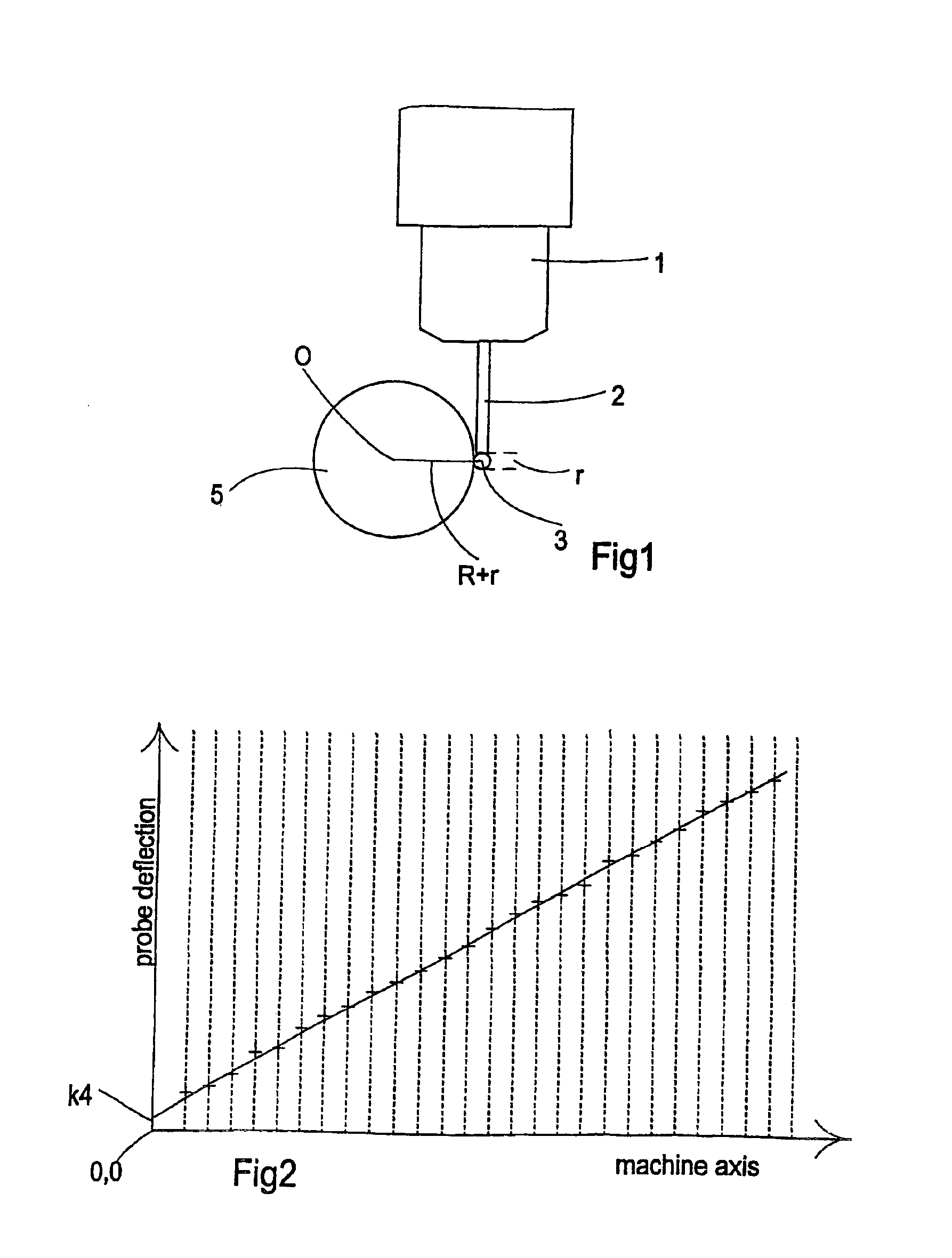

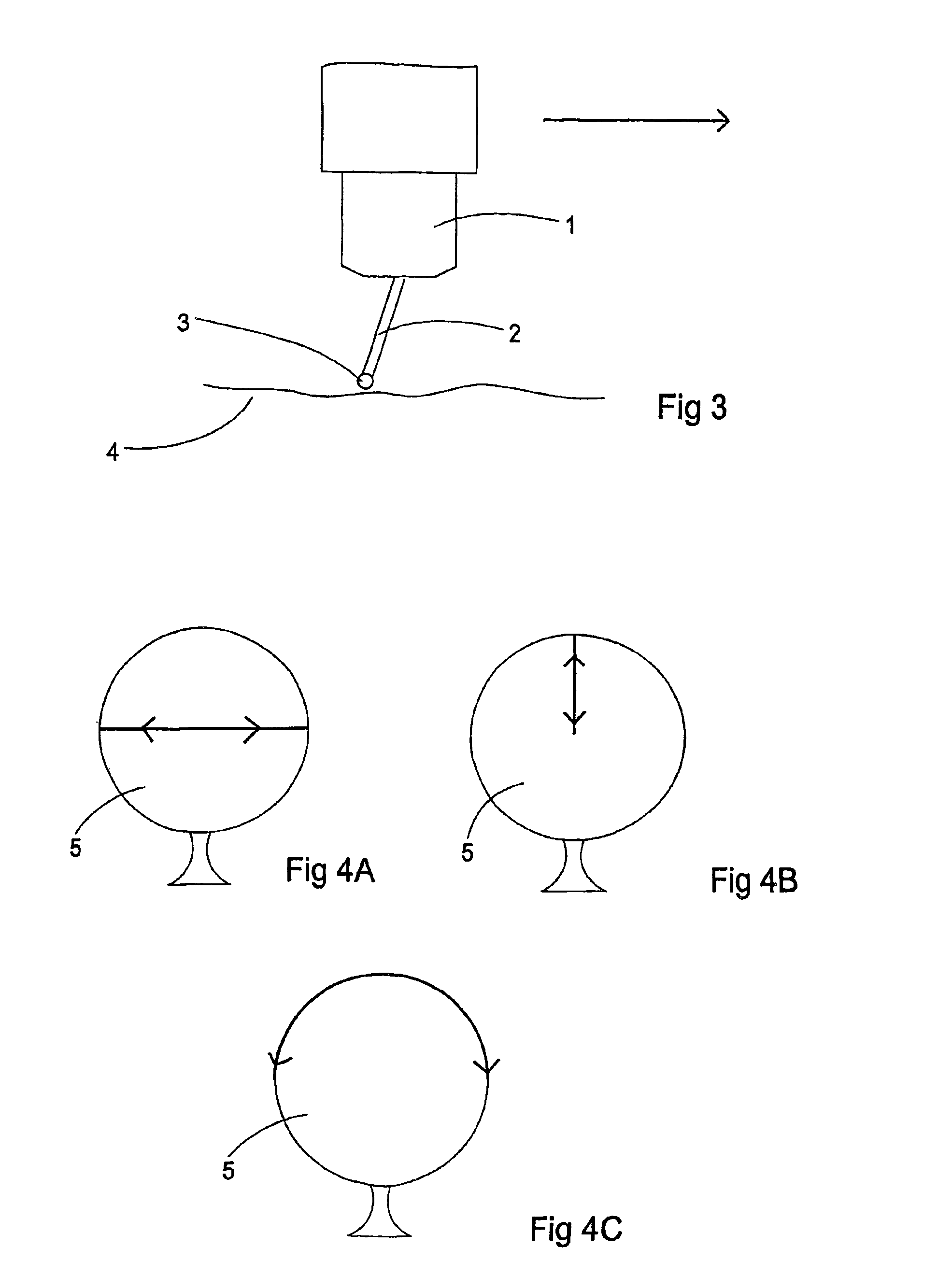

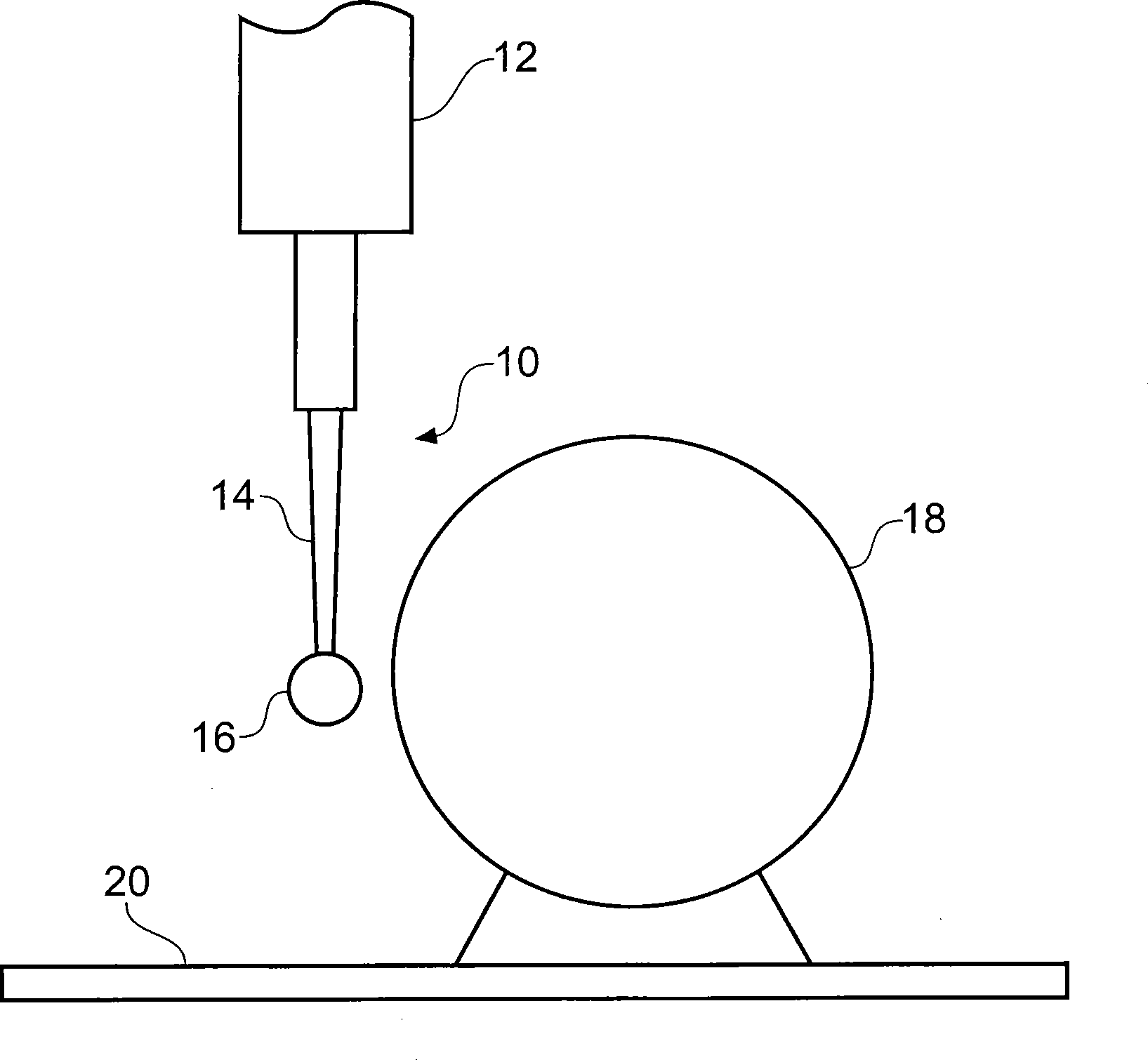

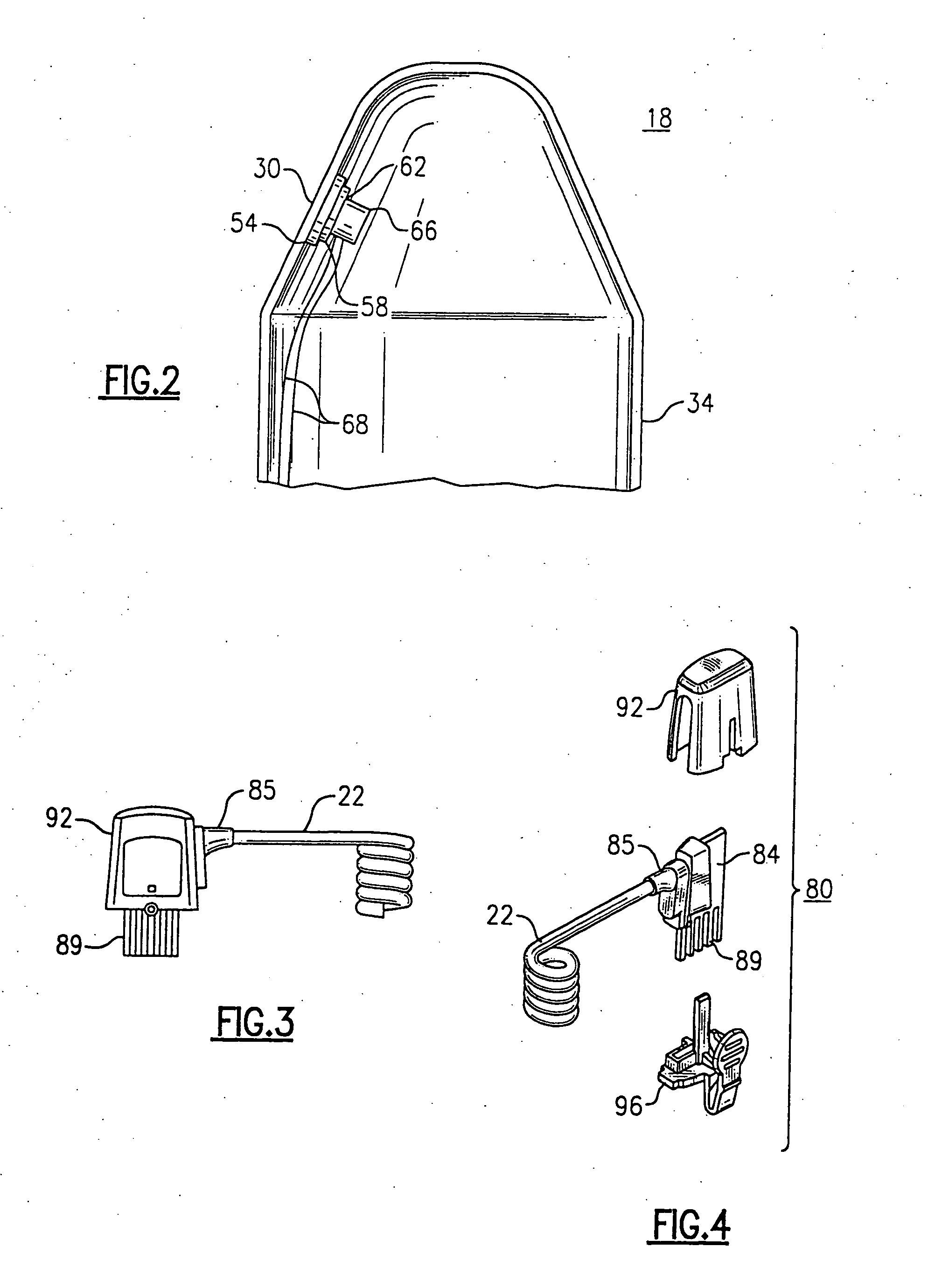

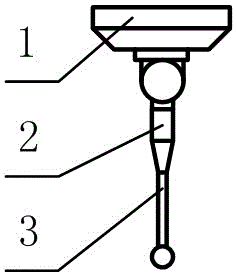

Differential calibration

ActiveCN101432592ARemove geometric errorsSuitable for 2D applicationsMeasurement devicesProbe calibrationPhysics

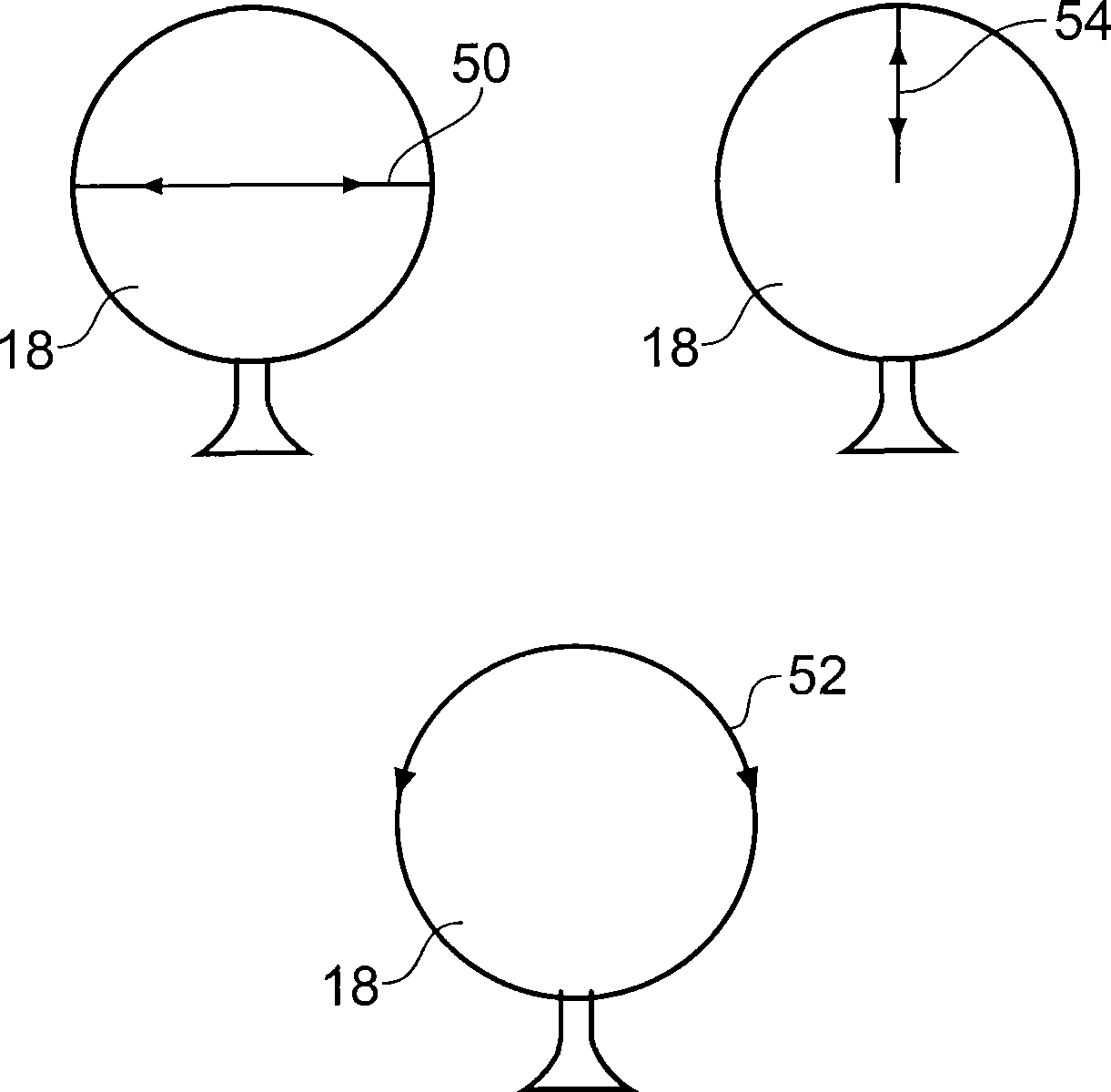

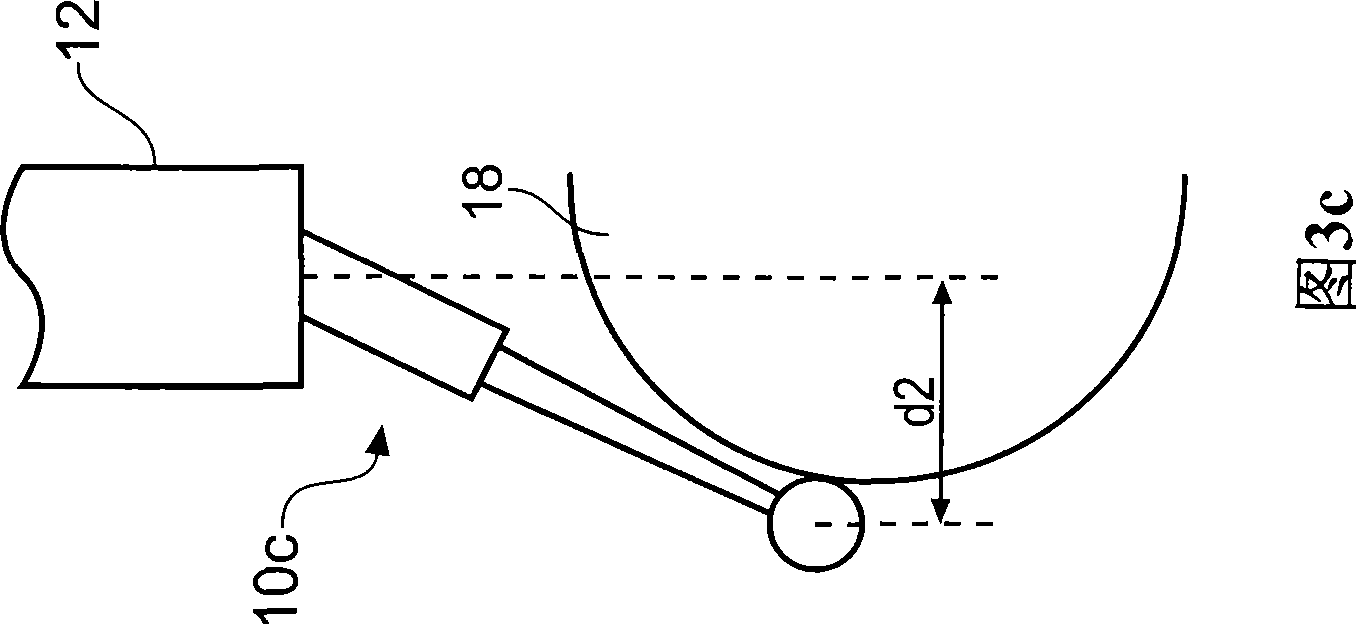

A method of calibrating a measurement probe (10) mounted on a machine is described. The measurement probe (10) has a stylus (14) with a workpiece contacting tip (16). The method comprises determining a probe calibration matrix that relates the probe outputs (a,b,c) to the machine coordinate system (x,y,z.). The method comprising the steps of scanning a calibration artefact (18) using a first probe deflection (d1) to obtain first machine data and using a second probe deflection (d2) to obtain second machine data. The first and second machine data are used to obtain a pure probe calibration matrix in which any machine errors are substantially omitted. Advantageously, the method determines the pure probe matrix numerically based on the assumption that the difference between the first and second machine position data is known.

Owner:RENISHAW PLC

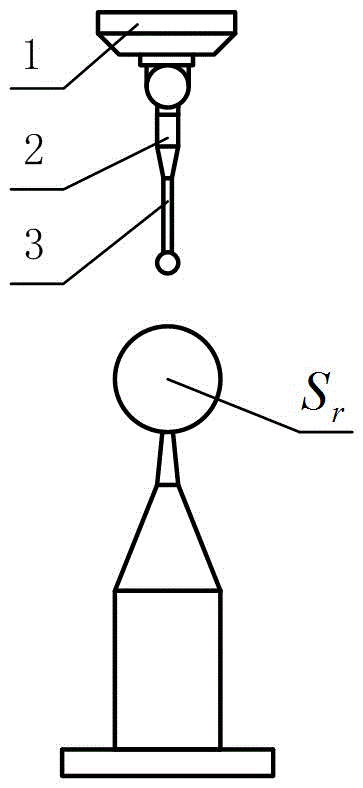

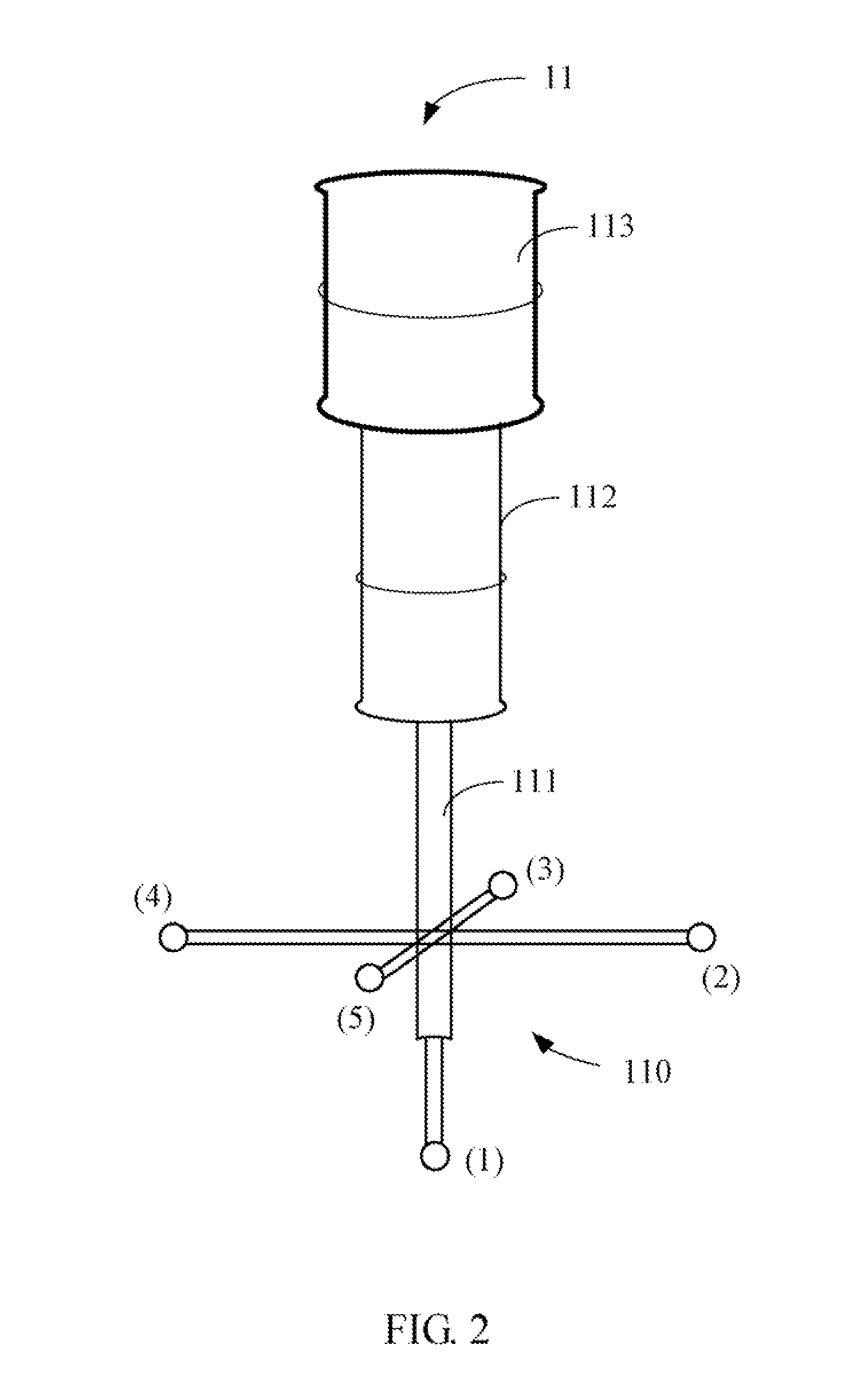

Pose estimation-based quick probe calibration device and method

InactiveCN104807476ARapid and accurate calibrationReplace at any timeUsing optical meansImaging processingOptical measurements

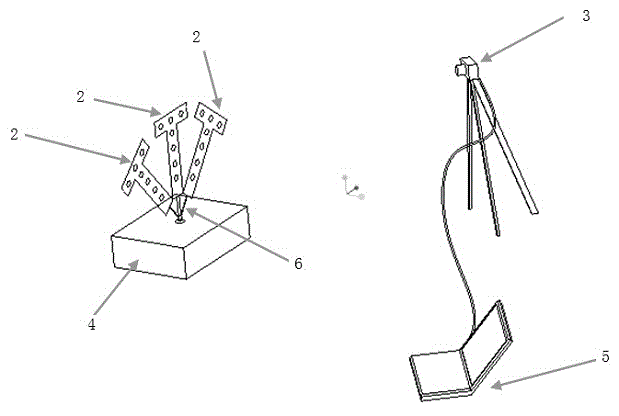

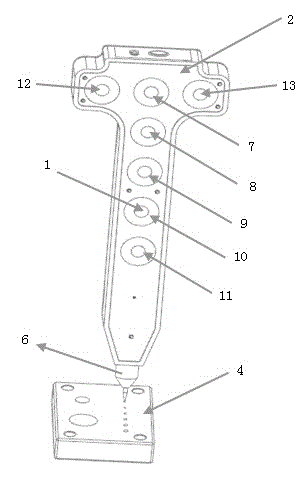

The invention relates to a pose estimation-based quick probe calibration device and method. The device comprises a probe with established distribution objective targets, a camera, a calibration accessory and a computer. The pose estimation-based quick probe calibration method comprises the following steps: the calibration accessory is placed within a camera viewing field range; the front end of a measuring head of the probe is placed in a fixed hole in the calibration accessory; the probe is swung along the fixed hole to enable the probe to be in n different poses, wherein n is a natural number greater than or equal to 3; meanwhile, the camera is used to shoot current poses of the probe, wherein the camera is connected with the computer; the collected images are utilized to obtain pose parameters of different poses on the computer through an image processing method, and accurate three-dimensional coordinates of center points of all of the objective targets in a right-handed coordinate system in which the measuring head center of the probe is used as an original point are calculated through related algorithms. The device and the method provided by the invention lay the foundation of the precision guarantee of a non-contact optical measurement system.

Owner:SHANGHAI UNIV

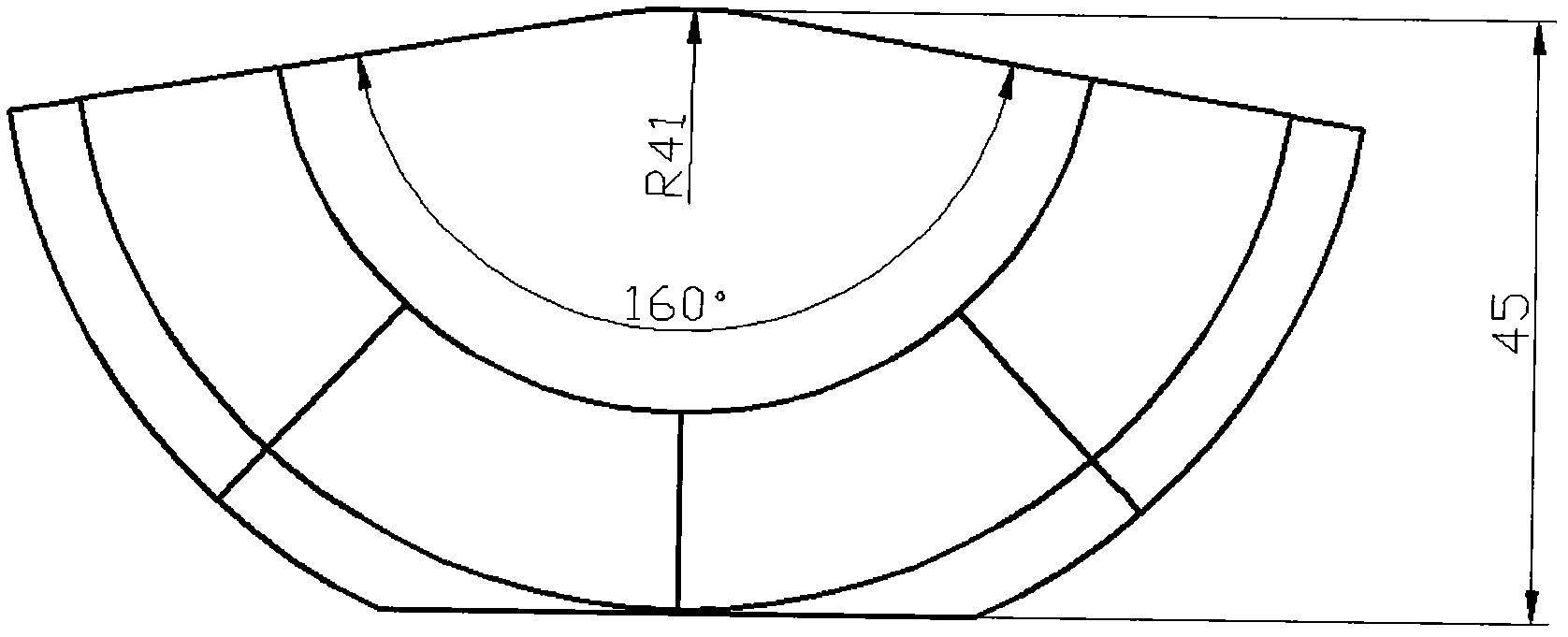

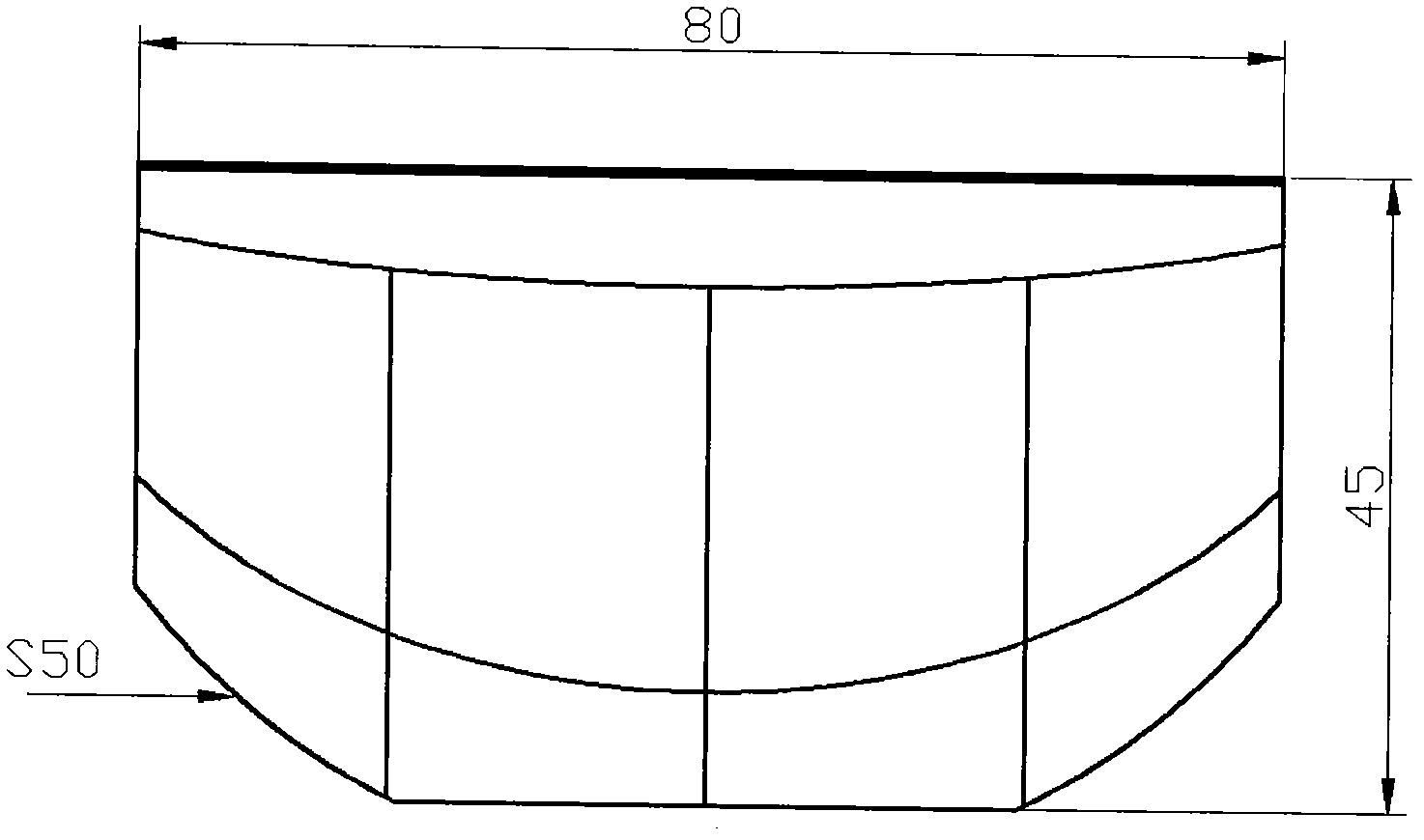

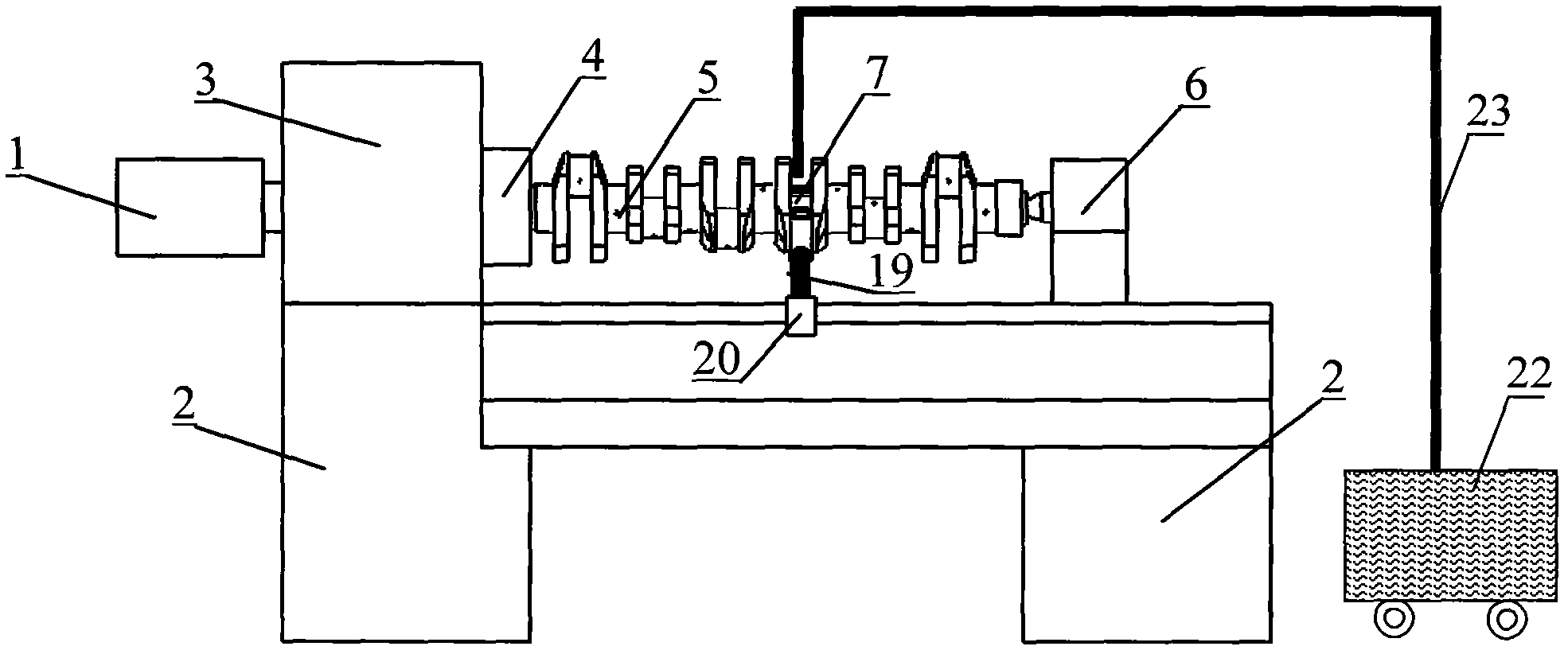

Automatic ultrasonic detecting method and device of defects inside old crank of engine

InactiveCN101975821AThe detection process is fastImprove detection accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesSingle crystalEngineering

The invention relates to an automatic ultrasonic detecting method and device of defects inside an old crank of an engine, belonging to the field of automatic ultrasonic detection. The method comprise the steps of: firstly, calibrating a single crystal angle probe by adopting a crank probe calibration test block, determining detection parameters of a real front rake angle beta and a real side rake angle beta' of the probe, a probe zero point, material sound velocity of the crank, and the like; and then detecting the crank by adopting a crank automatic ultrasonic detection device, wherein the detection device comprises a crank clamp and an ultrasonic probe clamp, the crank clamp is used for clamping the crank and enabling the crank to rotate at constant speed, the ultrasonic probe clamp is used for clamping the probe, and after the crank rotates for one circle, the probe can check a shaft neck for one circle. Internal defects of the shaft neck and an R angle can be automatically detected by adopting one probe, thus the reliability and the detection efficiency are furthest improved. The method can be used for detecting the defects of cracks, impurities, air holes and the like with equivalent size of above 1mm inside the shaft neck and at the R angle.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

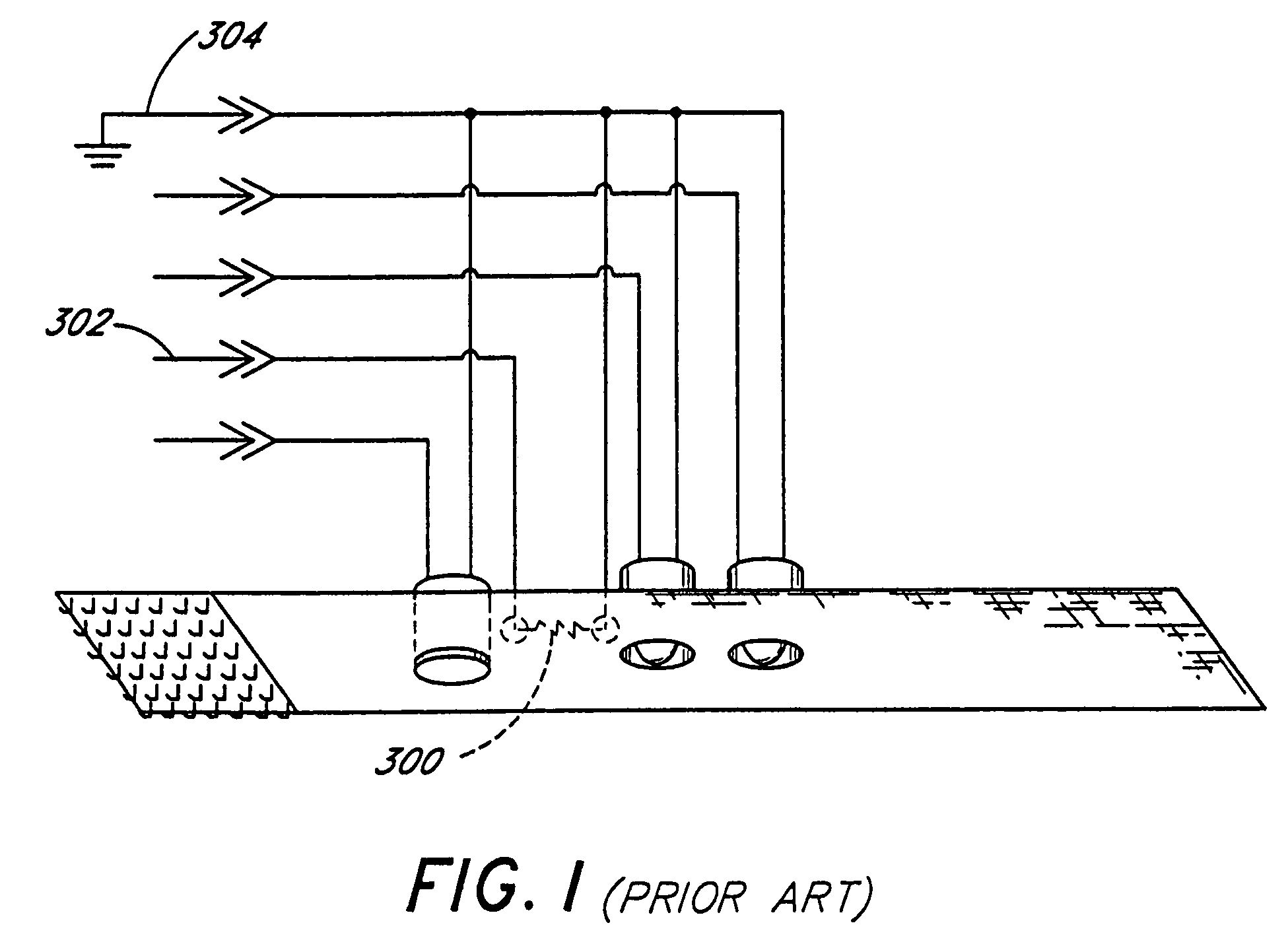

Manual and automatic probe calibration

InactiveUS20070112260A1Complicates designIncreased expenseRadiation pyrometrySpectrum investigationUltrasound attenuationPatient monitor

Embodiments of the present disclosure include an optical probe capable of communicating identification information to a patient monitor in addition to signals indicative of intensities of light after attenuation by body tissue. The identification information may indicate operating wavelengths of light sources, indicate a type of probe, such as, for example, that the probe is an adult probe, a pediatric probe, a neonatal probe, a disposable probe, a reusable probe, or the like. The information could also be utilized for security purposes, such as, for example, to ensure that the probe is configured properly for the oximeter, to indicate that the probe is from an authorized supplier, or the like. In one preferred embodiment, coding resistors could be provided across the light sources to allow additional information about the probe to be coded without added leads. However, any device could be used without it being used in parallel.

Owner:JPMORGAN CHASE BANK NA

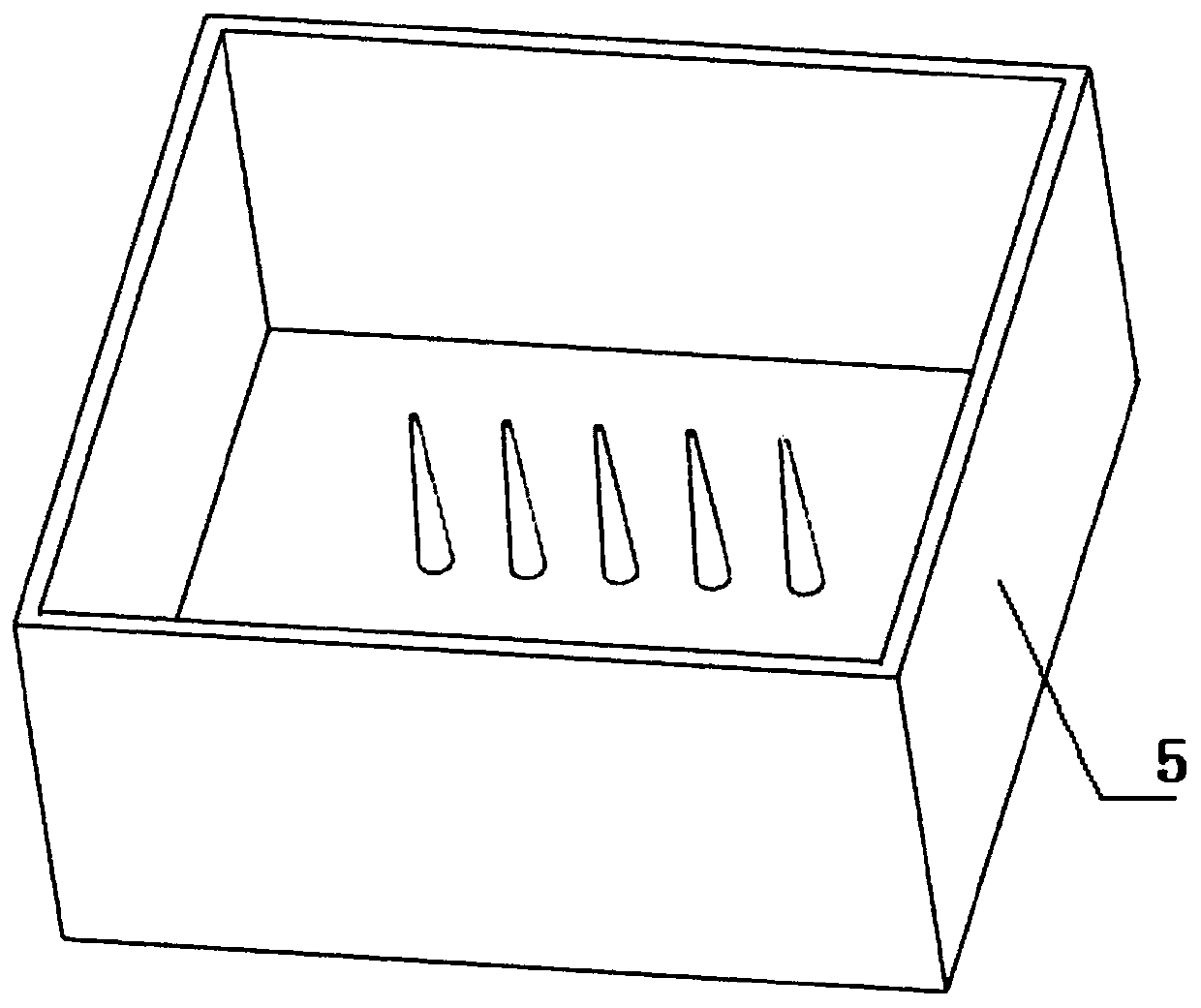

Ultrasonic probe calibration phantom and system as well as ultrasonic probe calibration method

ActiveCN105193445AImprove practicalityAvoid Unintended Jitter ErrorsUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsSurface typeProbe calibration

The invention provides an ultrasonic probe calibration phantom and system. A concaved groove is formed in the middle position of the upper surface of the ultrasonic probe calibration phantom, a plurality of taper holes are formed in the side surface of the ultrasonic probe calibration phantom, a two-dimensional ultrasonic probe is fixedly connected in the concave groove, NDI puncture probes are inserted into the taper holes, and tip ends of the NDI puncture probes can be acquired through ultrasound images. According to the ultrasonic probe calibration system adopting the structure, a neutral surface of the ultrasonic plane can just pass by the neutral surface of the ultrasonic probe calibration phantom along the middle seams, and the neutral surface of the ultrasonic plane just uses the tip ends of the NDI puncture probes, and the problem that a ''dot-type'' phantom and a two-dimensional ''surface-type'' phantom cannot be aligned to the ultrasonic plane is well solved. Besides, the invention further provides an ultrasonic probe calibration method.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

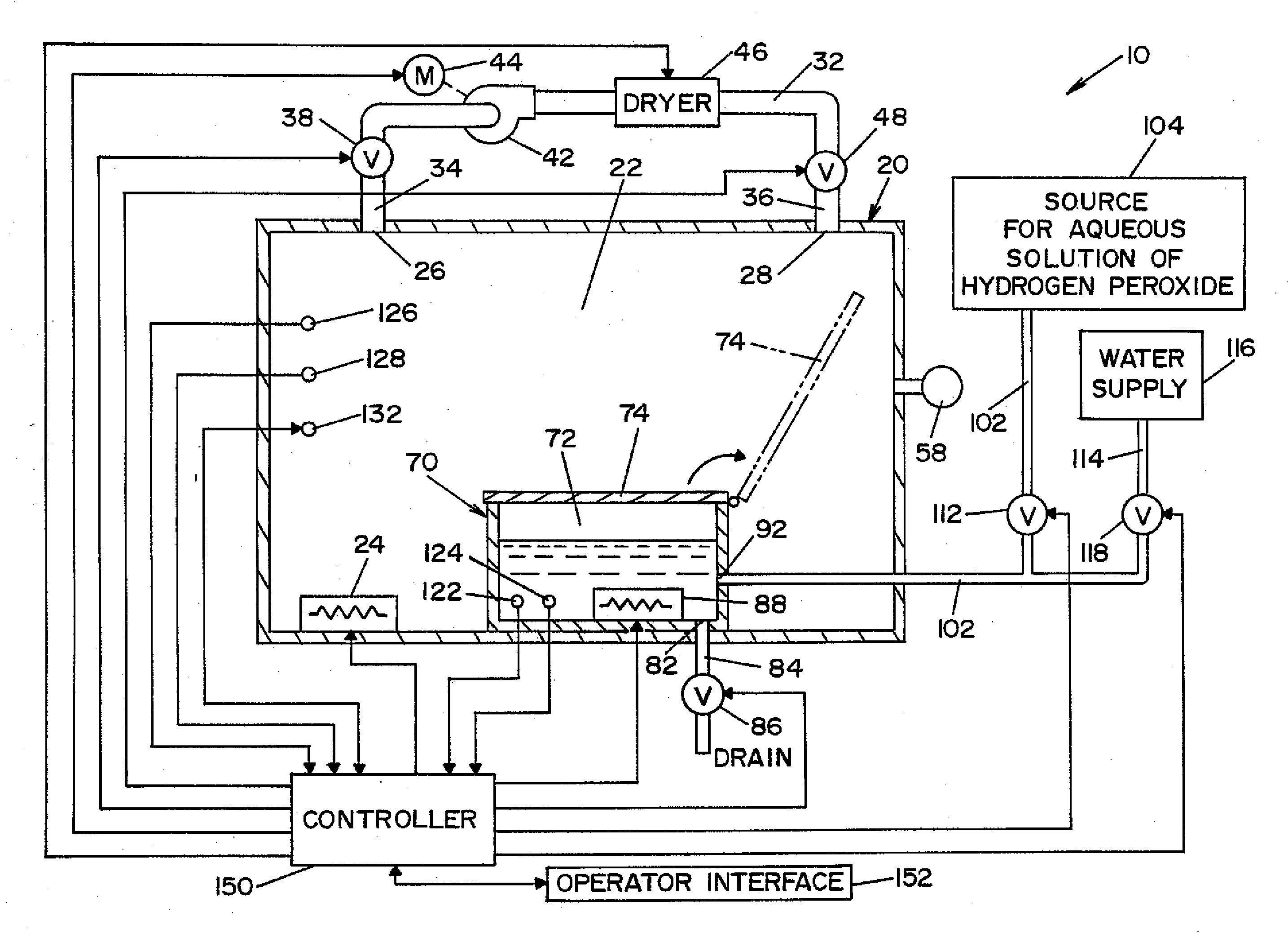

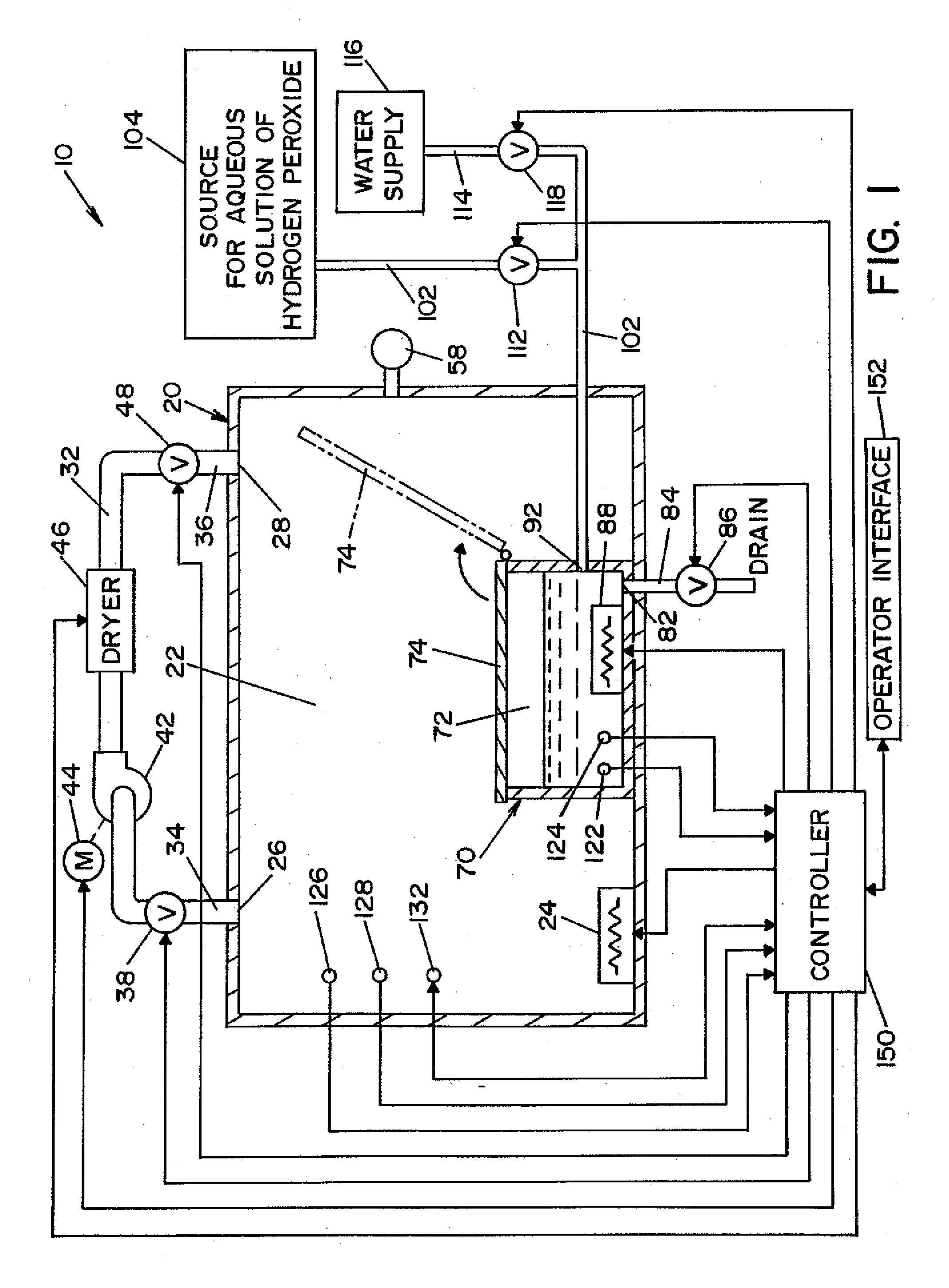

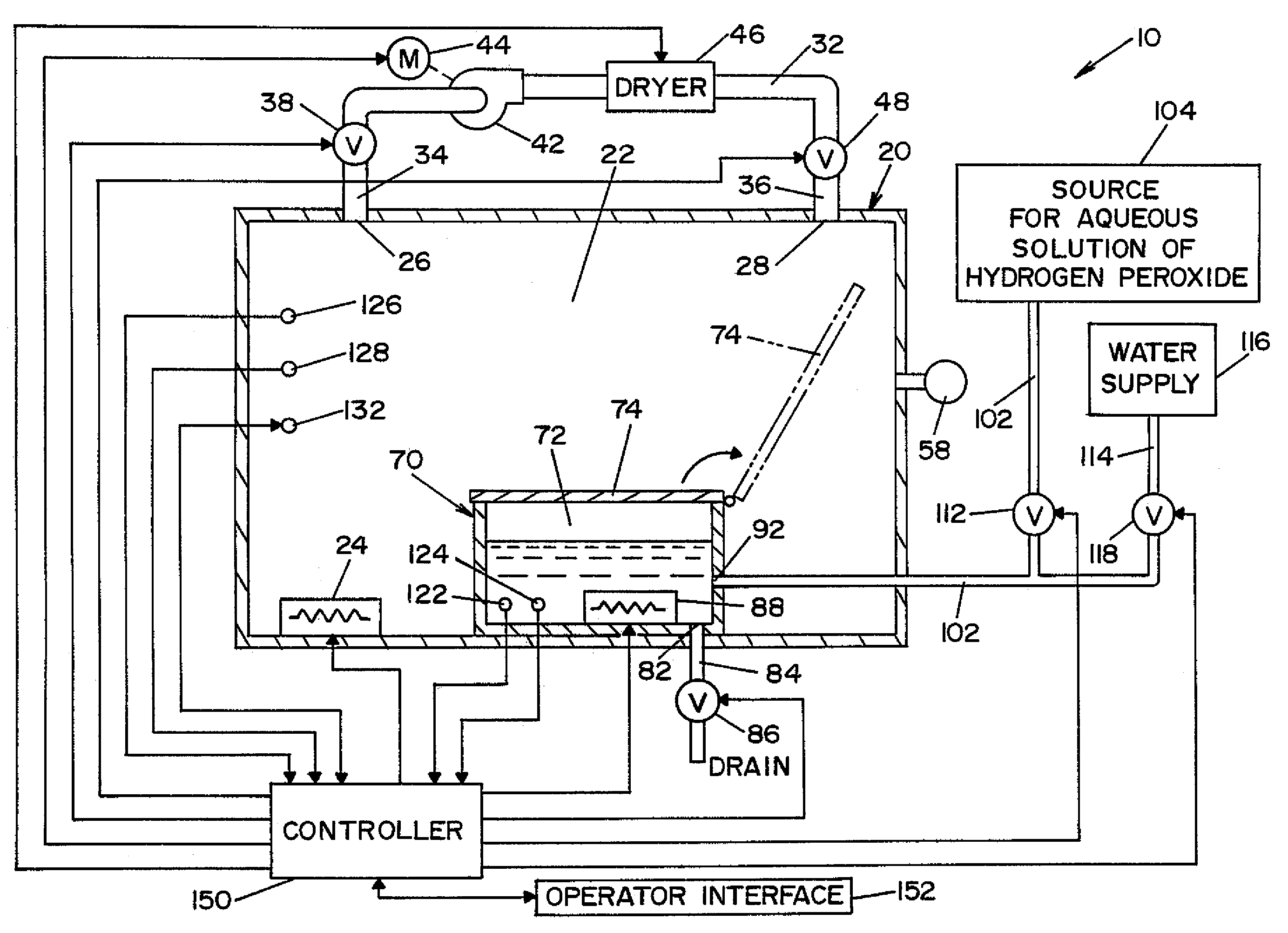

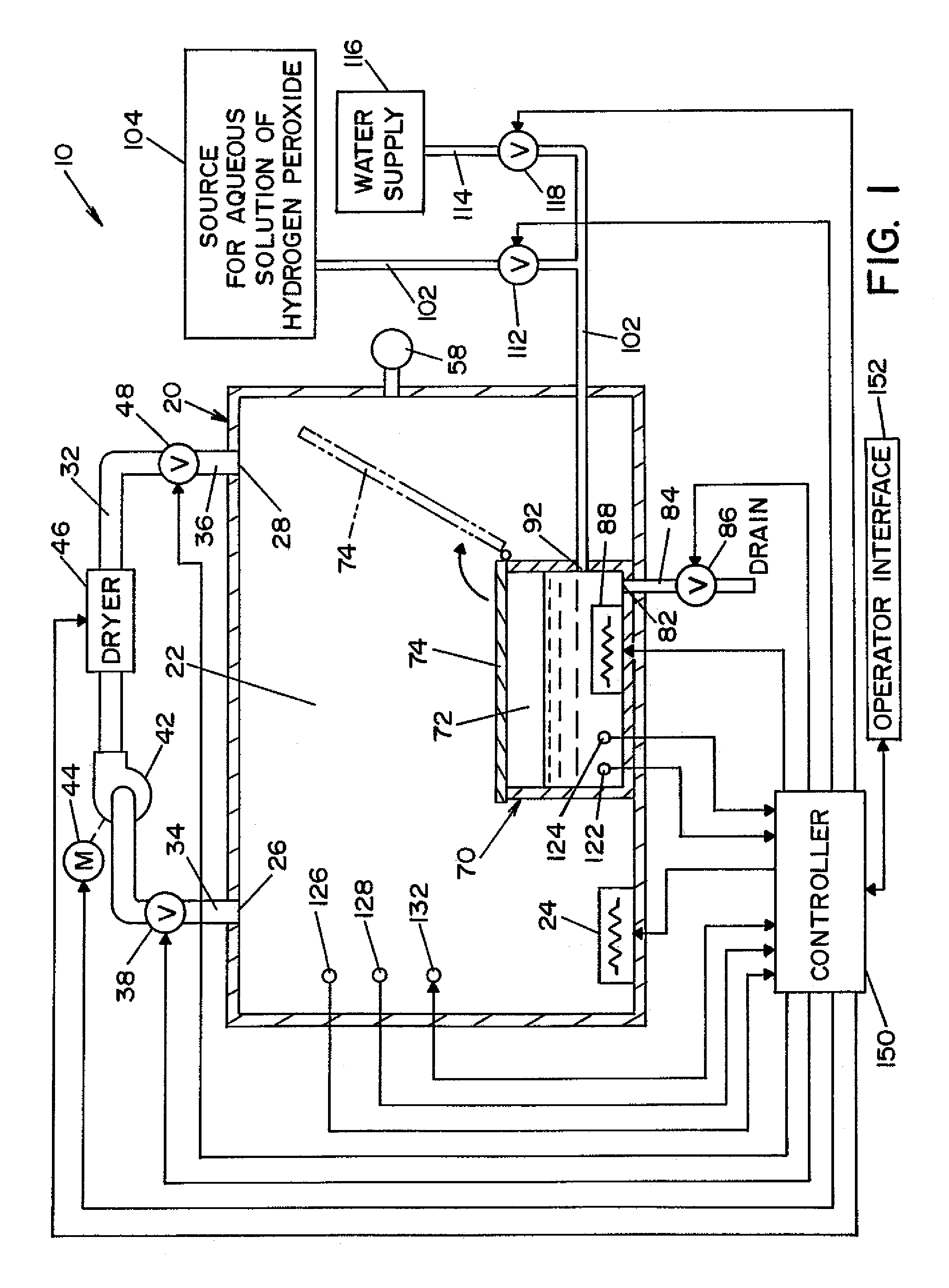

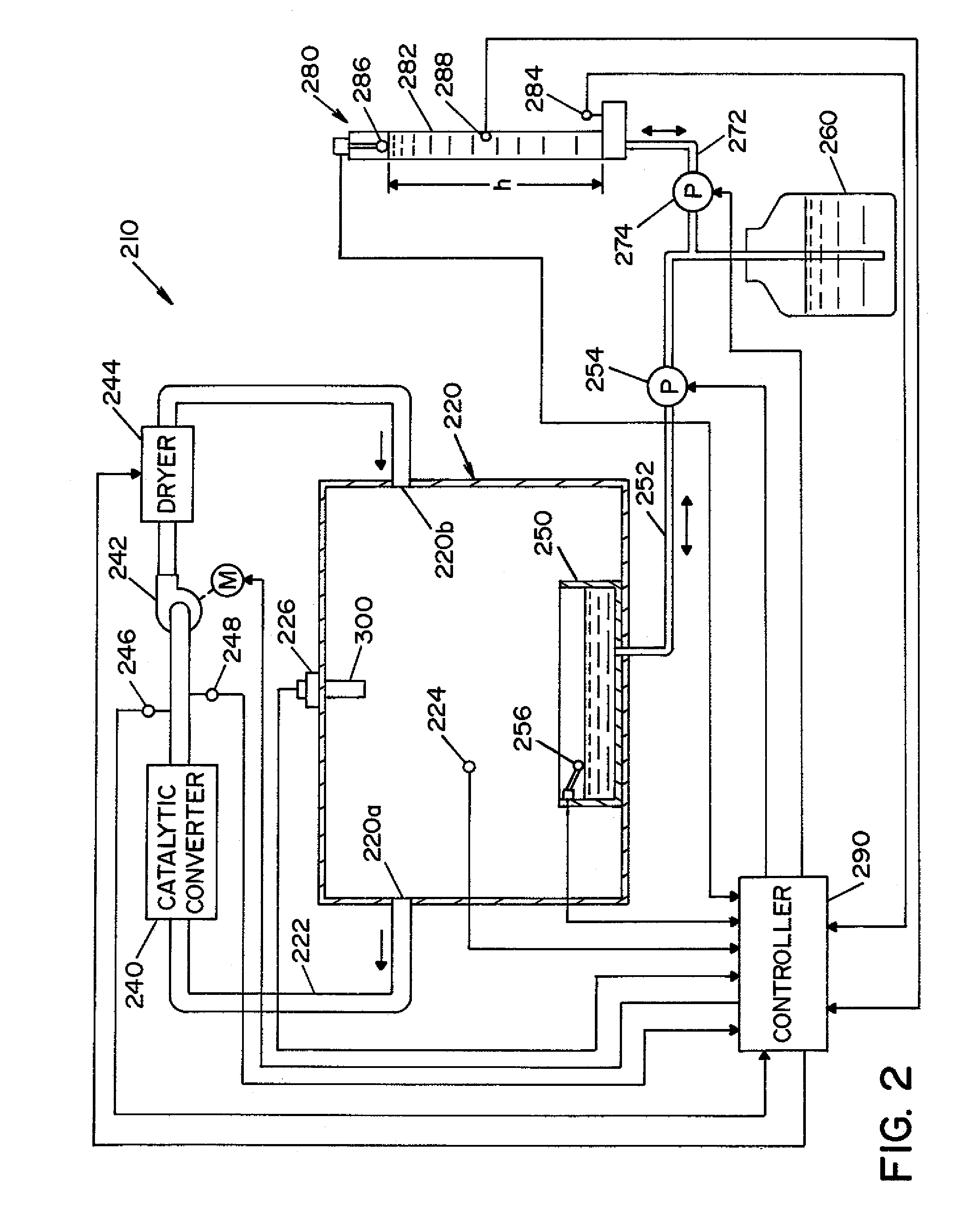

Vaporized hydrogen peroxide probe calibration rig

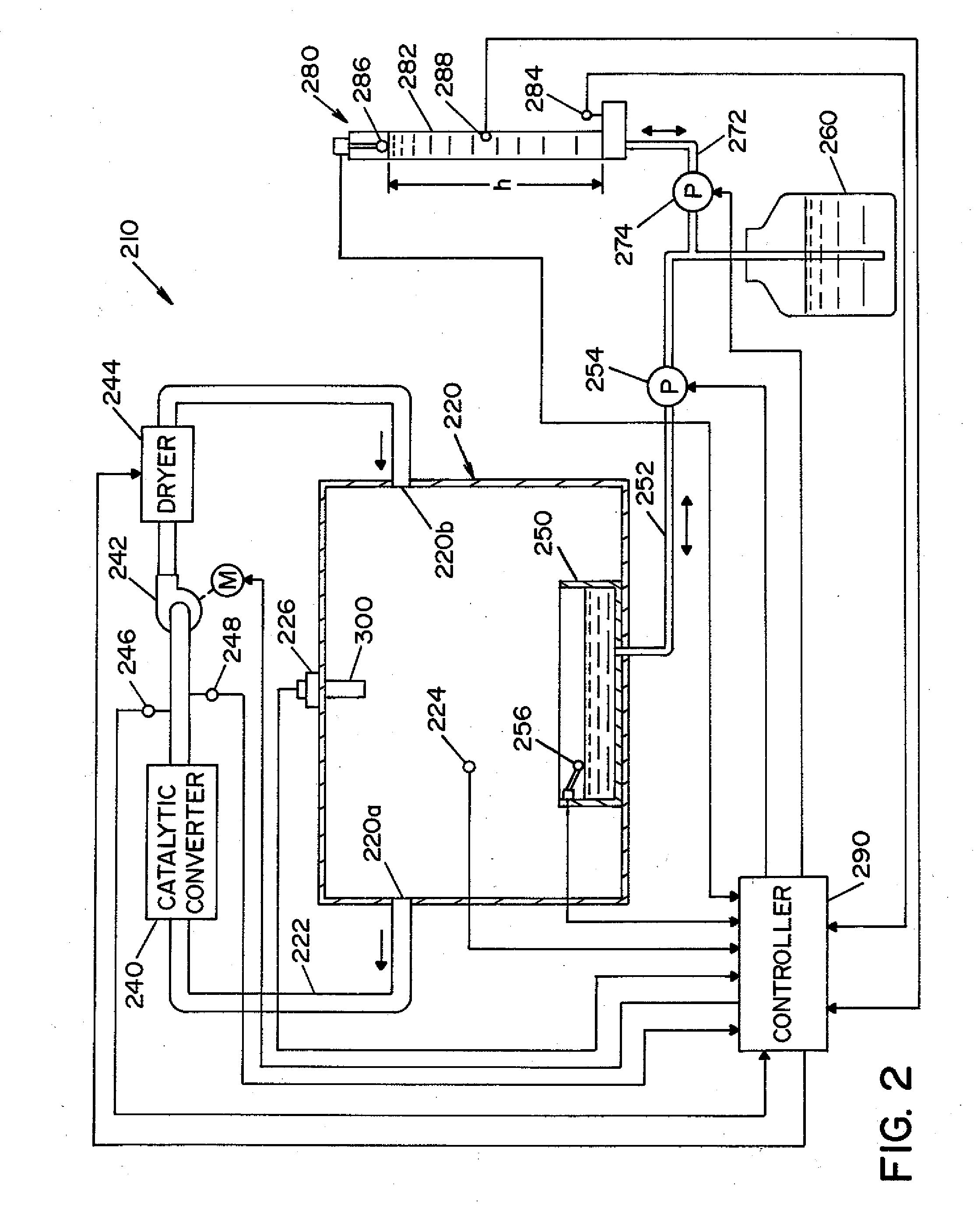

ActiveUS20080264140A1Accurate CalibrationMaterial analysis by electric/magnetic meansMaterial analysis by optical meansLiquid hydrogenAqueous solution

A method and apparatus for calibrating a sensor used to sense the concentration of vaporized hydrogen peroxide (VHP). A concentration of liquid hydrogen peroxide in an aqueous solution is determined and correlated with a corresponding concentration of vaporized hydrogen peroxide indicative of an “actual” vaporized hydrogen peroxide concentration. An error value is determined by comparing the “actual” vaporized hydrogen peroxide concentration to a “measured” vaporized hydrogen peroxide concentration, indicated by the sensor being calibrated. The error value is used to properly calibrate the sensor.

Owner:AMERICAN STERILIZER CO

Thermometry probe calibration method

InactiveUS20060072645A1Promote normalizationMinimize the differenceThermometers using electric/magnetic elementsUsing electrical meansProbe calibrationThermal mass

Owner:WELCH ALLYN INC

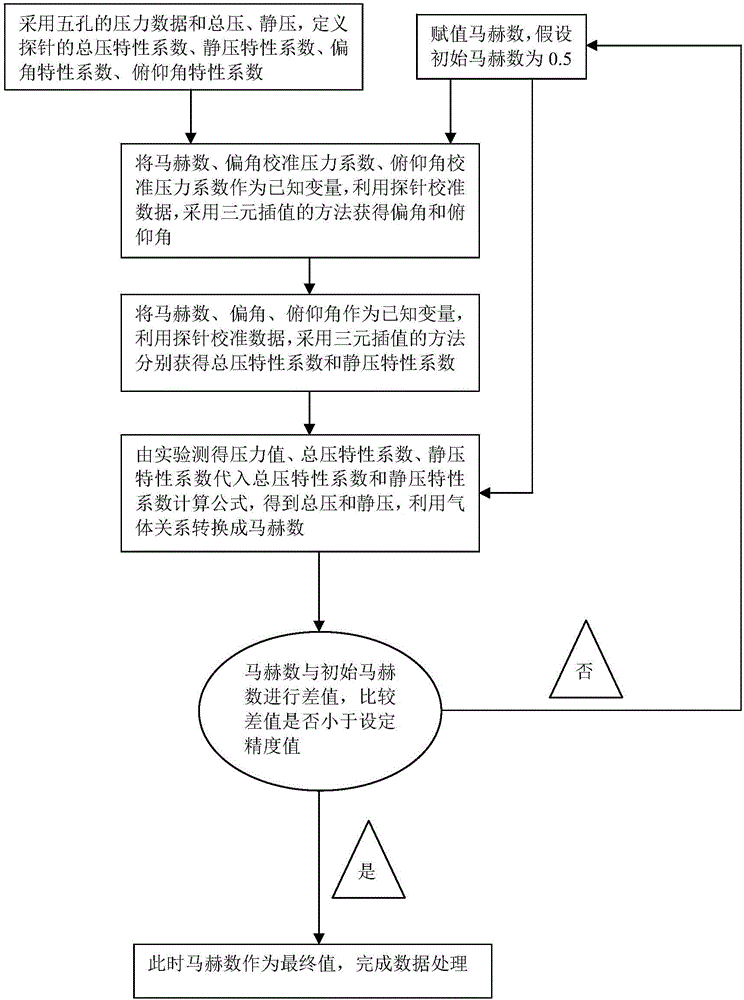

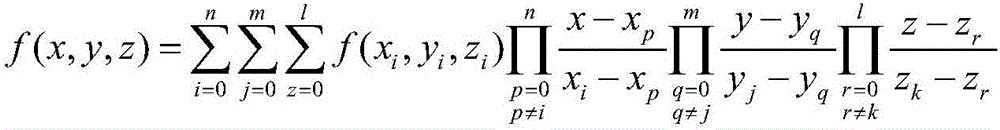

Data processing method for five-hole probe

ActiveCN106096223AHigh precisionImprove convenienceInformaticsSpecial data processing applicationsPressure dataProbe calibration

The invention discloses a data processing method used for improving the application efficiency of a five-hole probe, and the method is a triple interpolation-based data processing method for the five-hole probe. The method comprises the steps of firstly, assuming a Mach number, taking Mach number, deflection angle and pitch angle calibration pressure coefficients as known variables, substituting probe calibration data, and obtaining a deflection angle and a pitch angle by adopting triple interpolation; secondly, taking the Mach number, the deflection angle and the pitch angle as known variables, and obtaining total pressure and static pressure characteristic coefficients separately by adopting the triple interpolation; thirdly, substituting an experimental measurement value and the total pressure and static pressure characteristic coefficients into total pressure and static pressure characteristic coefficient formulae, and performing calculation to obtain a total pressure, a static pressure and a Mach number; and finally, performing difference operation on the obtained Mach number and the assumed Mach number, and performing iterative computing until a difference value is smaller than a set precision value. According to the novel data processing method, the pressure data measured by a five-hole probe experiment can be quickly and conveniently converted into flow field velocity magnitude and direction, and the data interpolation precision can be improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

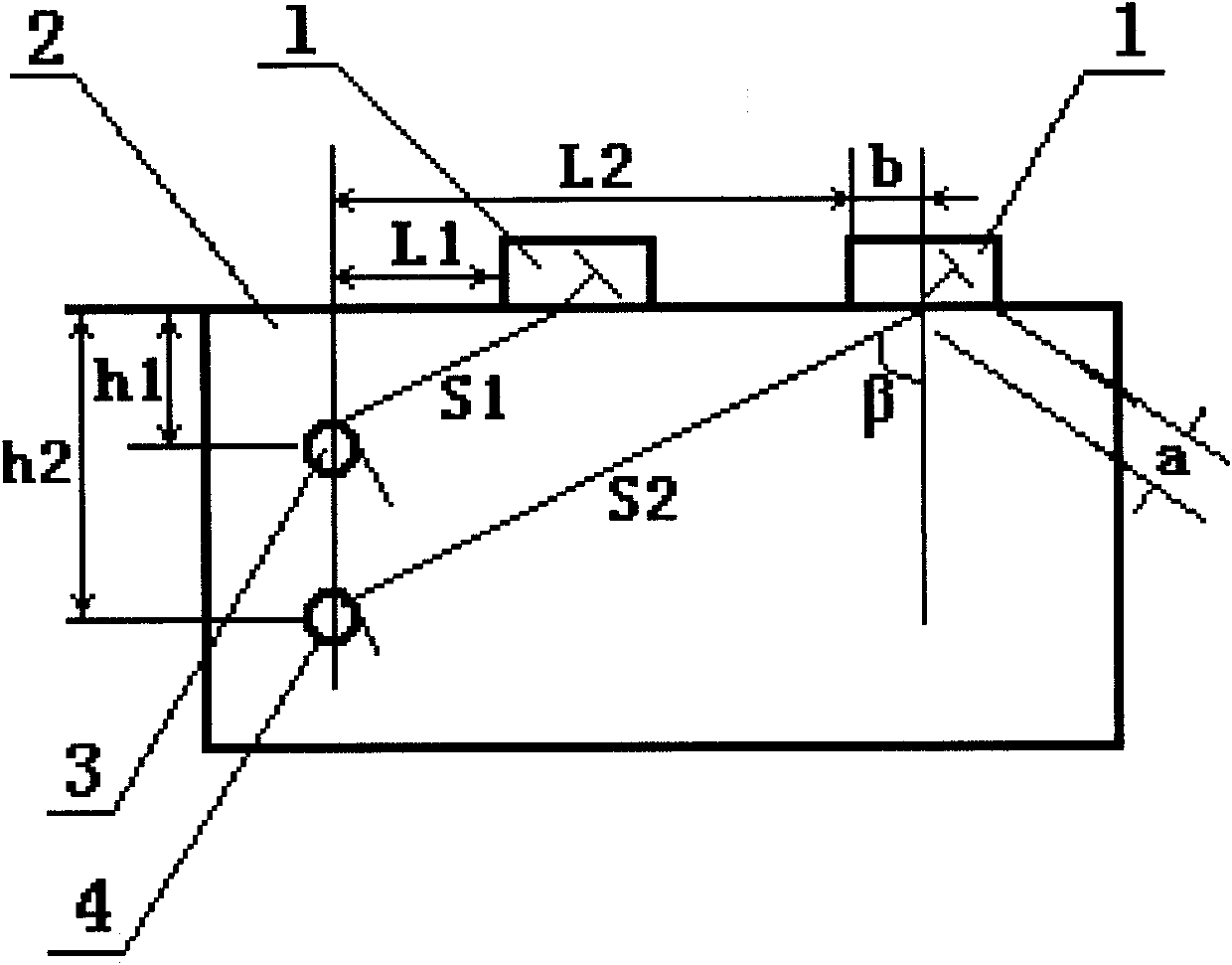

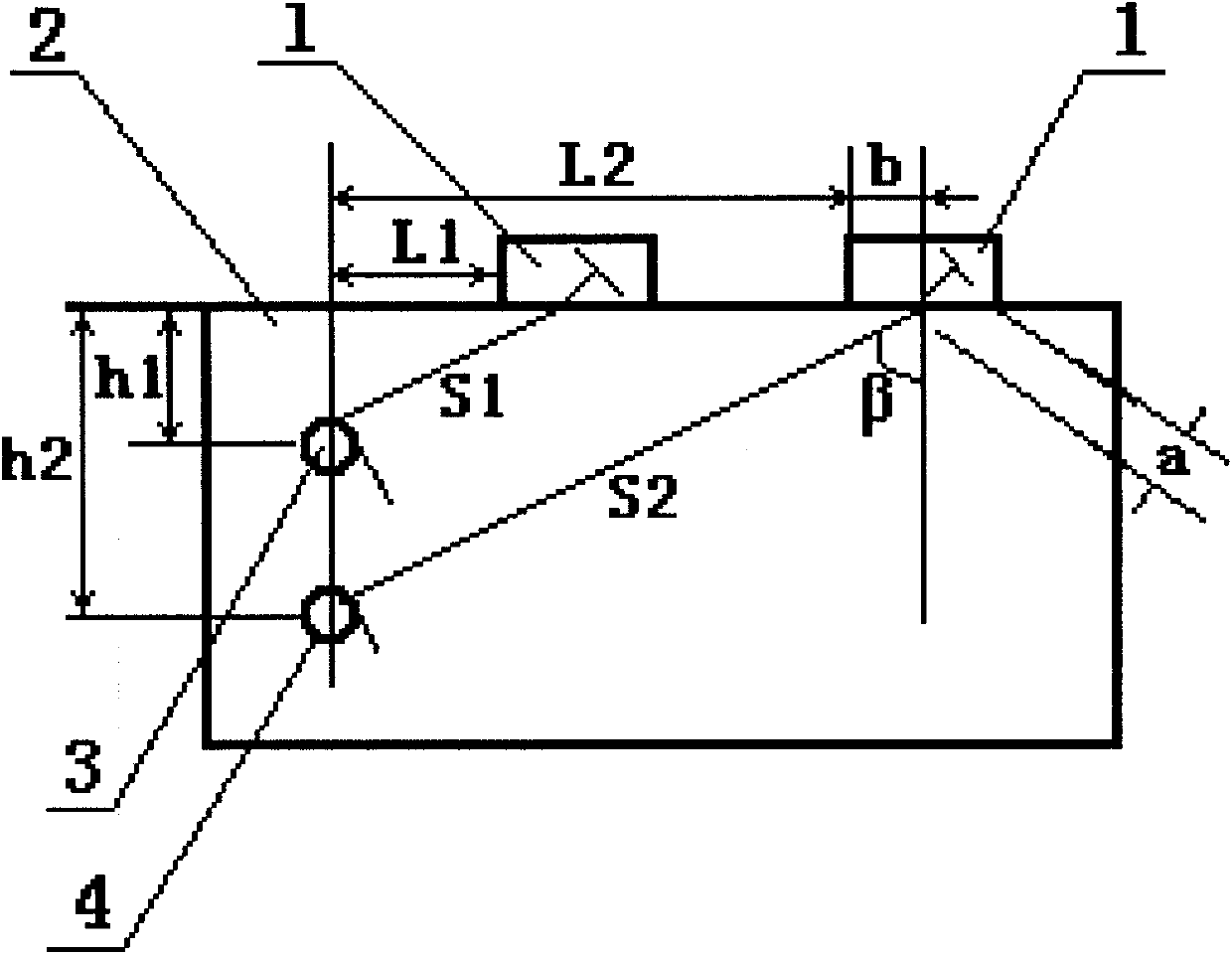

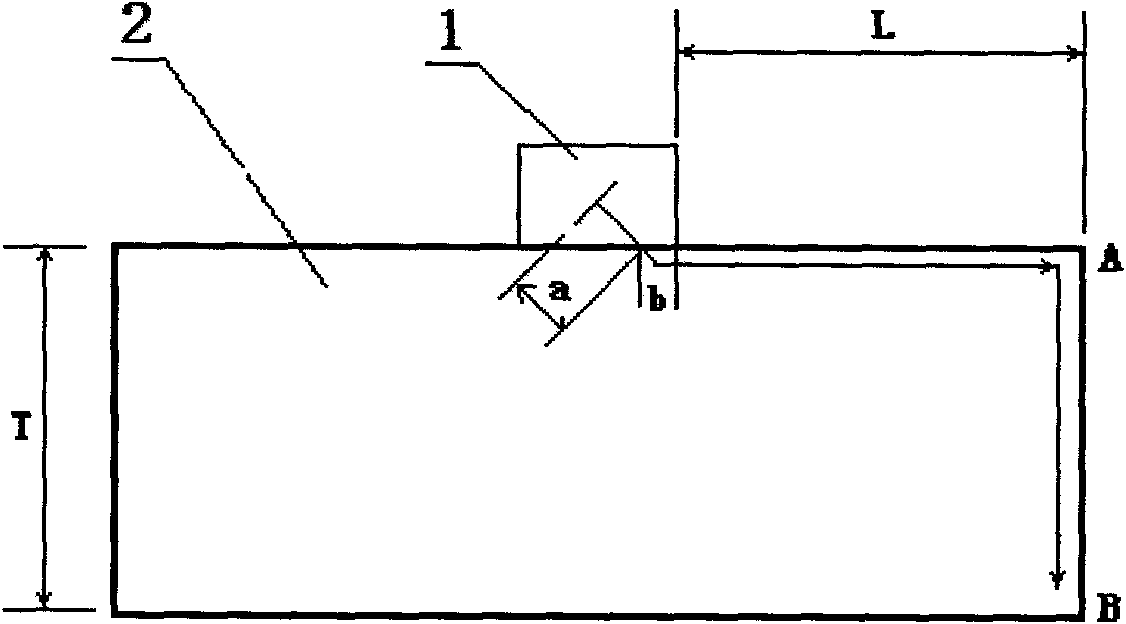

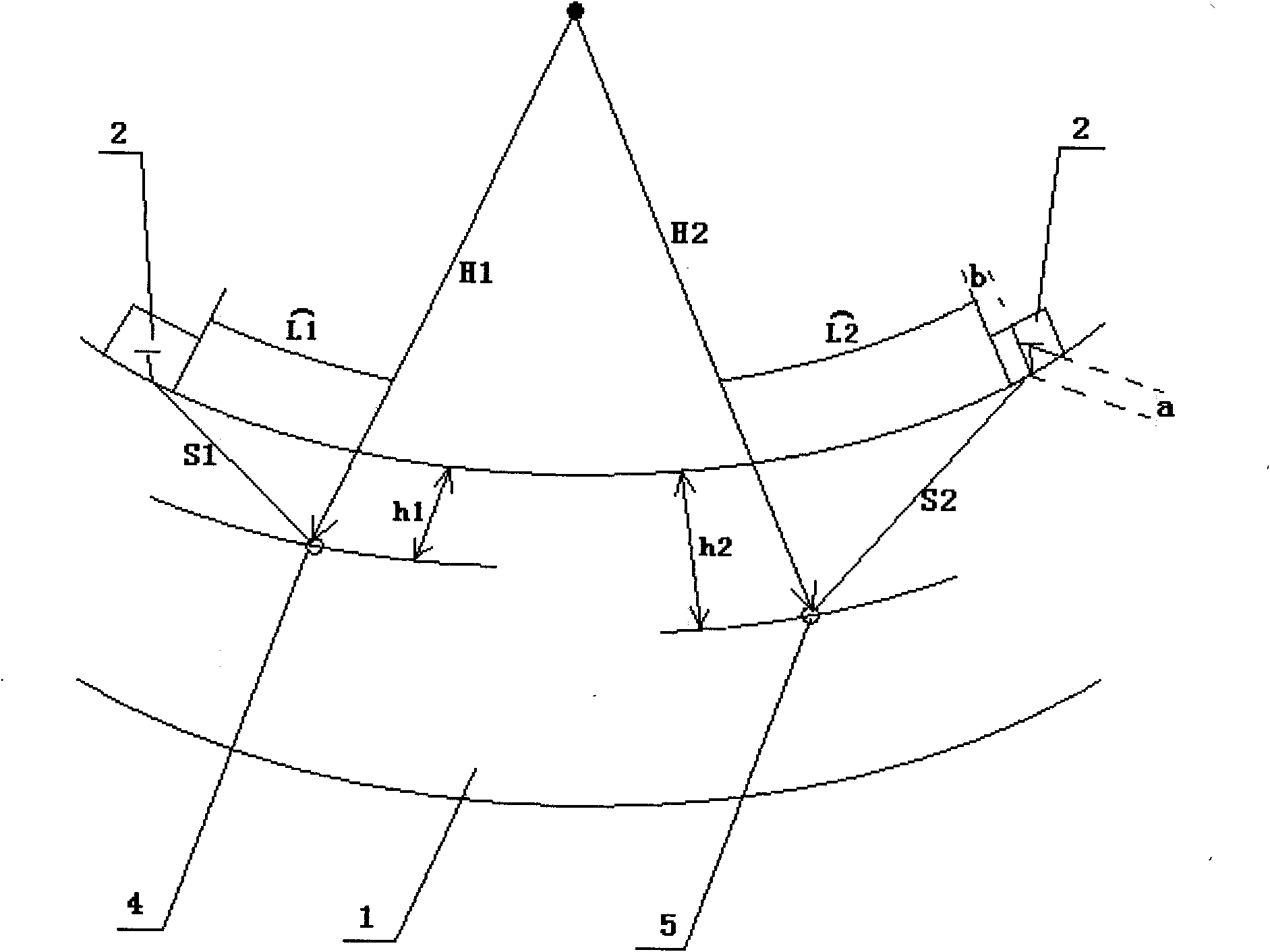

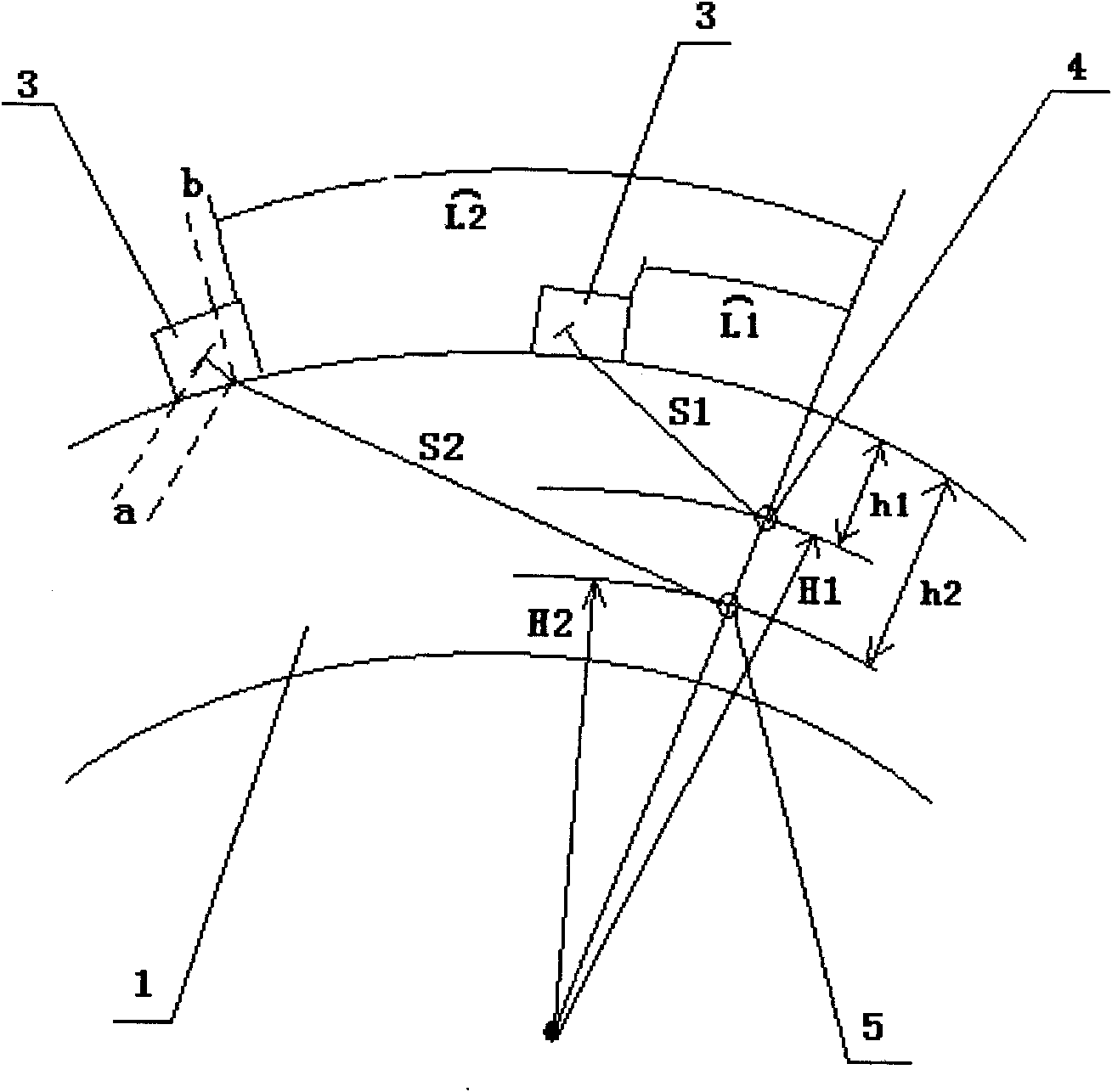

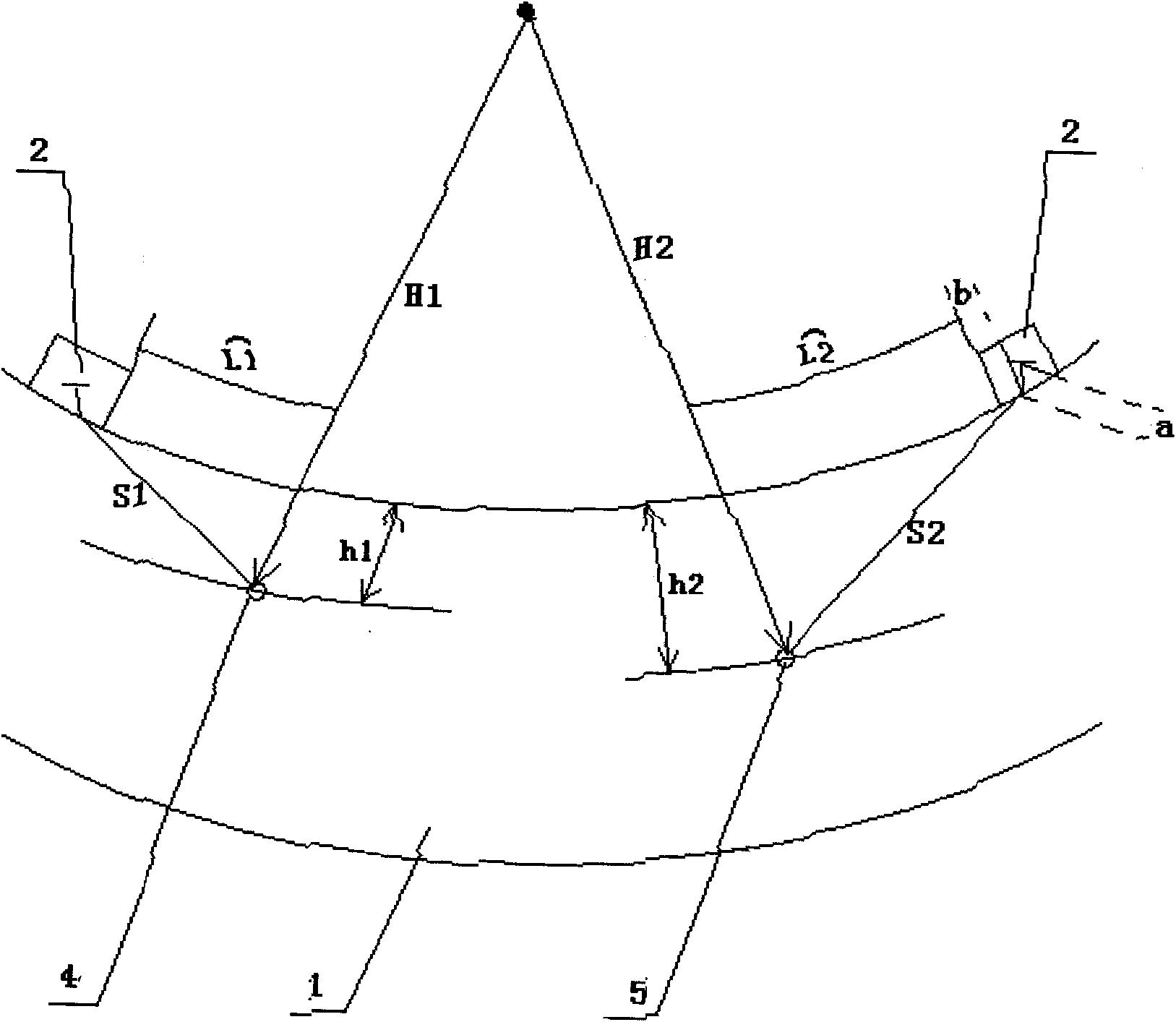

Method for calibrating large-angle or small-angle longitudinal wave angle probe for ultrasonic fault detector

InactiveCN101819183AThe method is simple and reliableShorten the timeMaterial analysis using sonic/ultrasonic/infrasonic wavesMathematical modelLongitudinal wave

The invention discloses a method for calibrating a large-angle or small-angle longitudinal wave angle probe for an ultrasonic fault detector, and relates to an instrument calibration method. The method comprises an ultrasonic fault detector, and sequentially comprises the following steps of: preparing a test block used for calibrating the probe and a large-angle or small-angle longitudinal wave angle probe, wherein the test block is a material used by a workpiece during actual fault detection, and drilling two holes with the horizontal heights of h1 and h2 beyond three times of near field of the test block respectively, wherein the h1 is unequal to the h2; moving the probe back and forth on the test block until the two holes display the highest reflection echo on the ultrasonic fault detector respectively, obtaining distances S1 and S2 from the end of transmitting ultrasonic waves in the probe to the two holes respectively, and measuring distances L1 and L2 from the two holes to the front end of the probe; and obtaining a probe inner sound path a, a probe front sound path b and a probe K value according to a mathematical model. The method for calibrating the large-angle or small-angle longitudinal wave angle probe for the ultrasonic fault detector overcomes the defect that proper methods and test blocks for calibrating the K value of the longitudinal wave angle probe, the probe inner sound path a and the probe front sound path b do not exist at present.

Owner:符丰

Triggering type probe calibration method of coordinate measuring machine

ActiveCN106247914AGuaranteed calculation accuracyGuaranteed measurement accuracyPoint coordinate measurementsOrthogonal coordinatesCoordinate-measuring machine

The invention discloses a triggering type probe calibration method of a coordinate measuring machine. According to the method, a probe is rotated to four or more different directions, a standard ball is measured under different probe compensation conditions, four or more measured spherical centers are used to construct a sphere in a least square method, the center of the constructed sphere serves as the center of the standard ball, and a theoretical value of the radius of the sphere equals the distance from an origin point of a probe coordinate system to the spherical center of a small ball in the end portion of a measuring rod. Thus, triggering type probe calibration can be completed via simple calculation. The probe calibration method is suitable for triggering type problems, using rotatable measuring seats, commonly used in the orthogonal coordinate measuring machine.

Owner:HEFEI UNIV OF TECH

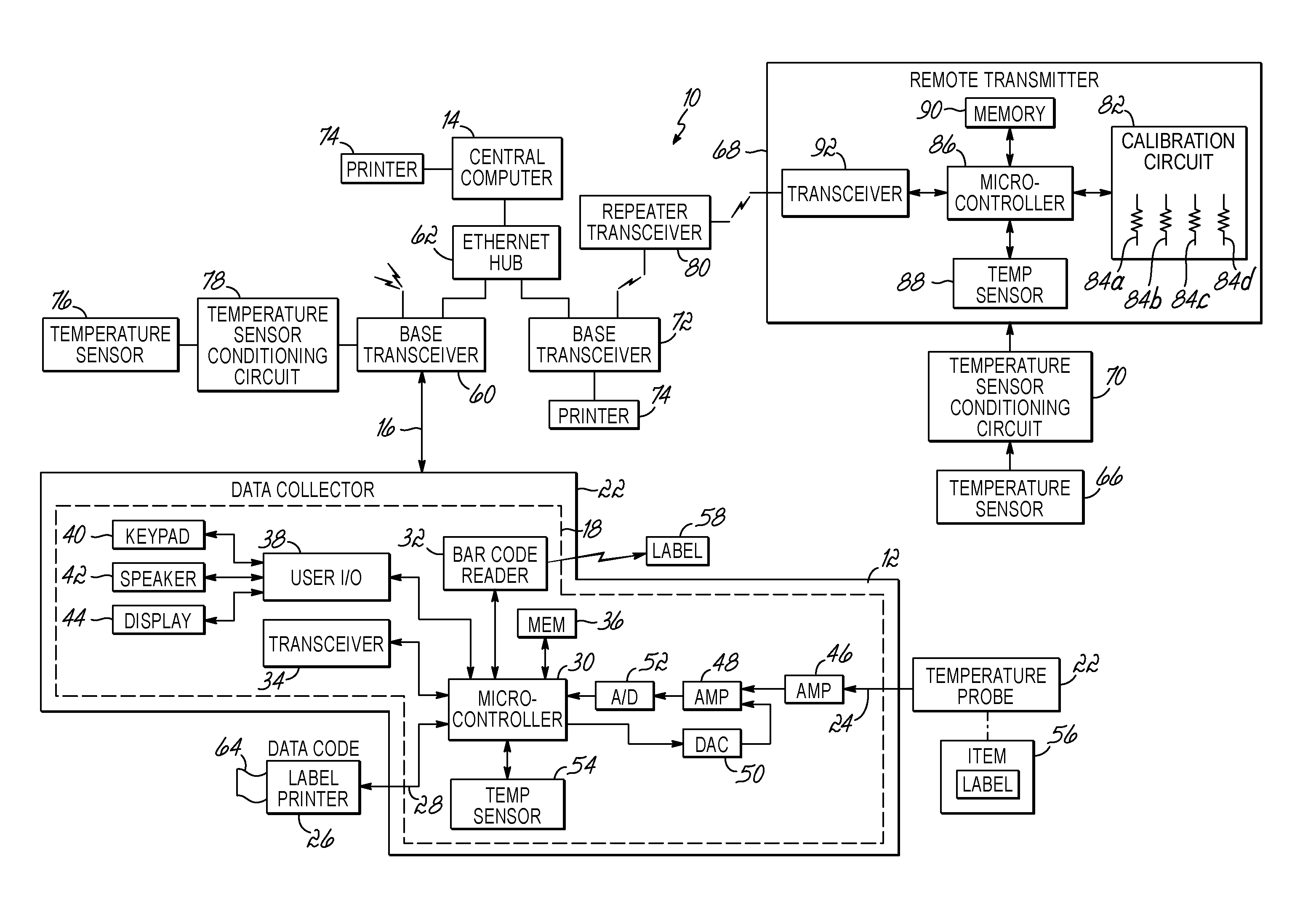

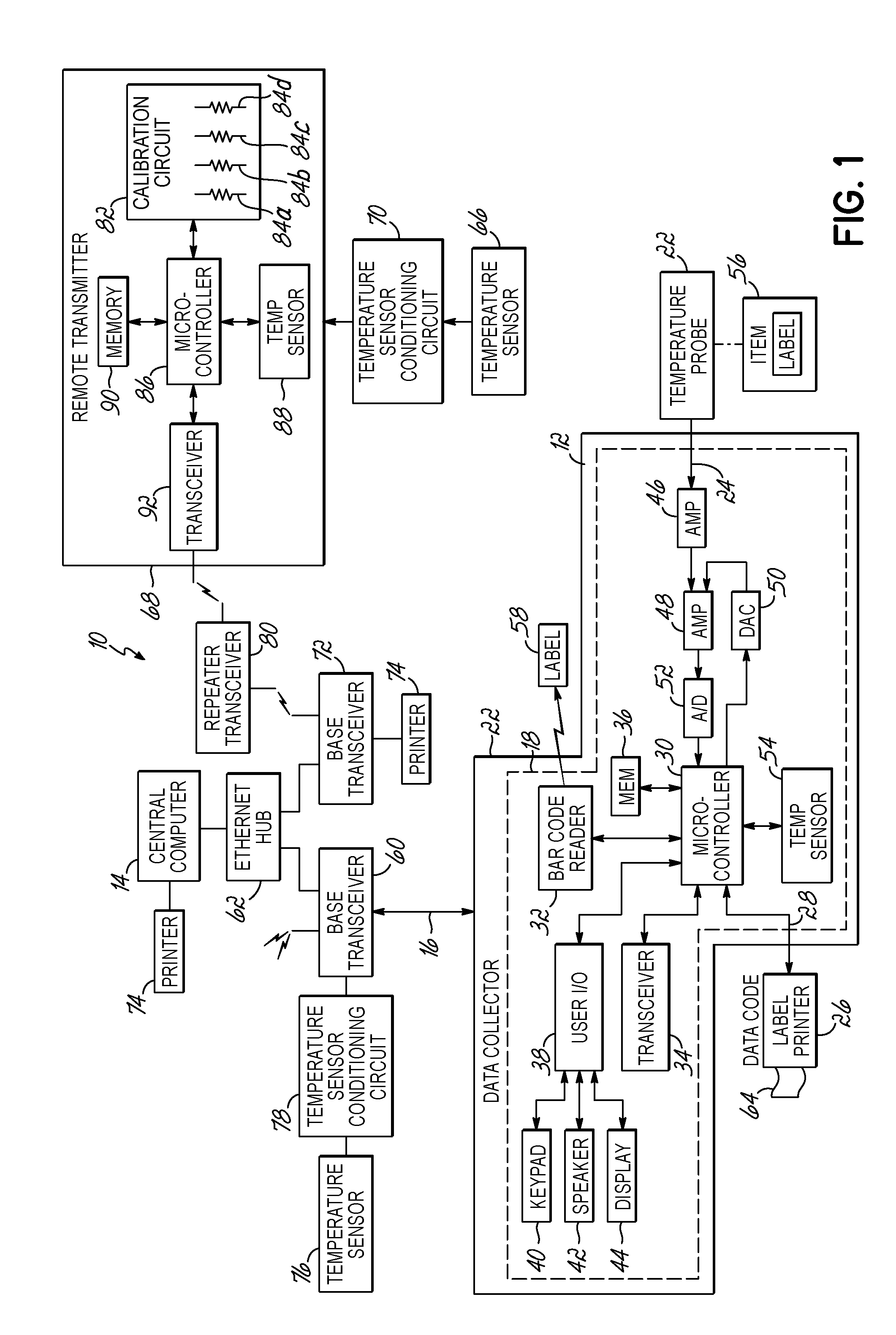

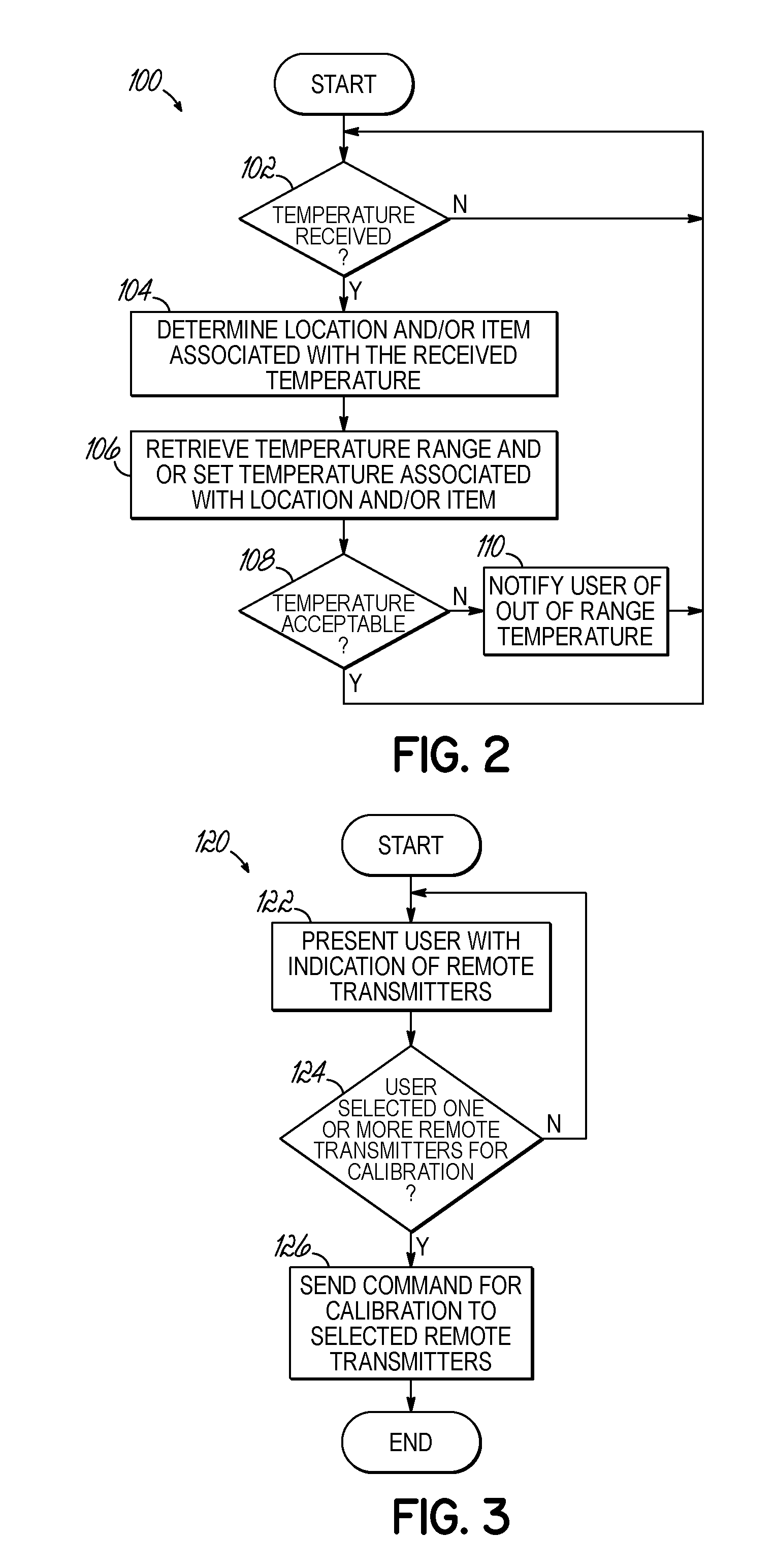

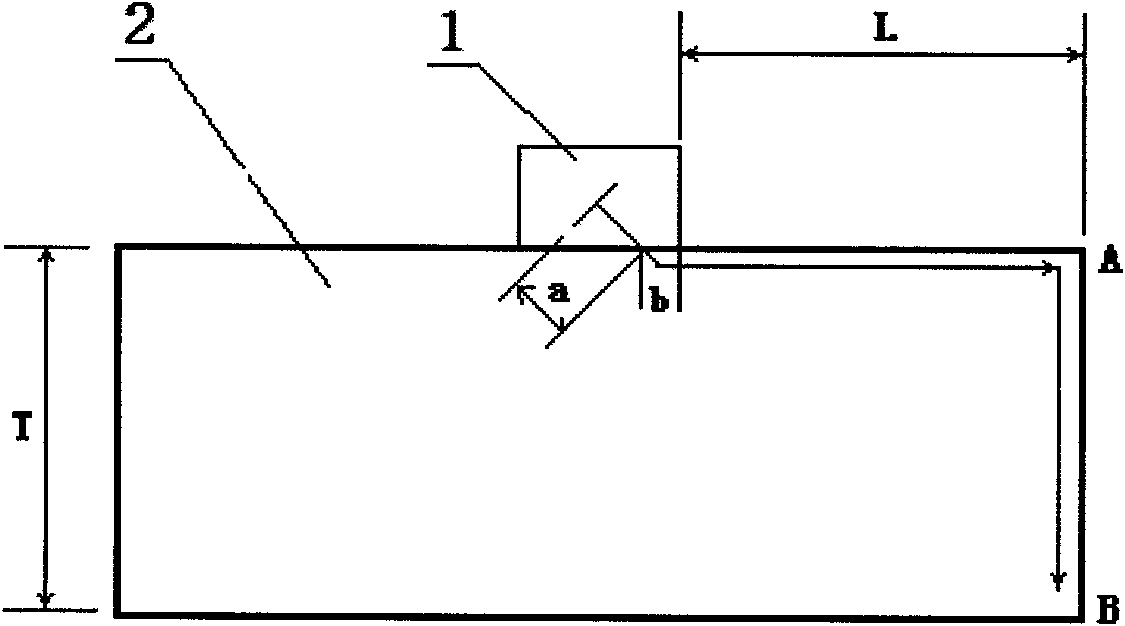

Wireless temperature probe calibration system and method

ActiveUS8600693B1Easy to storeEasy to takeThermometer detailsThermometers using material expansion/contactionEngineeringProbe calibration

A monitoring, tracking, and calibration system tracks temperature data and the validity of temperature measuring devices. If an item is temperature sensitive, the system permits temperature readings to be taken by a remote transmitter or other temperature measuring device and stored by a computer. A calibration device is built into the remote transmitter or attached in line to a temperature sensor and include at least one fixed value. The remote transmitter samples that fixed value periodically or in response to an instruction from the computer. The computer, in turn, compares the fixed value to a respective expected value. If the comparison indicates that the fixed value compares favorably to the at least one respective expected value, the remote transmitter is considered calibrated and functioning correctly. Otherwise, the remote transmitter is considered faulty and an error is reported so that corrective action may be taken.

Owner:THE VERACITY GROUP

Method for collecting surface wave and creeping wave of ultrasonic flaw detector

InactiveCN101813671AExtended service lifeReduce manufacturing costMaterial analysis using sonic/ultrasonic/infrasonic wavesCreeping waveFront edge

The invention discloses a method for collecting a surface wave and a creeping wave of an ultrasonic flaw detector, relating to an apparatus collecting method. The apparatus comprises an ultrasonic flaw detector which detects the flaw of a work piece by transmitting the ultrasonic wave through a probe head, wherein the detected distance of the flaw of the work piece is the sum of practical distance and corrected distance. The method sequentially comprises the following steps of: preparing a standard test block for correcting the probe head, and the surface wave or the creeping wave probe head for the ultrasonic flaw detector; leading the probe head to move on the test block back and forth till that the ultrasonic flaw detector displays that the surface wave and the creeping wave generate highest reflected wave at the flaw of the standard test block so as to obtain the distance S from an ultrasonic wave-transmitting end in the probe head to the flaw; detecting the distance L from the headmost end of the probe head to the flaw; and subtracting L from S to obtain the correcting distance for correcting ultrasonic flaw detector. The method fills in gap that the existing ultrasonic flaw detector is difficult to correct the front edge of the transverse wave (the surface wave and the creeping wave) probe head and the route of the ultrasonic wave in the probe head.

Owner:符丰

Enhanced wireless eddy current probe for a non-destructive inspection system

ActiveUS20090273342A1Increase currentOvercome problemsHysteresis curve measurementsMaterial magnetic variablesNon destructiveEddy current

An enhanced wireless eddy current probe is disclosed which has means to wirelessly couple to a non-destructive inspection (NDI) system situated some distance away from an inspection point on a material under inspection. The disclosed enhanced wireless eddy current probe provides means for executing advanced functions necessary for a complex eddy current inspection operation. These functions include, but are not limited to, storing, loading, and executing a predetermined firing sequence on an array of coil elements, probe balancing, probe calibration, and providing bibliographic information specific to said probe to a wirelessly coupled NDI system.

Owner:OLYMPUS NDT

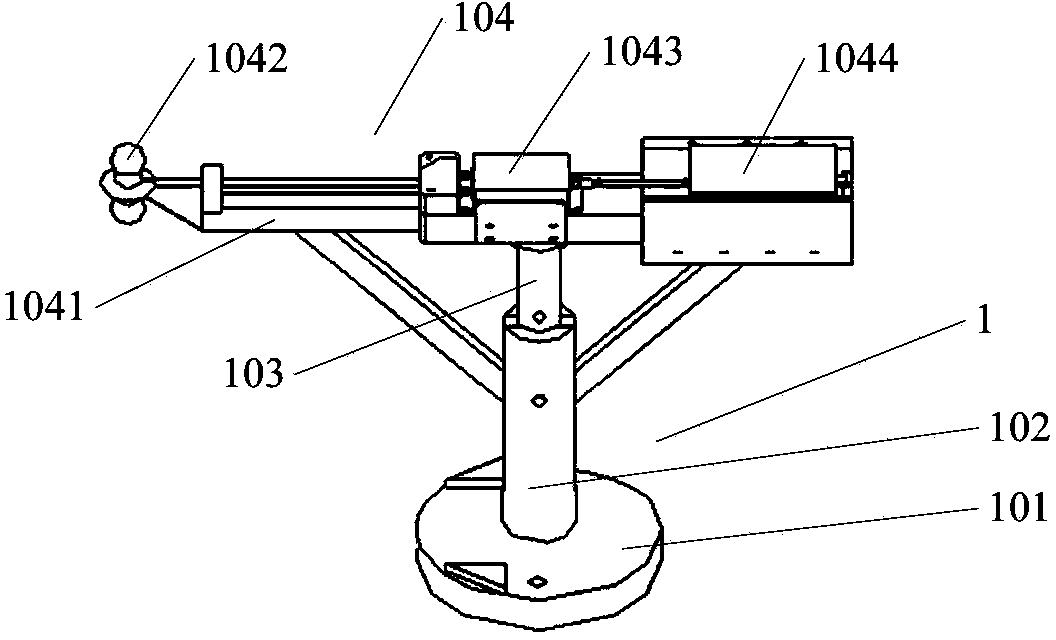

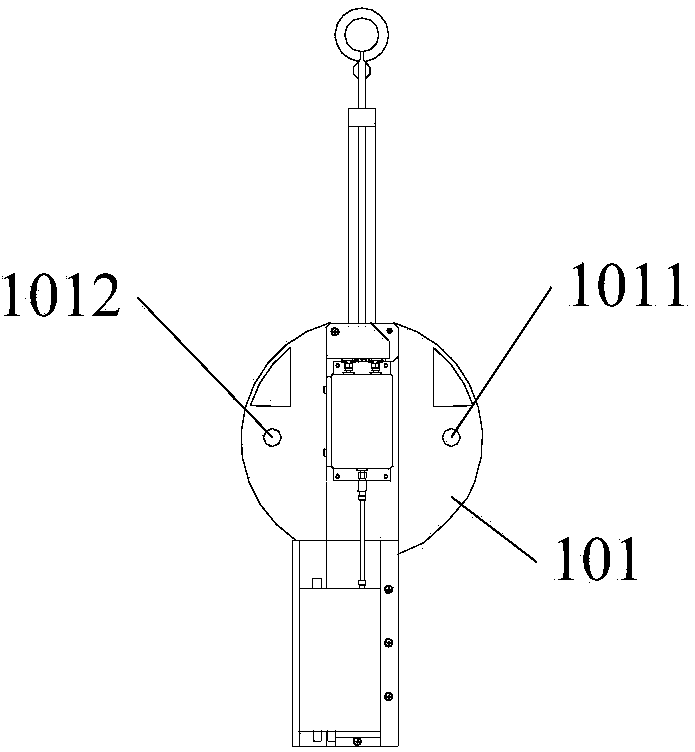

Probe calibration device

InactiveCN103645455AImprove applicabilityMeet the test requirementsElectromagentic field characteristicsEngineeringProbe calibration

The invention discloses a probe calibration device. The probe calibration device comprises a positioning datum disc, a first calibration support and a second calibration support; wherein the first calibration support comprises a first supporting base plate, a first supporting column with one end arranged on the first supporting base plate, and a first measuring assembly arranged on the other end of the first supporting column; the second calibration support comprises a second supporting base plate, a second supporting column with one end arranged on the second supporting base plate, and a second measuring assembly arranged on the other end of the second supporting column; the positioning datum disc is connected with the first calibration support through a first connecting plate, one end of the first connecting plate is hinged to the positioning datum disc, and the other end of the first connecting plate is fixedly connected with the first supporting base plate; the first calibration support is connected with the second calibration support through a second connecting plate, one end of the second connecting plate is hinged to the first connecting base plate, and the other end of the second connecting plate is hinged to the second supporting base plate. The probe calibration device can adjust the position of a probe through simple rotation, thereby improving the accuracy of testing and work efficiency.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

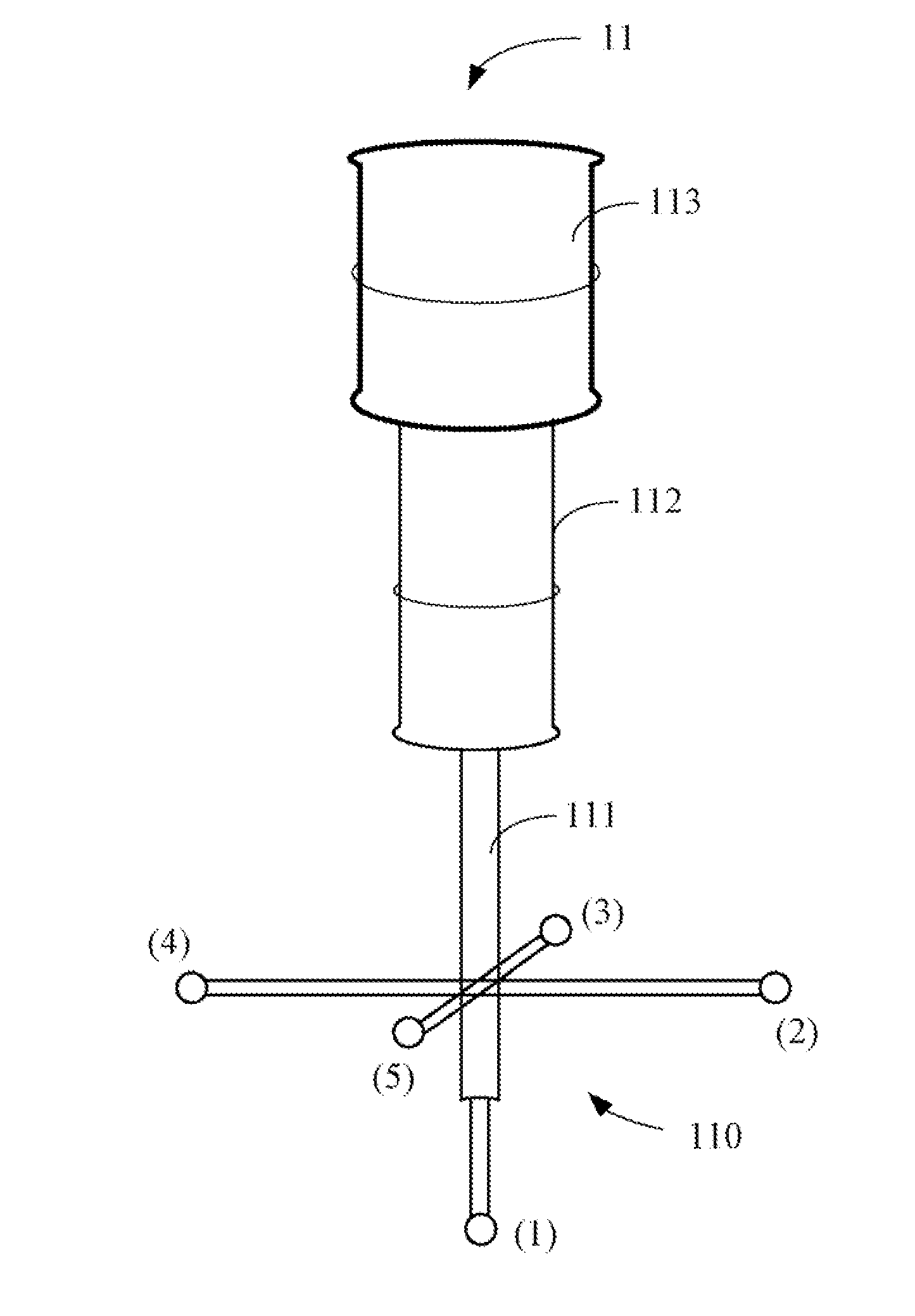

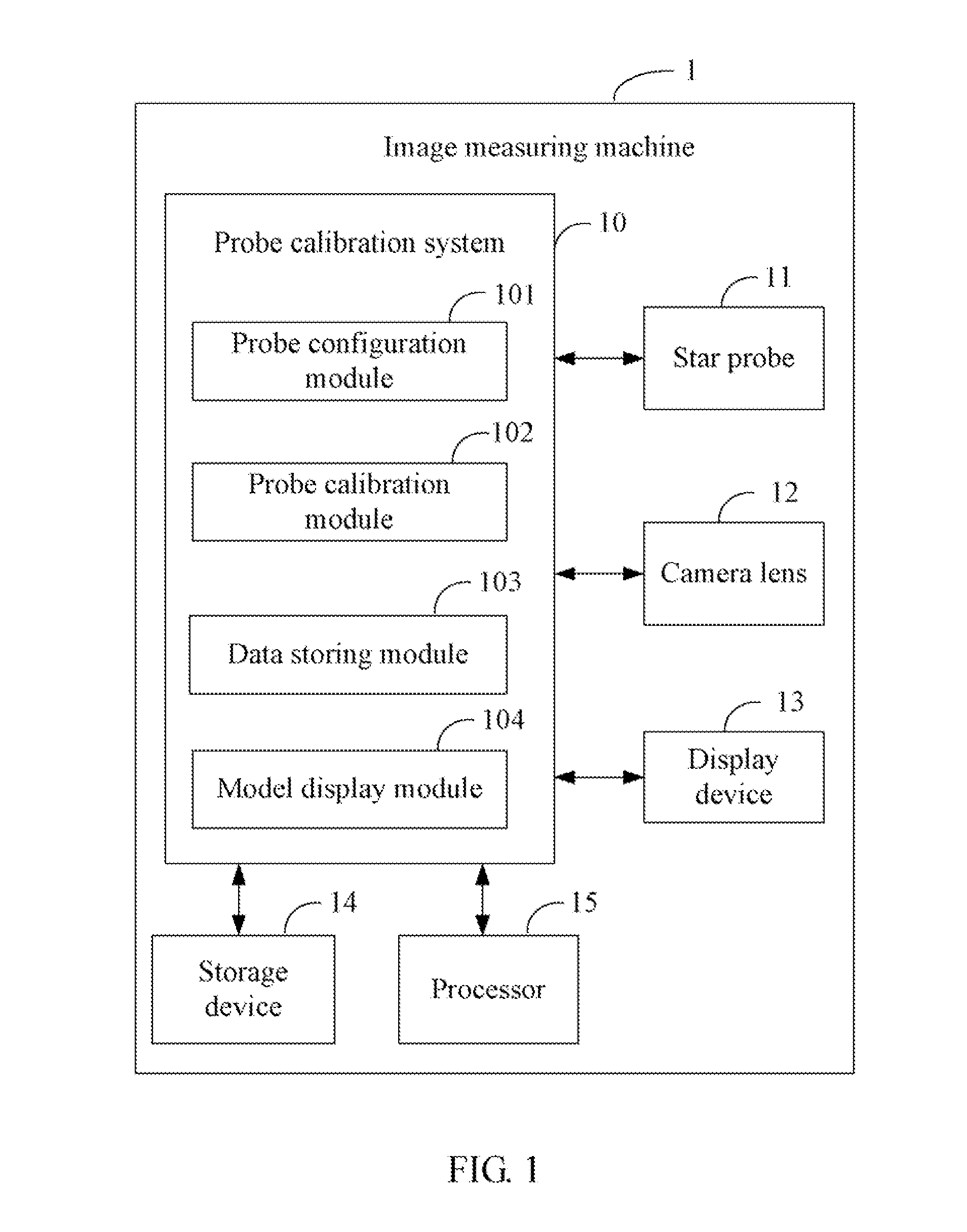

Computing device and method for calibrating star probe of image measuring machine

InactiveUS20130120562A1Color television detailsClosed circuit television systemsCamera lensDisplay device

In a method for calibrating a star probe of an image measuring machine, the star probe includes one or more probe heads. Probe configuration information for the star probe is configured when there is no probe configuration file of the star probe stored in a storage device of the image measuring machine, and one of the probe heads to be calibrated is selected from the star probe. The method calibrates a radius value of the selected probe head, and calibrates the deviation between the center point of the selected probe head and the focus of the camera lens. The method further generates a star probe model of the star probe according to the probe configuration information and the probe calibration information, and displays the star probe model of the star probe on a display device of the image measuring machine.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

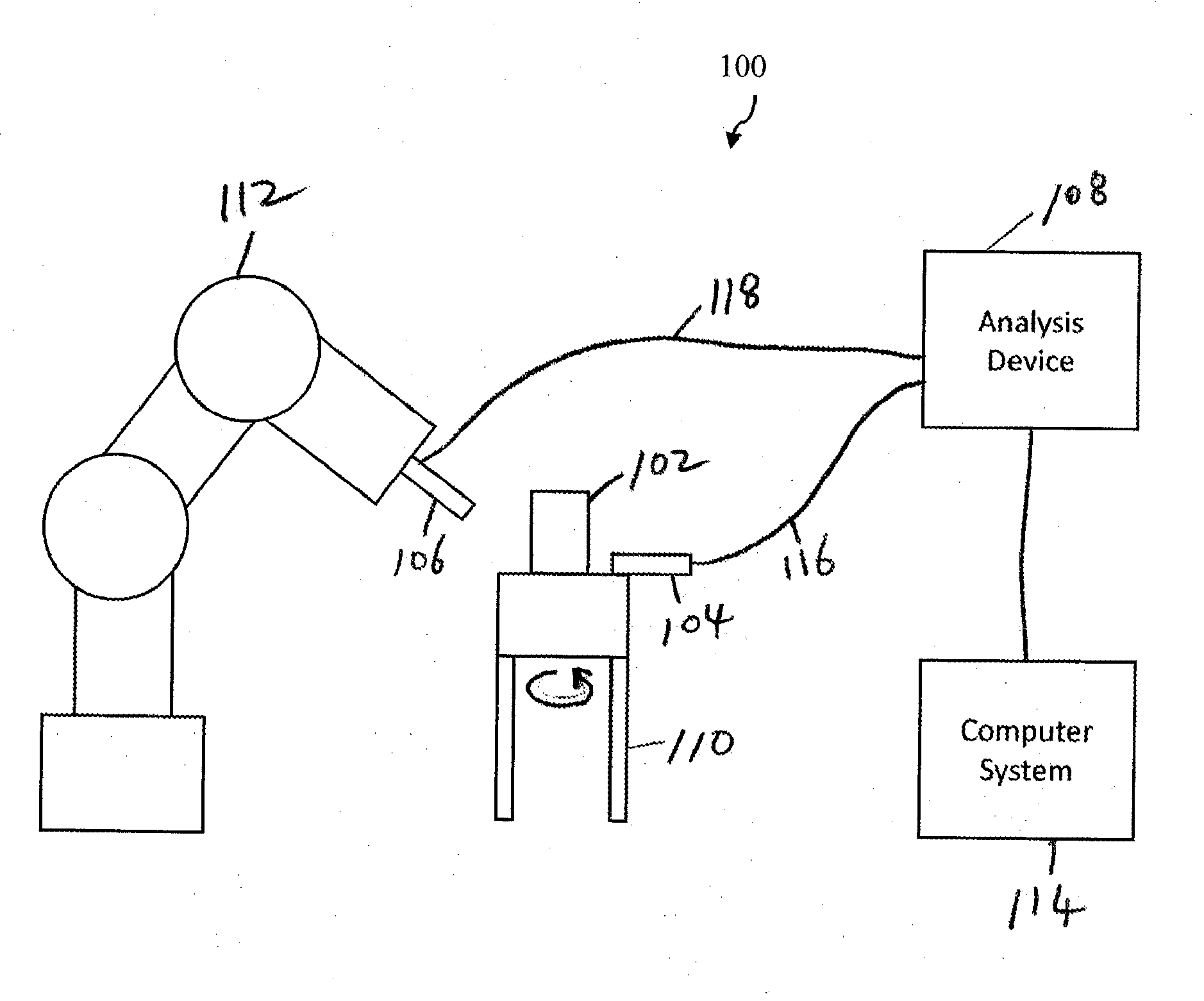

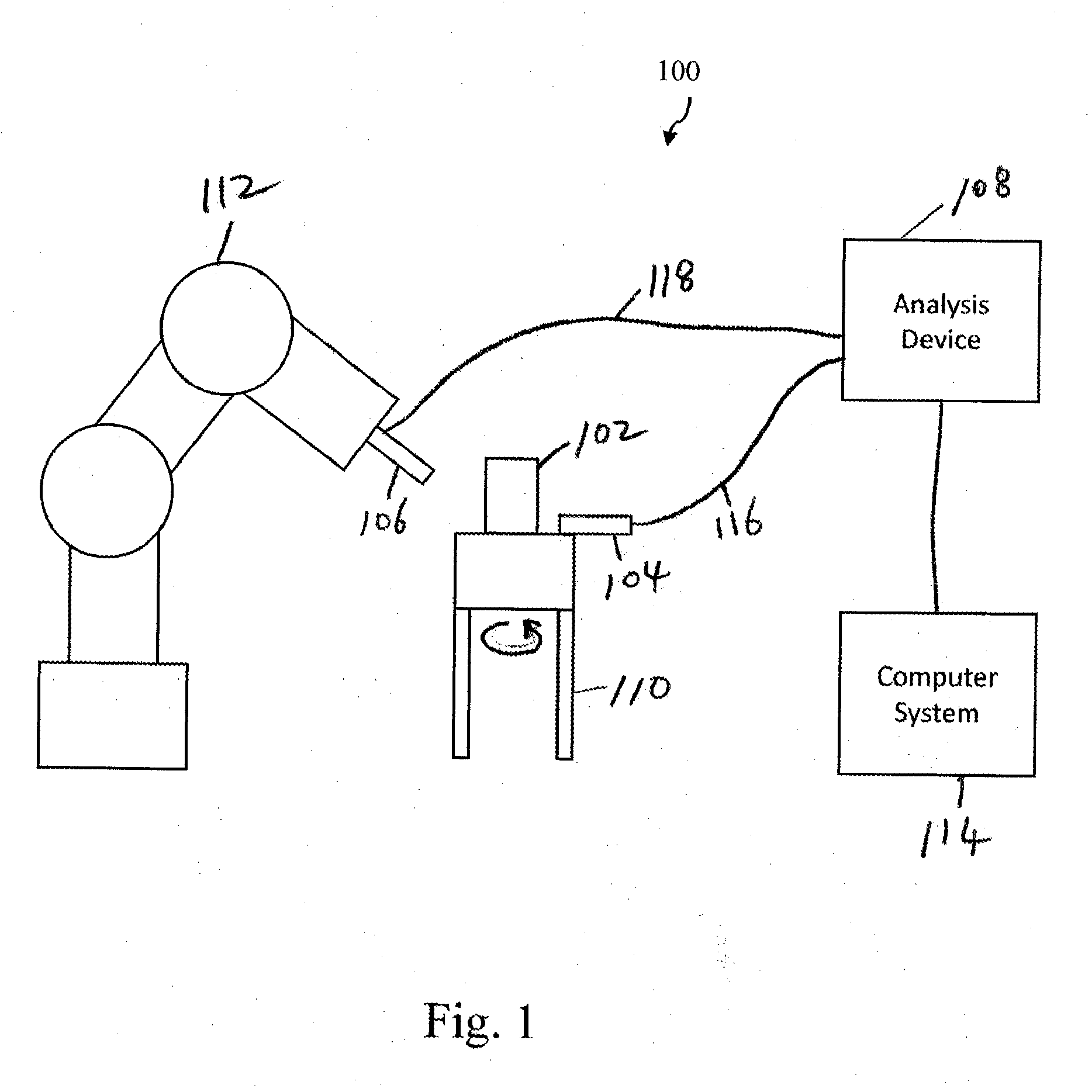

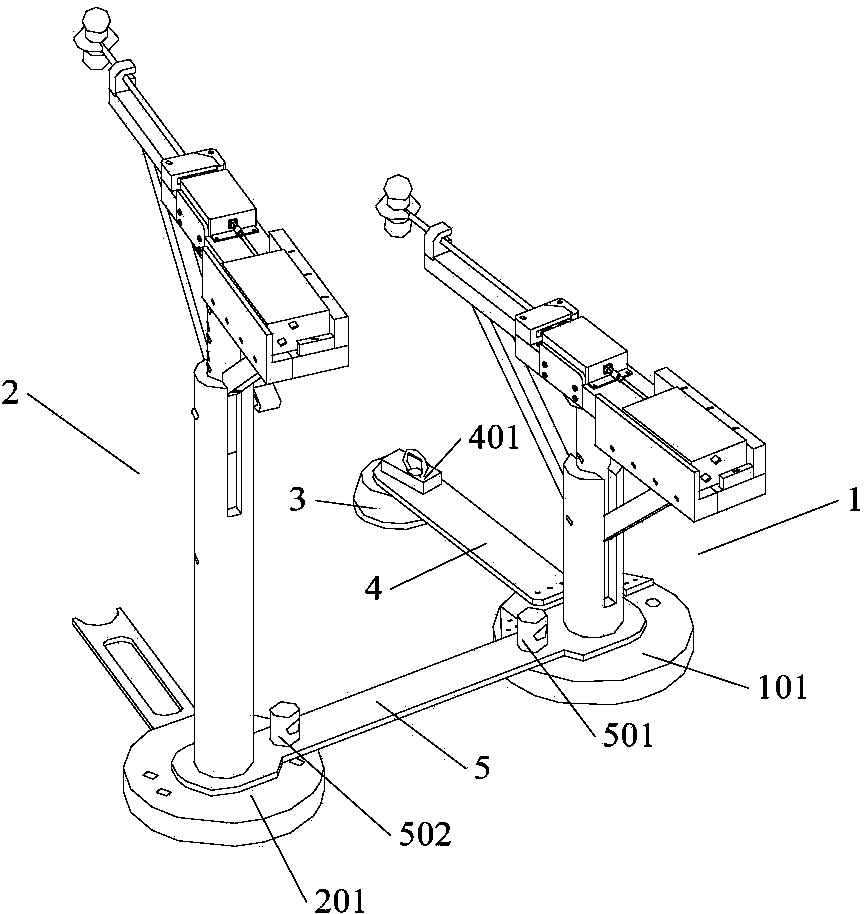

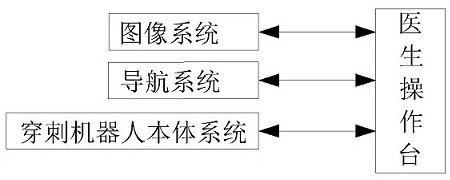

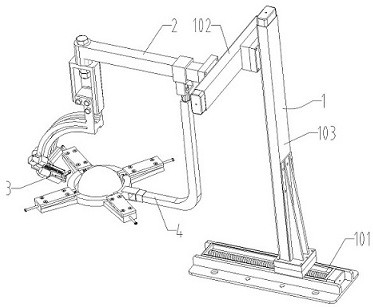

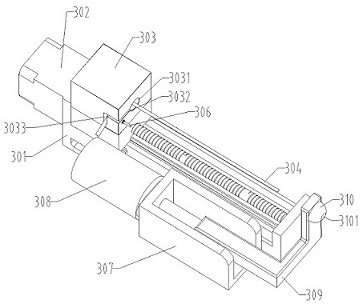

Space registration and real-time navigation method for minimally invasive mammary gland interventional surgical robot

InactiveCN113288429AMeet the requirements of biopsy punctureRealize visualizationSurgical navigation systemsSurgical manipulatorsMotion captureMammary gland structure

The invention discloses a space registration and real-time navigation method for a minimally invasive mammary gland interventional surgical robot. The method comprises the steps that S1, kinematics modeling and simulation of the robot are carried out; s2, positioning and registering by a navigation system; s3, coordinate scale calculation and spatial registration of an ICP registration algorithm; s4, the position and posture of the puncture needle are positioned in real time, kinematics modeling can be carried out on the puncture device, and forward and inverse kinematics solution is carried out; the degree of freedom, configuration and geometric parameters of the designed robot can meet the requirements of mammary gland biopsy puncture through preliminary verification, and the problem of inconsistent coordinate space scales is solved through an ICP iterative registration algorithm based on coordinate scale calculation and a registration algorithm simulation experiment; a navigation experiment platform is built based on an OptiTrack motion capture system and 3ds Max three-dimensional animation software, passive positioning probe calibration and image space registration are completed, and visualization and positioning tracking of the position and posture of a puncture needle are achieved.

Owner:SHANDONG INST OF COMMERCE & TECH

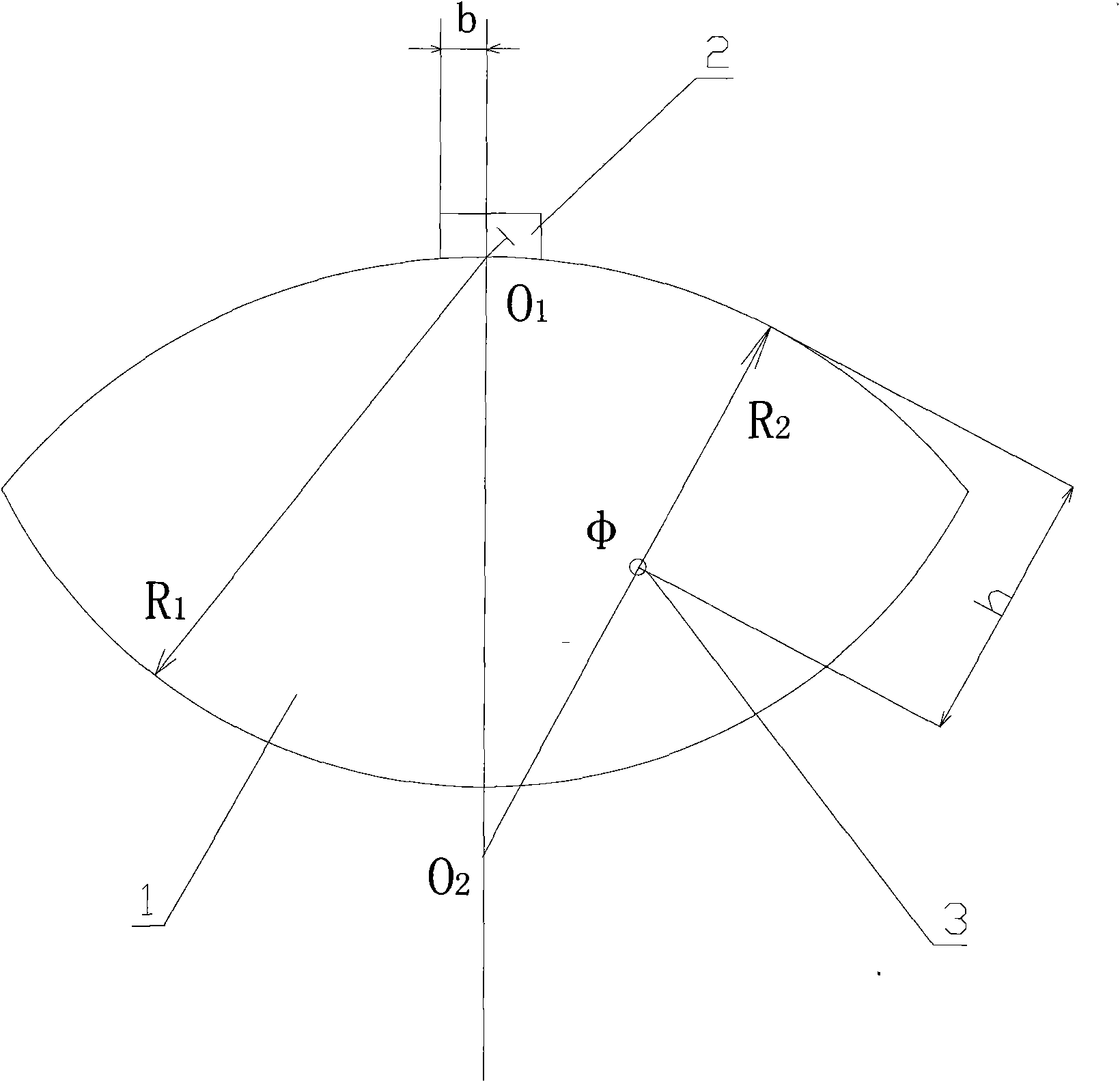

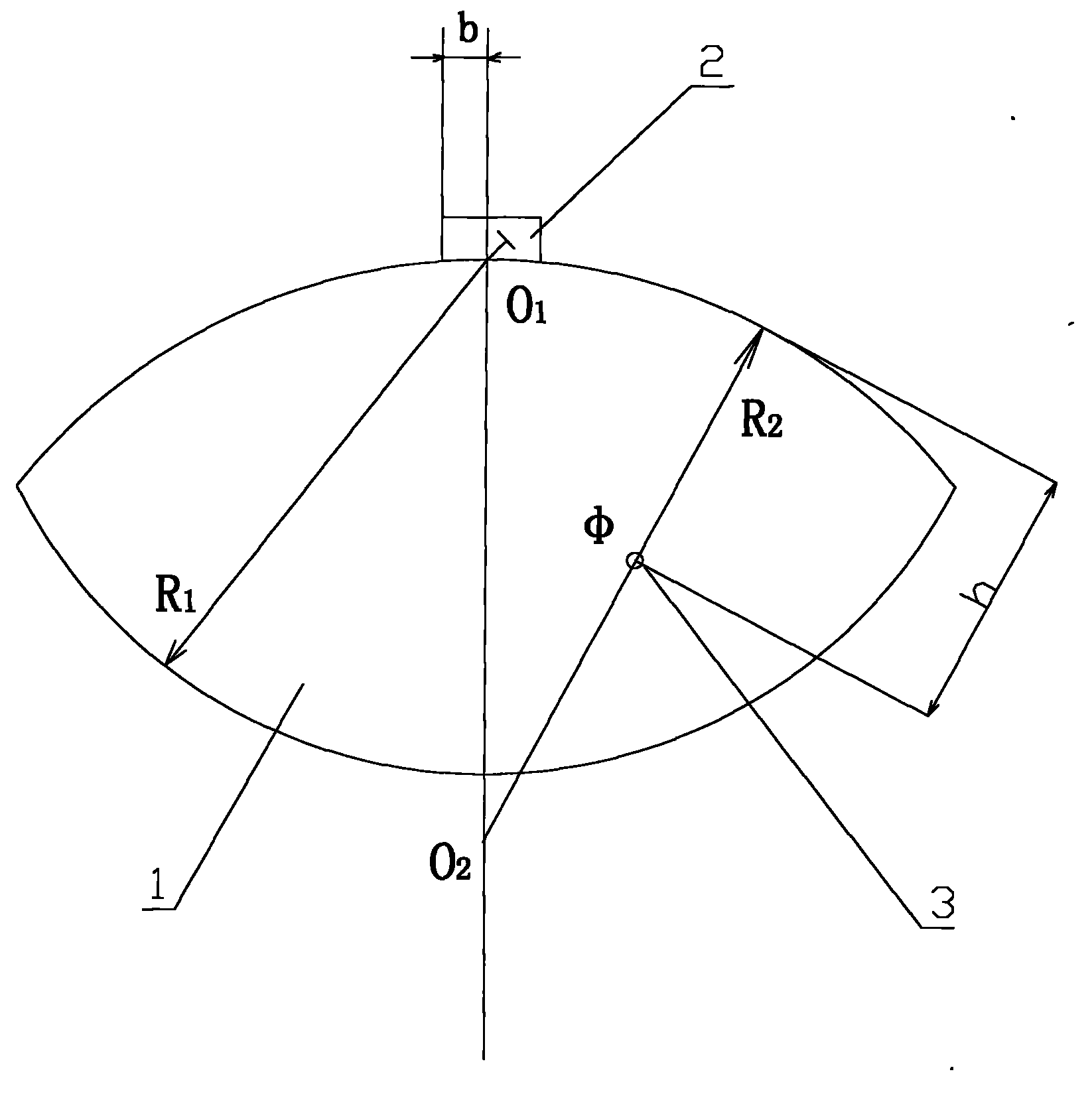

Method for calibrating small-diameter probe for ultrasonic flaw detector

InactiveCN101806779AReduce volumeReduce weightMaterial analysis using sonic/ultrasonic/infrasonic wavesFront edgeProbe calibration

The invention discloses a method for calibrating a small-diameter probe for an ultrasonic flaw detector, belonging to the method for calibrating an instrument. The method for calibrating the small-diameter probe for the ultrasonic flaw detector comprises the following steps in sequence: manufacturing a test block for calibrating the small-diameter probe for the ultrasonic flaw detector; moving the external circular arc probe near the point O1 on the surface of the arc of the test block back and force, wherein the arc of the test block is drawn by adopting the radius R2; obtaining the range S1 of the echo of a radius R1; measuring the distance between the point O1 and the foremost edge of the small-diameter probe, wherein the distance is the front edge b of the small-diameter probe; adjusting the direction of the small-diameter probe to make the small-diameter probe aligned to the direction of the hole, and obtaining the range S of the echo of the hole; and obtaining the range a of the echo in the small-diameter probe and the value K of the small-diameter probe. The invention makes up the blank of the calibration of the value K of the small-diameter probe, the front edge b of small-diameter probe and the range a of the echo in the small-diameter probe and reduces the loss cost of the small-diameter probe.

Owner:符丰

Vaporized hydrogen peroxide probe calibration rig

ActiveUS7640782B2Accurate CalibrationMaterial analysis by electric/magnetic meansMaterial analysis by optical meansLiquid hydrogenAqueous solution

A method and apparatus for calibrating a sensor used to sense the concentration of vaporized hydrogen peroxide (VHP). A concentration of liquid hydrogen peroxide in an aqueous solution is determined and correlated with a corresponding concentration of vaporized hydrogen peroxide indicative of an “actual” vaporized hydrogen peroxide concentration. An error value is determined by comparing the “actual” vaporized hydrogen peroxide concentration to a “measured” vaporized hydrogen peroxide concentration, indicated by the sensor being calibrated. The error value is used to properly calibrate the sensor.

Owner:AMERICAN STERILIZER CO

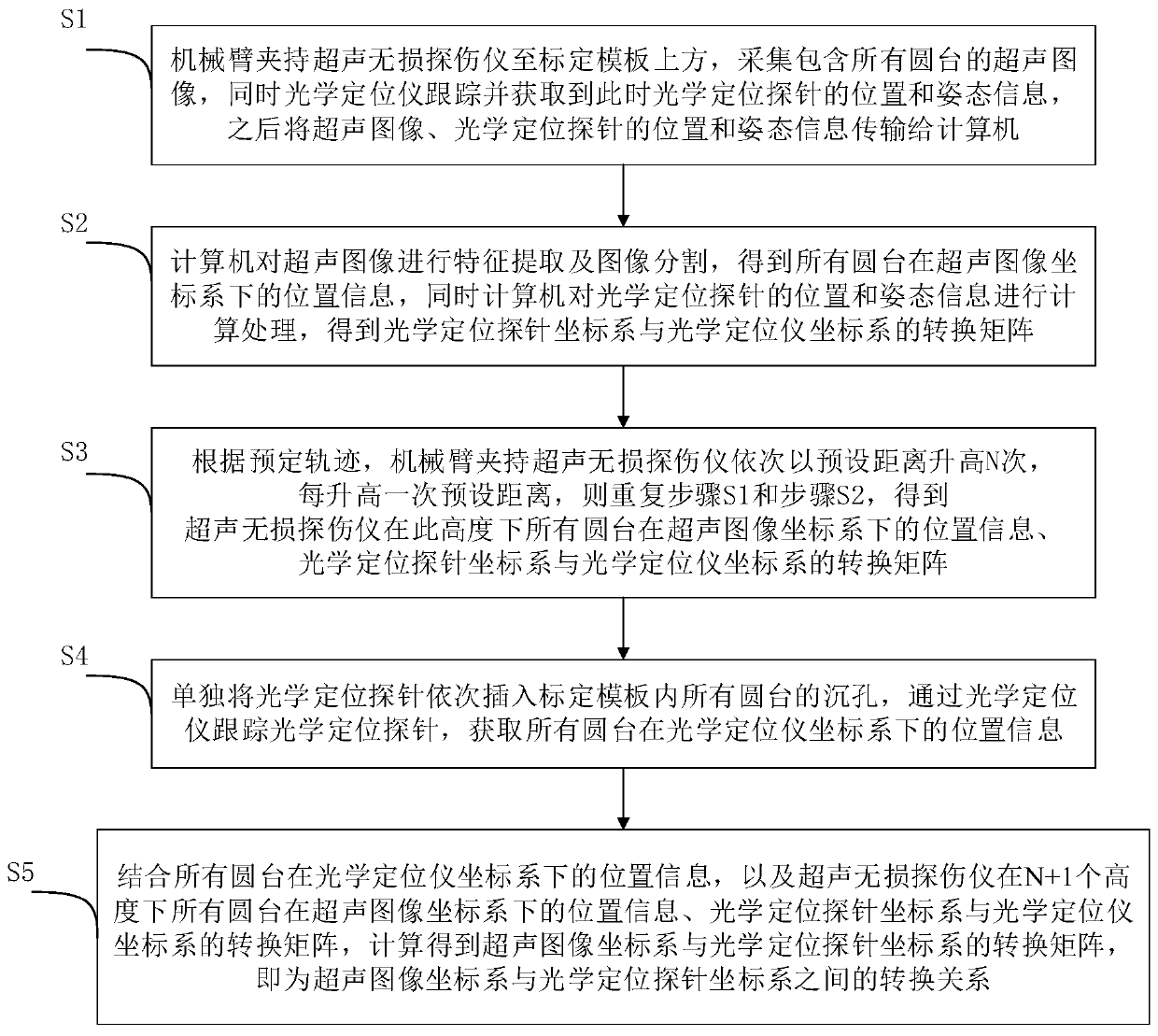

Three-dimensional ultrasonic probe calibration device and method for calibrating three-dimensional ultrasonic probe

ActiveCN110554095AImprove efficiencyImprove accuracyMaterial analysis using sonic/ultrasonic/infrasonic wavesAcousticsProbe calibration

The invention relates to a three-dimensional ultrasonic probe calibration device and a method for calibrating a three-dimensional ultrasonic probe. The three-dimensional probe calibration device comprises an optical positioning instrument, an optical positioning probe, an ultrasonic nondestructive flaw detector, a calibration template, a computer and a mechanical arm, wherein the optical positioning instrument and the ultrasonic nondestructive flaw detector are respectively connected with the computer, the optical positioning probe is fixed on the ultrasonic nondestructive flaw detector, the calibration template is a water tank of which the inner bottom is provided with a plurality of circular truncated cones, and counter bores are formed in the centers of the top surfaces of the circulartruncated cones. Compared with the prior art, the invention is based on optical localization, the improved calibration template is provided. Posture and pose information of the optical positioning probe is obtained through tracking, and the mechanical arm is adopted to clamp the ultrasonic nondestructive flaw detector for ultrasonic image scanning. And the optical positioning probe is directly contacted with the point target to obtain the position information of a point target, so that the operation difficulty of the calibration process is reduced, the additional calibration of the position information of the template point target is avoided, and the calibration precision and efficiency are improved.

Owner:SHANGHAI UNIV OF ENG SCI

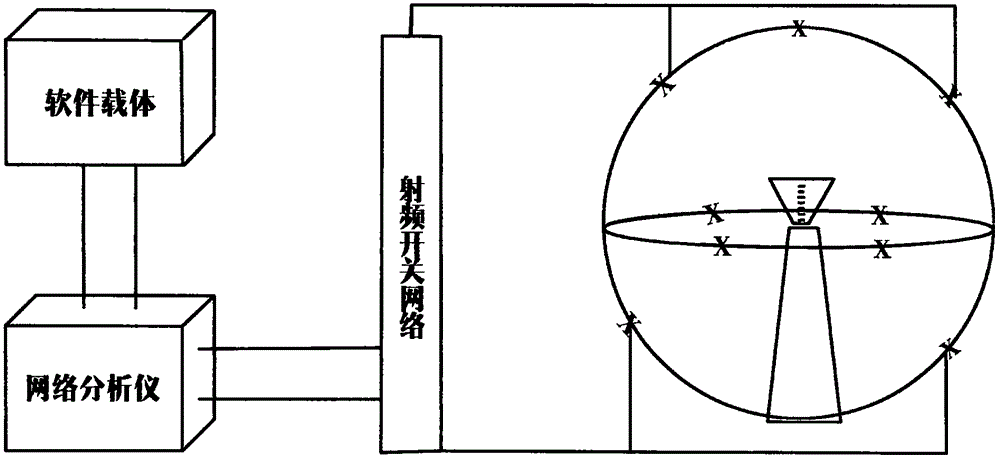

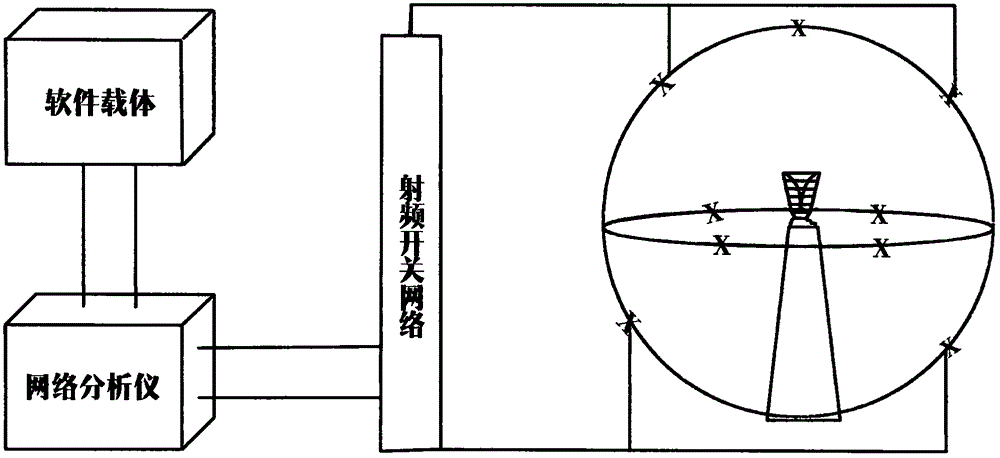

Probe calibration scheme for MIMO testing system

PendingCN106100760AImprove communication qualityThe test result is accurateTransmitters monitoringReceivers monitoringCommunication qualityData profiling

The invention discloses a probe calibration scheme for a MIMO testing system. The calibration method proposed by the invention comprises the following steps: proceeding from the formula Friis transmission of an antenna, determining the system consumption when the signal is at the radio wave darkroom part through the adoption of the two-antenna method, and performing normalized compensation on a probe antenna. The gain of one probe in a multi-probe antenna measurement system is selected as the reference standard, a network analyzer is used for receiving-transmitting a signal, the normalized processing is performed through the analysis and processing on the data read by the network analyzer and the compensation of different values for the probe. The scheme disclosed by the invention has the features of being large in system channel capacity, high in communication quality and accurate in testing result.

Owner:SUNYIELD TECH CO LTD

Correction method of inner arc probe or outer arc probe in ultrasonic flaw detector

InactiveCN101832975AEasy to prepareMake fastMaterial analysis using sonic/ultrasonic/infrasonic wavesMathematical modelCorrection method

The invention discloses a correction method of an inner arc probe or an outer arc probe in an ultrasonic flaw detector, in particular to an instrument correction method by using an ultrasonic flaw detector, an inner arc probe or an outer arc probe which is used in the ultrasonic flaw detector. The correction method comprises the following steps of: cutting a block on a workpiece to be detected asa probe-connecting test block; respectively drilling two holes in different distances on the test block; searching the two holes back and forth by using the inner arc probe until the highest reflection echoes of the two holes are displaced on the ultrasonic flaw detector; respectively acquiring the distances from an ultrasonic wave emitting end in the probe to the two holes; measuring an arc length from the foremost border of the probe to the normal line of the two holes; and respectively acquiring a sound path a, a probe front border b and a probe K value in the inner arc probe or the outer arc probe according to a mathematical model. The invention fills in gaps of the test block and the correction method for acquiring a connection K value, a valve a and a valve b of the inner arc probe or the outer arc probe in the ultrasonic flaw detector, shortens the manufacture period, reduces the manufacture cost of the test block, improves the service rates of the probes and prolongs the life cycles of the probes.

Owner:符丰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com