Method for collecting surface wave and creeping wave of ultrasonic flaw detector

A calibration method and ultrasonic technology, applied in the direction of material analysis, instruments, scientific instruments, etc. using sonic/ultrasonic/infrasonic waves, can solve problems such as increasing factory production costs, defect positioning errors, etc., to extend service life, reduce production costs, Simple and reliable method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

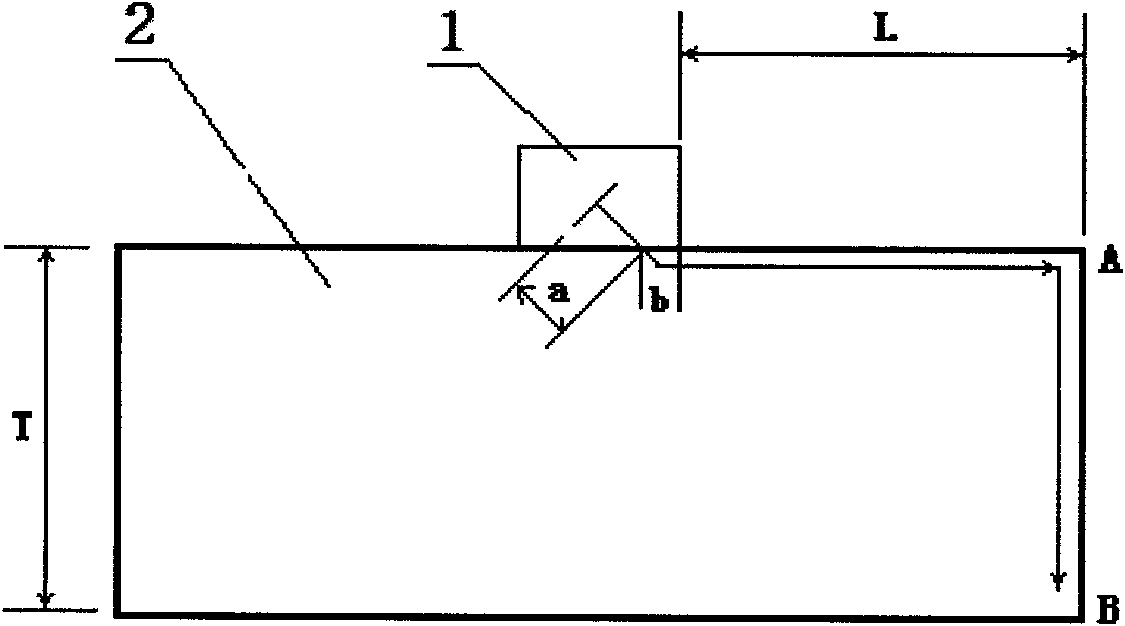

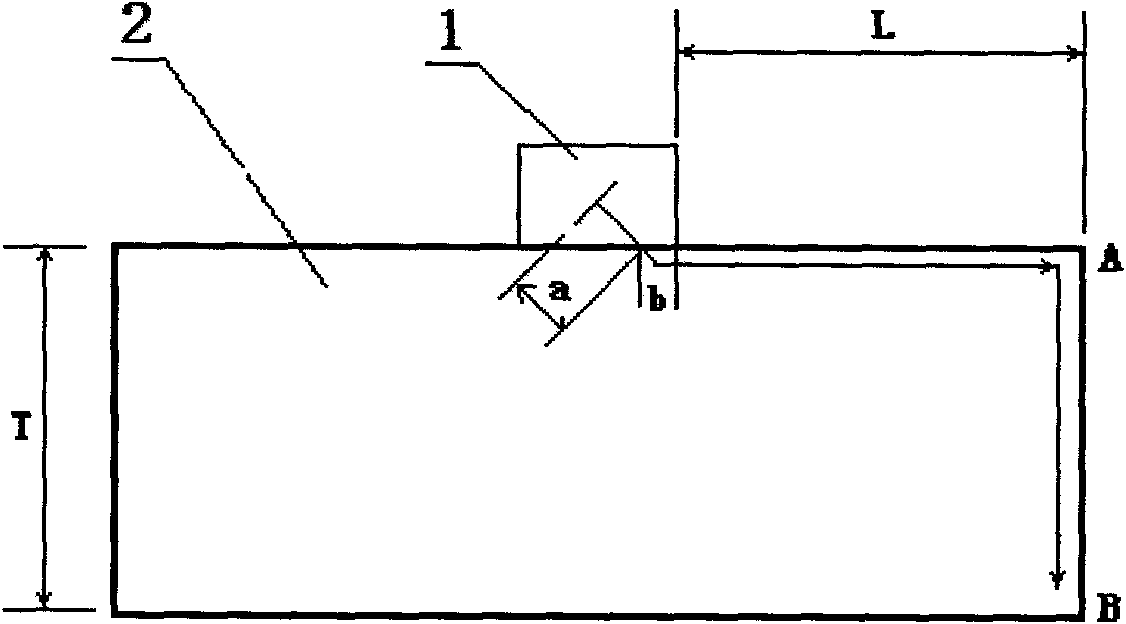

[0011] As an embodiment of the present invention, as shown in Figure 1, a surface wave and creeping wave calibration method for an ultrasonic flaw detector includes an ultrasonic flaw detector, which transmits ultrasonic waves through a probe to detect workpiece flaws, and the distance of workpiece defects obtained by the detection is The sum of the actual distance and the calibration distance, wherein the calibration distance is the sum of the sound path a that the ultrasonic wave travels inside the probe, and the sound path b that the ultrasonic wave propagates on the workpiece surface but is covered by the probe shell. The method includes the following steps in sequence:

[0012] 1) Prepare a standard test block 2 for probe calibration, such as various commercially available standard test blocks such as CSK-IA type, and a surface wave or creeping wave probe 1 for ultrasonic flaw detectors;

[0013] 2) Use the probe 1 to move back and forth on the test block 2 until the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com