Method for calibrating small-diameter probe for ultrasonic flaw detector

A calibration method and ultrasonic technology, which is applied in the direction of material analysis, instruments, and scientific instruments using sonic/ultrasonic/infrasonic waves, which can solve the problems that users cannot judge and calibrate, users can only replace probes, and increase the cost of users. , to achieve the effect of light weight, small size, and improved life cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

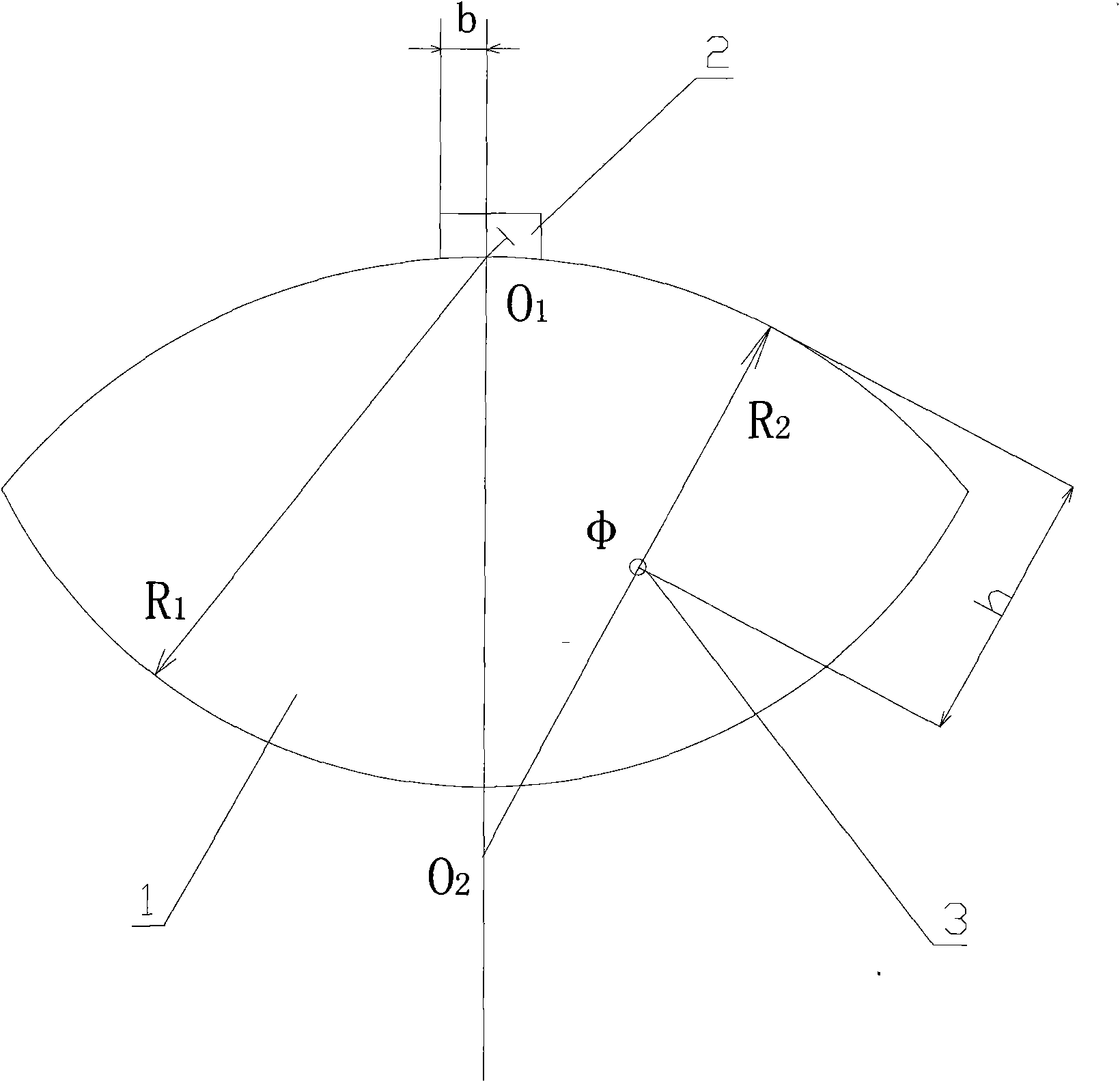

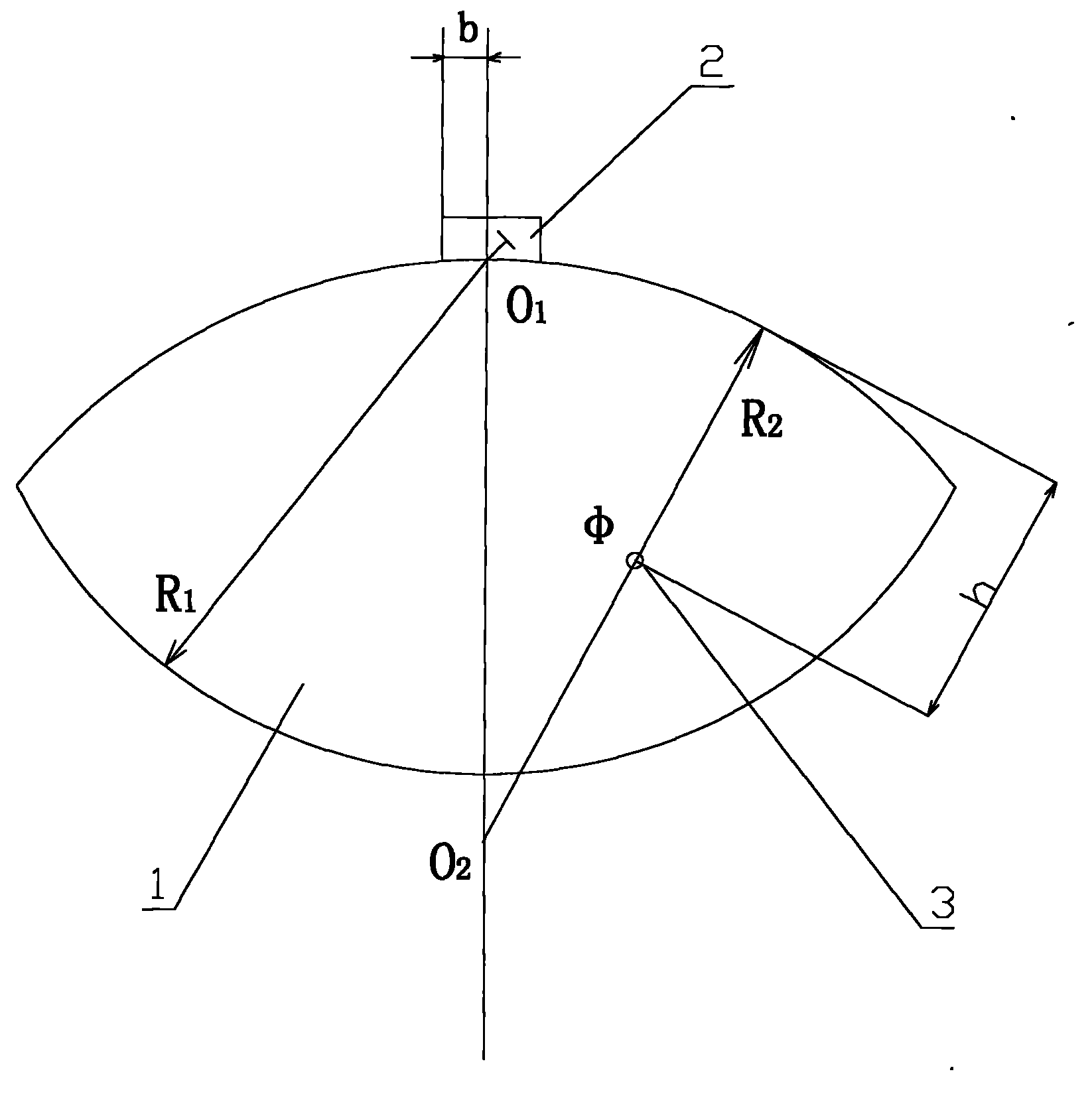

[0012] As an embodiment of the present invention, such as figure 1 As shown, a method for calibrating a small-diameter probe of an ultrasonic flaw detector includes an ultrasonic flaw detector that transmits ultrasonic waves through the probe to detect flaws in a workpiece, and includes the following steps in turn:

[0013] 1) Make the test block: take a plate with the same acoustic performance as the workpiece to be inspected, and place O on it 2 The point is the center of the circle, and the radius R of the outer circle of the workpiece to be inspected is 2 Draw an arc with the midpoint O of the arc 1 As the center of the circle, take the radius R 1 Draw another arc, and then drill a through hole 3 with a point in the area surrounded by the two arcs as the center. The diameter of the hole 3 is φ, and the hole 3 reaches the radius R 2 The distance of the arc is h, and the radius R 2 The normal line passing through the hole 3 on the arc intersects the arc to O 1 The arc l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com