Automatic ultrasonic detecting method and device of defects inside old crank of engine

An automatic detection and internal defect technology, which is applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, and using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve problems such as low detection efficiency, easy missed detection and false detection. , to achieve the effect of fast detection speed and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with embodiment: embodiment implements on the premise of technical scheme of the present invention, has provided detailed implementation, but protection scope of the present invention is not limited to following embodiment.

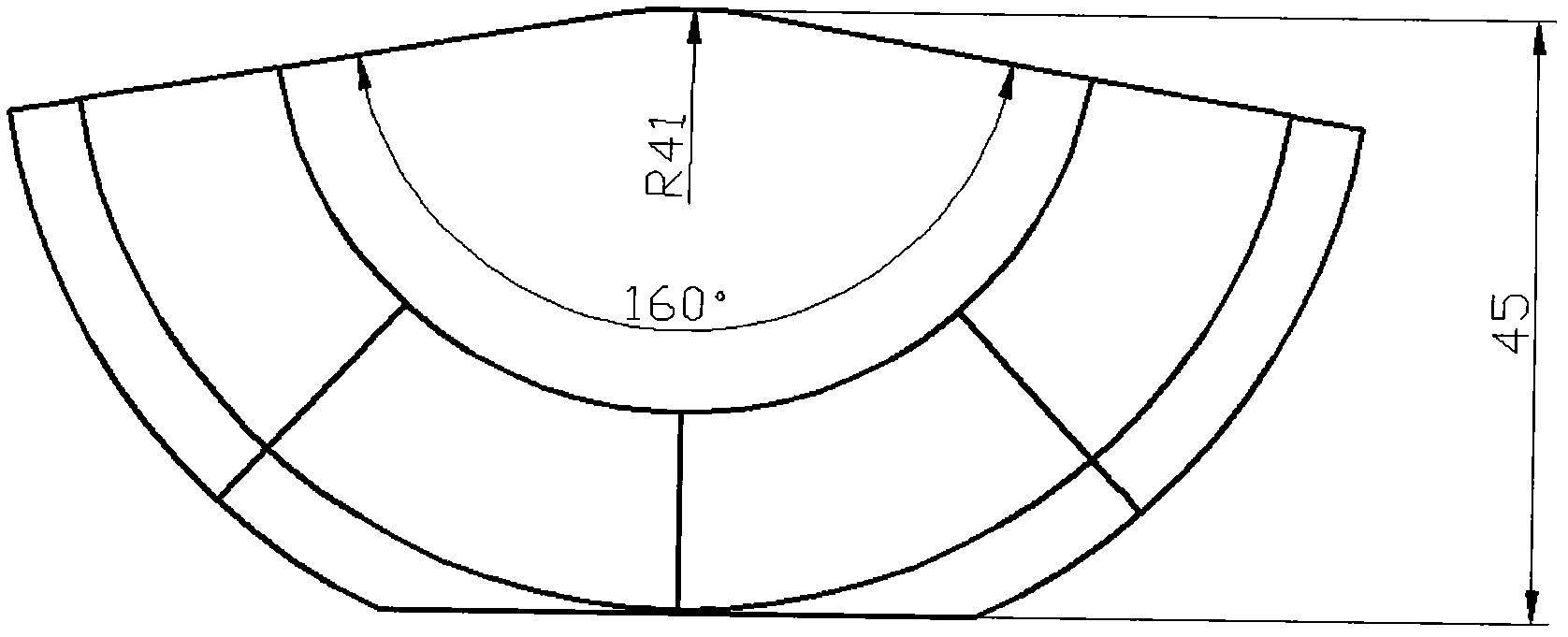

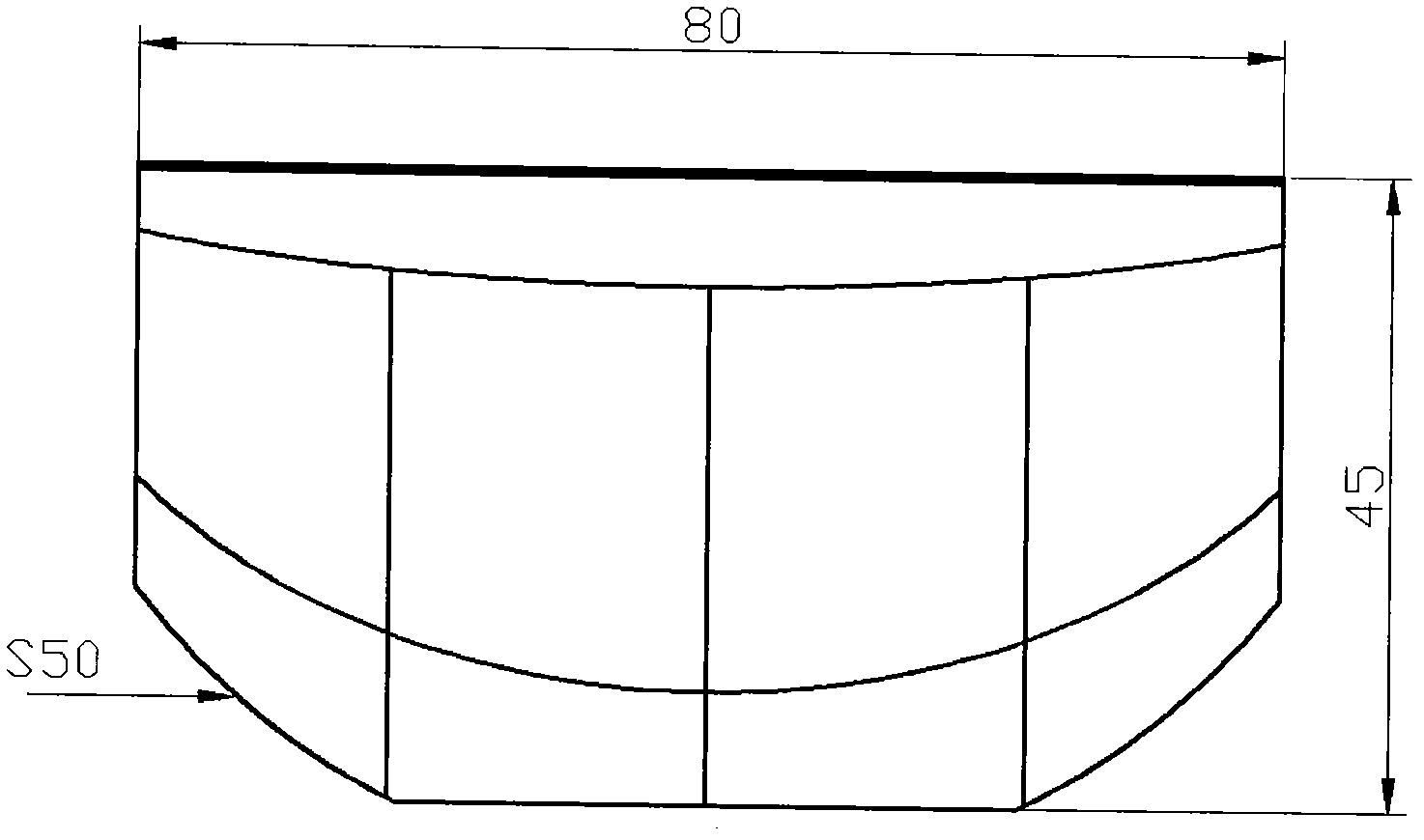

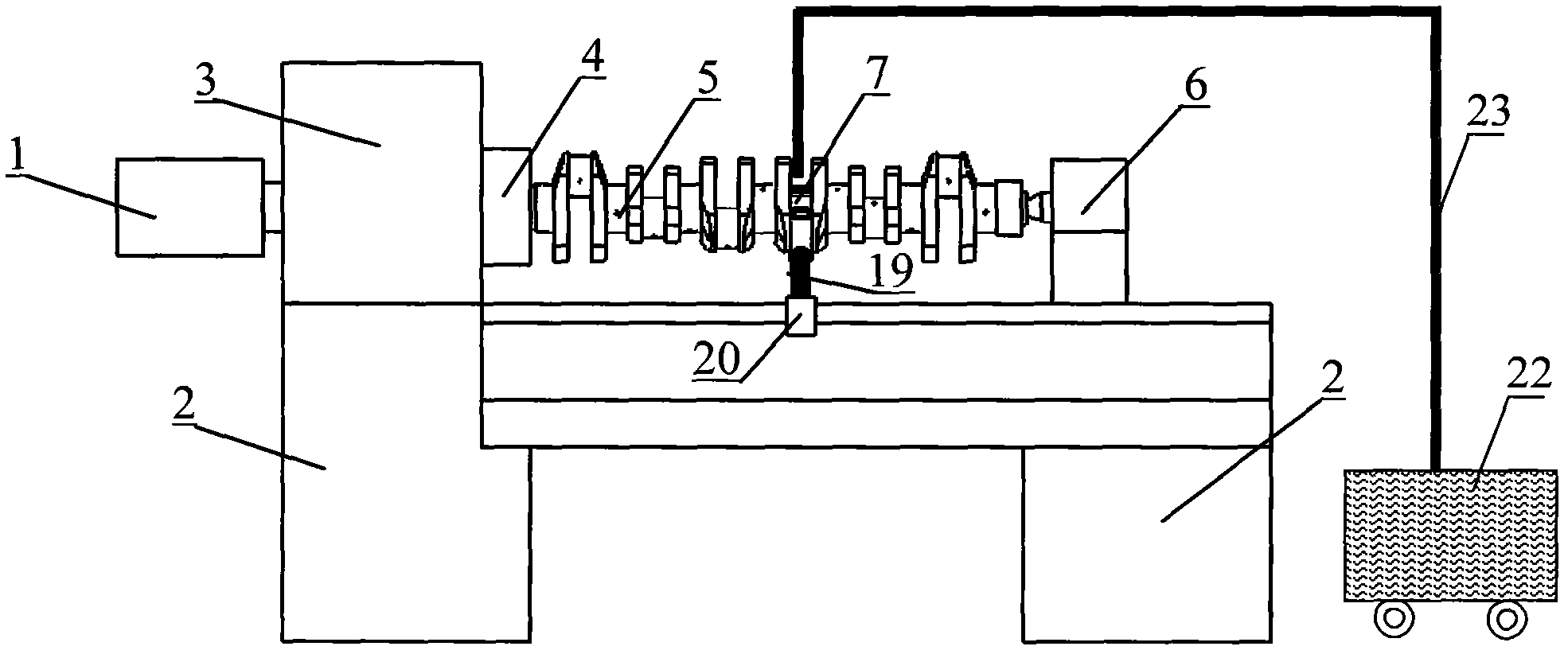

[0019] A 45# steel normalized waste crankshaft of Steyr engine was selected for ultrasonic testing. The whole crankshaft has 7 main journals and 6 connecting rod journals. First, select a curved single-crystal double-slope probe with a probe frequency of 2.5MHz, a chip size of 9mm×9mm, a forward tilt angle of γ of 45°, and a side tilt angle of φ of 10°. The size of the probe is 38mm×18mm×30mm, and the curvature of the lower surface of the probe The same curvature as the crankshaft main journal, the diameter of the main journal is 100mm. Select the material of the calibration test block as 45# steel, and follow the figure 1 and figure 2 The shapes shown are produced by finishing wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com