Method for calibrating large-angle or small-angle longitudinal wave angle probe for ultrasonic fault detector

An ultrasonic and flaw detector technology, which is applied in the field of large-angle and small-angle longitudinal wave oblique probe calibration of ultrasonic flaw detectors, can solve the problems of calibrating longitudinal wave oblique probes, increasing costs, prolonging cycle, etc., and achieving a simple and reliable method, reducing time and cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

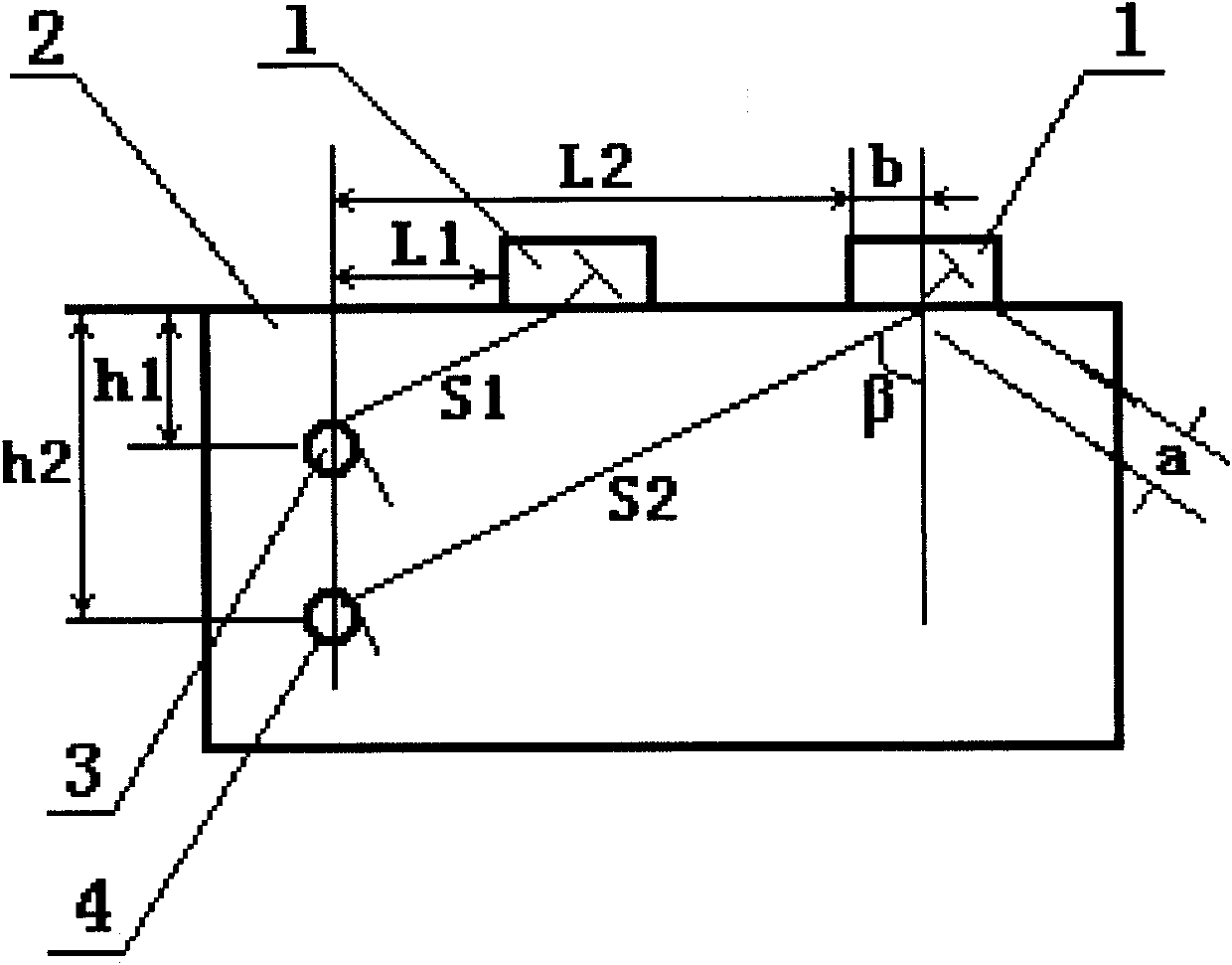

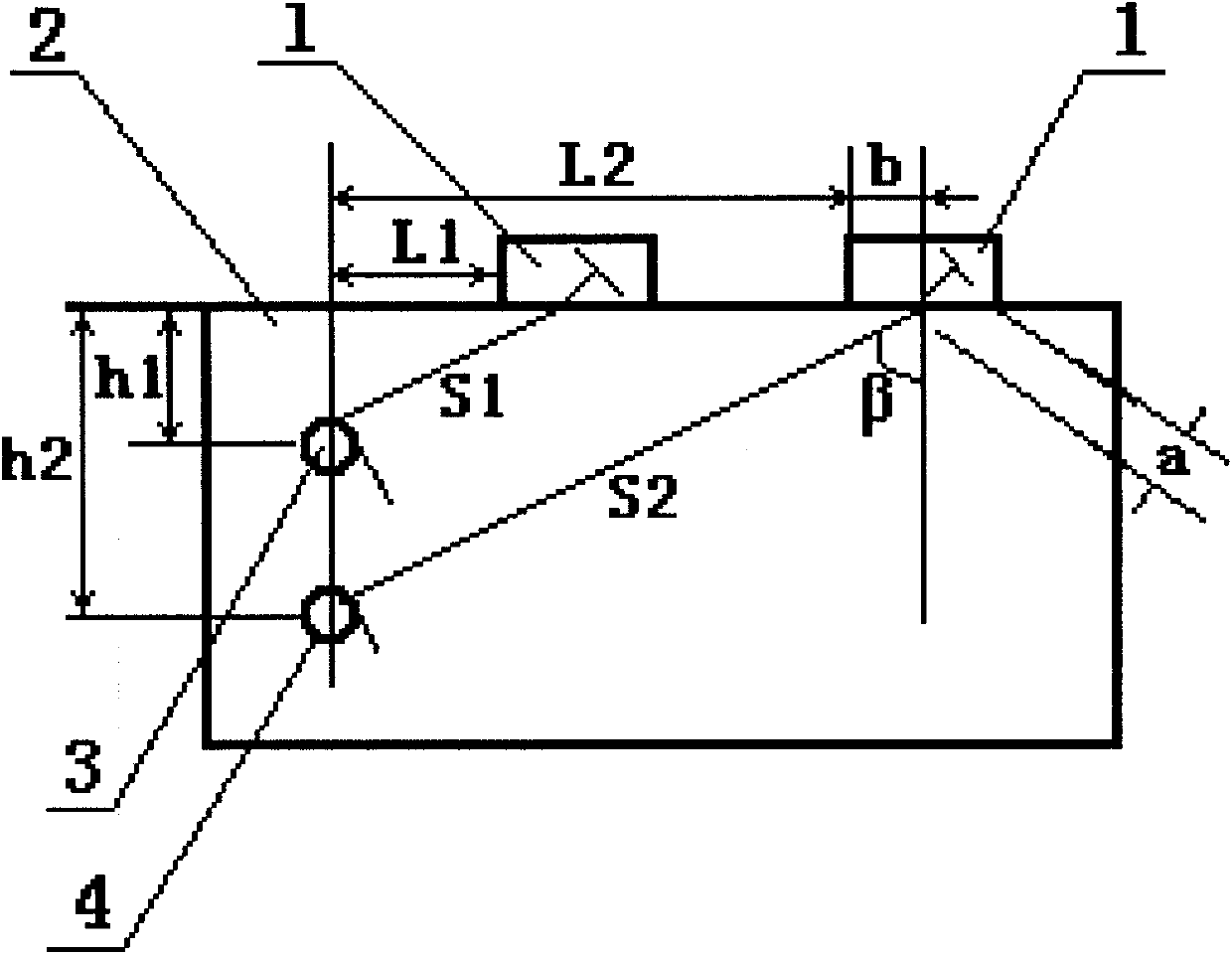

[0014] As an embodiment of the present invention, such as figure 1 As shown, a method for calibrating large-angle and small-angle longitudinal-wave oblique probes of an ultrasonic flaw detector includes an ultrasonic flaw detector that emits ultrasonic waves through a large-angle or small-angle longitudinal-wave oblique probe to detect workpiece defects. The sum of the distance and the calibration distance, where the calibration distance is the internal sound path a of the probe that the ultrasonic wave travels inside the probe, and the sound path b of the probe front that the ultrasonic wave propagates inside the workpiece but is covered by the probe shell, which is convenient for finding defects to the front of the probe The horizontal distance, this method comprises the following steps in turn:

[0015] 1) Prepare a test block 2 for probe calibration, and a large-angle or small-angle longitudinal-wave oblique probe 1 for ultrasonic flaw detectors. The test block 2 should be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com