Correction method of inner arc probe or outer arc probe in ultrasonic flaw detector

A calibration method, ultrasonic technology, which is applied in the direction of material analysis, instruments, and scientific instruments using sound waves/ultrasonic waves/infrasonic waves, which can solve problems such as the inability of users to judge and calibrate, increase the cost of users, and positioning deviations, so as to improve the use of Rate and use cycle, improve accuracy, shorten the effect of the cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

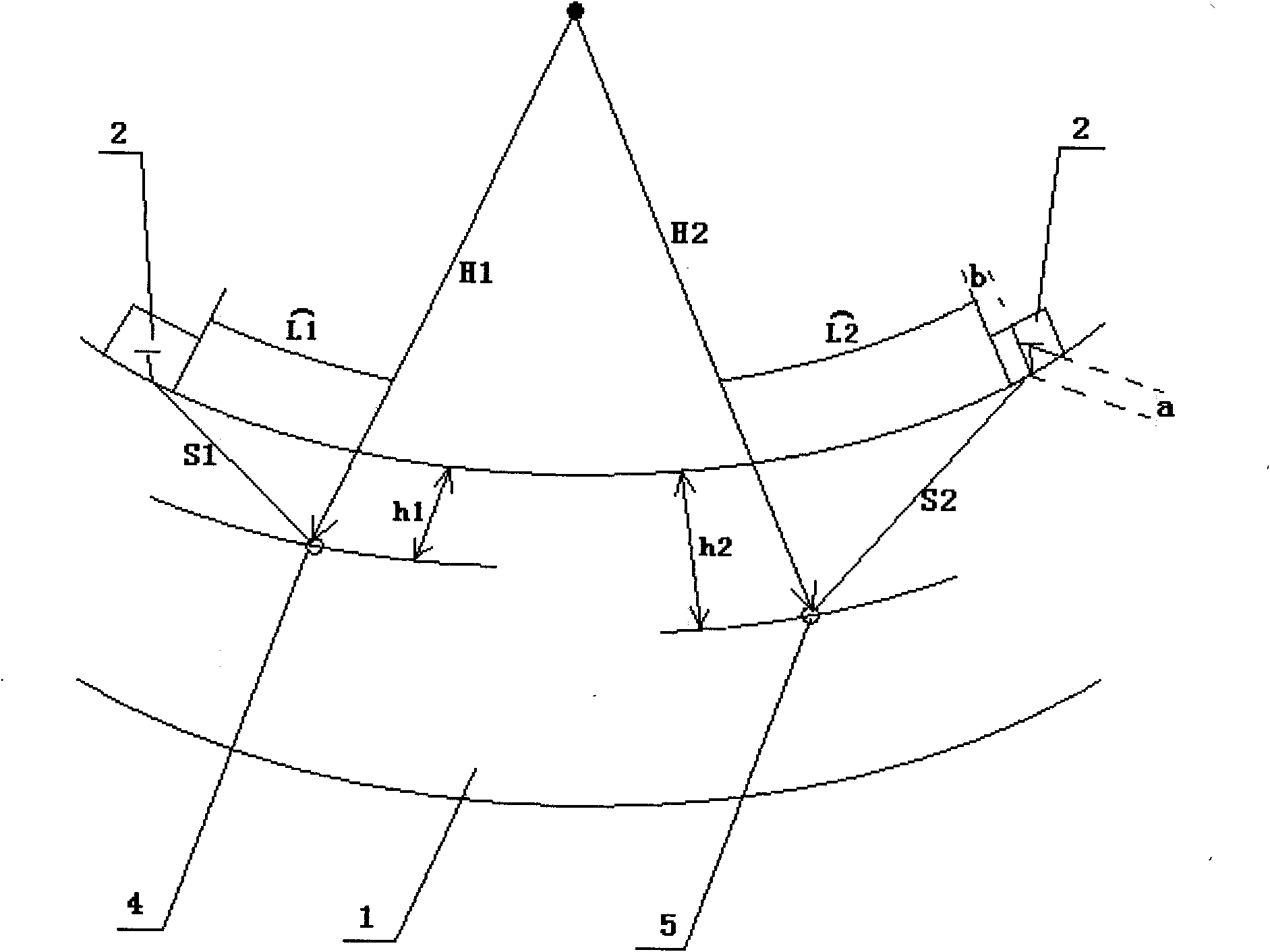

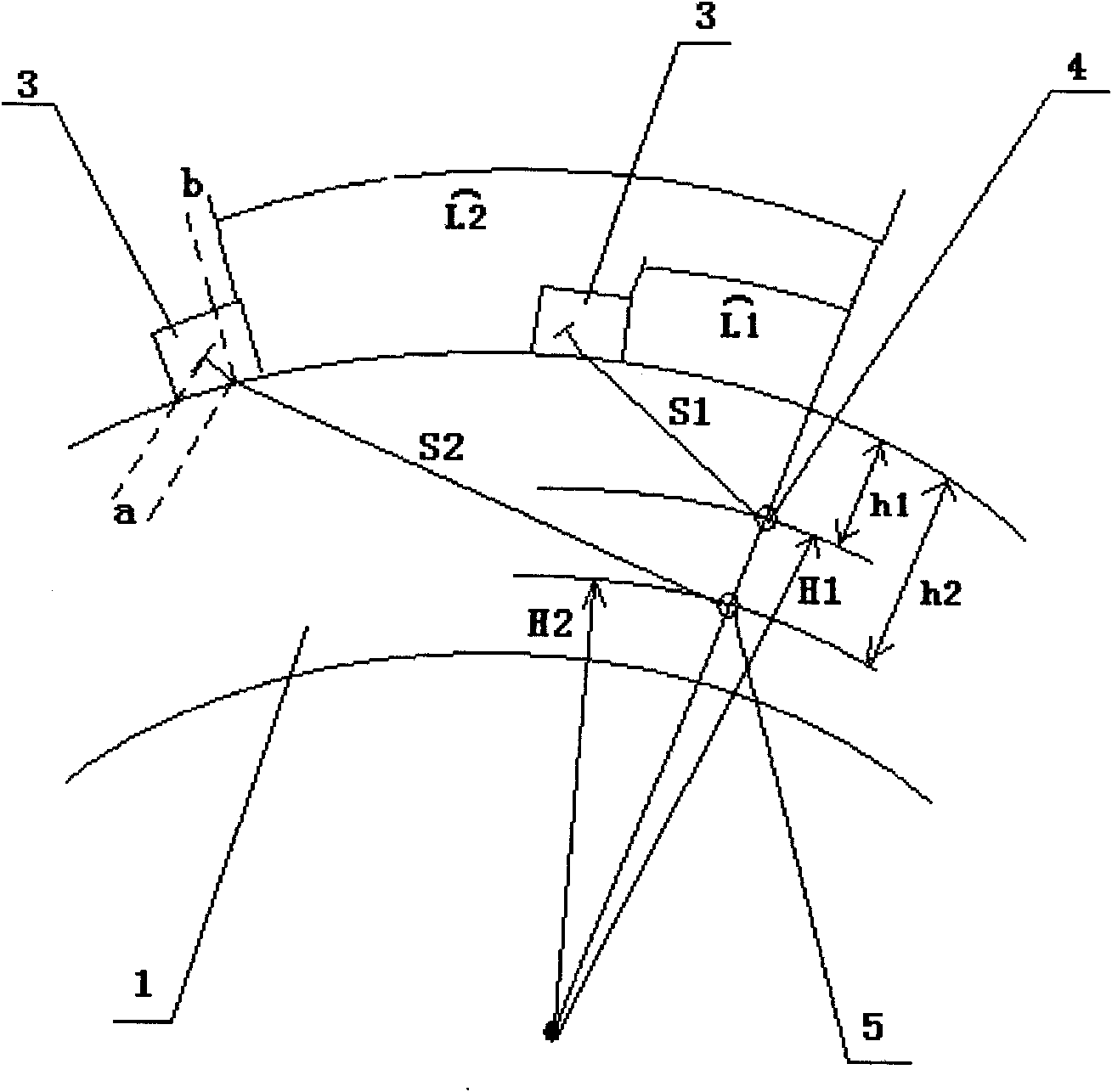

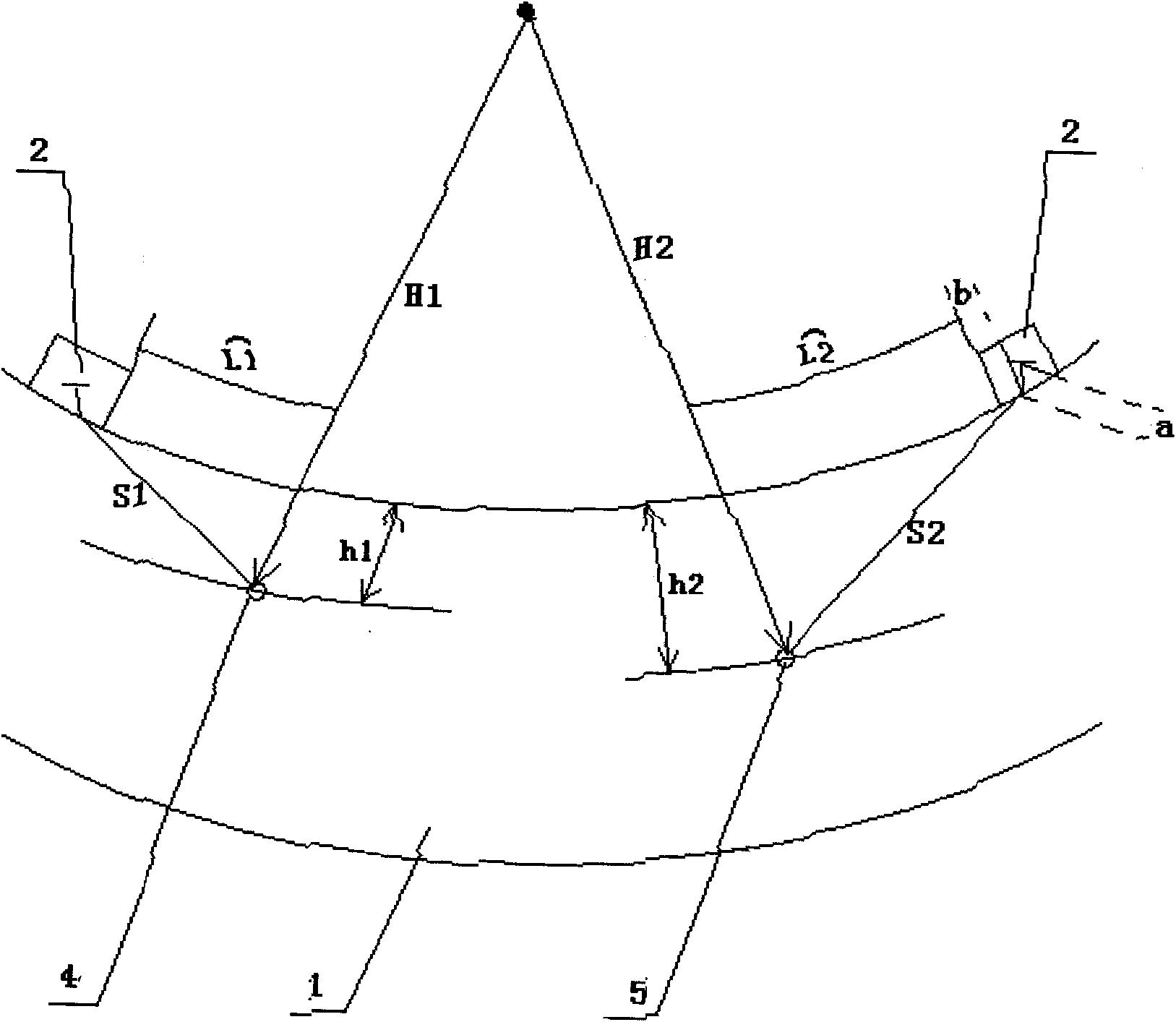

[0029] As an embodiment of the present invention, a method for calibrating the inner and outer circular arc probes of an ultrasonic flaw detector includes an ultrasonic flaw detector that transmits ultrasonic waves through the probe to detect flaws in workpieces. It is characterized in that the method includes the following steps in sequence:

[0030] 1) Take a piece of test block 1 for probe calibration on the workpiece to be detected. The outer diameter of the test block 1 is R, the inner diameter is r, and an inner arc or outer arc probe 2, 3 for the ultrasonic flaw detector, and Drill two holes h at the distances H1 and H2 from the axis of the test block 1 along its axis 1 4 and hole h 2 5. The diameter of the two holes 4 and 5 is φ, and H1≠H2;

[0031] 2) if figure 1 , 2 As shown, use the inner arc or outer arc probes 2 and 3 to search back and forth for the hole h on the inner or outer wall of the test block 1 1 4. Until the hole h is displayed on the ultrasonic flaw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com