Three-dimensional ultrasonic probe calibration device and method for calibrating three-dimensional ultrasonic probe

A technology of three-dimensional ultrasound and calibration devices, which is applied to measuring devices, material analysis using sound waves/ultrasonic waves/infrasonic waves, instruments, etc., can solve problems such as monotonous time-consuming, error, and high operator requirements, so as to improve efficiency and accuracy, and ensure Imaging clarity, avoiding the effect of additional calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

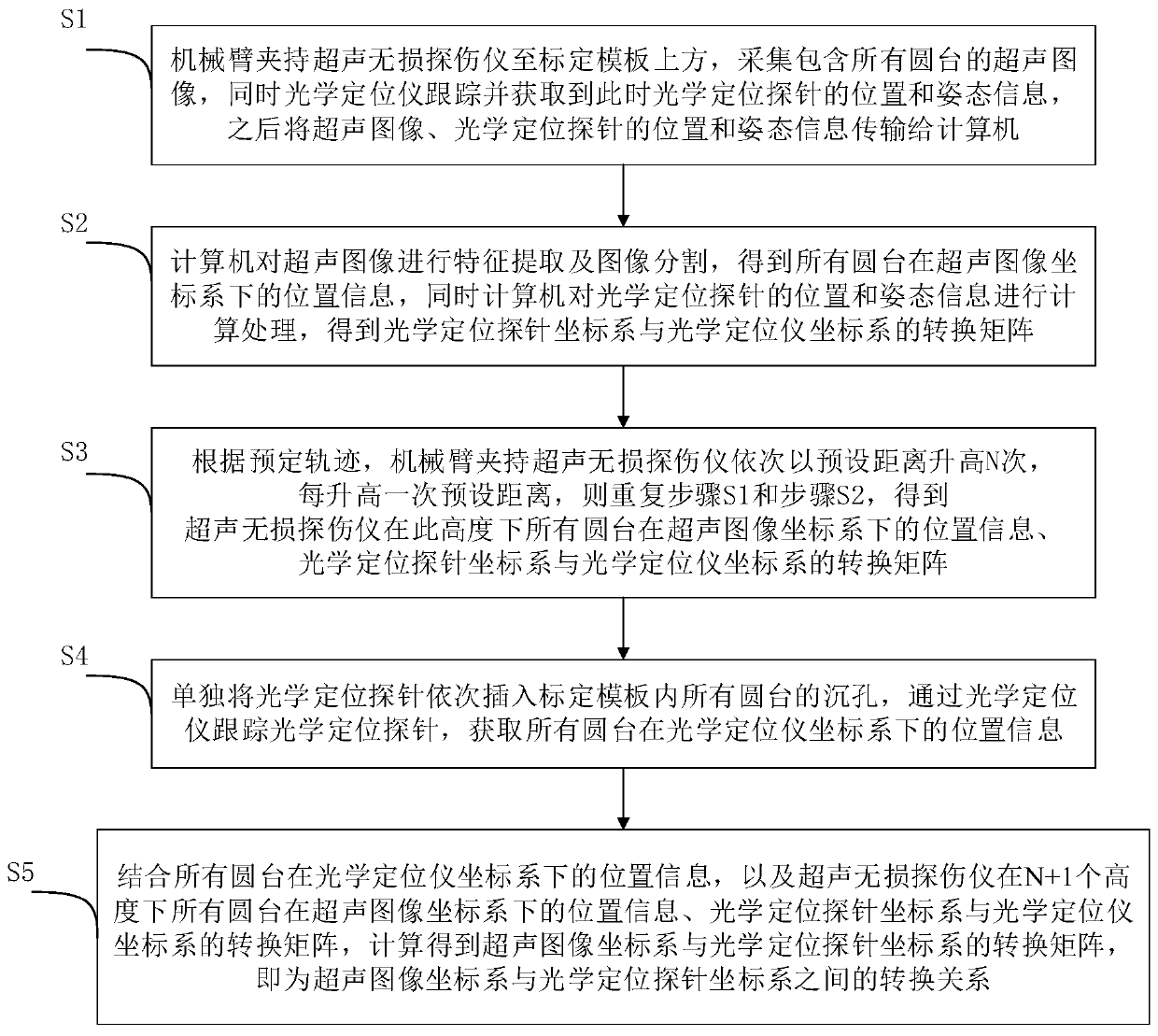

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

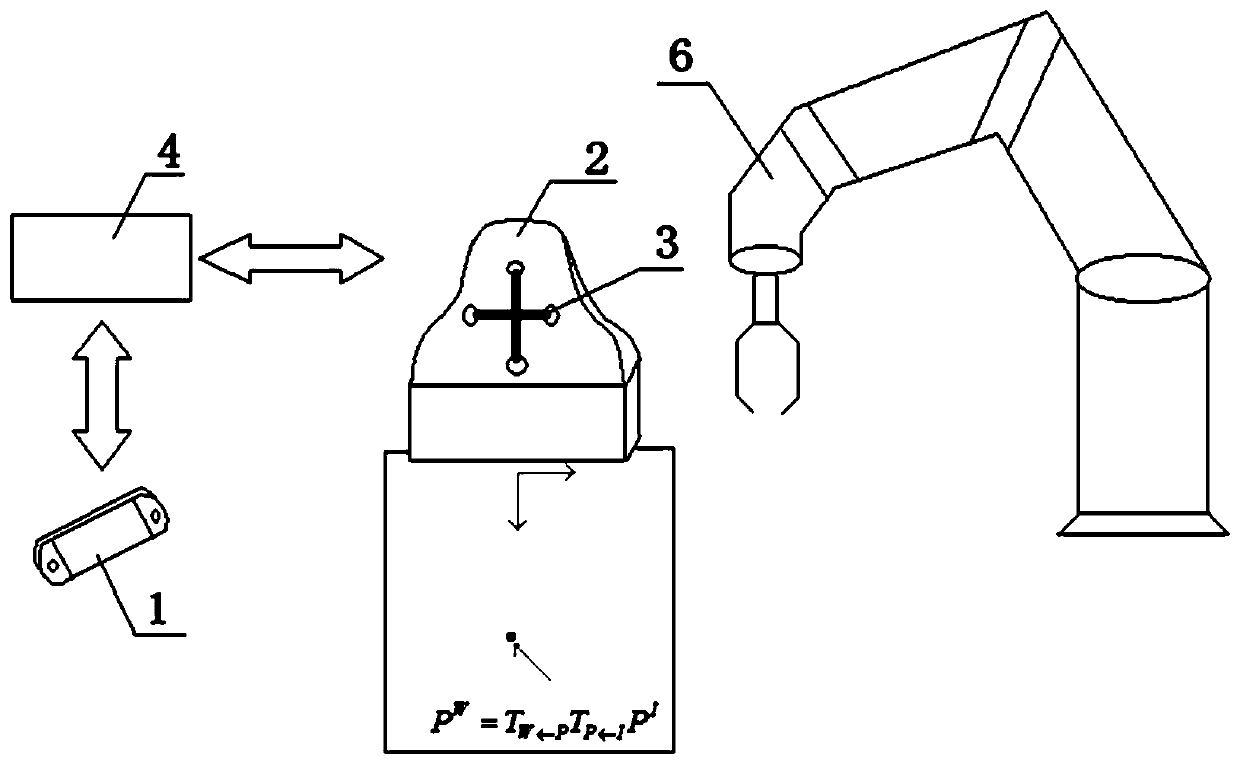

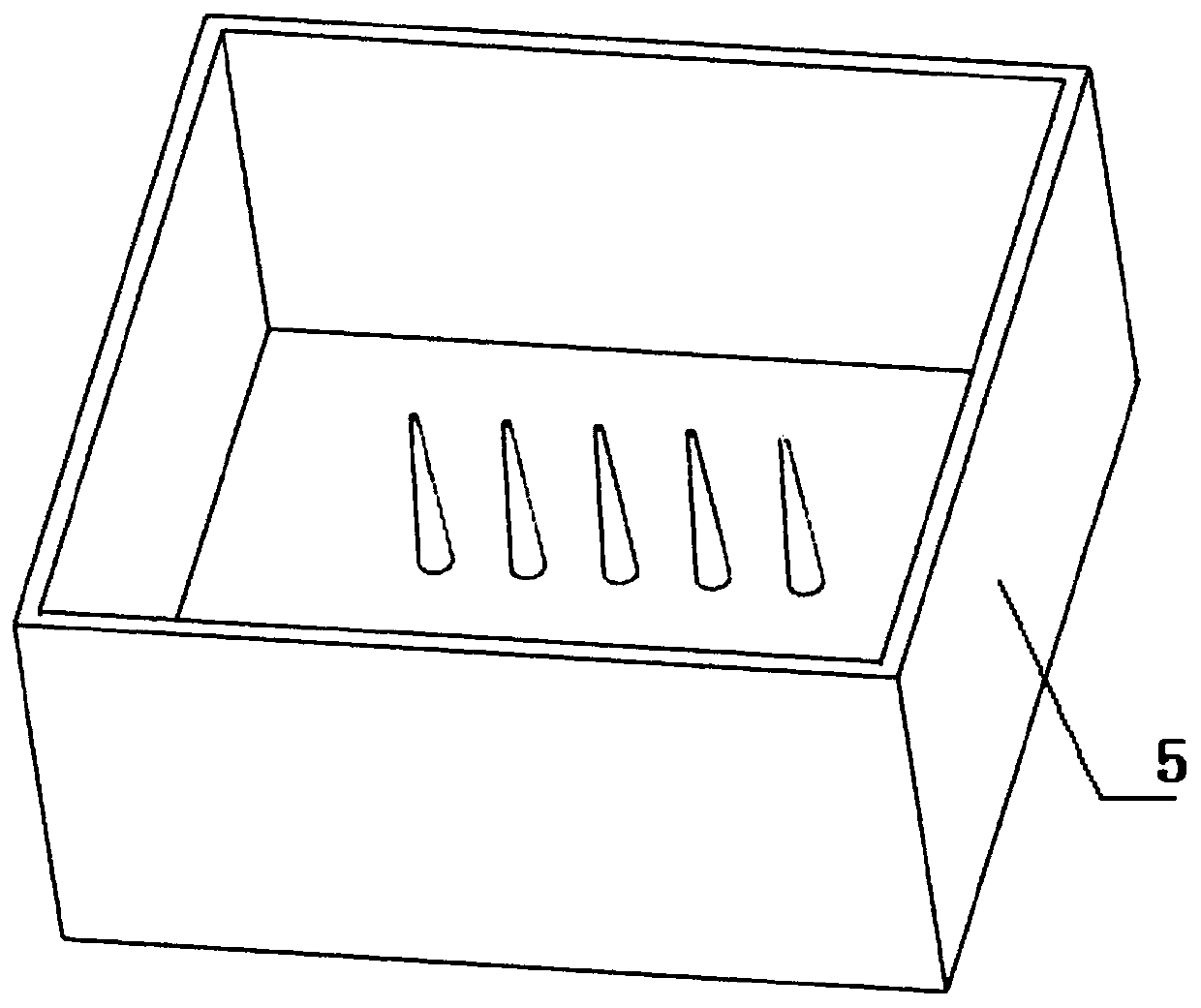

[0034] Such as figure 1 with figure 2 As shown, a three-dimensional ultrasonic probe calibration device includes an optical locator 1, an optical locating probe 3, an ultrasonic nondestructive flaw detector 2, a calibration template 5, a computer 4 and a mechanical arm 6, an optical locator 1 and an ultrasonic nondestructive flaw detector 2 They are respectively connected to the computer 4, the optical positioning probe 3 is fixed on the ultrasonic non-destructive flaw detector 2, the calibration template 5 is a water tank with multiple round tables at the inner bottom, and the optical positioning instrument 1 is used to track and obtain the position of the optical positioning probe 3 and attitude information;

[0035] The ultrasonic nondestructive flaw detector 2 is used to scan the calibration template 5 to obtain ultrasonic images;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com